Mingda MD-D01 User Manual

MINGDA TECHNOLOGY CO.,LTD

MINGDA MD-D01

Desktop 3D Printer

The User Manual

MINGDA Technology Co.,LTD

2013-11

1

MINGDA TECHNOLOGY CO.,LTD

Chapter 1 The Debugging of the machine

We will do our best to provide our customers more perfect 3D products. Our

principle is that make the user less trouble, and more easily. Before delivery,

we will debug the 3D printer precision from inside to outside. Ensure the

printing quality of the 3D printer

1. Open the packing box

Please when users receive the printer, make sure the integrity of the product

packaging, and check whether there is damage of printer.

Confirmed the packaging is completely, open box, now bring up 3Dprinter from

the box, carefully grasp the top of the frame, from both sides to lift the machine

(Caution: do not touch the internal drive belt and guide rail, have a chance to

cause a deformation of the guide rail, affect the performance of the machine.)

Gently bring up 3D printer from the box, put in your workstation.

Please open bag, you will find that all the parts have been out, Please don't

have to worry about the box there is missing any parts, because packagers

already in delivery sheet, inspection, inventory, to ensure that each delivery

integrity.

2、Install

After take out the machine you will find that most of the parts we have installed

for you, if not installed, then the machine we sent to you without adjustment

and test (note: this is not possible). So, you only need to install two parts: (1)

extruder. (2) The feeding. To the correct location, (extruder is fixed in inside

offrame and the feeding in accessories box.)

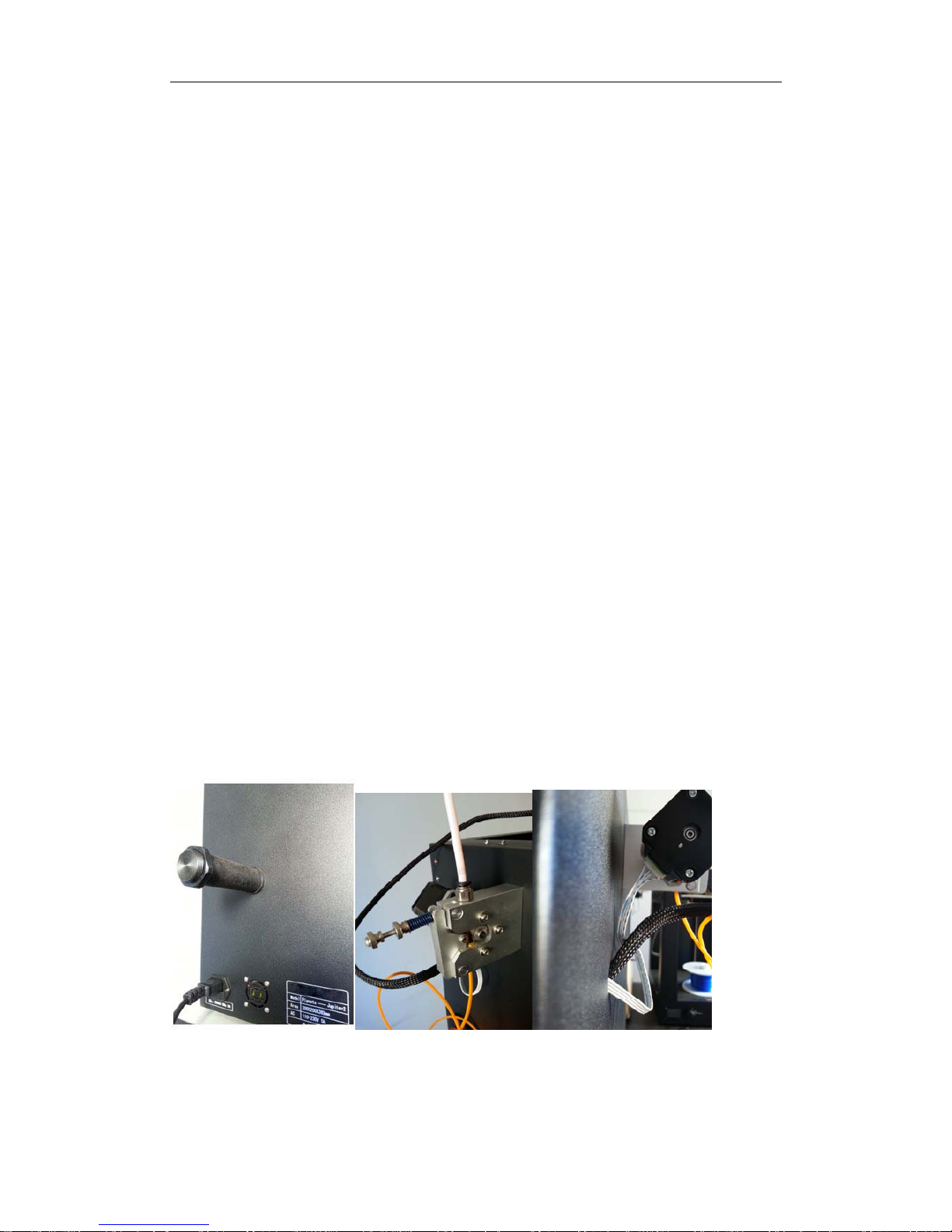

Left image feeding frame (Has been properly installed )

Middle image extruder (Has been properly installed)

2

MINGDA TECHNOLOGY CO.,LTD

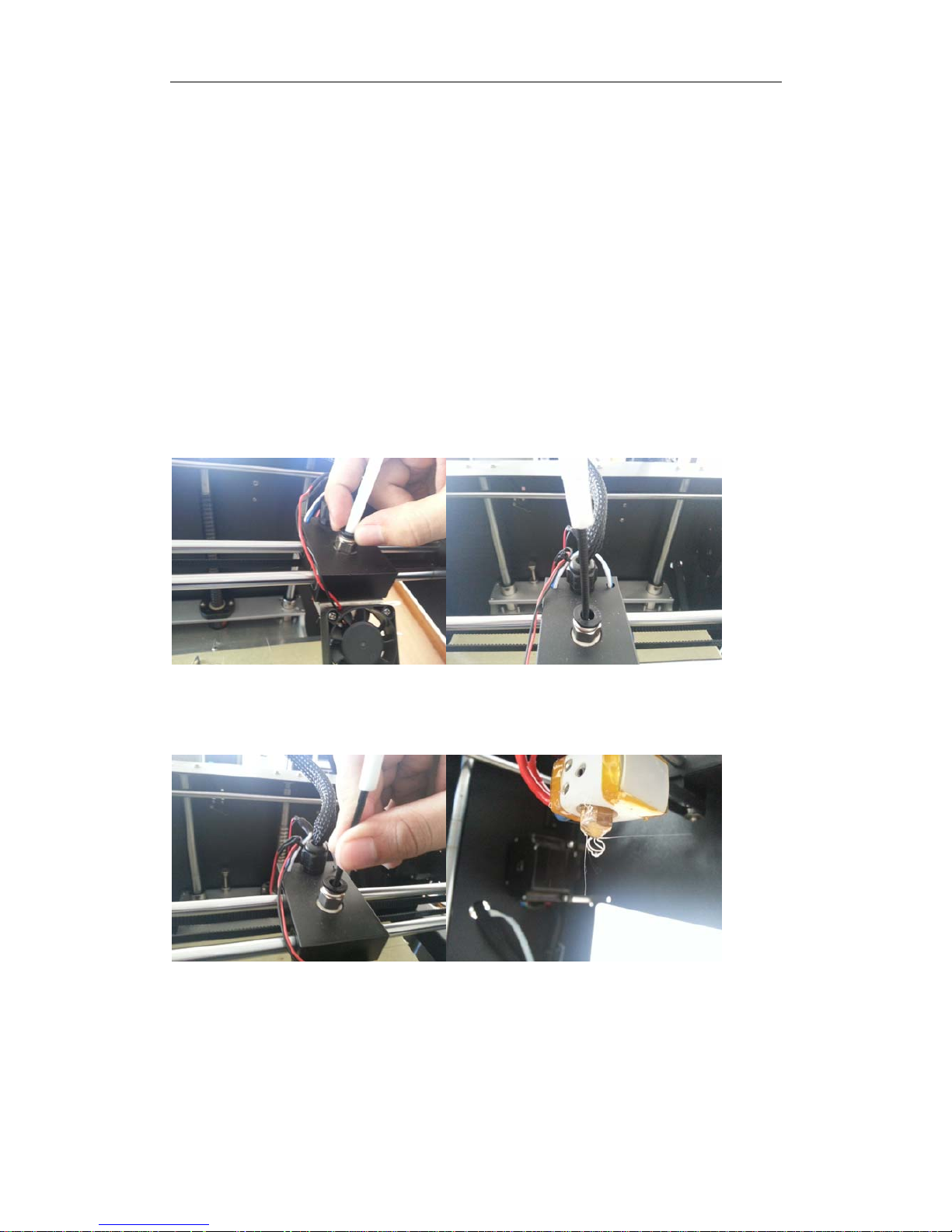

Note: remember to put the white line with installation extrusion as above

In addition, here we discuss the installation of filament. Before delivery goods

to you we have previously installed consumables line for you, so, here

introduce you how to change filament. and some matters need attention.

Filament(Has been properly installed)

If you want to remove the old filament , and put in the new line, that must be

done under the conditions of nozzle heating, loosen the extruder of the spring,

after the nozzle temperature reach consumable wire melting point, you can

remove the old line. After inserting new consumables line in, must pay

attention that inserted filament to the bottom of nozzle, and then continue to

push, and observe whether there is melting consumable wire extrusion, if have

a silk flow out from the nozzle then installation of filament is successful, and

please lock screw rod of extruder.

Note: when installing consumables line some users can't push it to the top to

the extrusion head(nozzle), and lead it can’t flow out the silk when start printing,

so, we suggest use scissors or fire make the filament to be apiciform, then it

will be the more reach the extrusion head.

filament head

3

MINGDA TECHNOLOGY CO.,LTD

3,If you don't take out the old line, or want to change the color when printing,

while printing, in the Extruder inlet of old line,

cut the back-end of old line to flat, and also cut the front of the new line which

you want to replace to flat, new line against the old line, while the gears

rotating the new filament to white catheter, finally finished the replacement of

old and new filament

Note: in some cases, using this changing line method, when the new line

reach the printing nozzle, the new line will be struck.

Then the user will find nozzle is not out of silk. Fixed circle, then the solution is

to press black fixed circle, pull out the white catheter, then manually pull plug,

pressure, control new line, until the nozzle print the new silk, now , the line

changing troubleshooting is successful. Please remember to inserted white

catheter back again

press the black fixed circle pull out the white catheter

Pull plug, pressure Nozzle out the silk of the new line

4

MINGDA TECHNOLOGY CO.,LTD

Chapter 2 Menu

1. Boot interface

Figure 2.1 Boot Interface

Plug the power, turn on the switch, the display shows the progress bar

2. Main Interface

Figure 2.2 Main Interface

Dance through the progress bar, enter the main interface, the main interface

shows the status of the machine at this time

3. Manu Interface

5

MINGDA TECHNOLOGY CO.,LTD

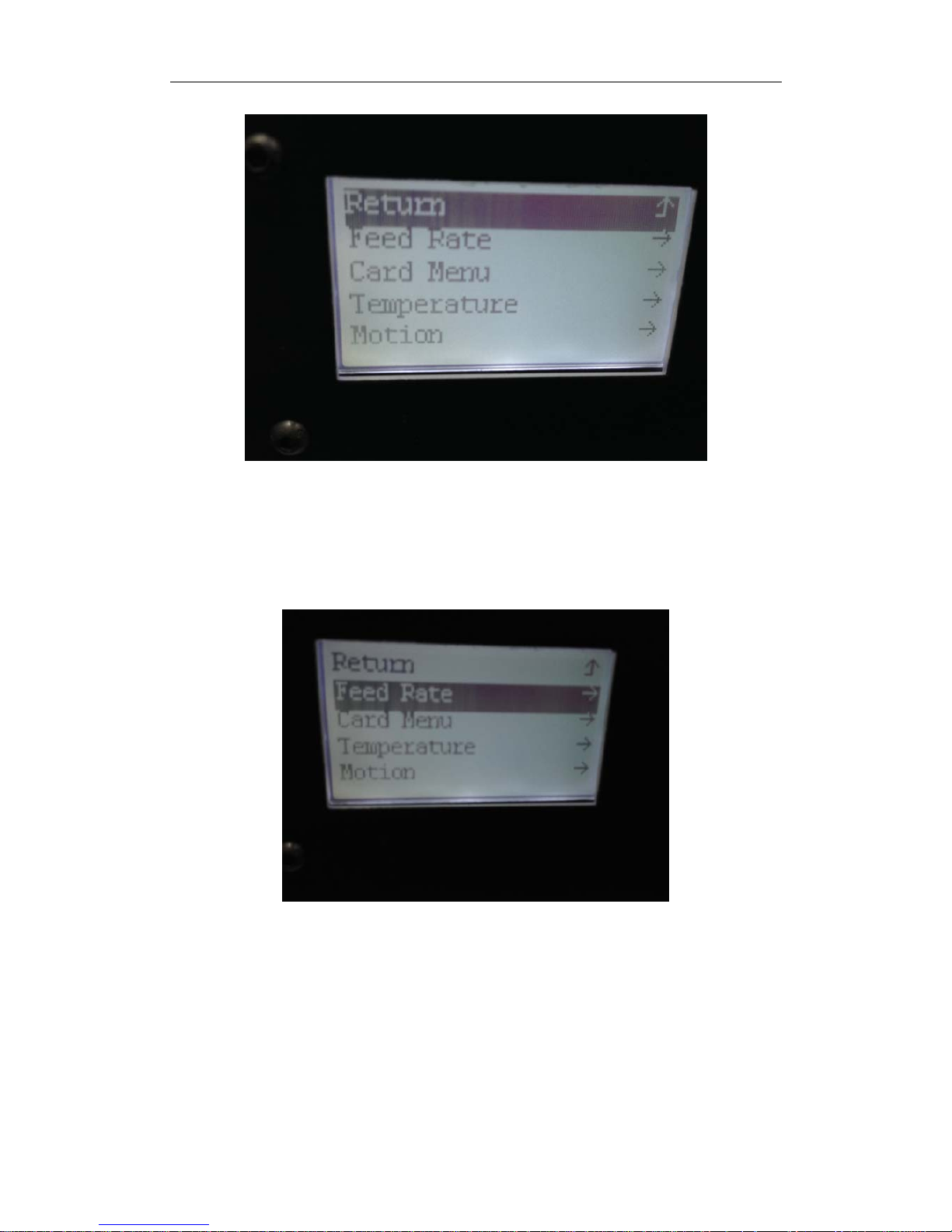

Figure 2.3 Menu Interface

MINGDA Master Menu, Knob to select the menu, press the knob to select and

option. (Including: speed ratio, SD card, temperature control, motion control,

time setting, screensavers time, storage parameters, language settings,

version information, expert mode, U disk mode)

3.1 Speed override

Figure 2.3.1aSpeed override

Oppression chose to enter the speed override interface

6

MINGDA TECHNOLOGY CO.,LTD

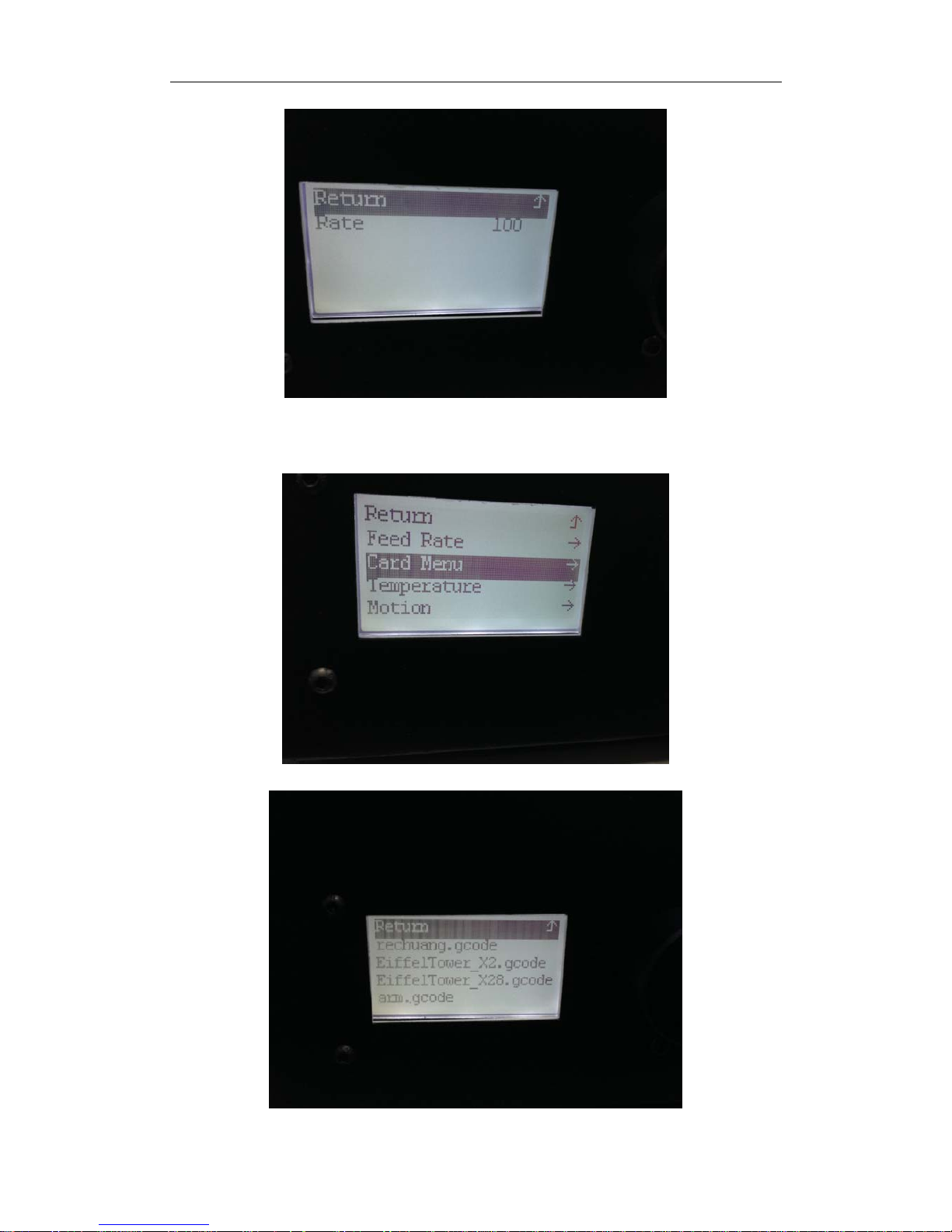

Figure 2.3.1b Speed override interface

Real-time adjustment of the printing speed ratio

3.2 SD Card

Figure 2.3.2a SD card

7

MINGDA TECHNOLOGY CO.,LTD

Figure 2.3.2b SD card interface

Enter the SD Card interface, the displayed file is stored on the SD card slice

files (G code), rotating selection, press “OK” to start the machine automatically

prints.

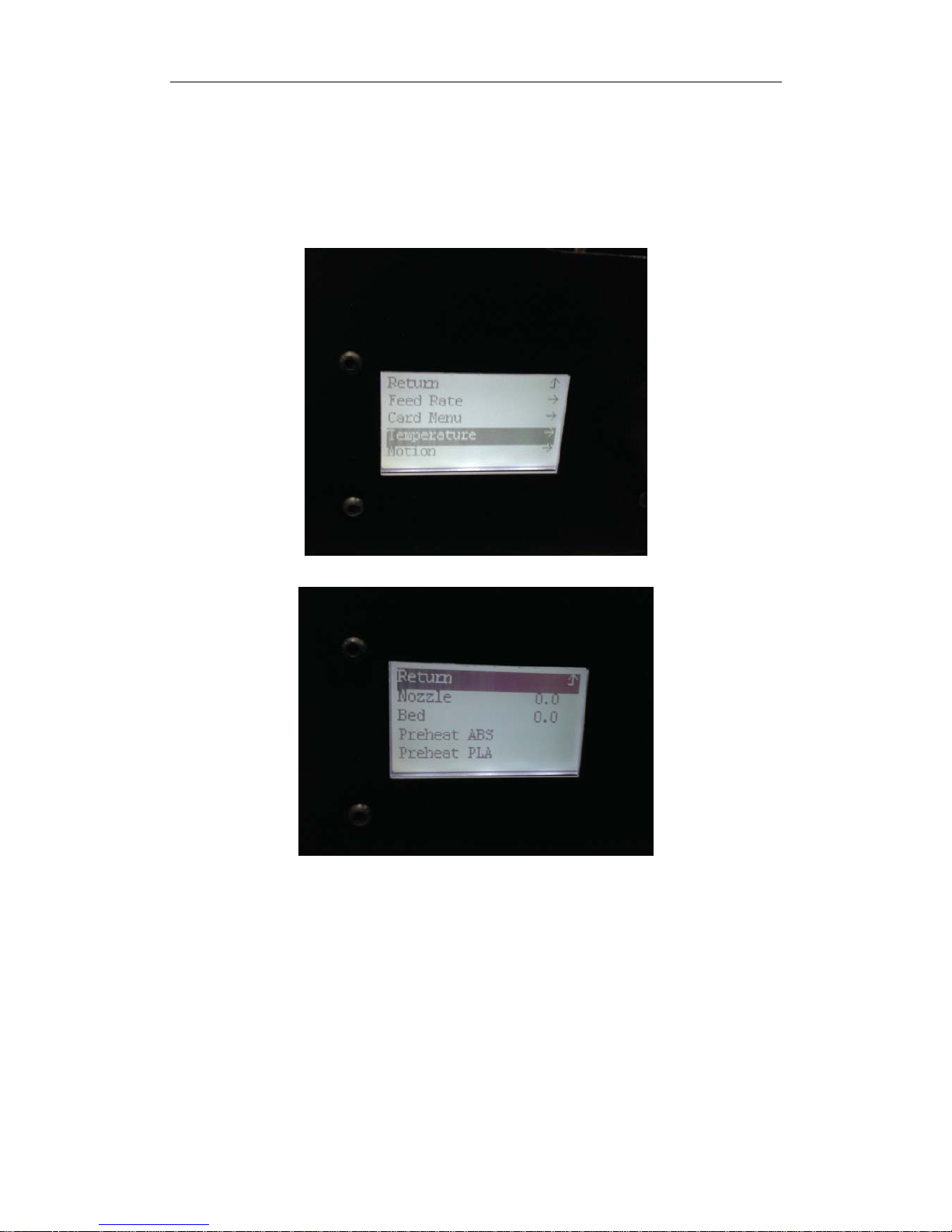

3.3 Temperature Control

Figure 2.3.3a Temperature Control

Figure 2.3.3b Temperature Control Interface

Nozzle: Press selected control adjustment nozzle temperature

Hot bed: Press selected hot bed temperature control and regulation

Preheat ABS: Press the selected, the nozzle temperature and thermal bed

temperature will be set automatically if the material is ABS

Preheat PLA: Press the selected, the nozzle temperature and thermal bed

temperature will be set automatically if the material is PLA

3.4 Motion Control

8

Loading...

Loading...