Page 1

INSTALLATION GUIDE – WALL-MOUNTED CONVECTOR NK2

1. UNIT DESCRIPTION

A wall-mounted NK2 heating unit equipped with fans.

Since the heater fully uses physical laws of thermodynamics it represents one of the most effi cient methods

of interior heating.

Benefi ts of heating convectors:

High output

Silent operation or low noise for units with fan

Lightweight compared to heating units with similar

output which use radiation principle

Low hot water consumption

Short response time

Design

Minimum requirements for operation and mainte-

nance

A great advantage of these convectors is the small

required installation space. This is benefi cial par-

ticularly in a situation where the heating units are

used in interior renovation and replacement of old

heaters with new ones and in situations where

suffi cient heating output is required.

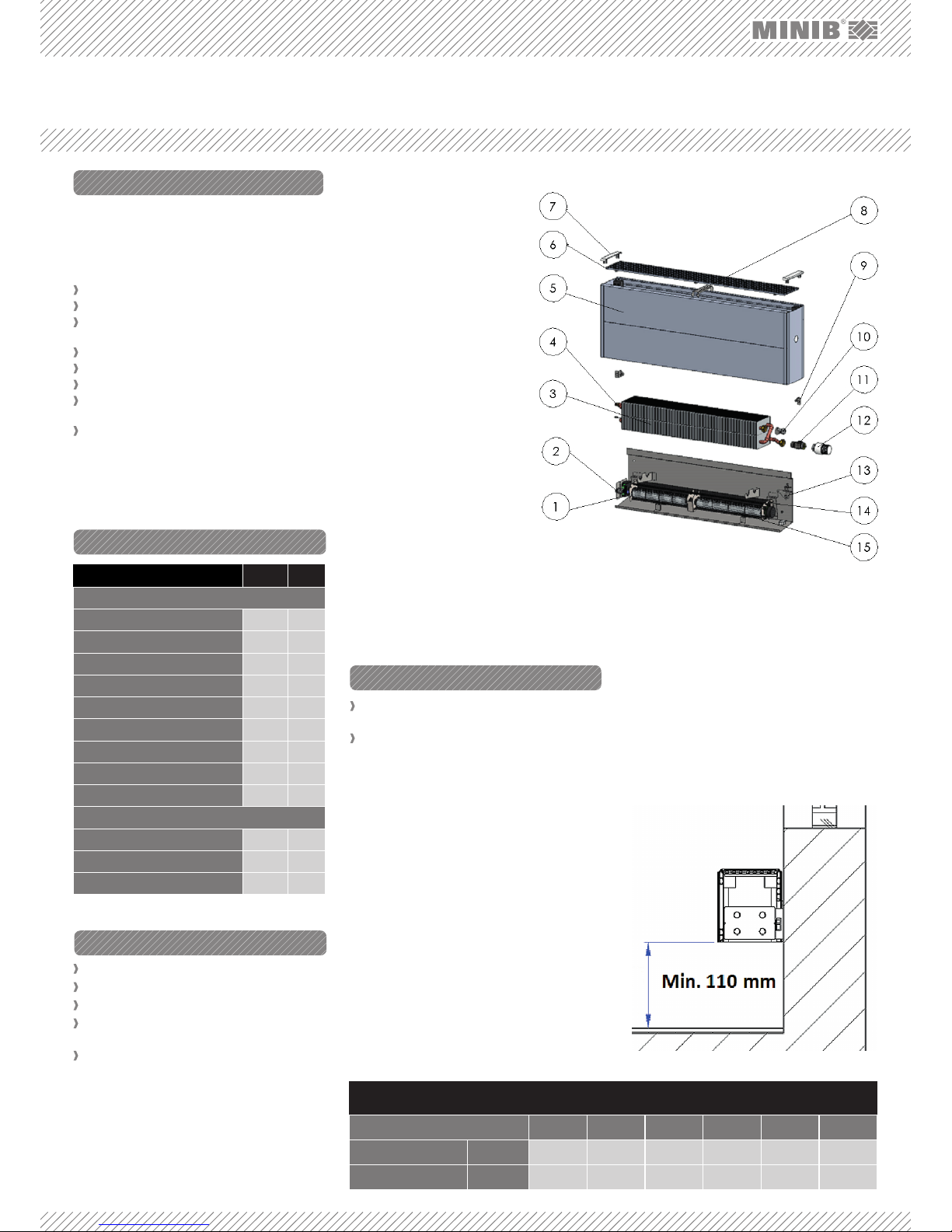

Contents of the box Position NK2

Convector

Plastic cover

7 2

Grille

6 1

Convector body

5 1

Support member

13 1

Heat exchanger

3 1

Grille reinforcement

8 1

Cable grommet

2 1

Fan

15 1-2

EB control unit

1 1

Accessories

Axial radiator valve 11 1

Thermostatic head 12 1

Control Screw fi tting 10 1

3. TECHNICAL PARAMETERS

Use: dry environment, according to the specifi cation.

Maximum operating pressure: 1 MPa.

Maximum operating temperature: 110 °C.

Operating medium: water. Water may not be mixed

with other substances, such as antifreeze fl uids!

Environment: interiors with temperatures ranging

between +5 °C and +40 °C.

1. EB CONTROL UNIT – fan motor control unit.

2. CABLE GROMMET – intended for cable installation

to the control unit.

3. HEAT EXCHANGER – copper pipes with pressedon aluminum fi ns through which the heating water

fl ows.

Each position in the table corresponds to Figure No. 1.

Select the correct convector type from the cata-

logue – see paragraph 4.1.

Select the correct convector position and location

– see paragraph 4.2.

4.1 Suitable Convector Type

Decide whether the convector will act as the main

source of heat, or an additional heating element or, as

the case may be, as a heat barrier.

As the main source of heat in your apartment /

room, the convector should suffi ciently cover the

entire thermal loss of the room. Therefore, always

choose a heating unit with a capacity that is higher

than the thermal loss of your apartment, room, or

other areas.

All wall-mounted convectors are designed for dry

environment. A dry environment is an environment

where the average annual relative humidity does

not exceed 75%. A wet environment is an environment where such average annual value is equal to or

greater than 75% or where the convector is exposed

to direct contact with water. In terms of convector

selection, a dry environment is in general any environment where no precipitation of vapor occurs in the

convector unit.

FIG. 1: COMPONENTS AND DESCRIPTION

OF THE PARTS OF THE CONVECTOR

Design of the heat exchanger

differs depending on the convector model.

4. AIR VENT VALVE – used for

venting (bleeding) the convector.

5. CONVECTOR BODY – aluminum

convector body.

6. CONVECTOR GRILLE – a design

piece within the convector. It

must not be covered!!!

7. PLASTIC COVER – used for

attaching the grille to the convector body.

8. GRILLE SUPPORTING MEMBER – for supporting the convector grille.

9. ADJUSTING SCREW – used for

vertical positioning of convector on the wall.

10. CONTROL SCREW FITTING –

a valve that controls / adjusts

the heating water fl ow.

11. AXIAL RADIATOR VALVE –

a valve used for fl ow regulation.

12. THERMOSTATIC HEAD – used

for manual regulation.

14. RUBBER ANTI-VIBRATION PAD – for fl exible

mounting of the fan module.

15. FAN – used for forced convection.

13. CONVECTOR SUPPORT MEMBER – a fi xing part of

the wall-mounted convector, supporting part for

the convector body and heat exchanger.

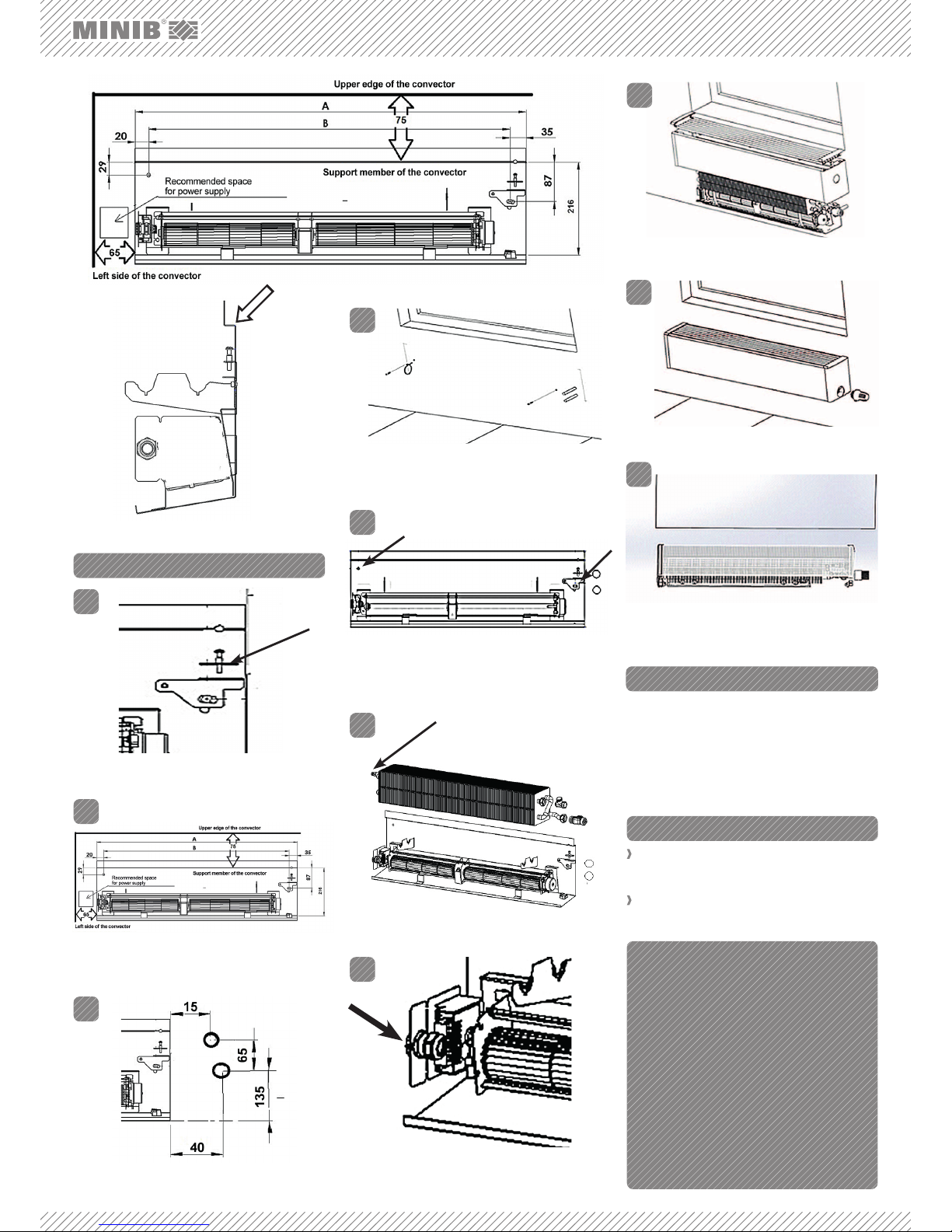

4.2 Convector Position

Wall-mounted convectors MINIB are intended for installation on the wall below window frames or sills.

Make sure to follow the principle that the distance

from the fl oor should never be less than 110 mm (Figure 2). Never cover the upper grille of the convector this would result in fl ow reduction and a considerable

decrease in the convector output.

2. CONTENTS OF THE BOX

4. BEFORE INSTALLATION

FIG. 2: For all models – convector position.

Dimensions for marking of mounting holes

Convector length 900 1 000 1 250 1 500 1 750 2 000

NK2

A 760 860 1 110 1 360 1 620 1 860

B 706 804 1 054 1 304 1 564 1 804

Page 2

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Connect the lines using the supplied standard accessories. An axial radiator valve is connected to the water

inlet of the heat exchanger. Control fi tting connected

with the outlet line via fl exible hose is to be installed on

the outlet line. Insert O-rings between the axial radiator valve / control fi tting and the heat exchanger. Use

gaskets for all the other connections.

6. CONNECTION OF THE FITTINGS

HEAD OFFICE

MINIB,a.s.

Střešovická 465/49, 162 00 Prague 6

Czech Republic

Tel.: +420 220 180 809, Fax: +420 220 180 779

E-Mail: export@minib.cz, www.minib.cz

PRODUCTION

Manufacturing plant of MINIB,a. s.

Býkev u Mělníka 84, 276 01 Býkev

Czech Republic

WWW.MINIB.CZ

7. VENTING THE UNIT

FIG. 4: Screw the adjusting stop dog of the supporting member

to a central position.

FIG. 5: Follow the instructions and installation dimensions

specifi ed in paragraph 4.2. in Fig. 3. Mark holes for screw

anchors and for the connection of the power supply cable, if

applicable (for models with a fan).

FIG. 6: Mark the position of the pipes. The upper pipe is the

outlet, the lower pipe is the inlet.

FIG. 7: Drill holes for fi xing, for the pipes and the power supply

cable, install screw anchors.

FIG. 8: Using the screws, attach the support member in the

prepared screw anchors on the stop dog and on the opposite

end. Do not tighten. Adjust the support member into horizontal position using the adjusting stop dog, tighten the screws.

FIG. 9: Position the heat exchanger on the supports, install the

pipes and connect valves as specifi ed in paragraph 6.

FIG. 10: Connect the cable through the grommet into the

control unit according to instructions and the type of control

selected. Check the function of the fan.

FIG. 11: Place the body, the grille

and the covers on the convector support member.

FIG. 12: Connect the thermostatic head.

FIG. 13: Set the axle alignment of the unit cover with the wall

using the adjusting screws which are located in the lower

part of the convector body.

FIG. 3a: Upper edge of the NK2 supporting member - side view.

5. INSTALLATION

› Vent (bleed) the unit using the air vent valve dur-

ing the fi rst use as necessary. The air vent valve is

located on the heat exchanger – see Fig. 9.

› For additional options see the catalog or visit:

http://www.minib.com/

FIG. 3: NK2 (for upper edge see Fig. 3a).

Air vent valve

Loading...

Loading...