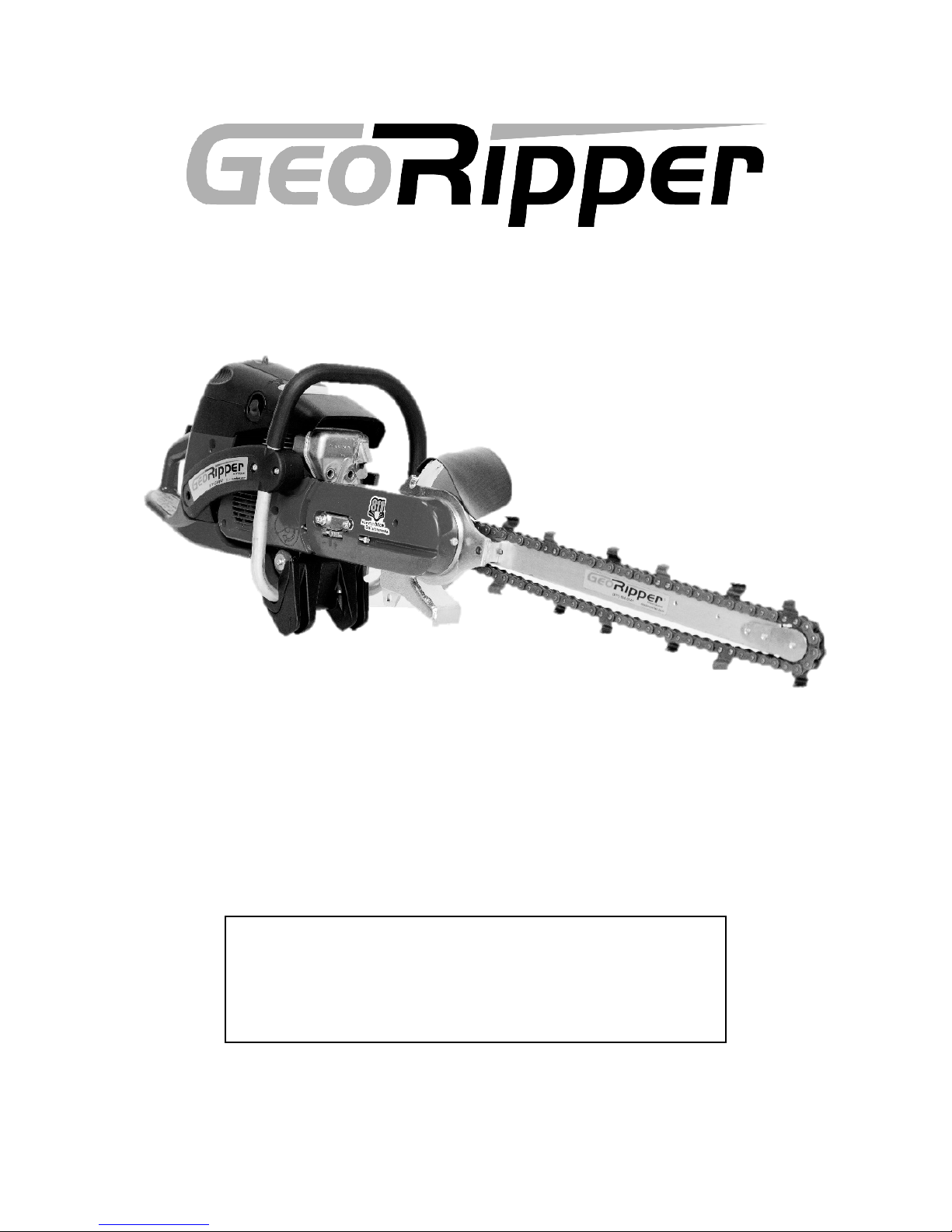

Reliable | Superior | Revolutionary

OPERATOR’S AND SAFETY MANUAL

FOR GEORIPPER MODELS GR16, GR20, GR27

WARNING!

Read and understand this Manual. Always follow safety

precautions in the Operator’s and Safety Manual.

Improper use can cause serious injury!

TERRATRENCH USA, INC. dba MiniTrencher

815 NE 172

nd

Avenue, Vancouver, WA 98684

877.694.0141 www.MiniTrencher.com

®

Thank you for purchasing the GeoRipper® minitrencher.

The unique features and benefits of the GeoRipper include multi-stage air filtration technology,

vibration isolation and the latest developments in durable digging chains. These lightweight

trenchers are designed to provide many years of dependable performance when used in

accordance to the instructions within this manual.

For more information and operating techniques, refer to the website:

www.MiniTrencher.com

WARNING!

Read and understand this Manual. Always follow safety precautions in the Operator’s and

Safety Manual. Improper use can cause serious injury!

WARNING!

FUELS WITH MORE THAN 10% ETHANOL ARE NOT APPROVED FOR USE IN GEORIPPER

2-STROKE AND 4-STROKE ENGINES! Use of alternative fuels, such as E-20 (20% ethanol), E-85

(85% ethanol) or any fuels not meeting MINITRENCHER requirements are not approved for

use in GEORIPPER MINITRENCHERS!

USE OF ALTERNATIVE FUELS CAN CAUSE THE FOLLOWING PROBLEMS:

Poor performance, loss of power, overheating, fuel vapor lock, improper clutch

engagement, premature deterioration of fuel lines, premature deterioration of gaskets,

premature deterioration of carburetors.

USING ALTERNATIVE FUELS AND/OR 2-STROKE OILS NOT ACCORDING TO JASO FC OR

ISO-L-EGD IN GEORIPPER MINITRENCHER 2-STROKE ENGINES WILL VOID YOUR ENGINE

WARRANTY!

i

CONTENTS PAGE

IMPORTANT SAFETY INSTRUCTIONS ........................................................................................... 1

ASSEMBLY INSTRUCTIONS ........................................................................................................... 3

DIGGING CHAIN INFORMATION .............................................................................................. 5

BEFORE YOU START TRENCHING ................................................................................................. 5

USING THE GEORIPPER® MINITRENCHER .................................................................................... 6

SPECIAL SITUATIONS ................................................................................................................ 7

MAINTENANCE, CLEANING AND STORAGE .............................................................................. 7

FUEL INFORMATION ................................................................................................................ 8

GUIDE TO MAINTAINING DIGGING COMPONENTS ................................................................. 9

USING MINITRENCHER EZ KART™ .............................................................................................. 10

TIPS FOR EZ KART™ USE ......................................................................................................... 11

GEORIPPER® TROUBLESHOOTING ............................................................................................. 11

SERVICE AND PARTS .................................................................................................................. 12

REPLACEMENT PARTS FOR GEORIPPER® MINITRENCHER ..................................................... 12

WARRANTY ................................................................................................................................ 13

EU DECLARATION OF CONFORMITY .......................................................................................... 14

ii

IMPORTANT SAFETY INSTRUCTIONS

To prevent serious injury:

All operators of the GeoRipper® minitrencher must read and fully understand this Operator’s

and Safety Manual prior to operating the minitrencher.

All operators must use required Personal Protection Equipment (PPE) as outlined by local or

national safety codes. PPE for feet, legs, eyes, hands, face and ears should be worn at all times

while operating the GeoRipper minitrencher. At minimum, the operator shall wear safety-toe

boots, safety glasses and ear plugs.

KEEP FEET AND HANDS CLEAR OF DIGGING CHAIN AT ALL TIMES.

Before you dig: check the location of all underground services, especially electric

cables. ELECTRIC SHOCK CAN CAUSE SEVERE OR FATAL INJURY.

Check that the powerhead, including handles, and all safety apparatus are in good working

order.

Ensure that the GeoRipper® minitrencher is correctly fitted to the powerhead, the chain and

belt are correctly tensioned, all nuts and bolts are tight and the belt guard is in place. Before

starting the engine, remove and inspect the digging chain for any damage.

When starting the powerhead (see Fig. B), use the correct safety starting techniques as outlined

in the powerhead operator’s manual and ensure that the digging chain is clear of contact with

the ground or any other object. For extra safety, make sure the area around the digging chain

is clear of loose vegetation, the digging chain may rotate upon startup of the powerhead. To

stop chain from rotating, depress throttle control to increase engine RPM. After engine slows

to idle, the chain should be stationary.

DIGGING CHAIN MUST BE STATIONARY WHEN POWERHEAD IS AT IDLE.

(Refer to powerhead operator’s manual for correct idle adjustment.)

1

Fig. B

Maintain firm footing and a firm grip on the powerhead during

digging. For easiest trenching, it is recommended to position

the blade at an angle (25 to 30 degrees from vertical.)

Digging with the blade vertical should be avoided (unless using

the EZ Kart™). Operating GeoRipper vertically allows the digging

chain dangerously close to the operator’s feet and legs. A

vertical orientation will also increase operator fatigue.

When trenching on an incline, always stand downhill of the

GeoRipper minitrencher (Fig. D) or with discharge chute facing

downhill. (Fig. E) In slippery conditions, always maintain firm

footing. Operator shall be aware of surroundings and stand so

a sudden loss of balance will not bring body into contact with

the trencher.

Minors shall not operate the GeoRipper® minitrencher.

The digging blade may kick back if the bar and digging chain contacts hard, solid ground or other

obstructions.

When tuning or testing the minitrencher, be sure to point the blade

away from self and others. The chain will rotate at high speed

without warning. People and animals shall be kept at a safe

distance.

Rocks and debris can be ejected from the trencher behind and to

the left of the operator (9 – 12 O’Clock.) Keep people, windows and

other property clear of these positions.

Loose clothing shall not be worn when operating minitrenchers.

When operating GeoRipper minitrenchers, dirt guards can become

hot to the touch. Be careful to not touch dirt guard with bare hands

as it will be hot and could burn.

Foot on thr ottle guard, c hain off the g round

Do NOT star t engine whil e holding the

machine off the ground

Do NOT star t with bar an d chain contacti ng the groun d.

Fig. D

Fig. E

2

ASSEMBLY INSTRUCTIONS

Before assembly, check parts list within product packaging. If anything is missing, please call

MiniTrencher or your local dealer immediately.

1. Removed powerhead from box and lay on its side on a non-marring surface. Position so

the digging bar bolts are visible. (Fig. F)

Using the 18mm wrench provide, undo and set aside the digging bar clamping bolts, lock

washers and bar clamp.

2. Hold the digging bar as shown (Fig. G) with the slot on the bar facing towards the main

block of the GeoRipper® minitrencher.

CAUTION: DIGGING BAR IS REVERSIBLE BUT DIGGING CHAIN DIRECTION IS CRITICAL (Fig. H)

Fig. F

Fig. G

Fig. H

3

3. Loop the digging chain around the nose sprocket of the digging bar.

If the digging chain has notches, the chain must be assembled with the directional notches

on rear of cutting teeth facing towards engine/operator when chain is running along the

top of the digging bar. (Fig. H)

4. Loop the digging chain over the GeoRipper® drive sprocket. Fit slotted section of the

digging bar to raised section of mounting block. Slide bar away from powerhead to lightly

tension chain. (Fig. J)

5. Install the two large clamping bolts, lock washers and bar clamp. Lightly tighten the two

large clamping bolts with 18mm wrench.

6. Insert a flat-blade screwdriver into the digging bar tensioning slot. (Fig. K)

Lever the digging bar away from the engine. Securely tighten the two large bolts while

keeping tension on the digging bar.

6a. If a bar tensioner is installed on the digging bar (standard all GR27, optional GR16 &

GR20) screw bar tensioning bolt with included 13mm wrench while clamping bolts

are lightly secured. Once tightened to preferred tension, securely tighten clamping

bolts with 18mm wrench. Tighten securing nut on bar tensioner to keep tensioning

bolt in place.

7. The GeoRipper® minitrencher is now ready to operate. Refer to both the section in this

manual and the powerhead manual for correct and safe operation of the GeoRipper®

minitrencher.

Fig. J

Fig. K

4

DIGGING CHAIN INFORMATION

When in rocky soil, decrease engine R.P.M. Typically, 3/4 engine throttle is necessary for

maximum productivity.

BEFORE YOU START TRENCHING

1. Visually inspect trencher before starting/restarting.

2. Ensure all nuts, bolts and screws are tight and secure.

3. Carry out all safety instructions as listed on pages 1 & 2.

4. Check with local authorities for any underground services.

ALL 811 BEFORE YOU DIG

In rural areas, check with landowners who may have a detailed knowledge of utility

location.

In many locations (along road sides and near subdivisions) surface re-grading may have

occurred after utilities were laid. This can result in cables or other utilities appearing

unexpectedly at shallower depths than regulations require. Stop trenching if something

doesn’t look or feel right.

5. Check along the desired trench line, clearing any obstructions, branches, large stones and

other obstructions that could cause the operator to slip or loose footing. If a long

continuous trench is planned, consider using the MiniTrencher EZ Kart™.

Soil Type

Adjustment (Sag at midpoint)

Hard

1 inch

Clay

1 inch

Stoney

1 ½ inch

Clean

1 inch

Easy

1 inch

Abrasive/Sand

1 ½ inch

5

USING THE GEORIPPER® MINITRENCHER

WARNING!

DO NOT ALLOW DIGGING CHAIN TO JAM OR SLOW TO A STOP WHILE HOLDING THE

THROTTLE ON. TURN OFF ENGINE, DISCONTINUE OPERATION AND INVESTIGATE. RUNNING

ENGINE AT MORE THAN IDLE WITH CHAIN JAMMED WILL CAUSE SEVERE CLUTCH AND/OR

BELT DAMAGE.

If GeoRipper® minitrencher has an adjustment screw for the belt tension, the tension must be

readjusted after the first hour of operation to prolong belt life. See Powerhead Operator’s

Manual for further instruction.

1. Start the powerhead per the manufacturer’s Operator’s manual. Start trenching with the

GeoRipper® minitrencher on the ground and tip the blade into the ground. Once the

digging bar and chain are in the ground, the operator can choose to stand and cut through

the ground backwards along their desired line or continue to “drag back and tip in.” Keep

the angle of the digging bar at 25-30-degree angle from vertical for comfortable operation.

In lighter soils, it may be necessary to make second pass through the trench to clear out

any spoils that fell back in.

2. Most powerheads are designed to operate best and develop maximum power near 3/4

throttle. Depending on soil type, best operating speeds will be from 3/4 to full throttle. For

greater control at shallow depths [8 inches (200 mm) or less] a 1/2 to 3/4 throttle will

improve trenching safety.

3. When trenching without a MiniTrencher EZ Kart in difficult soils, the “drag back and tip in”

method is recommended.

4. If you strike solid obstacles (large rocks, concrete, or large roots or buried timber) remove

the obstacle before continuing. The GeoRipper® minitrencher is designed to dig earth, not

large stones or tree roots over 3 inches (80mm) in diameter.

5. For wider trenches [2-3 inches (50 – 80mm)], rotate blade along the long axis of the blade

while trenching. For anything over 3 inches (80mm), make a second trenching cut at the

outside of the desired width and remove the soil between the two trenches.

6. Regular checking/adjustment of digging chains will extend chain life.

7. At the end of the job, and periodically during the project, brush the loose dirt off the

digging chain and around the digging sprocket. Inspect the digging teeth for any damage.

8. To trench down an incline, always stand downhill of the trencher.

9. To trench laterally across an incline, always direct the discharge chute downhill. This will

keep the spoils from falling downhill back into the trench.

10. In very rocky soils, the option rock shield can be used with the MiniTrencher EZ Kart™.

11. Cut grass before trenching to help recover spoils.

6

SPECIAL SITUATIONS

1. The GeoRipper® minitrencher is not designed to trench in solid rock.

2. For digging in light or sandy soils containing fine, hard stones, GeoRipper® minitrenchers

should be at full speed prior to contact the ground. When trenching is complete, lift the

digging bar and chain clear of the trench prior to throttling down. This will greatly reduce

the occurrence of rock jambs. Decreasing tension on the chain will also improve trenching

in these conditions.

3. When digging at full depth in difficult, wet, pliable clays, it is recommended to make two

half-depth passes in opposite directions. This will reduce operator fatigue, reduce engine

strain, and reduce the possibility of jamming the digging chain with mud.

4. When cutting curves or radiuses, it is advisable to use several shallow passes rather than a

single, full-depth cut.

5. When trenching across a roadway, it is recommended to first loosen the compacted

gravel/stones along the desired line. Removing larger rocks before trenching will also

increase productivity and avoid damaging the digging chain.

6. If digging chain is slowing or stopping because of excessive soil buildup, periodically stop

the machine and clear the material for the chain, sprockets and discharge chute. Some

soils will buildup on the sprocket and add tension to the chain. Loosening chain can help.

Keeping engine speed high and constant can also help.

MAINTENANCE, CLEANING & STORAGE

IMPORTANT! Inspect powerhead air filter daily. Clean or replace when necessary as per

powerhead Operator’s Manual.

Blow out and clean cooling find on powerhead with low-pressure, compressed air every 8-10

hours of operation. Clean out any embedded or sticky debris.

Check drive belt tension and inspect drive belts for cracking or other wear daily. Replace belt as

need. Check your orange tool pouch for an extra drive belt.

Replace anti-vibration mounts and other wearable powerhead components as required to

maintain the powerhead.

4-Cycle Engines: Change oil for the first time after 20 hours of use. After initial oil change, oil

shall be changed every 30-40 hours of operation.

To replace Nose Sprocket and Nose Assembly Plates

Heat screws to 500 degrees F (260 degrees C) to breakdown locking compound. An

impact driver with a 5mm hex bit will help to loosen screws. Add a stud locking compound (Red

Loctite) to screws before reinstalling. Tighten Nose bolts to 18 foot-lb torque.

When storing the GeoRipper® minitrencher, drain fuel from tank, run machine dry, and oil

digging chain. Follow storage instructions in powerhead Owner’s Manual.

7

2-STROKE FUEL & LUBRICATION INFORMATION

• Use a 30:1 fuel mixture for the first two tanks of fuel. 40:1 fuel mixture is recommended

after break-in period of two tanks.

• Use high quality, air-cooled, two-stroke oil. Preferably synthetic. Husqvarna® or

Dolmar®/Makita® two-stroke engine oil is also recommended.

DO NOT USE TWO-STROKE ENGINE OIL FOR OUTBOARD MARINE

OR WATER-COOLED ENGINES! IT IS NOT THE SAME!

• Use 90+ octane gasoline. Avoid bio fuels, ethanol or octane boosters, if possible.

• Use freshly-mixed fuel.

• Keep fuel container out of direct sunlight.

• Mix enough fuel only for the job at hand.

• Use a quality fuel stabilizer if using gas with ethanol.

WARNING!

FUELS WITH MORE THAN 10% ETHANOL ARE NOT APPROVED FOR USE IN GEORIPPER

2-STROKE AND 4-STROKE ENGINES! Use of alternative fuels, such as E-20 (20% ethanol), E-85

(85% ethanol) or any fuels not meeting MINITRENCHER requirements are not approved for

use in GEORIPPER MINITRENCHERS!

USE OF ALTERNATIVE FUELS CAN CAUSE THE FOLLOWING PROBLEMS:

Poor performance, loss of power, overheating, fuel vapor lock, improper clutch

engagement, premature deterioration of fuel lines, premature deterioration of gaskets,

premature deterioration of carburetors.

USING ALTERNATIVE FUELS AND/OR 2-STROKE OILS NOT ACCORDING TO JASO FC OR

ISO-L-EGD IN GEORIPPER MINITRENCHER 2-STROKE ENGINES WILL VOID YOUR ENGINE

WARRANTY!

4-STROKE FUEL & LUBRICATION INFORMATION

• Use 90+ octane gasoline. Avoid bio fuels, ethanol or octane boosters if possible.

• Use 10W40 motor oil in crankcase – high-grade, synthetic recommended.

• Change engine oil after first 20 hours of operation. After initial change, change oil every

30-40 hours.

To ensure correct fuel mix,

use a shelf-stable pre-

mixed 2-stroke fuel like

TruFuel or VP Performance.

8

GUIDE TO MAINTAINING DIGGING COMPONENTS

IMPORTANT!

Digging Components wear depending on soil, digging depth and operator.

Estimates are provided, but not guaranteed.

• Reverse digging bar as required. Estimate is every four digging chains.

• Replace digging bar when bar is worn on both sides.

• Replace nose bearing as required. Estimate is every three to four digging chains.

• Replace nose sprocket as required. Estimate is every six to eight digging chains.

• Replace digging chain drive sprocket as required. Estimate is every three to four

digging chains.

When finishing work, it is advisable to clean the digging chain and spray lightly with WD40, or

similar, to prevent corrosion while in storage. For long term storage, the digging chain should

be removed and soaked in a light oil or diesel fuel. Clean other surfaces with a brush or damp

cloth. Avoid using petroleum-based products, abrasives, or other solvents on labels. Remove

the drive belt guard, remove dust and dirt from belt housing and reinstall. Store the

GeoRipper® minitrencher is a safe, dry place.

9

USING THE MINITRENCHER EZ KART™

WARNING!

Electric shock can be fatal regardless of whether you are using the GeoRipper® minitrencher

manually or with the MiniTrencher EZ Kart™ system. Remember to check the location of all

underground services, especially electric cables, prior to digging.

CALL 811 BEFORE YOU DIG

Refer to instructions supplied with EZ Kart™ for assembly.

Lay the control handle on the ground so it is engaged with the rear/lowest detent position on

the axle. This position will keep the axle receiver mount in a level position.

Position the EZ Kart tongue, located at the bottom of the GeoRipper® adapter, into the axle

receiver mount (Fig. L.) Lock in place by engaging the latching slide bolt through the receiver

mount. Slide bolt handle rotate to lock into place on EZ Kart™ axle.

Pull control handle out of detent position and reposition in first/upper detent position.

The detents allow the operator to control the angle of the digging blade and chain. This allows

for greater depth consistency.

BEFORE STARTING POWERHEAD

Position throttle control assembly onto throttle handle of powerhead so that EZ Kart™ throttle

latch engages the powerhead throttle trigger. Secure in place by wrapping the attached Velcro

strap around powerhead handle.

With engine switched off, check for smooth throttle operation by operating remote throttle

lever and adjust throttle cables as required using the in-line cable adjuster on the throttle cable.

Make sure the engine will return to idle after operating remote throttle.

Place tow strap around lower back (at or below belt line) and adjust length for comfortable

operation. Proceed with trenching. (Refer to powerhead Owner’s manual and page ## of this

Manual for correct starting procedure.)

Fig. K

10

TIPS FOR EZ KART™ USE

Start digging your trench. Select a notch on the depth adjuster which gives both the desired

trench depth and a comfortable operating position for the control handle. Keep the handle as

close to vertical as possible with slight down pressure so that you retain control of the

GeoRipper® minitrencher at all times. You can use a finger under the remote throttle lever to

help control the RPM. Before changing to a different notch, throttle off and allow your digging

chain to come to a rest so that you retail full control of the GeoRipper® minitrencher at all times.

When trenching with the EZ Kart™, allow the GeoRipper® minitrencher to dig at a rate which

the soil type/condition allow. If excessive backwards pressure is used for the soil

type/condition, the GeoRipper® minitrencher will try to “surface” and the wheels will come off

the ground. This situation places unnecessary strain on all components, including the operator.

GEORIPPER® TROUBLESHOOTING

If engine does not start, check the air and fuel filters first. Replace filters if necessary. If engine

still does not start, check sparkplug for spark.

WARNING!

Not all sparkplugs are the same! Make sure to purchase the correct replacement plug for your

trencher. Incorrect sparkplugs can cause poor power, no power, or burnt piston. Using the

incorrect sparkplug will void the engine warranty.

Refer to powerhead Owner’s Manual for more information.

If you hear a squeal while trenching, or an unjammed digging chain will not rotate under full

throttle, check the belt tension of the trencher. Refer to powerhead Owner’s Manual for more

information.

11

SERVICE AND PARTS

GeoRipper® minitrenchers are professionally designed and engineered for easy service and

part replacement.

During the warranty period, any non-routine servicing shall be referred to MiniTrencher’s

service department or an authorized MiniTrencher service center to maintain warranty status.

This work will be charged at the normal rates unless found to be a warranty item. Beyond the

warranty period, replacement parts can be ordered through MiniTrencher and its dealers for

convenient field replacement.

WARNING!

Unauthorized parts and modifications not only void the warranty, they can be dangerous,

causing serious or fatal injury to operator or bystanders.

Only use genuine GeoRipper® minitrencher parts.

When ordering parts, accessories or service, please quote:

• The GeoRipper® minitrencher model number. (GR16, GR20, GR27)

• Powerhead manufacturer and model number.

• The GeoRipper® minitrencher number. (stamped on the bar mounting block)

REPLACEMENT PARTS FOR GEORIPPER® MINITRENCHER

Bar Accessories

GR1 Bar End Set

GR2 6-Tooth Nose Sprocket

GR2-11 11-Tooth Nose Sprocket

Digging Bars

GR3-16 16” (400mm) Digging Bar

GR3-20 20” (500mm) Digging Bar

GR3-27 27” (800mm) Digging Bar

GR3C-16 16” (400mm) Digging Bar w/ GR1, GR2

GR3C-20 20” (500mm) Digging Bar w/ GR1, GR2

GR3C-27 27” (800mm) Digging Bar w/ GR1, GR2-11

Digging Chains

GR4-16 16” (400mm) Digging Chain 2-Pack

GR4-20 20” (500mm) Digging Chain 2-Pack

GR4-27 27” (800mm) Digging Chain 2-Pack

Accessories

GR6 Bar Clamp Washer Only

GR8 Dirt Guard Ext. Kit

Conversion Kits & Accessories

GRP6102 Drive Sprocket Makita EK6101

GRP7602 Drive Sprocket Makita EK7651H/EK8100

GRPH7602 Drive Sprocket for Husqvarna K760/K970

GRPS7602 Drive Sprocket for Stihl TS700/TS800

EZ Kart™

GR EZM EZ Kart™ Makita

GR EZH EZ Kart™ Husqvarna

GR EZS EZ Kart™ Stihl

EZ Kart Accessories

GRPEZ08 Throttle Cable

GRPEZ10M Throttle Latch (No Cable) Makita

GRPEZ10H Throttle Latch (No Cable) Husqvarna

GRPEZ10S Throttle Latch (No Cable) Stihl

GRPEZ12 Handle Clip

GRPEZ14 Wheel Washer & Clips

GRPEZ16 Wheels

GRPEZ18 Pull Strap

GRPEZ20 Pull Strap Buckle

GRPEZ26 Axle Extender

GRPEZ27 Axle Extender Clip

GRPEZ28 Rock Shield Kit

12

WARRANTY

SIX MONTH MINITRENCHER LIMITED WARRANTY

1. MINITRENCHER WILL REPAIR OR REPLACE, AT ITS OPTION, ANY NEW GEORIPPER® MINITRENCHER PRODUCT WHICH

FAILS DUE TO A DEFECT IN MATERIALS OR WORKMANSHIP DURING THE APPLICABLE WARRANTY PERIOD SPECIFIED

IN SECTION 2 BELOW, SUBJECT TO THE EXCLUSIONS AS NOTED IN SECTION 3.

2. THE WARRANTY PERIOD APPLICABLE TO NEW GEORIPPER® MINITRENCHER PRODUCTS, DEPENDING ON THE END

USE OF THE PRODUCT AND PRODUCT TYPE, WITH COVERAGE COMMENCING FROM THE DATE OF SALE, IS SIX

MONTHS.

3. THIS WARRANTY DOES NOT IN ANY WAY COVER:

• NORMAL WEAR AND TEAR

• FAILURE ARISING FROM IMPROPER USE OF THE PRODUCT

• FAILURE ARISING FROM IMPROPER ASSEMBLY, MAINTENANCE OR STORAGE

• FAILURE ARISING FROM THE USE OF PARTS NOT MANUFACTURED OR SUPPLIED BY MINITRENCHER OR ITS

AUTHORIZED AGENTS

• DIGGING CHAIN AND GROUND-ENGAGING ITEMS INCLUDING NOSE BEARINGS, NOSE SPROCKET, NOSE

SPROCKET END PLATES, DIGGING BAR AND DRIVE SPROCKET.

• USE OF INCORRECT FUEL OR FUEL MIXTURE.

• LEAN SEIZURES

4. MAKITA SMALL ENGINE GENERAL AND EPA MANUFACTURER WARRANTIES ARE BACKED BY MINITRENCHER IF

MINITRENCHER INSTALLED THE MAKITA SMALL ENGINE ON THE GEORIPPER® MINITRENCHER PRODUCT. SEE

MAKITA GENERAL AND EPA WARRANTY FOR MORE INFORMATION.

5. MINITRENCHER DOES NOT WARRANTY ANY OTHER SMALL ENGINES ASSOCIATED WITH GEORIPPER PRODUCTS.

6. SHOULD ANY TROUBLE DEVELOP DURING THE SIX-MONTH PERIOD, RETURN THE COMPLETE PRODUCT, FREIGHT

PREPAID BY USER, TO ONE OF MINITRENCHER’S FACTORY OR AUTHORIZED SERVICE CENTERS. IF INSPECTION SHOWS

THE TROUBLE IS CAUSED BY DEFECTIVE WORKMANSHIP OR MATERIAL, MINITRENCHER WILL REPAIR (OR AT OUR

OPTION, REPLACE) WITHOUT CHARGE TO THE EXTENT ALLOWABLE.

7. THE SAFE AND CORRECT USE OF THIS PRODUCT IS BEYOND THE CONTROL OF THE MANUFACTURER. MINITRENCHER

WILL NOT BE LIABLE TO ANY PURCHASER OR ANY OTHER PERSON FOR ANY LOSS OF PROFITS OR ANY

CONSEQUENTIAL, INDIRECT OR SPECIAL LOSS, DAMAGE OR INJURY OF ANY KIND HOWEVER CAUSED (INCLUDING

NEGLIGENCE) ARISING DIRECTLY OR INDIRECTLY FROM OR IN CONNECTION WITH ANY GEORIPPER® MINITRENCHER

PRODUCT AND/OR ANY FAILURE OF OR ANY FAULT IN ANY GEORIPPER® MINITRENCHER PRODUCT. BY WAY OF

EXPLANATION, WE ARE NOT LIABLE IF YOU CAUSE OR SUFFER DAMAGE, INJURY OR LOSS WHEN USING A

GEORIPPER® MINITRENCHER PRODUCT.

8. IN NO EVENT SHALL MINITRENCHER BE LIABLE FOR (A) ANY INDIRECT, INCIDENTAL, PUNITIVE OR CONSEQUENTIAL

DAMAGES ARISING FROM THE SALE OR USE OF THE PRODUCTS SOLD UNDER THESE WARRANTIES, OR (B) ANY

AMOUNT IN EXCESS OF THE AMOUNT ACTUALLY PAID TO MINITRENCHER FOR THE PRODUCTS SOLD HEREUNDER.

THIS LIMITATION APPLIES BOTH DURING AND AFTER THE TERMS OF THE WARRANTY.

MINITRENCHER DISCLAIMS LIABILITY FOR ANY IMPLIED WARRANTIES, INCLUDING IMPLIED WARRANTIES OF

“MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE” AFTER THE EXPIRATION OF ANY EXPRESS WARRANTY.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM

STATE TO STATE. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. SOME STATES DO

NOT ALLOW LIMITATION ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT

APPLY TO YOU.

FOR HANDY REFERENCE, RECORD YOUR GEORIPPER® MINITRENCHER DETAILS HERE:

Model No. ________________________

Serial No. _________________________

13

EU Declaration of Conformity

In accordance with EN ISO 17050-1:2010

Object of the declaration:

Product Portable Handheld Trencher

Model/type GR M(Makita) H(Husqvarna) S(Stihl) then length 400-500-800mm

Batch/serial no. GR Alphabetical Revision then numerical sequentially

GR Manufacturing

5 Lilburn Street

Warkworth 0910

New Zealand

This declaration is issued under the sole responsibility of the manufacturer.

The object of the declaration described above is in conformity with the

relevant Union harmonisation legislation:

2006/42/EC The Machinery Directive

2014/30/EU The Electromagnetic Compatibility Directive

Conformity is shown by compliance with the applicable requirements of the following documents:

Reference & Date

EN 474 10 2007+A1 2009

EN ISO 3547 2004

EN ISO 12100 2010

EN ISO 14121-2 2012

Title

Earth Moving Machinery/Trenchers

Earth Moving Guard Requirements

Design/Risk Assessment & Risk Reduction

Machine Safety & Risk Assessment

Signed for and on behalf of: GR Manufacturing

Place of issue: Warkworth

Date of issue: 20-10-2016

Name: Michael Sylvester Smith

Position: Director

Signature: <Signature of person detailed above>

The technical documentation for the machinery is available from:

Name: DOC-EUPOINT

Address: www.doceupoint.com

®

GR MANUFACTURING, LTD

PO BOX 44

WARKWORTH 0910

NEW ZEALAND

14

TERRATRENCH USA, INC. dba MiniTrencher

815 NE 172

nd

Avenue, Vancouver, WA 98684

877.694.0141 www.MiniTrencher.com

Loading...

Loading...