FrameMaker Ver.5.5E(PC) COVER [GENERAL] FOR EP1054/EP1085/EP2030

98.09.11

FrameMaker Ver.5.5E(PC) COVER [GENERAL] FOR EP1054/EP1085/EP2030

98.09.11

EP1054/EP1085/EP2030 SERVICE MANUAL

EP1054/EP1085/EP2030

SERVICE MANUAL

Copyright

1998 MINOLTA CO., Ltd.

Printed in Japan

Use of this manual should

be strictly supervised to

avoid disclosure of

confidential information.

MINOLTA CO., LTD.

1174-7990-11 98114400

10794

[

GENERAL

GENERAL

[

]

]

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030

98.04.24

INDEX (GENERAL)

GENERAL

MECHANICAL/ELECTRICAL

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL

98.04.24

EP1054/EP1085/EP2030

GENERAL

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL

98.04.24

COTNENTS

1. SPECIFICATIONS ........................................................................................... G-1

1-1. Specifications of EP2030 .......................................................... ...............G-1

1-2. Specifications of EP1085 .......................................................... ...............G-4

1-3. Specifications of EP1054 .......................................................... ...............G-7

2. PRECAUTIONS FOR INSTALLATION ........... .................................................G-10

3. PRECAUTIONS FOR USE ..............................................................................G-11

4. HANDLING OF THE CONSUMABLES ............................... ................... .........G-12

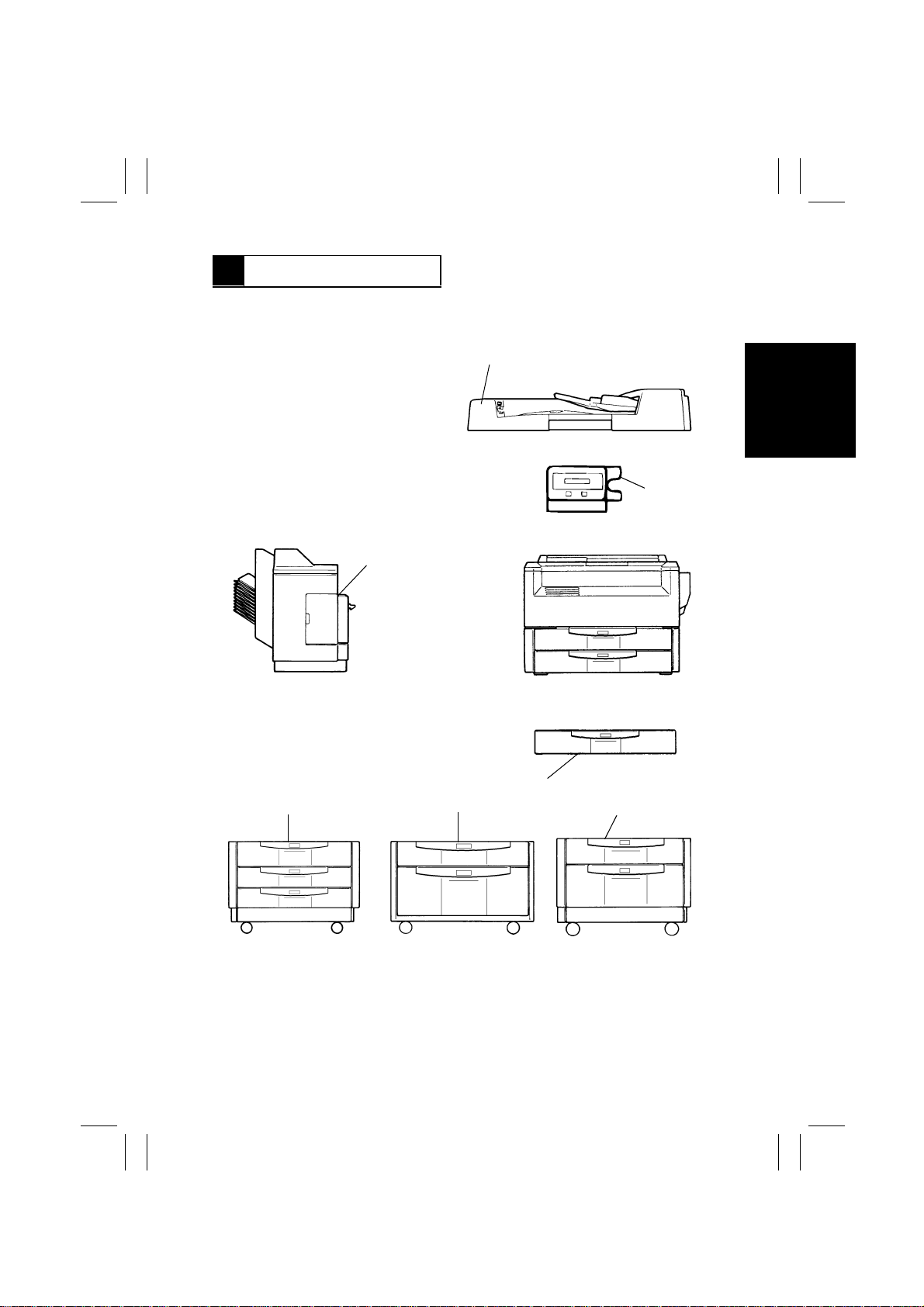

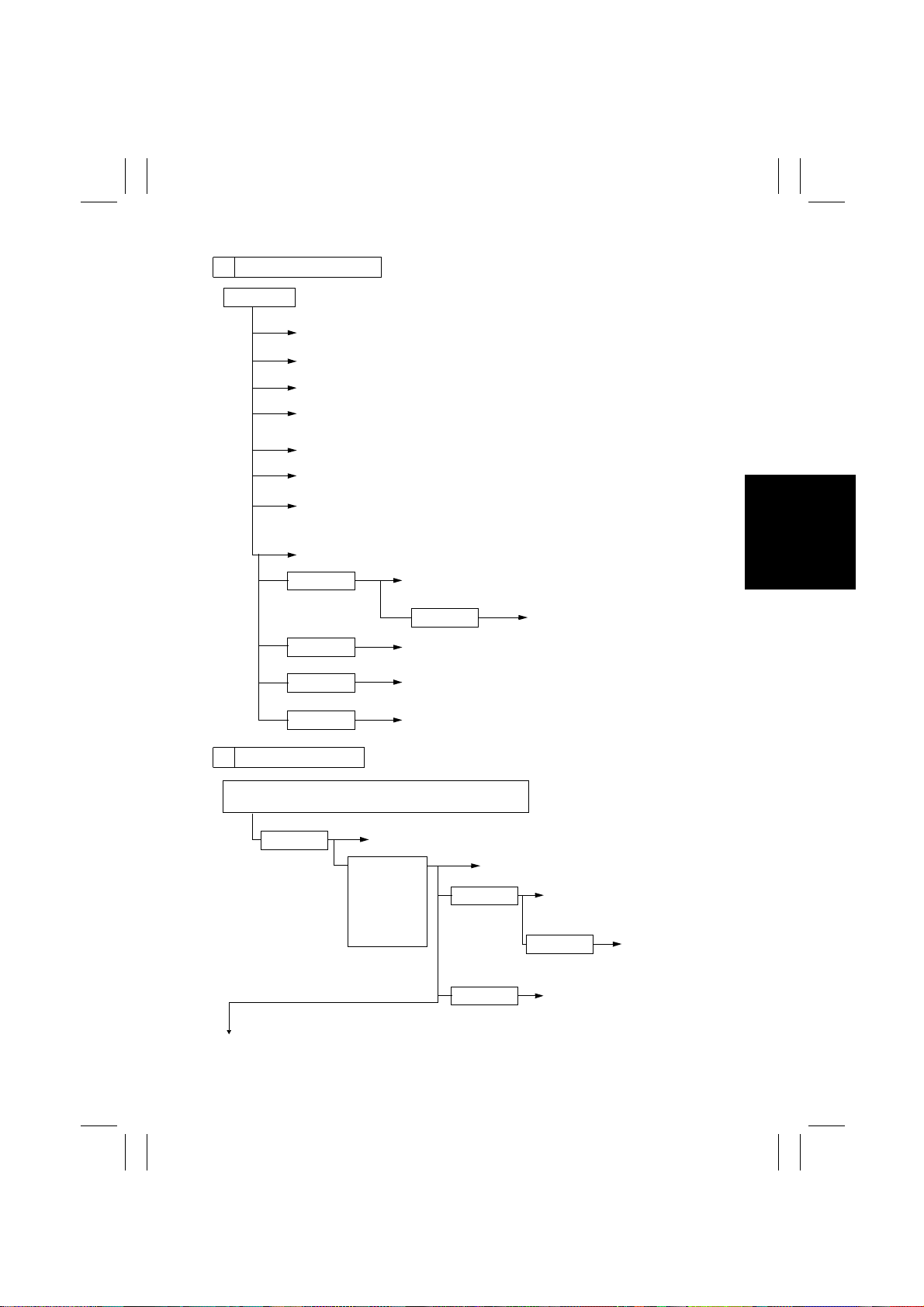

5. SYSTEM OPTIONS .........................................................................................G-13

5-1. System Options of EP2030 ............... ................... .................. ..................G-13

5-2. System Options of EP1085 ............... ................... .................. ..................G-14

5-3. System Options of EP1054 ............... ................... .................. ..................G-14

i

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL

98.04.24

1174SBG0100A

1 SPECIFICATIONS

1174SBG0101A

1-1. Specifications of EP2030

TYPE : Desktop

PHOT OCONDUCTOR : Organic Photoconductor

COPYING SYSTEM : Electrostatic Indirect Image Transfer to Plain Paper

PAPER FEEDING

SYSTEM

EXPOSURE SYSTEM : Mirror Scanning, Slit Exposure

DEVELOPING SYSTEM : Minolta New Micro-Toning System

CHARGING SYSTEM : Comb Electrode DC Negative Corona with Scorotron Sys-

IMAGE TRANSFER

SYSTEM

PAPER SEPARATING

SYSTEM

FUSING SYSTEM : Heat Roller

PAPER DISCHARGING

SYSTEM

MAXIMUM ORIGINAL

SIZE

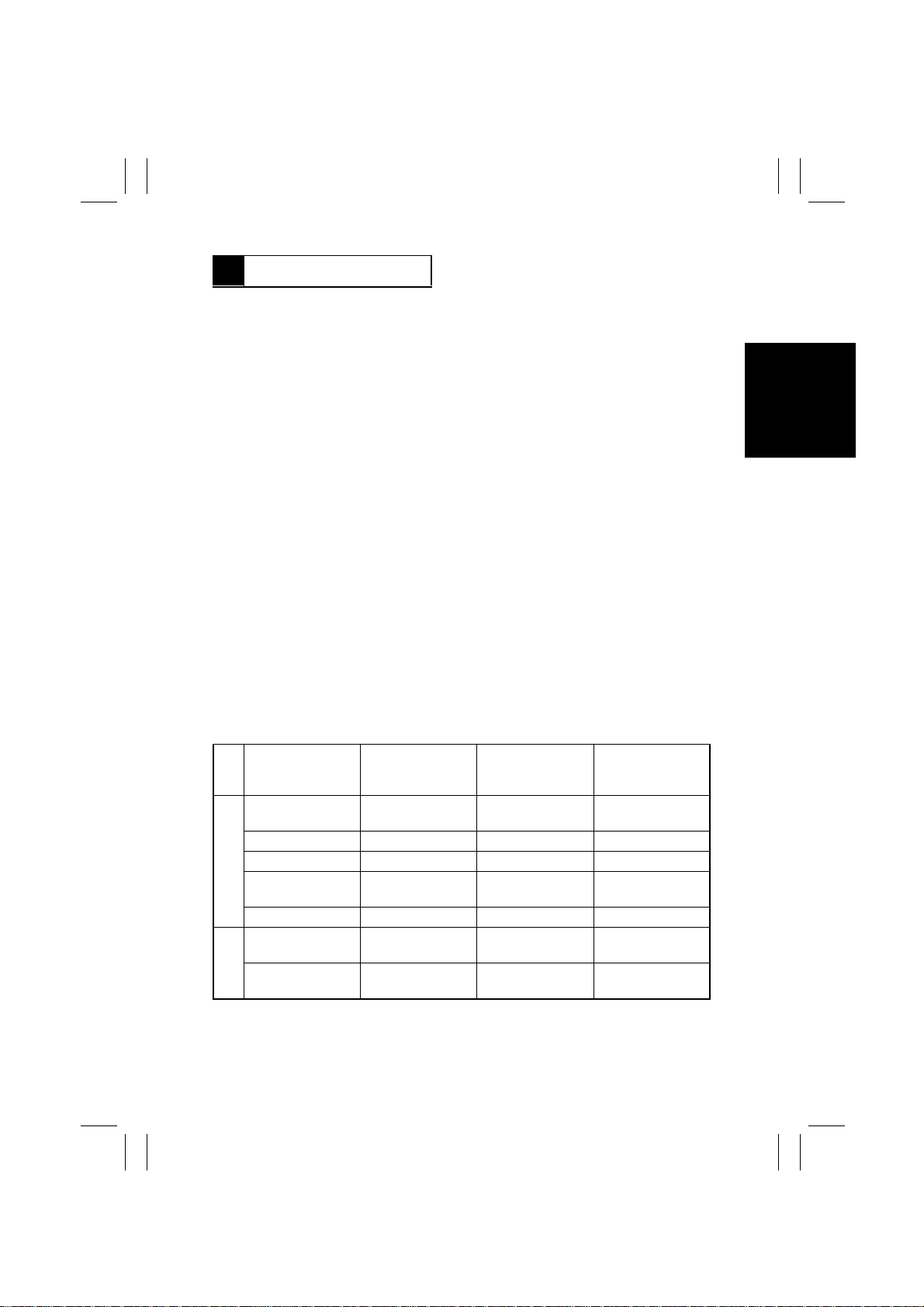

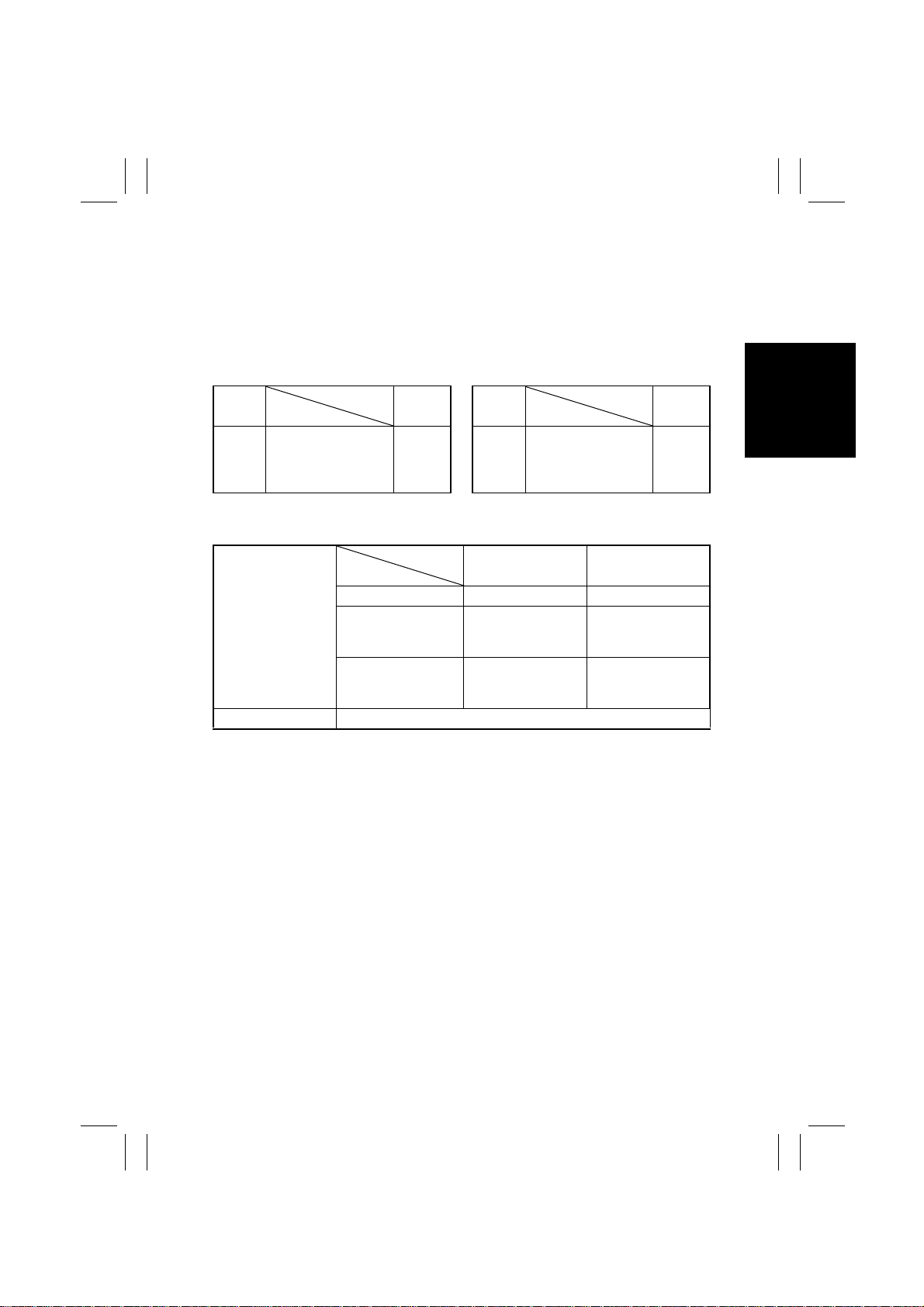

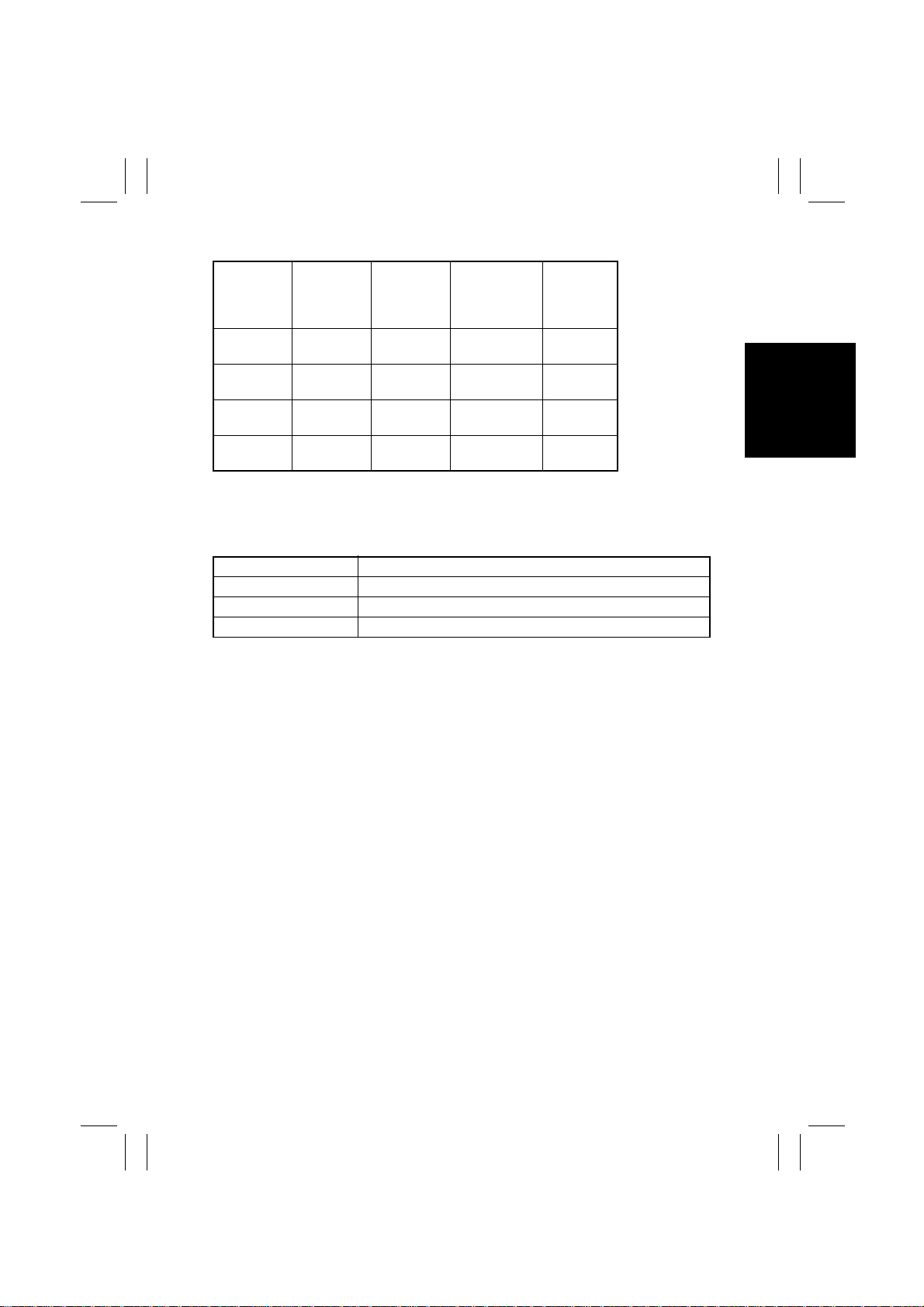

COPY MEDIUM

Plain paper

(60 to 90 g/m²)

Translucent paper – –

Transparencies – –

Medium

Thick paper

(91 to 157 g/m²)

Recycled paper

Maximum

(Width × Length)

Minimum

(Width × Length)

Dimensions

❍

: Permissible

–

: Not permissible

: 3-Way Feeding 1st Drawer: Universal Tray

2nd Drawer: Fixed Paper Size Tray

Multi Bypass Table

tem

: Visible Image Transfer by means of a Single-Wire DC

Negative Corona with Corotron System

: AC Corona with Corotron System, plus

Paper Separator Finger

: Charge Neutralizing Brush

: Metric-A3L; Inch-11” × 17”L (L: Lengthwise)

1st Drawer

(Automatic

feeding)

❍❍❍

––

❍❍❍

297 × 432 mm 297 × 432 mm 297 × 432 mm

140 × 182 mm 140 × 182 mm 100 × 140 mm

2nd Drawer

(Automatic

feeding)

(250 sheets of paper)

(250 sheets of paper)

Multi Bypass Table

❍

❍

❍

G-1

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

MULTIPLE COPIES : 1 to 99

WARMING-UP TIME : 30 sec. or less with room temperature of 23°C and rated

FIRST COPY TIME : A4C or 8-1/2”

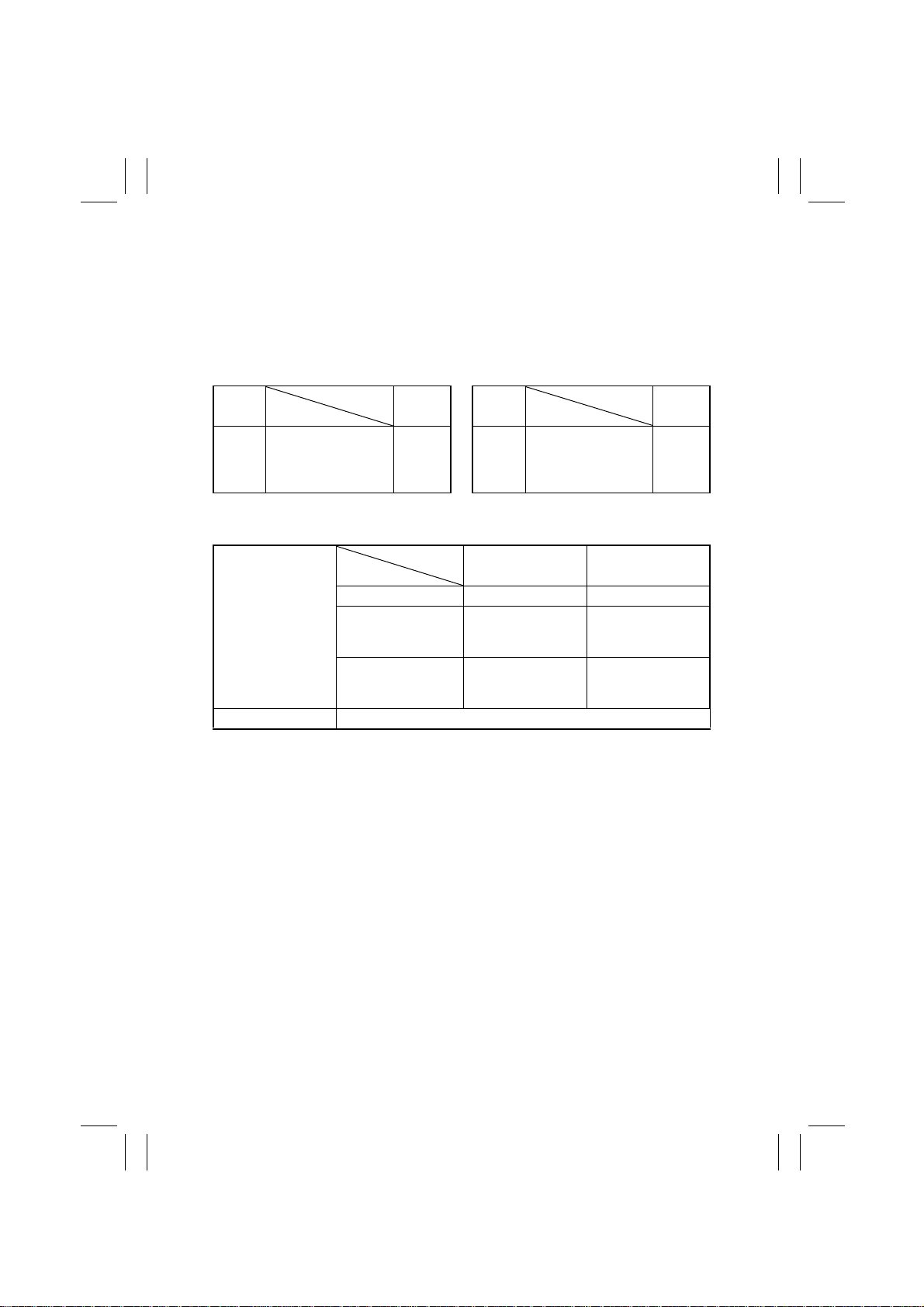

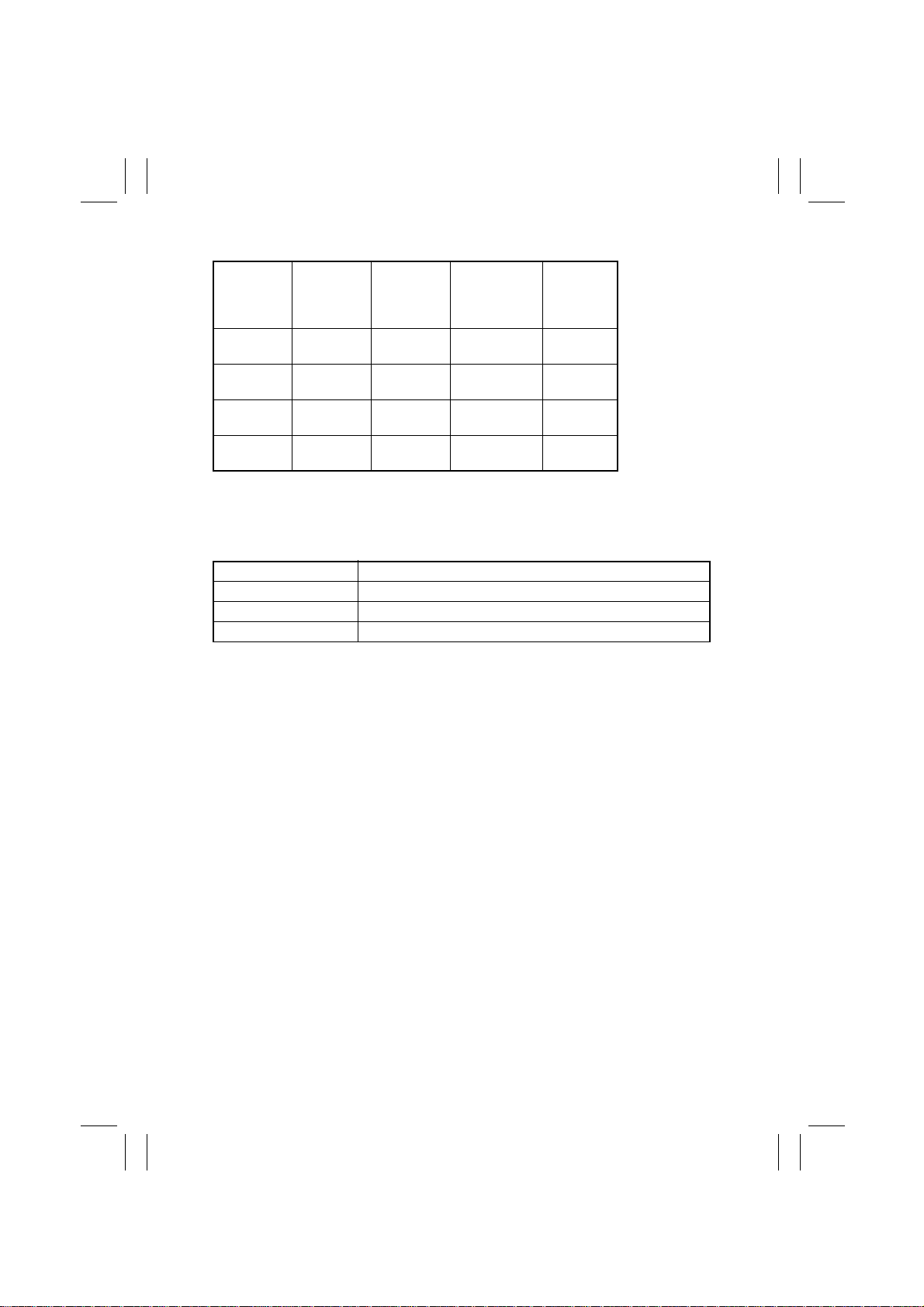

CONTINUOUS COPY SPEED (copies/min.): Fed from 1st Drawer

Area

Size Size

Metric

L: Lengthwise; C: Crosswise

ZOOM RATIOS

Fixed

Variable ×0.500 to ×2.000 (in 0.001 increments)

Zoom Ratio

A3L

A4L

A4C

B4L

Mode

power voltage

×

(in Full size Mode using 1st Drawer)

×

1.00 Area

13

17

23

13

Full Size

Reduction

Enlargement

11”C: 7.2 sec. or less

Inch

Area

×

×

×

×

×

×

×

Metric Inch

1.000

0.816

0.707

0.500

1.154

1.414

2.000

Zoom Ratio

11” × 17” (L)

8-1/2” × 11” (L)

8-1/2” × 11” (C)

5-1/2” × 8-1/2” (L)

×

1.000

×

0.785

×

0.647

×

0.500

×

1.214

×

1.294

×

2.000

×

1.00

13

17

23

21

LENS : Through Lens (F = 8.0, f = 180 mm)

EXPOSURE LAMP : Halogen Frost Tube Lamp

FUSING

TEMPERATURE

:195°C

G-2

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL

98.04.24

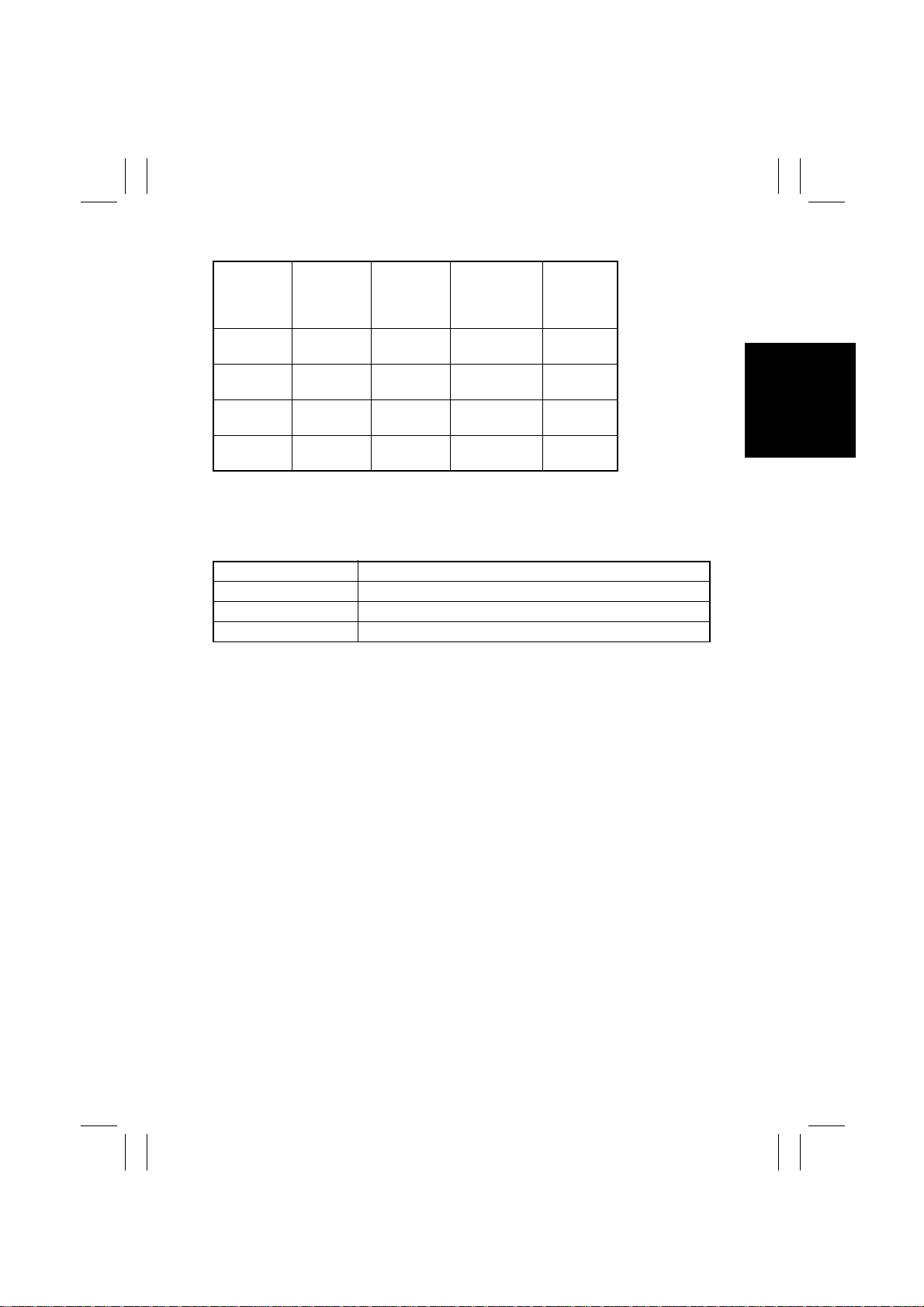

POWER/CURRENT CONSUMPTION (Copier Only)

Exposure

Voltage

115V

120V

120–127V

220–240V

POWER

REQUIREMENTS

ENVIRONMENTAL CONDITIONS

Temperature 10 to 30°C with a fluctuation of 10°C or less per hour

Humidity 15 to 85% RH with a fluctuation of 10% RH or less per hour

Ambient Illumination 3,000 lux or less

Levelness 1° (1.75 mm/100 mm)

Lamp

(Rating)

80V

225W

80V

225W

80V

225W

160V

240W

Fusing

Heater

Lamp

(Rating)

115–120V

900W

115–120V

900W

115–120V

900W

220–240V

900W

: 115 V, 120 V, 120

Max. Power

Consumption

1220–1290W 965– 1070W

1195–1270W 930– 1060W

In Standby

1180W 935W

1220W 965W

–

127 V, 220–240 V; 50/60 Hz

DIMENSIONS

(Copier Only)

WEIGHT : 57 kg (125-3/4 lbs)

: Width .... 650 mm (25-1/2”)

Depth .... 658 mm (26”)

Height ... 481 mm (19”)(including Original Cover)

G-3

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBG0102A

1-2. Specifications of EP1085

TYPE : Desktop (with Stationary Platen)

PHOT OCONDUCTOR : Organic Photoconductor

COPYING SYSTEM : Electrostatic Indirect Image Transfer to Plain Paper

PAPER FEEDING

SYSTEM

EXPOSURE SYSTEM : Mirror Scanning, Slit Exposure

DEVELOPING SYSTEM : Minolta New Micro-Toning System

CHARGING SYSTEM : Comb Electrode DC Negative Corona with Scorotron Sys-

IMAGE TRANSFER

SYSTEM

PAPER SEPARATING

SYSTEM

FUSING SYSTEM :

PAPER DISCHARGING

SYSTEM

MAXIMUM ORIGINAL

SIZE

: 2-Way Feeding Paper Drawer: Universal Tray

(250 sheets of paper)

Manual Bypass Table

tem

: Visible Image Transfer by means of a Single-Wire DC Neg-

ative Corona with Corotron System

: AC Corona with Corotron System, plus Paper Separator

Finger

Heat Roller

: Charge Neutralizing Brush

: Metric-A3L; Inch-11” × 17”L (L: Lengthwise)

COPY MEDIUM

(60 to 90 g/m²)

Translucent paper –

Transparencies –

Medium

(91 to 157 g/m²)

Recycled paper

(Width × Length)

(Width × Length)

Dimensions

❍

: Permissible

Plain paper

Thick paper

Maximum

Minimum

–

: Not permissible

Paper Drawer

(Automatic feeding)

❍❍

–

❍❍

297 × 432 mm 297 × 432 mm

140 × 182 mm 100 × 140 mm

Manual Bypass

(Single-sheet feeding)

❍

❍

❍

G-4

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL

98.04.24

MULTIPLE COPIES : 1 to 99

WARMING-UP TIME : 30 sec. or less with room temperature of 23°C and rated

FIRST COPY TIME : A4C or 8-1/2”

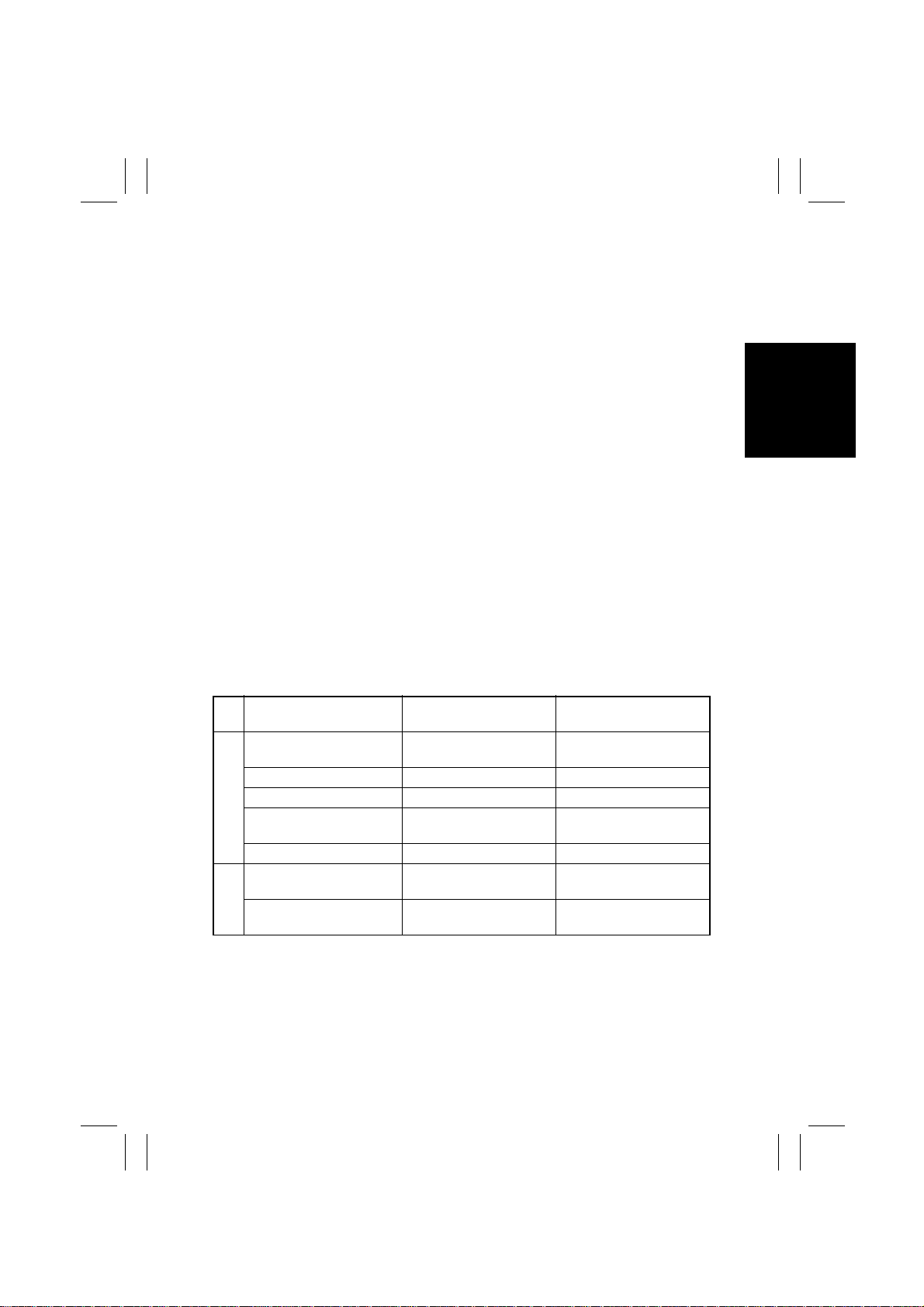

CONTINUOUS COPY SPEED (copies/min.): Fed from 1st Drawer

Area

Size Size

Metric

L: Lengthwise; C: Crosswise

ZOOM RATIOS

Fixed

Variable 50% to 200% (in 1% increments)

Zoom Ratio

A3L

A4L

A4C

B4L

Mode

power voltage

×

(in Full size Mode using 1st Drawer)

×

1.00 Area

12

16

18

13

Full Size 100% 100%

Reduction

Enlargement

11”C: 7.2 sec. or less

Inch

Area

Zoom Ratio

11” × 17” (L)

8-1/2” × 11” (L)

8-1/2” × 11” (C)

5-1/2” × 8-1/2” (L)

Metric Inch

81%

70%

50%

115%

141%

200%

78%

64%

50%

121%

129%

200%

×

1.00

11

16

18

18

LENS : Through Lens (F = 8.0, f = 180 mm)

EXPOSURE LAMP : Halogen Frost Tube Lamp

FUSING

TEMPERATURE

:195°C

G-5

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

POWER/CURRENT CONSUMPTION (Copier Only)

Exposure

Voltage

115V

120V

120–127V

220–240V

POWER

REQUIREMENTS

ENVIRONMENTAL CONDITIONS

Temperature 10 to 30°C with a fluctuation of 10°C or less per hour

Humidity 15 to 85% RH with a fluctuation of 10% RH or less per hour

Ambient Illumination 3,000 lux or less

Levelness 1° (1.75 mm/100 mm)

Lamp

(Rating)

80V

225W

80V

225W

80V

225W

160V

240W

Fusing

Heater

Lamp

(Rating)

115–120V

900W

115–120V

900W

115–120V

900W

220–240V

900W

: 115 V, 120 V, 120

Max. Power

Consumption

1220–1290W 965– 1070W

1195–1270W 930– 1060W

In Standby

1180W 935W

1220W 965W

–

127 V, 220–240 V; 50/60 Hz

DIMENSIONS

(Copier Only)

WEIGHT : 50 kg (110-1/4 lbs)

: Width .... 610 mm (24”)

Depth .... 637 mm (25”)

Height ... 401 mm (15-3/4”) (including Original Cover)

G-6

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL

98.04.24

1174SBG0103A

1-3. Specifications of EP1054

✽

Except the U.S.A., Canada

TYPE : Desktop (with Stationary Platen)

PHOT OCONDUCTOR : Organic Photoconductor

COPYING SYSTEM : Electrostatic Indirect Image Transfer to Plain Paper

PAPER FEEDING

SYSTEM

EXPOSURE SYSTEM : Mirror Scanning, Slit Exposure

DEVELOPING SYSTEM : Minolta New Micro-Toning System

CHARGING SYSTEM : Comb Electrode DC Negative Corona with Scorotron Sys-

IMAGE TRANSFER

SYSTEM

PAPER SEPARATING

SYSTEM

FUSING SYSTEM : Heat Roller

PAPER DISCHARGING

SYSTEM

MAXIMUM ORIGINAL

SIZE

: 2-Way Feeding Paper Drawer: Universal Tray

(250 sheets of paper)

Manual Bypass Table

tem

: Visible Image Transfer by means of a Single-Wire DC Neg-

ative Corona with Corotron System

: AC Corona with Corotron System, plus Paper Separator

Finger

: Charge Neutralizing Brush

: Metric-A3L; Inch-11” × 17”L (L: Lengthwise)

COPY MEDIUM

(60 to 90 g/m²)

Translucent paper –

Transparencies –

Medium

(91 to 157 g/m²)

Recycled paper

(Width × Length)

(Width × Length)

Dimensions

❍

: Permissible

Plain paper

Thick paper

Maximum

Minimum

–

: Not permissible

Paper Drawer

(Automatic feeding)

❍❍

–

❍❍

297 × 432 mm 297 × 432 mm

140 × 182 mm 100 × 140 mm

Manual Bypass

(Single-sheet feeding)

❍

❍

❍

G-7

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

MULTIPLE COPIES : 1 to 99

WARMING-UP TIME : 30 sec. or less with room temperature of 23°C and rated

FIRST COPY TIME : A4C or 8-1/2”

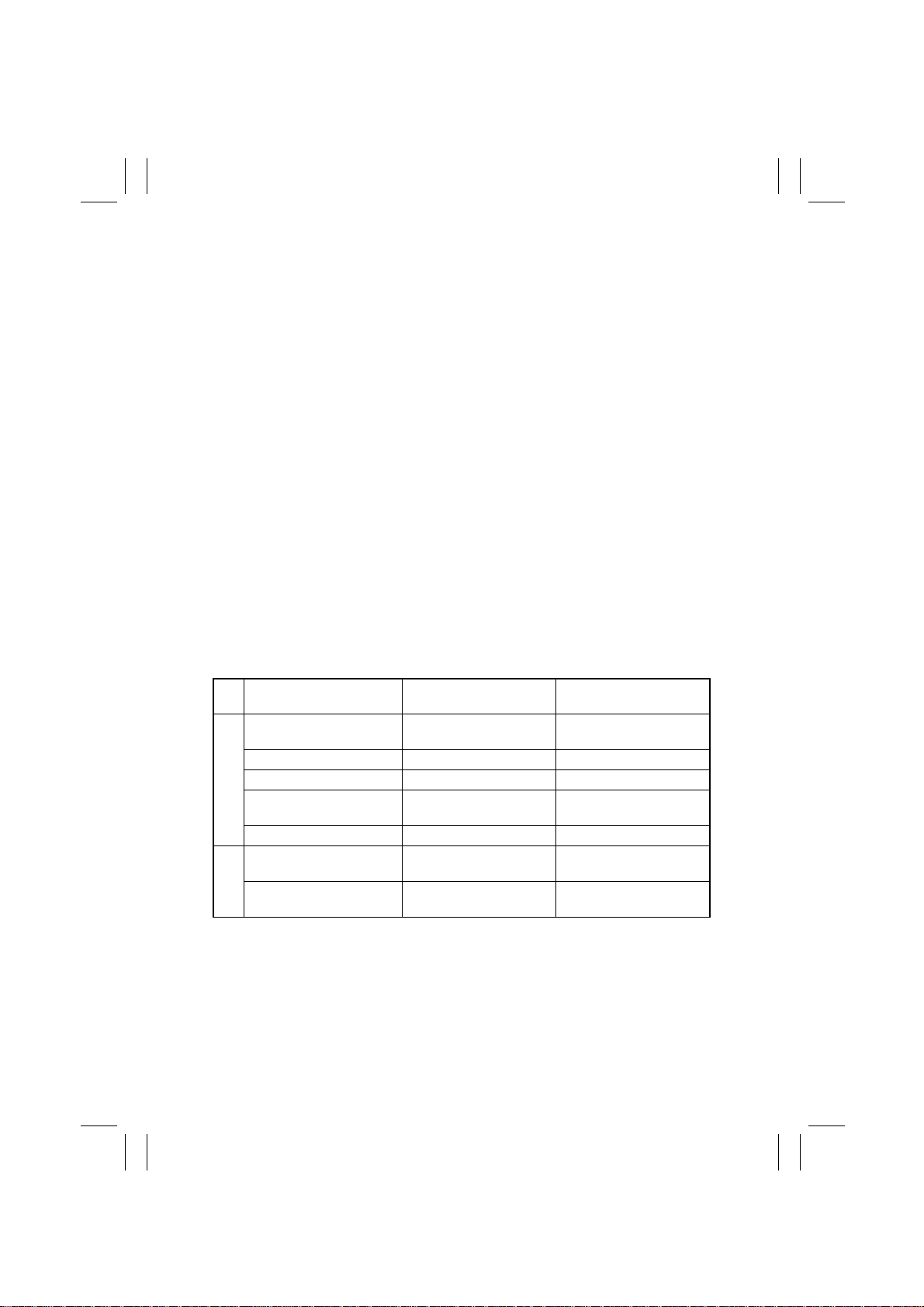

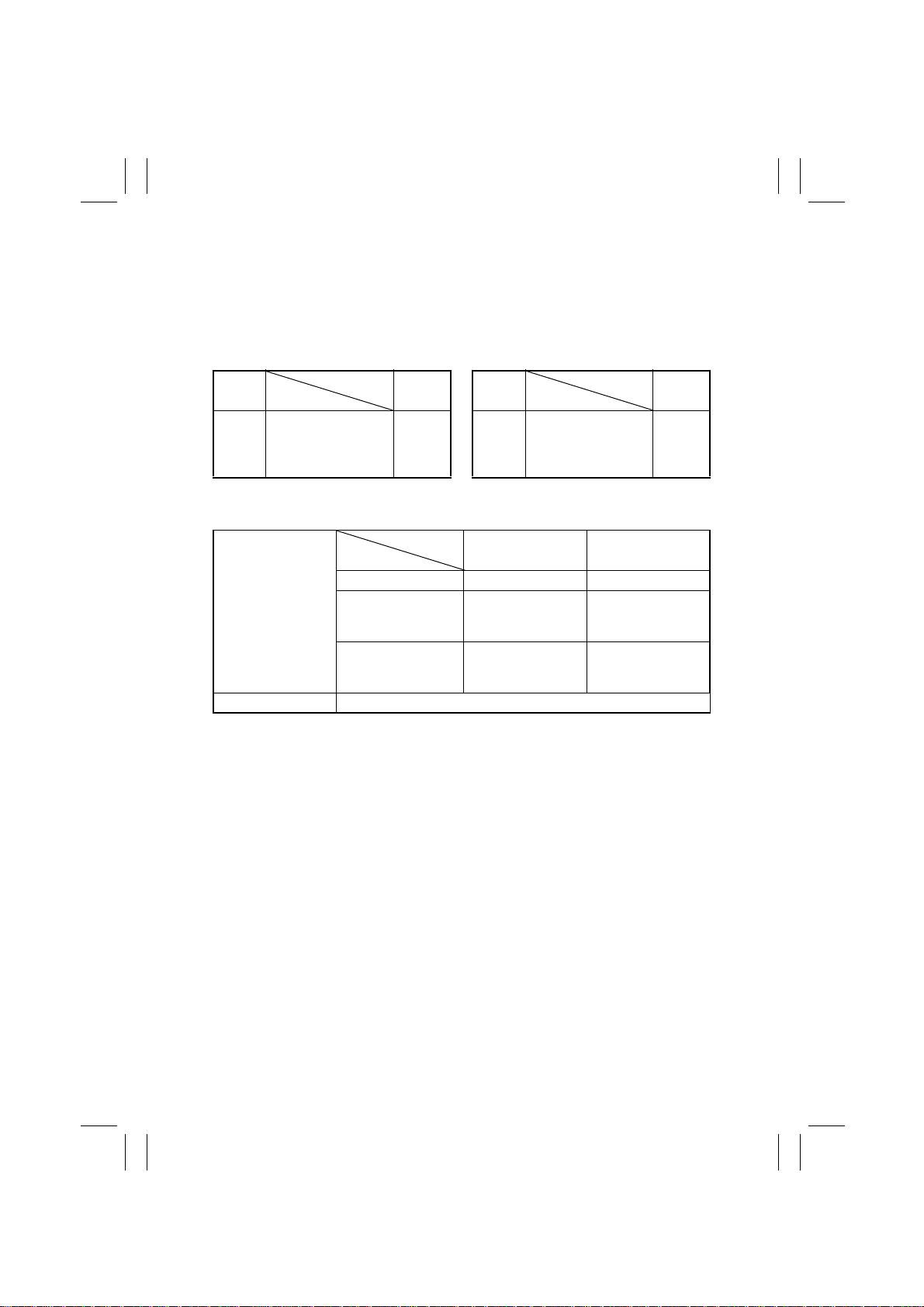

CONTINUOUS COPY SPEED (copies/min.): Fed from 1st Drawer

Area

Size Size

Metric

L: Lengthwise; C: Crosswise

ZOOM RATIOS

Fixed

Variable 50% to 200% (in 1% increments)

Zoom Ratio

A3L

A4L

A4C

B4L

Mode

power voltage

×

(in Full size Mode using 1st Drawer)

×

1.00 Area

12

15

15

13

Full Size 100% 100%

Reduction

Enlargement

11”C: 7.2 sec. or less

Inch

Area

Zoom Ratio

11” × 17” (L)

8-1/2” × 11” (L)

8-1/2” × 11” (C)

5-1/2” × 8-1/2” (L)

Metric Inch

81%

70%

50%

115%

141%

200%

78%

64%

50%

121%

129%

200%

×

1.00

11

15

15

15

LENS : Through Lens (F = 8.0, f = 180 mm)

EXPOSURE LAMP : Halogen Frost Tube Lamp

FUSING

TEMPERATURE

:195°C

G-8

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL

98.04.24

POWER/CURRENT CONSUMPTION (Copier Only)

Exposure

Voltage

115V

120V

120–127V

220–240V

POWER

REQUIREMENTS

ENVIRONMENTAL CONDITIONS

Temperature 10 to 30°C with a fluctuation of 10°C or less per hour

Humidity 15 to 85% RH with a fluctuation of 10% RH or less per hour

Ambient Illumination 3,000 lux or less

Levelness 1° (1.75 mm/100 mm)

Lamp

(Rating)

80V

225W

80V

225W

80V

225W

160V

240W

Fusing

Heater

Lamp

(Rating)

115–120V

900W

115–120V

900W

115–120V

900W

220–240V

900W

: 115 V, 120 V, 120

Max. Power

Consumption

1220–1290W 965– 1070W

1195–1270W 930– 1060W

In Standby

1180W 935W

1220W 965W

–

127 V, 220–240 V; 50/60 Hz

DIMENSIONS

(Copier Only)

WEIGHT : 50 kg (110-1/4 lbs)

: Width .... 610 mm (24”)

Depth .... 637 mm (25”)

Height ... 401 mm (15-3/4”)(including Original Cover)

G-9

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBG0200A

2 PRECAUTIONS FOR INSTALLATION

Installation Site

To ensure safety and utmost performance of the copier, the copier should NOT be used in a

place:

•

Where it will be subject to extremely high or low temperature or humidity.

•

Which is exposed to direct sunlight.

•

Which is in the direct air stream of an air conditioner, heater or ventilator.

•

Which puts the operator in the direct stream of exhaust from the copier.

•

Which has poor ventilation.

•

Where ammonia gas might be generated.

•

Which does not have a stable, level floor.

•

Where it will be subject to sudden fluctuations in either temperature or humidity. If a cold

room is quickly heated, condensation forms inside the copier, resulting in blank spots in

the copy.

•

Which is near any kind of heating device.

•

Where it may be splashed with water.

•

Which is dirty or where it will receive undue vibration.

•

Which is near volatile flammables or curtains.

Power Source

Use an outlet with a capacity of 115V, 1.18KW or more, or 120V , 1.22KW or more, or 120127V, 1.29KW or more, or 220

•

If any other electrical equipment is sourced from the same power outlet, make sure that

the capacity of the outlet is not exceeded.

•

Use a power source with little voltage fluctuation.

•

Never connect by means of a multiple socket any other appliances or machines to the

outlet being used for the copier.

•

Make the following checks at frequent intervals:

✽

Is the power plug abnormally hot?

✽

Are there any cracks or scrapes in the cord?

✽

Has the power plug been inserted fully into the outlet?

✽

Does something, including the copier itself, ride on the power cord?

•

Ensure that the copier does not ride on the power cord or communications cable of other

electrical equipment, and that it does not become wedged int o or underneath the mechanism.

–

240V, 1.27KW or more.

Grounding

To prevent receiving electrical shocks in the case of electrical leakage, always ground the

copier.

•

Connect the grounding wire to:

✽

The ground terminal of the outlet.

✽

A grounding contact which complies with the local electrical standards.

•

Never connect the grounding wire to a gas pipe, the grounding wire for a telephone, or a

water pipe.

G-10

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL

98.04.24

1174SBG0300A

3 PRECAUTIONS FOR USE

To ensure that the copier is used in an optimum condition, observe the following precautions.

•

Never place a heavy object on the copier or subject the copier to shocks.

•

Insert the power plug all the way into the outlet.

•

Do not attempt to remove any panel or cover which is secured while the copier is making

copies.

•

Do not turn OFF the Power Switch while the copier is making copies.

•

Provide good ventilation when making a large number of copies continuously.

•

Never use flammable sprays near the copier.

•

If the copier becomes inordinately hot or produces abnormal noise, turn it OFF and

unplug it.

•

Do not turn ON the Power Switch at the same time when you plug the pow er cord into the

outlet.

•

When unplugging the power cord, do not pull on the cord; hold the plug and pull it out.

•

Do not bring any magnetized object near the copier.

•

Do not place a vase or vessel containing water on the copier.

•

Be sure to turn OFF the Power Switch at the end of the workday or upon power failure.

•

Use care not to drop paper clips, staples, or other small pieces of metal into the copier.

Operating Environment

The operating environmental requirements of the copier are as follows.

✽

Temperature: 10°C to 30°C with a fluctuation of 10°C per hour

✽

Humidity: 15% to 85% RH with a fluctuation of 10% RH per hour

Power Requirements

The power source voltage requirements are as follows.

✽

Voltage Fluctuation:

✽

Frequency Fluctuation:

AC115/120/127/220/240V

±10% (Copying performance assured)

+6%, –10% (Only AC127V)

–15% (Paper feeding performance assured)

50/60 Hz ±0.3%

G-11

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBG0400A

4 HANDLING OF THE CONSUMABLES

Before using any consumables, always read the label on its container carefully.

•

Use the right toner. The applicable copier model name is indicated on the Toner Bottle.

•

Paper is apt to be easily damaged by dampness. To prevent absorption of moisture, store

paper, which has been removed from its wrapper but not loaded into the Drawer, in a

sealed plastic bag in a cool, dark place.

•

Keep consumables out of the reach of children.

•

Do not touch the PC Drum with bare hands.

•

Store the paper, toner, and other consumables in a place free from direct sunlight and

away from any heating apparatus.

•

The same sized paper is of two kinds, short grain and long grain. Short grain paper

should only be fed through the copier crosswise, long grain paper should only be fed

lengthwise.

•

If your hands become soiled with toner, wash them with soap and water immediately.

•

Do not throw away any used consumables (PC Drum, starter, toner, etc.). They are to be

collected.

NOTE

Do not burn, bury in the ground, or throw into the water any consumables

(PC Drum, starter, toner, etc.).

G-12

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL

98.04.24

1174SBG0500A

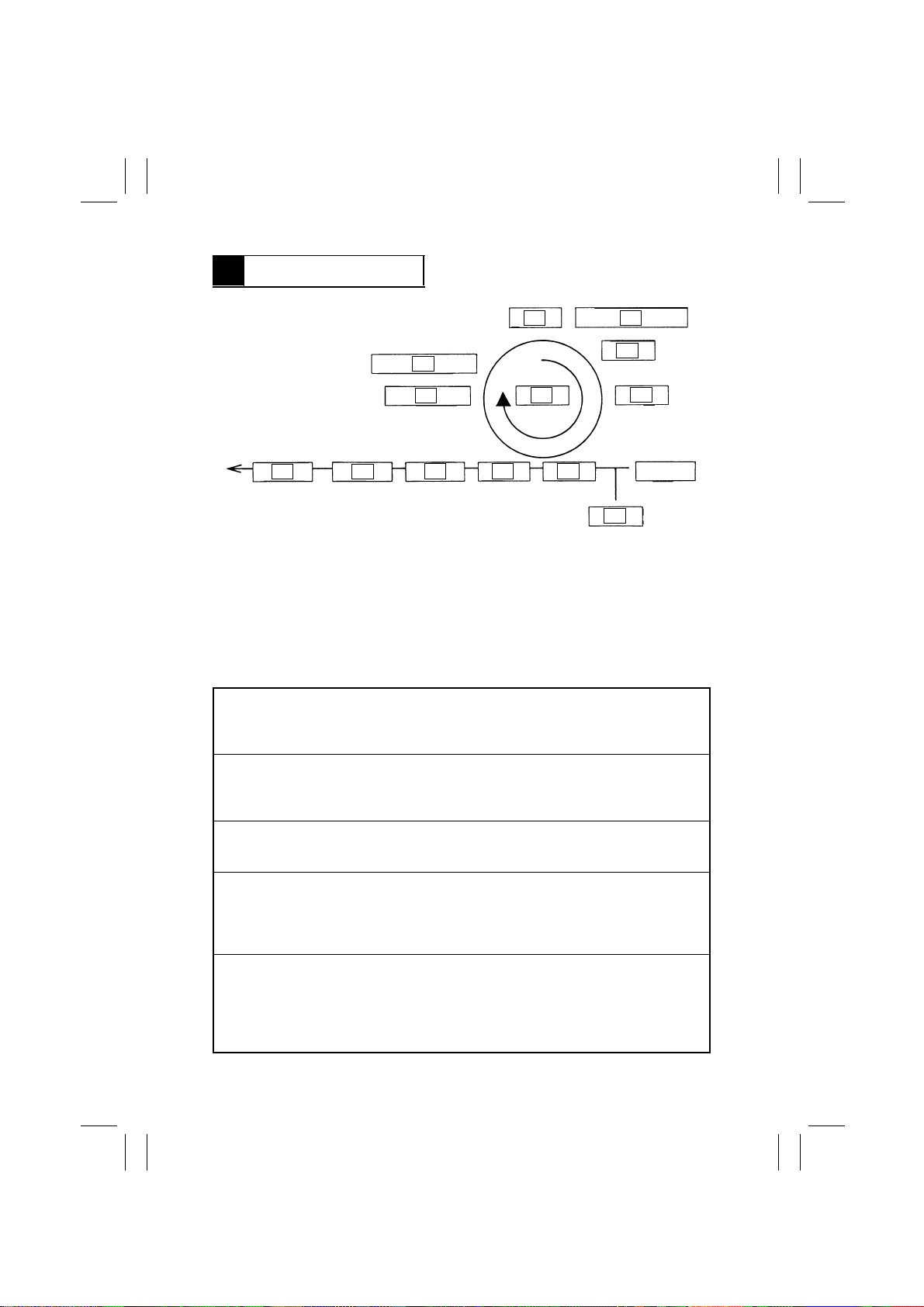

5 SYSTEM OPTIONS

1174SBG0501A

5-1. System Options of EP2030

1, 2

7, 8

1151O007AA

9

1138O525AA

1139O0020A

5

1174G003AA

1. Automatic Document Feeder AF-5

2. Duplexing Document Feeder AFR-12

3. Paper Feed Cabinet PF-112

4. Duplex Cabinet PF-6D

5. Paper Feed Cabinet PF-206

3

1174G004AA

6. Duplex Unit AD-11

7. 10-Bin Sorter S-106

8. Staple Sorter ST-104

9. Data Controller D-102

G-13

1174G001AA

1174G002AA

6

4

1174G006AA

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

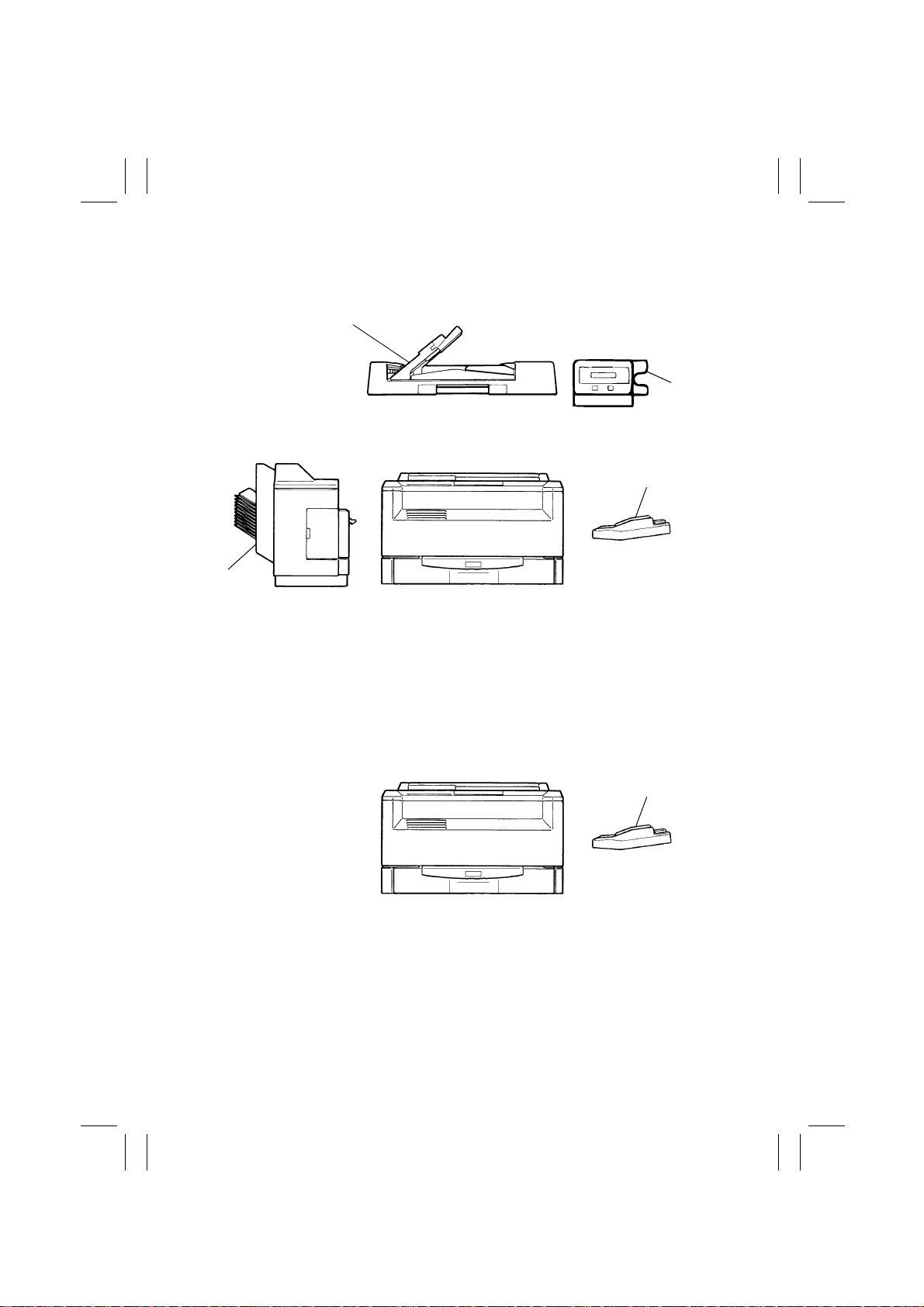

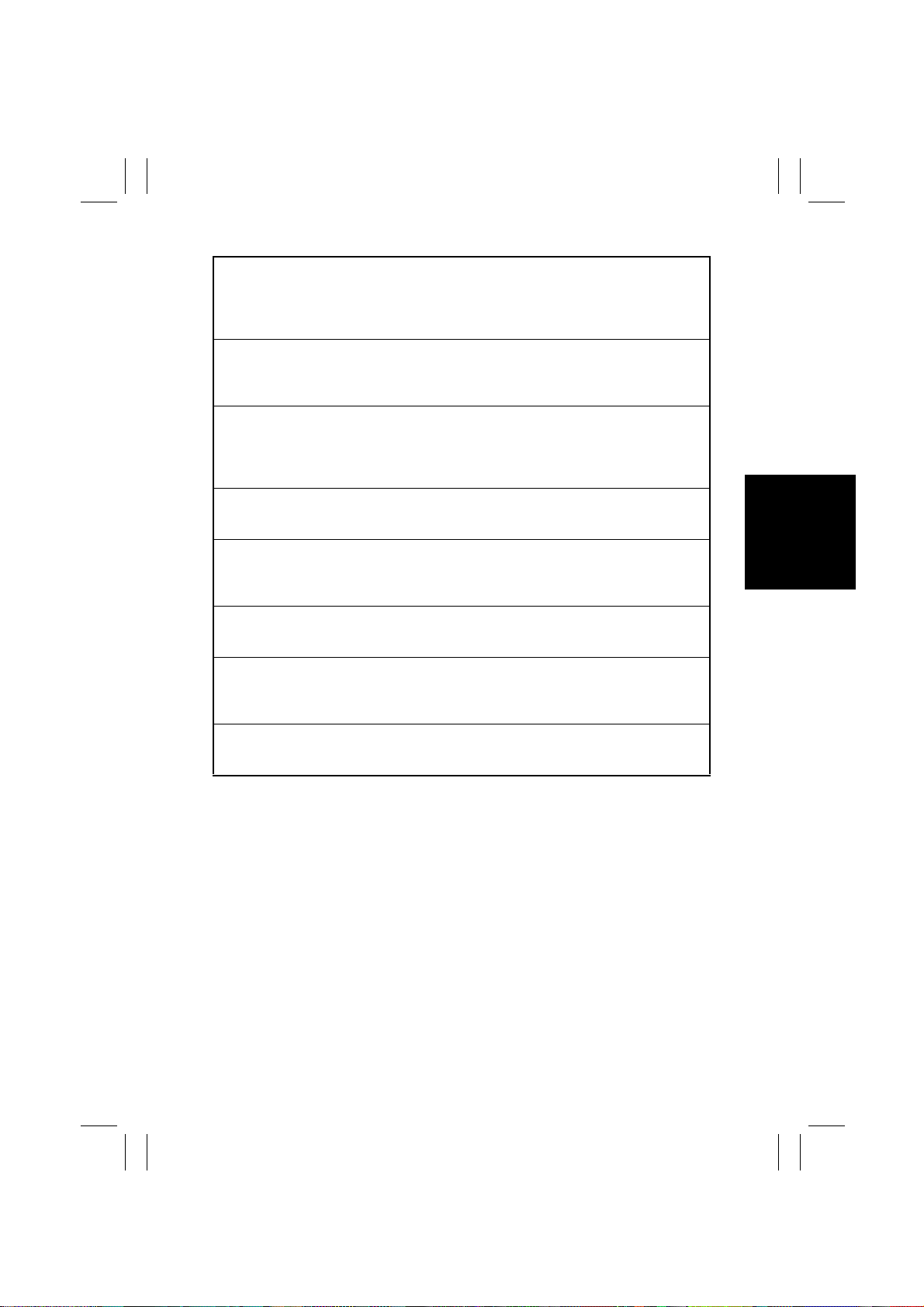

1174SBG0502A

5-2. System Options of EP1085

1

1139O0010A

3

1139O0020A 1174G005AA

1138O525AA

2

1139O0170A

4

1. Automatic Document Feeder AF-5

2. Multi Bypass Table MB-4

3. 10-Bin Sorter S-106

4. Data Controller D-102

1174SBG0503A

5-3. System Options of EP1054

✽

Except the U.S.A., Canada

1. Multi Bypass Table MB-4

1

1139O0170A

1174G005AA

G-14

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

EP1054/EP1085/EP2030

MECHANICAL/

ELECTRICAL

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

COTNENTS

1. CROSS-SECTIONAL VIEW ............................................................................M-1

1-1. Cross-Sectional View of 23 cpm Copier ....... ....................... ....................M-1

1-2. Cross-Sectional View of 18 cpm Copier ....... ....................... ....................M-2

1-3. Cross-Sectional View of 15 cpm Copier ....... ....................... ....................M-3

2. COPY PROCESS ............................................................................................ M-4

3. DRIVE SYSTEM ..............................................................................................M-6

4. SEQUENTIAL EXPLANATION ................... .....................................................M-7

5. IMAGING UNIT ................................................................................................M-12

5-1. Imaging Unit Drive ...................................................................................M-13

5-2. Imaging Unit Toner Recycling .................................................................M-14

5-3. Imaging Unit Fuse ....................................................................................M-14

6. PC DRUM ........................................................................................................M-15

7. DRUM CHARGING ..........................................................................................M-16

8. IMAGE ERASE LAMP .....................................................................................M-17

9. OPTICAL SECTION ... .....................................................................................M-20

9-1. Exposure Lamp .......................................................................................M-21

9-2. AE Sensor ...............................................................................................M-22

9-3. Lamp Reflectors ......................................................................................M-23

9-4. Aperture Plates .......................................................................................M-23

9-5. Scanner and 2nd/3rd Mirror Carriage Movement ...................................M-24

9-6. 4th Mirror Movement ............................................................................... M-26

9-7. Lens Movement ......................................................................................M-27

10. ORIGINAL SIZE DETECTING SENSORS (23 cpm COPIER ONLY) ..............M-28

10-1. Original Size Detecting Sensors .............................................................M-28

10-2. Original Size Detecting Operation ..........................................................M-28

10-3. Sensor Locations ....................................................................................M-29

10-4. Size Detection ........................................................................................M-30

10-5. Original Size Detection Timing ...............................................................M-31

10-6. Original Cover Angle Detection (23 cpm Copier Only) ...........................M-32

11. DEVELOPMENT .............................................................................................. M-33

11-1. ATDC Sensor .........................................................................................M-34

11-2. Magnet Roller .........................................................................................M-36

11-3. Developing Bias ......................................................................................M-37

11-4. Doctor Blade ........................................................................................... M-38

11-5. Sleeve/Magnet Roller Lower Filter .........................................................M-38

12. TONER HOPPER ........... ...................................................................... ...........M-39

12-1. Toner Hopper Locking/Unlocking ......................... ..................................M-39

12-2. Toner Replenishing ................................................................................M-39

12-3. Shutter ....................................................................................................M-40

12-4. Toner Hopper Home Position Detection ....................... ..........................M-40

12-5. Toner Bottle Vibration .................................... ........................................ .M-41

12-6. Toner Replenishing Control ............... ..................... ................................M-42

13. PAPER TAKE-UP/FEED SECTION (2ND DRAWER: 23 cpm

COPIER ONLY) ...................................................................................... .........M-43

13-1.Edge Guide and Trailing Edge Stop ........................................................M-44

13-2.Drawer Positioning ..................................................................................M-45

i

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL

98.04.24

13-3.Paper Lifting Plate ...................................................................................M-45

13-4.Drawer-in-Position Detection ...................................................................M-46

13-5.Universal Tray (1st Drawer) Paper Size Detection ..................................M-47

13-6.Paper Empty Detection ............................................................................M-48

13-7.Paper Separating Mechanism .................................................................M-49

13-8.Paper Take-Up Roll .................................................................................M-50

13-9.Paper Take-Up Retry Control ..................................................................M-51

13-10.VERTICAL PAPER TRANSPORT .........................................................M-52

14. MULTI BYPASS TABLE ..................................................................................M-53

14-1.Paper Take-Up Mechanism .....................................................................M-54

14-2.Paper Take-Up Retry Control ..................................................................M-55

14-3.Paper Separating Mechanism .................................................................M-56

14-4.Paper Empty Detection ............................................................................M-56

15. SYNCHRONIZING ROLLERS .........................................................................M-57

15-1.Upper Synchronizing Roller Positioning ..................................................M-58

15-2.Paper Dust Remover ...............................................................................M-58

15-3.Synchronizing Roller Control ...................................................... .............M-59

16. IMAGE TRANSFER AND PAPER SEPARATION ...........................................M-60

17. MAIN ERASE LAMP ........................................................................................M-62

18. PAPER SEPARATOR FINGERS ....................................................................M-63

19. CLEANING UNIT .............................................................................................M-64

19-1.Cleaning Bias ..........................................................................................M-65

20. PAPER TRANSPORT .....................................................................................M-66

21. FUSING UNIT ..................................................................................................M-67

21-1. Fusing Temperature Control ............................................. ......................M-68

21-2.Fusing Rollers Pressure Mechanism .......................................................M-69

21-3.Cleaning Roller ........................................................................................M-69

22. EXIT UNIT .............................................. .........................................................M-70

22-1.Upper/Lower Separator Fingers ........................................ ..................... .M-70

22-2.Paper Exit Sensor .................................................................................... M-71

23. EXIT/DUPLEX SWITCHING UNIT (OPTION) .................................................M-72

24. DEHUMIDIFYING SWITCH (OPTION) ............... .............................................M-73

25. COOLING FAN .............................................................................. ..................M-74

26. OPTICAL SECTION COOLING FAN ...............................................................M-75

27. MEMORY BACKUP .........................................................................................M-76

ii

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

1174SBM0100A

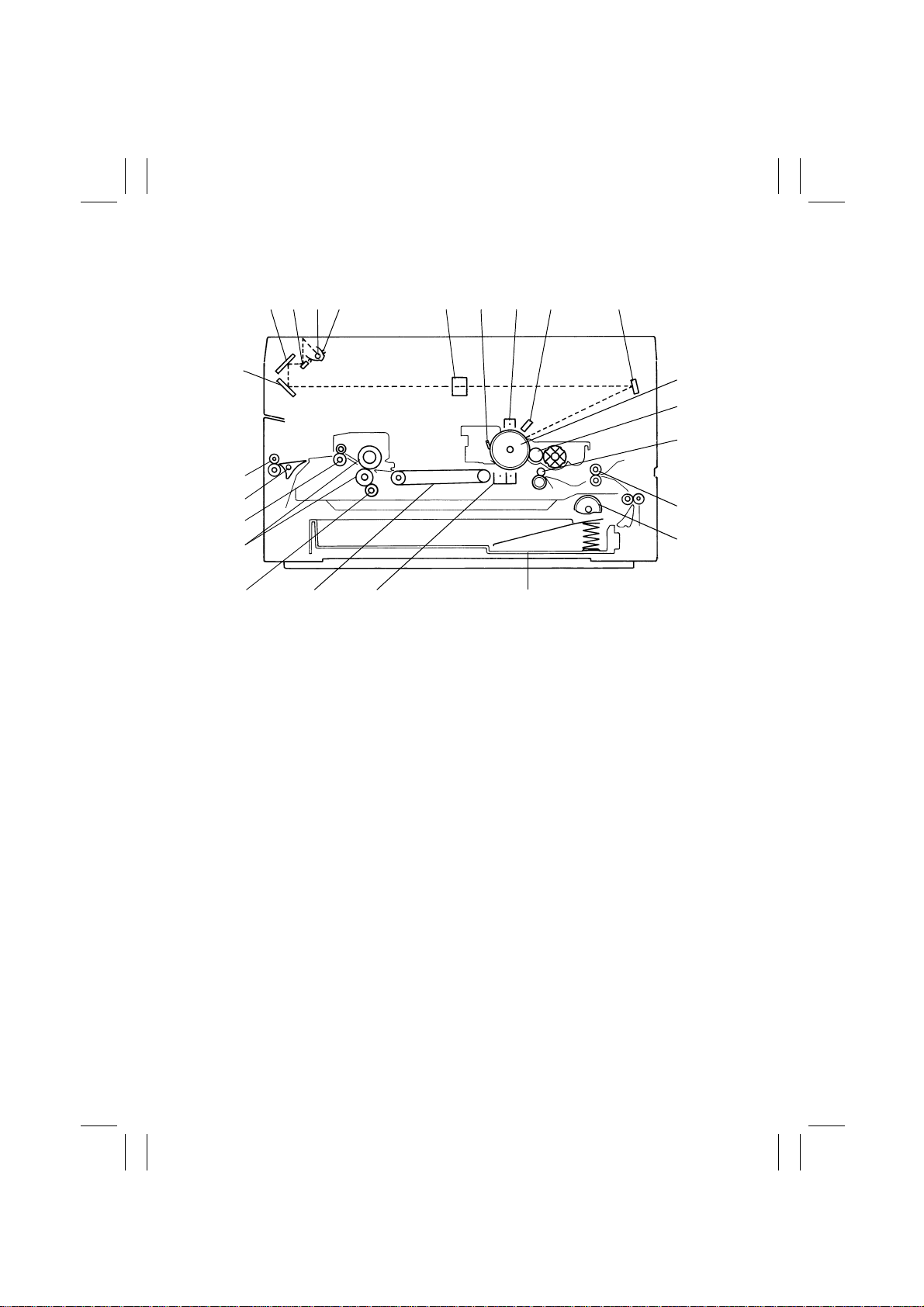

1 CROSS-SECTIONAL VIEW

1174SBM0101A

1-1. Cross-Sectional View of 23 cpm Copier

2345 6 7 8 9 10

1

22

21

20

23

19

18

24

1. 3rd Mirror

2nd Mirror

2.

3. 1st Mirror

4. Exposure Lamp

5. Lamp Reflector

6. Lens

7. Cleaning Blade

8. PC Drum Charge Corona

9. Image Erase Lamp

10. 4th Mirror

11. PC Drum

12. Sleeve/Magnet Roller

13. Synchronizing Roller

14. Transport Roller

15. 1st/2nd Drawer Paper Take-Up Roll

16. 1st/2nd Drawer

11

12

13

14

15

1617

17. Image Transfer/Paper Separator

Coronas

18. Suction Unit

19. Cleaning Roller

20. Upper/Lower Fusing Roller

21. Paper Exit Roller

22. Exit/Duplex Switchi ng Guide

(for optional Duplex Unit and Sorter)

23. Duplex Unit Vertical Transport Roller 1

(for optional Duplex Unit)

24. Duplex Unit Vertical Transport Roller 2

(for optional Duplex Unit)

1174M005AB

M-1

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM0102A

1-2. Cross-Sectional View of 18 cpm Copier

2345 6 7 8 9 10

1

23

22

21

20

19 18 17 16

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamp

5. Lamp Reflector

6. Lens

7. Cleaning Blade

8. PC Drum Charge Corona

9. Image Erase Lamp

10. 4th Mirror

11. PC Drum

12. Sleeve/Magnet Roller

13. Synchronizing Roller

14. Transport Roller

15. Paper Take-Up Roll

16. Drawe

17. Image Transfer/Paper Separator

18. Suction Unit

19. Cleaning Roller

20. Upper/Lower Fusing Roller

21. Paper Exit Roller

22. Exit/Duplex Switchi ng Guide

23. Paper Exit Roller in Exit/Duplex

11

12

13

14

15

1174M004AB

Coronas

(for optional Sorter)

Switching Guide Unit

(for optional Sorter)

M-2

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

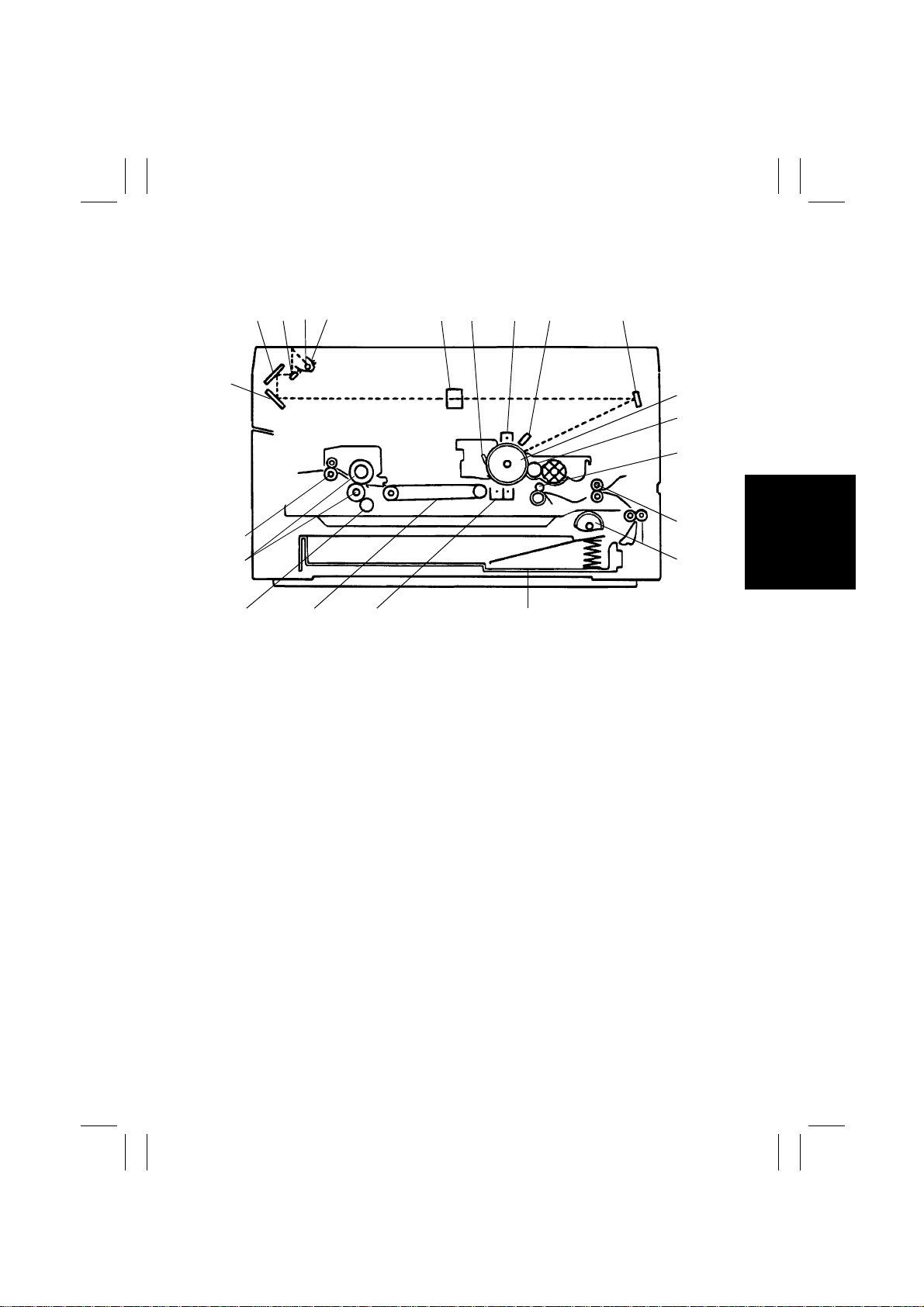

1174SBM0103A

1-3. Cross-Sectional View of 15 cpm Copier

✽

Except U.S.A., Canada

2345 6 7 8 9 10

1

21

20

19 18 17 16

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamp

5. Lamp Reflector

6. Lens

7. Cleaning Blade

8. PC Drum Charge Corona

9. Image Erase Lamp

10. 4th Mirror

11. PC Drum

12. Sleeve/Magnet Roller

13. Synchronizing Roller

14. Transport Roller

15. Paper Take-Up Roll

16. Drawer

17. Image Transfer/Paper Separator

18. Suction Unit

19. Cleaning Roller

20. Upper/Lower Fusing Roller

21. Paper Exit Roller

11

12

13

14

15

1174M011AA

Coronas

M-3

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

1174SBM0200A

2 COPY PROCESS

13

1. PC DRUM

2. DRUM CHARGING

3. IMAGE ERASE

4. EXPOSURE

5. DEVELOPING

6. PAPER FEEDING

2

10

9

12

11

1

8

8

7

7

8. PAPER SEPARATION

9. CLEANING

10.MAIN ERASE

11. TRANSPORT

12. FUSING

13. PAPER EXIT

6

3

4

5

5

MULTI BYPASS

TABLE

1139M002AA

7. IMAGE TRANSFER

1. PC Drum

The PC Drum is an aluminum cylinder coated with a photosensitive semiconductor.

It is used as the medium on which a visible developed image of the original is formed.

(For more details, see “6. PC DRUM”.)

2. Drum Charging

The PC Drum Charge Corona Unit is equipped with a Comb Electrode and a Scorotron

Grid to deposit a uniform negative charge across the entire surface of the PC Drum.

(For more details, see “7. DRUM CHARGING”.)

3. Image Erase

Any areas of charge which are not to be developed are neutralized by lighting up LEDs.

(For more details, see “8. IMAGE ERASE LAMP”.)

4. Exposure

Light from the Exposure Lamp reflected off the original is guided to the surface of the PC

Drum and reduces the level of the negative charges, thereby forming an electrostatic

latent image.

(For more details, see “9. OPTICAL SECTION”.)

5. Developing

Toner positively charged in the Developer Mixing Chamber is attracted onto the electrostatic latent image changing it to a visible, developed image . A DC negative bias voltage is

applied to the Sleeve/Magnet Roller to prevent toner from being attracted onto those

areas of the PC Drum which correspond to the background areas of the original.

(For more details, see “11. DEVELOPMENT”.)

M-4

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

6. Paper Feeding

Paper is fed either automatically from the 1st or 2nd Drawer, or manually via the Multi

Bypass Table or Manual Bypass Table. Each Drawer has fingers that function to separate

the top sheet of paper from the rest at take-up. (2nd Drawer: 23 cpm Copier Only)

(For more details, see “13. PAPER TAKE-UP/FEED SECTION”.)

7. Image Transfer

The single-wire Image Transfer Corona Unit applies a DC negativ e corona emission to the

underside of the paper, thereby attracting toner onto the surface of the paper.

(For more details, see “16. IMAGE TRANSFER AND PAPER SEPARATION”.)

8. Paper Separation

The single-wire Paper Separator Corona Unit applies an AC corona emission to the

underside of the paper to neutralize the paper. In addition, mechanical paper separation is

provided by the two PC Drum Paper Separator Fingers fitted to the Imaging Unit.

(For more details, see “16. IMAGE TRANSFER AND PAPER SEPARATION”.)

9. Cleaning

Residual toner on the surface of the PC Drum is scraped off by the Cleaning Blade.

(For more details, see “19. CLEANING UNIT”.)

10. Main Erase

Light from the Main Erase Lamp neutralizes any surface potential remaining on the surface of the PC Drum after cleaning.

(For more details, see “17. MAIN ERASE LAMP”.)

11. Transport

The paper is fed to the Fusing Unit by the Suction Belts.

(For more details, see “20. PAPER TRANSPORT”.)

12. Fusing

The developed image is permanently fused to the paper by a combination of heat and

pressure applied by the Upper and Lower Fusing Rollers.

(For more details, see “21. FUSING UNIT”.)

13. Paper Exit

After the fusing process the paper is fed out by the Paper Exit Roller onto the Copy Tray.

(For more details, see “22. EXIT UNIT”.)

M-5

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

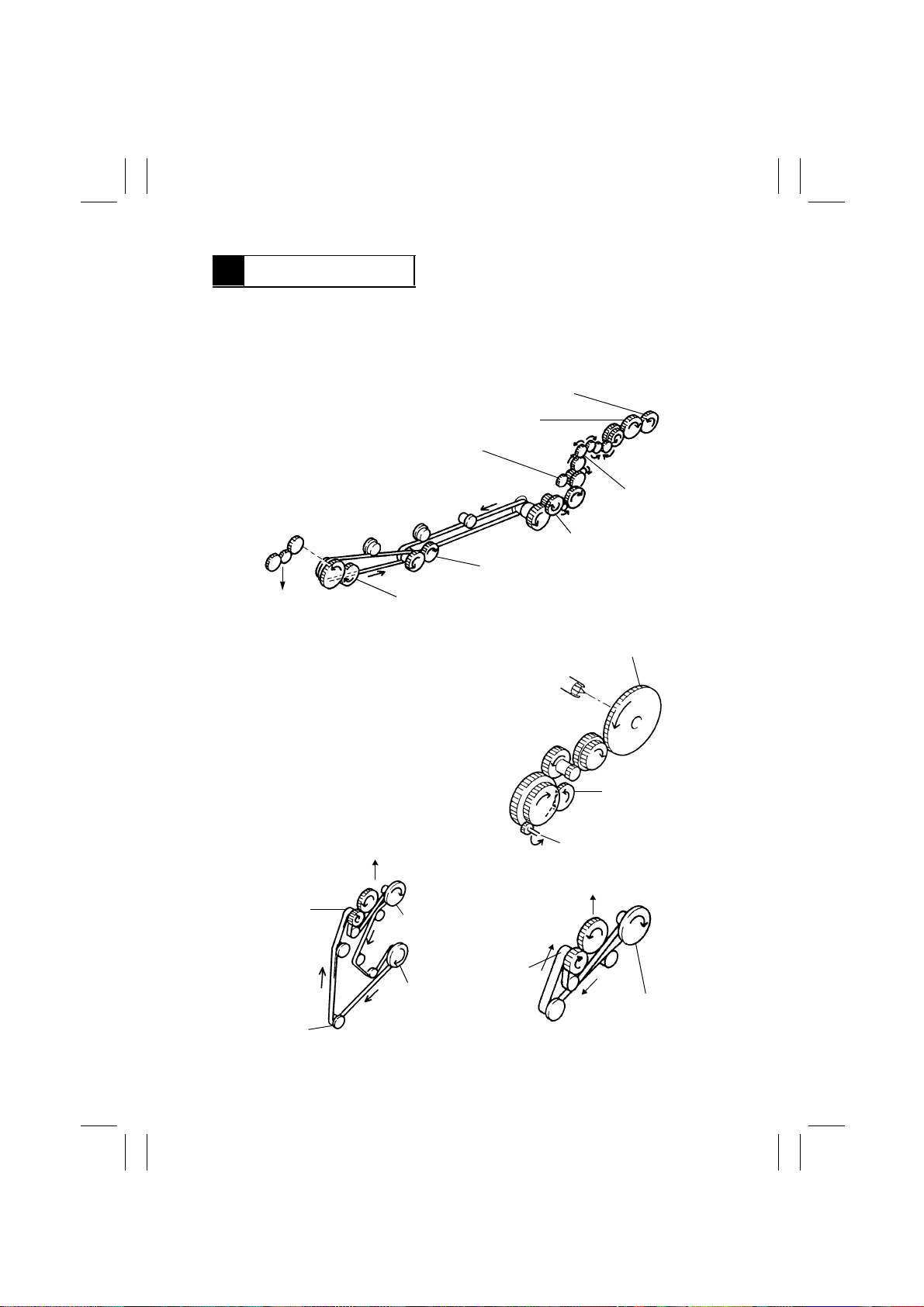

1174SBM0300A

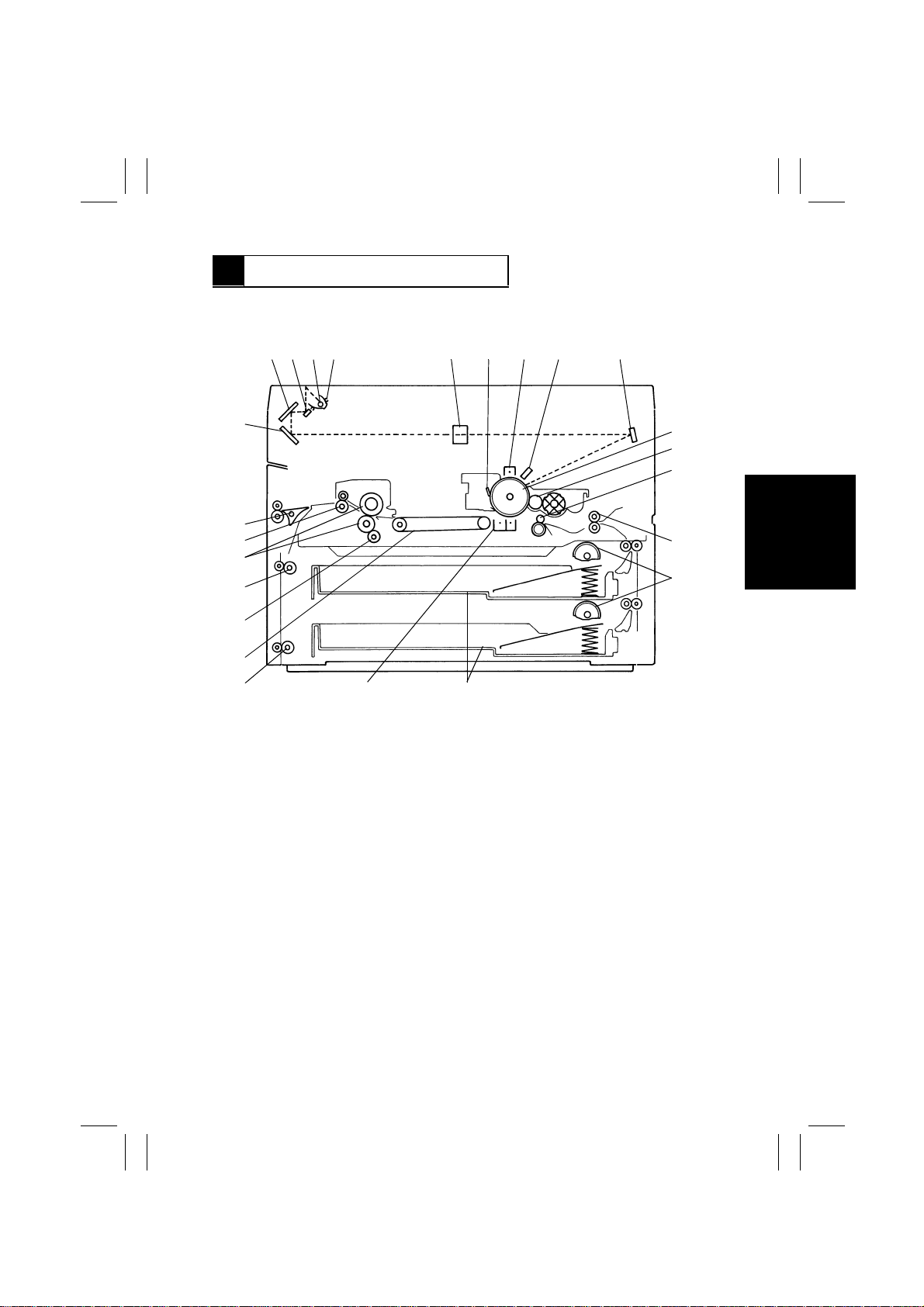

3 DRIVE SYSTEM

This copier is equipped with two main drive motors, the PC Drive Motor that drives the

upper half of the copier (Imaging Unit) and the Main Drive Motor which gives drive f or the

lower half of the copier (paper take-up/feeding, transport mechanism and Fusing Unit).

Each has its own drive transmitting gears and timing belts as illustrated below.

Drive Train for Lo wer Half of Copier

Coupled to Paper

Take-Up Unit

Drive Train for

Paper Take-Up Unit

<23 cpm Copier>

Coupled to Copier Gear

1st Vertical

Transport Roller

2nd Vertical

Transport Roller

1139M004AA

Coupled to Exit/Duplex

Switching Unit

Paper Exit Roller Drive

Suction Unit

Drive

Synchronizing Roller Clutch CL 1

Paper Transport

Clutch CL 2

<15/18 cpm Copier>

1st Drawer Paper

Take-Up Roll

Vertical

Transport Roller

2nd Drawer Paper

Take-Up Roll

Upper Fusing

Roller Drive

Main Drive Motor M2

1151M001YB

Drive Train for Upper

Half of Copier

PC Drum Drive

Imaging Unit

Drive

1139M005AA

PC Drive Motor M1

Coupled to Copier Gear

Paper Drawer Paper

Take-Up Roll

1142M002AA

M-6

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

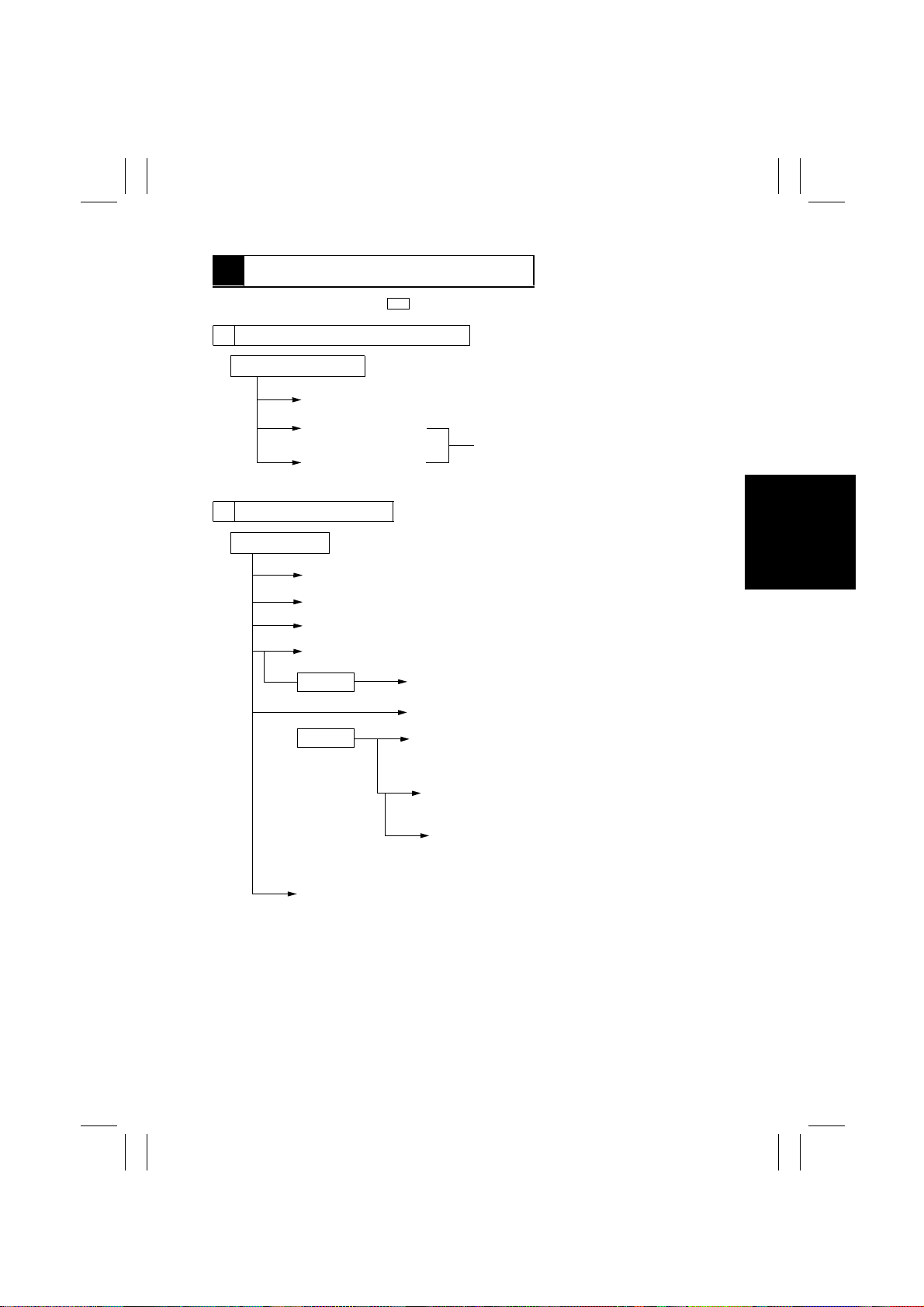

1174SBM0400A

4 SEQUENTIAL EXPLANATION

✽

Numbers given in rectangles in the following flowchart are timer values in seconds.

A The power cord is plugged into the outlet.

Po wer cord is pl ugged in.

ON

ON

ON

AC24V for Drum heating (Transformer)

Drum Dehumidifying

Heater

Paper Dehumidifying

Heater

B Power Switch is turned ON.

Power Switch ON

ON

ON

ON

ON

DC5V (Power Supply Unit)

DC24V (Power Supply Unit)

Control panel

The Cooling Fan turns at full speed.

Approx. 3

Approx. 1

Starter setup and ATDC Sensor automatic adjustment

✽ Only when the Imaging Unit is new. I/U Fuse blows when the

starter setup sequence is completed normally.

Only when Dehumidifying

Switch is ON

ON

The Cooling Fan turns at half speed.

ON

Fusing Heater Lamp

ON

Scanner Reference Position Sensor

✽If the Scanner is not at the home position, Scanner Motor is

energized to move the Scanner to the home position.

ON

Lens Reference Position Sensor

✽ If the Lens is not at the home position, Lens Motor is

ON

energized to move the Lens to the home position.

Mirror Reference Position Sensor

✽If the 4th Mirror is not at the home position, Mirror

Motor is energized to move the Mirror to the home

position.

M-7

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 GENERAL, MECHANICAL/ELECTRICAL

98.04.24

C The Fusing Unit temperature reaches 205°C.

Fusing Thermistor detects 205°C.

ON/OFF

Fusing Heater Lamp

✽ The Fusing Unit temperature control is started.

M-8

FrameMaker Ver.5.5(PC) EP1054/EP1085/EP2030 MECHANICAL/ELECTRICAL

98.04.24

D The Start Key is pressed.

Start Key ON

ON

PC Drive Motor

ON

ON

ON

Main Erase Lamp

Main Drive Motor

Image Erase Lamp

✽ All LEDs are turned ON.

ON

ON

ON

Developing Bias (High Voltage Unit)

Paper Separator Corona (High Voltage Unit)

Cleaning Bias (High Voltage Unit)

✽ Some models have no Bias Se al inst al led d epe ndin g on

ON

their marketing areas.

Synchronizing Roller Clutch ✽For approx 0.2 sec. only

Approx. 0.3

Approx. 0.2

ON

1st/2nd Drawer Paper Take-Up Solenoid

1st/2nd Drawer Paper Take-Up

Approx. 0.1

ON

PC Drum Charge Corona/Image Transfer Corona

OFF

Solenoid (2nd Drawer Paper TakeUp Solenoid: 23 cpm copier only)

Approx. 0.2

Approx. 2.5

ON

Paper Transport Clutch

ON

Synchronizing Roller Clutch

E Paper is taken up.

1st/2nd Drawer Paper Take-Up Solenoid ON

(2nd Drawer Paper Take-Up Solenoid: 23 cpm copier only)

Approx. 0.4

1

ON

1st/2nd Drawer Paper Take-Up Sensor

1st Drawer:

Approx. 0.7

2nd Drawer:

Approx. 1.4

(23 cpm copier

Only)

ON

Approx. 0.5

Approx. 0.2

M-9

Transport Roller Sensor

ON

Paper Leading Edge

Detecting Sensor

Approx. 0.2

ON

Exposure Lamp

OFF

Paper

Transpo rt

Clutch