Page 1

Version 1: January 2012

Part No: 4904-0005

F3 Metal Mine Detector

SERVICE MANUAL

F3 COMPACT Metal Mine

Detector

Page 2

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

2

Contents

1. Introduction .................................................................................................................................... 3

2. Mechanical & Functional Testing ..................................................................................................... 4

3. Disassembly & Reassembly Procedures .......................................................................................... 13

3.1 Opening the Detector Body .................................................................................................... 14

3.2 Closing the Detector Body ...................................................................................................... 17

3.3 Main Printed Circuit Board (PCB) ............................................................................................ 23

3.3.1 Removing the Main PCB ................................................................................................. 24

3.3.2 Main PCB Assembly ........................................................................................................ 27

3.3.3 Installing the Main PCB. .................................................................................................. 28

3.4 Coil ........................................................................................................................................ 31

3.4.1 Skid Plate Replacement .................................................................................................. 32

3.4.2 Removing the Coil .......................................................................................................... 32

3.4.3 Coil Pivot. ....................................................................................................................... 34

3.4.4 Removing Coil Pivot ........................................................................................................ 35

3.4.5 Fitting the Coil Pivot. ...................................................................................................... 36

3.4.6 Fitting the Coil ................................................................................................................ 39

3.5 Shafts ..................................................................................................................................... 42

3.5.1 Replacing a Camlock ....................................................................................................... 43

3.5.2 Removing the Shafts ....................................................................................................... 43

3.5.3 Fitting the Shafts ............................................................................................................ 45

3.6 Handle ................................................................................................................................... 46

3.6.1 Removing the Handle ..................................................................................................... 47

3.6.2 Fitting the Handle ........................................................................................................... 48

3.7 Armrest .................................................................................................................................. 49

3.7.1 Replacing the Armrest .................................................................................................... 49

3.8 Battery Compartment ............................................................................................................ 50

3.8.1 Battery Lid Replacement................................................................................................. 51

3.8.2 Battery Compartment Replacement ............................................................................... 51

3.9 Detector Body ........................................................................................................................ 53

3.9.1 Control Switches Replacement ....................................................................................... 53

3.9.2 Speaker Replacement ..................................................................................................... 56

3.9.3 Wiring Loom Earset Replacement ................................................................................... 57

3.9.4 Wiring Loom Handle Socket Replacement ...................................................................... 58

3.9.5 Detector Body Parts ....................................................................................................... 59

4 Fault Finding Procedures................................................................................................................ 62

4.1 Introduction ........................................................................................................................... 62

4.2 Trouble Shooting Table .......................................................................................................... 62

Page 3

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

3

1. Introduction

a. Servicing the F3 COMPACT includes fault finding, repair and maintenance and is

designed to be simple and fast thereby reducing the amount of time a detector is unusable.

Repair and maintenance is based on line replaceable units which can be fitted to a detector

without the need for adjustment or calibration. Additionally, serviceable line replaceable units

can be exchanged between detectors as required.

b. Line replaceable units are components or sub assemblies of the F3 COMPACT that can

be purchased from Minelab for the purpose of repairing the F3 COMPACT. Line replaceable

units include the following:

3004-0044 Coil Kit

3004-0045 Coil Pivot Kit

3004-0046 Shaft Kit

3004-0047 Camlock kit

3004-0048 Armrest Kit with Slide

3004-0049 Armrest Kit

3004-0050 Handle Kit

3004-0051 Battery Compartment Kit

3004-0052 Battery Lid Kit

3004-0053 Main PCB Kit

3004-0054 Switches Kit

3004-0056 Wiring Loom Handle Socket Kit

3004-0057 Speaker Kit

3004-0058 Wiring Loom Earset Kit

c. Servicing the F3 COMPACT can be conducted within the field (under clean and dry

conditions) or at local service centres. No special tools are required, but it is recommended

that the F3 COMPACT Service Tool Kit be used.

d. Servicing the F3 COMPACT is restricted to the exchange of line replaceable units

following the identification of a faulty sub-assembly. Servicing DOES NOT include any repairs to

printed circuit boards as this is only conducted at a Minelab facility.

e. This manual should be read in conjunction with the F3 COMPACT Operations Manual.

Additionally, from time to time, Minelab will issue Technical Service Notes which serve to

supplement the information contained in this manual.

f. Any questions regarding this manual or any repair procedure can be directed to Minelab

at Countermine@minelab.com.au

Page 4

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

4

2. Mechanical & Functional Testing

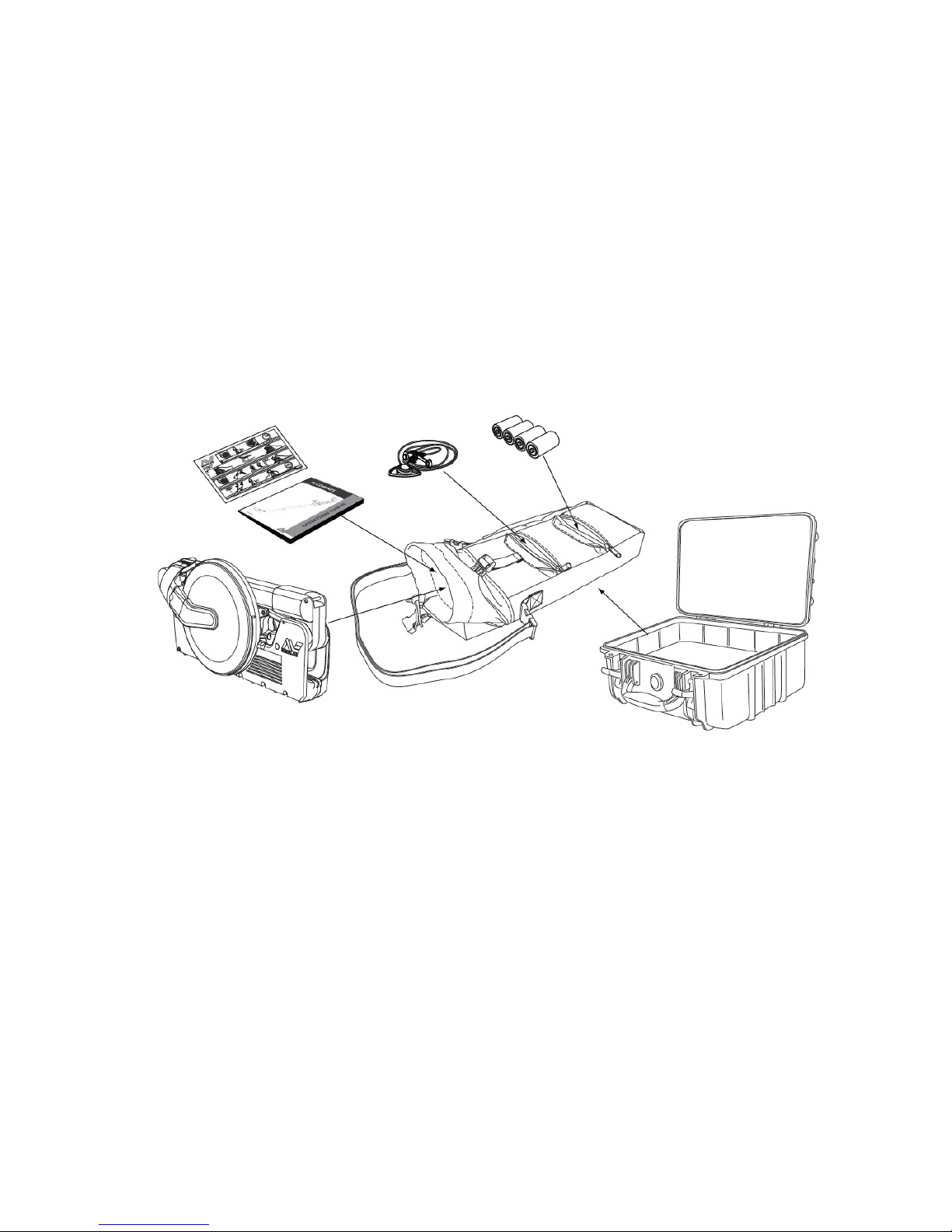

a. The detector set should be regularly checked to ensure all parts and accessories are

present and in good working order. The F3 COMPACT is supplied as a mine detecting set

comprising:

F3 COMPACT Detector 4901-0103 Operations Manual

5305-0111 Hard Case (optional) 4903-0047 Field Guide

3001-0064 Soft Carry Bag 8701-0022 Test Piece

4523-0027 Earset Speaker ON Four C-Cell Batteries

OR (Alkaline or Rechargeable)

4523-0025 Earset Speaker OFF

b. Whenever a detector is returned for servicing, mechanical and functional tests must be

completed to confirm and/or identify any faults.

c.

At the completion of any maintenance or repair procedure, ALL mechanical and

functional tests must be completed to confirm the detector is working correctly and no faults

remain.

d.

If a detector fails ANY of the mechanical or functional tests it must not be used in

demining operations.

Figure 1: Mine Detecting Set

Page 5

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

5

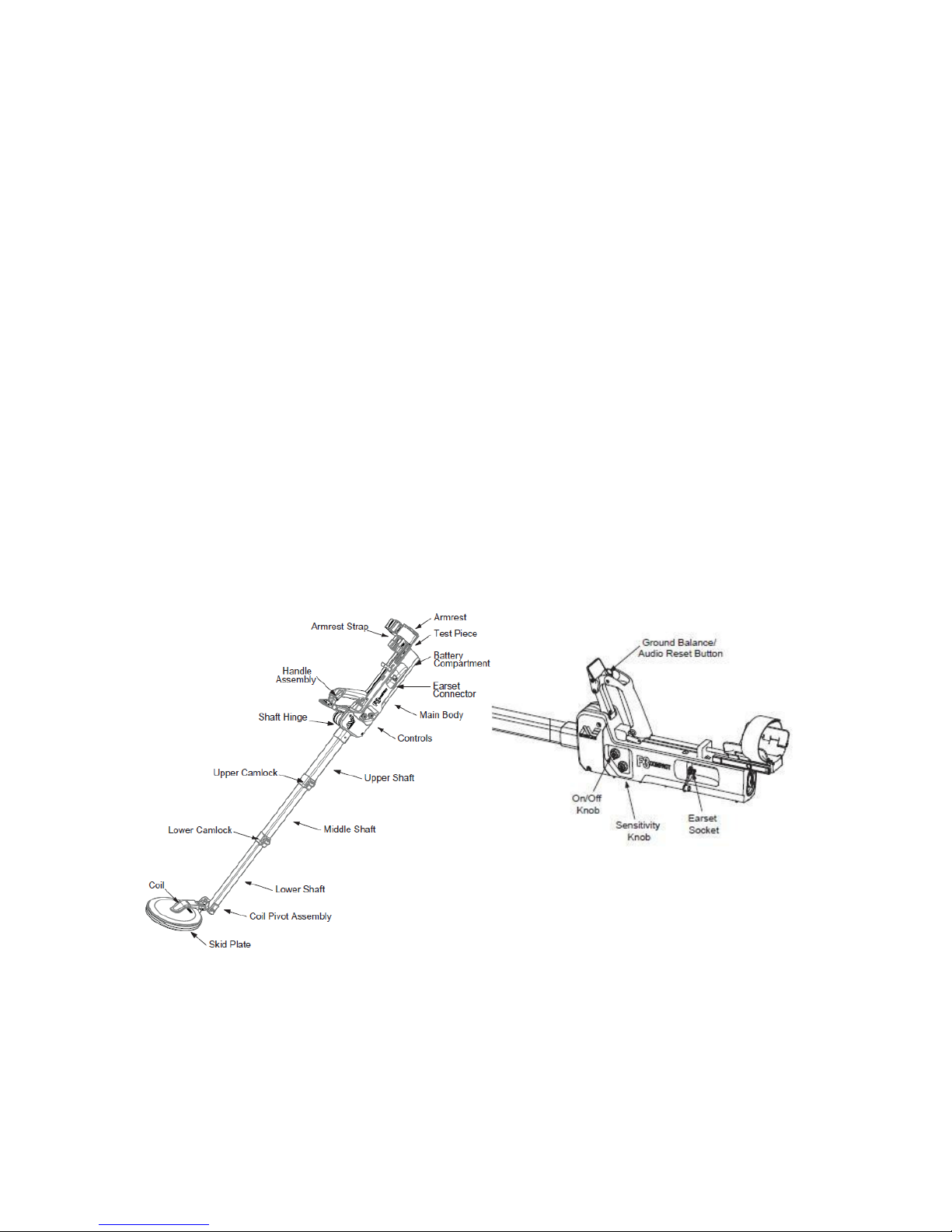

2.1 Mechanical Testing

a. Confirm all parts and accessories are present and in good working order. Unpack the

detector and prepare for use. Figure 2 identifies the major components of the F3 COMPACT.

Mechanical testing and inspection includes checking:

• the detector for any obvious signs of damage,

• coil movement is smooth in both axes and holds its position without drooping,

• the skid plate is firmly attached and has no holes or cracks,

• shafts extend and retract smoothly and the camlocks hold the shafts firmly in location,

• the shaft hinge moves freely when the handle is down and locks into extended position

when the handle is up,

• the battery lid opens and locks, the battery lid tether is in good condition, and the battery

lid O-ring is clean and in good condition,

• the handle slides up and down freely locking into position,

• the armrest extends and retracts smoothly,

• the armrest strap is in good condition,

• the earset dust caps are in good condition, and

• sensitivity and On/Off knobs do not turn unless lifted and rotated and then spring back

into the locked position when released.

b. The detector must pass all mechanical tests and checks to be considered acceptable for

operational use.

Figure 2: F3 COMPACT Major Components

Page 6

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

6

2.2 Functional Testing

a. Functional testing is used to confirm the serviceability of an F3 COMPACT before it is

returned to the field for use and whenever doubt exists about its serviceability. The F3 COMPACT

must pass all tests to be considered serviceable and ready for use. Whenever a line replaceable

unit is replaced or a repair is conducted, all functional testing must be completed.

b. Functional testing requires a ground balance test piece. The ground balance test piece

simulates mineralised ground which results in an alarm from the detector. A mineralised “hot”

rock or adequate amounts of local mineralised soil is suitable. Alternatively, a ceramic floor tile

or clay roof tile may be suitable for use as a ground balance test piece.

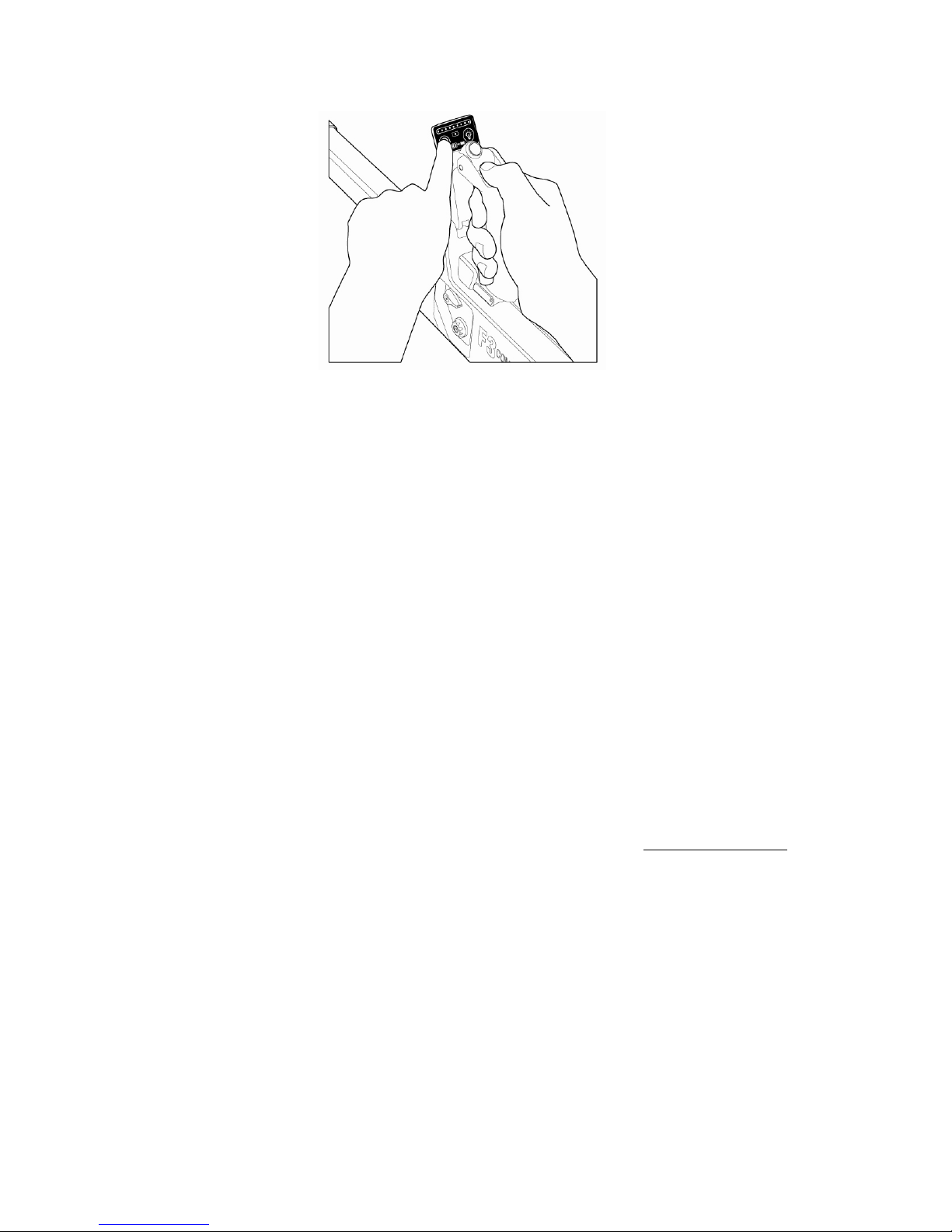

c. The Switch On Test. The switch on test checks that power is correctly supplied to the F3

COMPACT and internal diagnostics discover no system fault. The test is conducted as follows:

• Prepare the detector for use.

• Hold the coil at least 600mm (24in) away from the ground and any metal objects.

• Ensure the sensitivity knob is set to the default position 4.

• Switch on.

• Ensure that four or five rising tones occur over approximately 12 seconds. A steady

threshold tone should be heard a few seconds after the rising tones finish.

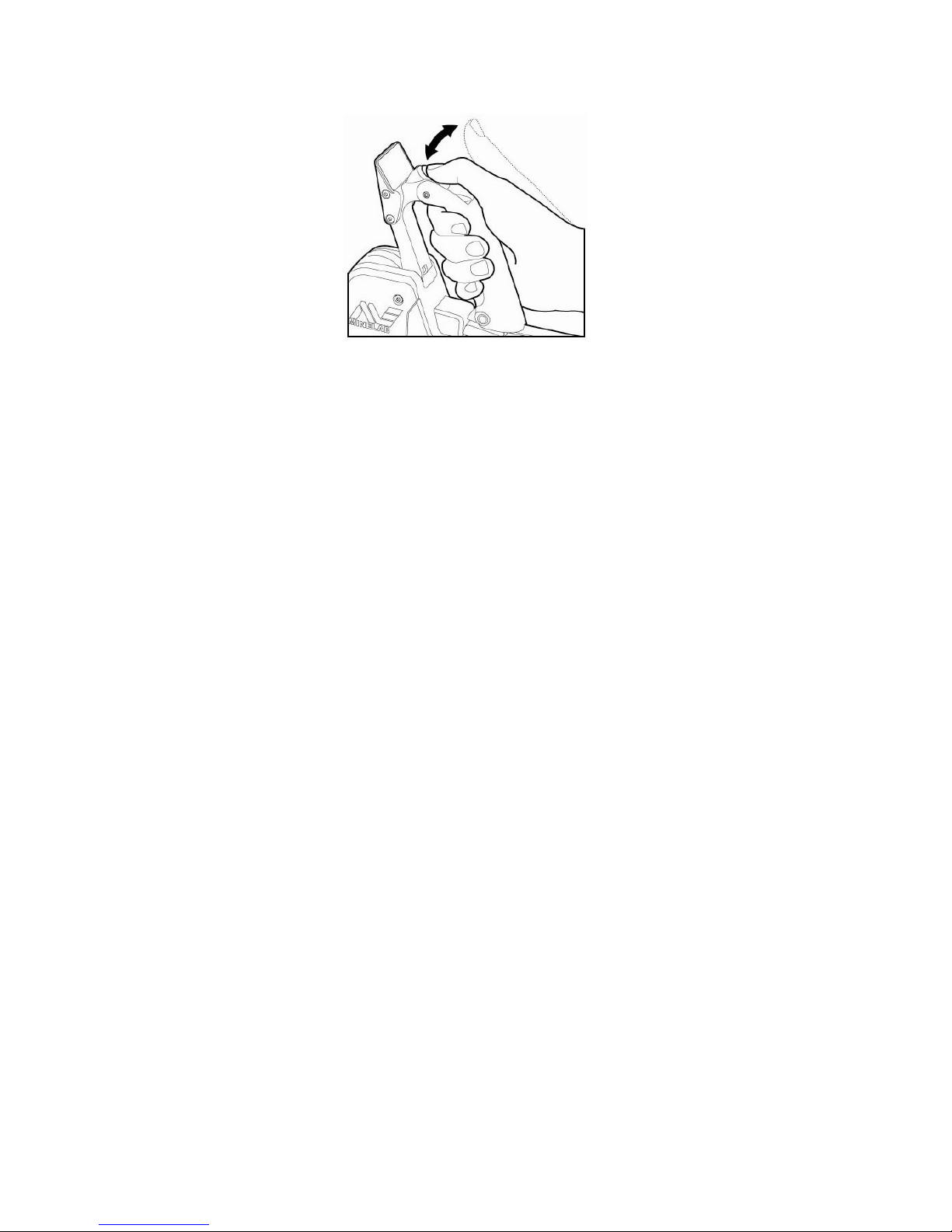

d. Noise Cancel Test. The noise cancel test ensures the F3 COMPACT successfully

completes the noise cancel procedure required whenever local electrical interference is present.

The test is conducted as follows:

• Hold the coil stationary and at least 600mm (24 in) off the ground and away from any

metal objects during the test.

• Press and immediately release the Noise Cancel button. (Figure 4)

Figure 3: Switch On

Page 7

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

7

Note

The coil should not be moved nor should metallic objects be brought near the coil during this

procedure.

• If functioning correctly, the noise cancelling procedure will commence with two single

beeps followed by 45 seconds of sharp double beeps and finish with four single beeps.

• During the 45 seconds the F3 COMPACT scans the environment searching for the source

of any electrical interference. Once detected, the detector will automatically select a

different operating frequency to eliminate or reduce the interference.

e. Audio Reset Test. This test confirms the audio reset button (also the ground balance

button) and the associated wiring and circuitry operates correctly. The objective is to ensure the

threshold tone returns to its correct volume if altered from its steady state. The test is

conducted as follows:

• Hold the coil at least 600mm (24in) off the ground and away from any metallic objects.

• Induce a threshold tone change in volume by slowly moving the coil toward a metal

object and once the threshold tone increases in volume hold the detector stationary.

• Once the threshold tone has increased in volume, press and immediately release the

green audio reset button. (Figure 5)

Note

If the ground balance button is not immediately released the F3 COMPACT will commence the

Ground Balance procedure.

Figure 4: Noise Cancel

Page 8

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

8

• Within two seconds the threshold tone should return to its correct level

f. Ground Balance Test. This test confirms the F3 COMPACT is capable of ground balancing

against mineralised ground. In doing so, it confirms the correct operation of the ground balance

button, coil and associated circuitry. The test is conducted as follows:

• Ensure hands and arms are free of metallic objects (watches, rings etc) and that no other

metallic objects are near the coil.

• Keep the detector stationary and away from ground or metal objects, press and hold the

ground balance button for five seconds then release the button.

Note

This action will cause the F3 COMPACT to delete the previously stored ground balance condition.

Unless this is done the detector will remember its last ground balance condition regardless of the

unit being switched off or the batteries removed.

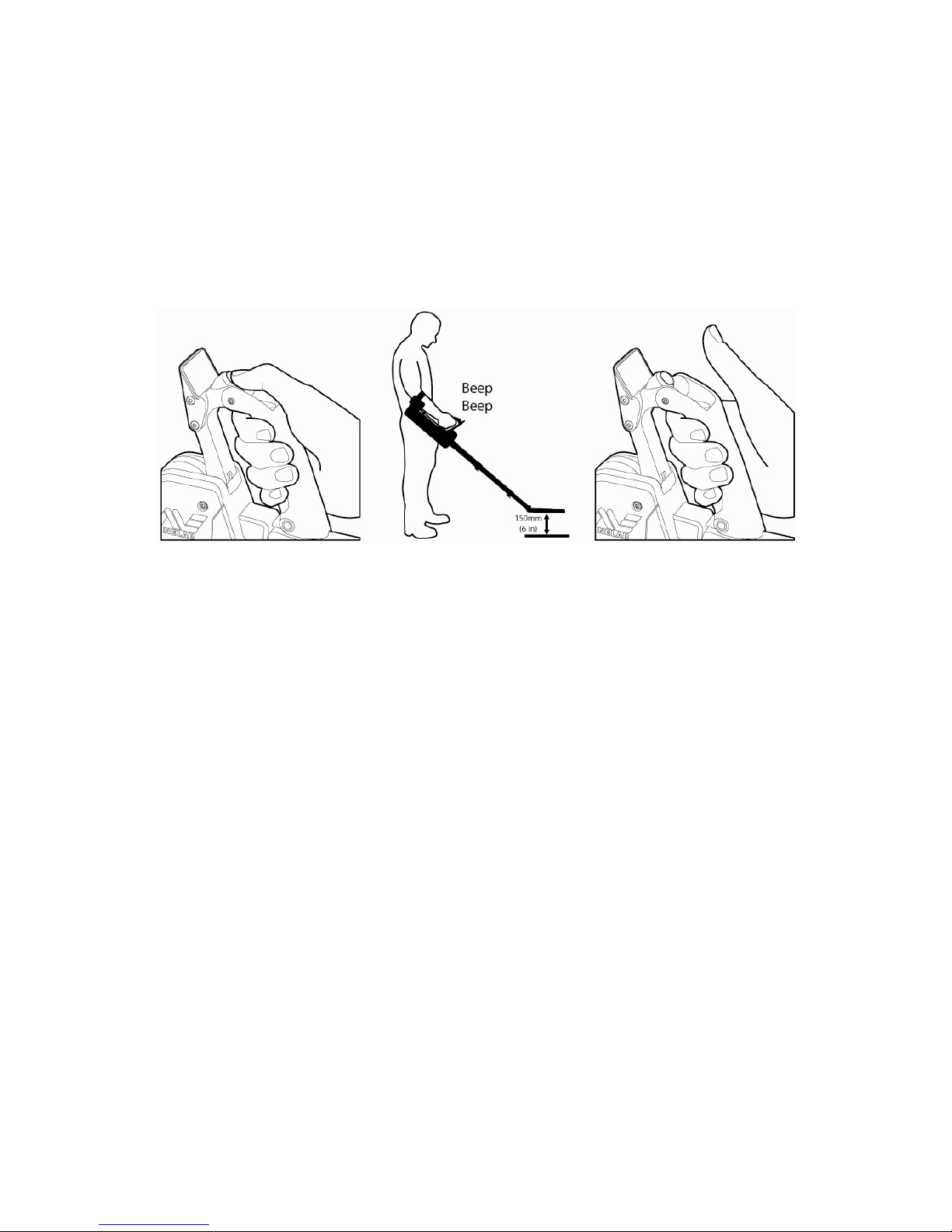

• Slowly move the ground balance test piece from approximately 150mm (6in) above the

coil towards the centre of the coil and confirm that a rise in threshold tone occurs. This

confirms that the detector is detecting the mineralised content of the ground balance

test piece.

• Press down and hold the ground balance button whilst slowly moving the ground balance

test piece from approximately 150mm (6in) above the coil towards the centre of the coil

(and touching the coil). Then, move the ground balance test piece away from the centre

of the coil to a distance of 150mm (6in).

• Repeat this process until the ‘Ground Balance OK’ tone consisting of a short high-pitched

double beep occurs. This tone confirms the ground balance procedure has been

completed correctly.

• Release the ground balance button and confirm that a steady low volume threshold tone

remains.

Figure 5: Audio Reset

Page 9

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

9

• Confirm the ground balance is correct by moving the ground balance test piece from

approximately 150mm (6in) above the coil towards the centre of the coil. If there is no

alarm from the ground balance test piece the ground balance procedure is functional.

Note

Where the ground balance test is conducted using local soil Figure 6 illustrates the procedure to

be followed.

Note

Successful ground balancing occurs within 5 to 10 seconds. Where the ground balance test piece

or local ground conditions are not sufficiently mineralised the ‘Ground Balance OK’ tones may

take up to 25 seconds to complete.

g. Earset Test. This test confirms the earset is operating correctly and is conducted as

follows:

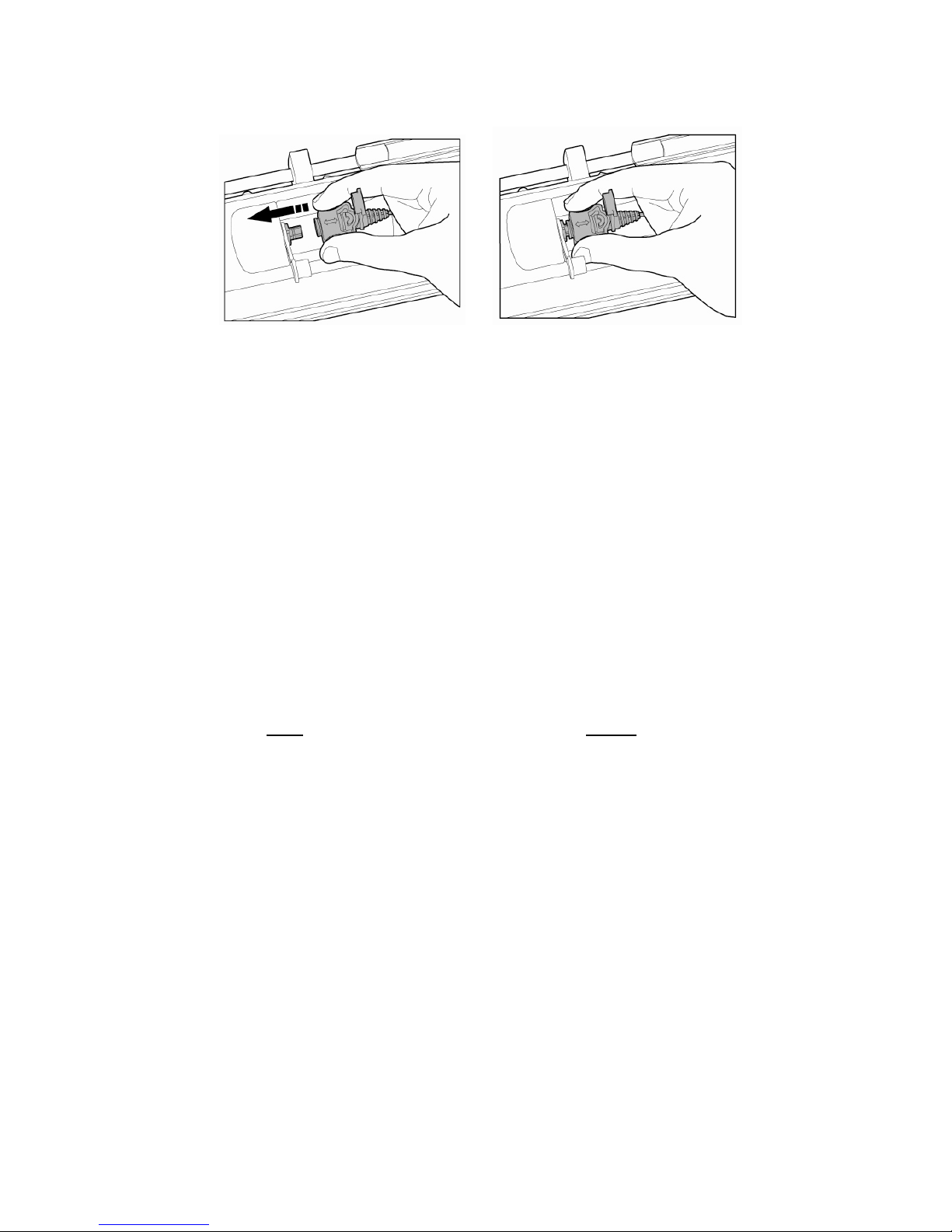

• Plug the earset into the detector as shown in Figure 7.

• Switch on the detector and confirm the threshold tone is audible using the earset.

• If an earset speaker On (4523-0027) is being tested check that the tones can also be

heard from the detector loudspeaker.

• If an earset speaker Off (4523-0025), identified by green band on the earset cable near

the plug, is being tested check that tones can only be heard in the earset and not the

detector loudspeaker.

Figure 6: Ground Balance

Page 10

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

10

h. LED Test. This test confirms the visual indicator (lights) can be enabled and operate

correctly. To conduct the test:

• Turn on the detector.

• Pass the coil over a metal object and check no LEDs are turned on.

• Press and release the LED button and check that a single LED is turned on when no metal

objects are near the coil.

• Pass the coil over a metal object and check that an increasing number of LEDs illuminate

as the target volume increases.

• Check that pressing and releasing the LED button toggles the LEDs on and off.

i. Battery Level Test. This test ensures that battery level indicator is operational, and is

conducted as follows:

• Turn the detector on.

• Press and hold the noise cancel button then press and release the LED button and then

release the noise cancel button.

• Confirm a series of LEDs illuminate indicating the level of battery power remaining.

• After three seconds the battery level indicator will extinguish and normal operation will

resume.

j. Test Piece Test. This test should be conducted in an environment that is free from

electrical interference and an earset must be connected. The test is conducted as follows:

• Ensure hands and arms are free of metallic objects (watches, rings etc) and that no other

metallic objects are near the coil.

• Set the sensitivity control to the default position 4 then switch on the F3 COMPACT and

confirm a steady threshold tone is present.

Figure 7: Connecting the Earset

Page 11

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

11

Note

Maximum sensitivity is only available 30 seconds after the threshold tone is heard. Do not test

the F3 COMPACT with the test piece until 30 seconds after the threshold tone is heard.

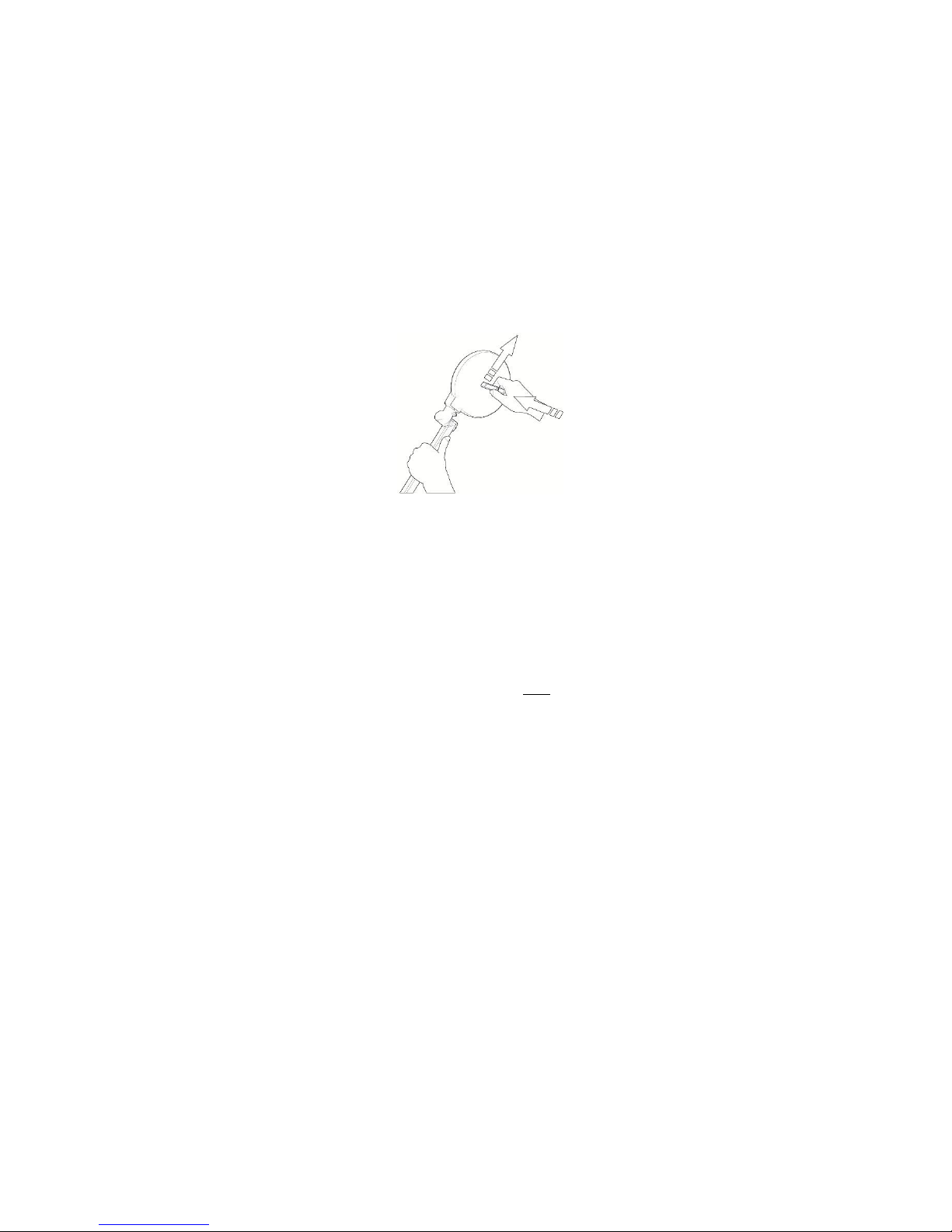

• Hold the test piece above the middle of the coil with the rounded end (containing

metallic target) away from the coil.

• Move the test piece towards the centre of the coil until it lightly touches the coil then

move it sideways off the coil.

Figure 8: Test Piece Procedure

• Confirm a faint but clear response (change in threshold tone and pitch) is heard.

• If the test piece is not heard conduct an audio reset and repeat the test.

Note

The test piece test can only be conducted with the sensitivity control in the green position

(Sensitivity No 4). When the sensitivity control is not set to the green position it is the

responsibility of the user to provide an appropriate target with which to confirm the sensitivity of

the detector satisfies operational requirements.

k. Sensitivity Control Test. This test confirms the sensitivity control allows the operator to

make adjustments to the sensitivity of the F3 COMPACT. The test is conducted as follows:

• Set the sensitivity to the default position 4.

• Turn on the detector.

• Conduct the test piece test (refer to Section 2.2.j). Check that a faint but clear audio tone

is heard and that more than one LED illuminates.

• Decrease the sensitivity of the F3 COMPACT by rotating the sensitivity knob counter

clockwise to position 2. A single low pitched beep will be heard to prompt the operator

that the sensitivity is being decreased.

• Conduct the test piece test again and ensure no audio or LED response occurs.

• Move the sensitivity knob to position 4 and confirm a double beep occurs. This prompts

the operator that default sensitivity (position 4) has been selected.

Page 12

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

12

• Rotate the sensitivity knob clockwise to position 6 and confirm that a single high pitched

beep is heard.

• Conduct the test piece test and confirm that a louder audio response and an increased

number of LEDs are illuminated when compared to the previous position 4 or 2.

Note

Regardless of minimum sensitivity at least one LED will remain illuminated providing an earset

speaker Off is not connected to the F3 COMPACT.

Page 13

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

13

3. Disassembly & Reassembly Procedures

a. This section describes the procedures required to exchange line replaceable units.

Whenever a unit is replaced, mechanical and functional testing as described in Section 2 must be

completed.

b. It is recommended that the 3004-0055 F3 COMPACT service tool kit be used to conduct

disassembly and reassembly procedures. The tool kit contains the following:

• Pull-through for coil cable

• Flat blade screwdriver

• 3mm hex key driver

• 2.5mm hex key driver

• 2mm hex key driver

• T20 Torx driver

• 18mm spanner

• 13mm spanner

• 10mm spanner

• 3mm pin punch

• Screwdriver Pozidrive No 1

• Screwdriver Pozidrive No 2

• Tube Spanner 7/8

• Silicone grease

Page 14

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

14

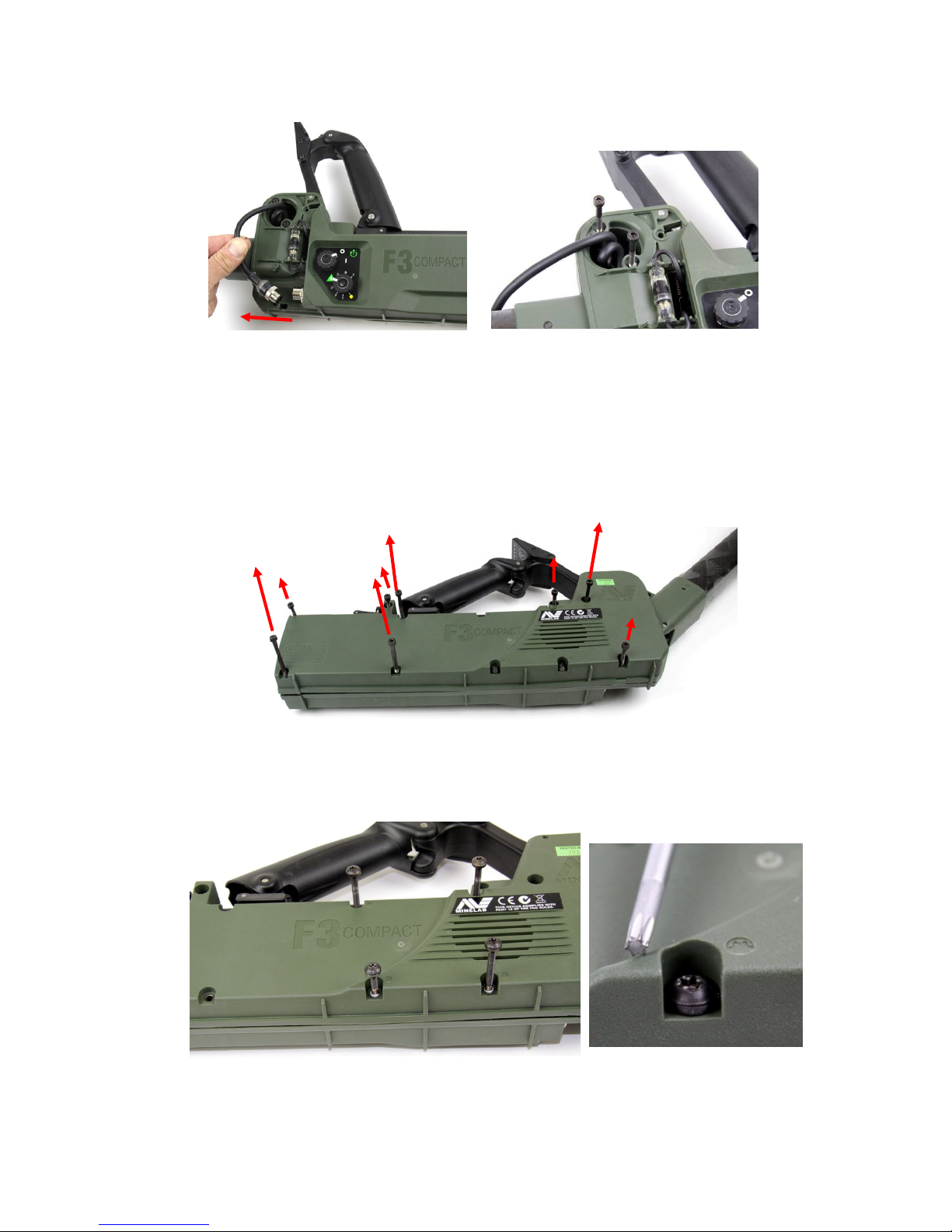

3.1 Opening the Detector Body

a. In order to conduct repairs and replace many of the parts of this detector, the first step

will often be to open the detector body. Many sections of this manual will refer back to this

section.

b. The following procedure outlines the steps involved in opening the detector body:

• Prepare a clean well lit workspace.

• Turn the detector off and remove the batteries.

• Remove the four screws (12mm) from the top of the armrest and remove the armrest.

• Place the detector on its right side with the ON/OFF knob uppermost and remove the two

screws (45mm) that secure the hinge cover.

• Remove the hinge cover.

• Unscrew and disconnect the coil plug.

• Remove the two screws (35mm) from the shaft hinge.

Figure 9: Removing the Armrest

Coil

Connector

Figure 10: Removing Hinge Cover

Page 15

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

15

• Turn the detector over onto its left side with speaker grill uppermost.

• Using the 3mm hex key driver, remove all eight screws from the detector body.

Note

There are four 35mm long screws and four 20mm long screws.

• Using a T20 Torx (star) driver unscrew all four screws (three 35mm and one 20mm) from

the right side of the detector.

Figure 12: Removing Eight Screws (Allen Key)

Figure 11: Disconnecting Coil Plug and Removing Screws

Figure 13: Removing Four Torx Screws

Page 16

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

16

• Using fingers gently separate the left and right body halves. The battery end of the

detector will come away easily. The shaft end is held by two locating pins and will require

more force to separate.

• Gently lift the right side off the left body half taking care not to pull or stretch the speaker

cable and connector.

• Locate the speaker connector on the interface PCB and disconnect the speaker from the

interface PCB. Remove the right half of the detector body.

• Remove the upper shaft from the detector body taking care not to snag and damage the

coil cable and plug.

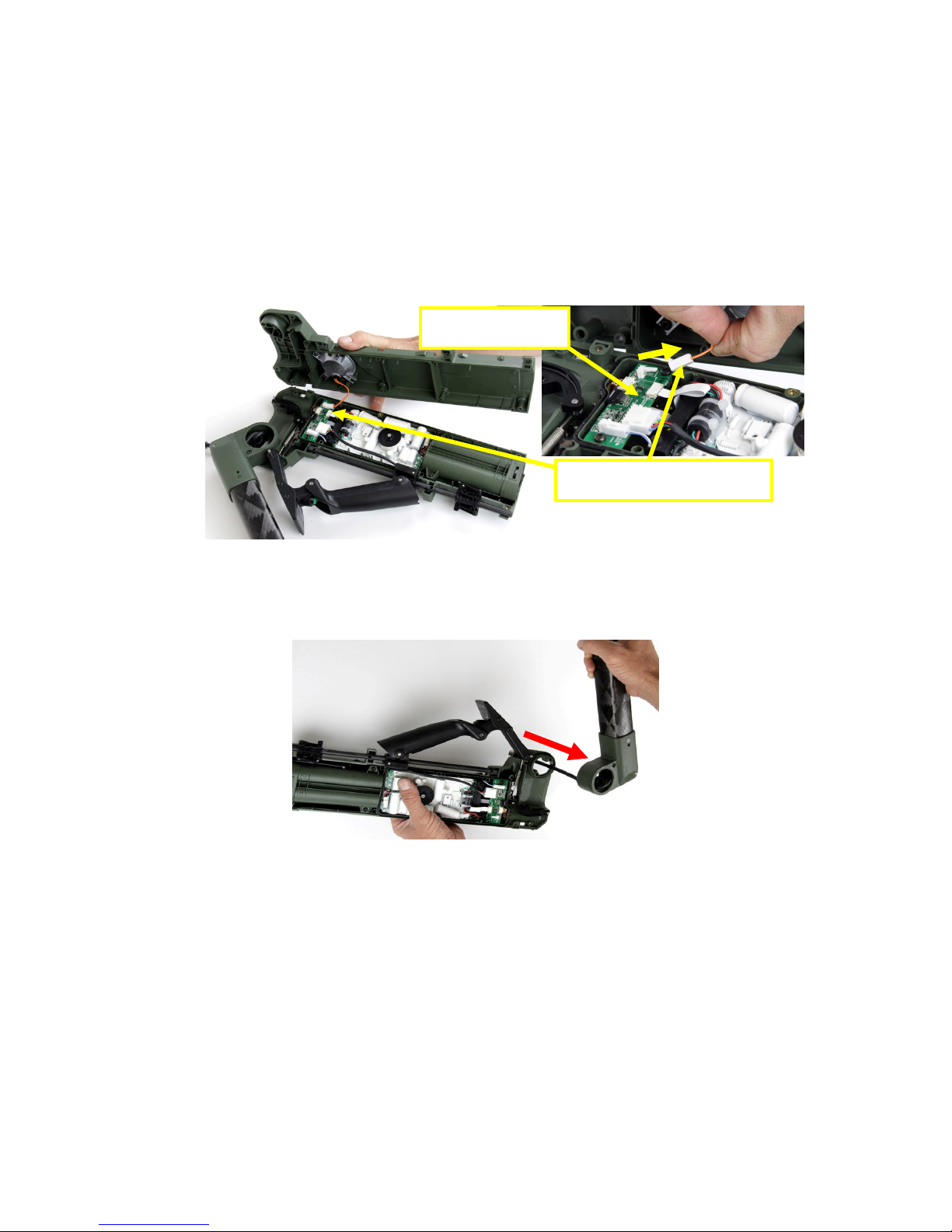

Interface PCB

Speaker Connector

Figure 14: Disconnecting Speaker Connector

Figure 15: Remov

ing Shafts

Page 17

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

17

c. The body of the detector is now opened revealing the internal components which can

now be replaced as required.

3.2 Closing the Detector Body

a. The following procedure outlines the steps involved in closing and resealing the detector

body:

• Ensure all parts are present, in good working order and lay the detector body on its left

side.

• Thread the coil cable through the detector hinge and position the upper shaft into the

detector body.

• Carefully turn the detector body over so that it is on its right side. Check the coil

connector nut is tight.

• Attach the coil connector to the socket and tighten the coil connector as tight as possible

with fingers.

Figure 16: Open Detect

or Body

Figure 17: Threading Coil Cable and Attaching Shafts

Page 18

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

18

• Fit the coil cable into the cable router and check that the loop of coil cable within the

shaft hinge is positioned so that it will not be trapped when the detector body is closed.

Refer to Figure 21.

• Fit the hinge cover but Do Not fit the two hinge cover screws. Turn the detector body

over so it is on its left side.

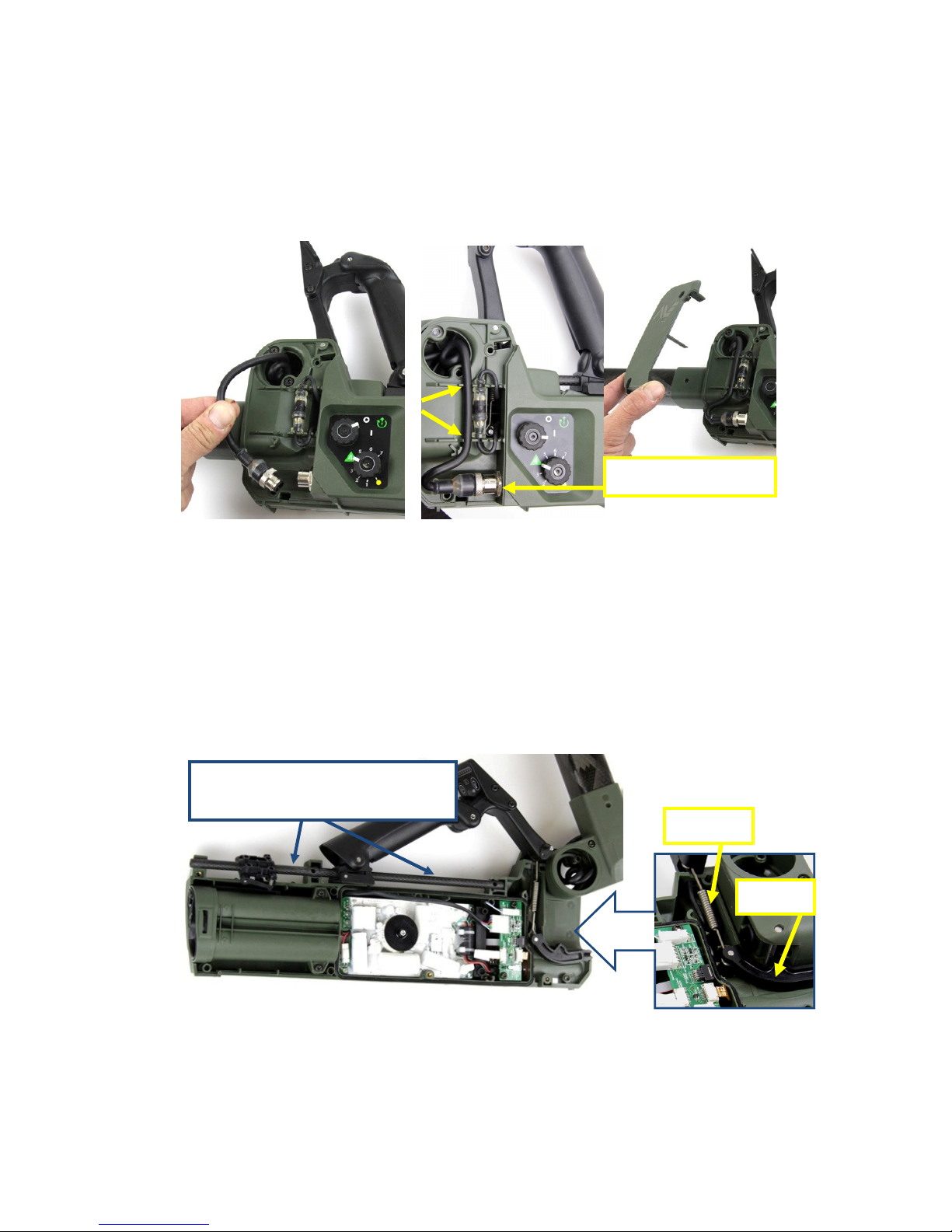

• Check the detector handle is correctly positioned on the detector as well as the armrest

slide. The rod detector slide must be positioned through the handle and armrest slide.

The holes in the rod detector slide must align with the holes in the detector body.

• Check that the latch hinge and spring latch hinge are correctly positioned into the left

side of the detector body with the latch connected to the spring.

Figure 18: Connecting Coil Cable and Removing Hinge Cover

Coil Connector Nut

Latch

Spring

Figure 19: Latch Hinge and Spring Latch Hinge

Rod Detector Slide passing

through Armrest Slide and Handle

Page 19

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

19

Note

The hinge cover holds the latch hinge and spring latch hinge in place. When the hinge cover

is removed the spring may unintentionally disconnect from the latch.

• Ensure the battery lid is closed.

• Connect the speaker connector to the PCB connector. Check all other connectors and

cables are connected.

• Check the O-ring in the detector body is clean, lightly greased and correctly positioned.

• Check all internal cables and wires are correctly positioned and will not be trapped.

• The coil cable must be located within the shaft hinge so that it is not trapped or damaged

when the halves of the detector body are fitted together. In particular, the coil cable

must not be positioned above the hinge screw bosses.

Coil Cable

Must Not be

above these

areas

Figure 21: Coil Cable Position in Shaft Hinge

Speaker Connector

Figure 20: Connecting Speaker

Speaker Assembly

Page 20

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

20

• Ease the two halves of the detector together. Align the detector body right side with the

locating pins either side of the shaft hinge.

• Check the latch hinge and spring latch hinge are in place and connected.

• Once the two sides of the detector are together check the handle, shafts and armrest

slide are correctly fitted. Carefully hold the detector together whilst turning the detector

over onto its right side with the hinge cover facing up.

• Remove the hinge cover to check the coil cable is not trapped within the shaft hinge.

• Check the latch hinge and spring latch hinge are still connected as shown in Figure 19.

• Refit the hinge cover.

• Insert the four screws (two 20mm and two 35mm) as indicated in Figure 22 but do not

fully tighten at this point.

• With the detector loosely held together check the handle slides up and down correctly.

Check the armrest slide also moves freely along the rod detector slide.

• Check the battery lid moves in and out and ensure the battery lid is closed.

• Starting with the two long (35mm) screws fit the four remaining screws into the right side

of the detector as indicated by the arrows in Figure 23.

• Tighten all eight screws.

Figure 22: Fitting Four Screws

Page 21

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

21

• Identify the four Torx screws and check they all have O-rings fitted. Insert the four Torx

screws into the right side of the detector. The Torx screw positions have a Torx symbol

next to their screw holes. Insert the three long screws first.

• Check the detector assembly and test all moving parts.

• Place the detector on its right side. Remove the hinge cover then insert and tighten the

two screws (35mm) into the shaft hinge.

Figure 25: Fitting Screws into the Shaft Hinge

Figure 23: Fitting Four Screws

Torx Screw symbol

marks location of

O-ring

Figure 24: Fitting Torx Screws.

Page 22

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

22

Note

Do not move the detector with the hinge cover removed as this may result in the spring

latch hinge and the latch hinge becoming disengaged.

• Confirm coil connector is tight and check the coil cable and the wiring loom are located

into the cable router.

• Check the latch and spring latch hinge are connected as shown in Figure 26. If the latch

and spring have become disconnected they must be reconnected. It is possible to

reattach the eyelet of the spring to the pin of the latch hinge through the opening under

the hinge cover. Alternately the detector body can be opened to reattach the spring to

the latch.

• Fit the hinge cover and make sure the protrusion on the underside of the hinge cover

engages into the slot on the detector body near the hinge. Fit the two screws (45mm)

into the hinge cover and tighten.

•

•

•

•

•

•

•

Figure 27: Fitting Hinge Cover

Cables held in

Cable Router

Spring Eyelet

located on pin of

Latch Hinge

Spring Latch

Hinge

Figure 26: Underneath Hinge Cover

Page 23

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

23

• Reattach the armrest with four screws (12mm).

• Check all moving parts for correct operation.

• Insert batteries, turn on the detector then conduct mechanical & functional testing as

described in Section 2 Mechanical & Functional Testing.

3.3 Main Printed Circuit Board (PCB)

a. The main PCB of the F3 COMPACT is a line replaceable unit and this section of the manual

describes the procedure for its replacement. Figure 30 shows the main parts associated with the

main PCB.

b. 3004-0053 Main PCB Kit, is a service kit containing the main PCB and the associated parts,

when a replacement main PCB is required this part number should be ordered.

Note

Repairs to and disassembly of the main PCB are not detailed in this manual. Repairs to the

main PCB should only be conducted by authorised Minelab Engineers.

Figure 28: Attaching the Armrest

Toroid Screw

Cable 10 Way

Main

PCB

Cable 6 Way Ribbon

Speaker Connector

Interface PCB

Battery Connector

Figure 29: Detector Body and Main PCB

Page 24

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

24

1 3004-0053 Main PCB Kit, contains all parts in this table.

2 0703-0208 Cover Toroid

3 0704-0009 Gasket Toroid

4 31-23040-980 Screw Toroid M3x40 skt

5 4005-0054 Spacer Toroid mid

6 4311-0080 Bracket Main PCB

7 CMINE 0672 Jumper 2 Way Quantity 3

8 67-50062 Cable 6 Way Ribbon 178mm

9 67-50104 Cable 10 way 50mm

3.3.1 Removing the Main PCB

a. To remove the main PCB, open the detector body as described in section 3.1 – Open the

Detector Body and:

• Remove the Nut (18mm) from the coil connector.

Figure 31: Opened Detector Body

4311

-

0080

67-50104

67-50062

4005

-

0054

0704

-

0009

0703-

0208

31-23040

-

980

Figure 30: Parts of the Main PCB

Table 1: Parts of Main PCB

Page 25

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

25

• Unscrew the screw toroid from the main PCB, using a 2.5mm hex key driver.

• Disconnect the battery connector from the main PCB.

• Remove the two Screws (12mm) from the interface PCB.

• Disconnect the 10 way connector from the interface PCB (Figure 35).

Figure 33: Screw Toroid & Battery Connector

Battery Connector

Screw Toroid

Mounting

Screws

Interface PCB

Figure 34: Interface PCB

Figure 32: Remov

ing the Coil Connector Nut (18mm)

Page 26

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

26

• Slide out the locking bails on the six way ribbon connector and disconnect the cable six

way ribbon.

• Slide the main PCB away from the battery assembly until the ends of the main PCB

disengage from the slots in the detector body near the battery compartment.

• Gently tilt the top side (near the detector handle) of the main PCB away from the housing

and lift the main PCB from the detector body.

b. The main PCB can now be replaced.

2

Figure 36: Lifting Main PCB Out of Detector

Figure 35: 10 Way Connector and Six Way Ribbon Cable

Cable

Six Way

Ribbon

10 way Connector

Page 27

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

27

3.3.2 Main PCB Assembly

a. When the line replaceable unit 3004-0053 Main PCB Kit is supplied by Minelab no

assembly is required. However, in the event a main PCB is salvaged from one detector for use in

another, it is important to check for correct assembly before fitting the main PCB to the

detector. Check for correct assembly as follows:

• Check that the six way ribbon cable is connected to the main PCB.

• To connect the six way ribbon cable, separate the two halves of the PCB and open the

connector bail. Insert six way ribbon cable and close the connector locking bail.

• Check the spacer toroid mid is in place between the two halves of the PCB.

• Connect the two halves together and check the PCB interconnectors are aligned and fully

inserted.

• Connect the 10 way ribbon cable, ensuring that the key on the connector is aligned with

the slot on the PCB.

Figure 38: Fitting Bracket

• Fit the bracket main PCB.

• Check that three jumpers are connected in the correct positions on the main PCB. Refer

to Figure 39.

10 Way Ribbon Cable.

Bracket Main PCB.

Figure 37: Connecting Six Way Ribbon Cable

Spacer Toroid Mid.

Page 28

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

28

b. The main PCB is now ready to install into the detector.

3.3.3 Installing the Main PCB.

a.

Having opened the detector body and removed the faulty main PCB, install a serviceable

main PCB as follows:

• Place the detector on its left side in a clean well lit area.

• Lower the main PCB into the detector, pushing the bottom side (away from the handle)

down and into place first. Gently position the main PCB flat inside the detector.

• Gently slide the main PCB rearward towards the battery compartment so that the ends of

the main PCB insert into the locating slots in the detector body.

• Position the coil connector ensuring the connector has a clean and correctly positioned

O-ring as shown in Figure 41.

• Fit the cable of the coil connector into the cable router as shown in Figure 41.

Figure 39: Three Jumpers on Main PCB

Figure 40: Fitting Main PCB

Page 29

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

29

• Fit the screw toroid as shown in Figure 42.

• Lay the cable 10 way under the interface PCB. Take note of the connector key tab that

aligns with the slot in the interface PCB.

• Gently align and connect the connector 10 way.

Figure 41: Coil Connector

O-Ring in place on

Coil Connector

Cable of Coil

Connector fitted

into Cable R

outer

Alignment Key

Figure 43: Connector 10 Way

Figure 42: Screw Toroid

Page 30

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

30

• Align the cable six way ribbon with its connector. Slide the connector locking bail

outwards to accept the cable six way ribbon.

• Insert the cable six way ribbon into the connector then push the locking bail to secure.

• Connect the battery connector to the main PCB.

• Make sure all connectors are firmly in place and all wires and cables are positioned so

that they will not cause obstruction or get damaged when the two halves of the main

body are fitted together.

• Fit the two screws (12mm) to the interface PCB.

Figure 45: Connecting Battery Connector

First Pull locking bail out to accept Cable

Push locking bail in

Figure 44: Connecting Six Way Ribbon Cable

Second insert Six Way Ribbon Cable

Figure 46: Interface PCB and Coil Connector Nut

Page 31

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

31

• Fit the nut (18mm) to the coil connector and tighten.

b. Finish assembling the detector by closing the detector body, as described in Section 3.2 –

Closing the Detector Body

3.4 Coil

a. The coil is a line replaceable unit and Figure 47 illustrates the major parts of the coil.

3004-0044 Coil Kit, is a service kit containing the coil and associated parts. 3004-0045 Coil Pivot

Kit, is included within the 3004-0044 Coil Kit and is also available as a separate service kit. All

parts are available individually.

1 3004-0044 Coil Kit, Includes all items in this table

2 2003-0055 Skid Plate

3 3004-0045 Coil Pivot Kit, included parts marked yellow

4 30-29011-514 O Ring 25mm ID

5 4311-0074 Pivot Coil Yoke

6 4311-0086 Pivot Lower Shaft

7 4003-0123 Screw Nylon M6x29

8 4003-0116 Screw Nylon M6x14

9 4003-0121 Screw Thumb Nylon 1/4BSW

10 0703-0204 Cap Shaft

30-29011

-

514

4311

-

0074

4308

-

0030

4003

-

0123

4003

-

0121

4308

-

0031

2003

-

0055

4311

-

0086

0703

-

0204

Lower Shaft

4003

-

0116

Figure 47: Parts of the Coil

Page 32

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

32

11 4308-0030 Pin Coil Pivot

12 4308-0031 Pin Coil Cable

3.4.1 Skid Plate Replacement

a. The skid plate is designed to protect the coil and may require replacement after long

periods of use. There is no requirement to remove the skid plate to clean inside during routine

maintenance or operation. To exchange the skid plate:

• Remove the skid plate using fingers to lever one side away from the coil. Place a match

stick in the opening or something soft that will not mark the coil or skid plate.

• Move around the circumference of the coil using fingers to lever the skid plate away from

the coil. Insert additional match sticks to stop the skid plate from re-attaching to the coil.

The skid plate can then be removed from the coil

Note

Do not use a knife, screwdriver or any other steel objects to remove the skid plate. This could

mark or damage the coil or skid plate.

• Re-attach the skid plate by positioning the skid plate underneath the coil and then

pressing it into position.

3.4.2 Removing the Coil

a. To remove the coil:

• Prepare a clean well lit area in which to work.

• Turn the detector off and remove the batteries.

• Place the detector on its right side and remove the two screws (45mm) that secure the

hinge cover.

• Remove the hinge cover.

Figure 48: Replacing the Skid Plate

Table 2: Coil Parts

Page 33

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

33

• Unscrew and disconnect the coil connector.

• Remove the pin coil cable from the upper end of the upper shaft. Turn the pin clockwise

then pull to remove.

• Remove the two screws (Nylon 14mm) from the cap shaft on the lower shaft as indicated

in Figure 52.

Figure 50: Disconnecting Coil Connector

Figure 51: Removing Pin Coil Cable

Coil

Connector

Figure 49: Removing Hinge Cover

Figure 52: Removing Screws from Lower Shaft

Page 34

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

34

• Insert a flat tip screwdriver into the slot underneath the cap shaft and lift and remove the

cap shaft.

• Slide the coil out and off the lower shaft, exposing the coil cable.

• Push the coil cable connector into the shaft hinge whilst gently pulling the coil cable out

of the end of the lower shaft. Once the coil connector has passed through the shaft hinge

it should slide out easily from the shafts. Do not force the coil cable or coil connector.

b. The coil can now be removed or replaced as required. To fit the coil to the detector refer

to section 3.4.6 - Fitting the Coil.

3.4.3 Coil Pivot.

a. The coil pivot is a line replaceable unit and Figure 55 illustrates the major parts. Each part

of the coil pivot can be ordered individually or as a 3004-0045 Coil Pivot Kit which includes all

parts shown in Table 3.

Figure 53: Sliding the Coil Off the Shaft

Figure 54: Coil Assembly

Figure 55: Coil Pivot Kit Parts

4003

-

0123

4311-0074

30-29011

-

514

4308

-

0030

4003-0116

0703

-

0204

4311-0086

4003

-

0121

Page 35

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

35

1 3004-0045 Coil Pivot Kit, contains all items in this Table

2 30-29011-514 O-Ring 25mm ID x2

3 4311-0074 Pivot Coil Yoke

4 4311-0086 Pivot Shaft

5 4003-0123 Screw Nylon M6x29

6 4003-0121 Thumb Screw Nylon 1/4BSW

7 4308-0030 Pin Coil Pivot

8 4003-0116 Screw Nylon M6x14

9 0703-0204 Cap Shaft

3.4.4 Removing Coil Pivot

a. To remove the coil pivot, first remove the coil as described in section 3.4.2 - Removing

the Coil. Once completed:

• Remove the thumb screw and screw (Nylon M6x29).

Note

The two screws can be used to adjust the friction of the coil pivot movement.

• Push the pin coil pivot out with a pin punch or hex key driver and remove the pin coil

pivot.

Figure 57: Rem

oving Pin Coil Pivot

Figure 56: Removing Two Screws

Table 3: Coil Pivot Kit Parts

Page 36

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

36

• Separate the pivot lower shaft from the pivot coil yoke. Gently feed the coil cable through

the pivot lower shaft removing the pivot shaft from the coil cable. Do not stretch the coil

cable.

• Pull the pivot coil yoke off the coil and carefully thread the coil cable through the pivot

coil yoke. If required remove the O-ring from the coil.

3.4.5 Fitting the Coil Pivot

a. To fit the coil pivot, firstly remove the coil from the detector as described in section

3.4.2 - Removing the Coil. Once completed:

• Fit the O-ring to the coil as shown in Figure 60.

Pivot Coil Yoke

Pivot Lower Shaft

Figure 5

8

: Removing Pivot

Lower

Shaft

Figure 59: Removing Pivot Coil Yoke

O-Ring

Page 37

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

37

• Identify the section of coil cable closest to the coil and wind or unwind the coil cable to

achieve five turns. The five turns of cable will be located within the pivot with the pin coil

pivot passing through the centre.

• Feed the pivot coil yoke onto the coil cable and carefully move the pivot coil yoke along

the coil cable to the coil. Align and then push the pivot coil yoke into place on the coil.

Check the pivot coil yoke rotates through 90 deg with end stops.

• Feed the pivot shaft onto the coil cable. Align the coil cable with the five turns of cable

inside the pivot then press the pivot shaft onto the pivot coil yoke. Ensure the coil cable

retains the five turns of cable within the pivot.

O-Ring

5 Coils inside

Pivot

Figure 60: O-Ring and Coil Cable

Figure 61: Fitting Pivot Coil Yoke

Figure 62: Fitting Pivot Lower Shaft

Page 38

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

38

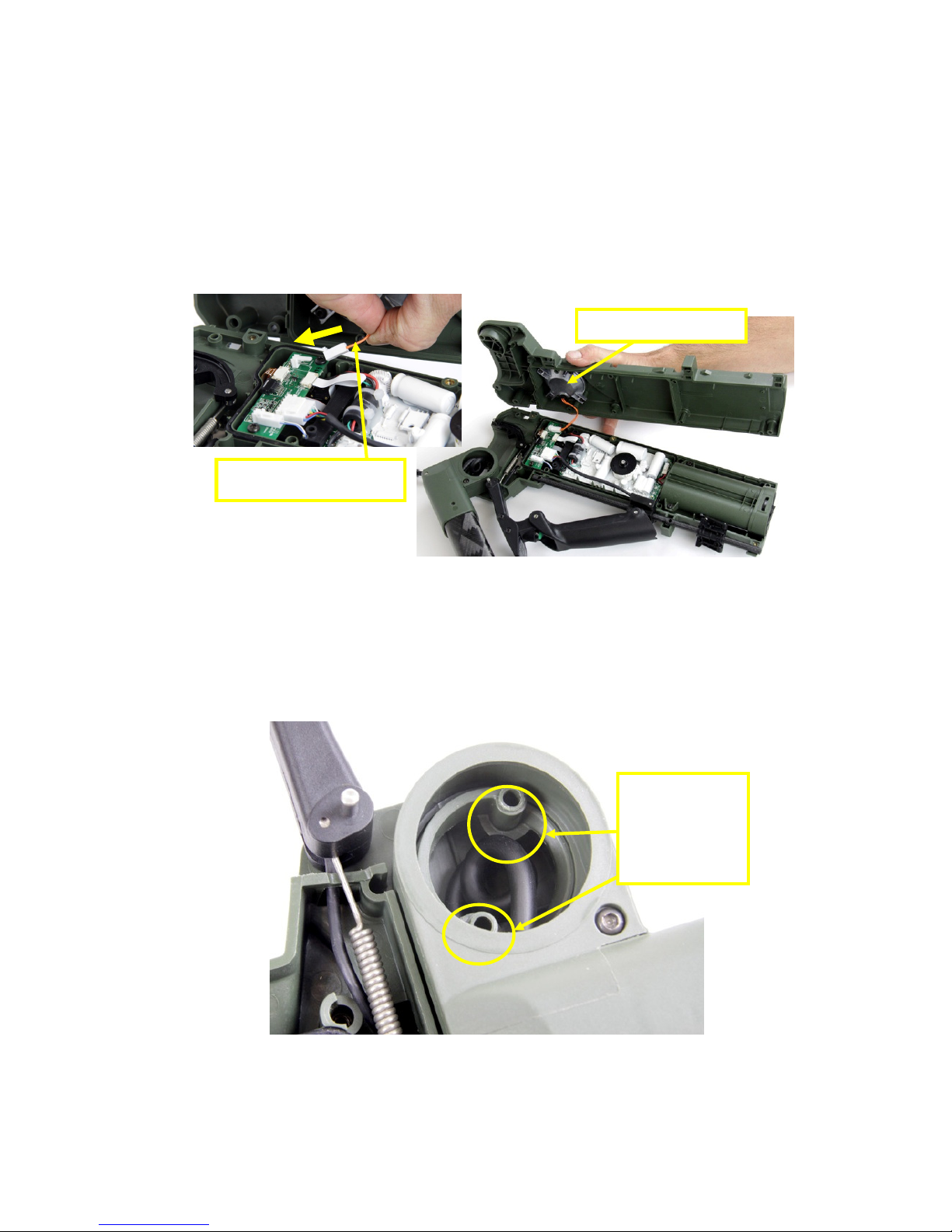

• Push the pin coil pivot into the pivot coil yoke. The pin must travel up the centre of the

five turns of cable inside the pivot. If there is resistance to inserting the pin open the

pivot and try again. Do Not Use Excessive Force. Push the pin in with fingers and click

into place.

Note

The pin coil yoke must thread through five turns of the cable inside the pivot.

• Check the movement of the pivot in both directions.

• Fit the screw (Nylon M6x29) into the pivot coil yoke and then fit the thumb screw.

Tighten both screws until the movement of the coil starts to become firm.

Note

The thumb screw will adjust the friction of the coil tilt. The thumb screw must be tight enough to

stop the coil from drooping. The screw (Nylon M6x29) will adjust the friction of the coil rotation.

b. Fit the coil to the shaft then fit onto the detector as described in Section 3.4.6 - Fitting the

Coil.

Figure 63: Inserting Pin Coil Pivot

Figure 64: Adjusting Screws

Page 39

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

39

3.4.6 Fitting the Coil

a. With practice and a pull through tool it is possible to fit the coil to the detector without

opening the detector body.

b. Open the detector body as described in Section 3.1 - Opening the Detector Body. Once

completed:

• Remove the shaft and coil from the detector. Section 3.4.2 - Removing the Coil

• Remove the cover shaft hinge from the shafts.

• Connect the coil cable pull-through to the coil connector. Alternatively, a piece of string

could be used to thread the coil cable into the shafts.

• Feed the coil cable pull-through into the coil end of the lower shaft and out through the

top (hinge end) of the upper shaft. Feed the coil cable until the coil connector is exposed.

• Insert the pin coil cable into the end of the upper shaft so that the pin engages into the

turns of the coil cable within the shaft. Turn the pin counter clockwise to lock it into

place.

Figure 66: Threading Coil Cable through Shafts

Figure 67: Fitting Pin Coil Cable and Cover Shaft Hinge

Figure 65: Removing Cover Shaft Hinge

Page 40

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

40

• Fit the cover shaft hinge to the shaft and screw into place.

• Slide the coil into the end of the lower shaft. Fit the cap shaft then fit the two screws

(14mm Nylon).

• Thread the coil cable through the detector hinge and fit the shaft onto the detector

hinge.

• Connect the coil connector and close the detector body described in Section 3.2 - Closing

the Detector Body.

Figure 68: Fitting Coil to Lower Shaft

Figure 69: Fitting Shaft and Coil

Figure 70: Connecting Coil Cable and Cover

Coil Connector Nut

Page 41

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

41

c. The coil has now been fitted to the detector. Check the assembly and all moving parts.

Insert batteries and then carry out mechanical & functional testing as described in Section 2 -

Mechanical & Functional Testing.

Page 42

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

42

3.5 Shafts

a. The complete shaft assembly of the detector is a line replaceable unit and Figure 71

illustrates the major parts.

1 3004-0046 Shaft Kit, contains all items in this table

2 3004-0045 Coil Pivot Kit

3 3004-0047 Camlock Kit, contains 3 items marked green

4 8008-0062 Pressure Block Camlock

5 8008-0061 Camlock Lever

6 4308-0014 Pin Camlock Lever

7 4308-0018 Pin Lock Latch

8 4311-0073 Hinge Upper Shaft

9 8007-0065 Shaft Upper

10 8009-0011 Shaft Guide Middle

11 8008-0059 Camlock Body Upper

12 8007-0064 Shaft Middle

13 8009-0012 Shaft Guide Lower

14 8008-0060 Camlock Body Middle

15 8007-0063 Shaft Lower

16 0703-0202 Cover Shaft Hinge

17 31-03512-982 Screw 3.5x12 skt head

4308

-

0018

4311

-

0073

8007

-

0065

4308

-

0014

8009

-

0011

8008

-

0062

8008

-

0061

8007

-

0064

8009

-

0012

8008

-

0059

8008

-

0060

8007

-

0063

Figure 71: Shaft Parts

0703

-

0202

3004

-

0045

Page 43

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

43

3.5.1 Replacing a Camlock

a. Camlock replacement can be achieved as follows:

• Open the camlock lever and using a pin punch and hammer drive the camlock pin out.

• Once the camlock pin has been removed the camlock pressure block can be removed and

replaced if needed.

Note

When the camlocks are closed they must hold the shafts firmly with no slippage. If the

camlock does not hold the shafts firmly in place then pressure blocks should be replaced.

• To reassemble the camlock, fit the pressure block to the camlock lever.

• Place the camlock lever with pressure block fitted into position within the camlock body

then press the camlock pin into place.

3.5.2 Removing the Shafts

a. To remove the shafts from the detector firstly open the detector body as described in

Section 3.1 – Opening the Detector Body. Once completed:

• Lift the shafts clear of the detector.

Figure 72: Removing Camlock Pin

Figure 73: Fitting Camlock Pin

Page 44

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

44

• Remove the pin coil cable from the upper end of the upper shaft. Turn the pin coil cable

clock wise and then lift out.

• Remove the two nylon screws from the cap shaft on the lower shaft as indicated in Figure

76.

• Insert a flat tip screwdriver into the slot underneath the cap shaft and lift and remove the

cap shaft.

• Slide the coil out and off the lower shaft, exposing the coil cable. Feed the coil cable

connector into the upper shaft and pull the coil cable out of the end of the lower shaft.

Figure 76: Removing Screws from Lower Shaft

Figure 75: Removing Pin Coil Cable

Figure 74: Shaft and Coil removed from Detector

Page 45

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

45

3.5.3 Fitting the Shafts

a. The detector body needs to be opened in order to fit the shafts to the detector, refer to

Section 3.1 – Opening the Detector Body.

b. The coil must be fitted to the shaft then the shaft fitted to the detector this process is

described in Section 3.4.6 - Fitting the Coil.

c. Assemble the detector as described in Section 3.2 - Closing the Detector Body.

d. Once the detector is fully assembled check the operation of all moving parts and test the

detector as described in Section 2 - Mechanical & Functional Testing.

Figure 77: Removing Coil Cable from Shafts

Figure 78: Detector Shaft and Coil

Page 46

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

46

3.6 Handle

a. The handle assembly is a line replaceable unit and Figure 79 illustrates the major parts of

the handle.

1 3004-0050 Handle Kit, contains all items in this table.

2 0703-0207 Housing, Display

3 3014-0016 LED Display Assy

4 31-03512-982 Screw 3.5x12 skt head

5 4006-0038 Spring Latch Hinge

6 4006-0041 Spring Handle Detent

7 4308-0022 Pin Lock Handle Detent

8 4308-0023 Pin Handle Main Lower

9 4308-0024 Pin Handle Main Upper

10 4308-0026 Pin Spring Latch hinge

11 4311-0076 Hinge Handle Slide

12 4311-0079 Lock Handle Slide

13 8005-0067 Handle Main

14 8005-0068 Handle Forward Right

15 8005-0069 Handle Forward Left

16 9511-0134 Wiring Loom Handle

0703

-

0207

31-03512-982

3014-0016

8005

-

0068

8005

-

0069

9511

-

0134

4308

-

0024

4006-0038

8005

-

0067

4006-0041

4308

-

0022

4311-0076

4308-0026

Figure 79: Handle Parts

Table 5: Handle Parts

Page 47

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

47

3.6.1 Removing the Handle

a. The detector body must first be opened to remove the handle as described in Section

3.1 - Opening the Detector Body. Once completed:

• Disconnect the wiring loom handle. Hold one side of the connector firm against the

detector body whilst gently pulling the other side.

• Disconnect the spring latch hinge from the latch hinge.

• Lift the handle off the pin handle pivot.

• Remove the rod handle slide from the handle.

• Pass the wiring loom handle through the top of the detector.

Pin Handle Pivot

Spring Latch Hinge

Latch Hinge

Handle

Rod Handle slide

Figure 81: Handle

Figure 82: Removi

ng Handle and Cable

Pin Handle Pivot

Figure 80: Disconnect Wiring Loom Handle

Page 48

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

48

3.6.2 Fitting the Handle

a. To fit the handle the detector body must be opened as described in Section 3.1 - Opening

the Detector Body. Once completed:

• Thread the wiring loom handle into the detector body.

• Push the handle onto the pin handle pivot.

• Connect the spring latch hinge to the latch hinge.

• Feed the rod handle slide through the handle and into position.

• Connect the wiring loom handle and fit into the cable router.

Figure 83: Threading the Wiring Loom

Pin Handle Pivot

Latch

Spring

Figure 84: Latch Hinge and Spring Latch Hinge

Rod passing through Armrest Slide

and Handle

Page 49

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

49

b. Assemble the detector and close the detector body as described in Section 3.2 - Closing

the Detector Body.

3.7 Armrest

a. The armrest is a line replaceable unit with or without slide as shown in Figure 86.

3.7.1 Replacing the Armrest

a. To replace the armrest:

• Prepare a clean well lit workspace.

• Turn the detector off and remove the batteries.

• Remove the four 12mm round head screws from the top of the armrest and remove the

armrest.

Figure 85: Correct Position of Wiring Loom Handle

3004

-

0048 Armrest Kit with Slide.

3004

-

0049 Armrest Kit

Figure 86: Armrest Service Kits

Page 50

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

50

b. The armrest assembly can now be replaced as an assembly. If the armrest slide assembly

must also be replaced then the detector body must be opened as described in Section 3.1 -

Opening the Detector Body.

• Reattach the armrest and fit the four screws (12mm)

• Check the armrest folds in and out correctly and also check that the armrest slides

backward and forward.

3.8 Battery Compartment

a. The battery compartment and the battery lid are line replaceable units and available as

service kits which include associated parts as shown in Figure 88.

1 3004-0051 Battery Compartment Kit, contains all items.

2 3004-0052 Battery Lid Kit

3 31-03512-982 Screw 3.5x12 skt head

4 31-23001-927 Washer M3 Nylon

5 8005-0070 Tether Battery Lid

6 4309-0075 O-ring Battery Lid

Figure 87: Removing the Armrest

8005

-

0070

Table 6: Battery Compartment

3004-0052 Battery Lid Kit

Armrest Slide

3004-0051 Battery Compartment Kit

4309

-

0075

Figure 88: Battery Service Kits

31-23001

-

927

31-03512

-

982

Page 51

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

51

3.8.1 Battery Lid Replacement

a. Open the detector body as described in Section 3.1 - Opening the Detector Body. Once

completed:

Note

The battery lid can be replaced without opening the detector body if the tether is unscrewed from

the battery lid.

• Check the battery lid has an O-ring correctly in place. The O-ring must be clean and can

be lightly greased.

• Check the battery lid closes onto the battery compartment. Fit and close the battery lid.

b. Close the detector body as described in Section 3.2 - Closing the Detector Body.

3.8.2 Battery Compartment Replacement

a. Open the detector body as described in Section 3.1 - Opening the Detector Body. Once

completed:

• Disconnect the battery connector.

• Remove the two screws (12mm) from the battery compartment.

• Slide the battery compartment rearward (away from the main PCB), threading the

battery connector out of the detector body.

Figure 89: Opened Detector Body

Battery Connector

Figure 90: Replacing Battery Compartment

Page 52

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

52

• Refit the battery compartment by first feeding the battery connector through the hole in

the detector body.

• Slide the battery compartment into position.

• Connect the battery connector.

• Refit the two mounting screws (12mm).

• Close and lock the battery lid.

b. Reassemble the detector by closing the detector body as described in Section 3.2 -

Closing the Detector Body.

Page 53

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

53

3.9 Detector Body

a. The detector body is not a line replaceable unit. The following assemblies within the

detector body are line replaceable units and are available as service kits:

• 3004-0054 Switches kit

• 3004-0056 Wiring Loom Handle Socket Kit

• 3004-0057 Speaker Kit

• 3004-0058 Wiring Loom Earset kit

b. All parts are available individually as spare parts.

3.9.1 Control Switches Replacement

a. The control switches are a line replaceable unit and are available as a service kit, 30040054 Switches Kit which includes all associated parts. Figure 91 illustrates all parts.

1 3004-0054 Switches Kit, includes all parts in this table

2 31-23006-989 Screw M3x6 skt csk

3 4005-0096 Bush Knob Lift and Turn

4 4006-0047 Spring Knob Lift and Turn

5 4305-0032 Knob Lift and Turn

6 5904-0177 Switches with Cable includes washer and nut

31-23006

-

989

4005

-

0096

4006

-

0047

4305

-

0032

Nut and Washer

5904

-

0177

Figure 91: Switches

Kit

Table 7: Switches Parts

Page 54

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

54

b. Open the detector body and remove the main PCB as described in Section 3.3.1 -

Removing the Main PCB. Once completed:

• Identify the six way ribbon cable from the control switches to the interface PCB.

• Open the locking bail of the connector on the interface PCB, disconnect the six way

ribbon cable.

• Lay the detector body on its side with the control knobs facing upwards. Set the controls

to off and setting 4.

• Using a 2mm hex key driver, undo the screws in the centre of each control knob and

remove the screw, bush, spring and knob from the switches.

• Take note of the orientation of the switches and the ribbon cable and use a 10mm

spanner to remove the nut and locking washer from both switches.

c. The control switches can now be removed and replaced.

Note

Use care handling the control switches and the flexible ribbon cable. These are internal

components and will be easily damaged if they are forced or misaligned.

Figure 92: Disconnecting Six Way Ribbon Cable

Figure 93: Removing Control Switch Knobs

Page 55

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

55

Note

Do not use a soldering iron on the switches or the flexible ribbon cable.

• Check each control switch has a clean and lightly greased O-ring correctly positioned on

the mounting face.

• Carefully align the control switches and the flexible ribbon cable within the detector body

as illustrated in Figure 94.

• Insert the control switches into the detector body; fit the lock washer and 10mm nut.

• Fit the switch knob then the spring followed by the bush and screw to the control switch.

• Check the switch knobs move through their arc of movement with end stops.

• Identify the connector on the interface PCB that mates with the flexible ribbon cable of

the control switches. Open the connector locking bail (slide out). As shown in Figure 92.

• Insert the six way ribbon cable into the connector on the interface PCB then close the

locking bail on the connector.

d. Reassemble the detector by fitting the main PCB then closing the detector body as

described in Section 3.3.3 - Installing the Main PCB.

O-Ring

Figure 94: Control Switches

Page 56

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

56

3.9.2 Speaker Replacement

a. The speaker is a line replaceable unit and available as a service kit, 3004-0057 Speaker

Kit. Figure 95 illustrates the major parts of the speaker.

1 3004-0057 Speaker Kit, contains all items in this table

2 0708-0011 Enclosure Speaker

3 30-05214-001 Circlip External 7mm

4 30-29011-011A O-Ring BS011 Silicone

5 30-39300-011 Tape Double Sided PVC 10x10x4.8mm

6 9511-0130 Wiring Loom and Speaker

7 30-29011-034 O-Ring BS034 Speaker

8 30-03512-982 Screw 3.5x12skt

b. Open the detector body as described in Section 3.1 - Opening the Detector Body. Once

completed:

• Remove the four screws (12mm) from the speaker assembly in the right side of the

detector body.

30-29011

-

034

30-05214

-

001

30-03512

-

982

30-29011

-

011

0708

-

0011

9511

-

0130

Figure 95: Speaker

Kit

Table 8: Speaker Parts

Page 57

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

57

• Check speaker assembly is in good working order and the speaker cable is correctly

sealed into the speaker assembly and the E-Clip is fitted.

• Check the speaker O-ring is clean, lightly greased and correctly positioned in its channel in

the detector body.

• Position the speaker assembly and fit the four screws (12mm).

c. Assemble the detector as described in Section 3.2 - Closing the Detector Body.

3.9.3 Wiring Loom Earset Replacement

a. The wiring loom earset is a line replaceable unit and is available as a service kit, 30040058 Wiring Loom Earset Kit which includes associated parts. Figure 97 illustrates the major

parts of the wiring loom earset.

1 3004-0058 Wiring Loom Earset Kit, includes all items in this

table

2 9511-0158 Wiring Loom Earset

3 4309-0069 Dust Cap Earset Connector

4 4002-0053 Nut Earset Connector

b. Open the detector body and remove the main PCB as described in Section 3.1 - Opening

the Detector Body and 3.3.1 - Removing the Main PCB. Once completed:

Figure

96

: Replac

ing Speaker Assembly

Table 9: Wiring Loom Earset

4309

-

0069

4002

-

0053

9511

-0158

Figure 97: Wiring Loom Earset

Kit

Page 58

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

58

Disconnect the wiring loom earset from the interface PCB.

• Unscrew the 13mm nut from the earset connector and remove the nut and the connector

dust cover.

c. The wiring loom earset can now be removed and replaced as required. The wiring loom

earset is fitted to the detector following the reverse order of the removal.

3.9.4 Wiring Loom Handle Socket Replacement

a. The wiring loom handle socket is a line replaceable unit and is available as a service kit,

3004-0056 Wiring loom Handle Socket Kit, which includes associated parts. Figure 98 illustrates

the major parts of wiring loom handle Socket.

1 3004-0056 Wiring Loom Handle Socket Kit, contains all

items in this table

2 9511-0136 Wiring Loom Handle Socket

3 30-29011-519 O-Ring BS012

4 30-05214-001 Circlip External 7mm

b. Open the detector body as described in Section 3.1 - Opening the Detector Body. Once

completed:

• Disconnect the wiring loom handle socket from the handle wiring loom.

• Disconnect the wiring loom handle socket from the interface PCB.

• Remove the E-Clip from the wiring loom handle socket at the entry point to the detector

body.

Table 10: Wiring Loom Handle Socket Kit

30-29011

-

519

30-05214

-

001

9511

-0136

Figure 98: Wiring Loom Handle Socket Kit

Page 59

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

59

c. The wiring loom handle socket can now be removed and replaced. To fit the wiring loom

handle socket follow the removal instruction above in reverse order. Then assemble the

detector as described in Section 3.2 Closing the Detector Body.

3.9.5 Detector Body Parts

This section of the manual describes the parts of the F3 COMPACT detector in the body of the

detector that are not covered by the range of service kits, figures 100 to 103 illustrate these

parts

Wiring Loom Handle Socket

Connector to Interface PCB

E-Clip

Figure 99: Wiring Loom Handle Socket

0703

-

0203

31-24045

-

982

Screw M4x45

2703

-

0040

0304

-

0027

31-24035

-

982

Screw M4x35

0703

-

0205

Figure 100: Detector left side

Page 60

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

60

31-24020

-

982

Screw M4x20mm

31-24035

-

982

Screw M4X35

2705

-

0061

30-43000

-

001

4003

-

0118

Screw M4x20 Torx

4003

-

0119

Screw M4x35 Torx

0703

-

0206

4309

-

0068

4007

-

0009

4308

-

0027

5904

-

0176

F

igure 102: Detector right side

Figure 103: Detector body

Figure 101: Detector right side

Page 61

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

61

1 0703

-

0203

Hinge Cover

2 31-24045

-

982 Screw M4x45skt head

3 0703

-

0205

Chassis Left (switches side)

4 0703

-

0206

Chassis Ri

ght (speaker side)

5 0304

-

0027

Rod Handle Slide

6 4309

-

0068

Seal Detector Body

7 4007

-

0009

Latch Hinge

8 4308

-

0027

Pin Handle Pivot

9 5904

-

0176

Pin Handle Pivot

10 2703

-

0040

Decal Switches

11 2705

-

0061

Decal Compliance

12 2705

-

0025

Decal Serial Num

ber

13 30-43000

-

001 Vent Gore

14 31-24020

-

982 Screw M4x20 skt head

15 31-24035

-

982 Screw M4x35 skt head

16 4003

-

0118

Screw M4x20 Torx with seal

17 4003

-

0119

Screw M4x35 Torx with seal

Table 11: Detector body parts

Page 62

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

62

4 Fault Finding Procedures

4.1 Introduction

a. A functional test failure can generally be repaired by replacing one or all of the line

replaceable units.

b. The F3 COMPACT is designed so that line replaceable units can be exchanged between

detectors without the need to calibrate. This means that where spare parts are not available

and more than one detector is faulty, then parts from one detector can be used to make another

serviceable. For example, if detector # 1 has an unserviceable coil and detector # 2 has an

unserviceable battery compartment, then the coil from detector # 2 can replace the coil on

detector # 1 thereby producing a serviceable detector.

4.2 Trouble Shooting Table

a. The following table identifies a number of faults and provides recommended solutions.

The suggested solutions should be investigated in the order they are listed.

Problem Recommended Solutions

Detector will not switch

on

● check batteries are installed correctly

● replace batteries with fresh batteries

● replace battery compartment

● replace main PCB

Detector will not switch

off

● remove batteries

● replace Main PCB

After switching on the

detector makes no

sound from speaker

● check for tone using the earset, turn LEDs on

● if there is tone through earset – replace the speaker

● if there is no tone through earset – replace main PCB

Threshold Tone is too

loud

● ensure area is free from local electromagnetic interference

● conduct Audio Reset

● conduct Noise Cancel

● check coil plug is tight

● replace coil

● replace main PCB

On switch on, the “Coil

Fault” tone occurs - “low

pitched double tone

every five seconds”

● check the coil plug is firmly secured

● inspect coil cable for damage – if no damage replace main

PCB

● if damaged replace with new coil

On switch on, the

“Equipment Fault” tone

occurs – “low pitched

slow oscillating tone

(ee-aww, ee-aww)

● turn off then on

● replace the switches

● replace main PCB

After working in hot

conditions, detector

makes a loud noise

● conduct Audio Reset

● check coil plug is tight

● replace coil

● replace main PCB

Page 63

F3 COMPACT Service Manual

_______________________________________________________________________________________________________________________

63

Ground Balance does

not work

● replace handle

● replace coil

● replace main PCB

Noise Cancel does not

work