Page 1

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

PF-6D/AD-11

SERVICE MANUAL

10794

Page 2

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

CONTENTS

GENERAL, MECHANICAL/ELECTRICAL

1. SPECIFICATIONS ........................................................................................... M-1

2. COMPONENT IDENTIFICATION ................... ........................... ......................M-1

3. CROSS-SECTIONAL VIEW ............................................................................M-2

4. DRIVE SYSTEM COMPONENT LAYOUT ......................................................M-2

5. ELECTRICAL PARTS LAYOUT ......................................................................M-3

6. DUPLEX UNIT DRIVE .....................................................................................M-4

7. DUPLEX UNIT VERTICAL TRANSPORT SECTION ......................................M-6

7-1. Middle Left Door Detection ......................................................................M-6

7-2. Lower Left Door Detection ....................................... ............................... .M-6

7-3. Duplex Unit Turnover Mechanism ...................................................... .....M-7

8. COPY STORAGE ............................................................................................M-8

8-1. Trailing Gate Unit Moving Mechanism ............................................ .........M-8

8-2. Trailing Gate Switching Mechanism .................................... ....................M-9

8-3. Front/Rear Edge Guide Plate Drive Mechanism ......................................M-11

9. DUPLEX PAPER TAKE-UP UNIT ...................................................................M-14

9-1. Leading Edge Guide Plate and Duplex Paper Take-Up Drive

Mechanism ..............................................................................................M-14

9-2. Duplex Paper Take-Up Drive Control ......................................................M-16

9-3. Paper Take-Up Operation ........................................................................M-17

10. VERTICAL TRANSPORT SECTION ...............................................................M-20

11. EXIT SECTION .................................. ............................ ........................... .......M-21

DIS/REASSEMBLY, ADJUSTMENT

1. DISASSEMBLY ...............................................................................................D-1

1-1. Removal of Exterior Parts ........................................................................D-1

1-2. Removal of Duplex Unit Drive Motor Assy ...............................................D-2

1-3. Removal of Paper Take-Up Unit ..............................................................D-2

1-4. Removal of Trailing Gate Unit ..................................................................D-3

1-5. Removal of Paper Guide Sheet ...............................................................D-4

1-6. Removal of Front/Rear Guide Plate Assy ................................................ D-4

1-7. Removal of Vertical Transport Unit .......................................................... D-5

1-8. Removal of Take-Up Roll/Feed Roll Assy ...............................................D-5

1-9. Removal of Separator Roll Assy ..............................................................D-6

1-10. Cleaning of Vertical Transport Rollers ........................ ................. ...........D-7

1-11. Cleaning of Duplex Unit Vertical Transport Roller/Slip Roll ....................D-7

1-12. Cleaning of Paper Take-Up Roll/Feed Roll/Separator Roll ....................D-8

1-13. Cleaning of Trailing Gate Unit Transport Rollers 1 & 2 ............. .............D-8

1-14. Parts Which Must Not Be Touched ........................................................D-8

2. ADJUSTMENT .................................................................................................D-9

2-1. Adjustment of Magnetic Catch ...................................................... ...........D-9

2-2. Adjustment of Clearance Between Release Lever Assy

and Guide Plate (This adjustment must be made after the

adjustment of the Magnetic Catch has been completed.) ........................D-9

2-3. Adjustment of Front/Rear Edge Guide Plate Timing Belt ...... ................. .D-9

2-4. Alignment of Front/Rear Edge Guide Holder ......................... ..................D-10

i

Page 3

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

2-5. Adjustment of Trailing Gate Unit Timing Belt .............................. .............D-10

2-7. Adjustment of Duplex Unit Gate Switching Solenoid SL31 Position ........D-11

2-8. Adjustment of Duplex Unit Rear Finger Solenoid SL32

Position .................................................................................................... D-11

2-9. Adjustment of Vertical Transport Timing Belt ................................... .......D-12

MISFEED DETECTION/MALFUNCTION DETECTION

1. MISFEED DETECTION .............................. ........................... ..........................T-1

1-1. Location of Misfeed Detecting Sensors ...................................................T-1

1-2. Misfeed Detection Types and Detection Timings ....................................T-1

2. MALFUNCTION DETECTION ................................ .............................. ...........T-2

ii

Page 4

FrameMaker Ver.5.5(PC) PF-112 OPTION FOR EP1054/EP1085/EP2030

98.06.08

GENERAL,

MECHANICAL/

ELECTRICAL

Page 5

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

1

98.06.08

1 SPECIFICATIONS

Type : Duplex Unit with a storage drawer

Installation : Fitted to copier

Copy Storage : Horizontal Copy Storage with Moving Trailing Gate Unit

Mode : 2-sided copy

Type of Paper : Plain paper, recycled paper

Paper Sizes : A5L to A3L, 5-1/2” × 8-1/2”L to 11” × 17”L

Paper Weight : 60 to 157 g/m² or 16 to 41-3/4 lbs.

Capacity : Up to 50 sheets (60 to 90 g/m² or 16 to 24-1/4 lbs.)

Power Requirements : DC24V, 5V (supplied from copier)

Power Consumption : PF-6D = 65W, AD-11 = 50W

Dimensions : PF-6D =Width ... 610 mm or 24”

Weight : PF-6D = 39.7 kg or 87-1/2 lbs.

Up to 20 sheets (91 to 157 g/m² or 24 to 41-3/4 lbs.)

Depth ... 595 mm or 23-1/2”

Height ... 472 mm or 18-1/2”

AD-11 = 14.2 kg or 29 lbs.

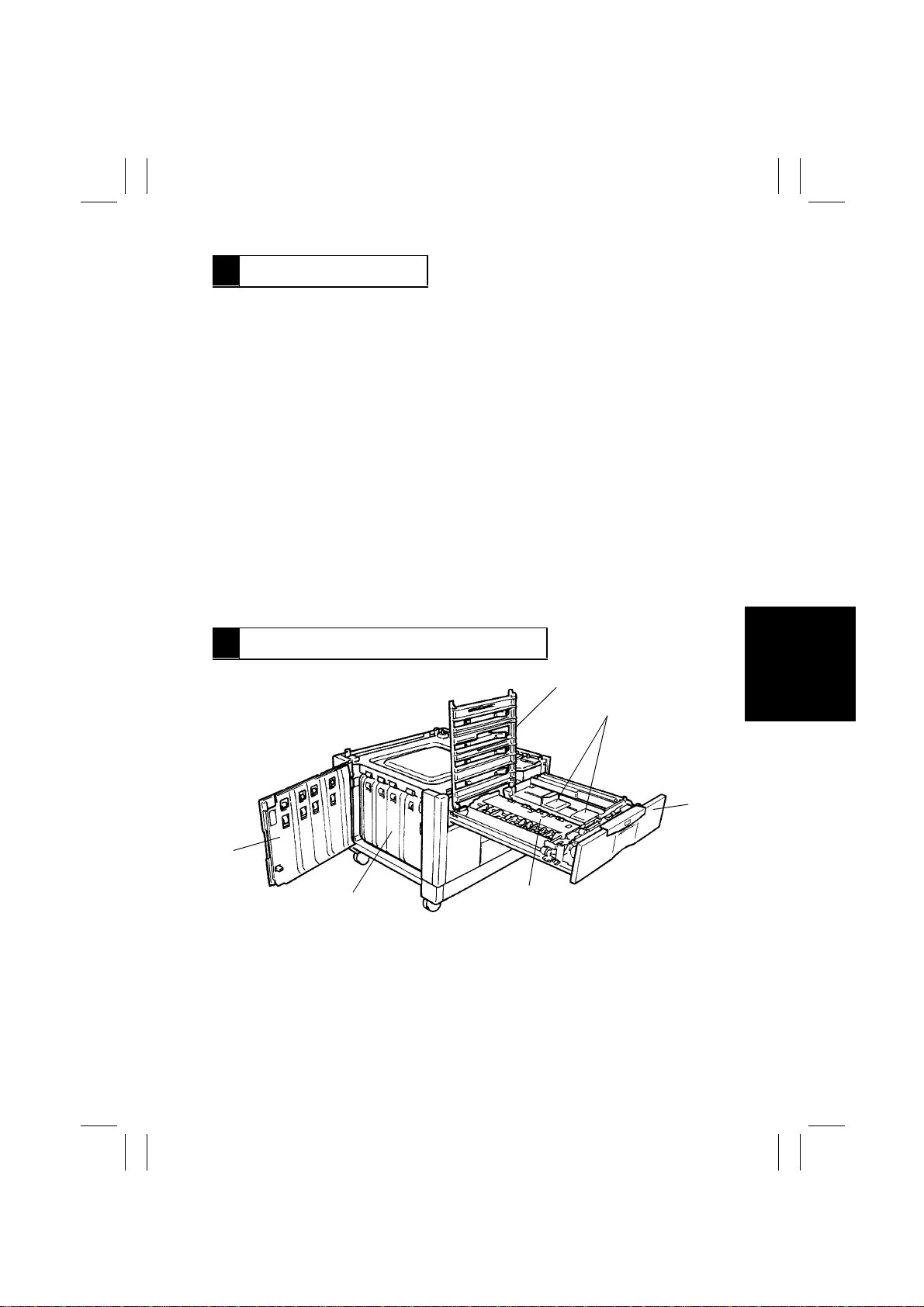

2 COMPONENT IDENTIFICATION

6

5

1. Upper Guide Plate Assy

2. Front/Rear Edge Guide Plates

3. Duplex Unit

4. Trailing Gate Unit

5. Vertical Transport Unit

6. Lower Left Door

M-1

2

3

4

1174M015AA

Page 6

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

3 CROSS-SECTIONAL VIEW

1 2 3 456 7

12

11

10

9

1. Paddle Roller/Duplex Vertical Transport

Roller

2. Trailing Gate Unit Gate 2 Transport

Roller

3. Trailing Gate Unit Gate 1 Transport

Roller

4. Paper Take-Up Roll

5. Feed Roll

6. Vertical Transport Roller (Drive)

7. Vertical Transport Roller (Driven)

8. Separator Roll

9. Roll B

10. Slip Roll

11. Release Lever

12. Roll A

4 DRIVE SYSTEM COMPONENT LAYOUT

Vertical Transport

Drive Section

Front/Rear Edge Guide

Plate Drive Section

8

4425M223AA

Duplex Unit Vertical

Transport Drive Section

Trailing Gate Drive Section

M-2

Duplex Unit Paper

Take-Up Drive Section

4425M226AA

Page 7

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

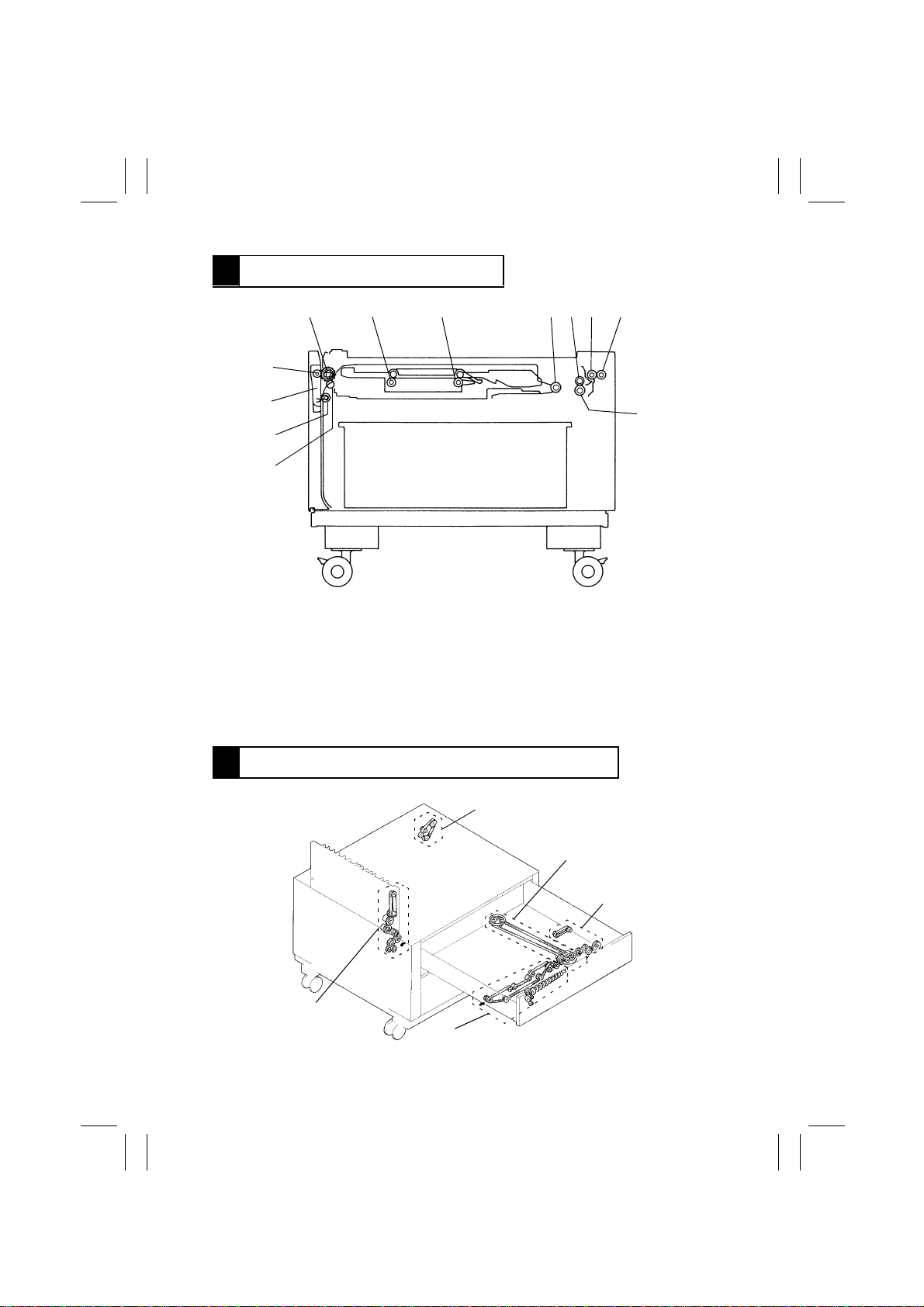

5 ELECTRICAL PARTS LAYOUT

M21

PC12

PWB-A

PC13

PC11

Symbol Name Symbol Name

CL31

M21

M31

M32

M33

PC8

PC9

PC10

PC11

PC12

Duplex Unit Paper Take-Up Clutch

Vertical Transport Motor

Duplex Unit Drive Motor

Gate Motor

Front/Rear Edge Guide Drive

Motor

Duplex Unit Gate Home Position

Sensor

Front/Rear Edge Guide Plate

Home Position Sensor

Middle Left Door Sensor

Lower Left Door Sensor

Duplex Unit Vertical Transport

Sensor

SL31

PC13

PC14

PC15

PC16

PC17

PC18

PWB-A

PWB-G

SL31

SL32

SL33

PC17

PC18

PC9

M33

PWB-G

PC14

Duplex Unit Tur n over Path Sensor

Duplex Unit Paper Entry Sensor

Duplex Unit Paper Empty Sensor

Duplex Unit Paper Take-Up

Sensor

Vertical Transport Sensor 3

Lower Right Door Sensor

Master Board

Duplex Unit Master Board

Duplex Unit Gate Switching

Solenoid

Duplex Unit Rear Finger Solenoid

Duplex Unit Pick-Up Solenoid

SL32

SL33

PC15

PC8

M31

M32

PC16

CL31

4481M003AA

M-3

Page 8

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

6 DUPLEX UNIT DRIVE

Duplex Unit Drive Mechanism

1.

•

Duplex Unit Drive Motor drives the Trailing Gate Unit and Duplex Unit Vertical Transport

Section through gears, transport belts and rollers.

•

Duplex Unit Paper Take-Up Clutch couples motor drive force to the paper take-up section.

•

When the Duplex Unit is slid into the Cabinet, Pulley Gear 1 meshes with Gear 1 and the

drive is transmitted to the Transport Section.

•

The figure below shows the Duplex Unit drive train.

Trailing Gate Switching Lever

Duplex Unit

Rear Finger

Pulley Gear 1

Gear 1

•

The Paddle Roller and Duplex Unit Vertical Transport Roller are assembled in one unit.

Paddle Roller

Paper Take-up Assy

Duplex Unit Paper

Take-Up Clutch CL31

Duplex Unit

Drive Motor M31

Duplex Unit Vertical

Transport Roller

4425M202AA

M-4

Page 9

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

2. Duplex Unit Drive Motor Control

A DC motor is used for the Duplex Unit Drive Motor. The Remote signal from pin 31 of IC1G

of the Duplex Unit Master Board energizes and deenergizes the Duplex Unit Drive Motor.

M31

Energized (forward) L

Deenergized (stopped) H

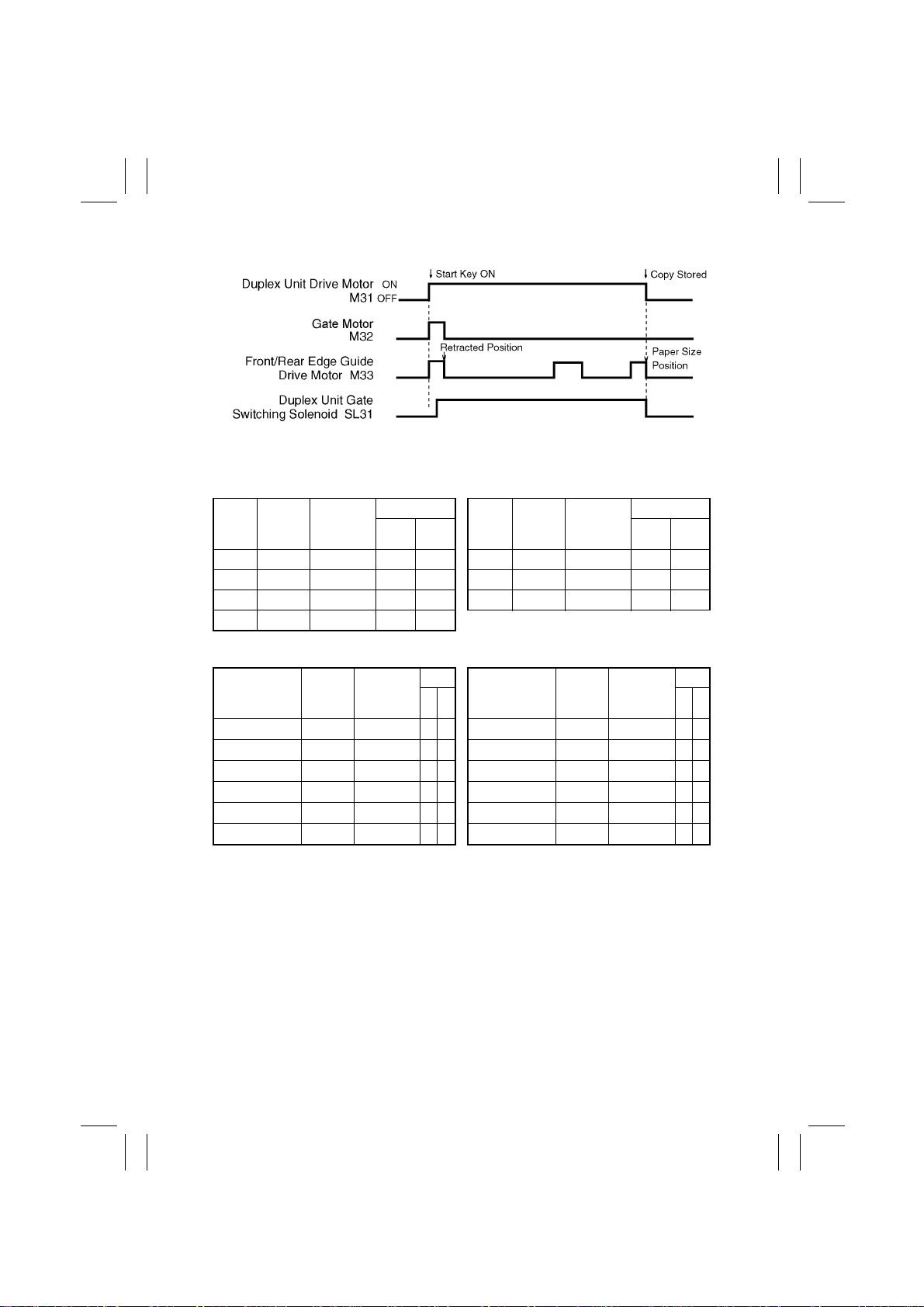

3. Duplex Unit Drive Motor Energization Timing

The motor is synchronized with the Main Drive Motor.

4. Duplex Unit Drive Motor Deenergization Timing

•

When a copy is to be stored in the Duplex Unit, the motor is briefl y deenergized after the

storage sequence has been completed. [The timing varies for different paper sizes, as

timed after the trailing edge of the paper moves past the Duplex Unit Trailing Edge Sensor (which goes HIGH).] It is then reenergized for the Duplex paper take-up sequence.

•

At the end of the copy process, the motor is deenergized after 1st Paper Exit Sensor has

detected the trailing edge of the paper. (It is synchronized with the Main Drive Motor.)

IC1G

31

M-5

Page 10

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

7 DUPLEX UNIT VERTICAL TRANSPORT SECTION

7-1. Middle Left Door Detection

•

When the Middle Left Door is closed, the Light Blocking Plate attached to t he Door bloc ks

the Middle Left Door Sensor installed in the Duplex Unit Vertical Transport Section of the

copier.

Duplex Unit Vertical

Transport Roller 1

Middle Left Door Sensor (PC10)

Duplex Unit Vertical

Transport Roller 2

4444M020AA

7-2. Lower Left Door Detection

•

When the Lower Left Door is closed, the Light Blocking Plate att ached to the Door b loc ks

the Lower Left Door Sensor installed in the Duplex Cabinet.

Lower Left Door

Sensor (PC11)

4444M021AA

M-6

Page 11

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

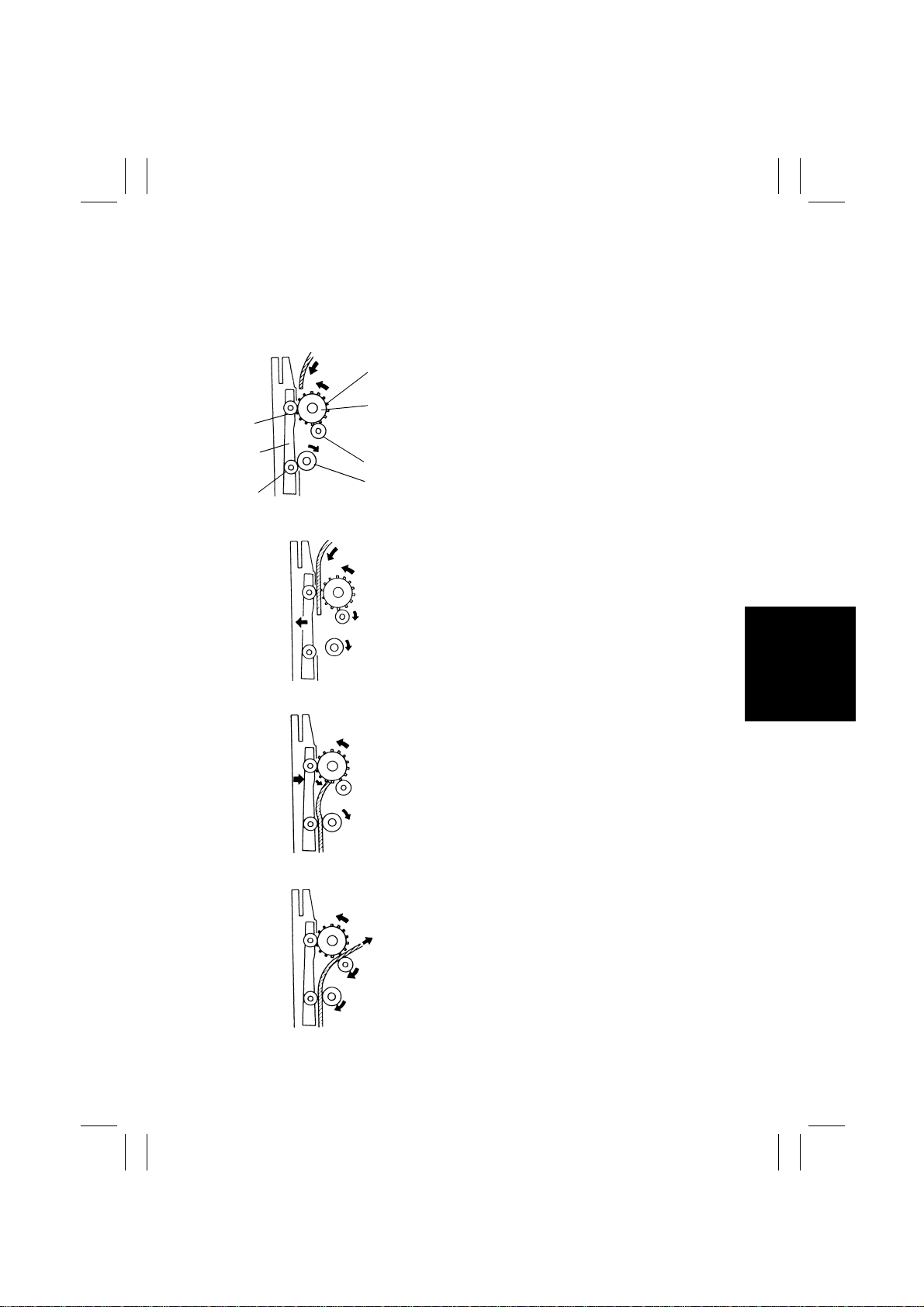

7-3. Duplex Unit Turnover Mechanism

•

The Duplex Unit Turnover Section first sends the paper to the Duplex Unit Vertical Transport Section and then switches the direction of paper travel with the Duplex Unit Drive

Motor to send the paper to the T railing Gate Unit.

•

Details of the turnover operation is as follows.

1. Paper is transferred from the Fusing

Section to the Duplex Unit Vertical

Transport Section. The Duplex Unit Vertical Transport Roller, Roll A, Slip Roll

and Roll C turn in the direction of the

arrow.

2. The Duplex Unit Vertical Transport

Roller and Roll A advance the paper

downward. The Release Lever moves in

the direction of the arrow, disengaging

Roll C from the Slip Roll.

Roll A

Release

Lever

Roll C

Paper

4425M203AA

Paddle

Roller

Duplex Unit

Vertical

Transport

Roller

Roll B

Slip roll

4425M204AA

4425M205AA

4425M206AA

3. As the trailing edge of the paper moves

past the Vertical Transport Roller and

Roll A, the Paddle Roller catches the

trailing edge and switches its direction of

travel. The Release Le ver returns to its

original position to press Roll C against

the Slip Roll, allowing the paper to move

upward.

4. The paper is sent to the Trailing Gate

Unit by the Duplex Unit Vertical Transport Roller/Roll B and Slip Roll/Roll C.

M-7

Page 12

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

8 COPY STORAGE

8-1. Trailing Gate Unit Moving Mechanism

1. Trailing Gate Unit Moving Operation

The Trailing Gate Unit is moved as necessary to store paper of different sizes.

•

The Trailing Gate Unit is moved as drive from the Gate Motor is transmitted via a gear

train to the Screw Cam and Screw Pin located at the front of the Trailing Gate Unit.

•

This is done to enhance the Unit’s paper storage performance.

•

The Trailing Gate Uni t moves to its home position (equivalent to A4 crosswise position) if

there is no copy left in Storage when Pow er Switch of the copier is turned ON, the Duplex

Unit is slid into position, or the Front Door of the copier is swung open and closed.

Trailing Gate Unit

Screw Pin

Screw Cam

4425M208AA

Gate Motor M32

2. Gate Motor Control

•

At the same time when the Start Ke y is pressed, the Gate Motor is energized to move the

Trailing Gate Unit to the position for the paper size selected.

•

When the 2-sided copy mode is canceled, the Gate Motor is energized to return the Trailing Gate Unit back to the home position.

•

The Gate Motor, a stepping motor, is controlled by the signals from pins 56, 57, 61 and

62 of IC1G of Duplex Unit Master Board.

•

The order of turning ON the signals determines the turning direction of the Gate Motor.

M-8

Page 13

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

8-2. Trailing Gate Switching Mechanism

1. Trailing Gate Switching Operation

•

When paper is to be stored in the Duplex Unit, the Trailing Gate Switching Lever is operated as necessary according to the paper size to switch the Trailing Gat e between Gate 1

and Gate 2.

•

The Trailing Gate Switching Lever is operated by Duplex Unit Gate Switching Solenoid

which is energized or deenergized according to the paper size to select Gate 1 or Gate 2

as shown in Table 1 on the next page.

•

Duplex Unit Gate Switching Solenoid is operated at the same time when the paper takeup sequence starts.

•

When the paper to be stored is 301 mm long or more, Duplex Unit Gate Switching Solenoid is energized to swing open the Trailing Gate Switching Lever to allow the paper

through Gate 2.

•

When the paper to be stored is 300 mm long or less, Duplex Unit Gate Switching Solenoid is deenergized, allowing the paper through Gate 1.

Duplex Unit Gate Switching Solenoid (SL31)

Trailing Gate 2

Trailing

Gate 1

Trailing Gate

Switching Lever

4425M212AA

M-9

Page 14

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

2. Trailing Gate Unit Travel Distance/Switching Operation

Table1 Metric Areas

Paper

Size

Length

(mm)

B5C 182 –28

A5L 210 0

A4C 210 0

B5L 257 +47

Trave l

Distance

(mm)

Gate

12 12

❍

– A4L 297 +87

❍

– B4L 364 +19 –

❍

– A3L 420 +175 –

❍

–

Size

Paper

Length

(mm)

Trave l

Distance

(mm)

4444T20MCB

Gate

❍

–

❍

❍

Inch Areas

Size

10-1/2”

×

10”

×

8-1/2”

5-1/2”

×

8-1/2” 215.9 +6

11”

×

8”

10”

×

8”

10-1/2” 266.7 +57

✽

Gate 1 … The Switching Lever remains stationary, guiding paper toward Gate 1.

✽

Gate 2 … The Switching Lever swings up to guide paper through Gate 2 into Storage.

✽

Tra vel distance … The Trailing Gate Unit moves in the “+” direction when it slides toward

Paper

Length

(mm)

203.2 –7

×

8”

8” 203.2 –7

215.9 +6

254 +44

Travel

Distance

(mm)

the Paddle Roller and in the “–” direction when it slides toward the

Paper Take-Up Unit of the Duplex in reference to its home position.

Gate

12 12

❍

–

❍

– 8-1/4”×13” 330.2 –15 –

❍

–

❍

– 8-1/2”×14” 355.6 +11 –

❍

–

❍

– 11”×17” 431.8 +87 –

Size

8-1/2”×11”

8-1/2”×13”

9”×14”

Paper

Length

(mm)

279.4 +69

330.2 –15 –

355.6 +11 –

Travel

Distance

(mm)

M-10

Gate

❍

–

❍

❍

❍

❍

❍

Page 15

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

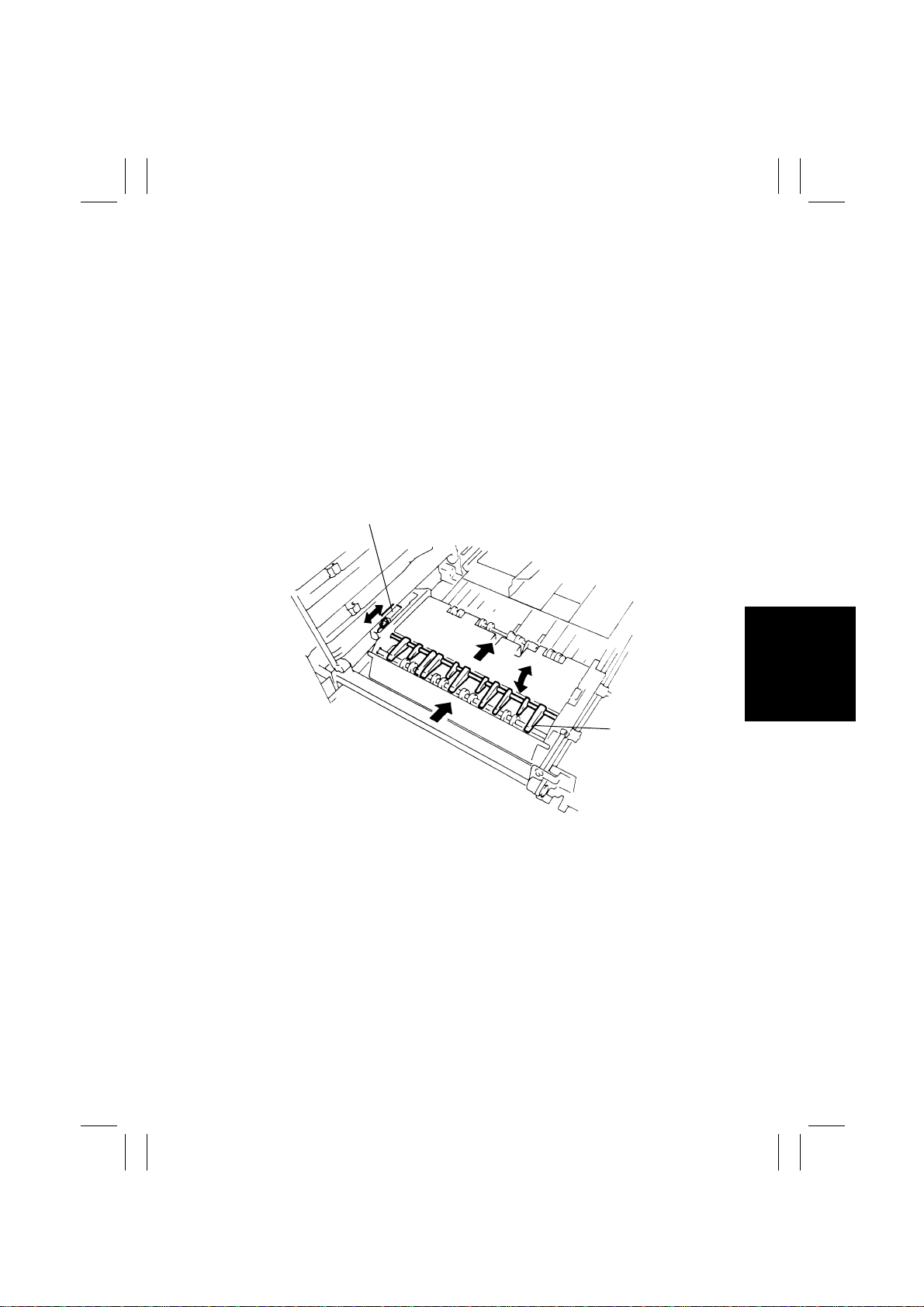

8-3. Front/Rear Edge Guide Plate Drive Mechanism

1. Front/Rear Edge Guide Plate Drive Operation

•

The Front/Rear Guide Plates in the Duplex Unit align the front and rear edges of the

paper being stored in the Duplex Unit.

•

The Rear Edge Guide Plate is moved to the front by the Front/Rear Edge Guide Drive

Motor through a gear and belt. The Front Edge Guide Plate makes a flipping motion as

the Cam is turned by the belt from the Front/Rear Edge Guide Drive Motor.

•

Front/Rear Edge Guide Drive Motor turns in steps, each step moving the Rear Edge

Guide Plate a distance of about 0.4 mm in respect to the position where Front/Rear Edge

Guide Plate Home Position Sensor is blocked. Front/Rear Edge Guide Drive Motor is

energized to move the Plate up to the corresponding paper size position.

Front/Rear Edge Guide

Drive Motor M33

Rear Edge Guide Plate

Front Edge Guide Plate

Cam

4425M213AA

2. Retracted Position

•

The Front Edge Guide Plate is tilted by the Cam.

•

The Rear Edge Guide Plate will move, according to the paper size , to one of the six positions each of which is located at a position at least +4mm greater than the paper width.

172mm 228mm 284mm

Light Blocking

Plate

305mm249mm193mm

4425M214AA

M-11

Page 16

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

3. Operation of the Front/Rear Edge Guide Plates (for A4L)

<At Home Position>

The Front/Rear Edge Guide Plates are located at a position where the Front/Rear Edge Guide Plate

Home Position Sensor is blocked.

4425M215AA

<When storing and taking up a copy>

Select the 2-sided copy mode and press the Start Key.

Front/Rear Edge Guide Drive Motor turns forward.

The Cam moves the Front Edge Guide Plate to a retracted (stand-by) position. The Rear Edge Guide

Plate moves to the stand-by position (paper size position + approx. 4 mm toward rear).

Approx. 4mm or more

4425M216AA

After the trailing edge of the paper to be stored in the Duplex Unit has unblocked Duplex Unit Trailing

Edge Sensor (H), Front/Rear Edge Guide Drive Motor turns forward to move the Front and Rear Edge

Guide Plates to the exact paper size positions.

4425M217AA

Duplex paper take-up operation starts when the Start Key is pressed.

When Duplex Unit Paper Empty Sensor is unblocked (H), Front/Rear Edge Guide Drive Motor turns

backward, returning the Rear Edge Guide Plate to the positi on where it previously blocked Front/Rear

Edge Guide Plate Home Position Sensor (L).

M-12

Page 17

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

4. Front/Rear Edge Guide Drive Motor Control

<When storing a copy>

•

Upon pressing the Start Key, Front/Rear Edge Guide Plate Drive Motor turns forward,

moving the Front/Rear Edge Guide Plates to the stand-by position.

•

As the paper to be stored has passed Duplex Unit Trailing Edge Sensor (H), the Front

Edge Guide Plate is moved to the alignment position by the Cam. The Rear Edge Guide

Plate is moved to the paper size position.

<When taking up a copy>

•

When Duplex Unit Paper Empty Sensor is unblocked (H) after a copy has been taken up

from the Duplex Unit, the Rear Edge Guide Plate returns to the position where it blocks

Front/Rear Edge Guide Plate Home Position Sensor (L).

•

Front/Rear Edge Guide Plate Drive Motor is a stepping motor, which is driven by the output signals from pins 35 to 38 of IC1G of Duplex Unit Master Board.

•

The output order of the signals determines the motor direction.

M-13

Page 18

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

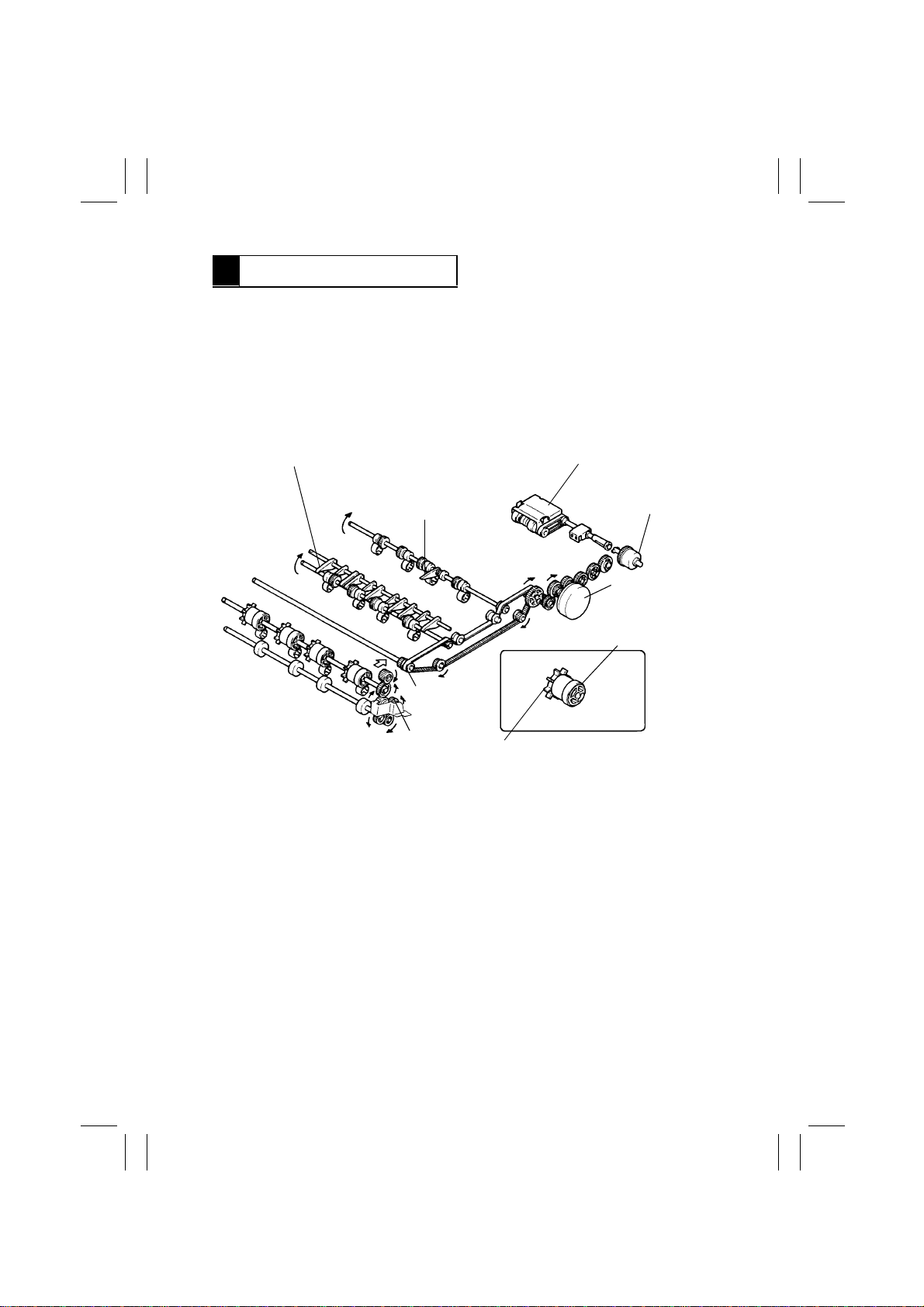

9 DUPLEX PAPER TAKE-UP UNIT

9-1. Leading Edge Guide Plate and Duplex Paper Take-Up Drive

Mechanism

•

Copies stored in the Duplex Unit are taken up and fed back into the copier by the Duplex

Take-Up Roll and Feed Roll which are driven via Duplex Unit Paper Take-Up Clutch by

the Duplex Unit Drive Motor. The top copy is separated from the remaining ones by a

paper separating mechanism with a torque limiter.

•

The Leading Edge Guide Arms align the leading edge of the copy being stored in the

Duplex Unit.

•

When Duplex Unit Pick-Up Solenoid is energized to begin a paper take-up sequence, the

Leading Edge Guide Arms are unlocked by way of the Retraction Lever. At the same

time, the Duplex Paper Take-Up Roll is pressed down against the copy to take it up.

Duplex Unit Pick-Up

Solenoid SL33

Retraction Lever

Slide Plate

Leading Edge Guide Arms

Duplex Unit Drive Motor M31

M-14

Duplex Unit Paper

Take-Up Clutch CL31

4425M240AA

Page 19

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

<When storing a copy>

•

When a copy is to be stored in the Duplex Unit, Duplex Unit Pick-Up Solenoid is deenergized to release, by way of the Retraction Lever, the Duplex Paper Take-Up Roll fr om the

copy or copies already in the Duplex Unit.

•

At the same time, the Leading Edge Guide Arms are locked into position by parts A of the

Slide Plate which meet the tabs on the Guide Plate, thereby aligning the leading edge of

the copy to be stored in the Duplex Unit.

Duplex Unit Pick-up

Paper Take-up Roll

Solenoid SL33

Slide Plate

Leading Edge

Guide Arm

Leading Edge

Guide Arm

A

4425M219AA

Leading Edge Guide Arm

4425M220AA

<When taking up a copy>

•

When a copy is to be taken up from the Duplex Unit, Duplex Unit Pick-Up Solenoid is

energized to lower the Retraction Lever and the Duplex Paper Take-Up Roll is pressed

against the copy in the Duplex Unit by spring force.

•

At the same time, the Leading Edge Guide Arms are unlocked from part A of the Slide

Plate.

•

When the copy is taken up and fed in, the leading edge of the copy pushes up the Leading Edge Guide Arms in the direction of the arrow.

M-15

4425M222AA4425M221AA

Page 20

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

9-2. Duplex Paper Take-Up Drive Control

1. Operation Timing of Duplex Unit Pick-Up Solenoid and Duplex Unit Paper Take-up

Clutch (Two 2-sided copies of A4C paper, using Duplexing/Automatic Document

Feeder)

4481T22MCB

2. Paper Take-Up Retry Control

•

If the paper to be taken up does not block Duplex Unit Paper Take-Up Sensor within a

given period of time, the paper take-up cycle starts again after Duplex Unit Pick-Up Solenoid and Duplex Unit Paper Take-Up Clutch are deenergized.

•

A paper misfeed results if a sheet of paper does not reach the Duplex Unit Paper TakeUp Sensor even after three paper take-up sequences.

NOTE

The paper take-up retry sequence is not performed in the Time Saver mode.

M-16

4481T07MCC

Page 21

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

9-3. Paper Take-Up Operation

1. Normal Mode

<Normal Mode with A4C Paper>

Press the Start Key to start paper take-up.

Duplex Unit Pick-Up Solenoid: Energized

Duplex Unit Paper Take-Up Clutch: Energized

The leading edge of the paper blocks Vertical Transport Sensor 3 (L).

Duplex Unit Pick-Up Solenoid and Duplex Unit Paper Take-Up Clutch: Deenergized

The trailing edge of the paper moves past Duplex Unit Paper Take-Up Sensor (H).

NO

Front/Rear Edge Guide Drive Motor is energized and the Front/Rear Edge Guide Plates return to the

home position.

Is the Duplex Unit empty?

YES

M-17

Page 22

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

2. Time Sa ver Mode

•

In the Time Saver mode, the copies stored in the Duplex Unit are taken up and fed back

into the copier in a different order from when in the normal mode. When the number of

copies remaining to be stored in the Duplex Unit becomes N, that copy is immediately

taken up and fed back to the copier and the subsequent ones are taken up each time

they have just been stored in the Duplex Unit. This saves a given amount of time in the

overall 2-sided copying cycle, which would otherwise be lost if Duplex take-up motion is

started after all copies have been stored.

•

The Time Saver mode is set only when the Automatic or Duplexing Document Feeder is

being used [in the standard mode (not in the Mixed Original Detection mode) with fullsize magnification and using paper less than 297 mm long].

•

When Duplex Unit Rear Finger Solenoid is energized, it turns the Duplex Unit Rear Finger so that the Finger presses the copy or copies stored in the Duplex Unit.

•

When all copies are fed out of the Duplex Unit, the Duplex Unit Rear Finger returns to its

home position.

No. Paper Length Time Saver Mode

1 139 mm ~ 257 mm

2 258 mm ~ 297 mm

The number of copies remaining to be stored in the Duplex Unit

is 4.

The number of copies remaining to be stored in the Duplex Unit

is 3.

Duplex Unit Rear Finger Solenoid

SL32

Duplex Unit Rear Finger

M-18

4425M225AA

Page 23

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

<Operation in Time Saver Mode: A4 crosswise paper, 10 copies>

The trailing edge of the sixth copy moves past Duplex Unit Paper Entry Sensor (H).

The Front/Rear Edge Guide Plates move to the set paper size position to align the copy.

At the same time, Duplex Unit Rear Finger Solenoid is energized and the Duplex Unit Rear Finger

presses the copies stored in the Duplex Unit.

The trailing edge of the 7th copy moves past Duplex Unit Paper Entry Sensor (H). (Each of

the 7th and subsequent copies is taken up and fed back into the copier each time it has

just been stored.)

The Front/Rear Edge Guide Plates move to the set paper size position to align the copy.

Duplex paper take-up sequence starts.

Duplex Unit Pick-Up Solenoid is energized.

Duplex Unit Paper Take-Up Clutch is energized.

The leading edge of the copy blocks V e rtical Transport Detection Sensor 3 (L). At the

same time, Duplex Unit Pick-Up Solenoid and Duplex Unit Paper Tak e -Up Clutch are

deenergized and the Front/Rear Edge Guide Plates move to the stand-by position.

NO

Have all copies been taken up for Time Saver?

After all copies for Time Saver have been taken up and fed in, the copies previously stored in the

Duplex Unit are taken up and fed in, one by one.

When all copies have been taken up from the Duplex Unit, the Duplex Unit Rear Finger returns to the

home position.

Duplex Unit Paper Empty Sensor, which has been in the blocked (L) state, is unblocked (H).

Front/Rear Edge Guide Drive Motor is energized and the Front/Rear Edge Guide Plates return to their

home positions.

YES

M-19

Page 24

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

10 VERTICAL TRANSPORT SECTION

1. Vertical Transport Drive Mechanism

•

V ertical Transport Motor drives the Transport Rollers via a belt to send the paper from the

Duplex Unit to the copier.

Vertical T ransport Roller

V ertical T r ansport

Motor M21

4425M250AA

2. Vertical Transport Motor Control

•

The Vertical Transport Motor, a stepping motor , is driven b y the signals from pins 1, 2, 17

and 4 of IC9A on the cabinet’s Master Board which is controlled by the copier Master

Board. The drive signals are fed into 2 windings in the motor.

M-20

4481T23MCB

Page 25

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

11 EXIT SECTION

1. Exit/Duplex Switching Mechanism

•

The paper path is switched by the Exit/Duplex Switching Plate which is operated by the

Exit/Duplex Solenoid.

•

The paper path is switched according to the copying mode as detailed below.

Copying Mode Exit/Duplex Solenoid SL61

Normal Deenergized

2-sided copy (when 1-sided copy is fed into

Duplex)

Operation in 2-Sided Copying Mode

The Front/Rear Edge Guide Plates and

Trailing Gate Unit move according to the

set paper size.

Energized

Select the 2-sided copying mode.

Press the Start Key.

4425M224AA

M-21

A given period of time after a TRON signal has been output, Exit/Duplex Solenoid is energized to feed the copy into

the Duplex Unit.

The paper is fed into the Duplex Unit.

Exit/Duplex Solenoid is deenergized a

given period of time after Synchronizing

Roller Clutch has been deenergized.

Page 26

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

2. Exit/Duplex Solenoid Control

•

Exit/Duplex Switching Solenoid is energized and deenergized by the Exit/Duplex Switching Solenoid Remote signal from pin 43 of IC5A of the copier Master Board.

<Exit/Duplex Switching Solenoid Energization Timing>

•

Exit/Duplex Switching Solenoid is energized at a predetermined time after the TRON (L)

signal has been output.

<Exit/Duplex Switching Solenoid Deenergization Timing>

•

Exit/Duplex Switching Solenoid is deenergized at a predetermined time after Synchronizing Roller Clutch has been deenergized.

•

For a multi-copy cycle, it is deenergized at a predetermined time after Synchronizing

Roller Clutch has been deenergized for the last paper.

M-22

Page 27

FrameMaker Ver.5.5(PC) PF-112 OPTION FOR EP1054/EP1085/EP2030

98.06.08

DIS/REASSEMBLY,

ADJUSTMENT

Page 28

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

1 DISASSEMBLY

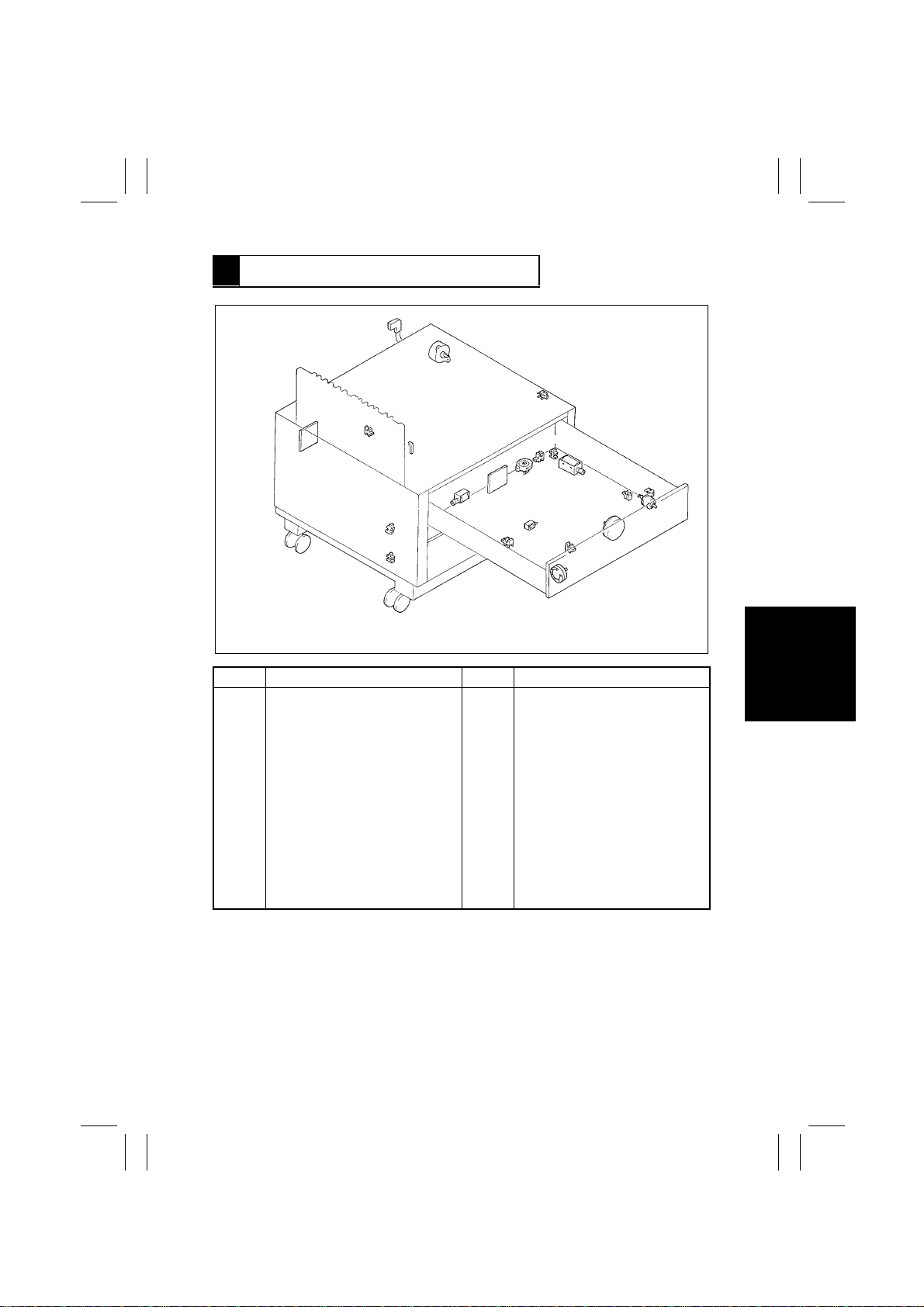

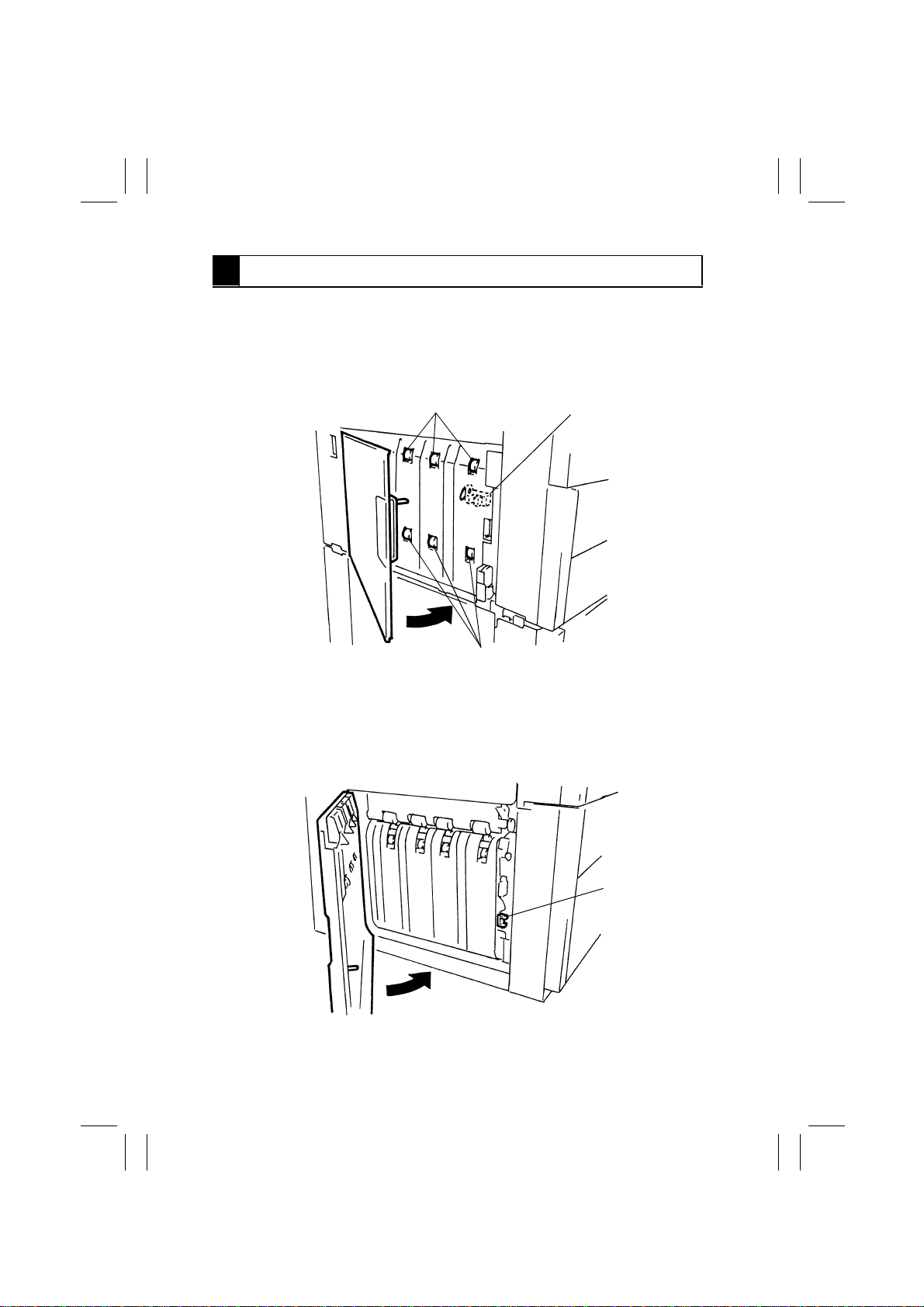

1-1. Removal of Exterior Parts

1

2

10

1174D003AA

screws.

screws.

3

9

5

4

No. Part Name Removal Procedure

1 Lower Right Door After removing Rear Right Cover, remove 2 screws.

2 Rear Right Cover Remove 2 screws.

3 Lower Right Cover After removing Front Right and Rear Right Covers, remove 2

4 Front Right Cover Remove 2 screws.

5 Lower Front Cover After removing Front Left and Right Covers, remove 2 screws.

6 Front Left Cover Remove 2 screws.

7 Middle Left Door Remove 4 screws.

8 Lower Left Cover After removing Front Left and Rear Left Covers, remove 2

9 Rear Left Cover Remove 2 screws.

10 Rear Cover Remove 2 screws.

7

8

4479D008AA

6

D-1

Page 29

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

1-2. Removal of Duplex Unit Drive Motor Assy

1. Slide out and remove the Duplex Unit.

2. Remove 4 screws and the Duplex Unit exterior

cover.

3. Remove 2 screws and the Duplex Unit interior

cover.

4425D231AA

4. Remove 2 screws and the cover.

4425D201AA

5. Remove 4 screws and the Duplex Unit Drive Motor

Assy .

4425D202AA

1-3. Removal of Paper Take-Up Unit

1. Remove the Duplex Unit Drive Motor Assy.

2. Remove 3 screws and the PWB-G cover.

4425D203AA

3. Remove 4 screws and the Duplex Unit Paper

Take-Up Unit.

4425D204AA

D-2

Page 30

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

4. Remove 2 connectors. Shift the Front/Rear Edge

Guide Plate Home Position Sensor to the side and

then remove the Paper Take-Up Unit.

4425D205AA

1-4. Removal of Trailing Gate Unit

1. Remove 1 screw and the Upper Guide Plate.

4425D206AA

2. Move the Trailing Gate Unit to the left as far as it

goes by turning the Screw Cam.

3. Remove 1 screw and the Upper Guide Plate Assy.

4425D207AA

4425D208AA

4425D210AA

4. Remove the E-ring and washer. Remove the Timing Belt from the Gear.

5. Snap off two E-rings and remove the Slide Shaft.

D-3

Page 31

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

6. Remove 2 screws, the ground wire and t he Trailing

Gate Unit.

4425D211AA

1-5. Removal of Paper Guide Sheet

1. Remove the Trailing Gate Unit.

2. Remove 4 screws and the Paper Mounting Plate.

4425D212AA

3. Remove 2 springs.

4. Remove 2 screws and the Paper Guide Sheet.

4425D213AA

1-6. Removal of Front/Rear Guide Plate Assy

1. Remove the Paper Take-Up Unit.

2. Unplug 2 connectors.

4425D214AA

3. Remove 2 screws and then the Front/Rear Edge

Guide Plate Assy.

CAUTION

When reinstalling the Front/Rear Edge Guide Plate

Assy, positively hook the fingers into the Mounting

Plate. Align the scale with that on the Mounting Plate.

4425D215AA

D-4

Page 32

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

1-7. Removal of Vertical Transport Unit

1. Remove 2 screws and the Rear Left Cover.

2. Remove 4 screws and the Lower Left Door.

4425D216AA

3. Remove 5 screws and 1 connector. Slide the Vertical Transport Unit to the rear and remove it.

4425D217AA

1-8. Removal of Take-Up Roll/Feed Roll Assy

4425D218AA

4425D219AA

1. Remove the Duplex Unit Drive Motor Assy.

2. Loosen 1 screw and remove the retainer spring.

3. Remove the C-clip and Paper Take-Up Sensor

Assy.

4. Remove 1 screw and the Cover.

5. Remove 2 screws and the ground spring. Lift up

and then remove the Solenoid Mounting Plate

Assy.

CAUTION

When reinstalling the Solenoid Mounting Plate Assy,

be sure to insert the Paper Take-Up Roll/Feed Roll

Assy bracket above the Rectraction Lever.

D-5

Page 33

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

6. Remove 2 C-clips. Lifting up the Paper Take-Up

Roll/Feed Roll Assy, move it toward the rear and

remove.

CAUTION

When reinstalling the Paper Take-Up Roll/Feed Roll

Assy, first engage the shaft coupling at the front and

then rehook the spring.

4425D220AA

7. Remove the bushing, E-ring, bushing and spring.

4425D221AA

8. Snap off 2 E-rings, pull out the shaft and then

remove the Feed Roll.

4425D222AA

9. Remove the E-ring, bushing and then the Paper

Take-Up Roll.

4425D223AA

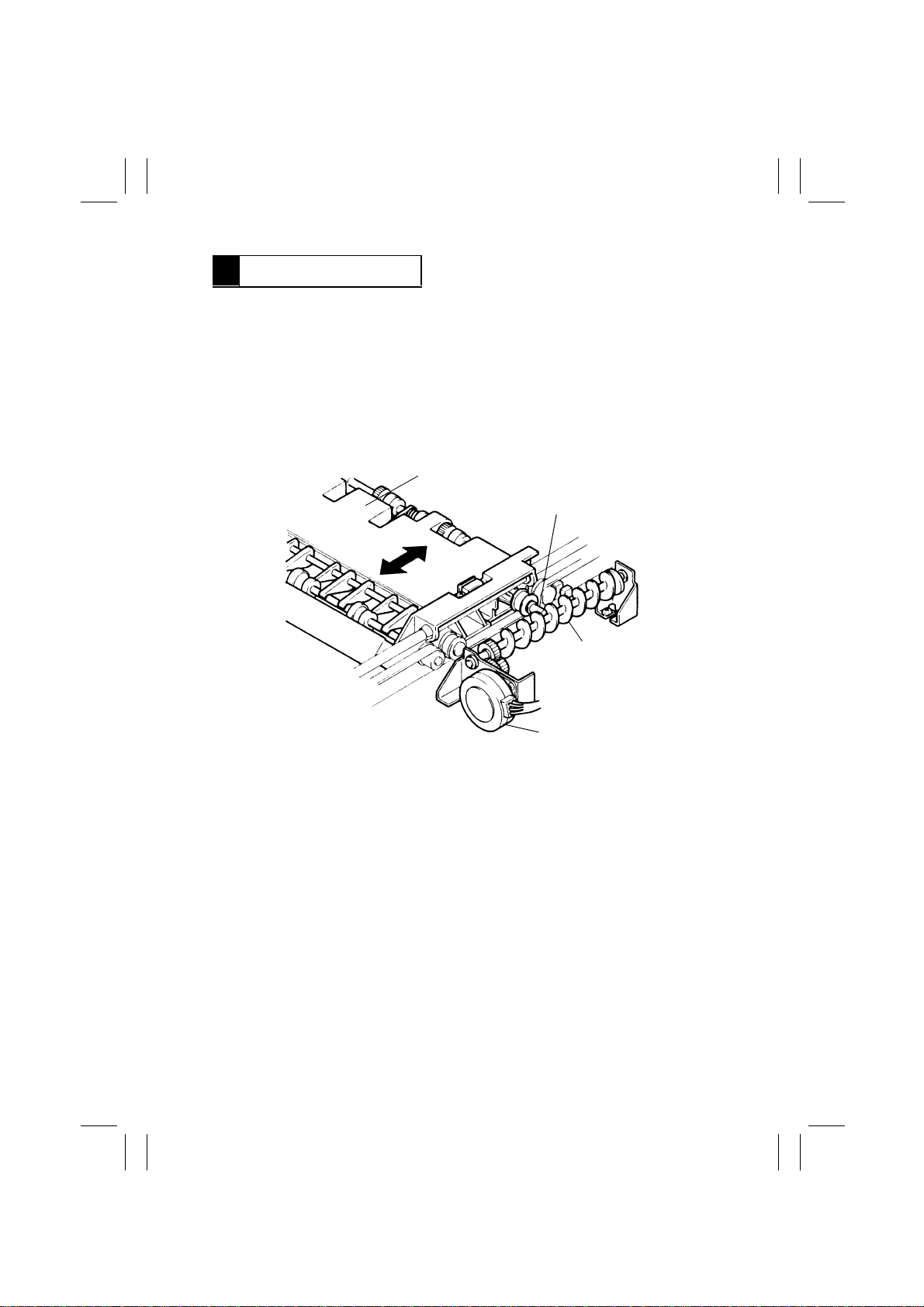

1-9. Removal of Separator Roll Assy

1. Remove 2 screws and then the Mounting Plate.

CAUTION

When reinstalling the Mounting Plate, align the locking

members.

4425D224AA

D-6

Page 34

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

2. Remove 1 C-clip and screw and then the Guide

Holder.

CAUTION

When reinstalling the screw, make sure that it is abov e

the Guide Holder.

4425D225AA

3. Remove the C-clip. Remove the Separator Roll

Assy by sliding it toward the rear and then upward.

4425D226AA

1-10. Cleaning of Vertical Transport Rollers

Using a soft cloth dampened with alcohol, wipe clean

the Transport Rollers.

4425D017AA

1-11. Cleaning of Duplex Unit Vertical Transport Roller/Slip Roll

Using a soft cloth dampened with alcohol, wipe clean

the Duplex Unit Vertical Transport Roller/Slip Roll.

4425D232AA

D-7

Page 35

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

1-12. Cleaning of Paper Take-Up Roll/Feed Roll/Separator Roll

1. Pull out the Duplex Unit.

2. Remove 2 screws and then the Mounting Plate

Assy .

3. Using a soft cloth dampened with alcohol, wipe

clean the Paper Take-Up Roll, Feed Roll and Separator Roll.

4425D233AA

1-13. Cleaning of Trailing Gate Unit Transport Rollers 1 & 2

1. Pull out and remove the Duplex Unit.

2. Open the Guide Plate Assy.

3. Using a soft cloth dampened with alcohol, wipe

clean the Trailing Gate Unit Transport Rollers 1 &

2.

4425D234AA

1-14. Parts Which Must Not Be Touched

Duplex Unit Pick-Up Solenoid SL33.

4425D228AA

D-8

Page 36

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

2 ADJUSTMENT

2-1. Adjustment of Magnetic Catch

1. Remove the Vertical Transport Unit.

2. Loosen two screws on the Magnetic Catch. Check

that each part marked with a circle in the fig. on the

left is in contact with the corresponding matching

part and then tighten the screws.

3. Swing open and close the Vertical Transport Unit

to check that each part is in contact with the other.

4425D235AA

2-2. Adjustment of Clearance Between Release Lever Assy

and Guide Plate (This adjustment must be made after the

adjustment of the Magnetic Catch has been completed.)

1. Close the Vertical Transport Assy.

2. Loosen one screw on each Release Lever Assy.

3. Move the Release Lever Assy up and down as

necessary to obtain a clearance of 1 to 3.0 mm

between the Le v e r Assy a nd Gui de Pla te. When the

specified clearance is obtained, tighten the screw.

4. Swing open the Vertical Transport Unit and turn the

4425D227AA

Paddle Roller one complete turn. Then, close the

Vertical Transport Unit and check for clearance again.

5. After the clearance has been checked, turn the

Paddle Roller to check to see if the Rolls in the

Release Lever turn.

2-3. Adjustment of Front/Rear Edge Guide Plate Timing Belt

1. Loosen two screws.

2. Hook a tension gage into the motor mounting hole

and then pull the gage in the direction of the arrow

with a force of 350 ± 50g.

3. Tighten the screws.

4444M023AA

D-9

Page 37

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

2-4. Alignment of Front/Rear Edge Guide Holder

Align the hole in the Front/Rear Edge Guide Plate

Holder with that in the Edge Guide Plate. Align the

hole in the Cam with another one in the Edge Guide

Plate. Fit an Allen wrench into the holes of the Cam

and Plate and screw the Holder into position.

4425D230AA

2-5. Adjustment of Trailing Gate Unit Timing Belt

1. With the tension given by the spring, tighten one

screw.

4481D001AA

2-6. Adjustment of Duplex Unit Reference Position

Requirement

•

Prepare a test chart (A3 size) as shown on the left.

Draw a line on the chart at a point 20 mm from the

right edge.

•

Dimension A on the copy should measure 20 ± 3.0

mm.

1074D089

1. Place the test chart on the Original Glass and align

the rear edge of the test chart with the reference

mark (▲). Lower the Original Cover.

2. Select 1 2 copy mode and make two copies of

the test chart in the full size mode (use A3 paper).

3. Compare the position of the reference line on the

second copy with that on the test chart.

1139D027AA

▲

D-10

Page 38

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

4. If the copied line deviates from the reference line,

pull out the Duplex Unit and open the Upper Guide

Assy .

5. Slide the Rear Edge Guide Plate forward. Loosen

the 2 screws securing the Front/Rear Edge Guide

Plate Assy. Adjust the position of the Assy and

then tighten the screws.

4425U305AA

NOTE

If copied width A < 17 mm, move the Front/Rear Edge

Guide Plate Assy toward the rear.

If copied width A > 23 mm, move the Assy toward the

front.

4425U306AA

2-7. Adjustment of Duplex Unit Gate Switching Solenoid SL31

Position

1. Move SL31 in the direction of the arrow and then

loosen the screws.

2. Manually place SL31 in the energized position and

check that the clearance between the Switching

Lever and round shaft measures 11 mm or more.

Check also that the Switching Lever is in tight contact with the round shaft when SL31 is in the deen-

4425M235AA

ergized position.

2-8. Adjustment of Duplex Unit Rear Finger Solenoid SL32

Position

1. Move SL32 in the direction of the arrow and then

loosen the screws.

2. Check that the Duplex Unit Rear Finger is operated

when SL32 is manually placed in the energized

position.

4425M234AA

D-11

Page 39

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

2-9. Adjustment of Vertical Transport Timing Belt

1. Remove the Rear Cover, Front Right Cover, Front

Left Cover, and Upper Front Cover.

2. Remove the Duplex Unit Guide Rail (Right).

3. Go to the rear of the Cabinet and, using a wrench,

loosen the hexagon screw used for adjustment of

the Vertical Transport Belt. Adjust so that the Belt

has no slack.

4425D018AA

4. Check the Belt for tension using a tension gage.

The gage should read 80 to 100 g when the Belt is

pushed to deflect 1 mm.

D-12

Page 40

FrameMaker Ver.5.5(PC) PF-112 OPTION FOR EP1054/EP1085/EP2030

98.06.08

MISFEED

DETECTION/

MALFUNCTION

DETECTION

Page 41

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

1 MISFEED DETECT ION

1-1. Location of Misfeed Detecting Sensors

Paper Exit Sensor

PC53

Duplex Vertical

Transport Sensor

PC12

Duplex Unit Paper

Entry Sensor PC14

Vertical Transport

Sensor 3 PC17

Duplex Unit Paper

Take-Up Sensor PC16

Duplex Unit Paper

Empty Sensor PC15

4425T202AA

1-2. Misfeed Detection Types and Detection Timings

Any of the following misfeeds occurring in the Duplex Unit is detected under the corresponding conditions and shown on the copier control panel.

Type Detection

Leading edge detection by

Duplex Unit Vertical

Transport Sensor PC12

Trailing edge detection by

Duplex Unit Vertical

Transport Sensor PC12

Leading edge detection by

Duplex Unit Paper Entry

Sensor PC14

Trailing edge detection by

Duplex Unit Paper Entry

Sensor PC14

PC12 is not blocked (L) after the lapse of a given period of

time after 1

PC12 is not unblocked (H) after the lapse of a given period of

time after PC53 has been unblocked (H).

PC14 is not blocked (L) after the lapse of a given period of

time after Duplex Unit Vertical Transport Sensor PC12 has

been blocked (L).

PC14 is not unblocked (H) after the lapse of a given period of

time (which varies with paper size) after it has been blocked

(L).

st

Paper Exit Sensor PC53 has been blocked (L).

T-1

Page 42

FrameMaker Ver.5.5(PC) PF-6D/AD-11 OPTION FOR EP1054/EP1085/EP2030

98.06.08

Type Detection

Storage Detection Duplex Unit Paper Empty Sensor PC15 is not unblocked (L)

Take-up failure detection Vertical Transport Sensor 3 PC17 is not blocked (L) after the

Take-up trailing Edge

detection

Time Saver take-up

detection

after a copy has been stored in the Duplex Unit.

lapse of a given period of time after Duplex Unit Paper TakeUp Clutch CL31 has been energized during the third paper

retry sequence.

Duplex Unit Paper Take-Up Sensor PC16 is not unblocked (H)

after the lapse of a given period of time (which varies with

paper size) after it has been blocked (L).

PC17 is not blocked (L) after the lapse of a given period of

time after CL31 has been energized for each of the copies for

Time Saver except the last.

2 MALFUNCTION DETECTION

Malfunction

Code

C0d00 F ront/Rear Edge Guide

C0d20 Trailing Gate Unit home

C0d50

C0d51 Duplex Unit Drive

Description Detecting Timing

Plate home position

detection

failure

position

detection failure

Duplex Unit Drive Motor

M31 failure to turn

Motor M31 turning at

abnormal timing

The home position is detected only in the initial

operation sequence. Front/Rear Edge Guide Plate

Home Position Sensor PC9 is not b loc ked (L) within

a given period of time after the initial operation

sequence has started (when the Power Switch is

turned ON, the Front Door is swung open and

closed, the Duplex Unit is slid into position, paper

take-up sequence from the Duplex Unit is completed, or 2-sided copy mode is canceled).

The home position is detected only in the initial

operation sequence. (When the Power Switch is

turned ON, the Front Door is swung open and

closed, the Duplex Unit is sli d into position, or the 2sided copy mode is canceled).

1. Duplex Gate Home Position Sensor PC8 is

blocked (L) at the start of the initial operation

sequence.

A. PC8 is unblocked (H) within a given period of

time.

B. PC8 is not blocked (L) within a given period of

time after it has been unblocked (H).

1. Duplex Gate Home Position Sensor PC8 is

unblocked at the start of the initial operation

sequence.

A. PC8 is not blocked (L) within a given period of

time.

The Motor Lock signal (H) is detected for a given

period of time after M31 has been energized.

The Motor Lock signal (L) is detected for a given

period of time after M31 has been deenergized.

T-2

Page 43

3568724

A

B

C

D

91

A

B

C

D

E

F

G

H

I

DWG.NO.

TITLE

MODEL

VOLTAGE

EFFECTIVE

MACHINE NO.

DATE ISSUED

4479-C003-0A

WIRING DIAGRAM

PF-6D/AD-11

From the copier

XX0201 AND ONWARD

Dec.1998

E

F

G

H

I

12345678

9

Page 44

A

B

C

D

E

F

G

H

9

8

7

I

9

8

7

6

5

4

3

6

5

4

3

2

DWG.NO.

TITLE

MODEL

1

A

B

C

D

E

F

G

H

VOLTAGE

EFFECTIVE

MACHINE NO.

DATE ISSUED

4479-C203-0A

CIRCUIT DIAGRAM PWB-A,G

AD-11/PF-6D

From the copier

XX0201 AND ONWARD

Oct.1998

I

2

1

Loading...

Loading...