miniature aircraft MA1033, MA1033-1 Assembly Instructions Manual

s

A

e

s

b

m

y

l

n

I

t

s

u

r

t

c

o

i

s

n

Gas

Helicopter Kit

MA1033 Flybar

MA1033-1 Flybarless

Step up to excellence with X-Cell

Table of Contents

Kit Introduction .................................................................................................................................. 3

R/C Helicopter Safety ........................................................................................................................ 3

Warning ...................................................................................................................................................3

General Guidelines .................................................................................................................................

Academy of Model Aeronautics (AMA) ...........................................................................................4

Kit Assembly ...................................................................................................................................... 5

Required Tools ........................................................................................................................................5

Other Required Components ..................................................................................................................

Assembly Tips ................................................................................................................................... 6

Kit Contents ....................................................................................................................................... 7

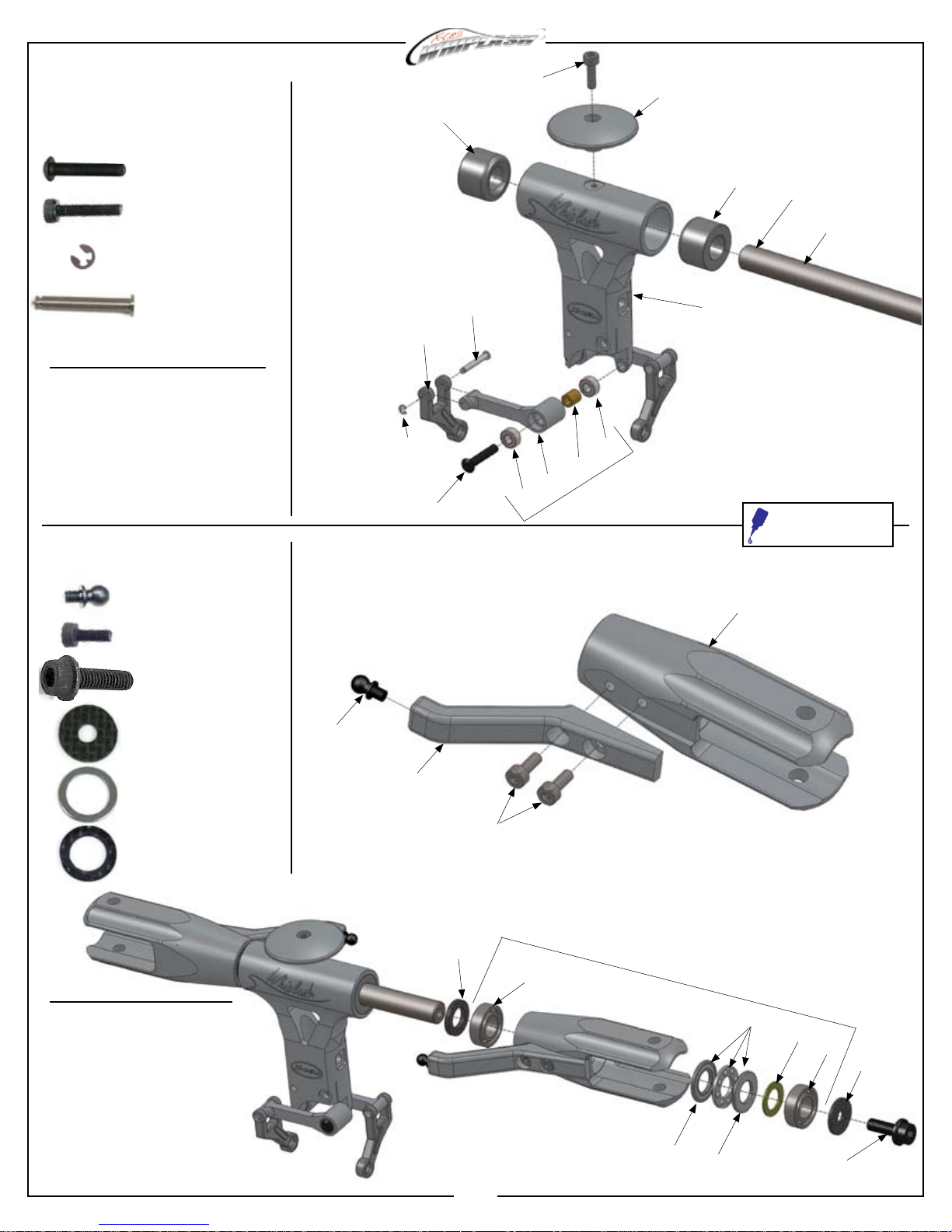

Flybarless Head Assembly (Whiplash Kit #MA1033-1) .................................................................... 9

Flybarless Head Parts List ......................................................................................................................9

Flybarless Head Assembly Instructions ................................................................................................

Flybarless Head Link Lengths ...............................................................................................................

Flybar Head Assembly (Whiplash Kit #MA1033) ............................................................................ 12

Flybar Head Parts List ..........................................................................................................................12

Flybar Head Assembly Instructions .......................................................................................................

Flybar Head Link Lengths .....................................................................................................................

Tail Assembly ...................................................................................................................................17

Tail Assembly Parts List ........................................................................................................................17

Tail Assembly Instructions .....................................................................................................................

Gas Frame Assembly ...................................................................................................................... 23

Gas Frame Assembly Parts List ............................................................................................................23

Gas Frame Assembly Instructions ........................................................................................................

Electronics Mounting Positions .............................................................................................................

Canopy Mounting ..................................................................................................................................

Whiplash Gas User Guide............................................................................................................... 34

Safety ....................................................................................................................................................34

Engine/Fuel/Oil .....................................................................................................................................34

Fuel Tank Plumbing ...............................................................................................................................

Mufers .................................................................................................................................................35

Air Filter .................................................................................................................................................

Spark Plug ............................................................................................................................................

Electronic Wiring ...................................................................................................................................

Initial Mixture Settings ...........................................................................................................................

Throttle Setup/Curves ...........................................................................................................................

Governor Setup/Sensors ......................................................................................................................

Starting ..................................................................................................................................................36

Rotor Blades .........................................................................................................................................

Pitch Curves ..........................................................................................................................................

Gear Ratios ...........................................................................................................................................

Running .................................................................................................................................................37

Additional Support References .............................................................................................................

Kit Hardware and Parts ................................................................................................................... 38

Warranty Information ...................................................................................................................... 39

10

11

13

16

18

24

33

33

34

35

35

35

35

36

36

37

37

37

37

3

5

For updates to this manual, or any other Miniature Aircraft USA manual,

go to www.miniatureaircraftusa.com and follow the “Manuals” link.

2

Kit Introduction

Thank you for purchasing the X-Cell Whiplash by Miniature Aircraft USA. This model is the culmination of

years of designing and manufacturing R/C helicopters. It is designed with the highest standards, and will

provide years of enjoyment. Whether this is your rst R/C model helicopter or you are an advanced R/C

helicopter modeler, the X-Cell Whiplash is a fantastic choice for a “700 size” model.

R/C Helicopter Safety

A radio controlled model helicopter is not a toy, but rather a technically complex device that must be built

and operated with care. It is also a fascinating and challenging part of the R/C sport, the mastery of which

is very rewarding. A model helicopter must be built exactly in accordance with the building instructions. The

kit manufacturer has spent much time and effort rening his product to make it reliable in operation and easy

to build. The essentially bolt together construction can proceed quite rapidly, giving the builder a strong

sense of accomplishment that encourages hasty progress from one construction phase to the next, so that

the completed model can be more quickly seen and enjoyed. It is essential to recognize and guard against

this tendency. Follow building instructions exactly. Vibration and stress levels are high and all fasteners and

attachments must be secure for safe operation.

Note that this is the rst use of the word SAFETY in these comments. Previously the kit manufacturer’s efforts

to ensure reliable operation were mentioned. That is ALL that he can do. Safe operation is the responsibility

of the builder/yer and starts with careful construction and continues with selection and installation of reliable

radio equipment and engine.

The need for safety is nowhere greater than at the ying eld. A number of guidelines for safe ight have

been developed by experienced yers and are set down here. It is urged that they be read, understood and

followed.

Warning! – Risk of death or serious injury

Remote Control (“R/C”) Helicopters can be dangerous. Inexperienced pilots of R/C Helicopters should

be trained and supervised by experienced operators. All operators should use safety glasses and other

appropriate safety equipment. All operators should exercise necessary precautions when fueling, repairing,

maintaining, ying and storing R/C Helicopters, and when using or storing R/C Helicopter accessories,

equipment, fuels, and related materials. R/C Helicopters should be used only in open areas free of obstacles

and far enough from people to minimize the possibility of injury from the helicopter or any of its components

falling or ying in unexpected directions.

This helicopter is not a toy but a complex ying machine that must be assembled with care by a responsible

individual. Failure to exert care in assembly, or radio or accessory installation, may result in a model

incapable of safe ight or ground operation. Rotating components are an ever present danger and source of

injury to operators and spectators. Since the manufacturer and his agents have no control over the proper

assembly and operation of his products, no responsibility or liability can be assumed for their use.

General Guidelines for Safe R/C Helicopter Flight

• Fly only at approved ying elds and obey eld regulations.

• Follow frequency control procedures. Interference can be dangerous to all.

• Know your radio. Check all transmitter functions before each ight.

• Be aware that rotating blades are very dangerous and can cause serious injury.

• Never y near or above spectators or other modelers.

• If you’re a beginner, get help trimming the model rst and ight training later.

• Don’t “track” the main blades by holding the tail boom. This is a temptation to builders who cannot hover

yet and is very dangerous.

• Follow all recommended maintenance procedures for model, radio and engine.

3

Academy of Model Aeronautics

Miniature Aircraft USA highly recommends joining the Academy of Model Aeronautics (AMA).

• AMA is the Academy of Model Aeronautics.

• AMA is the world’s largest model aviation association, representing a membership of more than 150,000

from every walk of life, income level and age group.

• AMA is a self-supporting, non-prot organization whose purpose is to promote development of model

aviation as a recognized sport and worthwhile recreation activity.

• AMA is an organization open to anyone interested in model aviation.

• AMA is the ofcial national body for model aviation in the United States. AMA sanctions more than a

thousand model competitions throughout the country each year and certies ofcial model ying records

on a national and international level.

• AMA is the organizer of the annual National Aeromodeling Championships, the world’s largest model

airplane competition.

• AMA is the chartering organization for more than 2,500 model airplane clubs across the country. AMA

offers its chartered clubs ofcial contest sanction, insurance and assistance in getting and keeping ying

sites.

• AMA is the voice of its membership, providing liaison with the Federal Aviation Administration, the Federal

Communications Commission, and other government agencies through our national headquarters in

Muncie, Indiana. AMA also works with local governments, zoning boards and parks departments to

promote the interests of local chartered clubs.

• AMA is an associate member of the National Aeronautic Association. Through NAA, AMA is recognized by

the Fédération Aéronautique Internationale (FAI), the world governing body of all aviation activity, as the

only organization which may direct U.S. participation in international aeromodeling activities.

For more detailed information, contact the Academy of Model Aeronautics

5161 E. Memorial Drive, Muncie, Indiana, 47302

or telephone (800) 435-9262.

You may also visit the AMA website at www.modelaircraft.org

4

Kit Assembly

Your Whiplash kit will require a number of different supplies and tools to ensure the best nal result. They

are as follows:

Required Lubricants and Compounds:

1. Medium Strength Thread Locking Compound - X-Cell Super Lock Blue (MA3200-20)

2. Tri-Flow Oil (MA3200-02)

3. MA Synthetic Hydrocarbon Grease (MA3200-10)

4. Medium Cyanoacrylate (CA)

5. Retaining Compound - X-Cell Super Lock Green (MA3200-22)

Required Tools:

1. m4 Nut Driver

2. m5 Nut Driver

3. m5.5 Nut Driver

4. m7 Nut Driver

5. 1.5mm Allen Driver

6. 2.0mm Allen Driver

7. 2.5mm Allen Driver

8. 3.0mm Allen Driver

9. 4.0mm Allen Driver x2

10. 5.0mm Allen Driver

11. Needle Nose Pliers

12. Phillips Screwdriver

13. Razor Knife (X-acto)

Other required components:

The X-Cell Whiplash is an airframe kit. To complete the model, several other items are required but are not

included with the kit. There are many choices for these other required components, and any competent

hobby retailer with R/C helicopter experience will be happy to make suggestions. You will need:

1. Engine, 23-29cc R/C format gas engine

2. Helicopter style mufer suited to the engine you choose.

3. Cyclic servos (Miniature Aircraft USA recommends high quality digital cyclic servos with no less than

80 oz. in. of torque.)

4. Throttle servo (Miniature Aircraft USA recommends a high quality ball bearing sevro)

4. R/C helicopter gyro (Miniature Aircraft USA recommends for Flybarless Kits a ybarless electronic

unit with rudder gyro and for Flybar Kits only a tail “heading hold” style gyro is needed)

5. Rudder servo suitable for use with the gyro you choose. Digital servo is recommended.

6. R/C helicopter transmitter and receiver with at least 6 channels, and eCCPM capabilities.

7. 690-710mm Main Blades and 105mm Tail Blades

8. R/C helicopter starting and fueling equipment compatible with gasoline fuel

9. R/C helicopter engine governor is recommended

Refer to the “Whiplash Gas User Guide” on page 34 of this manual for more information on

recommended equipment and setup.

5

Important Assembly Tips - PLEASE READ

• Follow the instructions. The methods of construction documented in this manual have been proven to

work. Do not rush the build of your model! You have purchased a world class model helicopter kit, take

your time and realize that the nal result is now up to you. Take the time to fully understand each step and

if you are unsure please contact Miniature Aircraft USA.

• Follow the order of assembly. The instructions have been organized into major sections and have been

written in such a way that each step builds upon the work done in the previous step. Changing the order of

assembly may result in unnecessary steps.

• Clean all metal parts. All of the steel parts in this kit are coated with a lubricant to prevent them from

rusting. This coating can interfere with the adhesives and thread locks needed for assembly. Use a solvent

such as alcohol or acetone to clean the various metal parts, especially threads. Be sure not to overtighten

bolts as damage to bearings and other components will occur.

• It is very important to lightly sand the edges of all carbon ber pieces. Miniature Aircraft USA recommends

doing so prior to the assembly process. Carbon ber edges are sharp and can easily cut component wires

and battery mounting straps. It is important to use safety precautions when creating carbon ber dust.

The use of a particulate mask, preferably one with a P100 HEPA lter is recommended. Always clean up

carbon ber dust with a damp rag right away.

• Use thread lock as indicated. Generally any bolt or screw that threads into a metal part requires thread

lock. Model helicopters are subject to vibration and failing to use thread lock on any non-locking assembly

may result in a part becoming loose or falling off.

6

Kit Contents

Please take some time to familiarize yourself with the contents of the kit. The Whiplash kit has been broken down into

three “bags”. Each bag contains parts and hardware. The hardware for each bag will be used only for that bag. There

will be no left over parts after each bag is assembled. The individual parts of the factory assembled parts are not listed

out here. They can be found in the components section of the manual.

Bag 1 - Flybarless Kits (MA1033-1)

Bag Part No. Part Description Qty

1-A 0869 Washout Link 2

1-A 128-176 Washout Pin 2

1-A 128-195 Head Button 1

1-A 128-314 Swashplate Follower 2

1-A 131-187 Head Axle 1

1-A 131-190 Damper (80D) 2

1-A 131-368 FBL Head Block 1

1-B 0133-1 M3x21.5 Ball Link 10

1-B 0217 Swashplate 1

1-B 121-4 Servo To Swash Linkage Rod 3

1-B 121-7 Swash To PA Linkage Rod 2

1-B 131-308 FBL Main Shaft 1

1-C 131-161 Main Blade Grip 2

1-C 131-163 FBL Pitch Arm 2

Bag 1 - Flybar Kits (MA10333)

Bag Part No. Part Description Qty

1-A 0133-1 M3x21.2 Ball Link 4

1-A 121-4 Servo To Swash Rod 2

1-A 128-189 Cage Bar 2

1-A 128-195 Head Button 1

1-A 131-155 Cage End 2

1-A 131-168 FB Head Block 1

1-A 131-187 Head Axle 1

1-A 131-190 Damper (80D) 2

1-B 120-7 5x15 C/F Safety Washer 2

1-B 128-196 Alumimum Bell Mixer 2

1-B 131-161 Main Blade Grip 2

1-B 131-162 FB Pitch Arm 2

1-B 131-184 9x14x.080 C/F Damper Washer 2

1-C 0217 Swashplate 1

1-C 0219 Washout Center Hub 1

1-C 0869 Washout Link 2

1-C 106-05 Washout Arm 2

1-C 128-176 Washout Pin 2

1-C 131-8 FB Main Shaft 1

1-D 0133 M2x21.2 Ball Link 2

1-D 0133-1 M3x21.2 Ball Link 10

1-D 0135 M2x16.4 Ball Link 2

Bag Part No. Part Description Qty

1-Hardware 0021 M4 Lock Nut 1

1-Hardware 0023 M5 Nut 2

1-Hardware 0051 M3x3 Set Screw 3

1-Hardware 0061 M3x8 Socket Bolt 4

1-Hardware 0063 M3x10 Socket Bolt 2

1-Hardware 0064-4 M3x16 Button Head Socket Bolt 2

1-Hardware 0067 M3x14 Socket Bolt 1

1-Hardware 0082-4 M5x32 Shouldered Socket Bolt 2

1-Hardware 0086-1 M5x16 Flanged Socket Bolt 2

1-Hardware 0107 M3x6 Threaded Steel Ball 5

1-Hardware 0109 M3x8 Threaded Steel Ball 4

1-Hardware 0447-1 M2 E-clip 2

1-Hardware 120-7 5x15 C/F Safety Washer 2

1-Hardware 131-83 Anti-rotation Pin 1

1-Hardware 131-184 C/F Damper Washer 2

1-Hardware 131-200 M4x33 Shouldered Socket Bolt 1

Bag Part No. Part Description Qty

1-D 0313 M2x10 Threaded Control Rod 2

1-D 120-25 Swash To Mixer Linkage Rod 2

1-D 121-4 Servo To Swash Linkage Rod 3

BOX 0303 Flybar 1

1-Hardware 0021 M4 Lock Nut 1

1-Hardware 0023 M5 Nut 2

1-Hardware 0050-1 M2.5 Set Screw 2

1-Hardware 0051 M3x3 Set Screw 3

1-Hardware 0057 M4x4 Set Screw 2

1-Hardware 0061 M3x8 Socket Bolt 4

1-Hardware 0063 M3x10 Socket Bolt 2

1-Hardware 0064-3 M3x6 Button Head Socket Bolt 4

1-Hardware 0067 M3x14 Socket Bolt 3

1-Hardware 0071 M3x18 Socket Bolt 2

1-Hardware 0082-4 M5x32 Shouldered Socket Bolt 2

1-Hardware 0086-1 M5x16 Flanged Socket Bolt 2

1-Hardware 0107 M3x6 Threaded Steel Ball 5

1-Hardware 0109 M3x8 Threaded Steel Ball 6

1-Hardware 0112 M3x9.5 Threaded Steel Ball 4

1-Hardware 0447-1 M2 E Clip 2

1-Hardware 131-83 Anti Rotation Pin 1

1-Hardware 131-200 M4x33 Shouldered Socket Bolt 1

7

Bag 2 - Tail Assembly

Bag Part No. Part Description Qty

Bag Part No. Part Description Qty

2-A 0133 M2x21.2 Ball Link 2

2-A 128-144 T/R Control Rod Guide 4

2-A 131-57 Torque Tube Ends 2

2-A 131-58 Torque Tube 1

2-A 131-62 Tail Boom 1

2-A 131-69-1 T/R Control Rod 1

2-A 131-80 Torque Tube Bearing Cup 2

2-A 131-81 Torque Tube Bearing Cup O-ring 4

2-A 131-86 Assembled Boom Support 2

2-B 131-34 Front Tail Transmission 1

2-B 131-35 Boom Clamp W/TX Holes 1

2-B 131-64 T/R Hub 1

2-B 131-75 T/R Pitch Slider Assembly 1

2-B 131-112 T/R Blade Grip 2

2-B 131-129 Tail Box 1

2-B 131-130 Tail Pitch Control Bellcrank 1

2-B 131-131 C/F Bellcrank Bracket 1

2-B 131-132 Bellcrank Slider Cup 1

Bag Part No. Part Description Qty

3-A 131-29 C/F X-Brace 1

3-A 131-47 C/F Servo Rail Spacer 2

3-A 131-53 C/F Gyro Plate 1

3-A 131-55 C/F Angled Battery Tray 1

3-A 131-148 C/F Servo Plates 14

3-A 131-153 C/F Canopy Breakaway Tabs 4

3-A 131-186 C/F Anti-rotation Bracket 1

3-A 133-94 C/F Fuel Tank Plate 1

3-A 133-107 C/F Front Doubler - Gas 2

3-A 133-108 C/F Rear Doubler - Gas 2

3-A 133-110 C/F Bottom Plate - Gas 1

3-A 133-117 C/F Left Frame - Gas 1

3-A 133-118 C/F Right Frame - Gas 1

3-B 128-57 Tray Mount 3

3-B 128-58 Frame Spacer 3

3-B 131-20 Mid Main Bearing Block 1

3-B 131-21 Upper Main Bearing Block 1

3-B 131-40 Lower Main Bearing Block 1

3-B 131-46 P/A Servo Rail 2

3-B 131-52 Delrin Tray Mount 2

3-C 0818-3 Mounting Block 2

3-C 128-57 Tray Mount 3

3-C 128-118 6mm Hex Adaptor 1

3-C 131-3 Start Shaft w/Sleeve (128-108) 1

3-C 131-179 Nitro X-Block 1

3-C 133-9 Assembled Gas Clutch Bell 1

3-C 133-18 18T Pinion w/Sleeve 1

3-C 133-119 Flanged Clutch Spacer 2

3-C 133-120 One Way Bearing Bracket 1

3-C 133-121 Motor Mount 1

3-D 0133-1 M3x21.2 Ball Link 2

3-D 0390 Wire Retainers 3

3-D 106-22 Rubber Canopy Grommet 4

3-D 121-6 M3x75 Threaded Control Rod 1

3-D 128-59 M4 Front Boom Support Brace 1

3-D 131-1 124T Main Gear 1

3-D 131-24 Main Gear Hub 1

3-D 131-50 Elevator Servo Mount 2

3-D 131-136 Struts 4

3-D 131-150 Front Canopy Post 2

3-D 131-151 Rear Canopy Post 2

3-D 131-154 Thumb Screw 4

3-D 133-135 Landing Gear Post 2

3-D 3200-48 3/4” Hook and Loop Tape 15”

2-C 128-80 Front Boom Clamp 1

2-C 128-149a Upper Rear Boom Support Mount 1

2-C 128-149b Lower Rear Boom Support Mount 1

2-C 131-60 C/F Tail Fin 1

2-C 131-128 C/F Boom Clamp Plate 1

2-Hardware 0009 M3 Washer 2

2-Hardware 0016-1 M4 External Serrated Lock Washer 2

2-Hardware 0019 M3 Lock Nut 3

2-Hardware 0056 M3x5 Dog-Point Set Screw 2

2-Hardware 0059-0 M2.5x4 Socket Bolt 6

2-Hardware 0059-1 M2.5x6 Socket Bolt 1

2-Hardware 0060-1 M3x6 Socket Bolt 4

2-Hardware 0061 M3x8 Socket Bolt 3

2-Hardware 0064-3 M3x6 Button Head Socket Bolt 2

2-Hardware 0065 M3x12 Socket Bolt 6

2-Hardware 0067 M3x14 Socket Bolt 2

2-Hardware 0069 M3x16 Socket Bolt 2

2-Hardware 0073 M3x20 Socket Bolt 1

2-Hardware 0078 M4x12 Socket Bolt 2

2-Hardware 0107 M3x6 Threaded Steel Ball 4

Bag 3 - Gas Frame Assembly

Bag Part No. Part Description Qty

3-E 0405 Fuel Pick up 1

3-E 0409 90 Degree Nipple 1

3-E 105-100 High Flex Fuel Line 24”

3-E 128-90 Tank Mounting Studs 2

3-E 128-92 Fuel Tank Plug 1

3-E 131-144 Rubber Fuel Tank Mount 4

3-E 133-99 Whiplash Gas Fuel Tank 1

3-E 133-140 Fuel Nipple 1

3-Hardware 0004 M4 Washer 1

3-Hardware 0003 3mm Washer 12

3-Hardware 0011 5mm Washer 1

3-Hardware 0011-4 5x15x.08 Washer 1

3-Hardware 0013 5mm Hex Nut 1

3-Hardware 0014F 5mm Hex Nut - Fine Thread 1

3-Hardware 0015 2mm Hex Nut 1

3-Hardware 0016-1 M4 External Serrated Lock Washer 2

3-Hardware 0017-2 2.5mm Hex Nut 5

3-Hardware 0021 M4 Lock Nut 1

3-Hardware 0032 M3 Self Tapping Screw 8

3-Hardware 0057 M4x4 Set Screw 6

3-Hardware 0059-1 M2.5x6 Socket Bolt 4

3-Hardware 0059-3 M2.5x10 Socket bolt 16

3-Hardware 0059-7 M2.5x20 Socket Bolt 4

3-Hardware 0060-1 M3x6 Socket Bolt 20

3-Hardware 0061 M3x8 Socket Bolt 48

3-Hardware 0063 M3x10 Socket Bolt 12

3-Hardware 0064-3 M3x6 Button Head 6

3-Hardware 0065 M3x12 Socket Bolt 4

3-Hardware 0081 M4x16 Socket Bolt 6

3-Hardware 0085 M5x16 Socket Bolt 4

3-Hardware 0088 M3x8 Tapered Socket Bolt 5

3-Hardware 0103 M2 Threaded Steel Ball 1

3-Hardware 0116 M2.5 Threaded Steel Ball 5

3-Hardware 131-201 M4x25 Shouldered Socket Bolt 1

BOX 131-139 Skids 2

BOX 131-152 Whiplash Canopy 1

BOX 133-230 Whiplash Gas Instruction Manual 1

BOX 3000-73 MA Towel 1

8

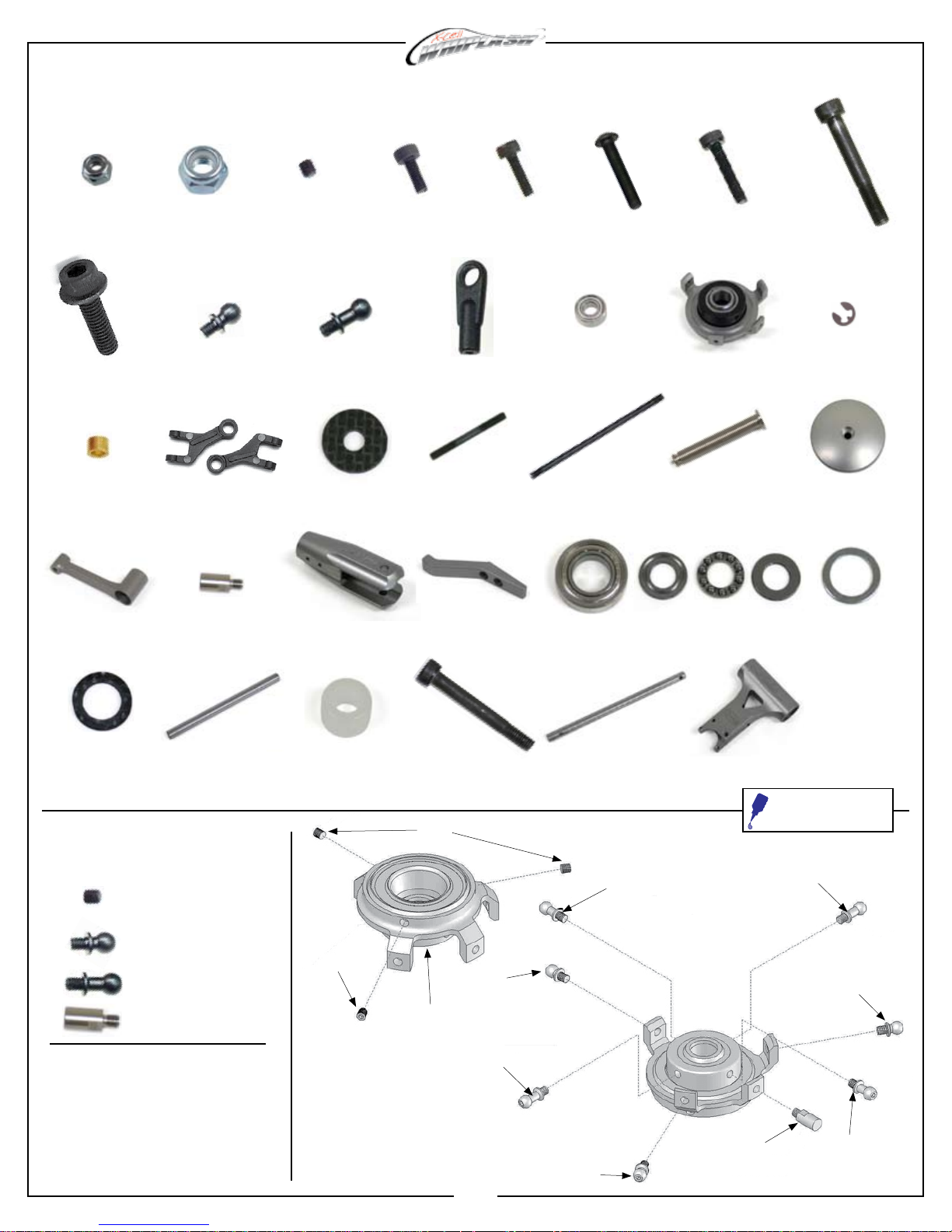

MA1033-1 - Flybarless Head Assembly Parts

0021

M4 Hex Locknut

0086-1

M5x16 Flanged Bolt

0597-4

M3x4.75x.215 Brass

Spacer

128-314

Swashplate Follower

0023

M5 Hex Locknut

0107

M3x6 Threaded Steel

Ball

0869

3D Washout Link

131-83

Swashplate Pin

0051

M3x3 Socket Set

Screw

0109

M3x8 Threaded Steel

Ball

120-7

M5x15 Carbon Fiber

Safety Washer

131-161

Aluminum Blade Grip

0061

M3x8 Socket Bolt

M3x21.2 Ball Link

M3x30 Threaded

Control Rod

Aluminum Pitch Arm

M3x10 Socket Bolt

0133-1

121-4

131-163

0063

0064-4

M3x16 Button Head

Socket Bolt

0159

3x7x3 Bearing

121-7

M3x65 Threaded

Control Rod

131-181

9x17x5 Bearing

0067

M3x14 Socket Bolt

0217

Swashplate

128-176

M2x.584 Washout

Pivot Pin

131-182

9x17x5 Thrust Bearing

0082-4

M5x32 Shouldered

Socket Bolt

0447-1

E-Clip

128-195

Aluminum Head Button

131-183

9x14x.75 Washer

131-184

Carbon Fiber Damper

Washer

131-187

Head Axle

Damper (80D)

Hardware for

this assembly

0051 x 3

M3x3 Socket Set

Screw

0107 x 3

M3x6 Threaded

Steel Ball

0109 x 4

M3x8 Threaded Steel

Ball

131-83 x 1

Swashplate Pin

Assembly Tip

• Install MA0051 M3x3 Socket Set

Screws only until they bottom out

against the lower bearing. Do not

overtighten or damage to swashplate

bearing will occur. Note: these are

used to adjust the bearing tolerance if

it develops play over time.

131-190

0051

131-200

M4x33 Shouldered

Socket Bolt

0051

0107

0217

9

0109

131-308

Flybarless Main Shaft

0109

0107

131-368

Flybarless Head Block

Apply a small amount of

medium thread lock when

threading into metal parts

131-83

0109

0107

0109

Hardware for

this assembly

131-190

0067

128-195

0064-4 x 2

M3x16 Button Head

Socket Bolt

0067 x 1

M3x14 Socket Bolt

0447-1 x 2

E-clip

128-176 x 2

M2x.584 Washout

Pivot Pin

Assembly Tip

• The use of a light grease such as

MA3200-06 Tri-Flow Synthetic Grease

is required for damper/head axle

lubrication

Hardware for

this assembly

0107 x 2

M3x6 Threaded

Steel Ball

0061 x 4

M3x8 Socket Head

Cap Screw

0086-1 x 2

M5x16 Flanged Bolt

0869

0447-1

0064-4

128-176

X2

0159

X2

0597-4

128-314

0159

Factory Installed

131-190

131-368

131-161

Apply

grease to

Head Axle

131-187

Apply a small amount of

medium thread lock when

threading into metal parts

120-7 x 2

M5x15 Carbon Fiber

Safety Washer

131-183 x 2

9x14x.75 Washer

131-184 x 2

Carbon Fiber Damper

Washer

Assembly Tips

• The use of a light grease

such as MA3200-06 Tri-Flow

Synthetic Grease is required

for thrust bearing lubrication

(pre-applied and assembled

from factory)

• 3 piece thrust bearing

(MA131-182) outer race with

larger I.D. (inside diameter)

installs closest to hub.

0107

131-163

131-184

10

0061

131-181

Bearings Factory Installed

in Blade Grips

131-182

Large

Small

I.D.

I.D.

131-183

131-181

120-7

0086-1

Hardware for

this assembly

0021 x 1

M4 Hex Locknut

0023 x 2

M5 Hex Locknut

0063 x 2

M3x10 Socket Bolt

0082-4

0082-4 x 2

M5x32 Shouldered

Socket Bolt

131-200 x 1

M4x33 Shouldered

Socket Bolt

Link Arm

Lengths and

Installation

0023

131-200

0063

131-308

0063

0021

0023

Apply a small amount of

medium thread lock when

threading into metal parts

X2

47.5mm

X3

13.5mm

0133-1

121-7

0133-1

0133-1

121-4

0133-1

11

MA1033 - Flybar Head Assembly Parts

0021

M4 Hex Locknut

0064-3

M3x6 Button Head

Socket Bolt

M3x8 Threaded Steel Ball

0109

0219

Washout Center Hub

0023

M5 Hex Locknut

0067

M3x14 Socket Bolt

0112

M3x9.5 Threaded Steel

6x10x3 Flanged Bearing

Ball

0283

0050-1

M2.5x3 Socket Set

Screw

0071

M3x18 Socket Bolt

0133

M2x21.2 Plastic

Ball Link

0303

M4x17.75” Flybar

0051

M3x3 Socket Set

Screw

0078-3

M4x6 Socket Bolt

0133-1

M3x21.2 Plastic

Ball Link

0313

M2x10 Threaded

Control Rod

0057

M4x4 Socket Set

Screw

0082-4

M5x32 Shouldered

Socket Bolt

0135

M2x16.4 Plastic

Ball Link

0447-1

E-clip

0061

M3x8 Socket Bolt

0086-1

M5x16 Flanged Bolt

0159

3x7x3 Bearing

0840-27

Washout Head Pin

0063

M3x10 Socket Bolt

M3x6 Threaded Steel Ball

0107

0217

Swashplate

0869

3D Washout Link

106-02

3x7x3 Flanged Bearing

128-176

M2x.584 Washout Pivot

Pin

131-157

Flybar Cross Tube

131-183

9x14x.75 Washer

106-05

Aluminum Washout Arm

128-189

Flybar Control Bar

131-161

Aluminum Blade Grip

131-184

Carbon Fiber Damper

Washer

2x5x.5 Flanged Bearing

Aluminum Bell Mixer

Flybar Pitch Arm

106-06

128-196

131-162

131-187

Head Axle

120-7

M5x15 Carbon Fiber

Safety Washer

128-195

Aluminum Head Button

131-166

4x8x3 Flanged Bearing

131-190

Damper (80D)

12

120-25

M2.6x86 Threaded

Control Rod

131-8

Flybar Main Shaft

131-168

Flybar Head Block

131-200

M4x33 Shouldered

Socket Bolt

121-4

M3x30 Threaded Control

Rod

131-83

Swashplate Pin

131-181

9x17x5 Bearing

122-28

M3x.125”x.79” Brass

Spacer

131-155

Flybar Cage End

131-182

9x17x5 Thrust Bearing

Loading...

Loading...