Page 1

I

1159SBTOOOAA

EPlO3O/EP1030F

EP1031/EP1031F

'w

~ TROUBLESHOOTING

MINOllLA

Page 2

1159SBTOOOBA

CONTENTS

1

1 1 INTRODUCTION

l-1.

General Precautions

I-2.HowtoUseThisBook

1-3. Reading the Text

1

2 1 PAPER TRANSPORT FAILURE

1

........................................

......................................T- 1

...........................................

T-

1

T-

1

1

2-l. Misfeed Detection Types and Detection Timings

2-2. Misfeed Clearing Procedures

1) Copier Paper Take-Up Misfeed

2) TransportMisfeed

-

3) Multi Bypass Misfeed

4)

Exit Misfeed

5) SDH Misfeed

1

3 1 MALFUNCTIONS

3-l. Detection Timings Classified by Malfunction Codes

3-2. Troubleshooting Procedures

1) COO: Main Drive Motors Failure to Turn

2) C04: Ozone Fan Motors Failure to Turn

3)

C40:

Exposure Lamp Malfunction

4)

C50:

Warming-up Failure

051: Abnormally Low Fusing Temperature

C52: Abnormally High Fusing Temperature

5)

C60:

Scanner Drive Malfunction

C61:

Lens Drive Malfunction (EPI

6)

CFI:

AE Sensor Malfunction

7) CF3: ATDC Sensor Malfunction

8)

EO: EEPROM Malfunction

9)

El: IU Toner Detection Failure

E2: Blown IU Fuse Detection Failure

3-3. Power Malfunctions

........................................

.............................................

(EP1031/EP1031

1

.........................................

................................

.............................

(EP1031/EP1031

F)

F)

..........................

.................................

..........................

..................................

............................

031/EP1031

...............................

............................

.................................

.............................

........................

................

...................

.............

..............

.....................

...................

..................

.............

F)

.-c

....

T- 2

T- 4

T- 4

T- 6

T-

8

T-10

T-12

T-14

T-l 6

T-l 6

T-17

T-18

T-19

T-20

T-20

T-21

T-22

T-23

T-24

T-25

T-26

T-26

T-27

Page 3

~

5 IMAGE FAILURE

5-I. Image Failure Troubleshooting

5-2. Initial Checks

5-3. Troubleshooting Procedures Classified by Image Failure

..............................................

...............................

.........

T-28

T-28

T-29

Page 4

1139SSTOlOOA

INTRODUCTION

1159SBTOlOlA

l-l. General Precautions

1,

When servicing the copier with its covers removed, use utmost care to prevent your hands, clothing, and

tools from being caught in revolving parts including the chains and gears.

2. Before attempting to replace parts and unplug connectors, make sure that the power cord of the copier

has been unplugged from the wall outlet.

3. Never create a closed circuit across connector pins except those specified in the text and on the printed

circuit.

4. When creating a closed circuit and measuring a voltage across connector pins specified in the text, be

sure to use the green wire (GND).

5. When the user is using a word processor or personal computer from a wall outlet of the same line, take

necessary steps to prevent the circuit breaker from opening due to overloads.

6. Keep all disassembled parts in good order and keep tools under control so that none will be lost or damaged.

7. Adjust, choice, count, and other types of data are stored in TC3 (EEPROM) on Master Board PWB-A.

Keep this in mind and take necessary precautions when replacing PWB-A.

1139SBT0102A

I-2.

How to Use This Book

1,

If a component on a PWB or any

you to replace the whole

within the defective unit.

2. All troubleshooting procedures contained herein assume that there are no breaks in the harnesses and

cords and all connectors are plugged into the right positions.

3. For the removal procedures of covers and parts, see

4. The troubleshooting procedures are given in the order of greater frequency of trouble or order of operation

5. The procedures preclude possible malfunctions due to noise and other external causes.

1139SBT0103A

1-3. Reading the Text

1.

The paper transport failure troubleshooting procedures are given according to the symptom. First identify

the location where the paper is present and

troubleshooting, start with step 1 and onward.

2. Make checks in numerical order of steps and, if an item is checked okay, go to the next step.

other

PWBorfunctional

functional unit including a motor is defective, the text only instructs

unit and does not give troubleshooting procedures applicable

DIS/REASSEMBLY,

startthe

procedure for that particular location. For malfunction

ADJUSTMENT.

Pattern 1

Step 1 Check ItemIResult 1 Action

1 I Is...?

2

Go

to step 2 if you answered NO.

YES IDo this.

I

I

1 I

1

I

I

T-l

Pattern 2

Step1

Check

Item

I

Result

I

Aa

Page 5

1159SST0200A

PAPER TRANSPORT FAILURE

1159SBT0201A

2-1. Misfeed Detection Types and Detection Timings

When a misfeed occurs, the corresponding misfeed code (the appropriate one of those shown below)

starts blinking to let the user know where the misfeed has occurred.

Misfeed Code

PC

J2

J3

J8

Type

Paper take-up misfeedl Paper Transport Sensor PC2 is not blocked

or Paper empty after the lapse of approx. 3.3 sec. after Paper

Take-Up Solenoid SL2 has been energized.

l

Paper Transport Sensor PC2 is not blocked (L) even

after the lapse of approx. 1.6 sec. after Multi Bypass

Paper Take-Up Solenoid SL3 has been energized.

Transport misfeed

l

Paper Exit Sensor PC3 is not blocked (L) even after

the lapse of approx. 2 sec. after Registration Clutch

CL1

has been energized.

l

PC2 is not unblocked (H) even after the lapse of

approx. 2.9 sec. (Cassette) or 3.2 sec. (Manual bypass) after Registration Clutch CL1 has been energized.

Exit misfeed

l

Paper does not move past Paper Exit Sensor PC3

even after the lapse of approx. 3 sec. after PC2 has

been unblocked (H).

l

PC3 remains blocked for approx. 2 sec. after CL1 has

been energized.

SDH misfeed

l

SDH Paper Transport Sensor PC23 is not blocked (L)

even after the lapse of approx. 2.3 sec. after SDH

Paper Take-Up Solenoid

l

SDH Original Exit Sensor PC24 is not blocked (L)

even after the lapse of approx. 1.3 sec. after SDH

Registration Clutch CL10 has been energized.

e

PC23 is not unblocked (H) even after the lapse of

approx. 4.4 sec. after

l

PC24 is not unblocked (H) even after the lapse of

approx. 1.7 sec. after PC23 has been unblocked (H).

Detection Timing

SLlO

has been energized.

CL1

0 has been energized.

(I_)

even

T-2

Page 6

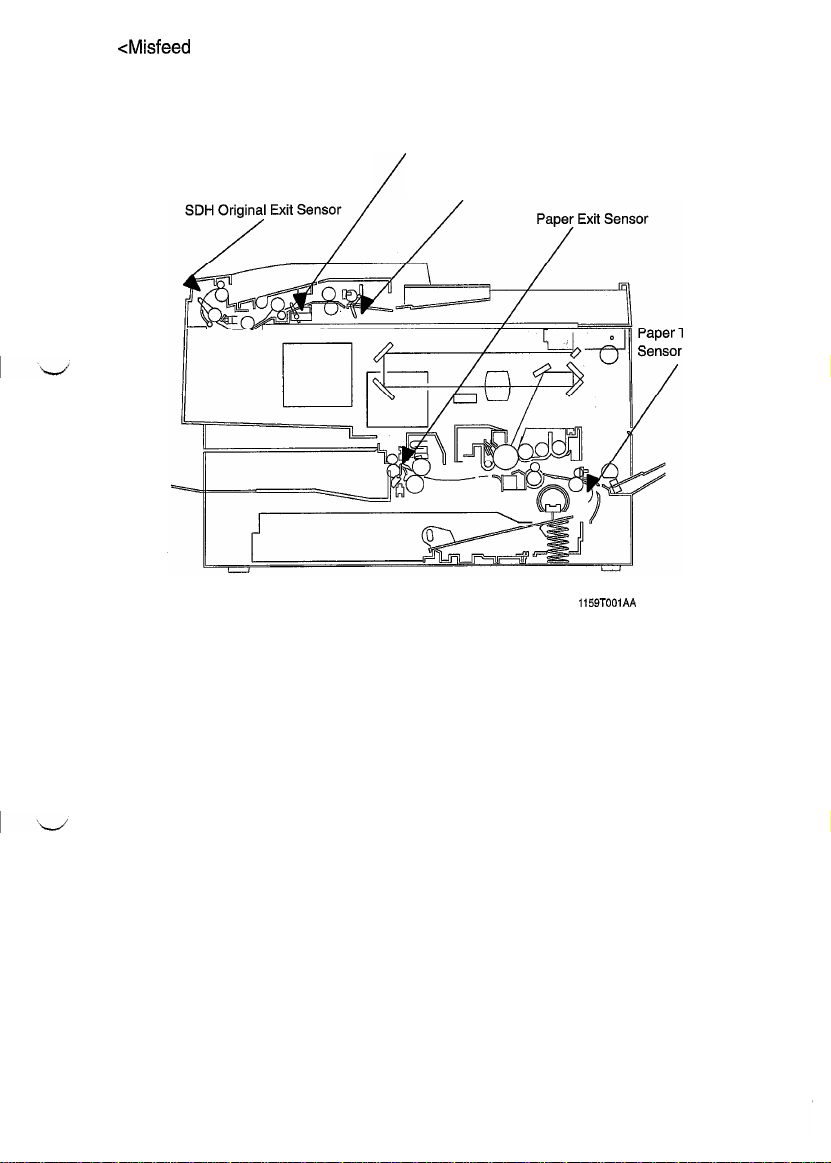

CMisfeed

Detecting Sensor Layout>

SDH Paper Transport Sensor

/

SDH Original Set Sensor

ransport

1159TOOlAA

T-3

Page 7

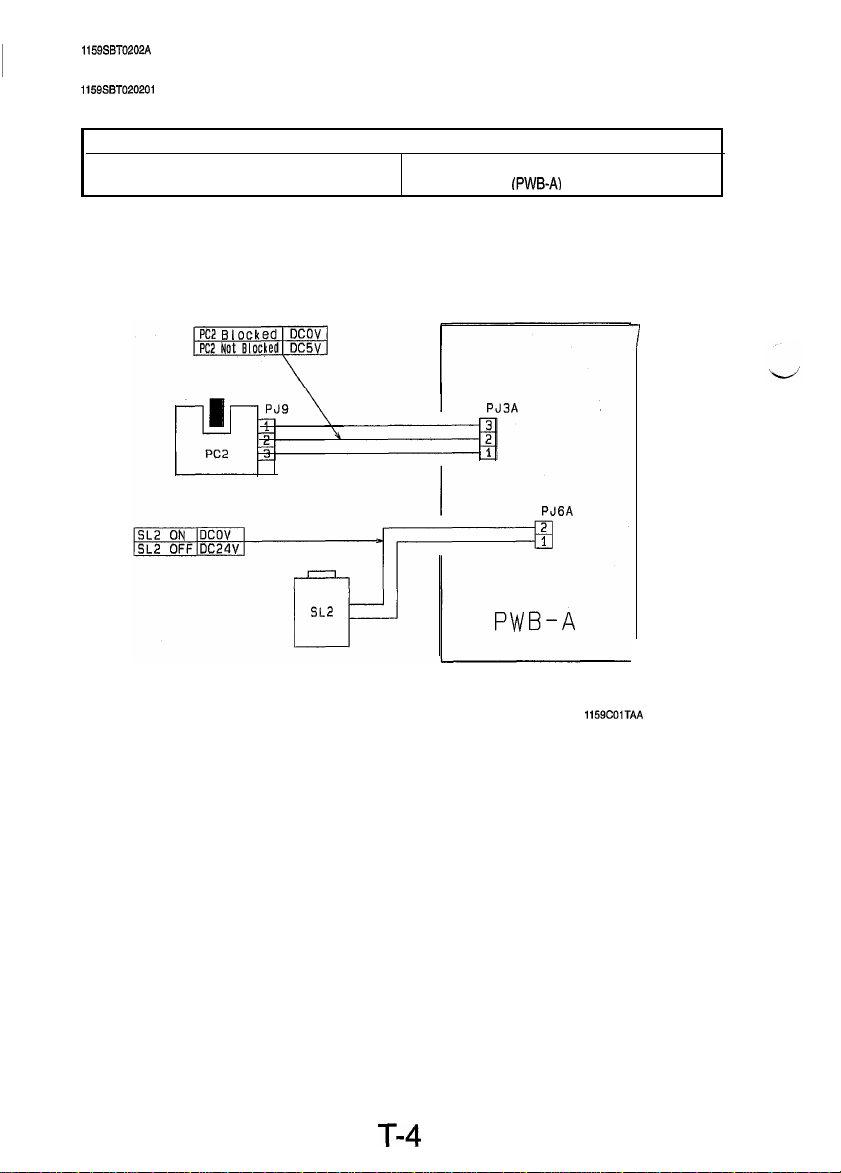

1159SBT0202A

2-2. Misfeed Clearing Procedures

1159SBTO20201

A

1) Copier Paper Take-Up Misfeed

Relevant Electrical Parts

l

Paper Transport Sensor (PC2)

l

Paper Take-Up Solenoid (SL2)

l

Master Board

(PWB-A)

7

T-4

1159COiTAA

Page 8

I

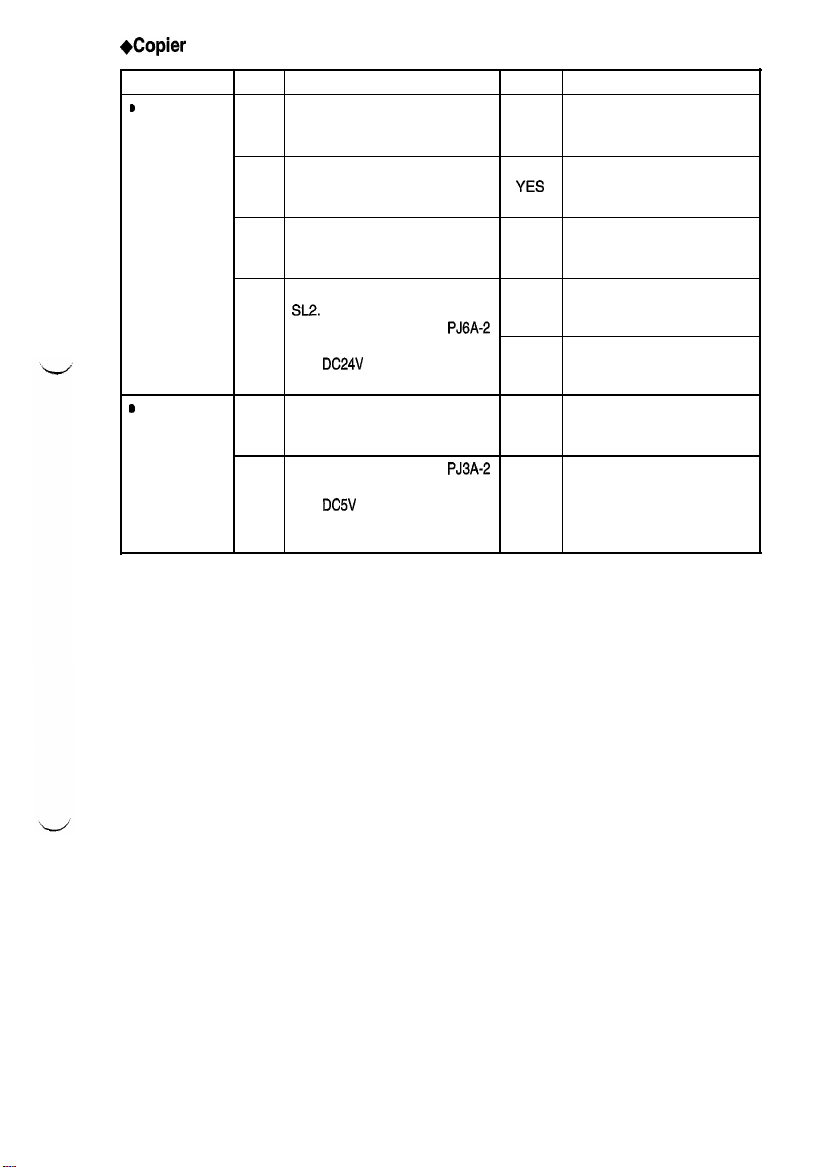

+Copier

Paper Take-Up Misfeed Clearing Procedure

Symptom

b

Paper is not

taken up at all.

s

Paper is

stationary at 1

the Transport

Rollers.

Step

Does the paper being used

meet product specifications?

1

Is the paper curled, waved, or Change the paper. Instruct

2

damp?

Is the Paper Take-Up Roll

deformed, worn, or dirty with

3

paper dust?

Check Paper Take-Up Solenoid

SL2.

Does the voltage across

4

on PWB-A and GND change

from

Start key is pressed?

Are the Transport Rollers

deformed, worn, or ditty with YES

paper dust?

Does the voltage across

on PWB-A and GND change operation and, if it checks

from

2

Paper Transport Sensor PC2 is

blocked?

Check item

DC24V

to DCOV when the

DC5V

to DCOV when

PJ6A-2

PJ3A-2

Result

instruct the user to use the

NO

paper that meets product

specifications.

the user in how to store the

YES

paper.

Clean or change the Paper

YES

Take-Up Roll.

Change SL2.

YES

Change PWB-A.

NO

Clean or change the Paper

Take-Up Roll.

Check the PC2 actuator for

okay, change PC2.

NO

Action

T-5

Page 9

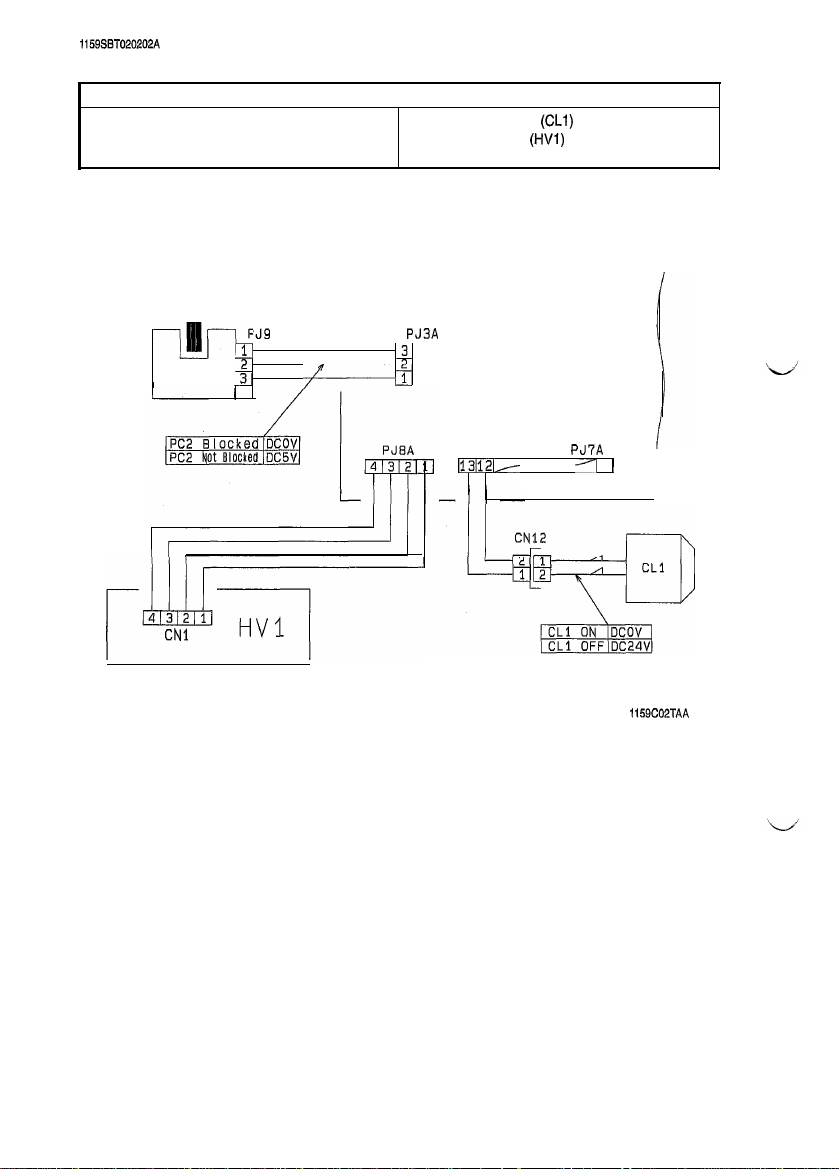

1159SST020202A

2) Transport Misfeed

l

Paper Transport Sensor (PC2)

Relevant Electrical Parts

l

Registration Clutch

l

High Voltage Unit

l

Master Board (PWB-A)

(CLI)

(HVl)

-p!lJ--

PC2

p&q----

CNl

PJ9

1 3

j&

3

I

I------l

PJ3A

1

Il3112b-

PWB-A

PJ7A

/I

1

I

1159C02TAA

T-6

Page 10

I

*Transport

Symptom

Paper is Is the paper curled, waved, or

stationary at the

Synchronizing paper.

Roller.

Paper is

stationary near

the PC Drum.

Paper is

stationary before 1

the Fusing Unit.

Misfeed Clearing Procedure

Step

1

2

3

4

1

2

3

4

5

6

Check Item

damp?

Does the paper being used Instruct the user to use the

meet product specifications? NO paper that meets product

Check Registration Clutch

CLl.

Does the voltage across

PJ7A-13 on PWB-A and GND

change from DC24V to DCOV

after the Start key has been

pressed?

Does the voltage across Check the PC2 actuator for

PJ3A-2 on PWB-A and GND

change from DC5V to DCOV

when Paper Transport Sensor

PC2 is blocked?

Is the Pre-Image Transfer

Guide Plate deformed or dirty?

Is the Image Transfer Corona

wire deteriorated or dirty?

Is the Comb Electrode

deteriorated or dirty? Electrode.

Is the paper guide at the Paper

Separator Corona deformed or

dirty?

Are the Synchronizing Rollers

deformed, worn, or dirty with

paper dust?

Is paper wound around the PC

Drum?

Do the Fusing Rollers turn

when the Main Drive Motor is

energized?

Result Action

Change the paper. Instruct

YES the user in how to store the

specifications.

Change CL2.

YES

Change PWB-A.

NO

operation and, if it checks

NO

okay, change PC2.

Clean or change the guide

YES

plate

Clean or change the wire.

YES

Clean or change the Comb

YES

Clean or change the paper

YES

guide.

Clean or change the

YES Synchronizing Rollers,

Change the Image Transfer/

YES

Paper Separator Coronas

Assy or

HVl.

Check the drive transmission

NO

path.

T-7

Page 11

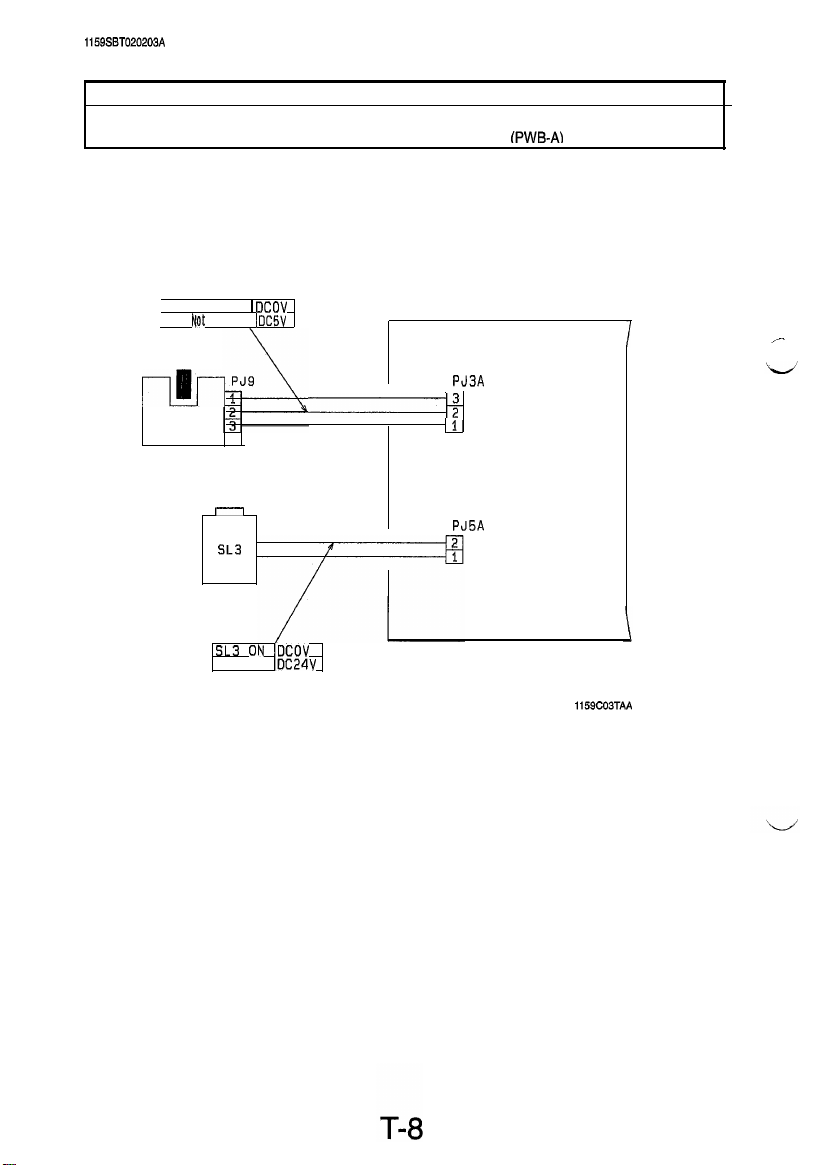

1159SBT020203A

3) Multi Bypass Misfeed

l

Paper Take-Up Sensor (PC2)

Relevant Electrical Parts

l

Multi Bypass Paper Take-Up Solenoid (SL3)

l

Master Board fPWB-AI

PC2 Blocked 1

PC2

-lllJ-

PC2

t@t

Blocked I

r-l

SL3

SL3 olu lDCOV

SL3 OFF

DCOV

DCSV

IDC24V

I

PJ3A

-+

1

PWB-A

PJ5A

1159C03TAA

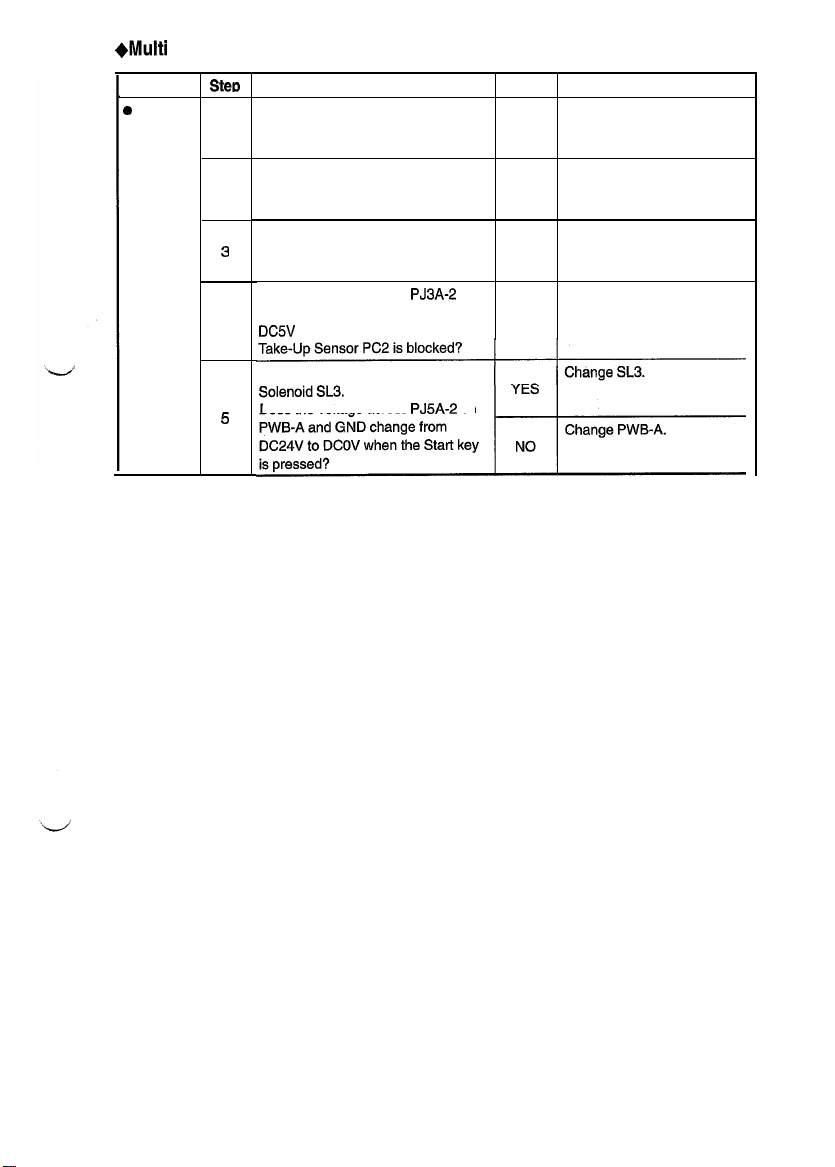

Page 12

+Multi

I

Bypass Misfeed Clearing Procedure

Symptom

0

Paper is

not taken

up at all.

Stecb

Does the paper being used meet

product specifications?

Is the paper curled, waved, or

damp?

2

Is the Multi Bypass Paper Take-Up

Roll deformed, worn, or dirty with

3

paper dust?

Does the voltage across PJ3A-2 on

PWB-A and GND change from

4

DC5V to DCOV when Paper

Check Multi Bypass Paper Take-Up

Does the voltage across PJ5A-2 on

5

Check Item

Result

Instruct the user to use the

NO paper that meets product

specifications.

Change the paper. Instruct

the user in how to store the

YES

paper.

Clean or change the Multi

Bypass Paper Take-Up Roll.

YES

Check the PC2 actuator for

operation and, if it checks

NO

okay, change PC2.

Action

T-9

Page 13

1159SST020204A

4) Exit Misfeed

l

Paper Exit Sensor (PC3)

Relevant Electrical Parts

l

Master Board (PWB-A)

PJ'IA

PWB-A

1159C04TAA

T-10

Page 14

+Exit

Misfeed Clearing Procedure

Are the

Separator Fingers deformed,

Fusing Roller Paper

defective paper separator

T-11

Page 15

1159SBT020205B

5) SDH Misfeed

l

SDH Paper Transport Sensor (PC23)

l

SDH Original Set Sensor (PC22)

l

SDH Original Exit Sensor (PC24)

(EP1030F/EP1031

F)

Relevant Electrical Parts

l

SDH Paper Take-Up Solenoid

l

SDH Drive Motor

l

SDH Registration Clutch

. SDH PWB (PWB-C)

l

Master Board

(MlO)

(PWB-AI

(CLlO)

(SLl

0)

T-12

1159CO5TAB

Page 16

+SDH

I

Misfeed Clearing Procedure

Symptom

Iocument

lot

taken up at ,

FlII.

Document is

stationary at

the Registration paper dust?

Roller.

Document is

stationary at

the Exit Roller.

Step

is

Does the document being used

meet specifications for reliable

feeding?

Do the documents loaded

2

teed the capacity of the SDH?

Are the Document Take-Up and Clean or change the

Separator Rolls deformed, YES

3

worn, or dirty with paper dust?

Does the voltage across

on PWB-C and GND change

from

4

Original Set Sensor PC22 is

blocked?

Check SDH Drive Motor Ml 0.

Is the voltage across

5

PWB-A and GND

the Start key is pressed?

Check SDH Paper Take-Up

Solenoid

Does the voltage across

6

on PWB-A and GND change

from

Start key is pressed?

Is the Registration Roller

deformed, worn, or dirty with YES

1

Does the voltage across

on PWB-C and GND change

2

from

Paper Transport Sensor PC23

is blocked?

Check SDH Registration Clutch

CL1 0.

Does the voltage across

3

on PWB-A and GND change

from

Start key has been pressed?

Is the Exit Roller deformed,

1

worn, or dirty with paper dust?

Does the voltage across

on PWB-C and GND change

from

2

Original Exit Sensor PC24 is

blocked?

Check Item

DC5V

to DCOV when SDH

SLlO.

DC24V

DC5V

DC24V

DCZV

to DCOV when SDH

ex-

PJ4C-2

PJl A-8

on

DC24V

when

PJl

A-6

to DCOV when the

PJ4C-5

to

DCOV when SDH

PJl

A-7

to DCOV after the

PJ4C-9

Result Action

Instruct the user to use a

document that meets

NO

specifications for reliable

feeding.

Ask the user to keep within

YES

the SDH document capacity.

Document Take-Up and

Separator Rolls.

Check the PC22 actuator for

operation and, if it checks

okay, change PC22.

NO

Change PWB-A or PWB-C.

NO

Change Ml 0.

YES

Change

SLl

YES

Change PWB-A or PWB-C.

NC

Clean or change the

Registration Roller.

Check the PC23 actuator for

operation and, if it checks

okay, change PC23,

NO

Change CL1 0.

YES

Change PWB-A or PWB-C.

N

O

Clean or change the Exit

YES

Roller.

Check the PC24 actuator for

operation and, if it checks

NO

okay, change PC24.

YES

Change PWB-C.

0.

T-13

Page 17

1159SBT0300A

MALFUNCTIONS

1159SBT0301A

3-1,

Detection Timings Classified by Malfunction Codes

Code

Description

Detection Timing

Main Drive Motor Mlsl The lock signal remains HIGH for a continuous I-sec. or

coo

failure to turn

period while Ml remains energized,

l

The lock signal remains LOW for a continuous 1 -sec. or more

period while Ml remains deenergized.

Ozone Fan Motor

co4

failure to turn

Exposure Lamp LA1

malfunction

c40

The lock signal remains HIGH for a continuous 1 -sec. or more

M3s

period while M3 remains energized.

l

The AE Sensor output at 91 msec. after the start of a scan motion

with LA1 ON is lower than the AE Sensor output when LA1 is

OFF.

l

The AE Sensor output at any timing when the Scanner is at home

position with LA1 OFF is higher than the AE Sensor output when

LA1 is ON.

Warming-up failure

The surface temperature of the Upper Fusing Roller does not

reach a given level after a given period of time during

warming-up as detailed below:

l

c50

Abnormally low fusing The surface temperature of the Upper Fusing Roller is below

c51

temperature

Abnormally high fusing

C52

temperature

Scanner drive

malfunc-

tion

From room temperature to

l

From 45 to

l

From 80 to 115C: 10 sec.

l

From 115 to 145C: 15 sec.

l

From 145 to

150C

after the copier has completed warming up.

80C:

160C:

10 sec.

The surface temperature of the Upper Fusing Roller is

higher after the copier has completed warming up.

<When the Power Switch is turned ON>

l

When the Scanner is at the home position, Scanner Home

Position Sensor

PC1

1

45C: 10

sec.

15 sec.

does not go from LOW to HIGH even after

the lapse of 1 sec. after the Scanner has started a scan motion.

l

When the Scanner is at a position other than home,

C60

not go from HIGH to LOW even after the lapse of 8.4 sec.

the Scanner has started a scan motion.

<When

the Start key is pressed>

l

PC11 does not go from LOW to HIGH even after the lapse of

1 sec. after the Scanner has started a scan motion.

l

PC11 does not go from HIGH to LOW even after the lapse of

8.4 sec. after the Scanner has started a return motion.

230C

PC11

more

or

does

after

T-14

Page 18

Code

1

Description

l

Lens drive malfunction

C61

AE Sensor malfunction

CFl

ATDC Sensor malfunction The output from ATDC Sensor UN3 is

CF3

EEPROM malfunction Data which must be retained even when power is turned OFF

EO

IU toner detection failure

Blown IU fuse detection

E2

failure

Lens Home Position Sensor PC12 does not go from LOW to

HIGH even when Lens Drive Motor M5 is energized for 750

pulses for the lens movement in the reduction direction.

l

PC12 does not go from HIGH to LOW even when M5 is

energized for 1400 pulses for the lens movement in the

enlargement direction.

The output from AE Sensor Board PWB-E is

less than

at home position.

than

cannot be written to, and read from, the EEPROM.

The output from ATDC Sensor UN3 remains less than 1 .OV

during an F8 operation.

The IU fuse is not blown during an F8 operation.

0.4V

0.4V.

Detection Timing

4.8V

when the Exposure Lamp is OFF and Scanner

4.8V

or more, or

or more, or less

T-15

Page 19

1159SBT0302A

3-2. Troubleshooting Procedures

1159SBTO30201

A

1) COO: Main Drive Motors Failure to Turn

Relevant Electrical Parts

l

Main Drive Motor (Ml)

l

Power Supply Unit

l

Master Board (PWB-A)

(PUl)

Step Check Item

Does the voltage across

1

from

DC5V

to DCOV when the Start key is pressed?

Is the voltage across

2

Power Switch Sl is turned ON?

Is the voltage across

3

is turned ON?

PJ4A-4

on PWB-A and GND change

PJ4A-3

on PWB-A and GND DCOV when

PJ4-1

on

PUl

and GND

DC24V

T-16

when

1159CWTAA

Result

NO

YES

Sl

NO

Action

Change PWB-A.

Change Ml.

Change

PUl.

Page 20

2) C04:

Ozone Fan Motors Failure to Turn

I

Relevant Electrical Parts

l

Master Board (PWB-A)

1159C07TAA

Check

step

Does the voltage across

1

from DC1 2V to DC24V when the Stat-t kev is Dressed?

Is the voltage across

2

when Sl is turned ON?

PJ13A-3

Item

PJ13A-1

on PWB-A and GND change

on PWB-A and GND

DC5V

Result

NO

I

YES

Actim

Change PWB-A.

I

Change M3.

I

Page 21

Ii 59SBT030203A

3)

C40:

Exposure Lamp Malfunction

I

Relevant Electrical Parts

PJlF

l-2.l

I

PWB-F

1159COBTAA

SteteD

I

Is the source voltage being supplied across

1

and -BR on PWB-F?

Is the circuit across PJGF-1 and -2 on the LA1 side

2

conducting when

Check Item

PJGF

is removed from PWB-F?

CNl

T-18

F-GY

I

Result

NO

I

I

Action

Check the power line.

I

I

I

Page 22

1159SBT030204A

4)

C50:

Warming-up Failure

C51:

Abnormally Low Fusing Temperature

C52: Abnormally High Fusing Temperature

Relevant Electrical Parts

l

Fusing Thermistor

l

Fusing Thermoswitch

(THl)

(TSI)

TSI

. AVR (PWB-F)

l

Master Board (PWB-A)

y

Fusing Rol

ler

1

PJ5F

1159C09TAA

T-19

Page 23

e

continuity

across

PJ4F

and

PJ5F

on

PWB-F

Change the

Fusing Unit.

Measure the

+C52

I

SteD

I

1

Is

THl

installed properly, or dirty? YES Reinstall or clean

Measure the resistance of

2

O?

resistance of THI.Isit

Check Item

THl

.

Is

infinite?

it 00 or close to

1

Result

I

YES Change

NO

Channe

Action

THl

.

THl

.

PWB-F or PWB-A.

1

T-20

Page 24

1159SBT030205A

5)

C60:

Scanner Drive Malfunction

C61: Lens Drive Malfunction

(EP1031/EP1031

F)

I

l

Scanner Home Position Sensor

l

Lens Home Position Sensor (PC12)

I

Relevant Electrical Parts

(PCll)

l

Scanner Drive Motor (M4)

l

Lens Drive Motor (M5)

l

Master Board

fPWB-A\

I

I

T-21

1159CiOTAA

Page 25

+C60

Step

I

Does the voltage across PJ

1

change from

Position Sensor

Is

PJll

A

2

on PWB-A connected properly?

+C61

Step

I

Does the voltage across PJ

1

change from

Sensor PC12 is blocked?

Is

PJ12A

2

on PWB-A connected properly? YES

Check Item

16A-5

DCXV

to DCOV when Scanner Home

PC1

1 is blocked?

Check Item

DCXV

to DCOV when Lens Home Position

on PWB-A and GND

17A-2

on PWB-A and GND

1

Result

YES

NO

I

Result

NO

1

Action

Change PWB-A or M4.

Connect it

I

Change PWB-A or M5.

Connect It properly.

orooerlv.

Action

I

T-22

Page 26

1159SBT030206A

6)

CFI:

AE Sensor Malfunction

l

AE Sensor Board (PWB-E)

Relevant Electrical Parts

l

Master Board (PWB-A)

PJlE '

-

PWB-E

Check

!N?p

Is

the voltage across

1

DC4.8V

or more, or

Lamp is OFF and Scanner at home position

0.4V

item

PJ18A-2

on PWB-A and GND

or less when the Exposure

PJ16A

:

3

4

6

6

PWB-A

1159CllTAA

R@sult

YES

NO

I

Action

Change PWB-E.

Change PWB-A.

T-23

Page 27

1159SST030207A

7) CF3: ATDC Sensor Malfunction

Relevant Electrical Parts

l

ATDC

Sensor

(UN3)

PWB-A

PJIOA

l

Master Board (PWB-A)

Is the voltage across

1

DC4.8V

or more, or

PJlOA-1

on PWB-A and GND

0.4V

or less?

T-24

1159C12TAA

I Result I

YES Change UN3.

f’.hanne

Action

PWR-A

Page 28

115993T030203A

8) EO: EEPROM Malfunction

i

I

l

Master Board (PWB-A)

Step

Does

EO

1

2

3

appear again after the malfunction has been

reset?

Does EO appear during a copy cycle? YES Change EEPROM.

Does

EO

appear when the Power Switch is turned ON? YES Change PWB-A.

Relevant Electrical Parts

Check Item Result Action

YES

I

I

Change EEPROM.

T-25

Page 29

1l59SET030209A

9) El: IU Toner Detection Failure

E2: Blown IU Fuse Detection Failure

Relevant Electrical Parts

l

ATDC Sensor

(UN3)

El

0

Imaging Unit (IU)

l

Master Board

(PWB-A)

Step Check Item

1

Did you peel off the seal from the Toner Cartridge?NOPeel off the seal.

Has the starter been loaded?

2

Result Action

YES

E2

Step

1

Check Item

Is the fuse blown?

Result

YES

Change

UN3 or PWB-A.

Action

Chanae the fuse or

-.

LA

PWB-A.

T-26

Page 30

I

1159SST0303A

3-3. Power Malfunctions

Power is not Turned ON (Control Panel Shows Nothing)

I

l

Power Switch

l

Noise Filter Board (PWB-D)

(Sl)

Relevant Electrical Parts

. AVR (PWB-F)

0

Power Supply Unit

l

MSC Board (PWB-B)

l

Master Board (PWB-A)

I

(PUI)

Step

1 Is the source voltage applied across 1 and 3 of

Is the source voltage being applied across 2 and 4 of

when it is turned ON?

Is the source voltage being applied across 1 and 2 of

PJ3 on PUl when Sl is turned ON?

Is the voltage across

DC24V

when Sl is turned ON?

Is the voltage across

GND

DC24V

Are PJ20A on PWB-A and

properly?

6

Check Item

PJSA-1

to -3 on PWB-A and GND

PJSA-1,

when Sl is turned ON?

-2, and -5 on PWB-A and

PJl

B on PWB-B installed

T-27

Sl?

1159C13TAA

Result

I

Action

Sl

Change PWB-F.

NO

Change PUl,

NO

Check the wiring

tween PUl and

NO

PWB-A and, if it is in-

tact, change

Change PWB-A,

PWB-B, and the

YES

harness, in that order.

NO

)

Install them properly.

be-

PUl.

Page 31

1149SAT0600A

IMAGE FAILURE

1159SBT0501A

5-1. Image Failure Troubleshooting

Image failures have many possible causes. For troubleshooting, it

is necessary to determine whether

ure is attributable to a basic cause or any other cause.

In this chapter, troubleshooting is divided into initial checks and troubleshooting procedures classified by

image failure. If an image failure has occurred, first make the initial checks, then proceed to the corresponding image failure troubleshooting procedure.

1159SBT0502A

5-2, Initial Checks

1)

Place of installation

l

Is the source voltage normal? Does the voltage vary greatly?

l

Is the copier installed in a hot, humid place or in a place where temperatures vary sharply?

l

Is the copier installed in a dusty place?

l

Is the copier subjected to direct sunlight?

l

Is the copier level?

2)

COPY

paper

l

Is the recommended paper used?

*Load

recommended paper and make copies to see if the problem persists.

l

Is the paper damp?

*Load

new paper and make copies to see if the problem persists.

3)

Original

l

Does the original used have a reddish background or is it written in light pencil?

*Use

the Test Chart to check the image.

l

Is the original transparent or are transparencies being used?

&over

with white paper and make a copy.

l

Are the Original Glass and ADF Transport Belt dirty or scratched?

*If

dirty, clean with alcohol. If scratched, replace.

a

fail-

5) Adjustment items (registration, focus, AE level, etc.)

l

Among the adjustment items given in

DIS/REASSEMBLY,

ADJUSTMENT, is there any adjustment that

may remedy the image failure?

T-28

Page 32

1149SST0503A

5-3. Troubleshooting Procedures Classified by Image Failure

<Image

Failure Samples>

1) Blank copy

4) Foggy background

7) Blank streaks or bands

5) Black streaks or bands

8) Void areas

3) Low image density

6) Black spots

9) Smear on back

-b

3C:DE

P 3C:DEI

1E 3C:DEI

I! 3C:DEE

P 3C:DEI

4’~CDE

9BCDI

ABWE

ABLOE

A3CDE

T-29

1

ABCDE

1149T012AA

1

Page 33

1159SBT050301A

1) Blank Copy

Exposure Lamps

failure to turn ON

Voltage Unit

PC Drum

Voltage Unit HVl

Is the PC Drum properly

grounded?

Is the developing bias contact normal?

Has condensation formed

on the mirrors, lens, or PC

Drum?

Are the mirrors installed

4

properly?

Does the Exposure Lamp

5

liaht uo?

HVI

Charge Corona

Check

Item

and the

and

ooro-

I

Result

NO

NO

YES

NO

NO

Action

Clean or change the PC

Drum.

Clean or replace the developing bias contact.

Clean the mirrors and lens,

and run the Drum Dehum.

operation.

Reinstall the mirrors.

Take the action for malfunction code

C40.

T-30

Page 34

I

1159SBT050303A

3) Low Image Density

rid mesh normal?

dirty or covered

with con-

T-31

Page 35

I

1159SST050304A

4) Foggy background

Cause

Cleaning failure

Optical failure

PC Drum failure

Developing failure

1159SRT050305A

I

Stet3

1

1

2

1

3

4

I-

5

6

c

Is the Cleaning Blade dirty

with foreign matter, paper

dust. etc. or is it scratched?

Are the mirrors and lens

dirty?

Is the PC Drum dirty with

foreign matter, etc.?

Is the PC Drum properly

grounded?

Is the Sleeve Roller abnormally dirty?

Is the developing bias contact normal?

5) Black Streaks or Bands

Are the Comb Electrode

and grid mesh dirty?

1

Cleaning failure

PC Drum failure

Optical failure

I

I

Is the Cleaning Blade dirty

with foreign matter, paper

2

dust, etc., or is it

scratched?

Is the PC Drum surface

dirty or scratched?

3

Is the Upper Fusing Roller

dirty or scratched?

Are the Upper Paper Sepa-

rator Fingers dirty or

formed?

Are the mirrors and lens

dirty with foreign matter?

Check Item

Check Item

de-

Resul;

YES

YES

YES

NO

YES

NO

I

Result

YES

YES

YES

YES

YES

YES

Action

Change the Cleaning

Blade.

Clean the mirrors and lens.

Clean or replace the PC

Drum. Change the Cleaning

Blade if necessary.

Clean or change the PC

Drum.

Clean the Sleeve Roller.

Check the Developer Scattering Prevention Seal to

see if it is deformed or dirty.

Clean or change the developing bias contact.

Action

Clean or replace the PC

Drum Charge Corona.

Check the toner suction

mechanism for operation.

Change the Cleaning

Blade.

Change the PC Drum. If

necessary, change the

Cleaning Blade.

Clean or replace the Upper

Fusing Roller.

Clean or replace the Upper

Paper Separator Fingers.

Clean the mirrors and lens.

T-32

Page 36

I

1159SBT050306A

6) Black Spots

Fusing failure

Developing failure

1159SBT050307A

r

2

3

4

5

7) Blank Streaks or Bands

Cause

Plugged Db

Drum charge failure

Image transfer

ure

Image Erase Lamp

lit at abnormal timing

fail-

I Step

1

2

3

4

Check Item

Is the PC Drum surface

scratched or dirty with

eign matter?

Is the Upper Fusing Roller

dirty or scratched? YES

Is the amount of toner on

the Sleeve Roller proper?

Is the toner-to-carrier ratio

relatively high?

Is the Developer Scattering

Prevention Seal deformed

or dirty?

Check Item

Is Db plugged with foreign

matter, caked toner, etc.? YES

Are the Comb Electrode

and grid mesh dirty?

Is the Image Transfer Corona wire dirty?

for-

I

Result

YES

YES

YES

YES

1

Result

YES

YES

Action

Clean or change the PC

Drum. Change the Cleaning

Blade if necessary.

Check the Fusing Thermistors. Clean or change the

Upper Fusing Roller.

Go to step 5.

Change the toner-to-carrier

ratio.

Clean or change the Developer Scattering Prevention

Seal.

Remove foreign matter. If

the problem persists,

change the developer.

Clean or change the PC

Drum Charge Corona.

Clean or change the Image

Transfer Corona.

Check the Image Erase

Lamp.

Fusing failure

5

6

Clean or change the Upper

Fusing Roller.

Clean

or change

Paper Separator

the Upper

Fingers.

T-33

Page 37

1159SBT050308A

8) Void Areas

Cause

Image transfer

ure

Damp copy paper

Small amount of toner supplied

Paper guide shorting

Fusing failure

1159SBT050309A

fail-

9) Smear on Back

Cause

Dirty Developing

Unit

Dirty Image Transfer

Corona

Dirty Fusing Unit

Step

1

2

5

6

Step

1

2

3

4

5

Check Item

Is the Image Transfer Coro-

na installed properly?

Is the Image Transfer

na wire dirty?

Is the paper guide shorted

to the frame?

Is the Lower Fusing Roller

scratched or deformed?

Check Item Result Action

Is the bottom part of the

Developing Unit dirty?

Is the Image Transfer

na dirty?

Is the Pre-Image Transfer

Guide Plate dirty?

Is the Fusing Unit Entrance

Guide Plate dirty?

Are the Upper and Lower

Fusing Rollers dirty?

Result Action

NC

Coro-

YES

NO

YES

YES

YES

Coro-

YES

YES

YES

YES

Reinstall.

Clean or change the Image

Transfer Corona wire.

Change the copy paper and

instruct the user in how to

store paper.

Check the Db value and

amount of developer, and

check the Bucket Roller for

operation.

Connect the paper guide

through the resistor to the

frame.

Replace the Lower Fusing

Roller.

Clean and check the

oper Scattering Prevention

Seal.

Clean the corona and

check the Developing Unit.

Clean the guide plate and

check the Developing Unit.

Clean the guide plate and

check the Developing Unit.

Clean or change the Upper

and Lower Fusing Rollers.

Devel-

T-34

Page 38

I

1159SBTOOOEA

MINOUA

Copyright

1997

MINOLTA

Printed in Japan

Use of this manual should

be strictly supervised to

avoid disclosure of

confidential information,

MINOLTA

Co., Ltd.

CO,, LTD,

I

1159-7998-l

1 97074370

Printed in Japan

Loading...

Loading...