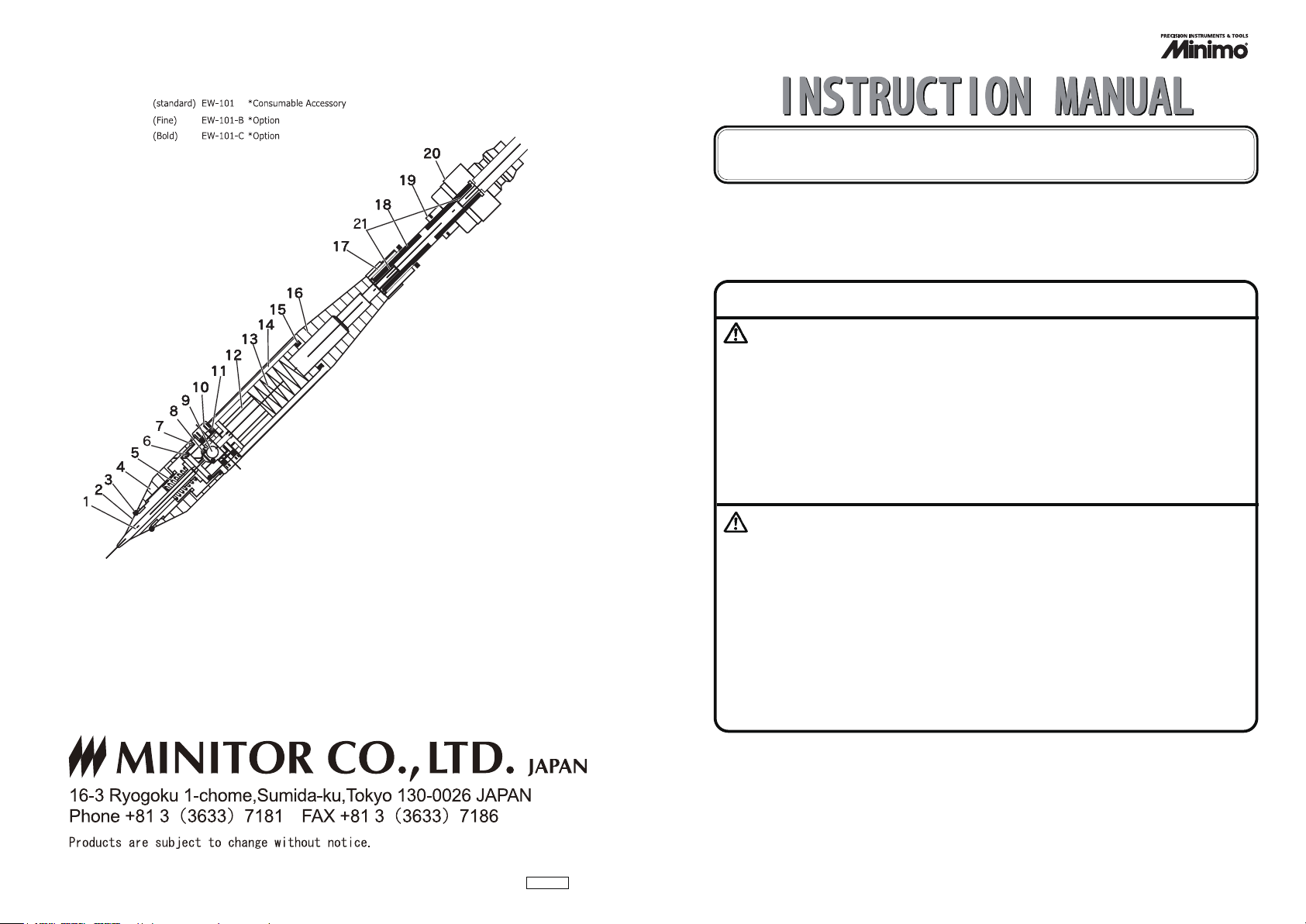

6. PARTS LIST

1.Point Tool

2.Bush

3.O-Ring

4.Front Housing

5.Front Spring

6.O-Ring (7.66×1.78)

7.O-Ring (12.1×1.6)

8.O-Ring (2.5×1.8)

9.Valve Ball

EW-102

EW-103

EW-104

EW-105

EW-106

EW-107

EW-108

EW-109

10.Switch Valve

11.O-Ring (3.1×1.6)

12.Ball Guide

13.Rear Spring

14.Housing

15.O-Ring (11.1×1.6)

16.Rear Housing

17.Hose Connector M7

18.Air Hose Black 2.5m

19.Hose Connector 1/4

20.Coupler

21.Bronze Bush

EW-110

EW-111

EW-112

EW-113

EW-114

EW-115

EW-116

EW-117

EW-118

EW-119

EW-120

EW-121

EW-01 WORK MARKER

Read following instructions before attempting to use.

Keep this manual always in the vicinity of use for your reference.

Before using the unit, check if there are any damages on the unit due to

transport conditions. If any damages are found, contact our Minimo dealer.

SAFETY PRECAUTIONS

WARNING

WARNING

(Indicates that incorrect operations presents significant danger of

(Indicates that incorrect operations presents significant danger of

accident resulting in death or serious injury to the user.)

accident resulting in death or serious injury to the user.)

Wear an appropriate eye protection and a respiratory protective equipment

○

when using the handpiece.

Use compressed air with the pressure 4

○

Do not attempt to disassemble and remodel the unit.

○

Do not touch the point tool when vibrating.

○

~

7 kgf / ㎠ (56~99psi)

CAUTION

(Indicates that incorrect operation presents possibility of injury to the

user or damage to the unit.)

○

Never push the point tool hard onto the workpiece.

Excessive force on the tool will cause damage to the tool and also reduce the

cutting power.

Use air filter and/or dryer to eliminate water, water vapor and any other dust

○

particle in compressed air.

Avoid any heavy impact to the unit. Do not drop it!

○

Keep the unit away from children.

○

2019.08.16 IME-EW-01

-1--4-

1. PACKING LIST

◇

WORK MARKER (EW-01) with air hose

◇

Instruction Manual

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

1 PC.

1 PC.

2. FEATURE

*To engrave on hardened metals with hardness less than 50 by HRC, glass,

plastic, etc.

*The point tool is made of tungsten carbide, and easy to replace.

Fine type and bold type are also available as options.

3. SETTING

1)Make sure that the switch valve is off.

2)Connect the coupler to air compressor while the switch valve is in off

position.

※Caution : Never connect the coupler to an air compressor while the switch

valve is “ON” .

It may cause an unexpected accident.

“OFF”

“ON”

5. MAINTENANCE

5-1. Lubrication

Lubricate with supplying air from the end of hose once a day or more

depending on frequency in use.

5-2. Replacing the point tool

1)Hold the center part of the housing,

and turn the front housing to loosen.

If it is too hard to turn, clamp the

housing softly by a small vise and

try to turn it loose.

*Do not clamp the housing too hard.

The housing may be broken.

2)Pull out the point tool from the front

housing.

Mount the O-ring and the front

spring on the new point tool as in the

right figure

3)Put the new point tool into the front

housing and tighten the front housing

back to the housing.

Loosen

Tighten

Point Tool

Housing

O-Ring

Front Spring

Front Housing

EW-104

EW-114

EW-106

EW-105

4. HOW TO USE

1)Push the switch valve on to start.

2)Hold the handpiece as close to the point as possible and engrave in

condition of handpiece close to vertical position.

3)Push the switch valve off to stop.

*Replace to our genuine parts for right

characteristics and dimensions.

*Prevent from entering foreign substances into the housing

when replacing the tool and/or other parts.

-3--2-

Loading...

Loading...