Page 1

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

EP1054/EP1085/EP2030

TR OUBLESHOOTING

10794

Page 2

I I

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030

98.05.15

TROUBLESHOOTING

CONTENTS

1.

INTRODUCTION

l-l.General Precautions

l-2. How to Use This Book

l-3. Reading the Text

2.

I/O PORT CHECK

2-l.Controlled Parts Check Procedure

2-2.

Port Check

3.

PAPER TRANSPORT FAILURE

3-l. Paper Misfeed

3-2.

Misfeed Detected Types and Detection Timings

3-3. Misfeed Clearing Procedures

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

4.

MALFUNCTIONS

4-l. Self-Diagnostic Function

4-2. Troubleshooting Procedures

(1)

(2)

(3)

(4)

(5)

(6)

CO500:

(7)

(8)

(9)

.............................................................................................

................................................................................

.............................................................................

.....................................................................................

...........................................................................................

........................................................................................

List

.....................................................................

..........................................................................................

..................................................................

Copier Take-Up

PF-206 Take-Up Misfeed (23 cpm Copier)

PF-112 Take-Up Misfeed (23 cpm Copier)

Port

Bypass

Transport/Separator Misfeed

Fusing/Exit Misfeed

Duplex Unit Vertical Transport/Storage Misfeed (23 cpm Copier)...T-2 8

Duplex Unit Take-Up Misfeed (23 cpm Copier) ...............................

COOOO: Main Drive Motors failure to turn

COO01 : Main

COOlO:

PC Drive Motors failure to turn

COO1 1: PC Drive Motor turning at abnormal timing

COO4C:

Cooling Fan Motors failure to turn

COO70:

Toner Replenishing Motors failure to turn

CO071: Toner Replenishing Motor turning at abnormal timing

CO400:

Exposure Lamps failure to turn ON

CO41 0: Exposure Lamp turning ON at abnormal timing

Warm-up failure

CO51 0: Abnormally low fusing temperature

CO520:

Abnormally high fusing temperature

CO600:

Scanner Motor malfunction

CO61 0: Lens Motor malfunction

CO620:

Mirror Motor malfunction .....................................................

CO900:

3rd Drawer Paper Lift-Up Sensor malfunction

CO904:

3rd Drawer Paper Lift-Up Motor malfunction

CO950:

4th Drawer Paper Lift-Up Sensor malfunction

C0954: 4th Drawer Paper Lift-Up Motor malfunction

CO990:

Main Tray Upward Motion Failure

CO991:

Main Tray Downward Motion Failure

C0992: Main Tray Downward Motion Failure

C0993: Main Tray Upward Motion Failure

Misfeed ................................................................. T-l 5

Misfeed ........................................................................

.........................................................................

............................................................................................

..........................................................................

....................................................................

Drive Motor turning at abnormal timing

*Only when options are used

..........................................................

.....................................

......................................

......................................

........................................................... T-24

......................

.........................

.....................................

..................

...................................

....................... T-49

......

T-l

T-l

T-l

T-l

T-2

T-2

T-3

T-l 1

T-11

T-l 3

T-15

T-18

T-20

T-22

T-26

T-31

T-33

T-33

T-39

T-39

T-40

T-41

..T-4 2

T-43

T-45

T-47

I I

I

Page 3

I I

FrameMaker

98.0515

Ver.5.5(PC)

EP1054/EP1085/EP2030 TROUBLESHOOTING

I I

C0994: Main Tray Elevator

(10) C0998: Shifter Transfer Failure

CO999:

Shifter Return Failure

C099A:

Shifter Return Failure

C099b:

Shifter Transfer Failure

CO99c:

Shifter Motor

(11)

C099E:

Shift Gate Position Detecting Failure

CO99F:

Shift Gate Position Detecting Failure

C0996: 3rd Drawer Lock Release Failure

COF79:

Paper

Empty

(12)

COdOO:

Duplex Unit Front/Rear Edge Guide Plates home position

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

detection failure

COd20: Duplex Unit Trailing Gate Unit home position detection failure

COd50: Duplex Unit Drive Motors failure to turn

COd51: Duplex Unit Drive Motor turning at abnormal timing

(13)

COFl

0: Faulty AE Sensor level

COF30:

ATDC

Sensor malfunction

(14) COF02: Original size detection error (Defective CPU)

COFE2 to COFFE: Original Size Detecting Sensor failure

(15)

Power is not TurnedON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T-61

(16) El, E2

5. IMAGE FAILURES

5-l. Image Failure Troubleshooting

5-2. Initial Checks

5-3.

Troubleshooting Procedures Classified by Image Failures

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blank copy .......................................................................................

Black copy

Low Image Density

Foggy background

Black

Black Spots

Blank Streaks

Void Areas

Smear on Back

.......................................................................................

or

Streaks

......................................................................................

or

.......................................................................................

M26s

Failure to Turn

M27s

Failure to Turn

Sensor Failure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..........................................................................

...........................................................................

Bands

...................................................................

Bands

...................................................................

................................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T-55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T-59

. . . . . . . . . . . . . . . . . . . . . . . . . . . T-51

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T-53

. . . . . . . . . ..T-57

. . . . . . . . . . . . . . . T-60

. . . . . . . . . . . . . . . . . . . . . T-65

T-63

T-64

T-64

T-64

T-66

T-66

T-67

T-68

T-69

T-69

T-70

T-71

T-7 1

ii

I

I

Page 4

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

1 INTRODUCTION

1-1. General Precautions

1. When servicing the co pier with its covers remo ved, use utmost c are to prev ent your

hands, clot hin g, and to ols from be ing caug ht in revol vin g parts includin g the chai ns and

gears.

2. Before attempting to replace parts and unplug connectors, make sure that the power

cord of the copier has been unplugged from the wall outlet.

3. Never cr ea te a closed c irc uit acros s connecto r pi n s except those s p ecified in the text

and on the printed circ ui t.

4. When creatin g a closed circuit and measuring a volt age across connector pins specified in the text, be sure t o use the green wire (GND).

5. When the user is us ing a word processo r or personal compute r from the wall outlet of

the same line, take necessary steps to prevent the circuit breaker from opening due to

overloads.

6. Keep all disassembled parts in good order and keep tools under control so that none

will be lost or damaged.

1-2. How to Use This Book

1. If a component on a PWB or any oth er func tio nal un it inc lud ing a motor is defectiv e , the

text only instructs you to replace the w hole PWB or functi onal unit and does not give

troubleshooting procedure applicable withi n the defect i ve unit.

2. All troub les hoo ti ng pr ocedu res c ontai ned h erei n as sume t hat t he re ar e no b rea ks in th e

harnesses and cords and all connectors are plugged into the right positions.

3. For the removal procedures of covers and parts, see DIS/REASSEMBLY, ADJUSTMENT.

4. The troub les hoo tin g pr ocedu res are given in the ord er of g rea te r f requ ency of t roub l e or

order of operation.

5. The procedures pre cl ude possi b le malf un ctio ns due t o nois e and ot her e xt ernal cau ses.

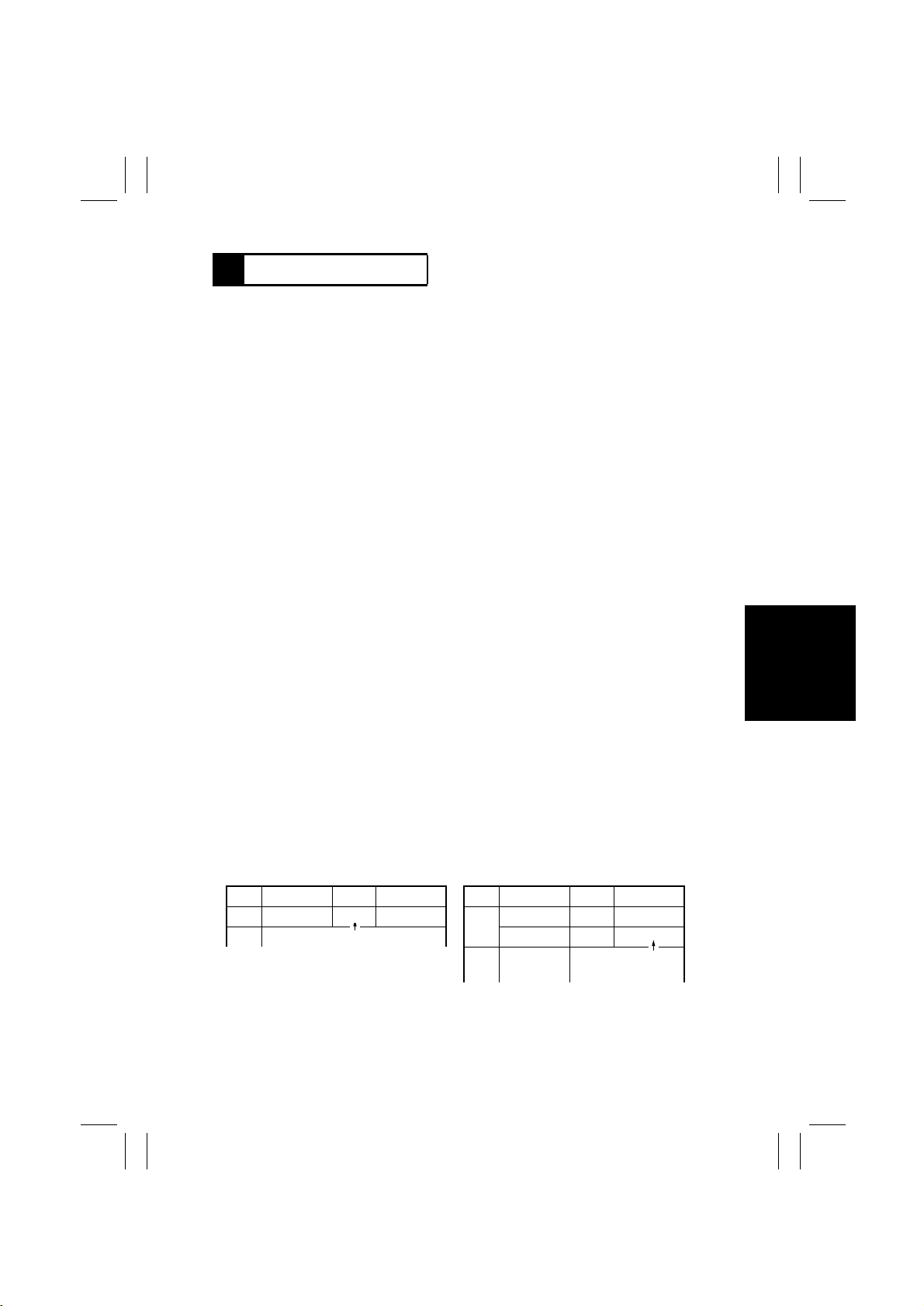

1-3. Reading the Text

1. The paper transport failure troubleshooting procedures are given according to the

symptom. First identify the location where the paper is present and start the procedure

for th at particular locatio n. For malfunction troubleshooting, start with step 1 and

onward.

2. Make checks in numerical order of steps and, i f an item is checked okay, go to the next

step.

Patt ern 1

Step Check Item Result Action

1 Is ...? YES Do this.

2 Go to step 2 if it checks okay.

Pattern 2

Step Check Item Result Action

Is ...? YES Do this.

1

2

NO Check that.

Go to step 2 if i t

checks okay.

T-1

Page 5

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

2 I/O PORT CHECK

2-1. Controlled Parts Check Procedure

To al low the Tech. Rep . to easily and safely determine whether a particular c ontrolled part

is fully operational, this copier pro vides the follow ing provision: chec king of the data of the I/

O port on the board IC with the copier in the standby state (inc luding a misf eed, malfunction, and closure failure condition) allows the Tech. Rep. to determine whether a signal is

properly input to, and output from, a controlled part.

<Procedure>

1. When a paper misfeed or malfunction occurs, identify t he I/O port of the possibly defective cont rolled part by reviewing the text or I/ O port check list.

2. Select the I/O Check func tion of the Service mode and show on the Touch Panel the

status of the I/O port identified in step 1.

3. Check the input or output port data to determine whether the controlled part is opera tional and signals are properly input and output.

<Controlled Part Check Procedure by Changing Input P ort Data>

Example

When a paper misfeed occurs in the paper take-up section of the copier, 1st Dra wer Paper

Take-Up Sensor PC55 is considered to be res ponsible for it.

<Procedure>

1. Remove the sheet of paper misfed.

2. Fr om the I /O port che c k li st , i t is found that the H/L inpu t sig nal to P C55 i s sup pl ied fr om

PWB-A (IC4A) APA1.

3. Select the I/ O Chec k fu nc tio n fr om the S ervice mode me nu and, usin g th e P a per S elec t

key, show the status of PWB-A (IC4A) APA1 on the control panel.

4. Check that the second LED from the right of the Exposure Level Display ligh ts up (sensor being unblocked).

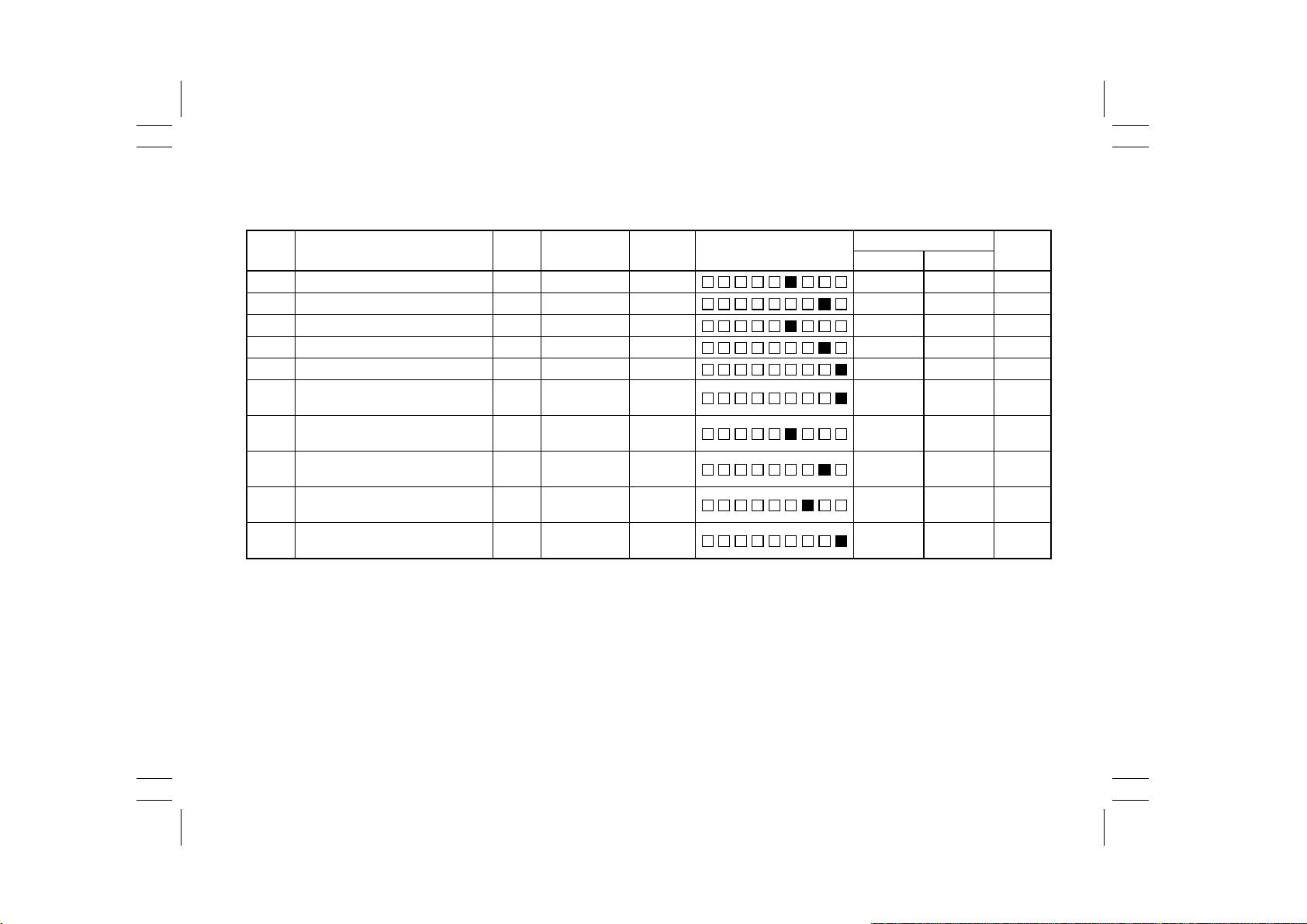

Zoom Ratio Indicator

•

Multi-Copy Display

•

Exposure Level Display

•

5. Move the PC55 actuator to block the sensor .

6. Check at this time that the LED goes out.

ON: PC55 is faulty. OFF: PC55 is operational.

XAPA

4A

1234567 0

T-2

Page 6

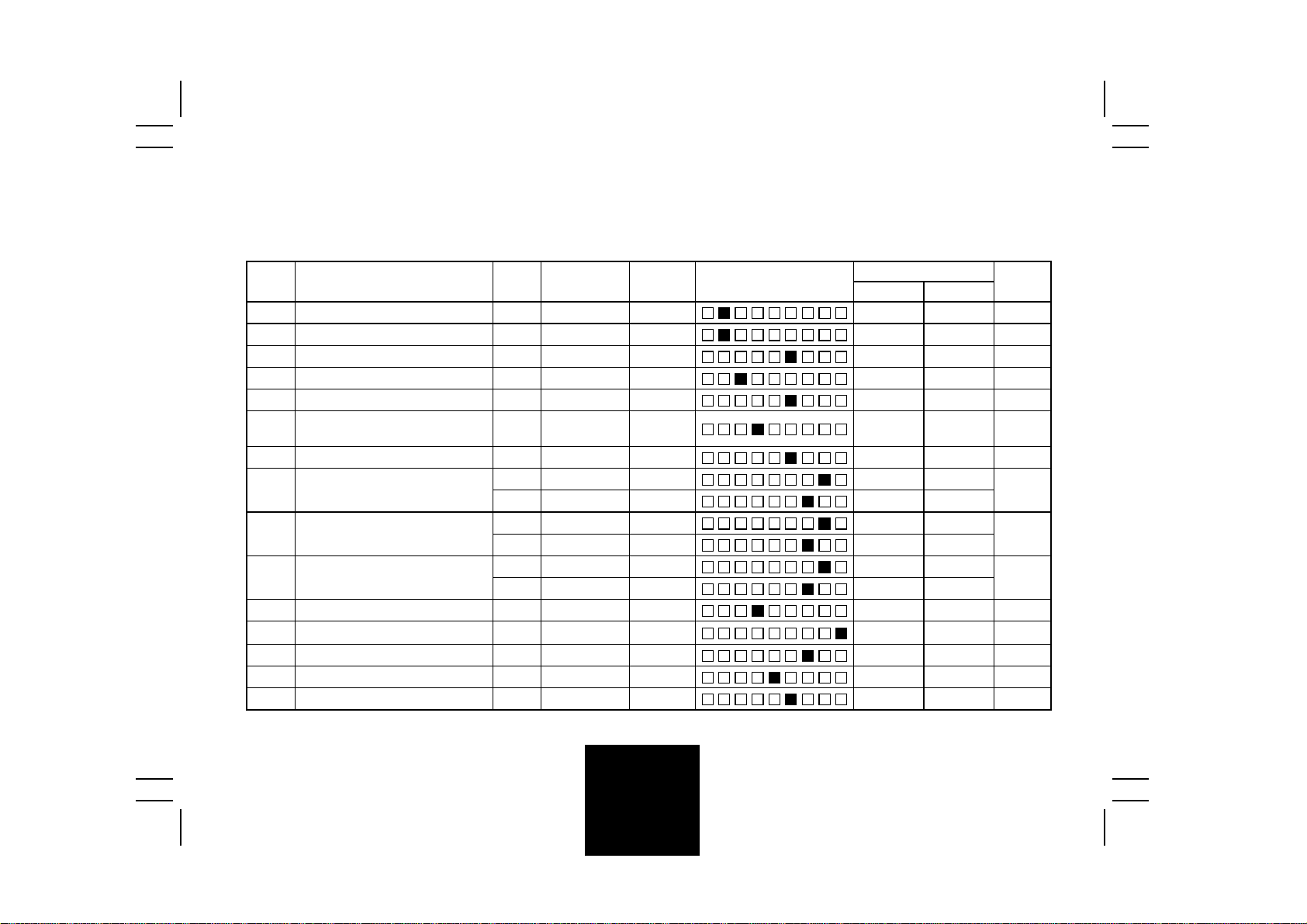

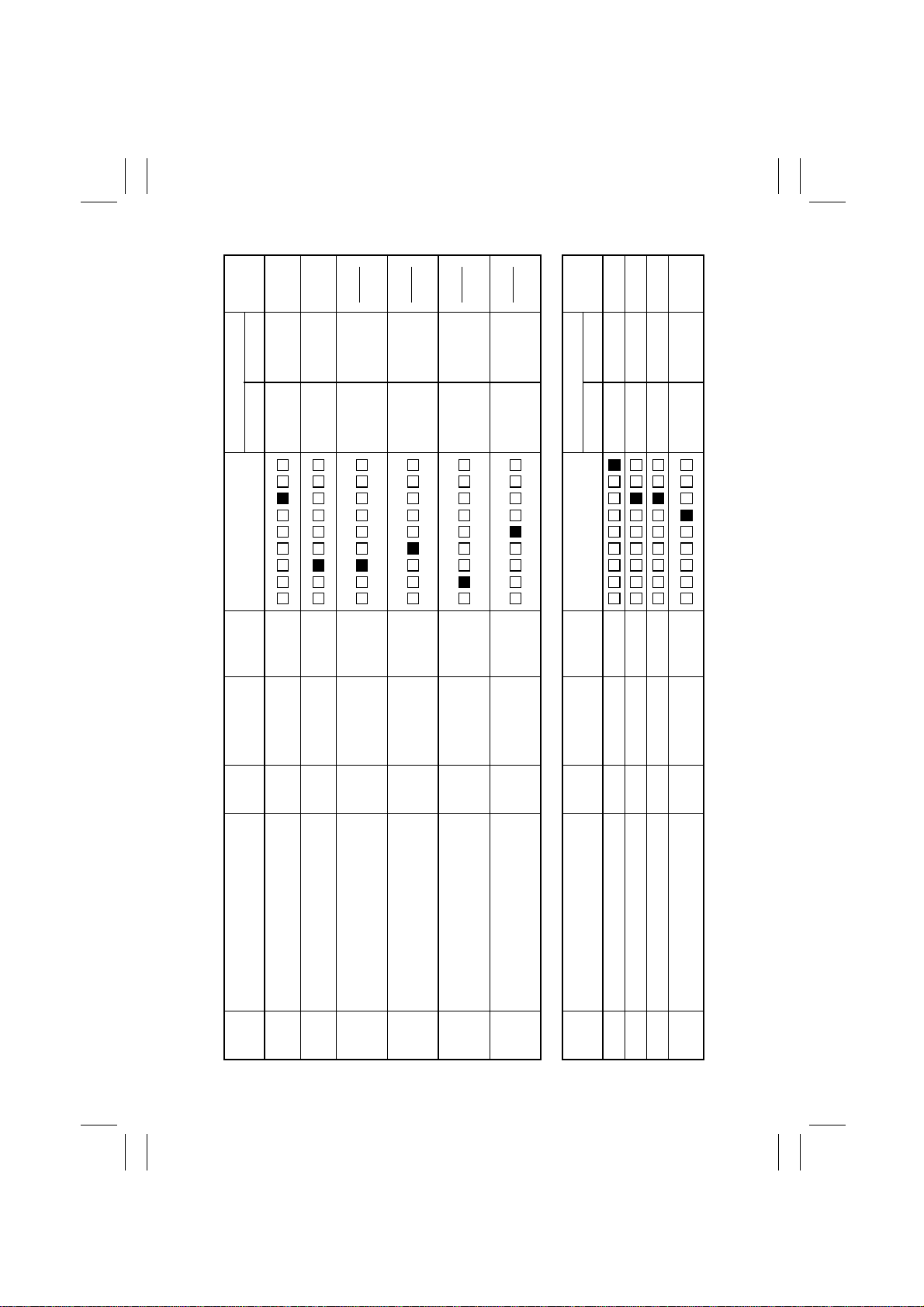

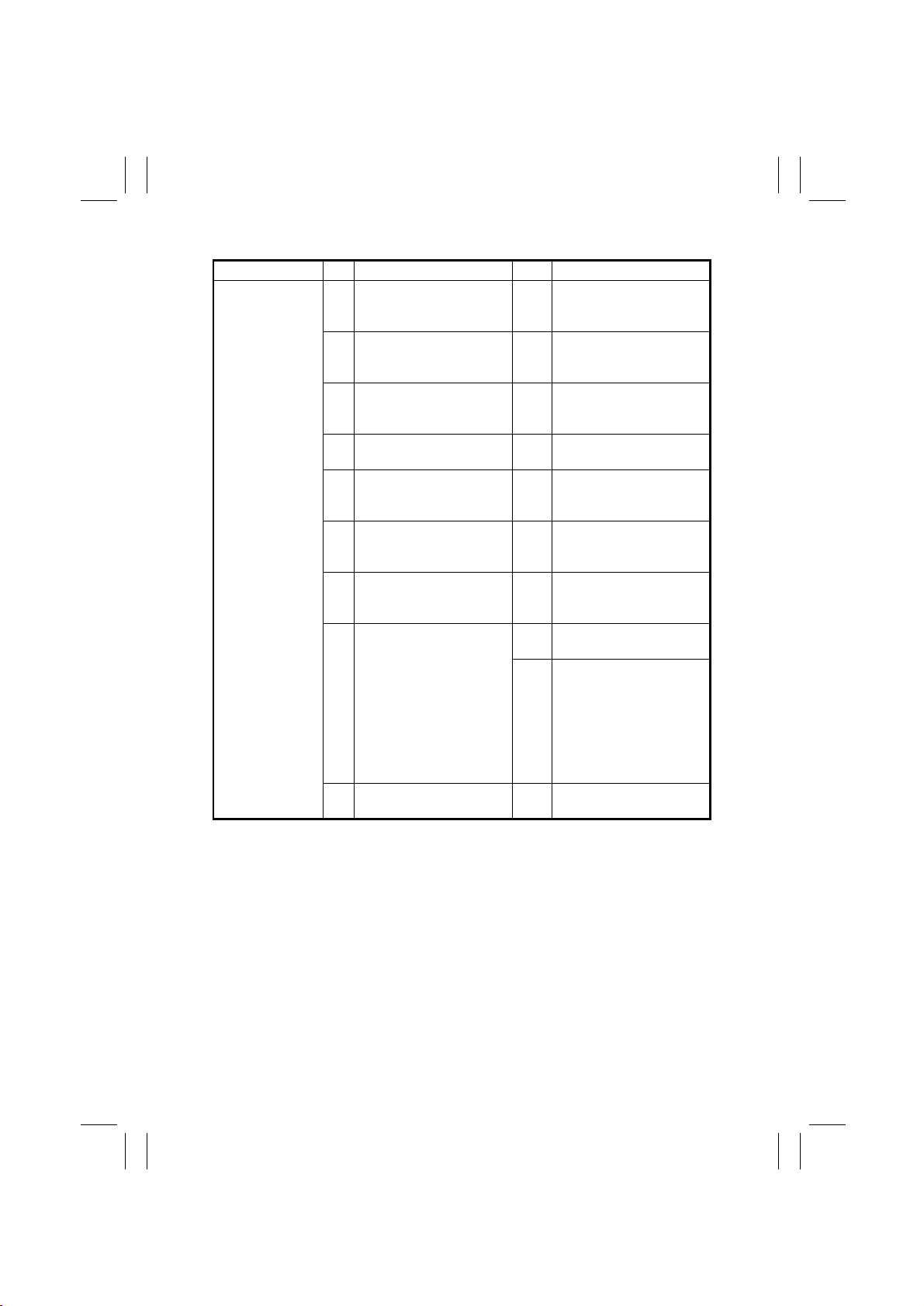

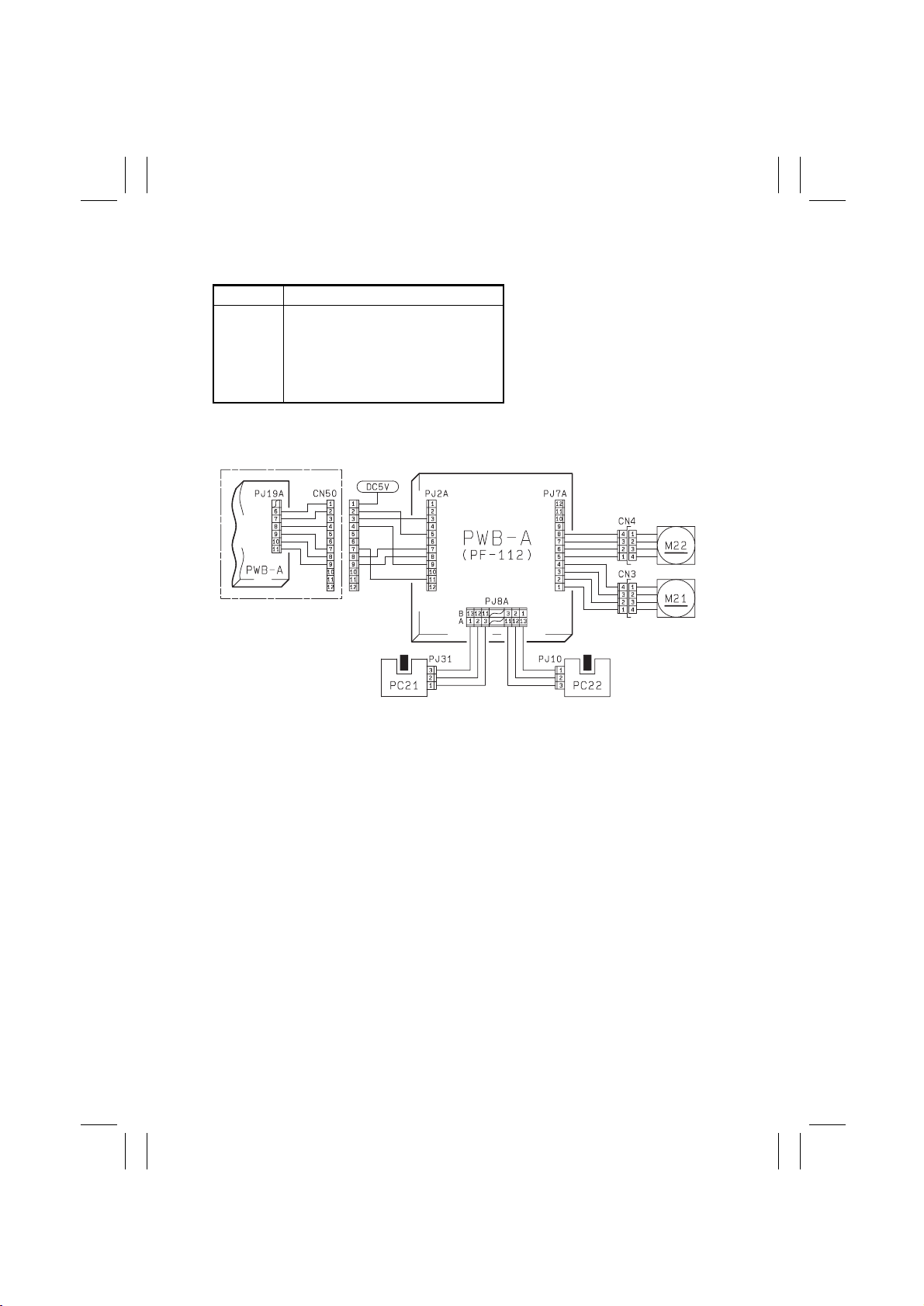

2-2. Port Check List

Copier

Symbol Name

M1 PC Drive Motor P47 P4 1A OFF ON

M1 PC Drive Motor lock signal P67 P6

M2 Main Drive Motor P43 P4

M2 Main Drive Motor lock signal P66 P6

M3 Optical Section Cooling Fan Motor P43 P4

Optical Section Cooling Fan Motor

M3

T-3

lock signal

M4 Suction Fan Motor P43 P4

M5 Scanner Motor

M6 Lens Motor

M7 Mirror Motor

M8 T oner Replenishing Motor BPA5 BPA 4A OFF ON PJ5A-6A

M9 Cooling Fan Motor

M9 Cooling Fan Motor lock signal APC2 APC 4A

SL2

1st Drawer Paper Take-Up Solenoid

2nd Drawer Paper Take-Up Solenoid

SL3

✽

1st Drawer paper take-up LED on the Monitor Display lights up.

Port

Magnification

No.

Ratio Indic ator

P65 P6

P61 P6

P62

P61

P62

P61

P62

OUTO

BPA4 BPA 4A OFF ON PJ4A-9

BPA3

↑↑

↑↑

↑↑

↑↑

↑↑

OUT 5A OFF ON PJ20A-1

↑↑

Multi-Copy

Display

↑

↑

↑

↑

↑

↑

↑

Manual Exposure

Indicator

Operation Characteristics

ON OFF

When locked When turned PJ 11A-11A

OFF ON

When locked When turned PJ 11A-13A

OFF ON PJ22A-2

When locked When turned

OFF ON PJ5A-9A

OFF ON

ON OFF

OFF ON

OFF ON

ON OFF

OFF ON

When locked When turned

OFF ON PJ3A-2

CN/PJ

No.

PJ11A-12A

PJ11A-14A

PJ22A-3

PJ16A-3B

PJ16A-1B

PJ16A-2B

PJ20A-3

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

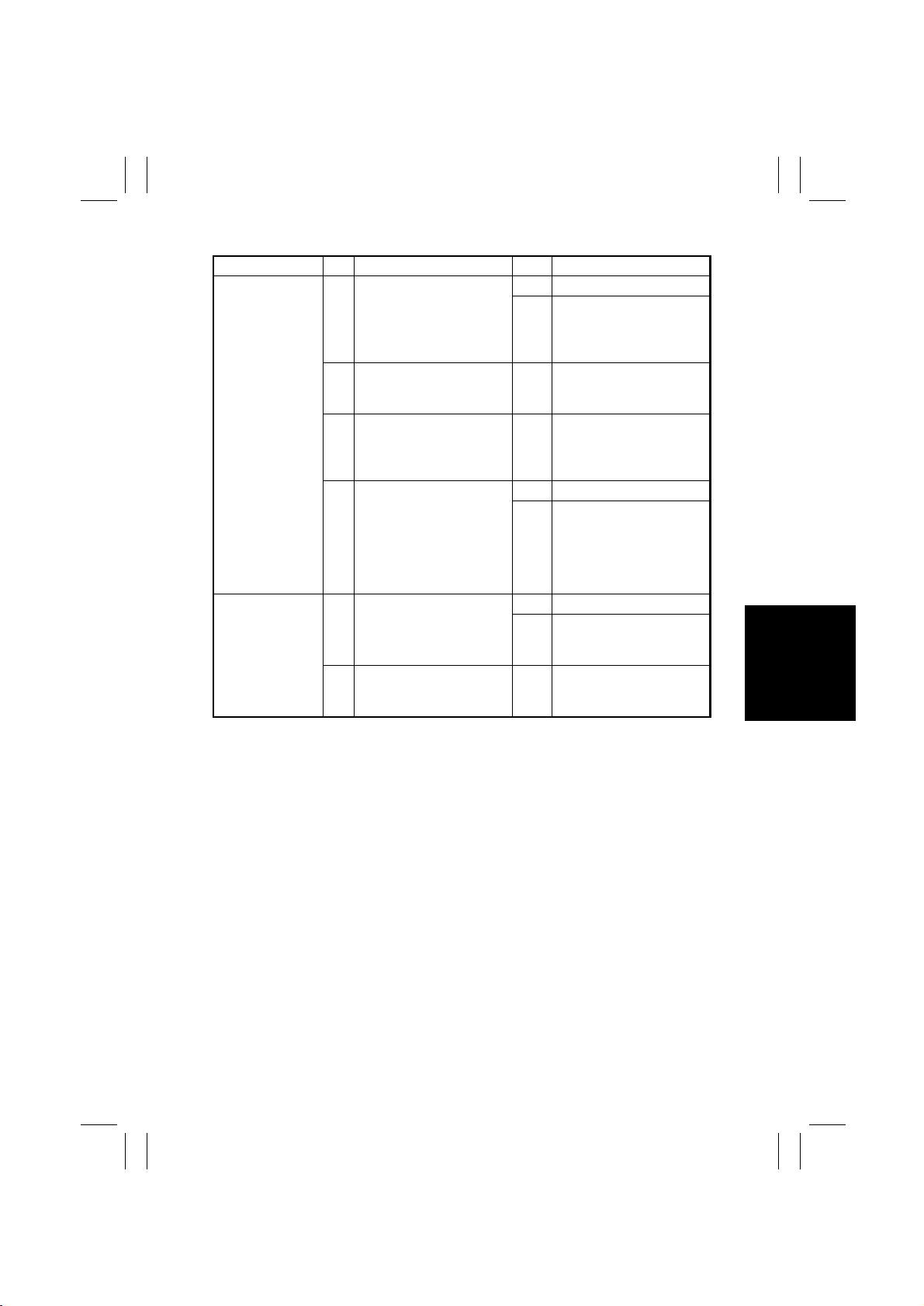

Page 7

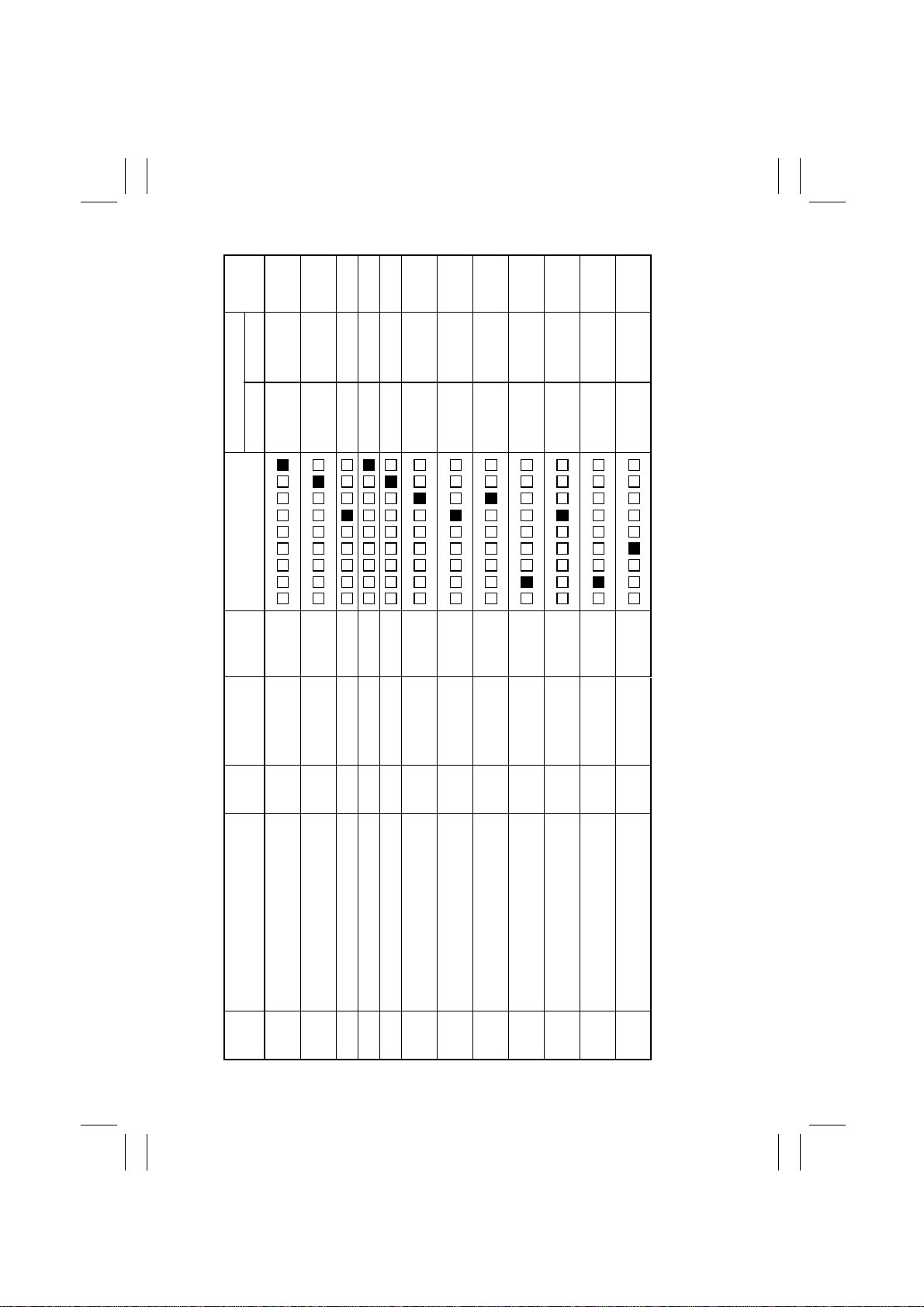

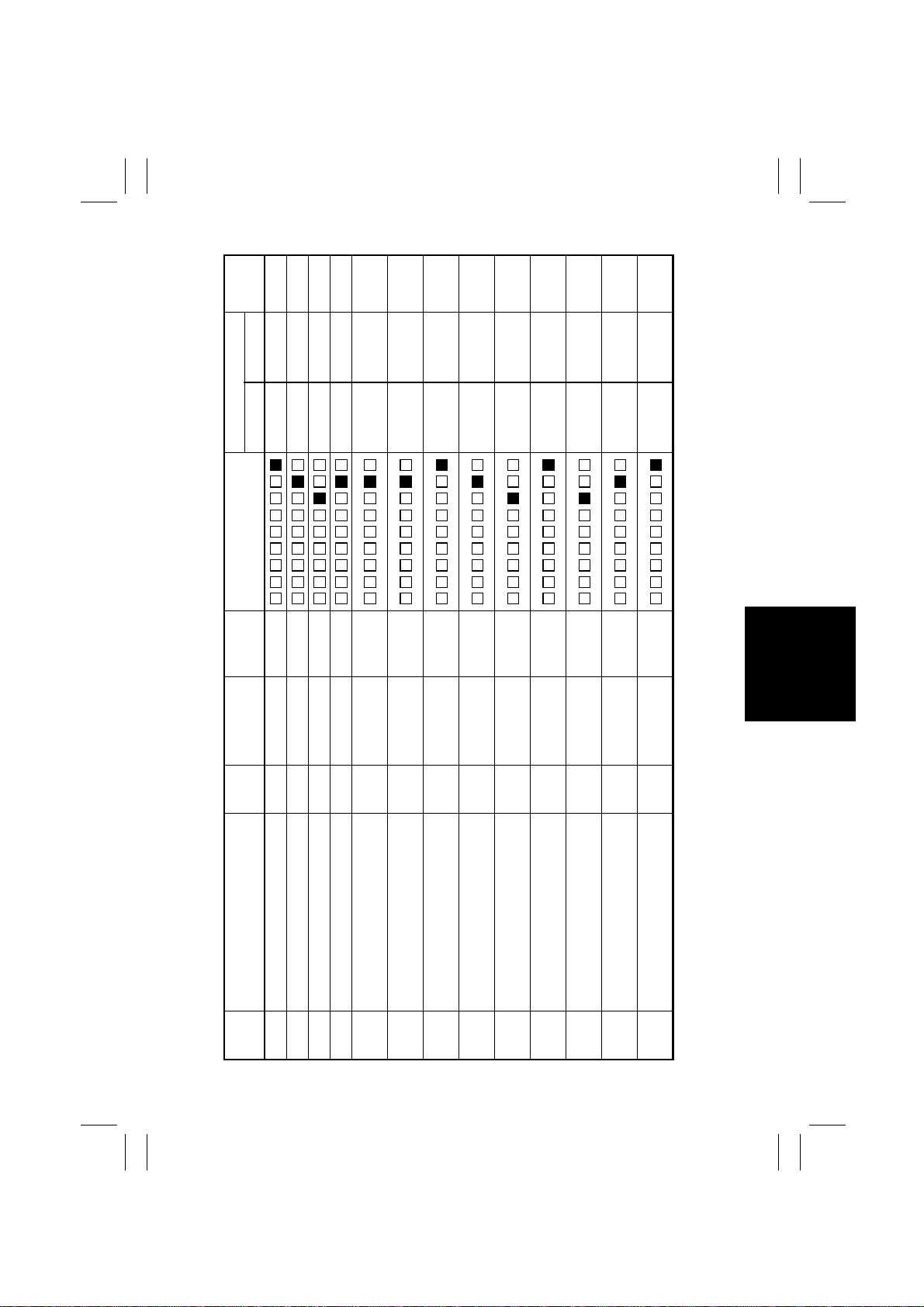

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

No.

CN/PJ

PJ12A-4

When

blocked

PJ19A-2

When

blocked

PJ12A-3

When

blocked

When

5A

blocked

8A

PJ17A-

When

blocked

PJ17A-

PJ5A-6B

When

blocked

ON OFF

Operation Characteristics

Indicator

Manual Exposure

Display

Multi-Copy

Magnification

Ratio Indic ator

No.

Port

OFF ON PJ5A-3B

OFF ON PJ12A-5

↑↑

↑↑

PB0 PB 5A OFF ON PJ5A-2B

PB1

OFF ON PJ5A-2A

↑↑

When

When

unblocked

↑

PB2 PB 5A OFF OFF PJ5A-4B

When

unblocked

↑↑

unblocked

When

When

unblocked

↑

When

unblocked

unblocked

↑↑

↑↑

Symbol Name

Manual Feed Paper Take-Up Solenoid

(down)

Manual Feed Paper Take-Up Solenoid

(up)

SL51

SL51

SL61 Turnover/Exit Switching Soleno id PB3

Manual Feed Paper Take-Up

Clutch

CL1 Synchronizing Roller Clutch BPA0 BPA 4A OFF ON PJ5A-4A

CL2 Paper Transport Clutch BPA1

CL51

PC10 Left Door Detecting Sensor PA3 PA1

PC12 Duplex Vertical Transport Sensor PA2

PC30 2nd Paper Exit Sensor APB7 APB 4A

PC31 Manual Feed Paper Empty Sensor APC3 APC

PC53 1st Paper Exit Sensor APC5

PC51 Transport Roller Sensor APC7

T-4

Page 8

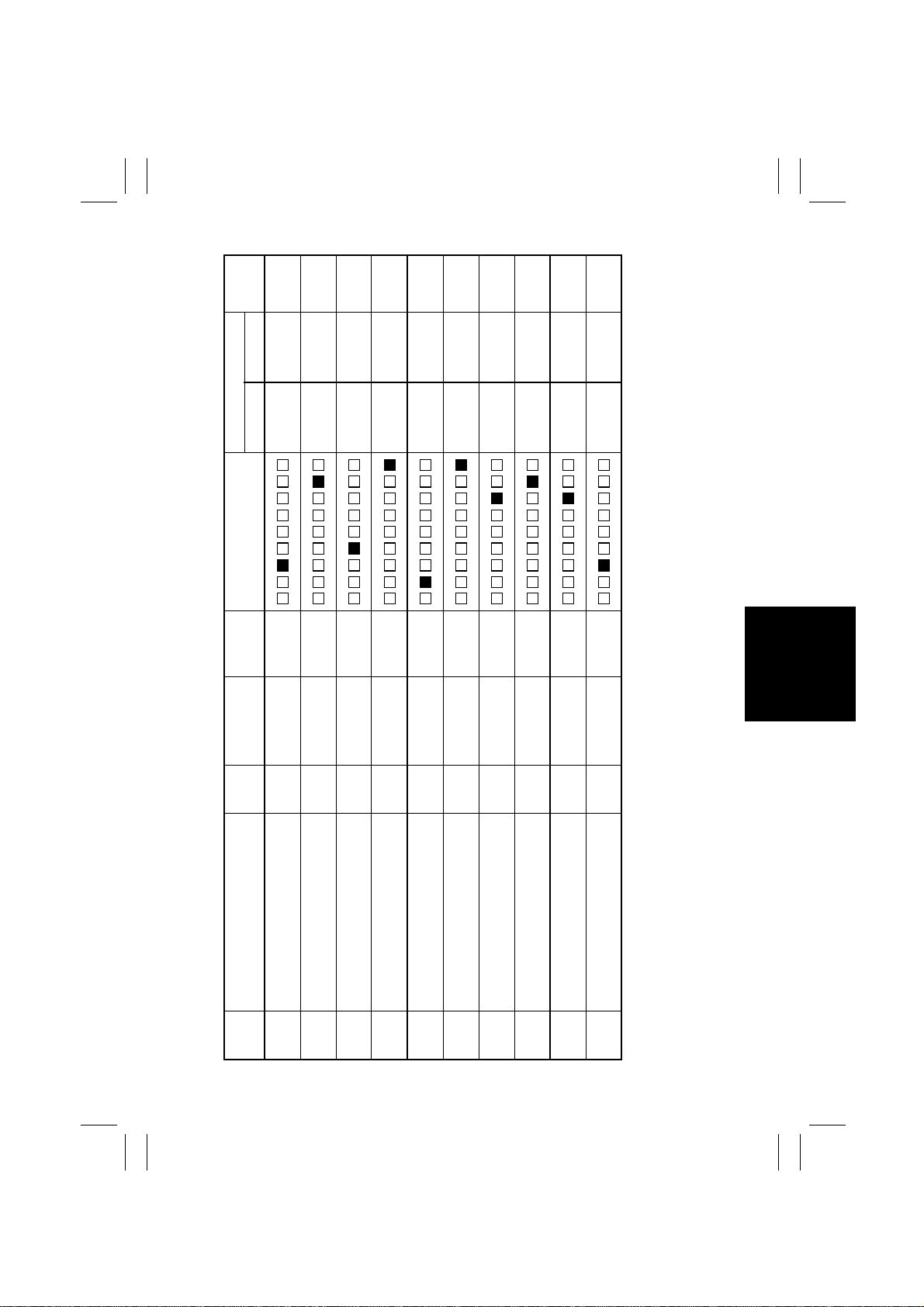

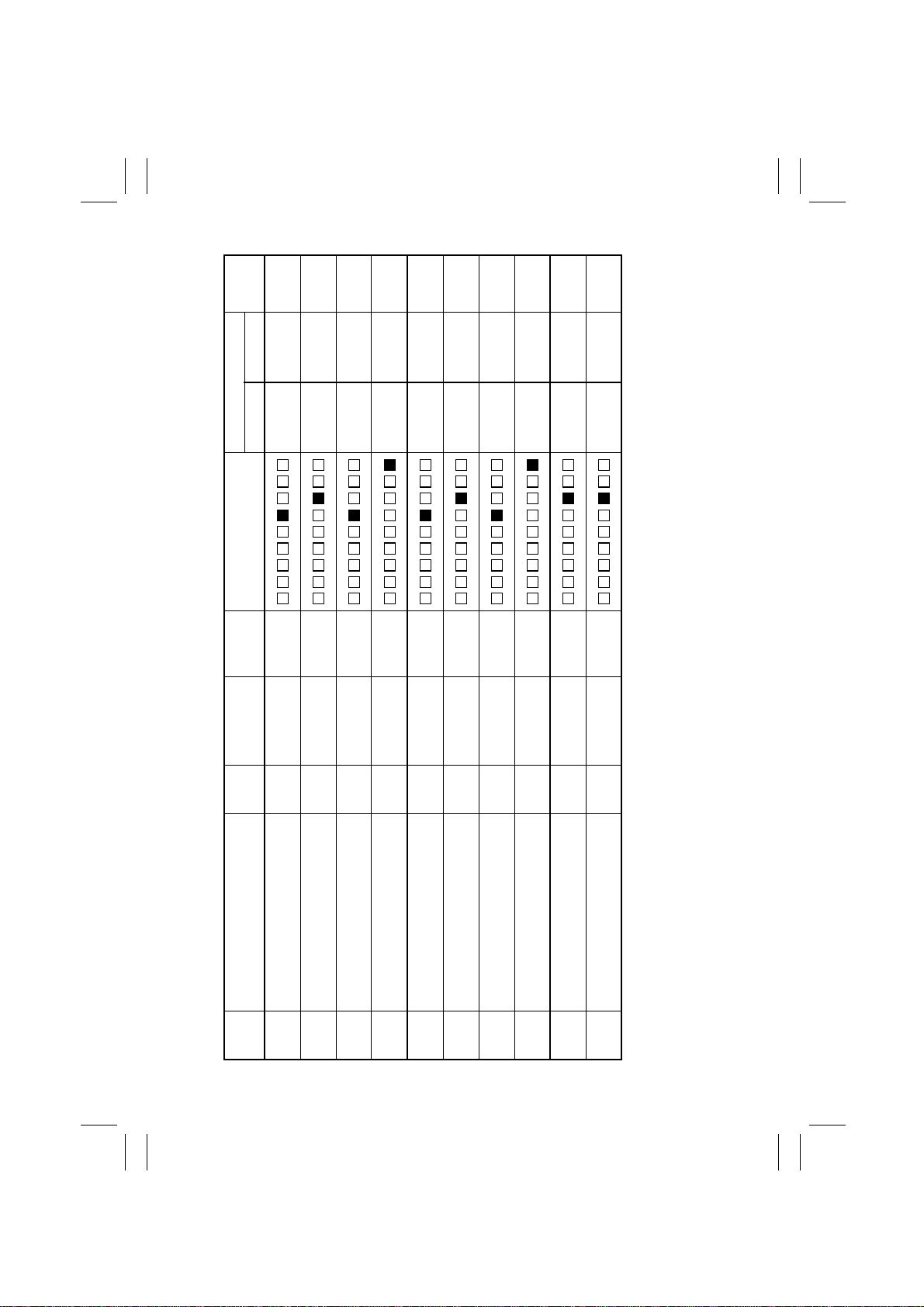

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

2A

No.

CN/PJ

PJ17A-

PJ4A-2

When

When

blocked

ON OFF

When

Operation Characteristics

Manual Exposure

Multi-Copy

unbloc ked

Indicator

Display

↑↑

When

blocked

When

When

unblocked

↑

5B

PJ3A-7

PJ17A-

When

blocked

unbloc ked

When

blocked

When

When

unblocked

7B

PJ17A-

PJ12A-2

blocked

unbloc ked

PJ22A-5

When

When

blocked

blocked

When

When

unblocked

unbloc ked

↑↑

PJ4A-6

PJ22A-8

When

blocked

When

unblocked

PJ3A-4

When

When

blocked

blocked

When

When

unblocked

unbloc ked

↑

Magnification

Port

Symbol Name

Ratio Indic ator

No.

APC6

Paper Leading Edge Det ecting

Sensor

PC54

PC55 1st Drawer Paper Take-Up Sensor APA1 APA

PC56 2nd Drawer Paper Take-Up Sensor PA5 PA1 5A

PC57 Right Door Detecting Sensor APA0 APA 4A

APB0 APB 4A

Scanner Reference Position

Sensor

PC69 2nd Drawer Set Sensor PA7 PA1 5A

PC81

PC86 Mirror Reference P osition sensor APB2

PC90 Lens Reference Position Sensor APB1 APB 4A

PC101 1st Drawer Paper Empty Sensor APA2 APA

PC102 2nd Drawer P aper Empty Sensor PA6 PA1 5A

T-5

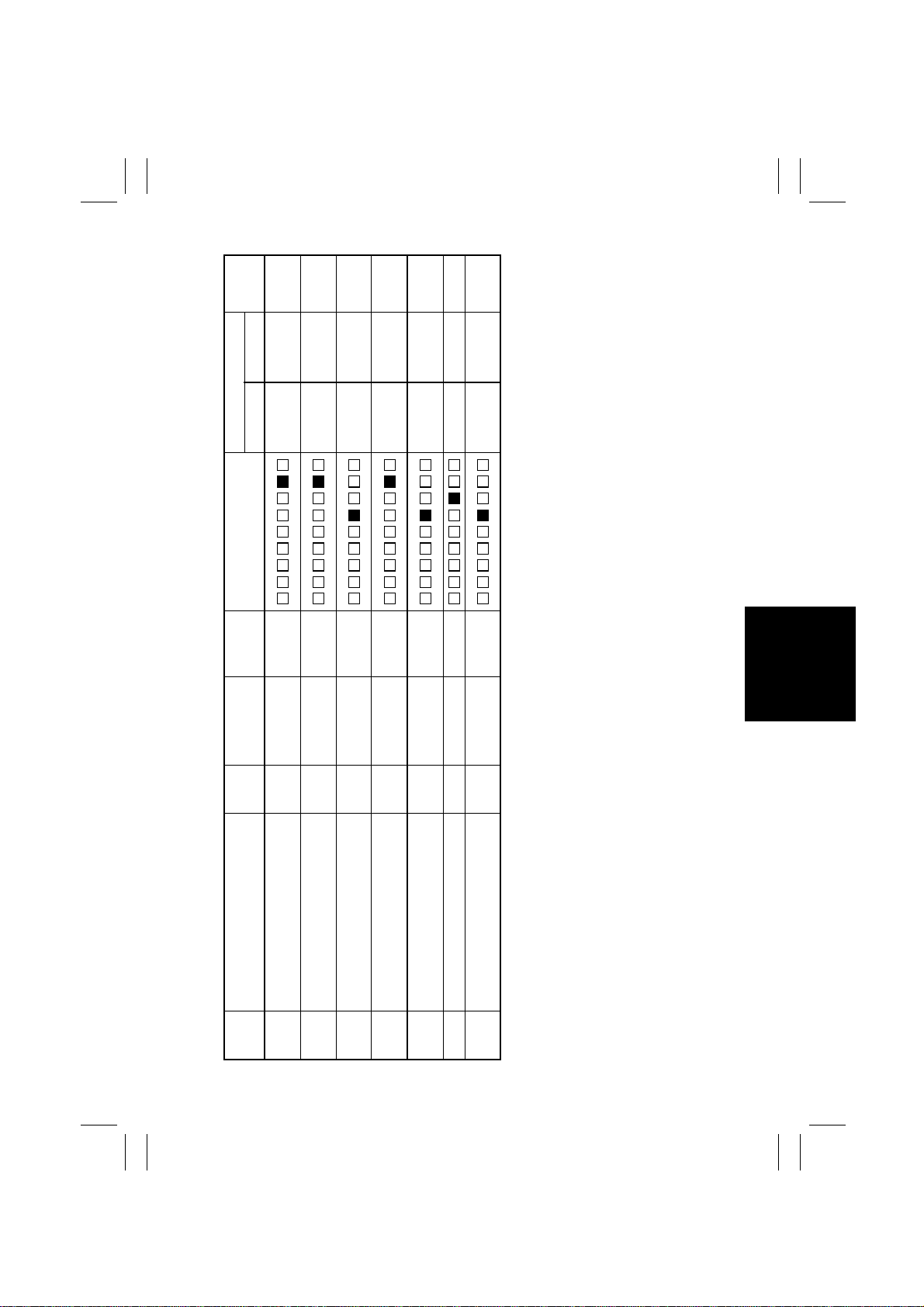

Page 9

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

No.

CN/PJ

When

ON OFF

When

Operation Characteristics

Indicator

Manual Exposure

Display

Multi-Copy

Magnification

Ratio Indic ator

2B

PJ17A-

PJ18A-2

When

blocked

unblocked

↑

When

blocked

When

When

unbloc ked

When

blocked

When

(blinking)

unbloc ked

When

blocked

When

(blinking)

unbloc ked

↑↑

When

blocked

unbloc ked

↑↑

blocked

When

(blinking)

(blinking)

unbloc ked

No.

CN/PJ

upward PJ10A-1

downward PJ10A-2

ON OFF

OFF ON PJ10A-1

stop/

Operation Characteristics

Indicator

Manual Exposure

Display

Multi-Copy

↑↑

3rd Drawer paper take-up LED on the Monitor Display lights up.

✽

Magnification

Ratio Indic ator

downward

stop/upward

↑↑

↑↑

Port

Symbol Name

No.

Toner Hopper Home Position

PC111 Original Cover Detecti ng Sensor PA2 PA0

PA6 PA0 5A

APB6 APB 4A

Sensor

Original Size Detecting Sensor

PC112

PC113

FD2

Original Size Detecting Sensor

PA5

PC114

CD1

Original Size Detecting Sensor

PA7

PC115

FD3

Original Size Detecting Sensor

PA4 PA0 5A

CD2

PC116

PF-206, PF-112

Port

Symbol Name

No.

PA2

Main Tray Elevator Motor (downward)

M24 3rd Drawer Paper Lift-Up Motor P A0 PA 1A OFF ON PJ10A-3

M25 4th Drawer Paper Lift-Up Motor PA2

M26

M26 Main Tray Elevator Mot or (upward) PA3

T-6

Page 10

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

No.

CN/PJ

return PJ10A-3

PJ9A-9

PJ3A-3

PJ3A-4

PJ3A-5

PJ9A-5

PJ9A-12

When

When

When

When

When

blocked

blocked

blocked

blocked

When

blocked

blocked

PJ5A-2

PJ8A-9B

When

blocked

PJ5A-5

When

When

blocked

blocked

ON OFF

Operation Characteristics

Indicator

Manual Exposure

Display

Multi-Copy

Magnification

Ratio Indic ator

No.

Port

OFF ON PJ10A-6

stop/return transfer PJ10A-4

stop/transfer

↑

↑↑

↑↑

When

When

When

When

When

When

When

When

unblocked

unblocked

unblocked

unblocked

unblocked

unblocked

unblocked

↑

↑↑

↑

↑

When

unbloc ked

unbloc ked

↑↑

Symbol Name

M27 Paper Shift Motor (transfer) PA1

M28 Shift Gate Motor PB2 PB

M27 Paper Shift Motor (return) PA0

PC1 Shift Tray Paper Empty Sensor PD1 PD 1A

PC2 Main Tray Lower Position Sensor PC 1 PC 2A

PC3 Shifter Home Position Sensor PC0

PC4 Shift Return Position Sensor PD1 PD

PC5 Elevator Motor Pulse Sensor PF2 PF 1A

PC6 Shift Motor Pulse Sensor PD0 PD

SL41 3rd Drawer Lock Solenoid PA1 PA 2A OFF ON PJ6A-2

PC7 3rd Drawer Set Sensor PG2 PG

PC11 Lower Left Door Set Sensor PB1 PB 2A

PC13 Duple x Uni t Turnover Path sensor PB0

T-7

Page 11

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

No.

CN/PJ

PJ8A-9A

PJ8A-5A

When

When

blocked

blocked

PJ8A-2B

PJ8A-12B

When

blocked

PJ8A-2A

When

When

blocked

blocked

PJ9A-2

PJ8A-12A

When

blocked

PJ9A-12

When

When

blocked

When

blocked

PJ9A-5

PJ8A-9B

When

blocked

blocked

ON OFF

When

When

unblocked

Operation Characteristics

Indicator

Manual Exposure

Display

Multi-Copy

Magnification

Ratio Indic ator

No.

Port

unblocked

↑

When

When

When

When

When

When

When

unblocked

unblocked

unblocked

unblocked

unblocked

↑

↑

↑

unblocked

↑

↑

When

unblocked

unblocked

↑

↑

Symbol Name

PC17 Vertical Transport Sensor 3 PC3 PC 1A

PC20 3rd Drawer Paper Empty Sensor PC0 PC

PC21 3rd Drawer Paper Take-Up Sensor PE3 PE

PC22 V ertical Transport Sensor 4 PC2 PC

PC23 4th Drawer Paper Li ft-Up Sensor PF3 PF

PC24 4th Drawer Paper Empty Sensor PD0 PD

PC25 3rd Drawer Set Sensor PG2 PG

PC18 Lower Righ t Door Set Sensor PE2 PE

PC19 3rd Drawer Paper Lift-Up Sensor PG3 PG 1A

PC26 4th Draw er Set Sensor PF2 PF

T-8

Page 12

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

No.

CN/PJ

ON OFF

Operation Characteristics

Indicator

Manual Exposure

PJ9A-9

PJ4A-2

PJ3A-7

PJ8A-5B

When

When

blocked

When

unblocked

When

blocked

blocked

When

When

unblocked

unblocked

PJ3A-6

When

When

blocked

blocked

When

When

unbloc ked

unbloc ked

PJ9A-2

When

blocked

When

unblocked

Multi-Copy

Magnification

Port

Symbol Name

↑

↑

Display

Ratio Indic ator

No.

PC1 PC

PD1 PD

3rd Drawer Paper Lift-Up Motor

Pulse Senso r

4th Drawer Paper Li ft-Up Motor

Pulse Senso r

PC27

PC28

PC29 4th Drawer Paper Take-Up Sensor PB3 PB 2A

PC34 Shift Gate Position Sensor PC1 PC 1A

2A OFF ON PJ3A-2

↑

PC35 Lower Position Sensor PB3 PB 2A

UN21 Paper Descent Key PC2

PWB-E Main Tray Paper Empty Board PF3 PF 1A

T-9

Page 13

T-10

AD-11/PF-6D

Symbol Name

M31 Duplex Unit Drive Motor PB3 PB 1A OFF ON PJ6G-2

M31 Duplex Unit Drive Motor lock signal PE1 PE

CL31 Duplex Unit Paper Take-Up Clutch PA3 PA

SL31

Duplex Unit Gate Switching Solenoid

SL32 Duplex Unit Rear Finger Solenoid PH0

PC8

Duplex Gate Home Position Sensor

Front/Rear Edge Guide Plate Home

PC9

Position Sensor

PC14 Duplex Unit Trailing Sensor PC1

PC15 Duplex Unit Paper Empty Sensor PC2

Duplex Unit Pap er Take-Up

PC16

Sensor

Port

No.

PH1 PH

PE0 PE

PC3 PC

PC0

The Duplex U nit LED on the Monitor Display lights up.

✽

Magnification

Ratio Indic ator

↑↑

↑↑

↑↑

↑↑

Multi-Copy

Display

↑

↑

↑

↑

↑

Manual Exposure

Indicator

Operation Characteristics

ON OFF

When locked When turned

OFF ON PJ2G-7

OFF ON PJ3G-5

OFF ON PJ3G-7

When

unblocked

When

unblocked

When

unblocked

When

unblocked

When

unblocked

When

blocked

When

blocked

When

blocked

When

blocked

When

blocked

CN/PJ

PJ6G-1

PJ7G-2

PJ7G-5

PJ3G-2

PJ2G-4

PJ2G-9

No.

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Page 14

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

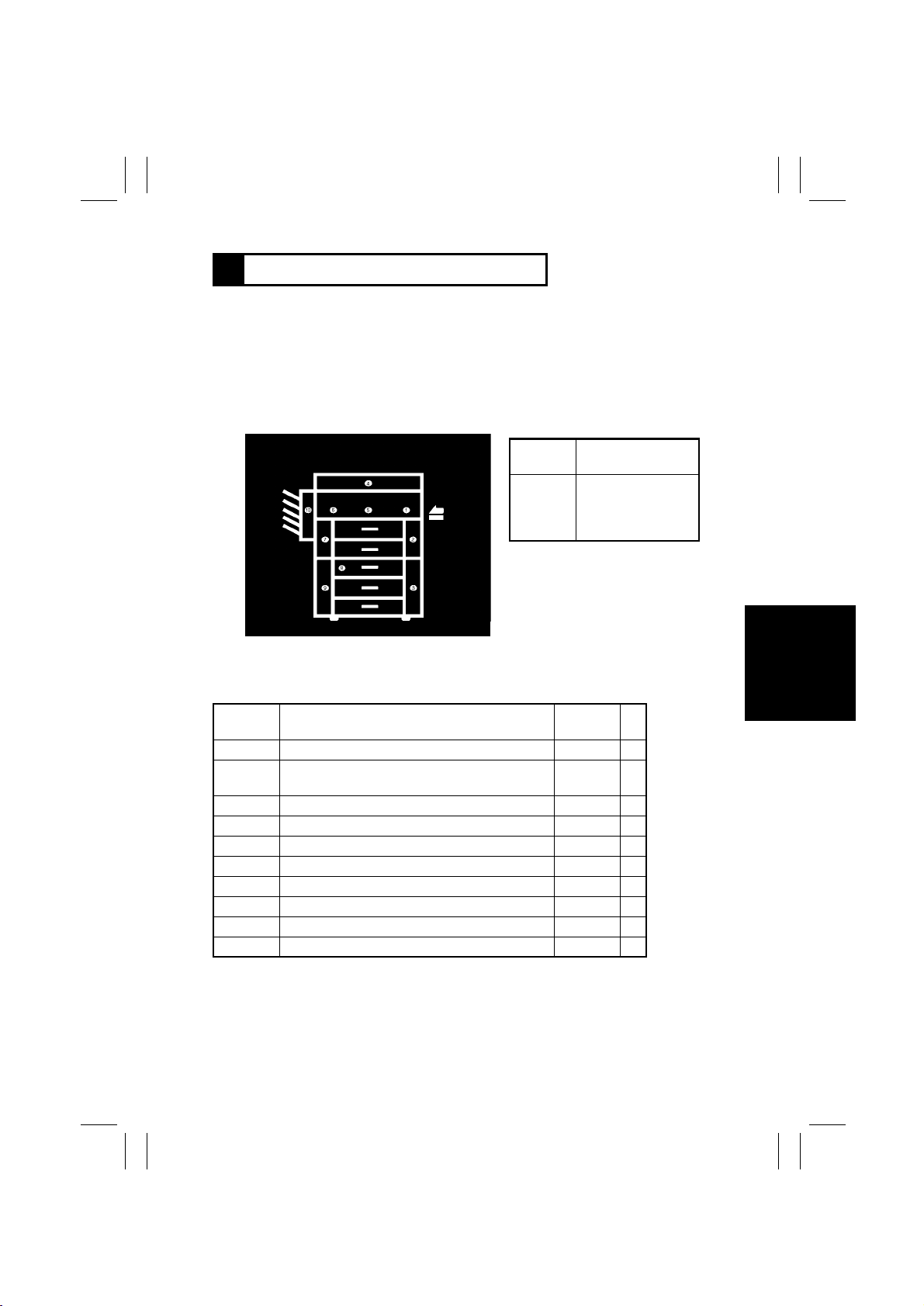

3 PAPER TRANSPORT FAILURE

3-1. Paper Misfeed

When a paper misfeed occurs in the copier, the corresponding Misfeed Location Mon itor

LED on the control panel blink s to let the user know where the misf eed has occurred. If an

LED lights up steadily, it indicates that there might be a sheet of paper present at that particular loc ation in the copier. If a paper misfeed occurs very frequently, carry out the nec essary troubleshooting proced ures according to the location of th e misfeed.

Blinking

LED

Copier take-up and vertical transport T-15~T-17

➁

Paper Feed Cabinet take-up and vertical trans-

➂

port

Bypass port T-22, T-23

➀

Transport/Separator T-24, T-25

➄

Fusing/Exit T-26, T-27

➅

➆ ➈

When option is installed

✽

Duplex Unit vertical transport T-28~T-30

Duplex Unit storage T-28~T-30

➇

Duplex Unit take-up T-31, T-32

➂

Sorter/Staple Sorter —

➉

Automatic/Duple xing Document Feeder —

➃

Blinking

Light

Steady

Light

1139T025AA

Misfeed Loc ation Ref. Page

There is a misf ee d at

that location.

There might be a

sheet of paper

stopped at that location.

T-1 8~ T-2 1

✽

✽

✽

✽

✽

✽

T-11

Page 15

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

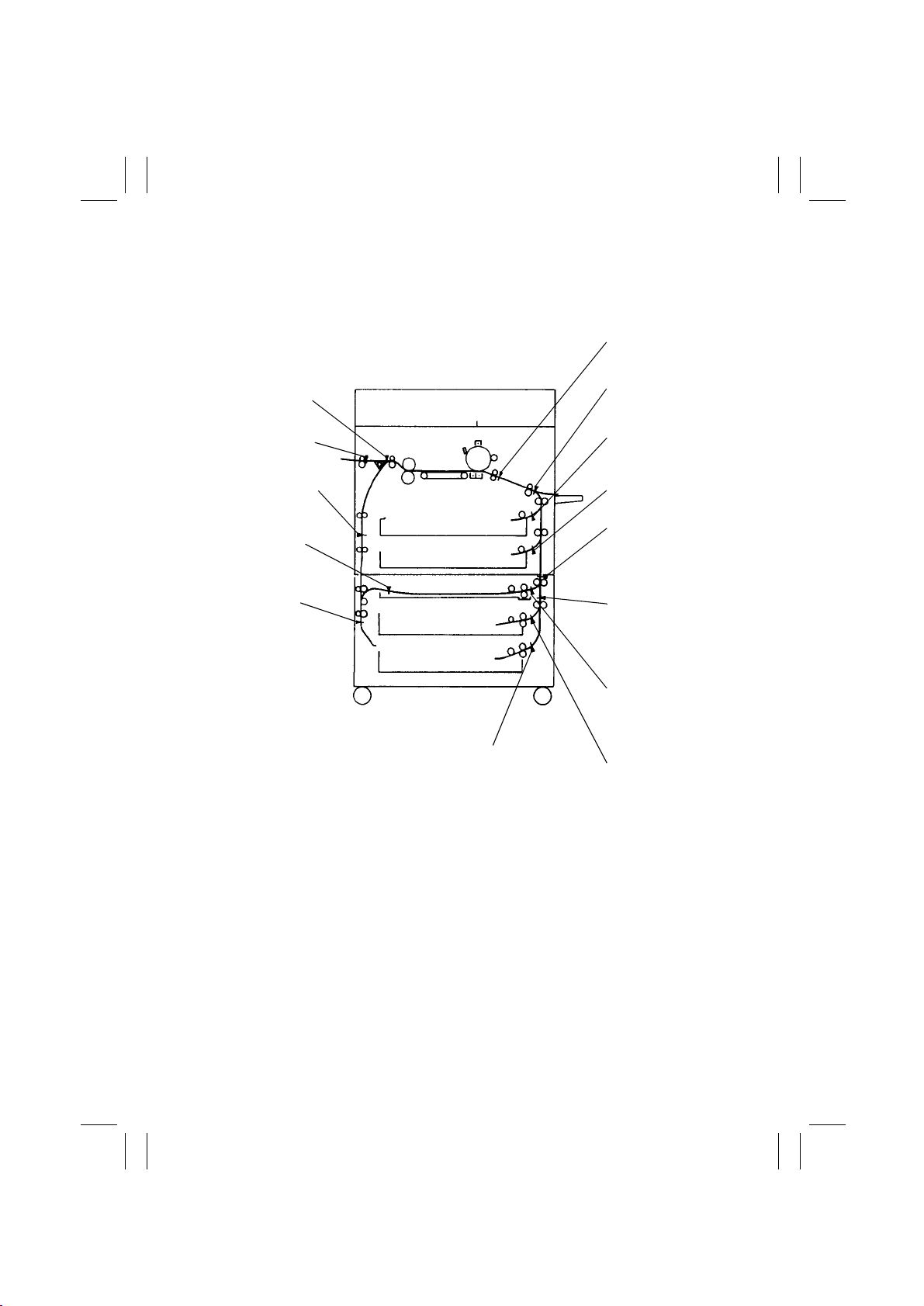

The paper misfeed, including a sheet of paper that is likely to be present, in the copier as

well as in t he paper feeder options is detected by the following sensors.

When options ar e i nstalled

✽

Paper Leading

Edge Detecting

Sensor PC54

Transport Roller

1st Paper Exit

Sensor PC53

2nd Paper Exit

✽

Sensor PC30

Duplex Vertical

✽

Transport

Sensor PC12

Duplex Uni t

✽

Trailing Sensor

PC14

Duplex Uni t

✽

Tu rnover Path

Sensor PC13

Sensor PC51

1st Drawer

Paper Take-Up

Sensor PC55

2nd Drawer

Paper Take-Up

Sensor PC56

Vertical

✽

Transport

Sensor 3

PC17

Vertical

✽

Transport

Sensor 4

PC22

✽

T-12

4425T201AA

4th Drawer

Paper Take-Up

Sensor PC29

Duplex Unit

✽

Paper Take-Up

Sensor PC16

3rd Drawer

✽

Paper Take-Up

Sensor PC21

Page 16

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

3-2. Misfeed Detected Types and Detection Timings

The foll ow ing tab le l ist s the t ypes of misfeed detection classifie d b y th e mis f eed locat ions

•

and their corre sponding detection timings.

Note

For the misfeed detection types and detection timings in the options, see the Service Manual for the options.

<Paper Take-up Misfeed>

Type Detection Timing

Pape r take-up failure

detection

Paper take-up trailing

edge detection

Leading edge detection

by Transport Roller Sensor PC51

1st Drawer Paper Take-Up Sensor PC55 is not blocked (L) after

the lapse of approx. 2.4 seconds after 1st Drawer Paper TakeUp Solenoid SL 2 has been energized during the third paper

take-up retry sequence.

2nd Draw er Paper T ake-Up Sensor P C56 i s n ot b lo c k e d (L) afte r

the lapse of approx. 2.4 seconds after 2nd Drawer Paper TakeUp Solenoid SL 3 has been energized during the third paper

take-up retry sequence.

PC55 is not unb l ocked (H) after the lapse of T seconds (which

varies for paper sizes) after it has been blocked (L).

PC56 is not unb l ocked (H) after the lapse of T seconds (which

varies for paper sizes) after it has been blocked (L).

PC51 is not b l ocked (L) after the lapse of approx. 1.7 seconds

after PC55 has been blocked (L).

PC51 is not b l ocked (L) after the lapse of approx. 2.5 seconds

after PC56 has been blocked (L).

<Multi-Bypass Misfeed>

Type Detection Timing

Pape r take-up failure

detection

Leading edge detection

by Paper Leading Edge

Detecting Sensor PC54

<Transport/Separator Misfeed>

Type Detection Timing

Trailing edge detection

by Transport Roller Sensor PC51

Leading edge detection

by Paper Leading Edge

Detecting Sensor PC54

Trailing edge detection

by PC54

PC51 is not b l ocked (L) after the lapse of approx. 2.7 seconds

after Manual Feed Paper Take-Up Clutch CL51 has been energized during t he third paper take-up retry sequence.

PC54 is not b l ocked (L) after the lapse of approx. 2.5 seconds

after Paper Transport Clutch CL2 has been energized.

PC51 is not unb l ocked (H) after the lapse of T seconds (which

varies for paper sizes) after the TRON signal has been input.

PC54 is not b l ocked (L) after the lapse of approx. 1.5 seconds

after PC51 has been blocked (L).

PC54 is not unb l ocked (H) after the lapse of approx. 1.6 seconds after PC51 has been unblocked (H) .

T-13

Page 17

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

<Fusing/Exit Misfeed>

Type Detection Timing

Leading edge detection

by 1st P aper Exit Sensor

PC53

Trailing edge detection

by PC53

Leading edge detection

by 2nd Paper Exit Sensor PC30

Trailing edge detection

by PC30

PC53 is not unb l ocked (H) after the lapse of approx. 4.5 seconds after the TRON signal has been input.

PC53 is not b l ocked (L) after the lapse of approx. 3.7 seconds

after PC54 has bee n unblocked (H).

PC30 is not b l ocked (L) after the lapse of approx. 2 seconds

after PC53 has bee n unblocked (H).

PC30 is not unb l ocked (H) after the lapse of approx. 2 seconds

after PC53 has been blocked (L).

T-14

Page 18

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

3-3. Misfeed Clearing Procedures

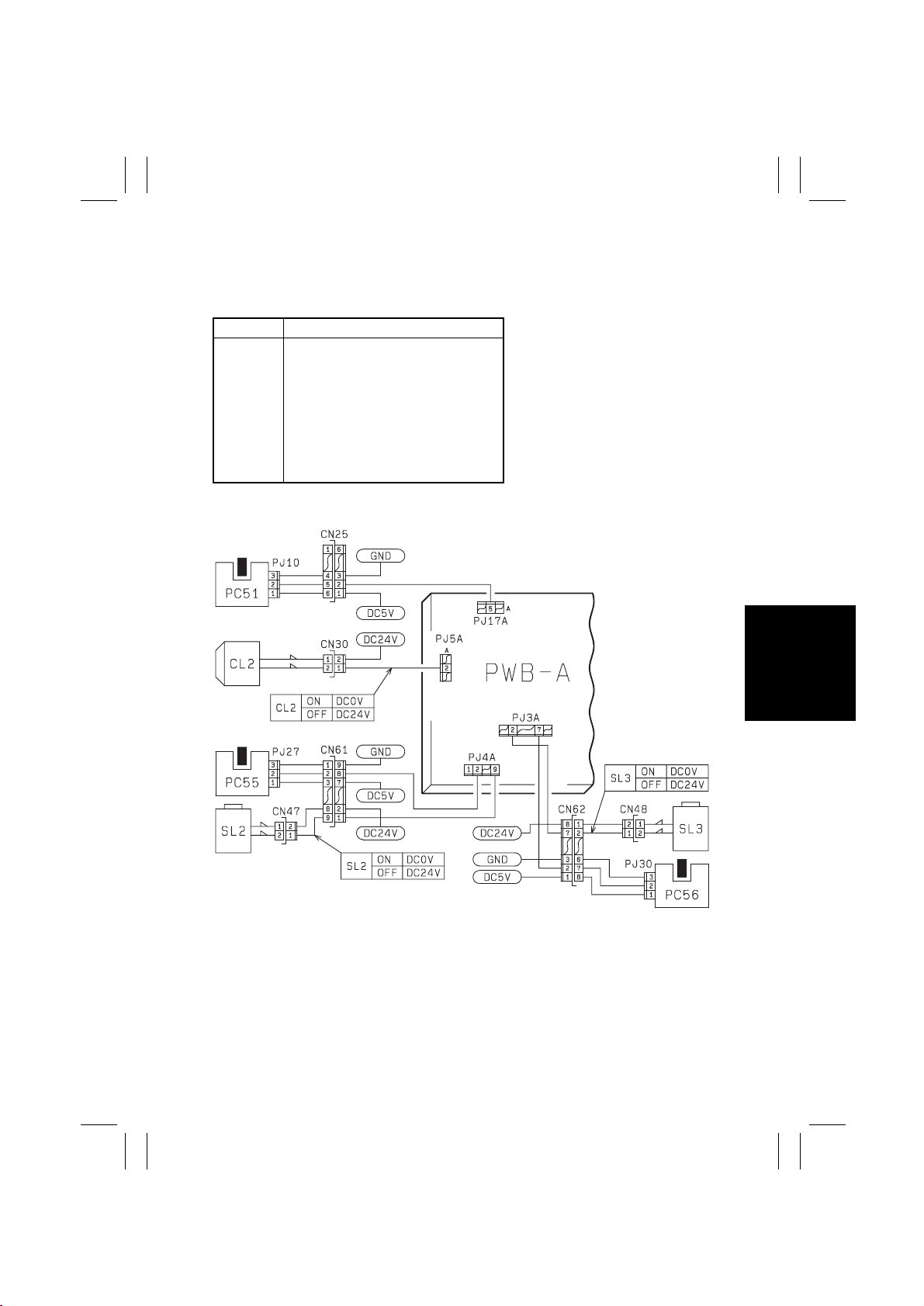

(1) Copier Take-Up Misfeed

Symbol Name

PC51

PC55

PC56

SL2

SL3

CL2

PWB-A

Transport Roller Sensor

1st Dra w er Paper Take-Up Sensor

2nd Drawer Paper Take-Up Sensor

(23 cpm Copier)

1st Dra w er Paper Take-Up Solenoid

2nd Drawer Paper Take-Up Solenoid

(23 cpm Copier)

Pape r Transport Clutch

Master Board

T-15

1174C01TAA

Page 19

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Copier Take-Up Misfeed Clearing Procedure

Symptom

Paper is not

•

taken up at all.

Paper is st ation-

•

ary before the

Paper Take-Up

Sensor.

Continued on next page

Step

1

2

3

4

5

6

7

8

9

Check Item

Does the pap er being used

meet product specifications?

Is the paper curled, waved,

or damp? YES

Are the Separ ator Fingers

on both s ides of t he D rawer

in position?

Are the Separ ator Fingers

deformed?

Is the Trailing Edge Stop or

Edge Guide in good position?

Are the Paper Lifting

Springs positioned correctly?

Are the Paper Take-Up

Rolls deformed, worn, or

dirty with paper dust?

Is a signal being output

from PWB-A to the Paper

Take-Up Solenoid?

Does the voltage across

✽

PJ4A-9 (1st Drawer) or

PJ3A-2 (2nd Dra w er) on

PWB-A and GND cha nge

from DC24V to DC0V

when th e St art Key is

pressed?

Is the Clutch Spr ing

deformed or worn?

Result

NO

NO

YES

NO

NO

YES

YES

NO

YES

Instruct the user to use the

paper that meets product

specifications.

Change the paper.

Instruct the user in how to

store the paper.

Instruct the user to l oad the

paper so that it res ts under

the Fingers.

Replace the Fing e r s.

Instruct the user in how to

position the Edge Stop or

Guide.

Change the position of the

Springs or add one as necessary.

Clean or replace the Paper

Take- Up Rolls.

Adjust the Solenoid stroke.

Check the Solenoid.

Replace PWB-A.

Replace the Clut c h Spring.

Action

T-16

Page 20

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Symptom

Paper is st ation-

•

ary before the

Vertical Transport Roller.

Paper is st ation-

•

ary at the Vertical Transport

Roller.

Paper is

•

stationary near

the Transport

Roller.

Step

10

11

12

13

14

15

Check Item

Check 1st/2nd Drawer

Pape r Take-Up Sensor

(PC55/PC56). See p.T-2.

PC55: PWB-A ( IC 4A) APA1

PC56: PWB-A ( IC 5A) PA5

Are the Vertical Transport

Rollers deformed, worn, or

dirty with paper dust?

Are the Paper Take-Up

Guide Plate and Vertical

Transport Guide Plate dirty

or defo rmed?

Is a signal being output

from PWB-A to the Clutch?

Does the voltage across

✽

PJ5A-2A on PWB- A and

GND change from

DC24V to DC0V when

the Start Key is pressed?

Check Transport Roller

Sensor PC51. See p. T-2

(PWB-A (IC4A) APC7).

Are the Transport Rollers

deformed, worn, or dirty

with paper dust?

Result

YES Replace PW B-A.

Check the Ac tuator for

operation.

NO

Check the Paper Take-Up

Sensor.

Clean or replace the

YES

V e rtical Transport Rollers.

Clean, correct, or replace

the Guide Plate.

YES

YES Check the Clutch.

Replace PWB-A.

NO

YES

Replace or check the PWB-A.

Check the Ac tuator for

NO

operation.

Check PC51.

Clean or replace the

YES

Transport Rollers.

Action

T-17

Page 21

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

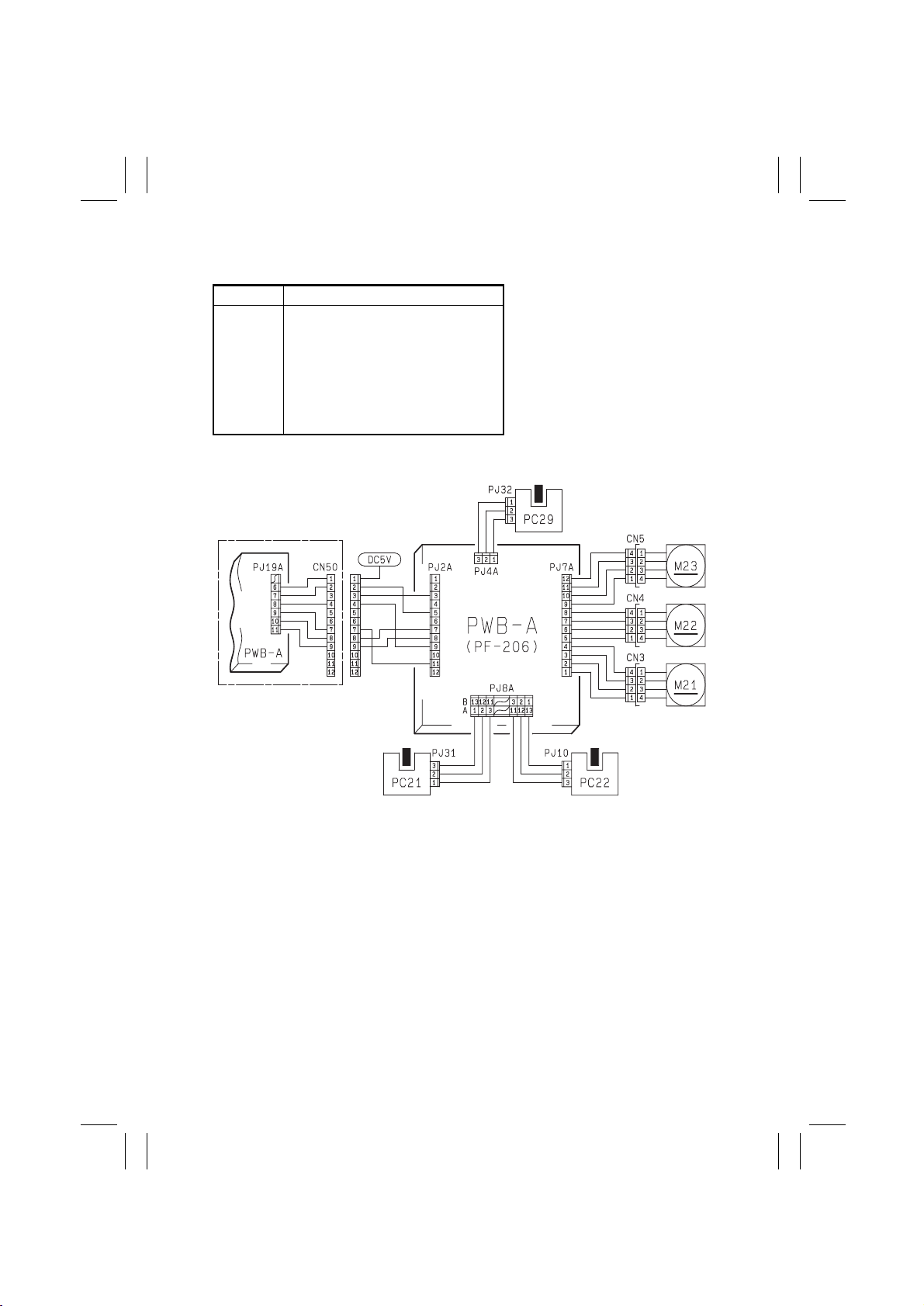

(2) PF-206 Tak e-Up Misfeed (23 cpm Copier)

Symbol Name

PC21

PC22

PC29

M21

M22

M23

PWB-A

PWB-A

3rd Drawer Paper Take-Up Sensor

Vertical Transport Sensor 4

4th Drawer Paper Take-Up Sensor

Vertical Transport Motor

3rd Drawer Paper Take-Up Motor

4th Drawer Paper Take-Up Motor

23 cpm Copier Master Board

PF-206 Master Board

T-18

1174C02TAA

Page 22

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Pape r Feed Cabinet Take-Up Misfeed Clearing Procedure

Symptom

Paper is not

•

taken up at all.

Paper is st ation-

•

ary before the

Paper Take-Up

Sensor.

Paper is

•

stationary

before the

Vertical Transport Rollers.

Paper is

•

stationary near

Vertical Transport Sensor 4

PC22.

Paper is

•

stationary

before the

copier.

Step

1

2

3

4

5

6

7

8

9

10

Check Item

Does the pap er being used

meet product specifications?

Is the paper curled, waved,

or damp? YES

Is the P a per Take-Up Motor

turning when the Start Key

is pressed?

Is the Paper Take-Up Roll

or Separa tor Roll deformed,

worn, or dirty with paper

dust?

Check 3rd/4th Drawer

Pape r Take-Up Sensor

(PC21/PC29). See p. T-2.

PC21: (PF-206) PWB-A

IC1A PE3.

PC29: (PF-206) PWB-A

IC2A PB3.

Is Vertical Transport Motor

M21 turning when the Start

Ke y is pressed?

Is the Vertical Transport

Roller or Guide Plate

deformed, worn, or dirty

with paper dust?

Check Vertical Transport

Sensor 4 PC22.

See p. T-2 (PF-206) PWB-A

IC1A PC2.

Check Vertical Transport

Sensor 4 PC22.

See p. T-2 (PF-206) PWB-A

IC1A PC2.

Is the Vertical Transport

Roller or Guide Plate

deformed, worn, or dirty

with paper dust?

Result

NO

NO

YES

YES

NO

NO

YES

YES

NO

YES

NO

YES

NO

Instruct the user to use the

paper that meets product

specifications.

Change the paper.

Instruct the user in how to

store the paper.

Check for possible overload.

Replace PWB-A or PF-206

PWB-A.

Check the Motor.

Clean or replace the Paper

Take-Up or Separator Roll.

Replace PWB-A or P F- 206

PWB-A.

Check the Ac tuator for

operation.

Check the Paper Take-Up

Sensor.

Check for possible overload.

Replace PWB-A or PF-206

PWB-A.

Check the Motor.

Clean or replace the

V e rtical Transport Roller or

Guide Plate.

Replace PWB-A or P F- 206

PWB-A.

Check the Ac tuator for

operation and check the

Sensor.

Replace PWB-A or P F- 206

PWB-A.

Check the Ac tuator for

operation and check the

Sensor.

Clean or replace the Vertical Transport Roller or

Guide Plate.

Check the Paper Feed Cabinet for po sitive connection

to the co pi e r.

Action

T-19

Page 23

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

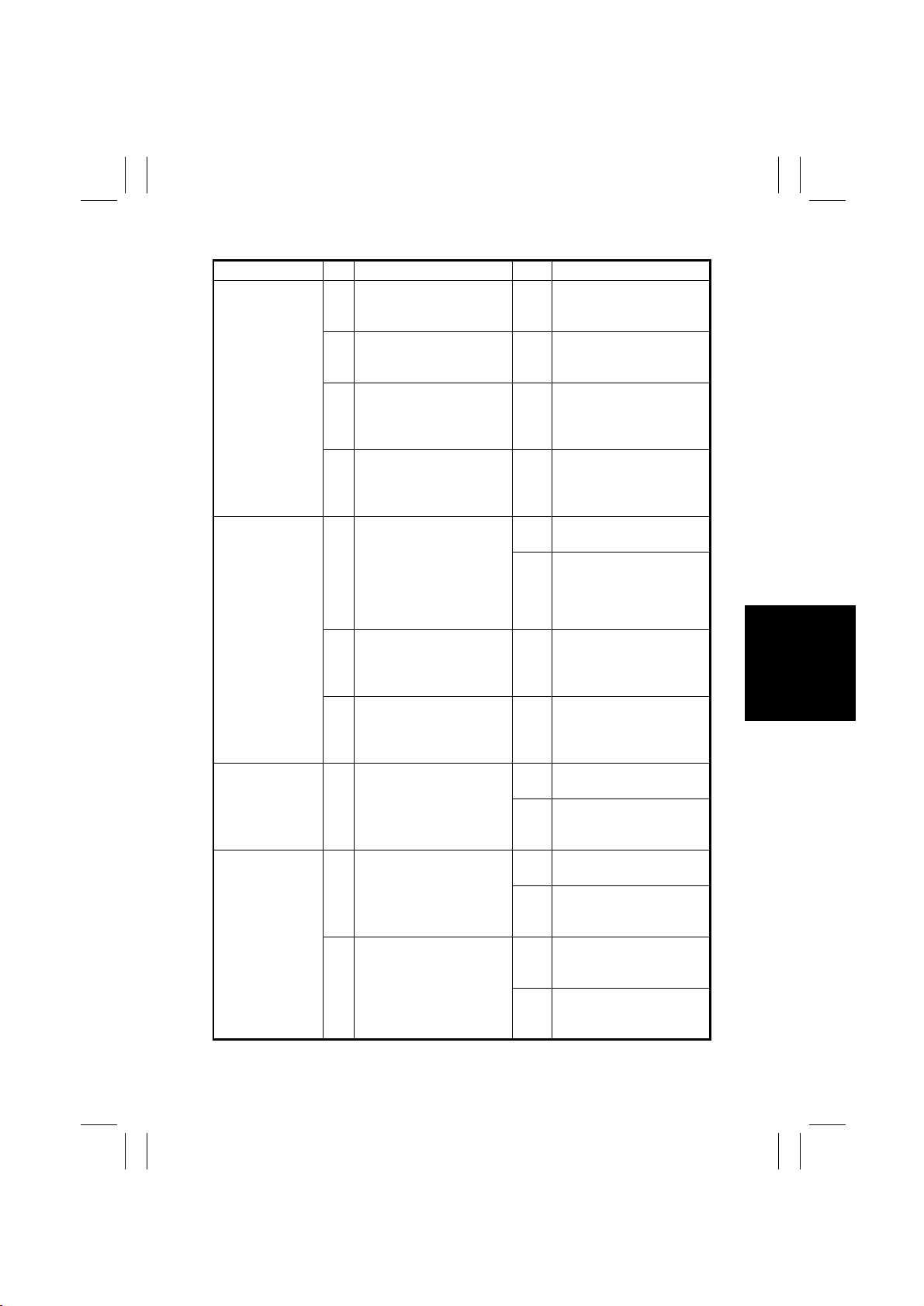

(3) PF-112 Tak e-Up Misfeed (23 cpm Copier)

Symbol Name

PC21

PC22

M21

M22

PWB-A

PWB-A

3rd Drawer Paper Take-Up Sensor

Vertical Transport Sensor 4

Vertical Transport Motor

3rd Drawer Paper Take-Up Motor

23 cpm Copier Master Board

PF-112 Master Board

T-20

1174C03TAA

Page 24

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Pape r Feed Cabinet Take-Up Misfeed Clearing Procedure

Symptom

Paper is not

•

taken up at all.

Paper is st ation-

•

ary before the

Paper Take-Up

Sensor.

Paper is st ation-

•

ary before the

Vertical Transport

Rollers.

Paper is

•

stationary near

Vertical Transport Sensor 4

PC22.

Paper is

•

stationary

before the

copier.

Step

1

2

3

4

5

6

7

8

9

10

Check Item

Does the pap er being used

meet product specifications?

Is the paper curled, waved,

or damp? YES

Is the P a per Take-Up Motor

turning when the Start Key

is pressed?

Is the Paper Take-Up Roll

or Separa tor Roll deformed,

worn, or dirty with paper

dust?

Check 3rd Drawer Paper

Take-Up Sensor PC21 .

See p. T-2.

PC21: (PF-112) PWB-A

IC1A PE3.

Is Vertical Transport Motor

M21 turning when the Start

Ke y is pressed?

Is the Vertical Transport

Roller or Guide Plate

deformed, worn, or dirty

with paper dust?

Check Vertical Transport

Sensor 4 PC22.

See p. T-2 (PF-112) PWB-A

IC1A PC2.

Check Vertical Transport

Sensor 4 PC22.

See p. T-2 (PF-112) PWB-A

IC1A PC2.

Is the Vertical Transport

Roller or Guide Plate

deformed, worn, or dirty

with paper dust?

Result

NO

NO

YES

YES

NO

NO

YES

YES

NO

YES

NO

YES

NO

Instruct the user to use the

paper that meets product

specifications.

Change the paper.

Instruct the user in how to

store the paper.

Check for possible overload.

Replace PWB-A or PF-112

PWB-A.

Check the Motor.

Clean or replace the Paper

Take-Up or Separator Roll.

Replace PWB-A or P F- 112

PWB-A.

Check the Ac tuator for

operation.

Check the Paper Take-Up

Sensor.

Check for possible overload.

Replace PWB-A or PF-112

PWB-A.

Check the Motor.

Clean or replace the

V e rtical Transport Roller or

Guide Plate.

Replace PWB-A or P F- 112

PWB-A.

Check the Ac tuator for

operation and check the

Sensor.

Replace PWB-A or P F- 112

PWB-A.

Check the Ac tuator for

operation and check the

Sensor.

Clean or replace the Vertical Transport Roller or

Guide Plate.

Check the Paper Feed Cabinet for po sitive connection

to the co pi e r.

Action

T-21

Page 25

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

(4) Bypass Port Misfeed

Symbol Name

PC31

PC54

SL51

CL2

CL51

PWB-A

Manual Feed Paper Empty Sensor

Pape r Leading Edge Detecting Sensor

Manual F eed Paper Take-Up Solenoid

Pape r Transport Clutch

Manual Feed Paper Take-Up Clutch

Master Board

T-22

1174C24TAB

Page 26

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Bypass Port Misfeed Clearing Procedure

Symptom

Paper is not

•

detected.

Paper is not

•

taken up at all. 2

Paper is

•

stationary near

the Transport

Roller.

Step

1

3

4

5

6

7

8

9

10

Check Item

Check Manual Feed Paper

Empty Sensor PC31. See

p. T-2 (PWB-A (IC4A) APC

3).

Does the paper being used

meet product specifications?

Is the paper curled, waved,

or damp? YES

Are the Paper Take-Up

Rolls pressed against the

paper stack when the Start

Ke y is pressed?

Does the voltage across

✽

PJ5A-2B on PWB-A and

GND change from

DC24V to DC0V when

the Start Key is pressed?

Does the voltage across

PJ5A-4B on PWB-A and

GND change from DC24V

to DC0V when the Start

Ke y is pressed?

Is the Pressure Pad or

Guide Plate deformed or

dirty?

Are the Paper Take-Up

Rolls deform ed, wor n, or

dirty with paper dust?

Check P aper Leading Edg e

Detecting Sensor PC54.

See p. T-2 (PWB-A (IC4A)

APC6).

Does the voltage across

PJ5A-2A on PWB-A and

GND change from DC24V

to DC0V when the Start

Ke y is pressed?

Is the Tr ansport Roller or

Guide Plate of the copier

deformed, worn, or dirty

with paper dust?

Result

YES Replace PWB-A.

NO

NO

YES

NO

YES Check the C l utch.

NO

YES

YES

NO

YES Check the C l utch.

NO

YES

Check the operation of the

actuator of PC31. If it operates properly, replace

PC31.

Instruct the user to use the

paper that meets product

specifications.

Change the paper.

Instruct the user in how to

store the paper.

Adjust the stroke of the

Solenoid.

Check the Solenoid .

Replace PWB-A.

Replace PWB-A.

Clean or replace the Pressure Pad or Guide Plate.

Clean or replace the Paper

Take-Up Rolls.

Check the Actuator for

operation.

Check PC54.

Replace PWB-A.

Clean or replace the Vertical Transport Roller or

Guide Plate.

Action

T-23

Page 27

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

(5) T ransport/Separator Misfeed

Symbol Name

PC51

PC54

CL1

M4

PWB-A

Transport Roller Sensor

Pape r Leading Edge Detecting Sensor

Synchronizi ng R oller Clutch

Suction Fan Motor

Master Board

T-24

1174C05TAA

Page 28

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Transport/Separator Misfeed Clearing Procedure

Symptom

Paper is st ation-

•

ary before the

Synchronizing

Roller.

Paper is st ation-

•

ary near the PC

Drum.

Paper is wedged

•

at the Paper Separator Fi ng ers.

Paper is st ation-

•

ary before the

Suction Belts.

Step

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Check Item

Is the paper curled, waved,

or damp? YES

Check Paper Leading Edge

Detecting Sensor PC54

See p. T-2 (PWB-A (IC4A)

APC6).

Check Synchronizing Roller

Clutch CL1.

Does the voltage across

✽

PJ5A-4A on PWB-A and

GND change from DC24V

to DC0V after the Start

Key has been pressed?

Is a given length of loop

formed before the Synchr o-

nizing Roller?

Is the Pre-Image Transfer

Guide Plate deformed or dirty?

Is the Corona Unit Cleaning

Lever (Lower) in correct

position?

Are the Image Transfer/

Paper Separator Corona

Wires deterior ated or dirty?

Are the Paper Guides

deformed or dirty?

Are the Synchronizing Roll ers deformed, worn, or dirty

with paper dust?

Are the Paper Separator

Fingers deformed or dirty? YES

Check Transport Roller

Sensor PC51. See p. T-2

(PWB-A (IC4A) APC7).

Check Paper Leading Edge

Detecting Sensor PC54.

See p. T-2

(PWB-A (IC4A) APC6).

Do the Suction Belts turn

properly?

Check Suction Fan Motor M4.

Does the voltage across

✽

PJ5A-9A on PWB- A and

GND change from

DC24V to DC0V when

the Start Key is pressed?

Result

Change the paper.

Instruct the user in how to

store the paper.

YES Replace PW B-A.

Check the Ac tuator for

NO

operation.

Check PC54.

YES Check the Clutch.

Replace PWB-A.

NO

Adjust the loop length or

NO

clean or replace the Transport Rollers.

Correct or clean the Guide

YES

Plate.

Place the Lever in position.

NO

Clean or replace the Wires.

YES

Clean or replace the Paper

YES

Guides.

Clean or replace the Syn-

YES

chronizing Rollers.

Correct or clean, or replace,

the Paper Separator Fingers.

Check the Ac tuator for

NO

operation.

Check PC51.

YES Replace PW B-A.

Check the Ac tuator for

NO

operation.

Check PC54.

Check the Belts and Drive

NO

Gear.

Check the DC24V line.

YES

Check M4.

Replace PWB-A.

NO

Action

T-25

Page 29

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

(6) Fusing/Exit Misfeed

Symbol Name

PC53

PC30

PC54

M4

PWB-A

1st Paper Exit Sensor

2nd Paper Exit Sensor

Pape r Leading Edge Detecting Sensor

Suction Fan Motor

Master Board

T-26

1174C06TAA

Page 30

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Fusing/Exi t Misfeed Clearing Procedure

Symptom

Paper is st ation-

•

ary before the

Fusing Roller.

The leading

•

edge of the

paper is

stationary near

the Fusing

Roller.

Paper is

•

stationary afte r

the Paper Exit

Roller/Rolls.

Step

1

2

3

4

5

6

7

8

9

Check Item

Is the paper curled, waved,

or damp? YES

Is the Guide Plate di rty with

toner? YES

Do the Suction Belts turn

properly?

Check Suction Fan Motor

M4.

Does the voltage across

✽

PJ5A-9A on PWB- A and

GND change from

DC24V to DC0V when

the Start Key is pressed?

Are the Fusing Rollers

scratched or dirty? Or, has

the replacement time

arrived for the Rollers?

Are the Paper Separator

Fingers dirty with toner or

worn? Are their edges

damaged?

Is the Oil Roller dirty? Or,

has the re p l acement ti m e

arrived for the Roller?

Check 1st/2nd Paper Exit

Sensor (PC53/PC30). See

p. T-2.

PC53: PWB-A ( IC 4A)

APC5

PC30: PWB-A ( IC 4A) A PB7

Check Paper Leading Edge

Detecting Sensor PC54.

See p. T-2 (PWB-A (IC4A)

APC6).

Result

NO

YES

NO

YES

YES

YES

NO

YES Replace PW B-A.

NO

Change the paper.

Instruct the user in how to

store the paper.

Clean th e G u i d e Pl a t e.

Check for possible

scattering of toner.

Check the Belts and Drive

Gear.

Check the DC24V line.

Check M4.

Replace PWB-A.

Clean or replace the

Rollers.

Clean or replace the

Fingers.

Clean or replace the Roller.

Check the Ac tuator for

operation.

Check PC53 or PC30, or

both.

Check the Ac tuator for

operation.

Check PC54.

Action

T-27

Page 31

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

(7) Duplex Uni t Vertical Transport/Storage Misfeed (23 cpm Copier)

Symbol Name

PC12

PC13

PC14

PC15

PC53

SL31

SL61

M31

PWB-A

PWB-A

PWB-G

Duplex Vertical Transport Sensor

Duplex Unit Tur nover Path Sensor

Duplex Unit Trailing Sensor

Duplex Unit Paper Empty Sensor

1st Paper Exit Sensor

Duplex Unit Gate Switching Solenoid

Turnover/Exit Switching Solenoid

Duplex Unit Drive Motor

23 cpm Copier Master Board

Master Board of PF-206/PF112/PF-6D

Duplex Unit Master Board

T-28

1174C07TAB

Page 32

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Duplex Unit Vertical Transport Misfeed C l eari ng Procedure

Symptom

Paper is st ation-

•

ary near the Exit

Section.

Paper is

•

stationary near

the Vertical

Transport Section of the

Duplex Unit.

Paper is st ation-

•

ary near the

Turnover Sec tion.

Continued on next page

Step

1

2

3

4

5

6

7

8

Check Item

Is the paper curled, waved,

or damp? YES

Does the voltage across

PJ12A-5 on PWB-A and

GND change from DC24V

to DC0V after the Start Key

has been pressed?

Are the Turnover/Exi t

Switching Plate and Upper

and Lower Guide Plates

deformed or dirty?

Is drive b eing tran smitt ed to

the V ertical Transport Roller

of the Duple x Unit? (Is

Duplex Unit Drive Motor

M31 turning after t he Start

Ke y has been pressed? )

Check Duplex Vertical

Transport Sensor PC12.

See p. T-2 (PWB-A (IC5A)

PA2) .

Check 1st Paper Exit Sensor PC53. See p. T-2

(PWB-A (IC4A) APC5).

Are the P addle Roller, Slip

Roller/Rolls, and Rolls B

Release Le ver deformed,

worn, or dirty with paper

dust?

Check Duplex Unit T urnove r

Pat h Sensor PC13. See p.

T -2 (PF- 206/PF-112/PF-6D)

PWB-A IC2 A PB 0 .

Result

YES

NO

YES

NO

NO

YES Replace PW B-A.

NO

YES

NO

YES

NO

Change the paper.

Instruct the user in how to

store the paper.

Adjust the stroke of the

Solenoid or check the

Solenoid.

Replace PWB-A.

Clean or replace the Plates.

Check for possible

overload.

Check the Duplex Un it drive

coupling or replace PWB-A

of PF-206/PF-112/PF-6D,

PWB-G, and/or M31.

Check the Ac tuator for

operation.

Check PC12.

Check the Ac tuator for

operation.

Check PC53.

Clean or replace the Roller

and/or Roll.

Check the Releas e Lever

mechanism.

Check th e drive coupl ing

from the Duplex Unit.

Replace PWB-A of PF - 20 6 /

PF-112/PF-6D.

Check the Ac tuator for

operation and PC13.

Action

T-29

Page 33

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Symptom

The leading

•

edge of the

paper is

stationary inside

the Duplex Unit.

Paper is st ation-

•

ary near the

take-up port of

the Duplex Unit.

Step

9

10

11

12

Check Item

Is the Paper Guide Mylar

deformed or dirty?

Does the Gate Switching

Plate operate properly?

(Is Duplex Unit Gate

Switching Solenoid SL31

energized for a paper

length of 300 mm or

longer?)

Does the voltage across

✽

PJ3G-5 on PWB-G and

GND change from

DC24V to DC0V af ter th e

Start Key has been

pressed?

Check Duplex Unit Trailing

Sensor PC14. See p. T-2.

(AD-11) PWB- G IC1G PC1.

Check Duplex Unit Pa per

Empty Sensor PC15. See

p. T-2.

(AD-11) PWB- G IC1G PC2.

Result

YES Clean or replace the Mylar.

Check the Mylar moving

NO

mechanism.

Adjust the stroke of the

YES

Solenoid or check the Solenoid.

Replace PWB-G or PWB-A

of PF-206/PF-112/PF-6D.

NO

Check the Ac tuator for

YES

operation and PC14.

Replace PWB-G or PWB-A

NO

of PF-206/PF-112/PF-6D.

Check the Ac tuator for

YES

operation and PC15.

Replace PWB-G or PWB-A

NO

of PF-206/PF-112/PF-6D.

Action

T-30

Page 34

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

(8) Duplex Unit Take-Up Misfeed (23 cpm Copier)

Symbol Name

PC16

PC17

SL33

CL31

M21

PWB-A

PWB-G

Duplex Unit Paper Take-Up Sensor

Vertical Transport Sensor 3

Duplex Unit Pick-Up Solenoid

Duplex Unit Pa per Take-Up Clutch

Vertical Transport Motor

Master Board of

PF-206/PF-112/PF-6D

Duplex Unit Master Board

T-31

1174C08TAA

Page 35

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Duplex Unit Take-Up Misfeed Clearing Procedure

Symptom

Paper is not

•

taken up at all. 1

Paper is

•

stationary near

the Vertical

Transport

Section.

Step

2

3

4

5

6

7

8

Check Item

Is the paper curled, waved,

or damp? YES

Is Duplex Unit Pick-Up Solenoid

SL33 energized when paper

take-up is about to occur?

Slide out the Duplex Unit and

✽

remove the PWB Cover.

Then, slide the Duplex Unit

back into the copier. D oes the

voltage across PJ2G-12 on

PWB-G and GND change

from DC24V to DC0V when

the Start Key is pressed in the

above condition?

Is Duplex Unit Paper Take-Up

Clutch CL31 energized when a

copy is taken up and fed into the

copier from the Duplex Unit?

Slide out the Duplex Unit and

✽

remove the PWB Cover.

Then, slide the Duplex Unit

back into the copier. D oes the

voltage across PJ2G-7 on

PWB-G and GND change

from DC24V to DC0V when

the Start Key is pressed in the

above condition?

Are the Take-Up Roll, Feed

Roll, and Separator Roll

deformed, worn, or dirty

with paper dust?

Is Vertical Transport Motor

M21 turning when a copy is

taken up and fed int o the

copier from the Dupl ex

Unit?

Are the Vertical Transport

Rollers and Guide Plate

deformed, worn, or dirty

with paper dust?

Check Duplex Unit Pa per

Take-Up Sensor PC16 .

(AD-11) PWB- G IC1G PC0.

Check Vertical Transport

Sensor 3 PC17.

See p. T-2

(PF-206/PF-112/PF-6D)

PWB-A IC1 A PC3 .

Result

Change the paper.

Instruct the user in how to

store the paper.

Adjust the stroke of the

YES

Solenoid or check the pickup mechanism.

Replace PWB-G or PWB-A

of PF-206/PF-112/PF-6D.

NO

YES Check the Clutch.

Replace PWB-G or PWB-A

of PF-206/PF-112/PF-6D.

NO

Clean or replace the Rolls.

YES

Check for possible overload.

Check the Duplex Unit drive

NO

coupling, or replace PWB-A

of PF-206/PF-112/PF-6D,

PWB-G, and/or M21.

Clean or replace the Vertical Transport Rollers and

YES

Guide Plate.

Check the Ac tuator for

NO

operation.

Check PC16.

Replace PWB-G or PWB-A

YES

of PF-206/PF-112/PF-6D.

Check the Ac tuator for

NO

operation.

Check PC17.

Action

T-32

Page 36

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

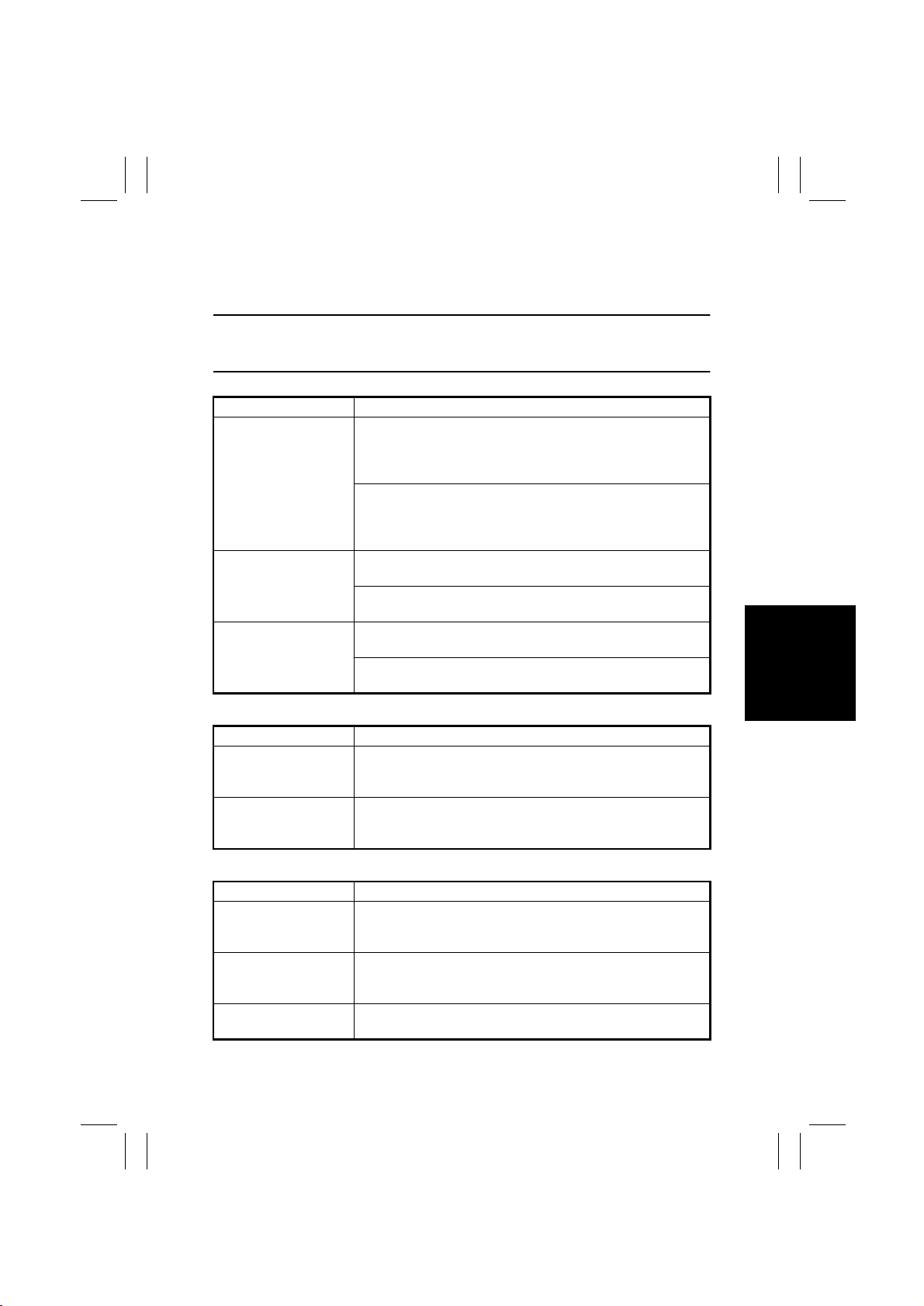

4 MALFUNCTIONS

4-1. Self-Diagnostic Function

The copier CPU is capable of self-diagnosis of the copier conditions and, when detecting a

malfunction, it shows the corresponding malfunction code across the Zoom Ratio Indicator

and Multi-Co py Display. Each malfunction code indicates the particular part which has

developed a malfunction and the type of malfunction. A listing follo ws showing all malfunction codes and the description and possible causes of each malfunction.

Zoom Ratio Indicator Multi-Copy Display

C0

Malfunctions can be reset by the following procedure.

•

Malfunction Resetting Procedure

•

Open and clos e the Front Door. The Trouble Reset Switch must be pressed after the

Power is switched ON to reset the malfunc ti on of the Fusing a nd Exposure Lamp Sections.

•

Disconnect and connect t he option or open and close the option do or for malfunctions of

options.

×××

×××

××××××

Represents the detail of the malfunction.

Indicates the particular malfunctioning part of the

greater physical unit.

Indicates the malfunctioning physical unit.

Copier/Paper Feed C abinet (Option)

✽

Code Description Detection Timing

C0000 Main Drive Motor's

failure to turn

C0001 Main Drive Motor turn-

ing at abnormal timing

C0010 PC Drive Motor's fa ilure

to turn

C0011 PC Drive Motor turning

at abnormal timing

C004C Cooling Fan Motor's

failure to turn

Drive

C0070 Toner Replenishing

Motor's failure to turn

C0071 Toner Replenishing

Motor turning at

abnormal timing

The lock signal remains HIGH for a continuous 1

second or more period while M2 is energized.

The lock signal remains LO W for a continuous 1

second or more period whil e M2 i s deenergized.

The lock signal remains HIGH for a continuous 1

second or more period while M1 is energized.

The lock signal remains LO W for a continuous 1

second or more period whil e M1 i s deenergized.

The lock signal remains HIGH for a continuous 3

second or more period while M9 is energized (it

turns at high speed).

Toner Hopper Home Pos i tion Sensor PC112

•

does not go from LOW to HIGH within 12 seconds after M8 has been energized.

PC112 does not go LOW within 12 seconds

•

after M8 has b een ene rgiz ed and PC1 12 g one

HIGH.

PC112 is HIGH 2 seconds afte r M8 has been de

energized.

T-33

Page 37

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Copier/Paper Feed C abinet (Option)

✽

Code Description Detection Timing

C0400 Exposure Lamp's failure

to turn ON

C0410 Exposure Lamp turning

ON at abnormal timing

Exposure Lamp

C0500 Warm-up failure

C0510 Abnormally low fusing

Fusing Unit

C0520 Abnormally high fusing

C0600 Scanner Motor malfunc-

C0610 Lens Motor malfunction

Optical Section

C0620 Mirror Motor malfunction•The output from the Mirror Reference Position Sensor

C0F10 F aulty AE Sensor level

C0F30 ATDC Sensor malfunc-

Sensors

temperature

temperature

tion

tion

The output from AE Sensor Board PWB-H does not

become 4.3V or less for the period between when LA1

turns ON and the Scanner starts a scan motion and when

the Scanner reaches the Image Leading Edge position.

With LA1 OFF, the output from PWB-H remains 4.1V or

less for a continuous 2 second period at any timing while

the Scanner is at the home position or the Original Cover

is lowered.

If a given period of time has elapsed during warming-up,

the surface temperature of the Upper Fusing Roller does

not reach:

50°C within 20 seconds;

•

90°C within 20 seconds after it has reached 50°C; or

•

150°C within 20 seconds after it has reached 90°C.

•

The copier does not complete its warming-up cycle within

15 seconds after the above surface temperature has

reached 150°C.

The surface temperature of the Upper Fusing Roller

•

remains less than 135°C for a continuous 1 second or

more period after the copier has warmed up.

The surface temperature of the Upper Fusing Roller

•

remains less than 80°C for a continuous 1 second or

more period while in energy saving mode.

The surface temperature of the Upper Fusing Roller

remains 230°C or more after the copier has warmed up.

When the Scanner is at a position other than home,

•

Scanner Reference Position Sensor PC81 does not go

from HIGH to LOW after the lapse of 20 seconds after

the Power Switch has been turned ON.

When the Scanner is at the home position, PC81 does

•

not go from LOW to HIGH after the lapse of 5 seconds

after the Scanner has started a scan motion.

PC81 does not go from HIGH to LO W after the lapse of

•

20 seconds after the Scanner has started a scan

motion.

The output from Lens Reference Position Sensor PC90

does not go from HIGH to LOW, or vice versa, after the

lapse of 15 seconds after M6 has started turning.

PC86 does not go from HIGH to LO W after the lapse of

10 seconds after M7 has started turning.

The output from PC86 does not go from LOW to HIGH

•

after the lapse of 3 seconds after M7 has started turn-

ing.

The output from PWB-H does not fall within the 2V – 4V

range during the initial F5 mode.

The output from UN3 remains 0.4V or less, or 4.6V or

more, for a continuous 2 second period 2 seconds after

PC Drive Motor M2 has started turning.

T-34

Page 38

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Malfunctions Detected by Copiers, Except in Europe

✽

Code Description Detection Timing

C0F02 Original size detection

C0FE2 Original Size Detecting

C0FE4 Original Size Detecting

C0FE6 Original Size Detecting

C0FE8 Original Size Detecting

C0FEA Original Size Detecting

C0FEC Original Size Detecting

C0FEE Original Size Detecting

C0FF0 Original Size Detecting

C0FF2 Original Size Detecting

Original Size Detecting Board

C0FF4 Original Size Detecting

C0FF6 Original Size Detecting

C0FF8 Original Size Detecting

C0FFA Original Size Detecting

C0FFC Original Size Detecting

C0FFE Original Size Detecting

error (Defective CPU)

Sensor ➋ failure

Sensor ➌ failure

Sensors ➋ and ➌ failure

Sensor ➍ failure

Sensors ➋ and ➍ failure

Sensors ➌ and ➍ failure

Sensors➋, ➌ and ➍ failure

Sensor ➎ failure

Sensors ➋ and ➎ failure

Sensors ➌ and ➎ failure

Sensors ➋, ➌ and ➎ failure

Sensors ➍ and ➎ failure

Sensors ➋, ➍ and ➎ failure

Sensors ➌, ➍ and ➎ failure

Sensors ➋, ➌, ➍ and ➎

failure

Either UN2 is faulty or a commu ni cation error

•

occurs w ith PW B-A.

Under normal conditions :

•

The fixed-cycle pulse signal (Busy) remains

HIGH or LOW for 3 seconds or more.

When the Power Switch is ON:

•

The Busy signal r emai ns HIGH or LOW for 5

seconds or more.

<Detection Timing>

After having read the output data from PC113 to

PC116, UN2 determines that there is a failure.

<Sensor Layout>

(Metric Areas)

: PC113, ➌: PC115 (option),

• ➋

: PC114, ➎: PC116 (option)

➍

PC115 and PC116 are standard for Mixed

✽

inch/metric areas.

A to E: Sensor locations

•

A

BCD E

A

B

➍

➎

(Inch Areas)

: PC113, ➌: PC115 (option),

• ➋

: PC114, ➎: PC116 (option)

➍

A

BCD E

A

B

➍

➎

➋

➋

➌

➌

T-35

Page 39

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Code Description Detection Timing

C0900 3rd Drawer Paper Lift-

Up Sensor malfun ction

C0904 3rd Drawer Paper Lift-

C0950 4th Drawer Paper Lift-

PF-206

C0954 4th Drawer Paper Lift-

C0d00 Duplex Unit Fron t/Rea r

C0d20 Duplex Unit Trailing

C0d50 Duplex Unit Drive

AD-11/PF-6D

C0d51 Duplex Unit Drive Motor

Up Motor malfunction

Up Sensor malfun ction

Up Motor malfunction

Edge Guide Plates

home position detection

failure

Gate Unit home position

detection failure

Motor's failure to turn

turning at abnormal timing

See the PF-206 Service Man ual.

See the AD-11/PF-6D Service Manual.

T-36

Page 40

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Code Description Detection Timing

C0990 Main Tray upward

motion failure

C0991 Main Tray downward

C0992 Main Tray downward

C0993 Main Tray upward

C0994 Main Tray Elev ator

C0996 3rd Drawer lo ck release

C0998 Shifter transfer failure

C0999 Shifter return failure

C099A Shifter return failure

PF-112

C099b Shifter transfer failure

C099c Shifter Motor's failure to

C0F79•3rd Drawer Paper

C099E Shift Gate position

C099F Shift Gate position

motion failure

motion failure

motion failure

Motor's failure to turn

failure

turn

Empty Sensor failure

Main Tray Paper

•

Empty Board failure

Shift Tray Paper

•

Empty Sensor

detecting failure

detecting failure

See the PF-112 Service Man ual.

T-37

Page 41

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

Malfunctions for Other Options

✽

Code Description Detection Timing

C0b10 Faulty P aper C lamp Uni t

movement

C0b11 Faulty P aper C lamp Uni t

movement

C0b30 Paper Aligning Motor

C0b31 Paper Aligning Motor

ST-104

C0b50 Improper stapling action

C0b51 Improper stapling action

C0b52 Improper stapling action

C0b60 Faulty Bin movement

C0b61 Faulty Bin movement

C0b62 Faulty Bin movement

C0b63 Faulty Bin movement

ST-104/S-106

C0b64 Faulty Bin movement

malfunction (Paper

Aligning Bar remaining

at home position)

malfunction (Paper

Aligning Ba r not at home

position)

(Stapler Arm remaining

at the home position)

(Stapler Arm not at

home position)

(stapling act i on occurring with no staples

driven into the paper)

(Defective Bin Moving

Motor)

(Defective drive)

(Defec tive Bin Positioning Sensor)

(Defective Bin Lower

Limit Position Sensor)

(M1 speed detection failure)

See the ST-104/S-106 Service Manual.

T-38

Page 42

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

4-2. Troubleshooting Procedures

(1) C0000: Main Drive Motor's fa il ure to turn

C0001: Main Drive Motor turning at abnormal timing

Symbol Name

M2

PWB-A

Main Drive Motor

Master Board

Step Check Item Result A ction

1 Is C0001 being shown? YES Begin with step 5.

Does M2 start to turn when the

2

Start Key i s pressed?

Does the voltage across PJ11A-14A on

PWB-A and GND change from DC5V to

3

DC0V when the Start Key is pressed?

Does the voltage across PJ11A-13A on

PWB-A and GND remain DC5V when

4

the Start Key is pressed?

Does the voltage across PJ11A-14A on

PWB-A and GND remain DC0V when

5

the Power Switch is turned ON?

Does the voltage across PJ11A-13A on

PWB-A and GND remain DC0V when

6

the Power Switch is turned ON?

Check rolls/rollers and gears for

NO

possible overload.

Replace PWB-A.

NO

YES Replace M2.

Replace PWB-A.

NO

Replace PWB-A.

YES

YES Replace M2.

Replace PWB-A.

NO

T-39

1174C25TAA

Page 43

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

(2) C0010: PC Drive Motor's failure to turn

C0011: PC Drive Motor turning at abnormal timing

Symbol Name

M1

PWB-A

PC Drive Motor

Master Board

Step Check Item Result A ction

1 Is C0011 being shown? YES Begin with step 5.

Does M1 start to turn when the Start

2

Key is pressed?

Does the voltage across PJ11A-12A on

PWB-A and GND change from DC24V

3

to DC0V when the Start Key is

pressed?

Does the voltage across PJ11A-11A on

4

PWB-A and GND remain DC5V when

the Start Key is pressed?

Does the voltage across PJ11A-12A on

5

PWB-A and GND remain DC0V when

the Power Switch is turned ON?

Does the voltage across PJ11A-11A on

PWB-A and GND remain DC0V when

6

the Power Switch is turned ON?

Check gears for possible overload.

NO

Replace PWB-A.

NO

YES Replace M1.

Replace PWB-A.

NO

Replace PWB-A.

YES

YES Replace M1.

Replace PWB-A.

NO

T-40

1174C26TAA

Page 44

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

(3) C004C: Cooling Fan Motor's failure to turn

Symbol Name

M9

PWB-A

Cooling Fan Motor

Master Board

C004C

Step Check Item Result A ction

Does the voltage across PJ20A-1

on PWB-A and GND change from

1

DC24V to DC12V when t he Power

is switched ON?

YES Replace M9.

Replace PWB-A.

NO

1174C27TAA

T-41

Page 45

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

(4) C0070: Toner Replenishing Motor's failure to turn

C0071: Toner Replenishing Motor turning at abnormal timing

Symbol Name

PC112

M8

PWB-A

Toner Hopper Home Position Sensor

Toner Replenishing Motor

Master Board

Step Check Item Result A ction

1 Is C0071 being shown? YES Begin with step 3.

Does the T oner Bottle turn when two

or three copies are made with the

2

Original Co ver raised?

Make two or three copies with the

Original Cover raised. Does the voltage

across PJ17A-2B on PWB-A and GND

3

change to DC0V when the Toner Bottle

is stopped and to DC5V when the Bottle

is turned during the copy cycle?

Make two or three co p ies with the O riginal Cover raised. Does the voltage

across PJ5A-6A on PWB-A and GND

4

change to DC0V when the Toner Bottle

is stopped and to DC24V when the Bottle is turned during the copy cycle?

YES Perform step 3.

Perform step 4.

NO

YES Replace PWB-A.

Check the Bottle Holder or PC112.

NO

YES Replace M8.

Replace PWB-A.

NO

T-42

1174C28TAA

Page 46

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

(5) C0400: Exposure Lamp's failure to turn ON

C0410: Exposure Lamp turning ON at abnormal timing

Symbol Name

LA1

TF2

PWB-A

PWB-H

PU1

Exposure Lamp

Exposure Lamp Thermal Fu se

Master Board

AE Sensor Boa r d

Exposure Lamp Regulator

T-43

1174C13TAC

Page 47

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

C0400

Step Check Item Result A ction

Does LA1 light up w hen the Start

1

Key is pressed? YES

Does the voltage across PJ14A-3

on PWB-A and GND become

2

DC4.3V or less when LA1 turns

ON?

Disconnect CN7 (2P). Is there con-

3

tinuity across CN7-1 and 2 on the

LA1 side?

Is the volt age across CN1-1 and 3

on PU1 AC1 00V?

4

C0410

Step Check Item Result A ction

Does LA1 turn ON when the P ower

Switch is turned ON or in the

1

standby state?

Does the voltage across PJ14A-3

on PWB-A and GND remain

2

DC4.1V or lower when the Power

Switch is turned ON or in the

standby state?

Check the photo receiver of the AE

Sensor for contamination.

Replace PWB-H o r PWB-A.

Replace PWB-A.

NO

Check LA1 and TF2 for continuity.

NO

YES Replace PU1.

Check Power Supply Unit PU2 and

NO

Power Supply Board PWB-C.

Check to see if the photo receiver of

the AE Sensor is receiving extrane-

NO

ous light.

Replace PWB-H o r PWB-A.

YES Replace PWB-A.

Replace PU1.

NO

T-44

Page 48

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 TROUBLESHOOTING

98.05.15

(6) C0500: Warm-up failure

C0510: Abnormally low fusing temperature

C0520: Abnormally high fusing temperature

Symbol Name

H1

TS1

TH1

PWB-A

SSR1

Fusing Heater La mp

Fusing Thermoswitch

Fusing Thermistor

Master Board

Fusing Heater Lamp SSR

T-45

1174C14TAA

Page 49