Page 1

User’s Manual

GP 3500

Minelab USA

871 Grier Drive, Suite B1

Las Vegas, Nevada 89119

UNITED STATES OF AMERICA

email: minelab@minelabusa.com

tel: +1-702-891 8809

Minelab Electronics Pty Ltd

PO Box 537 Torrensville Plaza

South Australia 5031

AUSTRALIA

email: minelab@minelab.com.au

tel: +61-8-8238 0888

Minelab International Limited

Laragh, Bandon

Co. Cork

IRELAND

email: minelab@minelab.ie

tel: +353-23 52101

Contact Details:

www.minelab.com

MINELAB

MINELAB

Page 2

the Minelab

GP 3500

l GP 3500 l

page i

GP 3500

page i

GP 3500

www.minelab.com

Minelab wishes to thank you for purchasing our most advanced gold detector ever, and

are confident the GP 3500 will lead you to success in your quest for gold and treasure.

An IMPORTANT MESSAGE from MINELAB

We ask YOU, as a responsible detector operator, to take all due care regarding the environment.

Minelab cannot stress enough the importance of being responsible when recovering targets.

BACKFILL EVERY HOLE YOU DIG.

If care and consideration is taken, during and after the removal of targets, especially with

respect to the back filling of holes, this should ensure the continued access to areas for

prospecting and treasure hunting. This will also ensure that the pristine condition of our

beautiful bushland, forests and dry land areas is maintained with a minimum of damage.

Minelab is working with you towards preserving our natural environment so that the benefits

of gold prospecting and treasure hunting can continue to be enjoyed in the years to come.

Every prospector and treasure hunter around the world and the staff of Minelab thank

you for your continued efforts towards protecting the environment.

GP 3500

Page 3

table of contents

page ii

l contents l

GP 3500

page ii

1. introduction 1

Introducing the Minelab GP 3500 1

Unpacking your GP 3500 [easy reference] 2

2. assembly 3

List of pre-assembled sections and parts 3

Complete assembly instructions 4

3. batteries 9

Battery and charging 9

4. controls and operation 11

Detector sounds [easy reference] 11

Quick start instructions [easy reference] 12

Rear control functions – rear panel 13

Front control functions – front panel 20

table of contents

l contents l

page iii

GP 3500

page iii

GP 3500

www.minelab.com

5. detecting 35

Detecting techniques 35

Prospecting techniques 39

Identifying target signals 40

Recovering the target 42

6. user information 44

Technical specifications for the Minelab GP 3500 44

Troubleshooting 45

Service repair form 46

Warranty 47

Glossary of common terms 48

Detector care and safety 51

Accessories 52

Page 4

contact

page iv

l contact l

GP 3500

page iv

Contact Minelab

Minelab is always interested in your opinions so if you have any questions or comments regarding

the GP 3500 or any other Minelab product, please feel free to contact us via your local Authorized

Minelab dealer, or write to us:

Visit our site on the World Wide Web: http://www

.minelab.com for the latest

information on Minelab products and services.

Minelab Electronics Pty Ltd

PO Box 537

Torrensville Plaza

South Australia 5031

Australia

email:

ho@minelab.com.au

tel: + 61 8 8238 0888

Minelab USA

871 Grier Drive

Suite B-1; Las Vegas

Nevada 89120

United States of America

email:

minelab@minelabusa.com

tel: + 1 702 891 8809

Minelab International Limited

IDA Industrial Estate

Laragh; Bandon

Co. Cork

Ireland

email:

minelab@minelab.ie

tel: + 353 23 52101

GP 3500

page 1

GP 3500

www.minelab.com

introducing the Minelab GP 3500

l 1 introduction l

page 1

The Minelab

GP 3500

utilises “Dual Voltage Technology” (DVT),

which assists accurate ground balance and increases sensitivity

by overcoming the potential problem of super-saturated

electro-magnetic fields in heavily mineralized ground.

Here are some features of the

GP 3500

:

• NEW Quick-Trak push button located in the handle

for fast and accurate ground balancing;

• NEW Manual Tune control for more precise

interference control & frequency band selection.

• NEW Operator select 3-Speed Ground Tracking

• Improved "Smart Point" diagnostic plug

• Separation of Level Adjust functions

• Easy Adjust Bow Knuckle and hand strap

Like its predecessor, the GP 3000, the

GP 3500

can handle heavily mineralized and salty ground

conditions with greater ease than previous detectors,

which effectively opens up NEW detecting areas.

The new Low-Noise circuitry found in the

GP 3500

results in a smoother threshold, enhancing your

ability to hear faint signals caused by small and

deep targets.

Page 5

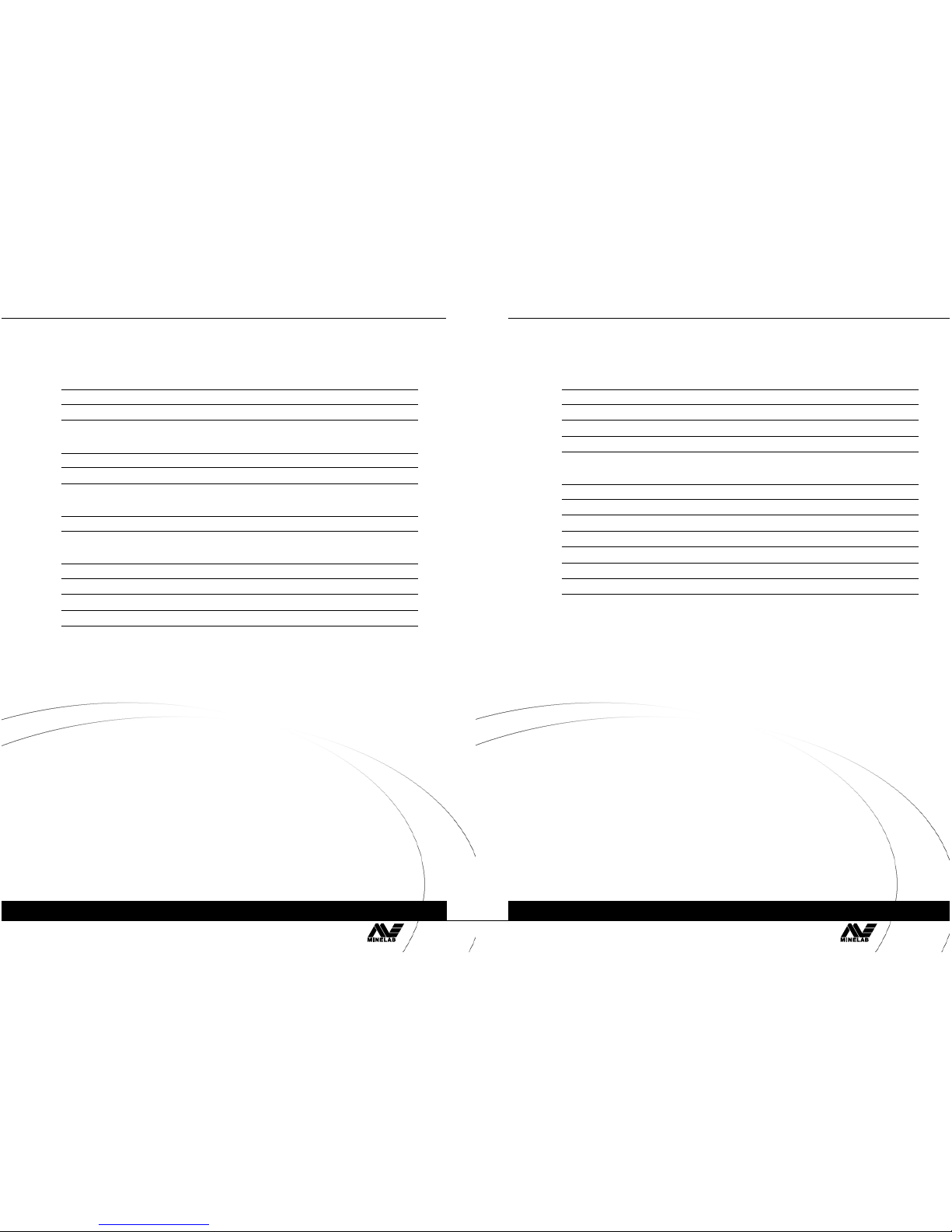

unpacking your GP 3500

easy reference

The GP 3500 as shipped

A. Shaft Assembly

B. 11 inch Coil

C. Headphones

D. Control Box

E. Battery and Backpack

F. 12V Charger

G. Handle Assembly

H. Mains Charger

I. Power Lead

J. Arm Rest

K. Instruction Manual

Figure 1.1 – Contents of the GP 3500 pack.

page 2

l 1 introduction l

GP 3500

page 2

A

B

C

D

E

F

G

H

I

J

K

list of pre-assembled sections and parts

l 2 assembly l

page 3

GP 3500

A.Lower Shaft Assembly

1. 11 inch Double D Coil

2. Coil Cable

3. Skid Plate

4. Fibreglass Lower Shaft

5. Teardrop Washers

6. Nylon Nut & Bolt

B.Upper Shaft Assembly

8. Upper Shaft

9. Handle with Quick-Trak

push button

10. Control Box

11. Armrest Parts (2)

12. Nylon Bolt (2)

13. Nylon Nut (2)

14. Arm Straps (2)

15. Armrest Cover

C.Headphones

1

6. Headphones

D.Battery and Battery Pack

17. Battery

18. Battery Back-Pack

19. Battery Power Cable

F. Extras

20. Velcro Cable

Straps (2)

21. Bungy Cord

22. Bow Knuckle

Figure 2.1 – Pre-assembled sections and parts list

page 3

GP 3500

www.minelab.com

Headphones (16)

Battery (17) &

Battery Pack (18)

Battery Power

Cable(19)

Velcro Cable

Straps (20)

Tear-drop Washers (5)

Nylon Nut & Bolt (6)

Arm Strap (14)

Upper Shaft (8)

Bungy Cord (21)

Coil Cable (2)

Bungy Knuckle (22)

Fibreglass

Lower Shaft (4)

Handle with

Wrist Strap (9)

11 inch Double D Coil (1)

& Skid Plate (3)

Nylon Nuts (13)

Armrest Parts (11)

Nylon Bolts (12)

Control Box (10)

Armrest Cover (15)

Page 6

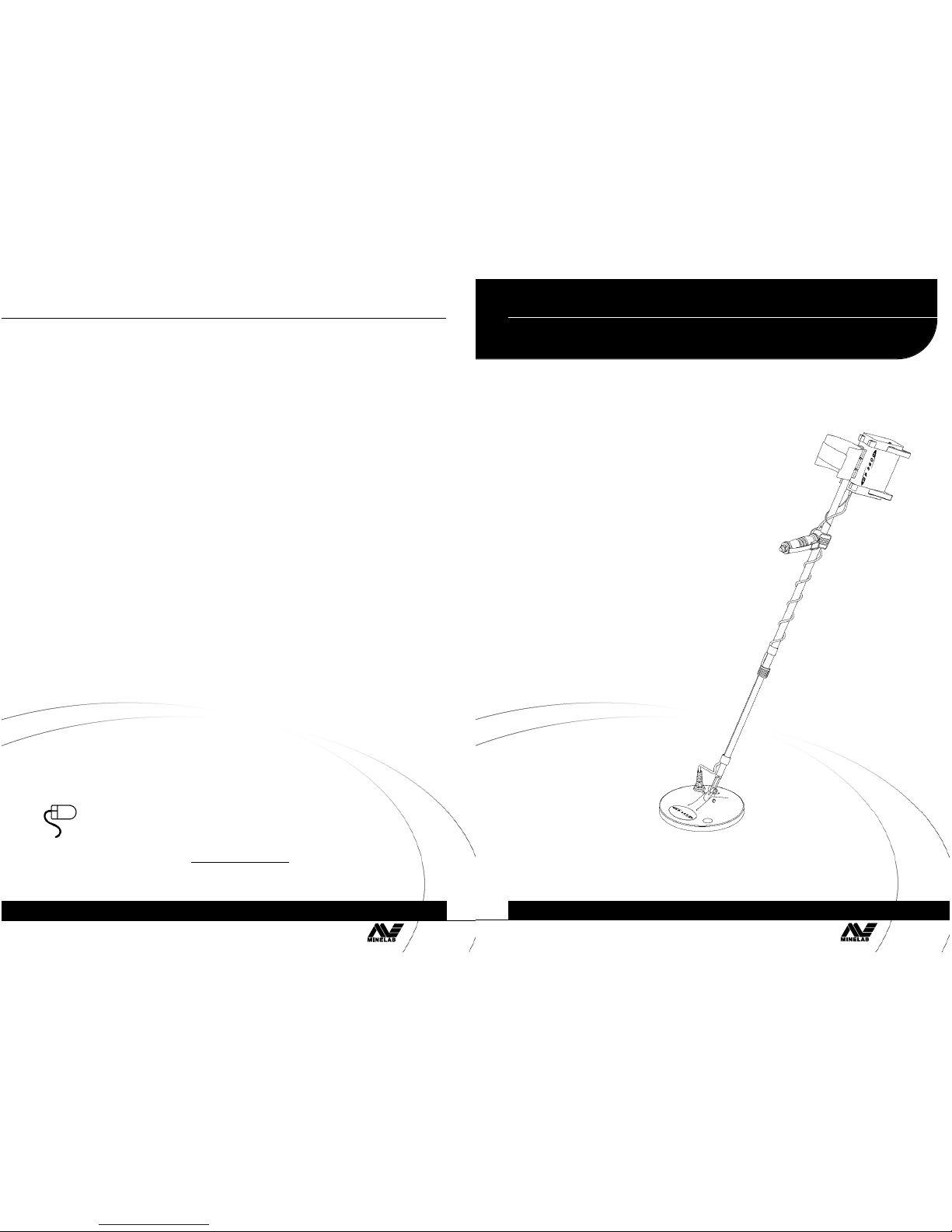

complete assembly instructions

page 4

l 2 assembly l

GP 3500

page 4

Figure 2.2 – The coil pivot end of the lower fibreglass shaft

You will need to assemble the

GP 3500

from all the various components, so we

have provided you with detailed assembly instructions.

Attaching the coil

Step 1. Check that the coil (1) has a skid plate (3) attached.

Step 2. Take two teardrop washers (5) from the bag and install them into the indentations

on the end of the lower fibreglass shaft (4).

NOTE – The washers should always be full thickness and should be replaced

regularly as they wear out and allow the coil to become loose.

Step 3.

Push the lower fibreglass shaft (4) into the mounting brackets on the coil and ensure

that the spring clip at the rear of the fibreglass shaft, faces the rear of the coil.

Step 4. Line up the holes in the coil with the pivot end of the fibreglass shaft (4). Push the

nylon bolt through the holes and fit the nylon wing nut and tighten by hand.

NOTE – Do not over tighten the nut as the coil housing may be crushed or damaged.

GP Series 1100 Coil (1)

& Skid Plate (3)

Tear-drop Washers (5)

Nylon Nut & Bolt (6)

complete assembly instructions

– continued

l 2 assembly l

page 5

GP 3500 GP 3500

www.minelab.com

page 5

Assembling the lower and upper shaft sections

Refer Figure 2.2

Step 1. Slide the lower shaft (4) with coil attached into the end of the upper shaft (8), snap

spring clip into place.

Attaching the handle and arm rest

Step 1. Slide the bow knuckle (22) onto the upper

shaft (8) and slide it halfway down.

Step 2. Slide the handle (9) onto the

upper shaft (8) and slide down.

Step 3. Place the two armrest halves (11)

on either side of the upper shaft (8)

and ensure that the bolt holes are

aligned.

Step 4. Slide the two nylon bolts (12)

through the bolt holes and screw the

nylon wing nuts (13) onto the bolts by a

couple of turns.

Step 5. Attach the armrest straps (14) using the press studs on both

sides of the arm rest.

Step 6. Push the armrest straps (14) through the slots in the

neoprene armrest cover (15) and then push the cover over

the armrest (11).

Step 7. Position your arm into the armrest and slide the handle to a

comfortable position. Tighten the two screws in the base of

the handle with a small screwdriver to hold the handle in position.

Tip: For the best balance, the rear of the armrest should be just in front of your elbow.

Figure 2.3 - Attaching the armrest

refer also Figure 2.1

Nylon Bolts (12)

Armrest Parts (11)

Nylon Nuts (13)

Page 7

complete assembly instructions

– continued

page 6

l 2 assembly l

GP 3500

page 6

Securing and connecting the coil cable

NOTE – Always ensure that the control box is turned Off before connecting or

disconnecting the coil, to avoid damage to the detectors electronics.

Step 1.

Wind the coil cable around the shaft and plug the coil connector into

the coil socket on the control box. Check that the cable is wound firmly

around the shaft without strain, leave enough slack at the bottom of the

cable near the coil to allow for adjusting the angle of the coil without

placing strain on the coil cable.

Step 2. Fasten the cable into position using the Velcro straps provided (20).

Step 3. Secure the bungy cord through the bow knuckle (22). Slide the knuckle up

or down the shaft (8) to find the balance point and tighten the wing-nut.

HINT If the coil cable is able to move around, especially near the coil, it will be

‘seen’ by the detector and cause random noises which may be confusing.

Figure 2.4 – Handle and bungy cord

Attaching the Control Box and achieving balance

Step 1. Position the ‘T-section" on top of the control box (10) into the armrest with the

battery plug at the rear. Tighten the nylon wing nuts by hand.

Step 2. Loop the Quick-Trak button cable from the handle, back along the shaft and plug it

into the Smart Point connection in the control box (10). (See page 33)

Step 3. Adjust the shaft length and coil angle for a comfortable position. The lower

fibreglass shaft can be set into position by locating the spring clip into

the holes provided in the upper shaft and hand tightening the

locking nut at the end of the shaft. The correct length of shaft

for your height, is at the point that the coil can be

swung in front without you bending, dropping your

shoulder or work in a position that will

be uncomfortable.

Bow Knuckle (22)

Bungy Cord (21)

Handle with

Wrist Strap (9)

complete assembly instructions

– continued

l 2 assembly l

page 7

GP 3500 GP 3500

www.minelab.com

page 7

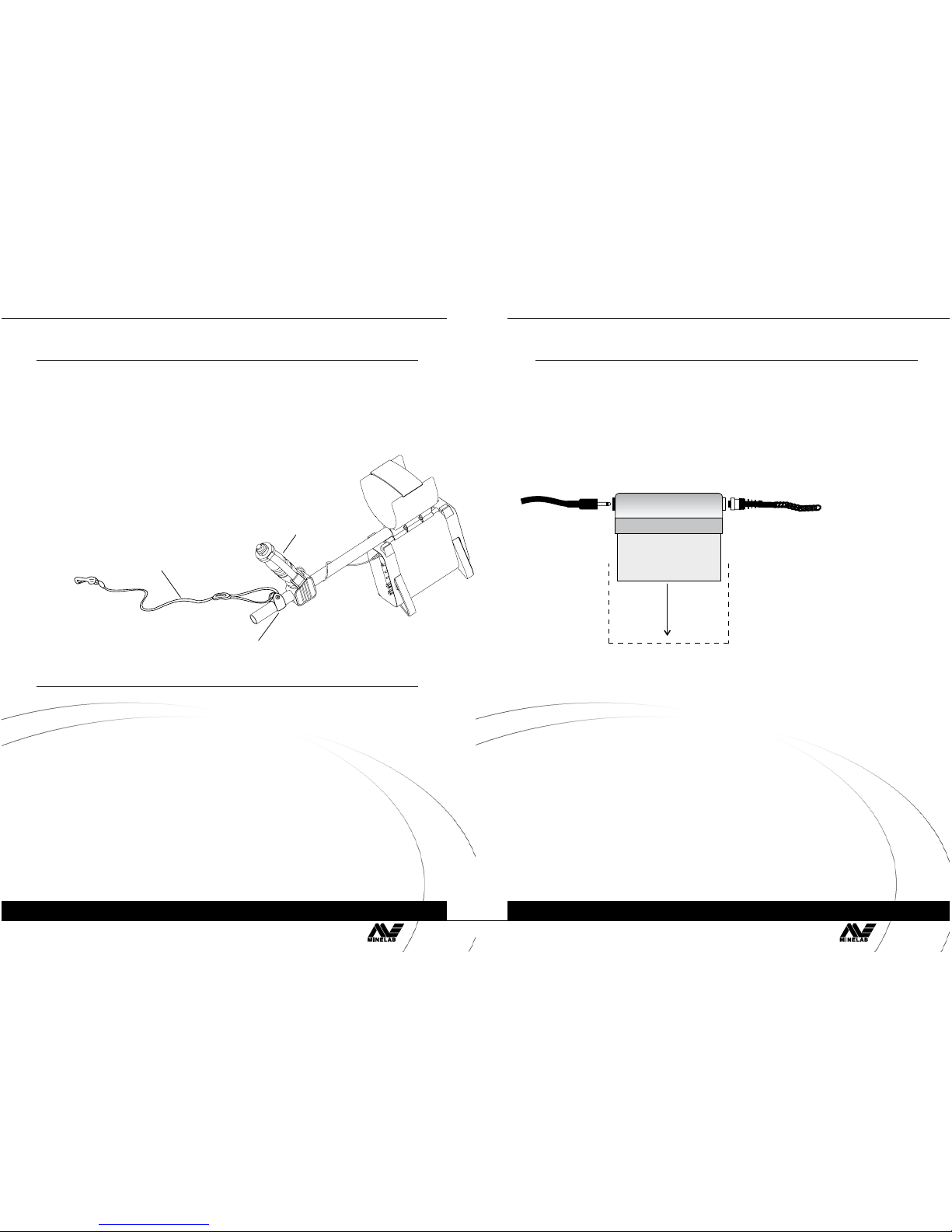

Figure 2.5

The GP 3500 battery assembly

Headphones (16) Power Cable to Detector (19)

Backpack Pouch (18)

6Volt Battery (17)

Fitting and connecting the battery pack

Step 1. Fit the battery (17) into the backpack pouch (18).

Step 2. Connect the headphones (16) and the power cable (19) to the appropriate sockets in

the cap of the battery.

Step 3. Put on the backpack (18).

CAUTION – Use only the 6V battery supplied.

Step 4.

Ensure that the power switch on the control box is switched Off before plugging

the power cable connector (19) into the socket on the control

box. This cable connects the battery and headphones to the detector.

Page 8

complete assembly instructions

– continued

page 8

l 2 assembly l

GP 3500

page 8

Adjust for your own comfort

Step 1. Adjust the bungy cord (21) from the knuckle (22) on the shaft

to the correct length to take some of the weight when prospecting.

Step 2. Adjust the hand strap on the handle (9) for your own comfort.

Step 3. Adjust the rear harness strap on the battery bag so that the battery

sits at a comfortable position on your back. The ideal position is when

the weight of the battery counter balances the weight of the detector, and

you can still switch on the detector without putting excess strain on the

bungy cord. Taking the time to adjust your detector properly is very

important for comfortable long term detecting.

TIP: You may need to change the length of the bungy cord or the position of the

bow knuckle when you change coils or detect on sloping ground.

batteries

l 3 batteries l

page 9

GP 3500 GP 3500

www.minelab.com

page 9

The Battery

The 6V rechargeable battery can provide enough power to operate the detector for

14-15 hrs, when fully charged.

The battery may be recharged at any time during the discharge cycle.

It is very important to fully charge the battery before storage.

Do not leave a battery fully discharged for longer than one day.

CAUTION: Never use a 12V battery because this could damage the detector. This damage

is not covered by warranty. The GP 3500 power supply is internally regulated and using an

external regulated power supply is not necessary, and may damage your detector. If you wish

to operate your detector at full power for longer, we would recommend that you own two

batteries and swap halfway through the day.

Low battery indication

If the battery level drops below the required power to give adequate function, a series of alarm

signal pulses are given at half second intervals.

Charging the battery

Step 1 Turn the detector Off before disconnecting the battery.

Step 2 Disconnect the battery cable from the detector and connect to the appropriate

charger.

Battery chargers

Two types of battery chargers (Mains and 12V Vehicle Charger) are supplied.

Important

When charging, the battery must be kept in an upright position.

Page 9

batteries

– continued

page 10

l 3 batteries l

GP 3500

page 10

Mains battery charger

The mains battery charger will charge the battery from local mains (AC) power outlets.

Step 1.

Connect the mains charger to a mains outlet.

Step 2. Connect charger to the battery using the power cable.

Step 3. Switch the mains outlet on.

The charger will recharge a completely flat battery in approximately 24 hours. Partially

discharged batteries will require a shorter period to recharge. Allow approximately 1.5 to

2 hours charging for each hour the battery was in use. The flashing rate of the charger

LED will decrease as the battery gains charge.

Vehicle battery charger

The vehicle battery charger will charge the battery from the cigarette lighter socket of most

motor vehicles.

Step 1. Connect the charger to the cigarette lighter socket and turn the ignition switch

to Accessories.

Step 2. Connect the detector battery to the charger using the power cable.

This supplies 12V power to the cigarette lighter socket. This voltage is converted by

the charger to charge the detector battery. A red LED indicator will flash while the

battery is charging. When the battery is flat the LED may flash fast enough so as to

appear constantly on. As the battery gains charge, the LED will flash at a slower rate.

Step 3. Leave the battery to charge for approx. 10 hours using this charger.

If the battery voltage of your vehicle drops below 11V, the charger will stop operating.

Therefore the battery charger should not flatten the vehicle battery. Check that your

vehicle battery is in good condition before camping in remote areas and run your

engine above idle speed for at least 30 minutes each day to keep your vehicle battery

charged.

CAUTION – The Vehicle Battery Charger is designed for use with vehicles, which

have a negative earth electrical system. Most cars manufactured after 1970 should have

negative earth electrical system. Connecting the charger to a vehicle with a positive earth

system will cause the fuse in the cigarette lighter plug to blow and the LED indicator will

not light. If you need to replace the fuse located in the cigarette lighter plug, you will need

to use a 3ag/10amp fuse.

detector sounds

l 4 controls and operation l

page 11

GP 3500 GP 3500

www.minelab.com

page 11

easy reference

DETECTOR SOUNDS - Explanations

In the course of operating your detector, there will be various noises and sounds that you may

hear. Here is an explanation of some of these sounds.

Threshold and Tone

This is the background sound produced by the detector. The level is set using the Threshold

control. The tone of the threshold is set using the Tone control.

Target Signal

This is the abrupt change of the tone and volume of the threshold sound when a target is

detected.

• The maximum level is set by the Volume control.

• The amount of tone variation is set by the Signal control.

• If the tone falls first and then rises, as the coil is passed over a target, this generally

indicates a large target.

• If the tone rises first and then falls, as the coil is passed over a target, this generally

indicates a small target.

Ground Noise

Irregular noises that are difficult or impossible to pinpoint when moving the coil over the

ground. Ground noise is caused by the changing chemistry or 'mineralization' of the ground.

Maintaining an accurate ground balance will greatly reduce this effect.

Tune Indication

An initial beep sounds, then while the detector is testing the range of bands for the most

stable, the threshold may become more quiet or chattery. Once selection is complete, three

sharp ‘beeps’ are given.

Low Battery Indication

If the battery level drops below the desired power to give adequate function,

a series of alarm signal pulses are given at half second intervals.

Page 10

Quick start instructions controls and operation

– continued

easy reference

page 12

l 4 controls and operation l

GP 3500

page 12

Step 1. Set the Coil switch to Double D.

Step 2. Set Soil switch to N (Normal).

Step 3. Set Balance switch to Fixed.

Step 4. Set Iron Discriminate knob to All Metals.

Step 5. Set Boost to N (Normal) for general detecting.

Step 6. Set Volume to maximum and Signal to 2 o’clock.

Step 7. Turn Power Switch on and adjust the Threshold control so that a faint sound is

heard through the headphones.

Step 8. Adjust the Tone to suit your hearing.

Step 9. To tune out interference, hold the detector at waist height with the shaft

horizontal and the coil vertical.

Step 10. Slowly move the coil around your body through a half-circle until the noise from

the interference is loudest.

Step 11. Place the detector on the ground in that position and push the Tune button

once to start the tuning function. Leave the detector undisturbed until

finished sequence.

Step 12. Tuning takes approximately 60 seconds. A series of 3 beeps will indicate that the

optimum frequency has been selected.Do not move the detector during the

tuning process

Step 13. Keep the All Metal / Disc control in the All Metal position.

Step 14. Put the Balance switch to Fixed and while moving the coil up and down hold

down the Quick-Trak push button in the handle. This puts it into Tracking Mode

Step 15. Once Ground Balance has been achieved, release the push button.

Step 16. The detector is now ready for operation.

controls and operation rear controls

l 4 controls and operation – rear l

page 13

GP 3500 GP 3500

www.minelab.com

page 13

TRY OUR WAY FIRST!

Take the time to read this manual thoroughly. The GP 3500 introduces new functions and

changes the way some others that you may have been familiar with, now work. However

experienced you are at using a metal detector, it is important that you read this chapter to

understand these new controls and how to use the GP 3500 to its full capacity.

Rear Control

Functions

There are two control panels: the rear panel and the front panel.

Figure 4.1

Rear Panel

Page 11

rear controls

– continued

page 14

l 4 controls and operation – rear l

Figure 4.2

Threshold - On/Off

control

GP 3500

page 14

Figure 4.3

Threshold control – too high

NOTE – Small targets or large deep targets may not produce a distinct target signal, but may cause

only a small variation in the threshold level. If the threshold level is set too high or too low, these very

small variations may be missed. Experiment with known targets to assist in setting all controls to suit

your hearing.

Threshold - On/Off

NOTE – Always switch the detector Off before connecting or

disconnecting the coil or battery pack and when not in use.

This switch turns the power from the battery to the detector, On and Off.

It is also used to set the background “hum” of the detector. This “hum”

is known as the Threshold.

Operating Instructions:

The Threshold control should be set at a

point where the threshold is just audible and stable. This level should

not be at a level where prolonged use may become irritating. Ideally it

should be a smooth, gentle hum.

In Figures 4.3 - 4.5, the dotted line represents the level at which the

audio output becomes audible; signals cannot be heard if they are below

the dotted line.

If the threshold level is set too high then small variations in audio signal

might not be discernible above the threshold level and the threshold will

drown out very soft signals. An example of this would be to hear a

whisper within a crowded noisy room.

If the threshold level is set too low there is no audible background signal

and small target signals will not go above the threshold of audibility.

Figure 4.4

Threshold control – too low

Figure 4.5

Threshold control – just right

rear controls

– continued

l 4 controls and operation – rear l

page 15

GP 3500 GP 3500

www.minelab.com

page 15

Volume

Sets a maximum loudness of the target signal obtained from a large

target. Refer to Figures 4.7 - 4.9. The dotted line in these figures

represents the level of volume set by the volume control.

Operating Instructions:

• If the Volume is set to maximum (fully clockwise), the target signal

is unaltered and proportional to the target size and depth

(see Figure 4.7).

• If the Volume control is turned down to half way, the target signal

is unaltered for a small target, but is limited for a bigger target

(see Figure 4.8).

• If the Volume were to be turned down close to minimum, it

potentially will limit all signals to such a degree that most targets

will be lost (see Figure 4.9).

NOTE – Threshold should be reset after adjusting the

Volume level.

Volume should be set so that target signals are clear and easy to hear

but loud signals are not uncomfortable to your hearing.

Set the Volume by passing the coil across a large target and adjusting

volume to a comfortable level. Now test a very small target at this level.

Figure 4.6

Volume control

Figure 4.7

Maximum volume

Figure 4.8

Mid-range volume

Figure 4.9

Minimum volume

Page 12

rear controls

– continued

page 16

l 4 controls and operation – rear l

GP 3500

page 16

Tone

Adjusts the tone of the threshold. The user may set this to the preferred

tone, e.g. the tone at which the operator’s hearing is most sensitive.

Some people will find that their hearing is best in a particular range of

pitch, setting the tone control to this pitch will mean that the operator is

listening more acutely, and probably more comfortably.

At minimum position, threshold gives a low tone. Turning clockwise

increases the tone to a higher pitch.

Operating Instructions:

Adjust the Tone control until the threshold

is at a comfortable tone for your hearing then test it on a couple of small

targets. Adjust until you obtain the best signal response.

HINT Setting Tone to a high pitch may be more fatiguing, but is more

suitable for identifying soft target signals.

Figure 4.10

Tone control

rear controls

– continued

l 4 controls and operation – rear l

page 17

GP 3500 GP 3500

www.minelab.com

page 17

Figure 4.11

Signal control

Signal Audio

Human hearing is sensitive to changes in tone, so the operator is more

likely to hear a target signal when both the volume and the tone change

rather than volume alone. Interpretation of the target signals involves

understanding the difference between the rising and falling tone and

volume of the threshold in response to different targets.

The Signal control gives the operator the ability to choose between a

target signal that has a large variance of tone, or one which has less

variation. High variance can give the operator more signal definition to

interpret, however in highly mineralized ground this high variance of

signal may cause confusion and make the detector appear noisy so a

lower setting may be preferred.

The Signal Audio control adjusts the pitch response of the target signal.

As a target is located, the target signal will change tone. For small

targets it will often drop to a deeper pitch then rise to a higher pitch.

The range of variation is controlled using the Signal knob.

Operating Instructions:

In Figures 4.12 and 4.13 the curving line represents the high/low pitch

response to a target. The dotted line represents the threshold tone.

• At minimum position the high/low pitch variance of the target signal

is reduced.(see fig. 4.12) So target signals are more monotone.

• At maximum position the high/low pitch variance of the target signal

is increased.(see fig 4.13) So that there is a large variance between

high and low pitch of the target signal.

Figure 4.12

Reduced pitch variance

Figure 4.13

Increased pitch variance

Page 13

rear controls

– continued

page 18

l 4 controls and operation – rear l

GP 3500

page 18

Boost (Shallow/N/Deep)

Boost switch selects the type of processing and filtering applied to

the detector signals to enhance different target signals in different

circumstances.

•

N (Normal) mode may be used for general detecting conditions.

This does not boost any signals.

•

Shallow mode boosts signals from small targets close to the

surface.

This makes faint target signals easier to hear. This setting may also

boost some ground noise, therefore Shallow is better suited for

'quiet' ground conditions or for pinpointing tiny targets.

•

Deep may be used when searching for large targets at greater depth

in 'noisy' ground. Random soil signals are smoothed, making small

changes in the audio signal from large deep targets easier to hear.

This may mask some signals from very small targets near the

surface.

Selection of the more suitable position should be after considering both

the expected target size/depth and ground conditions.

NOTE – When Boost is changed, Threshold may also need to be

adjusted. External amplifiers may be used in addition to the Boost

switch, provided that they have loudness limiters built in. This

prevents loud signals becoming unpleasant or dangerous to the

user's hearing.

Figure 4.14

Boost switch

rear controls

– continued

l 4 controls and operation – rear l

page 19

GP 3500 GP 3500

www.minelab.com

page 19

Soil (Sensitive/Normal/Salt)

This switch is used to optimise the detector for different soil conditions

and targets by changing the signal processing.

Operating Instructions:

• N (Normal) mode may be used in all areas, including areas with

highly mineralized soil. This position has very good sensitivity to

a wide range of nugget sizes and is the most versatile of the three

positions.

•

Sensitive mode may be used when searching for small nuggets,

especially in areas with highly mineralized soil. The extra stability

allows the coil to be used closer to the ground in areas of excessive

ground noise. Sensitive may not work well if the ground is salty.

This setting may reduce the depth at which large nuggets are

likely to be found.

•

Salt mode may be used in areas containing a high salt content,

be they neutral or heavily mineralized. In highly mineralized

areas without salt, this setting may be less sensitive to small

nuggets than Normal or Sensitive settings, but the difference to

large targets is marginal

Figure 4.15

Soil switch

(Normal/Sensitive/Salt)

Page 14

front controls

page 20

l 4 controls and operation – front l

GP 3500

page 20

Figure 4.16

Front Panel

Front Control

Functions

Smart Point

- A quality initiative from Minelab Electronics

The Smart Point is an intuitive new feature of the GP 3500. It serves two

functions

1) It is the connection point for the Quick-Trak push button to

connect with the control box circuitry; (see page 33 - Quick-Trak

reset button for more details.

2) It is a diagnostic/test port that ensures that your detector is

operating at peak performance before it leaves the factory.

Smart Point also allows Authorized Minelab Service Engineers

worldwide to service and test your machine to ensure consistent

and maximum performance at all times. For service information

please contact your local Authorized Dealer. (See p45)

front controls

– continued

l 4 controls and operation – front l

page 21

GP 3500

www.minelab.com

Fig 4.17

Smart Point

page 21

GP 3500

Smart

Point

Page 15

All Metal/Iron Discriminate

Discrimination is the ability of a detector to distinguish between

different types of metal objects and to assist the user in identifying

a target

.

The GP 3500 is capable of rejecting many iron objects while still

detecting non-ferrous metals. The ability of the detector to discriminate

ferrous targets means that, while detecting in littered goldfields, much

of the iron rubbish may be ignored, with a high probability that valuable

targets will not be missed.

When the control is turned off ( anti-clockwise), you will detect in

All Metal and will detect any type of metal. This is the preferred setting

for most operators and the use of discrimination is restricted for use in

high trash areas.

In All Metal mode, it will give varying volume and pitch signals but this

information does not indicate the type of metal in the object.

By rotating the control clockwise past the ‘click’, you switch into the

ferrous discrimination mode. In Disc, a strong response from a ferrous

(iron) object will cause the threshold and target signal to be momentarily

'blanked' or silenced.

NOTE – If the target response is too weak for accurate

discrimination, the detector will give a normal target signal

until you dig closer to the target and the signal strength improves.

As the control is turned further clockwise, the operator it able to

influence the recognition of a target being ferrous or non-ferrous metal.

Figure 4.18

All Metal / Iron

Discriminate switch

page 22

l 4 controls and operation – front l

GP 3500

page 22

front controls

– continued

l 4 controls and operation – front l

page 23

Iron discrimination with the GP 3500 is the silencing or ‘blanking’ of the threshold and target

signal, which occurs when the detector determines a target is comprised of ferrous metal.

There is no discrimination when Iron Discrimination is set to All Metal.

When a target has been located using Disc, the coil should be rapidly passed back and forth

over the target centre several times. Remember to set Ground Balance to Fixed for this and

keep the sweep across the target at a level height and as close to the ground as possible.

You should always test the target from at least two directions (90

o

to each other)

so that the detector sees the target from different profiles.

When detecting a piece of iron, a normal target signal will start to be heard until the

target signal becomes strong enough for the detector to determine that the object

is ferrous. At this point, the signal will 'blank'.

TIP: For large very deep targets, the hole being dug may not be wide enough for the coil to

move sideways across the target. Therefore the discrimination will not be accurate.

Figure 4.19 – Discrimination levels

Discrimination - continued

front controls

– continued

GP 3500

www.minelab.com

page 23

Page 16

page 24

l 4 controls and operation – front l

GP 3500

page 24

Figure 4.21

Discrimination target

signal on a ferrous

target

Figure 4.20

A normal signal on a

non-ferrous target.

Discrimination - continued

The strength of the target response required for discrimination to occur may be altered by

rotating the control knob.

There is usually some merging of characteristics between targets, which are clearly ferrous

and others that ‘may-be’ ferrous. Rotation of the control knob allows the operator to make a

fine adjustment in the determination of the ‘may-be’ signals.

• (Fully anti-clockwise) – just past the ‘click’ turning discrimination on, will keep the

discrimination cautious and ‘may-be’ targets will respond with a normal non-ferrous

signal and only definite ferrous targets give the blanking. (as per Figure 4.20).

• (Fully clockwise) In this position, the control becomes a little less cautious and some

‘may-be’ targets will be seen as ferrous and give a blanking signal (as per Figure 4.21).

In this position some small non-ferrous targets eg: coated in ironstone, could be

mistaken for ferrous.

front controls

– continued

front controls

– continued

l 4 controls and operation – front l

page 25

GP 3500

Discrimination - continued

Keeping the control anti-clockwise requires a slightly stronger signal before discrimination

occurs, rotating it clockwise means that discrimination will occur on a weaker target.

Discrimination functions will only work with strong, positive target responses. Weak

responses will give normal 'all metal' type signals.

HINT It is usually best to dig out all targets and only use the discrimination

function in areas where a large amount of rubbish makes the digging of everything

impractical.

Discrimination will give the best results when used in combination with the specially designed

GP Series Double-D coils and will not work correctly when using mono coils.

NOTE – If Pinpointing a target prior to digging, best results will be from switching out

of discrimination and into all metals.

Selection of how far to turn the discrimination knob should be determined by how cautious

you want to be and how much trash is in the area. If the area is heavily littered, you may want

to use a less cautious discrimination and have the knob in the 5.00 o’clock position. If there is

little trash in the area and most close to the surface you may prefer a more cautious position

of 9 – 12.00 o’clock.

TIP: If you are on a known gold producing site or successful patch, it is best to dig up all targets.

GP 3500

www.minelab.com

page 25

Page 17

front controls

– continued

page 26

l 4 controls and operation – front l

GP 3500

page 26

Coil (Double-D/M/Cancel)

This control changes the sensitivity and search pattern of the coil to allow

the GP series of Double-D coils to become multi-versatile with different

characteristics to suit different environments. This is achieved by altering

the pattern of transmit (TX) and receive (RX) fields of the coil and how the

control box interprets the response. Selection of different positions of this

switch, changes the electromagnetic field of the coil, thus giving better

performance in certain environments.

•

Double-D has the coil operate in a conventional Double D search

pattern and can be used in most areas of medium to very high

mineralization, being the most able to cope with these conditions.

It is also excellent for pinpointing targets as the response is strongest

from the centre of the coil.

•

M (Mono) changes the way the coil transmits and receives its signal

and may be used in most locations of low to medium mineralization,

and for locating small nuggets with Soil switch set to Sensitive. Use of

Mono will often increase the sensitivity of the detector but may also be

a little more unstable in heavily mineralized ground. Pinpointing is not

centred in the middle of the coil, but to one side and may give a

complex signal when the target is very close to the coil.

•

Cancel changes the electromagnetic field of the coil so that it is

particularly stable in areas of electrical interference. This position

is ideal in areas where the operator wants to detect close to suburbia

or where the Tune function has difficulty selecting a quiet operational

frequency (e.g.: near power lines, phone towers or under poor

atmospheric conditions). Pinpoint in Cancel will again be to one side

of centre and signals may be complex if the target is close to the coil.

This setting will limit sensitivity to deep targets.

Figure 4.22

Coil switch

NOTE – Coils not specifically designed for the GP 3500 may behave erratically or be

ineffective in either M (Mono) or Cancel modes.

Minelab Monoloop coils can be used on the GP 3500 with excellent results and we recommend their

use in conjunction with the coil switch in the M (mono) mode. This allows the use of monoloop coils

in soils where prospectors previously had to revert to using Double D coils.

In extreme mineralization, particularly heavy ironstone concentrations, you may experience a loud

signal spike when attempting to ground balance or while searching. The signal is random and very

sharp and it is not characteristic of a normal target signal. To prevent it from occurring, keep your

coil a few centimetres from the ground, or opt to use in Double D mode.

IMPORTANT

You will need to re-ground balance every time you select a new position for the ‘Coil’ switch.

front controls

– continued

l 4 controls and operation – front l

page 27

GP 3500 GP 3500

www.minelab.com

page 27

Page 18

front controls

– continued

page 28

l 4 controls and operation l

GP 3500

page 28

Balance (Fixed/Tracking)

The ground you’re searching in contains not only sand, but also many

different chemicals, minerals and salts. These extra materials are referred

to as ground mineralization. This ground mineralization may often produce

a sound from the detector, known as ‘ground noise’.

The GP 3500 has the ability to cancel out the effects of ground

mineralization automatically. This minimises ground noise and retains

maximum sensitivity to metal targets. Cancelling the effects of ground

mineralization is referred to as 'ground balancing'. This ensures that

target signals from objects, such as gold, are not confused with interfering

ground noise.

The GP 3500 automatic ground balance continually adjusts to minimise

the effects of changing ground mineralization when balance is set to

Tracking. The GP 3500 may be operated with fixed ground balance or

automatic tracking ground balance.

• When Balance is set to Fixed, the ground balance remains at the

current level. To re-balance, you just press the Quick-Trak push button

which triggers a fast re-balance, then returns to Fixed to continue

detecting once this button is released.

• When the ground is variable in mineral content requiring repeated

re-balancing, use Tracking as the detector continuously tests the

ground and makes changes to suit. (see Tracking Speed (p.32) for

more information.)

Figure 4.23

Balance switch

(Fixed/Tracking)

front controls

– continued

l 4 controls and operation l

page 29

GP 3500 GP 3500

www.minelab.com

page 29

Ground Balancing Procedure

• Have the Fixed / Tracking switch in Fixed position

• Move the coil up and down between 20mm and 100mm above the ground and, while

moving the coil, press down the Quick-Trak push button in the handle

• When the button is depressed, the Tracking program initiates its automatic ground

balance. This begins with a 5 second very fast ground balance, therefore it is important

to be moving the coil when the button is held down.

• Keep moving the coil and keep the button depressed until all ground noise has stopped.

• A persistent signal may indicate a target in the ground. If this occurs, then move the coil

to a new location and repeat the procedure.

When there is no longer a change in the threshold, while the coil is being raised and

lowered, the detector is 'ground balanced'.

• Release the Quick-Trak button and you can commence searching.

You are now searching in Fixed position.

Figure 4.24

Ground Balancing

Procedure

20 – 100mm

Page 19

front controls

– continued

page 30

l 4 controls and operation l

GP 3500

page 30

Operating the GP 3500 in Fixed mode

In medium to quiet ground you will achieve better depth by operating your GP 3500 in the

Fixed position and using the Quick-Trak push button to re-balance when the ground changes

and/or threshold becomes erratic. If the ground is highly mineralized or variable, then

searching in Tracking may be the preferred position.

HINTS

• Where possible always search in Fixed position for best depth and only use Tracking mode

in areas with excessive ground noise or rapidly changing ground.

• When searching in Fixed position remember to re-balance periodically by pressing the

Quick-Trak push button in the handle. This returns you to Fixed once the re-balance is

completed and you release the button.

• Always Pinpoint a potential target in Fixed.

• If mineralization is excessive you may need to lift the coil off the ground by a cm or two,

rather than keeping it right on the ground. This will help to reduce the effects of high

ground mineralization and let you hear more targets much easier.

front controls

– continued

l 4 controls and operation l

page 31

GP 3500 GP 3500

www.minelab.com

page 31

Operating the GP 3500 in Tracking mode

If the ground is highly mineralized or variable, search in Tracking mode.

To search in Tracking mode, switch the Fixed / Tracking switch on the control box into

Tracking position.

In this position the detector is continuously testing and re-balancing to compensate for

changes in the ground mineralization. There are three tracking speeds that you can search

in – Fast; Medium & Slow. – see next chapter for details.

When searching in Tracking mode, the Quick-Trak push button takes you into Fixed mode

while the button is depressed.

While in Tracking mode, the detector usually stops ground balancing when a target signal is

detected. However, a weak target response may not be recognised as a target if the coil is

repeatedly passed over it, and especially if operating in medium or fast tracking.

For this reason the push button should be used to change to Fixed when pinpointing a target.

When searching in Tracking, after locating a target or what you believe is a target, sweep the

coil around the target area, without passing across it, then hold in the Quick-Trak push button

and pinpoint the target location.

When releasing the button, the detector engages a short, fast tracking mode (indicated by a

beep) then returns to the Tracking mode.

TIP: When in tracking, you can use the push button as a ground balance reset.

Simply raise and lower the coil a few centimeters, periodically to check the

ground balance, and if it not completely balanced just push and release the

button while continuing the ground balance procedure.

Page 20

front controls

– continued

page 32

l 4 controls and operation l

GP 3500

page 32

Tracking Speed

If searching in Tracking position, the operator can choose the speed that

is best suited to the area. In effect, this gives the operator 4 options to

search in: Slow, Medium & Fast plus the 4th being Fixed Balance which

is the recommended position subject to variability of the ground mineralization.

NOTE – The Tracking Speed switch does not effect the speed of

the initial very fast auto-ground balance. This very fast initial

ground balance only lasts 5 seconds.

If the area being detected has the mineralization changing too often for

the operator to search in Fixed position, the GP 3500 now allows the

operator to gradually step through from Slow auto-tracking, into Medium

speed, then into Fast auto-tracking.

Choosing the preferred speed of tracking should be simply stepping

through the speeds from Slow through to Fast, with the preferred speed

being the slowest speed which still keeps up with the variability of the

ground mineralization.

Tracking

Speed

Figure 4.25

Tracking

speed

front controls

– continued

l 4 controls and operation l

page 33

GP 3500 GP 3500

www.minelab.com

page 33

Quick-Trak push button

Located in the handle of the GP 3500 is a push button which allows easy operation of

ground balancing.

The Quick-Trak push button has two functions depending on where the balance switch is set

on the control box.

If set to Fixed mode:

If the Balance switch on the control box is set into the Fixed position, the detector will

operate with Fixed ground balance while detecting. When the ground mineralization changes

and the operator needs to rebalance, by holding in the Quick-Trak push button, a 5 second

fast rebalance will occur. Once this has been completed, the push button can be released

and the operator can continue detecting in Fixed mode.

If set to Tracking mode:

If the Balance switch on the control box is set to Tracking, the detector will continuously

test and change ground balance to compensate for changes in the ground mineralization,

(the speed of this is controlled by the Tracking speed switch). If a target signal is heard,

the operator can change into Fixed mode by pressing and holding in the Quick-Trak push

button and while the the button is depressed, the detector will operate in Fixed mode for

better pinpointing.

On release of the button a short “beep” will be heard

and a quick auto-ground balance is initiated prior to

returning to Tracking Mode.

NOTE – The Quick-Trak

push button is only

engaged and changing

the operating mode

while the button is

depressed. Once the

button is relaxed, the

Balance mode returns

to that selected on

the control box.

Figure 4.26

Quick-Trak

Push Button

Page 21

front controls

– continued

page 34

l 4 controls and operation l

page 34

GP 3500

Tune

The Tune function reduces the effects of electromagnetic interference

from sources such as power lines, radio transmitters and other metal

detectors. There are two controls allowing the operator the greatest

flexibility.

Auto push button

Pressing and releasing the Tune button starts automatic tuning. The

tuning process takes approx. 60 sec. and completion is indicated by

three sharp ‘beeps’. Once pressed, the GP 3500 scans through a wide

range of search bands, testing each one for it’s susceptibility to outside

electromagnetic waves in the same or similar bands that would cause

interference. On completing the search, it selects the most stable band

for operating in the environment of operation.

NOTE – Interference in some locations can change during the

course of the day so you may need to re-tune from time to time to

maintain a smooth threshold as you move around the area.

Figure 4.27

Tune control & button

front controls

– continued

l 4 controls and operation l

page 35

www.minelab.com

Set the Tune control

Tuning should be done initially with the Coil switch in Double D or in M (Mono). If the

interference is still severe after completing the tuning operation, change the Coil switch to

Cancel and then re-tune the detector again.

• Hold the detector at waist height and the coil vertical and slowly rotate through a

half-circle (eg: from East to West, or from North to South).

• Listen for any increase in interference as you move and when the interference is loudest,

stop moving. Lay the detector on the ground, facing that position, and keeping the

coil vertical.

• Press and release the Tune button.

• The detector will then scan through the available range of transmission frequencies and

automatically select the frequency that results in the greatest reduction of noise from

electromagnetic interference.

• The end of the tuning process (which takes approx. 60 sec.) is announced by three beeps.

NOTE – While the detector is selecting the preferred frequency, the coil must be

kept motionless and clear of metal objects. If you move the coil or allow it

to sense a metal target, the testing for the quietest band will be influenced.

When tuning the detector in close proximity to other detectors, each

operator needs to take turns tuning.

Do not try to tune two detectors at one time

.

Figure 4.28

The Tuning

Process

page 35

GP 3500

Page 22

front controls

– continued

page 36

l 4 controls and operation l

page 36

GP 3500

After completing the Auto-tune, pick the detector up and with the coil rotated flat, into the

search position, listen to see if it is stable. If a slight interference is still present, you can use

the manual control to fine tune the selected band.

Manual Control

Manual tuning can now be used by the operator to fine tune after the Auto tuning is

completed. In areas where there is no interference being experienced, the Manual control

can be used to select a personal search band.

After completing the auto-tune, to fine tune the band, start turning the manual control quite

slowly in one direction, listening if the threshold becomes more stable or flaky. If this direction

does not improve it, try the opposite direction. It is quite important that you turn the control

slowly to make very fine adjustments.

If the interference persists after tuning, consider using the Coil switch set to Cancel position

and retune again

Hint: If detecting in a benign area of no interference, you may find that you can select a band

at one end of the scale or the other. Frequency bands in the counter-clockwise ‘start’ direction

are lower frequency bands and higher frequency bands are toward the clockwise end. Turn

the control in the desired direction until the one beep or two beep signal is heard. Then using

slow turns in the reverse direction find a band which is stable. This will not make much

difference but low frequency bands can give a little more depth to larger targets and high

frequency bands can give slightly more sensitivity to smaller targets close to the surface.

Important: The manual control will signal when you have moved to the end of the

range of frequency bands. When you arrive at the counter clockwise starting point

you will hear a single beep to denote that this is the start, moving clockwise to the

other end, you will hear two beeps to denote that it is the finish.

Note – When turning the control rapidly to move to the desired

end you want, you will notice noise caused by the rapid

movement through the frequencies. This is normal and

will not be present when the control is turned slowly.

There are 14 turns of the control from start to finish.

Hints and techniques for better detecting and happy prospecting that will help you to

utilise the power of your GP 3500

Some user tips:

• Always ensure that the battery is at full charge so that your detector is working at

optimum performance. A worthwhile recommendation is to own a spare battery which

you can swap half-way through the day thus making sure that you are always working

with full power.

• The battery should be worn in the backpack harness supplied. This places the battery

at the furthest practical distance from the coil.

• Ensure that you do not set the shaft length too short. If the coil is too close to your

body it might detect your pick, the battery or any other metal which you are carrying.

Steel toe boots can obviously cause a problem with false signals. If false signals are

occurring as you sweep the coil, check that they are not produced by any metal that you

are carrying. Move the coil closer, and then further away from your body, in order to

check if the signals are coming from items such as your pick, boots or battery. If they are,

you must increase the distance between the coil and these items.

• Take the time to experiment with the different settings, to fully understand how to get the

most out of your detector in different locations.

Motion detection

The GP 3500 is a 'motion' detector. Therefore the detector must be moving

over a target to detect it.

Parallel Sweeping Procedure

• The coil should be swept over the ground in

a side-to-side sweeping motion.

• While sweeping the coil, it is important to

keep it parallel to, and at the same height

from, the ground at all times. Lightly skidding

the coil across the ground can sometimes

help in this, depending on mineralization.

• Do not raise the coil at the ends of each

sweep as this will reduce the detection depth

and may cause false signals.

Figure 5.1 - Parallel Sweeping

GP 3500

www.minelab.com

page 37

detecting techniques

l 5 detecting l

page 37

Page 23

detecting techniques

– continued

page 38

l 5 detecting l

page 38

GP 3500

Covering the search area

• As the user moves forward slowly, the search pattern should resemble a snaking path.

• To ensure that productive ground is thoroughly searched, approach the area from

3 different directions.

Overlap each sweep

• Each sweep of the coil should overlap the area covered by the previous sweep to ensure

a full coverage of the area being searched.

• Be aware of the search pattern of the coil being used and overlap sweeps to take this

pattern into account. If using a Monoloop coil a tighter overlap is required to ensure that

targets at maximum depth are not overlooked.

• See also Pinpointing Technique,

page 41.

Figure 5.2 Search path

Figure 5.3 Search area from

3 directions

prospecting techniques

l 5 detecting l

page 39

GP 3500 GP 3500

www.minelab.com

page 39

The GP 3500 has superior ground balancing and it is possible to find quite large

objects near the surface in well-worked areas where other detectors have been unable

to cope with the high degree of mineralization and/or salt. Therefore the user should

dig all target signals, even in previously detected areas.

• Very sudden or large changes in the mineralization of an area may produce a signal

from the detector. Usually this signal is very broad, and often only present in one

direction.

• In some goldfields, a response may be received from a concentration of orange/reddish

dyke material or clay. Remember, a metal target will get louder by getting the coil even

centimeters closer.

• If detecting areas of extremely variable mineralization, detecting with the contours rather

than across the changes will often stabilize the effect.

• In some ground (particularly heavily mineralized areas) the operator may need to sweep

the coil 1 or 2 cm above the ground. This should give a more stable threshold and less

ground noise.

• With faint or indistinct signals that you are not sure of scrape a few centimetres off the

surface with your pick and see if the signal becomes clearer.

Big GOLD.

Many detector operators have no trouble finding their share of small gold, but often are

disappointed at the lack of larger gold found at depth, even though they have dug up to

1m for a soft drink can or a horse shoe. The reason is that big gold gives a much

different response to the smaller shallower pieces. The signal is often quite broad, and

there is very little pitch variance. Just something to be aware of.

For Maximum Gold Recovery

• Keep the coil as close to the ground as possible.

• Listen very carefully - this is more important than looking.

• SLOW DOWN! Do not rush, take your time.

• Have a positive mind set, and imagine a nugget at every next sweep!!

• Remember that covering a small section of ground thouroughly will be

more productive than randomly searching a larger area.

Page 24

identifying target signals

page 40

l 5 detecting l

page 40

GP 3500

Metallic targets will usually give a 'solid' sounding signal when the coil is swept

across the object from any direction. A metallic target generally produces a short,

sharp and mostly symmetrical signal. Ground noises usually give a broad uneven

signal when the coil is swept from different directions and often may only give a

signal from one direction and no signal on the return sweep.

If you are not sure if the sound is ground noise or a target signal, you need to investigate.

Scrape a shallow hole about 70-100mm deep over the suspected target. Sweep the coil over

the hole at the original ground level. Do not dip the coil into the hole. If the signal has

decreased in volume or is less defined, it is probably ground noise.

If the signal remains the same or becomes louder, it is likely a metallic target. If you are still

not sure, make the hole deeper and repeat the process.

A 'halo effect', which may be built up around a buried metal object, makes the object appear

to be larger to the detector than it actually is. This will be reduced once the target is disturbed

from its position in the ground (e.g. a small object, detected at a substantial depth, may be

more difficult to detect once disturbed from the ground and lying in the loose dirt. If the object

is reburied, the 'halo effect' will not be present).

HINT Do not try to eliminate what might appear to be a faint, isolated ground noise by

balancing the detector on top because you may be 'balancing out' the target response from

a deeply buried metallic target. Better to ground balance around the target without going

across it, then switch to Fixed and try Pinpointing.

identifying target signals

– continued

l 5 detecting l

page 41

GP 3500 GP 3500

www.minelab.com

page 41

Pinpointing

To find an object and reduce the size of the hole required to remove it from the ground, it is

necessary to pinpoint the exact location of the object.

If a target is heard, first confirm it by setting an accurate ground balance and then pinpointing.

To ground balance, if detecting in Fixed position, hold down the Quick-Trak push button and

pass the coil around the area of the target, making sure that the target is not detected (keep

the coil well away from where the target is). Once completed relax the push button.

If detecting in Tracking mode, move the coil slowly around the area of the target, keeping well

away from the target itself, then hold down the Quick-Trak push button to go to Fixed and pinpoint across the target.

When a target is detected, sweep the general area with the coil, taking note of where the

strongest signal is received.

By shortening the length of the sweep it should be possible to draw an imaginary line in the

ground where the strongest signal is located.

Line up the target at 90° from the initial direction and repeat the process. The object is located

where the two imaginary lines cross (see Figure 5.4).

NOTE – Pinpointing will not locate a target in the centre of the coil if operating

with the Coil switch set to M (Mono) or Cancel, it will be slightly to one

side of centre

Figure 5.4 Pinpointing technique

Target could be

anywhere in

this Area

Imaginary Line of

Strongest Signal

Sweep Coil 90 degrees

to Previous Sweep

Sweep

Direction

Exact

Location

of Target

Page 25

recovering the target

page 42

l 5 detecting l

page 42

GP 3500

When you are sure of the location of the target, it is necessary to dig it out. In order

to preserve the environment, the hole should be as small as possible. Afterwards,

always replace the soil and grass which is removed.

It is essential to carry at least one of the following digging tools with you when searching:

• small, strong digging spade or shovel.

• pick with broad scraping blade.

• crowbar (for very deep objects in hard ground).

Step 1 Before digging, clear the area of loose surface material and check that the target

signal is still there. If it is not, the target should be amongst the surface material.

Also remember if there are other signals close to your target. This is important

so that when you come to dig your hole, you do not heap the loose dirt on top of

another target already in the ground.

Step 2 If the target signal is still present, use your pick to dig to a depth of approx. 50mm.

Step 3 Sweep the coil over the hole to determine if it has been dug. If the target signal is

not heard, then the target should be in the pile just dug.

Step 4 Otherwise dig a little deeper and check again.

Step 5 Take care when you dig, as damaging a nugget may reduce its value. Start digging

approx. 100mm in front of the target to reduce the chance of damage.

Step 6 Pile the diggings carefully, ensuring that you do not make the pile on top of another

target (see step 1.), as it may be necessary to search them.

Step 7 If the target is located in the soil, which was removed, sweep the coil over the pile

and pinpoint its exact position.

Step 8 Keep halving the pile which has the target.

Step 9 If it is still difficult to find the target, place the detector on the ground with the

coil horizontal.

Step 10 Take a handful of the diggings and pass over the coil.

NOTE – Your hands and wrists must be free of any metallic jewellery and watches.

Step 11

If there is no signal, place the handful carefully in a new pile and repeat with

another handful.

Important: Always refill any holes before leaving, and scatter leaves, etc. to restore the

area to its original condition. Any rubbish you recover should be taken away with you and

disposed of properly. Removing rubbish and refilling holes will help metal detector users

maintain a good reputation. This should lead to more areas being readily accessible

for prospecting

recovering the target

– continued

l 5 detecting l

page 43

GP 3500 GP 3500

www.minelab.com

page 43

Recovering Deep Targets

The GP 3500 has depth capabilities that will surprise both new and experienced prospectors.

If the target appears to be buried deeply, it should help to use the following technique:

Step 1 Use the cross sweeping method to locate the target accurately.

Step 2 Dig a hole large enough to insert the coil, approx. 100mm deep.

Step 3 Keep testing the target location as you dig deeper.

Step 4 Take care that the target is not in the wall of the hole. You may dig past it.

Try pinpointing again to check your hole is in the correct position.

HINT

When the object has been recovered, it may be worthwhile sweeping the hole again to ensure

that there are no other targets.

If you find an object in a particular location, search the surrounding area very carefully.

It is likely that there are more objects nearby.

If you hear a target signal, keep searching until you find the object;

it is there and may be valuable.

Salty Environments

The GP 3500 will find objects at great depths in salty environments.

However, the interfering signals caused by highly concentrated salt may

not be able to be completely 'balanced out' if using automatic ground

balance alone.

HINT Change Soil switch to Salt setting for salty environments. To use the salt

setting, you will have to use the specially designed GP series range of coils.

Page 26

technical specifications

page 44

l 6 user info l

GP 3500

page 44

The GP 3500

Length Maximum 1300mm

Minimum 1100mm

Weight Complete with 11" coil 2400g

(excluding battery)

Configuration Shaftmount

Transmission Bi-level Pulse Induction

Technology Dual Voltage MPS Technology

Ground Rejection Automatic ground balance

Search Mode Motion detector

Controls On/Off - Threshold Pot w/ switch

Signal 1 turn control

Tone 1 turn control

Volume 1 turn control

Boost ( shallow/N/deep) 3 pos. Switch

Soil ( sens/N/salt) 3 pos. Switch

Tune (auto) Push switch

Tune (manual) Digital pot

Iron Discriminate (All Metal/Disc) Pot w/ switch

Coil ( DoubleD/M/Cancel)) 3 pos. switch

Track Speed ( Fast/M/Slow) 3 pos. switch

Balance (Fixed/Tracking) 2 pos. switch

Audio Output 6.35mm (1/4") headphone socket

Headphones Supplied

Coil (standard) 11" Double D

Coil (accessory) 18" Double D or 18", 11" and 8" Mono

Battery 6VDC 12Ahr sealed lead acid 14-15hrs

Patents Apply

NOTE: In the interest of product improvement, Minelab reserves the right to

make changes without notice.

troubleshooting

l 6 user info l

page 45

GP 3500

page 45

GP 3500

www.minelab.com

If you need to return your detector to Minelab for service, please

supply as many details as possible about the fault. This will enable our

service engineers to rectify the fault quickly and efficiently.

Return the detector in a cardboard box for protection along with a copy of

the Service Repair Form supplied in this manual.

Please supply your name, address and phone number along with purchase

date and serial number when sending detector parts for repair.

Do not open the control box as this will void your warranty.

Use the following table to check for suggested solutions to problems.

Fault Suggestion

No sound Turn Threshold control fully clockwise.

Tur n

Volume control clockwise.

Check power cable and connections.

Check headphones.

Check battery.

Threshold but no target signal Try testing different coils.

Random noises Check for other detectors interfering.

Retune using

Tuning button.

Charge the battery.

Set Coil switch to

Cancel.

Ground balance again.

Check for thunderstorm build-up.

Battery will not charge Check for power to cigarette lighter socket

using vehicle charger in vehicle.

Check 10 amp fuse in charger plug.

Battery not holding charge Try alternative charger.

Check power cable.

Very noisy threshold Check for interference and re-tune.

Try detecting in a different location.

Set Coil switch to

Cancel.

Page 27

service repair form

page 46

l 6 user info l

GP 3500

page 46

Today’s date:

Detector Model: Serial No. :

Purchased from:

Purchase date:

Faulty part(s):

Description of fault:

Owner’s name:

Address:

Phone: Day ( ) Home ( )

Fax :( ) Email:

warranty

l 6 user info l

page 47

GP 3500

page 47

GP 3500

www.minelab.com

The GP 3500 control box has a 2 year warranty covering parts and labour. Refer to your

warranty card for details. The GP series coils have a warranty for one year against

malfunction.

Refer to either your supplier or Minelab directly for service.

The commencement of the warranty is the date of purchase.

The Minelab warranty does not cover damage caused by accident, misuse, neglect,

modifications or unauthorised service.

For specific details of the Minelab warranty please refer to the Product Warranty card.

It is the responsibility of the owner to pay all transport costs for the detector to Minelab.

The repaired detector will be returned to the owner freight free.

NOTE – This warranty is not transferable or valid unless the enclosed warranty

registration card is returned to Minelab Electronics Pty. Ltd. or an authorised

Minelab Electronics Pty. Ltd. regional distributor within 14 days of the

original purchase date,

Repairs

In the unfortunate circumstance that the detector needs to be

returned to Minelab for service, please fill out the Minelab Service Repair Form

(or a photocopy of the same) and enclose it with the detector.

Please supply as much detail about the fault as possible. This will assist our

service engineers to rectify the problem quickly and efficiently. (See p46)

Page 28

Control Box The control box encloses the electronic circuitry of the detector. The

control box originates the TX (transmit) signals sent by the coil and

interprets the RX (receive) signals detected by the coil. All user selectable

functions (knobs & switches) are located on the front and rear panels of

the control box.

Discrimination The ability of a metal detector to estimate if a located target is made from

ferrous metal (iron or steel) or non-ferrous metal (non-magnetic).

Double-D Coils Double D coils are coils that have two windings of wire that overlap in the

shape of two D's (one reversed). The characteristics of a Double D coil

are stability, especially in heavily mineralized ground, good depth and

sensitivity and a very thorough search pattern.

Electromagnetic Commonly called the 'signal from the coil'. An electromagnetic field is

Field generated within the wire windings of the search coil and this field is

pulsed or sent into the ground. The presence of a metal target in the

ground will disturb the pattern of this field and this disturbance is

registered by the receive system of the detector and indicated to the

operator by an audible target signal "beep".

False Signal False signals are signals, which sound similar to target signals but are

caused by other factors. Common causes for false signals are incorrect

ground balance, hot rocks, signals caused by knocking the coil on

obstacles, etc. With experience, the operator will learn methods to

minimise false signals and to hear subtle differences between target

signals and false signals.

Ferrous Metals Metals composed of or containing iron. A ferrous item is one, which is

attracted to a magnet and is predominantly or completely made of iron

or steel.

Ground Balance The ability of the metal detector to compensate for the effects of ground

mineralization. The GP 3500 has "automatic ground balance". When it is

used in Tracking mode it continually compensates for changes in the

ground mineralization.

glossary of common terms

page 48

l 6 user info l

page 48

GP 3500

Halo Effect After a metal object has remained undisturbed in the soil for a

considerable amount of time, a diffusion occurs around the object.

This has the effect of the object appearing to the detector to be

a larger size.

Hot Rocks A hot rock is an individual rock which has a particularly high

degree of mineralization as compared to the average ground

around it. Due to this high difference, the detector does not have

the opportunity to ground balance on the individual rock so

therefore gives a false signal.

Interference Electricity or radio waves in the area being detected can cause

instability or chattering of the detectors threshold. The types of

interference commonly occur due to power lines, underground

cables, radar, other detectors or climatic conditions like

thunderstorms.

Mineralization Most ground contains certain minerals, which can cause false

Ground signals to be given by a detector. Heavily mineralized ground

requires different ground processing than does neutral or lightly

mineralized ground (see Ground Balance).

Ground containing heavy salt concentrations require entirely

different processing again (sea salt).

Monoloop Coils Monoloop coils are the style of coil where the multiple strands of

wire are wound in a single loop around the circumference of the

coil. The field of search of Monoloop coils tend to be cone shaped.

Non - Ferrous Metals not containing significant levels of iron. Non-ferrous

Metals metals are non-magnetic such as Gold, Silver, Copper, Brass,

Lead or Aluminium.

Pinpoint The method of locating the precise location of a target prior to

digging. Pinpointing uses the design of the search coil windings

to determine the exact position of the detected target.

RX RX refers to the response or electromagnetic field which is

received back by the coil and is used by the control box circuitry

to detect a metal item in the ground.

glossary of common terms

– continued

l 6 user info l

page 49

GP 3500 GP 3500

www.minelab.com

page 49

Page 29

glossary of common terms

– continued

page 50

l 6 user info l

page 50

GP 3500