Page 1

0990-7701-02

ColorPageWorks

User'sManual

Page 2

Page 3

i

Color PageWorks

This manual explains the functions and operation of the MINOLTA Color PageW o rk s printer. It also

gives some troubleshooting tips as well as general precautions to be observed when operating this printer.

To ensure the best performance and effective use of your printer, please read this manual carefully from

cover to cover. After you have read through the manual, keep it near your printer for handy reference.

It should help in solving any operational questions you may have.

Trademark acknowledgments

Color PageWorks is a trademark of Minolta in the U.S. and Canada.

Minolta is a registered trademark of MINOLTA CO., LTD.

Adobe and PostScript are trademarks of Adobe Systems Incorporated.

Agfa and Agfa Intelifont, Agfa font Manager are registered trademarks of Agfa Corporation.

Apple, AppleTalk, ColorSync, Macintosh and TrueType are registered trademarks of Apple Computer Inc.

HP, LaserJet and PCL are registered trademarks of Hewlett-Packard Company.

IBM, PC/ AT and PS/ 2 are registered trademarks of International Business Machines Corporation.

Microsoft, MS-DOS, Excel, Windows 3.1, Windows NT and Windows 95 are registered trademarks of

Microsoft Corporation.

Novell, NetWare, and NDS are registered trademarks of Novell Inc.

All other brand or product names are trademarks or registered trademarks of their respective companies

or organizations.

7701

Please follow the instructions given in this manual when handling your printer and do not

touch any part of the machine which the manual does not cover. NEVER attempt to disassemble or remodel the printer.

Page 4

ii

Safety Information

LASER SAFETY

This is a page printer which operates by means of a laser. There is no possibility of danger from the laser, provided the printer is operated

according to the instructions in this manual provided. Since radiation emitted by the laser is completely confined within protective housin g, t he

laser beam cannot escape from the mac hi ne during any phase of user operation.

INTERNAL LASER RADIATION (For all Users)

Maximum Radiation power: 1.0 ✕ 10

This is a class IIIb Laser Diode Assy. that has an in visible laser beam. The printer head unit is NOT A FIELD SERVICE ITEM. Therefore, the

printer head unit should not be opened under any circumstances.

-3

(W) Wavelength: 770- 810 (nm)

For United States Users

Laser Safety

This printer is certified as a Class 1 Laser product under the U. S. Department of Health and Human services (DHHS) Radiation Perfor-

mance Standard according t o t he Food, Dru g and Cosmetic Act of 1990. This means that the printer does not produce hazardous l aser radiation.

CDRH Regulations

The Center for Devices and Radiological Health (CDRH) of the U. S. food and Drug Administration implemented regulations for laser

products on August 2, 1976. Complia nce is mandatory fo r products marketed in the United Stat es. The label shown below indicates compliance with the CDRH regulations and must be attached to laser products marketed in the United States.

WARNING: Us e of controls, adjustments or performance of procedures other than tho s e specified in this manual may result in haza rdous

radiation exposure.

For Other Countries Users

WARNING: Us e of controls, adjustments or performance of procedures other than tho s e specified in this manual may result in haza rdous

radiation exposure.

-3

10

W and the wavelength is 770- 810 nm.

This is a semiconductor laser. The maximum power of the laser diode is 1.0

✕

7701

Page 5

Safety Information

USER INSTRUCTIONS (FOR U.S.A. Users)

FCC PART 15- RADIO FREQUENCY DEVICES WARNING

(Note: Color PageWorks printer without Minolta Network option installed.)

WARNING

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference in a residential inst allation. This equipment generates, uses,

and can radiate radio frequency energy and, if not in stalled and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarant ee th at inte rfere nc e will n ot oc cur in a pa rtic ular in sta llatio n. If this equipment does cause

harmful interference to radio or television reception, which can be determined by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment to an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/ TV technician for help.

• Any changes or modifications not expressly approved by Minolta could void the user’s

authority to operate this equipment.

A LAN adapter is only to be used in industrial areas including commercial areas. Use of a LAN adapter in residential areas is forbidden.

This device must be used with shielded interface cables. The use of non-shielded cables is likely to result in interference with radio communications and is prohibited under FCC rules.

The design and production of this unit conform to FCC regulations, and any changes or modifications must be registered with the FCC and are

subject to FCC control. Any changes made by the purchaser or user without first contacting the manufacturer will be subject to penalty under

FCC regulations.

iii

FCC PART 15- RADIO FREQUENCY DEVICES WARNING

(Note: When the network cable is attached to either of the IEEE 802.3

connectors the printer meets the requirement of FCC Class A,

Color PageWorks printer with Minolta Network option installed.)

WARNING

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is op erated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

This device must be used with shielded interface cables. The use of non-shielded cables is likely to result in interference with radio communications and is prohibited under the FCC rules.

The design and production of this unit conform to FCC regulations, and any changes or modifications must be registered with the FCC and are

subject to FCC control. Any changes made by the purchaser or user without first contacting the manufacturer will be subject to penalty under

FCC regulations.

7701

Page 6

iv

Safety Information

USER INSTRUCTIONS (FOR Canadian Users)

INTERFERENCE-CAUSING EQUIPMENT STANDARD

(ICES-003 ISSUE 2) WARNING

(Note: Color PageWorks printer without Minolta Network option installed.)

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appil numérique de la class B respecte t outes les exigences du Règlement sur le matériel brouilleur du Canada.

INTERFERENCE-CAUSING EQUIPMENT STANDARD

(ICES-003 ISSUE 2) WARNING

(Note: Color PageWorks printer with Minolta Network option install.)

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appil numérique de la class A respecte t outes les exigences du Règlement sur le matériel brouille ur du Canada.

OZONE RELEASE (For all Users)

During printer operation, a small quantity of ozone is released. This amount is not large enough to harm anyone adversely. However, be sure

the room where the printer is being used has adequate ventilation, especially if you are printing a high volume of materials, or if the printer is

being used cont inuously over a long period.

WARNING LABEL

7701

Page 7

Highlight

v

1. High quality printing

Clear text and excellent graphics with true

•

600 dpi.

Excellent graphics (106 lpi, 122gray levels)

•

Super Fine Micro Toning (Fine-MT)

•

developing system.

8µm small particle toner.

•

Color matching technology.

•

- Apple ColorSync (is available only when

the optional Adobe PostScript ROMSIMM is installed).

- Windows95 ICM.

- Printer embedded color matching.

4. Paper handling versatility

OHP, labels, thick paper, envelopes.

•

2. Adobe PostScript Level 2

Option

•

3. High speed printing

Full color 3ppm, B/W 12ppm.

•

High performance RISC processor.

•

- Intel i960JF/ 33MHZ.

High speed data transfer.

•

- IEEE 1284 compliant interface.

- Network option

(Ethernet/ TokenRing).

5. Compact size

Width 505mm/ 20"

•

Depth 527mm/ 20-3/4”

•

Height 403mm/ 15-3/4”

•

6. Network ready with option

Ethernet / TokenRing

•

Server: UNIX, Windows NT, NetWare

3.X/ 4.X (Bindery & NDS)

Client: Windows 95/ 3.1, Macintosh

(option)

8. Environmentally friendly

Ozone free.

•

Power save mode

•

(Energy Star compliant).

7. Easy maintenance and operation

Easy maintenance with cartridge type

•

consumables.

GUI driver.

•

7701

Page 8

vi

Using This Manual

Organization

This manual consists of 6 c hap ter s. Chap te rs 1 a n d 2 g ive the basi c i nform at ion a bout the p rin te r, chapter 3 in trod uc e s th e menu utilities of the

printer operation, chapter 4 through 6 cover maintenance of the printer and some troubleshooting tips.

Please read chapter 1 and 2 before attempting to use your printer.

Reading these chapters will help you understand the installation and basic operation of your printer.

Read chapter 3 as necessary when you want to use the more advanced menus the machine offers.

Chapters 4 and 5 are to be read when you need to add paper, service or troubleshoot the printer. An explanation is given of each

operation, allowing you t o read only those pages dealing with the operation to be performed.

Chapter 6 contains a quick reference overview of the menu utilities setting procedure, specifications, and index.

Locating the Information You Need

Using the Master Table of Contents

The master table of contents gives an overview of how this manual is organized so that you can quickly locate the information

you need. It provides you with the most basic keys for locating what you need to know.

Using the Contents at the Beginning of Each Chapter

The first page of each chapter contains a table of contents which provides greater detail than the Master Table of Contents. This provides a

quick reference for each chapter.

Using the Index

At the back of the book is a n alp ha b etica l in d ex which is function-, ite m- , o r ter m-orie nt ed ; i. e. , if y ou kn ow the name of a pa r ti cu lar fun c tio n,

item or term, use this section to find a reference to the appropriate page numbe r.

If You Need More Information (U. S.A. Technical Support)

If you continue to experi ence technical difficulty with the operation of your printer product, please contact your support representative:

To ll free at 1-800-459-3250

Hours of operation and toll free nature of our support program is subject to change with out prior notice .

or via our website at

http://www.minoltappd.com.

7701

Page 9

Page Layout

Operational Heading

Before operation: Gives an overview of the function/ operation covered herein.

vii

Page Number: Used to locate your page.

Note: Calls your attention to a particular point in the pro cedure.

Continuation marker: Indicates that there is more information to complete

an operation on the next page.

Index: Used to locate your chapter quickly.

Step No.: Sequential number to follow in performing the procedure.

7701

Page 10

viii

CONTENTS

Energy Star Information

Introduction i

Safety Information ii

Highlight v

Using This Manual vi

Contents viii

Chapter 1 Installation 1

1. Preparation for Installation 2

Installation Site/ Po wer Sou rc e/ Groun ding 2

Space Requirements 3

2. Precautions for Use 4

Operating Environment/ Using the Printer Properly 4

Care of Printer Supplies/ Moving the Printer 5

3. Setting-Up 6

Checking print operation 6

Connecting Printer to Host Computer 8

Expansion Memory (option) Setting-Up 10

Adobe PostScript ROM SIMM (option) Setting-Up 1 2

Network Board (option) Setting-Up 14

Chapter 2 Using the Printer 17

1. Printer Parts and Accessories 28

⋅

Printer 18

⋅

Accessories 19

⋅

Control Panel keys 20

⋅

Operation and warning Labels 22

2. Turning ON and OFF the Printer 23

3. Printing Paper 24

⋅

Type/ Size 24

⋅

Print Area/ Capacity/ Care of paper 25

4. Loading the Printing Paper 26

⋅

Loading Plain Paper/ Recycled Paper 26

- TRAY 1 (Multi Purpose Tray) 26

- TRAY 2 (Second Cassette)/ TRAY 3 (Third Cassette: option) 27

⋅

Loading OHP sheets/ Labels 29

- TRAY 1 (Multi Purpose Tray)

- TRAY 2 (Second Cassette)/ TRAY 3 (Third Cassette: option) 30

⋅

Loading Special Paper (Letterhead/ Envelopes/ Postcard / Thick P ape r) 32

- TRAY 1 (Multi Purpose Tray) 32

5. Printing 34

29

7701

Page 11

ix

Chapter 3 Changing the Printer

Settings 45

1. List of MENU Utilities 36

2. Setting the MENU Utilities 38

3. Outline of the MENU Utilities 40

⋅

RESET MENU/ TEST PRINT MENU 40

⋅

PRINT MENU 41

⋅

CONFIG MENU 42

⋅

IMAGE MENU/ MEMORY MENU 43

⋅

PCL MENU 44

⋅

PS MENU / MAINTENANCE MENU 45

Chapter 4

Maintaining Your Printer 47

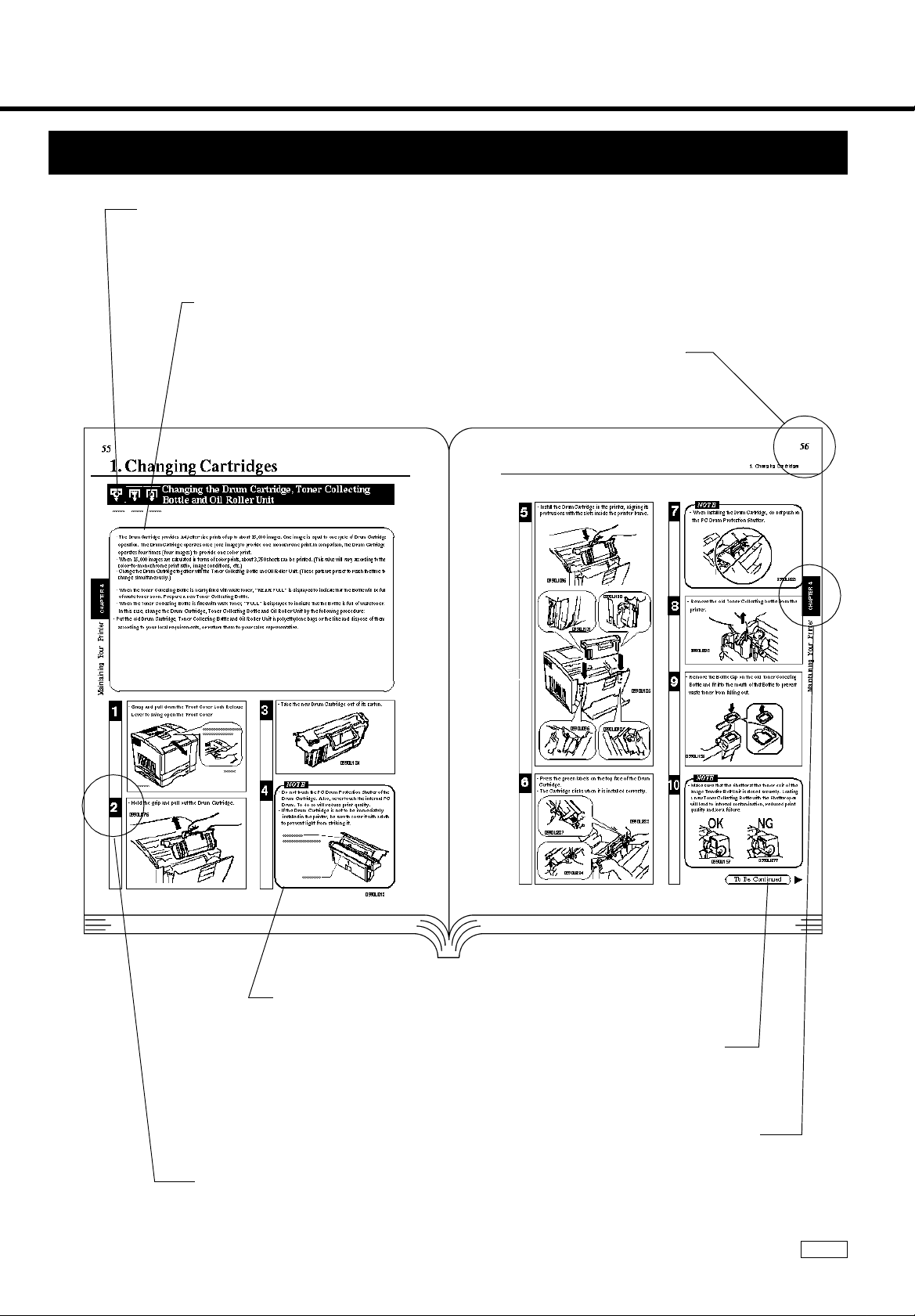

1. Changing Cartridges 48

⋅

Changing the Toner Cartridge 48

Auto Mode 48

Manual Mode 52

⋅

Changing the Drum Cartridge, Toner Collecting Bottle and Oil Roller Unit

⋅

Changing the Fusing Uni t an d Transfer Roller Unit 62

⋅

Changing the Image Transfer Belt Unit 66

2. Cleaning the Printer 70

56

CONTENTS

CHAPTER 1

Installation

CHAPTER 2

Using the

Printer

CHAPTER 3

Changing the

Printer Settings

CHAPTER 4

Maintaining

Your Printer

CHAPTER 5

Trouble

shooting

CHAPTER 6

Appendices

Chapter 5 Troubleshooting 73

1. How to Troubleshooting 74

2. A Problem Exists in the preparation stage

and during a Print Cycle 75

−

A Problem Exists in Preparation Stage 75

−

A Problem Occurs When You Attempt to Start a Print Cycle 75

−

When a Message Appears 76

−

When a Paper Misfeed has Occurred 80

3. Print Results are Faulty 84

Chapter 6 Appendices 87

1. Quick Reference Guide of MENU 88

2. List of MENU Utilities 90

3. Specifications of Printer 92

4. Specifications of 250 sheet Third Cassette Unit 95

5. Index 96

7701

7701

Page 12

x

7701

Page 13

For U.S.A./ Canada Users

As an ENERGY STAR Partner, MINOLTA Co., Ltd has determined

that this printer meets the ENERGY STAR Guidelines for

energy efficiency.

For Other Country Users

This printer meets the *EPA’s ENERGY STAR Guidelines

for energy efficiency.

*The U. S. Environmental Protection Agency.

What is an Energy Star Printer?

Energy Star Printers have a feature that allows them to automatically “go to sleep” after

a period of inactivity. This auto-feature can reduce a machine’s annual electricity cost

by 60 percent.

7701

Page 14

Chapter 1

Installation

This chapter covers site preparation, precautions for use, and

set-up procedure.

1. Preparation for Installation 2

Installation Site 2

Power Source 2

Grounding 2

Space Requirements 3

2. Precautions for Use 4

Operating En vir on men t 4

Using the Printer Properly 4

Care of Printer Supplies 5

Moving the Printer 5

3. Setting-Up 6

Checking print op eration 6

Connecting Printer to Host Computer 8

Expansion Memory (option) Se ttin g-Up 10

Adobe PostScript ROM SIMM (option) Setting-Up 12

Network Board (option) Setting-Up 14

1

1

CHAPTER 1

CHAPTER 1

Installation

Installation

Page 15

2

1. Preparation for Installation

CHAPTER 1Installation

Installation Site

To ensure a longer life for the printer, it is highly important to select an appropriate installation site. Choose a site that meets the following requirements.

- A well-ventilated place.

- An area which will not generate ammonia or other organic gas.

- A place which is near a power outlet so that the power cord can be easily plugged in and unplugged.

- An area free from direct sunlight.

- A place which is out of the direct air stream of an air conditioner, heater, or ventilator and is not subject to extremely

high or low temperature or humidity.

- A stable and level location not subject to undue vibration.

- A place free from an obj e ct that could block the heat exhaust duct of the printer.

- A place away from a curtain or the like that may catch fire and burn easily.

- An area where there is no possibility of being splashed with water or other types of liquid.

- A dust-free location.

Power Source

The power source voltage requirements are as follows.

- Power source: voltage fluctuation within +10% to -10%

- Frequency fluctuation: within +3Hz to -3Hz

NOTES

NOTE

- Use a power source with little voltage and frequency fluctuation.

- Use an outlet with the specified voltage capacity only.

- Be sure to plug the power cord all the way into the outlet. The outlet should also be located near the printer and easily

accessible so that the power cord can be unplugged immediately if printer trouble occurs.

- Make sure that the outlet is visible, without being hidden behind this printer or any other office equipment.

- If any other electrical equipment is sourced from the same outlet, make sure that th e capacity of the outlet is not

exceeded.

- If an extension cord is needed, use one with a capacity greater than the power consumption of the printer. A cord which

falls short of the capacity requirements could lead to a fire.

- Never connect any other appliances or machines by means of a multiple socket to the outlet being used for the printer.

Grounding

To prevent receiving electrical shocks in the case of electrical leakage, always ground the printer. Consult your Technical Representative if you are unable to make gr ounding connecti ons.

Connect the grounding wire to:

- The ground terminal of the outlet.

- A grounding contact which compli es with the local electrical standa rds.

*NEVER connect the grounding wire to a gas pipe, the grounding wire for a telephone, or a water pipe.

Page 16

1. Preparation for Installation

3

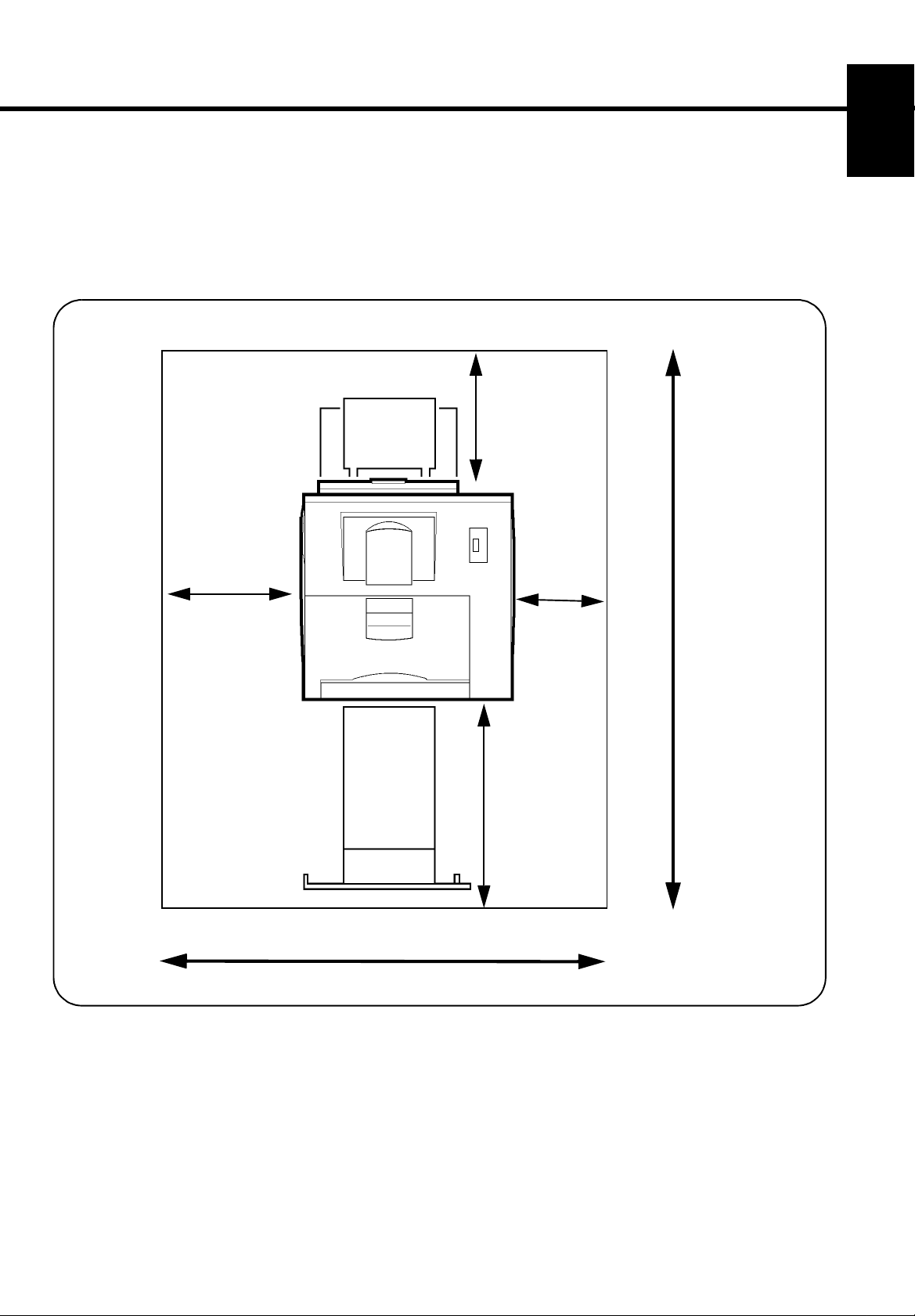

Space Requirements

You must provide open space on all sides of the Printer. Allow at least 300 mm (11 -3 /4 in c h) of space above the printer as well, so that

you can open the printer cover to replace supplies and clear paper mis fits. You also will need easy access to the rear of the printer t o

connect the printer cable and clear paper misfits.

300mm

(11-3/4 inch)

300mm

(11-3/4 inch)

100mm

(4 inch)

CHAPTER 1

Installation

905mm (35-3/4 inch)

1,380mm

(54-1/4 inch)

550mm

(21-3/4 inch)

Page 17

4

2. Precautions for Use

CHAPTER 1Installation

Operating Environment

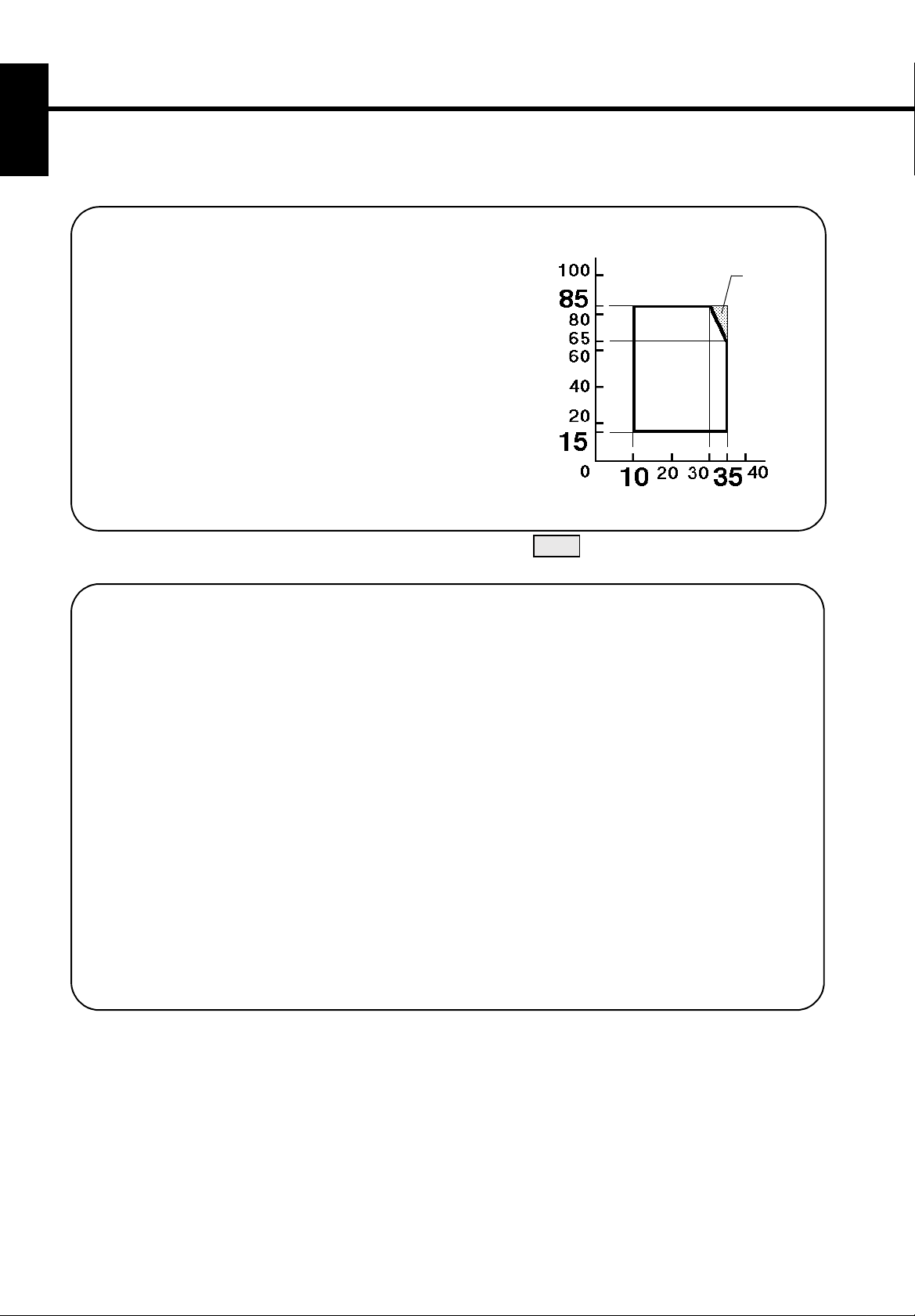

The operating environmental requirements of the printer are as follows.

- Temperature: 10°C (50°F) to 35°C (86°F) with a fluctuation

of 10°C (50°F) per hour.

- Humidity: 15% to 85% RH with a fluctuation of 20% per ho ur.

* The environmental zone marked “X” on the right represents

a critical environment in which the printer can be left to stand.

However the manufacturer does not ensure good paper passage

performance and print image in this zone. Be sure to use the printer

within the operating environment marked by the bold line.

Using the Printer Properly

To ensure the optimum performance of the printer, follow the precautions listed below.

- NEVER open any door, or turn OFF the printer during operation.

- NEVER bring any magnetized object or flammable gas or liquid near the printer.

- NEVER pull on the cord an d ALWAYS hold the plug when un plu gging the power cord. A da maged cord cou ld r e s u lt in a fire or

cause an electrical shock.

- NEVER attempt to unplug the p ower cord with a wet hand, as it could cause an electrical shock.

- ALWAYS unplug the power cord whenever attempting to move the printer. Moving the printer with the power cord plugged in

can damage the cord, resulting in a fire or causing an electrical shock.

- ALWAYS unplug the power cord when the printer is not to be used for a long time.

- NEVER remove any panel or cover which is secured. The printer contains a high-voltage component inside which can cau se an

electrical shock.

- NEVER remodel the printer, as a fire or electrical shock could result.

- NEVER place a heavy object on the power cord, or pull or bend it, as a fire or electrical shock could result.

- ALWAYS ensure that the printer does not ride on the power cord or commun ications cable of other electrical equipment, and it

does not get such a cord or ca ble wedged into its own mechanism, as malfunctioning equipm ent or fire could result.

- NEVER drop paper clips, staples, or other small pieces of metal through the vents or other openings in the printer, as a fire or

electrical shock could result .

- NEVER place a vase or vessel containing water on the printer. If fluid gets inside, it can cause a fire or electrical shock. In case

a piece of metal or fluid gets inside the printer, immediately turn it OFF, unplug the power cord, and call your technical

representative. A fire or electrical shock could result if the printer is run without taking necessary action.

- NEVER leave the printer running when it becomes inordinate ly hot, or emits smoke, unusual smell, or noise. I f that happens,

immediately turn OFF the printer, unplug it, and call your technical repres enta tive. A fire or electrical shock could result if the

printer is run without taking necessary action.

Humidity (%)

: Outside guarantee of paper

X

X

T emperature (

passage and image reliability

C)

°

Page 18

2. Preparation for Installation

NOTE

NOTE

= Locate the printer in a Well Ventilated Room =

A negligible amount of ozone is generated du ring normal operation of this printer. An unpleasant odor ma y, however, be

created in poorly ventilated rooms during extensive printer operations. For a comfortable, healthy, and safe operating

environment, it is recommended that the room be well ventilated.

REMARQUE

REMARQUE

= Placer le imprimante dans une pièce largement ventilée =

Unequantité d’ ozone négligable est dégagée pendant le fonctionnement du imprimante quand celui-ci est utilisé

normalement. Cependant, use odeur désagréable pent être ressentie dans les pièces dont l’ aération est insuffisante et

lorsque une utilisation prolongée du imprimante est effectuée. Pour avoir la certitude de travailler dans un environnement

das conditions de confort, anté et sécurité, il est préférable de bien aérer la pièce ou se trouve le imprimante.

Care of Printer Supplies

Use the following precautions when handling the printer supplies (Toner Cartridge, Drum Cartridge, and paper).

5

CHAPTER 1

Installation

- Avoid storing the supplies at any of t he f ollowing places:

A place subject to direct sunlight. (The Drum Cartridge should not be exposed to fluorescent light, either.)

A hot place with an open flame.

A humid place.

A dusty place.

- Store paper, which has been removed from its wrapper but not loaded in the printer tray, in a sealed plastic bag in a cool,

dark place.

- Use only the Toner Cartridge and toner for the exclusive use of this printer.

- Keep supplies out of the reach of children.

- If your hands beco me soile d w ith tone r, wash them with soap and wa te r imm e di ately.

NOTE

NOTE

Whenever the Drum Cartridge has been removed from the printer, immediately wrap it in a cloth to protect it from

light.

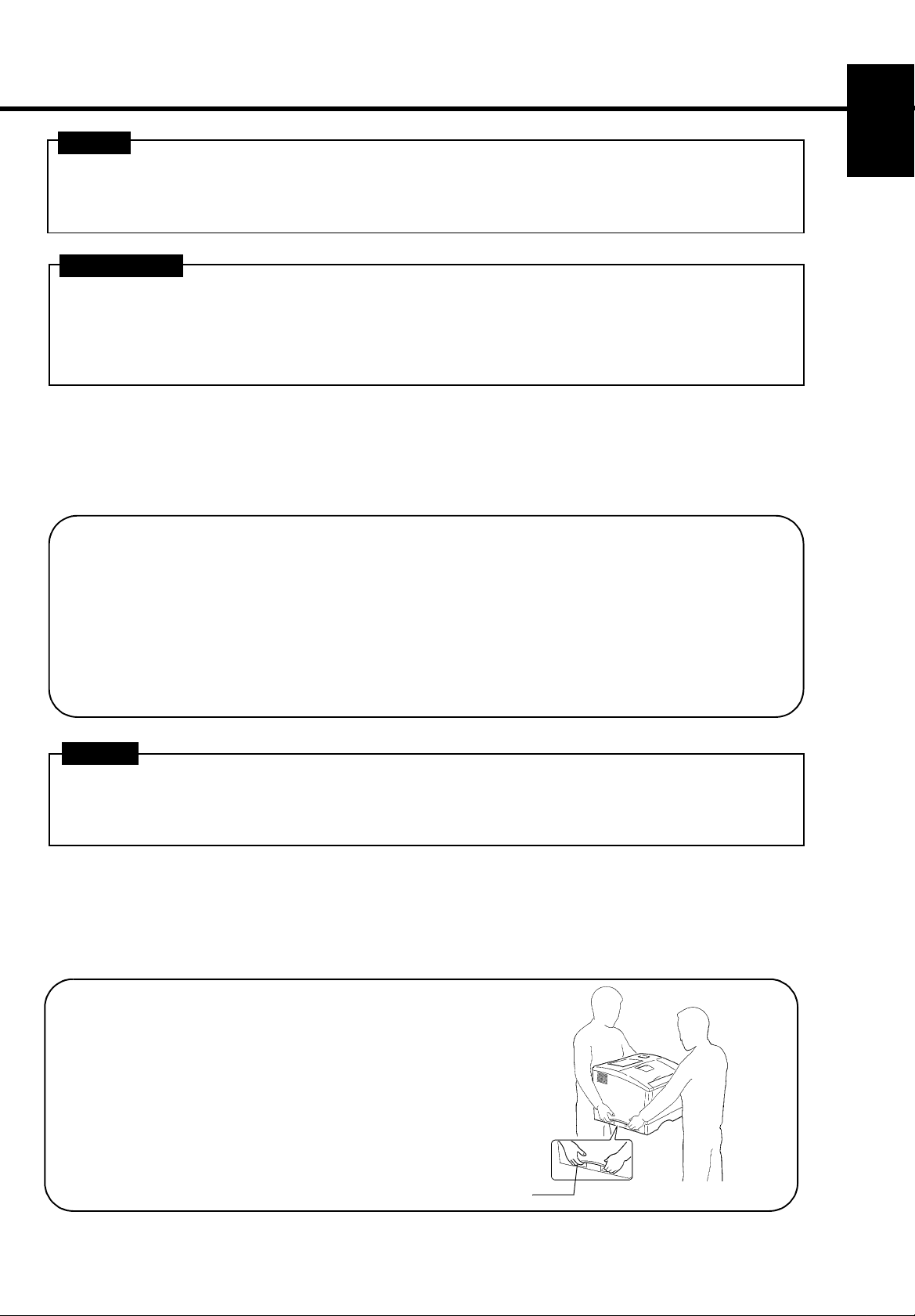

Moving the Printer

Observe the following prec autio ns when mo v ing the print er.

- When the Third Cassette Unit is installed, remove it from the

printer and carry the printer.

- Since the printer weighs approximately 35kg (77-1/4 lbs.),

two people are required to lift it.

- If you need to transpor t the pr in te r over a long distance, consult your

Technical Representative.

Grips

Page 19

6

3. Setting-Up

CHAPTER 1Installation

- The following four different procedures must be performed to set up the printer. Perform them step by step.

Unpacking/ Setting-Up Instructions*

1. Hardware Setting-Up (Printer and 250-Sheet Third Cassette Unit)

2. Checking Print Operation ☞p. 6

3. Connecting Printer to Host Computer ☞p. 8

Printer Driver User's Manual*

4. Software Setting-Up

NOTE: *1Read the Unpacking/ Setting-Up Instructi ons (that is shipped together with the accessories that

come with this printer set and the 250-Sheet Third Cassette Unit).

*2Read the Printer Driver User's Manual separately provided (that is shipped together with

the accessories that come with this prin t er set) and install the printer driver according to the

operating system of the host computer to be used.

- When the optional Network Board, Expansion Memory, and/or Adobe PostScript ROM SIMM are to be used, perform the steps

according to the s etting-up procedure for each option.

: Expansion Memory ☞p. 10

: Adobe PostScript R OM SIMM ☞p. 12

: Network Board ☞p. 14

- For the parts that come with the Printer and Third Cassette Unit see the UNPACKING/ SETTING-UP INSTRUCTIONS.

☞

2

☞

1

CAUTION

- ALWAYS use a shielded cable for the interface cable. Use of an unshielded interface cable could result in radio

frequency interference.

- Keep all packing materials out of the reach of children. They are to be used when transporting the printer.

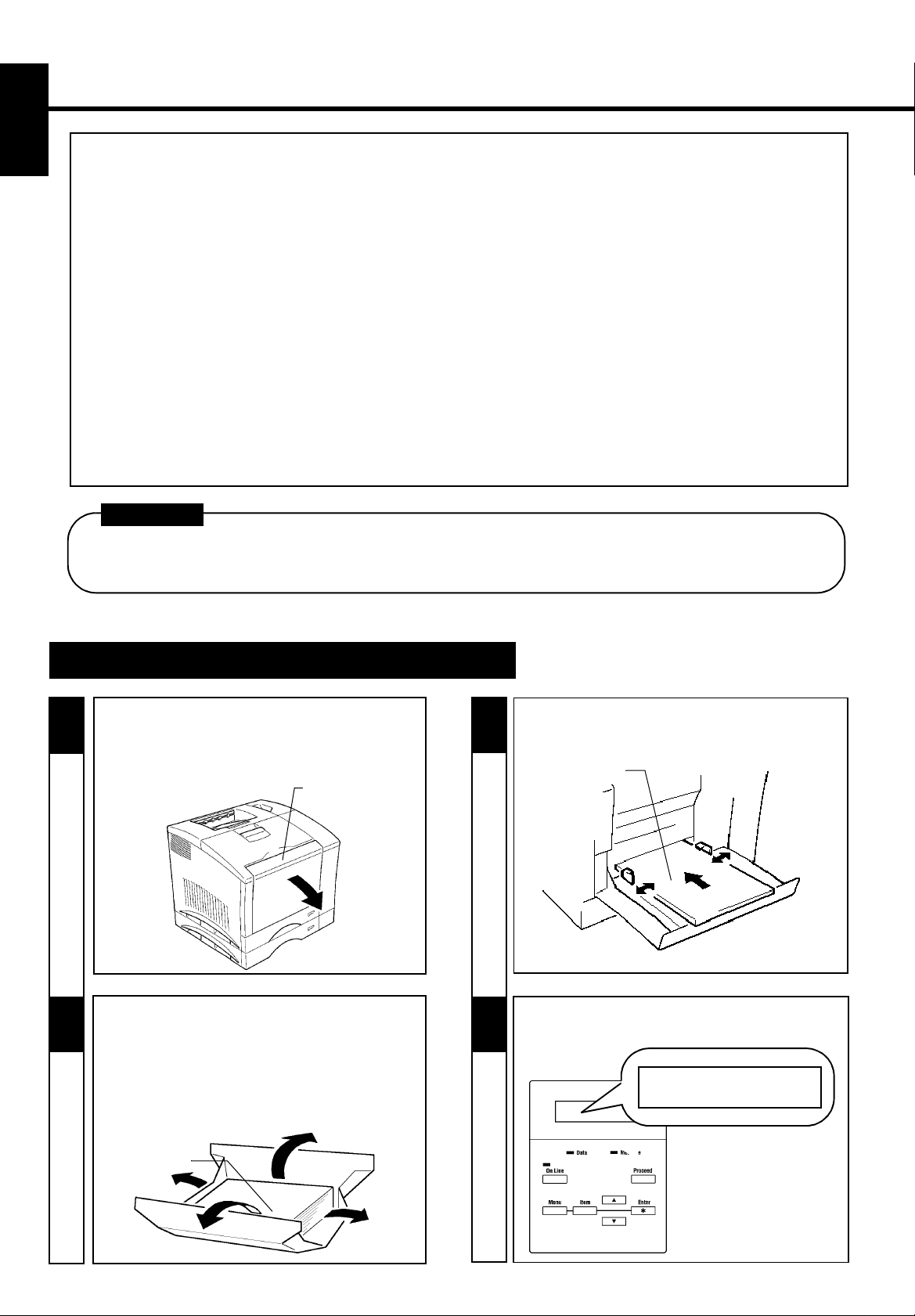

CHECKING PRINT OPERATION

Make sure that the “Hardware Setting-Up”

-

2

1

2

2

procedure has been completed

Setting-Up Instructions.

- Open the Multi-Purpose Tray.

Ready several sheets of paper for test prints.

-

Use plain paper of A4 or Letter siz e, weighing

2

60 g/m

Open the wrapper of the paper.

-

- Fan the paper stack thoroughly and align its

edges.

(16 lbs.) to 90 g/m2 (24 lbs.).

Unpacking/

☞

the

Multi-Purpose

Tray

- Adjust the Paper Guides to fit the size of the Paper.

- Load the paper stack on the tray facing up.

3

Face up

Check that “READY” is shown on the Message

-

4

Display.

READY

READY

Paper Face

Page 20

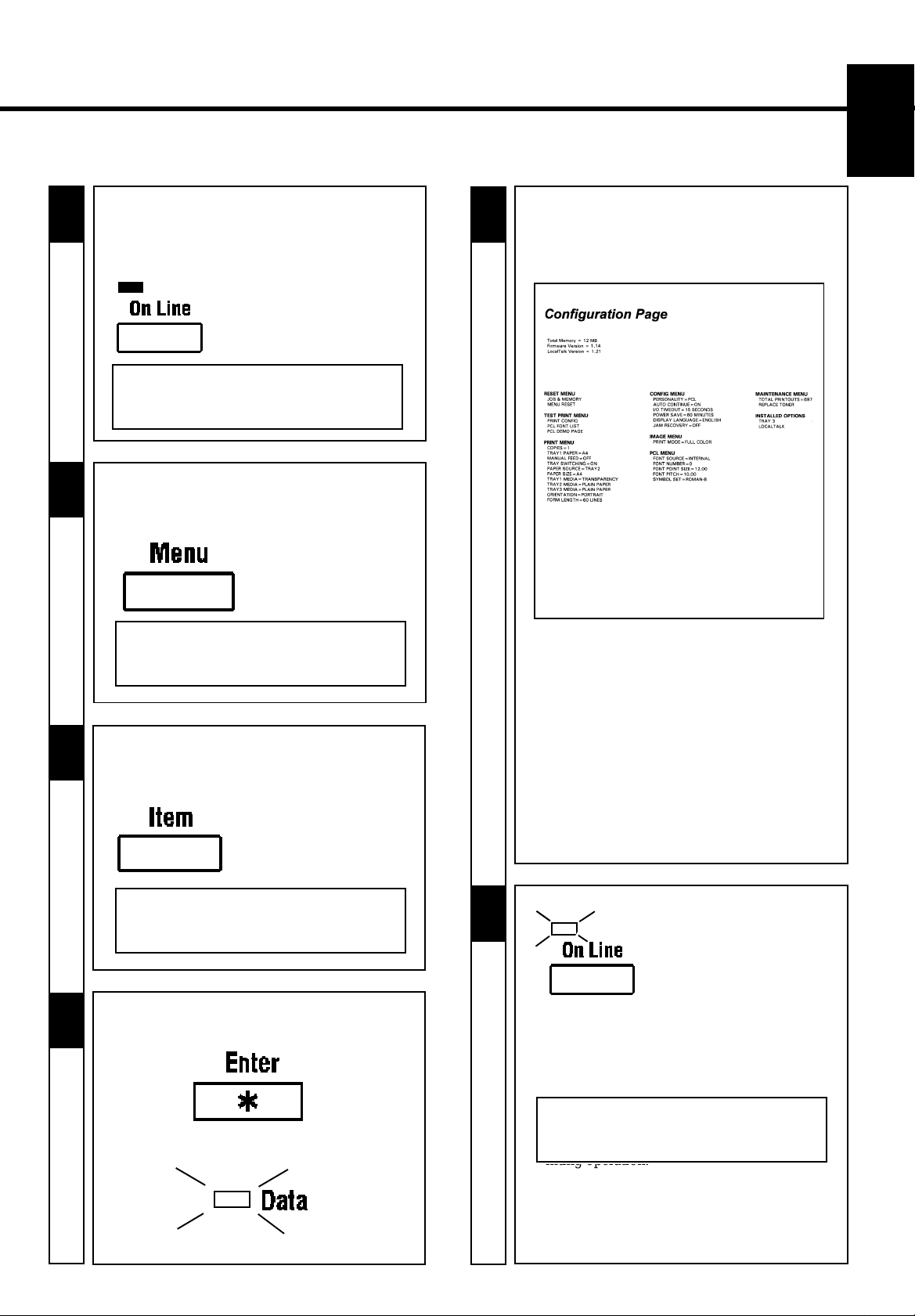

5

6

Press the On Line key on the control panel.

-

Check that “OFF LINE” appears on the Message

-

Display.

Check that the On Line Indicator goes out.

-

✕ Once

OFFLINE

Press the Menu key on the control panel twice.

-

Check that “TEST PRINT MENU” appears on

-

the Message Display.

9

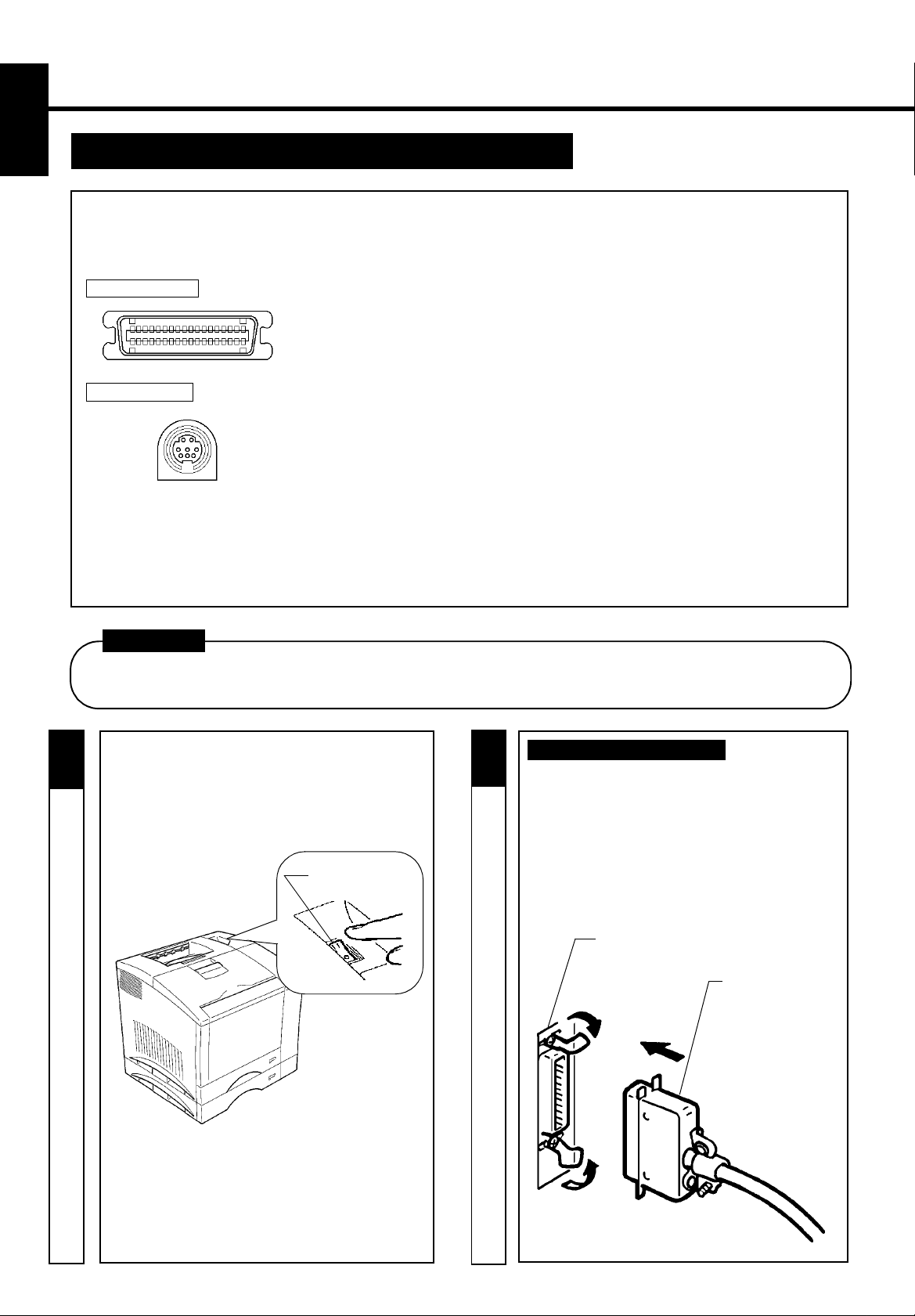

Check that the data on the following

-

demonstration page is printed.

Typical Printout:

7

3. Setting-Up

CHAPTER 1

Installation

7

8

✕ Twice

TEST PRINT MENU

Press the Item key on the control panel once.

-

Check that “PRINT CONFIG” appears on the

-

Message Display.

✕ Once

PRINT CONFIG

ENTER TO PRINT

Press the Enter key on the control panel.

-

The Data Indicator on the control panel lights up.

-

10

If the printer turns out blank sheets of paper

-

without printing the data, the “Hardware

“was not probably done properly.

Setting

In this case, turn the Power Switch OFF and

perform the “Hardware Setting-Up (Unpacking/

Setting-Up Instructions)” procedure.

If the data on the demonstration screen is still not

printed, contact your Technical Representative.

Press the On Line key on the control panel .

-

✕ Once

Check that “READY” appears on the Message

-

Display.

Make sure that the On Line Indicator lights up.

-

READY

This completes the checking procedure for the

-

printing operation.

Let's then connect the printer to the host com-

-

puter.

☞p. 8

Page 21

8

3. Setting-Up

CHAPTER 1Installation

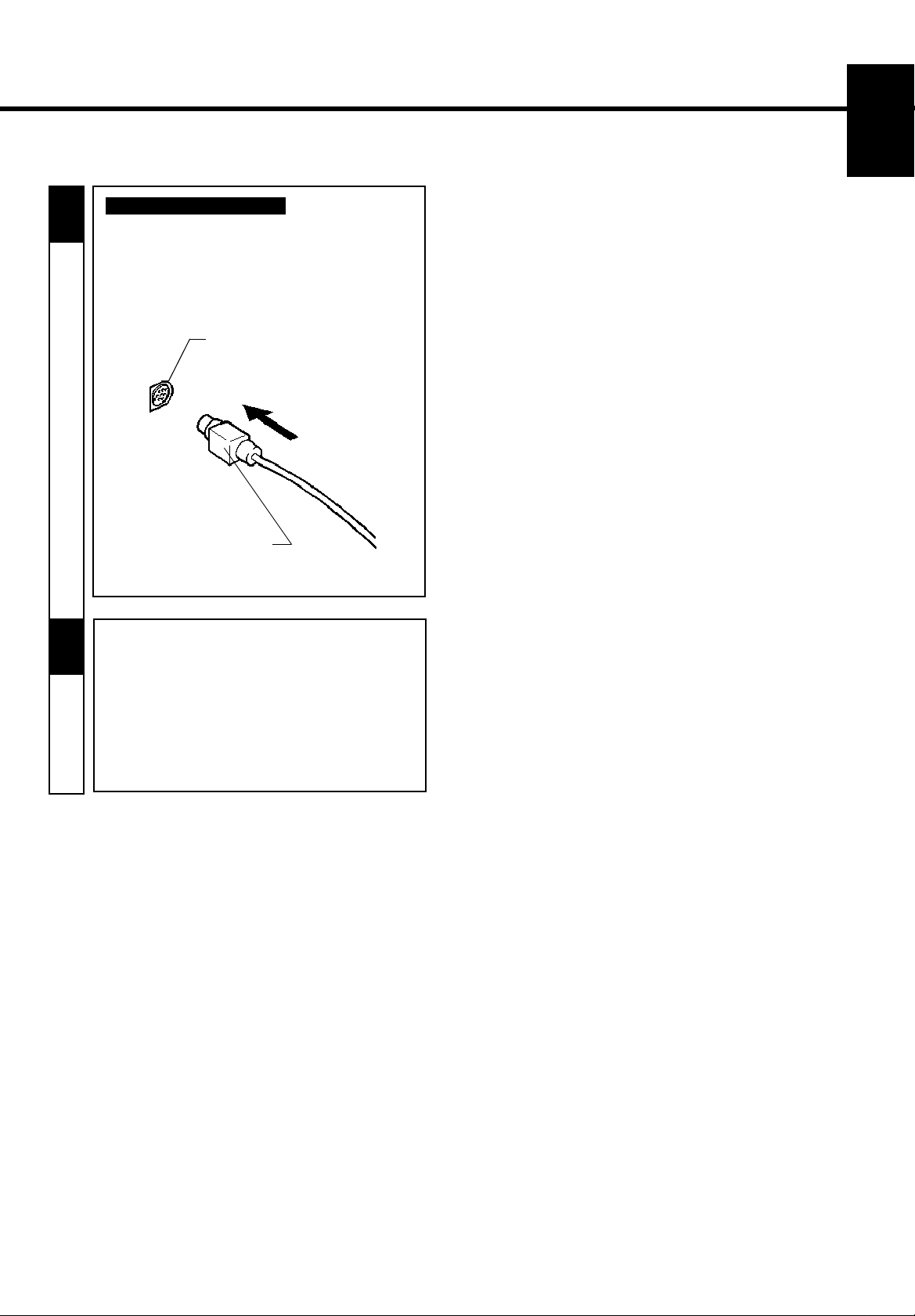

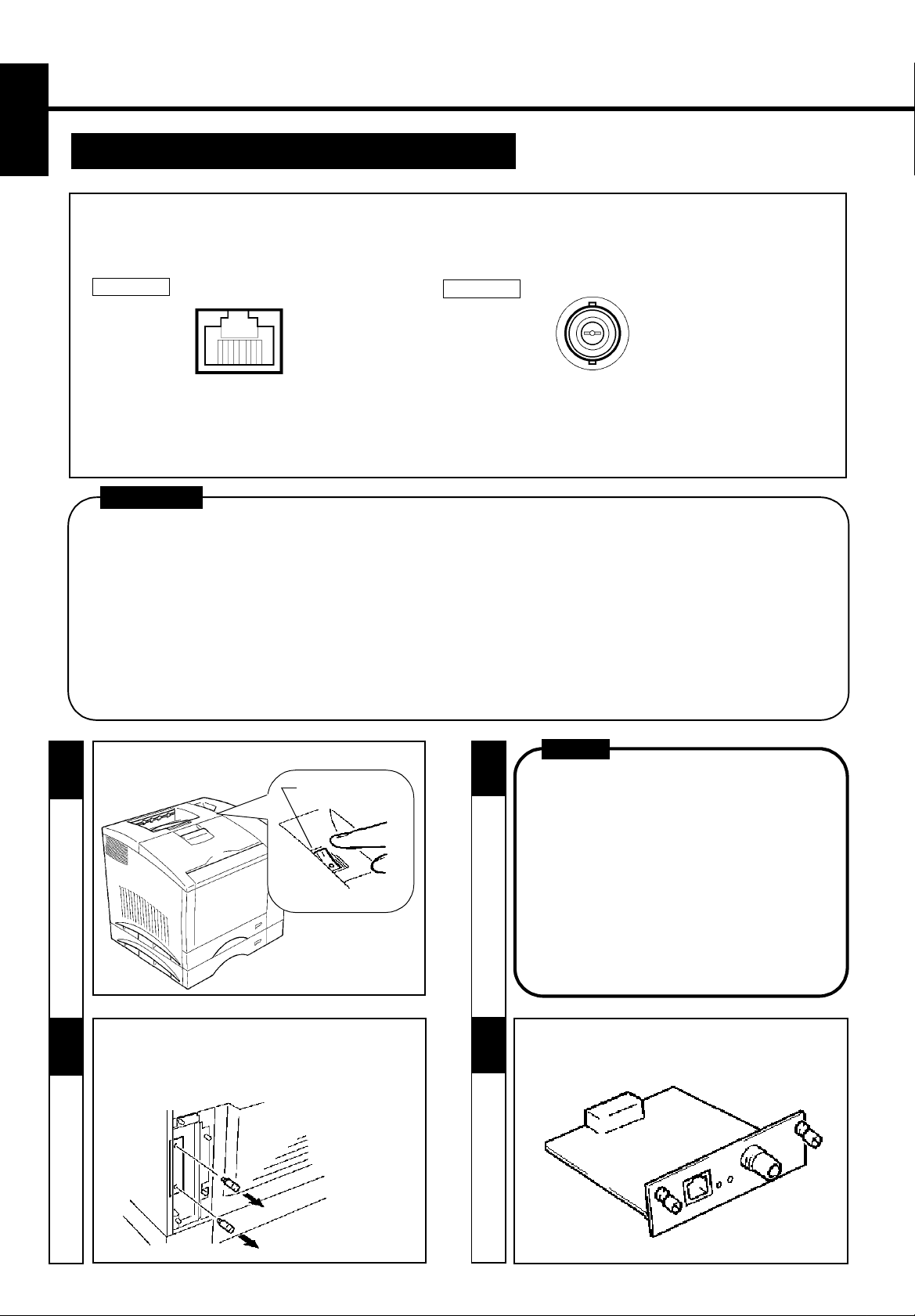

Connecting Printer to Host Computer

PRECAUTION

This printer is equipped with the following two types of interface connectors for connection to the host computer.

-

Select the correct interface to suit the host computer to be used.

Parallel interface

Connector type: IEEE 1284 36-pin Amphenol (full)

-

Typical compatible computer models: IBM PC/AT or compatible

-

(OS: Windows 3.1/3.11/95)

Serial interface

Connector type: LocalTalk DIN-8 (only can use with optional PostScript SIMM)

-

Typical compatible computer models: Apple Macintosh series

-

(OS: System Level 7 or higher)

The type of interface cable used for connecting the printer to the host computer varies depending on the type of

-

computer used. (This printer set does not contain an interface cable.)

Study the operator's manual of your computer and purchase the correct interface cable applicable to this printer and

computer.

CAUTION

- ALWAYS use a shielded cable for the interface cable. Use of an unshielded interface cable could result in radio

frequency interference.

Make sure that the “Hardware Setting-Up

1

-

the Unpacking/ Setting-Up Instructions

☞

and “Checking Print Operation ”

procedures have been completed.

Turn the printer OFF

-

.

Power Switch

☞

p. 6

2

For Parallel Interface

- Connect one end of the interface cable

to the parallel port of the host computer.

- Connect the other end of the interface cable to

the interface connector on the back side of the

printer.

- Secure the plug by closing the two clips

provided.

Parallel Interface connector

Interface cable

- Check that the host computer to be connected to

the printer is OFF.

Page 22

3. Setting-Up

9

CHAPTER 1

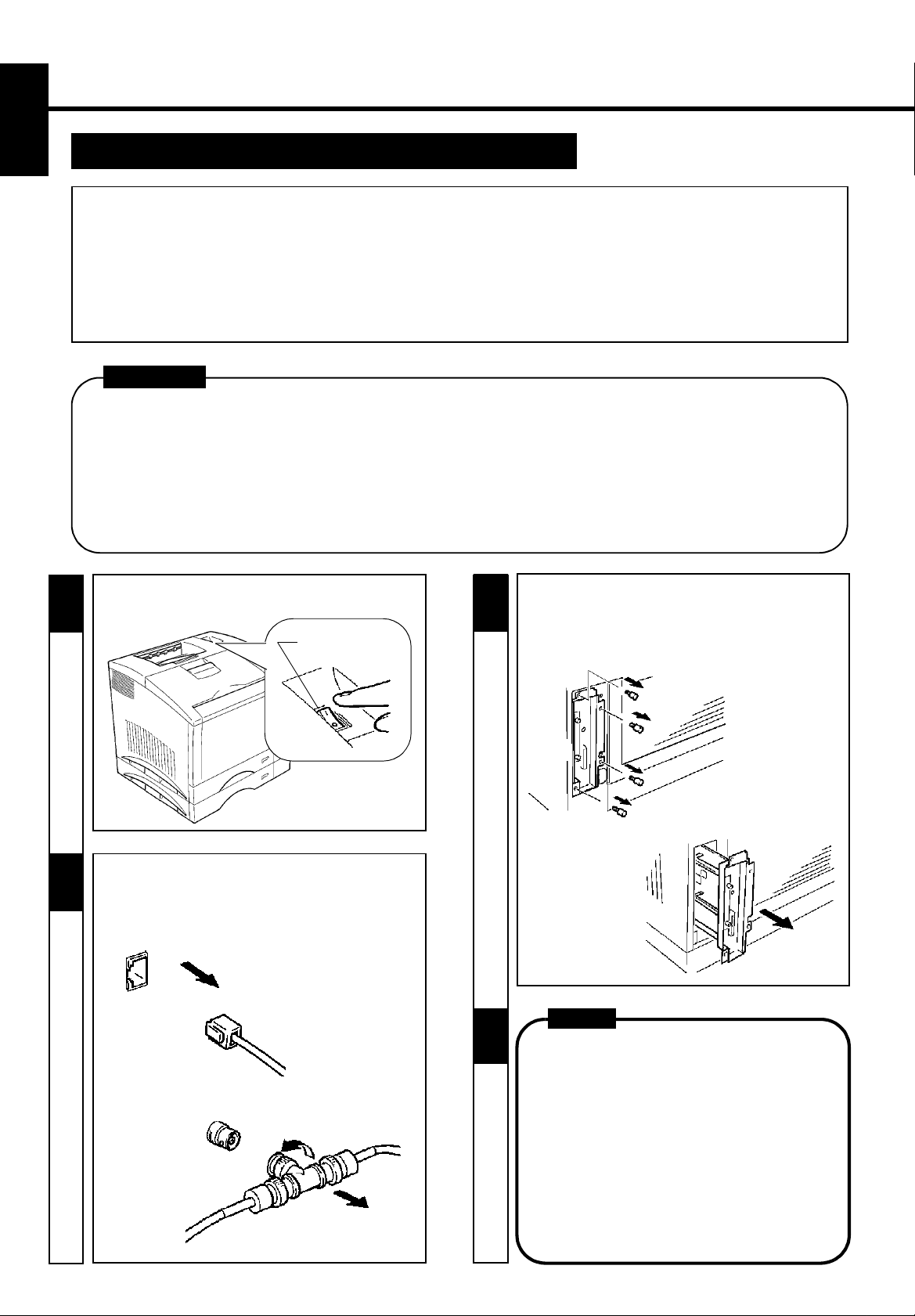

3

4

- Connect one end of the interface cable to the

serial port of the host computer.

- Connect the other end of the interface cable to

the interface connector on the back side of the

printer.

Serial Interface connector

Interface cable

This completes the connection of the printer to

-

the host computer.

- You next install the printer driver (software).

Read the Printer Driver User’s Manual

separately provided (that is shipped together with

the accessories that come with this printer set)

and install the printer driver according to the

operating system of the host computer to be used.

For Serial Interface

Installation

Page 23

10

3. Setting-Up

CHAPTER 1Installation

Expansion Memory (Option) Setting-Up

PRECAUTION

This printer is equipped with two sockets for the installatio n of expansion memory.

-

The optional expansion memories come in five different capacities: 1 MB, 2 MB, 4 MB, 8MB, 16 MB, and 32 MB.

-

The combination in which expansion memories of different capacities are plugged in allows the memory capacity

of the printer to be expanded up to 68 MB (standard 4 MB + expansion 64 MB). Purchase the expansion memory

according to your particular need.

CAUTION

- Before opening the optional packages or handling the options, briefly touch the metal part of the printer to

remove any electrostatic charge from your body.

- When options are taken out of their conductive bags or off their mats, hold them by their edge to avoid touching the

terminals or the patterned surfaces.

- When the Controller board is taken out of the printer, hold it by the edges to avoid touching the terminals or the

patterned surfaces.

- After removing the options or Controller board, be su re to pla ce it on an anti-static mat or a piece of aluminu m foil.

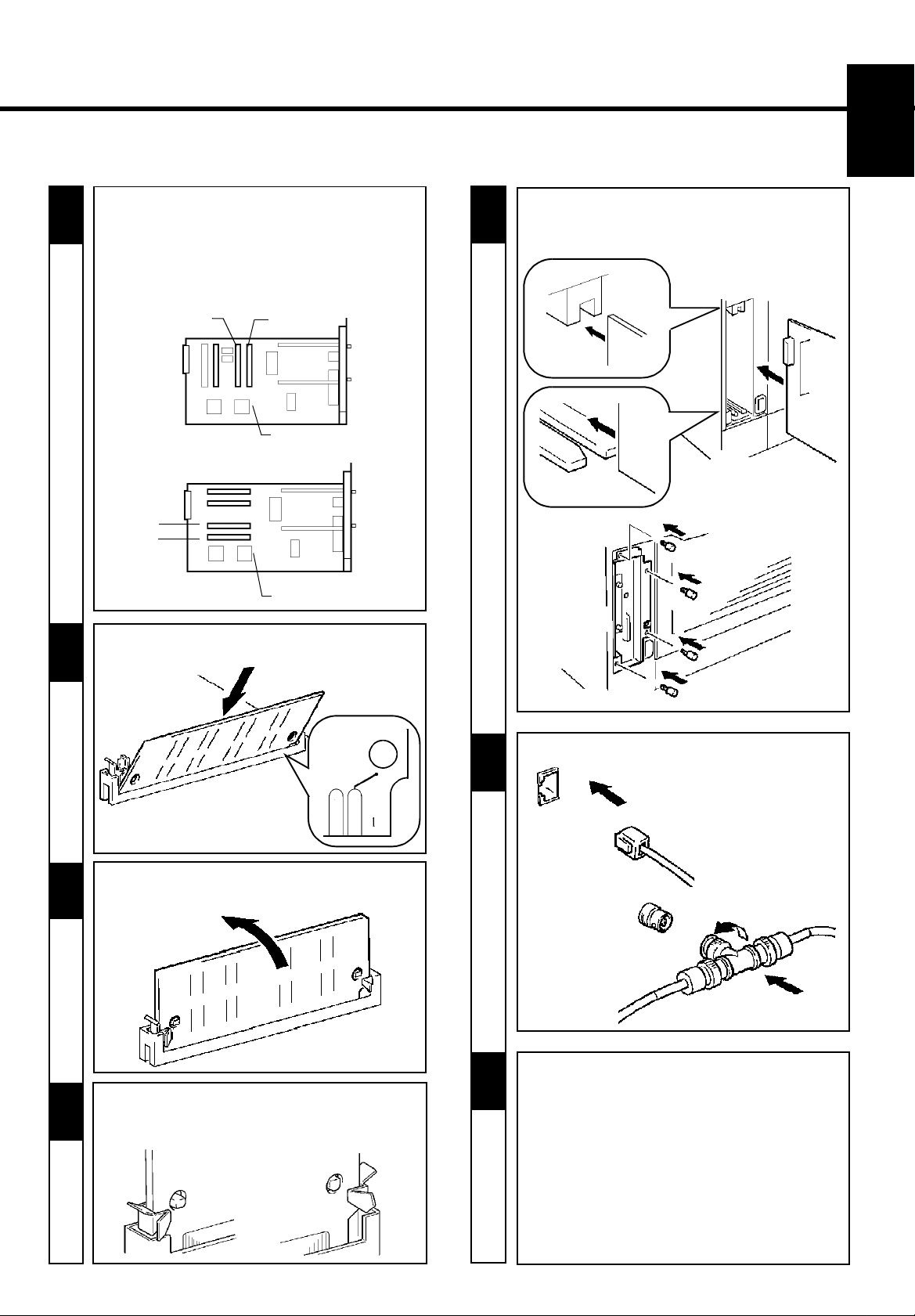

Remove the four screws that secure the controller

-

3

board on the back of the printer.

- Slide out the controller board.

1

Turn the printer OFF.

-

Power Switch

2

Disconnect the cable from the interface connector

-

(Parallel or Serial) or network connector

(10BASE-T or 10BASE-2) on the ba ck of the

printer.

4

NOTE

When the Controller board is taken ou t of the

-

printer,

the terminals or the patterned surfaces.

After removing the options or Controller board,

-

be sure to place it on an anti-static mat or a

piece of aluminum foil.

hold it by the edges to avoid touching

Page 24

5

Take the Expansion Memory out of its carton.

-

Check which type of Controller board is installed

-

in your printer.

Mount the expansion memory in the socket

-

(SIMM3 or 4) at the location shown on the

controller board.

9

3. Setting-Up

Insert the controller board into the guide rails.

-

Secure the controller board in position with the

-

four screws.

11

CHAPTER 1

Installation

6

SIMM3

SIMM3

SIMM4

Insert the expansion memory pin into the socket.

-

SIMM4

Controller board (a)

Controller board (b)

10

Reconnect the interface cable or network cable.

-

- Push the expansion memory down in the

7

8

direction of the arrow.

Check that the expansion memory is mounted

-

securely.

Left Side

Right Side

11

This completes the procedure to mount the

-

expansion memory in the printer.

You now change the setting for <Installed

-

memory> that is one of the setup items of the

printer driver on the host computer

For details, see the Printer Driver

Operator's Manual separately provided (that is

shipped together with the accessories that come

with this printer set).

.

Page 25

12

3. Setting-Up

CHAPTER 1Installation

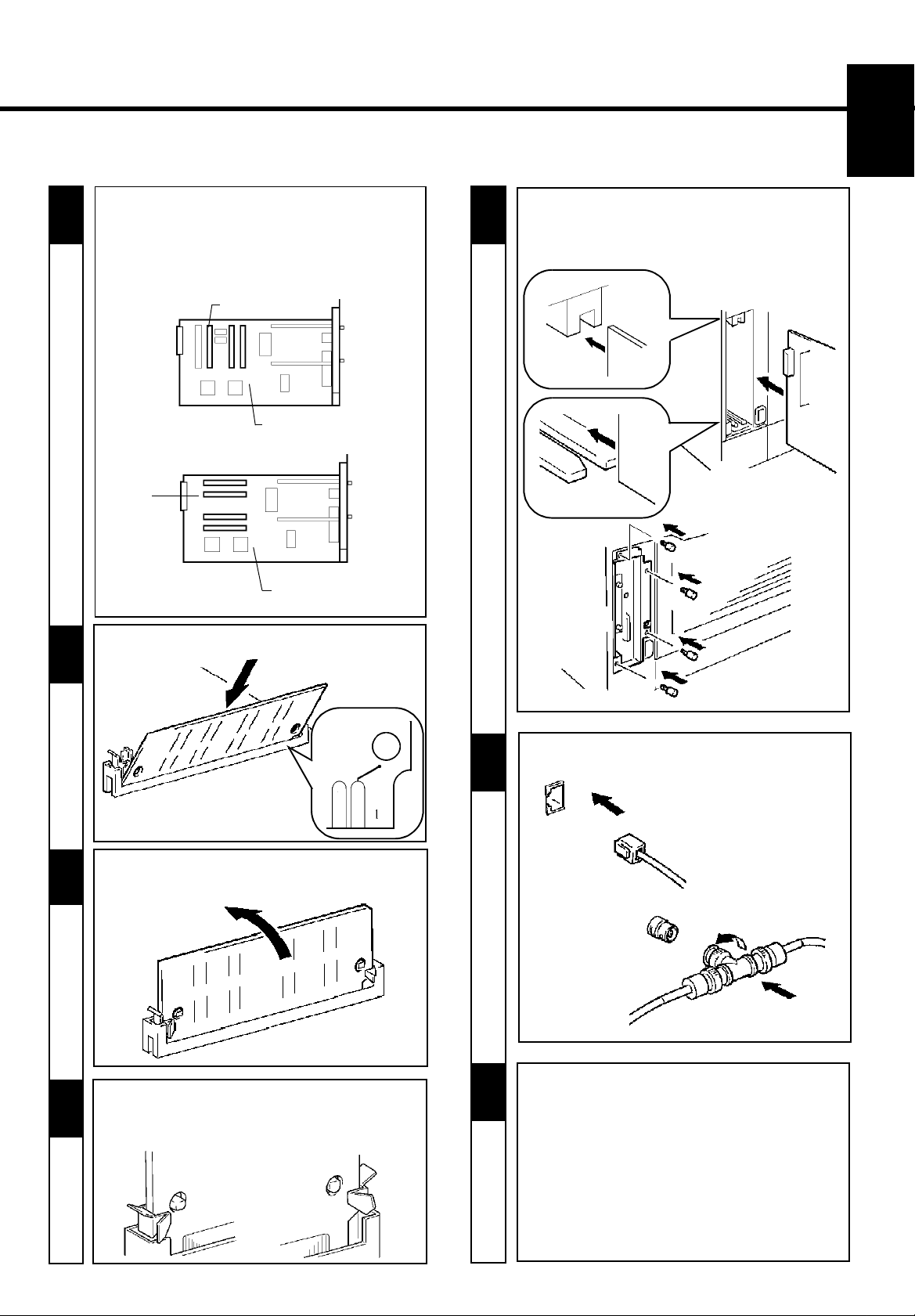

Adobe PostScript R OM SIMM (Option) Setting-Up

PRECAUTION

This printer is equipped with a socket for the installation of an Adobe PostScript ROM SIMM. When the printer is

-

equipped with an Adobe PostScript ROM SIMM, it can function as a PostScript printer.

CAUTION

- Before opening the optional packages or handling the options, briefly touch the metal part of the printer to

remove any electrostatic charge from your body.

- When options are taken out of their conductive bags or off their mats, hold them by their edges to avoid touching the

terminals or the patterned surfaces.

- When the Controller board is taken out of the printer, hold it by the edges to avoid touching the terminals or the

patterned surfaces.

- After removing the options or Controller board, be sure to place it on an anti-static mat or a piece of aluminum foil.

Remove the four screws that secure the controller

-

3

board on the back of the printer.

- Slide out the controller board.

1

Turn the printer OFF.

-

Power Switch

2

Disconnect the cable from the interface connector

-

(Parallel or Serial) or network connector

(10BASE-T or 10BASE-2) on the back of the

printer.

4

NOTE

When the Controller board is taken out of the

-

printer, hold it by the edges to avoid touching

the terminals or the patterned surfaces.

After removing the options or Controller board,

-

be sure to place it on an anti-static mat or a

piece of aluminum foil.

Page 26

5

Take the PostScript ROM out of its carton.

-

Check which type of Controller board is installed

-

in your printer.

Mount the PostScript ROM in the socket

-

(SIMM2) at the location shown on the controller

board.

SIMM2

Controller board (a)

9

3. Setting-Up

Insert the controller board into the guide rails.

-

Secure the controller board in position with the

-

four screws.

13

CHAPTER 1

Installation

6

7

SIMM2

Controller board (b)

Insert the PostScript ROM pin into the socket.

-

Push the PostScript ROM down in the direction of

-

the arrow.

10

Reconnect the interface cable or network cable.

-

8

Check that the PostScript ROM is mounted

-

securely.

Left Side

Right Side

11

- This completes the procedure to mount the

PostScript ROM in the printer.

- You now install the printer driver (software).

Read the PostScript User’s Guide separately

provided (that is shipped together with the

accessories that come with this Adobe

PostScript ROMM SIMM set) and install the

printer driver according to the operating system

of the host computer to be used.

Page 27

14

3. Setting-Up

CHAPTER 1Installation

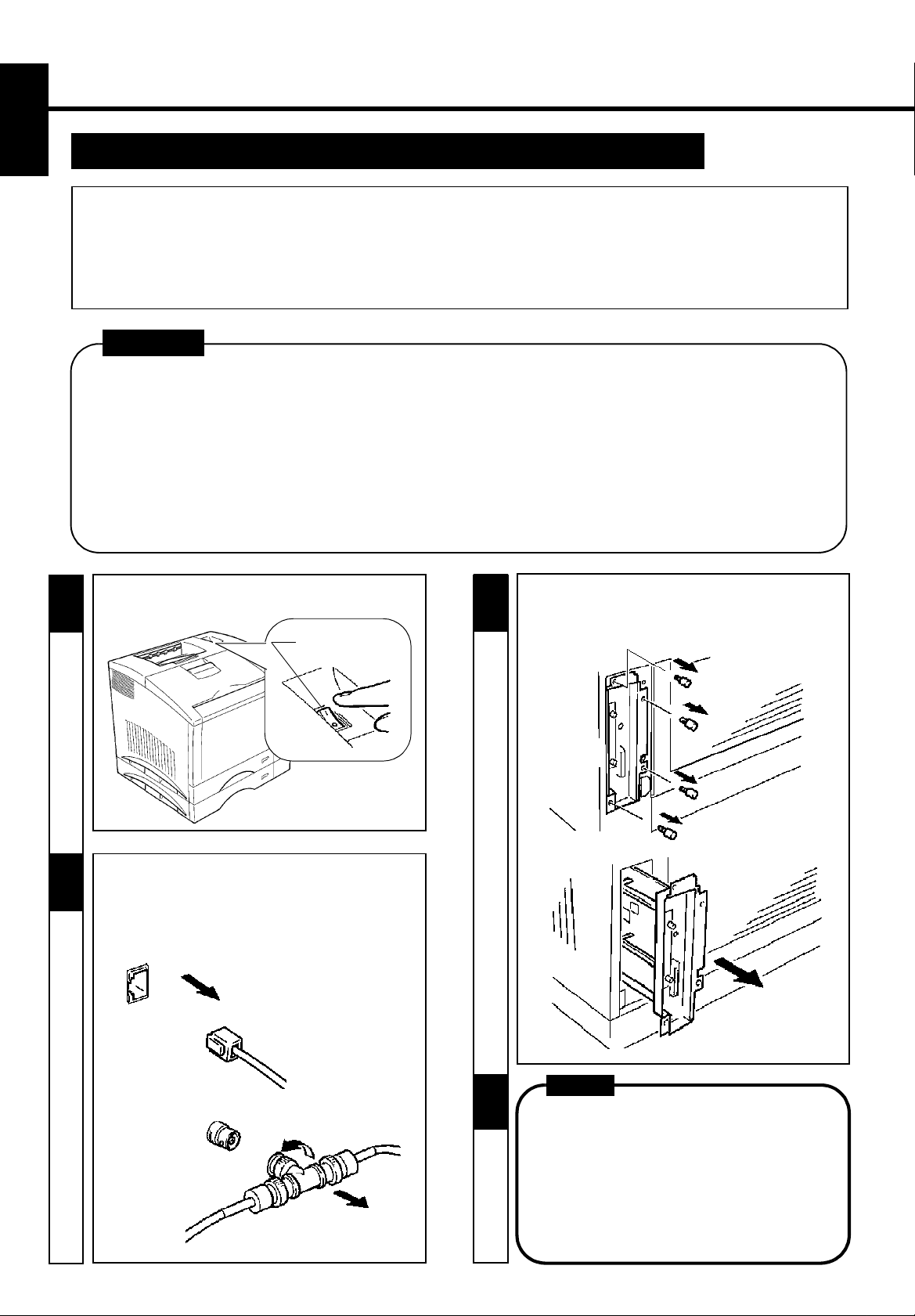

Network Board (Option) Setting-Up

PRECAUTION

The network board is equipped with the following two types of interface con nectors for connection to th e network server.

-

Select the correct interface to suit the network to be used.

10BASE-T

The type of cable used for connecting the printer to the network server varies depending on the connection method

-

Expansion Memory Setting-

of the network to be used. (The accessories that come with the network board do not contain a cable.)

Study the operator's manual of your network and purchase the correct cable applicable to the connection between the

CAUTION

printer and network server.

CAUTION

- Do not make connections both to 10BASE-T and 10BASE-2 at the same time, because it will deactivate the automatic

detection function of the connector connected, disabling communications.

- Before opening the optional packages or handling the options, briefly touch the metal part of the printer to

remove any electrostatic charge from your body.

- When options are taken out of their conductive bags or off their mats, hold them by their edges to avoid touching the

terminals or the patterned surfaces.

- When Controller board is taken out of the printer, hold it by the edges to avoid touching the terminals or the

patterned surfaces.

- After removing the options or Controller board, be sure to place it on an anti-static mat or a piece of aluminum foil.

10BASE-2

3. Setting-Up

1

2

Turn the printer OFF.

-

Power Switch

Remove the two screws that secure the network

-

board panel on the back of the printer.

Remove the network board panel.

-

3

4

NOTE

- When the Network Board is taken out of its

conductive bag or off its mat, hold the

Network Board by the edges to avoid

touching the terminals or the patterned

surfaces.

Take the Network Board out of its carton.

-

Page 28

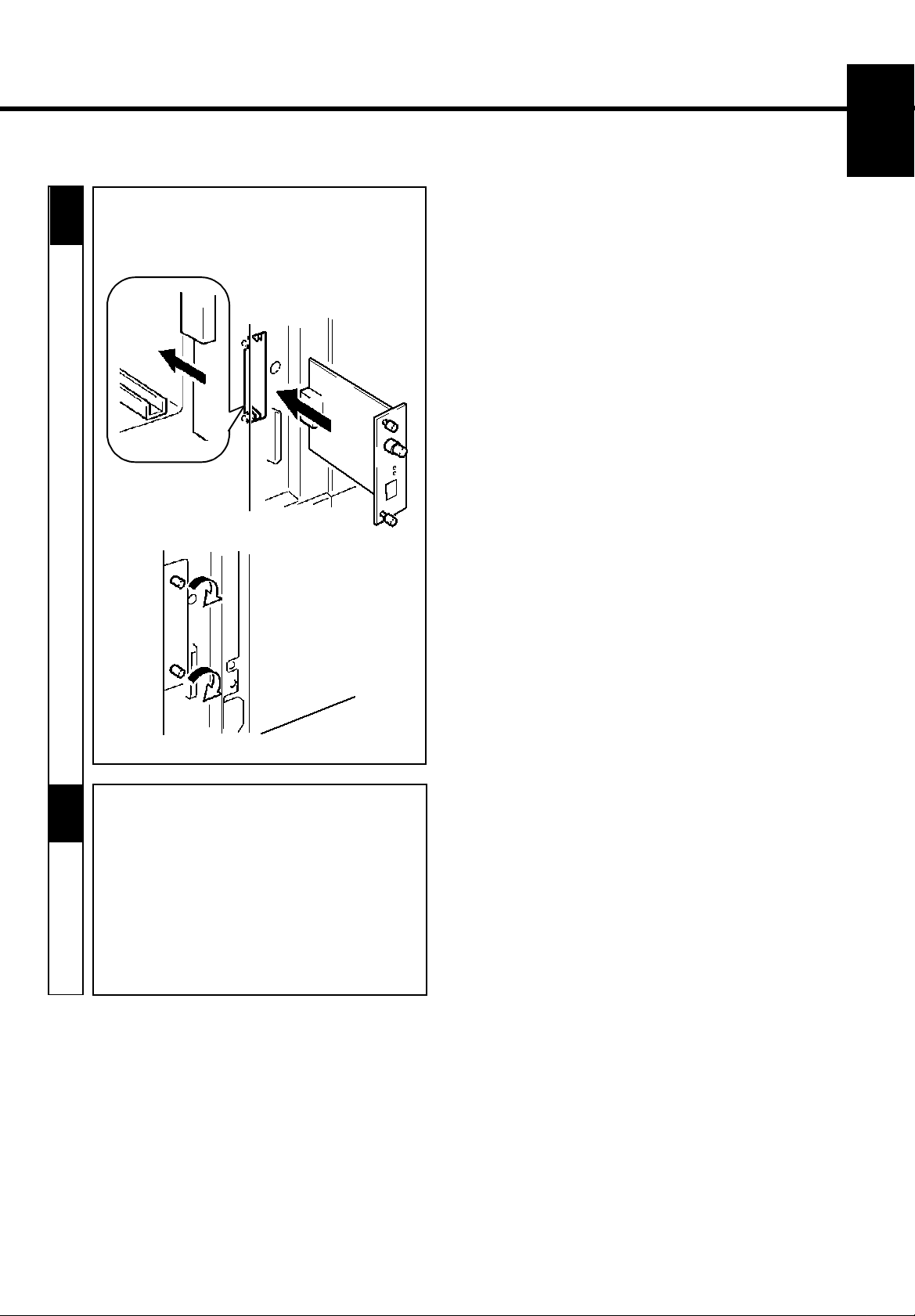

Insert the network board into the mounting rails.

-

5

- Tighten the two screws that secure the network

board in positio n.

15

CHAPTER 1

Installation

6

This completes the procedure to mount the

-

network board in the printer.

Now, read the Network Printer Operator's

-

Manual separately provided (that is shipped

together with the accessories that come with the

Network Board set), connect the network cable

and set the network environment variable

through the host computer.

Page 29

16

CHAPTER 1Installation

3. Setting-Up

Page 30

Chapter 2

Using the Printer

This chapter gives basic information on the different parts of the

printer and shows you how to use the printer.

1. Printer Parts and Accessories 18

⋅

Printer 18

⋅

Accessories 19

⋅

Control Panel keys 20

⋅

Operation and W arning Labels 22

2. Turning ON and OFF the Printer 23

3. Printing Paper 24

⋅

Type 24

⋅

Size 24

⋅

Capacity 24

⋅

Print Area 25

⋅

Care of paper 25

4. Loading the Printing Paper 26

⋅

Loading Plain Paper/ Recycled Paper 26

- TRAY 1 (Multi Purpose Tray) 26

- TRAY 2 (Second Cassette)/ TRAY 3 (Third Cassette: option) 27

⋅

Loading OHP sheets/ Labels 29

- TRAY 1 (Multi Purpose Tray) 29

- TRAY 2 (Second Cassette)/ TRAY 3 (Third Cassette: option) 30

⋅

Loading Special Paper (Letterhead/ Envelopes/ Postcard/ Thick Paper)

- TRAY 1 (Multi Purpose Tray) 32

5. Printing 34

32

17

17

CHAPTER 2

CHAPTER 2

Installation

Installation

Using the Printer

Using the Printer

Page 31

18

1. Printer Parts and Accessories

PRINTER

Print Tray

The printed paper is fed out face down onto

this tray. The tray can hold 250 sheets

CHAPTER 2

of printed paper. ☞p. 34

Using the Printer

Power Switch

Use to turn the printer ON and OFF ☞p. 23

Front Cover

Swing open to change supplies such as the To ner Cartridge or to clear

a paper misfeed.

Control Panel

-Allows the operator to make various settings.

-The LCD Display shows the current status of the printer.

For more details, see “Control Panel Keys.” ☞p. 20

Front Cover Lock Release Lever

Pull down to unlock the Front Cover.

TRAY 1 (Multi Purpose Tray)

- Swing open toward you to load paper

- Holds up to 150 sheet s of paper. ☞p. 24

TRAY 2 (250-Sheet Second Cassette)

Holds up to 250 sheets of paper. ☞p. 24

Œ

.

TRAY 3 (250-Sheet Third Cassette: Option)

Holds up to 250 sheets of paper. ☞p. 24

250-Sheet Third Cassette Unit (Option)

When installed under the Printer, houses a third cassette increasing paper capacity to 650 sheets.

Grips

- Two grips are provided on each side of the printer (four in all). Used to hold the printer when installing or moving it.

- The printer should be lifted by two persons. ☞p. 5

Network Board Panel

Use to mount the optional network boa rd.

-

☞

p. 14

Rear Cover Lock Release Lever

Pull down to swing open the Rear Cover.

Rear Cover

Swing open to change the Oil Roller Assembly or clear a paper

misfeed.

Interface Connector (Serial Connector)

Provides connection bet w een the printer and host computer.

☞

p. 8

Interface Connector (Parallel Connector)

Provides connection between the printer and host compu ter.

☞

p. 8

Power Cord Socket

Connect the power cord of the printer to this socket.

Page 32

ACCESSORIES

19

1. Printer Parts and Accessories

Waste bottle

- Used to collect and contain waste toner.

- Replace this Bottle with a new one when it

is filled with waste toner.

- Put the old bottle in a polyethylene bag or

the like and dispose of it according to your

local regulations. ☞p. 56

Toner Cartridge

Image Transfer Belt Unit

Drum Cartridge

- There are four different color Toner Cartridges:

Black, Yellow, Magenta and Cyan.

- Replace this cartridge with a new one when it runs

out of toner.

- Put the old Cartridge in a polyethylene bag or the like

and dispose of it accordin g to yo ur loc al

☞

p. 66

☞

☞

p. 52

p. 56

regulations.

- Transfers the image created by

the Drum Cartridge onto paper. Handle with utmost

care.

- The image is formed on it. Handle with utmost care.

- Replace this Cartridge with a new one when it

reaches the time to change.

- Put the old Cartridge in a polyethylene bag or the

like and dispose of it according to your loc al

regulations.

CHAPTER 2

Installation

Using the Printer

Image Transfer Roller Unit

Transfers the image created by the Drum Cartridge onto paper. Handle with utmost care.

☞

p. 62

Oiling Roller

Fusing Unit

- Supplies the Fusing Rollers with oil and cleans them off.

- Replace this Roller with a new one when it reaches the time to change.

- Put the old Roller in a polyethylene bag or the like and dispose of it

according to your local regulations. ☞p. 56

Permanently fixes the image onto paper.

☞

p. 62

Page 33

20

1. Printer Parts and Accessories

CONTROL PANEL KEYS

Data Indicator

CHAPTER 2

Using the Printer

Data Indicator ON

When data received from the host computer is stored in the printer

memory.

Data Indicator OFF

When no data is stored in the printer memory, usually

immediately after power on or reset.

Data Indicator Flashing

When the printer is receiving data from the host computer.

Message Display

Shows the message telling the current status

-

of the printer.

- Shows the setting made for the var i ous

functions.

Message Indicator

Message Indicator Flashing

When the printer is asking the user for something to

occur or when an error occurs.

Message Indicator OFF

Otherwise.

☞

☞

p. 38

p. 38

Menu mode

, the printer exits the menu

On Line Key

One Line

The

If the key is pressed while in the

and returns on-line. All keys except this key are valid during the off-line

state.

key changes the state between on-line and off-line.

On-line Indicator

Œ

Proceed key

The Proceed key clears most recoverable e rrors

and returns the printer back to

The key overrides manual feed and paper size

requests.

On-line.

On-line Indicator ON

When the printer can receive data from the host compute r.

On-line Indicator Flashing

During Power On Self Test and initialization.

On-line Indicator OFF

When the printer can’t receive data from the host computer.

Page 34

Menu Key

☞

21

1. Printer Parts and Accessories

p. 38

Accesses the print and configuration menus. The menus goes through a loop until the

Item Key

Accesses the list of items after selecting a

pressed when

The items go through a loop until the

When the

pressed, the next

Menu

On Line

is selected otherwise no action takes place while displaying “

key is pressed, the printer returns to

Menu

selection is displayed. ☞p. 38

Menu

On Line

key is pressed or the

On Line

and selects the menu item. This key must be

key is pressed.

On Line

Menu

key is pressed.

and when the

Off Line”

Menu

key is

.

CHAPTER 2

Installation

Using the Printer

UP & DOWN Keys

These two keys display the next or the previous setting for the current menu item. If the UP or

tinuously when one of the following items are on the LCD, (FONT NUMBER, and PT SIZE), the value is incremented /

decremented faster.

☞

Enter Key

This key saves the menu settings while in the

indicate the current menu setting. Pressing the

appropriate

PS DEMO PAGE

p. 38

TEST PRINT MENU

.

including

Item

menu mode. An asterisk appears at the right of the LCD to

Enter

key in the

PRINT CONFIG, PCL FONT LIST, PCL DEMO PAGE

TEST PRINT MENU

Down

key is pressed con-

, the printer executes the

and

Page 35

22

1. Printer Parts and Accessories

OPERATION AND WARNING LABELS

Installing the Toner Cartridge

CHAPTER 2

- Describes how to replace the Toner Cartridge when it runs out of toner. For details of operation, refer to “Changing the Toner

Cartridge” on page 48.

Changing the Waste bottle, Drum Cartridge and Oiling Roller

Using the Printer

- Describes how to replace the Waste bottle, Drum Cartridge and Oiling Roller. For details of

operation, refer to “Changing the Drum Cartridge, Waste bottle and Oiling Roller” on page

46.

- The Waste bottle, Drum Cartridge and Oiling Roller are preset t o reach the time

to change simultaneousl y. Replace these three Units at the same t ime.

Clearing Paper Misfeed in Paper Path

- Describes how to remove paper using the Misfeed Removal Cover and Roller Lock Release Lever if a

paper misfeed occurs in the paper path.

- For details of operation, refer to “When a Paper Misfeed has Occurred” on page 78.

Loading Paper

- Describes how to replenish the Paper Feeding Tray with paper.

- For details of operation, refer to “Loading the Printing Paper” on page 26.

WARNING! HIGH TEMPERATURE

Œ

- Alerts you to the high temperature of the area where the label is applied on the Fusing Unit.

Do not touch this area when you change the Oiling Roller or clear a misfeed.

Page 36

2. Turning ON and OFF the Printer

Turning Printer ON

Turning Printer ON

Press the Power Switch to the ❙ (ON) position.

Turning Printer OFF

Turning Printer OFF

Press the Power Switch to the (OFF) position.

23

CHAPTER 2

Installation

Using the Printer

When Printer is Turned ON

When Printer is Turned ON

The printer will be ready to make a print approx. 90

sec. after the Power Switch is turned ON.

NOTE

NOTE

- If no print commands are sent from the host computer t o the printer for 15 min., the printer automatically enters standby in the

Power save mode

- You can set the time it takes to enter the

CONFIG MENU

.

. For details, see

Power save mode

Chapter 3 “Changing the Printer Settings”

, or turn the mode

OFF (no power save)

through the

. ☞p. 35

Page 37

24

3. Printing Paper

PRECAUTION

This printer is designed to print the following types of paper. Any other types of paper must not be

used.

Type

CHAPTER 2

*: Does not support Legal L size Thick Paper.

Using the Printer

Size

Standard size

Paper

Feeding

Port

Tray 1

Tray 2

Tray 3

Paper

Feeding

Port

Tray 1

Plain

Paper

weighing:

60 to 90 g/m

16 to 24 lbs.

A4

210✕297 mm

8-1/4”✕11-3/4”

Recycled

Paper

2

weighing:

60 to 90 g/m

16 to 24 lbs.

JIS B5

182✕257 mm

7-1/4”510”

OHP

Sheet

2

A5

148✕210 mm

5-3/4”✕8-1/4”

Special Paper

J-

Labels

None None None None None

None None None None None

Letterhead

Envelopes

Post(Postcard)

size:

100 ✕ 148 mm

4" ✕ 5-3/4”

Thick Paper*

weighing:

90 to 157 g/m

24 to 4 1-1 /4 l bs.

Œ

*: Does not support Legal L size Thick Paper.

Legal *

8-1/2”514”

216✕356mm

Letter

8-1/2”511”

216✕279mm

Executive

7-1/4”✕10-1/2”

184✕267mm

2

Invoice

5-1/2”✕8-1/2”

140✕216mm

Tray 2

Tray 3

None None None None

None None None None

Non-Standard size (TRAY 1 only)

Full-color printing: Widths from 92 to 216mm (3-1/2” to 8-1/2”), lengths from 148 to 277mm (5-3/4” to 11-3/4”)

Monochrome printing: Widths from 92 to 216mm (3-1/2” to 8-1/2”), lengths from 148 to 356mm (5-3/4” to 14")

Capacity

*: Does not support Legal size Thick Paper.

Plain

Paper

Feeding

Port

Paper

weighing:

60 to 90 g/m

16 to 24 lbs.

Recycled

Paper

2

weighing:

60 to 90 g/m

16 to 24 lbs.

OHP

Sheet

2

Labels

Tray 1 150 150 50 50 50 20 50 50

Tray 2 250 250 50

Tray 3 250 250 50

None None None None None

None None None None None

Special Paper

Letterhead

Envelopes

JPost(Postcard)

size:

100 ✕ 148 mm

4" ✕ 5-3/4”

L: Lengthwise

Thick Paper

weighing:

90 to 157 g/m2

24 to 41-1/4 lbs.

*

Unit: sheets

Page 38

Print Area

25

3. Printing Paper

4mm

(0.16")

4mm

(0.16")

Printable

area

4mm

(0.16")

For full-color

printing

293mm

(11-1/2”)

For monochrome

- Monochrome (black) printing can be done on paper up to

352mm (13-3/4”) in length, with the exception of four

4mm (0.16") margins.

- Full color printing can be done on paper up to 293mm

(11-1/2”) in length, with the excep tion of four 4mm

(0.16") margins.

printing

352mm

4mm

(0.16")

(13-3/4”)

Care of Paper

Use the following precautions when handl ing the paper.

- Avoid storing the supplies at any of the following places:

A place subject to direct sunlight.

A hot place with an open flame.

A humid place.

A dusty place.

- Store paper, which has been removed from its wrapper but not loaded in the printer tray, in a sealed plastic bag in a cool, dark place.

- Keep paper supplies out of the reach of children.

CHAPTER 2

Installation

Using the Printer

NOTE

⋅

Do not use Legal size Thick paper. (Does not support Legal size Thick Paper.)

⋅

Do not use the following paper. To do so will lead to reduced print quality, a misfeed or a failure.

- Paper already used in a thermal transfer printer or ink jet printer.

- Paper that is too thin or too thick.

- Paper folded, curled or broken.

- Paper having binding holes or perforations.

- Paper of which surfaces are too smooth or too rough or which is very different in roughness between both surfaces .

- Paper whose surfaces have a special coating, such as carbon pap er, heat-sensitive paper and pressure-sensitive paper.

- Sheets of paper varying in size.

- Paper not cut at right angles.

- Paper bound by gluing, stapling or clipp ing.

- Labels which are easy to peel.

⋅

Envelop es should meet the following requirements:

- Edges and folds are sharp.

- General mailing envelopes with no seals on the glued portion.

- Those having flaps the full width of the envelope. (Unacceptable if the flap is glued, but not the mating surface.)

- Wrinkle-free, no fasteners.

⋅

Generally, envelopes perform well, but some types may wrinkle. We strongly recommend testing any type of envelope before buying

it in large amounts.

⋅

The Following transparencies are recommended;

- For color printing, Minolta CF-200 (D) or 3M CG3710

- For monochrome pr inting, Minolta M-100 (D) or 3M PP2500

To purchase Minolta transparencies please contact your local Minolta dealers, on call 1 (888) 2-MINOLTA. (for U.S.A. Users only)

⋅

For more information, refer to “Loading the Printing Paper”.

Page 39

26

4. Loading the Printing Paper

Loading Plain Paper / Recycled Paper

PRECAUTIONS

⋅

Do not use the following pap er. To do so will lead to reduced print quality, a misfeed or a failure.

- Paper already used in a thermal transfer printer or ink jet printer.

CHAPTER 2

Using the Printer

- Paper that is too thin (under 60 g/m2, 16 lbs.) or too thick (over 157 g/m2, 41-1/4 lbs.).

- Paper folded, curled or broken.

- Paper having binding holes or perforations.

- Paper of which surfaces are too smooth or too rough or which is very different in roughness between both surfaces .

- Paper whose surfaces have a special coating, such as carbon paper, heat-sensitive paper and pressure-sensitive paper.

- Sheets of paper varying in size.

- Paper not cut at right angles.

- Paper bound by gluing, stapling or clipping.

TRAY 1 (Multi Purpose Tray

- Open the TRAY 1 (Multi Purpose Tray).

1

- Open the wrapper of the paper.

2

- Fan the paper stack thoroughly and align its edges.

2

Paper Face

)

- To load a paper stack of lon g si ze, open the Paper

4

Support.

Paper Support

Œ

NOTE

- The paper should be loaded no higher than the Max.

5

Level Indic at or.

OK

NG

- When paper remains in the tray, do not load more

paper on the remaining paper.

- If you load the paper forcibly, it may cause a paper

misfeed.

- Adjust the Paper Guides to fit the size of the Paper.

- Load the paper stack on the tray facing up.

3

Face up

- When you want to replenish the paper, take out th e

remaining paper and stack it on the add itio na l pape r.

Then fan the paper and load it.

- We recommend replenishing the paper supply only

when the Tray is empty.

Page 40

TRAY 2 (Second Cassette) / TRAY 3 (Third Cassette: option)

27

4. Loading the Printing Paper

- Slide out the TRAY 2 (second Cassette) or TRAY 3

1

2

2

(Third Cassette).

- Press down the Paper Lifting Plate until it locks.

-Pressing the Guide Lock Lever, adjust the Paper Guides

5

6

to fit the size of the Paper.

Paper Guides

Guide Lock Lever

- Set the Paper Size Indicator to fit the size of the paper

used.

A4

Legal

Letter

CHAPTER 2

Installation

Using the Printer

- Install the Trailing Edge Guide to fit the size of the

2

3

4

paper to be loaded.

Trailing

Edge

Guide

- When loading Legal-size paper, the Trailing Edge

NOTE

Guide is not used. Return it to the Guide space

in the Cassette.

1

2

A4

Letter

NOTE

7

- If the Paper Size Indicator is not reset to the corre-

sponding size, th e printed image may not be printed

at the correct size. When you have changed the

paper size, always reset the Paper Size Indicator

without fail.

- Open the wrapper of the paper.

8

Paper Face

Paper Size

Indicator

Guide space

To Be Continued

Page 41

28

4. Loading the Printing Paper

TRAY 2 (Second Cassette) / TRAY 3 (Third Cassette: option)

9

CHAPTER 2

Using the Printer

- Load the paper stack in the Cassette facing down, its

10

- Fan the paper stack thoroughly and align its edges.

corners are under the Paper Separator and it s leading

edge makes contact with the front side of the Cassette.

Face down

Paper

Separator

- Slide in the Cassette.

12

Œ

2

11

NOTE

- The paper should be loaded no higher than the Max.

Level Indicator.

OK

NG

- When paper remains in the tray, do not load more

paper on the rema ining paper.

- If you load the paper forcibly, it may cause a paper

misfeed.

- When you want to replenish the paper, take out the

remaining paper and stack it on the add itio na l pape r.

Then fan the paper and load it.

- We recommend repleni s hing the paper supply only

when the Paper Tray is empty.

Page 42

4. Loading the Printing Paper

Loading OHP sheets / Labels

PRECAUTIONS

⋅

Labels must be loaded in the TRAY 1 (Multi Purpose Tray). Do not load them in the TRAY 2 (Second) / TRAY 3 (Third Cassette).

⋅

When handling OHP sheets, it is recommended to wear gloves so that they are not soiled with fingerprints and smears. Soiled OHP

sheets may lead to a defective printed image.

⋅

Do not use the following paper. To do so may lead to reduced print quality, a misfeed or a failure.

- Labels which are easy to peel.

- Labels which have already been peeled partially.

- Labels from which adhesive has come out.

We recommend test ing any type of label be fore buying it in large amou nts.

⋅

OHP sheets or labels can be printed continuously but the feeding capability may be affected by the material used and the

operating environment. If they cannot be fed successfully, it is recommended not to load several sheets at a time but to load

them one by one.

⋅

The Following transparencies are recommended;

- For color printing, Minolta CF-200 (D) or 3M CG3710

- For monochrome printing, Minolta M-100 (D) or 3M PP2500

To purchase Minolta transparencies please contact your local Minolta dealers, on call 1 (888) 2-MINOLTA. (for U.S.A. Users only)

29

CHAPTER 2

Installation

Using the Printer

TRAY 1 (Multi Purpose Tray)

- Open the TRAY 1 (Multi Purpose Tray).

2

1

- Open the wrapper of the paper.

2

3

Paper Face

- Adjust the Paper Guides to fit the size of the OHP

or Label sheets.

- To load a paper stack of long size, open t he Paper

Support.

- Load the standard OHP or Label sheet stack on the tray

facing up.

Face up

Paper Support

4

NOTE

- Load the recommended OHP (Minolta CF-200 (D).

3M CG3710, Minolta CF-100 (D) or 3M PP2500) so

that the front side (on which the white tape is fitted)

faces down

White Tape

- Do not load more than 50 sheets on the tray.

- When OHP or Label sheets remain in the tray,

do not load more sheets on the remaining sheets.

- If you load the OHP or Label sheets forcibly, it may

cause a misfe ed.

- When you want to replenish the OHP or Label sheets,

take out the remaining sheets an d stack them on the

additional OHP or Label sheets.

Then fan the OHP or Label sheets and load them.

- We recommend replenishing the OHP or Label sheets

only when the Tray is empty.

in the tray.

Face down

Page 43

30

4. Loading the Printing Paper

TRAY 2 (Second Cassette) / TRAY 3 (Third Cassette: option)

- Slide out the TRAY 2 (second Cassette) or TRAY 3

1

CHAPTER 2

Using the Printer

2

(Third Cassette).

- Press down the Paper Lifting Plate until it locks.

-Pressing the Paper Guide Lock Lever, adjust the

5

5

6

Paper Guides to fit the size of the Pa pe r.

Paper Guides

Guide Lock Lever

- Set the Paper Size Indicator to fit the size of the paper

used.

A4

Legal

Œ

Letter

- Install the Trailing Edge Guide to fit the size of

2

3

4

the OHP to be loaded.

Trailing

Edge Guide

- When loading Letter-size OHP, the Trailing Edge

NOTE

Guide is not used. Return it to the Guide space in the

Cassette.

1

2

Guide space

A4

Letter

7

8

Paper Size

Indicator

NOTE

- If the Paper Size Indicator is not reset to the corre-

sponding size, th e printed image may not be printed

at the correct size. When you have changed the

paper size, always reset the Paper Size Indicator

without fail.

- Open the wrapper of the OHP.

Paper Face

Page 44

TRAY 2 (Second Cassette) / TRAY 3 (Third Cassette: option)

31

4. Loading the Printing Paper

9

10

- Load the standard OHP stack in the Cassette facing

down, its corners are under the Paper Separator, and its

leading edge makes contact with the front side of the

Cassette.

Paper

Separator

Face down

NOTE

- Load the recommended OHP (Minolta CF-200 (D).

3M CG3710. Minolta CF-100 (D) or 3M PP2500) so

that the front side (on which the while tape is fitted)

faces up

White

in the Cassette.

Face up

2

11

12

NOTE

- When you want to replenish the OHP, take out the

remaining OHP and stack them on the additional

OHP. Then fan the OHP and load them.

- We recommend replenishing the OHP only when the

Cassette is empty.

- Slide in the Cassette.

CHAPTER 2

Installation

Using the Printer

- The OHP should be loaded no higher th an the Max.

Level Indicator.

OK

NG

- When OHP remain in the cassette, do not load more

sheets on the remaining sheets.

- If you load the OHP forcibly, it may cause a misfeed.

Page 45

32

4. Loading the Printing Paper

Loading Special Paper (

Letterhead/ Envelopes/ Postcard/ Thick Paper)

Œ

PRECAUTIONS

⋅

Do not use Legal L size Thick paper. (Does not support Legal L size Thick Paper.)

⋅

Do not use the following paper. To do so will lead to reduced print quality, a misfeed or a failure.

CHAPTER 2

Using the Printer

- Paper already used in a thermal transfer printer or ink jet prin t er.

- Paper that is too thin (under 60g/m

- Paper folded, curled or broken.

- Paper having binding holes or perforations.

- Paper of which surfaces are too smooth or too rough or which is very different in roughness between both surfaces.

- Paper whose surfaces have a special coating, such as carbon paper, heat-sensitive paper and pressure-sensitive paper.

- Sheets of paper va r y ing in siz e.

- Paper not cut at right angles.

- Paper bound by gluing, stapling or clipping.

- Postcards that are warped.

⋅

Envelop es should meet the following requirements:

- Edges and folds are sharp.

- General mailing envelopes with no seals on the glued portion.

- Those having flaps the full width of the envelope. (Unacceptable if the flap is glued, but not the mating surface.)

- Wrinkle-free, no fasteners.

⋅

Generally, envelopes perform well, but some types may wrinkle. We strongly recommend te sting any type of envelope before buying it

in large amounts.

⋅

Special paper can be printed continuously but the paper feed capability may be affected by the material of the paper used and the

operating environment. If paper cannot be fed successfully, it is recommended not to load several sheets of paper at a time but to load

them one by one.

2

, 16 lbs.) or too thick (over 90g/m2, 24 lbs.).

Œ

TRAY 1 (Multi Purpose Tray)

- Open the TRAY 1 (Multi Purpose Tray).

1

2

Open the wrapper of the paper.

2

Paper Face

- Fan the paper stack thoroughly and align its edges.

3

- Adjust the Paper Guides to fit the size of the Paper.

- To load a paper stack of long size, open the Paper

4

Support.

- Load the paper stack on the tray facing up.

Face up

Paper Support

Page 46

TRAY 1 (Multi Purpose Tray)

33

4. Loading the Printing Paper

- When printing Envelopes, fold their flaps securely and

5

6

load them on the Tray with their flap side down.

Face up

- When printing Letterhead, load it on the Tray with

the Header end at the take-up end.

NOTE

- Generally, envelopes perform well, but some types

may wrinkle.

W e strongly recommend testing any type of envelopes

before buying it in large amounts.

9

4

NOTE

remaining paper and stack it on the additional paper.

Then fan the paper and load it.

- We recommend repleni s hing the paper supply only

when the Tray is empty.

CHAPTER 2

Installation

Using the Printer

7

8

- When printing paper, load it on the Tray after

straightening warped paper, if any.

NOTE

- Do not load more than 50 sheets of paper on the

tray.

- When paper remains in the tray, do not load more

paper on the remaining paper.

- If you load the paper forcibly, it may cause a paper

misfeed.

- When you want to replenish the paper, take out the

Page 47

34

5. Printing

Paper can be fed for printing either from the TRAY 1 (Multi Purpose Tray), the TRAY 2 (Second Cassette) or the TRAY 2 (Third

Cassette optional). As available paper depends on the paper port, use the paper port that suits your application.

Œ

CHAPTER 2

Using the Printer

- Turn the printer on.

1

- Load the Paper.

2

“Turning ON and OFF the Printer” ☞p. 23

“TRAY 1 (Multi Purpose Tray)” ☞ pp. 26, 29, 32

“TRAY 2 (Second Cassette) / TRAY 3 (Third

Cassette)” ☞ pp. 27, 30

- Input a print command from the host computer.

4

5

The printed paper is fed out onto the Print Tray with

the image face down.

NOTE

- The Print Tray can hold up to 250 sheets of paper.

Use care not to exceed this limit when making

multiple prints.

Œ

Face down

2

-To print long-size paper, open the Paper Support in the

Print Tray.

3

Page 48

Chapter 3

Changing the Printer Settings

This chapter covers using the MENU Utilities provided by the

printer.

35

35

1. List of MENU Utilities 36

2. Setting the MENU Utilities 38

3. Outline of the MENU Utilities 40

⋅

RESET MENU 40

- JOB & MEMORY/ MENU RESET

⋅

TEST PRINT MENU 40

- PRINT CONFIG/ PCL FONT LIST/ PS FONT LIST

/ PCL DEMO PAGE/ PS DEMO PAGE

⋅

PRINT MENU 41

- COPIES/ TRAY1 PAPER/ MANUAL FEED/ TRAY SWITCHING/

PAPER SOURCE/ PAPER SIZE/ TRAY1 MEDIA/ TRAY2 MEDIA/

TRAY3 MEDIA/ ORIENTATION/ FORM

⋅

CONFIG MENU 42

- PERSONALITY/ AUTO CONTINUE/ I/O TIMEOUT/

POWER SAVE/ DISPLAY LANGUAGE

⋅

IMAGE MENU 43

- PRINT MODE

⋅

MEMORY MENU 43

- PCL CONTEXT SAVE/ PS CONTEXT SAVE

⋅

PCL MENU 44

- FONT SOURCE/ FONT NUMBER/ FONT PITCH /

FONT POINT SIZE/ SYMBOL SET

- Understanding Fonts 45

⋅

PS MENU 45

- PRINT PS ERROR

⋅

MAINTENANCE MENU 45

- TOTAL PRINTOUTS/ REPLACE TONER

LENGTH

CHAPTER 3

CHAPTER 3

Changing the Printer Settings

Changing the Printer Settings

Page 49

36

1. List of MENU Utilities

MENU

The

There are a total of

1. RESET MENU 1. JOB & MEMORY ENTER to reset.

utilities refer to the functions which have settings you can change to suit your particular operating needs.

34

features available in the

MENU

utilities, classified under

MENU ITEM SETTING

2. MENU RESET ENTER to reset.

Nine

major groups as detailed below.

2. TEST PRINT

CHAPTER 3Changing the Printer Settings

MENU

3. PRINT MENU 1. COPIES

1. PRINT CONFIG ENTER to print.

2. PCL FONT LIST ENTER to print.

3. PS FONT LIST *1 ENTER to print.

4. PCL DEMO PAGE ENTER to print.

5. PS DEMO PAGE *1 ENTER to print.

1 to 999

2. TRAY 1 PAPER

3. MANUAL FEED

4. TRAY

SWITCHING

5. PAPER SOURCE

6. PAPER SIZE

7. TRAY1 MEDIA

8. TRAY2 MEDIA

*

2

A4 / A5/

COM10/ C5/ DL/ MONARCH/ J-POST

OFF / ON

ON / OFF

TRAY1 / TRAY2 /

*2

A4 / A5/ *3 LETTER / INVOICE/ JIS B5/ LEGAL/ EXECUTIVE/

COM10/ C5/ DL/ MONARCH/ J-POST

PLAIN PAPER / TRANSPARENCY/ THICK PAPER / ENVELOPE

PLAIN PAPER / TRANSPARENCY

*

3

LETTER / INVOICE/ JIS B5/ LEGAL/ EXECUTIVE/

Œ

*4

TRAY3

9. TRAY3 MEDIA*4

10. ORIENTATION

11. FORM LENGTH

4. CONFIG MENU 1. PERSONALITY

2. AUT O CONTINUE

3. I/ O TIMEOUT

4. POWER SAVE

5. DISPLAY

LANGUAGE

PLAIN PAPER / TRANSPARENCY

PORTRAIT / LANDSCAPE

5 to 128 LINE (

*

1

AUTOMATIC / PCL/

ON / OFF

OFF / 5 SECONDS/ 15 SECONDS/ 30 SECONDS / 1 MINUTE/

3 MINUTES

15 MINUTES / 30 MINUTES/ 60 MINUTES / OFF

ENGLISH / DEUTSCH/ FRANCAIS/ ITALIANO/

NEDERLANDS

*2

64 LINES or *3 60 LINES)

*

1

POSTSCRIPT

Page 50

MENU ITEM SETTING

37

1. List of MENU Utilities

5. IMAGE MENU 1. PRINT MODE

6. MEMORY

MENU

*5

1. PCL CONTEXT

SAVE

2. PS CONTEXT

SAVE

7. PCL MENU 1. FONT SOURCE

2. FONT NUMBER

3. FONT PITCH

4. FONT POINT

SIZE

5. SYMBOL SET

8. PS MENU

9. MAINTE NANCE

*1

1. PRINT PS ERROR

1. TO TAL

PRINT OUTS

MENU

2. REPLACE TONER

FULL COLOR/ MONOCHROME

OFF/ ON

OFF/ ON

INTERNAL / SOFT FONT

INTERNAL: 0 to 52 (SOFT FONT: 0 to max. 999)

0.44 to 99.99 (10.00 )

4.00 to 999.75 (12.00 )

*

3

ROMAN-8/ ISO L1, ISO L2, ISO L5,

*

2

PC-8, PC-8 D/N,

PC-850, PC-852, PC8-TK, WIN L1, WIN L2, WIN L5, DESKTOP,

PS TEXT, VN INTL, VN US, MS PUBL, MATH-8, PS-MATH,

VN-MATH, PI FONT, LEGAL, ISO-4, ISO-6, ISO-11, ISO-15,

ISO-17, ISO-21, ISO-60, ISO-69, and WIN 3.0

OFF/ ON

BLACK / YELLOW/ MAGENTA/ CYAN

CHAPTER 3

Changing the Printer Settings

*1 : The range of items to choose from when the printer is equipped with an Adobe Postscript ROM SIMM.

*2 : Default for European models.

*3 : Default for North American models.

*4 : The range of items to choose from when the printer is equipped with a 250-sheet Third Cassette Unit.

*5 : The range of items to choose from when the printer is equipped with 12MB or more Expansion Memory and Adobe

Postscript ROM SIMM.

Page 51

38

2. Setting the MENU Utilities

Example: Print Menu

4

✕ 3 times

1

Make sure that "READY" is shown on the

-

Message Display and the On Line Indicator is lit.

RAEDY

READY

PRINT MENU

CHAPTER 3Changing the Printer Settings

- Press the Item key on the control panel as many

times as is necessary to select the desired

item.

Check that the desired item is shown on the

-

Message Display.

Example:

PAPER SOURCE

2

Press the On Line key on the control panel.

-

Check that "OFF LINE" appears on the Message

-

Display.

Make sure that the On Line Indicator goes out.

-

5

✕ Once

OFFLINE