Page 1

I

1l$9SBSOOOAA

EP1030/EP103OF

~EPl031/EP1031F

~ SWITCHES ON

PWBs/

~ TECH, REP, SETTINGS

MINOLTA

Page 2

ll59SSSOOOSA

CONTENTS

1

PRECAUTIONS FOR HANDLING THE

l-1. Precautions for Transportation and Storage

1-2. Precautions for Replacement and Inspection

2

CONTROL PANEL KEYS AND INDICATORS

.

EP1031/EP1031

. EPI

030/EP103OF

F

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . n . . . , , . . .

PWBs

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

S-l

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

S-2

.

S-4

S-l

S-l

s-2

4 USER MODE

4-l. Functions Available from User Mode

4-2. User Mode Setting Procedure

4-3. User Mode Setting Details

5 SERVICE MODE

5-1.

Service Mode Function Tree

5-2.

Entering the Service Mode

Counter Display Procedure

5-3.

Setting in the Service Mode ..............................

5-4.

l.Display

2. Tech. Rep. Choice

3.Adjust ...............................................

4.Test .................................................

6

FUNCTION SETTING REQUIREMENTS AT REPLACEMENT OF PART

.................................

......................

............................

...............................

.............................................

..............................

...............................

...............................

..............................................

....................................

..i

............

. .

m

S-6

S-6

S-6

S-6

s-7

S-7

S-7

S-8

S-9

S-9

S-10

S-13

S-16

S-l 8

Page 3

1151SSSOlOOA

PRECAUTIONS FOR HANDLING THE

1151SBS0101A

PWBs

1-1. Precautions for Transportation and Storage

a) Before transporting or storing the

are not subjected to high temperature (and they are not exposed to direct sunlight).

b) Protect the

c) Once the PWB has been removed from its conductive case or bag, never place it directly on an object

that is easily charged with static electricity (such as a carpet or plastic bag).

d) Do not touch the parts and printed patterns on the

1151SSS0102A

PWBs

from any external force so that they are not bent or damaged.

PWBs,

put them in protective conductive cases or bags so that they

PWBs

with bare hands.

1-2. Precautions for Replacement and Inspection

a) Whenever replacing the PWB, make sure that the power cord of the copier has been unplugged.

b) When the power is on, the connectors should never be plugged in or unplugged.

c) Use care not to strap the pins of an IC with a metal tool.

d) When touching the PWB, wear a wrist strap and connect its cord to a securely grounded place

whenever

possible.

before touching the PWB.

If you cannot wear a wrist strap, touch the metal part to discharge static electricity

S-l

Page 4

1159SSS0200A

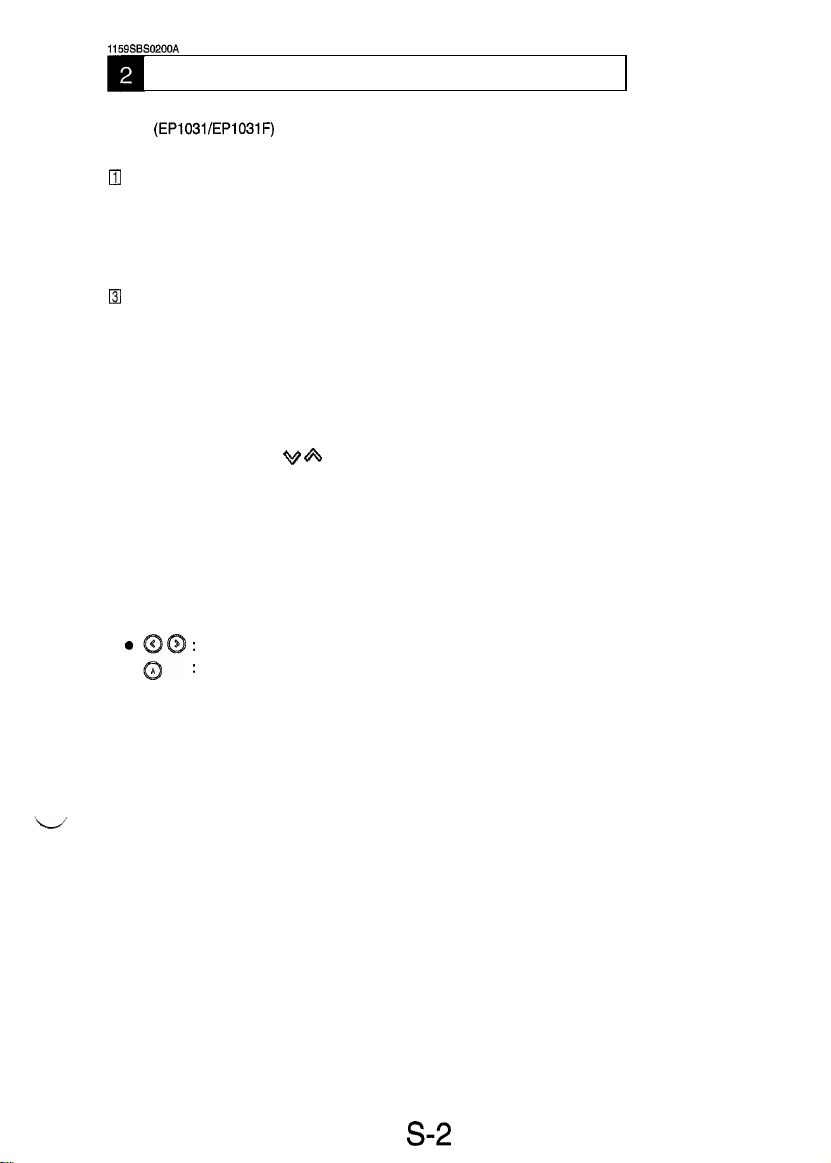

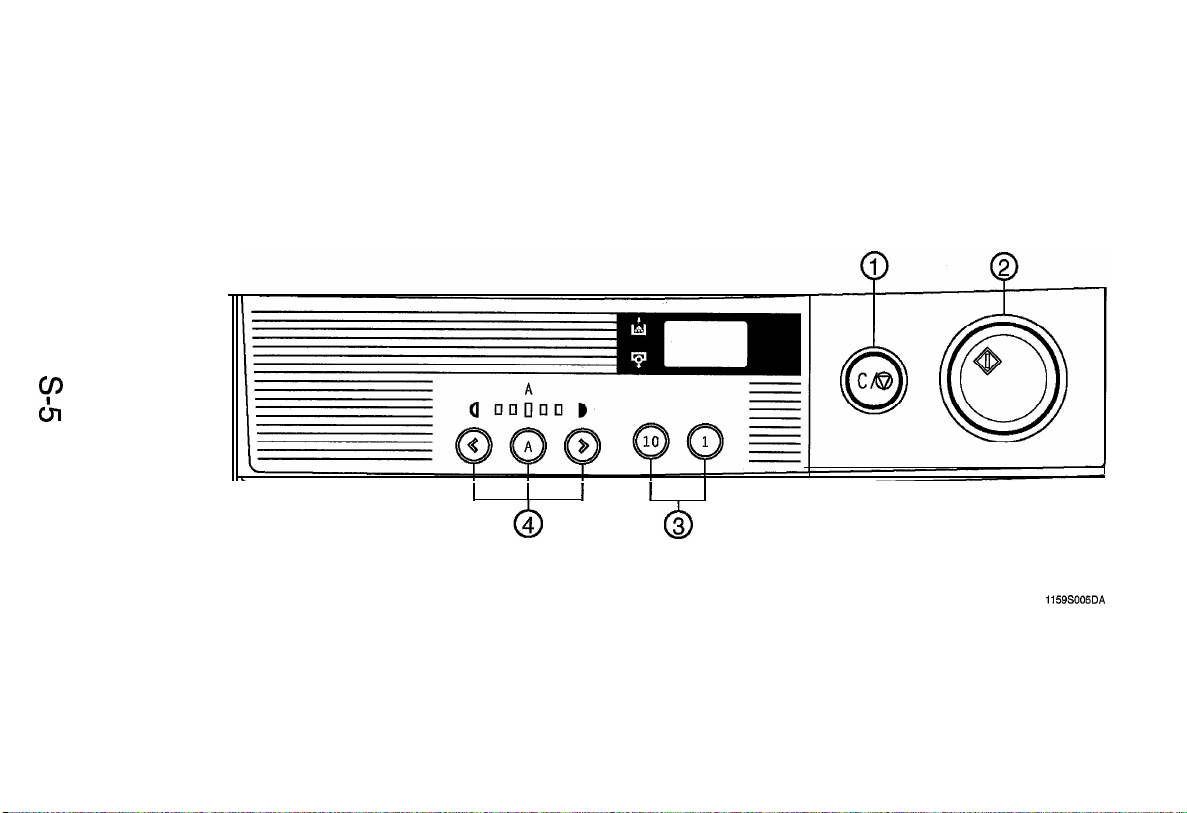

CONTROL PANEL KEYS AND INDICATORS

1

* For more details, see the Operators Manual shipped with the copier.

.

(EP1031/EP1031F)

Qj

Paper Source Key

l

Selects the paper source.

q

Clear/Stop Key

l

Returns the copy setting to one (1). Returns the zoom ratio to 100% and stops the copying operation.

I Start Key

l

Starts the copying operation.

q

Copy Quantity and Zoom Keys

l

Used to set the number of copies to be made and manual zoom settings. When used for setting the

number of copies, the number in the display panel will increase by one each time the one (1) key is

pressed and increase by ten each time the ten (10) key is pressed.

l

When used to set the zoom ratio, the number in the display panel will increase or decrease by one each

time the respective key

q

Copy Quantity/Zoom Selection Key

l

Switches the operation of the 1 and 10 keys between copy quantity and zoom functions.

++$- &

is pressed. The zoom range is from 64% to 156%.

I Fixed Zoom Ratio Key

l

Selects and displays a fixed zoom ratio setting.

q

Exposure Control Keys

0

l

:

Controls the density of the copy image.

:

For selecting the Auto Exposure/Manual Exposure Mode.

s-2

Page 5

1

Q

2

Q

3

Q

cs

&J :;::;

lil

70%*

A4

81%.

85 bA5

115%.

B5

141%. A5

bA5

,A4

bA4

64%-156%

TtbeirIVA

cm

0

0

1159S007DA

Page 6

*

For more details, see

.

(EP1030/EP1030F)

q

Clear/Stop Key

l

Returns the copy setting to one (1). Stops the copying operation.

[ZI

Start Key

l

Starts the copying operation.

q

Copy Quantity Keys

l

Used to set the number of copies to be made. The number in the display panel will increase by one each

time the one (1) key is pressed and increase by ten each time the ten (10) key is pressed.

q

Exposure Control Keys

a

l

: Controls the density of the copy image.

:

For selecting the Auto Exposure/Manual Exposure Mode.

the Operators

Manual

s-4

Page 7

I

I

I I

1159S005DA

Page 8

1159SBS0400A

USER MODE

l

This mode is used to make various setting to the Users needs.

1159SBS0401A

4-l. Functions Available from the User Mode

No.

Ul

1159SBS0402A

Function

Auto clear ON/OFF

I

4-2. User Mode Setting Procedure

<Setting Procedure>

1. Holding down the Exposure Control Key@, turn ON the Power Switch. (Ul appears on the

Display Panel.)

2. Press the Start Key to show the data set the selected function.

3. Using the Copy Quantity and Zoom Keys, change the set data.

4. Press the Clear/Stop Key to validate the new setting. (The function no. reappears.)

<Resetting Procedure>

the User Mode.

l

Press the Clear/Stop

1159SBS0403A

49.

User Mode Setting Details

Function No.

Ul

to quit

Key

[User Mode]

Setting (The default is

<Auto

clear ON/OFF>

Select whether or not to activate the auto clear (panel reset) function after the

lapse of a given period of time after a copy cycle has been completed or a key

on the control panel has been

operated.

m

.)

S-6

Page 9

1159SBS0500A

SERVICE MODE

l

This mode is used by the Tech. Rep. to set, check, adjust, and/or program various service functions.

1159SBS0501

5-l. Service Mode Function Tree

A

d2 : Previous IU Counter count display

A0

:

Lens focal length correction

Al : Lens full size position correction

A2 : Feeding-direction zoom ratio correction

A3 : Full size registration adjustment

r

Adjust

1

A4 : Enlargement registration adjustment

A5 : Reduction registration adjustment

A8 : SDH registration adjustment

AA : Leading edge erase width adjustment

Ab : ATDC Sensor adjustment data

AC : Max. Exposure Lamp voltage adjustment data

-

F3 : Exposure Lamp Voltage Adjustment

F8 : ATDC Sensor Automatic Adjustment

F9

:

IU Check, Optimum Exposure Adjustment

1159SBS0502A

5-2.

Entering the Service Mode

<Setting Procedure>

1. Perform the following steps to set the copier in to Service Mode.

I)

Clear Stop Key ON

I)

Exposure Control Key @ ON

2. Select the Service Mode function using the Copy Quantity and Zoom Key @ and then press the Start

Key. (The functions are shown in the order of d, c, A, and F.)

<Leaving Service Mode>

l

Press the Clear/Stop Key twice to quit the Service Mode.

Exposure Control Key @ ON

e

Clear Stop

Key

ON

I)

s-7

Page 10

1159SBS0503A

5-3. Counter Display Procedure

<Display Procedure>

--t

1. Hold down the Clear/Stop Key for 3 sec.

2. Hold down the Clear/Stop Key for another 3 sec.

<Display Example>

The counter reading is shown on the Display Panel in the following order.

l

Total Counter

(Example : 1234)

The Total Counter count appears.

-+

The IU Counter or CP Counter appears.

The IlJ Counter count is displayed when

Note:

when 1 is set for

~2.

Vis

set for

c2and

CP Counter counter is displayed

S-8

Page 11

ii

59SBS0504A

5-4.

Setting in the Service Mode

1159SBS050401A

1. Display

l

This function tests for display of the warming-up time, current

IU

Counter, previous IU Counter, and the

control panel.

<Setting

Procedure>

1. Select the Display mode.

2. Select the function to be checked or set using the Copy Quantity and Zoom Key

(d0

appears on the Display Panel.)

@

and press the

Start Key.

3, Press the Clear/Stop Key to stop the display sequence.

<Leaving

the Function>

l

Select the next Display subfunction using the Copy Quantity and Zoom Key @or press the Clear/Stop

Key to quit the Display function,

[Service Mode b Display]

Display Function

d0

dl

d2

d3

Displays the warm-up time on the Display Panel.

<Current

Displays the count of the current IU Counter on the Display

Panel.

<Previous IU Counter count display>

Displays the count of the previous IU Counter on the Display

Panel.

Blinks all

LEDs

on the control panel other than the ready

indicator.

Setting

<Warm-up

time>

IU Counter count display>

<Display test>

:Display

Example>

The warm-up time and IU Counter count are shown on the Display Panel in the following order.

l

Warm-up time display

(Example : 46.50 sec.)

l

IU Counter count display

(Example : 12034)

S-9

Page 12

1159SBS050402A

2. Tech. Rep. Choice

l

This function allows the Tech. Rep. to make various settings and adjustments.

<Setting

Procedure>

1. Select the Tech. Rep. Choice function. (cl appears on the Display Panel.)

2. Select the subfunction to be set or adjusted using the Copy Quantity and Zoom Key

Start Key.

3. Change the set data as necessary using the Copy Quantity and Zoom Keys.

4. Press the Clear/Stop Key to validate the setting.

<Leaving the Function>

l

Select the next Tech. Rep. Choice subfunction using the Copy Quantity and Zoom Key @or press the

Clear/Stop Key to quit the Tech. Rep. Choice function.

[Service Mode b Tech. Rep. Choice]

Choice No.

The correct fixed zoom ratios and paper sizes are selected according to the

marketing area setting selected.

Setting (The default is

<Marketing area>

m

@

.)

and press the

c

c2

c3

di

Note:

Do not select

T

for this subfunction.

<IU

control mode>

Select whether to use the copier or Tech. Rep. to keep track of the replacement time of the IU.

>I

Note:

IU control : Controlled by

IU control = IU Counter; PM control = CP Counter

<Auto

Power OFF Disabling>

PM control : Not controlled

Select whether to enable or disable the Auto Power OFF that is to be acti-

vated after the lapse of a given period of time after a copy cycle has been

completed or a key pressed.

Data

Description

0 . . . . . . . . . . . . . . . . . . . .

0

min.

. . . . . . . . . . . . . .

m

. . . . . . . . . . . . . . . . . 12

30

min.

. . . . . . . . . . . . .

120

min.

s-10

Page 13

[Service Mode b Tech. Rep. Choice]

Select the ATDC control

T/C ratio 4.5%

le

T/C ratio 6.5%

T/C ratio 7.0%

I

s-11

Page 14

<Details of Data Cleared>

CP-related counters: Cleared only in

PA#

s-12

control mode.

ueareo

Page 15

1159SBS050403A

3. Adjust

l

This function allows the Tech. Rep. to set the correction values for making up for machine-to-machine

variations.

<Setting Procedure>

1. Select the Adjust function.

2. Select the subfunction to be set or adjusted using the Copy Quantity and Zoom Key

the Start Key.

3. Change the set data as necessary using the Copy Quantity and Zoom Keys.

4. Press the Clear/Stop Key to validate the setting.

<Leaving the Function>

l

Select the next Adjust subfunction using the Copy Quantity and Zoom Key

Key to quit the Adjust function.

(AO

appears on the Display Panel.)

@

and press

@

or press the Clear/Stop

[Service Mode b Adjust Mode]

Ad]ust

Mode

Corrects variations in the Lens focal length (according to the grouping of the

Lenses).

A0

Setting (The default is

<Lens focal length

m

correction>

.)

Al

A2

Corrects the zoom ratio in the crosswise direction by varying the Lens full size

position.

Data 33

Description

Corrects the zoom ratio in the feeding direction by varying the scan speed.

Data

Description

<Lens full size position correction>

. . . .

0

steps

43

-2.1%

. . . .

. . . .

. , . .

(Reduction

direction)

<Feeding-direction zoom ratio correction>

(Reduction

direction)

m .I..

17 steps

m

zkO%. . .

67

. . . .

38 steps

(Enlagement

direction)

. . . .

.

+2.1%

(Enlagement

direction)

57

I

s-13

Page 16

Adjust Mode

[Service Mode b Adjust Mode]

Setting (The default is

<Full size registration adjustment>

Corrects registration between the leading edge of the original and that of the

image in the full size made by varying the Synchronizing Roller start timing.

m

.)

A3

A4

A5

pi

Corrects registration between the leading edge of the original and that of the

image in an enlargement made by varying the Synchronizing Roller start

timing.

~1

Corrects registration between the leading edge of the original and that of the

image in a reduction made by varying the Synchronizing Roller start timing.

~~

Corrects registration between the leading edge of the original fed via the SDH

and that of the image by varying the SDH Registration Roller start timing.

<Enlargement registration adjustment>

<Reduction registration adjustment>

cSDH

registration adjustment>

s-14

Page 17

Adjust

Mode

AA

Ab

[Service Mode b Adjust Mode]

Setting (The default is

Corrects the leading edge erase width by varying the lmag Erae Lamp ON

timing.

Manually enter the setting value previously recorded when the starter has

been changed or the setting value data automatically set by an

cleared.

NOTE

Y

details, see

<Leading edge erase width adjustment>

<ATDC

Sensor adjustment data>

DWREASSEMBLY; ADJUSTMENT.

m

.)

F8

operation is

AC

Manually enter the setting value previously recorded if the max. Exposure

Lamp voltage adjustment data set by an F3 operation is cleared with Data

Clear of Tech. Rep. Choice.

For

r-

<Max. Exposure Lamp voltage adjustment data>

NOTE

details, see

DWREASSEMBLY; ADJUSTMENT.

s-15

Page 18

1159SBS050404A

4. Test

l

This function allows the Tech. Rep. to perform various functional test and adjustment.

<Setting Procedure>

1. Select the Test function.

2. Select the subfunction to be adjusted or checked using the Copy Quantity and Zoom Key @ and

press the Start Key.

<Leaving the Function>

l

Select the next Test subfunction using the Copy Quantity and Zoom Key @ or press the Clear/Stop

Key to quit the Test function.

(Fl

appears on the Display Panel.)

[Service Mode b Test]

Test No.

Fl

F2

F3

This test moves the paper through the copier for correct passage.

<Procedure>

1. Press the Start Key to start the sequence.

2. Press the Clear/Stop Key to stop the sequence.

Do not use this test as it is only for factory adjustment.

This test allows the Tech. Rep. to adjust the maximum Exposure Lamp

voltage and the optimum exposure setting in the Manual Exposure mode. (It

runs for 30 sec.)

NOTE

r details, see

<Exposure Lamp Voltage Adjustment>

DWREASSEMBLY;

Description

<Paper Passage Test>

<Corona output>

ADJUSTMENT.

F5

F8

F9

cAE

This test automatically adjusts the AE sensor. (It runs for 5 sec.)

NOTE

r details, see DWREASSEMBLY; ADJUSTMENT

This test automatically adjusts the ATDC sensor.

NOTE

r details, see

Do not use this test as it is only factory adjustment.

Sensor Automatic Adjustment>

cATDC Sensor Automatic Adjustment>

DWREASSEMBLY;

cIU Check, Optimum Exposure Adjustment>

ADJUSTMENT:

S-16

Page 19

[Service Mode b Test]

-

Components Energized in the Test

-

0 : Energized

-

:

Remain deenergized

s-17

Page 20

1159SSSO6OOA

0

If a part is replaced as part of troubleshooting and other service jobs, some parts require that a Test

operation be run and data values reentered and/or cleared.

01

02

0 : Required

(~6)

of Tech.

PWB-A

(*5)

I

0

1

I

Starter Exposure AE

IU

(3)

F3 (MAX)

F3

(Manual)

1

F5 (Auto)

F8

(ATDC)

Cleaning of CP-

related Counter

Make the adjustments in numerical order.

0

Clear the CP-related counter, select 2: CP-related counter in the Data Clear mode

*1:

Rep. Choice mode, then switch the power off/on.

When replacing the IU, F8 and CP-related counter are automatically cleared.

*2:

Including the replacement of the ATDC Sensor.

*3:

*4:

Including the Cleaning of Lamp Regulator and optical system.

When replacing PWB-A, if the EEPROM (IC3A) from the old PWB-A is installed on the new PWB-A,

*5:

these adjustments are not necessary.

Input the F3 setting on the factory label inside the front door.

*6:

*7:

Input the Ab setting on the factory label inside the front door.

(*I)

02 01

I

03 I 02

01

0(*2)

0(*2)

I I I

I

0

Lamp(*4)

01

02

1

I

Sensor Unit

I

0

I I

Power

I

P3)

1

(*7)

0

S-18

Page 21

MINOUA

Copyright

1997

MIIUOLTA

Printed in Japan

1

Use of this manual should

be strictly supervised to

avoid disclosure of

confidential information.

Co.,

Ltd

1

MINOLTA

CO,, LTDn

1159-7997-l 1 97074370

Printed in Japan

Loading...

Loading...