Page 1

F3 Mine Detector

Rev: 6

Part No: 4901 0043

OPERATIONS MANUAL

F3L Configuration

(Optional)

Page 2

WARNING

THIS DOCUMENT CONTAINS INTELLECTUAL PROPERTY,

TECHNICAL AND PROPRIETARY DATA AND INFORMATION

AND OTHER MATERIAL OWNED SOLELY BY MINELAB

ELECTRONICS PTY LIMITED. THIS MATERIAL MUST NOT BE

USED WITHOUT THE PRIOR WRITTEN PERMISSION OF

MINELAB ELECTRONICS PTY LTD.

© MINELAB ELECTRONICS PTY LTD. ALL RIGHTS RESERVED

This document is protected by copyright. Apart from any use

permitted under the Australian Copyright Act 1968 (Cth) or other

applicable laws, any unauthorised use, appropriation or reproduction

of this document or any part of it is strictly prohibited. No part of this

document may be used or reproduced by any means or by any

process, in any form, without the prior written permission of the

copyright owner Minelab Electronics Pty Ltd of 118 Hayward

Avenue, Torrensville, SA 5031, Australia.

Page 3

Page 4

1

Table of Contents

1. Introduction ____________________________________ 3

2. General Description and Preparation ________________ 5

2.1 Mine Detecting Set. _______________________________ 5

2.2 F3 Main Components. ____________________________ 7

2.3 F3 Preparation. __________________________________ 8

2.4 Use of Battery Pack Bag and Extension Cable. _______ 13

2.5 Changing Endcaps. _____________________________ 14

3. Functional Description ___________________________ 15

3.1 Functional Controls. _____________________________ 15

3.2 Sensitivity Endcaps. _____________________________ 17

3.3 Functional Tones. _______________________________ 18

3.4 Test Piece – Functional Test. _____________________ 20

4. F3L Configuration_______________________________ 21

4.1 Introduction. ___________________________________ 21

4.2 Description. ____________________________________ 21

4.3 Operation-Volume/Sensitivity Control. ______________ 22

4.4 Operation-LED Display. __________________________ 23

4.5 Battery Status. _________________________________ 25

5. F3S Configuration Yellow Endcap. _________________ 26

5.1 Introduction. ___________________________________ 26

5.2 Description. ____________________________________ 26

6. Operating Procedures ___________________________ 27

6.1 Introduction. ___________________________________ 27

6.2 Standard Procedure. ____________________________ 28

6.3 Optional Procedure. _____________________________ 32

Page 5

2

6.4 Sweeping Procedure. ____________________________ 36

6.5 Pinpointing Procedure. __________________________ 37

6.6 Multiple Targets. ________________________________ 39

6.7 Operating Multiple Detectors in Close Proximity. _____ 41

6.8 Completion of Operations. ________________________ 42

7. Care and Trouble Shooting _______________________ 43

7.1 Routine Care. __________________________________ 43

7.2 Trouble Shooting. _______________________________ 44

8. Specifications ___45

Page 6

3

1. Introduction

1.1 Since 1996, Minelab has designed, developed and

manufactured its range of detectors to meet the requirements of

mine and explosive ordnance clearance operations throughout the

world. Through its patented and unique technology, Minelab has

emphasised equipment capability and operator safety in its products.

1.2 The F3 mine detector incorporates patented Bi-polar

technology that enhances Minelab‟s renowned and highly successful

Multi-Period-Sensing (MPS) technology. Through MPS, the

sensitivity of a detector remains consistent regardless of the

mineralised content of soil. Additionally, Bi-polar technology assists

in eliminating the possibility of initiating a magnetic influence mine.

Combined with “static coupling” the F3 does not require motion to

detect a target thereby making pin-pointing techniques fast and

accurate.

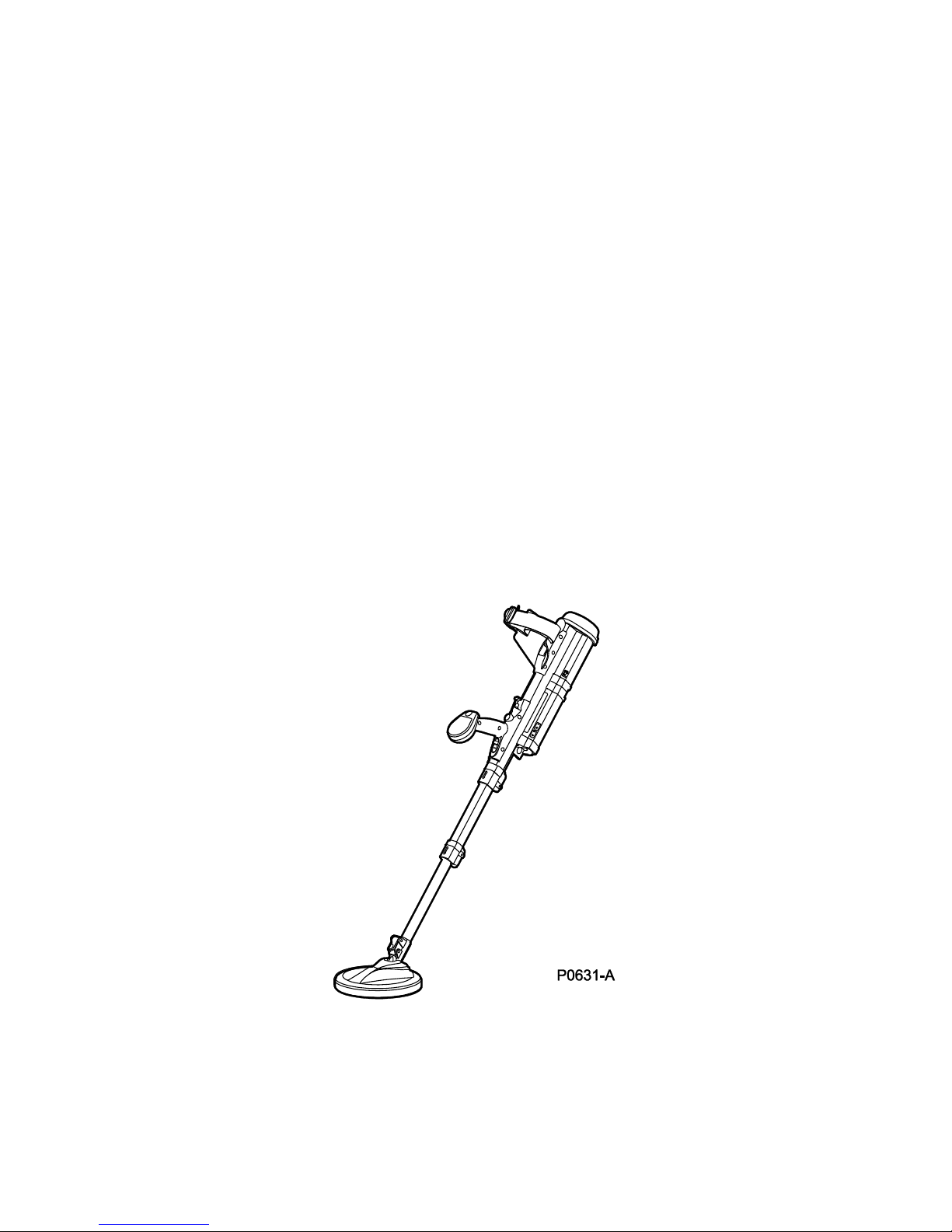

Figure 1: F3 Mine detector

Page 7

4

1.3 The F3 is a robust detector that is extremely simple to

operate. There are no complicated controls resulting in the operator

being able to focus on the vital task of mine detection. If mine

detection occurs in a “difficult” environment that includes highly

mineralised ground or electrical interference from overhead power

lines or other sources, simple and quick semi-automatic procedures

can be initiated by an operator to allow the detector to continue

performing at maximum capability.

1.4 The F3 incorporates several safety features such as Low

Battery and Fault warnings; audible confirmation at the completion of

specific operational procedures; and continuous microprocessor

controlled internal self-testing. The inclusion of a Test Piece

provides an operator with a quick and easy test to ensure the

detector is working to its operational capability.

1.5 The F3 can be supplied with an optional Light Emitting

Diode (LED) display and Volume/Sensitivity Control. In this

configuration, the detector is known as the F3L.

1.6 Components of the F3 are manufactured within tightly

controlled parameters so that they can be interchanged in the field

without any requirement for calibration.

1.7 The F3 is designed to satisfy MIL STD 810F:

Method 512.4 Water Immersion (IP67)

Method 514.5 Vibration

Method 516.5 Shock

NOTE

Although the F3 can withstand immersion to a depth of 3m for short

periods of time, it is NOT designed for use as an underwater

detector.

Page 8

5

2. General Description and Preparation

2.1 Mine Detecting Set.

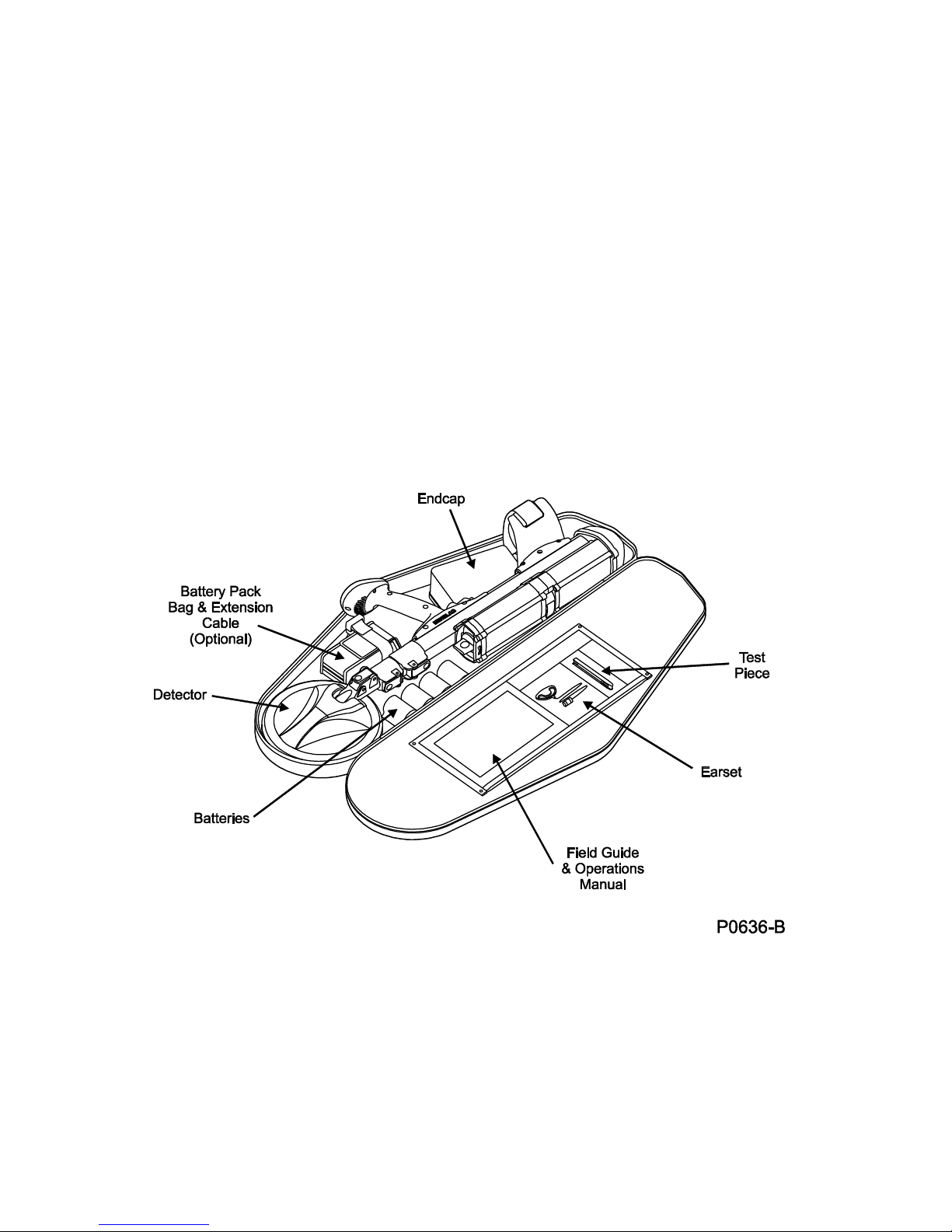

The F3 is supplied as a mine detecting set (Figure 2) comprising:

Hard Case Test Piece

Detector Operations Manual

Soft Carry Bag Field Guide

Earset

Red Endcap (Low Sensitivity)

Four D-Cell Batteries (Alkaline or Rechargeable)

Battery Pack Bag and Battery Pack Extension Cable (optional)

Figure 2: F3 Mine Detecting Set

Page 9

6

a. As illustrated in Figure 2, the Hard Case includes an insert for

easy placement of the F3 and accessories. The case also

provides protection for the detector and it is recommended that

the F3 be secured in its Hard Case whenever it is not in use or

during transit. Failure to transport the detector in the supplied

Hard Case may void warranty.

b. A Soft Carry Bag is supplied to allow an operator to comfortably

carry the detector when use of the Hard Case is impractical (e.g.

when walking through rough terrain). The Soft Carry Bag is not

designed to transport the detector by road or air. The detector

must be packed in the Hard Case during road or air transport.

Figure 3 illustrates the position of the F3 inside the Soft Carry

Bag.

Figure 3: F3 Packed in the Soft Carry Bag

Page 10

7

2.2 F3 Main Components.

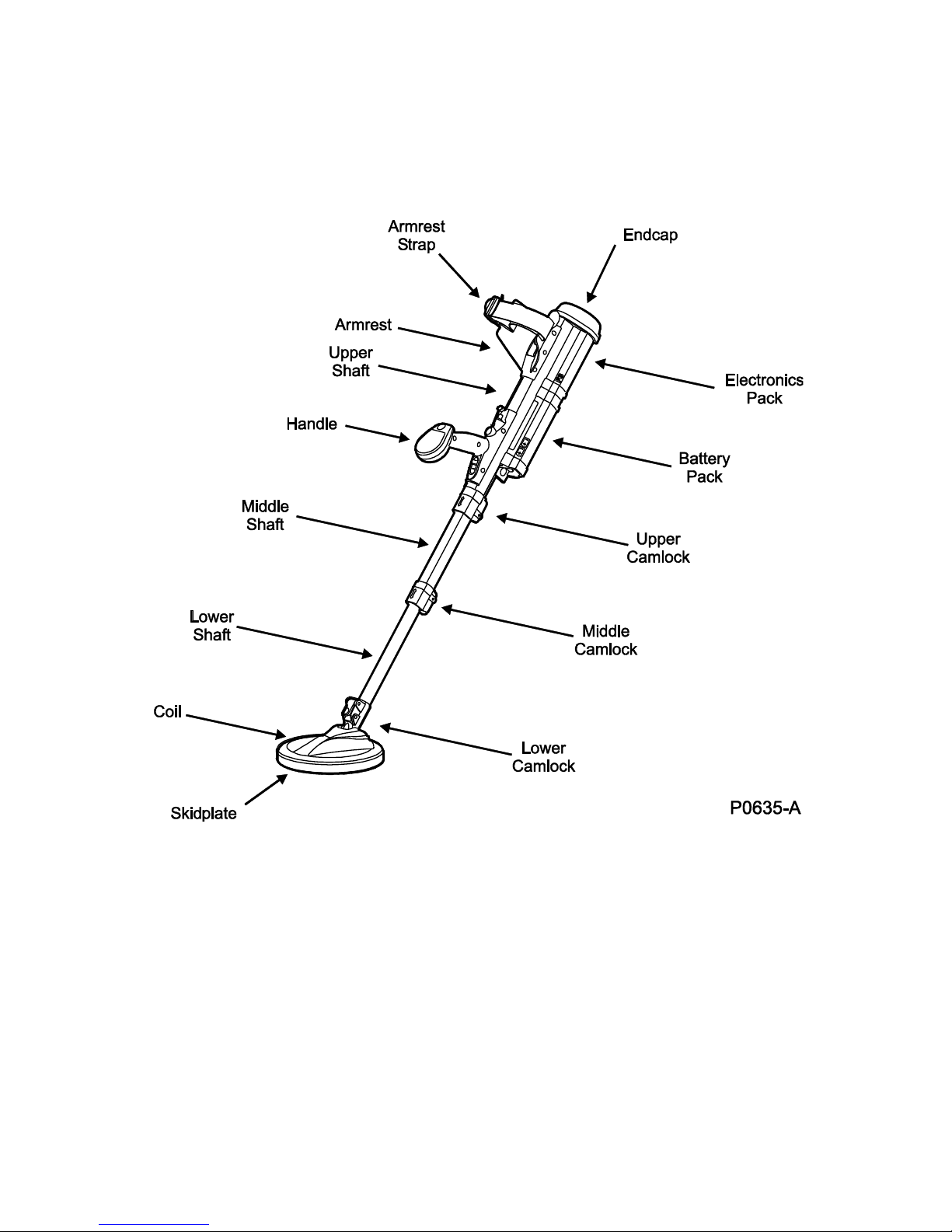

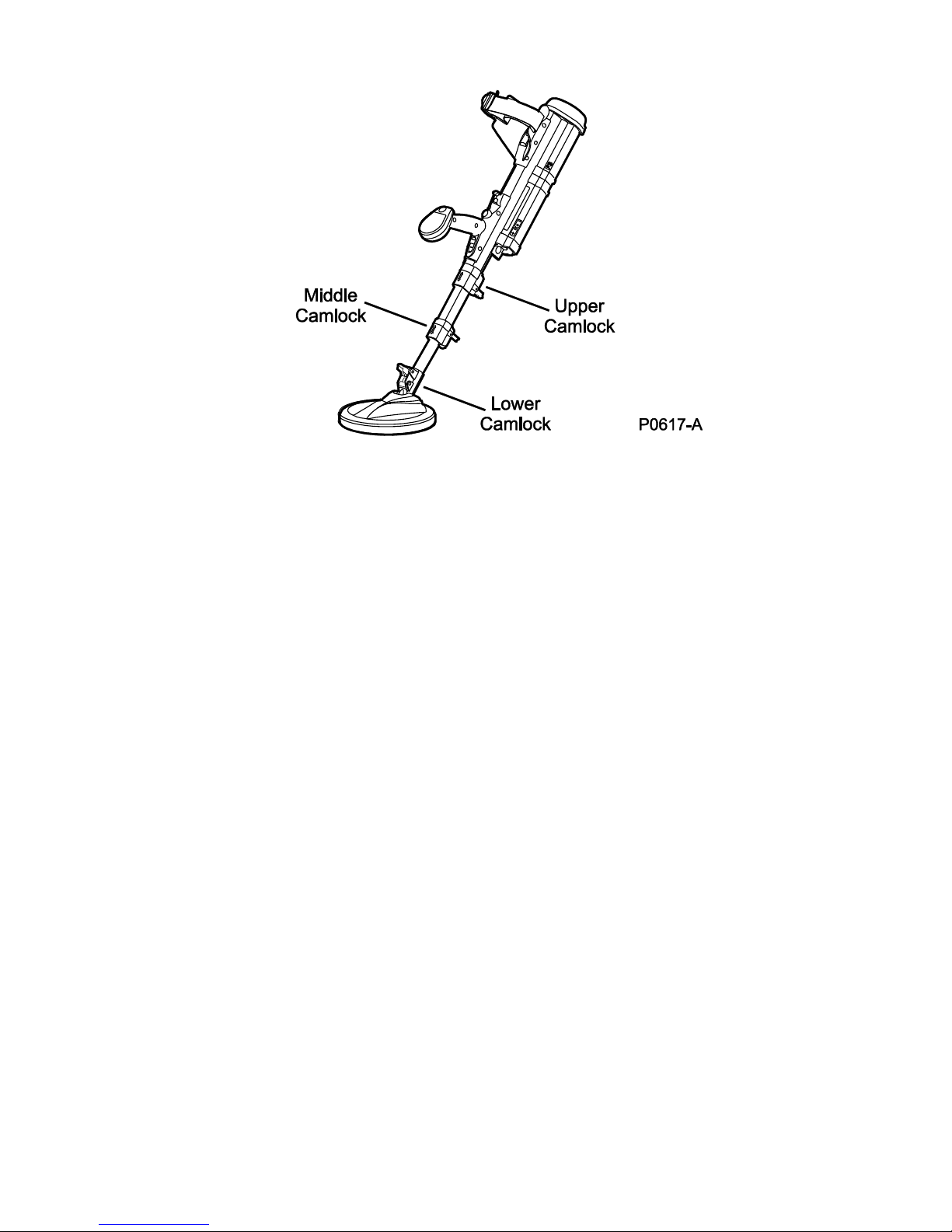

Figure 4 identifies the main components of the F3 which comprise:

Figure 4: F3 – Main Components

a. Sensitivity Endcap – the sensitivity of the F3 can be changed by

using either the Black (maximum), Red (minimum) or Yellow

(variable) Endcaps.

b. Armrest Strap – provided for operator comfort when the F3 is

used for prolonged periods.

c. Armrest – adjustable (via a camlock) to maximise comfort of use

for an operator.

Page 11

8

d. Electronics Pack – contains the electronics of the F3 and is

permanently fixed to the detector.

e. Upper Shaft – made of aluminium for increased robustness and

provides mounting for the Handle, Battery Pack, Electronics Pack

and Armrest.

f. Battery Pack – removable to reduce the weight of the F3 for

periods of prolonged use – contains four D cell batteries.

g. Handle – ergonomically designed for operator comfort and

includes Earset connector and F3 controls.

h. Middle Shaft – made of aluminium for robustness and adjustable

for operator comfort or for changes in demining positions.

i. Lower Shaft – made of impact resistant carbon fibre and is

adjustable.

j. Lower, Middle and Upper Camlocks – self-cleaning locking

mechanisms to position the coil, lower and middle shafts.

k. Coil – enclosed waterproof coil to eliminate possible interference

from vegetation – can be rotated 180 degrees – a monoloop

design that ensures consistent sensitivity around the entire

circumference of the coil and across the complete surface of the

coil.

l. Skid Plate – removable plastic disk that protects and prolongs the

life of the coil thereby reducing maintenance costs.

2.3 F3 Preparation.

To prepare the detector for use, conduct the following procedure:

a. Open the Hard Case or Soft Carry Bag.

b. Remove the F3 and inspect for obvious signs of damage.

c. Check that the correct Sensitivity Endcap is selected and fitted

correctly (if not, exchange Endcaps as described at Section 2.5).

d. Hold the F3 in an inverted position with the Endcap resting

against the inside of the Hard Case (or Soft Carry Bag).

Page 12

9

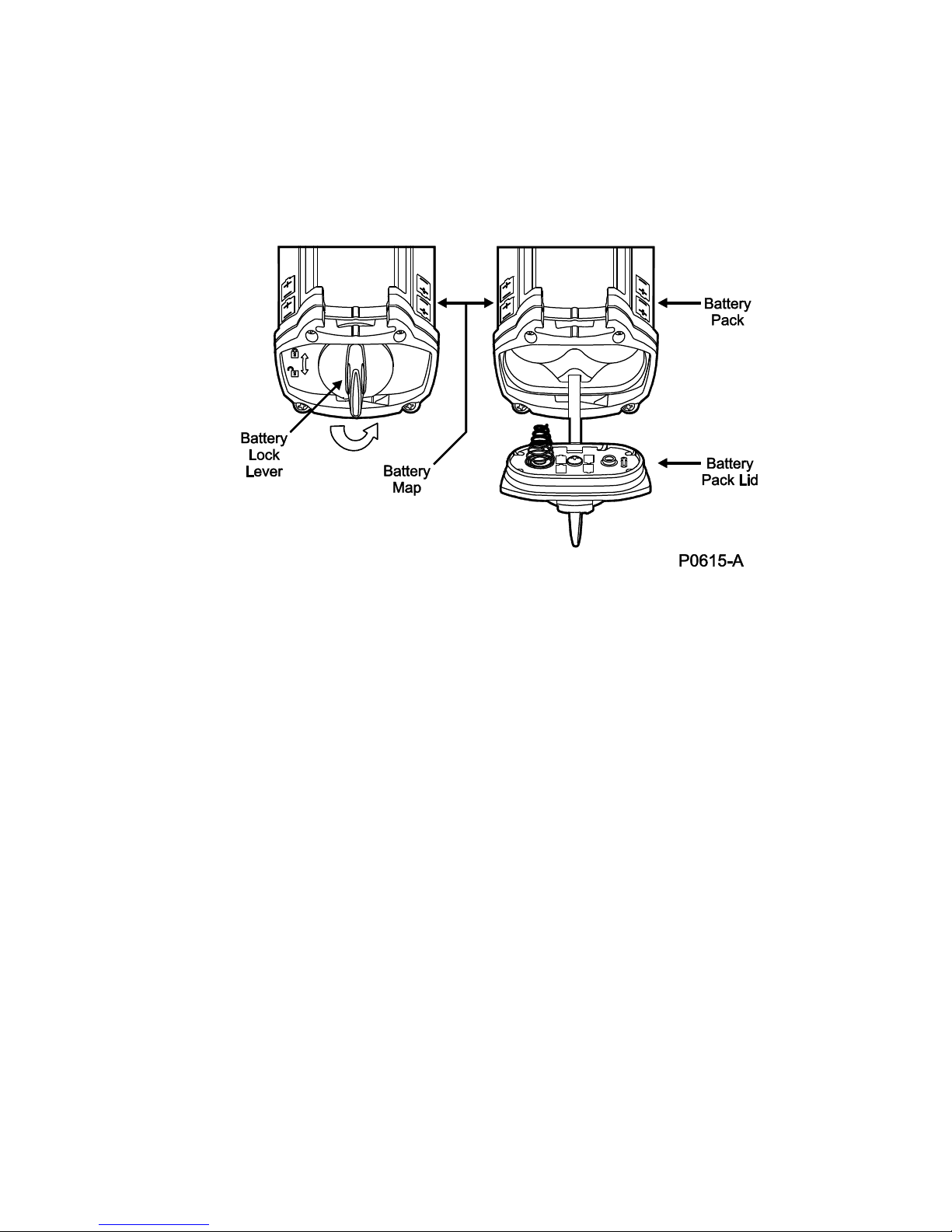

e. Unlock the Battery Pack Lid by twisting the Battery Lock Lever

counter clockwise one-quarter turn. Once unlocked, pull the lid

away from the Battery Pack (the lid will stay attached to the

Battery Pack by a tether – Figure 5).

Figure 5: Removing the Battery Pack Lid

f. Using the battery maps, located on the side of the Battery Pack

and on the inside of the Battery Pack Lid, insert four D cell

batteries. Replace the Battery Pack Lid and rotate the Battery

Lock Lever clockwise one-quarter turn. If the batteries are

inserted incorrectly, the F3 will fail to function when switched on.

NOTE

The F3 requires 4 D cell batteries for operation. Use only high

quality alkaline (LR20) or rechargeable batteries. Minelab

recommends that only rechargeable batteries with a capacity of

4000 mAH or greater be used with the F3. Rechargeable batteries

have specific charge/discharge maintenance requirements, which

should be strictly followed to ensure maximum battery life. Only

NiCad and NiMh type D cell rechargeable batteries are suitable for

use with the F3.

Page 13

10

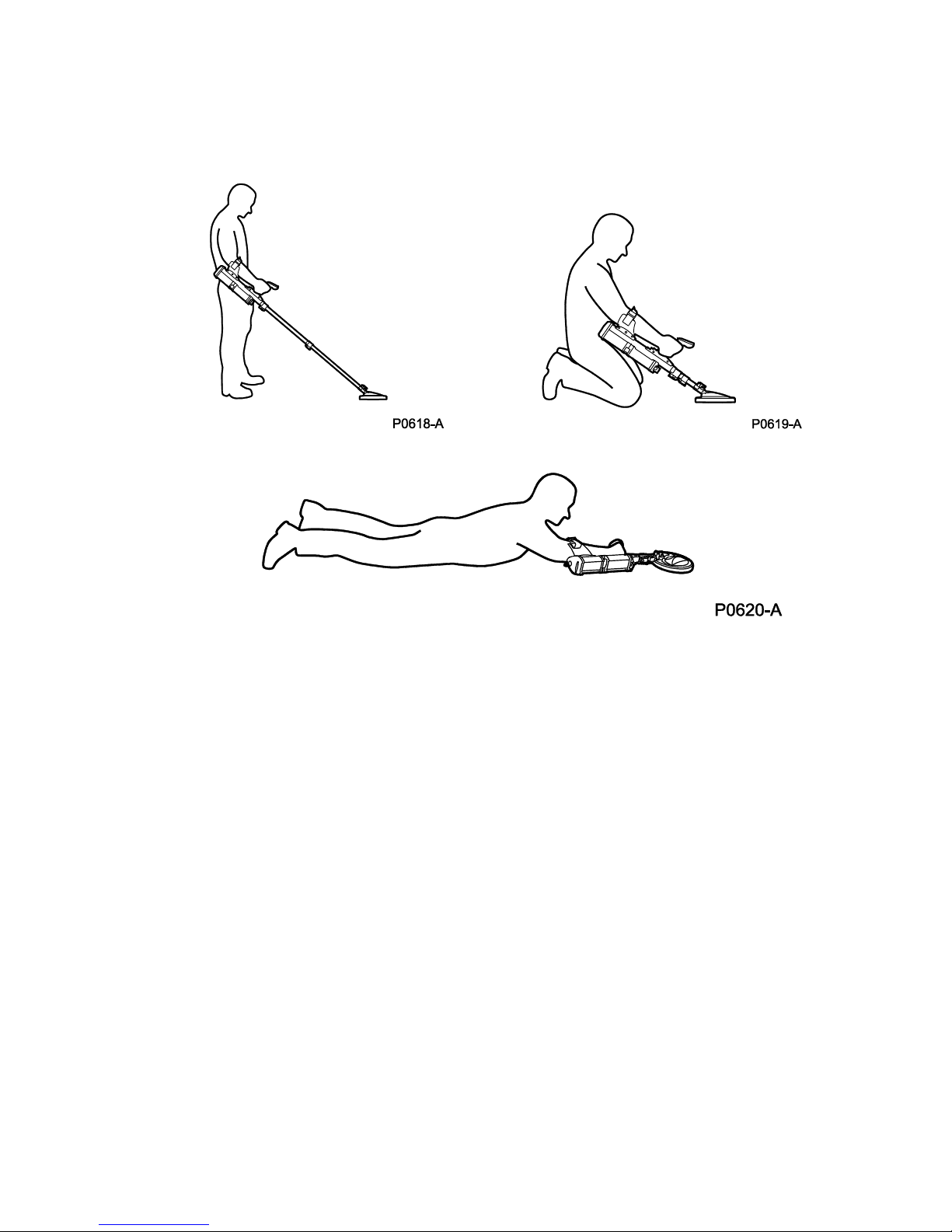

g. Extend the Lower and Middle Shafts to suit the selected

demining position as shown in Figure 6. For use in the standing

position:

Figure 6: F3 in the Standing, Kneeling or Prone Positions

Open the Lower Camlock and rotate the coil to the desired

position. The normal operating position of the coil is in line with

the shaft. However, the coil can also be positioned at right angles

to either side of the shaft (required if the F3 is to be used in the

prone position). Once the position of the coil is selected, lock it

into position by closing the Lower Camlock.

Page 14

11

Figure 7: Camlock Locations

Holding the detector with the coil pointing toward the ground,

open the Middle Camlock and extend the Lower Shaft to the

desired length. Lock the Lower Shaft into position by closing the

Middle Camlock.

NOTE

The Lower Shaft must be extended at least 100mm (4ins). Incorrect

operation of the detector may result if the detector is used with the

Lower Shaft fully retracted.

Open the Upper Camlock and extend the Middle Shaft to the

desired length. Lock the Middle Shaft into position by closing the

Upper Camlock.

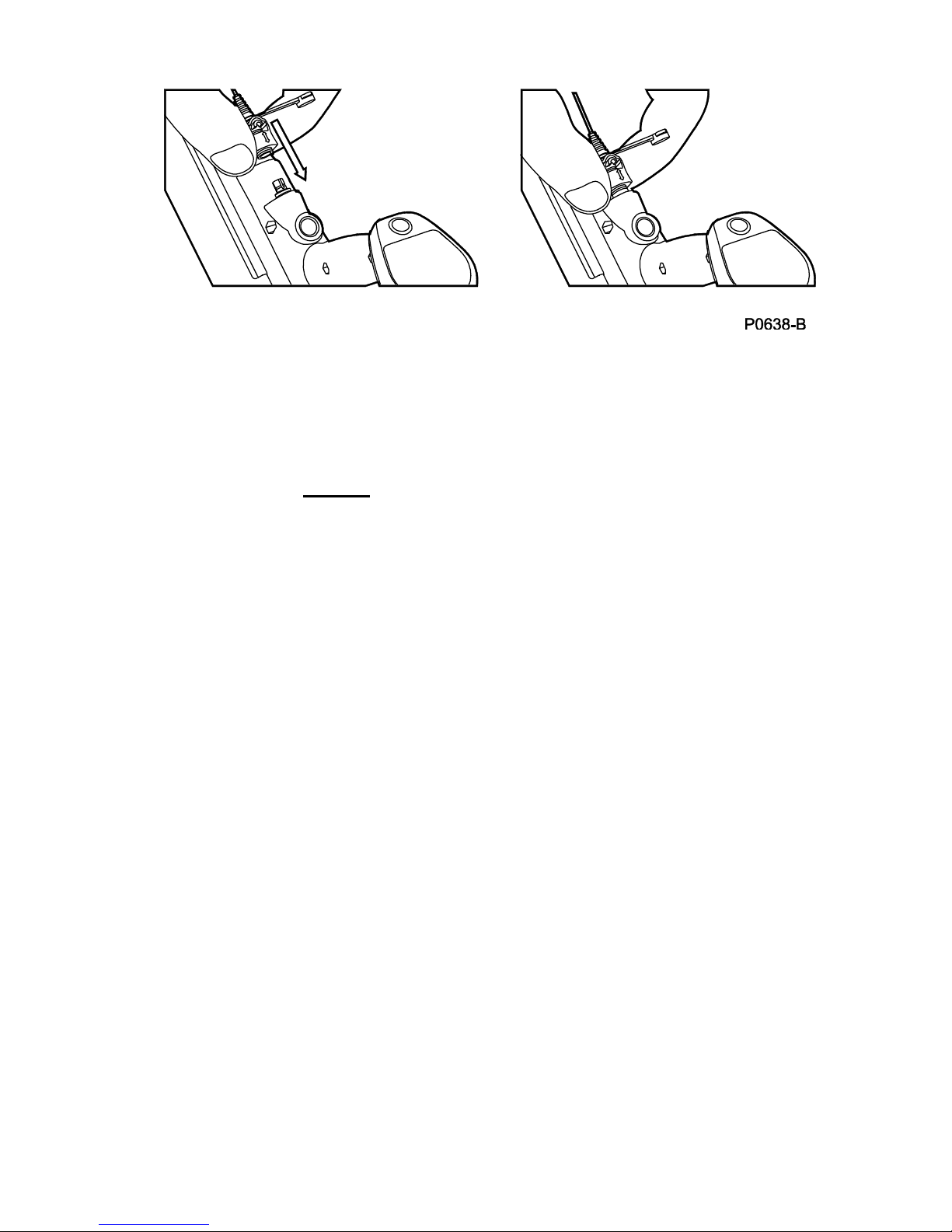

h. Undo the dustcaps from the Earset plug and Earset socket on the

detector. As shown in Figure 8, gently hold the Earset by the

rubber collar using thumb and index finger (raised double arrow

should be uppermost). Align the plug with the Earset socket and

firmly slide the collar onto the socket. Confirm the plug is locked

into position by gently pulling back on the rubber collar.

Page 15

12

Figure 8: Fitting the Earset

NOTE

The Earset connector is waterproof and it is most important that it is

connected and disconnected from the Earset socket by holding the

rubber collar. Do not attempt to connect or disconnect the Earset by

pushing or pulling on the strain relief or wire at the rear of the rubber

collar.

i. For operator comfort, adjust the Armrest by opening the Armrest

Camlock and then slide the Armrest to the desired position. Lock

the Armrest Camlock and tighten the Armstrap as required.

j. The F3 is now ready for use. Refer to Chapter 3 for Functional

Description and Chapter 6 for Operating Procedures.

k. To repack the F3, the procedure described above should be

reversed.

NOTE

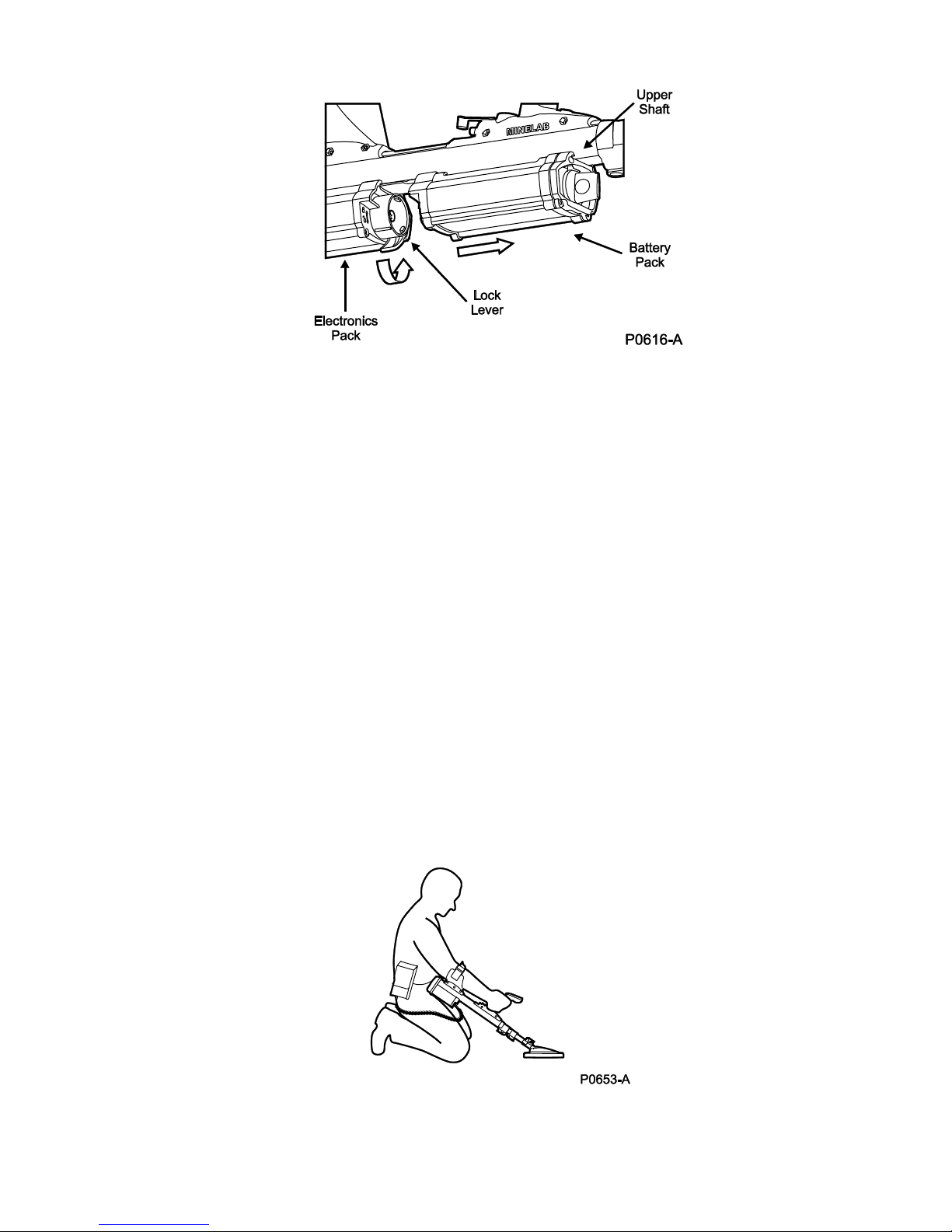

Batteries can be inserted and removed from the Battery Pack while

attached to the Upper Shaft as described at Section 2.3.e.

Alternatively, the Battery Pack can be removed from the Upper Shaft

by pulling down the Lock Lever located between the Battery Pack

and the Electronics Pack as shown in Figure 9.

Page 16

13

Figure 9: Battery Pack Removal

To refit the Battery Pack, ensure that the Lock Lever at the front of

the Electronics Pack is in the unlocked position and position the

Battery Pack on the rail underneath the Upper Shaft.

Slowly slide the Battery Pack towards the Electronics Pack until the

connector is firmly engaged. Secure the Battery Pack by rotating

the Lock Lever in a clockwise motion into the locked position.

2.4 Use of Battery Pack Bag and Extension Cable.

If required, the Battery Pack can be separated from the Upper Shaft

thereby reducing the overall weight of the detector. Using the

bayonet connectors at each end of the Extension Cable, connect the

cable to the Battery Pack and feed the cable through the base of the

Battery Pack Bag before connecting to the Electronics Pack. The

Battery Pack Bag can then be clipped onto a belt worn by the

operator as shown in Figure 10.

Figure 10: Battery Pack Separated from Upper Shaft

Page 17

14

2.5 Changing Endcaps.

The F3 can be used with Black, Red or Yellow Sensitivity Endcaps.

The decision on which Endcap to use will be provided by the local

authority. To fit a Sensitivity Endcap:

a. Ensure the F3 is switched off.

b. Place the thumb of one hand in the centre of the Endcap and curl

the fingers under the base of the Endcap.

c. Gently push inwards with the thumb and simultaneously pull the

base of the Endcap away from the Electronics Pack (Figure 11).

d. Exchange or replace the Endcap by gently positioning the inside

of the base of the Endcap under the base of the Electronics Pack.

Using the palm of the hand, apply light pressure to fit the Endcap

into position.

Figure 11: Removing a Sensitivity Endcap

**WARNING**

The Sensitivity Endcap also provides impact protection to

the Electronics Pack. Whenever an Endcap has been

removed from the Electronics Pack never place the base of

the detector against the ground or sharp objects.

Page 18

15

3. Functional Description

3.1 Functional Controls.

For ease of use, all controls for the F3 are located on the Handle.

For information on the additional controls included in the F3L

configuration, refer to Chapter 4. Figure 12 illustrates the location of

all controls:

Figure 12: F3 Controls

a. On/Off Switch.

The F3 is switched on by sliding the On/Off Switch toward the

Handle. When switched on, the F3 completes a series of internal

start-up functions including initialisation of the microprocessor

and self-tests which check internal power supplies, transmitter

etc.

These internal diagnostics take approximately 12 seconds to

complete during which the operator will hear a series of rising

tones (known as the Start-Up Tones).

At the completion of the Start-Up Tones the F3 emits a low

steady tone known as the Threshold Tone, which confirms to the

operator that the F3 is functioning correctly.

Page 19

16

During operation, continuous internal self-testing continues and

an alarm tone is triggered on detection of any fault condition

(refer to Section 3.3 for a description of the alarm tones).

To turn the F3 off, slide the On/Off Switch away from the Handle.

b. Ground Balance/Audio Reset Button. Easily identifiable as the

Green Button located on top of the Handle, this dual action button

carries out the following functions:

Ground Balance. A key feature of the F3 is its ability to detect

metallic mines in all ground conditions. False alarms due to

mineralised (magnetic/lateritic) soils are automatically removed

through use of the Ground Balance function.

Audio Reset. On occasion, the Threshold Tone may become

louder than normal. Holding the coil stationary over a metallic

object or over mineralised ground for an extended period of time

may cause this. Also, if the detector is being used in the kneeling

position (shafts retracted), any movement of the coil relative to

the shaft may cause the Threshold Tone to increase. The

Threshold Tone can be returned to the normal volume level using

the Audio Reset function.

c. Noise Cancel Button.

Interference from electrical motors, lights, power lines and other

detectors can occasionally cause the Threshold Tone to vary in

pitch and volume. When this occurs, the ability of an operator to

distinguish targets may be degraded.

Using the Noise Cancel function, an operator can initiate an

automatic frequency scanning sequence resulting in the F3

selecting an operating frequency that minimises the effect from

interference.

d. Earset Socket.

The F3 has an internal speaker located inside the Handle.

However, the F3 can also be fitted with an Earset via the Earset

Socket. The procedure for connecting the Earset is described at

Section 2.3.h.

Page 20

17

A standard humanitarian demining Earset (Earset Speaker On)

permits the F3‟s internal speaker to continue to function even

when the Earset is connected.

For military countermine applications, an Earset that mutes the

F3‟s internal speaker when the Earset is connected is available

(Earset Speaker Off). The Earset Speaker Off is identified by a

short length of green tubing located at the rear of the Earset plug.

3.2 Sensitivity Endcaps.

A unique feature of the F3 is its ability to change sensitivity through

the exchange of Sensitivity Endcaps. This design feature eliminates

the possibility of an operator selecting the wrong sensitivity through

manipulation of knobs or switches. The Sensitivity Endcap provides

an obvious visual cue that confirms the level of sensitivity selected in

the F3. The F3 is supplied with Black and Red Sensitivity Endcaps.

Black Sensitivity Endcap. With the Black Sensitivity Endcap

fitted, the F3 performs at maximum sensitivity. The Black Endcap

MUST be selected when searching for minimum metal mines or

when maximum clearance depth is required.

Red Sensitivity Endcap. With the Red Sensitivity Endcap fitted,

the F3 performs at reduced sensitivity. This feature may be

useful when there is a need to ignore small metal fragmentation

on the surface but still detect large targets at depth.

NOTE

If the Red Sensitivity Endcap is not fitted correctly, or there is no

endcap fitted, the detector automatically defaults to the maximum

sensitivity setting (Black Sensitivity Endcap). If the Red Sensitivity

Endcap is partially dislodged or removed during use, an alarm tone

will sound.

**WARNING**

Minelab strongly recommends that an operator should

always wear an Earset when using the F3 detector.

Page 21

18

3.3 Functional Tones.

The F3 emits tones that vary in pitch and volume to alert an operator

to targets, automatic detector functions or equipment alarm

conditions. The following table summarises the tones that an F3 can

produce:

Tones

Event

Description

Start-Up

Internal checks when

the F3 is switched on

Four rising tones over

12 seconds

Threshold

Signifies correct

operation of detector

Steady low volume

continuous tone

Ground Balance

Indicates successful

Ground Balance

procedure completed

One fast high pitched

double beep

Target

Indicates metal target

detected

Increases volume

(compared to

Threshold Tone) and

high or low pitch

depending on target

metal composition and

**WARNING**

Where a minimum metal mine threat exists, the F3 MUST

be operated with the Black Sensitivity Endcap.

Depending on the size of the target and the depth of

detection required, the Red Sensitivity Endcap may not be

suitable for use. It is recommended that, prior to

operational use, the capability of the F3, fitted with the Red

Sensitivity Cap, be tested against the local threat to ensure

detection occurs.

Page 22

19

depth

Low Battery

Indicates batteries do

not have enough

charge to continue

detection

High pitched fast

continuous oscillating

tone

Equipment Fault

Indicates failure of

detector component or

a dislodged Red

Sensitivity Endcap

Low pitched slow

oscillating tone (eeaww, ee-aww)

Coil Fault

Indicates coil not

connected or not

receiving sufficient

current

Low pitched double

tone every five

seconds

Noise Cancel

Indicates Noise Cancel

procedure is occurring

Two single beeps

followed by 45 seconds

of short double beeps

finishing with four

single beeps

NOTE

Circuitry within the F3 ensures that its performance remains

consistent as the charge state of the batteries begins to reduce.

When the batteries can no longer supply the necessary power to

sustain correct performance of the detector, a Low Battery Alarm will

alert the operator.

**WARNING**

When Low Battery Alarm occurs the operator must

immediately STOP demining operations. The F3 should be

switched off and new or recharged batteries inserted into

the Battery Pack (Refer to Section 2.3.e /f for instruction on

changing batteries).

Page 23

20

3.4 Test Piece – Functional Test.

The F3 is supplied with a Test Piece specially designed to confirm

that the detector is working to correct specifications. The sensitivity

of the detector should be checked with the Test Piece before, during

and after demining operations, (in compliance with local Standard

Operating Procedures). In some instances, a user may prefer to use

inert mines as test pieces because they represent the local threat.

Minelab recommends that the detector always be first tested with the

supplied Test Piece before local test pieces are used for testing.

NOTE

When switched on, maximum sensitivity is available 30 seconds

after the Threshold Tone commences. Do not test the detector with

the Test Piece until 30 seconds after the Threshold Tone begins.

Page 24

21

4. F3L Configuration

4.1 Introduction.

Detectors fitted with the LED Display and Volume/Sensitivity (V/S)

Control leave the factory with the LED Display and

Volume/Sensitivity Control enabled. The LEDs give an operator a

visual indication of the size and proximity of a target. The V/S

Control provides the facility to reduce or increase V/S levels to suit

specific detection circumstances. If required, the LED display and

the ability to vary V/S levels can be disabled on the F3L.

4.2 Description.

The F3L is fitted with a modified speaker pod comprising (Figure

13):

13 red LED display to display target strength and proximity

Volume/Sensitivity increase button and Volume/Sensitivity

decrease button .

Red “Battery Low” alarm LED.

Quick guide to enable and disable all LEDs.

Quick guide to enable and disable V/S control buttons.

Quick guide to display battery level status.

Figure 13: F3L Speaker Pod

Page 25

22

**WARNING**

Decreasing the Volume/Sensitivity of the F3 detector also

decreases the sensitivity (depth of detection) of the detector,

thereby increasing the possibility of missing minimum metal

mines.

4.3 Operation-Volume/Sensitivity Control.

From the default (middle) V/S setting, it is possible to increase or

decrease V/S levels in five steps. Regardless of the V/S level

selected, the volume of the Threshold Tone will remain the same.

For safety reasons, the V/S setting will always commence at the

default (middle) setting every time the F3L is switched on. The Test

Piece Procedure must ALWAYS be carried out at the default V/S

level setting.

a. Increasing Volume/Sensitivity. To increase the V/S level,

press and release the Volume/Sensitivity button the required

number of times (maximum five times from default level). During

each button press, a short high-pitched tone will be heard. When

the maximum V/S level is reached a long high-pitched tone will

be heard.

b. Decreasing Volume/Sensitivity. To decrease the V/S level,

press and release the Volume/Sensitivity button the required

number of times (maximum five times from default level). During

each button press, a short low-pitched tone will be heard. When

the minimum V/S level is reached a long low-pitched tone will be

heard.

c. Resetting Volume/Sensitivity to Default Setting. Where the

V/S setting has been adjusted, it can be restored to default level

by:

pressing and releasing the or buttons as required until a

double tone is heard,

pressing and holding the button and then simultaneously

quickly pressing and releasing the black Noise Cancel Button, or

Page 26

23

switching the F3L off and on.

d. Disabling and Enabling Volume/Sensitivity Control. The F3L

factory pre-set is V/S Control enabled but this feature can be

disabled or enabled as follows:

Disable. To disable the V/S Control after the detector has been

switched on, press and hold the button and simultaneously,

quickly press and release the black Noise Cancel Button. If done

correctly, a double tone will be heard.

Enable. To enable the V/S Control after the detector has been

switched on, press and hold the button and simultaneously,

quickly press and release the black Noise Cancel Button. If done

correctly, a double tone will be heard.

NOTE

If the or buttons are pressed and the V/S Control has been

disabled, then a double tone will be heard signifying that adjustment

of the V/S has been disabled and the F3L is operating at the default

V/S setting.

If the V/S control has been disabled, it will remain disabled

regardless of switching the F3L Off and On. It will remain disabled

until the V/S Control is enabled.

4.4 Operation-LED Display.

The LED display is located on top of the speaker pod and comprises

13 red LEDs, which provide an indication of target size and

proximity. Additionally, a “Battery Low” alarm red LED will

commence flashing (along with the Battery Alarm tone) when battery

power is not sufficient to maintain consistent equipment sensitivity.

Typical illuminations are illustrated in Figure 14:

No target

Threshold Tone only

Page 27

24

NOTE

If more than one LED is illuminated or the display is erratic (in

combination with a variable tone response), conduct Audio Reset

and/or Noise Cancel.

Test Piece Procedure

at V/S default setting with Black Endcap

Up to three LEDs illuminated

Small/deep target response Medium target response

Large/shallow target response Low Battery Alarm

Figure 14: Typical LED Responses

Page 28

25

a. Disabling and Enabling LED Display. The F3L factory pre-set

is LED display enabled but this feature can be disabled or

enabled as follows:

Disable. With the detector switched on, to disable the LED

display, press and hold the button and simultaneously, quickly

press and release the green Ground Balance button.

NOTE

Once the LED display is disabled, unless subsequently enabled, the

LEDs will remain extinguished even if the detector is repeatedly

switched off and on.

Enable. With the detector switched ON, to enable the LED

display, press and hold the button and simultaneously, quickly

press and release the green Ground Balance button.

NOTE

Once the LED display is enabled, unless subsequently disabled, the

LEDs will be illuminated whenever the detector is switched on.

If an Earset Speaker OFF is connected to the detector, the LED

display will be automatically disabled for tactical reasons. However,

if required the LED display can be enabled as described above.

4.5 Battery Status.

The F3L detector can display the battery voltage level at any time by

pressing and holding down the button and then pressing and

immediately releasing the button. Once completed the LED

display will indicate the battery status for a period of three seconds.

Page 29

26

5. F3S Configuration Yellow Endcap.

5.1 Introduction.

The F3S permits the volume, sensitivity and ground balance

parameters of a detector to be customised.

5.2 Description.

To customise the performace of the F3S detector a Yellow

Sensitivity Endcap is fitted and the detector is connected to a

computer via the Earset Socket with a proprietary Minelab

programming cable. Using the Minelab „Configuration Editor‟

software the sensitivity, audio volume and ground balance can be

checked, reset to default or edited.

When a Yellow Sensitivity Endcap is connected to an F3S the

detector will switch to the settings last uploaded from the

configuration editor. If the F3S has not been previously programmed

the detector will default to the same settings as the Black Sensitivity

Endcap.

Details on how to use the configuration editor are provided in the

Help File contained in the software.

**WARNING**

When using an F3S with Yellow Sensitivity Endcap and

customised sensitivity, audio volume or ground balance it is

the responsibility of the user to provide a suitable test piece

to confirm the performance of the F3S.

Page 30

27

6. Operating Procedures

6.1 Introduction.

The F3 is designed to ensure that operation of the detector is as

simple as possible. Additionally, the F3 is extremely capable, safe

to use, robust and eliminates the need for complicated controls or

lengthy training requirements. This Chapter describes procedures

for safe and effective operation of the F3. Where these procedures

contravene local Standard Operating Procedures, local procedures

should take precedence provided all Minelab recommended safety

procedures are followed.

Figure 15: F3 Detector

Page 31

28

6.2 Standard Procedure.

After unpacking the F3 and preparing it for use as described in

Chapter 2 (appropriate Sensitivity Endcap fitted as directed by the

local authority), complete the THREE step standard procedure as

follows:

Figure 16: F3 Controls

a. STEP 1 Switch ON

Hold the coil at least 600mm (24ins) from the ground and away

from any metallic objects. Turn the detector on by sliding the

On/Off switch back towards the handle.

Figure 17: Switching on the Detector

Page 32

29

The F3 will emit a series of four rising tones over 12 seconds

(internal diagnostic checks occurring).

At the completion of the Start-Up Tones a low volume Threshold

Tone will remain audible.

Figure 18: Switch On

If the Threshold Tone is steady continue with STEP 2. If the

Threshold Tone is noisy or uneven when the coil is stationary,

perform a Noise Cancel (Section 6.3.a).

If the Threshold Tone is steady but seems louder than normal

when the coil is away from the ground and metallic targets,

perform an Audio Reset (Section 6.3.b).

b. STEP 2 Ground Balance

Ensure this procedure is carried out on ground free of metal and

hold the coil about 150mm (6 ins) above the ground.

Press down and hold the green Ground Balance button

and slowly lower the coil directly to the ground then lift the coil up

again 150mm (6ins). Refer to Figure 19.

Continue to slowly lower and raise the coil until the „Ground

Balance OK‟ tone is heard. („Ground Balance OK‟ tone consists

of a short high-pitched double beep).

Release the Ground Balance button.

Page 33

30

Figure 19: Ground Balance Procedure

NOTE

Movement of the coil during the entire Ground Balance procedure

should be slow, continuous and smooth and each down and up

movement should take 3 to 4 seconds.

If the Ground Balance OK tone is not heard within

30 seconds of starting the procedure, release the Ground Balance

button and repeat this procedure.

If there is metal in the ground under the coil whilst Ground

Balancing, the detector will not Ground Balance correctly. Move the

detector and repeat the Ground Balance over ground that is free of

any metallic objects.

After the Ground Balance procedure is completed the detector will

automatically cancel interference from the ground under the coil. If

ground conditions change (changing mineralisation in the ground)

this procedure may need to be repeated.

c. STEP 3 Test Piece

Ensure the operator‟s hands and arms are free of metallic objects

(watches, rings etc), and that no other metallic objects are near

the coil. The orientation of the Test Piece during the test is

dependent on which Sensitivity Endcap is connected to the

detector.

Page 34

31

NOTE

Maximum sensitivity is only available 30 seconds after the Threshold

Tone commences. Do not test the detector with the Test Piece until

30 seconds after the Threshold Tone begins.

Black Sensitivity Endcap:

Hold the Test Piece above the middle of the coil with the rounded

end (containing metallic target) AWAY from the coil.

Move the Test Piece towards the centre of the coil until it lightly

touches the surface then move it sideways off the coil (the Test

Piece should be moved slowly and smoothly during this procedure).

A faint but clear response (change in Threshold Tone volume and

pitch) should be heard indicating the sensitivity of the detector is

correct.

Figure 20: Test Piece Procedure

Red Sensitivity Endcap:

Hold the Test Piece above the middle of the coil with the rounded

end (containing the metallic target) TOWARDS the coil.

Move the Test Piece towards the centre of the coil until it lightly

touches the surface then move it sideways off the coil (the Test

Page 35

32

Piece should be moved slowly and smoothly during this procedure).

A clear response (change in Threshold Tone volume and pitch)

should be heard indicating the sensitivity of the detector is correct.

NOTE

The Test Piece not only ensures the sensitivity of the detector is

correct but also gives the operator an example of how a minimum

metal mine might sound when deeply buried: for example Type 72A

at 15cm . (Black Endcap only).

Yellow Sensitivity Endcap:

When the F3 detector is programmed with Sensitivity, Audio Volume

or Ground Balance settings that differ from the default black endcap

settings the Minelab test piece cannot be used to confirm the

performance of the detector. When using the yellow endcap with

user customised configuration it is the responsibility of the user to

provide a test piece or appropriate target to confirm the detector

satisfies operational requirements.

6.3 Optional Procedure.

If after Step ONE the Threshold Tone is not low and steady, conduct

one or both of the following:

a. Noise Cancel. If the Threshold Tone is noisy or uneven when

the coil is stationary, conduct Noise Cancel as follows:

NOTE

The detector cannot be used for clearing operations during Noise

Cancel. The coil should not be moved during this procedure nor

should metallic objects be brought near the coil during this

procedure.

Holding the coil stationary and at least 600mm (24ins) above the

ground press and immediately release the Noise Cancel button

(Black Button located behind the handle).

Page 36

33

Figure 21: Noise cancel

Noise Cancel will commence with two single beeps followed by

45 seconds of sharp double beeps finishing with four single

beeps.

During the 45 seconds, the detector scans the environment

searching for any electrical interference. Once detected, the F3

will automatically select a different operating frequency to

eliminate or reduce the interference.

b. Audio Reset. Whenever the Threshold Tone sounds louder than

normal perform the Audio Reset procedure as follows:

NOTE

The detector cannot be used for clearing operations during the

Audio Reset procedure.

Audio Reset should be carried out whenever the threshold

volume seems louder than normal.

Hold the coil away from any metallic objects. Press and

immediately release the Ground Balance button (Green Button

Page 37

34

located on top of the Handle). Within two seconds the threshold

tone will return to its correct level.

Figure 22. Audio Reset

NOTE

If the Audio Reset button is held too long, the detector will

commence the Ground Balance procedure.

Noise Cancel and Audio Reset procedures can be performed at any

time the Threshold Tone becomes noisy, uneven, or rises in volume.

Once Noise Cancel or Audio Reset is complete, continue with steps

2 and 3. Figure 23 illustrates this sequence. Once completed, the

F3 can commence operations in compliance with local Standard

Operating Procedures.

Having completed STEPS 1, 2 and 3 the F3 remembers the Ground

Balance setting even after the detector has been switched off.

After Noise Cancel is completed the F3 remembers the frequency

selected to minimise interference, even if the detector is switched

off.

Page 38

35

Figure 23: Standard & Optional Procedure

Y

STEP 1

SWITCH ON

STEP 2

GROUND BALANCE

STEP 3

TEST PIECE

NOISE

CANCEL

AUDIO

RESET

Threshold

Noisy/Uneven

Threshold

Louder than

Normal

Y

N

N

Optional

Procedure

Page 39

36

6.4 Sweeping Procedure.

The F3 should be swept with a smooth even motion at a speed of

0.6 m/s (2 ft/s). If the detector is swept too fast or too slow, small or

deep targets may be missed. The coil should always be kept at the

same height above the ground with care taken to ensure that the coil

is not inadvertently raised at the end of each sweep (Figure 24).

Figure 24: Sweeping Procedure

a. Depth of detection depends on target distance from the coil, not

depth of the target under the ground. Therefore, the coil should

be swept as close to the ground as possible to maximise

detection depth. (Local Standard Operating Procedures take

precedence.)

NOTE

Minelab recommends a half coil (100mm / 4ins) overlap on

successive sweeps as an operator moves forward in a mine lane

b. When a target is initially detected, an operator should stand in

place and continue to sweep the F3 beyond the target in an

attempt to find clear ground. In doing so the operator will:

immediately gain an impression of the size of the target prior to

commencing the pin-pointing procedure; and

confirm the target is not in close proximity to a second target

thereby avoiding a possible booby trap.

Page 40

37

6.5 Pinpointing Procedure.

The design of the F3 makes pinpointing accurate and fast. The F3‟s

monoloop coil means there are no gaps in sensitivity around the

coil‟s circumference or across its surface. Pin-Pointing is conducted

as follows:

a. STEP 1 Mapping the Target

Having detected a target and obtained a rough idea as to its size

and location using the sweeping procedure, the precise location

of the target can be “mapped” using the F3‟s “Edge Detection”

technique.

Edge Detection makes use of the coil‟s consistent sensitivity

around its circumference to detect the area of a target. To

conduct edge detection, the coil should approach the target

location from a variety of angles as shown in Figure 25.

As the coil approaches the target, the Threshold Tone will change

indicating the coil is in close proximity to the target. At the

change of the Threshold Tone, the operator should mentally mark

the position on the ground, move the coil away, and approach the

target from another angle.

This process continues until the operator achieves a mental

picture of the target area.

Figure 25: Mapping the Target

Page 41

38

b. STEP 2 Determine Centre of Target

In Step 1, the area of a target was determined. If the metal in the

target is sufficiently small, the area mapped will also be small and

therefore it is a relatively simple matter to pin-point the centre of

the target.

For larger targets, to determine the centre, the coil should be

slowly moved across the mapped area. As the coil approaches

the centre of the target, the threshold tone will increase to a

maximum volume (pitch may be high or low depending on the

composition of the metal). Where maximum volume is achieved,

the coil can be considered to be above the centre of the target.

Once confirmed, local Standard Operating Procedures should be

followed to mark the target.

**WARNING**

Extreme care must be taken when mapping the target to

ensure that the coil does not touch the ground (or any

exposed parts of the mine) or snag on any previously

undetected trip wires.

For large minimum metal anti-tank mines, it is possible

that the area mapped out may be less than the actual

area of the mine.

After an initial detection, if the coil is repeatedly swept

over a small deeply buried target, the response may

fade. If this occurs, move the coil away from the target

and perform an Audio Reset procedure (Section 6.3.b)

then return to the target location and continue with the

pin-pointing procedure.

Page 42

39

Figure 26: Determining Target Centre

NOTE

An operator can confirm that the centre of a target has been located

by moving the coil slightly, in any direction, and returning to the

centre. In doing so the volume of the Threshold Tone should

decrease from maximum as the coil leaves the centre and return to

maximum as the coil returns to the centre.

6.6 Multiple Targets.

There may be occasions when an operator will encounter multiple

targets. For example, small anti-personnel mines may be laid in a

cluster, or a large anti-tank mine may be surrounded by smaller antipersonnel mines or booby-traps. Regardless, the pin-pointing

procedure for the F3 can be used to effectively map a suspicious

area as follows:

a. STEP 1 Mapping the Target

Using the procedure described in Section 6.5.a, an area

enclosing the multiple targets can be mapped.

Maximum Volume

Page 43

40

Figure 27: Mapping Multiple Targets

NOTE

To an experienced operator the shape of the mapped area can

indicate whether multiple targets may be present.

b. STEP 2 Determining the Centre of Target

The pitch of the Threshold Tone will rise or fall depending on the

combination of metals or the composition of metal in a mine. This

means that, in some instances, experienced operators may be

able to identify one mine against another (Figure 28).

By slowly moving the coil across the mapped area, it may be

possible to detect tonal differences indicating multiple targets.

**WARNING**

The volume from a large target may mask that of a small

target if the small target is located very close to the large

target.

Page 44

41

Figure 28: Multiple Targets

6.7 Operating Multiple Detectors in Close Proximity.

On occasion it may be necessary to operate F3 detectors in close

proximity. In normal circumstances, an F3 detector can operate as

close as 2 metres (7 feet) to another F3 detector without suffering

excessive mutual interference. To achieve this minimum operating

distance between detectors, Noise Cancel is to be conducted as

follows:

a. With all other detectors switched off, switch on the first detector

and perform Noise Cancel as described in Section 6.3.a.

b. Once Noise Cancel is finished on the first detector, leave it

switched on and switch on the second detector (at least 2 metres

away) and conduct Noise Cancel using the Noise Cancel button

of the second detector.

c. Continue this process for all detectors being used in close

proximity.

+

Page 45

42

NOISE CANCEL

2 metres

Figure 29: Operating Detectors in Close Proximity

6.8 Completion of Operations.

At the completion of operations, the F3 should be checked with the

Test Piece before switching off to ensure satisfactory performance

before being packed away. Once completed:

a. Turn the detector off.

b. Clean the detector and inspect for any signs of damage (Chapter

7).

c. Remove the batteries from the Battery Pack and stow in the Hard

Case or Soft Carry Bag.

d. Disconnect the Earset.

e. Retract the Middle and Lower Shafts rotating the Coil to the

stowed position.

f. Stow the detector in the Hard Case or Soft Carry Bag.

g. Check all components are accounted for (especially the Test

Piece and Earset) and are correctly packed.

Page 46

43

7. Care and Trouble Shooting

7.1 Routine Care.

The F3 is designed for lasting use in harsh operating environments.

However, proper care and maintenance will ensure long-term

reliability. Key to ensuring the survivability of the F3 is the correct

stowage of the detector into its Hard Case whenever the detector is

not in use. Additionally, operators of F3 detectors should be aware

of the following:

a. During rest periods, wherever possible, the detector should be

sheltered from direct sun, rain, snow etc.

b. At the completion of operations, with the F3 fully extended, all

shafts should be wiped with a damp cloth to remove any dirt or

dust before collapsing the shafts.

c. Do not use solvents to clean the F3. If any part of the detector

comes into contact with corrosive substances (including salt

water), wash the detector with clean fresh water and dry with a

clean cloth.

d. Ensure the F3 is dry before stowing in the hard case.

e. Ensure the batteries are removed from the Battery Pack before

stowing the detector.

f. The Skid Plate is designed to protect the coil and may require

replacement after long periods of use. There is no requirement to

remove the skid plate to clean the inside during routine

maintenance. To replace the Skid Plate, remove the original

using fingers to lever it from the coil. It is then a simple matter to

push the replacement Skid Plate onto the coil.

Figure 30: Replacing the Skid Plate

Page 47

44

7.2 Trouble Shooting.

The following table provides several trouble shooting procedures in

response to a variety of possible problems:

Problem

Recommended Procedure

F3 will not switch On

1. Check batteries have been inserted correctly

into the Battery Pack - or

2. Replace batteries - or

3. Remove Battery Pack and reconnect ensuring

battery Lock Lever is locked into position - or

4. Exchange Battery Packs (if this solves the

problem, the original Battery Pack may be faulty)

After switching On there is

a very loud noise

1. Ensure Lower Shaft is extended at least

100mm (4ins) beyond the Middle Shaft - or

2. Conduct Audio Reset

After switching On the

Threshold Tone varies in

pitch and volume with the

coil stationary

1. Conduct Noise Cancel

There is no sound from the

Earset

1. Disconnect and reconnect the Earset - or

2. Try a known serviceable Earset (if this solves

the problem, the original Earset may be faulty, if

this does not solve the problem, the Earset socket

may be faulty)

There is no sound from the

Speaker

1. Switch Off and On - or

2. Disconnect Earset, Switch Off and On

Cannot hear the Test Piece

with the Black Sensitivity

End Cap

1. Ensure that the detector has been turned on

for at least 30 seconds

2. Conduct Audio Reset

Cannot hear the Test

Piece with the Red

Sensitivity End Cap

1. Repeat the Test Piece test and make

sure the metal in the Test Piece is pointed

toward the coil surface

2. Conduct Audio Reset

Page 48

45

8. Specifications

Length:

Operating Length

1500mm/59.4ins to 750mm/30ins

Weight:

Operating weight with

batteries (complete)

3.2kg/7lbs

Operating weight without

Battery Pack

2.3kg/5lbs

Battery Pack with batteries

0.9kg/2lbs

Shipping weight (in hard

case with batteries)

10.5kg/23lbs

Transmission:

Pulse Induction

Bi-polar Multi-Period-Sensing

Output:

Audio

Internal Loudspeaker

Earset (various configurations avail)

Visual

13 LED Display (F3L Configuration)

Data Output

RS-232 (bi-directional)

Page 49

46

Environmental:

Temperature (Operating)

-30 deg C to 60 deg C

-22 deg F to 140 deg F

Temperature (Storage)

-30 deg C to 80 deg C

-22deg F to 176 deg F

Environmental Resistance

To MIL STD 810F:

Method 512.4 (Water immersion

IP67)

Method 514.5 (Vibration)

Method 516.5 (Shock)

Batteries (4 required):

Alkaline

D cell LR20

Rechargeable

NiCad or NiMh D cell minimum

4000mAh capacity

Battery Reverse Polarity

Protection:

Yes

Patents and Trademarks:

Patents and trademarks may apply to this product.

Patents: www.minelab.com/patents.

Page 50

47

Disclaimer

As a world leader in metal sensing technology, Minelab strives to

continually improve its product range. Minelab reserves the right to

introduce changes to the design, technical features and accessories

of this product.

Contact Details:

Minelab Electronics Pty Ltd

Tel: +61 (0)8 8238 0888

email: countermine@minelab.com.au

Minelab Americas Inc

Tel: +1 630 401 8150

email: countermine@minelab.com.au

Minelab International Ltd

Tel: +353 (0)21 423 2352

email: countermine@minelab.com.au

www.minelab.com

Page 51

Loading...

Loading...