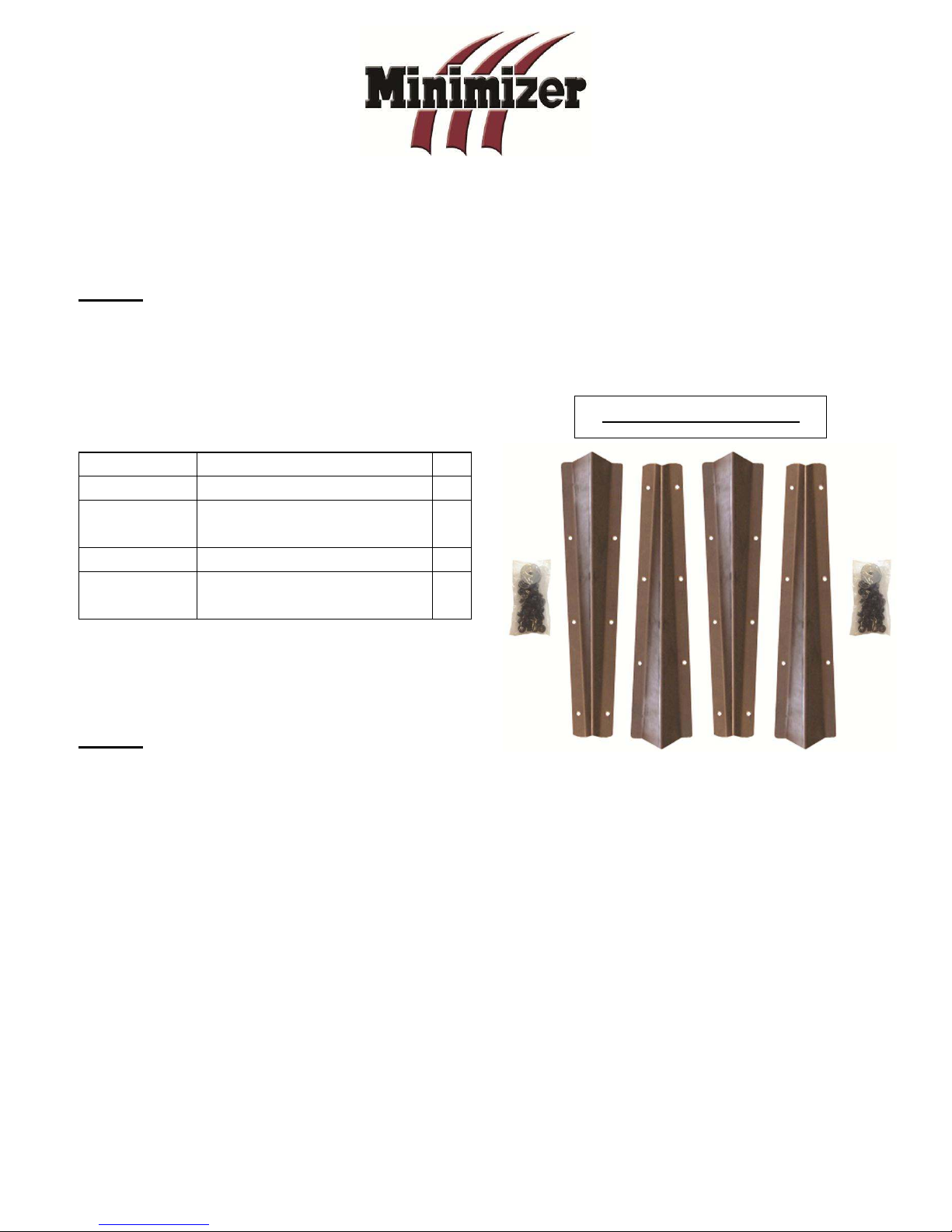

PART NUM BER DESCRI PTI ON QTY.

PB5010 5010 TAPERED BRACKET 4

131C100BSF/R

BZ

5/16-18 X 1 HEX WASHER

HEAD BL

24

I31N150WFEZ 5/16 X 1 1/2 FENDER WASHER 24

131CNCF/RBZ

5/16-18 CLASS G FLANGE

LOCK

24

B100WOA Mounting Kit

Figure 1

B100WOA

Fender Mounting Instructions for MIN100, MIN150, MIN1600, MIN161200, MIN1900,

MIN2200, MIN2218, MIN2260, MIN2480 & MIN9950 Fenders

STEP 1

A. Unpack all cartons and lay out parts.

B. Compare the parts with the hardware kit B100WOA as shown in Figure 1.

STEP 2

A. Measure the suspension travel. This measurement is used to determine the distance

between the fender and the wheel.

a. For air suspension systems, let the air out of the air bags.

b. For spring systems, measure from the stops on the springs to the bottom of the

frame.

NOTE: For air suspensions with travel exceeding 6”:

In some cases a travel stop may need to be installed to prevent such large gaps

between the fenders & tires. This will help with alignment and 5th wheel plate clearance.

(Please call Minimizer @ 800-248-3855 for questions regarding this issue).

B. Gap the fenders ¾” over the maximum travel point of the suspension system. The goal is

to make sure the fender does not rub on the tire. A gap larger than ¾” may be necessary

if using worn tires.

Revised 12/29/2014 Page 1

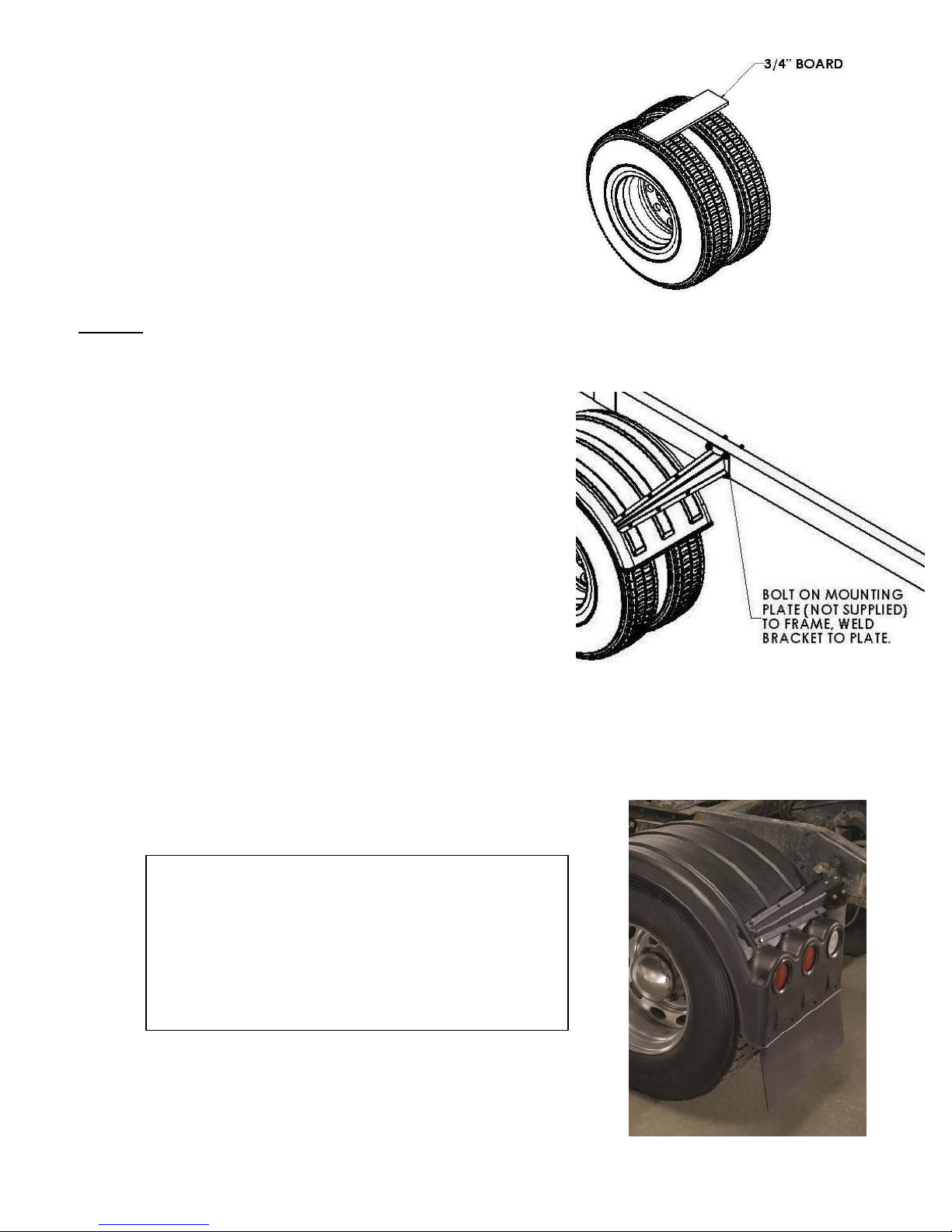

Figure 2

Figure 3

NOTE: Do not drill into the weld or any other

part of the light box. If a mud flap is mounted to

the light box style fender and the mud flap is

backed over, it may cause the interior welded

plate to become loose. Slot the mud flaps to

prevent this issue. This is NOT covered under

warranty.

Figure 4

TIP: Establish the ¾” minimum gap required in Step 2B.

a. For an air suspension system, place a ¾”

board on top of the tires after the air has

been let out of the airbags (Figure 2).

Place the fender on top of the board.

b. For a spring suspension system, add ¾”

to the measurement from Step 2A.

STEP 3

A. Position the fenders exactly where they will be mounted.

a. Visually pick and mark the locations that

the brackets will attach to the frame.

B. It is possible to bolt a plate (not supplied)

to the frame and weld the brackets to that

plate (Figure 3). Another option is to weld

the bracket directly to the frame.

a. Plate should be a minimum

of ¼” thick steel.

Tip: Check owner’s manual before

welding directly to the frame. Most

manufacturers do not suggest welding

anything directly to the frame.

NOTE: Depending on the length of the truck frame and the placement of the mud flap hangers,

the fender may tuck inside the mud flap hanger. Figure 4 shows a truck with flaps and fenders.

Revised 12/29/2014 Page 2

Figure 5

Figure 6

C. If possible, position the mounting brackets

so they are located within 15” of the bottom

of the fender. This protects against wind

blowing the leading edge of the fender back

into the tire (Figure 5).

Tip: If the front fender bracket is

mounted higher than 15”, refer to:

http://www.minimizer.com/instruction

s .html for further suggestions on

adding additional support.

STEP 4

A. Attach the bracket (PB5010) to the fender.

a. Drill six 5/16” holes through the fender using

the holes in bracket PB5010 as a guide.

b. Install the 5/16” x 1” bolts through the

bracket and into the fender.

c. Use six 5/16” fender washers and 5/16” nuts

provided with the kit on the underside of the

fender.

d. Tighten the fender bolts. Recommended

torque for the 5/16” x 1” bolts is 10-15 ft-

lbs.

e. Make sure the fenders are square and

aligned (Figure 6). Twists or

bows in the fender will fatigue the

material over time.

STEP 5

A. For trucks with air suspension, raise and lower the suspension one final time to confirm that there

is adequate clearance between the fenders and wheels.

B. Recheck all brackets and bolts to ensure they are tightened to the recommended torque.

Revised 12/29/2014 Page 3

Loading...

Loading...