MINN KOTA Terrova 70, Terrova 50, Terrova 80, Terrova 101, Terrova 112 User Manual

...

BOW-MOUNT TROLLING MOTOR

TERROVA

USER MANUAL

CE MASTER USER MANUAL (FOR CE/C-TICK CERTIFIED MODELS)

Made by Minn Kota

Johnson Outdoors

Marine Electronics, Inc.

121 Power Drive

Mankato, MN 56001 USA

Trolling Motors

Produced in 2012

Terrova 55 48”

MODEL 1358800

SER NO M365 MK12345

Conforms to 89/336/EEC (EMC) under standards EN 55022A, EN 50082-2 since 1996 LN V9677264

THANK YOU

Thank you for choosing Minn Kota. We believe that you should spend more time fi shing and less time positioning your boat.

That’s why we build the smartest, toughest, most intuitive trolling motors on the water. Every aspect of a Minn Kota trolling motor

is thought out and rethought until it’s good enough to bear our name. Countless hours of research and testing provide you the

Minn Kota advantage that can truly take you “Anywhere. Anytime.” We don’t believe in shortcuts. We are Minn Kota. And we are

never done helping you catch more fi sh.

REMEMBER TO KEEP YOUR RECEIPT AND IMMEDIATELY REGISTER YOUR TROLLING MOTOR.

A registration card is enclosed or you can complete registration on our website at minnkotamotors.com.

NOTE: Do not return your Minn Kota motor to your retailer. Your retailer is not authorized to repair or replace this unit. You may obtain service

by: calling Minn Kota at (800) 227-6433; returning your motor to the Minn Kota Factory Service Center; sending or taking your motor to any

Minn Kota authorized service center. A list of authorized service centers is available on our website, at minnkotamotors.com. Please include proof of

purchase, serial number and purchase date for warranty service with any of the above options.

Please thoroughly read this user manual. Follow all instructions and heed all safety and cautionary notices below. Use of this motor is only

permitted for persons that have read and understood these user instructions. Minors may use this motor only under adult supervision.

ATTENTION: Never run the motor out of the water, as this may result in injuries from the rotating propeller. The motor should be disconnected from

the power source when it is not in use or is off the water. When connecting the power-supply cables of the motor to the battery, ensure that they are

not kinked or subject to chafe and route them in such a way that persons cannot trip over them. Before using the motor make sure that the insulation

of the power cables is not damaged. Disregarding these safety precautions may result in electric shorts of battery(s) and/or motor. Always disconnect

motor from battery(s) before cleaning or checking the propeller. Avoid submerging the complete motor as water may enter the lower unit through

control head and shaft. If the motor is used while water is present in the lower unit considerable damage to the motor can occur. This damage will not

be covered by warranty.

CAUTION: Take care that neither you nor other persons approach the turning propeller too closely, neither with body parts nor with objects. The

motor is powerful and may endanger or injure you or others. While the motor is running watch out for persons swimming and for fl oating objects.

Persons whose ability to run the motor or whose reactions are impaired by alcohol, drugs, medication, or other substances are not permitted to use

this motor. This motor is not suitable for use in strong currents. The constant noise pressure level of the motor during use is less than 70dB(A). The

overall vibration level does not exceed 2,5m/sec2.

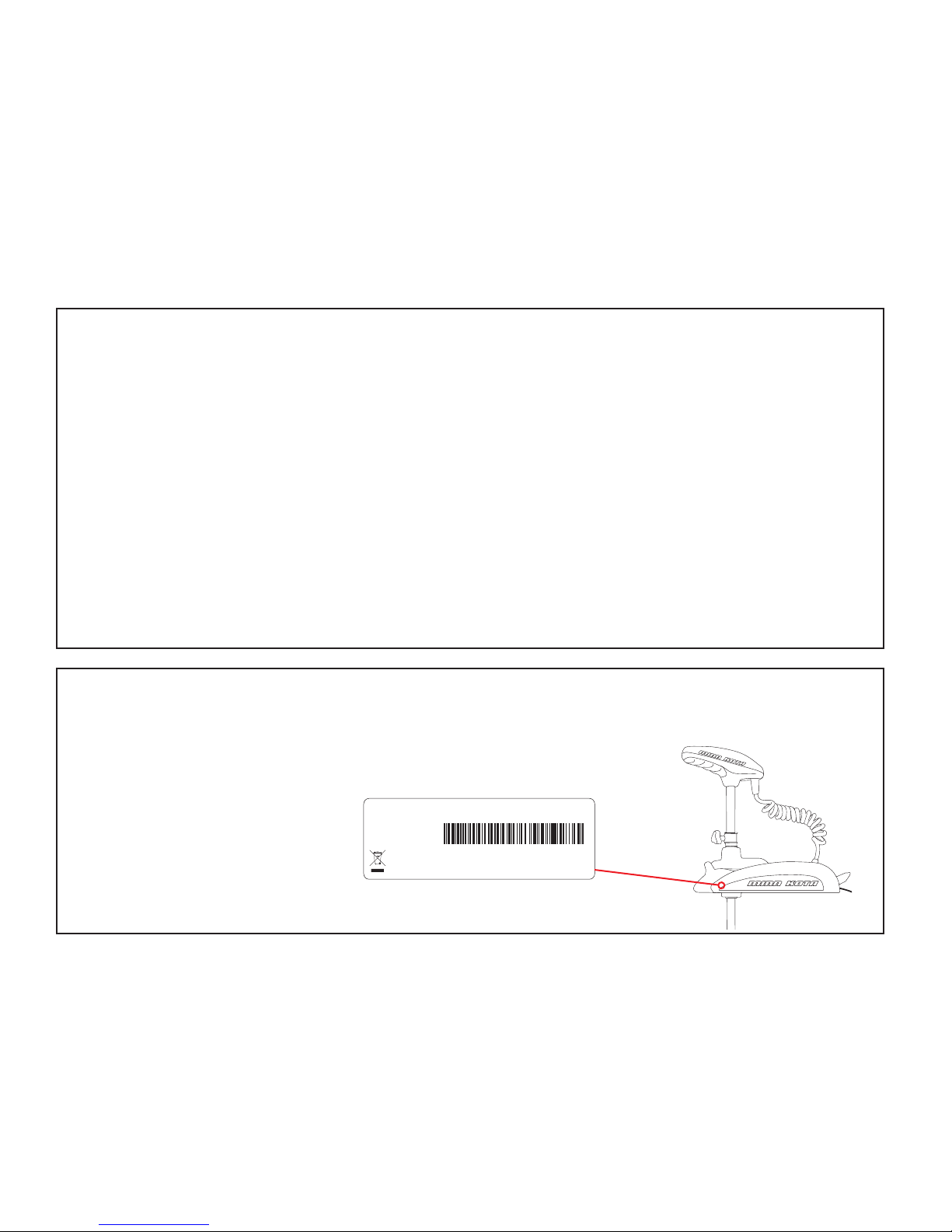

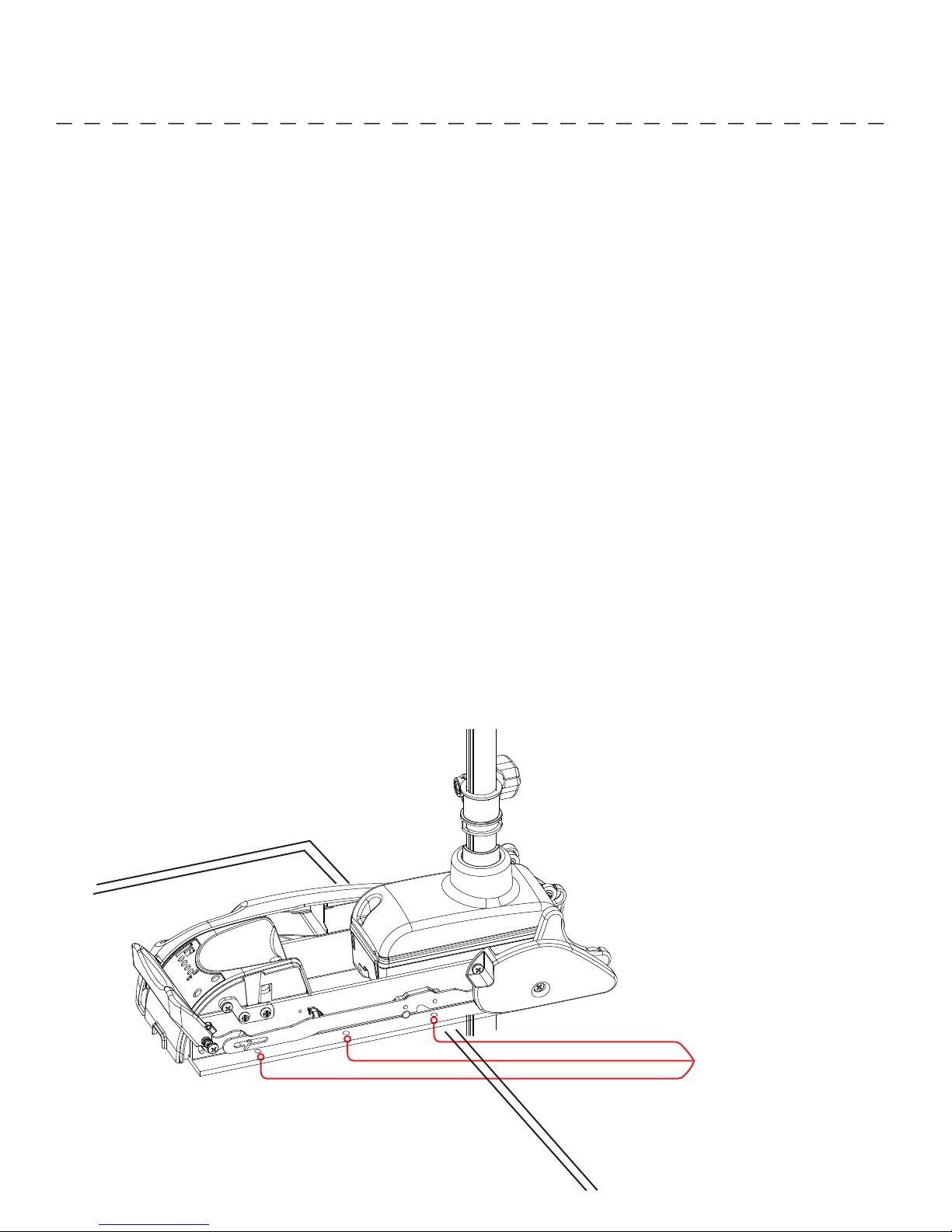

LOCATING YOUR SERIAL NUMBER

Your Minn Kota 11-character serial number is very important. It helps to determine the specifi c model and year of manufacture. When contacting

Consumer Service or registering your product, you will need to know your product’s serial number. We recommend that you write the serial number

down in the space provided below so that you have it available for future reference.

The serial number on your Terrova is located

inside the mount, below the motor rests.

EXAMPLE

Model: _________________________________________________________________________________________________________________________

Serial Number: _______________________________________________________________________________________________________________

Purchase Date: _______________________________________________________________________________________________________________

Store Where Purchased: ____________________________________________________________________________________________________

2 | minnkotamotors.com

©2014 Johnson Outdoors Marine Electronics, Inc.

TABLE OF CONTENTS

Two-Year Limited Warranty 4

Features 5

Mount Installation 6

Battery & Wiring Installation 7-9

Boat Rigging & Product Installation 7

Conductor Gauge and Circuit Breaker Sizing Table 7

Selecting the Correct Batteries 8

Connecting the Batteries 8-9

Push-to-test Battery Meter 9

Motor Wiring Diagram 10

Using The Motor 11-13

Stowing & Deploying 11

AutoPilot Controls 12

Adjusting the Depth of the Motor 12

Installing the External Transducer 13

Using the Foot Pedal 14

Service & Maintenance 15

Troubleshooting 16

Parts Diagram 17

Parts List 18-19

Environmental Compliance Statement 20

Notes 21

©2014 Johnson Outdoors Marine Electronics, Inc.

minnkotamotors.com | 3

TWO-YEAR LIMITED WARRANTY

WARRANTY ON MINN KOTA FRESHWATER TROLLING MOTORS

Johnson Outdoors Marine Electronics, Inc. (“JOME”) extends the following limited warranty to the original retail purchaser only. Warranty coverage is not

transferable.

MINN KOTA LIMITED TWO-YEAR WARRANTY ON THE ENTIRE PRODUCT

JOME warrants to the original retail purchaser only that the purchaser’s new Minn Kota freshwater trolling motor will be materially free from defects in materials

and workmanship appearing within two (2) years after the date of purchase. JOME will (at its option) either repair or replace, free of charge, any parts found by

JOME to be defective during the term of this warranty. Such repair, or replacement shall be the sole and exclusive liability of JOME and the sole and exclusive

remedy of the purchaser for breach of this warranty.

MINN KOTA LIMITED LIFETIME WARRANTY ON COMPOSITE SHAFT

JOME warrants to the original retail purchaser only that the composite shaft of the purchaser’s Minn Kota trolling motor will be materially free from defects in

materials and workmanship appearing within the original purchaser’s lifetime. JOME will provide a new composite shaft, free of charge, to replace any composite

shaft found by JOME to be defective during the term of this warranty. Providing a new composite shaft shall be the sole and exclusive liability of JOME and the

sole and exclusive remedy of the purchaser for breach of this warranty; and purchaser shall be responsible for installing, or for the cost of labor to

install, any new composite shaft provided by JOME.

EXCLUSIONS & LIMITATIONS

This limited warranty does not apply to products that have been used in saltwater or brackish water, commercially or for rental purposes. This limited warranty

does not cover normal wear and tear, blemishes that do not aff ect the operation of the product, or damage caused by accidents, abuse, alteration, modifi cation,

shipping damages, acts of God, negligence of the user or misuse, improper or insuffi cient care or maintenance. DAMAGE CAUSED BY THE USE OF

OTHER REPLACEMENT PARTS NOT MEETING THE DESIGN SPECIFICATIONS OF THE ORIGINAL PARTS WILL NOT BE COVERED BY

THIS LIMITED WARRANTY. The cost of normal maintenance or replacement parts which are not in breach of the limited warranty are the responsibility

of the purchaser. Prior to using products, the purchaser shall determine the suitability of the products for the intended use and assumes all related risk and

liability. Any assistance JOME provides to or procures for the purchaser outside the terms, limitations or exclusions of this limited warranty will not constitute

a waiver of the terms, limitations or exclusions, nor will such assistance extend or revive the warranty. JOME will not reimburse the purchaser for any expenses

incurred by the purchaser in repairing, correcting or replacing any defective products or parts, except those incurred with JOME’s prior written permission.

JOME’S AGGREGATE LIABILITY WITH RESPECT TO COVERED PRODUCTS IS LIMITED TO AN AMOUNT EQUAL TO THE PURCHASER’S

ORIGINAL PURCHASE PRICE PAID FOR SUCH PRODUCT.

MINN KOTA SERVICE INFORMATION

To obtain warranty service in the U.S., the product believed to be defective, and proof of original purchase (including the date of purchase), must be presented

to a Minn Kota Authorized Service Center or to Minn Kota’s factory service center in Mankato, MN. Any charges incurred for service calls, transportation or

shipping/freight to/from the Minn Kota Authorized Service Center or factory, labor to haul out, remove, re-install or re-rig products removed for warranty service,

or any other similar items are the sole and exclusive responsibility of the purchaser. Products purchased outside of the U.S. must be returned prepaid with

proof of purchase (including the date of purchase and serial number) to any Authorized Minn Kota Service Center in the country of purchase. Warranty service

can be arranged by contacting a Minn Kota Authorized Service Center or by contacting the factory at 1-800-227-6433 or email service@minnkotamotors.com.

Products repaired or replaced will be warranted for the remainder of the original warranty period [or for 90 days from the date of repair

or replacement, whichever is longer]. For any product that is returned for warranty service that JOME fi nds to be not covered by or not

in breach of this limited warranty, there will be a billing for services rendered at the prevailing posted labor rate and for a minimum of at

least one hour.

NOTE: Do not return your Minn Kota product to your retailer. Your retailer is not authorized to repair or replace products.

THERE ARE NO EXPRESS WARRANTIES OTHER THAN THESE LIMITED WARRANTIES. IN NO EVENT SHALL ANY IMPLIED

WARRANTIES INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE, EXTEND

BEYOND THE DURATION OF THE RELEVANT EXPRESS LIMITED WARRANTY. IN NO EVENT SHALL JOME BE LIABLE FOR PUNITIVE,

INDIRECT, INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES. Without limiting the foregoing, JOME assumes no responsibility for

loss of use of product, loss of time, inconvenience or other damage.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or consequential damages, so the above

limitations and/or exclusions may not apply to you. This warranty gives you specifi c legal rights and you may also have other legal rights which vary from state

to state.

4 | minnkotamotors.com

©2014 Johnson Outdoors Marine Electronics, Inc.

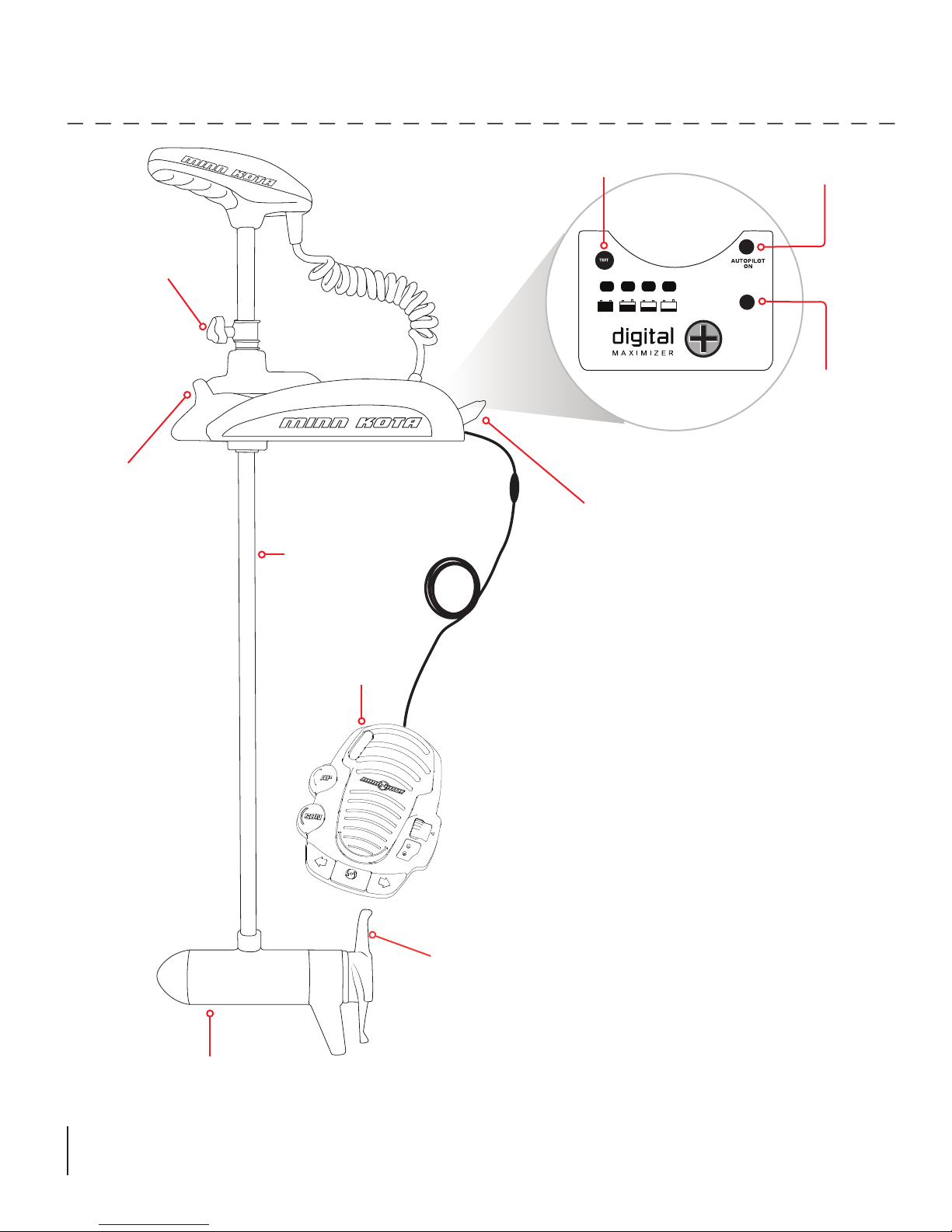

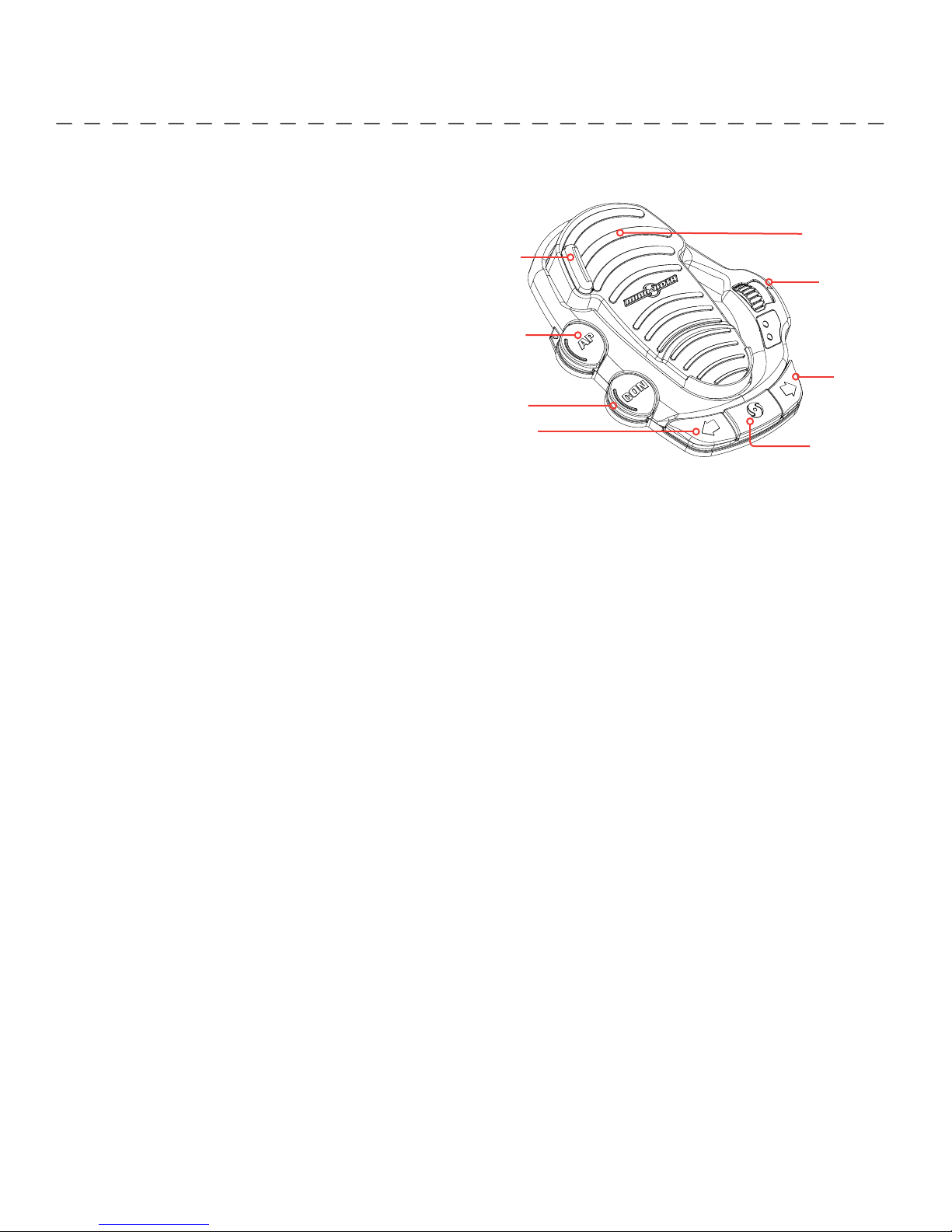

FEATURES

Adjustable Depth Collar

Fall Away Ramps

Lifetime

Warranty Flexible

Composite Shaft

Push-to-Test Battery Meter

Stow/Deploy Lever

AutoPilot Indicator

(functional on equipped motors only)

System Ready

Indicator

Cool Quiet

Power Motor

Low Profile

Foot Pedal

Weedless Wedge 2 Propeller

Specifications subject to change without notice.

*This diagram is for reference only and may differ from your actual motor.

©2014 Johnson Outdoors Marine Electronics, Inc.

minnkotamotors.com | 5

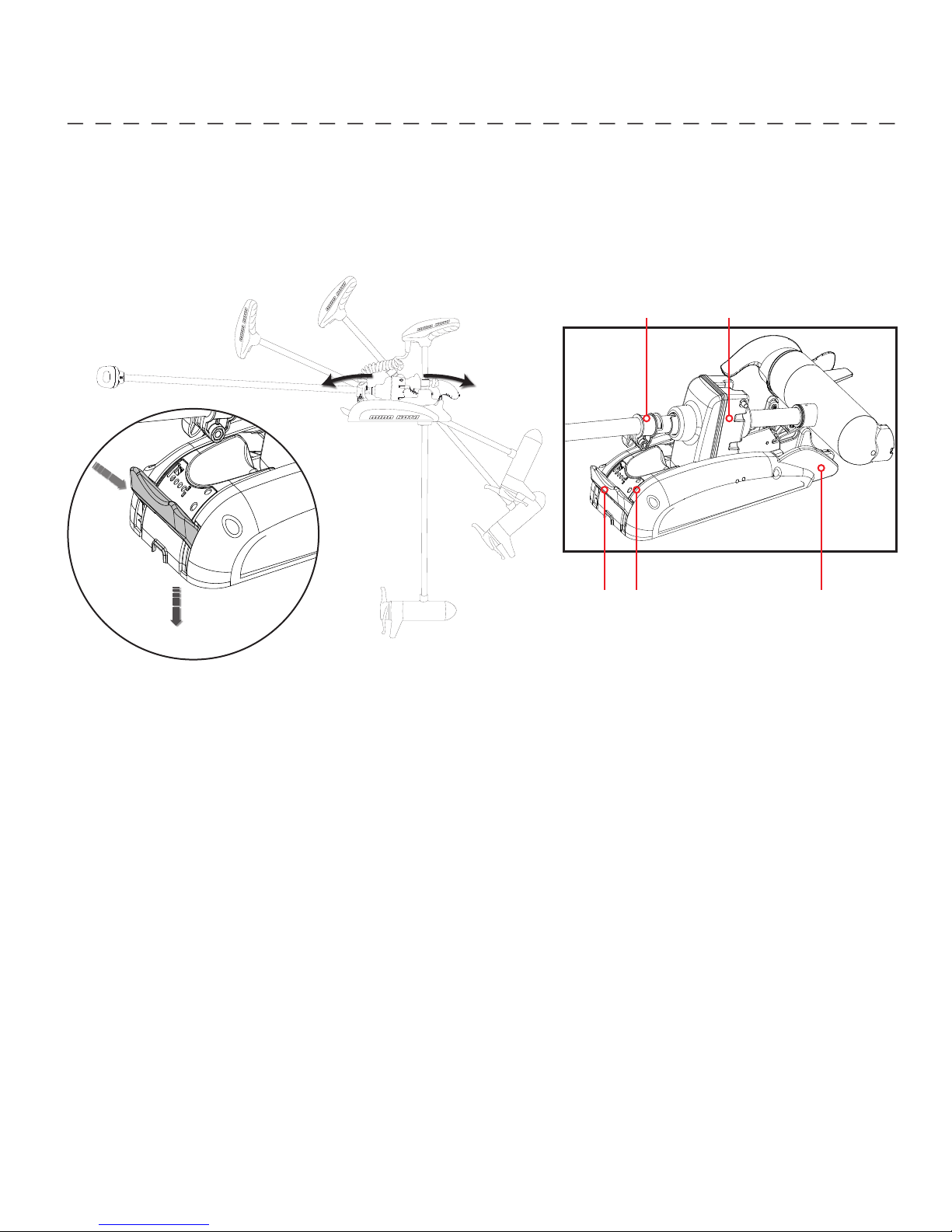

MOUNT INSTALLATION

TOOLS AND RESOURCES REQUIRED:

• #3 Phillips Screw Driver

• Drill

• 9/32” Drill Bit

• 7/16” Box End Wrench

• A second person to help with the installation

1. Remove the four sideplate screws. Remove the right sideplate and swing the left sideplate out and away from the base

extrusion.

2. Place the motor on the bow of the boat in the deployed position.

a. We recommend that the motor be mounted as close to the centerline of the boat as possible.

b. Make sure that the area under the mounting location is clear and unobstructed

for drilling and accessible for you to attach nuts and washers.

c. Make sure the mount is positioned so that the shaft is out beyond the rub rail of the boat by 1-1/2”. The lower unit, as it is

lowered into the water or raised into the boat, must not encounter any obstructions.

CAUTION: Make sure the motor is mounted on a level surface and is not connected to

a power source. Use the rubber washers to create a leve surface if necessary.

3. Once in position, mark four of the six holes (two on each side) provided in the bow mount base for drilling. If possible, use the

four holes that are farthest apart. Drill through the marked holes using the 9/32” drill bit.

4. Mount the plate to the bow using the provided bolts, nuts, and washers.

5. Replace the sideplates and sideplate screws.

Mounting Holes

(3 Per Side)

6 | minnkotamotors.com

©2014 Johnson Outdoors Marine Electronics, Inc.

BATTERY WIRING & INSTALLATION

BOAT RIGGING & PRODUCT INSTALLATION

For safety and compliance reasons, we recommend that you follow American Boat and Yacht Council (ABYC) standards when

rigging your boat. Altering boat wiring should be completed by a qualifi ed marine technician. The following specifi cations are for

general guidelines only:

CAUTION: These guidelines apply to general rigging to support your Minn Kota motor. Powering multiple motors or additional

electrical devices from the same power circuit may impact the recommended conductor gauge and circuit breaker size. If you are

using wire longer than that provided with your unit, follow the conductor gauge and circuit breaker sizing table below. If your wire

extension length is more than 25 feet, we recommend that you contact a qualifi ed marine technician.

An over-current protection device (circuit breaker or fuse) must be used. Coast Guard requirements dictate that

each ungrounded current-carrying conductor must be protected by a manually reset, trip-free circuit breaker or fuse. The type

(voltage and current rating) of the fuse or circuit breaker must be sized accordingly to the trolling motor used. The table below gives

recommended guidelines for circuit breaker sizing.

Reference:

United States Code of Federal Regulations: 33 CFR 183 – Boats and Associated Equipment

ABYC E-11: AC and DC Electrical Systems on Boats

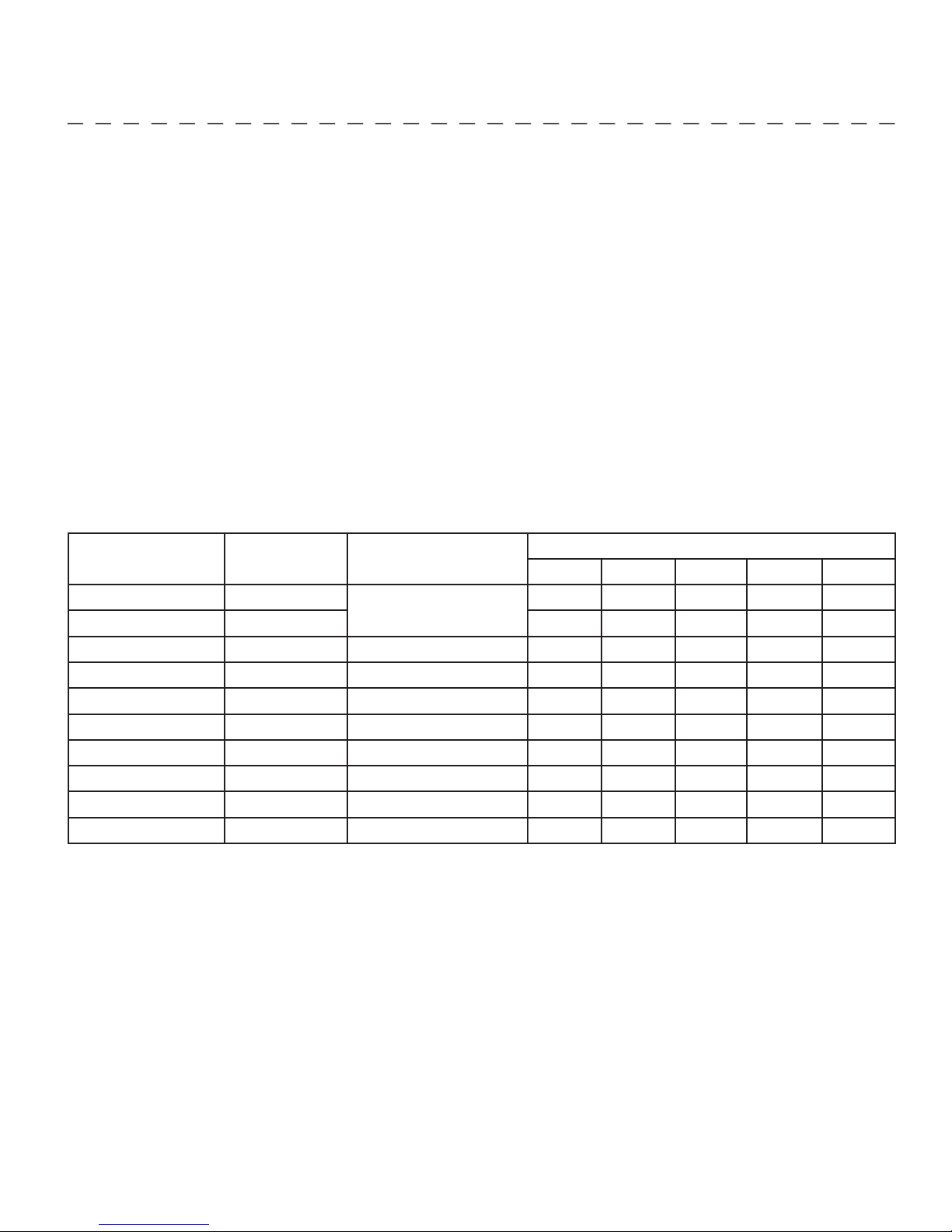

CONDUCTOR GAUGE AND CIRCUIT BREAKER SIZING TABLE

Motor Thrust /

Model

30 lb. 30

40 lb., 45 lb. 42 10 AWG 8 AWG 6 AWG 4 AWG 4 AWG

50 lb., 55 lb. 50 60 Amp @ 12 VDC 8 AWG 6 AWG 4 AWG 4 AWG 2 AWG

70 lb. 42 50 Amp @ 24 VDC 10 AWG 10 AWG 8 AWG 8 AWG 6 AWG

80 lb. 56 60 Amp @ 24 VDC 8 AWG 8 AWG 8 AWG 6 AWG 6 AWG

101 lb. 46 50 Amp @ 36 VDC 8 AWG 8 AWG 8 AWG 8 AWG 8 AWG

Engine Mount 101 50 60 Amp @ 36 VDC 8 AWG 6 AWG 4 AWG 4 AWG 2 AWG

112 lb. 52 60 Amp @ 36 VDC 8 AWG 8 AWG 8 AWG 8 AWG 8 AWG

Engine Mount 160 116 (2) x 60 Amp @ 24 VDC 2 AWG 2 AWG 2 AWG 2 AWG 2 AWG

E-Drive 40 50 Amp @ 48 VDC 10 AWG 10 AWG 10 AWG 10 AWG 10 AWG

This conductor and circuit breaker sizing table is only valid for the following assumptions:

1. No more than 3 conductors are bundled together inside of a sheath or conduit outside of engine spaces.

2. Each conductor has 105° C temp rated insulation.

3. No more than 5% voltage drop allowed at full motor power based on published product power requirements.

*Wire Extension Length refers to the distance from the batteries to the trolling motor leads.

Max Amp Draw Circuit Breaker

5 feet 10 feet 15 feet 20 feet 25 feet

10 AWG 10 AWG 8 AWG 6 AWG 4 AWG

50 Amp @ 12 VDC

Wire Extension Length *

©2014 Johnson Outdoors Marine Electronics, Inc.

minnkotamotors.com | 7

BATTERY WIRING & INSTALLATION

SELECTING THE CORRECT BATTERIES

The motor will operate with any lead acid, deep cycle marine 12 volt battery/batteries. For best results, use a deep cycle, marine

battery with at least a 105 ampere hour rating. Maintain battery at full charge. Proper care will ensure having battery power

when you need it, and will signifi cantly improve the battery life. Failure to recharge lead-acid batteries (within 12-24 hours) is the

leading cause of premature battery failure. Use a multi-stage charger to avoid overcharging. We off er a wide selection of chargers

to fi t your charging needs. If you are using a crank battery to start a gasoline outboard, we recommend that you use a separate

deep cycle marine battery/batteries for your Minn Kota trolling motor.

Advice Regarding Batteries:

• Never connect the (+) and the (–) terminals of the same battery together. Take care that no metal object can fall onto the

battery and short the terminals. This would immediately lead to a short and extreme fi re danger.

• It is highly recommended that a circuit breaker or fuse be used with this trolling motor. Refer to “Conductor Gauge and Circuit

Breaker Sizing Table” in the previous section to fi nd the appropriate circuit breaker or fuse for your motor. For motors requiring

a 60-amp breaker, the Minn Kota MKR-19 60-amp circuit breaker is recommended.

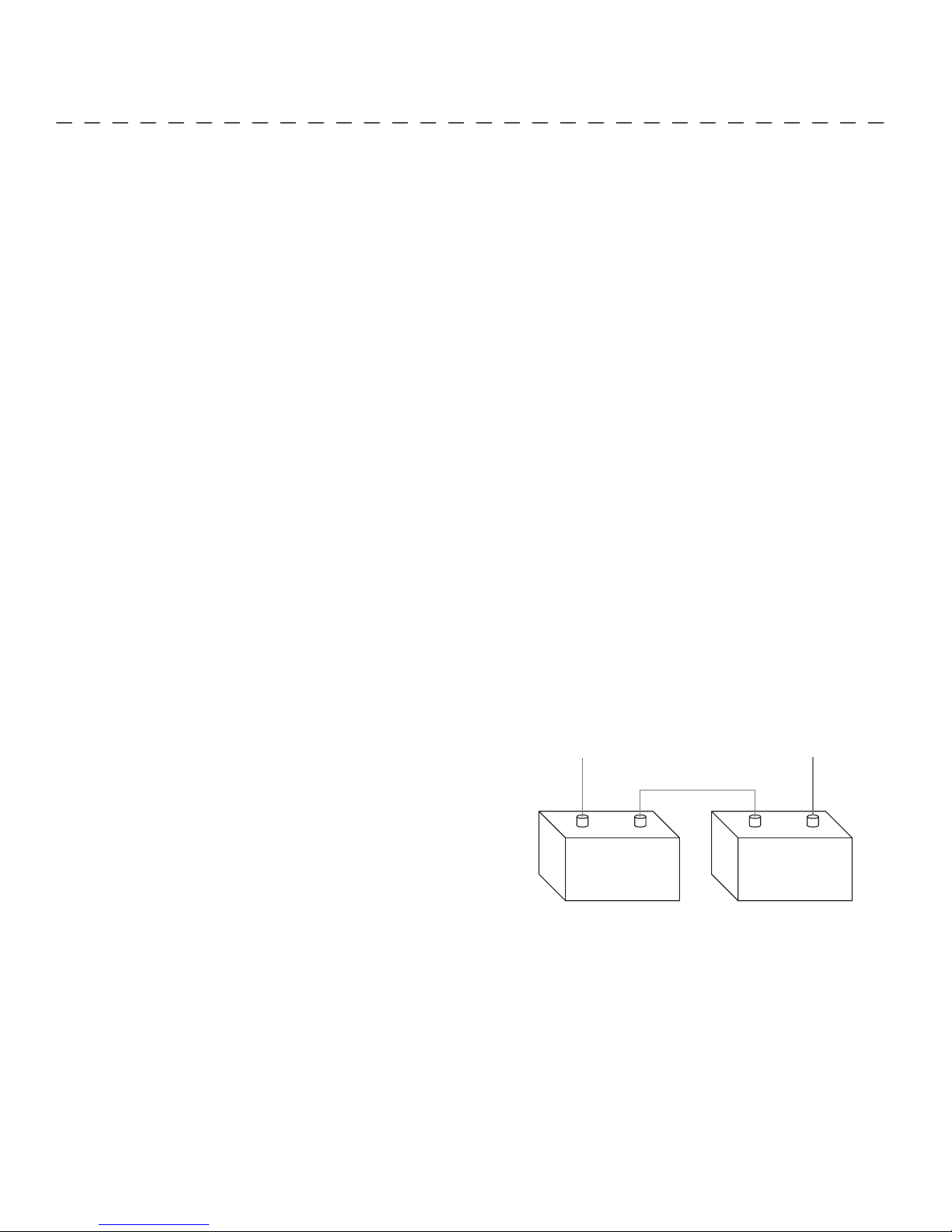

CONNECTING THE BATTERIES

12 VOLT SYSTEMS:

1. Make sure that the motor is switched off (speed selector on “OFF” or “0”).

2. Connect positive ( + ) red lead to positive ( + ) battery terminal.

3. Connect negative ( – ) black lead to negative ( – ) battery terminal.

4. For safety reasons do not switch the motor on until the propeller is in the water.

CAUTION:

For safety reasons, disconnect the motor from the battery/batteries when the motor is not in use or while the

battery/batteries are being charged.

CONNECTING THE BATTERIES IN SERIES (IF REQUIRED FOR YOUR MOTOR)

24 VOLT SYSTEMS:

1. Make sure that the motor is switched off (speed selector on “0”).

2. Two 12 volt batteries are required.

3. The batteries must be wired in series, only as directed in wiring

To trolling motor negative

24 Volt Connection

diagram, to provide 24 volts.

a. Connect a connector cable to the positive ( + ) terminal of

battery 1 and to the negative ( – ) terminal of battery 2.

Neg - Neg -Pos + Pos +

b. Connect positive ( + ) red motor lead to

positive ( + ) terminal on battery 2.

Battery #1 (Low Side)

c. Connect negative ( – ) black motor lead to

negative ( – ) terminal of battery 1.

24 Volt Series Connection

4. For safety reasons do not switch the motor on until the propeller is in the water. If installing a leadwire plug, observe proper

polarity and follow instructions in your boat owner’s manual. See wiring diagram on following pages.

CAUTION

• For safety reasons, disconnect the motor from the battery or batteries when the motor is not in use or while

the battery/batteries are being charged.

• Improper wiring of 24/36 volt systems could cause battery explosion!

• Keep leadwire wing nut connections tight and solid to battery terminals.

• Locate battery in a ventilated compartment.

+24 Volts to trolling motor

positive (or circuit breaker)

Battery #2 (High Side)

8 | minnkotamotors.com

©2014 Johnson Outdoors Marine Electronics, Inc.

BATTERY WIRING & INSTALLATION

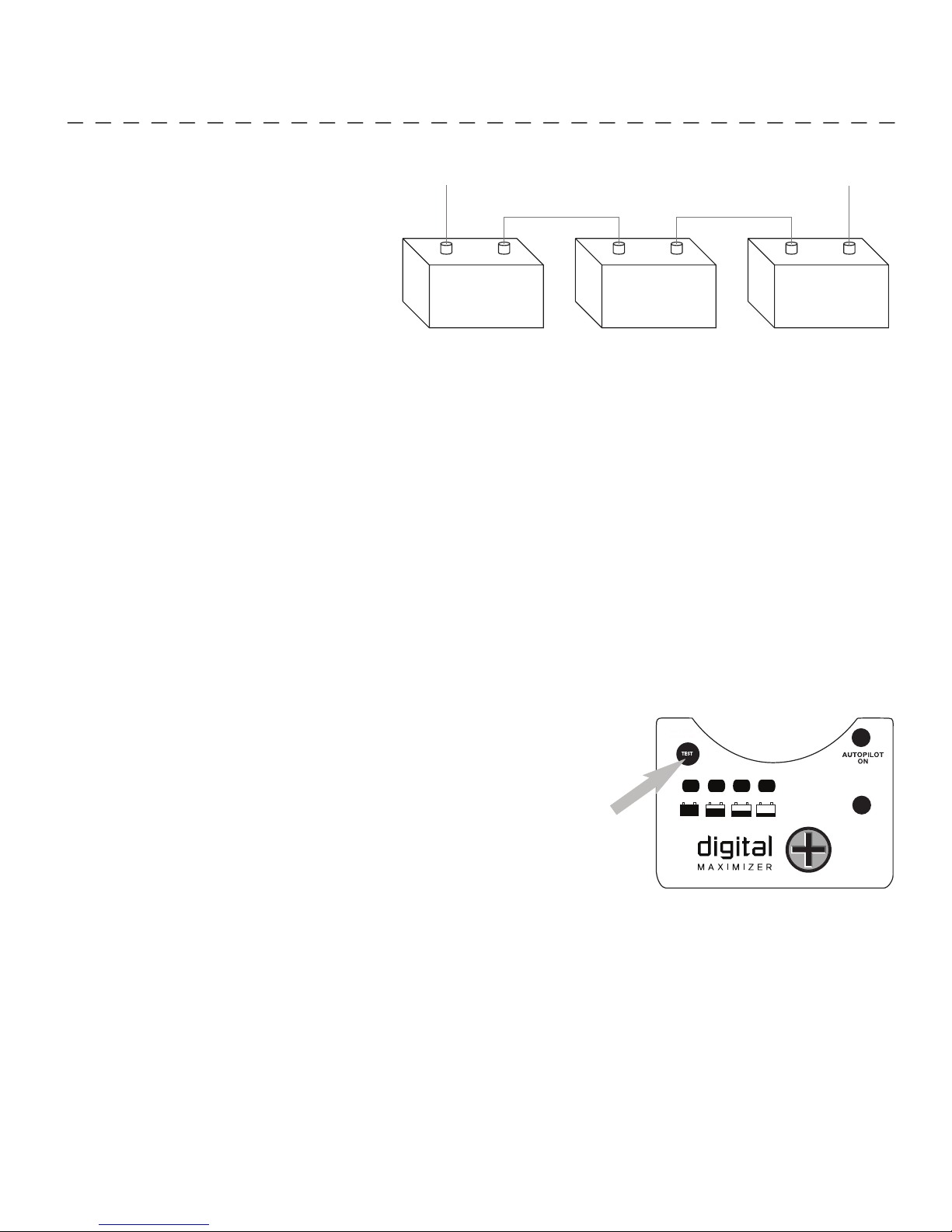

36 VOLT SYSTEMS:

1. Make sure that the motor is switched off

(speed selector on “0”).

2. Three 12 volt batteries are required.

To trolling motor negative

24 Volt Connection 36 Volt Connection

+36 Volts to trolling motor

positive (or circuit breaker)

3. The batteries must be wired in series, only as

directed in wiring diagram, to provide 36 volts.

a. Connect a connector cable to the positive

( + ) terminal of battery 1 and to the

negative ( – ) terminal of battery 2 and

another connector cable from the positive

( + ) terminal of battery 2 to the negative

Neg - Neg - Neg -Pos + Pos + Pos +

Battery #1 (Low Side)

Battery #2 (Middle) Battery #3 (High Side)

36 Volt Series Connection

( – ) terminal of battery of battery 3.

b. Connect positive ( + ) red motor lead to positive ( + ) terminal on battery 3.

c. Connect negative ( – ) black motor lead to negative ( – ) terminal of battery 1.

4. For safety reasons do not switch the motor on until the propeller is in the water. If installing a leadwire plug, observe proper

polarity and follow instructions in your boat owner’s manual. See wiring diagram on following pages.

CAUTION

• Improper wiring of 24/36 volt systems could cause battery explosion!

• Keep leadwire wing nut connections tight and solid to battery terminals.

• Locate battery in a ventilated compartment.

• For safety reasons, disconnect the motor from the battery or batteries when the motor is not in use or while

the battery/batteries are being charged.

PUSH-TO-TEST BATTERY METER

This motor is equipped with a “push to test” battery meter. The LED provides an accurate

display of the remaining charge in the battery. It is only accurate when the motor is off .

The meter reads as:

• One light indicates recharge.

• Two lights indicate low charge.

• Three lights indicate good charge.

• Four lights indicate full charge.

©2014 Johnson Outdoors Marine Electronics, Inc.

minnkotamotors.com | 9

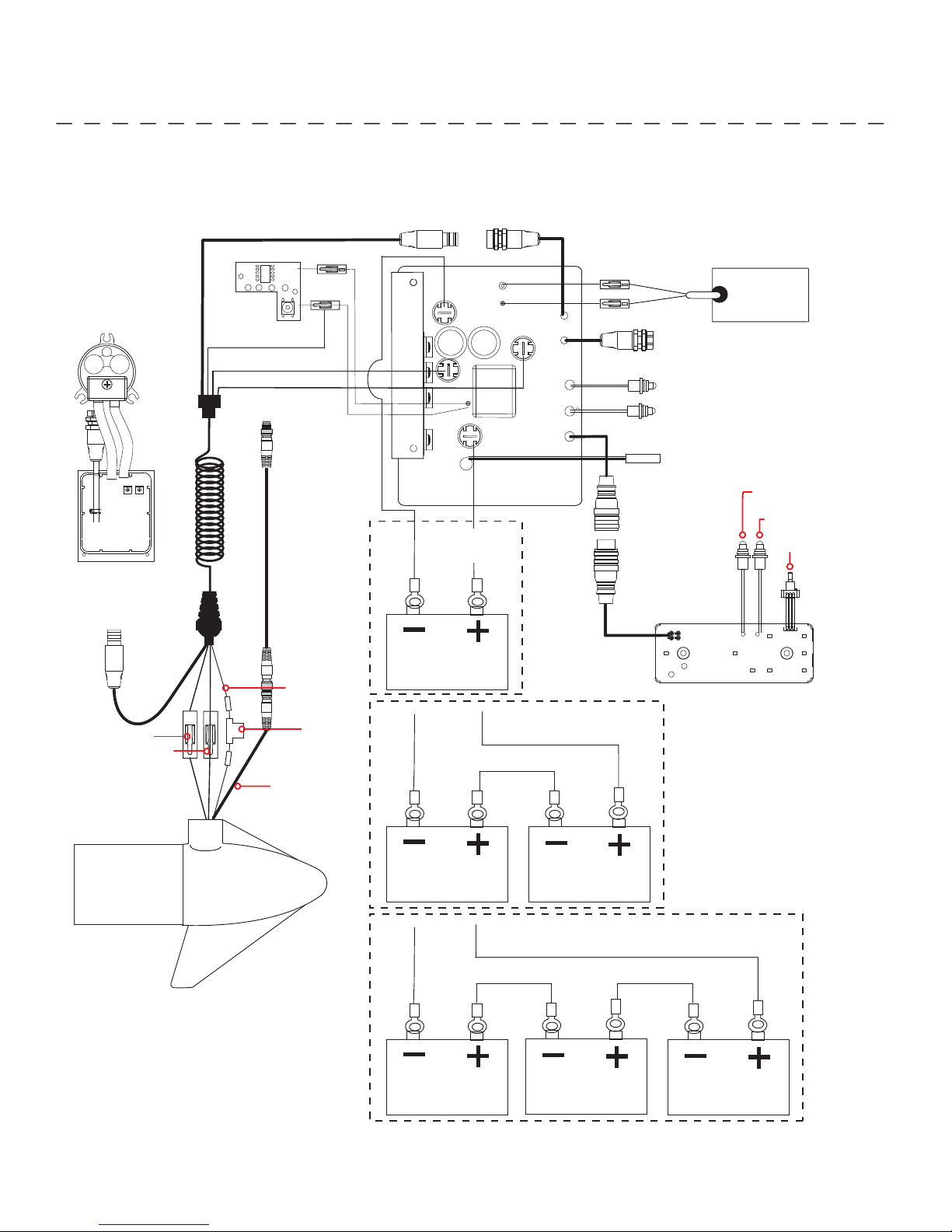

MOTOR WIRING DIAGRAM

NOTE: This is a universal, multi-voltage diagram. Double check your motor's voltage for proper connections. Over-Current

Protection Devices not shown in this illustration.

COMPASS

SENSOR

BOARD

AUTOPILOT

ON EQUIPPED MOTORS ONLY

ACCESSORY PLUG

BATTERY GAUGE

BROWN

BLACK M-

RED M+

COIL CORD

UNIVERSAL SONAR 2 EXTENSION WIRE*

BROWN*

RED

BLACK

BLACK B-

M-

BATTERY 1

CONTROL BOARD

B-

B+

RED B+

12v

M+

WHITE

BLACK

STEERING MOTOR

ACCESSORY PLUG

AUTOPILOT INDICATOR, RED

SYSTEM READY, INDICATOR, GREEN

REED SWITCH

AUTOPILOT INDICATOR, RED

MOMENTARY/CONSTANT

INDICATOR, GREEN

SPEED ADJUSTMENT

KNOB

FOOT PEDAL

CONTROL BOARD

RED M+

BLACK M-

MOTOR

* UNIVERSAL SONAR2 MOTORS ONLY

FUSE*

UNIVERSAL

SONAR 2 WIRE*

24v

BATTERY 1 BATTERY 2

36v

BATTERY 1 BATTERY 2 BATTERY 3

10 | minnkotamotors.com

©2014 Johnson Outdoors Marine Electronics, Inc.

USING & ADJUSTING THE MOTOR

STOWING AND DEPLOYING THE MOTOR

WARNING:

When raising or lowering the motor, keep fingers clear of all hinge and pivot points and all moving parts.

STOW/DEPLOY LEVER OPERATION:

1. Push in

2. Push down

1

2

GENERAL

System Ready (green LED): The motor is equipped with a system ready indicator. Indicator light will be on when motor is

deployed and power is applied to the motor. When the motor is properly stowed the indicator light will go off indicating all power

has been turned off to the motor. If this indicator light does not come on when deployed, check that motor is connected to battery

properly and motor is completely deployed. If indicator light does not go off when stowed, be sure that stow/deploy lever is fully

latched and locked into the stowed position.

Stow/Deploy

Depth Collar Steering Housing

Fall Away Ramps

Lever

System Ready

Indicator

TO DEPLOY THE MOTOR

Push in and rotate the stow/deploy lever down. Gently slide the motor out from the ramps. Lower the motor to the desired depth,

making sure that it clicks into a secure, verticle position. The System Ready indicator light (green) will be lit, indicating motor is

ready for operation.

TO STOW THE MOTOR

Push and hold the stow/deploy lever down. Gently tilt and pull the composite shaft or control head until the motor engages the

motor ramps. Motor should rest on the motor ramps and lock into place. The stow/deploy lever should latch automatically into the

stowed position. The system ready indicator light (green) MUST go off for the motor to be stowed properly.

TRANSPORTATION

In conditions where the stowed motor is subject to high levels of shock or vibration, ensure the motor is securely stowed. Move

the depth collar snug against the steering motor and tighten.

©2014 Johnson Outdoors Marine Electronics, Inc.

minnkotamotors.com | 11

USING & ADJUSTING THE MOTOR

AUTOPILOT™ CONTROLS

(ON AUTOPILOT EQUIPPED MOTORS ONLY)

™

The Minn Kota AutoPilot

you want to go. Each time the wind or water current moves the boat off course, the AutoPilot senses the change and steers itself

back to the original heading. The AutoPilot direction is set every time a steering change is made. To change direction, steer until

the control head points to the desired course. The AutoPilot will pull the bow of the boat around and correct automatically until

the boat is moving in the direction you chose.

1. This unit has an automatic steering shutdown for safety. In conditions where an obstruction prevents the trolling motor from

turning, or in extremely windy conditions, the automatic steering may stop. Any steering input will reset the system to normal.

2. When the AutoPilot is on and the trolling motor is pulled out of the water to the stow position, the steering motor will continue

to run until the motor is stowed properly. Once the motor is stowed properly, AutoPilot will turn off and the System Ready

indicator will go off .

3. This unit uses a magnetic compass to detect direction of travel. The compass can be adversely aff ected by magnets or large,

ferrous metal objects near (within 12” of) the trolling motor control head.

uses a magnetic compass and a microprocessor chip to keep the trolling motor pointed in the direction

4. After steering to a new direction, there is a short delay before the direction is locked in to allow the compass to stabilize.

5. Obstructions on the propeller may cause excessive vibration of the motor head. This vibration can cause the compass to

wander and erratic steering to occur. Clear the obstruction to return the motor to normal operation.

6. When broad speed changes are made, the motor heading may change slightly. This is normal.

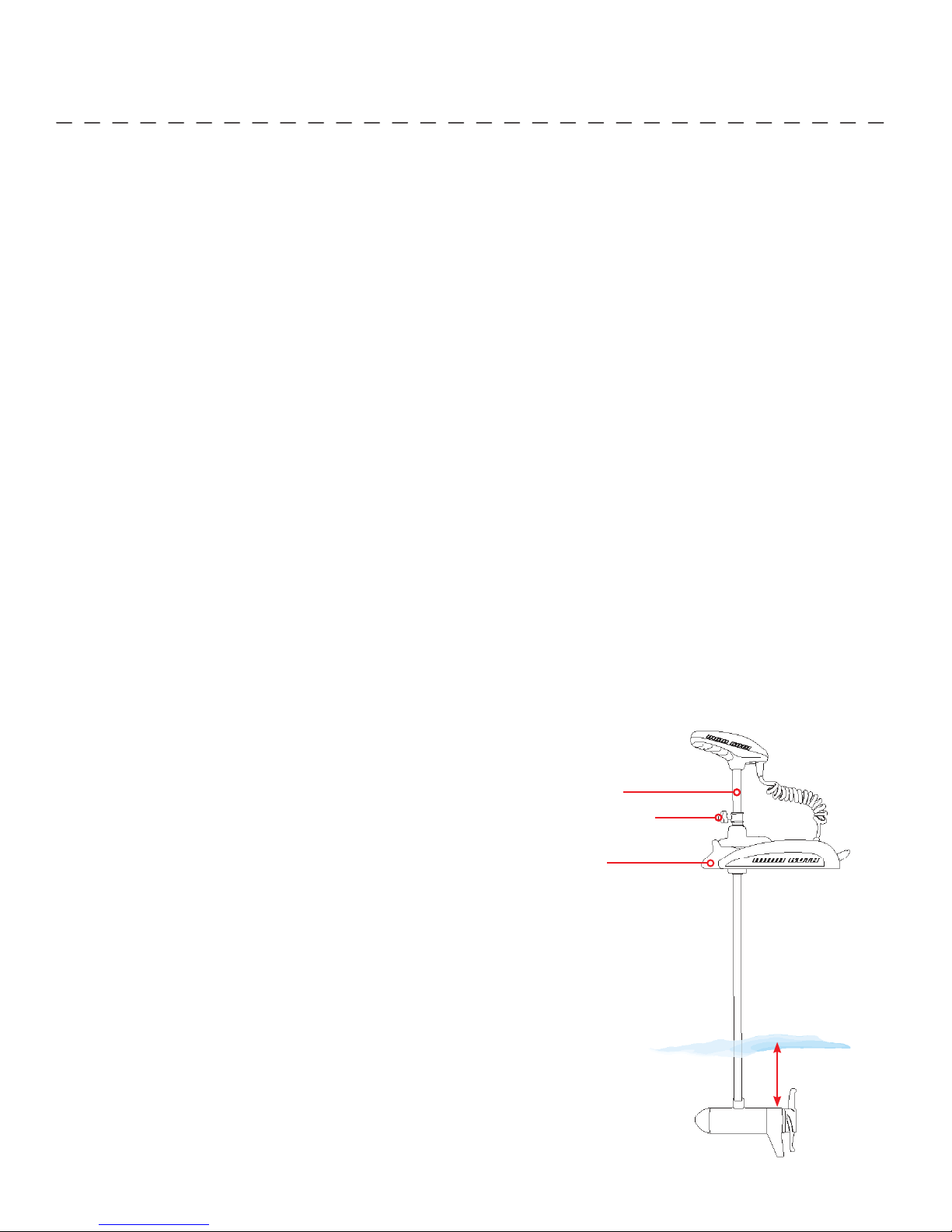

ADJUSTING THE DEPTH OF THE MOTOR

When setting the depth be sure the top of the motor is submerged

at least 12” to avoid churning or agitation of surface water. The

propeller must be completely submerged.

1. With the motor deployed, fi rmly grasp the composite shaft above

the mount.

2. Loosen the adjustable depth collar until the shaft slides freely.

3. Raise or lower the motor to the desired depth.

4. Turn the motor control head to the desired position.

Composite Shaft

Adjustable Depth Collar

Motor Mount

5. Tighten adjustable depth collar to secure the motor in place.

12 | minnkotamotors.com

12” Minimum Depth

©2014 Johnson Outdoors Marine Electronics, Inc.

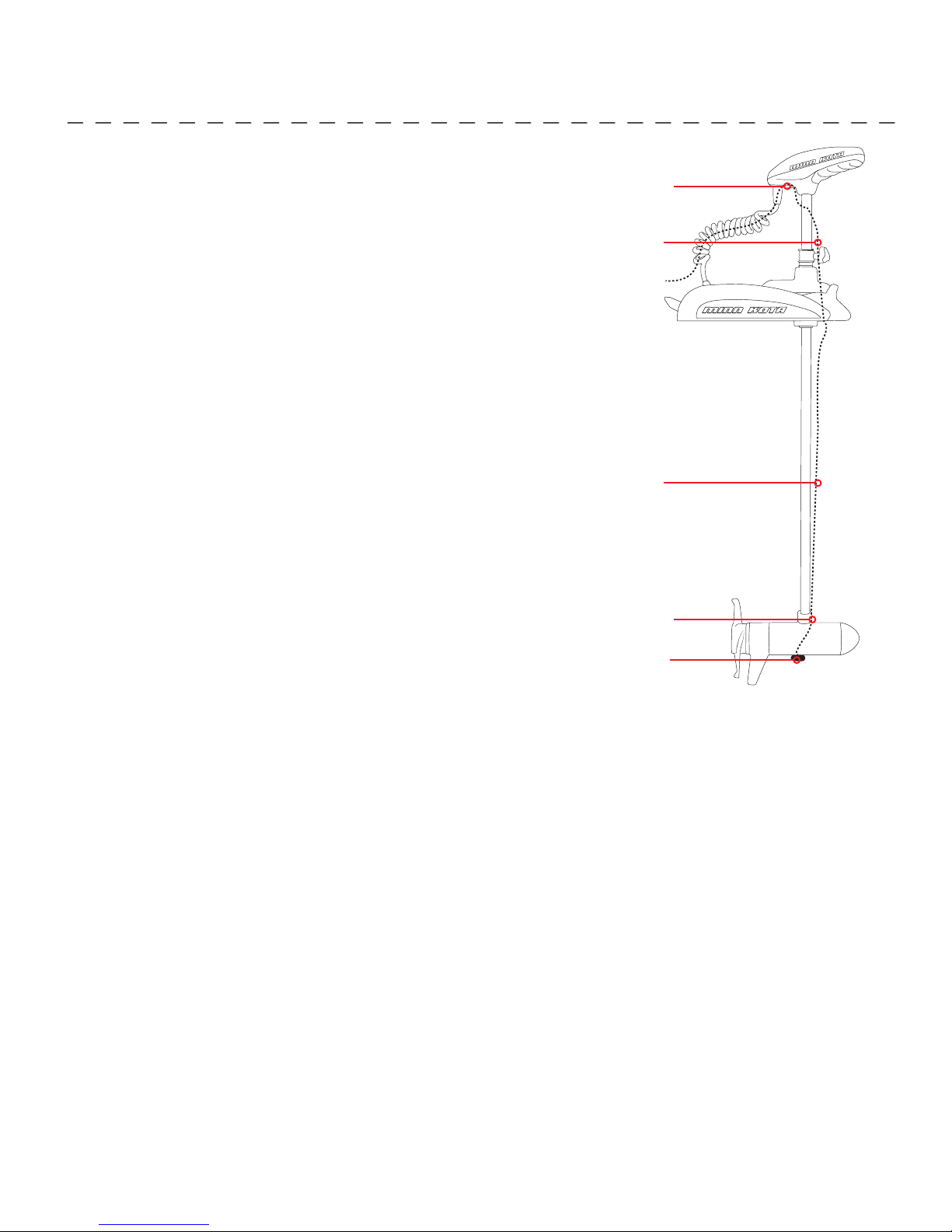

INSTALLING THE EXTERNAL TRANSDUCER

An external sonar transducer can be installed onto the motor as shown.

1. Transducer cables should be routed through the coil cable as

depicted in the illustration to the right.

2. Leave enough slack for proper stow and deploy.

3. Mount transducer according to transducer instructions.

Note: An external transducer is not included with your trolling motor.

Your trolling motor may be pre-installed with a Universal Sonar 2

transducer system. In this case, the transducer is integrated into the

motor unit.

For compatibility and more information on Universal Sonar 2, please

visit minnkotamotors.com/us2.

USING & ADJUSTING THE MOTOR

Tie wrap cable

Leave slack

Transducer

cable

Leave slack

ACCESSORY RECOMMENDATIONS:

• Minn Kota Transducer Mounting Kit (MKR-15)

Tie wrap cable

Transducer

©2014 Johnson Outdoors Marine Electronics, Inc.

minnkotamotors.com | 13

USING THE FOOT PEDAL

All the controls in the foot pedal are easy to operate by either foot or hand. A light touch is all that is necessary.

MOMENTARY

A toe touch on either of the two momentary buttons

turns the propeller on. Let up and the propeller stops.

MOM/CON SWITCH

A toe touch to the Mom/Con button toggles the motor

between momentary and constant. When the motor

Momentary on

AutoPilot

“ON” / “OFF”

Heel/toe

steering

Variable speed

control

is in constant the propeller will run continuously with

out keeping your foot on the pedal. When the motor

is in momentary, a toe touch is required to one of the

momentary on buttons to turn the propeller on. The

Constant On indicator light will be lit when the motor is

Momentary / Constant

“ON” / “OFF”

Left steer

Right

steer

Momentary on

in constant state.

RIGHT/LEFT

Place your foot in the center of the heel/toe pedal, rocking forward steers right. Rocking back steers left. Left and right steering

control can also be done with the Left/Right steering buttons. Holding the left or right steering button down steers left or right.

Small steering changes of less than one degree can be made by quickly and lightly tapping the left or right steering controls.

NOTE: The steering system is designed to turn your motor 360°. Be careful to avoid over-wrapping the coil cord around the

composite shaft.

FORWARD/REVERSE

The propeller always turns in the forward direction. You can reverse the direction of thrust by turning the motor 180˚.

SPEED CONTROL

The speed selector is the rotating knob on the right side of the foot pedal. The speed control knob provides variable speed

control. Use your hand or foot to rotate the knob to adjust speed.

AUTOPILOT (AUTOPILOT MODELS ONLY)

A toe touch to the AP button toggles the AutoPilot On and Off . The AutoPilot On indicator light will be lit on the foot pedal and

the center console of the motor when AutoPilot is on.

NON-CARPETED BOAT USE

Enclosed with your motor are four (4) rubber bumpers. If the foot pedal is to be used primarily on non-carpeted surfaces, insert

the rubber bumpers into the keyhole slots on the underside of the pedal. Slide the bumpers into the slot until they are locked into

position.

14 | minnkotamotors.com

©2014 Johnson Outdoors Marine Electronics, Inc.

Loading...

Loading...