Operating Instructions

Process Controller Maxxis 5 PR 5900

Translation of original operating instructions 9499 050 59900 Edition 6.1.1 02/26/2018

Release 2.26.xx-Exx

Minebea Intec GmbH, Meiendorfer Str. 205 A, 22145 Hamburg, Germany

Phone: +49.40.67960.303 Fax: +49.40.67960.383

Foreword

Must be followed!

Any information in this document is subject to change without notice and does not represent a commitment on

the part of Minebea Intec unless legally prescribed. This product should be operated/installed only by trained

and qualied personnel. In correspondence concerning this product, the type, name, and release number/serial

number as well as all license numbers relating to the product have to be cited.

Note

The product is partially protected by copyright. It may not be changed or copied, and it may not be used without

purchasing or written permission from the copyright owner (Minebea Intec). Its use constitutes acceptance by

you of the above-mentioned provisions.

Process Controller Maxxis 5 PR 5900 Table of contents

Table of contents

1 Introduction......................................................................................................................................... 6

1.1 Read the manual.........................................................................................................................................................6

1.2 This is what operating instructions look like..........................................................................................................6

1.3 This is what lists look like........................................................................................................................................... 6

1.4 This is what menu items and softkeys look like..................................................................................................... 6

1.5 This is what the safety instructions look like..........................................................................................................6

1.6 Hotline.......................................................................................................................................................................... 7

2 Commissioning..................................................................................................................................... 8

2.1 Display and control panel.......................................................................................................................................... 8

2.1.1 Overview............................................................................................................................................................8

2.1.2 Display elements..............................................................................................................................................8

2.1.3 Operating elements........................................................................................................................................ 11

2.1.4 Display and operation using VNC client..................................................................................................... 18

2.2 Data security and data storage .............................................................................................................................. 18

2.2.1 Power failure................................................................................................................................................... 18

2.2.2 Warm start....................................................................................................................................................... 18

2.2.3 Cold start ......................................................................................................................................................... 18

2.3 Switching on the device........................................................................................................................................... 19

2.4 Switching o the device..........................................................................................................................................20

2.5 Device warm-up time...............................................................................................................................................20

2.6 Operating via front-panel keys/PC keyboard......................................................................................................20

2.7 Overwrite protection................................................................................................................................................20

2.7.1 CAL switch.......................................................................................................................................................20

2.7.2 Software..........................................................................................................................................................22

2.8 Switching on blackbox device ................................................................................................................................24

2.8.1 Connecting to remote terminal PR 5900/6x, ../7x...................................................................................24

2.8.2 Network settings............................................................................................................................................24

2.8.3 Connecting to notebook/PC ........................................................................................................................25

2.9 Operating via a notebook/PC.................................................................................................................................26

2.9.1 Finding and connecting the device automatically in the network .........................................................26

2.9.2 Finding and connecting a device with a notebook/PC ............................................................................26

2.9.3 Searching the device in the network with "IndicatorBrowser" ...............................................................27

2.9.4 Resetting the network address....................................................................................................................29

2.9.5 Operation using VNC.....................................................................................................................................29

2.9.6 Operation via a web browser .......................................................................................................................30

3 Operation and control ........................................................................................................................ 32

3.1 User login/logout .....................................................................................................................................................32

3.1.1 User login ........................................................................................................................................................32

3.1.2 User Logout....................................................................................................................................................33

EN-1 Minebea Intec

Process Controller Maxxis 5 PR 5900 Table of contents

3.2 User management.................................................................................................................................................... 33

3.3 Selecting the operating language..........................................................................................................................34

3.4 System menu.............................................................................................................................................................34

3.5 Help functions...........................................................................................................................................................36

3.6 Alibi memory.............................................................................................................................................................36

3.7 Showing the calibration data.................................................................................................................................. 37

3.8 Increased resolution (10-fold) of the weight value .............................................................................................37

3.9 Functions via the website........................................................................................................................................ 37

3.9.1 Display weighing points in a table ..............................................................................................................39

3.9.2 Browse database........................................................................................................................................... 40

3.9.3 Browsing the Alibi memory......................................................................................................................... 40

3.9.4 Displaying manuals ....................................................................................................................................... 41

3.9.5 Browse the event log..................................................................................................................................... 41

3.9.6 Browse log les ..............................................................................................................................................42

3.9.7 Displaying a log of the last system error....................................................................................................42

3.9.8 Screenshot ......................................................................................................................................................43

3.9.9 Export database.............................................................................................................................................43

3.9.10 Export Alibi memory......................................................................................................................................44

3.9.11 Export service report.....................................................................................................................................44

3.9.12 Backup and restore setup data....................................................................................................................45

3.9.13 Loading language les..................................................................................................................................47

3.10 BIOS BOOT menu .....................................................................................................................................................47

3.10.1 Open BIOS BOOT menu................................................................................................................................48

3.10.2 BIOS BOOT menu in blackbox device.........................................................................................................54

3.10.3 System messages in blackbox device.........................................................................................................54

4 System setup......................................................................................................................................56

4.1 Connected devices ...................................................................................................................................................57

4.1.1 Remote display............................................................................................................................................... 57

4.1.2 ModBus-RTU master.....................................................................................................................................59

4.1.3 PC via EW-Com............................................................................................................................................... 61

4.1.4 Printer..............................................................................................................................................................63

4.1.5 Remote terminal .............................................................................................................................................71

4.1.6 Barcode scanner (with Ex approval).............................................................................................................71

4.2 Date & time ................................................................................................................................................................73

4.3 Operating parameters .............................................................................................................................................75

4.4 Network parameters ............................................................................................................................................... 80

4.5 Network share connections ....................................................................................................................................83

4.5.1 Add...................................................................................................................................................................84

4.5.2 Change.............................................................................................................................................................86

4.5.3 Remove............................................................................................................................................................87

4.6 Fieldbus parameters ................................................................................................................................................88

4.6.1 Fieldbus settings for the SPS .......................................................................................................................89

Minebea Intec EN-2

Process Controller Maxxis 5 PR 5900 Table of contents

4.7 Weighing points........................................................................................................................................................90

4.7.1 Internal weighing point.................................................................................................................................92

4.7.2 Liquid counter .............................................................................................................................................. 123

4.7.3 User scale ...................................................................................................................................................... 126

4.7.4 A+B (scale)..................................................................................................................................................... 129

4.7.5 xBPI scale ...................................................................................................................................................... 132

4.7.6 SBI scale......................................................................................................................................................... 157

4.7.7 Pendeo Truck.................................................................................................................................................161

4.7.8 Pendeo Process............................................................................................................................................ 187

4.7.9 PR-Net weighing point ............................................................................................................................... 213

4.7.10 Mettler-Scale ................................................................................................................................................216

4.7.11 SMA scale ...................................................................................................................................................... 221

4.8 Display settings.......................................................................................................................................................225

4.9 License settings ......................................................................................................................................................226

4.9.1 Application license.......................................................................................................................................227

4.9.2 Demo mode ..................................................................................................................................................227

4.9.3 Default (restoring factory settings)...........................................................................................................229

4.10 User management..................................................................................................................................................229

4.10.1 Create user .................................................................................................................................................... 231

4.10.2 Copy user.......................................................................................................................................................234

4.10.3 Change user settings...................................................................................................................................235

4.10.4 Remove user.................................................................................................................................................236

4.10.5 Deactivate user management....................................................................................................................238

4.10.6 Error logging in ............................................................................................................................................238

4.11 Alibi memory.......................................................................................................................................................... 240

4.11.1 Tidy up records............................................................................................................................................. 241

4.11.2 Delete.............................................................................................................................................................242

5 System information..........................................................................................................................244

5.1 Show version .......................................................................................................................................................... 245

5.2 Show status ............................................................................................................................................................ 246

5.3 Show alarm information........................................................................................................................................247

5.4 Show HW options .................................................................................................................................................. 248

5.5 Show ModBus-TCP I/O module .......................................................................................................................... 249

5.6 Browsing the Alibi memory................................................................................................................................... 251

5.6.1 Search for specic date in Alibi memory.................................................................................................. 251

5.6.2 Search for a given sequence number ...................................................................................................... 254

5.6.3 Status Alibi memory ....................................................................................................................................255

5.7 Show calibration check number...........................................................................................................................256

5.8 Show Pendeo data..................................................................................................................................................257

5.9 Show event log....................................................................................................................................................... 260

5.10 Print conguration settings.................................................................................................................................. 261

EN-3 Minebea Intec

Process Controller Maxxis 5 PR 5900 Table of contents

6 System maintenance ........................................................................................................................ 263

6.1 Backup..................................................................................................................................................................... 264

6.1.1 SD card...........................................................................................................................................................265

6.1.2 USB stick........................................................................................................................................................267

6.1.3 Shared directory.......................................................................................................................................... 269

6.2 Restore..................................................................................................................................................................... 271

6.2.1 SD card........................................................................................................................................................... 273

6.2.2 USB stick........................................................................................................................................................275

6.2.3 Shared directory...........................................................................................................................................278

6.3 Export....................................................................................................................................................................... 281

6.3.1 USB stick........................................................................................................................................................282

6.3.2 Shared directory.......................................................................................................................................... 284

6.4 Import...................................................................................................................................................................... 286

6.4.1 USB stick....................................................................................................................................................... 288

6.4.2 Shared directory........................................................................................................................................... 291

6.5 Alibi memory maintenance .................................................................................................................................. 294

6.5.1 Export selection of records.........................................................................................................................295

6.5.2 Export + tidy up selection of records....................................................................................................... 298

6.5.3 Print selection of records........................................................................................................................... 302

6.5.4 Print + tidy up selection of records.......................................................................................................... 305

6.6 SD card maintenance ............................................................................................................................................ 308

6.6.1 Format SD card............................................................................................................................................ 309

6.6.2 Cleanup backups.......................................................................................................................................... 310

6.7 Create service report...............................................................................................................................................311

6.8 Shutdown & power o........................................................................................................................................... 313

6.8.1 Shutdown & Power o (without SD card)................................................................................................. 314

6.9 Update software ..................................................................................................................................................... 314

6.9.1 Update (soft key).......................................................................................................................................... 315

6.9.2 Update software............................................................................................................................................317

6.9.3 Update software with FlashIt .....................................................................................................................326

6.9.4 Update software for remote terminal.......................................................................................................329

6.9.5 Remove application.....................................................................................................................................330

6.9.6 Restore software from SD card.................................................................................................................. 331

6.10 Factory reset............................................................................................................................................................ 331

6.11 Test hardware..........................................................................................................................................................332

6.11.1 Display test....................................................................................................................................................333

6.11.2 Keyboard test ...............................................................................................................................................334

6.11.3 I/O cards test ................................................................................................................................................335

7 ModBus protocol ............................................................................................................................. 345

7.1 General description ................................................................................................................................................345

8 Fieldbus interface ............................................................................................................................ 346

Minebea Intec EN-4

Process Controller Maxxis 5 PR 5900 Table of contents

8.1 General notes ......................................................................................................................................................... 346

8.2 Scale protocol......................................................................................................................................................... 346

8.2.1 Data exchange range ................................................................................................................................. 346

8.2.2 Reading and writing data with function numbers................................................................................. 349

8.2.3 Reading and writing bits directly ............................................................................................................. 350

8.2.4 Waiting for the result of the action........................................................................................................... 351

8.2.5 Function numbers........................................................................................................................................ 351

8.2.6 Example: reading the gross weight...........................................................................................................356

8.2.7 Special note for DeviceNet and EtherNet IP............................................................................................357

8.3 SPM protocol ...........................................................................................................................................................357

8.3.1 Data exchange range ..................................................................................................................................357

8.3.2 Function numbers....................................................................................................................................... 358

8.3.3 Error code......................................................................................................................................................359

8.3.4 Data exchange modes................................................................................................................................ 360

9 Error messages ................................................................................................................................ 363

9.1 Error messages measuring circuit........................................................................................................................363

9.2 Error messages for xBPI scales............................................................................................................................ 364

9.3 Error messages for Pendeo load cells .................................................................................................................365

9.4 Error messages at PR-Net weighing point .........................................................................................................366

9.5 Error messages at "Mettler-Scale" weighing point ...........................................................................................366

9.6 Warnings when assigning a weighing point.......................................................................................................366

9.7 Error messages during calibration.......................................................................................................................367

9.7.1 Determine MAX (maximum capacity) .......................................................................................................367

9.7.2 Determining the scale interval.................................................................................................................. 368

9.7.3 Determining the dead load ....................................................................................................................... 368

9.7.4 Calibrating with weight...............................................................................................................................369

9.8 Error status in "LAST_ERROR"..............................................................................................................................370

10 Printouts ...........................................................................................................................................371

10.1 Conguration printout............................................................................................................................................371

10.2 Test printout............................................................................................................................................................375

10.3 Alibi printout ...........................................................................................................................................................376

EN-5 Minebea Intec

Process Controller Maxxis 5 PR 5900 1 Introduction

1 Introduction

1.1 Read the manual

- Please read this manual carefully and completely before using the product.

- This manual is part of the product. Keep it in a safe and easily accessible location.

-

1.2 This is what operating instructions look like

1. - n. are placed before steps that must be done in sequence.

is placed before a step.

describes the result of a step.

1.3 This is what lists look like

- indicates an item in a list.

1.4 This is what menu items and softkeys look like

[ ] frame menu items and softkeys.

Example:

[Start]- [Applications]- [Excel]

1.5 This is what the safety instructions look like

Signal words indicate the severity of the danger involved when measures for preventing

hazards are not followed.

DANGER

Warning of personal injury

DANGER indicates death or severe, irreversible personal injury which will occur if the

corresponding safety measures are not observed.

Take the corresponding safety precautions.

WARNING

Warning of hazardous area and/or personal injury

WARNING indicates that death or severe, irreversible injury may occur if appropriate

safety measures are not observed.

Take the corresponding safety precautions.

CAUTION

Warning of personal injury.

CAUTION indicates that minor, reversible injury may occur if appropriate safety

measures are not observed.

Take the corresponding safety precautions.

Minebea Intec EN-6

1 Introduction Process Controller Maxxis 5 PR 5900

NOTICE

Warning of damage to property and/or the environment.

NOTICE indicates that damage to property and/or the environment may occur if

appropriate safety measures are not observed.

Take the corresponding safety precautions.

Note:

User tips, useful information, and notes.

1.6 Hotline

Phone: +49.40.67960.444

Fax: +49.40.67960.474

eMail: help@minebea-intec.com

EN-7 Minebea Intec

.

Process Controller Maxxis 5 PR 5900 2 Commissioning

2 Commissioning

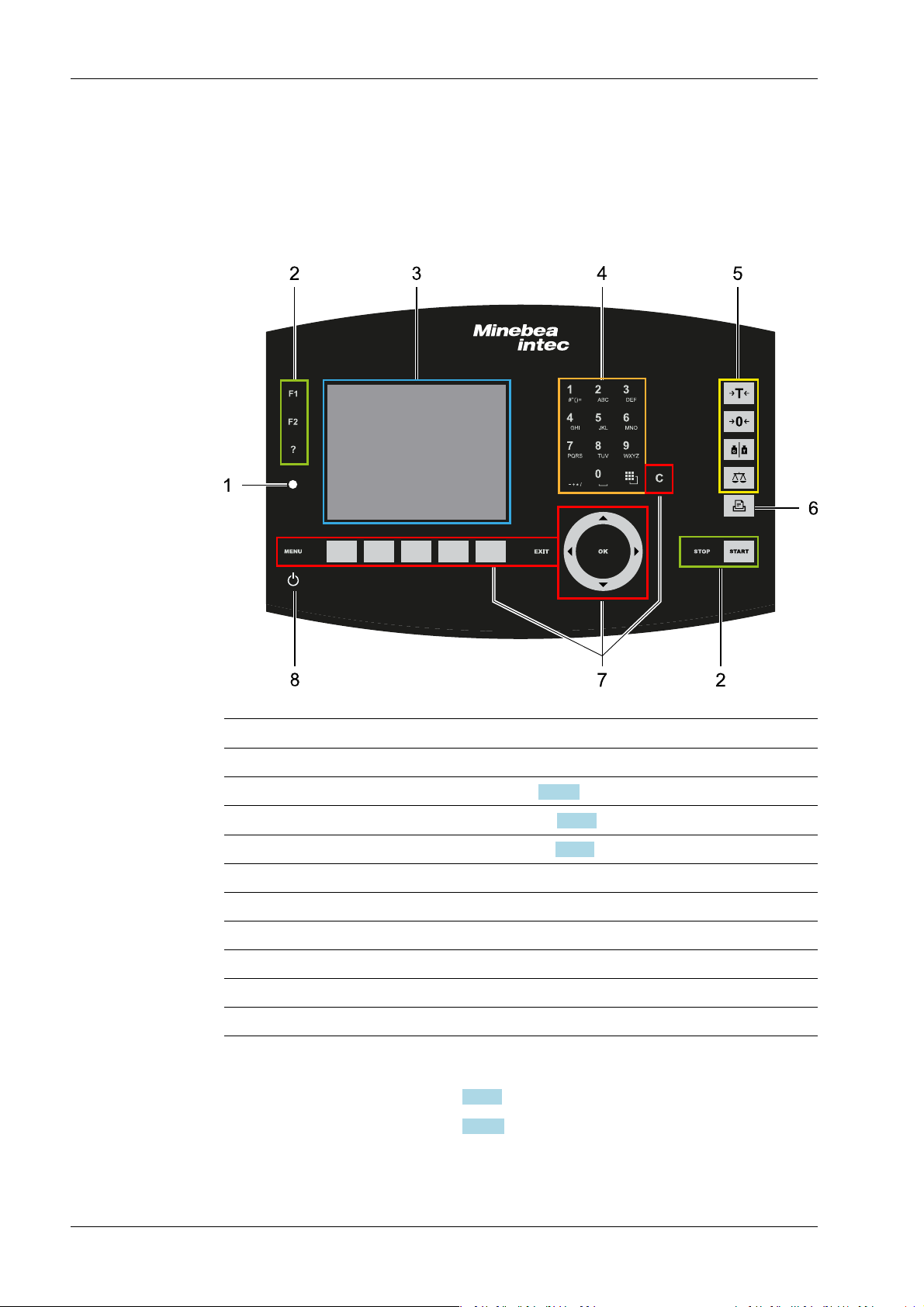

2.1 Display and control panel

2.1.1 Overview

No. Name

1 LED status display, see Chapter 2.1.2.2

3 5.7" TFT color display, see Chapter 2.1.2.1

2 Function keys

4 Alphanumeric keypad

5 Indicator keys

6 Application keys

7 Navigation/menu keys, incl. soft keys

8 On/o button

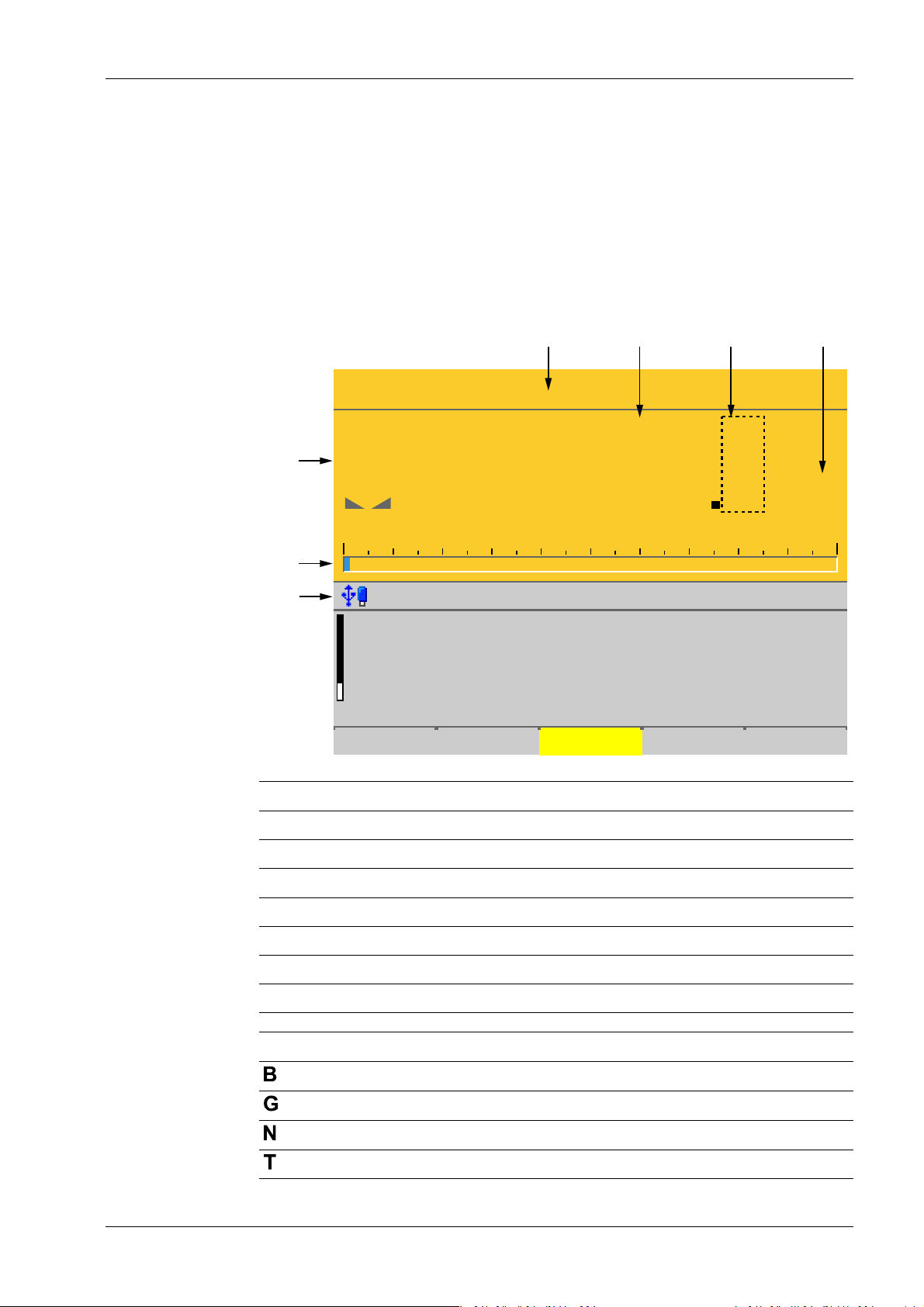

2.1.2 Display elements

- TFT screen display, see Chapter 2.1.2.1

- LED status display, see Chapter 2.1.2.2

Display elements

Operating elements, see Chapter 2.1.3.1

Minebea Intec EN-8

WP-A

Max 12200g d= 0.1g

Min 5g e= 1g

9

041

g

N

+

5g 12200g

Weighing point A @admin

Net=Gross

Net

Tare

<1115.[9] g>

<140.[9] g>

975.0 g

A

A

A

Set tare

7654

3

2

1

2 Commissioning Process Controller Maxxis 5 PR 5900

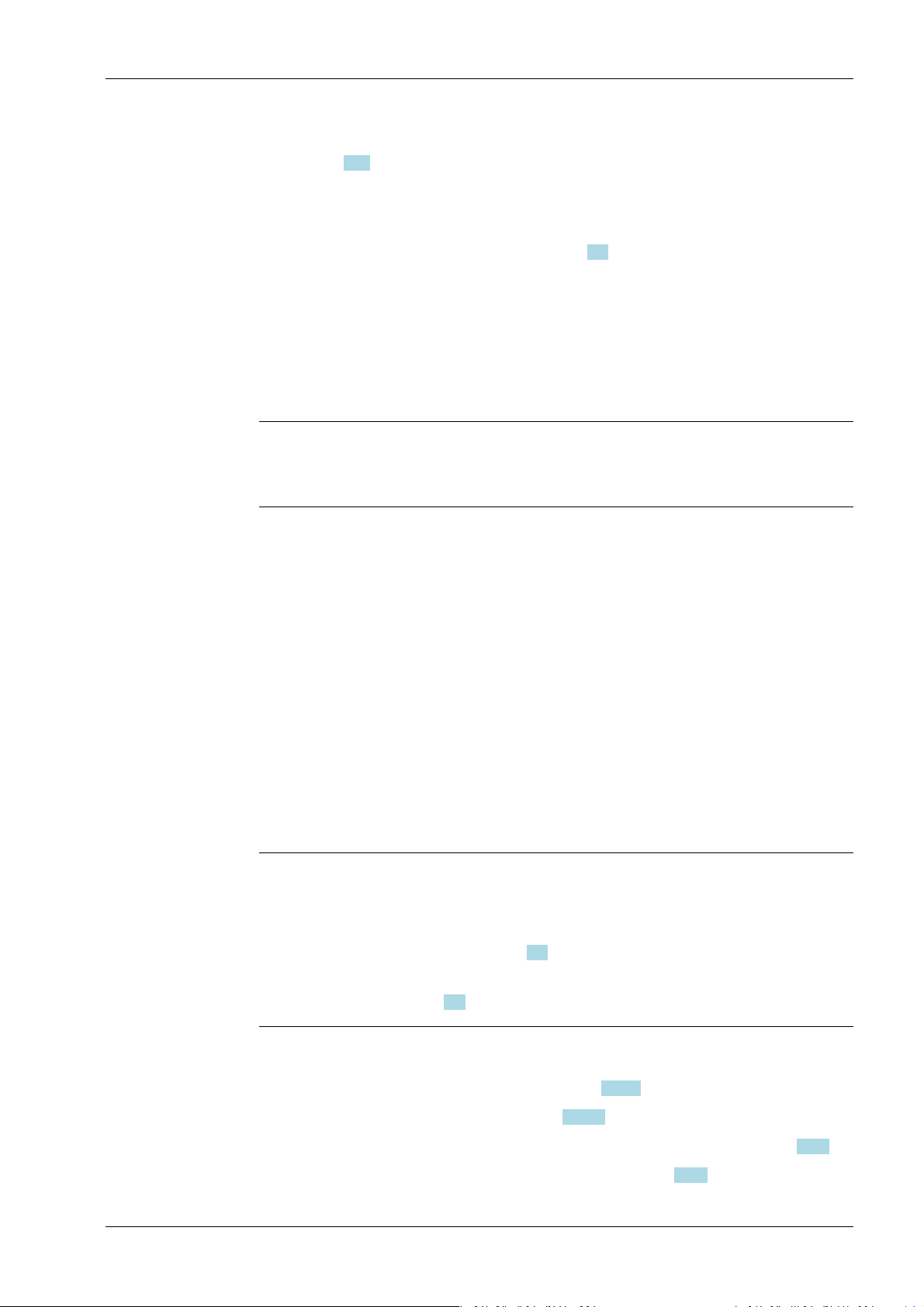

2.1.2.1 TFT user interface display

The TFT color graphics display can show weight values of up to 7 digits with decimal point

and plus or minus sign. The available mass units are t, kg, g, mg, lb, or oz.

The lb and oz units are not permitted for use in legal metrology in the EU and EEC.

Below the weight display, the currently displayed weight is shown in a bar graph that

indicates the percentage of the maximum capacity (Max). 0 is on the left, and 100% on the

right.

No. Description

1 Info line

2 Bar graph

3 Weight type/plus or minus sign/standstill

4 Status display

5 Weight value

6 Border around decimal place

7 Symbols/mass unit

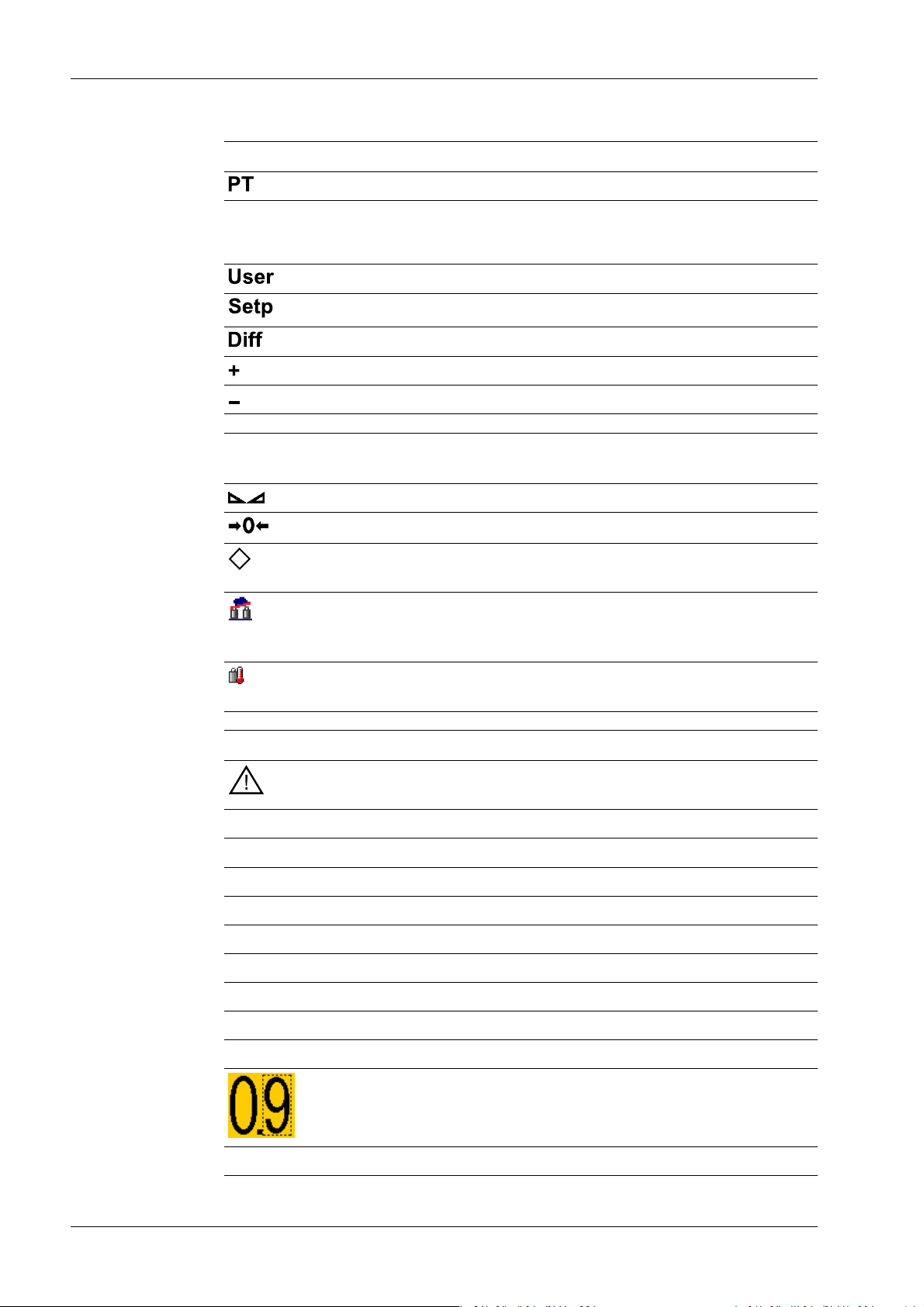

Weight type/plus or minus sign Description

EN-9 Minebea Intec

Gross weight

Gross weight in NTEP or NSC mode

Net weight (Net = gross - tare)

Tare weight

Process Controller Maxxis 5 PR 5900 2 Commissioning

Weight type/plus or minus sign Description

Preset tare, not tared

No display - Test value

- Gross, not tared

Additional weight display, application-dependent

Additional weight display, application-dependent

Additional weight display, application-dependent

Positive value

Negative value

Standstill/zero/batching/monitoring

Symbols/mass unit Description

R1 Range 1

R2 Range 2

R3 Range 3

Description

Weight value standstill

The gross weight value is within ±¼ d of zero

Batching mode: ashes when batching is "stopped";

rapid ashing indicates "error status"

Pendeo load cells: Plausibility monitoring; the average deviation of the individual load cells is calculated

Pendeo load cells: Temperature monitoring; 1–n

load cells above or below permissible temperature

Value not permissible in legal metrology (e.g., 10x

resolution, deactivated load cell)

WP A Weighing point A

WP B Weighing point B

WP C Weighing point C

WP D Weighing point D

Max Maximum capacity (weighing range)

Min Minimum weight

Only if W&M is selected: Border around inadmissible

decimal place.

t, kg, g, mg, lb, oz These mass units are available.

Minebea Intec EN-10

2 Commissioning Process Controller Maxxis 5 PR 5900

Status icons in the info line

Icon Description

Remote control via VNC (Virtual Network Computing) is active.

- The clock battery is empty.

- The standby battery is empty.

The standby battery is too hot and is not charging.

If this does not go away, the ambient temperature

must be checked, see PR 5900 installation manual

under [Technical data] - [Environmental inuences]

- [Ambient conditions].

- An unsupported USB device is connected.

- The maximum current of i

= 200 mA has be-

max

en exceeded.

Check newly connected devices.

2.1.2.2 LED status display

Operating status Color LED status Description

Normal operation O

System ready (standby) Red Continuous illu-

Power interruption

<5 seconds

Power interruption

>5 seconds

USB stick was recognized and is operational.

Stick is in use and may not be removed.

Conict in the network settings of the IP address.

Interface (C1/CX1) was detected. However, there is

no connection to the operator terminal.

The display (screen) is switched

mination

o.

Red Slow ashing After 5 seconds, the device re-

turns to normal operation.

Red Fast ashing The device is running a data ba-

ckup. Once power is restored, the

device returns to normal operation (LED o).

After the data backup,

O The device switches o.

there is still a power interruption.

Power is restored O The device initiates a warm start,

see Chapter 2.2.2.

2.1.3 Operating elements

- Operation using the front-panel keys, see Chapter 2.1.3.1

EN-11 Minebea Intec

Process Controller Maxxis 5 PR 5900 2 Commissioning

- Operation using the soft keys, see Chapter 2.1.3.2

- Operation using the navigation keys, see Chapter 2.1.3.3

- Operation using the PC keys, see Chapter 2.1.3.4

- Operation using the VNC program, see Chapter 2.1.4

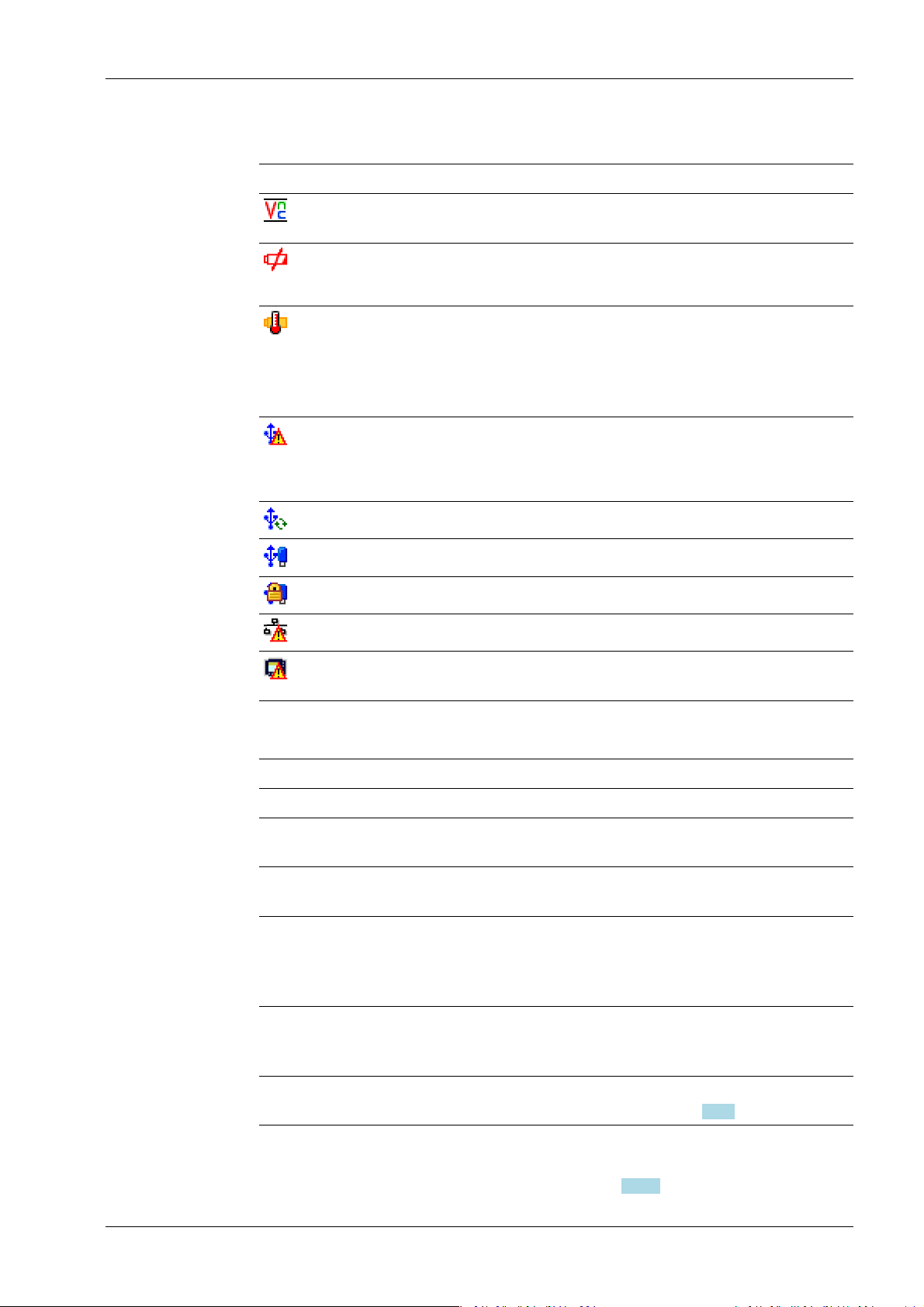

2.1.3.1 Operation using the front-panel keys

The following table shows the basic meanings of the symbols on the front-panel keys.

Depending on the applications, the keys may also have other meanings.

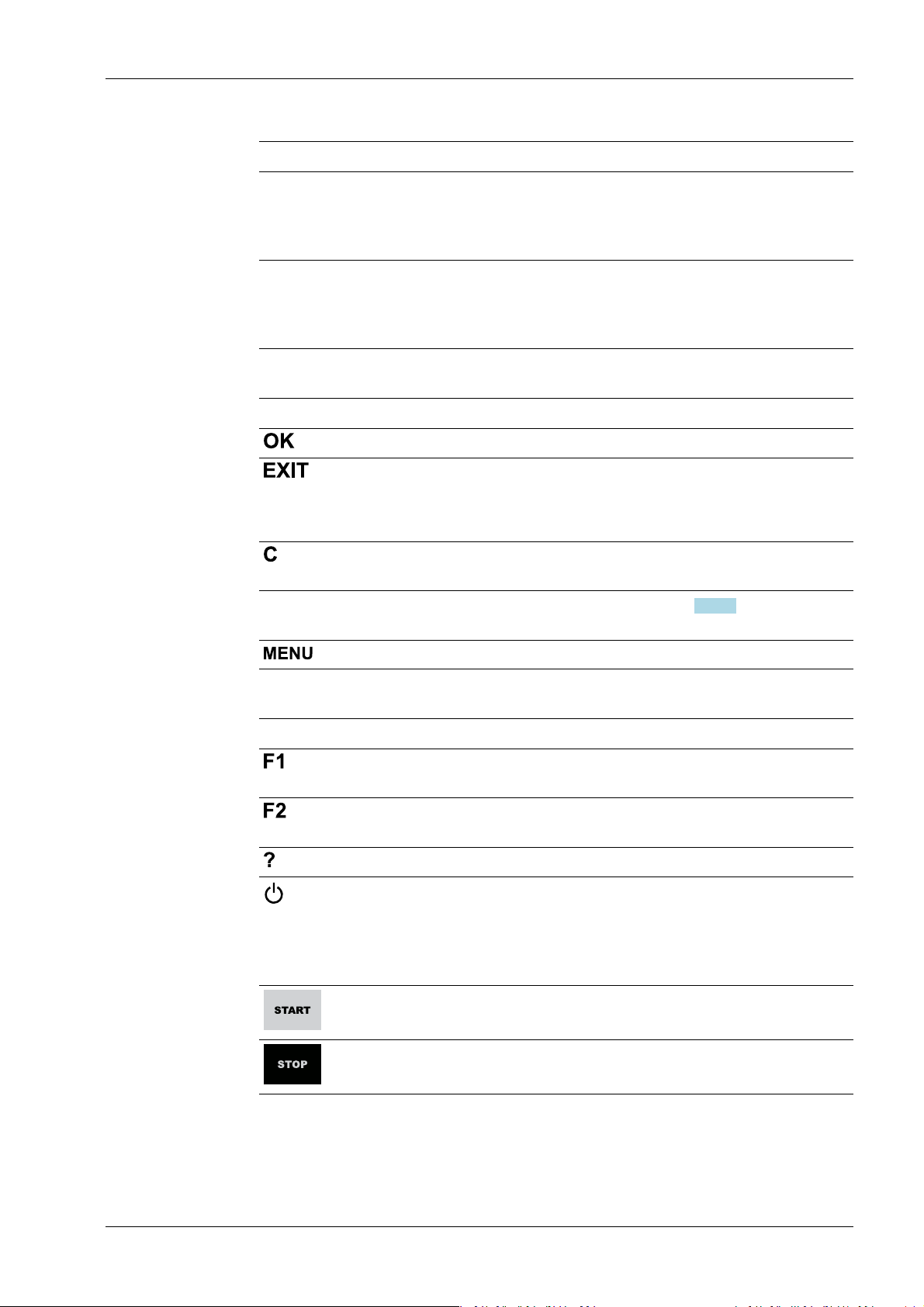

Indicator keys

Key Description

Set tare

The current gross weight is stored in the tare memory, provided that

- the weight value is stable.

- the device is not in error status.

(Function is dependent on conguration)

Sets gross weight to zero, provided that

- the weight value is stable.

- weight is within zero setting range.

(Function is dependent on conguration)

Display gross/tare weight

Pressing the key switches to the next weight (only with tared scale).

During calibration, pressing this key displays the weight for 5 seconds with

10x resolution.

Switching of display between the weighing points:

- WP‑A

- WP‑B

- WP‑C

- WP‑D

Application keys

Key Description

Starts an application-specic printout.

Navigation keys

Key Description

▲ Scroll up in the menu.

▼ Scroll down in the menu.

Minebea Intec EN-12

2 Commissioning Process Controller Maxxis 5 PR 5900

Key Description

◀ - Cursor to the left

- Selection

- Exit menu window.

▶ - Cursor to the right

- Selection

- Conrm input/selection.

Menu keys

Key Description

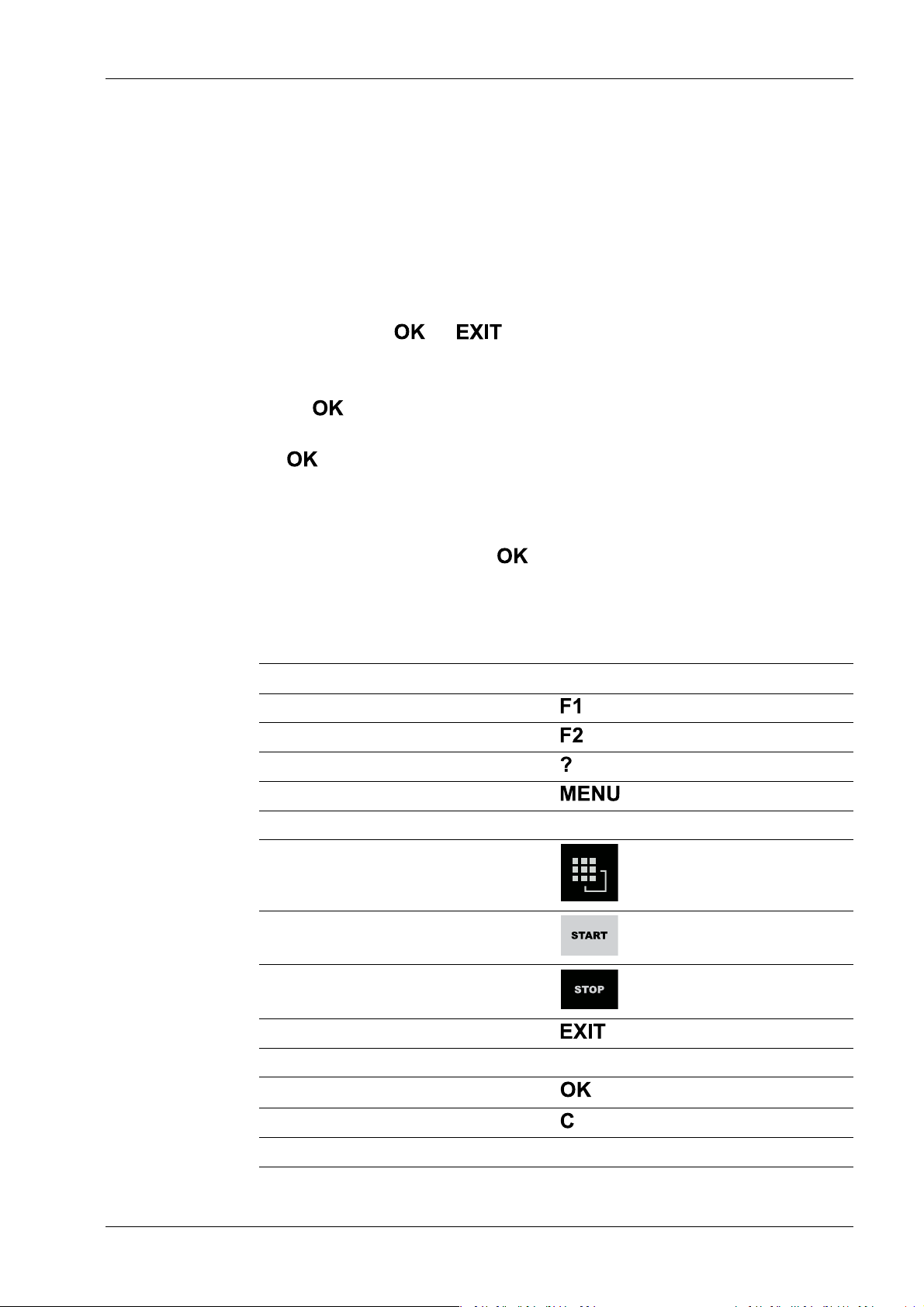

Conrm input/selection.

- Cancel entry/selection (after a conrmation prompt) without saving

the change.

- Exit parameters/menu window.

Pressing the delete key deletes individual characters (within an entry) or

whole strings of characters.

Soft key 1 to5Select appropriate menu function, see also Chapter 2.1.3.2.

Switch to the operating menu.

Function keys

Key Description

Assigned to a dened function (see system menu [System setup] - [Operating parameters]).

Assigned to a dened function (see system menu [System setup] - [Operating parameters]).

Displays the relevant help window.

- Turns o the display.

- Ignores all key presses.

- LED is red.

Pressing again will switch the display on again.

Starts an application-specic function.

Stops an application-specic function.

EN-13 Minebea Intec

.

Process Controller Maxxis 5 PR 5900 2 Commissioning

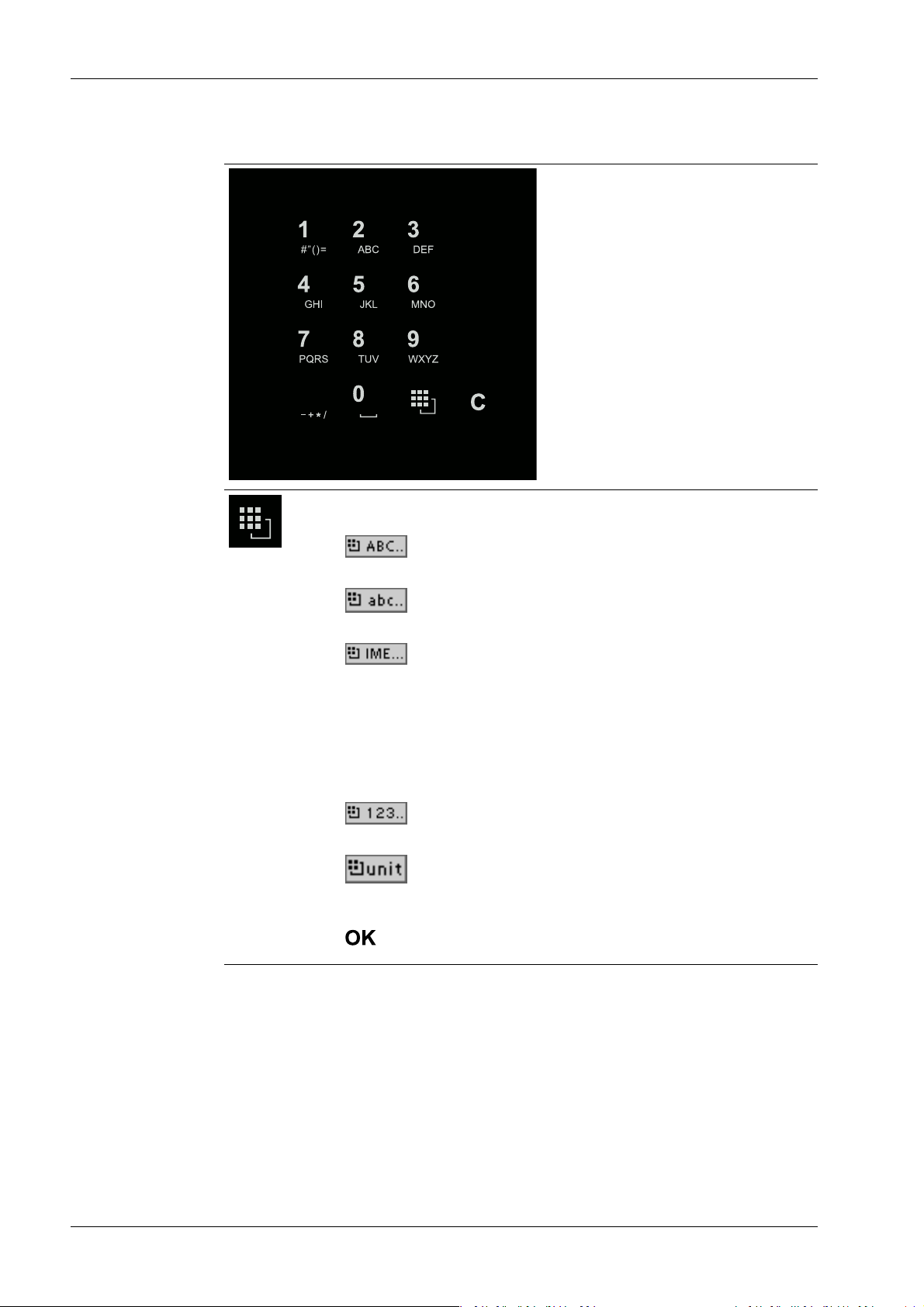

Alphanumeric keypad

Toggle key

Pressing switches between the following functions:

-

Uppercase letters

-

Lowercase letters

-

Pinyin

When Chinese has been selected or set under [Operating parameters]

- [Input method].

- Hepburn

When Japanese has been selected or set under [Operating parameters] - [Input method].

-

Numbers

-

Units

Select the unit using the cursor keys ▲/▼ and conrm using the key

.

Minebea Intec EN-14

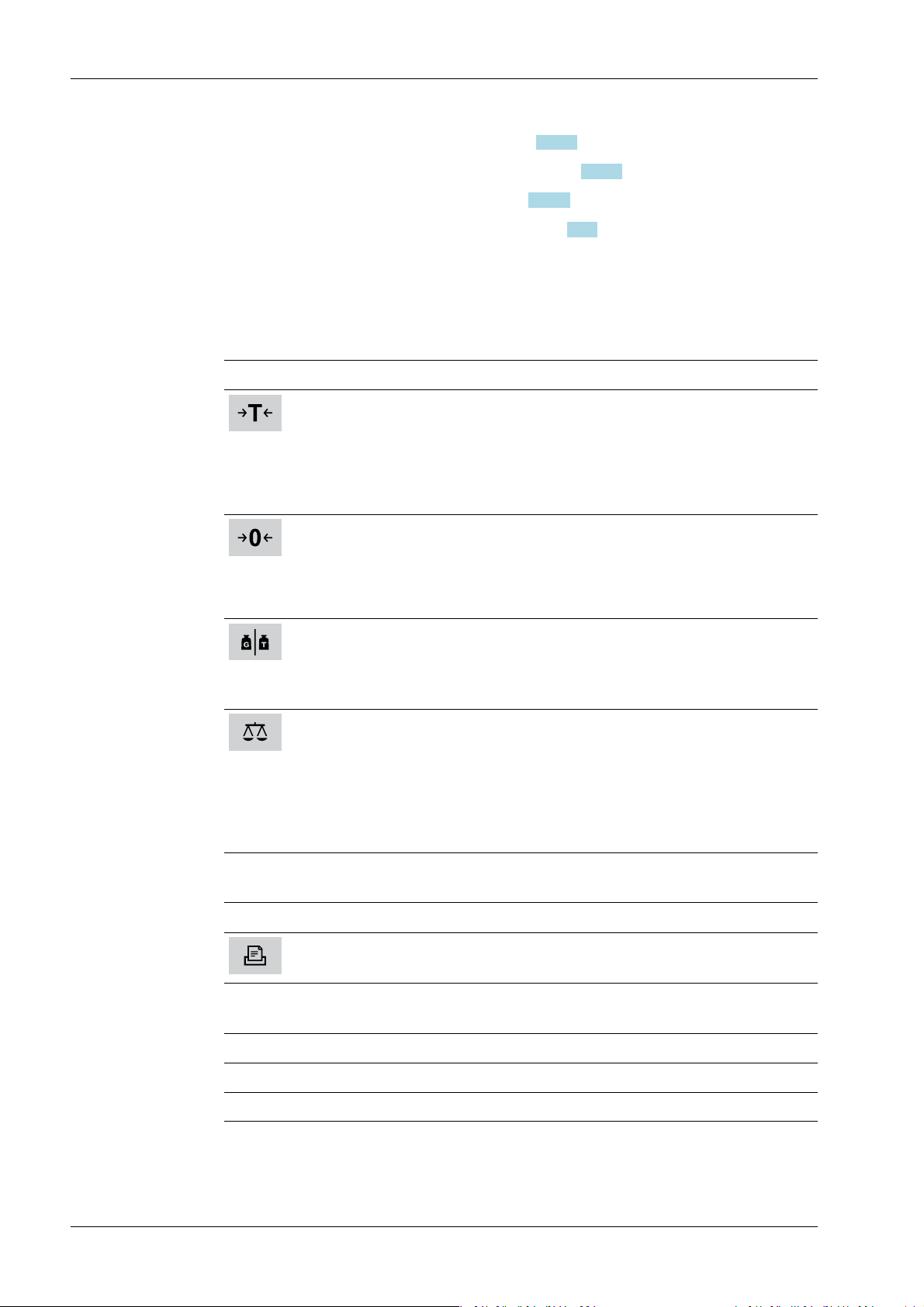

2 Commissioning Process Controller Maxxis 5 PR 5900

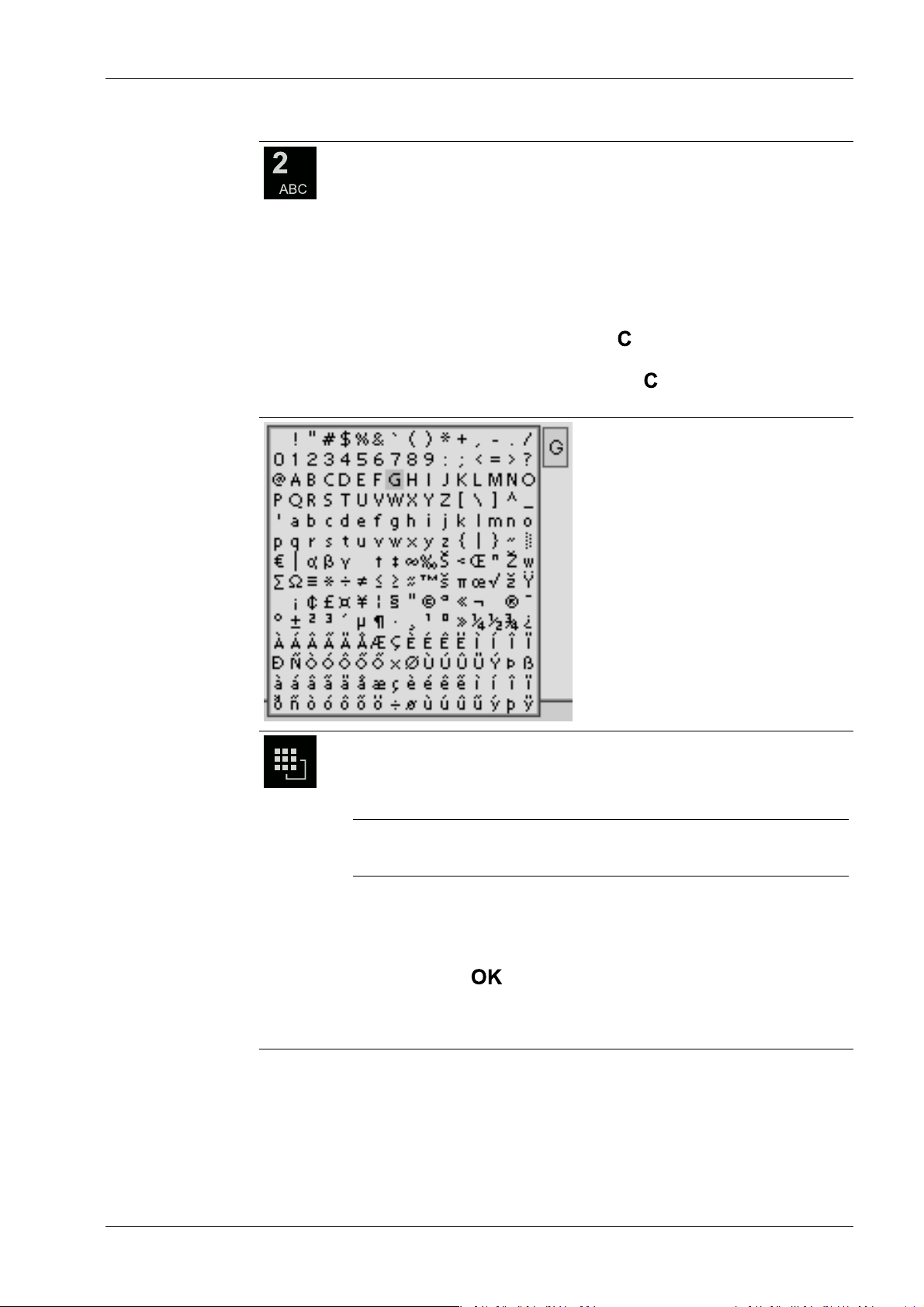

Input without the character table

Pressing once displays the corresponding rst character, e.g., "A", at the

cursor position. After pressing twice, "B" is displayed at the cursor position

and after pressing three times, "C" is displayed.

Press the cursor keys ▼/▲ to nish entering a character or wait approx.

2 seconds.

If only numeric values are required for input, letters are not enabled.

Press the cursor key ◀ within an entry to return to the previous character.

Press the cursor key ▶ within an entry to select the next character.

Within an entry, pressing the delete key deletes the character to the left

of the cursor.

Outside of an input, pressing the delete key deletes the whole string of

characters.

Input with the character table

Double-clicking on the key displays the character table.

Only characters authorized for this input are displayed.

Note:

The switching function is turned o.

Procedure:

- Highlight the desired character with the cursor.

- The selected character is shown magnied in the eld at the top right.

- Press the key to enter the character in the input eld.

- Another double-click on the toggle key and other characters can be in-

put as described previously.

EN-15 Minebea Intec

WP-A

Max 3000g d= 0.1g

+

A

B

C

Enter user name and password

User name

Password

********

WP-A

Max 3000g d= 0.1g

+

Enter user name and password

User name

Password

********

ABC..

Default Save

Process Controller Maxxis 5 PR 5900 2 Commissioning

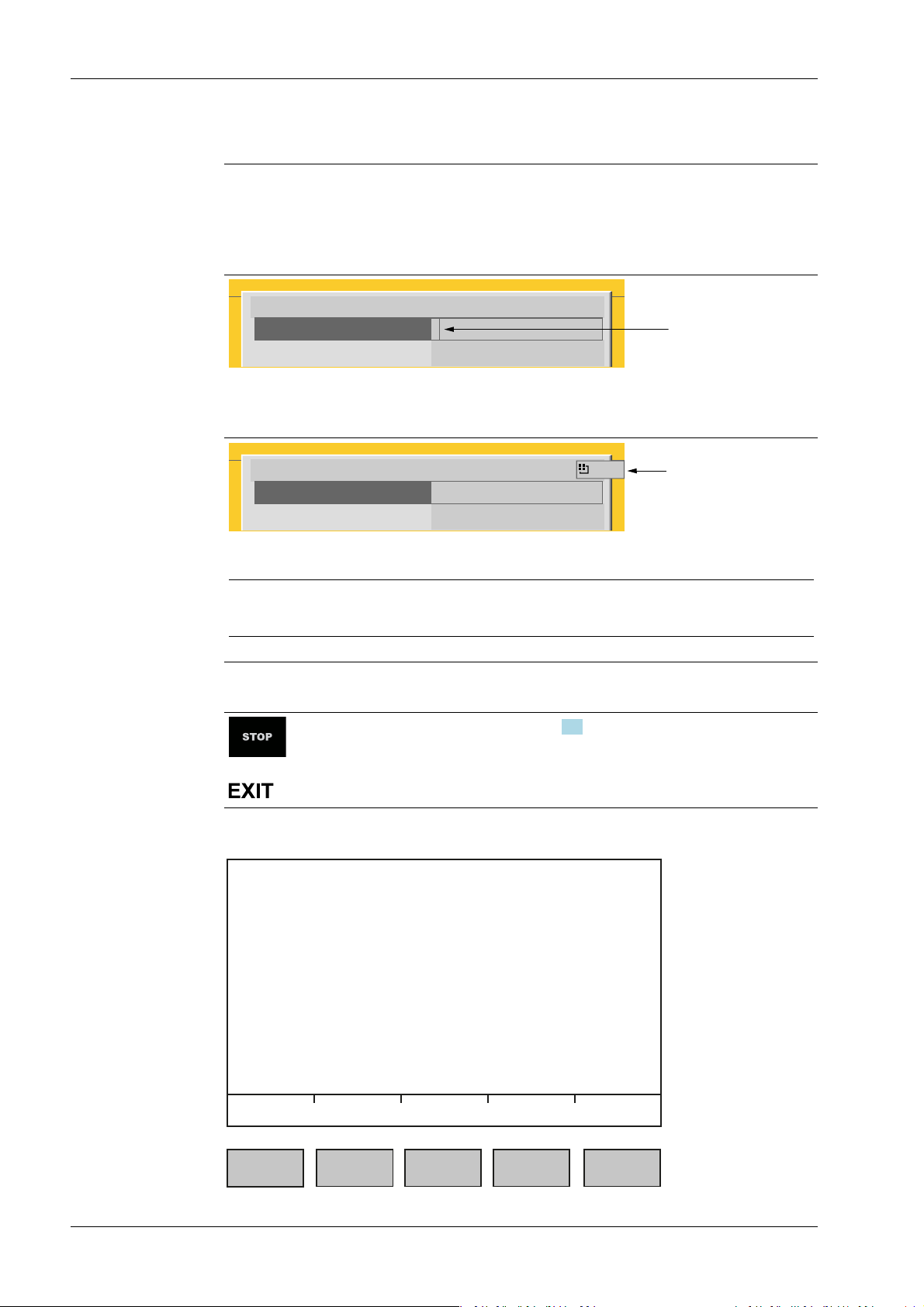

Input eld

In principle:

If alphanumeric characters are already present in the input eld of the selected line, they

will be completely overwritten after immediate entry.

If alphanumeric characters are already present in the input eld of the selected line, you

can press the cursor key ▶ to select the characters to be overwritten and overwrite them.

In front of the input eld it is indicated whether numeric and/or alphabetic characters

can be entered (see arrow).

Switch to the input eld using the cursor key ▶.

The respective options are displayed (see arrow).

Note:

The character table is turned o.

Keyboard shortcuts

+

2.1.3.2 Operation using softkeys

Trigger a cold start, see also Chapter 4.3.

Minebea Intec EN-16

2 Commissioning Process Controller Maxxis 5 PR 5900

The functions of the ve softkeys below the graphic display are indicated in the

bottommost text line of the display. Softkey functions shown in gray cannot be selected

at the active menu level or with the current access privileges.

In the descriptions of operating sequences which entail the use of softkeys, the softkey

function to be selected is shown in square brackets; the softkey symbol is not displayed;

example: [Save].

2.1.3.3 Navigation key operation Menu

The cursor keys, the and keys are used to navigate through the menus.

Parameters

Use the ▼/▲ cursor keys to select the individual parameters.

Use the key to conrm the selection.

The required values | texts are entered via the alphanumeric keys.

The key is used to check the ☑ box.

If the list of parameters is long, a vertical bar graph on the left (black and gray) shows

which part of the list is displayed.

An existing selection list is indicated by an arrow ▶ following it.

The parameter is selected using the key.

2.1.3.4 Operation via PC keys

The device can also be operated using a PC keyboard. The corresponding key assignment

is shown in the table below:

PC keyboard Front keypad

F1

F2

F3

F4

F5…F9 Softkey 1…5

F10

F11

F12

ESC

Cursor keys: ↑, ↓, ←, → ▲, ▼, ◀, ▶

Enter key: ↵

Backspace key: ←

Numeric keypad Alphanumeric keypad

EN-17 Minebea Intec

Process Controller Maxxis 5 PR 5900 2 Commissioning

2.1.4 Display and operation using VNC client

The display and operating elements are described in the following chapters:

- Overview of front of device, see Chapter 2.1.1.

- User interface of TFT screen, see Chapter 2.1.2.1.

- Operation using the front-panel keys, see Chapter 2.1.3.1.

Setting up the VNC client, see Chapter 2.9.5.

2.2 Data security and data storage

The calibration data and parameters of the internal weighing electronics system are saved

to the EAROM (Electrically Alterable ROM) on the weighing electronics board. Additional

write protection is provided for calibration data and parameters (see Chapter 2.7.2).

The event logger is saved to the SPI ash (Serial Peripheral Interface ash) memory.

The FlashPROM contains:

- BIOS

- Firmware

- Application Program

- Alibi memory

- XML conguration les (for user management, system setup, calibration and

The backups are stored on the SD card (Secure Digital card) (see also PR 5900 installation

manual under [Hardware construction]- [Main board]- [SD card slot] ).

2.2.1 Power failure

The entire content of the working memory is stored to a NAND ash memory and remains

there permanently when the power is interrupted or the device is disconnected from the

power.

The SD card and the USB stick are buered by a battery.

If a HUB (splitter) is inserted into the USB slot and turned o, the connection between the

USB stick and battery is broken.

2.2.2 Warm start

When power is restored, all data are reloaded from the NAND ash memory to the

working memory and the device is restored to the operating status before the

interruption. Filling programs are stopped/started depending on user settings.

2.2.3 Cold start

application data)

A cold start is performed if the device nds no saved data with which the last operating

state can be restored.

A cold start can have various causes:

- The battery has not been charged properly or is faulty, and it was not possible to save

all the data when the power was disconnected.

- The device was restarted using the STOP+EXIT keys, see Chapter 2.2.3.1.

- The reset key was pressed, see Chapter 2.2.3.2

Minebea Intec EN-18

2 Commissioning Process Controller Maxxis 5 PR 5900

- The STOP key was held down during startup and cold start was then selected, see

Chapter 3.10.

If available, the database from the last backup is restored after a cold start.

2.2.3.1 STOP+EXIT buttons Pressing STOP+EXIT simultaneously (see Chapter 4.3) initiates a cold start of the device:

- The settings are retained.

- The database is initialized.

- The device automatically searches for an existing database on the SD card and asks

whether this should be loaded.

- The application must be restarted.

Note:

If [Operating]- [System setup]- [Operating parameters]- [Cold start with STOP+EXIT][disabled] is selected in the menu, the device cannot be restarted with STOP+EXIT.

2.2.3.2 Reset key

Briey pressing (< 1 sec.) the reset key (see PR 5900 installation manual under [Process

controller]- [Housing]- [Housing dimensions]- [Control cabinet housing] ) initiates a cold

start of the device:

- The LED ashes once.

- The settings are retained.

- The database is initialized.

- The device automatically searches for an existing database on the SD card and asks

whether this should be loaded.

- The application must be restarted.

2.3 Switching on the device

Note:

The following steps must be followed when connecting the device to mains voltage for

the rst time:

- Set the date and time, see Chapter 4.2.

- Set up the network (only necessary if the device is to be used or congured in the

network), see Chapter 4.4.

The device can be set up as follows:

- Via keys on the front of the device, see Chapter 2.1.3.1.

- Via an external PC keyboard, see Chapter 2.1.3.4.

- Via a notebook/PC using the VNC software (included on the CD), see Chapter 2.9.5.

- Via a notebook/PC using an Internet browser, see Chapter 2.9.6.

EN-19 Minebea Intec

WP-A

Max 3000g d= 0.1g

00

+

g

0g 3000g

22.08.2012 15:20:46

Login

Process Controller Maxxis 5 PR 5900 2 Commissioning

When the device is powered up, the following appears:

Checking…

Booting…

Restore…

No signal Error message: if no load cells are connected, see also Chapter 9.1.

No values from

scale

Scale not ready Error message: if no load cells or no scale is connected (see also Chap-

The weight display appears.

The device is booting up.

Error message: if there is no communication with the xBPI scale (see

also Chapter 9.2).

Error message: unable to read weight values from the ADC (analog-digital converter); see also Chapter 9.1.

ter 9.1).

2.4 Switching o the device

Switching o the device, see Chapter 6.8.

2.5 Device warm-up time

A warm-up time of 30 minutes for the device is required before calibration is started.

2.6 Operating via front-panel keys/PC keyboard

The following options are possible:

- Via keys on the front of the device, see Chapter 2.1.3.1.

- Via an external PC keyboard (USB connection), see Chapter 2.1.3.4.

2.7 Overwrite protection

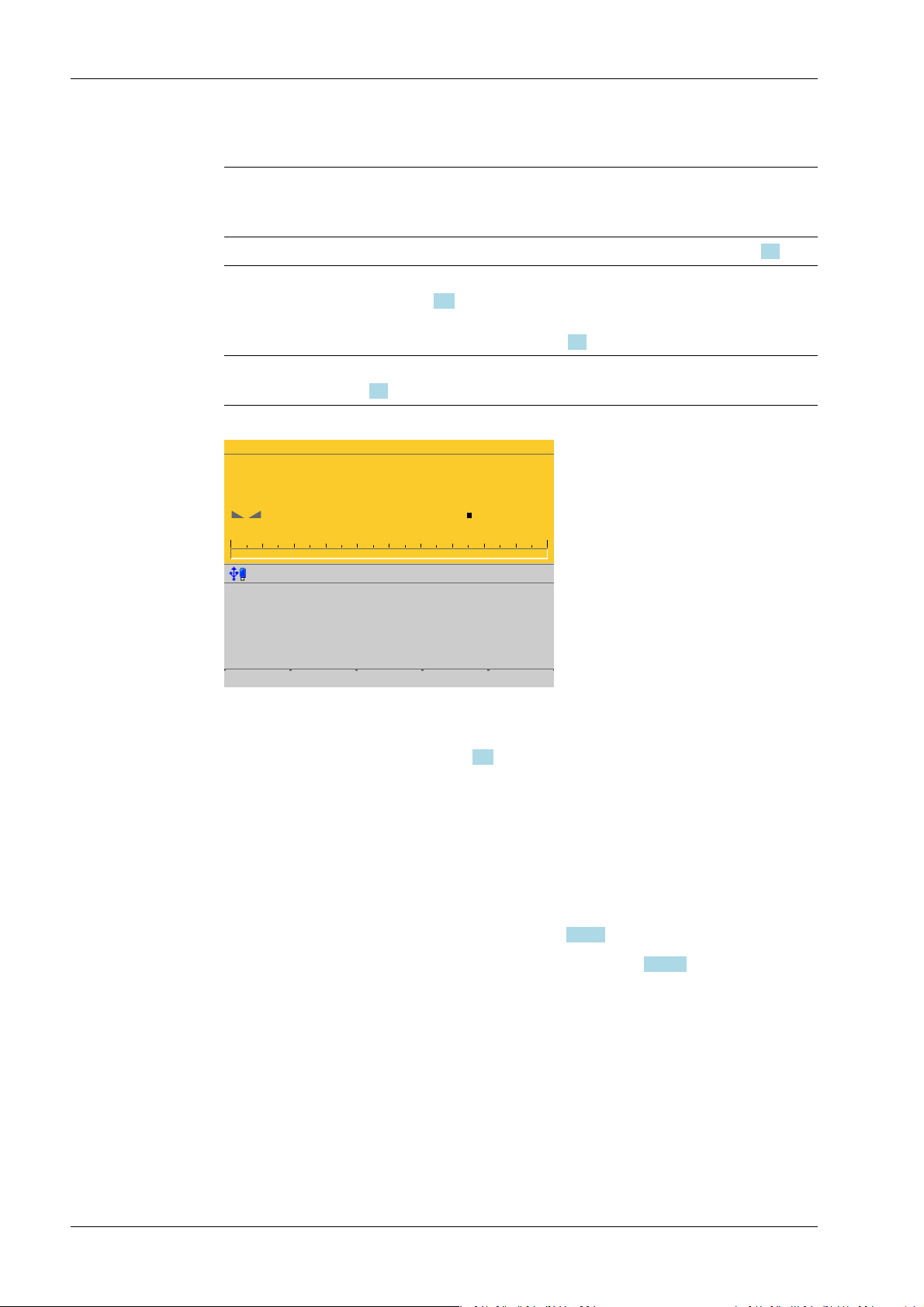

2.7.1 CAL switch

Overwrite protection can be activated using the CAL switch to prevent unauthorized

access to or overwriting of the calibration data/parameters.

The device can have up to 4 CAL switches. CAL switches 1 and 2 are located on the main

board and are accessible via two holes in the housing.

Minebea Intec EN-20

CAL 2

CAL 1

CAL 2

CAL 1

2 Commissioning Process Controller Maxxis 5 PR 5900

Depending on the model, CAL switches A and B may also be present. They are located on

the corresponding weighing electronics board (see PR 5900 installation manual). These

switches can only be accessed by removing the device housing.

The exact function of individual switches is listed in the table below.

Note:

In general, we recommend activating the overwrite protection features via the software

after calibration to prevent overwriting/data loss (see Chapter 2.7.2).

Write protection active Write protection inactive

CAL switches A and B

closed opened

CAL switches 1 and 2

closed

opened

CAL switch Meaning of "Write Protection Active"

A Prevents the calibration data/parameters of weighing electronics A

from being changed

B Prevents the calibration data/parameters of weighing electronics B

from being changed

1 The following changes are prevented:

- Allocation of weighing electronics to logical weighing points

- Calibration data and parameters of other weighing points

- Alibi settings

2 The following is prevented:

- Loading/ashing of rmware and BIOS to the device, see also

Chapter 6.9

- Changing of license settings

This CAL switch is sealed for use in legal metrology.

Note:

Changing means:

Changing by entering data into the input elds as well as changing via the functions

[Restore] (see Chapter 6.2) and [Import] (see Chapter 6.4).

EN-21 Minebea Intec

WP-A

Max 3000g d= 0.1g

00

+

g

Weighing points @admin

Weighing point A

Weighing point B

Weighing point C

Weighing point D

Internal weighing point

Internal weighing point

xBPI scale

Pendeo Process

Parameters Calib Units

CAL switch A is closed.

WP-A

Max 3000g d= 0.1g

00

+

g

Calibration (CAL switch is closed) @admin

Max

Scale interval

Dead load at

Max at

calibrated at

Sensitivity

3000.0 g

0.1 g

mV/V

mV/V

mV/V

µV/d

0.040800

1.177298

0.987557

0.470919

30000 d

1 d

103.966 g

3000.000 g

2516.5 g

98.11 cnt/d

Process Controller Maxxis 5 PR 5900 2 Commissioning

When a CAL switch is closed, a tool tip is displayed in the menu [Weighing points].

The data under the soft keys [Parameters], [Calibration], and [Units] is displayed only.

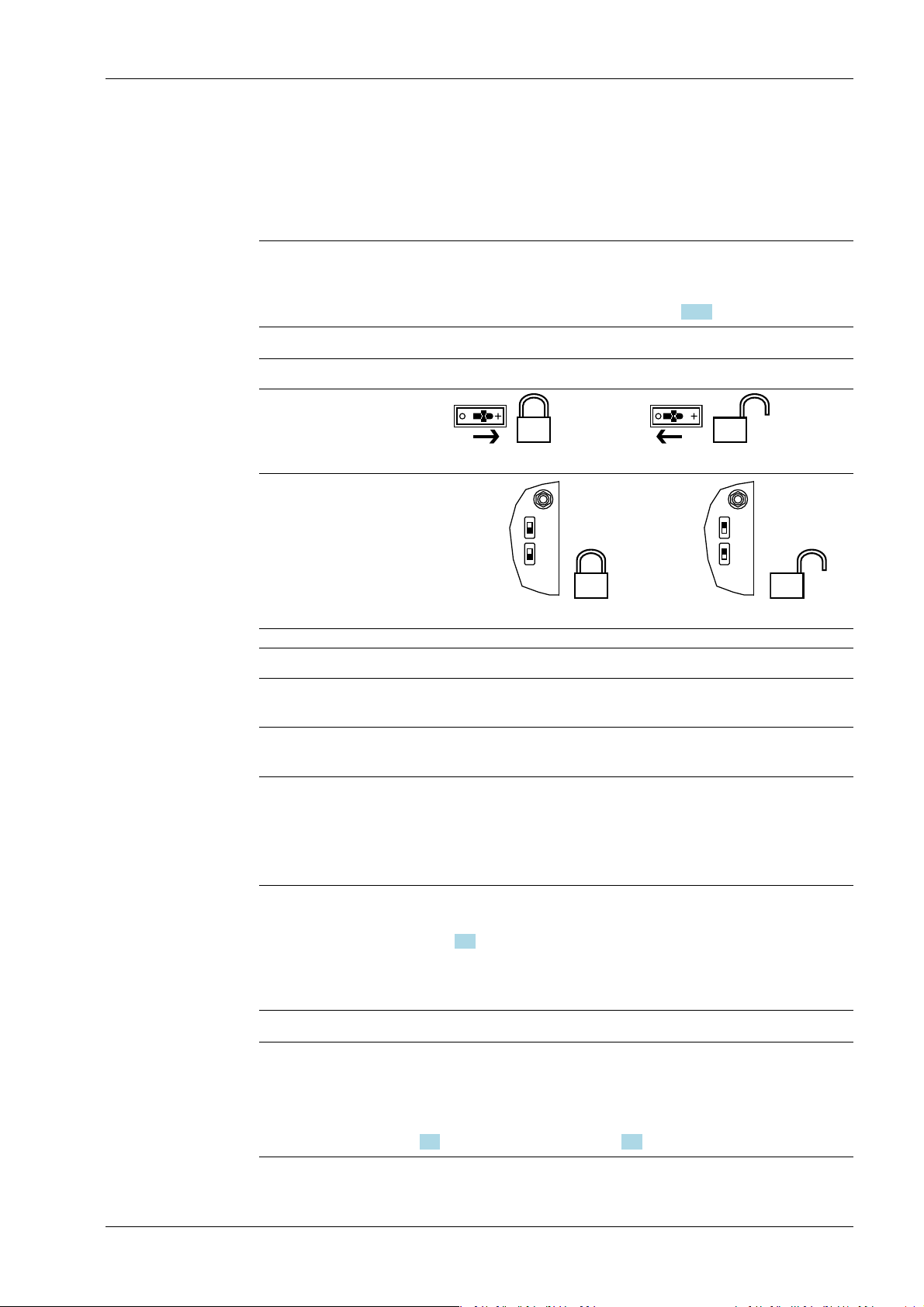

2.7.2 Software

Minebea Intec EN-22

Example of calibration data.

Overwrite protection can be activated via software to prevent unauthorized access to or

overwriting of the calibration data/parameters.

Note:

A unique check number is created every time a calibration or changed parameters are

saved. This can be viewed in the menu [Operating] - [System information] - [Show

calibration check numbers] (see Chapter 5.7) and may also be written on the W&M label.

Accessible via MENU – [Operating] - [System setup] - [Weighing points] - [Weighing

point x] - [Parameters] - [Settings locked].

WP-A

Max 3000g d= 0.1g

00

g

Weighing points @admin

Weighing point A

Weighing point B

Weighing point C

Weighing point D

Internal weighing point

Pendeo Truck

xBPI scale

User scale

Parameters Calib Units

WP-A

Max 3000g d= 0.1g

00

g

Weighing points @admin

Settings locked

W&M

Measurement time

Digital filter

Cutoff frequency

External load cell supply

none

160 ms

aperiodic

2.00 Hz

below or equal 8 V

Default Save

2 Commissioning Process Controller Maxxis 5 PR 5900

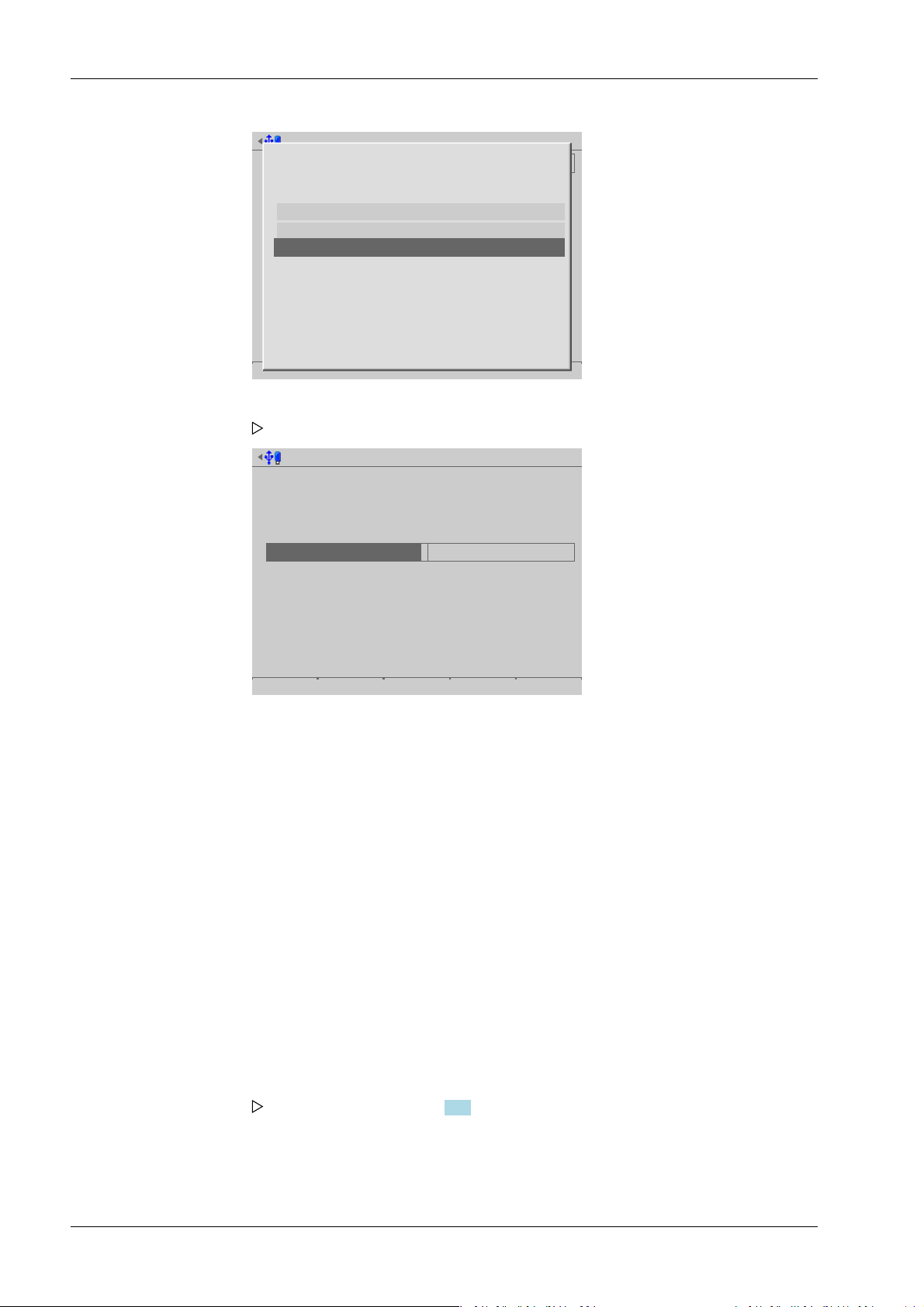

Each weighing point has a [Settings locked] parameter in the menu item [Parameters].

EN-23 Minebea Intec

If this parameter is set for the weighing point,

- the calibration data and parameters of the corresponding weighing point and the

weighing point allocation are only viewed as if the corresponding CAL switch were

closed.

- Only the [Settings locked] parameter can be changed.

- [Restoring]/[Importing] a weighing point is disabled.

Note:

If [Settings locked] and [W&M] have been selected for at least one weighing point, this

has the same eect as a closed CAL 1 and CAL 2 switch, see Chapter 2.7.1.

WP-A

Max 3000g d= 0.1g

00

+

g

Weighing points @admin

Weighing point A

Weighing point B

Weighing point C

Weighing point D

Internal weighing point

Pendeo Truck

xBPI scale

User scale

Parameters Calib Units

'Settings locked' is set

WP-A

Max 3000g d= 0.1g

00

+

g

Calibration (Settings locked) @admin

Max

Scale interval

Dead load at

Max at

calibrated at

Sensitivity

3000.0 g

0.1 g

mV/V

mV/V

mV/V

µV/d

0.040346

1.177703

0.987896

0.471081

30000 d

1 d

102.774 g

3000.000 g

2516.5 g

98.14 cnt/d

Process Controller Maxxis 5 PR 5900 2 Commissioning

If [Settings locked] is active, a tool tip appears in the menu [Weighing points].

The data under the soft keys [Parameters], [Calibration], and [Units] is displayed only.

2.8 Switching on blackbox device

2.8.1 Connecting to remote terminal PR 5900/6x, ../7x

2.8.2 Network settings

Minebea Intec EN-24

Example of calibration data.

The blackbox device can be operated with the PR 5900/6x, ../7x remote terminal.

There are no setting options for the connection to the remote terminal.

If the installation has been carried out correctly, the connection to the remote terminal is

automatically established.

Note:

For information on installation and switching on the remote terminal, see PR 5900/6x,

../7x instrument manual.

The device has the following factory settings:

- Device IP address (default): 192.168.1.2

- Subnet mask (default): 255.255.255.0

2 Commissioning Process Controller Maxxis 5 PR 5900

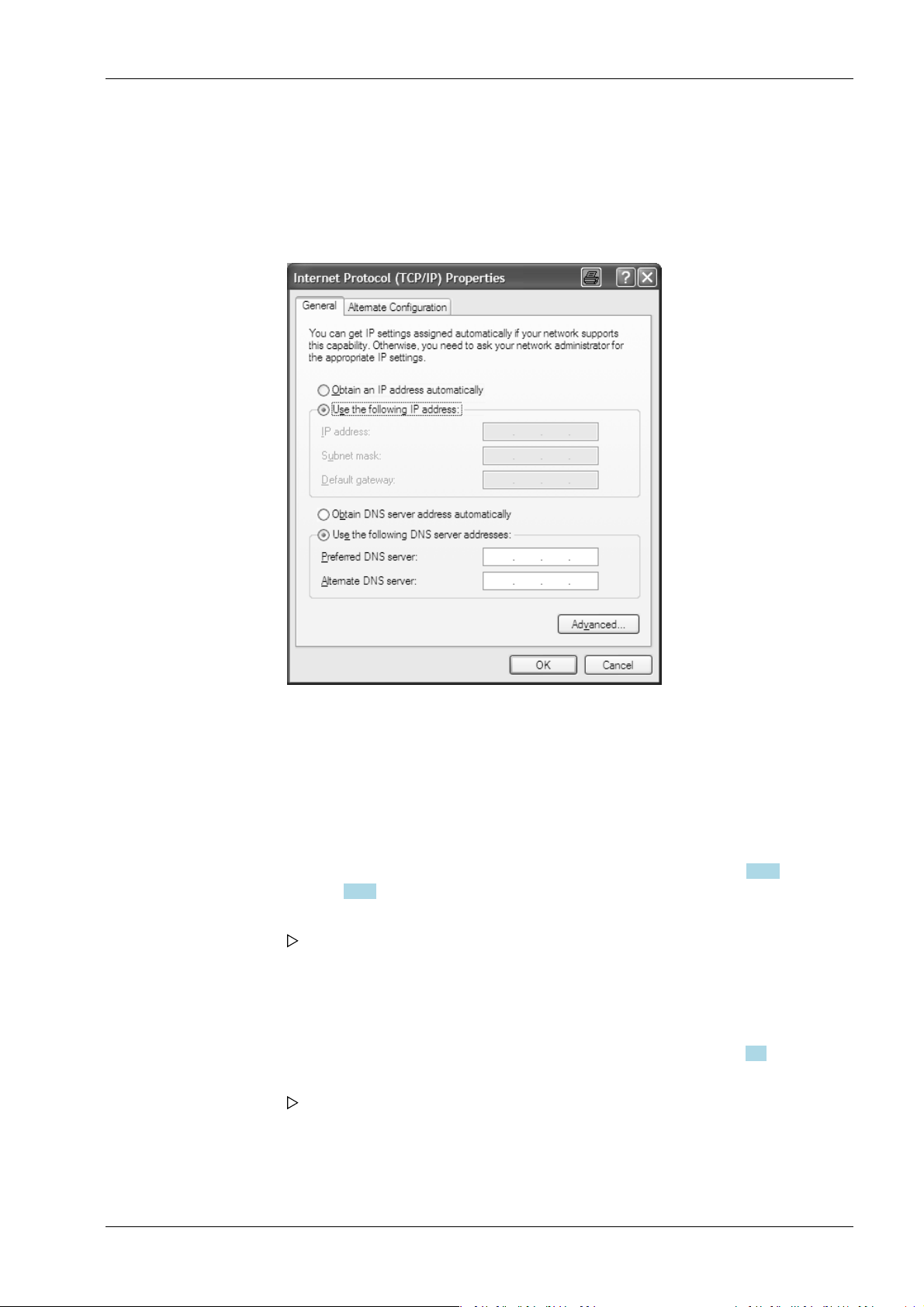

2.8.3 Connecting to notebook/PC

1. Do not establish a connection between the blackbox device and the network to begin

with!

2. Note down the notebook/PC network settings.

3. Disconnect the notebook/PC from the network.

4. In the notebook/PC, click the second line [Use the following IP address] (DHCP is now

deactivated).

5. Enter the xed IP address "192.168.1.2" and the subnet mask "255.255.255.0" and

save.

6. Directly connect the notebook/PC and blackbox device with a network cable (without

a splitter).

7. Open a web (Internet) browser (e.g. Microsoft Internet Explorer, Mozilla Firefox, etc.).

8. Enter the IP address of the blackbox device: 192.168.1.2, see Chapter 2.9.5 or

Chapter 2.9.6.

9. Conrm the entry.

The device name entered under [Host name] appears under the header in

brackets.

10. Note down the host name (here: "PR5900-27FF07").

11. In the menu [Operating]- [System setup]- [Network parameters] modify the network

address of the blackbox device to the required address or activate DHCP according to

the responsible system administrator's instructions; see also Chapter 4.4.

12. Save the settings.

The blackbox device sets itself to the new address.

This means that the connection to the notebook/PC is lost.

13. Disconnect the cable connection between the notebook/PC and blackbox device.

14. Connect the blackbox device to the network using a network cable.

EN-25 Minebea Intec

Process Controller Maxxis 5 PR 5900 2 Commissioning

15. Re-enter the network settings (as noted previously) on the notebook/PC.

The blackbox device will now be available on the network under the new address

and ready for operation.

Note:

Resetting the network settings (see also Chapter 2.8.2) by:

- Holding down the reset button for > 5 s, see Chapter 2.9.4.

- Selecting and conrming the menu [Operating]- [System setup]- [Network

parameters]- [Default] .

2.9 Operating via a notebook/PC

The following options are possible:

- Via VNC Viewer (on the enclosed CD-ROM), see Chapter 2.9.5.

- Via the internet browser, see Chapter 2.9.6.

Requirement:

The Java application must be supported by the web browser.

2.9.1 Finding and connecting the device automatically in the network

If the DHCP server is active in the network, the connected device (if activated in the menu

[Operating] - [Default conguration] - [Network parameters] - [use DHCP]) is

automatically assigned an IP address.

On the notebook/PC, the host names of the connected devices in the network are listed

under [Network].

Double-click the host name to open the device page in the web browser. The IP address is

displayed on the bottom right.

Note:

If the web browser supports the Java application, the device can be operated via[remote

conguration (VNC).]

If the web browser does not support the Java application, the menu items will be

inaccessible (grayed out).

2.9.2 Finding and connecting a device with a notebook/PC

If the device is connected to a notebook/PC via a point-to-point connection, an IP

address is negotiated via function "AutoIP". This can take up to 2 minutes!

NOTICE

When the IT/DHCP network cable is temporarily connected between the notebook/

PC and a device, the DHCP server is lost and the notebook/PC returns to the auto-IP

address within approx. two minutes!

Reason: The DHCP server/client relationship is checked cyclically at 23-minute

intervals.

Minebea Intec EN-26

2 Commissioning Process Controller Maxxis 5 PR 5900

1. On the notebook/PC, set the LAN local and Internet Protocol properties to "Obtain an

IP address automatically" depending on the operating system.

2. On the device, under MENU - [Default conguration] - [Network parameters] activate

the "Use DHCP" parameter (factory/default settings).

The DHCP devices nd each other because they fall into an "auto-IP address" in

the range 169.254.0.1169.254.255.254 with the associated auto-subnet mask

255.255.0.0 after a cyclical automatic DHCP server search run due to time

overow (23 minutes).

Example:

If the search time is exceeded (because there is "no server found"), the PR 5900 is

assigned to an IP address automatically (e.g. 169.254.0.123). The same applies to

the notebook or PC (e.g. 169.254.0.54).

These IP addresses are dierent on both sides:

- equal regarding the rst 2 octets of the IP address (e.g. network ID 169.254.)

- dierent in the last 2 octets of the IP address (e.g. host ID 0.123.)

2.9.3 Searching the device in the network with "IndicatorBrowser"

The IP address can be found out using the "IndicatorBrowser" application (supplied on

CD-ROM) and via the "host name" of the device.

The "host name" is composed of the device name and the last 3 bytes of the MAC ID. A

label with the complete MAC ID is located on the outside of the device.

Host name: PR5900-6B6A5E

For this, the program must be installed and started on a notebook/PC.

EN-27 Minebea Intec

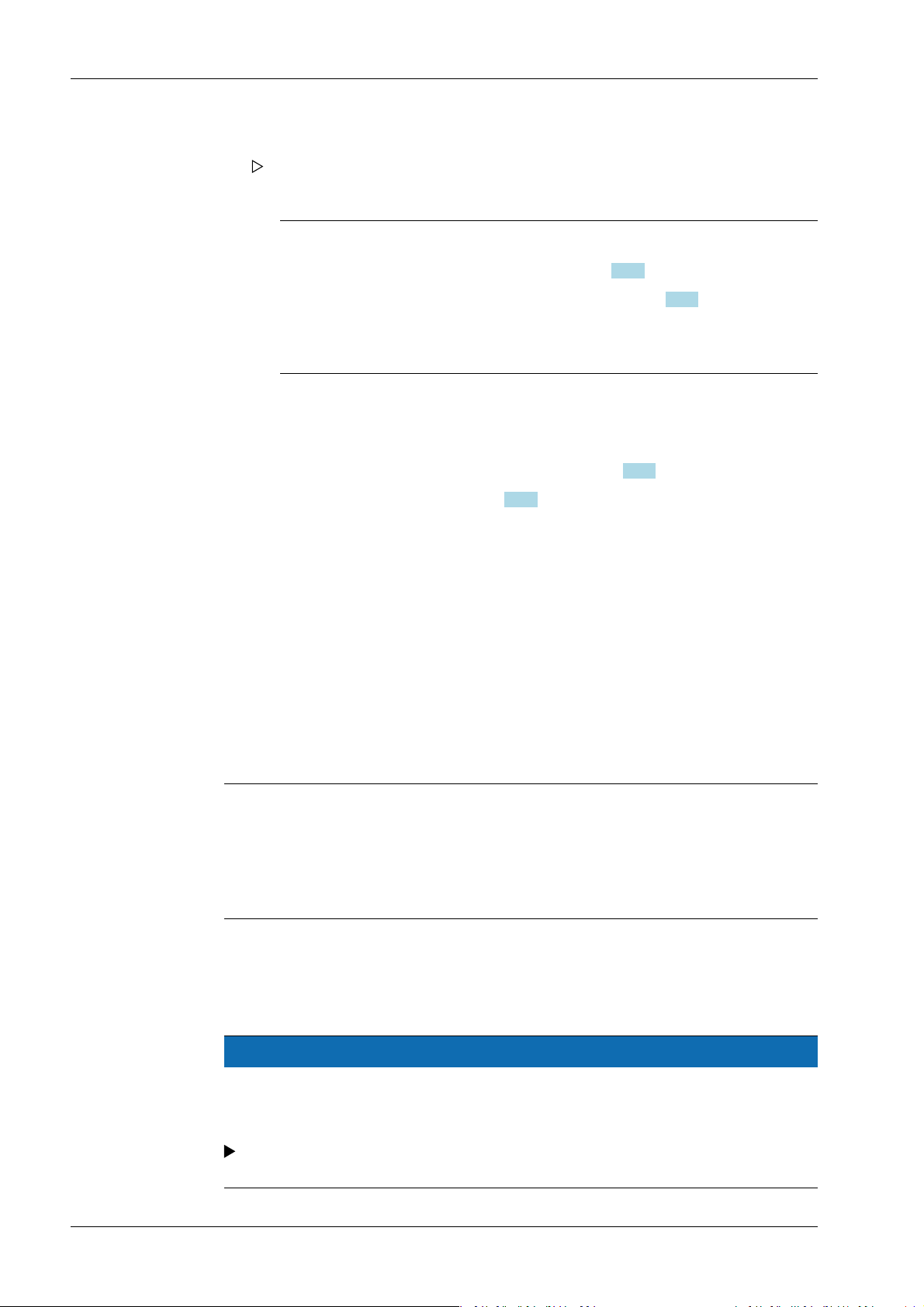

Process Controller Maxxis 5 PR 5900 2 Commissioning

Legend

No. Description

1 The program searches within the current network ID, e.g. 169.254. and 172.24.,

on all available network adapters in the PC (several possible/recommended,

e.g. LAN global/LAN local)

Result:

List of all connected devices with status: search??? – online - byebye – lost???

2 Click the button to open the "standard" Internet Browser, e.g. Microsoft Inter-

net Explorer, directly with the marked IP‑address.

3 Click the button to localize the associated device.

Short-term visual feedback from the device:

Regular running light in LED 1, 2, 3.

4 Click the button to re-start the network search run.

Waiting 2…3 minutes is essential!

5 Acoustic signal for each device that was detected as "online."

Note:

If the browser window remains empty after the minimum wait time, or if the expected

device is not listed, the network ID of the local notebook/PC must be checked and

changed, if necessary.

Only certain Minebea Intec devices are supported by the "indicator browser"!

Minebea Intec EN-28

2 Commissioning Process Controller Maxxis 5 PR 5900

2.9.4 Resetting the network address

Note:

Holding down (> 5 sec.) the reset key triggers a cold start:

- The settings are not changed.

- The database is emptied.

- Current process steps are deleted.

- The application must be restarted.

- The database must be restored.

Holding down (> 5 sec.) the rest key initiates a reset of the network settings to the

factory/default settings.

This means

- "DHCP" is activated.

- "Hostname" is initialized to, e.g. PR 5900-6B6A5E (type MAC-ID).

Example of MAC ID: 00-90-6C-6B-6A-5E

This ensures that a valid address for identication of the device in the network can be

assigned to the device from a server, see also Chapter 4.4.

Note:

The last 3 bytes of the MAC ID are displayed. A label with the complete MAC ID is located

on the outside of the device.

If the device is connected to an IT network (company network) with a DHCP server and if

the parameter [use DHCP] is activated in the menu [Operating] - [Default conguration]

- [Network parameters] (factory/default settings), no further actions are required except

for a waiting time of 2…3 minutes. Subsequently, a network connection is established

automatically (device <-> workstation/PC).

2.9.5 Operation using VNC

VNC (on the enclosed CD-ROM) stands for "virtual network computing" and is a program

for remote operation of computers.

The program distinguishes between the VNC server and VNC client (viewer). The server

program is part of the device software, the client program (viewer) must be run on the

notebook/PC in order to operate the device.

Note:

If the colors appear distorted, a better color format must be selected in the VNC viewer.

EN-29 Minebea Intec

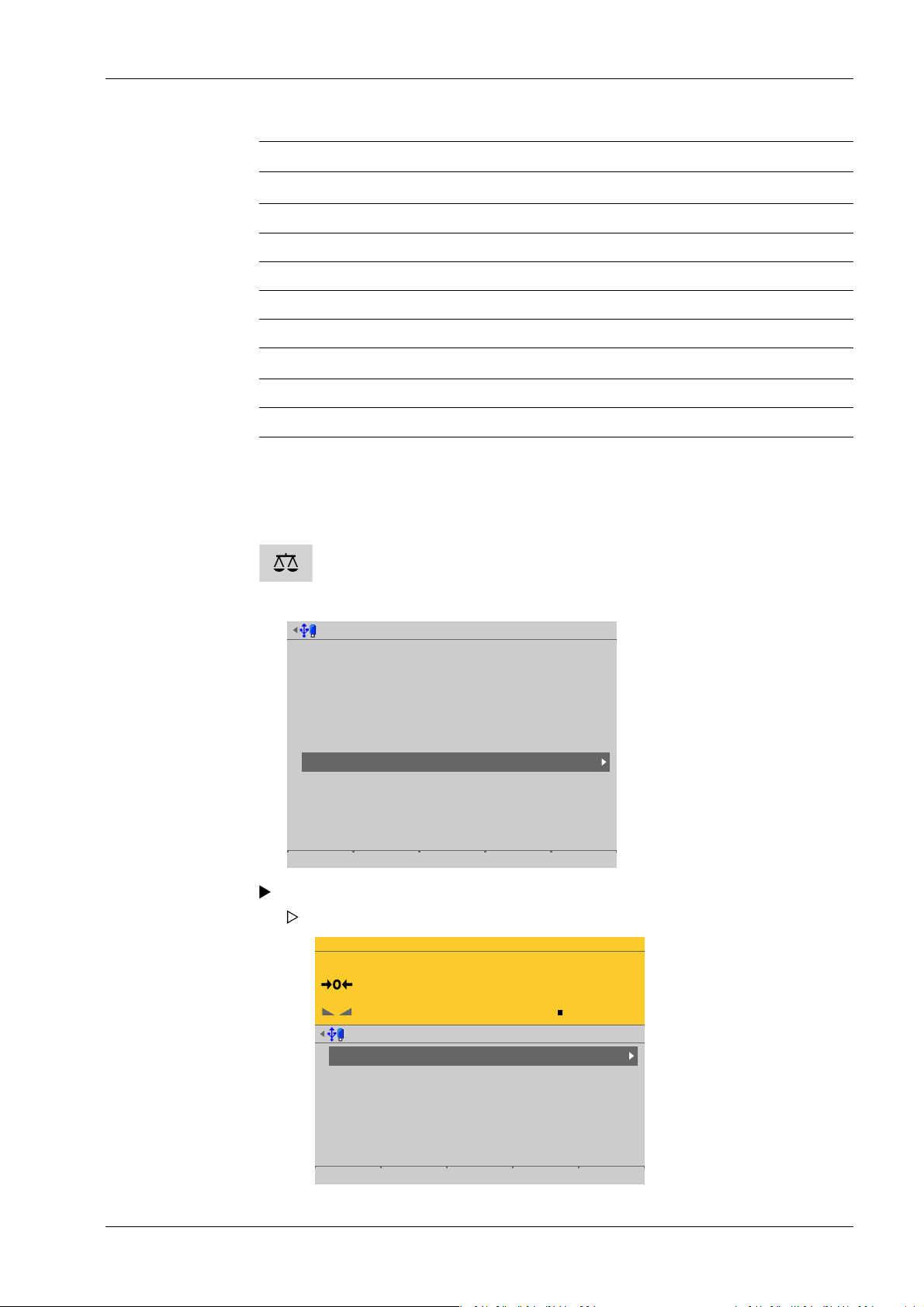

.

WP-A

Max 3000g d= 0.1g

00

+

g

0g 3000g

22.08.2012 15:20:46

Anmelden

Process Controller Maxxis 5 PR 5900 2 Commissioning

For direct operation using the VNC program, the IP address (extended by :1) must be

specied when you run the program, e.g., 172.24.20.233:1.

Note:

In the device, the VNC access to certain notebooks/PCs in the network can be limited,

see Chapter 4.4.

The VNC user interface is displayed.

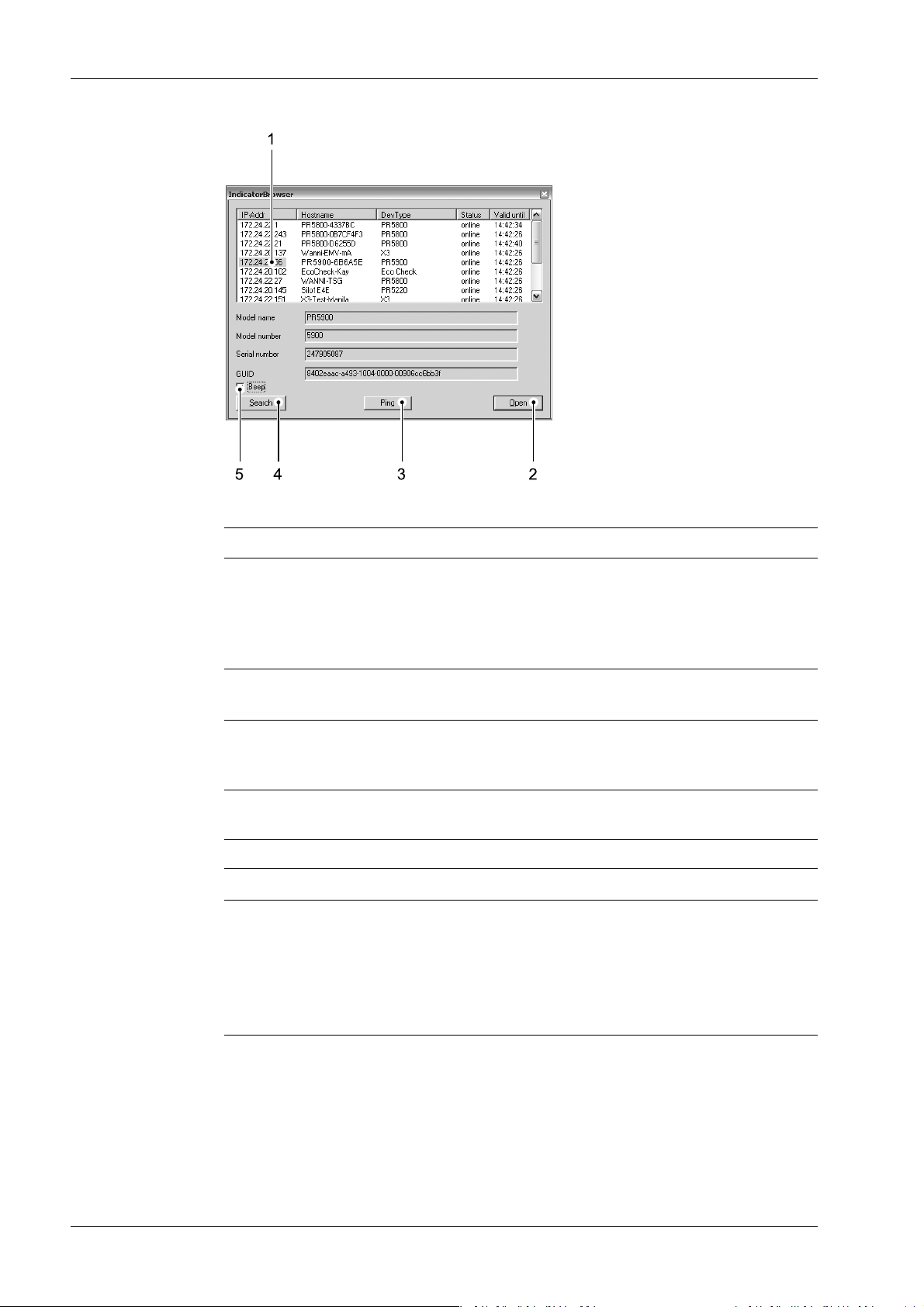

2.9.6 Operation via a web browser

Instead of the VNC viewer, the web browser can also be used directly.

The disadvantage is that an additional "Java" installation is required.

Minebea Intec EN-30

Note:

If the web browser supports the Java application, the device can be operated via[remote

conguration (VNC).]

If the web browser does not support the Java application, the menu items will be

inaccessible (grayed out).

In addition to VNC, this includes:

2 Commissioning Process Controller Maxxis 5 PR 5900

- easy operation for printing out the conguration

- easy operation for displaying and saving protocols

- easy operation for saving and loading conguration and calibration data

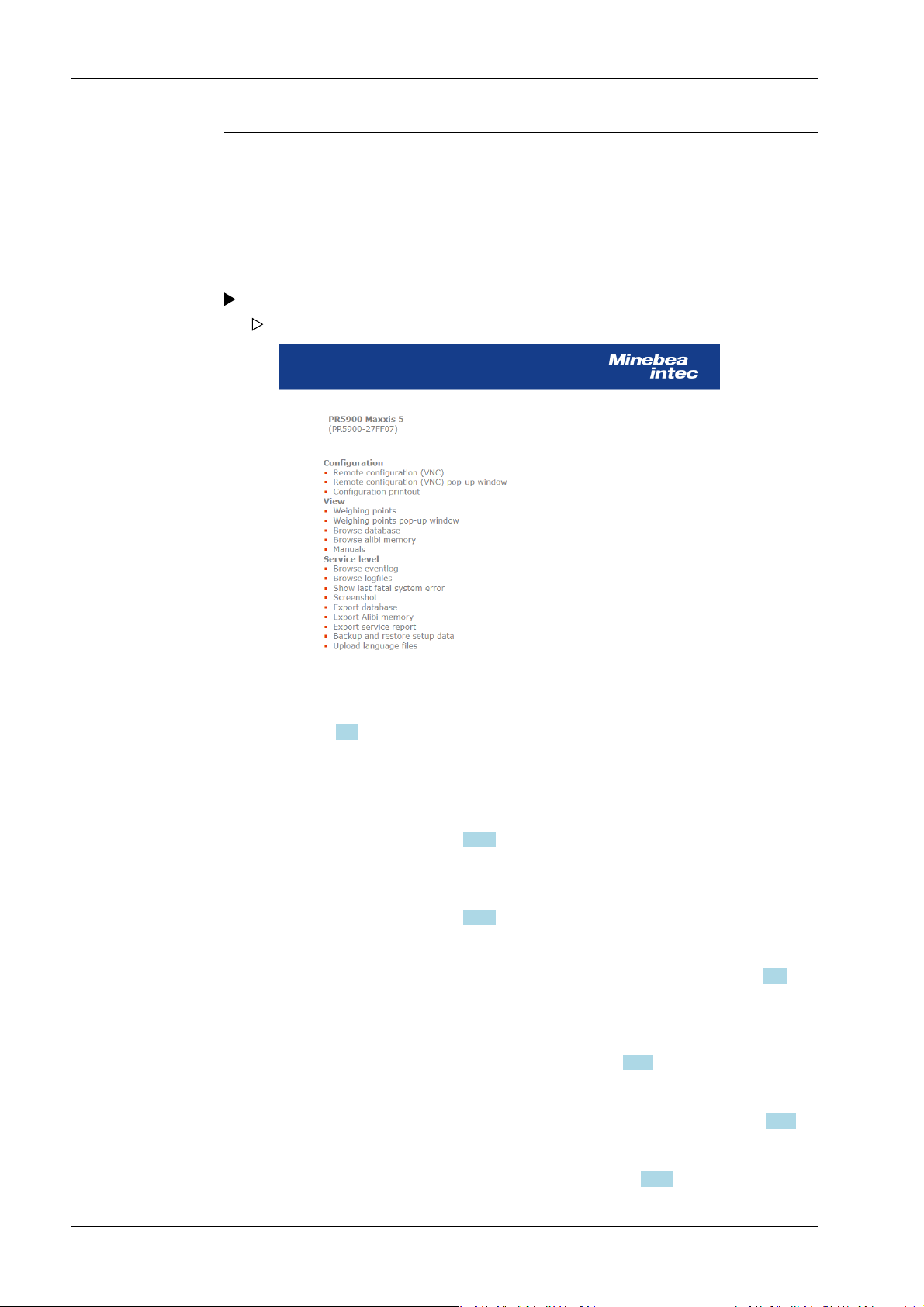

Example:

Enter the IP address in the Internet browser and conrm.

The web menu is displayed.

For description of the web menu see Chapter 3.9.

EN-31 Minebea Intec

WP-A

Max 3000g d= 0.1g

00

+

g

0g 3000g

22.08.2012 15:20:46

Login

WP-A

Max 3000g d= 0.1g

00

+

g

0g 3000g

22.08.2012 15:20:46

Login

A

B

C

Enter user name and password

User name

Password ********

Process Controller Maxxis 5 PR 5900 3 Operation and control

3 Operation and control

3.1 User login/logout

If user management is activated, the user must log in to operate and congure the device:

- User login, see Chapter 3.1.1.

- User logout, see Chapter 3.1.2.

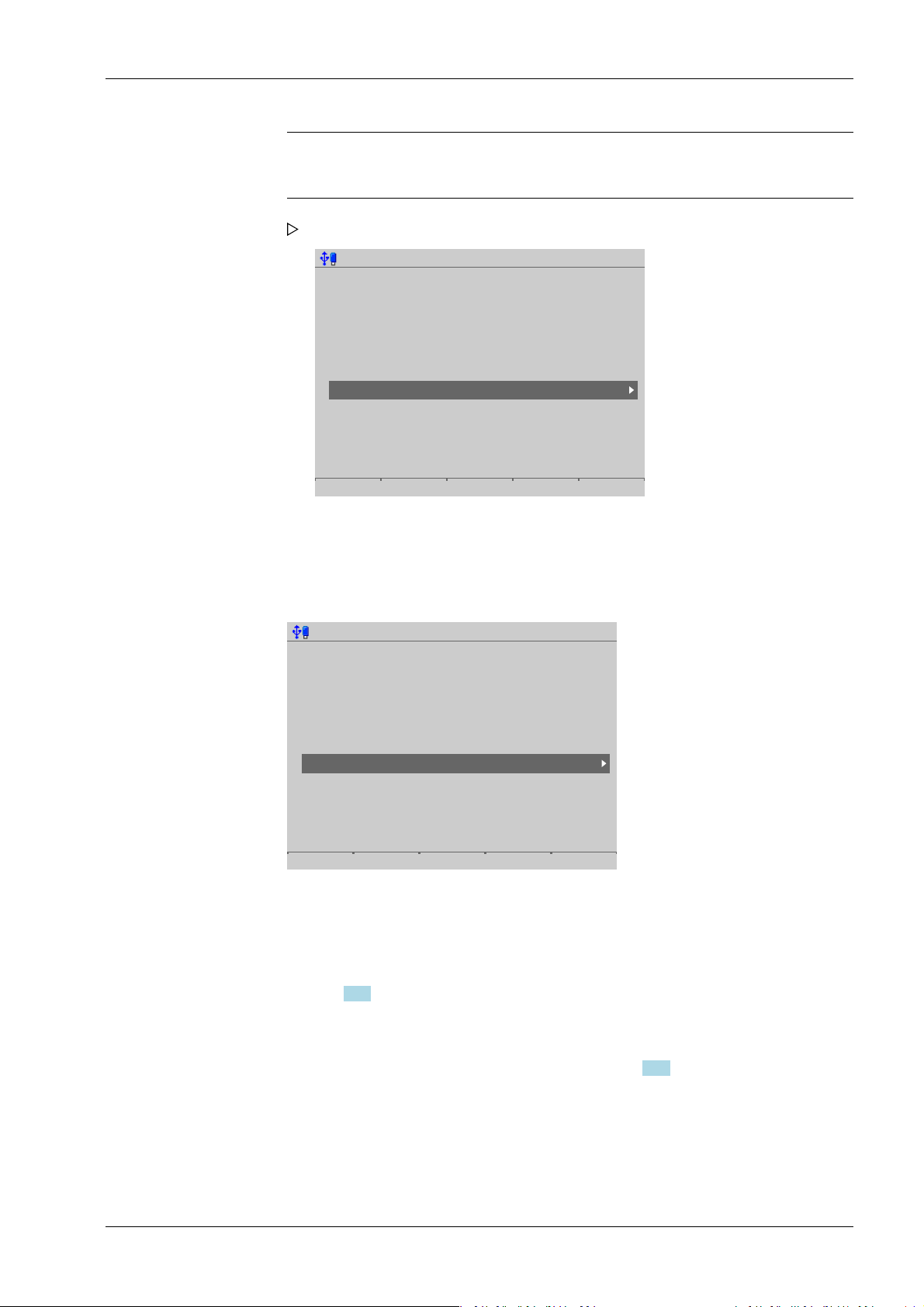

3.1.1 User login

An authorized user must log in to start the application or enter parameters.

This window only appears if no user is logged in.

1. Press the [Login] soft key to log in as a specic user.

Note:

If the "default" user is active, a password does not need to be entered. The empty

entry window only needs to be conrmed to log in.

A login window appears.

2. Enter and conrm the user name.

3. Enter and conrm the password (access code).

Minebea Intec EN-32

Operating @admin

Application menu

Weighing

Check weighing

Device employed as terminal

Configuration

System menu

System setup

System information

System maintenance

Logout

Operating @admin

Application menu

Weighing

Check weighing

Device employed as terminal

Configuration

System menu

System setup

System information

System maintenance

Logout

3 Operation and control Process Controller Maxxis 5 PR 5900

Note:

Default setting: User name: admin; password: admin

The Operating window appears.

3.1.2 User Logout

In this menu item, the logged-in user is logged out.

Accessible via MENU - [Operation]- [Logout] .

1. Press the MENU key to switch to the operating menu.

The user who is currently logged in is shown in the top right-hand corner of the

display.

2. Press the [Logout] soft key to log out the user who is currently logged in.

If a password is required to log out the user (option activated in the user settings, see

Chapter 4.10), the entry window appears accordingly.

3.2 User management

EN-33 Minebea Intec

User management is deactivated by default, see Chapter 4.10.

By means of user management, access to various menu levels of the device can be

limited, if the necessity arises. This includes system setup, system maintenance, access

via the website and the various levels of the application (application-specic).

Process Controller Maxxis 5 PR 5900 3 Operation and control

Note:

User management can be activated optionally. However, it is not required for normal

operation.

During system installation and set-up, we recommend leaving user management

deactivated. This facilitates access to the various menus and to the website.

User management should usually be activated if:

- several people work with the device or have access to it.

- the aim is to prevent unauthorized people from making changes to the device or

from inuencing the processes controlled by the device.

3.3 Selecting the operating language

Factory settings: system language = operating language (display language)

The operating language can be changed as follows:

- Select and conrm the desired language in the menu [Operating]- [System setup]-

[Operating parameters]- [Display language] . Save the change using the [Save] soft

key, see also Chapter 4.3.

- Select and conrm in the menu [Operating]- [System setup]- [User management]-

- With the function keys F1 and F2, if a key has been assigned to [Change language] in

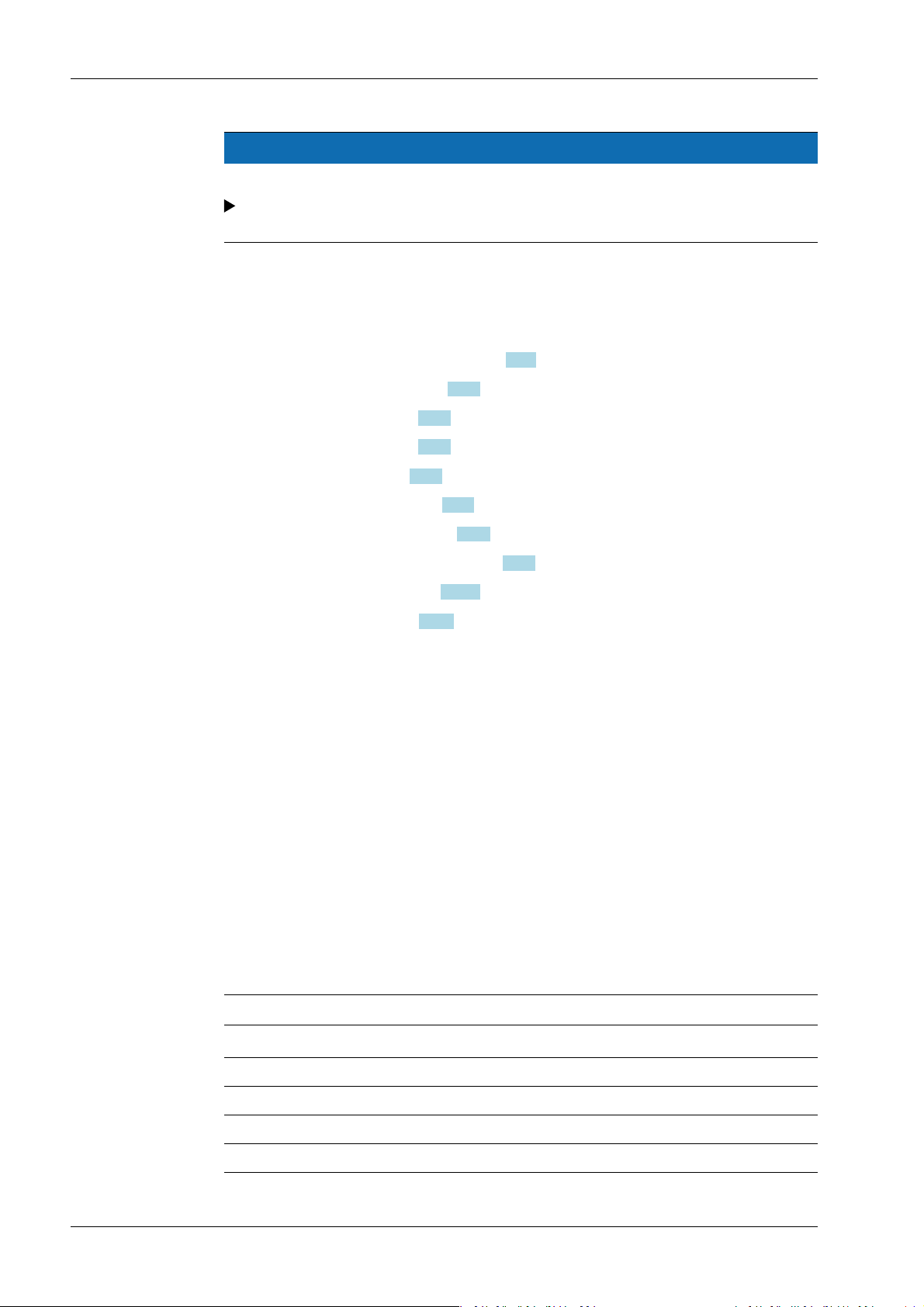

3.4 System menu

Under System menu in the Operating menu, the process controller is set up, information

is accessed and the system is managed.

[Create/copy/modify user]- [ Language] . Save the change using the [Save] soft key,

see also Chapter 4.10.1.

the menu [Operating]- [System setup]- [Operating parameters]- [F1/F2 key] , see

Chapter 4.3. The operating language can be changed from any menu.

Note:

When user management is activated, the operating language only changes once the

currently logged-in user logs out. It is only possible to switch languages immediately

using the F1 or F2 key.

Note:

The menu items under Application menu depend on the application in question and are

described in a separate operating manual.

Accessible via MENU key - [Operating].

Minebea Intec EN-34

Operating @admin

Application menu

Weighing

Check weighing

Device employed as terminal

Configuration

System menu

System setup

System information

System maintenance

Logout

3 Operation and control Process Controller Maxxis 5 PR 5900

System menu:

- [System setup], see Chapter 4.

All parameters relating to weighing electronics can be found under [Weighing

points].

- [Connected devices], see Chapter 4.1.

- [Date and time], see Chapter 4.2.

- [Operating parameters], see Chapter 4.3.

- [Network parameters], see Chapter 4.4.

- [Network share connections], see Chapter 4.5.

- [Fieldbus parameters], see Chapter 4.6.

- [Weighing points], see Chapter 4.7.

- [Display settings], see Chapter 4.8.

- [License settings], see Chapter 4.9.

- [User management], see Chapter 4.10.

- [Alibi memory], see Chapter 4.11.

- [System information], see Chapter 5.

- [Show version], see Chapter 5.1.

- [Show status], see Chapter 5.2.

- [Show alarm information], see Chapter 5.3.

- [Show HW options] (hardware options), see Chapter 5.4.

- [Show ModBus-TCP I/O module], see Chapter 5.5.

EN-35 Minebea Intec

- [Browse the Alibi memory], see Chapter 5.6.

- [Show calibration check number], see Chapter 5.7.

- [Show Pendeo data], see Chapter 5.8.

- [Show event log], see Chapter 5.9.

- [Print conguration settings], see Chapter 5.10.

- [System maintenance], see Chapter 6.

- [Backup], see Chapter 6.1.

Process Controller Maxxis 5 PR 5900 3 Operation and control

- [Restore], see Chapter 6.2.

- [Export], see Chapter 6.3.

- [Import], see Chapter 6.4.

- [Alibi memory maintenance], see Chapter 6.5.

- [SD card maintenance], see Chapter 6.6.

- [Create service report], see Chapter 6.7.

- [Shutdown & Power o] (switch o device), see Chapter 6.8.

- [Update software], see Chapter 6.9.

- [Factory reset], see Chapter 6.10.

- [Test hardware], see Chapter 6.11.

3.5 Help functions

The help function can be accessed from any parameter window using the ? key. A window

appears in which you can scroll up and down through the content using the cursor keys (↑,

↓, ▲, ▼). The window can be closed using the EXIT key.

3.6 Alibi memory

The individual functions of the Alibi memory are described in the following menu items:

- In the System setup menu, the conditions for a full Alibi memory are congured

- The Alibi memory is searched in the System information menu (menu [Operating]-

- In the System maintenance menu the records of the Alibi memory are exported or

Note:

The help text is given in English as a default if the corresponding language is

unavailable.

(menu [Operating]- [System setup]- [Alibi memory] ), see Chapter 4.11.

- [Tidy up records], see Chapter 4.11.1.

- [Delete] (complete Alibi memory), see Chapter 4.11.2.

[System information]- [Browse Alibi memory] ), see Chapter 5.6.

- [Search for specic date in Alibi memory], see Chapter 5.6.1.

- [Search for a given sequence number], see Chapter 5.6.2.

- [Status Alibi memory], show status, see Chapter 5.6.3.

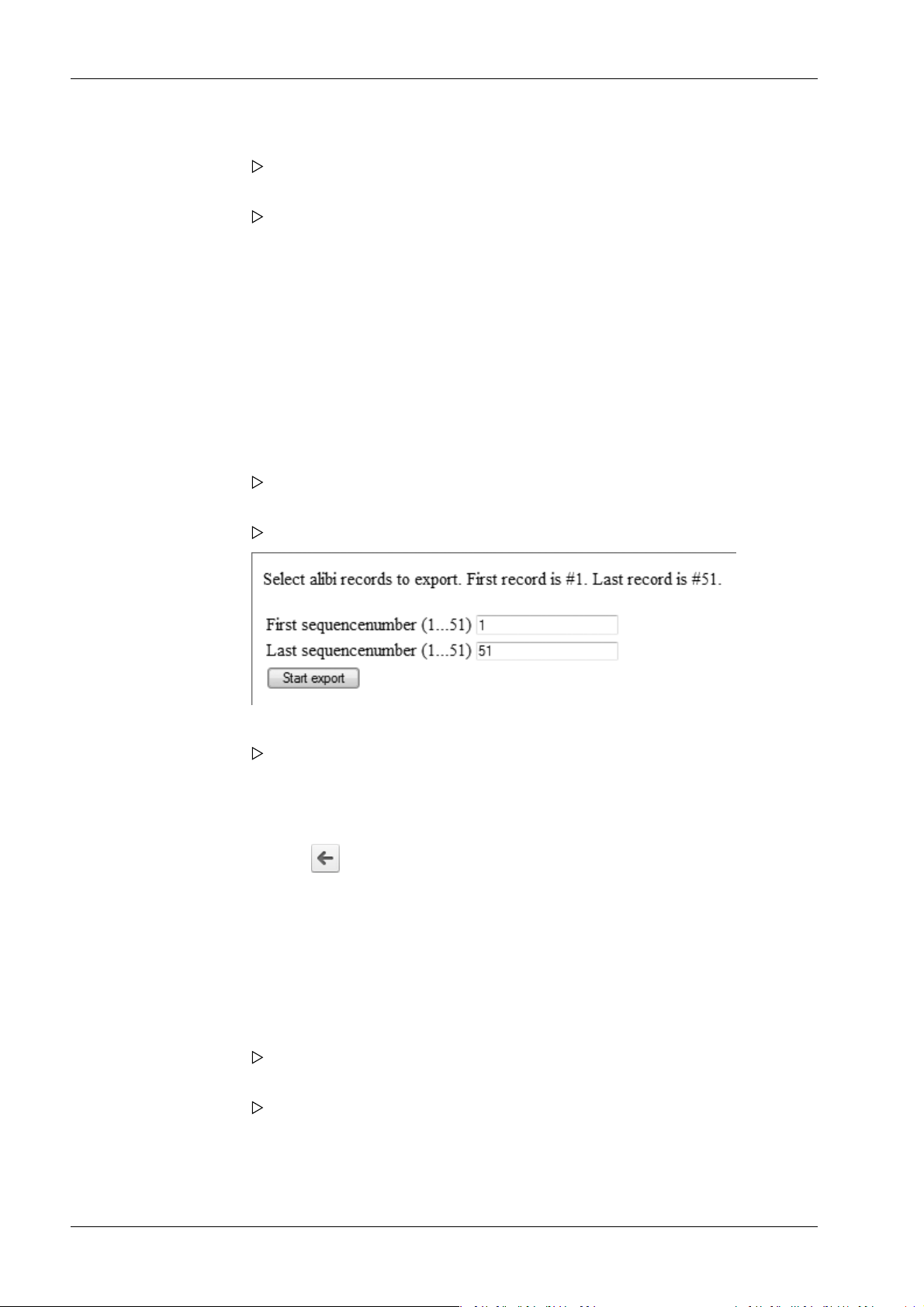

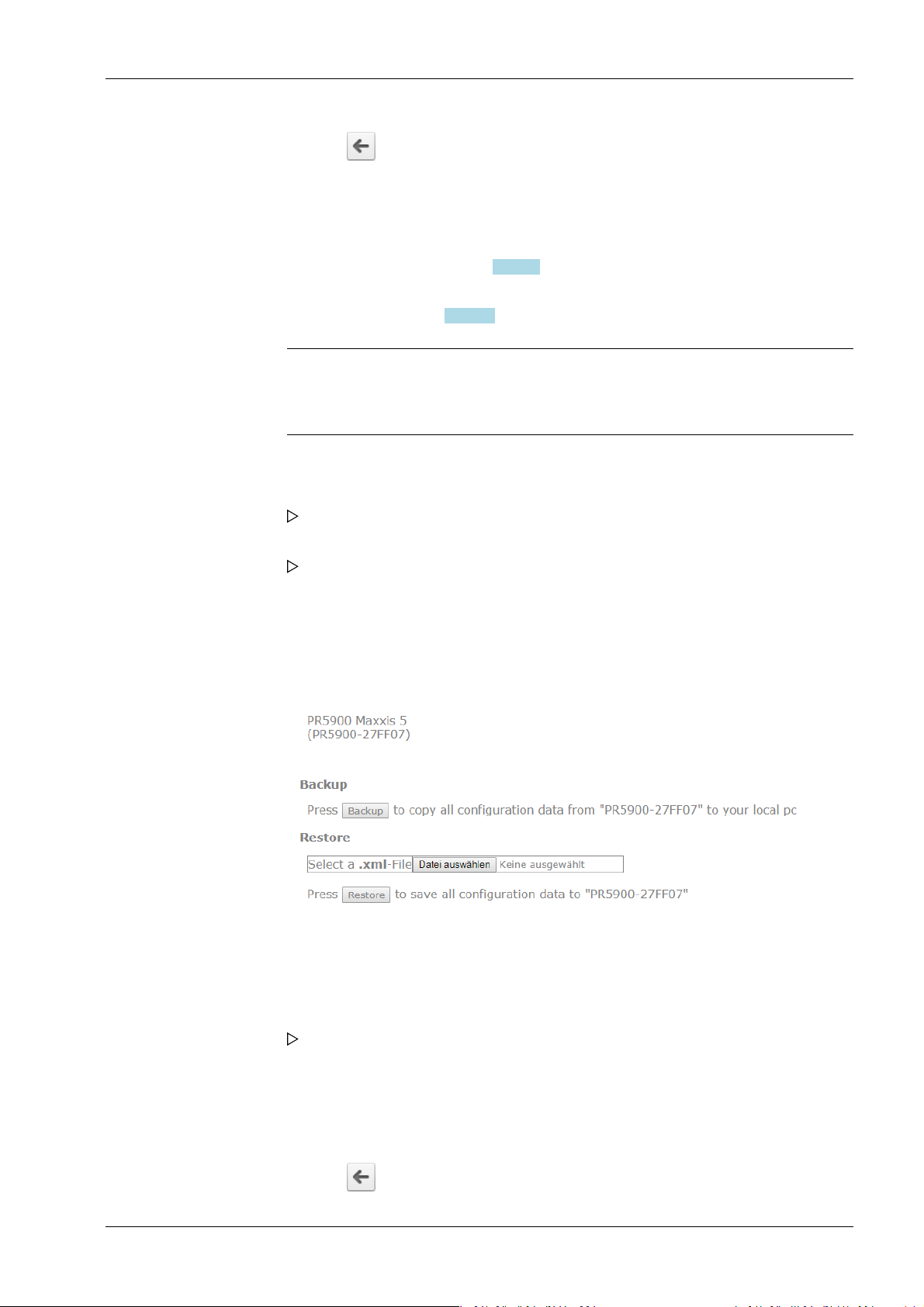

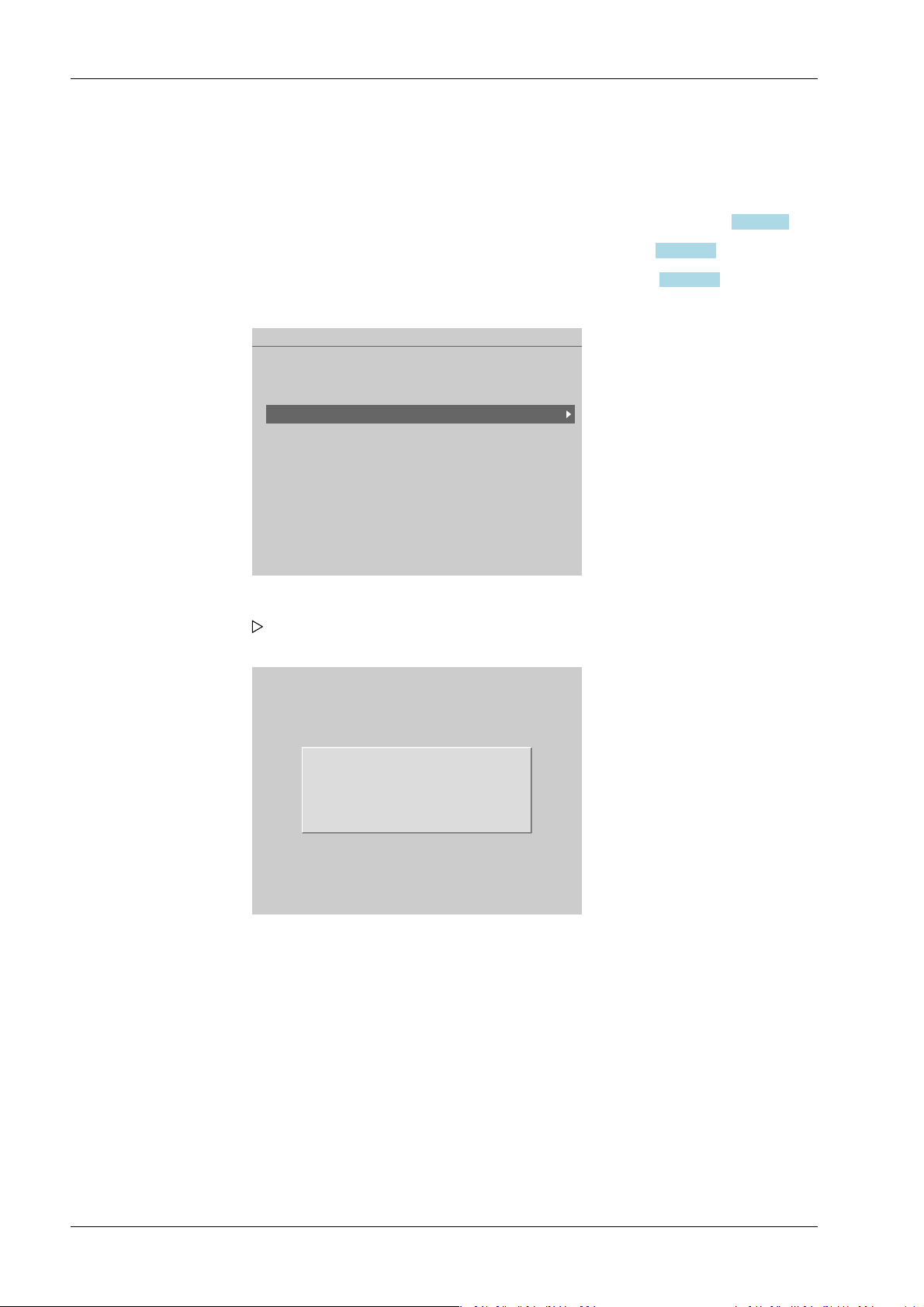

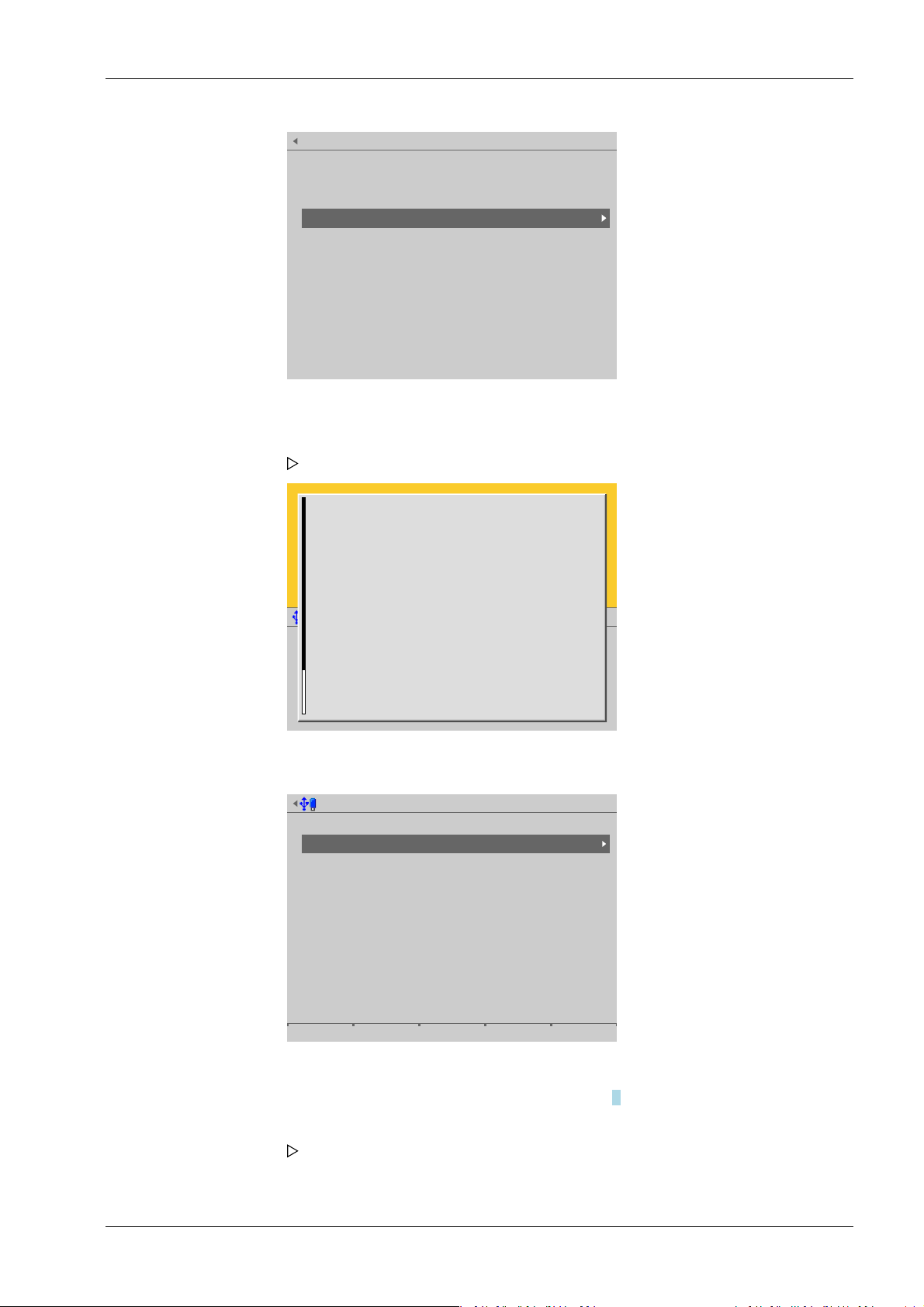

printed and deleted if necessary ([Operating]- [System maintenance]- [Alibi memory