Page 1

EP1054/EP1085/EP2030

MECHANICAL/

ELECTRICAL

I

MINOLTA

Page 2

COTNENTS

I. CROSS-SECTIONAL VIEW

l-l. Cross-Sectional View of 23 cpm

I-2. Cross-Sectional View of I8 cpm Copier

l-3. Cross-Sectional View of 15 cpm

2. COPY PROCESS

3. DRIVE SYSTEM

4. SEQUENTIAL EXPLANATION

5. IMAGING UNIT

5-l. Imaging Unit Drive

5-2.

Imaging Unit Toner

5-3. Imaging Unit Fuse

6. PC DRUM

7. DRUM CHARGING

8. IMAGE ERASE LAMP

9. OPTICAL SECTION

9-I. Exposure Lamp

9-2. AE Sensor

9-3. Lamp Reflectors

9-4. Aperture Plates

9-5.

Scanner and 2nd/3rd Mirror Carriage Movement

9-6. 4th Mirror Movement

9-7. Lens

IO. ORIGINAL SIZE DETECTING SENSORS (23 cpm COPIER ONLY) . . . . . . . . . . . . . . M-28

1 O-I. Original Size Detecting Sensors

1 O-2. Original Size Detecting Operation

I O-3. Sensor Locations

1 O-4. Size Detection

1 O-5. Original Size Detection Timing

I O-6. Original Cover Angle Detection (23 cpm Copier Only)

11. DEVELOPMENT

11-l.

ATDC Sensor

I I-2. Magnet Roller

I l-3. Developing Bias

I I-4. Doctor Blade

1 I-5. Sleeve/Magnet Roller Lower Filter

12. TONER HOPPER

12-l. Toner Hopper Locking/Unlocking

12-2. Toner Replenishing

12-3. Shutter

12-4. Toner Hopper Home Position Detection

12-5.

Toner Bottle Vibration

12-6. Toner Replenishing Control

13. PAPER TAKE-UP/FEED SECTION (2ND DRAWER: 23 cpm

COPIER ONLY)

13-I

.Edge

13-2.Drawer Positioning

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*...............................................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...*....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Movement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Guide and Trailing Edge Stop

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-I

Copier

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copier

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recycling

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-I 4

. . . . . . . . . . . . . . M-20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . M-32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

M-l

M-2

M-4

M-6

M-7

M-12

M-13

. . . . . . . . . M-14

M-15

. . . . . . . . . . . . M-16

M-17

. . . . . . . . . . . . M-21

M-22

M-23

. . . . . . . . . . . . M-23

M-26

M-28

M-28

M-29

M-30

M-31

. . . . . . . . . . . . M-33

M-34

. . . . . . . . . . . . M-36

M-37

. . . . . . . . . . . M-38

.._...................

M-38

. . . . . . . . . . M-39

M-39

M-39

M-40

M-40

M-42

M-43

M-44

M-45

Page 3

13-3.Paper Lifting Plate

13-4.Drawer-in-Position Detection

13-5.Universal Tray (1 st Drawer) Paper Size Detection

13-6.Paper Empty Detection

13-7.Paper Separating Mechanism

13-8.Paper Take-Up Roll

13-9.Paper Take-Up Retry Control

13-lO.VERTICAL

14.

MULTI BYPASS TABLE

14-1 .Paper Take-Up

14-2.Paper Take-Up Retry Control

14-3.Paper Separating Mechanism

14-4.Paper

15.

SYNCHRONIZING

15-l .Upper Synchronizing Roller Positioning

15-2.Paper Dust Remover

15-3.Synchronizing

16. IMAGE TRANSFER AND PAPER SEPARATION

17. MAIN ERASE LAMP

18. PAPER SEPARATOR FINGERS

19.

CLEANING

19-l .Cleaning Bias

20. PAPER TRANSPORT

21. FUSING UNIT

21-1. Fusing Temperature Control

21-2.Fusing

21-3.Cleaning

22. EXIT UNIT

22-l .Upper/Lower Separator

22-2.Paper Exit Sensor

23. EXIT/DUPLEX SWITCHING UNIT (OPTION)

24. DEHUMIDIFYING SWITCH

25. COOLING

26. OPTICAL SECTION COOLING FAN

27. MEMORY BACKUP

Empty

UNIT

..................................................................................................

Rollers Pressure

Roller

.......................................................................................................

FAN

...................................................................................

...................................................................

............................................................................

.................................................................

.................................................................................

..................................................................

PAPER TRANSPORT

..................................................................................

Mechanism .....................................................................

Detection

ROLLERS

Roller Control

.............................................................................................

................................................................................................

............................................................................

.........................................................................

...............................................................................

........................................................................................

..........................................................................................

.....................................................................................

Mechanism

........................................................................................

Fingers

....................................................................................

(OPTION)

.........................................................................................

.........................................................

..................................................................

.................................................................

..................................................

...................................................................

....................................................................

...................................................................

.......................................................

..............................................................

............................................................

...............................................................

..................................

...........................................

.................................................

M-45

M-46

M-47

M-40

M-49

M-50

M-51

M-52

M-53

M-54

M-55

M-56

M-56

M-57

M-58

M-58

M-59

M-60

M-62

M-63

M-64

M-65

M-66

M-67

M-68

M-69

M-69

M-70

M-70

M-71

M-72

M-73

M-74

M-75

M-76

ii

Page 4

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM0100A

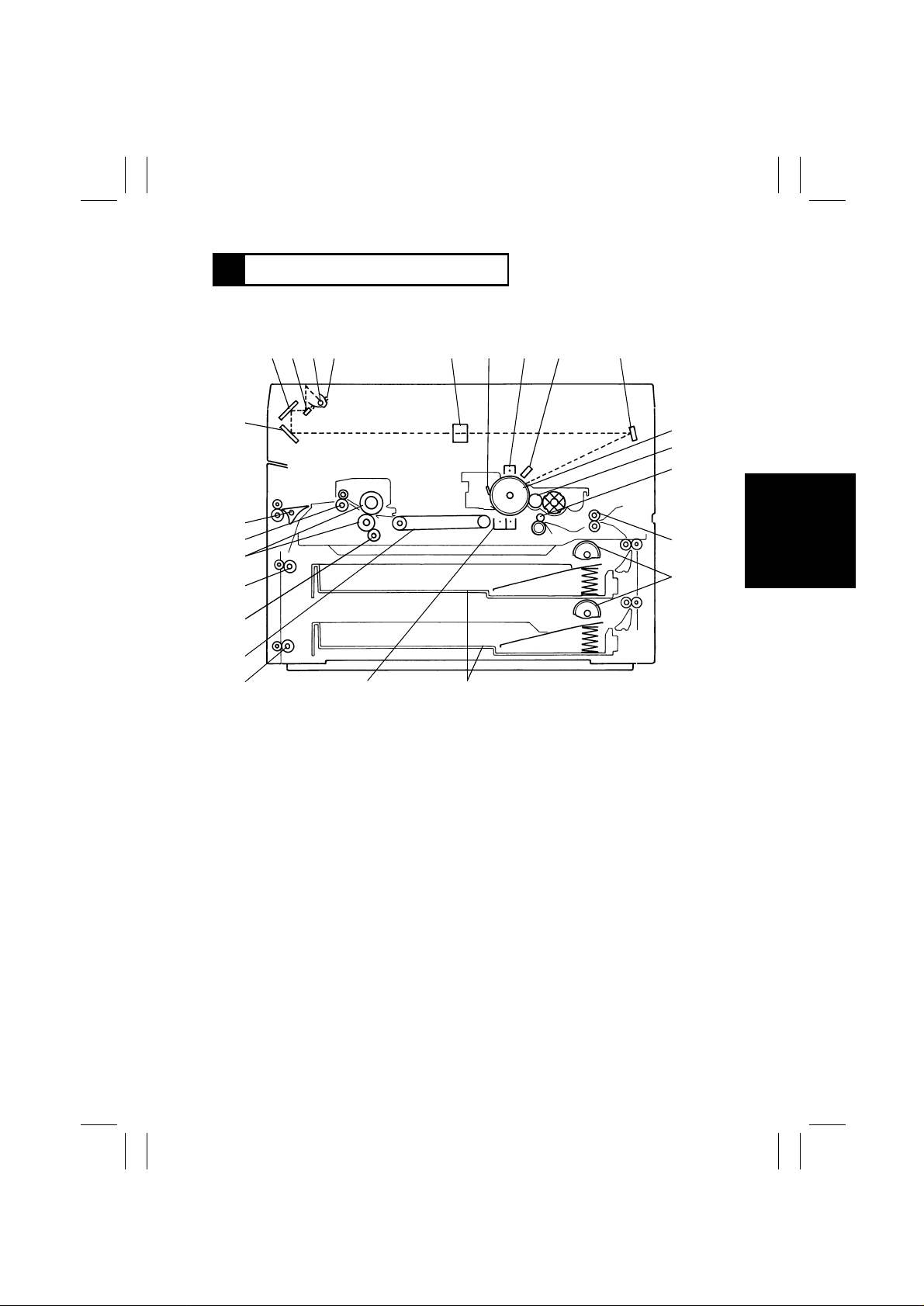

1 CROSS-SECTIONAL VIEW

1174SBM0101A

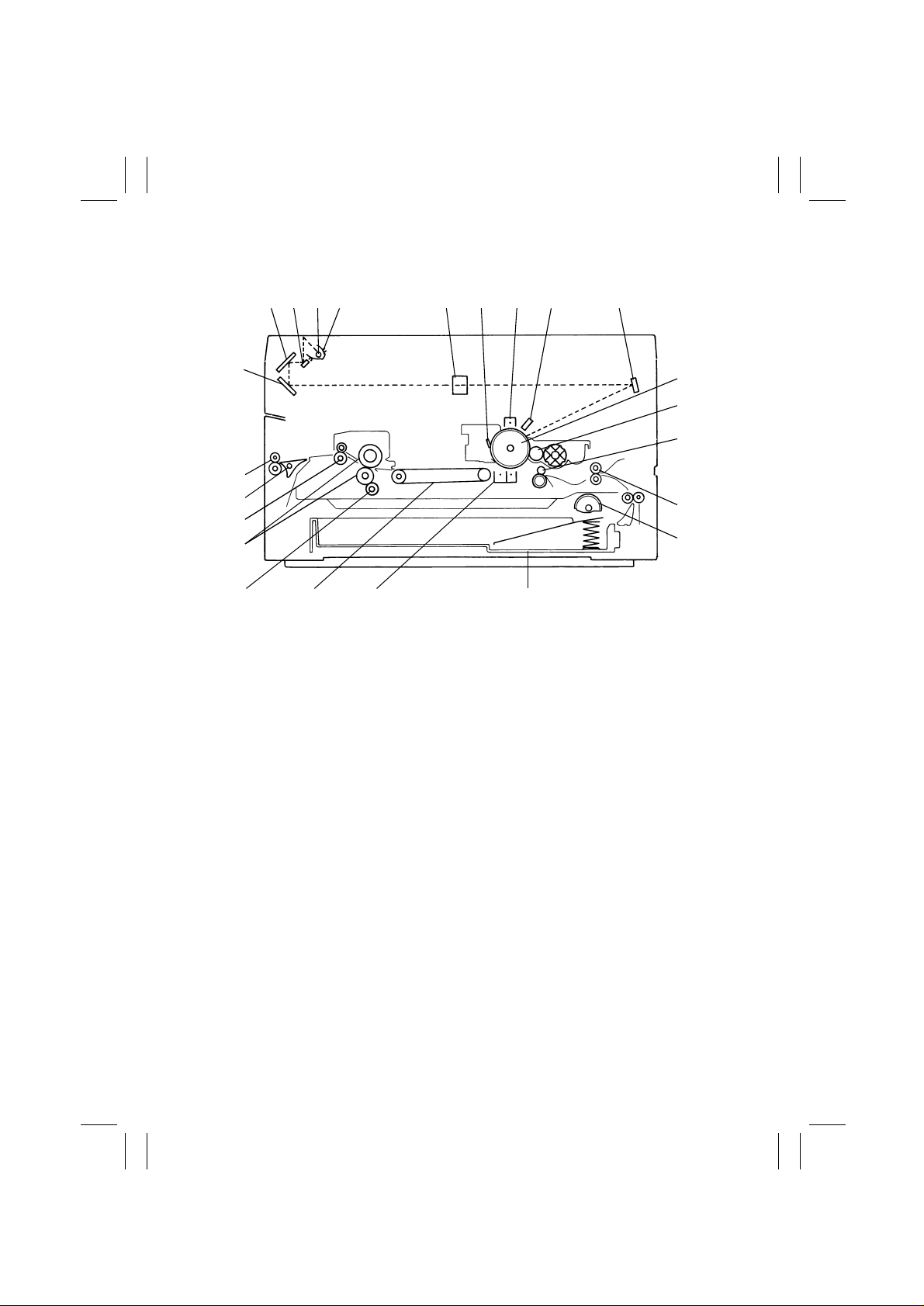

1-1. Cross-Sectional View of 23 cpm Copier

2345 6 7 8 9 10

1

22

21

20

23

19

18

24

1. 3rd Mirror

2nd Mirror

2.

3. 1st Mirror

4. Exposure Lamp

5. Lamp Reflector

6. Lens

7. Cleaning Blade

8. PC Drum Charge Corona

9. Image Erase Lamp

10. 4th Mirror

11. PC Drum

12. Sleeve/Magnet Roller

13. Synchronizing Roller

14. Trans port Roller

15. 1st/2nd Drawer Paper Take-Up Roll

16. 1st/2nd Drawer

1617

17. Image Transfer/Paper Separator

Coronas

18. Suction Unit

19. Cleaning Roller

20. Upper/Lower Fusing Roller

21. Paper Exit Rol ler

22. Exit/Duplex Switching Guide

(for optional Duplex Uni t and Sorter)

23. Duplex Unit Vertical Tr ansport Roller 1

(for optional Duplex Unit )

24. Duplex Unit Vertical T ransport Roller 2

(for optional Duplex Unit )

1174M005AB

11

12

13

14

15

M-1

Page 5

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM0102A

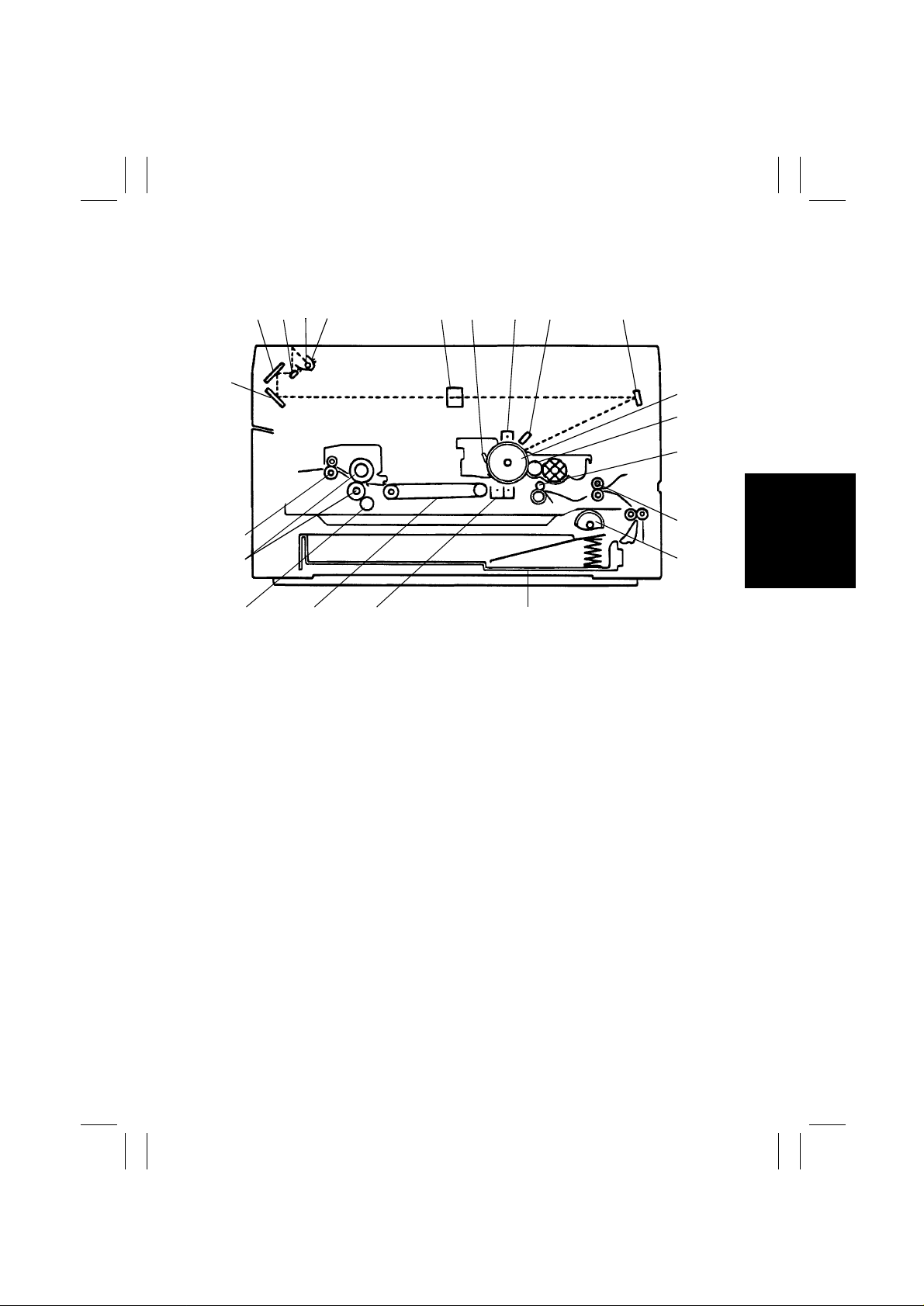

1-2. Cross-Sectional View of 18 cpm Copier

2345 6 7 8 9 10

1

23

22

21

20

19 18 17 16

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamp

5. Lamp Reflector

6. Lens

7. Cleaning Blade

8. PC Drum Charge Corona

9. Image Erase Lamp

10. 4th Mirror

11. PC Drum

12. Sleeve/Magnet Roller

13. Synchronizing Roller

14. Trans port Roller

15. Paper Take-Up Roll

16. Drawe

17. Image Transfer/Paper Separator

18. Suction Unit

19. Cleaning Roller

20. Upper/Lower Fusing Roller

21. Paper Exit Rol ler

22. Exit/Duplex Switching Guide

23. Paper Exit Roller in Exit/Duplex

11

12

13

14

15

1174M004AB

Coronas

(for optional Sorter)

Switching Guide Unit

(for optional Sorter)

M-2

Page 6

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM0103A

1-3. Cross-Sectional View of 15 cpm Copier

Except U.S.A., Canada

✽

2345 6 7 8 9 10

1

21

20

19 18 17 16

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamp

5. Lamp Reflector

6. Lens

7. Cleaning Blade

8. PC Drum Charge Corona

9. Image Erase Lamp

10. 4th Mirror

11. PC Drum

12. Sleeve/Magnet Roller

13. Synchronizing R ol ler

14. Transport Roller

15. Paper Take-Up Roll

16. Drawer

17. Image Transfer/Paper Separator

18. Suction Unit

19. Cleaning Roller

20. Upper/Lower Fusing Roller

21. Paper Exit Rol ler

11

12

13

14

15

1174M011AA

Coronas

M-3

Page 7

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM0200A

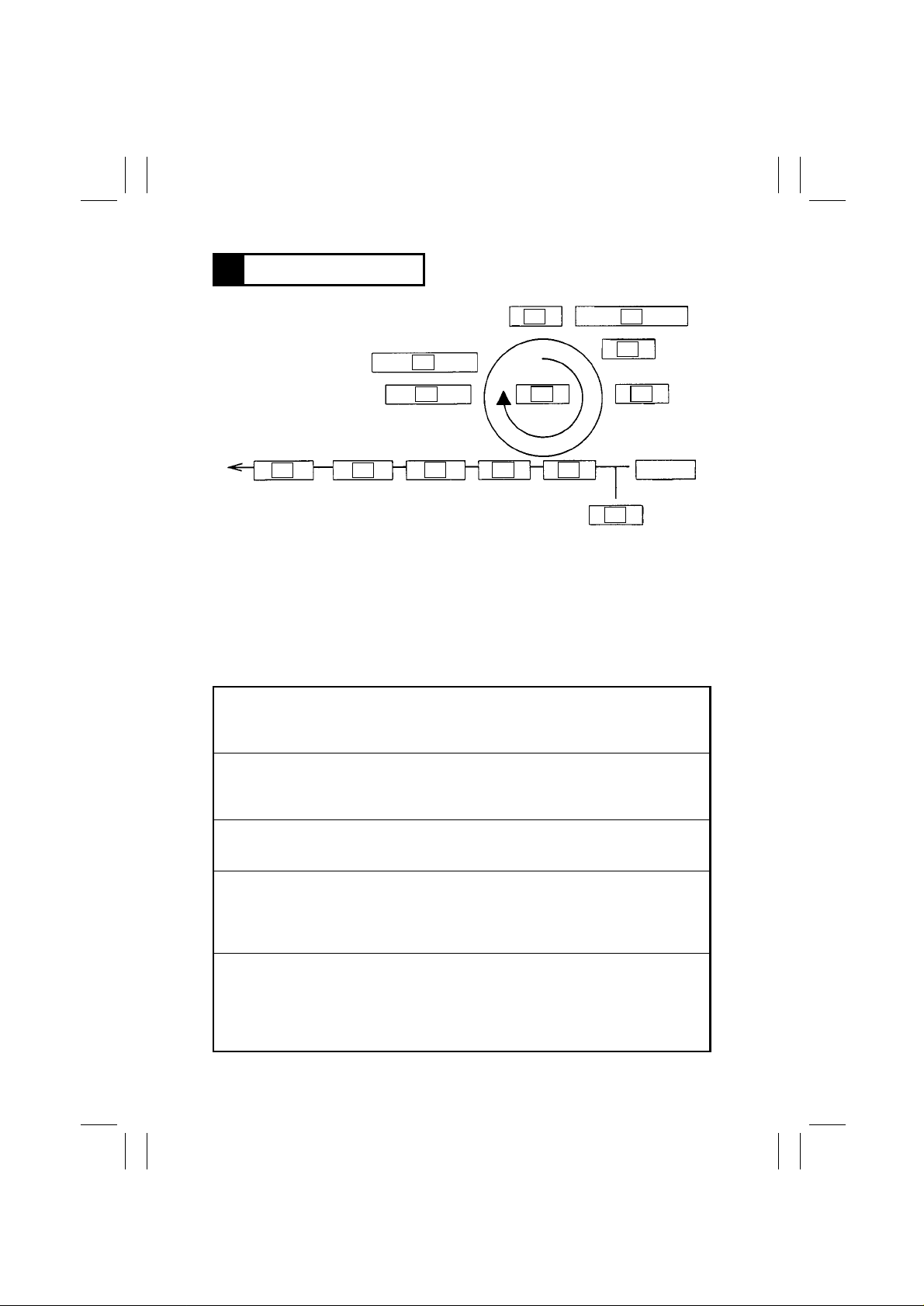

2 COPY PROCESS

2 3

6

4

5

5

MULTI BYPASS

T ABLE

1139M002AA

13

1. PC DRUM

2. DRUM CHARGING

3. IMAGE ERASE

4. EXPOSURE

5. DE VELOPING

6. PAPER FEEDING

10

9

12

11

1

8

8

7

7

8. PAPER SEPARAT ION

9. CLEANING

10.MAIN ERASE

11. TRANSPORT

12. FUSING

13.PAPER EXIT

7. IMAGE TRANSFER

1. PC Drum

The PC Drum is an aluminum cylinder coated with a photosensitive semiconductor.

It is used as the medium on which a visib l e developed image of the original is formed.

(For more details, see “6. PC DRUM”.)

2. Drum Charging

The PC Drum Charge Coron a U nit is equipped wit h a Co mb Electrode and a Scorotron

Grid to deposit a uniform negative charge across th e entire surf ace of the PC Drum.

(For more details, see “7. DRUM CHARGING”.)

3. Image Erase

Any areas of charge which are not to be developed are neutralized by lighting up LED s.

(For mor e details, see “8. IMAGE ERASE LAMP”. )

4. Exposure

Light from the Exposure Lamp reflect ed off the original is gui ded to the surface of the PC

Drum and reduces the level of the negative charges, thereby forming an electrostatic

latent image.

(For mor e details, see “9. OPTICAL SECTION”.)

5. Developing

Toner positively charged in the Developer Mixi ng Chamber is attracted onto the electrostatic lat ent i mage c ha ngin g it to a v is ib le , devel oped i ma ge. A DC negat ive bias v oltag e i s

applied to t he Sle eve/Magn et Roller to pr event toner from being a ttr ac te d onto th os e area s

of the PC Drum which correspond to the background areas of the original .

(For mor e details, see “11. DEVELOPMENT”.)

M-4

Page 8

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

6. Paper Feeding

Pape r is fed either au tomatically fro m the 1st or 2nd Drawer, or manually via the Multi

Bypass Table or Manual Bypass Table. Each Dra wer has fingers that function to separate

the top sheet of paper from the rest at take-up. (2nd Drawer: 23 cpm Copier Only )

(For more details, see “13. PAPER TAKE-UP/FEED SECTION”.)

7. Image Transfer

The single-wir e Image Transfer C orona Uni t ap plies a DC neg ati v e c orona emi ssi on to t he

underside of the paper, thereby attracting toner onto the surface of the paper.

(For more details, see “16. IMAGE TRANSFER AND PAPER SEPARATION”.)

8. Paper Separation

The single-wire Paper Separator Cor ona Unit applies an AC corona emission to the

underside o f the p ape r to neutr al i ze t he pap er. In addition, mechanic al paper s epa rati o n is

provided by the two PC Drum Paper Separator Fingers fitted to the Imaging Unit.

(For more details, see “16. IMAGE TRANSFER AND PAPER SEPARATION”.)

9. Cleaning

Residual toner on the surface of the PC Drum is scraped off by the Cleani ng Blade.

(For mor e details, see “19. CLEANING UNIT”.)

10.Main Erase

Light from the Main Erase Lamp neutralizes an y surface potential remaining on the surface of the PC Drum after cleaning.

(For mor e details, see “17. MAIN ERASE LAMP”.)

11. Transport

The paper is fed to the Fusing Unit by the Suction Belts.

(For more details, see “20. PAPER TRANSPORT”.)

12. Fusing

The developed imag e is permanently fused to the paper by a combi nation of heat and

pressure applied by the Upper and Lower Fusing Rolle rs.

(For more details, see “21. FUSING UNIT”.)

13.Paper Exit

After the fusing process the paper is fed out by the Paper Exit Roller onto the Copy Tray.

(For mor e details, see “22. EXIT UNIT”.)

M-5

Page 9

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM0300A

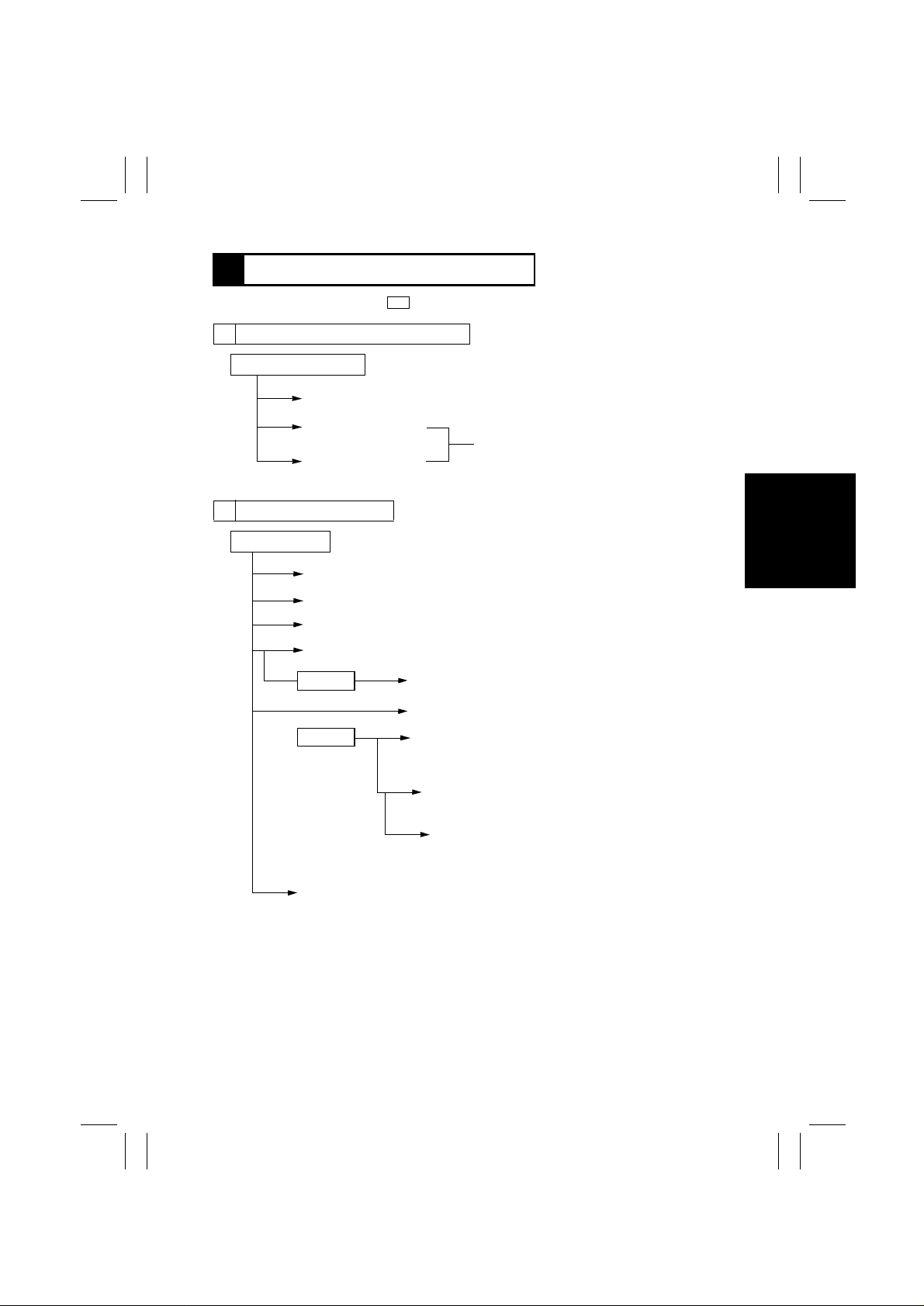

3 DRIVE SYST EM

This copier is equipped with two main drive motors, the PC Drive Motor that drives the

upper half of the copier (Imaging Unit) and the Main Drive Motor which gives drive for the

lower half of the copier (paper take-up/feeding, transport mechanism and Fusing Unit).

Each has its o wn drive transmitting gears and timing belts as illustrate d bel ow.

Drive Train for Lower Half of Copier

Coupled to Paper

Take-Up Unit

Drive Train for

Paper Take-Up Unit

<23 cpm Copier>

Coupled to Copier Gear

1st Vertical

Transport Roller

2nd Vertical

Transport Roller

1139M004AA

Coupled to Exit/Duplex

Switching Unit

Paper Exit Roller Drive

Suction Unit

Drive

Synchronizing Roller Clutch CL 1

Pape r Transport

Clutch CL 2

<15/18 cpm Copier >

1st Draw er Paper

Take-Up Roll

Vertical

Transport Roller

2nd Drawer P ape r

Take-Up Roll

Main Drive Motor M2

1151M001YB

Drive Train for Upper

Half of Copier

PC Drum Drive

Imaging Uni t

Drive

1139M005 AA

PC Drive Motor M1

Coupled to Copier Gear

Paper D rawer Paper

Take-Up Roll

1142M002AA

Upper Fusing

Roller Drive

M-6

Page 10

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM0400A

4 SEQUENTIAL EXPLANATION

Numbers given in rectangles in the following flowchart are timer values in seconds.

✽

A The power cord is plugged into the outle t.

Power cord is plugged in.

ON

AC24V for Drum heating (Transformer)

ON

B Power Switch is turned ON.

Power Switch ON

ON

ON

ON

ON

Drum Dehumidifying

Heater

ON

Paper Dehumidifying

Heater

DC5V (Power Supply Unit)

DC24V (Power Supply Unit)

Control panel

The Cooling Fan turns at full speed.

Approx. 3

Approx. 1

ON

ON

ON

The Cooling Fan turns at half speed.

Fusing Heater Lamp

Scanner Reference Position Sensor

Only when Dehumidifying

Switch is ON

✽If the S cann er i s n ot at the home posi ti on, Scan ner Mot or i s

energi z ed to move the Scanner to the home position.

ON

Lens Reference Position Sens or

✽If the Lens is not at the home position, Lens Motor is

ON

energized to move the Lens to the home position.

Mirror Reference Position Sensor

✽If the 4th Mirror is not at the home position, Mirror

Motor is energized to move the Mirror to the home

Start er setup and ATDC Sensor a ut omatic adjustment

position.

✽Only when the Imaging Unit is new. I/U Fuse blows when the

starter setup sequence is completed normally.

M-7

Page 11

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

C The Fusing Unit temperature reaches 205°C.

Fusing Thermistor detects 205°C.

ON/OFF

Fusing Heater Lamp

✽The Fusing Unit temperature control is started.

M-8

Page 12

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

D The Start Key is pressed.

Start Key ON

ON

PC Drive Motor

ON

ON

ON

Main Erase Lamp

Main Drive Motor

Image Erase Lamp

✽All LEDs are turned ON.

ON

ON

ON

Developing Bias (High Voltage Unit)

Paper Separator Corona (High Voltage Unit)

Cleaning Bias (High Voltage Unit)

✽Some model s ha v e n o Bia s Seal ins tal led de pendi ng o n

ON

their marketing areas.

Synchronizing Roller Clutch ✽For appr ox 0.2 sec. onl y

Approx. 0.3

Approx. 0.2

ON

1st/2nd Drawer Paper Take-Up Solenoid

1st/2nd D r awer Paper Take-Up

Approx. 0.1

ON

PC Drum Charge Corona/Image Transfer Corona

OFF

Solenoid (2nd Drawer Paper TakeUp Solenoid: 23 cpm copier only)

Approx. 0.2

Approx. 2.5

ON

Paper Transport Clutch

ON

Synchr onizing Roller C lutch

E Paper is taken up.

1st/2nd Drawer Paper Take-Up Solenoid ON

(2nd Drawer Paper Take-Up Solenoid: 23 cpm copier only)

Approx. 0.4

1

ON

1st/2nd Drawer Paper Take-Up Sensor

1st Drawer :

Approx. 0.7

2nd Drawer:

Approx. 1.4

(23 cpm copier

Only)

ON

Approx. 0.5

Approx. 0.2

M-9

Transport Roller S ensor

ON

Paper Leading Edge

Detecting Sensor

Approx. 0.2

ON

Exposure Lamp

OFF

Paper

Transport

Clutch

Page 13

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1

ON

Approx. 0.5

Scanner Motor

OFF

Scanner Reference Position Sensor

Approx. 0.2

Approx. 0.5

F A scan motion is completed.

SCEND signal: LOW

Approx. 0.2

Approx. 0.3

ON

All LEDs of Image Erase Lamp ON

Scanner starts return motion.

Approx. 0.6

✽For A4 crosswise, ×1.000

Approx. 0.3

OFF

Exposure Lamp

Image Erase Lamp LEDs ON/OFF control is started.

ON

Synchronizing Roller Clutch

ON

Paper Transport Clutch

ON

Scanne r Reference Positio n Sensor

M-10

Page 14

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

G The last paper moves past Transport Roller Sensor.

Transport Roller Sensor OFF

Approx. 0.6

Approx. 0.9

Approx. 1.2

OFF

Paper Leading Edge Detecting Sensor

OFF

Approx. 0.4

Approx. 0.7

Approx. 0.5

ON

1st Paper Exit Sensor

OFF

Paper Transport Clutch

Synchronizing Roller Clutch

OFF

PC Drum Charge Corona/Image Transfer

Corona (High Voltage Unit)

Approx. 0.7

OFF

OFF

OFF

OFF

PC Drive Motor

OFF

Main Erase Lamp

OFF

Image E ra se Lamp

Developing Bias (High Voltage Unit)

Cleaning Bias (High Voltage Unit)

✽Some mode ls have no Bias Seal installed

depending on their marketing areas.

Paper Separator Corona (High Voltage Unit)

H The paper moves past 1st P aper Exit Sensor.

1st Paper Ex i t S ensor OFF

Approx. 1.5

OFF

Main Drive Motor

M-11

Page 15

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM0500A

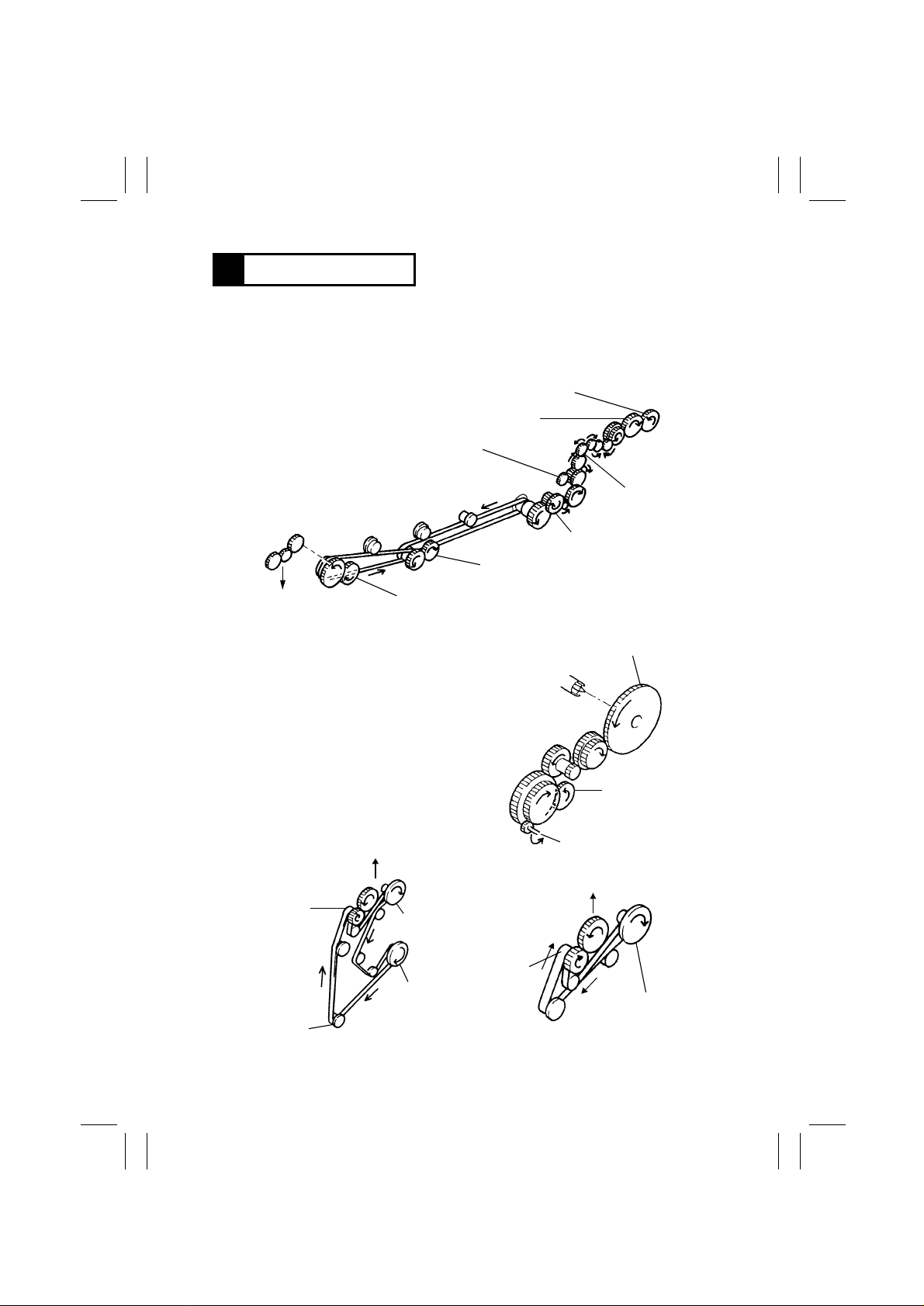

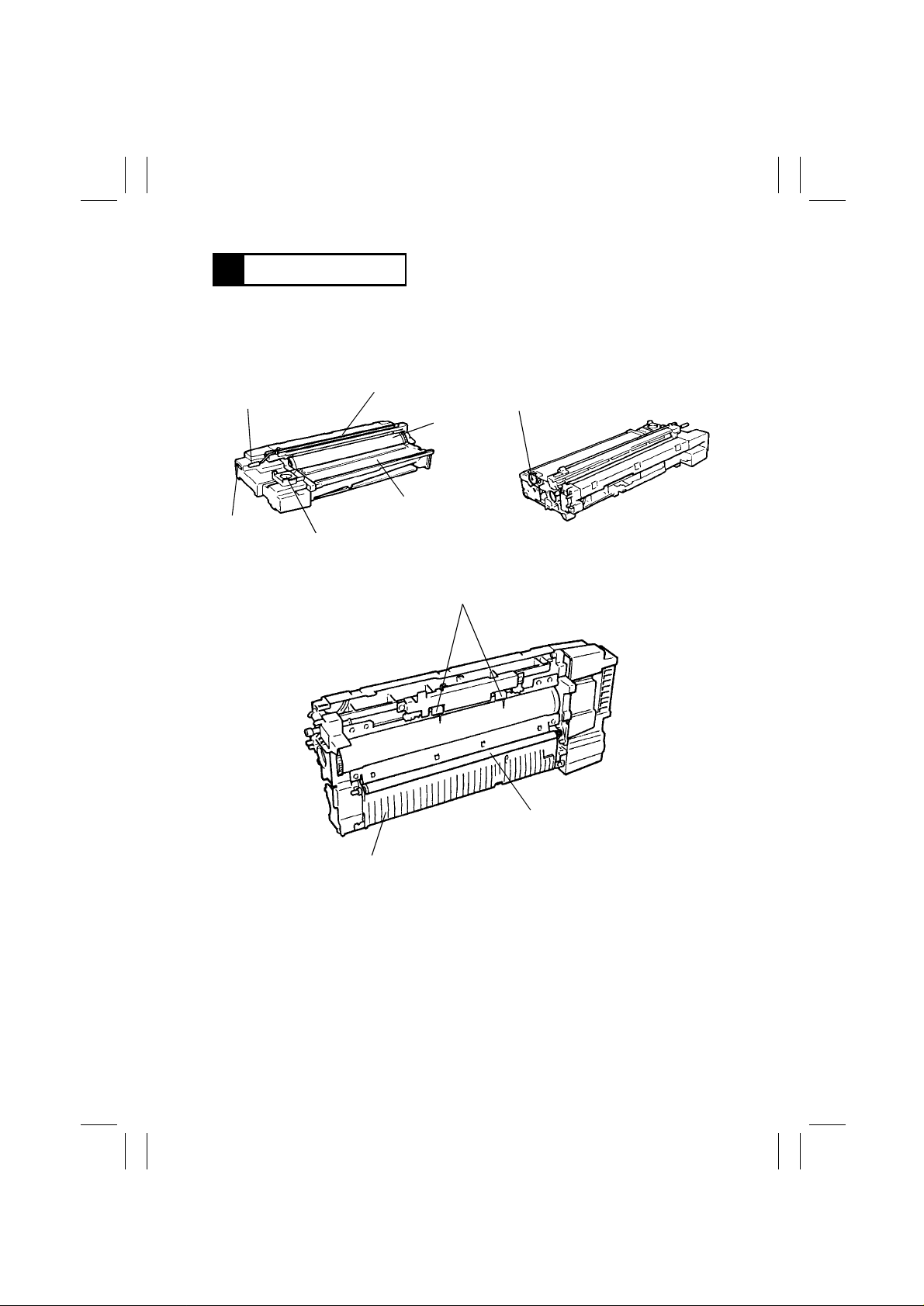

5 IMAGING UNI T

This copier is equipped w ith an Imagi ng U nit, or IU, which in tegrates a PC Drum, PC Drum

Charge Corona, Developing Unit, Cleaning Unit, and Toner Recycling mechanism into one

assembly. The Unit also includes the Upper Synchronizing Roller which facilitates clearing

of a paper misfeed.

Corona Unit Cleaning

Lever

Counter

Toner Supply Port

PC Drum

Charge Corona

Coupled to Gear in

Copier

PC Drum

Developer Mixing Chamber

1139M009AA 1139M010AA

Paper Separator Fingers

Upper Synchronizing Roller

1174M014AA

Paper Guide Plate

M-12

Page 16

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM0501A

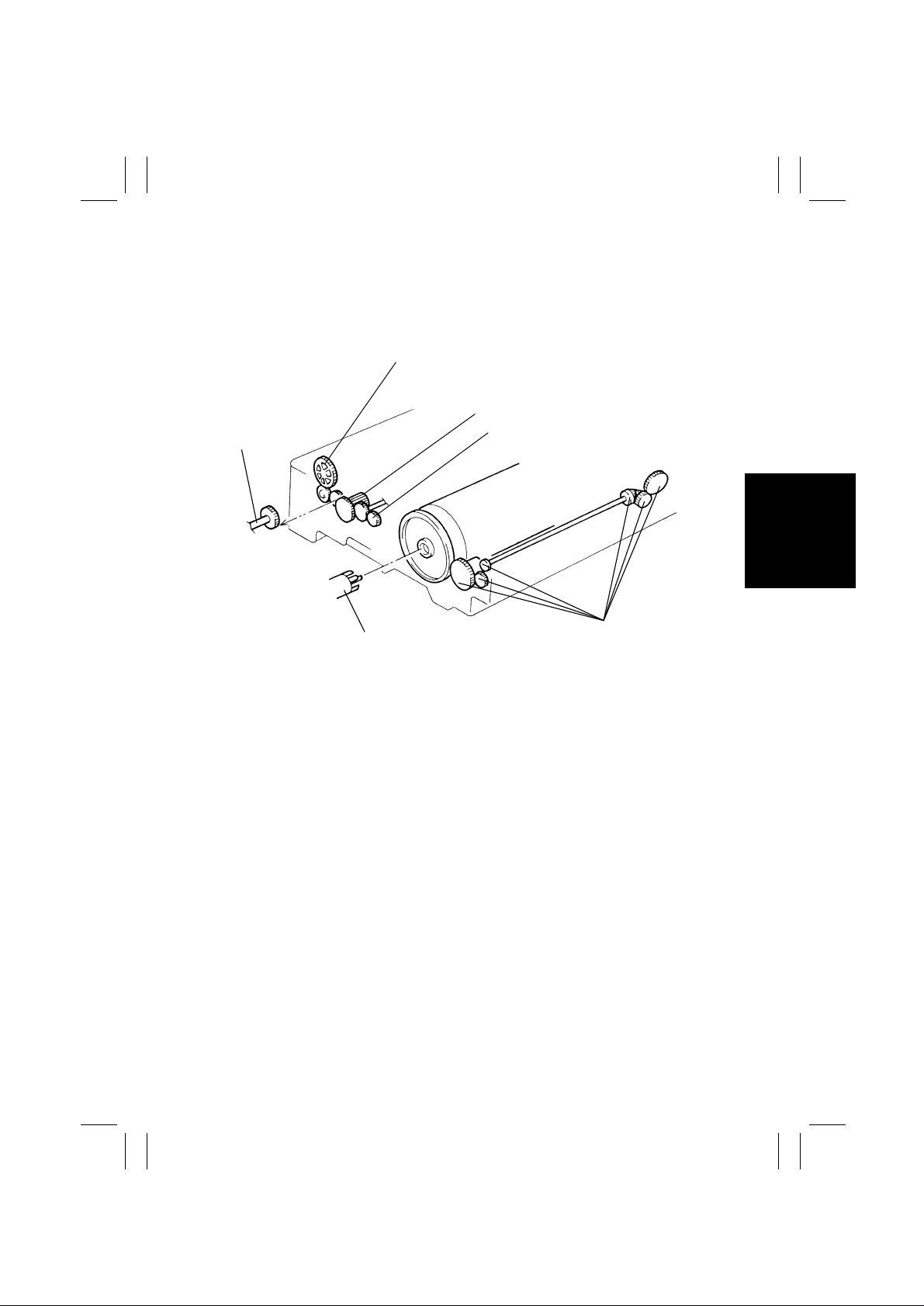

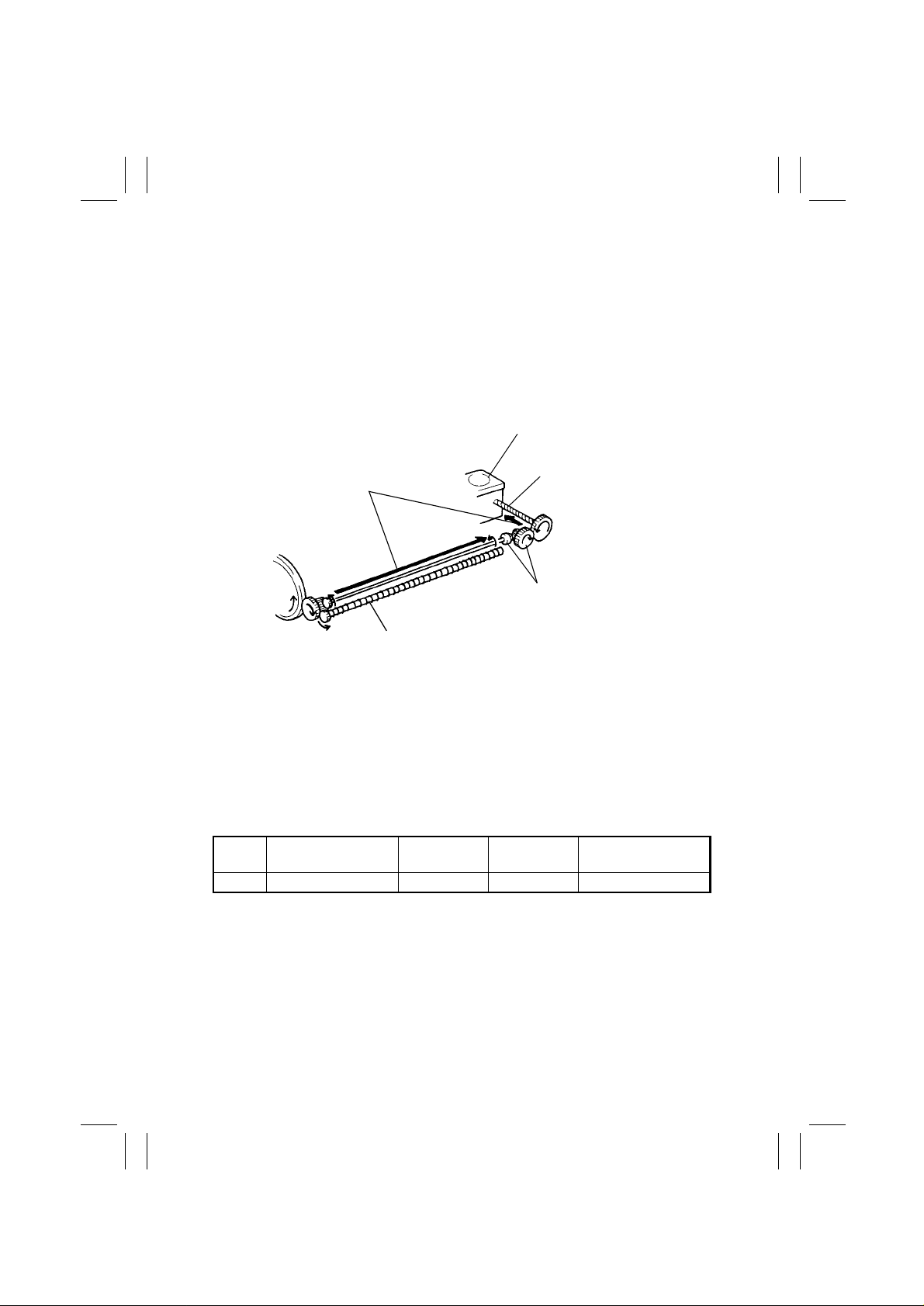

5-1. Imaging Unit Drive

Drive for the Imaging Unit is transmitte d by one of the gears on the Unit.

This particular gear is in mesh with the Imaging Unit Drive Gear in the copier.

Dev eloper Mixing Screw Drive Gear

Bucket Roller Drive Gear

Imaging Unit Drive

Gear (in Copier)

Sleeve/Magnet Roll er

Drive Gear

Coupling (in Copier)

1139M012AA

T oner Recycling Coil

Drive Gears

M-13

Page 17

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM0502A

5-2. Imaging Unit Toner Recycling

The copier is provided with a ton er recycling mechanism . The toner, which has been

scraped o ff t he surface of the PC Drum by the C lean ing Bla de and c olle cted in t he Clean ing

Unit, is conv e y ed by the tw o Toner Recycling Coils t o the Toner Supply Port and, fr om there ,

it is returned back to the Developer Mixing Chamber of the Developing Unit.

One of the gears of the Toner Recycling mechanism rece ives drive through a gear at the

rear end of the PC Drum.

Toner Supply Port

Toner Recycling Path

Toner Recycling Coil

Bev el Gears

1139M013AA

Toner Recycling Coil

1174SBM0503A

5-3. Imaging Unit Fu se

The Imaging Unit is provided with a fuse called the I/U Fuse. When a new Imaging Unit is

installed in the copier and the Power Switch turned ON, an I/U Set signal is output c ausing

the copier t o st art the starter setup sequence and ATDC Sensor automatic adjustment.

When the starter setup sequence is compl eted normally, an I/U Fuse Blow signal is output

to blow the I/U Fuse. Once the I/U Fuse is b lown, the I/U Set signals are no longer output.

This means that the starter setup sequence and ATDC Sensor automatic adjustment will

not be carried out w hen the Po w er Switch is ther eafter turned ON.

Control Signal

When Fuse is

not Blown

Fuse PWB- A PJ 1 0 A- 6 H L 2-I

When Fuse is

Blown

WIRING DIAGRAM

M-14

Page 18

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM0600A

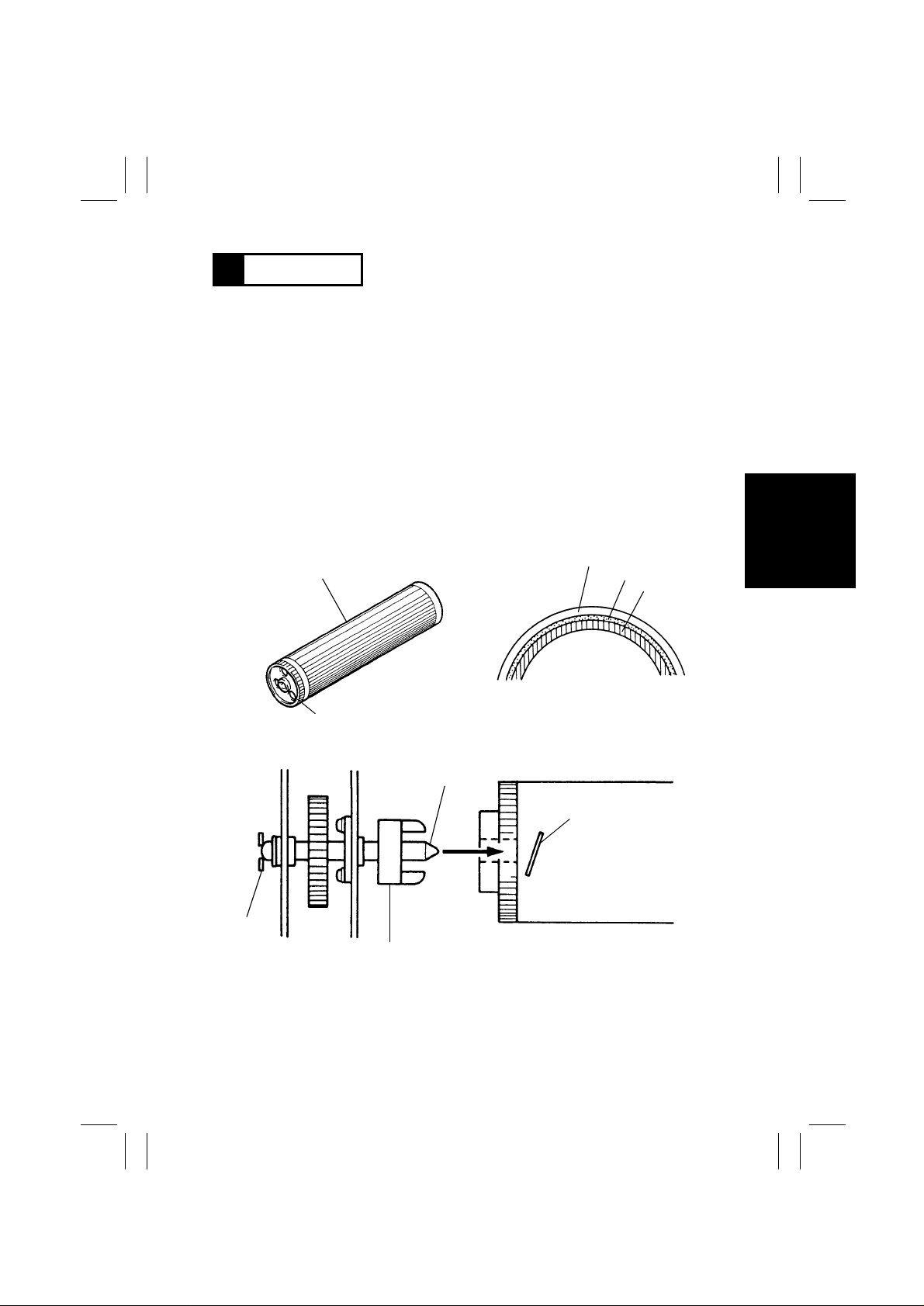

6 PC DRUM

The photoconductive drum used in t his copier is the organi c photoconductor (OPC) type.

The drum is made up of two disti nct, semiconductive materials on an aluminum all oy base.

The outer of the tw o l a yers is calle d the C har ge Transport Lay er ( CTL ), wh il e the i nner layer

is called the Ch arge Generating Layer (CGL).

The PC Drum has its grounding point in side at its rear end. When the Imaging Unit is

installed in the copier, the shaft on which the PC Drum Drive Coupling Gear is mounted

contacts this grounding point.

Handling Precautions

This photoconductor exhibits greatest light fatigue after being exposed to light over an

extended period of time. I t must theref ore be protected from light by a clean, s oft cloth

whenever the Imaging U ni t has been removed from the copier. Further, use utmost care

when handling the PC Drum to prevent it from being contaminated.

PC Drum Cross-Sectional View

Grounding

Plate

PC Drum

Gear

1139M006AA

PC Drum Drive Coupling Gear

CTL

CGL

Aluminum

Cylinder

1139M007AA

Shaft

Grounding Point

1139M008AA

M-15

Page 19

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM0700A

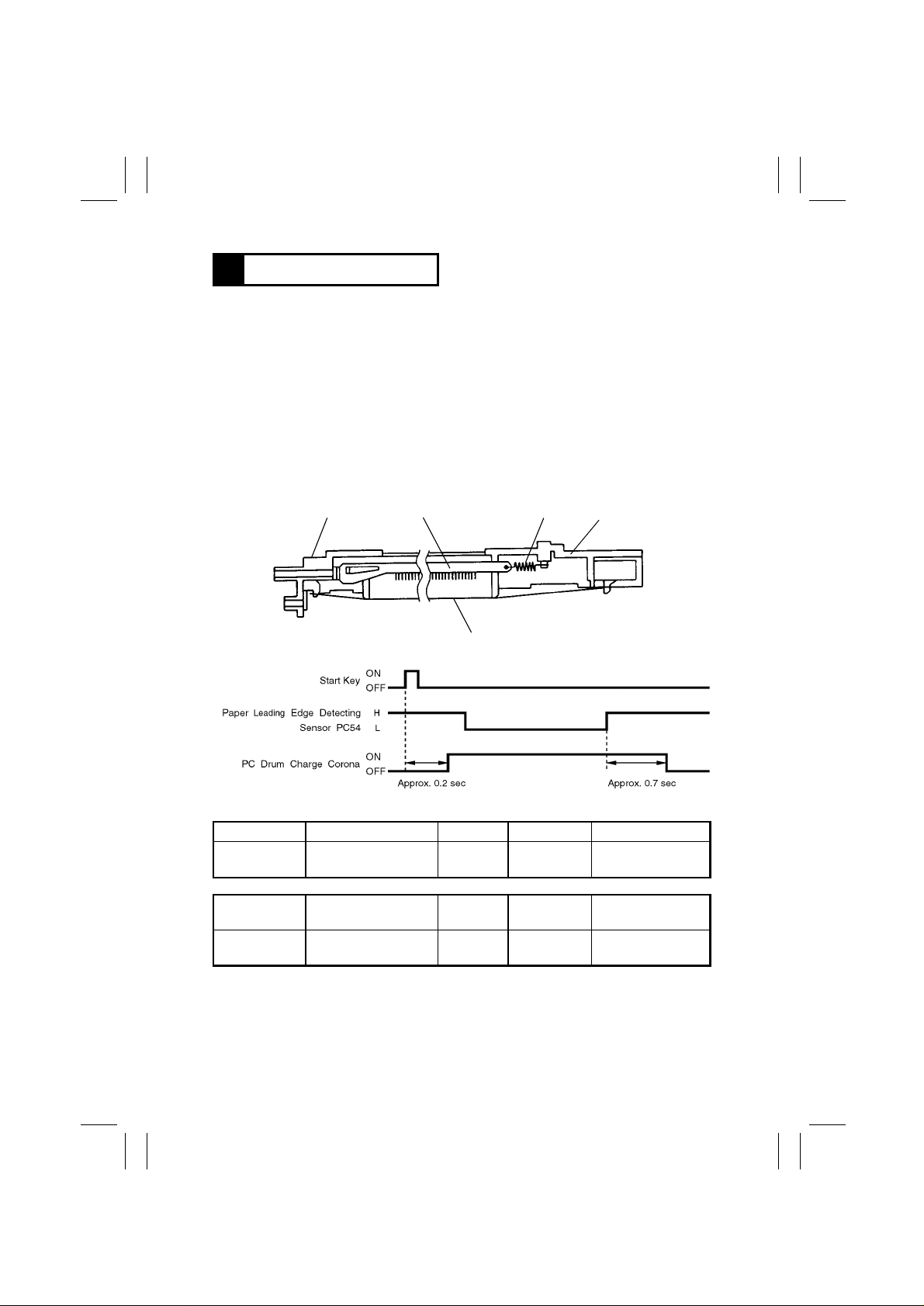

7 DRUM CHARGING

The PC Drum Charge Cor ona ha s a Scor otron grid t o depo si t a negat iv e D C charg e evenly

across the surface of the PC Drum. The grid voltage (VG) applied to the grid mesh is

selected bet w een - 650V i n the no rmal mode and -520V in th e Ph ot o mode b y the Co nsta ntVoltage Circui t in the High Voltage Unit.

The Corona Unit has a Comb Electrode which minimizes the amount of ozone produced.

The conventional wire type corona unit pro duces a large amount of ozone due to corona

discharge in ra di al dir ecti ons. The comb electro de t ype , on the ot he r hand, di sc har ges only

toward the Grid Mesh, meaning a reduced amount of ozone is produced.

The Comb Electrode can be cleaned by the user who pulls out to the front the shaft on

which a Cleaning Roller is mounted.

PC Drum

Charge Corona

Grid Voltage

(VG)

Holder

Comb Electrode

Spring

Holder

1139M030AA

Grid Mesh

Control Signal ON OF F WIRING DIAGRAM

PWB-A PJ11A-9A L H 4-C

Control Signal

Normal

Mode

Photo Mode WIRING DIAGRAM

PWB-A PJ11A-10A L H 4-C

1174T20MCA

M-16

Page 20

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM0800A

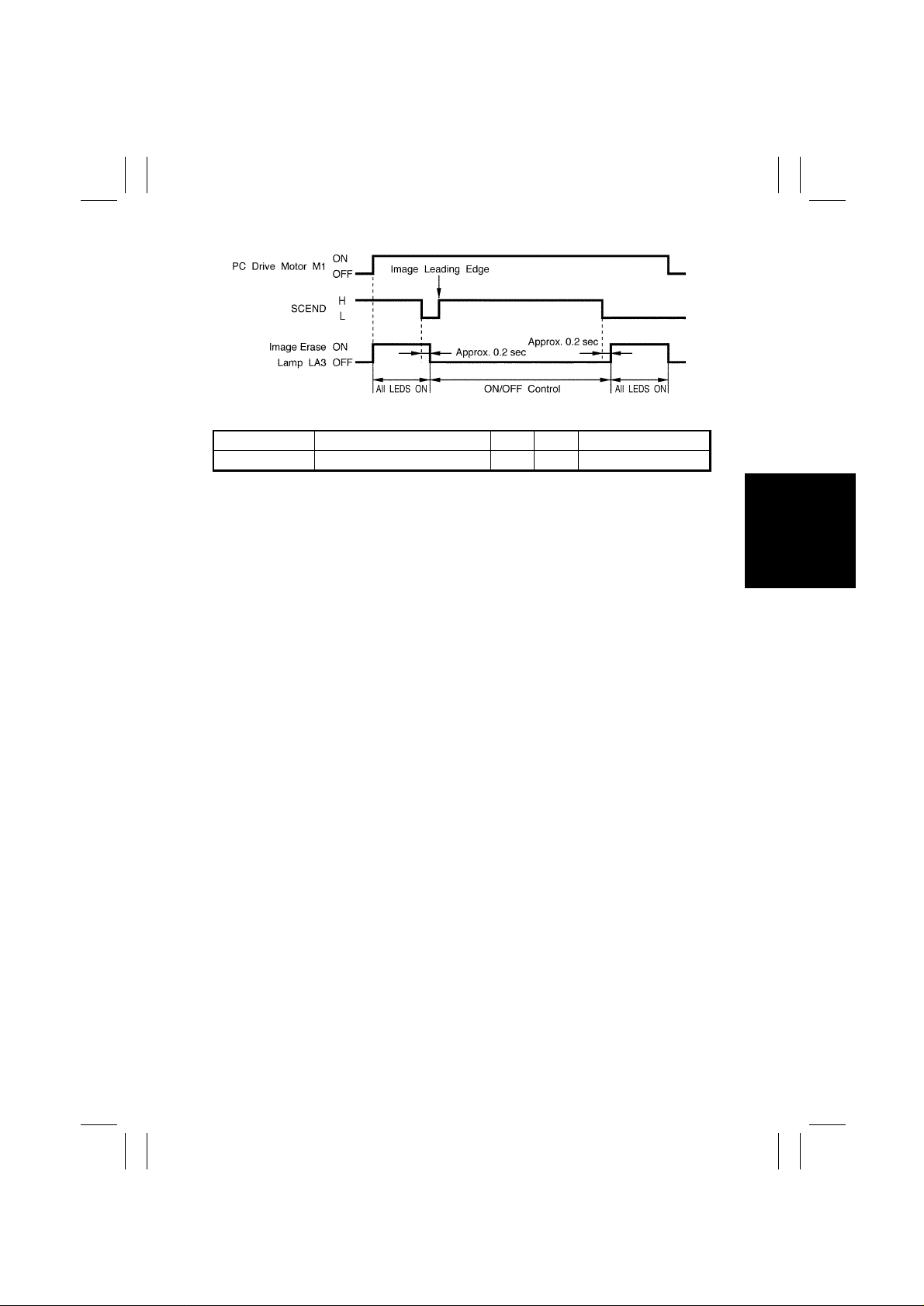

8 IMAGE ERAS E LAMP

To prevent a b lack band fro m occ urring across both the leading and trailing edges, and

along the front and rear edges, of the electrostatic latent i m age, 31 LEDs of the Im age

Erase Lamp are turned ON before development takes place, thereby reducing to a minimum the unnecessary potential on the surface of t he PC Drum. Because of the light path

involved, this copier has the edge erasing cycle between drum chargi ng and exposure.

PC Drum Charge Corona

Image Erase Lamp LA3

Exposure

1139M031AA

The position of the Image Eras e Lamp can be adjusted using the adjusting screw on the

front of the copier.

Copier F r ont Frame

Copier Rear

Frame

Compression

Spring

Image Erase Lamp

1139M032AA

Image Erase La mp

Adjusting Screw

M-17

Page 21

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

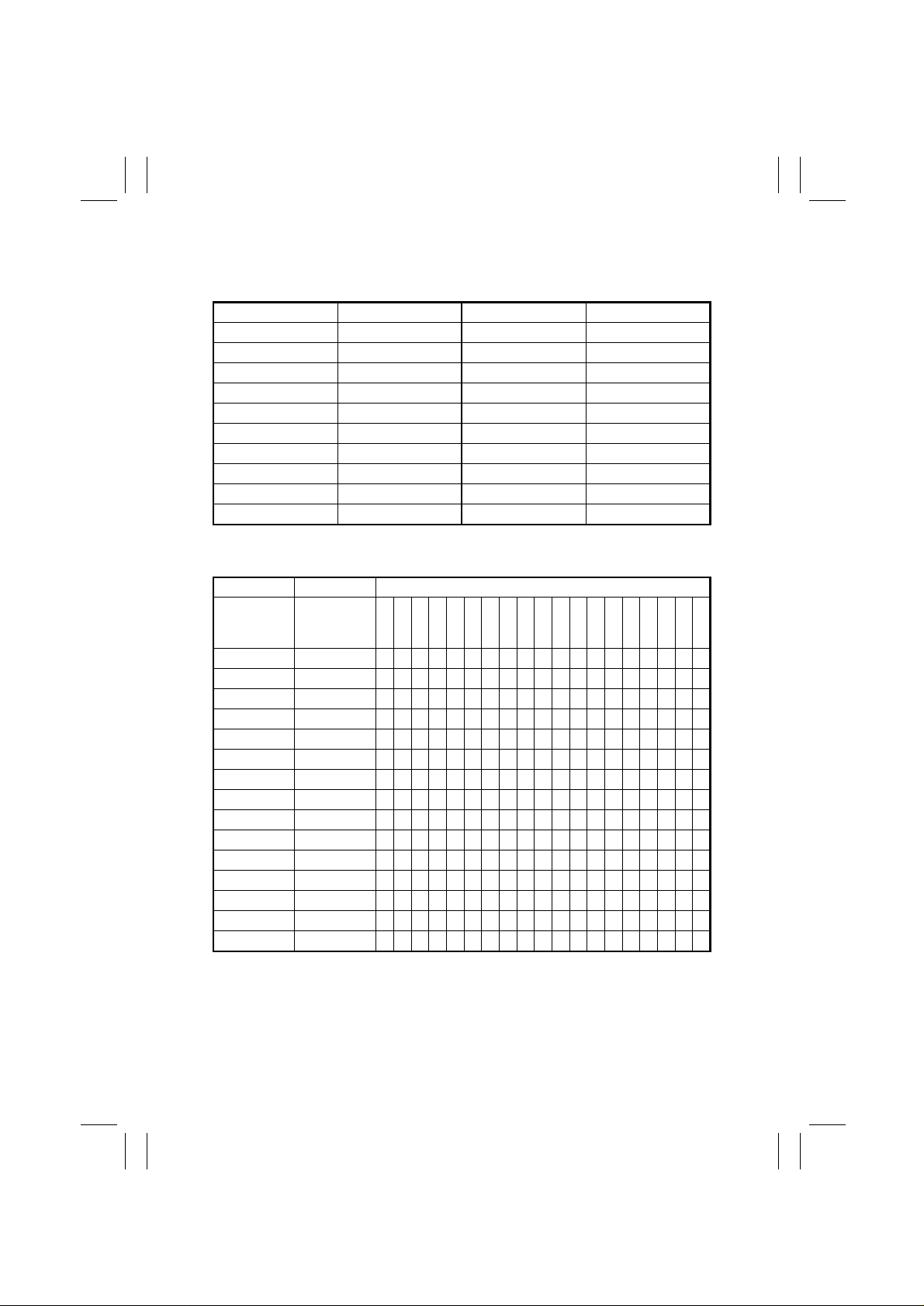

The 31 LEDs of the Image Erase Lamp are grouped as shown below. The table at the bot tom of this pag e sho ws wh ich LE Ds turn ON and OFF f o r dif f ere nt paper s iz es an d dif f e rent

zoom r atio s.

LED Group No. LED No. LED Group No. LED No.

00 LED 1 10 LED 23

01 LED 2 to 6 11 LED 24

02 LED 7 to 11 12 LED 25

03 LED 12 to 16 13 LED 26

04 LED 17 14 LED 27

05 LED 18 15 LED 28

06 LED 19 16 LED 29

07 LED 20 17 LED 30

08 LED 21 18 LED 31

09 LED 22

The smaller the number , the nearer the LED i s to the front side of the copier.

✽

LED ON/OFF Pattern

Zoom Ratio Paper Width LED Group No.

From - To

Less Than

(%)

50~53 to 152

53~57 152 to 163

57~61 163 to 173

61~64 173 to 183

64~67 183 to 192

67~70 192 to 201

70~74 201 to 212

74~78 212 to 223

78~82 223 to 235

82~86 235 to 247

86~90 247 to 259

90~93 259 to 270

93~96 270 to 281

96~99 281 to 291

99~ 291 to

: ON;

–

❍

Max. width (291 mm or more) applies to manu al bypass copying in which the copier is

✽

unable to detect paper width.

: OFF

From - To

Less Than

(mm)

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18

–––

❍

––––

❍

–––––

❍

––––––

❍

–––––––

❍

––––––––

❍

–––––––––

❍

––––––––––

❍

–––––––––––

❍

––––––––––––

❍

–––––––––––––

❍

––––––––––––––

❍

–––––––––––––––

❍

––––––––––––––––

❍

–––––––––––––––––

❍

❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍

❍❍❍❍❍❍

❍❍❍❍❍

❍❍❍❍

❍❍❍

❍❍

❍

M-18

Page 22

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

Control Signal ON OFF WIRING DIAGRAM

LA3 PWB-A PJ16A-4A ~ 9A L H 1-G

1174T22MCB

M-19

Page 23

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM0900A

9 OPTICAL SECTION

As the Scanner is moved by the Scanner Motor, the light from the Exposure Lamp is

reflecte d off the original and gui ded through the four Mirrors onto the surface of the PC

Drum to form the electrostatic la tent image.

The image is enlarged or reduced as necessary by changing the position of the Lens and

4th Mirror and varying the angle of the 4th Mirror.

23 cpm Copier

•

4th Mirr o r

Mirror Motor M7

Scanner

Lens Motor M6

AE Sensor Board

(PWB-H)

Scanner Motor M5

15/18 cpm Copier

•

Scanner Motor M5

Scanner Shaft

Lens

2nd/3rd Mirrors

Carriage

1149M008AA

1139M033AA

M-20

Page 24

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM0901A

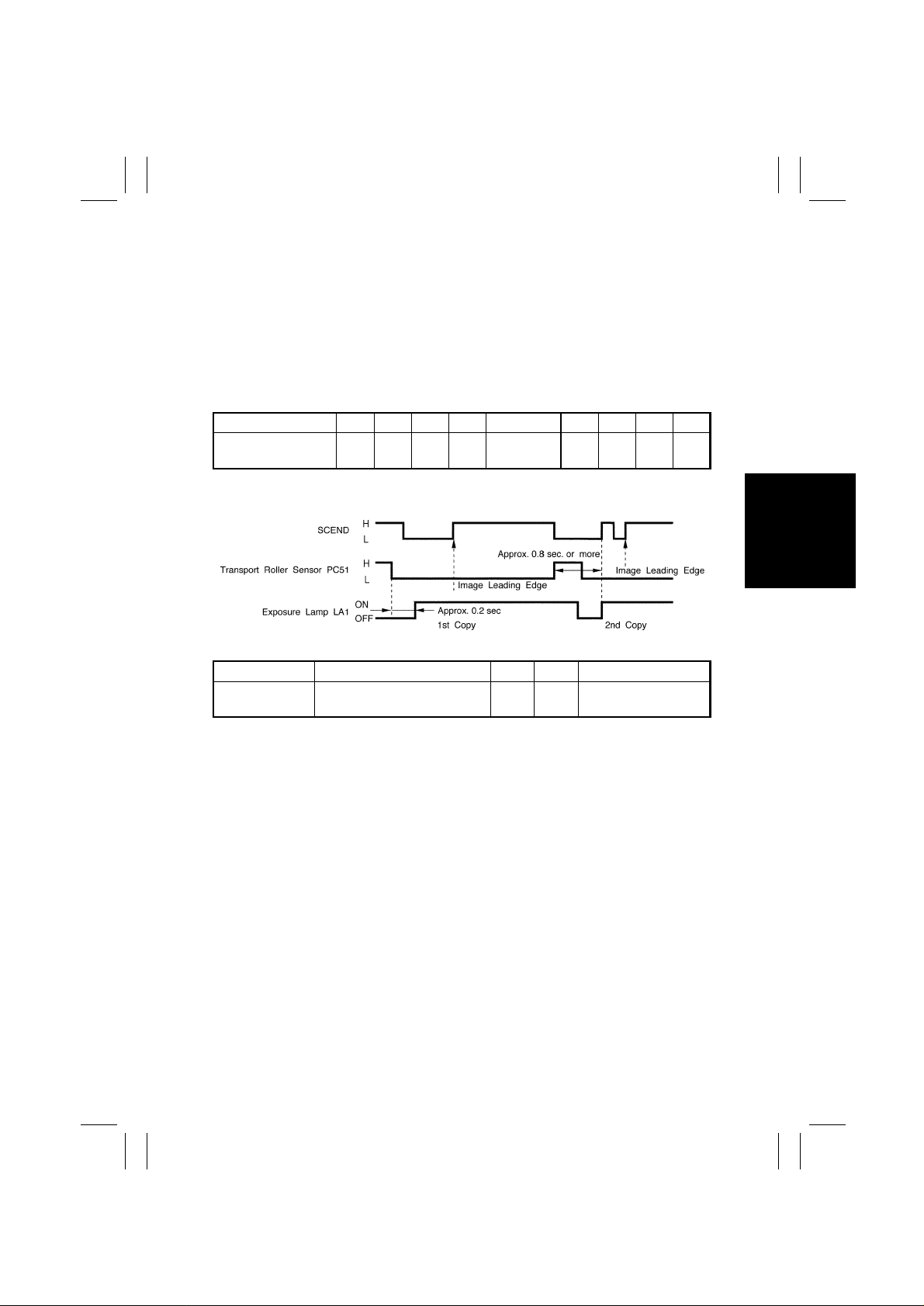

9-1. Exposure Lamp

An AC halogen lamp is used as the Exposure Lamp.

As the exposure le vel is adjust ed on the control panel, the duty ratio of the pulse of AVR

Remote from the Master Board changes t o i ncrease or decrease the Exposure Lamp v oltage, the r eby changing the image density.

In Photo mode , the v ol tage s are varied on a level 5V lo w er th an the ma n ual Ex posu re L amp

voltage s .

Manual EXP Setting9876 5 432✽1

Lamp Voltage

Diffe rence (V)

At Manual Exp osure Setting 1 only VG is reduced, thereby gi ving a lamp Voltage differ-

✽

ence equivalent to +8V.

–8 –4 –2 –1 Reference +1 +2 +4 +4

1174T13MCA

Control Signal ON OFF WIRING DIAGRAM

AVR Remote

Signal (LA1)

If reduction copie s are made using large size pa per, the trailing edge of the first copy

✽

moves past the Transport Roller Sensor after the SCEND signal for the second copy has

been generated. If the Exposure Lamp is turned ON for the sec ond copy at the same timing as the first one, therefore, the imag e for the second copy is produced on the trailing

edge of the fi rs t copy. T o p revent thi s f rom o ccurrin g, th e E xpos ure Lamp i s tu rned ON for

the second and subs equent copies whe n all of the foll owing conditions are met:

Approx. 0.8 sec. or more have elapsed after the first cop y deactiva ted the Transport

•

Roller Sensor.

The Transport Roller Sensor output i s HIGH.

•

The SCEND signal for the secon d copy is output.

•

PWB-A PJ14A- 3 L H 6-D

M-21

Page 25

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM0902A

9-2. AE Sensor

In the A u to Ex pos ure Mode , the A E Sens or on the AE Sen sor B oar d me asure s th e i nte nsit y

of the light reflected off the original, which results in the black/white ratio of a 210-mm-wide

area from the reference position of the origin al being measur ed. According to this measure ment, th e Exp osure La mp v o lta ge i s au to matica lly in creas ed or dec re ased so t ha t co pies of

consistent quality are produced.

The output from the AE Sensor is appl i ed to the Master Board which, in turn, varies the

duty rati o of the AVR Remote from it to vary accordingly the Exposure Lamp voltage.

Original Density (B/W Ratio) High Low

Intensity of Reflected Light Low High

AE Sensor Board Output High Low

AVR Duty Increased Decreased

Exposu r e La m p Voltage Increase d Decre ased

Control Signal ON OFF WIRING DIAGRAM

PWB-H

(AE Sensor)

AVR Remote

Signal (LA1)

PWB-A PJ9A-3 L H 4-F

PWB-A PJ14A- 3 L H 6-D

M-22

Page 26

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM0903A

9-3. Lamp Reflectors

The Main Reflector ensures that light from the Exposure Lamp exposes all areas of the

original. Th e Auxiliary Ref lect or r efl ects l ight o nt o t he are as that the Ex posu re Lamp cann ot

illuminate when an original that does not lie flat on the Original Glass (such as a book) is

being used. This reduces shadows which would otherwise be transferred to the co py.

The Main Reflector is of aluminum, while the Auxiliary Reflector is aluminum to which film

has been deposi ted. The same fi lm as that used on th e A uxiliary Refl ector is affix e d to both

ends of the frame to compensate for the redu ced intensity of li ght around both ends of the

Exposure Lamp.

Auxiliary Reflector

Main Reflector

Exposure Lamp LA1

1151M021AA

1174SBM0904A

9-4. Aperture Plates

Four Aperture Plates are moved to the right or left to ens ure ev en l i ght distribut i on.

M-23

Aperture

1151M020AA

Page 27

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM0905A

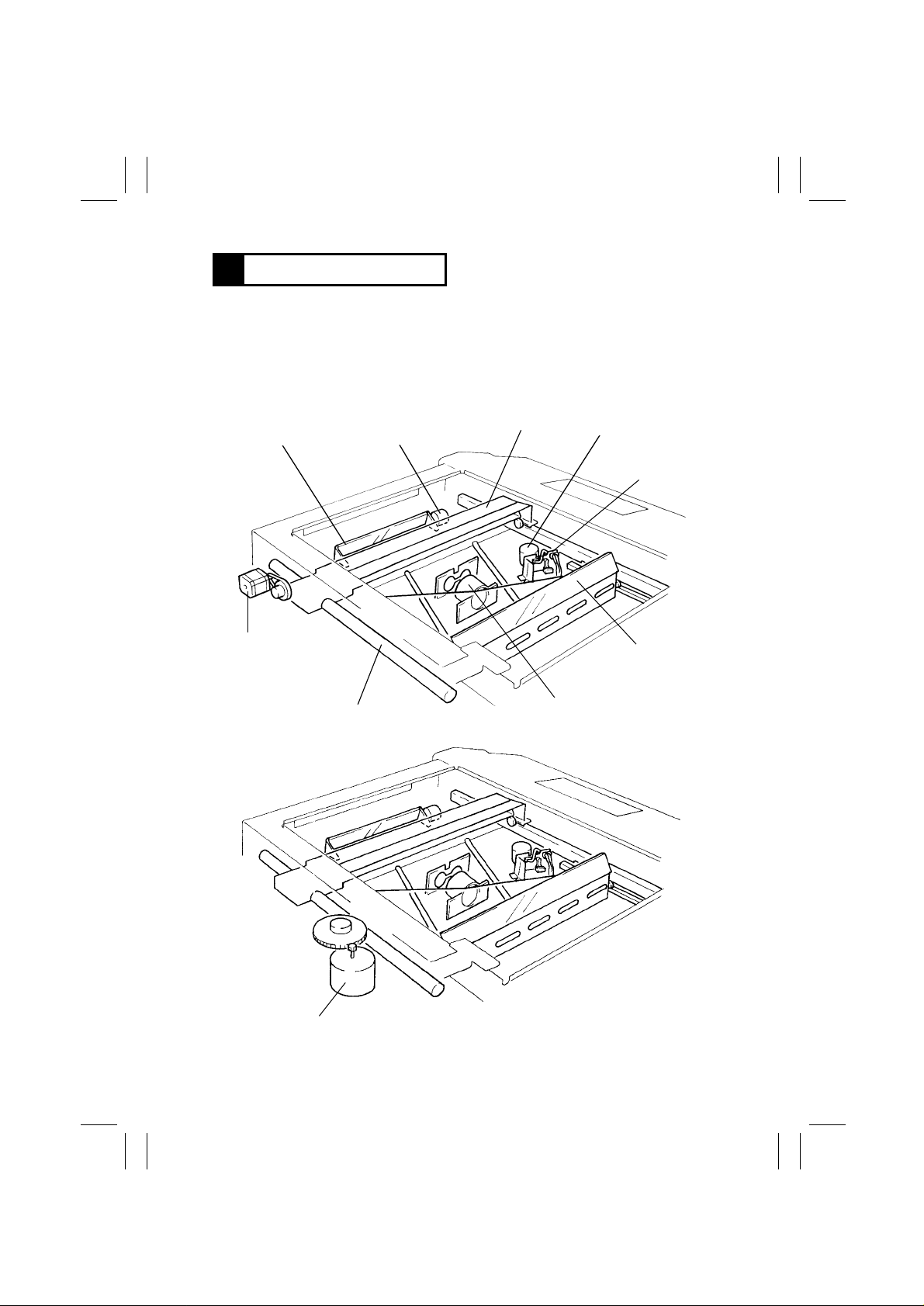

9-5. Scanner and 2nd/3rd Mirror Carriage Movement

The Scanner and 2nd/3rd Mirrors Carriage are moved by the Scanner Drive Cable fitted in

the rear side of the copier. The Cable is driven by the Scanner Motor.

Both the Scanner and 2nd/3rd Mirrors Carriage slide along th e Scanner Shaft at the rear

side. At the front side, there is a Slide Bushing attached to the underside of each of the

bodies and th at Bushing slides over the Slid e R ail. The speed of the Scanner and 2nd/3rd

Mirrors Carriage varies with different zoom rati os.

The Scanner Reference Position Sensor detects the home position of the Scanner and

2nd/3rd Mirr ors Carriag e . If the y ar e not a t th e home po si tio n whe n t he co pier is tu rned ON,

the Scanner Motor is energized to move them to the home position.

23 cpm Copier

•

Scanner

Slide Rail

2nd/3rd Mirrors

Carriage

15/18 cpm Copier

•

Scanner Shaft

Scanner Drive Cable

Scanner Motor M5

Scanner Motor M5

Scanner

Reference

Position

Sensor PC81

1149M009AA

1151M022YA

M-24

Page 28

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

The Scanner starts the scan motion as a Scan signal is output from the Master Board. At

the start of a scan motion and other heavy load conditions, the Scanner Motor requires a

large amount of current. The Current 1 or 2 signal from the Motor Drive Board is selected

accordingly to vary the amount of current supplied to the Scanner Motor.

The Current signal selection timing is control led by software.

✽

Current 1 H H L

Current 2 H L H

Operation

On receiving the Scan signal, the Motor Drive Board applies motor drive pulses, which are

out-of-phas e wit h each other, to the Scanner Motor . Th e mot or spee d is varied by changi ng

the width of the pulses applied to the Scanner Motor.

M5

Scan Signal

M5

Current

Switching

Signal 1

M5

Current

Switching

Signal 2

When the scan

speed reaches a

given level.

Control Signal Energized Deenergized WIRING DIAGRAM

PWB-F (23 cpm Copier)

PWB-E (15/18 cpm

Copier)

PWB-F (23 cpm Copier)

PWB-E (15/18 cpm

Copier)

PWB-F (23 cpm Copier)

PWB-E (15/18 cpm

Copier)

At scan start and during scan deceleration.

LH

LH

LH

At return start and

during return motion.

8-D/8-H

Control Signal Blocked Unblocked WIRING DIAGRAM

PC81 PWB-A PJ17A-7B L H 11-A

M-25

Page 29

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM0906A

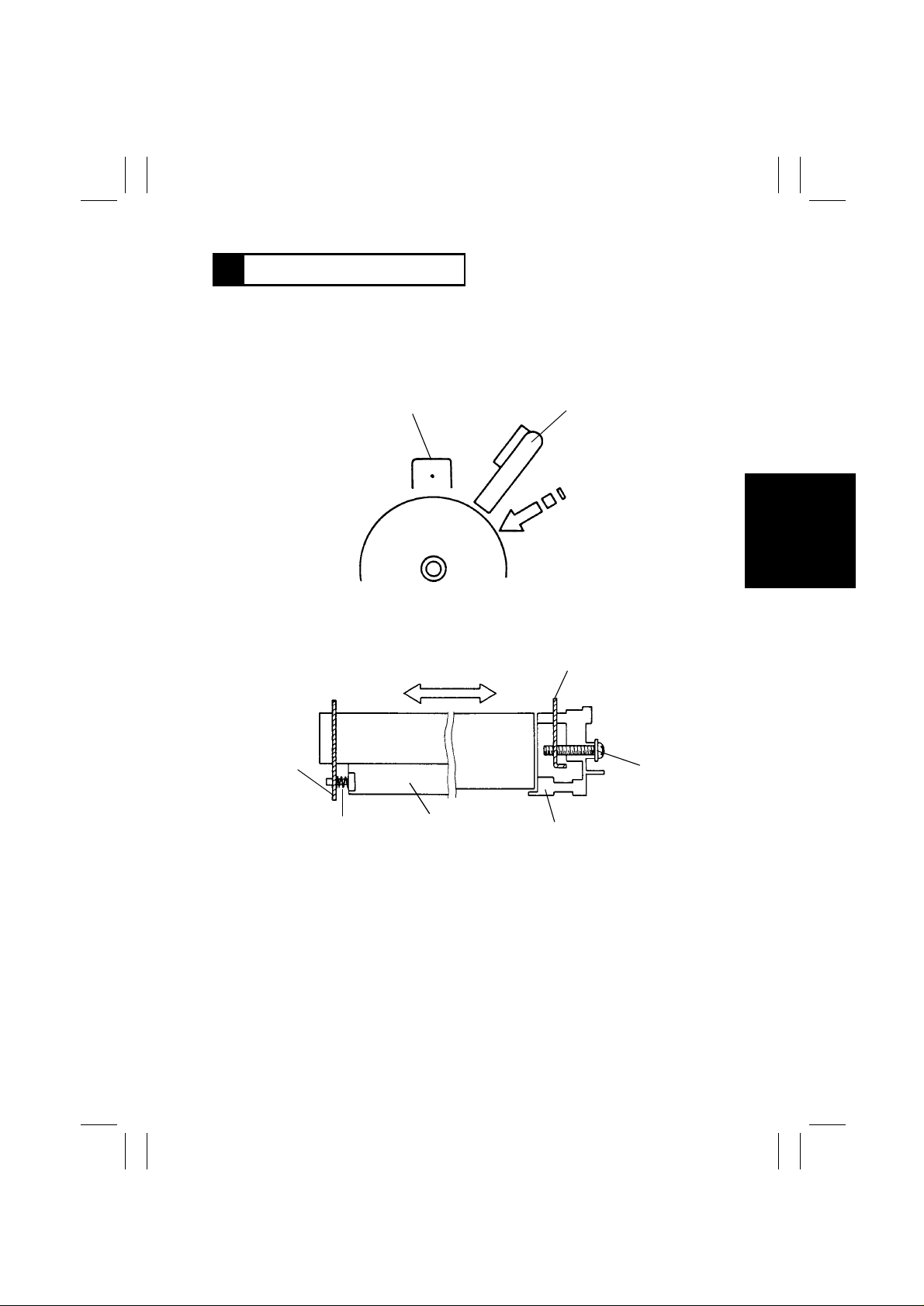

9-6. 4th Mirror Mo vement

The 4th Mirror is moved to vary the conj ugat e dist ance for a particular zo om ra ti o by drivin g

the rack -and-pinion gears at the front and rear ends of the mirror using the Mirror Motor

(stepping motor). The Levers of the Holder t o w hi ch the Mirror is mounte d slide along a

tilted r ail to chang e t he Mirro r angl e. Thi s ensur es that the li ght stri ke s th e sur face of th e PC

Drum in the direction of the normal, thereby preventing resolut i on from being degraded.

The Mirror Reference P osition Sens or i s used to control th e position of the 4th Mi rror. It

ensures that the Mirror is located at the home position when the copier is turned ON.

Mirror Reference

Position Sensor (PC86)

Levers

Mirror

Drive Shaft4th Mirror

Motor

M7

Lever

Tilt Adjusting Screw

1139M038AA

1139M037AA

Control Signal Energized Deenergized WIRING DIAGRAM

M7 PWB-A PJ16A - 2B L H 8-B/8-F

Control Signal Blocked Unblocked WIRING DIAGRAM

PC86 PWB-A PJ22A-5 L H 12-A

M-26

Page 30

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM0907A

9-7. Lens Movement

The Lens is mo ved by the Lens Drive Cable whi ch is driven by the Lens Motor (stepping

motor). The motor drive pulses sent from the Motor Drive Board drive the Lens Motor to

move the Lens a given di stance, corresponding to the zoom ratio , from the reference position determined by the Lens Reference Position Sensor.

There is a fixed-type Lens Aperture Cover provided at the rear of the Lens (on the 4th Mirror end). It limits the amount of li ght striking the surface of the PC Drum.

Lens Reference Position Sensor PC 90

Lens Base Bra cket

Shaft

Lens

Spring

Lens Drive Cable

Lens Motor M6

Lens Aperture Cover

Lens

Lens Aperture Cover

Cam

1151M023AA

1149M010AA

Control Signal Energized Deenergized WIRING DIAGRAM

M6 PWB-A PJ16A - 1B L H 8-B/8-F

Control Signal Blocked Unblocked WIRING DIAGRAM

PC90 PWB-A PJ22A-8 L H 12-B

M-27

Page 31

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM1000A

10

ORIGINAL SIZE DETECTING S ENSORS (23 cpm COP IER ONLY)

The four sensors fixed in the optical section receive the light reflected off the original t o

determine the size of the original in the Auto Paper and Auto Size mode. (The i m age density of the origi nal, or OD, that can b e detected is 0.6 or l ess.)

1174SBM1001A

10-1. Original Size Detecting Sensors

Original Size Detecting

Sensor CD1 PC11 4

Original Size Detecting

Sensor CD2 PC116

Size Reset Switch

S108

1174SBM1002A

Original Size Detecting

Board UN2

Original Cover Detecting

Sensor PC111

Original Size Detecting

Sensor FD3 PC115

Original Size Detecting

Sensor FD2 PC113

1174M009AA

10-2. Original Size Detecting Operation

Each photo receiver of the original size detecting sens ors responds to reflected light of a

given intensity with reference to the i ntensity of the light emitted by each LED. This allows

the Original Size Detecting Board to determine whet her or not there is an ori ginal within a

set distanc e.

Photo Receiver

Original

Original Glass

Set Distance

LED

1136M020AA

M-28

Page 32

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM1003A

10-3. Sensor Locations

The number and lo cation of the Original Size Detecting Sensors vary depending on the

•

marketing area as shown below.

Sensors

Areas

Metric Areas

Inch Areas

Mixed inc h/ m etric Are as

U.S.A and Canada Areas

: Standard●: Optional

❍

NOTE

If the optional sensors are installed, set Jumper Connector JP2 on the Original Size Detect ing Board as illustrated below and run the F7 operation.

CD1

(PC114)

CD2

(PC116)

FD2

(PC113)

FD3

(PC115)

❍●❍●

❍●❍●

❍❍❍❍

●●●●

Width (Metric)

A5L

B5L

A4L

B4L, B5C

A3L, A4C

Length (Metric)

Length (Inch)

CD1

CD2

LED1 LED2

Letter C

Letter L

FD2 FD3

B5C A4C,

A5L

Original Size Detecting Board UN2

Legal

FLS

B5L A4L B4L A3L

CN1

JP1

JP2

CD2 and FD3

Position

of JP2

are mounted

CN4

CN3

CN2

11”×17”

Width (Inch)

L: Lengthwise

C: Crosswise

CD2 and FD3

are not mounted

Invoice

Legal,

Letter L

Letter C,

11”×17”

M-29

1174M012AB

Page 33

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM1004A

10-4. Size Detection

The Original Size Detecting Board reads the output data provided by the original size

•

detecting sensors. By comparing the data from each sensor with the threshold level, it

determines whether there is an original placed on the Orig i nal Glass. The Origi nal Size

Detecting Board then determines the size of the original according to the combination of

the data.

Metric Area

FD2 FD3 CD1 CD2

Original Size

A3L A3L (A3L)

B4L B4L (B4L)

A4L A4L (A4L)

A5L A5L (A5L)

A4C A4C (A4C)

Letter L:

8-1/2”×11”

11”×17” 11”×17” (A3L)

Legal:

8-1/2”×14”

FLS:

8-1/2”×13”

Letter C :

11”×8-1/2”

No Original A5L

Inch Area

Original Size

11”×17” 11”×17” (11”×17”)

Legal:

8-1/2”×14”

Letter L:

8-1/2”×11”

Letter C :

11”×8-1/2”

FLS:

8-1/2”×13”

Invoice:

5-1/2”×8-1/2”

No Original Invoice

: Original Present

✽❍

If no optional sensors are mounted, data is processed as i ndicated in ( ) and the original

✽

sizes determined by the Size Detecting Board are as indicated in ( ).

The Original Size Detecting Board does not use the d ata provided by LED2 of Original

✽

Size Detecting Sensor CD2 f or the determination of the original size.

Any non-standard size is rounded off to the n earest standard size.

✽

When all sensors detect no original , the Original Siz e Detecting Board determines that

✽

A5L or Invoice size is present.

Size Determined

by UN2

Letter L (Letter L)

Legal (A4L)

FLS (A4L)

Letter C (A4C)

Size Determined

by UN2

Legal (Legal)

Letter L (Letter L)

Letter C (Letter C)

FLS (Legal)

Invoice

●

LED1 LED2 LED1 LED2 LED1 LED2 LED1

❍❍❍(❍)❍(●)❍❍❍(❍

❍❍❍(❍)❍(●)●❍●(●

❍❍●(●)●(●)●●●(●

●●●(●)●(●)●●●(●

●●●(●)●(●)❍❍❍(❍

❍●●(●)●(●)●●●(●

❍❍❍(❍)❍(●)❍❍●(❍

❍❍❍(●)❍(●)●●●(●

❍❍❍(●)●(●)●●●(●

●●●(●)●(●)❍❍●(❍

●●●(●)●(●)●●●(●

FD2 FD3 CD1

LED1 LED2 LED1 LED2 LED1 LED2

❍❍❍

❍❍❍

❍●●

●●●

❍❍❍

●●●

●●●

: Original No t Present

(❍)❍(❍)

(❍)❍(❍)

(●)●(●)

(●)●(●)

(❍)●(❍)

(●)●(●)

(●)●(●)

❍❍

●●

●●

❍❍

●●

●●

●●

)

)

)

)

)

)

)

)

)

)

)

M-30

Page 34

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM1005A

10-5. Original Size Detection Timing

Master CPU on the Master Board affirms and resets t he readings of the original size at the

followin g timi ngs.

Takes size readings : When the Original Cover is r aised to an angle of 15° or more (Origi-

•

nal Cover Detecting Sensor is deactivated).

Affirms size readings: When the Original C over is lo wered to an angle of 15° or less

•

(Original Cover Detecti ng Sen s or is just acti v a te d); or, when the Start key is p ress ed wit h

the Original Cover Detecting Sensor in the deactivated state.

Resets size readings: When the Original Cover is raised (Size Reset Switch is deactu-

•

ated).

M-31

Page 35

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM1006A

10-6. Original Cover Angle Detection (23 cpm Copier Only)

The Original Cover De tecting Sensor detects the angle of the Ori gi nal Cover as it is raised.

The following control is provided.

Original Cover raise d to an angle of 15° or more:

The size of the original is read by the Original Size Detecting Sensors.

Original Cover raised to an angle of less than 15 °:

When the Origin al Co v e r Det ect ing Senso r is act iv at ed , the origina l siz e da ta is lat ched and

Original Size Detecting Board UN2 transmits the size data to the Master Board. As soon as

the Size Reset Switch is turned ON, the size data is validated and the paper size is shown

on the control panel.

The paper size selected is reset when the Size Res e t Switch is turned OFF.

Original Cover Detecting

Sensor PC111

Size Reset

Switch S108

Magnet

1139M093AA

Control Signal Blocked Unblocked WIRING DIAGRAM

PC111 PWB-A PJ18A-2 L H 12-B

Control Signal ON OF F WIRING DIAGRAM

S108 PWB-A PJ23A-11B L H 6-C

M-32

Page 36

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

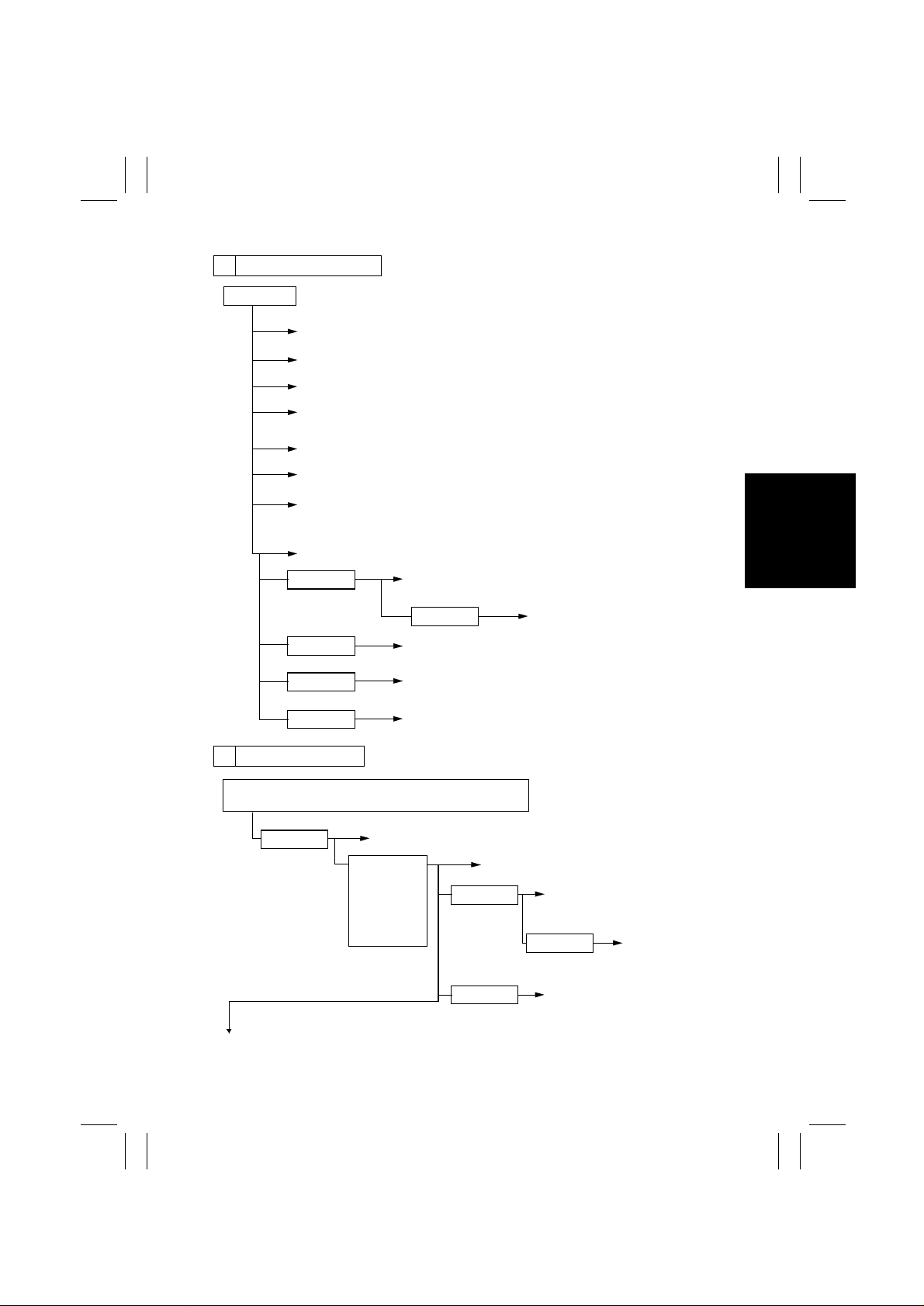

1174SBM1100A

11 DEVELOPMENT

The Developing Unit built into the Imaging Unit performs the following functions:

Mixes the t oner and carrier well to ensure that a suffici ent amount of toner is positively

•

charged.

Detects the tone r-to-carrier ratio of the developer by means of the ATDC Sensor and

•

replenishes the supply of toner as necessary.

Detects a toner em pty condition by means of the ATDC Sensor.

•

Ensures that a proper amount of toner is attracted to the PC Drum by means of its

•

Sleeve/Magnet Roller, Developing Bias, and Doctor Blade.

PC Drum

Devel oper Mixing Screw

Doctor Blade

M-33

1139M015AA

ATDC Sensor (UN3)Sleeve/Magnet Roller Bucket Roller

Page 37

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM1101A

11-1. ATDC Sensor

The ATDC Sensor instal l ed on the underside of the Developer Mi xing Chamber det ects the

varying ton er-to- carrie r r ati o of t he devel oper w hi ch fl ow s o ver it in th e Ch amber. The copier

CPU compares the detected ratio with the ratio set by the ATDC Detection Level Mode

(Tech. Rep. Choice C-90) to control toner r epl enishment.

Set T/C (%) ATDC Output Voltage (V)

6.0 2.5 (Standard)

Toner is replenished for 5 seconds (the Toner Bottle is t urned one turn, which is equivalent

to a run of 2 copy cyc l es) for each Toner Replenishing signal.

If the toner-to-carrier ratio becomes lower than 3.5% in a ton er-empty condition, the copier

inhibits the initiation of a new copy cycle (this feature can be enabled or disabled by a Tech.

Rep. Choice mode). When a ratio of 4% or more is recovered as a result of Auxiliary Toner

Replenishi ng, the copier permits the initiation of a new copy cycle.

If the Front Door is swung open and closed with a T/C ratio of less than 4%, t he copier initiates an Auxiliary Toner Replenishing sequence. (It stops the sequence as soon as a T/ C

ratio of 4.5% is reached.)

ATDC Sensor Automatic Adjustment

An automatic adjustment of the ATDC Sensor is made in the F8 Test Mode operation and

when a new Im agi ng Unit is instal led in the copier.

When a New Imag ing Unit is Installed in the Copier:

✽

Follo wing th e ex ec ution of the starter setup mod e upon pow er-up , the copier CPU read s the

output value of the ATDC Sensor and estab l ishes the reading as the reference value.

When F8 is Run after St arter Has Been Changed:

✽

Follo wi ng t he e xecution of the starter setup mode upo n pr essi ng o f the St art Key, the copier

CPU reads the out put value of the ATDC Sensor and establishes the reading as the reference value.

NOTE

If an F8 operation is run at a time w hen the starter has not been changed, it ca n result in a

wrong T/C reference val ue being set by the copier. Av oid casual use of F8.

If the setti ng value has been cleared because of the R AM Board being replaced, however,

enter the ATDC control value before the repla cement using the Zoom Up/Down Keys in the

F8 operation (without pressing the Start Key).

M-34

Page 38

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

Toner Empty Detection

The copier has no toner empty detect ing sensor and, instead, the ATDC Sensor performs

that functi on. The ATDC Sensor checks the toner-to-carrier ratio and, if it reads a T/C ratio

lower than the set level for 37 copies and, f urther, if it next reads a ratio 1% lower than the

setting , this is a toner-emp ty condition. The toner-empty cond ition is canceled after detection under any of the following conditions when the Fr ont Door is sw ung open and closed:

T/C is 4% or more: The toner-empty condit i on is canceled.

•

T/C is less than 4%: The copier initiates an Auxiliary Toner Replenishing sequence and

•

cancels the toner-empty condition as soon as T/C reaches 4.5%.

Standard

Control Signal Set T/C

UN3 PWB-A PJ10A-3 6.0% 2.5 2-H

Output

Voltage

WIRING DIAGRAM

M-35

Page 39

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM1102A

11-2. Magnet Roller

The Magnet Roller of the Sleeve/Magnet Rol ler of this copier has the following magnetic

characte rist ic s. P art of pol e S2 b efore the princ ipa l N1 pol e (i.e., the area mark e d as S2b in

the Fig. below) provides a very weak magnetic force. If developer i s compacted and clogs

at the Doctor Blade and, as a result, part of the surface of the Sleeve/M agnet Roller is not

covered with developer, the nearby developer around S2b goes to those uncovered areas

because of it s weak magnetic force. This helps prevent blank lines from occurring on the

copy .

The Sleeve Roller, onto which developer is attracted by the magnetic fields of force set up

by the poles of the Magnet Roller, turns to convey the developer toward the po i nt of development.This al so means that de veloper fresh from the Developer Mixing Cha m ber is

alwa ys brought to the point of development.

As noted ea rlie r , t he Ima ging Uni t i nte gr at es t he Developing U nit w ith t he PC Dr um in to one

body. Because of that, it is impossible to move the Developing Unit against the PC Drum,

thereb y providing a certain d istance between the PC Drum and Sleeve/Magnet R oller . The

Sleeve/Magnet Roll er has therefore been made mov able: the Bushing is pressed by compression springs thereby pressing the Positioning Collars on both ends of the Sleeve/Magnet Roller ag ai nst the PC Drum. This ensures a given distance between the PC Drum and

the Sleeve/Magnet Roller.

Magnetic Pole Positioning

Pole Having Wea k

Magnetic Force

Movable Bushi ng

Compression Spring

Fixed Bushing

M-36

PC Drum

1139M016AA

1139M017AA

Page 40

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM1103A

11-3. Developing Bias

A negativ e v ol tag e (Vb = De v e lopin g Bi as vo lt age) is a pplie d to th e Sl ee ve Roller to prevent

a foggy background on the cop y. The amount of toner attracted onto the surface of the PC

Drum depends on how much lower the PC Drum surface potential (Vi) is than Vb (i.e., the

potential difference).

When the potential difference is large, a greater amount of toner is attracted.

•

When the potenti al difference is small, a small er amount of toner is attracted.

•

Because the Sl eeve/Magnet Roller of this copier is mov able, a flat s pri ng is used as the

Bias Terminal which fol l ows the movement of the Sleeve/Magnet Roller.

Sleeve/Magnet R oller

Bias Terminal

1139M018AA

1151T01MCA

Control Signal ON OFF WIRING DIAGRAM

Developing Bias PWB-A PJ11A-8A L H 2-H

M-37

Page 41

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM1104A

11-4. Doctor Blade

The Doctor Bl ade installed over the Sleeve/Magnet Roller regulates the height of the developer brush on the surface of the Sleeve Roller. The Blade is perpendicular to t he di rection

of movement of the Sleeve/Magnet R ol ler to minimiz e variations in the distance betw een

the Doctor Bl ade and Sleeve/Magnet Roller as the Sleeve/Magnet Roller moves .

Doctor Blade

Direction of Magnet

Roller Movement

Sleeve/Magnet Roller

1139M019AA

1174SBM1105A

11-5. Sleeve/Magnet Roller Lower Filter

Except the U.S.A., Canada, and Europe

✽

There is a slit provided under t he Sleeve/Magnet Roller to collect insu fficiently charged

toner in the grounded Toner Antispill Trap. This effectively prevents the toner from spilling

onto the mechanisms inside the co pier.

Sleeve/Magnet Roller

Slit

1139M020AA

M-38

Page 42

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM1200A

12 TONER HOPPER

1174SBM1201A

12-1. Toner Hopper Locking/Un locking

The Toner Hopper is not inte grated into the Imaging Unit; instead, it is secured to the

copier. To replace an empty Toner Bottle, the user first nee ds to swing the Toner Bottle

Holder out 40° to th e f ron t. T he Ho lder pi v ots abo ut th e Toner Suppl y Port as it is swung out

or in, which effectively prevents toner from spilling when the Holder is swung out or in.

Copier Frame

Lock

Toner Replenishing

Motor M8

Toner Supply Port

1139M024AA

1174SBM1202A

40°

Toner B ottle

Toner Bottle Holder

12-2. Toner Replenishing

Drive from the Toner Replenishing Motor is tr ansmitted via the mot or shaft to the Bottle

•

Cap Claw, which turns the Toner Bottle. As the Toner Bottle is fitted to the Coupling, both

turn together during t oner replenishing.

A Metering Chamber pr ovided at the toner supply port of the Coupling regulates the

•

amount of toner that falls through the port.

There is a supply port for the exclusive use of the starter. The starter does n ot pass

•

through the Metering C hamber, which means that it takes a shorter time to loa d the

starter.

Starter

Supply Port

Metering Chamber

Coupling

Opening

1139M025AA

Bottle Cap Cla w

Toner Replenishing Motor M8

1151M018YA

M-39

Page 43

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM1203A

12-3. Shutter

The connection between the Toner Hopper and I maging Unit is provided with a Shutter

which prevents toner from spilling when the Imaging Unit is slid out of the copier.

Imaging Unit Out of Copier Imaging Unit i n Position in Copier

Shutter

1139M026AA

1139M027AA

Imaging Unit

1174SBM1204A

12-4. Toner Hopper Home P osition Detection

The Coupling is fitted with a Home Position Plate which is detect ed by the Toner Hopper

Home Position Sens or. This ensures that the Toner Bottle is located so that it s opening is

positione d on top whenever the Toner Replenishing Motor is deenergized.

Toner Replenishing Motor M8

Home Position Plate

1151M019AA

Toner Hopper Home

Position Sensor PC 112

M-40

Page 44

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM1205A

12-5. Toner Bottle Vibration

When the indentations at three places on the left-hand end ( as viewed when the Toner Bottle is in position) of the Toner Bottle move past the protrusion in the Toner Bottle Holder, the

Toner Bottle is vibrated to prevent some of the toner from remaining unconsumed in the

Bottle.

Toner Bottle

Indentations

Protrusion

1139M029AA

Toner Bottle Holder

M-41

Page 45

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM1206A

12-6. Toner Replenishing Control

1. The ATDC Sensor installed in the Imaging Unit reads the toner-to-carrier rati o of the

developer in the Developer Mixing Chamber for each copy cycle.

2. It samples the ratio 16 times and compares each with the preset level.

3. If eight or more readings out of the total 16 are lower than the preset level, a Toner

Replenishi ng signal is output.

4. The Toner Replenishing Motor is turned one complete turn for each Toner Replenishing

signal (which is equivale nt to a supply of 0.3 to 0.6 g toner).

The readings taken while the Toner Replenishing Motor is turning (it takes 5 seconds for

✽

the Toner Replenishing Motor to turn one complete turn) are igno red. This mean s that, in

a multi-copy cycle, the ATDC Sensor may take readings as the next copy cycle is started

while the Toner Replenishi ng Motor is turning; but, those readings are ignored.

Control Signal Energiz ed Deenergized WIRING DIAGRAM

M8 PWB-A PJ5A-6 H L 2-D

Control Signal Blocked Unblocked WIRING DIAGRAM

PC112 PWB-A PJ17A-2B L H 2-D

Control Signal Set T/C

UN3 PWB-A PJ10A-3 6.0% 2.5 2-H

Reference

Voltage

WIRING DIAGRAM

M-42

Page 46

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM1300A

PAPER T AKE-UP/FEED SECTION (2ND DRAWER: 23 cpm COPIER ONLY)

13

The copier is equipped with two Paper Drawers, 1st and 2nd, that can be slid out to the

front of th e copier. Each can hold up to 250 sheets of paper.

The 1st Drawer is a universal paper size type, whi le the 2nd Drawer is a fix ed paper size

type.

Paper Take-up

Solenoids (SL2, SL3)

1st Drawer Set

Detecting Switch

S65

Marketing

Area Switch

S66

Pape r Size

Detecting Switches

(S61 ~ S64)

2nd Draw er Set

Sensor PC69

Paper Sizes That Can be Loaded

Marketing

Area

Switch

S66

Inch

Inch

Areas

Metric

Paper

Take-Up Rolls

5.5” × 8.5”, 8.5” × 11”, 8.5” × 14”,

11” × 8.5”, 11” × 14”, 11” × 17”

A5L, A4L, A4 C, A3L

8” × 13”, 8.5” × 13” [G.LEGAL]

8-1/4” × 13”

Paper Take-Up Sensors (PC55, PC56)

Paper Empty Sensors (PC101, PC102)

1st Drawer

(Universal Paper Size)

2nd Drawer

(Fixed Paper Size)

1151M004YA

1st Drawer 2nd Drawer

8.5” × 11” [LETTER], 11” × 8.5”

[LETTER], 8. 5” × 13” [G.LEGAL],

8.5” × 14” [LEGAL],

11” × 17”, 5.5” × 8.5” [INVOICE],

8” × 10.5” [G.LETTER]

10.5” × 8” [G.LETTER], 8-1/4” × 13”,

10” × 14”, 11” × 14”, 210 × 280,

280 × 210, 216 × 297, 216 × 320,

220 × 280, 220 × 330, 280 × 420

M-43

Page 47

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

Marketing

Area

Switch

1st Drawer 2nd Draw er

S66

Metric

Metric

Areas

Inch

Except Taiwan

✽

1174SBM1301A

A3L, B4L, A4L, A4C, A5L, B5C,

B5L (Taiwan Only), 8” × 13”,

8.5” × 13”✽, 8-1/4” × 13”

5.5” × 8.5” [INVOICE],

8.5” × 11” [LETTER]✽,

8.5” × 14” [LEGAL]✽, 11” × 17”

A3L, B4L, A4L, A 4C, A5L, 8” × 13”

8-1/4” × 13”, 10” × 8” [QUARTO],

210 × 280, 216 × 297, 297 × 216,

216 × 320, 220 × 280, 297 × 430

✽

13-1. Edge Guide and Trailing Edge Stop

1st Drawer

The 1st Drawer is a universal type allowing the user to slide freely the Edge Gui de and

Trailing Edge Stop to accommodate paper of different sizes.

The Edge Gu ide and Trailing Edg e S to p can be lo cked into po si tio n b y meshi ng t he no tche s

in the Lock Lever wi t h t h ose in the Drawe r.

Draw er Side

Lock Lever

Trailing Edge Stop

1139M053AA

1139M052AA

Edge Guide

1139M054AA

2nd Drawer

The 2nd Dr awer is a fixed paper size typ e, in which the Edge Guide and Trailing Edge Stop

are screwed into fi xed positions.

The Edge Guid e is provided wit h an Edge Pad (whi ch is Velcro) that prevents double feed

and ensures that the paper stack keeps its correct alignment with regard to the paper path

reference positio n.

M-44

Page 48

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM1302A

13-2. Drawer P ositioning

Each of the 1st and 2nd Drawers is positioned by fitting its Positioning Plat e on the paper

take-up end into the groove in the Drawer Frame. It is then secured in positi on by the magnet insta lled in t he Dr a we r Front Cov er on the paper tak e- up end . The tabs on both sid es at

the front of the Draw er ensure that the Drawer cl i cks into p osition. Any deviation in the

paper path reference position can be adjusted within ±2 mm by movin g the Fron t C over of

the Drawer to the front or rear.

Tab

Rear End

Positioning

Plate

Front End

1139M056AA

Position

Plate

1151M024AA

1139M057AA

1174SBM1303A

13-3. Paper Lifting Plate

The Paper Lifting Plate of each Drawer is raised at all times by two Paper Lifting Springs.

For the 2nd Drawer, the type and position of the Paper Lifting Springs must be changed

according to the paper size. (For details, see DIS/R EASSEMBLY, ADJUSTMENT.)

Paper Lifting Plate

Pape r Li fting Springs

M-45

1139M058AA

Page 49

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM1304A

13-4. Drawer-in-Position Detection

The copier detects that the Drawer is slid into position as follows.

1st Drawer

When the 1st Drawer is slid into the copier, the Drawer Fr ame presses the 1st Drawer Set

Detecting Switch installed on the back panel of the copier.

2nd Drawer

When the 2nd Drawer is slid into the copier, the Rib on the Drawer Frame blocks the 2nd

Drawer Set Sensor.

Paper Size

Detecting Switches

S61

S62S63

1st Drawer Set

Detecting Switches S65

1139M060AA

Drawer Frame

2nd Drawer Set Sensor PC69

<Control>

Control Signal ON OF F WIRING DIAGRAM

S65 PWB-A PJ15A-11 L H 15-B

Control Signal Blocked Unblocked WIRING DIAGRAM

PC69 PWB-A PJ2A-2 L H 17-A

1139M061AA

M-46

Page 50

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM1305A

13-5. Universal Tray (1st Drawer) Paper Size Detection

The length (feeding direction) and width (crosswise direction) of the paper are independently detec ted and the copier determines the paper size by combining the two separate

detections made.

On the bottom of the tray is a le v er fit ted to the Trailing Edge Stop and another lev er f itted to

the Edge Guide. These le vers actuat e and deactuate Paper Size Det ecting Switches to

allow the copier to determine a particular paper size.

The Marketing Area Switch is used t o set the type of paper to be used (inch or metric).

S62

Marketing Area

Switch S66

S61

S63

S64

Drawer Set Detecting

Switch S65

NOTE

The number and the installed position of

the Pap er Take-Up Roll s vary depe nding o n

the marketing areas: inch or metric. See

pp. M-43 and M-44 for the sizes of the

paper that can be taken up and f ed out of

the drawer.

1151M003AA

Paper Size Detecting Switches

Length (FD) Width (CD)

S61 S62 S63 S64

ON ON ON – 402.0~402.0 A3 11” × 17”

ON ON OFF

ON OFF OFF

OFF OFF OFF – 317.2~272.0 A4L Letter L

OFF OFF ON

OFF ON ON

OFF O N OFF

The 2nd Dra w e r acc epts only pa per of a fi x ed s iz e an d ha s no pa per si z e de te ctin g syst em.

(The paper size is input from the control panel using a Tech. Rep. Mode.)

OFF

ON 11” × 14”

OFF

ON 11” × 14”

OFF

ON Letter C

OFF

ON A4L Letter C

OFF

ON Letter L

Paper Length

402.0~349.2 B4

349.4~317.2 FLS

272.0~222.0 B5L

222.0~195.0

195.0~195.0 B5C

Inch/Metric Setting Switch S66

Metric Inch

8-1/2” × 14”

8-1/2” × 14”

Letter L

A5L Invoice L

Letter C

M-47

Page 51

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

<Control>

Control Signal ON OF F WIRING DIAGRAM

S61 PWB-A PJ15A-1 L H 14-A

S62 PWB-A PJ15A-3 L H 14-A

S63 PWB-A PJ15A-6 L H 15-A

S64 PWB-A PJ15A-9 L H 15-A

S66 PWB-A PJ2A-4 L H 17-B

1174SBM1306A

13-6. Paper Empty Detection

When the Dr a we r runs ou t of p ape r, the Ac tuat or for the Paper Empty Sens or drops int o the

cutout in the Paper Lifting Plate. This activates the Paper Empty Sensor and the copier

detects that the Drawer has run out of paper.

As noted ea rlie r , t he Paper Lif tin g Pl ate is ra ised a t all t imes b y the Paper Lifting Springs. To

prevent the Actuator for the Paper Empty Sensor from being caught by the paper stack

when the Drawer is slid out of the copier, it is tilted slightly. This, however, results in the

operating stroke of the Actuator becoming small, which increases the possibility of the

Actuator activating the Sens or by the flexing of a sheet of paper a s it is ta ken up and fed in.

To prevent thi s false detection of a paper-empty condition, the paper empty detection is

enabled only when the P aper Take-Up Roll is in the retracted positio n.

Paper Empty Sensor (PC101, PC102)

1139M062AA

Actuator

<Control>

Control Signal Blocked Unblocked WIRING DIAGRAM

PC101 PWB-A PJ4A-6 L H 17-F

PC102 PWB-A PJ3A-4 L H 17-D

M-48

Page 52

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM1307A

13-7. Paper Separat ing Mechanism

Each Dra wer has Fingers that separate the top sheet of paper from the rest of the paper

stack at paper take-up. The Fingers are fi tted to the right front and rear corners of the

Drawer. When the Paper Take-Up Rol l starts turning to tak e up the top sheet of paper, its

turning f orce is di rectl y t r ansmit ted t o the to p she et of pa per as it is in dire ct con tact wit h the

Pape r Take-Up Roll. That force overcomes the block of the Fingers, causi ng the top sheet

of paper to ride over the Finge rs and be fed out of the Drawer into the copier.

As to the s econ d s hee t of pap er, the paper transport f orce obt ain ed t hro ugh fri cti on w it h the

top sheet of pa per is weak and does not al l ow the second sh eet of paper to ride over the

bloc k of the Fingers. Hence, the second sheet of paper remains stationary with the rest of

the paper s ta ck in t h e D rawe r.

When there are only two sheets of paper left in the Drawer, the bottom sheet can be fed

with the top one if the fricti on of the Paper Lifting Plate is weak. The F r iction Plate affixed to

the Paper Lifting Plate prevents this from happening.

Paper Take-Up Roll

Paper

Paper Lifting PlateFriction Plate

Separator Finger

1139M063AA

M-49

Page 53

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM1308A

13-8. Paper Take-Up Roll

Since the Paper Lifting Plate is raised at all times by the Paper Lifting Springs, paper is

wedged in the mec hanism when the Drawer is slid out of the copier if the Paper Take-Up

Roll is rou nd in s hape . So t he Take-Up Ro ll i s s emici rcula r a nd th e circ u lar part of th e Roll i s

positioned on top at times other than take-up. For convenience, we call this position of the

Paper Take-Up Roll the “retracted” position.

The Pap er Take-Up Roll is g rooved to k eep good friction e ven under hea vy l oadi ng. T he 1st

Draw er, which is a universal type to accommodate paper of di fferent sizes, is provided with

five (four in areas usi ng only inch paper) Paper Take-Up Rolls. T he 2nd Drawer accommodating paper of a fixed size only is equip ped with two Rolls whose positions must be

changed acc ording to the paper size. (F or the positions, see DIS/REASSEMBLY, ADJUSTMENT.)

The Paper Take-Up Roll is driven wh en the Paper Take-Up Solenoid is energized. The Roll