minicopter

Diabolo „S“

Ord.-No. 4950

Manual

minicopter

Rheinstahlring 47

34246 Vellmar

Germany

+49 561 988 2800

info@minicopter.de

www.minicopter.de

Congratulations to your new Diabolo S, one of the fastest model helicopters. This model was

created to reach the highest possible speed under highest possible power with best possible aerodynamic. The Diabolo S was designed without any comromise. It is extremly small,

the fuselage section has a shape like a symmetrical airfoil to minimize drag. To mount all the

mechanics and electronics into it you need some informations what is the intention of this manual. For the basic mechnical assembly you can also use the classical Diabolo manual. The

assembling technic of the Diabolo and Diabolo S mechanics are very similar. Only the parts

are a little bit different, so there is a part-no. translator attached. This manual was created

to show the special differences of this model including some assembling and justation hints.

Have fun with the assembly and if you have any questions you can send us an e-mail to

info@minicopter.de . We wish you also a lot of fun with the fl ights of your Diabolo S!

Recommended equipment:

Motor: X-Nova 4535-510 4+4 YY1.6 Pyro 850-50L Pyro 750-50/56 BE

Controller: Kosmik 200 Cool14s YGE320HV16s

Servos: Servos like BLS451 with max 18mm from mounting surface to upside servo arm

FBL-System: BD3-(S)X, AC-3X, V-Stabi

Receiver: 2,4GHz

Flight battery: 2x7s/4400/>60C -2x8s/3850/>60C

Receiver battery: 2s/1600-1800/25-30C (alternativly combine with Kosmik BEC on 8,0V)

Rotorblades: DH691 or DH711

These are components we have tested and we can recommend. Of course you can use

compinents from other manufacturers too, but you must decide individually if they are ok

for the Diabolo S or not.

Maintenance and Security

A radio controlled model helicopter and a speed helicopter especially is not a toy. A mistake

can result in serious accidents and injuries. So keep the following rules always in your mind:

1- Start always with an Idle Up 1 of about 1600 rpm and switch up to Idle Up 2 fi rst when the

model is at least 10 metres high and 20 metres away.

2- Fly high speed passes always with a minimum distance of 50 metres / 150 ft to you. No person should be between you and the model (f.e. modelers with cameras).

3- Keep a minimum fl ight height of 30 metres. Nore that reaching extreme speeds you reach

at the blades tips the transsonic area which can result in particulary stalls on the airfoil. To rescue the model you need a minimum height to react and start actions to save the model.

4- Fly with discipline. Do not fl y more passes that you have calculated before. Do never fl y

deep and closed to enlarge the impressions of spectators.

5- Do not fl y with crosswind that press the model in your direction. All aerodynamic bodies,

also the Diabolo S are sensitive against crosswinds and can move cross to you more than you

have expected.

6- Do not go over your personal limit. High speed fl ight needs a lot of training and experience

that you must learn fi rst. With increasing speed you must calibrate your FBL system perhaps

different, modify parametres like headspeed and pitch.

7- Do not fl y faster and only so far away how your eyes allow this. The model can climb after a

pass very fast heights and distances that are diffi cult to observe. So be careful.

8- The most important rule: Do never start if you are not absolutely sure that everything is ok!

Maintenance: The Diabolo S was designed for a high standard reliability and durability. But

that does not mean that you must not do any maintenance. After each fl ight you should do a

check of ALL mechanical parts. Look for loose screws, cables. Check the bearings, gears, all

electric connections, ball joints, antennas.

The second stage gear must be lubricated. Calculate that after each fl ight you must add two or

three drops from the oil bottle that is in the kit. In each casee it may never run dry. Avoid to fl y

in a dusty environment and if you do that then climb up fats from the ground to minimize dust

in the body.

Pitch adjustments: -6°/+5°/+16°

Idle up 1: 1600 rpm Idle up 2: 2200 rpm Idle up 3: Max rpm

Because we cannot control what a modeler is doing with the model we cannot give any warranty.

Vellmar, in February 2014

Part-No. translator Diabolo - Diabolo S

The following parts are similar between both models but not the same. So use this tarnslator to fi nd the right part no. if you need any spare.

D1 upper left side frame D258

D2 upper right frame D259

D14 mainshaft D220

D16 lower mainshaft bearing plate D272

D17 Upper bearings plate D271

D70 First stage bearing D243

D71 Mainshaft bearing D230

D13 Main gear wheel D274

D15 distance bush mainshaft D224

048 washer shim 0,1mm D231

033 washer shim 0,2mm D232

D7 gear wheel fi rst stage D7a

D5 fi rst stage distance bush D195

D4 main gear pinion D275

D21 tailboom D280

D46 tail pulley D249

D43 tail gear housing D246

068 tailshaft bearing D247

D47 distance shim D250

044 washer shim 0,1mm D46

D45 tailrotor shaft D245

D18 roll servo holder D273

D28 vertical U-Profi le D284

D25 belt tensioner arm D261

D34 shock absorber D262

902 landing skids pair D281

D20 distances elevator servo D270

D89 elevator servo screws D83

D23 rear tailservo mounting block D283

D50 swashplate D226

D58 conic distance bush swashplate D233

D104 screw for D58 D102

D91 screw for distance bush D90

D32 distance bush for swash holder D244

D90 screw for D32 D88

D52 mainrotor hub D229

521 feather spindle D235

586 damping insert D236

047 washer shim 0.5mm 757

071 blade grip bearing D238

509 inner grip bush D239

100 thrust bearing D237

052 washer shim feather spindle D242

034 spindle screw D234

538 mainblade grip D240

593 swash driver distance bush D241

110 tailrotor hub D255

979 conic ring D257

1471 tailslider D256

D49 tail bellcrank D264

347 tailslider guidance bush D288

D155 battery plate D269

- Battery plate stopping block D279

The following parts are new and not in the normal Diabolo manual:

D191 support bearing block

D263 holder for D262

D265 L-Profi le left

D266 L-Profi le right

D267 front skid holder

D268 rear skid holder

D276 canopy connector 3.5mm

D277 canopy connector 4mm

D278 triangle plate CF

D285 maingear lubrication oil 60ml

D286 mounting bush Kosmik

D287 battery tray stopping block

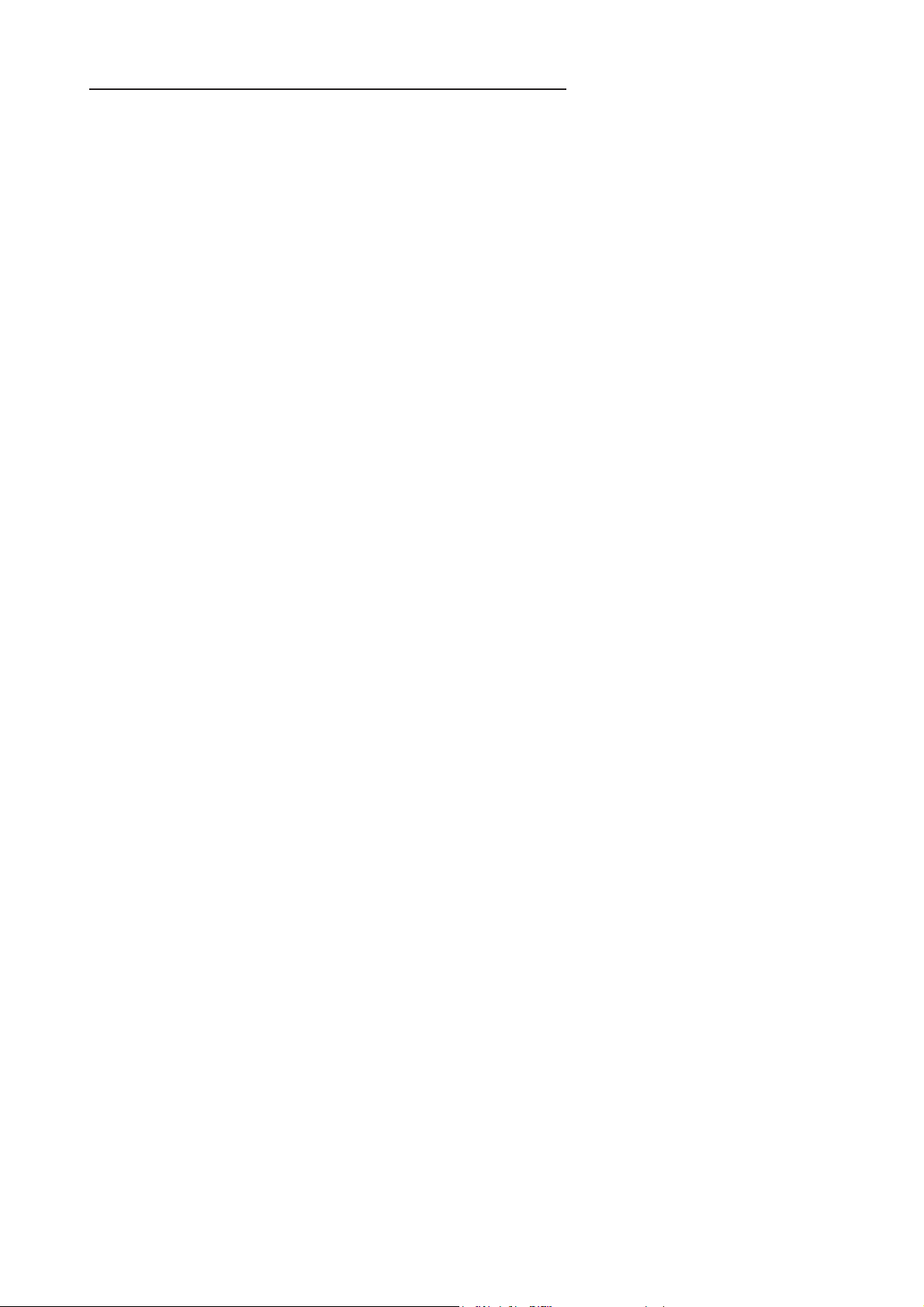

This is the mechanic in

delivery condition.

Remove the battery plate for

the rear fl ight battery.

Remove the roller. Later the

roll servo cables will be placed

between the spacers under the

roller.

Remove the rear tail servo

holder. Do not lose the screw.

Keep both parts together.

Open bag 7 and sort the parts

on the table.

Start with mounting the fl y-

barless system. We recommend to mount it directly on

the U-profi le. On the picture

we mount a Bavarian Demon

HC3X.

Mount the ball joints on the

servo arms using for each

arm a hex lense screw M3x16

D103, two 3mm washers 002

and a M3 lock nut 008. Attach

two rods D54 with four ball

joints D72.

The overall length of both roll

servo rods should be 103 mm

about.

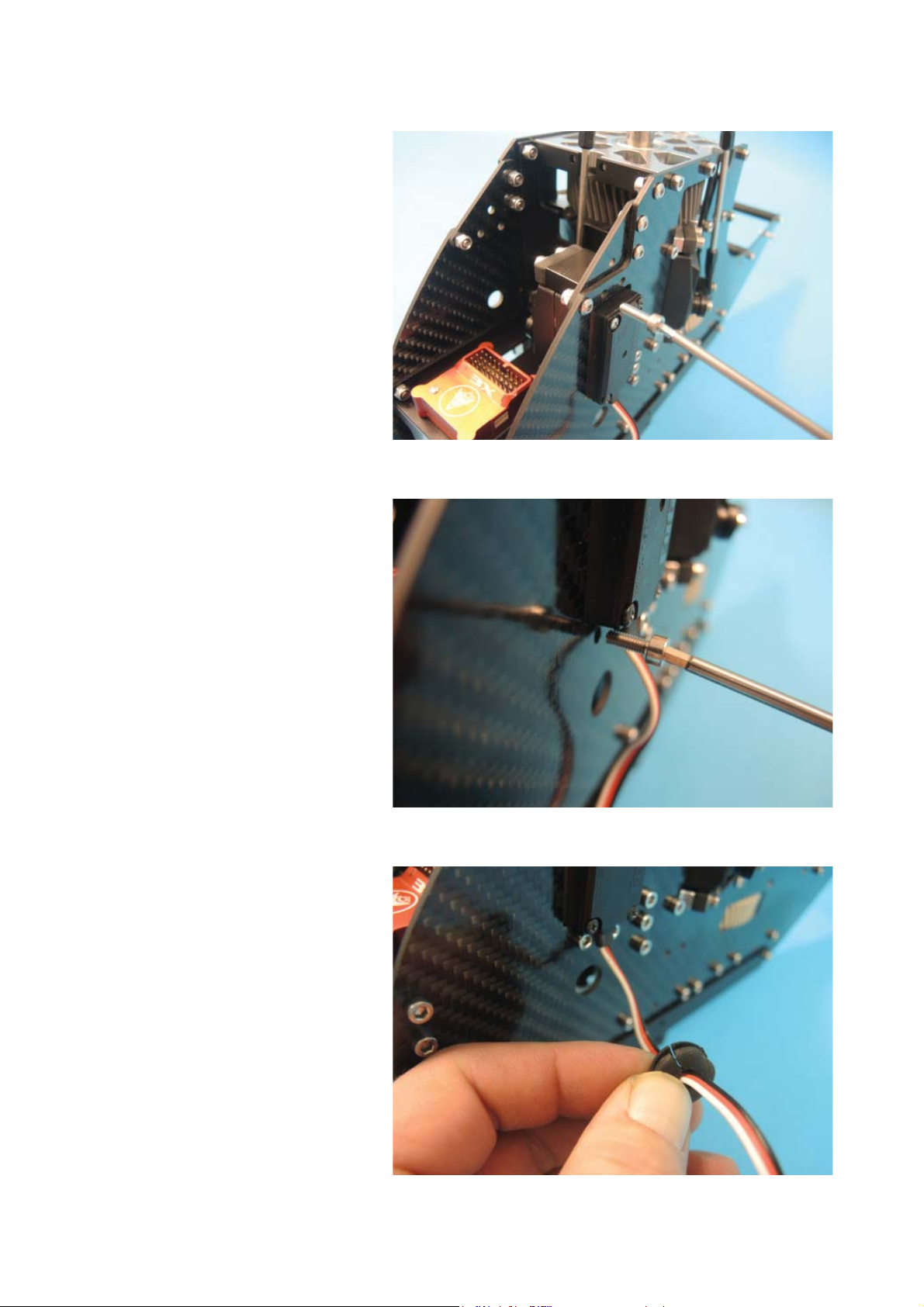

Insert the left roll servo into the

frame. Look that the cable is

going downwards.

Fix the servo with four hex

screws M3x12 D84 and

washers 002 using Loctite

on the screw thread. Do not

overtighten the screws. Then

the thin bushes in the rubber

blocks would be compressed.

Now mount the right roll servo

in the same way.

Look that both cables are

placed as shown.

The screws are easier to

mount if you look before attaching the screws into the hole

to what direction the thread is

going about. The rubber blocks

are elastic so during mount it

is not always guaranteed that

the thread is also in the center

of the bush. After attaching all

screws it will be centered.

Mount the screws using Loctite

on the thread.

Two plastic blocks must be

mounted on the elevator servo

with four hex screw D84 and

washers 002 (use no Loctite!).

Note that the block D270 on

the cable side is 2 mm higher

than the block D299 on the

other side.

Blocks in mounted condition.

Length of elevator servo arm

should be 102.5mm.

The small triangle carbon part

makes it a little bit diffi cult to

insert the servo but a servo like

Futaba BLS451 defi netly fi ts. If

you have problems then loose

for the servo mount the three

lense screws of the triangle a

little bit and tighten them again

when the servo is placed.

Mount the upper block with

two hex screw M3x10 D83 (no

Loctite!). Do not overtight the

threads in the blocks.

For the lower block use two

hex screws M3x8 D82.

Cut the rubber grommet D80

with a knife and insert the servo cable. Then insert the servo

connector into the hole of the

CF frame and fi nally press the

grommet in.

All servo cables should be under the mechanic right now.

Now mount the roller block.

The best is to attach fi rst the

screws and from inside the

spacers. Then add the roll

servo cables between and add

Loctite on the screws threads.

Then add the roller block.

During tightening have an eye

on it that the cables are not

squeezed beteen the contact

planes of the parts. The result (with a contacted impulse

cable) could be sudden movements of the servo arms.

For better identifi cation when

you plug in the connectors in

the fl ybarless system it makes

sense to add a „R“ and „L“ on

the roll servo cables.

Install the cables as shown on

the pic.

The tail servo holders should

be mounted with four hex

screws M3x12 D84 and

washers 002 using Loctite.

Note that the block with the

countersunk hole is placed on

the cable side. The fuselage is

very narrow at this area so a

countersunk screw is necessary there.

Insert the tailservo in the

shown way. A MKS 980 servo

just fi ts into the frame, also

of course the smaller Futaba

BLS 251/256. On the servo

the arm must be attached with

a screw using Loctite. If you

are not sure if the arm is in the

right position on the toothed

shaft then do not mount the

two screws that fi x the servo

mounts on the frame. Tighten

them after FBL calibration, but

do not forget it!

If you are sure the servo arm is

in correct position then add the

countersunk screw M3x12 471

on the rear servo block using

Loctite.

Accordingly mount the front

block with a hex screw M3x14

D85 using Loctite.

Now plug in the connectors

into the FBL system.

Important: After you have

mounted all plugs in the system fi x them with hot glue that

they cannot come out under

vibrations. This suggestion is

independent from the type of

used fl ybarless system.

Press all cable length that is

not necessary under the Uprofi le. There is a lot of space

for cables and the upper side

looks very nice without unnecessary cables.

Attach a piece of double sided

foam (about 3mm or 1/8“) on

the reiceiver.

Place the receiver, here a

Futaba 6303SB, as shown. If

your receiver is bigger you fi nd

alternative places under the Uprofi le, outside the frame or on

the additional gyro platform.

Add now the swashplate body

D226 on the justation help

D289 on the mainshaft.

Mount the left servo rod using

a hex lense screw M3x12

D102 and a conic spacer

D233. For maximum safety

here add righ Loctite on BOTH

threads and remove unnecessary Loctite at once.

The swash plate guidance is

made from a hex screw M3x25

D90, a brass spacer D55 and

a conic bush D233. Add also

with rich Loctite on both ends.

Check that brass bush is moving free in the guidance after

tightening the screw.

Add the swash guidance D32

using two hex screws M3x25

D90 and two spacers D244

using Loctite.

Have a fi nal check that the

swash guidance is parallel to

the mainshaft.

Now prepare the rotorhead.

Open bag 8 and sort the parts

on the table. The big washer

shims are not necessary and

only added for individual tightening of the spindle.

The length of the linkages is

about 62 mm.

Attach the linkages on the

arms with two hex lense

screws M3x12 D102 using

Loctite. Note that the joint with

the left thread (marked with a

small ring) is upwards (mounted on the blade arm).

Add the two joints bolts M3x4

076 on the swashplate using

Loctite.

Mount the swashdriver arms

D65 as shown in the pic using

Loctite. The screw for mounting on the hub is a hex lense

M3x10 D101 with a washer

3x6x0.2 455, the outer one is

a M3x12 D102 that is screwed

into the bush D241. Finally the

joint 385 is fi xed with a cross

screw M2.5x12 509 (no Loctite!). Finally mount both units

on the hub using Loctite.

Put the rotorhead on the

mainshaft. Do not forget to

loose the two black M3 screws

in the hub before.

Fix the rotorhead with a special

M4 jesus bolt M4 D78.

Tighten both black screws

M3x12 D119 using Loctite.

After tightening you can press

the links 385on the joint bolts

076.

Mount the linkages on the

swashplate using hex lense

screws M3x12 D102 using

Loctite.

Now the mechanic should be

in the shown condition. We

continue with the motor mount.

Open bag 6 and sort the

screws on the table. Dependend from the motor type

(some motors need very short

M4 screws there are two

lengths included. If possible

use always the longer ones.

Mount the motor using four M4

hex lense screws- Note that

the rounded contour of the

motor carrier is showing to the

front.

Attach the pinion on the motor shaft. The delivered pinion

is normally 20T with 6mm

shaft. There are also pinions

with 8mm hole available, also

pinions from 15-22T with 6mm

shaft and from 18-22T with

8mm shaft. If the motor shaft

has no fl at spot then add one

at the end of the shaft (mark

the position before, pinion

should be 0.5-1mm away from

the lower motor carrier plane).

Tighten now the grub screws

M4x5 D35, beginning with the

one on the fl at spot.

Now install the motor using

four hex screws M3x8 and

washers 3mm 002 using Loctite. The plastic gear wheel is a

high temperature high tech polymer that is uncritical against

any heat. You should feel a

small but noticable play between pinion and gear wheel.

For 21 or 22T pinions you must

fi le the long holes 0.5 or 1mm

to the front using a needle fi le.

During mount press the motor

down that it is really vertical.

Now the mechanic should be

in this condition.

Remove from the front end of

the tailboom with a fl at fi le a

part of the anodizing as shown

on the picture. This is necessary to eliminate electric noise

from the belt.

Now press the boom carefully

in.

Look that all cables are between boom and U-profi le and

that no cable will be hurt when

you insert the boom into the

front clamp.

Adjust the boom that it is some

millimetres out of the front

clamp.

Now insert provisorically the

brackets into the tail housing to

fi nd the right orientation of the

boom for tightening.

Remove the rubber band.

After pulling the belt thru the

boom with a long wire with

bended end put on the tailrotor

housing that the screws of the

brackets fi t fully in the slots of

the boom. Lokk in the housing

that the brackets are vertical. If

not yet then open the screws a

bit more.

Insert the tail pulley into the

belt from the side that has no

washer yet and put it into the

tail housing.

Now put the tailshaft D245 in

and look that the belt is positioned completey on the pulley.

Tighten the belt pulling the

tailboom outwards. Note that

on the Diabolo S there is not

much tail thrust necessary and

on the other hand the power

lost of a too much tightened

belt should be as low as possible. So do not tighten the belt

too much. Pull with about 2

kgs / 4lb. After fi nding the best

position tighten the screws in

the boom clamps (Loctite!) and

then tighten both lower right

clamp screws.

Finally attach the tail servo rod

in the usual way that is shown

in the Diabolo manual. Note

that the length of the rod is

here some mm longer than in

the Diabolo.

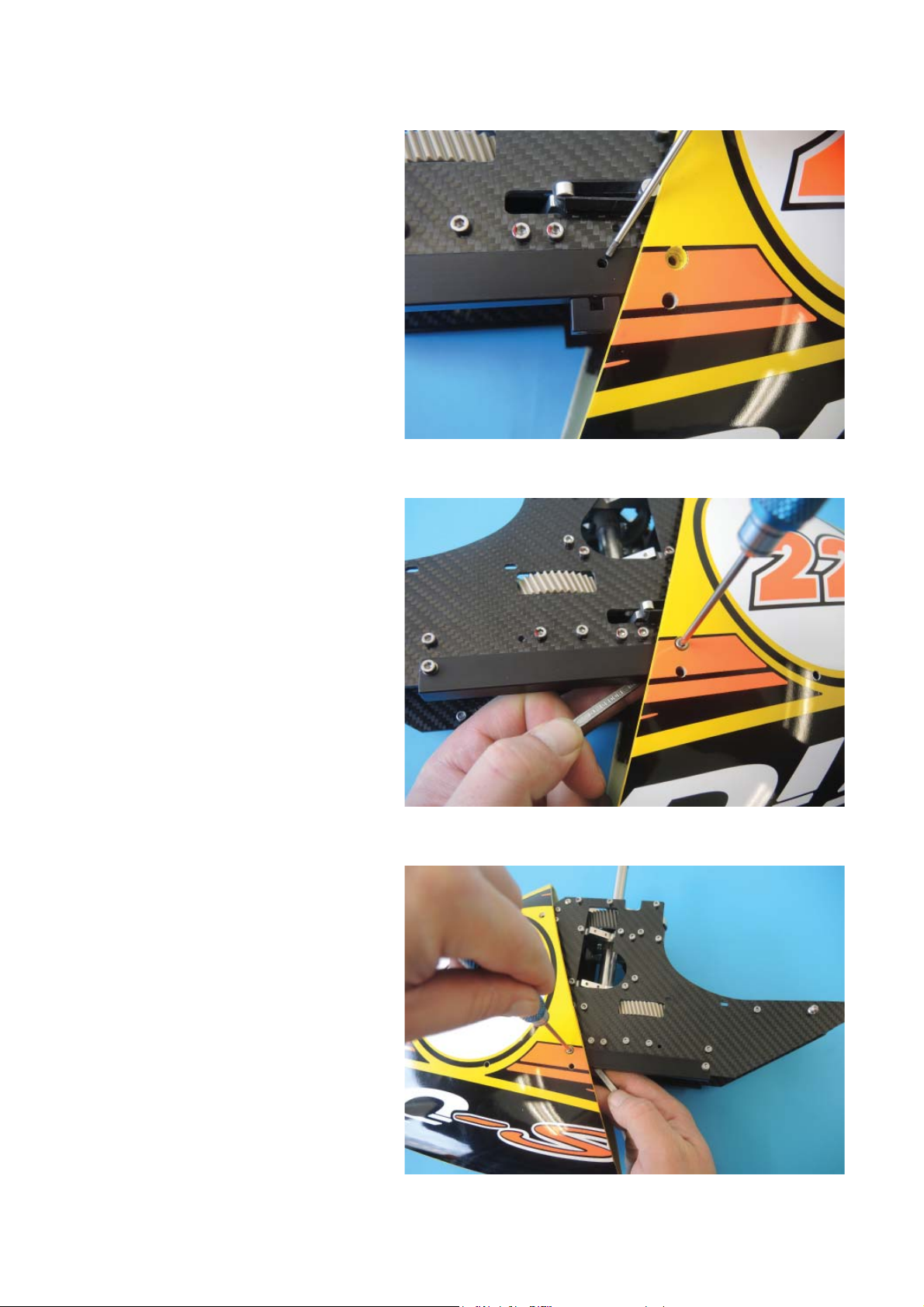

Fuselage mount

Pull the tailbelt thru the boom

(a wire with a bended end

works best). Remove with a

fi le or sanspaper the black

anodizing a little bit at the front

end so that there is an electric

contact between frame and

boom. Insert the boom with the

clamp into the frame.

Attach the screws for the tailboom clamps with Loctite 243.

Tighten the lower right screws

fi rst when you have tightened

the long screw D93 in the

boom clamps.

Now press the boom careful in

the fuselage tail. Look that the

foam on the boom will newhere be damaged. This foam is

necessary to eliminate noisy

resonance vibrations from

the fuselage. Note that the fi t

between fuselage and mechanic was factory tested and so

you should use no force for the

mount.

The lower left mounting screw

must correspond with this hole.

In the pics only the preassembled mechanic is shown. Of

course you must fi nish the me-

chanic fi rst before you insert it.

Also it is highly recommended

to make the fi rst tests and jus-

tations with naked mechanic.

If the holes are concentric then

use for the mount a hex screw

M3x12 and a lock nut M3.

Look that all electric cables

are free and no mechnical

part is touching the fuselage.

Start as shown with the lower

left screw. Do not tighten the

screw too much. Note that there is wood between that could

be unneccesary compressed.

Now do the same procedure

with the lower right screw.

Then attach the upper right

screw. To get the holes concentric you must press now the

end of the boom to the upper

end of the fuselage (compress

the foam).

Finally mount the upper left

screw.

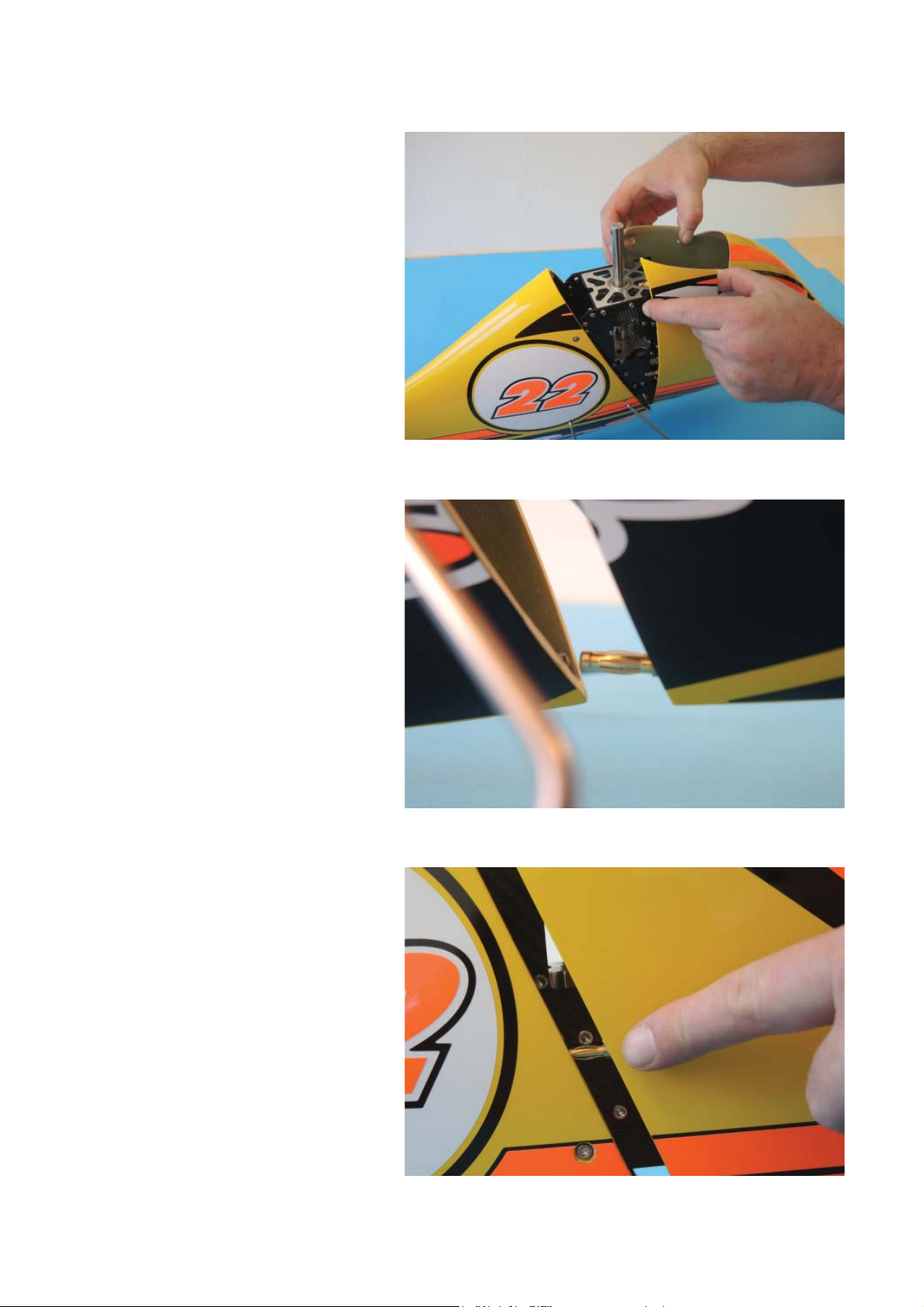

When you mount now the

landing bows be careful that

you do not scratch the surface

of the fuselage. To minimize

this risk press fi rst the wire

into the front hole. Look before

that holes in the fuselage and

landing bow holder under the

mechanic are corresponding. If

not then open the four fuselage

mounting screws again and

press the fuselage a little bit in

teh right direction. Alternatively

you can widen the hole with a

thin needle fi le.

Now turn carefully the wire

and look that you do not make

scratches on the fuselage. A

bit of masking tape can help to

avoid this.

Now, holding the front end in,

press the rear end into the

slot. Take care that the hole

in the fuselage and in the rear

skid holder of the mechanic

are corresponding. Press the

skid as long in as the radius

is reached. If you look from

inside the skid should end

exactly at the inner edge of the

skid holder. If not then move it

as long if this is the case.

Then tighten the rear grub

screws using Loctite 243 with

a long 2mm hex driver. Take

care that the landing bow wire

is not coming out of the block.

The batteries could be damaged from it.

Tighten now the front screws

using also Loctite 243.

The tailgear mount is different

to the normal Diabolo because

you have no access to the

boom clamps. So you must

tighten the mechanic correct

before you insert it into the

fuselage (we have done this

for you). For easier mount now

remove the rubber ring from

the belt tensioner. Take care

that the belt is in the correct

orientation (90° to the right

from parallel belt position).

Note that the tailgear must

be ready assembled with

bellcrank and fi n (not as

shown). The tightening blocks

D43a must be mounted and

the screws attached with Loctite 243. Now press the gear

housing on and look that you

feel an and (where the boom

has contact with the end of the

inner housing).

Tighten the screws, look inside

that they are parallel together

and that the tail fi n is parallel to

the mainrotor shaft.

To mount the belt wheel the

right washer shim of the wheel

(on the side without grub

holes) must be removed. Then

put it in over the belt (Careful!

Do not damage the belt).

Add the washer shim (side with

the cone to the left/belt side).

Have a look that you use the

correct holes and not the holes

that are used from the other

washer shim.

Then tighten the washer shim

using three lense screws M3x6

D99 and Loctite.

Now add the small special

washer that fi ts exactly in your

tail housing. Do not loose it.

It was made induvidually. To

be on the safe side you can

measure the shim with a digital

caliper and if you later would

loose it we can turn a new one

for you that fi ts perfect too.

Then add the tailshaft and

tighten it with two grub screws

M4x4 #573. The shaft end is

corresponding with the outer

end of the left bearing.

For mounting the front canopy

widen the upper rear end and

move the front part over the

mechanic. Look that you do

not hurt any cable.

For mounting the front part

the slot between the fuselage

part must be ALWAYS parallel

and all the fi ve connector pairs

must correspond together.

Note that we have spent many

time that it fi ts perfect, so you

need also time and patience to

mount it (removing it in panic

situations is much faster).

If you would ever damage a

spring cage of a male connector you can use a normal

4mm connector #1964 and

must simply remove the spring

with your thumb nails and then

press it carefully onto the front

bolt.

It is necessary for high speed

fl ight to attach about 6“/15cm

of clear tape on each side

before each fl ight. During turns

with zero forward speed the

front fuselage could else be

opened a little bit what is reducing speed.

The slot between the two fuselages parts should be nearly

zero now.

For easy removal of the tape

turn the lower 5mm about that

they are free from the fuselage. So in urgent situations the

stripes can be removed within

one second each.

Loading...

Loading...