Page 1

1159SBD000AA

EP1030/EP1030F

_EPlO3l/EPlO3lF

DE/REASSEMBLY,

ADJUSTMENT

,

L

MINODA

Page 2

1159Sl3DOOOOBA

+

For the Utmost safety

e

For replacement parts, use the genuine parts with their part numbers specified in the parts manual. Use

of a wrong part could cause an overload or dielectric breakdown resulting in an electric shock or fire.

l

Replace a blown fuse or thermal fuse with the corresponding genuine part with its part number specified

in the parts manual. Use of a fuse with a different rating or one with the same rating but of a

type can result in a fire.

Especially when a thermal fuse blows frequently, the thermal control system is probably faulty.

Be sure to take necessary action.

l

Before attempting to disassemble the machine, be sure to unplug its power cord. The machine contains

a hlgh voltage unif and a circuit with a large current capacity that may cause an electric shock or burn

from sparking.

The machine also contains quick moving parts, which could injure a person.

If the machine uses a laser, a person can lose his/her eyesight by a laser beam leak.

l

Wherever feasible, keep the covers and parts mounted when energizing the machine.

If it is absolutely necessary to energize the machine with its cover removed, do not touch an exposed

part that is being charged and use care not to allow your clothing to be caught by a timing belt, gear,

or other moving part.

l

Do not leave the machine unattended while it is being energized,

+

! Warning

A

*

differeni

! Caution

A

l

To actuate an interlock switch with a cover removed or opened, be sure to use the interlock switch actuating jig. Use of folded paper can damage the interlock switch mechanism.

Page 3

! Caution

A

l

A high voltage is being applied to the part marked with the symbol shown

on the right. Touching it can cause an electric shock. Be sure to unplug the

power cord when servicing this part or other parts near it.

l

When the machine is energized with any of its covers removed, never use a flammable spray near it,

as a fire can result,

l

Make sure that correct screws (diameter and length of the screw, binding/tapping screws) are used in

the correct places when assembling parts. If a wrong screw is used, a short insulating distance could

result. It could also result in collapsed threads, which provides only a poor grounding connection, resulting in an, electric shock,

l

A toothed washer and spring washer, if used originally, must be reinstalled. If they are left out, a contact

failure results causing an electric shock or fire,

l

Replace a lithium cell only with one having the part number specified in the parts manual. An explosion

could result if the cell is installed with wrong polarity or a wrong cell is installed.

Dispose of a used lithium cell according to the applicable local regulations. Never throw it away or abandon it on the users premises.

+

Other Precautions

l

While the machine is being energized, do not unplug or plug in a connector on a PWB or relay harness.

o

Since the Magnet Roller of the Imaging Unit generates a strong magneticforce, do not bring a CRT, watch,

floppy disk, or magnetic card near it.

l

Use of an air gun

parts to break down. Be sure therefore to use a blower brush or cloth to clean these parts. If a unit is to

be cleaned, be sure to remove the sensors in advance.

l

MCS

ICs

tions given in

l

The PC Drum is highly delicate. When handling the PC Drum, follow the precautions given in HANDLING

OF THE PC DRUM.

l

To reassemble, reverse the order of disassembly unless otherwise specified.

l

Note that replacement

or vacuum

are susceptible to static electricity. When handling a PWB loaded with

INSTRUCTIONS

+

generates static electricity which can cause the ATDC Sensor and associated

MOS ICs,

follow precau-

FOR HANDLING THE

of,a

PWB may call for readjustments or resetting of particular items.

PWBs

WITH MOS

ICs.

ii

Page 4

1159SBDOOOBA

CONTENTS

1

SERVICE INSTRUCTIONS

I-1, PRECAUTIONS FOR DISASSEMBLY/ADJUSTMENTS . . , , . . D-l

1-2. INSTRUCTIONS FOR HANDLING THE

WITH MOS

1-3. HANDLING OF THE PC DRUM. . . . . . . . . . . . . . . . . . . . . , . . . . D-3

1-4. PARTS WHICH MUST NOT BE TOUCHED . . . n . . e . . . . . . . . . D-5

2 DISASSEMBLY/REASSEMBLY

ICs . . , . . . . . . a . . m . . . . . . . . m n , . . . . . . . . . . . . . m . . .

PWBs

D-3

2-1. DOORS, COVERS,

IDENTIFICATION AND REMOVAL PROCEDURES.i

2-2. REMOVAL OF

2-3. PAPER TAKE-UP/TRANSPORT SECTIONS

Removal of the Paper Take-Up Roll and

(1)

Separator Roll Assy

Cleaning of the Paper Take-Up Rolls

(2)

Cleaning of the Separator Rolls

(3)

Removal of the Synchronizing Roller

(4

Cleaning of the Synchronizing Roller

(5)

Cleaning of the Multi Bypass Paper Take-Up Roller

(6)

2-4. OPTICAL SECTION

(1) Cleaning of the Original Grass

(2) Cleaning of the Scanner Rail and Bush

(3) Cleaning of the Exposure Lamp

(4) Removal of the Thermal Fuse

(5) Cleaning of the Ist, 2nd and 3rd Mirrors

.

(6) Cleaning of the Lens and 4th and 5th Mirrors

(7) Cleaning of the Cooling Fan Filter

(8) Removal of the Scanner Drive Motor M4

(9) Removal of the Scanner Drive Cable

(10) Winding of the Scanner Drive Cable

2-5. IMAGINGUNIT

(1) Removal of the Imaging Unit

(2) Replacement of the PC Drum

(3) Replacement of the Cleaning Blade

(4) Replacement of the Ds Positioning Collars

(5) Replacement of the Starter

(6) Cleaning of the Toner Antispill Mylar

(7) Cleaning of the Toner Satteing Prevention Mylar

(8) Cleaning of the Paper Dust Removal Cleaner

AND

EXTERIOR PARTS:

PWBs

...................................

. :

.............

..................................

....................

........................

....................

....................

....................................

.........................

..................

........................

..........................

................

.............

......................

................

....................

...................

.........................................

...........................

..........................

.....................

...............

............................

....................

.......

.......

..........

............

D-6

D-8

D-l 0

D-10

D-11

D-12

D-12

D-l 2

D-13

D-14

D-14

D-14

D-14

D-15

D-16

D-16

D-l 7

D-17

D-18

D-20

D-23

D-23

D-23

D-24

D-25

D-26

D-26

D-27

D-27

. . .

III

Page 5

CONTENTS

2-6. PC DRUM CHARGE CORONA AND

IMAGE TRANSFER/PAPER SEPARATOR CORONAS, . , . r , D-28

(1)

Removal of the PC Drum Charge Corona

(2) Cleaning of the Main Eraser

(3) Cleaning of the PC Drum Charge Corona Housing

(4) Cleaning of the Comb Electrode, Drum Charge Corona

(5) Cleaning of the PC

(6) Removal of the Image Transfer/Paper Separator

Coronas

(7) Cleaning of the Image Transfer/Paper Separator

Coronas Housing

(8) Cleaning of

(9) Cleaning of the Comb Electrode, Paper Separator

Corona

(IO) Cleaning of the Pre-Image Transfer Guide Plate

2-7.

FUSINGUNIT..................................~

(1) Removal of the Fusing Unit

(2) Cleaning of the Upper Fusing Roller

(3) Cleaning of the Fusing Paper Separator Fingers

(4) Cleaning of the Fusing Thermistor

(5) Cleaning of the

(6) Removal of the Lower Fusing Roller

(7) Cleaning of the Lower Fusing Roller

(8) Cleaning of the Fusing Unit Entrance Guide Plate

2-8. SDH UNIT

(1) Removing the Paper Feed Roller/Pick-up Roller/

Separator Roller

(2) Cleaning the Paper Feed Roller/Pick-up Roller

(3)

rCleaning

(4) Cleaning of the Upper Synchronizing Roller

(5) Cleaning of the Lower Synchronizing Roller . . r . . n . I , . . , . . D-37

(6) Cleaning the Upper Glass Roller

(7) Cleaning the Transport Roller

(8) Cleaning the Exit Roller

............................................

the

.............................................

(EP1030F/EP1031

of the Separator Roll

#Drum

.....................................

Image Transfer Charge Wire

<Fusing

......

...........................

Charge Corona Grid Mesh , . a . , . D-29

.............

Thermoswitch TSI

F Only)

..~.............IL~ ..........

.........................

.......................

..............

................................

................

. 1

*

..............

....................

THl...

.

i

.............

.1.............

....................

.......i............

.....................

...........

..............

...........

,

........

.

...........

.I.

....,..

.......

..........

.........

....

D-28

D-28

D-28

D-29

D-29

D-29

D-30

D-30

D-30

D-31

D-31

D-32

D-32

D-32

D-33

D-33

D-33

D-33

D-34

D-34

D-36

D-37

D-37

D-37

D-37

D-38

I

iv

Page 6

3 ADJUSTMENT

CONTENTS

3-l. JIGS AND TOOLS USED . . .

s

r

.

. . . .

a.. . n . . . . n t , , , , . , . m , . .

D-39

3-2. ADJUSTMENT REQUIREMENTS LIST . . . . , . , , . . , , , . . . , . . . D-40

3-3. ACCESSING THE TECH. REP. MODE . . . . m . , . . . . . . . . . . . . n D-41

3-4. ELECTRICAL/IMAGE ADJUSTMENTS . , . . , . . . . . , . . . . . m . , . D-42

(1) Adjustment of the Maximum Exposure Lamp Voltage for

the Manual Mode . . . . . . . . . . , . . . , . . . . . . . . . . , . . . . . . . . . . . D-42

(2) Adjustment of Optimum Exposure Setting in

Exposure Mode

(3)

Adj,ustment

....,.....,.....n....I

of Exposure Level in

the,+Auto

thee

Manual

1.1..3...,..~,.,

D-44

Exposure Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-46

(4) ATDC Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I . . . a . . D-47

(5) Adjustment of the Aperture Blades . . . . . . . . . . . . . . . , , . . . . . D-48

(6) Adjustment of Zoom Ratio in the Crosswise Direction

(EPl031/EP1031FOnly) nIIII I,..1. Ir.,..~I

(7) Adjustment of Zoom Ratio in the Feeding Direction

. . . . . . . . . . . D-49

. . . . . . .

D-51

(8) Adjustment of the Reference Position of

the Manual Bypass Table . . , . . . , n I . . . . . . . . . , _ . . . . . . . . . . D-53

(9) Adjustment of Paper Feed Cabinet

Reference Position , . . . . . . . . . . . . I . . . . . . . . , . . . . . . . . . . , . D-54

(IO) Adjustment of the Leading Edge Registration . . . . . I . . . . . D-55

@Leading Edge Registration in Full Size Mode , . . . I . . , , . D-55

*Leading Edge Registration in Enlargement Mode

(EP1031/EP1031Fonly)

@Leading

Edge Registration in Reduction Mode

(EP1031/EP1031Fon!y)

(11)

Adjustment of the Image Leading Edge Erase Width . . . . . D-61

(12) Adjustment of Edge Erase

. . . . . s . . .

,.. ..I..1L.. ._ ,,,. .

D-57

~~~~C~~~~~.~~sls~........... D-59

(EP1031/EP1031

F only) . . . . . . D-63

(13) Adjustment of SDH Reference Position

(EPI 03OF/EP1031

F Only) . . . . . n . . . . . . I . . . . . . . . . . . . . . . D-64

(14) Adjustment of SDH Leading Edge Registration

(EP1030F/EPi

031 F Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-65

(15) Adjustment of SDH Center Alignment

(EPI 030F/EP1031

3-5. OTHER ADJUSTMENT

(1)

Focus-Positioning of the Scanner and Mirrors

F Only) . . . . I . . . . . . . . . . . . . . . . . . . . . . , D-67

. . m . , . . . . . . . . . . , . . . . . . . . . . . . . . . . .

D-68

Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-68

3-6. POWER SOURCE VOLTAGE

ROOT-MEAN-SQUARE-

VALUE-TO-MEAN-VALUE CONVERSION TABLE . , . . , . , . . . . D-69

Page 7

1139SSD0100A

SERVICE INSTRUCTIONS

1159SSD01OlA

l-l. PRECAUTIONS FOR DISASSEMBLY/ADJUSTMENTS

Observe the following precautions whenever servicing the copier.

l

Be sure to unplug the copier from the outlet before attempting to service the copier.

l

The basic rule is not to operate the copier anytime during disassembly.

If it is absolutely necessary to run the copier with its covers removed, use care not to allow your clothing

to be caught in revolving parts such as the timing belt and gears.

l

Be sure to use the Interlock Switch Actuating Jig whenever it is necessary to aotuate the Interlock Switch

with the covers left open or removed,

e

Do not plug in or unplug print jacks on the Board or connect or disconnect the Board connectors while

power is being supplied to the copier.

l

Do not use flammable spray around the copier in operation.

l

The Magnet Roller of the Imaging Unit generates strong magnetioforce. Do not bring it nearacathode-ray

tube or watch.

l

DQ not use an air gun or vacuum cleaner for cleaning the ATDC Sensor and

Cause

electrostatic destruction. Use a blower brush and cloth, If a unit containing these sensors is to be

cleaned, first remove the sensors from the unit.

l

When handling the

e

When handling the PC Drum, observe precautions given in Handling of the PC Drum.

e

Note that replacement of a PWB may call for readjustments or resetting of particular items.

l

Use the right screw in the right place at reassembly. Note that some are longer and some are thickerthan

PWBs

with MOS

ICs,

observe Instructions for Handling the

others.

l

A toothed washer is used with the screw that secures the ground wire to ensure positive conduction. Do

not forget to insert this washer at reassembly.

e

To reassemble the copier, reverse the order of disassembly unless otherwise specified.

l

If it becomes necessary to replace the thermal fuse or any other fuse mounted on a board, be sure to use

one of the rating marked on the blown fuse.

Always note the rating marked on the fuse, as the rating and mounting site or number used are subject

to change without notice.

l

Do not pull out the Toner Hopper while the Toner Bottle is turning, as a

or locking mechanism

If the copier is to be run with the Front Door swung down, make sure

csuld

result.

thatthe

position.

other sensors,

PWBs

damaged

Toner Replenishing Motor

as they can

with MOS

Toner Hopper is in the locked

ICs.

D-l

Page 8

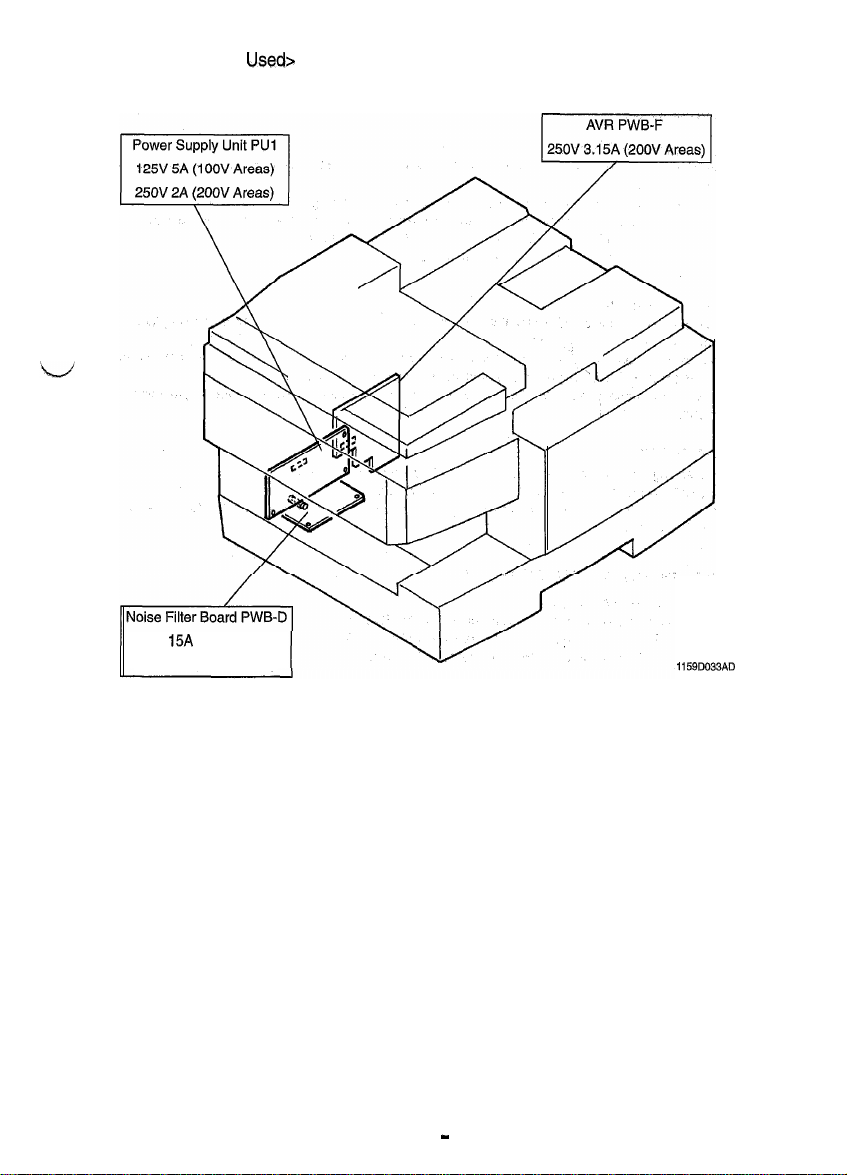

<List of Fuses

250V

15A

(1 OOV Areas)

250V 8A (200V Areas)

Usedr

1159D033AD

I

D2

Page 9

1139SBDOlOZA

1-2. INSTRUCTIONS FOR HANDLING THE

must be

The following precautions

Semiconductor)

ICs.

observed when handling

PWBs

WITH MOS

P.W.

Boards

ICs

with

MOS Oxide

During Transportation/Storage:

l

During transportation or when in storage, new P.W. Boards must not be indiscriminately removed from

their protective conductive bags.

l

Do not store or place P.W. Boards in a location exposed to direct sunlight.

l

When it becomes absolutely necessary to remove a Board from its conductive bag or case, always place

it on its conductive mat in an area as free as possible from static electricity.

l

Do not touch the pins of the

During

Replacement:

l

Before unplugging connectors from the P.W. Boards, make sure that the power cord has been unplugged

ICs

with your bare hands.

from the outlet.

l

When removing a Board from its conductive bag or conductive case, do not touch the pins of the

the printed pattern. Place it in position by holding only the edges of the Board,

l

Before plugging connectors into the Board, make sure that the power cord has been unplugged from the

I

ICs

or

power outlet.

During Inspection:

l

Avoid checking the IC directly with a multimeter; use connectors on the Board.

l

Never create a closed circuit across IC pins with a metal tool.

e

When it is absolutely necessary to touch the

ICs

and other electrical components on the Board, be sure

to ground your body.

1151SBD0103A

1-3. HANDLING

OF THE PC

DRUM

During Transportation/Storage:

l

Use the specified carton whenever moving or storing the PC Drum.

l

The storage temperature is in the range between -20C and

l

In summer, avoid leaving the PC Drum in a car for a long time.

+4OC.

Handling:

l

Ensure that the correct PC Drum is used.

l

Wheneverthe PC Drum has been removed from the copier, store it in its container or protect it with a Drum

Cloth.

l

The PC Drum exhibits greatest light fatigue after being exposed to strong light over an extended period

of time. Never, therefore, expose it to direct sunlight.

l

Use care not to contaminate the surface of the PC Drum with oil-base solvent, fingerprints, and other for-

eign matter.

l

Do not

saratch

l

Do not apply chemicals to the surface of the PC Drum.

l

Do not attempt to wipe clean the surface of the PC Drum.

the surface of the PC Drum.

D-3

Page 10

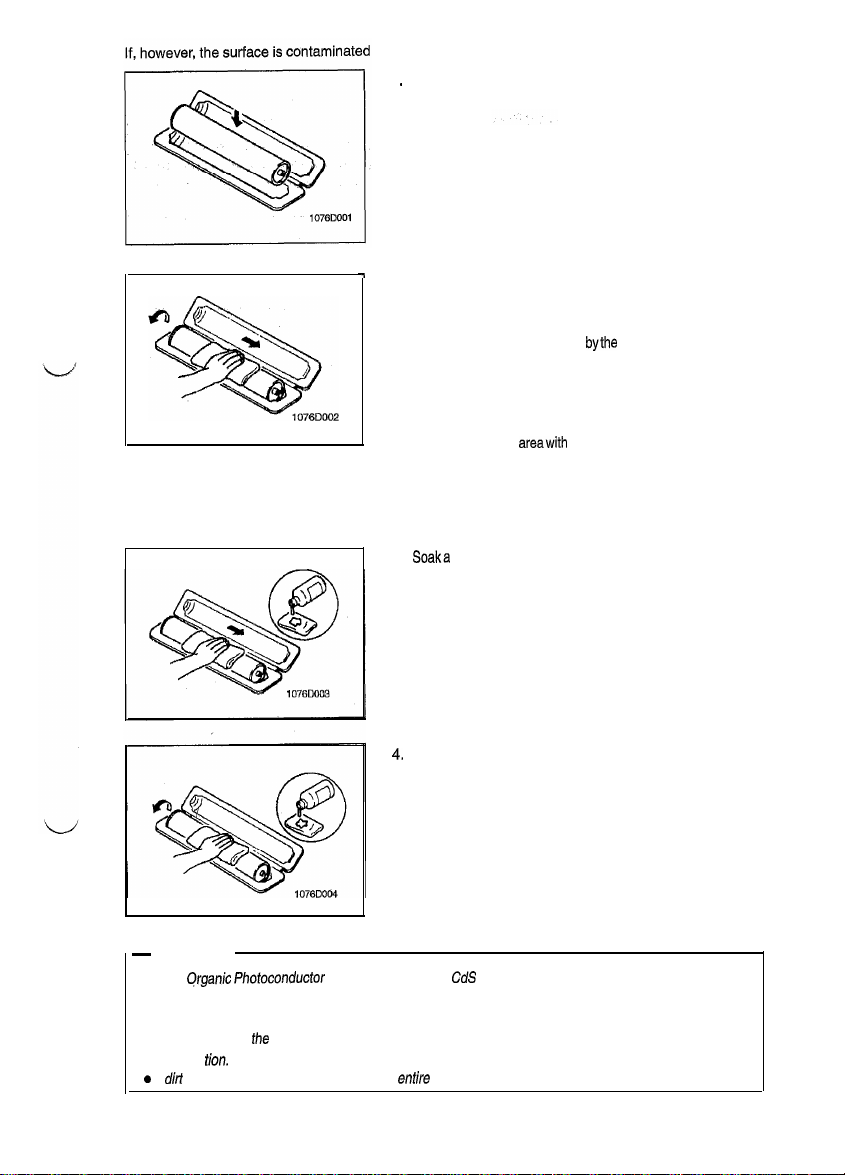

fingerprints, clean it using the following procedure.

with

.

Place the PC Drum into

1

2. Gently wipe the residual toner off the surface of the PC

one half of its container.

Drum with a dry, Dust-Free Cotton Pad,

a) Rotate the PC Drum so that the area of its surface on

which the line of toner left

bythe

Cleaning Blade is present is facing straight up. Wipe the surface in one continuous movement from the rear edge of the PC Drum to

the front edge and off the surface of the PC Drum.

b) Rotate the PC Drum slightly and wipe the newly ex-

posed surface

areawith

a CLEAN face of the Dust-Free

Cotton Pad. Repeat this procedure until the entire sur-

face of the PC Drum has been thoroughly cleaned.

* At this time, always use a CLEAN face of the dry Dust-Free

Cotton Pad until no toner is evident on the face of the Pad

after wiping.

3.

Soaka

small amount of either ethyl alcohol or isopropyl alcohol into a clean, unused Dust-Free Cotton Pad which

has been folded over into quarters. Now, wipe the surface

of the PC Drum in one continuous movement from its rear

edge to its front edge and off its surface one to two times.

* Never move the Pad back and forth.

Using the SAME face of the Pad, repeat the procedure ex-

4.

plained in the latter half of step 3 until the entire surface of

the PC Drum has been wiped. Always OVERLAP the

areas when wiping. Two complete turns of the PC Drum

would be appropriate for cleaning.

J

-

NOTES

l

The

Qrganic Photoconductor

Drum is softer than

CdS

and Selenium Drums and is therefore

susceptible to scratches.

l

Even when the PC Drum is only locally dirtied, wipe the entire surface.

l

Do not expose

illumina

a

If

dir/

remains after cleaning, repeat the

Uon.

fhe

PC Drum to direct sunlight. Clean it as quickly as possible even under interior

entire

procedure from the beginning one more time.

D-4

Page 11

1159SBD0104~

1-4. PARTS WHICH MUST NOT BE TOUCHED

(1) Screws

-

Purpose of Application of Red Paint

Red paint is applied to the screws which cannot be readjusted, set, or reinstalled in the field.

The basic rule is not to remove or loosen the screws to which red paint is applied. In addition, be advised

that, if two or more screws are designated as those which must not be touched on a single pat-t, only

one representative screw may be marked with red paint.

(2) Variable Resistors on Board

po

not turn the variable resistors on boards for which no adjusting instructions are given in

MEI+

ADJUST-

I

Page 12

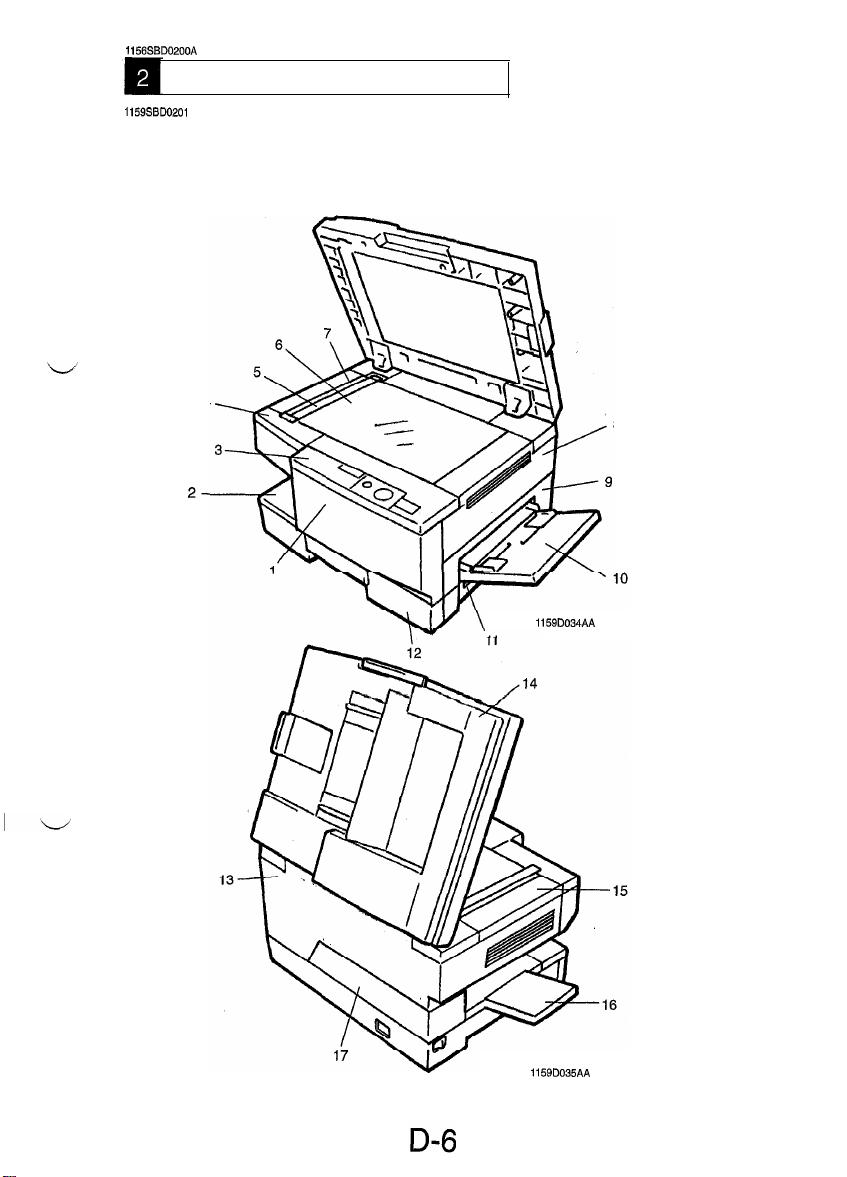

1156SBD0200A

DISASSEMBLY/REASSEMBLY

1159SBD0201

2-1. DOORS, COVERS, AND EXTERIOR PARTS: IDENTIFICATION AND

A

REMOVAL PROCEDURES

4

8

2-

1159D034AA

1159D035AA

Page 13

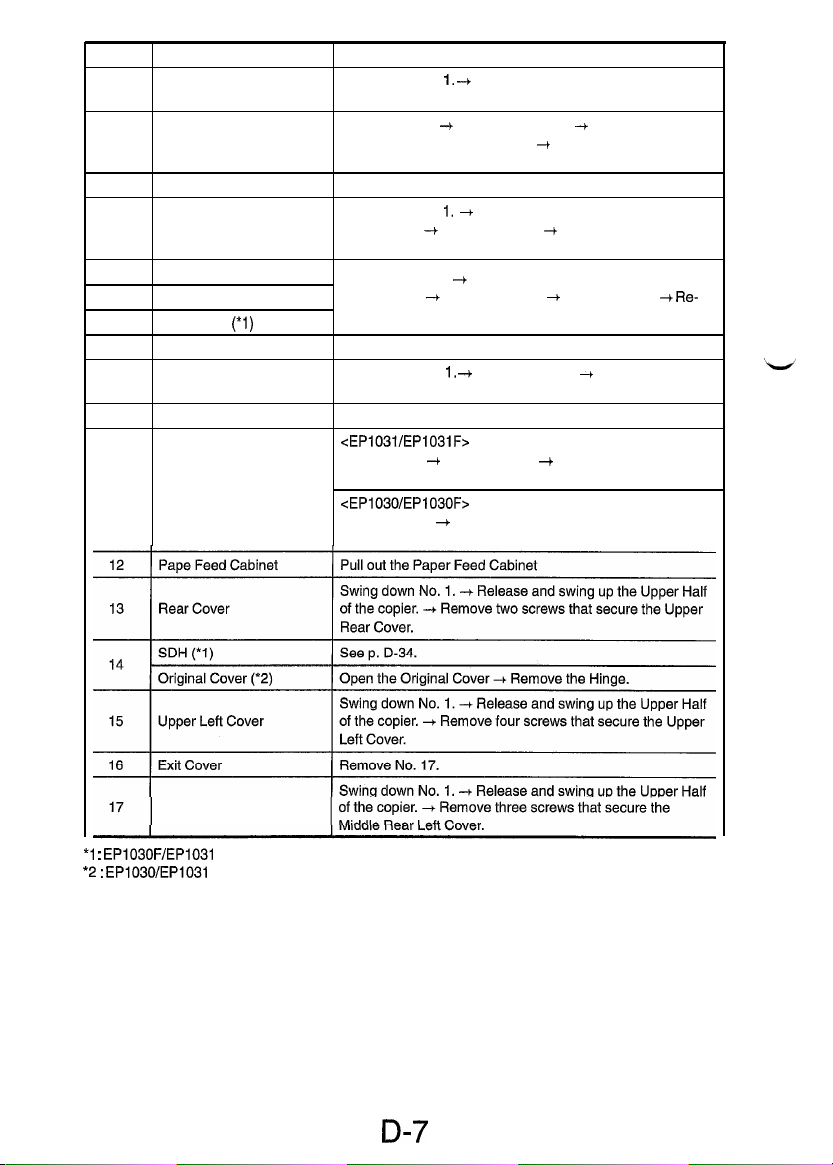

No.

1

2

3

4 Upper Front Left Cover

5

6

7 SDH Glass

8

9

10

11

Parts Name

Front Door

Middle Front Cover up the Upper Half of the copier. -I Remove two screws that

Control Panel Remove two screws that secure the Control Panel.

Original Scales

Original Glass

(*l)

Upper Right Cover

Middle Right Cover

Manual Bypass Table Remove two screws that secure the Manual Bypass Table.

Right Door

Swing down No.

move from the right side.

Pull out No. 12. -+ Swing down No. 1. + Release and swing

secure the Middle Front Cover.

Swing down No. 1. + Release and swing up the Upper Half

of the copier. -+ Remove No. 15. -I Remove two screws that

secure the Upper Front Left Cover.

Swing down No. 1. -I Release and swing up the Upper Half

of the copier. -I Remove No. 15. + Remove No. 4.

move two screws that secure the Original width Scales.

Remove two screws that secure the Upper Right Cover.

Swing down No. 1, -+ Remove No. 11. -I Remove two

screws that secure the Middle Right Cover.

<EP1031/EP1031F>

Open No. 11. -I Remove No. 9. -I Remove two screws that

secure the Right Door.

<EP1030/EP1030F>

Remove No. 9. + Remove two screws that secure the Right

Door.

Removal Procedure

1.

-t

Open Front door to the right and re-

--t Re-

*l

:

EP1030F/EP1031

*2

:

EP1030/EP1031

Middle Rear Left Cover

F only

only

D-7

Page 14

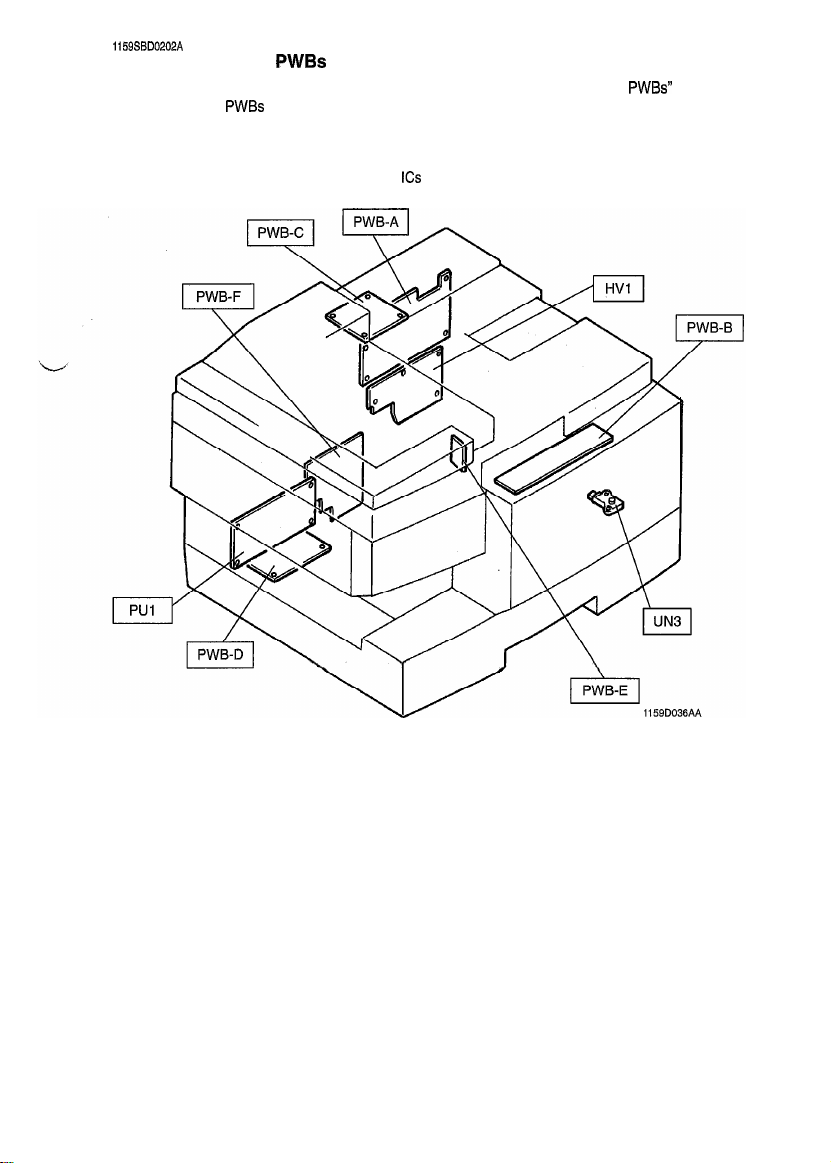

I

1159SBD0202A

2-2. REMOVAL OF

l When removing a circuit board, refer to PRECAUTIONS FOR HANDLING THE

SWITCHES ON PWBs and follow the corresponding removal procedures given on the next page.

l

Replacement of a circuit board may call for readjustment or resetting of particular items.

l

The removal procedures given on the next page omit the removal of connectors and screws securing the

circuit board support or circuit board.

l

Where it is absolutely necessary to touch the

to ground your body.

PWBs

PWBs

contained in

ICs

and other electrical components on the board, be sure

D-8

Page 15

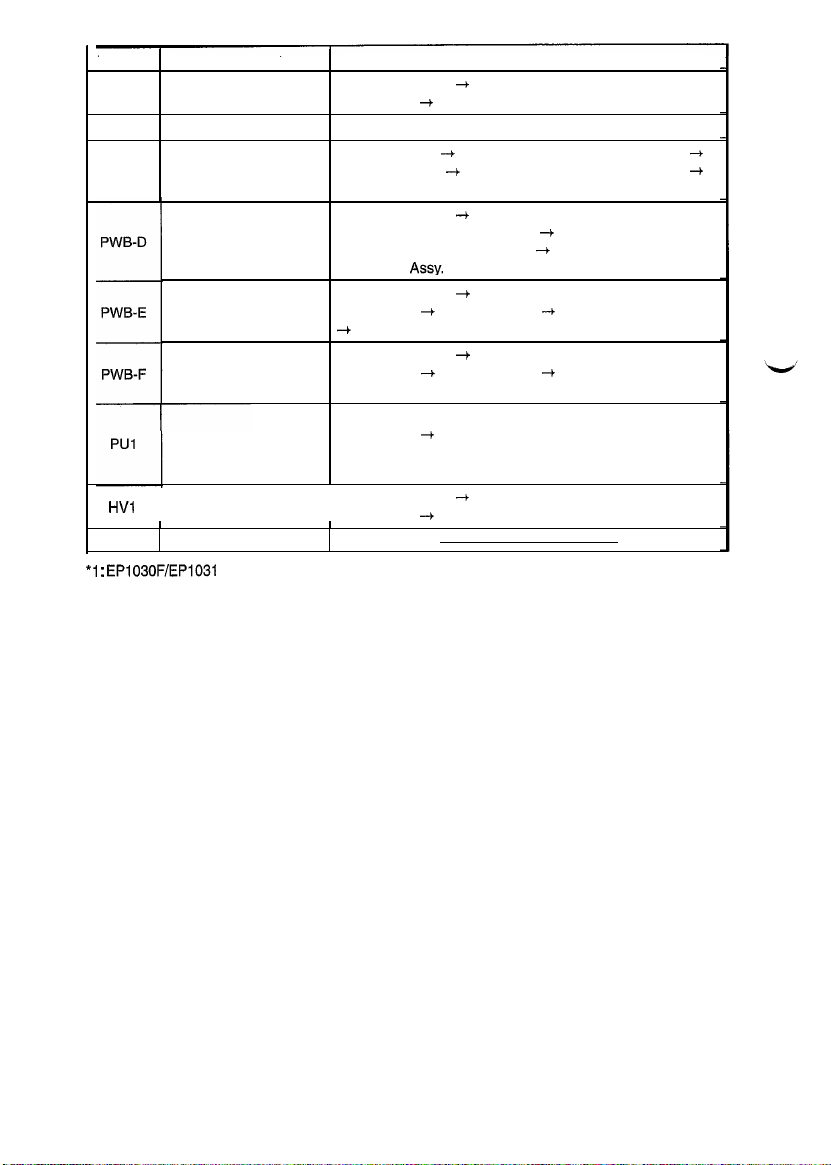

Symbol

r

PWB-A Master Board

PWB-B MSC Board

PWB-C SDH Board (1)

HVl

UN3

*l

:

EP1030F/EP1031

Parts Name

Noise Filter Board

AE Sensor Board

AVR

Power Supply Unit

Hight Voltage Unit

I

ATDC Sensor

F only

Removal Procedure

Swing down No. 1. + Release and swing up the Upper Half

of the copier. + Remove No. 13.

Remove No. 3.

Remove No. 14. -+ Remove the SDH Lower Rear Cover.

Remove the Mat. -I Remove the SDH Front Rear Cover.

Remove the SDH PWB Mountina Bracket Assv.

Swing down No. 1.

of the copier. -t Remove No. 17. + Remove the Power Sup-

ply Unit Mounting Bracket Assy. -I Remove the AVR Mounting Bracket Assy.

Swing down No. 1. + Release and swing up the Upper Half

of the copier. + Remove No. 15. -+ Remove No. 5, 6, and 7

4

Remove the AE Sensor Board Mounting Bracket Assy.

Swing down No. 1. + Release and swing up the Upper Half

of the copier.

Plate.

Swing down No. 1.4 Release and swing up the Upper Half

of the copier. 4 Remove No. 17.

NOTE: Never replace individual parts within the Power Supply

when repairing it. Always replace the entire Power Supply Unit.

Swing down No. 1. -I Release and swing up the Upper Half

of the copier. 4 Remove No. 13.

I

--t

Release and swing up the Upper Half

--f

Remove No. 17. + Remove the Contact

--t

+

D-9

Page 16

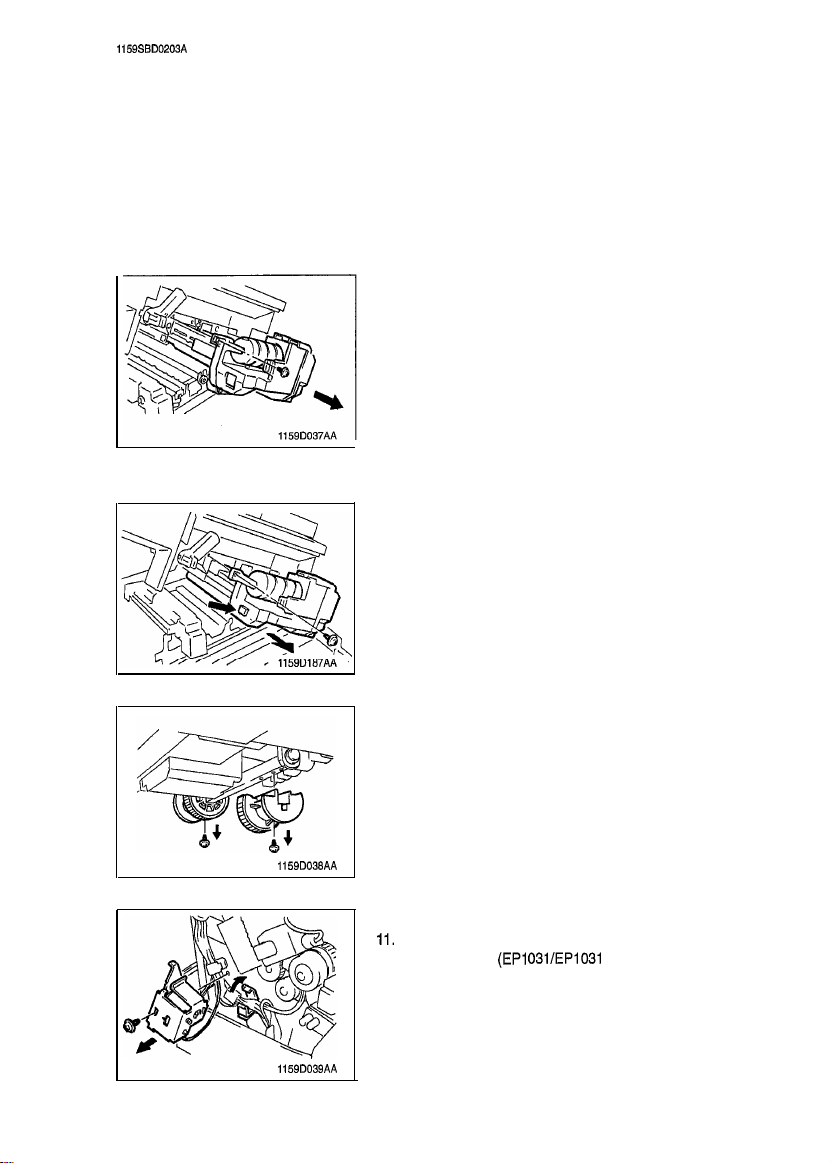

1159SBD0203A

~

2-3. PAPER TAKE-UP/TRANSPORT SECTION

(1) Removal of the Paper Take-Up Roll and Separator Roll Assy

Remove two screws and the Upper Right Cover.

1.

2.

Remove two screws and the Middle Right Cover.

3.

Remove one screw and the Right Door.

4.

Pull out the Paper Feed Cabinet.

5.

Swing down the Front Door.

6.

Release and swing up the Upper Half of the copier.

7.

Remove three screws and the Rear Cover.

<USA, Canada>

8.

Remove one screw and the Imaging Unit from the copier.

<Except USA, Canada>

8.

Push the lock lever and remove the IU.

1159D038AA

1159D039AA

9.

Remove each of the two screws and the Paper Take-Up

Roller.

10. Open the Cord Clamp.

11.

Remove one screw and the Multi Bypass Paper Take-Up

Solenoid Assy.

(EPI

03VEP1031 F Only)

D-10

Page 17

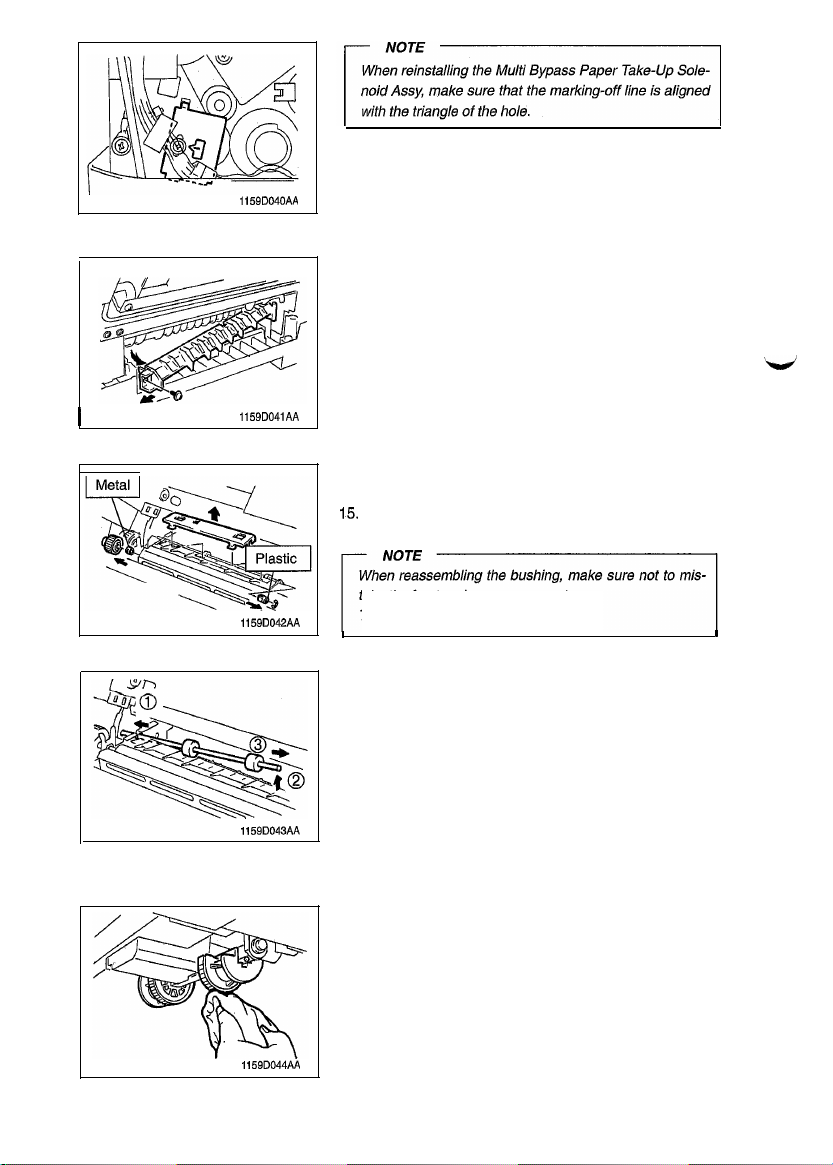

1159D040AA

12. Remove one screw and the Gide Plate.

I

1159D041AA

1159D042AA

1159D043AA

13. Remove the Separator Roller Guide Plate.

14. Remove the Rear Gear.

Snap off the one E-ring to remove the front and rear Bush-

15.

ings.

take the front and rear components.

The front is plastic and the rear is metal.

I

Move the Separator Roller to the rear and, as shown in by

16.

the sequence in the illustration to the left, remove it from

the front.

(2) Cleaning of the Paper Take-Up Rolls

Pull out the Paper Feed Cabinet.

1.

Using a soft cloth dampened with alcohol, wipe clean the

2.

two Paper Take-Up Rolls.

I

1159D044AiI

D-11

Page 18

,

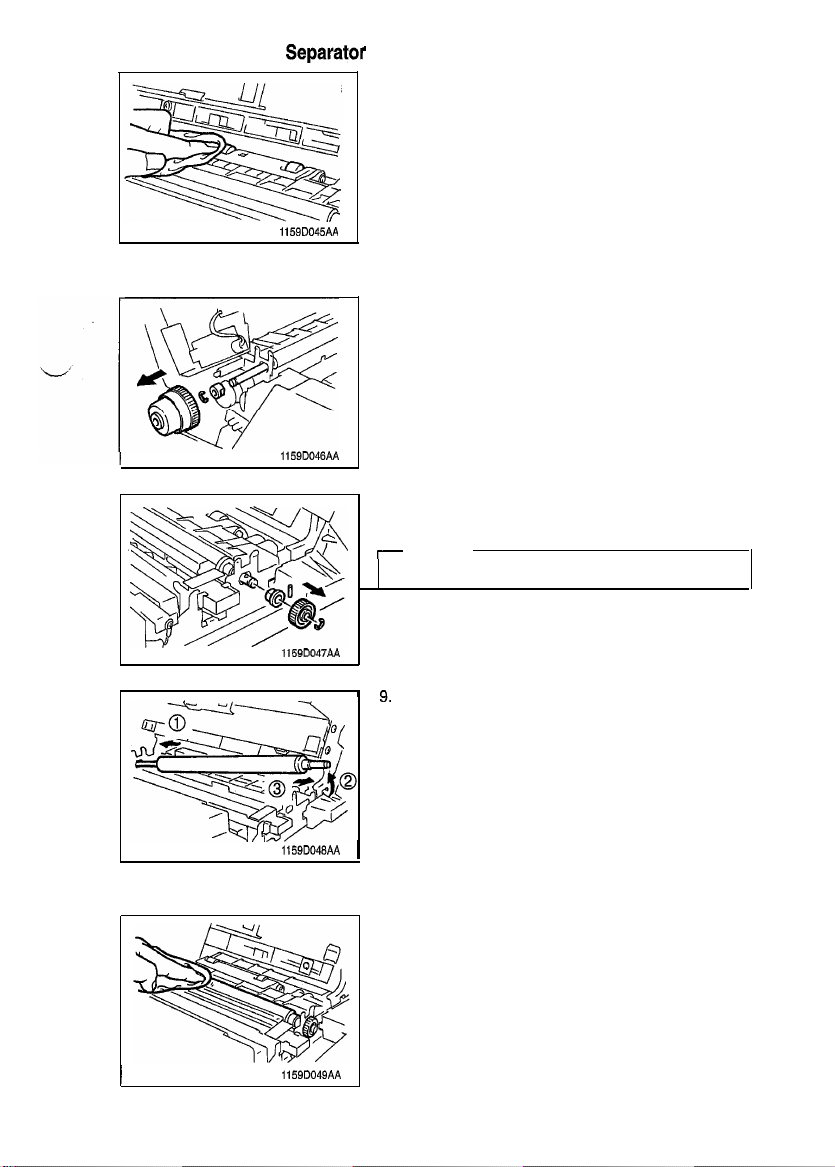

(3) Cleaning of the

Separator

1159D045AA

Rolls

1.

Swing down the Front Door.

Release and swing up the Upper Half of the copier.

2.

Remove one screw and the Imaging Unit from the copier.

3.

Using a soft cloth dampened with alcohol, wipe clean the

4.

two Separator Rolls.

(4) Removal of the Synchronizing Roller

1.

Swing down the Front Door.

2.

Release and swing up the Upper Half of the copier.

Remove the Imaging Unit from the copier.

3.

Remove three screws and the Rear Cover,

4.

Snap off the one E-ring to remove the Timing Clutch.

5.

Snap off the one E-ring to remove the Rear Bushing.

6.

1159D046AA

Snap off the one E-ring to remove the Gear.

7.

8.

Remove the front Bushing.

I

NOTE

Use care not to loose the Set Pin when removing the Gear.

116QD047AA

I

n

3.

Move the Timing Roller to the rear and, as shown in the illustration to the left, remove it from the front.

1159D048AA 1

(5) Cleaning of the Synchronizing Roller

Swing down the Front Door.

1.

Release and swing up the Upper Half of the copier.

2.

Using a soft cloth dampened with alcohol, wipe clean the

3.

Synchronizing Roller.

I

1159D049AA

D-12

Page 19

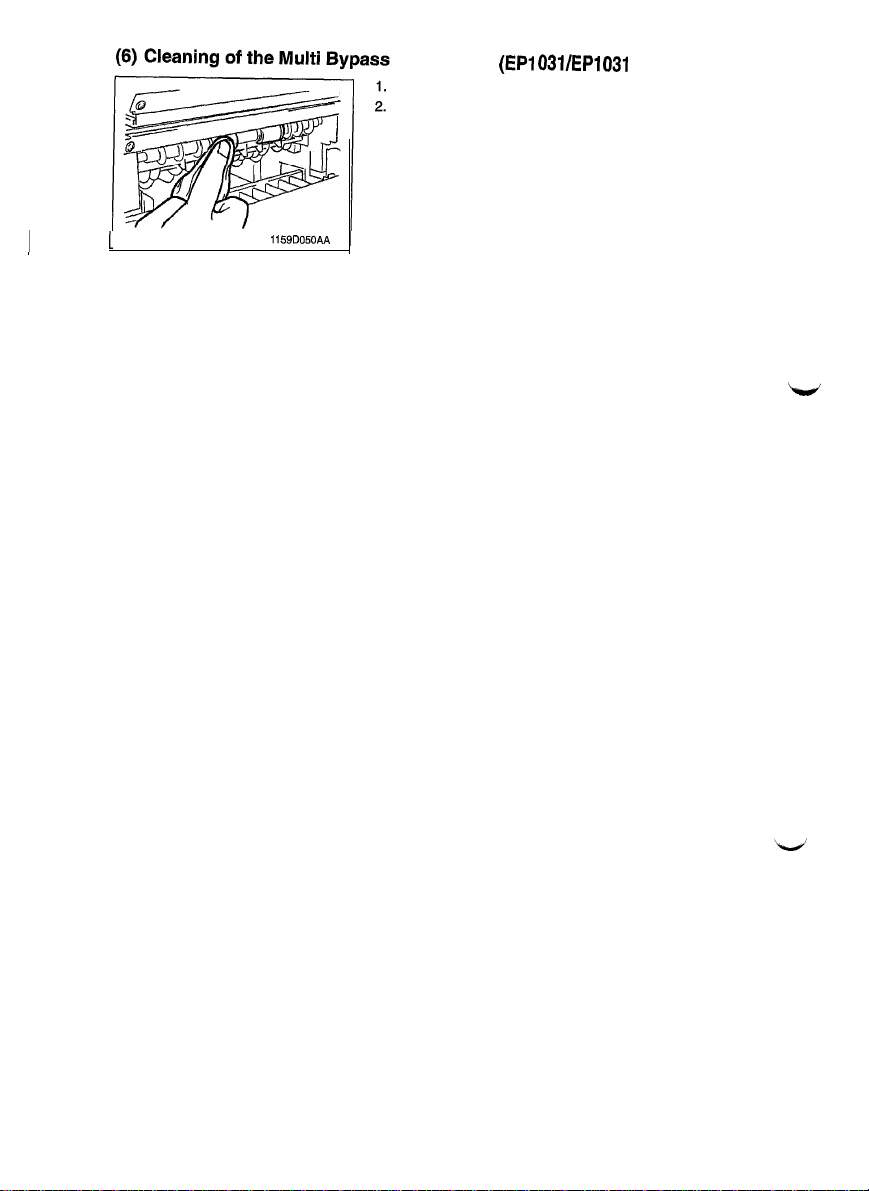

Feed Roller (EPI

Open the Right Door.

Using a soft cloth dampened with alcohol, wipe clean

two Multi Bypass Paper Feed Rollers.

031/EP1031

F Only)

the

I

1

1159D050AA

D-13

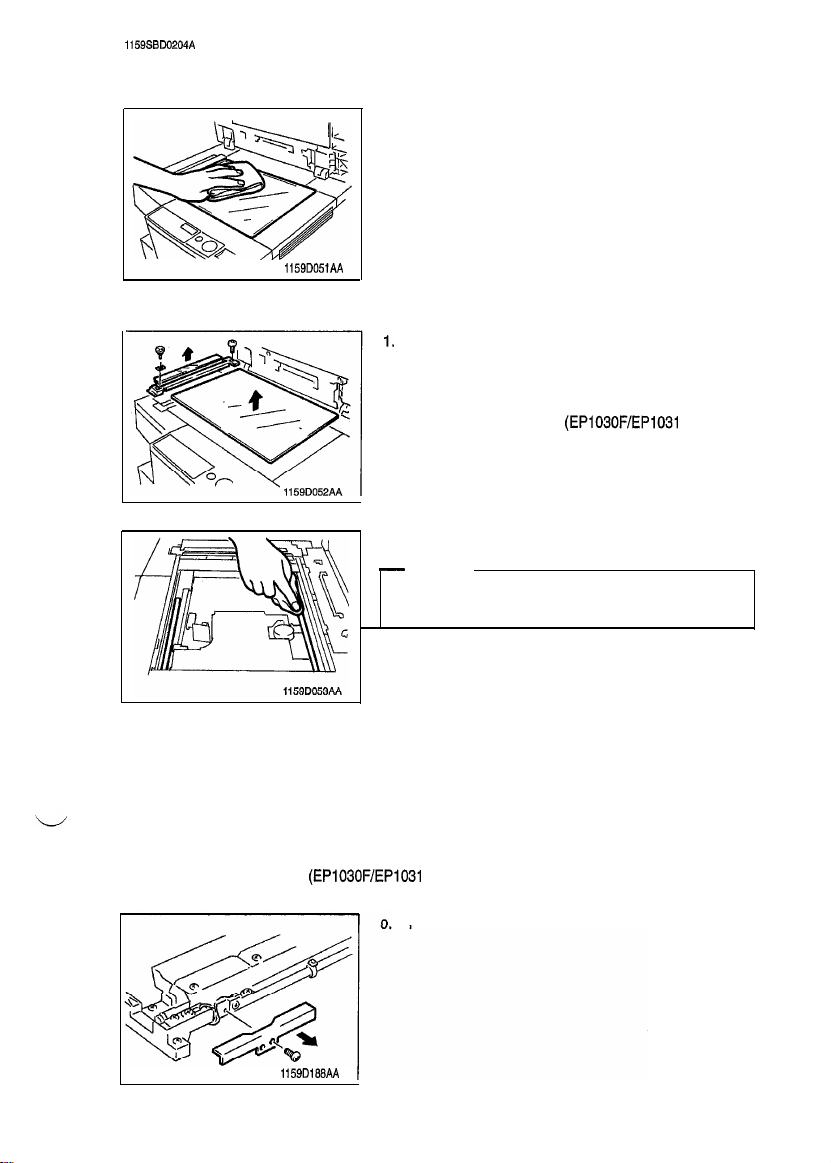

Page 20

1159SBD0204A

2-4. OPTICAL SECTION

(1) Cleaning of the Original Grass

1.

1159D051AA

Wipe clean the Original Glass with a soft cloth.

(2) Cleaning of the Scanner

Rail and Bush

1.

Swing down the Front Door.

2.

Release and swing up the Upper Half of the copier.

3.

Remove four screws and the Upper Left Cover.

4.

Remove two screws and the Original Width Scale.

5.

Remove the SDH Glass. (EP1030F/EP1031 F Only)

6.

Remove the Original Glass.

7.

Wipe clean the Scanner Rail and Bush with a soft cloth.

-

NOTE

Be

Brush have been cleaned.

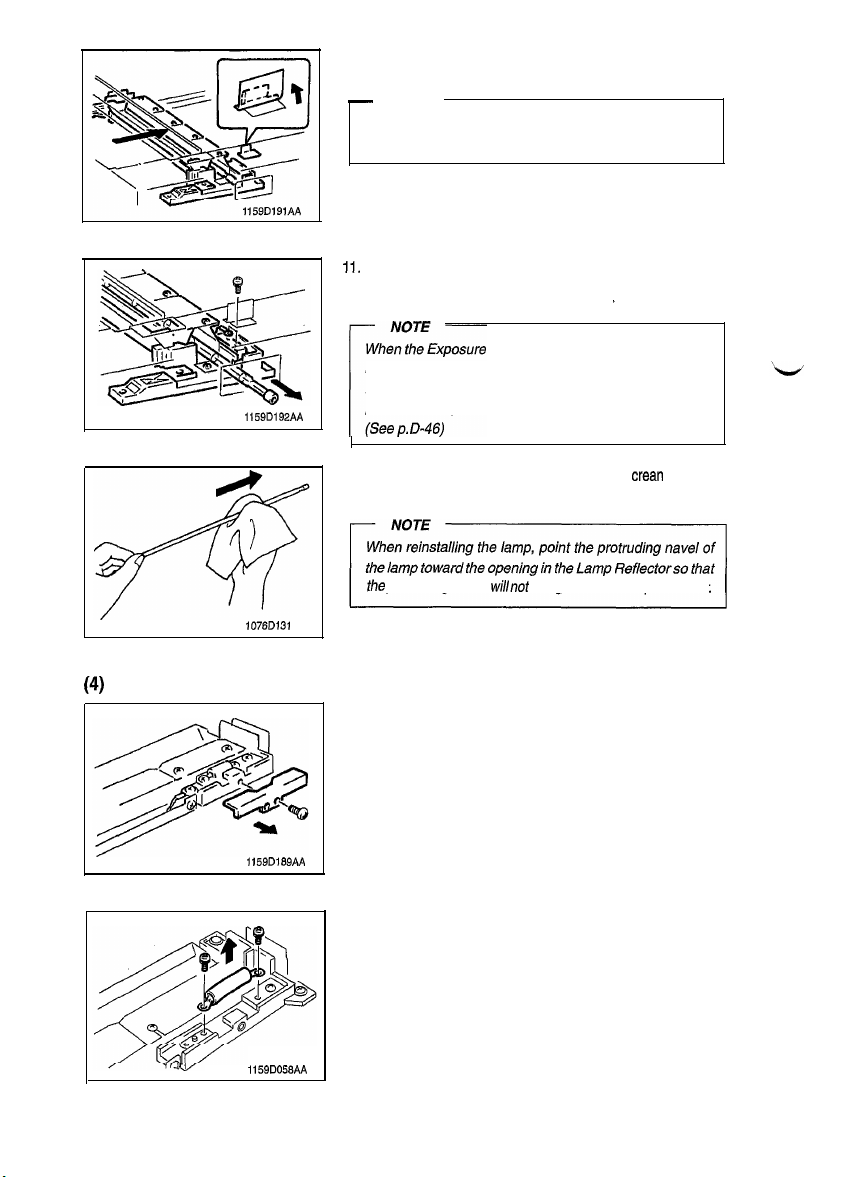

(3) Cleaning of the Exposure Lamp

1.

Swing down the Front Door.

2.

Release and swing up the Upper Half of the copier.

3.

Remove four screws and the Upper Left Cover.

4.

Remove one screw and the Upper Front Left Cover.

5.

Swing down and lock the Upper Half of the copier.

6.

Remove two screws and the Original Width Scale.

7.

Remove the SDH Glass. (EP1030F/EP1031 F Only)

8.

Remove the Original Glass.

Remove one screw and front terminal cover.

sure to apply lubricating oil after the Scanner Rail and

1159D198AA

D-14

Page 21

1159D192AA

10. Move the Scanner to the position shown on the left and

peel the seal partly off the copier frame.

-

NOTE

Do not peel the seal completely off the frame.

cleaning steps have been completed, affix it back again.

Remove one screw and front Scanner Harness.

11.

Remove one screw and the Exposure Lamp Terminal.

12.

13.

Slide out the Exposure Lamp.

Lamp has been cleaned or replaced,

be sure to make the adjustment ofopfimum exposure setting in the Manual Exposure mode. (Seep. D-44) and ad-

justment of exposure Level in the Auto Exposure mode.

After the

1076D131

(4)

Removal of the Thermal Fuse

1159D169AA

I

Using a soft cloth dampened with alcohol,

14.

by gently wiping its surface in one direction.

the

protruding

1.

Remove one screw and rear terminal cover.

Remove two screws and the Thermal Fuse.

2.

navel willnot hit

against

the Lamp Reflector.

crean

the lamp

1159D056AA

D-15

Page 22

I

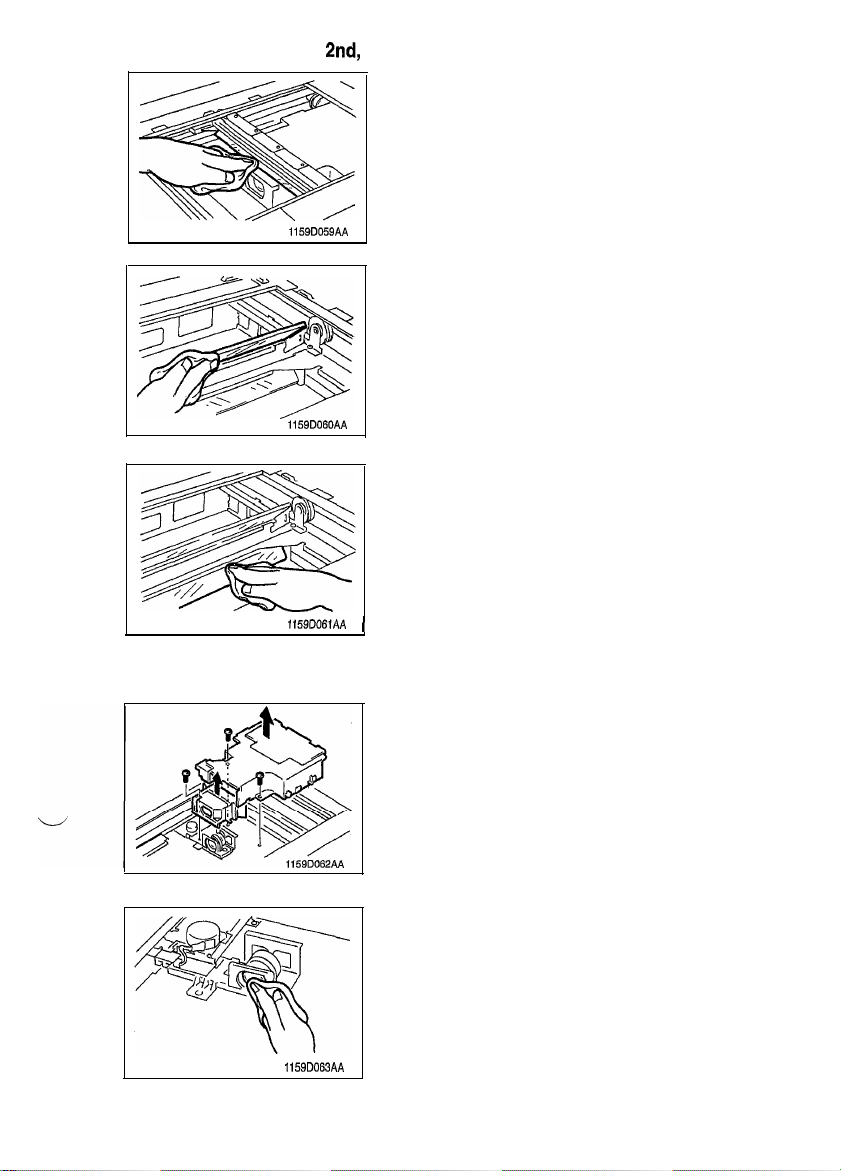

(5) Cleaning of the Ist,

2nd,

1159D059AA

1159D060AA

1159D061AA (

and 3rd Mirrors

1.

Wipe clean the 1st Mirror with a soft cloth.

2.

Wipe clean the 2nd Mirror with a soft cloth.

3.

Wipe clean the 3rd Mirror with a soft cloth.

(6) Cleaning of the Lens and 4th and 5th Mirrors

1.

Remove the Original Glass.

2.

Remove two screws and the Optical Cover.

3.

Remove two screws and the Lens Cover.

4.

Gently dust off the surface of the Lens using a soft cloth.

1159D063AA

D-l 6

Page 23

5.

Wipe clean the 4th and 5th Mirrors with a soft cloth.

1159D064AA

(7) Cleaning of the Cooling Fan Filter

1.

Swing down the Front Door.

2.

Release and swing up the Upper Half ofthe copier.

3.

Remove three screws and the Rear Cover.

4.

Clean the Cooling Fan Filter using a brush or a vacuum

cleaner.

1159D065AA

(8) Removal Scanner Drive Motor M4

1.

Remove the Upper Right Cover.

2.

Swing down the Front Door.

3.

Release and swing up the Upper Half of the copier.

4.

Remove three screws and the Rear Cover.

5.

Remove the 17 connectors from the PWB-A.

1159D067AB

1159D068AA

6.

Remove the PWB-A.

7.

Remove the three screws and the Ozone Fan Motor Assy.

8.

Free the Mylar.

D-17

Page 24

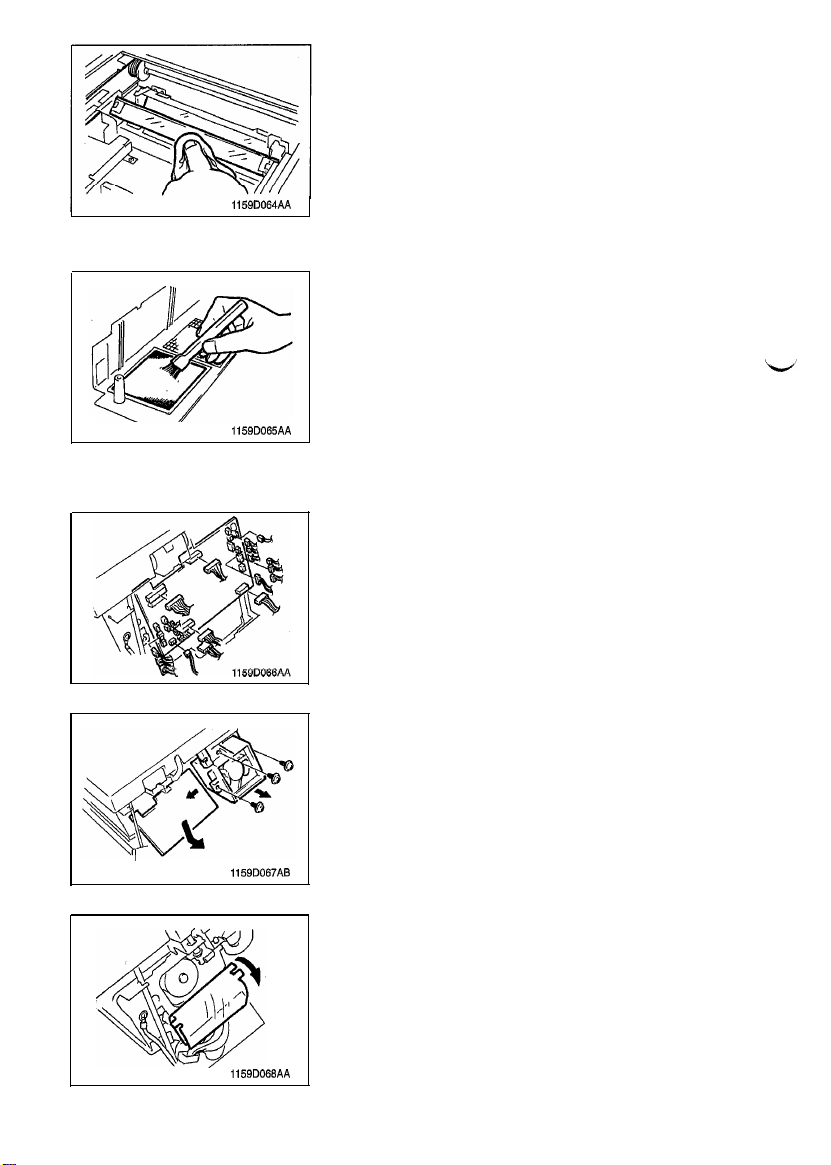

9.

Remove the Harness for the Scanner Drive Motor

Locking Edge Cover and remove it from the Cord Clamp.

10.

Remove two screws and the Scanner Drive Motor M4.

1159D069AA

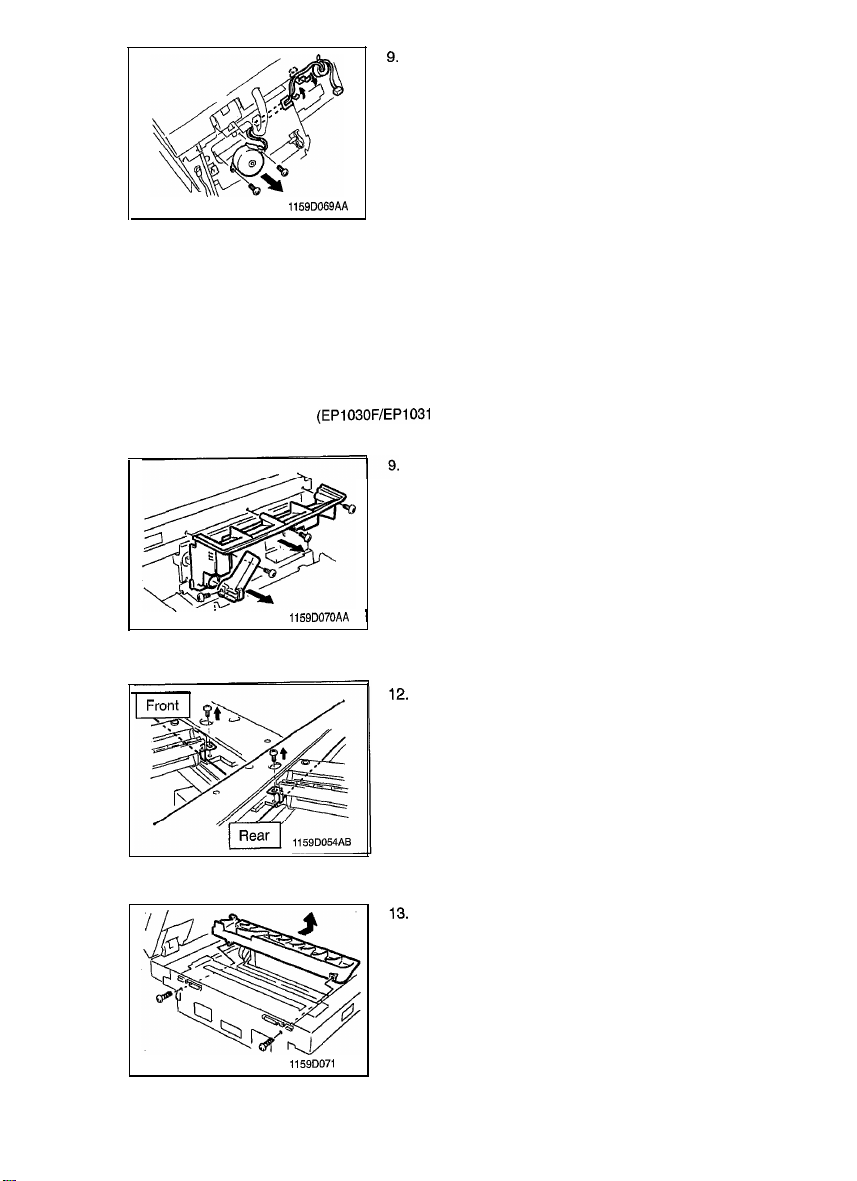

(9) Removal of the Scanner Drive Cable

Swing down the Front Door.

1.

Release and swing up the Upper Half of the copier.

2.

3.

Remove the Imaging Unit from the copier.

4.

Remove the Upper Left Cover, Upper Front Left Cover and Rear Cover.

Swing down and lock the Upper Half of the copier.

5.

Remove the Original Scale and Original Glass.

6.

Remove the SDH Glass. (EP1030F/EP1031 F Only)

7.

a.

Remove the Upper Right Cover.

Remove the two screws and one connector and the Control Panel.

Remove the one screw and the Upper Unit Release Lever.

10.

11.

Remove the three screws and the Lower Panel Cover.

1159D070AA 1

from

the

1159DO71 AA

Move the Scanner to the center and remove the one screw

and the front and rear Scanner Mounting Brackets.

Remove the two screws and the Optical Section Cooling

Duct.

D-18

Page 25

1159D073AA

I

NOTE

When reassembling the Optical Section Cooling Duct,

make sure

lus

14.

Remove two screws and the Optical Cover.

15.

the Rear Wire is retained as

tra tion.

Unhook each of the two springs at the front and rear and

remove the cable.

shown in the

il-

I

I i

1159D075AC

1159D076AC

16.

Snap off the one E-ring from the Pulley Shaft.

17.

Remove the one screw from the Drive Belt Pulley.

18.

Remove each screw from the front and rear Cable Drive

Pulleys.

19. Remove the Pulley Shaft.

20. Remove the Cable Drive Pulley.

D-l

9

Page 26

(10) Winding of the Scanner Drive Cable

+

Remark

WheneverScanner Drive Cable has been rewound, be sure to make theAdjustment of the Scanner/Mirrors

Carriage Position. See p.D-67.

1159D077AA

1.

From the bead on the rear pulley, wrap the shorter of the

Cable counterclockwise four times towards the rear.

I

1159D07BAA 1

1159D079AC

1159D080AA

N

2.

Wrap the longer of the Cable clockwise three times to-

wards the front and secure with the Tape.

3.

From the bead on the front pulley, wrap the longer of the

Cable in clockwise three times towards the front.

D-20

Page 27

/.

/

9

1159D081AC

1159D082AC

1159DOMAA 1

4.

Wrap the shorter of the Cable in counterclockwise four

times towards the rear and secure with the Tape.

Mount the front and rear Cable Drive Pulleys, Drive Belt

5.

Pulley and Pulley Shaft.

6.

Install the three set screws to the front and rear Cable

Drive Pulleys and the Drive Belt Pulley and mount the one

E-ring to the Pulley Shaft.

Wrap the shorter of the two Cable in the rear around

7.

Pulley B and secure it to the frame.

1159D084AA

1159D085AA

8.

Pull the longer of the two Cable and wrap it around

Pulleys A and B.

9.

Wrap the shorter of the two Cable in the front around

Pulley B and secure it to the frame.

D-21

Page 28

1159D097AA

10.

Pull the longer of the two Cable and wrap it around Pulleys

A and B.

l The longer Cable is wrapped around the outside of

Pulley B.

l

The shorter Cable is wrapped around the inside of Pulley

B.

1159D089AA

I

NOTE

Set the Rounded Tip as shown in the illustration to the left.

r

11.

Set the front and rear Cable in the groove for the Cable

Guide and attach to the Spring.

12.

Peel tape

13.

Secure the Optical Cover with two screws.

cuff

the Cable Drive Pulleys.

1159D196AA

D-22

Page 29

1159SSD0205A

2-5.

IMAGING UNIT

(1) Removal of the Imaging Unit

1.

2.

<USA,

Canada>

3.

Swing down the Front Door.

Release and swing up the Upper Half of the copier.

Remove one screw and the Imaging Unit from the copier.

<Exceet

USA, Canada>

3.

(2) Replacement of the PC Drum

1.

1159D090AB

2.

3.

I

1159DOQlAB

Push the lock lever and remove the

Remove the two Covers.

Remove the Connectors for the Ground-Shielded Harness.

Remove the Drum Charge Corona.

IU.

D-23

Page 30

Remove the three screws and the Hopper Unit.

4.

Remove two shoulder screws and the Cleaning Blade.

5.

Turn the Bushing in the direction of the arrow and remove.

6.

Push in on the rear

7.

and replace it.

=Y/

1159D096AA

(3) Replacement of the Cleaning Blade

Remove the two Covers.

1.

1159DOQOAB

D-24

of

the PC Drum, remove

it

from

the front

Page 31

1159D091AB

1159D092AC 1

2.

Remove the Ground-Shielded Harness Connector.

3.

Remove the Drum Charge Corona.

4.

Remove the three screws and the Hopper Unit.

5.

Remove and replace the Cleaning Blade.

(4) Replacement of the Ds Positioning Collars

Remove the three screws and the Hopper Unit.

1.

1159D093AA

Remove the one screw and the Recycling Pipe.

2.

D-25

Page 32

1159D190AA

Snap off the two E-rings to remove the one screw and the

3.

Drive Gear.

Remove the front Ds Positioning Collar and replace.

4.

NOTE

When replacing the front Ds Positioning Collar, hold the

shaft behind the Bucket Roller.

r

Snap off the one E-ring to remove the rear Ds Positioning

5.

Collar and replace.

(5) Replacement of the Starter

1159D165AA

1.

Damp the developer out of the Developing Unit.

2.

Set the Starter Bottle to IU and perform adjustment of

the F8 ATDC Adjustment. (See

p.D-46)

D-26

Page 33

3.

Remove the Starter Bottle and set the Toner Bottle.

NOTE

Shake the Toner Bottle before setting it in place.

r

1159DlWAA

(6) Cleaning of the Toner Antispill Mylar

1.

Remove the two screws, the Receiver Plate and the

Toner Antispill Mylar.

2.

Using a brush, whisk dust off the Toner Antispill Mylar.

11590166AB

(7) Cleaning of the Toner Scattering Prevention Mylar

1.

Using a brush, whisk dust off the Toner Scattering Prevention Mylar.

1159Dl69AA

(6) Cleaning of the Paper Dust Removal Cleaner

I.

Remove the Timing Roller.

2.

Using a brush, wihisk dust off the Paper Dust Removal

Cleaner.

D-27

Page 34

2-6. PC DRUM CHARGE CORONA AND IMAGE TRANSFER/

PAPER SEPARATOR CORONAS

(1) Removal of the PC Drum Charge Corona

1.

Remove the two Covers.

1159D090AB

2.

Remove the Ground-Shielded Harness Connector.

3.

Remove the Drum Charge Corona.

1159DO91 AB

(2) Cleaning of the Main Eraser

1.

Using a soft cloth dampened with alcohol, clean the Main

Eraser by gently wiping its surface in one direction.

1159D200AA

(3) Cleaning of the PC Drum Charge Corona Housing

1.

Press the Mesh Holder on the front of the Corona Unit in

the direction of arrow to remove the Grid Mesh.

1159D172AB

2

1159D173AB 1

2.

Remove the End CUDS from the front and rear end of the

Unit.

D-28

Page 35

I

[

3.

Remove the Comb Electrode, Drum charge Corona.

-

NOTE

Use care not to deform the Electrode. When removing it,

first snap off its spring end.

/

1159D174AB

(4) Cleaning of the Comb Electrode, Drum charge Corona

1.

Use a blower brush to clean the Comb Electrode, Drum

charge Corona.

-

NOTE

If

the blower brush is not effective in cleaning the Comb

Electrode, Drum Charge Corona use a soft cloth dampened with alcohol to clean serious contamination.

I

I

1159D175AA

(5) Cleaning of the PC Drum charge Corona Grid Mesh

Blow all foreign matter off the Grid Mesh a blower brush.

tamination.

1159D176AA 1

(6) Removal of the Image Transfer/Paper Separator Coronas

1.

Swing down the Front Door.

2.

Release and swing up the Upper Half of the copier.

3.

Pull out the Image Transfer/Paper Separator Coronas.

1159D177AA

(7) Cleaning of the Image Transfer/Paper Separator Coronas Housing

1.

Remove the Image Transfer/Paper Separator Corona

Housing,

1159D178AA

D-29

Page 36

2.

Using a soft cloth dampened with alcohol, wipe the housing clean of dirt.

11590179AA

(8) Cleaning of the Image Transfer Charge Wire

1.

Clamp a soft cloth (gauze) dampened with alcohol with

tweezers and clean the Charge Wire in one direction.

Wipe from the Hook side to the Spring side.

1159D180AA

(9) Cleaning of the Comb Electrode, Paper Separator Corona

1.

Use a blower brush to clean the Comb Electrode, Paper

Separator Corona.

(10) Cleaning of the Pre-Image Transfer Guide Plate

1.

Use a soft cloth dampened with alcohol to clean the

Image Transfer Guide Plate.

D-30

Pre-

Page 37

1159SBD0207A

2-7. FUSING UNIT

(1) Removal of the Fusing Unit

1.

2.

3.

4.

5.

1159D097AB

6.

7.

Swing down the Front Door.

Release and swing up the Upper Half of the copier.

Removal three screws and the Middle Rear Left Cover.

Remove the Harness for the Fusing Unit from the Edge

Cover and remove it from the Cord Clamp.

Remove the two terminals for the Fusing Unit.

Remove the one screw, two washers and Ground Wire

from the Fusing Unit.

Remove the one Shoulder Screw, turn the Fusing Unit in

the direction of the arrow and remove it.

1159DlOlAA

Remove one screw and the Bracket.

8.

Remove the three screws and the Cover for the Fusing

9.

Unit.

10.

Remove the one screw and front Heater Harness.

11.

Remove two screws and the Fusing Thermoswitch.

12. Remove one screw and the Fusing Thermistors.

D-31

Page 38

13.

Remove the two screws and the front Power Supply Brush

Assy.

Remove the two screws and the rear Power Supply Brush

14.

Assy.

1159D102AB

15. Remove two C-clips.

16. Remove one Spur Gear.

Remove the front and rear Bushings and remove the Roll-

17.

er.

1159D103AB

(2) Cleaning of the Upper Fusing Roller

Using a soft cloth dampened with alcohol or silicone oil,

1.

wipe clean the Upper Fusing Roller.

1159D104AA

1

(3) Cleaning of the Fusing Paper Separator Fingers

Using a soft cloth dampened with alcohol or silicone oil,

1.

wipe clean the Fusing Paper Separator Fingers.

1159D105AA

(4) Cleaning of the Fusing Thermistor

1159D106AA

1

THl

Using a soft cloth dampened with alcohol or silicone oil,

1.

wipe clean the Fusing Thermistor

D-32

THl.

Page 39

~

(5) Cleaning of the Fusing Thermoswitch TSI

Using a soft cloth dampened with alcohol or silicone oil,

1.

wipe clean the Fusing Thermoswitch

TSl.

I

1159D107AA

(6) Removal of the Lower Fusing Roller

1.

Remove the one screw and one washer, Lift the Fusing Entrance Guide in the direction of the arrow and remove.

Y

11~9D108AA

1159D133M

1.

Remove the Fusing Unit.

2.

Using a soft cloth dampened with alcohol, wipe clean the

Fusing Unit Entrance Guide Plate.

D-33

Page 40

1159SBD020SA

2-8. SDH Unit

(EP1030F/EP1031

F Only)

(1) Removing the Paper Feed Roller/Pick-up Roller/Separator Roller

1.

Swing down the Front Cover.

2.

Release and swing up the Upper Half of the copier.

3.

Remove three screws and the Rear Cover.

4.

Remove the one Connector from the PWB-A.

5.

Remove the one screw, one washer and the Ground Wire.

1159D111AB

Open the SDH and remove the one screw, one washer and

the Ground Wire.

11590112AC (

1 7.

Remove the six screws and SDH.

I

1159D113AB

8.

Remove the two screws and Lower Rear SDH Cover.

-

NOTE

The SDH, left attached to the copier, can also be

clisas-

sembled.

1159D114AA

9.

Remove the three screws and Lower Front SDH Cover.

D-34

Page 41

1159D118AB

10. Remove the Harness.

11. Remove the four screws and the Transport Guide Plate

Assy.

12. Remove the three Collars and the Harness.

13.

Remove the three screws and free the PWB-C Assy.

14.

Remove the two screws and free the Lead Switch Assy.

15.

Remove the eight screws and the Transport Assy.

. \

1159D119AB

1159Dl

ZOAA

16.

Move the Bushing to the rear and remove the Paper Roller

Assy.

17.

Snap off the one E-ring to remove the Paper Feed Holder

Assy.

D-35

Page 42

1159D122AA

1159D123AA

1159D124AA

Snap off the one E-ring to remove the Paper Feed Roller

18.

Assy.

Snap off the one E-ring to remove the Pick-up Roller from

19.

the Paper Feed Holder Assy.

20.

Remove the Separator Holder and Spring from the Transport Guide Plate.

21. Snap off the one E-ring to

Assy.

(2) Cleaning the Paper Feed Roller/Pick-up Roller

1.

Remove the Paper Feed Roller/Pick-up Roller.

Using a soft cloth dampened with alcohol, wipe clean the

2.

Rollers.

1159D126AA

D-36

remcve

the Separator Roller

Page 43

(3) Cleaning of the Separator Roll

Remove the Separator Roller Assy.

1.

Using a soft cloth dampened with alcohol, wipe clean the

2.

Separator Roil.

(4) Cleaning of the Upper

I

1159D128AA

nchronizing Roller

s1

Open the

Using a soft cloth dampened with alcohol, wipe clean the

Upper Synchronizing Roller.

OpeningKioseing

(5) Cleaning of the Lower Synchronizing Roller

Remove the Transport Assy.

1.

2.

Using a soft cloth dampened with alcohol, wipe clean the

Lower Synchronizing Roller.

1159D129AA 1

(6)

Cleaning the Upper Glass Roller

Remove the Transport Assy.

1.

Using a soft cloth dampened with alcohol, wipe clean the

2.

Upper Glass Roller.

Guide

.

1159D130AA

(7) Cleaning the Transport Roller

Remove the Transport Assy.

1.

Using a soft cloth dampened with alcohol, wipe clean the

2.

Transport Roller.

1159D132AA

Page 44

(8) Cleaning the Exit Roller

1159D131AA

.

1.

Using a soft cloth dampened with alcohol, wipe clean the

Exit Roller.

D-38

Page 45

1156SSD0300A

ADJUSTMENT

1159SBD0301A

3-1. JIGS AND TOOLS USED

+

Important

l

These jigs are used when adjusting the Scanner for correct positioning.

DScanner Adjusting jig (Front)

1159D196AS

@Scanner Adjusting jig (Rear)

I

1159D197AB

D-39

Page 46

1159SBD0302A

3-2. ADJUSTMENT REQUIREMENTS LIST

Adjustment of Optimum

Setting in the Manual

Adjustment of Zoom

Adjustment of

ing Edge Registration in Full

Adjustment of

Exposure

Exposure

Ratio in the

Reference Position

Edge

Erase (*I)

o. 1 and covering No. 2

Width B -Width A = f 1 .O mm

Adjustment of SDH Center

ment (2)

*1:

EPl03l/EPl03lF

*2: EPl030F/EPlO31

Only

F Only

(100 %) 20

Align-

Width B -Width A = f 1 .O mm

f

D-40

2.0 mm

Mounting Screw on

left side of SDH

D-67

Page 47

3-3. ACCESSING THE TECH.

.

Perform the following steps to set the copier in to Service Mode.

h[

1

I)

1

II)

Exposure Control Key

REP.

-1

MODE

@

I)

Exposure Control Key

Press the Keys in order of [I],

and

[4].

2.

Use the Copy Quantity and Zoom

and press the Start Key. (Display will appear in sequence d, c, A, F)

Display

1159DOOlAA

1159D002AA

($)

[2], [3],

Set the Display Panel to a flashing d.

Key

a

to select the Service Mode No.

1159D002AA

forthe

setting to be performed

1159D003AA

Tech. Rep. Choice

t

I

1159D004AA 1159D005AA

+

Adjust

D-41

Page 48

1159SBD0304A

~

3-4. ELECTRICAL/IMAGE ADJUSTMENTS

(1) Adjustment of the Maximum Exposure Lamp Voltage for the Manual Mode

+

Requirement

l Maximum Exposure Lamp Voltage

+

Important

l

After the Maximum Exposure Lamp Voltage has been adjusted, be sure to make the following adjustments: Optimum Exposure Setting in the Manual Exposure Modeand Exposure Level in the Auto Exposure Mode.

1159D133AB

3.

Set to Service Mode.

4.

To adjust the MAX. Exposure Lamp Voltage, press the following keys in the indicated sequence: Copy

Quantity and Zoom Key @ three times: the Start Key one time and the Copy Quantity and Zoom Key

0

two times.

:

80 f 1 V (115 V-127 V Areas)

: 180 f 2 V (220 V-240 V Areas)

Remove the Control Panel/lower Panel Cover.

1.

2.

Insertthe probes

sure Lamp Voltage measurement connector.

of

the multimeter intothegap in the Expo-

1159D007AB

Press the Keys in order of

1159D006AA

[l],

[23, [3],

I

F3

will appear in the Display Panel.

[41, PI, and El.

5.

Check that the upper segment of

Exposure Control Key @I to turn OFF the lower segment and light up the upper one.

6.

Press the Start Key to turn on the Exposure Lamp and check its voltage.

7.

Use the value shown on the Tester and the Specification Table on page D-43 to calculate the Correction Value, (For Example: 164 V - 160 V = + 4 V (the Correction Value)

8.

Use the Correction Value to find the Number of Steps and then push the Exposure Control Keys to

change the settings for adjusting the MAX. Exposure Lamp Voltage.

9.

Push the Clear/Stop Key to set the settings.

1

v

to the left of

F3

is lit up. If the lower segment is lit up, press

NOTE

For the Root Mean Square values and Mean values, see

p.69-70.

Most testers, voltmeters, or

multi-

meters used in the field show only the mean values.

D-42

Page 49

*If the measurement does not fall within the specifications through on setting, try

a

4.

Afterthe

adjustments have been made, press the Clear/Stop Key three times to restore the copier to

the normal copy mode.

00000

L

B

Touch This key if

L

Touch This key if

ID is Low.

ID is High.

1159D008AA

another setting.

Correction Value

for 80 V

Specifica-

tions (V)

-l-4

*3

i-2

+l

0

-1

-2

-3

-4

Correction Value

for 160 V

Specifi-

cations (V)

+8

I6

+4

+2

0

-2

-4

-6

-8

EG%e

Keys

0

<

>

0

D-43

Number

of Steps

4

3

2

1

0

1

2

3

4

LED Position

ro~oo

lq---Jxl

q

l~OO

ol~lm

00~00

q

o~lO

OOr-JlO

oo~m

Page 50

(2) Adjustment of Optimum Exposure Setting in the Manual Exposure Mode

+

Requirement

l

Exposure Lamp voltage setting range in the Manual Exposure mode . . . 46 to 54

l

When the manual exposure setting is at the central indication, no image of step no. 1 of a Kodak Gray

Scale should be produced on the copy, but a faint image of step no. 2 should be produced.

5

2

3 4

+

Important

A 1

This adjustment should be made only after completing the Adjustment of the MAX. Exposure Lamp

Voltage for the Manual Mode.

1.

Place the Kodak Gray Scale (KGS) in the center of the

Original Glass, place a sheet of A4 or 8-l/2 x 14 paper

on top of it and close the Original Cover.

2.

Use the Control Panel to manually set the exposure position to EXP 5 (the center position), make one copy at the

1

:l

zoom ratio and confirm that it passes over 1 and into

2.

*

1159D134AA

If the image density is outside the specifications, make the

following adjustment,

6 M

1136D300AA

3.

Set to Service Mode.

4.

To adjust the voltage the AC MAX Exposure Lamp, press the following keys in the indicated sequence:

Copy Quantity and Zoom Key @ three times; Start key onoe: and Copy

Quantrty

and Zoom Key

@

twice. Or, holding down Exposure Control Key@, turn ON the Power Switch to set the F3 Max. Exposure Lamp Voltage.

When the Power Switch is turned ON with Exposure Control

on the Display Panel.

Press the Keys in order of [l],

[2], [3],

Key@held

down, F3 does not appear

1159D199AA

F3

will appear in the Display Panel.

[41, 151, and PI.

D-44

Page 51

5.

Check that the lower segment of I to the left of

Exposure Control Key @ to turn OFF the upper segment and light up the lower one.

6.

Look at the image density of the sample copy. Press the Copy Quantity and Zoom Keys to change

the settings for adjusting the voltage for the Exposure Lamp.

7.

Press the Clear/Stop Key to set the settings.

Setting Instructions

l

If the image density low, decrease the setting value.

l

If the image density high, increase the setting value.

*

If

the image density does not fall within the specifications through one setting, try another setting

8.

After the adjustments have been

the normal copy mode.

made, press the Clear/Stop

F3

is lit up. If the upper segment is lit up, press

Key two

times to restore the copier to

D-45

Page 52

(3) Adjustment of Exposure Level in the Auto Exposure Mode

+

Important

l

When making adjustments, the exposure position on the Control Panel must be set to Auto.

I

l

For the adjustment, place about five blank sheets of A4 or 8-l/2 x 14 paper one on top of the

other on the Original Glass and lower the Original Cover.

l

After this adjustment, be sure tocheckthe Adjustment of optimum exposure setting in the Manual

Exposure mode.

1.

Confirm that the exposure position on the Control Panel is set to Auto. Stack five blank sheets of A4

or 8-l/2 x 14 paper on top of each other on the Original Glass and close the Original Cover.

I

1

I

2.

Set to Service Mode.

3.

To adjust the

F5AE

1159D012AA

Sensor

1

Automatic Adjustment,

press the

following

keys in the indicated sequence:

1159D135AA

Copy Quantity and Zoom Key @ three times; the Start Key one time and the Copy Quantity and Zoom

Key 0 three times.

4.

Press the Start Key to perform adjustment of the Auto Exposure. (Approximately 15 Seconds)

bbb

Press the Keys in order of

[41,[51,

5.

After the adjustments have been made, press the Clear/Stop Key two times to restore the copier to

1159D013AA 1159D014AA

PI and

[l], [2], [3],

[71.

F5

will appear in the Display Panel.

the normal copy mode.

D-46

Page 53

(4) ATDC Adjustment

+

Important

l

ATDC adjustment is not necessary when a new IU is used. (Set the Starter and ATDC adjustment will be

automatically entered when the power is turned on.)

l

Always perform ATDC adjustment when a new Starter has been set with a existing

1.

Set the Starter and close the Front Door.

2.

Set to Service Mode.

3.

To adjust the F8AE Sensor Automatic Adjustment, press the following keys in the indicated sequence:

Copy Quantity and Zoom Key 0 three times; the Start Key one time and the Copy Quantity and Zoom

Key

@ four times.

NJ.

W

bbbb

Press the Keys in order of [I],

1169D015AA

[2], [3],

F8

will appear in the Display Panel.

1159D016AA

/41, C51, and PI.

4.5.Press the Start Key to perform adjustment of the ATDC.

After the adjustments have been made, press the Clear/Stop Key two times to restore the copier to

the normal copy mode.

D-47

Page 54

(5) Adjustment of the Aperture Blades

+

Requirement

l

There should be no dark or light bands running in the feeding direction on copies produced. (Adjust to

obtain the mean image density for all areas.)

+

Important

l

If dark and light bands running in the feeding direction occur on copies, make this adjustment after

checking following.

1) The surfaces of the Mirror and Lens are free of dirt.

2) The surfaces of the Exposure Lamp and Main Erase Lamp free of scratches and dirt.

1.

Make copies in the following modes.

1159D137AA

1159D139AA

Original

Paper

:

A4 or

8-112

:

A4 or8-l/2 x 14

x 14

Magnification ratio : 100 %

Exposure

:

Manual

(setting convenient for check)

-I

Remove the Original Glass.

Turn the copy on the Copy Tray Around as shown to reverse the leading and trailing edges and align it with the

Aperture Blades.

Adjust to obtain the mean image density

for

all areas of the

COPY.

D-48

Page 55

(6) Adjustment of Zoom Ratio in the Crosswise Direction

(EPI 031/EP1031

+

Requirement

a

This adjustment is made for the Zoom ratio in the crosswise direction.

l

A scale is placed on the Original Glass to run parallel with the scanner and the length of the scale on

the copy is compared with that of the actual scale. The adjustment must be made so that the difference

between the two dimensions falls within the following specifications.

The difference should be within rt 0.5 % of the actual length.

I

Against

200mm,

allowance is 200 mm x 0.005 = 1 .O mm

F Only)

I

Zoom Ratio

Full size

( x

1 .OOO)

+

Important

This adjustment must be made before the Reference Position Adjustment.

I

I

I

Specifications

220 f

l.Omm

11590139AA 1

1134D124AA

1.

2.

Adjusting Mode

Adjust Al

Place a scale in parallel with the Original Width Scale and

make a copy.

*

Make a one copy using A4 or 8-l

zoom ratio.

* If the scale is of plastic and transparent, place a blank

sheet of paper on it.

Measure the crosswise zoom ratio of the sample copy.

Measure the length of the scale on the copy with the actual

scale to determine if there is any deviation.

If the zoom ratio deviates from the specifications, go to the

next step.

=Lens

Full

Size Position

Setting Range

33 to 67

/2

x 14 paper at a 1

I

:l

D-49

Page 56

3.

Set to Service Mode.

4.

To

correct

the Al Lens Full Size Position, press the following keys in the indicated sequence: Copy

Quantity and Zoom Key @ one time; the Start Key one time and the Copy Quantity and Zoom Key

one time.

@

1159D017AA

Press the Keys in order of

and

[4].

5.

w

Press the Start Key and press the Copy Quantity and Zoom Keys to change the setting for correcting

the Lens Full Size Position.

6.

Press the Clear/Stop Key to set the settings.

[l], [2], [3],

Al will appear in the Display Panel.

1159D018AA

Setting Instructions

l

If the scale on the copy is longer than the actual scale, decrease the setting value.

l

If the scale on the copy is shorter than the actual scale, increase the setting value.

* If the measurement does not fall within the specifications through one setting, ty another setting.

Measurement is Shorter

-Touch

This Key

If

Measurement is Longer.

1159D019AA

7.

After the adjustments have been made, press the Clear/Stop Key three times to restore the copier to

the normal copy mode.

D-50

Page 57

(7) Adjustment of Zoom Ratio in the Feeding Direction

+

Requirement

l

This adjustment is made for the zoom ratio in the feeding direction.

l

A scale is placed on the Original Glass Perpendicularly to the Scanner and the length of the scale on

the copy is compared with that of the actual scale. The adjustment must be made so that the difference

The difference should be within f 0.5 % of the actual length.

I

Against 200 mm, allowance is 200 mm x 0.005 = 1 .O mm

Zoom Ratio

Full size (x 1 .OOO)

+

Important

This adjustment must be made before the Adjustment of the Leading Edge Registration.

Specifications

200 f

l.Omm

1159D140AA

1.

2.

Adjusting Mode Setting Range

Adjust A3

Place a scale in parallel with the Original Length Scale and

make a copy.

* Make a one copy using A4 or 8-W x 14 paper at a 1

zoom ratio.

*If the scale is of plastic and transparent, place a blank

sheet of paper on it.

Measure the crosswise zoom ratio of the sample copy.

Measure the length of the scale on the copy with the actual

scale to determine if there is any deviation.

*

If the zoom ratio deviates from the specifications, go to the

next step.

=Feed

Direction

Mag. Ratio

43 to 57

I

I

:l

1130Dl54AA

D-51

Page 58

3.

I

Set to Service Mode.

4.

To correct the A2 feeding direction zoom ratio, press the following keys in the indicated sequence:

Copy Quantity and Zoom Key @ two times; the Start Key one time and the Copy Quantity and Zoom

Key @two times,

Lm

C/B

O\

i

\

0

3

12

I

4 5

I

c111c113

Press the Keys in order of

141, and PI.

5.

Press the Start Key and press the Copy Quantity and Zoom Keys to change the setting for correcting

the feeding direction zoom ratio.

6.

Press the Clear/Stop Key to set the settings.

-

Setting Instructions

l

If the scale on the copy is longer than the actual scale, decrease the setting value.

l

If the scale on the copy is shorter than the actual scale, increase the setting value.

* If the measurement does not fall within the specifications through one setting, try another setting.

1159DOZOAA

[l], [2], [3],

L

Touch This Key if

Measurement is

Touch This Key

Measurement is Longer.

if

Shorter.

1159D019AA

A2

will appear in the Display Panel.

7.

After the adjustments have been made, press the Clear/Stop Key two times to restore the copier to

the normal copy mode.

D-52

Page 59

(8) Adjustment of the Reference Position of the Manual Bypass Table

l

As shown in the illustration on the left, use a A4 test chart

or a sheet of 8-l/2 x 14 paper to draw a reference line

ci

+

Important

1

l Specification . . . . . , . . . . . . . .

! 1

/

20 mm from the left edge.

.

20 f 3.0 mm

This adjustment should be made after the adjustment of zoom ratio in the crosswise direction.

Place the test chart on the reference position for the original scale and close the Original Cover.

Use the Manual Bypass Table to make a one copy using

A4 or

8-l/2

x 14 paper at a 1 :l zoom ratio.

Check if dimension A (from

theedge

up to the reference

line) on the copy is up to the specifications.

<EP1031/EP1031 F>

If dimension Adeviatesfrom the specifications, loosen two

screws that secure the Manual Bypass Table and more the

table in the direction of the arrow as necessary.

Adjusting Instructions

l

If dimension A deviates on the copy is shorter than 17

mm move the table to the rear of the copier.

l

1159D142AA

If dimension A deviates on the copy is longerthan 23 mm

move the table to the front of the copier.

<EPi 030/EP1030F>

n

II

II

n

1159D143AA

D-53

Page 60

(9) Adjustment of Paper Feed Cabinet Reference Position

+

Requirement

s

As shown in the illustration on the left, use a A4 test chart

or a sheet of 8-l/2 x 14 paper to draw a reference line

20 mm from the right edge.

*Specification . . . . . . . . . . . . . . . 20 f 3.0 mm

l

Important

This adjustment should be made after the adjustment of zoom ratio in the crosswise direction.

I

Place the test chart on the reference position for the original width scale and close the Original Cover.

2.

Use the Paper Feed Cabinet to make a one copy using A4

or 8-l/2 x 14 paper at a

3.

Check if dimension A (from

line) on the copy is up to the specifications.

4.

If the reference position is outside of the specification,

loosen the one mounting screw for the Original Width

Scale and use the confirmation sample to adjust the Original Width Scale in the correct direction.

1:l

zoom ratio.

theedge

up to the reference

115ODl44AA

Adjusting Instructions

l

If dimension A on the copy is longer than 22 mm, move the position Plate to the front of the copier.

l

If dimension A on the copy is Shorter than

18

mm, move the position Plate to the rear of the copier.

D-54

Page 61

(10) Adjust of the Leading Edge Registration

+

Requirement

l

As shown in the illustration on the left, use a A4 test chart

or a sheet of 8-l/2 x

20 mm from the leading edge.

Adjust so that on the copy, the width of A at the center

section of the leading edge of the test chart will be within

the specifications shown below.

14

paper to draw a reference line

Zoom Ratio

Full Size

( x 1

l

(10)-l.

.OOO)

20 f: 1.5 mm Cabinet Section

XIc;o~O mm Manual Bypass

The adjustment of the registration for enlargement and reduction need only be performed on the

EP1031/EP1031F

Leading Edge Registration in Full Size Mode

Specifications

should be made after the adjustment of zoom ratio in the feeding direction.

Place the Test Chart on the reference position for the Original Width Scale and close the Original Cover.

Make one copy using A4 or

zoom ratio.

If the leading edge registration of the 1 :l copy is within the

standards, proceed with the adjustment for adjustment of

the zoom leading edge registration.

1159D145AA 1

only) If it is outside the specifications, adjustment must be

made using the following procedure.

Adjusting Mode1 Setting Range

Adjust A3

Adjust A4

Adjust A4

I

=Lens

Position

Full Size

=Lens

Position

Enlargement

=Lens

Position

Reduction

8-112

x 14 paper at a 1

(EP1031/EP1031

26 to 74

42 to 58

:l

F

D-55

Page 62

4.

Set to Service Mode.

5.

To adjust the A3 Full Size Registration, press the following keys in the indicated sequence: Copy

Quantity and Zoom Key @two times; the Start Key one time and the Copy Quantity and Zoom Key

0

three times.

it!? b b

Press the Keys in order of

[41, PI, and PI.

6.

Press the

7.

Press the Clear/Stop Key to set the settings.

-

Setting Instructions

l

If dimention A on the copy is longer than 21.5 mm, increase the setting value.

l

If dimention A on the copy is Shorter than 18.5 mm decrease the setting value.

* If the measurement does not fall within the specifications through one setting, try another setting.

Start

1159D022AA 1159D023AA

A3

[l], [2], [3],

Key to change the settings for the Full Size Registration.

will appear in the Display Panel.

1

Measurement is Shorter.

8.

After the adjustments have been made, press the Clear/Stop Key to restore the copier to the normal

copy mode.

D-56

Page 63

(IO)-2. Leading Edge Registration in Enlargement Mode

1.

Once the 1: 1 Zoom Registration has been adjusted, make

one copy using A4 or

largement ratio.

2.

If the registration is up to the specifications, go to the adjustment in the reduction mode. If it deviates from the spec-

ifications, perform the following steps to make the adjust-

ment of leading edge registration in the enlargement

1159D146AA

+

Important

l

This adjustment should be made after the adjustment of leading edge registration in the full size

mode.

Set to Service Mode.

3.

4.

To adjust the A4 Enlargement Registration, press the following keys in the indicated sequence: Copy

Quantity and Zoom Key @two times; the Start Key one time and the Copy Quantity and Zoom Key

0

four times.

Press the Keys in order of [l],

[41,

FL

PI, and IA.

[2], [3],

mode.

8-112

x 14 paper at a x 1.58 en-

1159D026AA

A4

will appear in the Display Panel.

D-57

Page 64

I

5.

Press the Start Key and use the Copy and Zoom Keys to change the settings for the Enlargement Registration.

6.

Press the Clear/Stop Key to set the settings.

-

Setting Instructions

l

If dimention A on the copy is longer than 33.6 mm, increase the setting value.

l

If dimention A on the copy is Shorter than 28.8 mm, decrease the setting value.

* If the measurement does not fall within the specifications through one setting, try another setting.

L

b

7.

After the adjustments have been made, press the Clear/Stop Key to restore the copier to the normal

Touch This Key if

Measurement is Longer.

Touch This Key if

Measurement is Shorter.

1159D024AA

copy mode.

D-58

Page 65

(IO)-%

Leading Edge Registration in Reduction Mode

1.

Once the Enlargement Registration has been adjusted,

make one copy using A4 or 8-l/2 x 14 paper at a x

0.64 reduction ratio.

2.

If the registration is up to the specifications, go to the ad-

justment in the reduction mode. If it

ifications, perform the following steps to make the adjustment of leading edge registration in the enlargement

mode.

+

Important

l

This adjustment should be made after the adjustment of leading edge registration in the full size

mode.

3.

Set to Service Mode.

To adjust the A5 Reduction Registration, press the following keys in the indicated sequence: Copy

4.

Quantity and Zoom Key @two times; the Start Key one time and the Copy Quantity and Zoom Key

0

five times.

A5

Press the Keys in order of

141,

Fl,

PI, [71, and PI.

[l], [2], [3],

will appear in the Display Panel.

deviates from

1159D028AA

the spec-

D-59

Page 66

5.

Press the Start Key to and use the Copy Quantity and Zoom Keys to change the settings for the Reduction Registration Adjustment.

6.

Press the Clear/Stop Key to set the settings.

I

Setting Instructions

l

If dimention A on the copy is longer than 14 mm, increase the setting value.

l

If dimention A on the copy is Shorter than 16 mm decrease the setting value

* If the measurement does not fall within the specifications through one setting, try another setting.

7.

After the adjustments have been made, press the Clear/Stop Key three times to restore the copier to

the normal copy mode.

.~l

D-60

Page 67

(11) Adjustment of the Image Leading Edge Erase Width

+

Requirement

l

As shown in the illustration on the left, use a

or a sheet of 8-l/2 x 14 paper to draw black mark 20

approximately20 mm from the

ing edge. Adjust so that this black mark will image erase

3.0 to 4.0 mm from the leading edge.

0

u

+

Important

l

This adjustment should be made after the adjustment of the leading edge registration.

5.

To adjust the AA Leading Edge Erase Width, press the following keys in the indicated sequence: Copy

Quantity and Zoom Key @two times; the Start Key one time and the Copy Quantity and Zoom Key

0

seven times.

1074D107

1159D149AA

Specification

l

Adjustment Setting Range

Place the test chart on the reference position for the original Width scale and close the Original Cover.

Make a one copy using A4 or 8-l/2 x 14 paper at a

zoom ratio.

If the erase width deviates from the specifications, perform

the following steps to make the adjustment of image lead-

ing edge erase width.

..,,...,.......

. . . .

center

3.5 f 0.5

38 to 68

A4

test chart

section of the lead-

mm

I:1

,-

1159D029AA

Press the Keys in order of [I],

[41,

PI,

PI, [71, PI,

PI, and

[lOI.

[2], [3],

D-61

1159D030AA

AA

will appear in the Display Panel.

Page 68

I

6.

Press the Start Key to and use the Copy Quantity and Zoom Keys to change the settings for the Leading Edge Erase Width Adjustment.

7.

Press the Clear/Stop Key to set the settings.

-

Setting Instructions

l

If dimention A on the copy is longer than 4.0 mm, increase the setting value.

l

If dimention A on the copy is Shorter than 3.0 mm, decrease the setting value.

* If the measurement does not fall within the specifications through one setting, try another setting.

L

Touch This Key if

W

8.