Page 1

EPlO52

TROUBLEStiOOTING

MINOUA

Page 2

1158SBTOOOBA

1 1

INTRODUCTION

CONTENTS

*:Only

when options are used

I-1. General Precautions

1-2. How to Use This Book

I-3. Reading

2

I/O

PORT CHECK

2-l. Method for Checking the Control Parts with Loads

2-2.

I/O

3 1 PAPER TRANSPORT FAILURE

1.

Paper

I-l. Misfeed Detected When Copier is Turned ON

1-2. Copier Take-Up Misfeed

I-3. Bypass Port Misfeed (*Multi Bypass Table)

1-4. Transport/Separator Misfeed

I-5. Fusing/Exit Misfeed

2.

Wrinkles in Paper

3.

Double Feed

4.

SkewedFeed

4 MALFUNCTIONS

1.

Self-Diagnostic Function

1-I.

1-2.

I-3.

1-4.

1-5.

I-6. CO500:

1-7. CO600:

theText

Port Check List

Misfeed

...............................................

...............................................

03000:

cooo1:

coo1 0:

coo1 1:

coo4c:

coo70:

coo71

co400:

co41 0:

co51 0:

CO520:

CO61 0:

CO620:

Main Drive Motors failure to turn _ _ . . . . . . . . I . . . . . . . I T-25

Main Drive Motor turning at abnormal timing

PC Drive Motors failure to turn . . . . . . . . . . . . . . . . . . . . T-27

PC Drive Motor turning at abnormal timing

Cooling Fan Motors failure to turn . . . . . , . . . . . . . . . . . T-29

Toner Replenishing Motors failure to turn . . . . . . . . . . . T-31

Toner Replenishing Motor turning at abnormal

:

timing

Exposure Lamps failure to turn ON . . . . . . . . . . . . , . , . T-33

Exposure Lamp turning ON at abnormal timing

Warming-up failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T-35

Abnormally low fusing temperature

Abnormally high fusing temperature

Scanner Motor malfunction. . . . . . . . . . . . . . . . . . . . . . . T-37

Lens Motor malfunction

Mirror Motor malfunction

........................................

......................................

...........................................

.........................................

...............................................

.................................

.................

.............................

.....................................

...........................................

.....................................

..............

...............

T-l

T-l

T-l

T-2

T-4

T-7

T-l 0

T-l 1

T-14

T-l 6

T-19

T-21

T-21

T-22

T-23

i

Page 3

1-8.

COFI

0: Faulty AE Sensor level . . . . . . . . . . . . . . . . . . . . . . . . . . . T-39

COF30: ATDC Sensor malfunction

1-9.

COF02: Original size detection error (Defective CPU) . . . . . . . . T-41

COFEI

To COFFF: Original Size Detecting Sensor failure

2.

Power is not Turned ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T-43

3.

El,E2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T-45

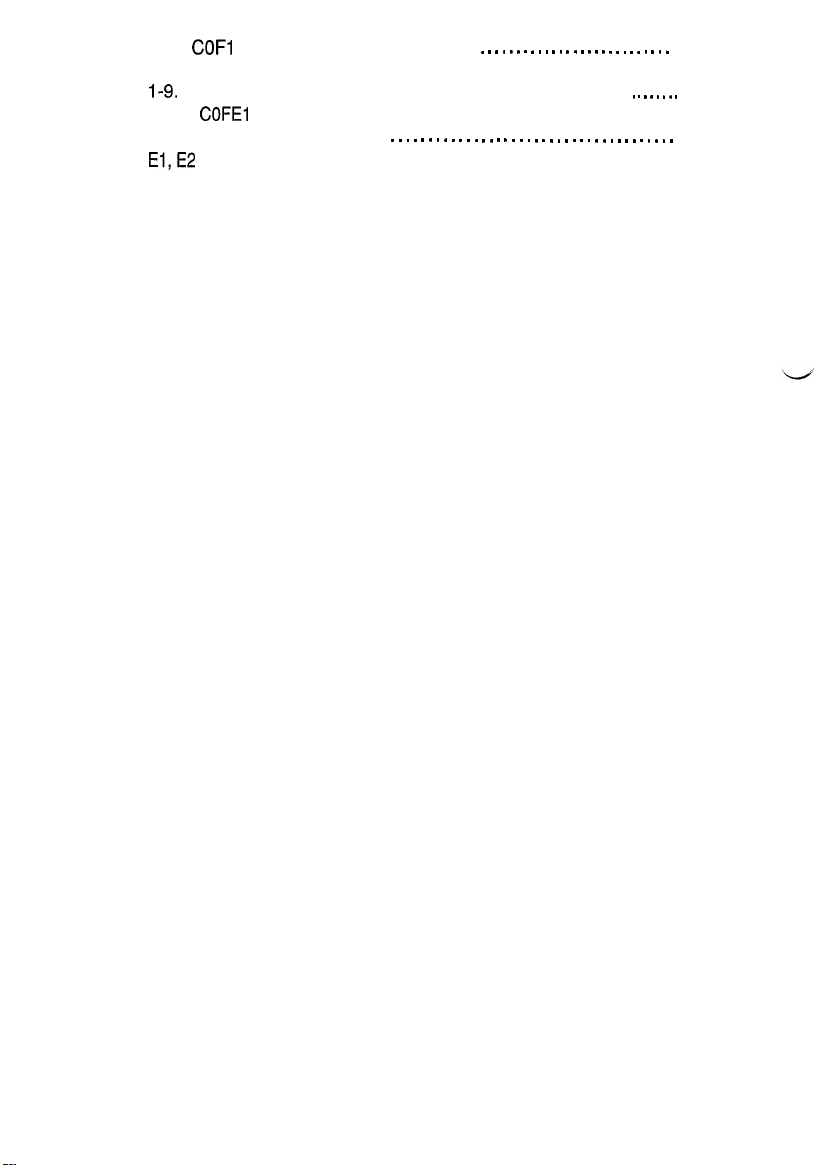

Page 4

1139SBTOlOOA

INTRODUCTION

1139SBTOlOlA

l-1. General Precautions

1. When servicing the copier with its covers removed, use utmost care to prevent your hands, clothing, and

tools from being caught in revolving parts including the chains and gears.

2. Before attempting to replace parts and unplugging connectors, make sure that the power cord of the

copier has been unplugged from the wall outlet.

3.

Never create a closed circuit across connector pins except those specified in the text and on the printed

circuit.

4. When creating a closed circuit and measuring a voltage across connector pins specified in the text, be

sure to use the green wire (GND).

5. When the user is using a word processor or personal computer from the wall outlet of the same line, take

necessary steps to prevent the circuit breaker from opening due to overloads.

6. Keep all disassembled parts in good order and keep tools under control so that none will be lost or

damaged.

1139SBT0102A

1-2. How to Use This Book

1.

If a component on a PWB or any other functional unit including a motor is defective, the text only instructs

you to replace the whole PWB or functional unit and does not give troubleshooting procedure applicable

within the defective unit.

2. All troubleshooting procedures contained herein assume that there are no breaks in the harnesses and

cords and all connectors are plugged into the right positions.

3. For the removal procedures of covers and parts, see

4. The troubleshooting procedures are given in the order of greater frequency of trouble or order of

operation.

5. The procedures preclude possible malfunctions due to noise and other external causes.

1139SBT0103A

1-3. Reading the Text

1.

The paper

the location where the paper is present and start the procedure

troubleshooting, start with step 1 and onward.

2. Make checks in numerical order of steps and, if an item is checked okay, go to the next step.

Pattern 1

Step Check Item

1

2

I I

transport failure

Is--?

I

Go to step 2 if it checks okay.

troubleshooting procedures are given according to the symptom. First identify

Result

1 YFS 1

Do this.

Action

1

DISREASSEMBLY,

Pattern 2

11

I

ADJUSTMENT.

forthat

particular location. For malfunction

T-l

Page 5

1151SBT0200A

I/O

PORT CHECK

1158SBT0201A

2-1. Controlled Parts Check Procedure

To allow the Tech. Rep. to easily and safely determine whether a particular controlled part is fully

operational, this copier provides the following provision: the check of the data of the

the board IC with the copier in the standby state (including a misfeed, malfunction, and closure

failure condition) allows the Tech. Rep. to determine whether a signal is properly input to, and

output from, a controlled part.

cProcedure>

When a paper misfeed or malfunction occurs, identify the

part by going over the text or

Select the

port identified in step 1).

Check the input or output port data to determine whether the controlled part is operational and signals

are properly input and output.

I/O

Check function of the Service mode and show on the Touch Panel the status of the

I/O

port check list.

I/O

port of the possibly defective controlled

I/O

port on

I/O

T-2

Page 6

---c_--~~----------------~----

Example:

<Procedure>

1)

2)

3)

4)

5)

6)

I

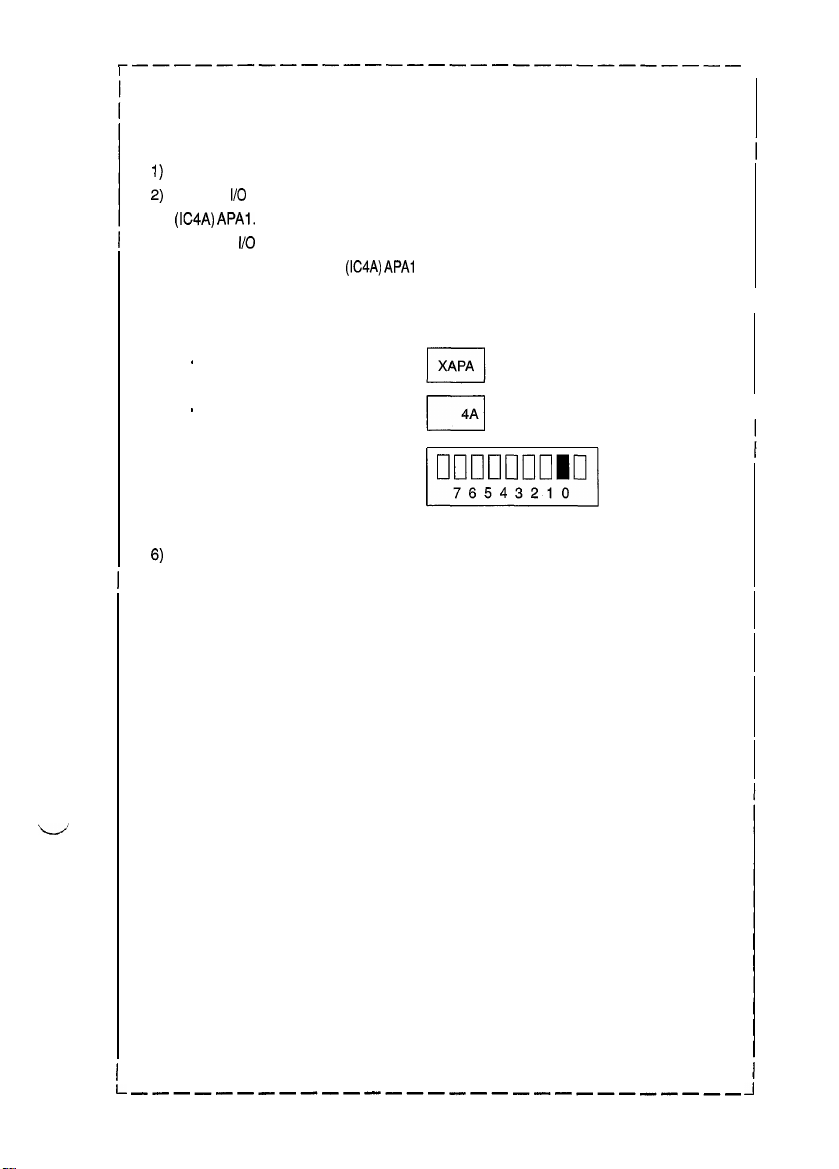

<Controlled Part Check Procedure by Changing Input Port Data>

When a paper misfeed occurs in the paper take-up section of the copier, Paper Take-Up

Sensor PC55 is considered to be responsible for it.

Remove the sheet of paper misfed.

From the

I/O

port check list, it is found that the H/L input signal to PC55 is supplied from PWB-A

(IC4A) APAI.

Select the

show the status of PWB-A

Checkthat the second LED from the right of the Exposure Information Display lights up (sensor

being unblocked).

Move the PC55 actuator to block the sensor.

Check at this time that the LED goes out.

I/O

Check function from the Service mode menu and, using the Paper Select key,

(IC4A) APAl

*

Zoom Ratio Indicator

.

Multi-Copy Display

. Exposure Information Display

ON: PC55 is faulty. OFF: PC55 is operational.

on the control panel.

1

L/

I

l-

-------__-__---___---_--__-__

J

T-3

Page 7

I

1158SBT0202A

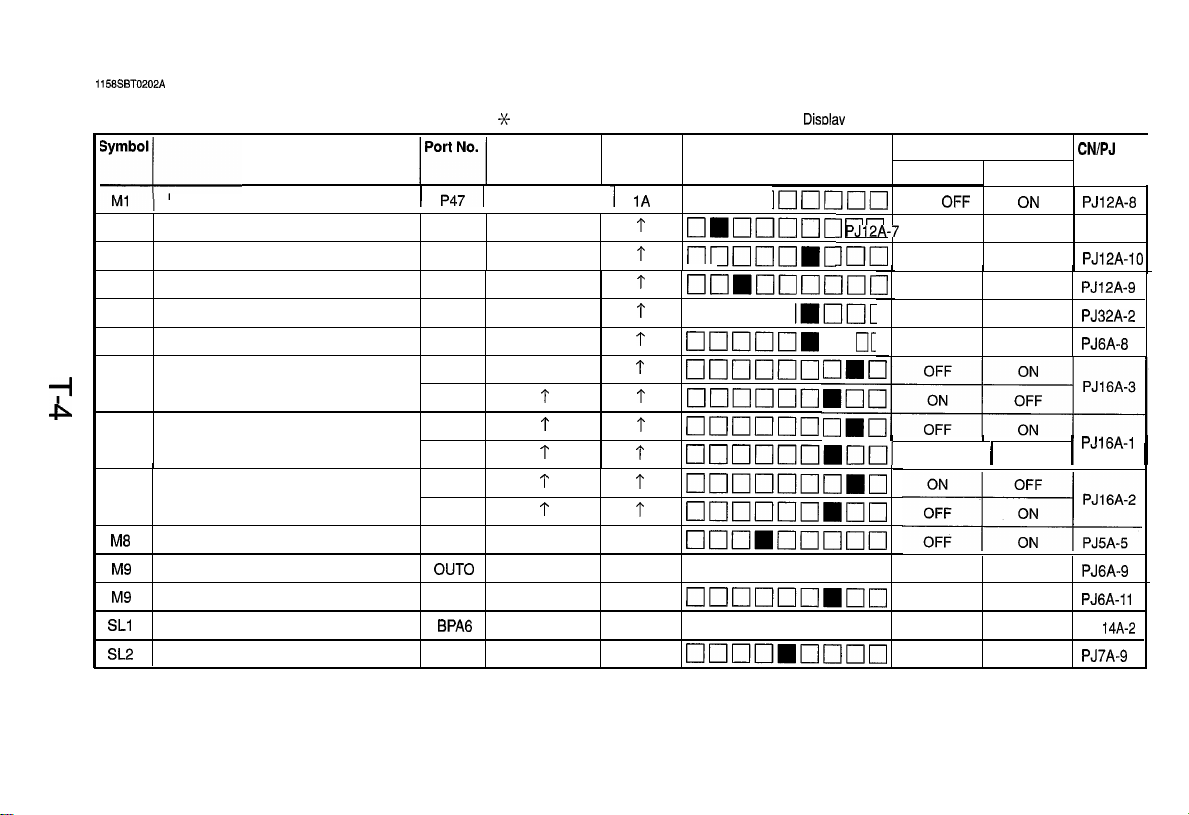

2-2. Port Check List

TI

P

(Copier)

Name

PC Drive Motor

PC Drive Motor lock signal

Ml

Main Drive Motor

M2

Main Drive Motor lock signal

M2

Optical Section Cooling Fan Motor

M3

Suction Fan Motor

M4

Scanner Motor

M5

Lena Motor

M6

Mirror Motor

M7

Toner Replenishing Motor

Ma

Cooling Fan Motor

M9

Cooling Fan Motor lock signal

M9

Separator Solenoid

SLl

Paper Take-Up Solenoid

SL2

1

BPA5 BPA

OUT0

APC2

BPA6

BPA4

33

1

st Drawer paper take-up LED on the Monitor

Magnification Multi-Copy

Ratio Indicator

P471

P4 1

P67

P43

P66 P6

P43 P4

P43

P61

P62

P61

P62

P61

P62

OUT

APC

BPA

BPA

P6

P4

P4

P6

Displav

liahts up.

Manual Exposure

Display

1A

q mclc

?

[7mcl1clclc

t

nnnnr

t

GIL--_

t

q ucloG_

1

cl00011

1

clclclnoo

?

?

t

1

t

1

cloclclclcl

1

cl0017cl10

t

nnnnnn

____--U[

1

I7noncl1oclmo

1

clcloouo~clo

4A

clclclmclclclclcl

5A

q clclnoooom

4A

~~~~~~~~

4A

q nanooooo OFF ON

4A

~~~~~~~~

Indicator

1~~~~~

~~~_

] n n

___.-lmI

]nn

lmnrlclcJclC

MIICIIC

q

Operation Characteristics

ON

OFF

When locked When turnedPJl2A-7

OFF ON

1

When locked When turned

OFF ON

1

OFF

1

CIC

I

InI

OFF ( ON

-When locked When turned

OFF ON

I

OFF ON

CN/PJ

OFF

ON

ON PJ6A-6

PJ12A-6

PJ12A-10

PJ12A-9

PJ32A-2

PJ16A-1

1

PJ6A-9

PJGA-11

PJ

14A-2

PJ7A-9

No.

1

I

Page 8

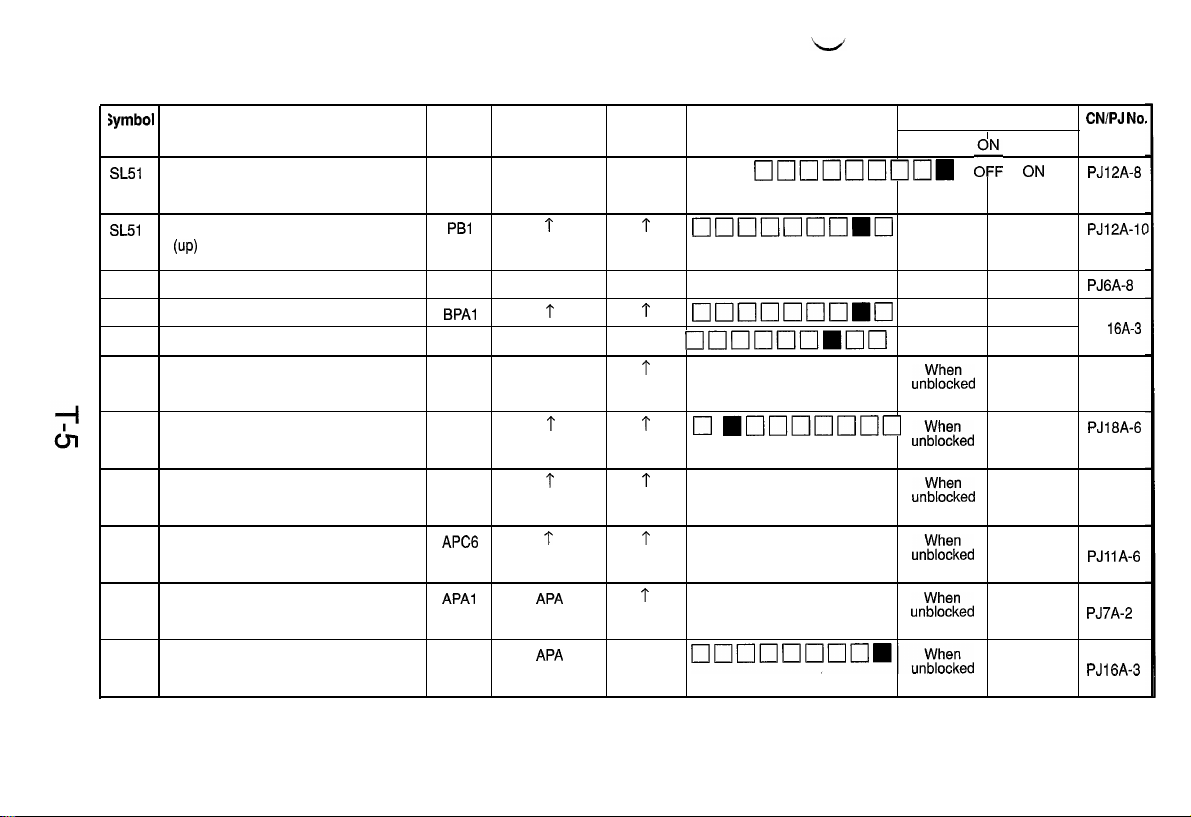

Symbol

SL51

Name

Manual Feed Paper Take-Up Solenoid

(down)

Port No.

PBO

Magnification Multi-Copy

Ratio Indicator Display

PB

4A

Manual Exposure

Indicator

tl~~~Ic]~~~

Operation Characteristics

OFF

,o, ON

CNlPJ No,

PJ12A-8

SL51

CL?

CL2

CL51

PC31

PC51

PC53

PC54

PC55

PC57

Manual Feed Paper Take-Up Solenoid

(up)

Synchronizing Roller Clutch

Paper Transport Clutch

Manual Feed Paper Take-Up Clutch

Manual Feed Paper Empty Sensor

Transport Roller Sensor

Paper Exit Sensor

Paper Leading Edge Detecting Sensor

Paper Take-Up Sensor

Right Door Detecting Sensor

PBl

BPAO

BPAl

PB2

APC3 APC

APC7

APC5

APC6

APAl

APAO

t

BPA

1

PB

1

1

f

APA

APA 4A When

1

~~~~0~~~

4A

q oouooonm

1

~~~~~~~~

5A

00n~~mnn

1

q oooomooo un;;ELed

t

q

mo~1ooooo

1

q oomooooo un;;ELed

1

q omoooooo

1

q oouonnmo

OFF ON

OFF ON PJ6A-8

OFF ON

OFF

un;;iced

un;;f=Led

unt;t-=Led

OFF

When

blocked

When PJ18A-6

blocked

When

blocked

When

blocked

When

blocked

blocked

PJ12A-lt

PJ

16A-3

PJ21 A-2

PJllA-6

PJ7A-2

PJ16A-3

Page 9

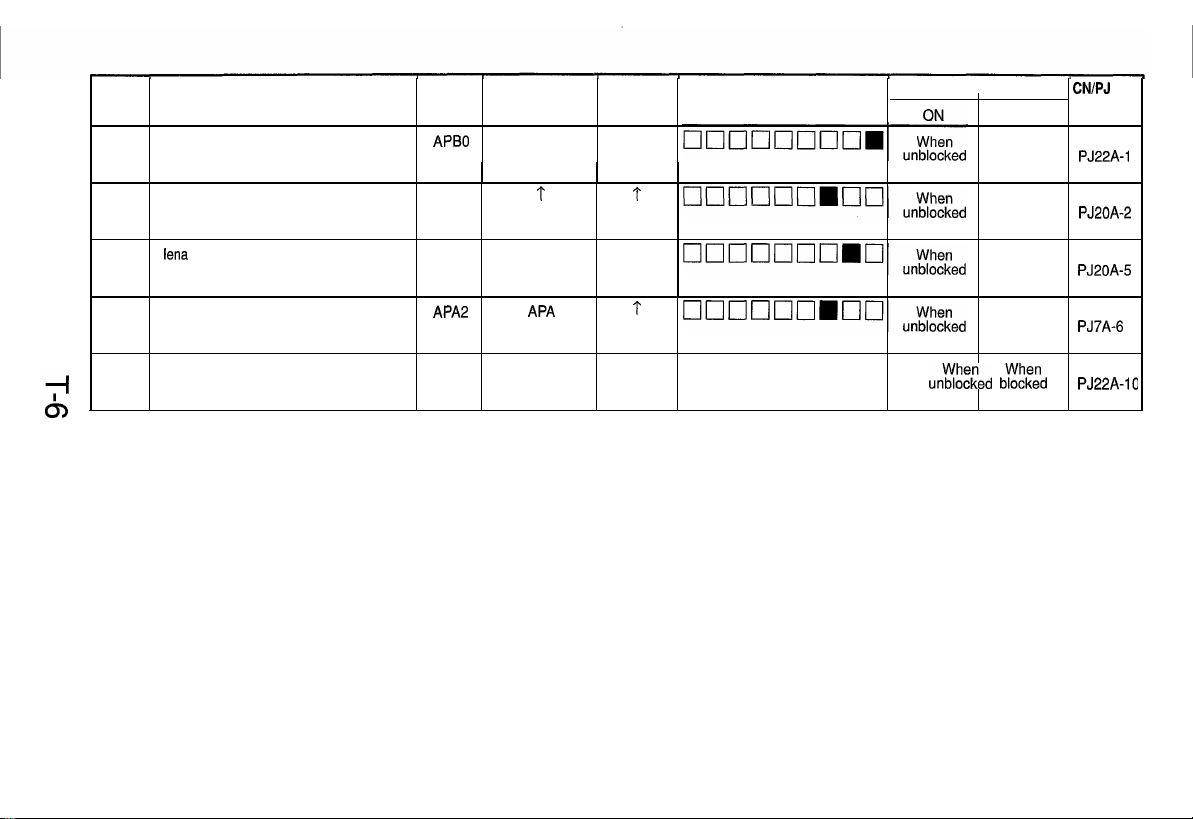

Symbol

PC81

Name

Scanner Reference Position Sensor

Port No.

APB0 APB 4A

Magnification Multi-Copy

Ratio Indicator

Display

Manual Exposure

Indicator

Operation Characteristics

OFF

When

blocked

CN/PJ

PJ22A-1

No.

PC86

PC90

PC101

PC112

Mirror Reference Position sensor

lena

Reference Position Sensor

Paper Empty Sensor

Toner Hopper Home Position Sensor

APB2

APB1 APB 4A

APA

APB6

*r

APA

APB

t

1

4A

q oonnooo

When

blocked

When

blocked

When

blocked

ur$%ed bEEE:d

PJ20A-2

PJ20A-5

PJ7A-6

PJ22A-10

Page 10

1151SBT0300A

PAPER TRANSPORT FAILURE

1158SBT0301A

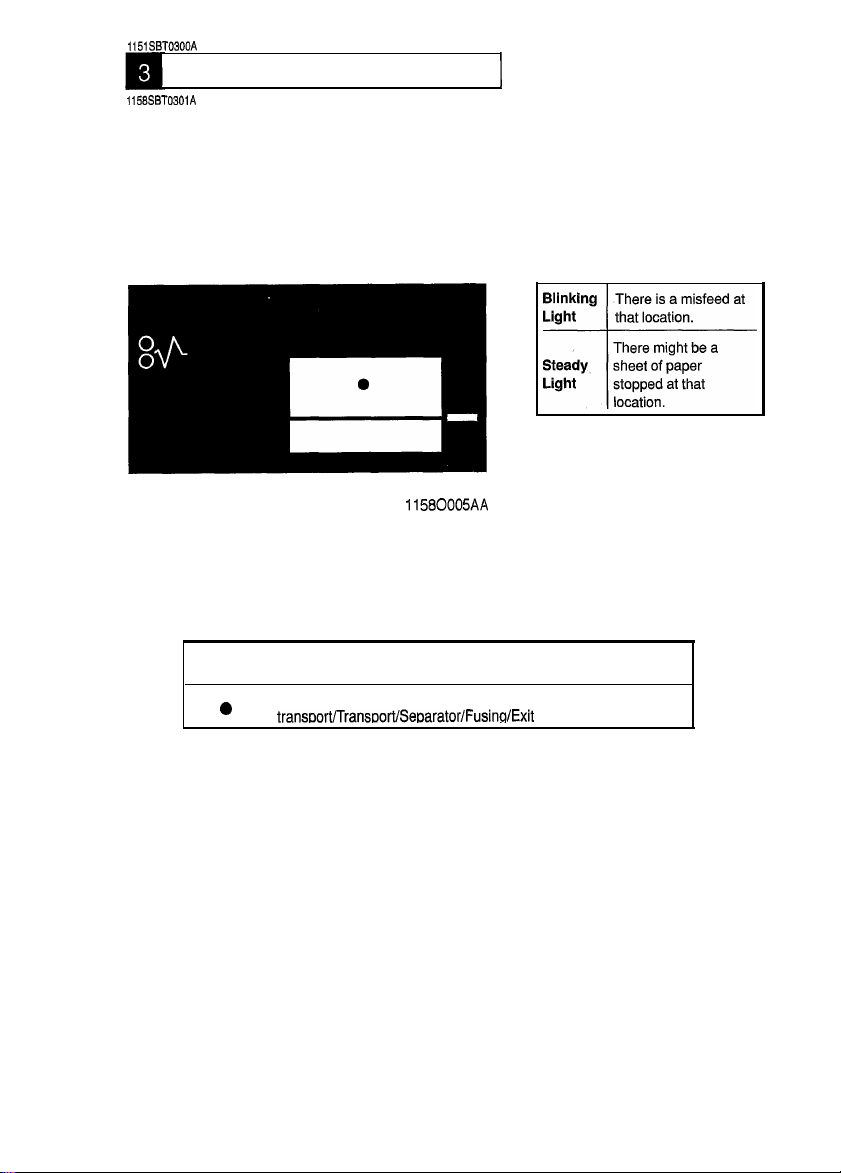

1. Paper Misfeed

When a paper misfeecl occurs in the copier, the corresponding Misfeeci Location Monitor LED on

the control panel blinks to let the user know where the misfeed has occurred. If an LED lights up

steadily, it indicates that there might be a sheet of paper present at that particular location in the

copier. If a paper misfeed occurs very frequently, carry out the necessary troubleshooting

procedures according to the location of the misfeed.

1

Blinking

LED

0

Blinking

Light

Steady

Light

-I--

11580005AA

Misfeed Locatlon

Paper take-up/Bypass port/Vertical

transoort/Transoort/SeDarator/Fusinn/Exit

There is a misfeed at

that location.

There might be a

sheet of paper

stopped at that

location.

T-7

Page 11

I

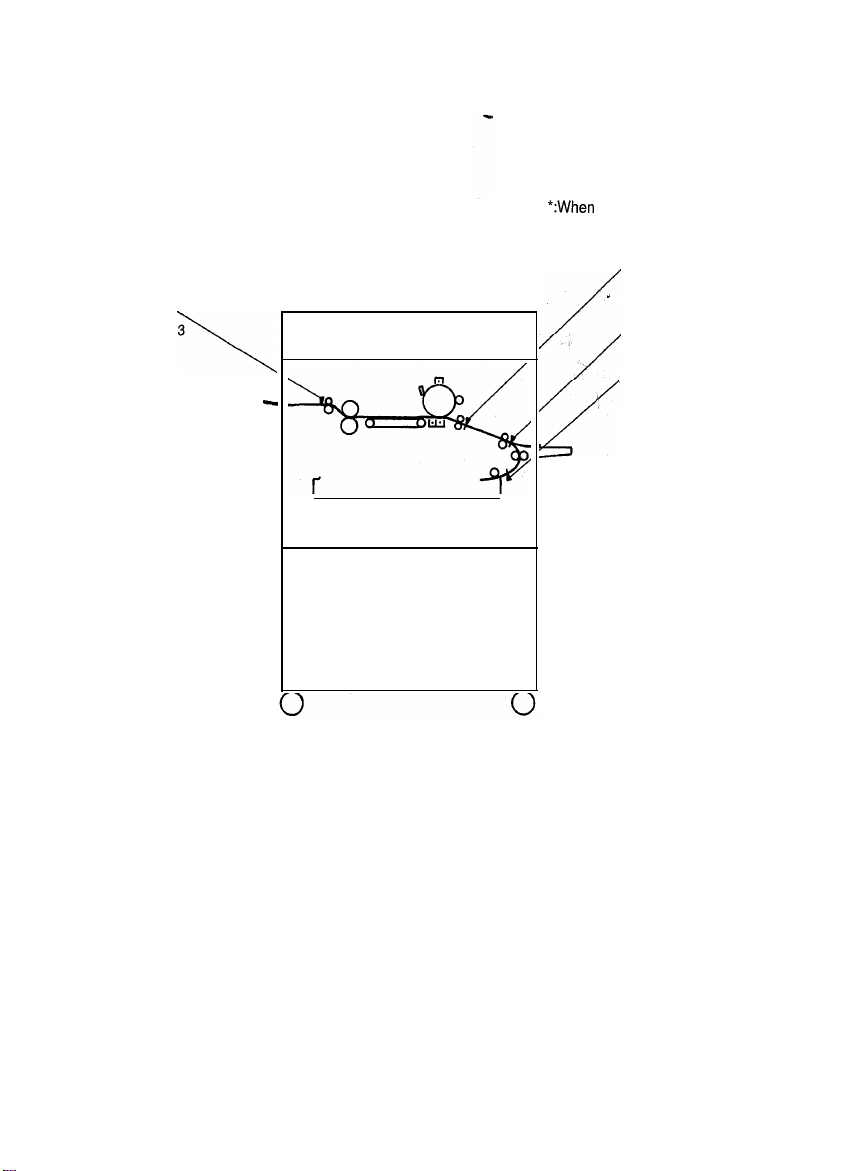

The paper misfeed, is detected by the following sensors.

Paper Exit

Sensor PC53

\

-

*:When

option is installed

(Exit/Duplex Switching Unit)

Paper Leading

I

Edge Detecting

Sensor PC54

/

/

Transport Roller

Sensor PC51

Paper Take-Up

Sensor PC55

4

T-8

Page 12

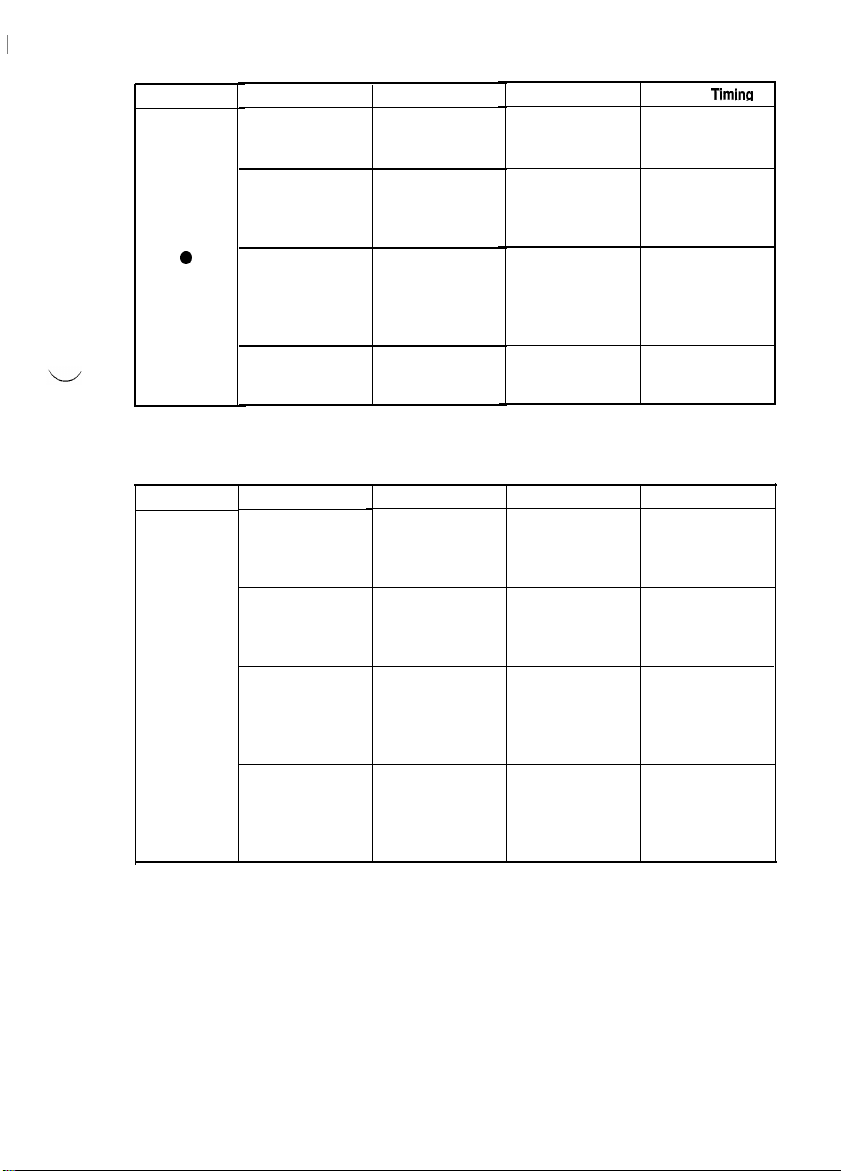

l

Here is an at-a-glance listing of misfeed detections made by the various sensors of the copier.

A: Misfeed Detected in Conjunction with Leading Edge Detection

Sensor

Blinking LED

0

B: Misfeed Detected in Conjunction with Trailing Edge Detection

Blinking LED

l

Location

Before the Paper

Take-Up Sensor

Before the

Transport Roller

Before the Paper

Leading Edge

Detecting Sensor

From Image

Transfer Corona to detection by the

Fusing Unit

Location

Vertical Transport

Section

Near the Transport

Roller Sensor

Near the Paper

Leading Edge

Detecting Sensor

From the Suction

to Fusing Unit

Description

Take-up failureIPaper take-up start

Leading edge

detection by the

Transport Roller

Sensor Sensor

Leading edge

detection by the

Paper Leading

Edge Detecting

Sensor

Leading edge

Paper Exit Sensor

Description

Trailing edge

detection by the

Paper Take-Up

Sensor

Trailing edge

detection by the

Transport Roller

Sensor

Trailing edge

detection by the

Paper Leading

Edge Detecting

Sensor

Trailing edge

detection by the

Paper Exit Sensor

Timer Start

Leading edge

detection by the

Paper Take-Up

Leading edge

detection by the

Transport Roller

Sensor

TRON signal

Timer Start Sensor Timing

Leading edge

detection by the

Paper Take-Up

Sensor

TRON signal

Trailing edge

detection by the

Transport Roller

Sensor

Trailing edge

detection by the

Paper Leading

Edge Detecting

Sensor

Paper Take-Up

Sensor

(leading edge)

Transport Roller

Sensor

(leading edge)

Paper Leading

Edge Detecting

Sensor

(leading edge)

Paper Exit Sensor

(leading edge)

Paper Take-Up

Sensor

(trailing edge)

Transport Roller

Sensor

(trailing edge)

Paper Leading

Edge Detecting

Sensor

(trailing edge)

Paper Exit Sensor

(trailing edge)

Timing

T-9

Page 13

1158SBT030101A

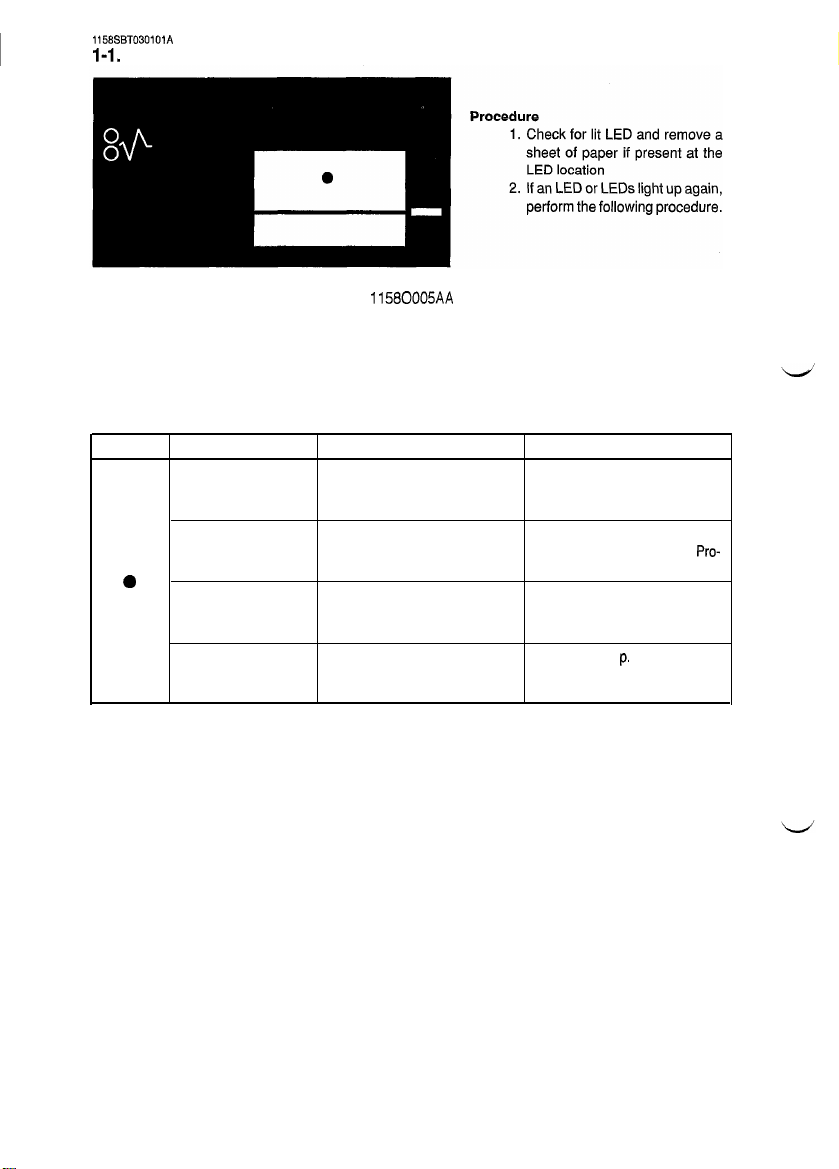

I-1. Misfeed Detected When Copier is Turned ON

11580005AA

Lit LED Paper Location Sensor

Drawer

Transport Roller

a

Synchronizing Roller Paper Leading Edge See step 2 on p. T-i 7

Exit Section Paper Exit Sensor PC53 See step 8 on p. T-20

Paper Take-Up Sensor PC55

Transport Roller Sensor PC51

Detecting Sensor PC54

Action

See step 10 on p. T-i 3 (Copier

Take-Up Misfeed Clearing Procedure).

See step 14 on p. T-l 3 (Copier

Take-Up Misfeed Clearing

cedure).

(Transport/Separator Misfeed

Clearing Procedure).

(Fusing/Exit Misfeed Clearing

Procedure).

Pro-

T-10

Page 14

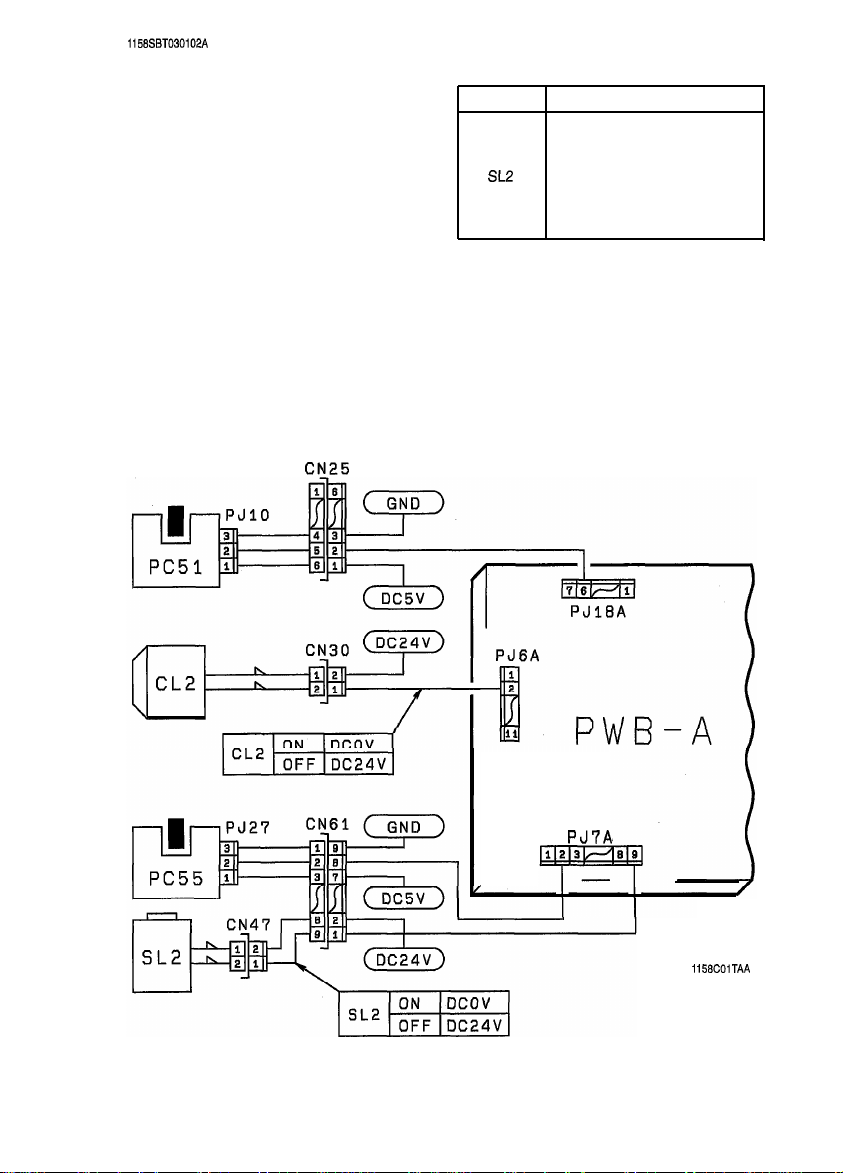

1158SBT030102A

1-2. Copier Take-Up Misfeed

CN_25

Symbol

PC51

PC55

SL2

CL2

PWB-A

Transport Roller Sensor

Name

Paper Take-Up

Sensor

Paper Take-Up

Solenoid

Paper Transport Clutch

Main Control Board

T-11

PJ7A

L

1158COlTAA

Page 15

+

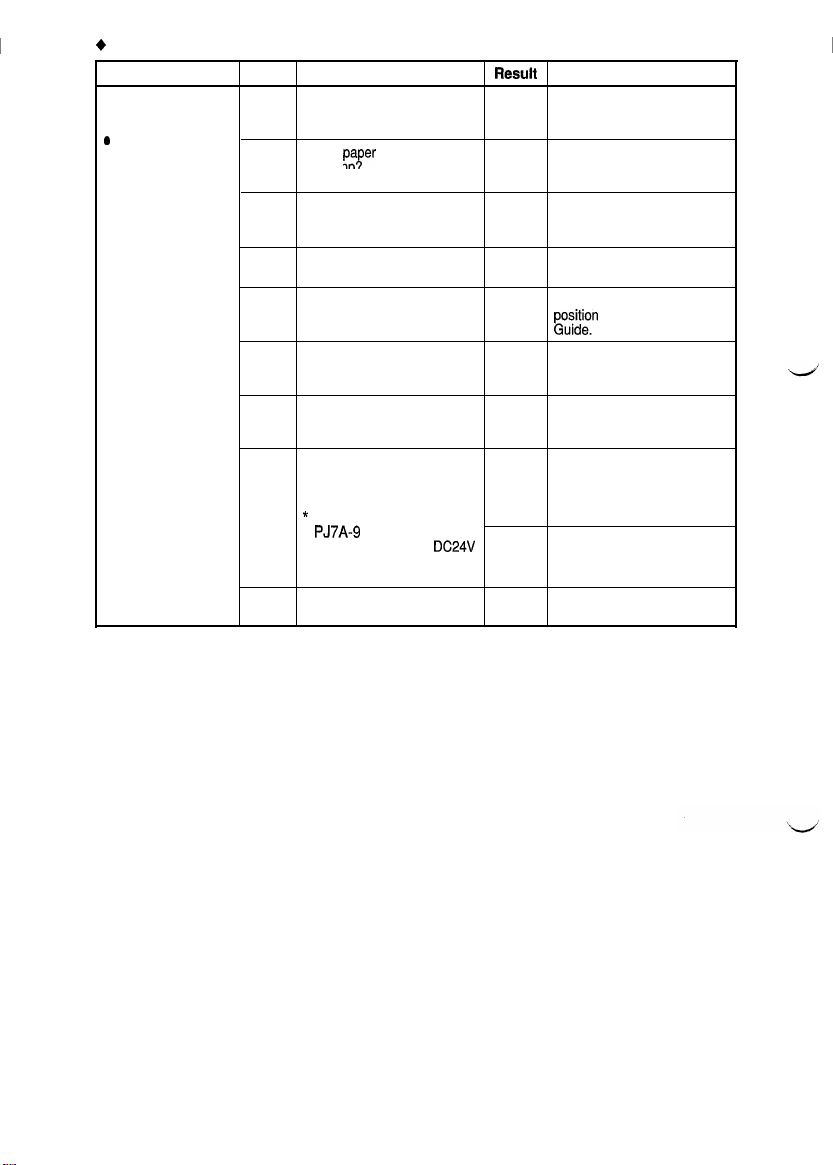

Copier Take-Up Misfeed Clearing Procedure

Symptom

l

Paper is not taken

up at all.

0

Paper is

stationary before

the Paper

Take-Up Sensor.

Continued on next page

Step Check Item

Is the paper being used up

1

to product specifications?

Is the pafer curled, waved,

or damp.

2

Are the Separator Fingers

3

on both sides of the Drawer

in position?

Are the Separator Fingers

4

deformed?

Is the Trailing Edge Stop or

5

Edge Guide in good

position?

Are the Paper Lifting

6

Springs positioned

correctly?

Are the Paper Take-Up

7

Rolls deformed, worn, or

dirty with paper dust?

Is a signal being output

from PWB-A to the Paper

Take-Up Solenoid?

8

*

Does the voltage across

PJ7A-9

on PWB-A and

GND change from

to DCOV when the Start

Key is pressed?

Is the Clutch Spring

9

deformed or worn?

DC24V

R@SUll:

Instruct the user to use the

NO

paper that is up to product

specifications.

Change the paper.

YES

Instruct the user in how to

store the paper.

Instruct the user to load the

NO

paper so that it rests under

the Fingers.

Replace the Fingers.

YES

Instruct the user in how to

NO

gu;)stn

the Edge Stop or

Change the position of the

NO

Spring or add one as

necessary.

Clean or replace the Paper

YES

Take-Up Rolls.

Adjust the Solenoid stroke.

Check the Solenoid.

YES

Replace PWB-A.

NO

Replace the Clutch Spring.

YES

Action

T-12

Page 16

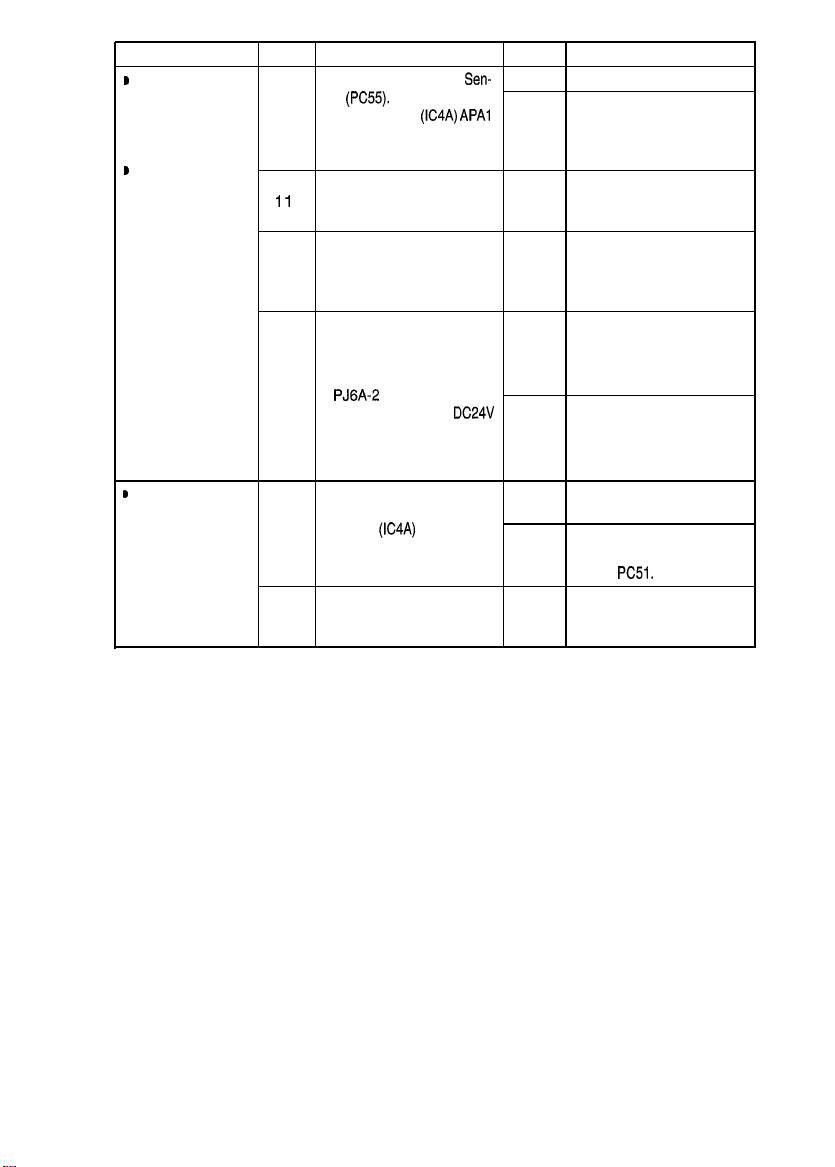

Symptom

D

Paper is

stationary before

the Vertical

Transport Roller.

D

Paper is

stationary at the

Vertical Transport

Roller.

step

10

1 1

12

13

Check Item Result Action

YES

Check Paper Take-Up

sor

(PC55).

PC55: PWB-A

Are the Vertical Transport Clean or replace the

Rollers deformed, worn, or

dirty with paper dust?

Are the Paper Take-Up Clean, correct, or replace

Guide Plate and Vertical

Transport Guide Plate dirty

or deformed?

Is a signal being output

from PWB-A to the Clutch?

* Does the voltage across

Seep.T-3.

PJ6A-2

on PWB-A and

GND change from

to DCOV when the Start

Key is pressed?

Sen-

(IC4A) APAl

DC24V

Replace PWB-A.

Check the Actuator for

operation.

NO

Check the Paper Take-Up

Sensor.

Vertical Transport Rollers.

YES

the Guide Plate.

YES

Check the Clutch.

YES

Replace PWB-A.

NO

D

Paper is

stationary near

the Transport

Roller.

Check Transport Roller Replace or check the

Sensor PC51 See p. T-3

(PWB-A

(IC4A)

14

Are the Transport Rollers

deformed, worn, or dirty

15

with paper dust?

APC7).

YES

PWB-A.

Check the Actuator for

operation.

NO

Check

Clean or replace the

Transport Rollers.

YES

PC51.

T-13

Page 17

I

1158SBT030103A

1-3. Bypass Port Misfeed

Symbol

PC51

Transport Roller Sensor

Name

T-14

1151COPTAA

Page 18

+

I

Bypass Port Misfeed Clearing Procedure

Symptom

D

Paper is not taken

up at all.

I Paper is

stationary near

the Transport

Roller.

step

1

2

3

4

5

6

7

a

9

10

11

Check Item Result

Does the misfeed occur Perform the troubleshooting

when the Manual Bypass

Table is used? Transport/Separator

Is paper taken up and fed in

properly from the Drawer? procedure for Copier

Is the paper being used up

to product specifications?

Is the paper curled, waved, Change the paper.

or damp?

Are the Paper Take-Up Adjust the stroke of the

Rolls pressed against the Solenoid.

paper stack when the Start

Key is pressed?

* Does the voltage across

PJli A-2

on PWB-A and

GND change from

to DCOV when the Start

Key is pressed?

Does the voltage across Check the Clutch.

PJ7A-5

on PWB-A and

GND change from

to DCOV when the Start

Key is pressed?

Is the Pressure Pad or

Guide Plate deformed or YES Pressure Pad or Guide

dirty?

Are the Paper Take-Up

Rolls deformed, worn, or

dirty with paper dust?

Check Transport Roller Check the Actuator for

Sensor PC51 Seep. T-3

(PWB-A

(IC4A)

Does the voltage across Check the Clutch.

PJ6A-6

on PWB-A and

GND change from

to DCOV when the Start

Key is pressed?

Is the Transport Roller or

Guide Plate of the copier

deformed, worn, or dirty

with paper dust?

DC24V

DC24V

APC7).

DC24V

Action

procedure for

YES

Misfeed.

Perform the troubleshooting

Take-Up and

NO

Transport/Separator

Misfeed.

Instruct the user to use the

paper that is up to product

NO

specifications.

YES

Instruct the user in how to

store the paper.

Check the Solenoid.

YES

Replace PWB-A.

NO

YES

Replace PWB-A.

NO

Clean or replace the

Plate.

Clean or replace the Paper

Take-Up Rolls.

YES

operation.

NO

Check

PC51.

YES

Replace PWB-A.

NO

Clean or replace the

Vertical Transport Roller or

YES

Guide Plate.

T-15

Page 19

1158SBT030104A

l-4.

Transport/Separator Misfeed

Symbol

PC51

PC54

SLl

CL1

M3

PWB-A

Transport Roller Sensor

Name

Paper Leading Edge Detecting

Sensor

Separator Solenoid

Synchronizing Roller Clutch

Suction Fan Motor

Main Control Board

PWB-

T-16

A

1151C24TAA

Page 20

+

I

Transport/Separator Misfeed Clearing Procedure

Symptom

l

Paper is

stationary before 1

the Synchronizing

Roller.

@

Paper is

stationary near

the PC Drum.

Step Check Item

Is the paper curled, waved, Change the paper.

or damp?

Check Paper Leading Edge

Detecting Sensor PC54

2

See p. T-3 (PWB-A

APCG).

Do the Synchronizing

Rollers turn?

* Does the voltage across

3

PJ6A-4

on PWB-A and

GND change from

to DCOV after the Start

Key has been pressed?

Is a given length of loop Adjust the loop length or

4

formed before the

Synchronizing Roller? Transport Rollers.

Is the Pre-Image Transfer Correct or clean the Guide

Guide Plate deformed or

5

dirty?

Is the Corona Unit Cleaning Place the Lever in position.

Lever (Lower) in correct

6

position?

Are the Image

Transfer/Paper Separator

7

Corona Wires deteriorated

or dirty?

Are the Paper Guides

8

deformed or dirty?

Are the Synchronizing Clean or replace the

Rollers deformed, worn, or

9

dirty with paper dust?

(IC4A)

DC24V

Result Action

YES instruct

YES Replace PWB-A.

NO

YES

NO

NO

YES

NO

YES

YES

YES

the user in how to

store the paper.

Check the Actuator for

operation.

Check PC54.

Check the Clutch.

Replace PWB-A.

clean or replace the

Plate.

Clean or replace the Wires.

Clean or replace the Paper

Guides.

Synchronizing Rollers.

T-17

Page 21

Symptom

D

Paper is wedged

at the Paper

Separator Fingers.

B

Paper is

stationary before 12

the Suction Belts.

Step

1 o

11

13

14

15

Check Item

Does the voltage across Adjust the Solenoid, or

PJI 4A-2

on PWB-A and

GND change from

to DCOV after the Start Key

has been pressed?

Are the Paper Separator

Fingers deformed or dirty?

Check Transport Roller Check the Actuator for

Sensor PC51 See p. T-3

(PWB-A

(IC4A)

Check Paper Leading Edge YES

Detecting Sensor PC54

See p. T-3

(PWB-A

Do the Suction Belts turn

properly?

Is Suction Fan Motor M4

turning when the Start Key Check M4.

is pressed?

* Does the voltage across

PJ6A-8

on PWB-A and

GND change from

to DCOV when the Start

Key is pressed?

DC24V

APC7).

(IC4A) APCG).

Result Action

YES

NO Replace PWB-A.

YES

NO

NO

YES

YES

DC24V

No

check the Paper Separator

Fingers for operation and

clearance.

Correct or clean, or replace,

the Paper Separator

Fingers.

operation.

Check

Replace PWB-A.

Check the Actuator for

operation.

Check PC54.

Check the Belts and Drive

Gear.

Check the

Replace PWB-A.

PC51.

DC24V

line.

T-18

Page 22

1158SBT030105A

l-5. Fusing/Exit Misfeed

T-19

1158C02TAA

Page 23

6

F~rsindFxit

_ . __...

J, -

hllinfnnri

,... . . .._.___

Symptom

l

Paper is

stationary before 1

the Fusing Roller.

*The leading edge

of the paper is

stationary near

the Fusing Roller.

l

Paper is

stationary after

the

Paper

Exit

Roller/Rolls.

Clnnrinn Procedure

-.--a

.__---._

.

Step

Is the paper curled, waved,

or damp?

Is the Guide Plate dirty with

2

toner?

Do the Suction Belts turn

3

properly?

Is Suction Fan Motor M4

turning when the Start Key

is pressed?

4

* Does the voltage across

PJ6A-8

GND change from

to DCOV when the Start

Key is pressed?

Are the Fusing Rollers

scratched or dirty? Or, has

5

the replacement time

arrived for the Rollers?

Are the Paper Separator

Fingers dirty with toner or

6

worn? Are their edges

damaged?

Is the Oil Roller dirty? Or,

has the replacement time

7

arrived for the Roller?

Check Paper Exit Sensor

(PC53) See p. T-3.

8

PC53:

Check Paper Leading Edge

Detecting Sensor PC54

9

See p, T-3 (PWB-A

APCG).

Check

Item

on PWB-A and

DC24V

PWBA (IC4A)

Al%5

(IC4A)

Result Action

Change the paper.

Instruct the user in how to

YES

store the paper.

Clean the Guide Plate.

Check for possible

YES

scattering of toner.

Check the Belts and Drive

YES

Gear.

Check the

DC24V

Check M4.

YES

Replace PWB-A.

No

Clean or replace the Rollers.

YES

Clean or replace the

Fingers.

YES

Clean or replace the Roller.

YES

Check the Actuator for

operation.

NO

Check PC53 or both.

Replace PWB-A.

YES

Check the Actuator for

NO

operation.

Check PC54.

line.

T-20

Page 24

1151SBT0302A

2. Wrinkles in Paper

!

step Cause

Paper

1

Paper Take-Up

Section

2

Transport Section

3

4

Pre-Fusing

Guide Plate toner or other foreign matter? YES

Check Item Result

Is the problem solved when

new paper is used?

Is

the paper taken up and Check the Drawer and Paper

fed in properly?

Are any of the Belts left slack

or the Suction Deck dirty?

Is the Guide Plate dirty with

Change the paper (that is up

to product specifications).

YES

Instruct the user in how to

store the paper.

Take-Up Rolls and adjust,

NO

clean, and/or replace the parts

as necessary. (See Skewed

Feed that appears later.)

Replace the three Belts at

YES once or clean the Suction

Deck.

Clean the Guide Plate.

Action

5

6 s

-LL

7

8

1158SBT0303A

Thermistor Is the Thermistor damaged

C

?

._

2

Fusing Rollers Has the Roller replacement

Width of area Does the location of wrinkles Replace the two Pressure

of contact

between the

Upper and

Lower Fusing

Rollers

or dirty with toner?

Is the Thermistor in positive

contact with the Upper

Fusing Roller?

time arrived?

change when the position of Springs at once.

the left and right Pressure

Springs are changed?

Clean or replace the

YES

Thermistor.

Move the Thermistor Mounting

Bracket up or down as

necessary so that the

NO

Thermistor comes in positive

contact with the Upper Fusing

Roller.

Replace the Rollers.

YES

YES

3. Double Feed

Step Cause

Paper Is the problem solved when Change the paper (that is up

1

g

Paper

g

Take-Up Roll

2 w

3

d,

3

Paper

z Separator Roll dirty?

3

B

a

Check Item

new paper is used?

Is the Paper Take-Up Roll Clean or replace the Paper

dirty, or has its replacement

time arrived?

Is the Paper Separator Roll

Result

to product specifications).

YES

Instruct the user in how to

store the paper.

Take-Up Roll.

YES

Clean or replace the Paper

Separator Roll.

YES

Action

T-21

Page 25

I

1158SBT0304A

4. Skewed Feed

Step Cause

Paper

1

5

Paper

.g

Take-Up Roll

2

G

9

s

$

3

Paper

3

a

Separator Roll dirty?

Paper Dust Is the Paper Dust Remover Clean the Paper Dust

4

5

-lz

6

7

8

Remover

Transport Are the Transport Rollers

g

Rollers

9

8

UI

g

Synchronizing

2

Rollers

$

Suction Unit Are any of the Belts left slack Replace the three Belts at

Pre-Fusing Guide

Plate toner or other foreign matter?

Check Item Result

Is the problem solved when

new paper is used?

Is the Paper Take-Up Roll Clean or replace the Paper

dirty, or has its replacement

time arrived?

Are the Paper Take-Up Rolls

located correctly? (For the

Copiers 1 st Drawer)

Is the Paper Separator Roll

dirty with paper dust?

dirty or worn? Or Has their

replacement time arrived?

Are the Synchronizing

Rollers dirty or worn? Or Has Adjust Mode.

their replacement time

arrived? Synchronizing Rollers.

or the Suction Deck dirty? YES once or clean the Suction

Is the Guide Plate dirty with

Change the paper (that is up

to product specifications).

YES

Instruct the user in how to

store the paper.

YES

Take-Up Roll.

Change the locations of the

YESFRolls according to the paper

size being used

Clean or replace the Paper

YES

Separator Roll.

YES

Remover and Upper

Synchronizing Roller.

Adjust the loop length in the

Adjust Mode.

YES

Clean or replace the Transport

Rollers.

Adjust the loop length in the

YES

Clean or replace the

Deck.

Clean the Guide Plate.

YES

Action

T-22

Page 26

1151SBT0400A

MALFUNCTIONS

1158SBT0401A

1. Self-Diagnostic Function

The copier CPU is capable of self-diagnosis of the copier conditions and, when detecting a malfunction, it

shows the corresponding malfunction code across the Zoom Ratio Indicator and Multi-Copy Display. Each

malfunction code indicates the particular part which has developed a malfunction and the type of

malfunction.8 listing follows showing all malfunction codes and the description and possible causes of each

malfunction.

Zoom Ratio Indicator

I

Multi-Copy Display

n

coxxx

Represents the detail of malfunction.

Indicates the particular malfunctioning unit of

TT’

*

Copier/Paper Feed Cabinet (Option)

Description

Main Drive Motors failurel Defective M2

to turn

Main Drive Motor turningl Defective M2

at abnormal timing

PC Drive Motors failure to

turn

PC Drive Motor turning at

abnormal timing

Cooling Fan Motors

failure to turn

Toner Replenishing

Motors failure to turn

Toner Replenishing Motor

turning at abnormal timingl Defective M8

,g

B

Code

coooo

coo01

coo1 0

coo11

coo4c

coo70

co711

the greater physical unit.

Indicates the malfunctioning physical unit.

Possible Cause

l

Defective PWB-A

l

Overloaded rolls/roller,

l

Defective PWB-A

l

Defective

l

l

l

l

l

l

l

l

l

l

l

Ml

Defective PWB-A

Overloaded gear

Defective

Ml

Defective PWB-A

Defective

M9

Defective PWB-A

Defective Toner Hopper Position Sensor PC1 12

Defective M8

Defective PWB-A

Defective Toner Hopper Position Sensor PC1 12

Defective PWB-A

aear,

and belt

T-23

Page 27

Lens

Motor malfunction

l

Defective Lens Motor M6

l

Defective Lens

Reference Position Sensor PC90

Position Sensor

T-24

Page 28

Page 29

1151SBT040101A

I-l. COOOO: Main Drive Motors failure to turn

COOOI:

Main Drive Motor turning at abnormal timing

1

Symbol

M2

I

PWB-A

1

Main Drive Motor

Main Control Board

Nat& 1

I

PJ12A

1151C18TAA

T-25

Page 30

Step

Is COO01 being shown? YES

1

Does M2 start to turn when the Start

2

Key is pressed?

Does the voltage across

PWB-A and GND change from

3

to DCOV when the Start Key is

pressed?

Does the voltage across

4

PWB-A and GND remain

the Start Key is pressed?

Does the voltage across

PWB-A and GND remain DCOV when

5

the Power Switch is turned ON?

Does the voltage across

6

PWB-A and GND remain DCOV when

the Power Switch is turned ON?

Check Item

PJ12A-10

PJ12A-9

DC5V

PJl2A-10

PJl2A-9

on

DC5V

on

when

on

on

Result Action

Begin with step 5.

Check rolls/rollers and gears for

YES

possible overload.

Replace PWB-A.

NO

Replace M2.

YES

Replace PWB-A.

NO

Replace PWB-A.

YES

Replace M2.

YES

Replace PWB-A.

NO

T-26

Page 31

1151SBT040102A

1-2.

COOIO:

PC Drive Motors failure to turn

COO11 : PC Drive Motor turning at abnormal timing

8m!4

Rotat

M1 fhtu#

Lock

ON

M1 OFF

I on

DClJv

DC5V

DCOV \

DC24V

+h

GND )

I

PWB-A

1151C17TAA

T-27

Page 32

Step

1

Is COO11 being shown?

Does Ml start to turn when the Start

2

Key is pressed?

Does the voltage across

PWB-A and GND change from

3

to DCOV when the Start Key is

pressed?

Does the voltage across

4

PWB-A and GND remain

the Start Key is pressed?

Does the voltage across

PWB-A and GND remain DCOV when YES

5

the Power Switch is turned ON?

Does the voltage across

6

PWB-A and GND remain DCOV when

the Power Switch is turned ON?

Check Item

PJ12A-8

PJI 2A-7

DC5V

PJI 2A-8

PJ12A-7

on

DC24V

on

when

on

on

Result

YES

YES

NO

YES

NO

YES

NO

Action

Begin with step 5.

Check gears for possible overload.

Replace PWB-A.

Replace Ml.

Replace PWB-A.

Replace PWB-A.

Replace M

Replace PWB-A.

1.

T-28

Page 33

1151SBT040103A

1-3.

COO4C:

Cooling Fan Motors failure to turn

f@B@il4

Ful

I-Speed DC24V

Rotation

M9

+~El$L?E~

Half-Speed DC12V

Rotation

Symbol

M9 Cooling Fan Motor

PWB-A

Main Control Board

Name

Y

M9

1151C16TAA

T-29

Page 34

coo4c

Step

1

2

3

Check Item Result Action

Is MS turning at low speed when the

Power Switch is in the ON position?

Does the voltage across

PWB-A and GND change from DC1 2V

to

DC24V

when the Start Key is

pressed?

Is the voltage across

A and GND DC1 2V when the Power

Switch is in the ON position?

PJ6A-9

PJ6A-9

on

on

PWB-

NO

YES

NO

YES

NO

Begin with step 3.

Replace

M9.

Replace PWB-A.

Replace

M9.

Replace PWB-A.

T-30

Page 35

1151SST040104A

1-4.

COO70:

Toner Replenishing Motors failure to turn

COO71 : Toner Replenishing Motor turning at abnormal timing

I

PJGA

Symbol

PC112

M8

PWB-A

Toner Hopper Home Position

Name

Sensor

Toner Replenishing Motor

Main Control Board

PJ22A

T-31

1151C09TAA

Page 36

Step

1

Is COO71 being shown?

Does the Toner Bottle turn when two

2

or three

Original Cover raised?

Make two or three copies with the

Original Cover raised. Does the

voltage across

and GND change to DCOV when the

3

Toner Bottle is stopped and to

when the Bottle is turned during the

copy cycle?

Make two or three copies with the

Original Cover raised. Does the

voltage across

and GND change to DCOV when the

4

Toner Bottle is stopped and to

when the Bottle is turned during the

copy cycle?

Check Item Result Action

copies are made with the

PJ22A-10

PJ6A-5

on PWB-A

on PWB-A

DC5V

DC24V

YES

Begin with step 3

Perform step 3.

YES

Perform step 4.

NO

Replace PWB-A.

YES

Check the Bottle Holder or PC1 12.

NO

Replace M8.

YES

Replace PWB-A.

NO

T-32

Page 37

1151SBT040105A

l-5.

CO400:

CO410:

Exposure Lamps failure to turn ON

Exposure Lamp turning ON at abnormal timing

Symbol

LA1

TF2

PWB-A

PWB-H

PUl

Exposure Lamp

Exposure Lamp Thermal Fuse

Main Control Board

AE Sensor Board

Power Supply Unit

Name

or

T-33

1151C03TAA

Page 38

co400

Step

1

2

3

4

co41 0

Step

A

B

I

Does LA1 light up when the Start Key

is pressed?

Does the voltage across

PWB-A and GND become

less when LA1 turns ON?

Disconnect CN7

continuity across

LA1 side?

Is the voltage across

PUl

AC1 OOV?

I

Does LA1 turn ON when the Power Check to see if the photo receiver of

Switch is turned ON or in the standby

state?

Does the voltage across

PWB-A and GND remain

lower when the Power Switch is turned

ON or in the standby state?

Check Item

(2P).

Is there

CN7-1

and 2 on the

PJ2-1

Check Item

PJ12A-11

DC4.3V

and 2 on

PJ12A-11

DC4.3V

or

on

or

on

I

Result

I

Check the photo receiver of the AE

YES

Sensor for contamination.

I

I

I

Result

!

Replace PWB-H or PWB-A.

I

Replace PWB-A.

Check LA1 and TF2 for continuity.

NO

I

YES Replace

Check DC Power Supply Unit PU2 and

NO

Power Supply Board PWB-C.

I

the AE Sensor is receiving extraneous

NO

light.

Replace PWB-H or PWB-A.

!

PUl

Action

.

Action

T-34

Page 39

1151

SBT040106A

1-6.

CO500:

co51 0:

co520:

Warming-up failure

Abnormally low fusing temperature

Abnormally high fusing temperature

T-35

1151C14TAA

Page 40

co500,

co51 0

* After resetting a CO51 0 condition, CO500 will be shown if the same problem recurs. For this reason, the

same troubleshooting procedure is used for CO500 and CO51 0.

Step

Does HI light up when the Power

1

Switch is turned ON?

I

1

Disconnect CN14 (4P). Is the

2

resistance across

THl

side infinity?

Does the voltage across

PWB-A and GND change from

to DCOV when the Front Door is closed

3

with the Power Switch in the ON

position?

-1

Disconnect CN5 (2P). Is there

4

continuity across

Fusing Unit side?

CO520

Step

Does Hl remain lit up even after the YESABegin with step B.

copier has completed warming up?

Does the voltage across

PWB-A and GND remain DCOV even

B

after the copier has completed

warming up?

1

Disconnect CN14 (4P). Is the circuit1

I

C

across CNl4-2 and 3 on the Fusing

Unit side short-circuited?

Check Item

CNl4-2

CN5-1

Check Item Result Action

and 3 on the

PJ3A-2

on

DC4.5V

and 2 on the

PJ3A-2

on

Result

YES

Check

THl

for installation or clean it.

NO

I

Begin with step 3.

I -

Replace

YES

NO

1

Replace

Replace PWB-A.

THl

PWB-A.

NO

Check Hl and

NO

Begin with step C.

NO

Replace PWB-A.

YES

Replace

UNl.

THl.

Replace PWB-A.

YES

NO

NO

1

Replace

Action

.

TFl

for continuity.

I

I

T-36

Page 41

1151SBT040107A

I-7.

CO600:

CO61 0:

CO620:

Scanner Motor malfunction

Lens Motor malfunction

Mirror Motor malfunction

JIE

Symbol

M5

M6

M7

PC81

PC86

PC90

PWB-A

PWB-E

I

Scanner Motor

Lens Motor

Mirror Motor

Scanner Reference Position

Sensor

Mirror Reference Position

Sensor

Lens Reference Position Sensor

Main Control Board

Motor Drive Board

1

Name

T-37

PJ22A

PWB-A

1151C13TAA

Page 42

I

CO600

step

1

2

3

CO61 0

Step

A

B

C

D

Check Item Result Action

Does the Scanner start moving after

the Power Switch has been turned ON?

Does the voltage across

PWB-A and GND change from

to DCOV after the Power Switch has

been turned ON?

Check Scanner Reference Position

Sensor

PC81.

See p, T-3 (PWB-A

1

Does M6 start turning after the Power

Switch has been turned ON?

Does the voltage across

PWB-A and GND change from

to DCOV after the Power Switch has

been turned ON?

Is the voltage across

PWB-E and GND

Power Switch has been turned ON?

Check Lens Reference Position

See p. T-3 (PWB-A

Check Item Result

PJ16A-3

(IC4A)

APBO)

PJ16A-1

PJ3E-5

DC24V

on

after the

(IC4A)

APBl) YES

on

DC5V

on

DC5V

PC90.

YES

YES

NO

YES

NO

YES

I

NO

YES

NO

NO

Perform step 3.

Replace PWB-E or M5.

Replace PWB-A.

Check the Scanner Drive Cable for

tension and overload. Or, replace

PWB-A.

Check

PC81,

Action

Perform step D.

I

Replace PWB-A.

Replace PWB-E or M6.

Check the 24V line.

Check the Lens Drive Cable for

tension and overload. Or, replace

PWB-A.

Check

PC90.

step

Does M7 start turning? YES Perform step III.

I

Does the voltage across

PWB-A and GND change from

II

to DCOV when the Mirror moves?

Check Item Result

PJ16A-2

on

DC5V

Reference Position PC86.

(PWB-A

(IC4A)

APB2)

YES

NO

YES

NO

T-38

Action

Replace PWB-E or M7.

Replace PWB-A.

Check for overload. Or, replace

PWB-A.

Check PC86.

Page 43

1158SBT040084A

1-8.

COFI

COF30:

Faulty

AE

0:

ATDC Sensor malfunction

Sensor level

CN39

UN3

1151ClOTAA

T-39

Page 44

I

COFlO

Step

1

COF30

Step

A

B

and

and

Check Item

PJl2A-3

DC4V

when the Start Key is

Check Item

PJl

A-3 on

DC4.5V

after the Start

on

~_

Is the voltage across

PWB-A and GND in the range between

DC2V

pressed in the F3 operation?

Is the voltage across

PWB-A and GND DCOV after the

Power Switch has been turned ON?

Is the voltage across PJl A-3 on

PWB-A and GND in the range between

DC0.5V

Key has been pressed?

Result

1 ~~

/

~~~~

/

Result Action

YES

YES

NO

PWB-A.

Check the photo receiver of the AE

Sensor for contamination or replace

Check the ATDC Sensor and the

connection between the Imaging Unit

and copier.

Replace PWB-A.

Replace the ATDC Sensor.

Action

I

T-40

Page 45

1158Si3T040109A

1-9. COF02: Original size detection error (Defective CPU)

COFEP

to COFFF: Original Size Detecting Sensor failure

Original Size Detecting Sensor

FD2

Original Size Detecting Sensor

CD1

Original Size Detecting Sensor

FD3

Original Size Detecting Sensor

CD2

Original Size Detecting Board

Master Board

Name

I--l

PJ43

1

PJ5

8

PJ

1151C09TAA

T-41

Page 46

Check

Step

Is any code from among COFE2 to

COFFF being shown?

Are jumper straps installed in the

following position for Jl and J2 of

2

Jl

:

On the end not marked with 0

J2: On the end not marked with 0

Does the LED of

3

(IC5A)

PA3 blink after the Power

Switch has been turned ON?

Is the Sensor located at the correct

4

position?

Does the problem persist even after

the corresponding Sensor has been YES

5

replaced?

Item

I/O

port check PWB-A

UN2?

Result

Perform step 4.

YES

Change the strap position of Jl and

NO

Replace PWB-A.

YES

Replace UN2.

NO

Change the position of the Sensor.

NO

Replace UN2 or PWB-A.

Action

J2.

T-42

Page 47

1158SBT0402A

2. Power is not Turned ON

PIUS

c

JlThidkT

1 PJl

-

PJ2

Symbol

PWB-A

PWB-C

PU2

Sl

521

RYl

Master Board

Name

Power Supply Board

DC Power Supply Unit

Power Switch

Front Door Interlock Switch

Main Relay

PU2

J-

P

T-43

115 1

C08TAA

Page 48

Symptom

ower is not

;upplied

to the

:opier

at all.

3nly

the control

)anel

Indicators

ight up.

qY1

is not

energized.

* If the problem persists even after the above procedures, the harness is probably short-circuited.

Check the harnesses.

step

1

2

3

4

5

6

7

6

Check Item Result Action

Is the source voltage being Check Fuse or line voltage.

supplied to the circuit

across

PJl-1

PU2?

Is the voltage across

of PU2 and GND, and

across

GND,

Is the voltage across Check Sl and S21.

PJl

GND, and across

on PWB-C and GND,

DC24V?

Is

LDl

Is the voltage across

PJl

GND

Is the voltage across

PJl A-14

GND, and across

on PWB-A and GND, near

DCOV?

Is the voltage across

PJl

GND

Power Switch has been

turned ON?

Is the voltage across

PJl

GND DCOV after the Power

Switch has been turned

ON?

and 3 of

PJ3-1

PJ3-3

on PU2 and

DC24V?

C-3 on PWB-C and

on PWB-A lit up?

C-3 on PWB-C and

DC24V?

on PWB-A and

C-2 on PWB-C and

DC24V

C-l on PWB-C and

PJl

PJlA-15

after the

C-5

NO

Check Fuse of PU2 or

place PU2.

NO

NO

Check Fuse of PWB-C or

NO

replace PWB-C.

Check S21.

NO

Replace PWB-A.

NO

Replace PWB-C.

NO

Check

RYl.

NO

re-

T-44

Page 49

1151

SBT0403A

3. El, E2

rSvmbol

UN3

F4

PWB-A

I

1 Sl:

ON 1 DCO.

1

ATDC Sensor

I/U

Fuse

Master Board

I

Name

5V*4.

5V

1

T-45

1151C07TAA

Page 50

Code Step

1

El

2

E2

A

Check Item Result Action

Is

the seal peeled off the opening

or starter been fully charged?

Is the voltage across

PWB-A and GND in the range

between

DC0.5V

ter the Start Key has been turned

ON?

Is the voltage across

PWB-A and GND OV (is F4

blown)?

and

PJl

A-3 on

DC4.5V

PJl

A-6 on

af-

Peel off the seal and turn the

NO

Power Switch OFF, then ON.

Replace PWB-A.

YES

Replace the ATDC Sensor.

NO

Replace PWB-A.

YES

Replace F4 or PWB-A.

NO

T-46

Page 51

MINOLTA

Copyright

1996 MINOLTA CO., LTD

Printed in Japan

Use of this manual should

be strictly supervised to

avoid disclosure of

confidential information.

MINOLTA CO,, LTD.

1158-7998-l 2 97110150

Printed in Japan

Loading...

Loading...