Page 1

INSTALLATION GUIDE – LP CONVECTORS

3. TECHNICAL PARAMETERS

4. BEFORE INSTALLATION

Use: dry environment

Maximum operating pressure: 1 MPa.

Maximum operating temperature: 90 °C.

Operating medium: water. The use of other media

is prohibited. Water may not be mixed with other

substances, such as antifreeze fl uids!

Environment: interiors with temperatures ranging

between +5 °C and +40 °C.

Maximum panel loading: 150 kg.

Contents of the box LP 1000 LP 1250 LP 1500

Convector

Convector body 1 1 1

Convector supporting

frame

1 1 1

Heat exchanger 1 1 1

Top panel – GRANIT

1 1 -

Top panel – ALL-WOOD

(BEECH)

1 1 1

Accessories

Axial radiator valve

1 1 1

Thermostatic valve

1 1 1

Screw fi tting – angular ½´´

1 1 1

O-RING 18X2 NBR70

2 2 2

Large anti-vibration

mounting

6 6 6

Base 6 6 6

Wood screw 3.9x30 6 6 6

Screw M6 x18 4 6 6

Screw anchor No. 10 4 4 4

Wood screw 6x50 4 4 4

VALVE CONNECTION

TEMPLATE

1 1 1

1. UNIT DESCRIPTION

2. CONTENTS OF THE BOX

A free-standing heater which uses the convection

heating principle. Since the heater fully uses physical

laws of thermodynamics it represents one of the most

effi cient methods of interior heating. The convector

can be equipped with stone or a wooden panel.

Benefi ts of free-standing LP convectors:

High output

Radiating component of thermal output in case

of stone panel usage (lengths 1000 and 1 250 mm

only)

Silent operation

No need for additional energy supply

Low water consumption

Very short response time

Design

Minimum requirements for operation and mainte-

nance

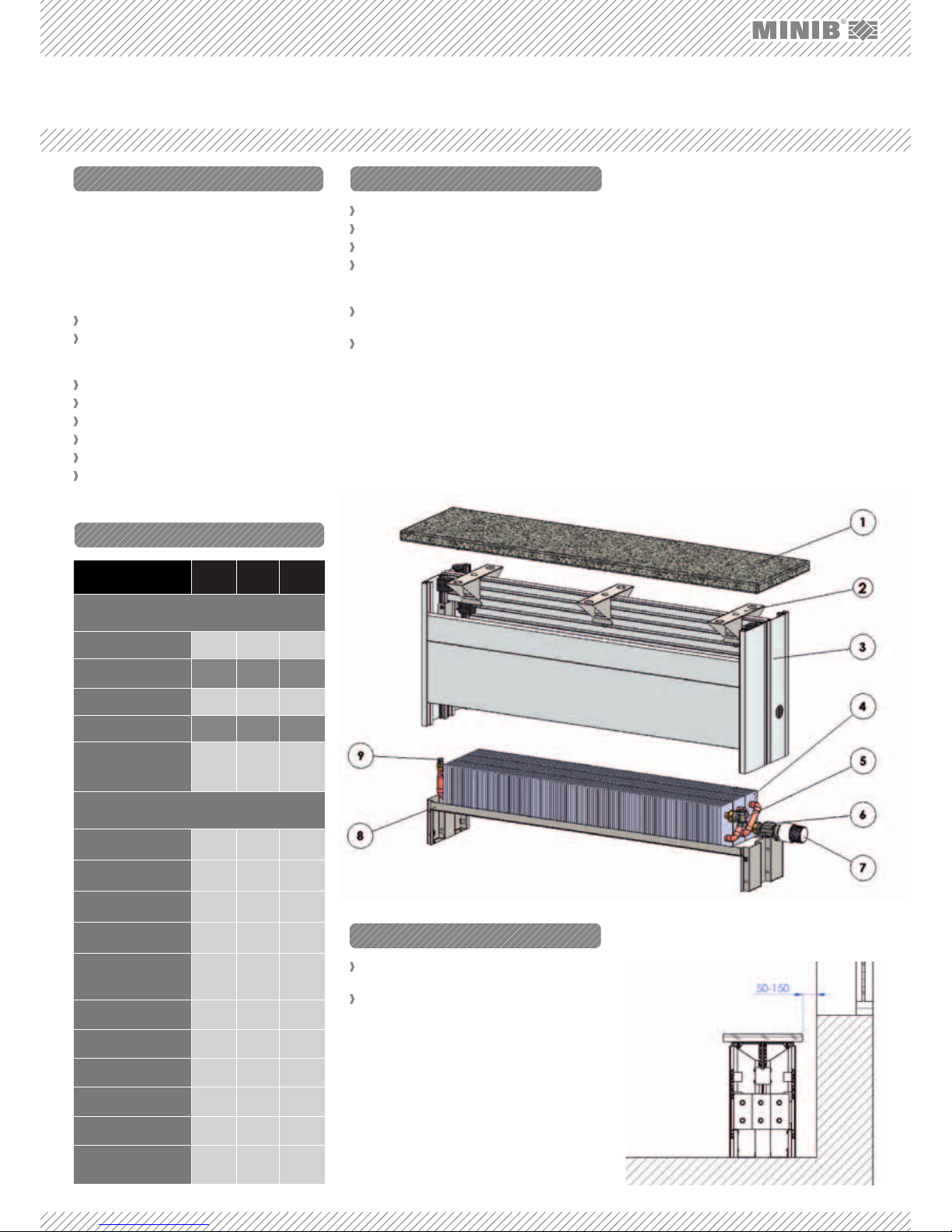

1. TOP PANEL – design element protecting the convector outlet. (wood or granite).

2. CONSOLE OF THE CONVECTOR PANEL – used for

convector mounting.

3. CONVECTOR BODY – aluminum convector body.

4. HEAT EXCHANGER – assembly of copper pipes

with pressed-on aluminum fi ns through which the

heating water fl ows.

5. CONTROL SCREW FITTING – a valve that controls/

adjusts heating water fl ow.

6. AXIAL RADIATOR VALVE – a valve used for fl ow

regulation.

7. THERMOSTATIC VALVE – used for manual regulation.

8. BEARING PIECE OF THE CONVECTOR – Convector supporting frame, bearing piece for convector

body and heat exchanger.

9. AIR VENT VALVE – used for venting (bleeding) the

convector

Select the correct convector position and location

– see paragraph 4.1.

In terms of manufacturing, there is no difference

between left and right connection. It is achieved

by rotating the entire unit.

4.1 Convector Position

The free-standing DP convector made by MINIB is to

be fl oor-mounted. Place the convector so that it does

not disturb the overall aesthetic experience of the

room. We recommend leaving a 50–150 mm space

between the convector and the wall – Figure 2. Never

cover the bottom and top outlet grille of the convector

– this would result in fl ow reduction and a considerable

decrease in the convector output.

FIG. 1: COMPONENTS OF LP CONVECTOR

FIG. 2

Page 2

TEMPLATE

TEMPLATE

TEMPLATE

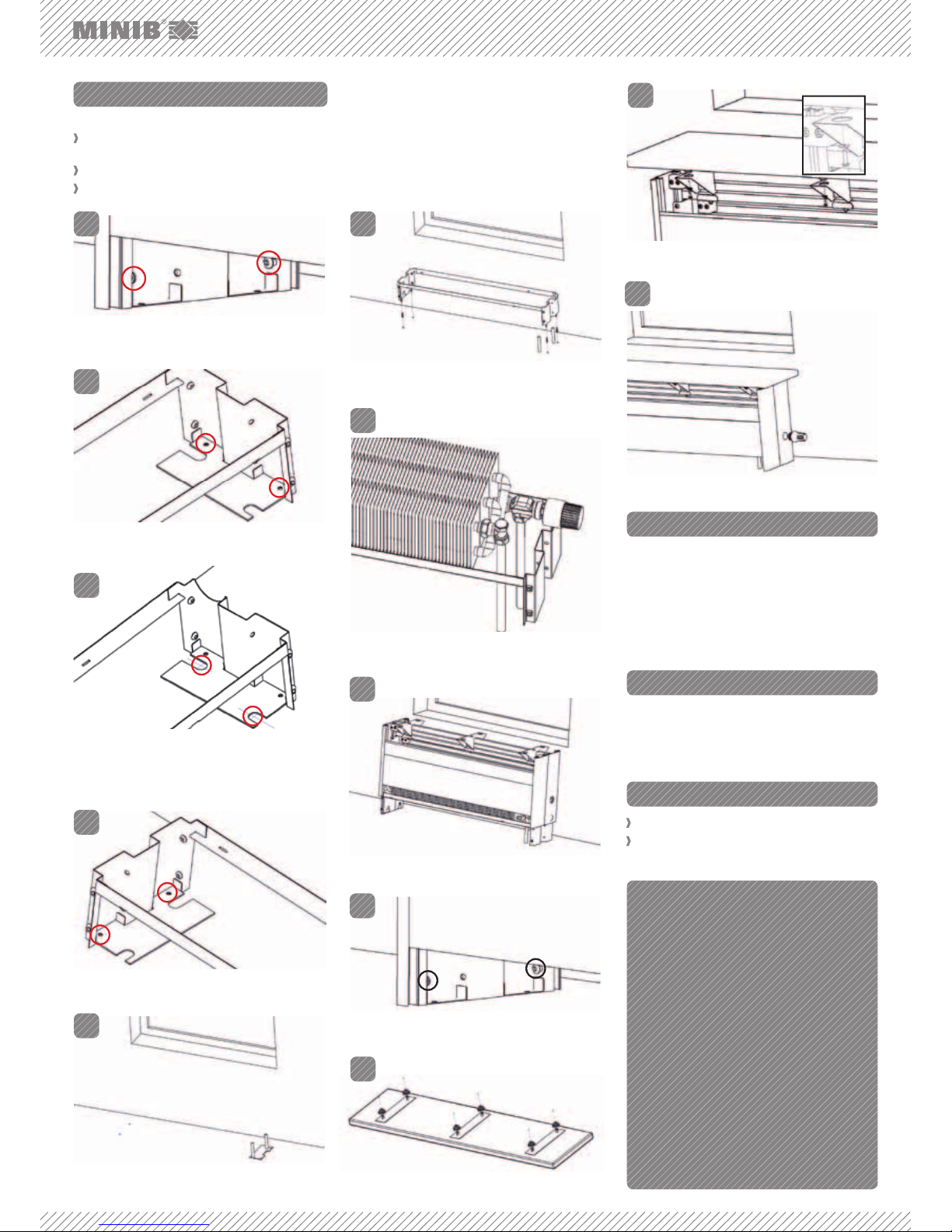

FIG. 3: Loosen screws on both legs of the convector body

and remove the top cover. (do not remove the screws

completely!!!).

FIG. 8: Insert the screw anchors and fi t the convector bearing

frame. Fix the convector with screws.

FIG. 14: Connect the thermostatic valve.

FIG. 9: Fit the heat exchanger and connect the fi ttings – see

paragraph 6. Test fi tting connection tightness.

FIG. 10: Replace the top cover on the convector frame.

FIG. 11: Tighten the screws on convector legs.

FIG. 12: Place the rubber anti-vibration rings on the panel.

FIG. 13: Attach the panel to the convector body.

FIG. 4: Remove the convector body. Adjust the convector

bearing frame to the required position. Mark the holes for

convector fi xing in the fl oor.

FIG. 5: Mark the heating water pipe position and the return

pipe position on the fl oor. The supply pipe leads toward

the bottom outlet of the heat exchanger. This is where the

thermostatic valve is installed. The control screw fi tting is

installed on the outlet – top pipe.

FIG. 6: Use the template to mark the convector fi xing holes

also on the opposite side.

5. INSTALLATION

Please read the following instructions before you start.

Plan the exact position of the heating water distribution layout before installation. The template which is included in

the accessories of the LP convector is to be used for determination of the exact position.

Fix the LP convector using the supplied mounting accessories.

A correctly installed convector is in horizontal position and fi rmly supported along the entire width of the leg.

6. CONNECTION OF THE FITTINGS

Connect the fi ttings using the supplied standard accessories.

Connect the individual inlet and outlet valves. The axial

radiator valve is connected to the water inlet point into

the convector. The control screw fi tting is installed on the

outlet pipe. Insert the O-rings between the axial radiator

valve / control screw fi tting and the heat exchanger.

HEAD OFFICE

MINIB, a.s.

Střešovická 465/49, 162 00 Prague 6

Czech Republic

Tel.: +420 220 180 809

Fax: +420 220 180 779

E-Mail: export@minib.cz, www.minib.cz

PRODUCTION

Manufacturing plant of MINIB, a. s.

Býkev u Mělníka 84, 276 01 Býkev

Czech Republic

WWW.MINIB.CZ

8. OPTIONAL ACCESSORIES

Granite panel

Wooden board (beech – natural varnish)

7. VENTING THE UNIT

Vent (bleed) the unit using the air vent valve during the

fi rst use as necessary. The air vent valve is located on

the opposite side of the heating water inlet/outlet on

the heat exchanger pipe.

FIG. 7: Install the supply and return pipes in the fl oor and drill

the holes for attaching the convector to the fl oor.

1. 6.

7.

8.

9.

10.

2.

3.

4.

5.

11.

12.

Loading...

Loading...