Page 1

INSTALLATION GUIDE – WALL-MOUNTED DESIGN CONVECTOR GS

1. UNIT DESCRIPTION

Design wall-mounted GS convector with a face cover

panel. The glass panel can be removed from the convector body. The stainless steel body of the convector

is equipped with adjusting screws in the lower part of

the back side which are used to compensate for the

deflection from the wall.

3. TECHNICAL PARAMETERS

4. INSTALLATION AND FIXING OF THE UNIT

Table 1: Dimensions for drilling.

1 000 1 250

A B A B

GS 280 772 198 1 022 198

GS 360 772 288 1 022 288

GS 480 772 385 1 022 385

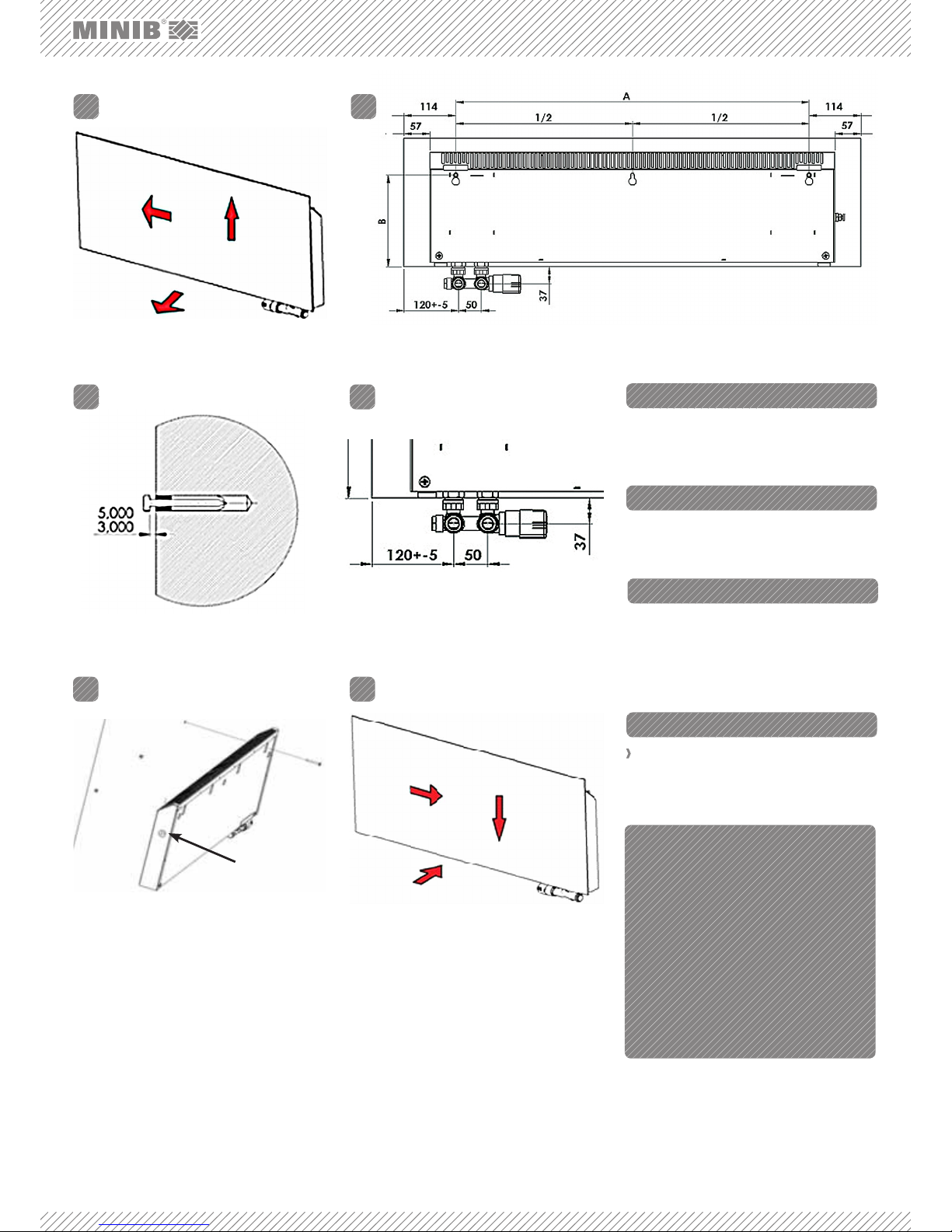

FIG. 1: GS CONVECTOR – REAR VIEW

1. CONVECTOR BODY – supporting member of the

convector parts (heat exchanger, valves and front

panel).

2. COVER PANEL – a design piece within the convector – GS glass.

3. AIR VENT VALVE – used for venting (bleeding) the

convector.

4. ANGLE VALVE DUO – a valve used for flow regulation.

5. THERMOSTATIC VALVE – used for manual regulation.

6. FIXING HOLES – for attaching the convector to the

wall.

GS design convectors are to be mounted on the wall or a partition wall with adequate load-bearing capacity with vertical positioning using the adjusting screws located in the

lower part of the back side of the convector body. The accessories include fixing screws for attachment. Standard dimensions of the GS convector: Height 280 mm, 360 mm

and 480 mm; length 1 000 mm and 1 250 mm.

Read the installation instructions before the installation. Attach the unit to the wall using the screws and

screw anchors from the accessories supplied. Hang

the unit using the holes cut out in the back side of the

stainless steel body of the convector.

Benefits of the GS design convector:

Possibility to choose your own design from the

MINIB catalogue

High output

Silent operation

Low hot water consumption

Minimum requirements for operation and mainte-

nance

Use: dry environment, according to the specifica-

tion.

Maximum operating pressure: 1 MPa.

Maximum operating temperature: 90 °C.

Operating medium: water. Water may not be mixed

with other substances, such as antifree¬ze fluids!

Environment: interiors with temperatures ranging

between +5 °C and +40 °C.

2. CONTENTS OF THE BOX

FIG. 2: Dimensions for drilling, rear view.

Page 2

1

2

3

Air vent valve

3

2

1

1.

3. 4.

5. 6.

2.

5. CONNECTION OF THE FITTINGS

6. VENTING THE UNIT

7. HANGING OF THE PANEL

8. OPTIONAL ACCESSORIES

WWW.MINIB.CZ

The convector is terminated with a female ½“ Euro

thread. In the GS convector it is used for connecting

the Duo angle valve. For additional options see the accessories table.

Vent (bleed) the unit using the air vent valve during the

first use as necessary. The air vent valve is always located on the side of the heat exchanger – see Figure 7.

For the sake of easier access we recommend hanging

the front panel after the unit has been vented. Install

the glass front panel back to the fixed convector body

with the connected heat exchanger. Fit the panel locks

in the locks on the convector body according to the

sequence of the arrows on Figure 8.

GS front panels: selection of panels and sizes

according to the MINIB catalogue

› For additional options see the catalogue or visit:

http://www.minib.com/

HEAD OFFICE:

MINIB,a.s., Střešovická 465/49, 162 00

Prague 6, Czech Republic

Tel.: +420 220 180 780, Fax: +420 220 180 779

Email: office@minib.cz, www.minib.cz

PRODUCTION

Manufacturing plant of MINIB, a. s

Býkev u Mělníka 84, 276 01 Býkev

Czech Republic

FIG. 3: By holding it by the edges remove the glass panel from

the convector body following the direction of the arrows

pictured.

FIG. 5: Install the 6 x 50 screws with anchors in the holes. Do

not tighten the screws.

FIG. 6: Measure the inlet and outlet of the heating line accor-

ding to Figure 2.

FIG. 7: Hang the unit, check whether it is installed horizontally,

and slightly tighten. Compensate the deflection, if any, from

the wall using the adjusting screws located in the lower

part of the unit, and finally tighten. Connect the valves to the

heating line. Fit the thermostatic valve.

FIG. 8: Place the glass panel onto the supporting member.

Follow the sequence of the arrows.

FIG. 4: Measure and mark the points for drilling the holes for the fixing screws according to the dimensions on Fig. 2 and Table1.

Loading...

Loading...