Minebea Intec PR 5220, PR 5220/01, PR 5220/04, PR 5220/00, PR 5220/07 Instrument Manual

...

Presented By

Dallas HoustonAustinFt Worth

NicolScales.com

800.225.8181

Contact Us

Nicol Scales & Measurement is an ISO Accredited Calibration

Company that has provided calibration, repair and sales of all types

of weighing and measurement products since 1931.

Instrument manual

Transmitter Series PR 5220

Translation of the original instrument manual 9499 050 52201 Edition 10.1.1 05/24/2017

Release 4.50

Minebea Intec GmbH, Meiendorfer Str. 205 A, 22145 Hamburg, Germany

Phone: +49.40.67960.303 Fax: +49.40.67960.383

Foreword

Must be followed!

Any information in this document is subject to change without notice and does not represent a commitment on

the part of Minebea Intec unless legally prescribed. This product should be operated only by trained and

qualied personnel. In correspondence concerning this product, the type, designation and version number as

well as all license numbers relating to the product have to be cited.

Note

The complete product is protected by copyright. It may not be changed or copied, and it may not be used

without purchasing or written permission from the copyright owner (Minebea Intec). Its use constitutes

acceptance by you of the above-mentioned provisions.

Transmitter Series PR 5220 Table of contents

Table of contents

1 Introduction......................................................................................................................................... 7

1.1 Read the manual......................................................................................................................................................... 7

1.2 This is what instructions look like............................................................................................................................. 7

1.3 This is what lists look like........................................................................................................................................... 7

1.4 This is what menus and soft keys look like............................................................................................................. 7

1.5 This is what safety instructions look like................................................................................................................. 7

1.6 Hotline..........................................................................................................................................................................8

2 Safety instructions............................................................................................................................... 9

2.1 General information................................................................................................................................................... 9

2.2 Intended use................................................................................................................................................................ 9

2.3 Incoming goods inspection....................................................................................................................................... 9

2.4 Before operational startup........................................................................................................................................9

2.4.1 Installation ........................................................................................................................................................9

2.4.2 Supply voltage connection........................................................................................................................... 10

2.4.3 Protective conductor connection................................................................................................................ 10

2.5 RF interference suppression................................................................................................................................... 10

2.6 Failure and excessive stress.................................................................................................................................... 10

2.7 Important note........................................................................................................................................................... 11

2.8 Repairs and maintenance......................................................................................................................................... 11

2.8.1 General information ....................................................................................................................................... 11

2.8.2 Electrostatically sensitive parts ....................................................................................................................11

2.8.3 Replacing fuses ............................................................................................................................................... 11

3 Device description ..............................................................................................................................12

3.1 Transmitter versions .................................................................................................................................................12

3.1.1 General information .......................................................................................................................................12

3.1.2 PR 5220/00.....................................................................................................................................................12

3.1.3 PR 5220/01 ProBus DP................................................................................................................................12

3.1.4 PR 5220/04 DeviceNet ..................................................................................................................................13

3.1.5 PR 5220/06 ProNet I/O...............................................................................................................................13

3.1.6 PR 5220/07 EtherNet IP ................................................................................................................................13

3.2 General information..................................................................................................................................................13

3.3 Overview of the device .............................................................................................................................................13

3.3.1 Communication protocols............................................................................................................................ 14

3.4 Housing...................................................................................................................................................................... 14

3.4.1 Sticker .............................................................................................................................................................. 14

3.4.2 Dimensions ......................................................................................................................................................15

3.5 Display and control panel.........................................................................................................................................15

3.5.1 General information .......................................................................................................................................15

3.5.2 Overview.......................................................................................................................................................... 16

EN-1 Minebea Intec

Transmitter Series PR 5220 Table of contents

3.5.3 Display ............................................................................................................................................................. 16

3.5.4 Operating elements....................................................................................................................................... 19

3.6 Overview of connections.........................................................................................................................................23

4 Device installation..............................................................................................................................24

4.1 General information.................................................................................................................................................24

4.2 Mechanical preparation...........................................................................................................................................24

4.2.1 Control cabinet units .....................................................................................................................................24

4.3 EMC-compliant installation ....................................................................................................................................25

4.4 Hardware construction ............................................................................................................................................26

4.4.1 Notes for connection.....................................................................................................................................26

4.4.2 Network port...................................................................................................................................................26

4.4.3 RS-485 interface............................................................................................................................................28

4.4.4 Analog outputs............................................................................................................................................... 33

4.4.5 Digital inputs ..................................................................................................................................................34

4.4.6 Digital outputs................................................................................................................................................36

4.4.7 Connecting analog load cells and platforms .............................................................................................38

4.5 Interfaces ...................................................................................................................................................................47

4.5.1 ProBus-DP interface ...................................................................................................................................47

4.5.2 DeviceNet interface .......................................................................................................................................50

4.5.3 ProNet I/O interface.....................................................................................................................................51

4.5.4 EtherNet-IP interface ....................................................................................................................................52

5 "Standard" application ......................................................................................................................54

5.1 Functions....................................................................................................................................................................54

5.1.1 General information ......................................................................................................................................54

5.1.2 Display functions............................................................................................................................................54

6 "EasyFill" application......................................................................................................................... 55

6.1 Functions....................................................................................................................................................................55

6.1.1 General information ......................................................................................................................................55

6.1.2 Display functions............................................................................................................................................55

6.1.3 Filling mode ....................................................................................................................................................55

6.2 Application menu [Start] .........................................................................................................................................55

7 Commissioning................................................................................................................................... 57

7.1 Power failure/Data backup/Restart ......................................................................................................................57

7.1.1 Power failure................................................................................................................................................... 57

7.1.2 Data backup.................................................................................................................................................... 57

7.1.3 Overwrite protection..................................................................................................................................... 57

7.1.4 Restart .............................................................................................................................................................59

7.2 Switching on the device...........................................................................................................................................59

7.3 Switching o the device ..........................................................................................................................................60

7.4 Warm-up time...........................................................................................................................................................60

Minebea Intec EN-2

Transmitter Series PR 5220 Table of contents

7.5 Finding and connecting the device automatically in the network....................................................................60

7.6 Finding and connecting a device with a notebook/PC....................................................................................... 61

7.7 Searching the device in the network with "IndicatorBrowser".......................................................................... 61

7.8 Resetting the network address ..............................................................................................................................63

7.9 Operation using VNC ...............................................................................................................................................63

7.10 Operation via a web browser..................................................................................................................................65

7.11 System setup.............................................................................................................................................................65

7.11.1 Serial ports parameter ..................................................................................................................................66

7.11.2 Operating parameter ....................................................................................................................................66

7.11.3 Fieldbus parameter........................................................................................................................................66

7.11.4 Network parameter .......................................................................................................................................66

7.11.5 Weighing points .............................................................................................................................................67

7.11.6 Limit parameter.............................................................................................................................................. 73

7.11.7 Digital I/O parameters .................................................................................................................................. 73

7.11.8 Analog output parameter............................................................................................................................. 73

7.12 Calibrating internal weighing point.......................................................................................................................74

7.12.1 General information ......................................................................................................................................74

7.12.2 Displaying calibration data...........................................................................................................................74

7.12.3 Selecting the calibration mode.................................................................................................................... 75

7.12.4 Setting maximum load.................................................................................................................................. 78

7.12.5 Determining the scale interval..................................................................................................................... 79

7.12.6 Determining the dead load ......................................................................................................................... 80

7.12.7 Calibrating with weight................................................................................................................................. 81

7.12.8 Calibrating with mV/V...................................................................................................................................82

7.12.9 Calibrating with load cell data (smart calibration)....................................................................................84

7.12.10 Subsequent dead load correction...............................................................................................................85

7.12.11 Linearization...................................................................................................................................................86

7.12.12 Calculating the test value .............................................................................................................................89

7.12.13 Saving the calibration....................................................................................................................................89

7.12.14 Cancelling a calibration.................................................................................................................................90

7.12.15 Parameter Input ............................................................................................................................................. 91

7.13 Calibrating xBPI-scale..............................................................................................................................................96

7.13.1 General information ......................................................................................................................................96

7.13.2 Parameters for serial interface ....................................................................................................................97

7.13.3 Parameters for the xBPI-weighing function..............................................................................................98

7.13.4 Setting up an xBPI platform.........................................................................................................................99

7.13.5 xBPI-parameter tables.................................................................................................................................101

7.13.6 Setting the xBPI dead load.........................................................................................................................104

7.13.7 xBPI calibration with user specied weight............................................................................................. 106

7.13.8 xBPI calibration with automatic weight detection ................................................................................. 107

7.13.9 xBPI calibration with default weight......................................................................................................... 108

7.13.10 xBPI calibration with built-in weight ........................................................................................................109

EN-3 Minebea Intec

Transmitter Series PR 5220 Table of contents

7.13.11 xBPI linearization.........................................................................................................................................109

7.14 Calibrating digital load cells of type "Pendeo" ...................................................................................................110

7.14.1 General information .....................................................................................................................................110

7.14.2 Selecting and conguring RS-485 interface .............................................................................................111

7.14.3 Selecting the load cell type .........................................................................................................................112

7.14.4 Calibration procedure ..................................................................................................................................112

7.14.5 Searching load cells ......................................................................................................................................113

7.14.6 Assigning load cells ......................................................................................................................................114

7.14.7 Calibrating load cells ....................................................................................................................................116

7.14.8 Assigning load cell names ...........................................................................................................................118

7.14.9 Service function.............................................................................................................................................118

7.14.10 Corner correction..........................................................................................................................................119

7.14.11 Terminating/saving calibration..................................................................................................................121

7.14.12 Parameter Input............................................................................................................................................121

7.14.13 Subsequent dead load correction ............................................................................................................. 123

7.14.14 Displaying weighing point serial number ................................................................................................124

7.15 General parameter settings .................................................................................................................................. 124

7.15.1 Selecting and conguring serial interfaces ............................................................................................. 125

7.15.2 Operating parameters................................................................................................................................. 130

7.15.3 Fieldbus parameters.................................................................................................................................... 132

7.15.4 Network parameters.................................................................................................................................... 135

7.15.5 Conguring limit values...............................................................................................................................137

7.15.6 Conguring digital inputs........................................................................................................................... 142

7.15.7 Conguring digital outputs........................................................................................................................ 145

7.15.8 Conguring analog output......................................................................................................................... 149

7.16 System information................................................................................................................................................ 150

7.16.1 Displaying the version..................................................................................................................................151

7.16.2 Displaying the status....................................................................................................................................151

7.16.3 Showing hardware options ........................................................................................................................ 152

7.16.4 Displaying Pendeo data.............................................................................................................................. 153

8 Production........................................................................................................................................157

8.1 General information............................................................................................................................................... 157

8.2 Starting the application ......................................................................................................................................... 157

8.3 Conguration via a notebook/PC ........................................................................................................................158

8.3.1 Conguring production mode................................................................................................................... 158

8.3.2 Conguring digital inputs and outputs..................................................................................................... 161

8.3.3 Conguring material ................................................................................................................................... 163

8.4 Filling ........................................................................................................................................................................166

9 Extended functions .......................................................................................................................... 168

9.1 Hardware test.......................................................................................................................................................... 168

9.1.1 Serial interfaces............................................................................................................................................ 168

Minebea Intec EN-4

Transmitter Series PR 5220 Table of contents

9.1.2 Inputs and outputs ...................................................................................................................................... 169

9.2 Functions via the WEB site .................................................................................................................................... 174

9.2.1 General information .................................................................................................................................... 174

9.2.2 Displaying weighing points in a table....................................................................................................... 175

9.2.3 Conguration printout................................................................................................................................ 175

9.2.4 Log les ..........................................................................................................................................................177

9.2.5 Screenshots................................................................................................................................................... 178

9.2.6 Error log......................................................................................................................................................... 179

9.2.7 Conguration data.......................................................................................................................................180

9.3 Resetting the device to the factory settings .......................................................................................................181

9.4 Updating new software with FlashIt.................................................................................................................... 182

9.4.1 Updating with a xed IP address .............................................................................................................. 182

10 ModBus protocol ............................................................................................................................. 186

10.1 General description ................................................................................................................................................186

10.2 SPM data in PR 1612 ModBus mode.................................................................................................................... 186

11 SMA protocol ................................................................................................................................... 188

11.1 General information............................................................................................................................................... 188

12 Fieldbus interface ............................................................................................................................ 189

12.1 Fieldbus interface conguration..........................................................................................................................189

12.2 Scale protocol (8-Byte) for the "standard" application .................................................................................... 189

12.2.1 Write window (input area)...........................................................................................................................190

12.2.2 Read window (output area) .........................................................................................................................191

12.2.3 Reading and writing data ............................................................................................................................191

12.2.4 Description of the I/O area (read/write window).................................................................................... 192

12.2.5 Special hints for DeviceNet and EtherNet-IP .......................................................................................... 197

12.2.6 Fieldbus register .......................................................................................................................................... 197

12.3 Filling protocol (64-Byte) for the "EasyFill" application .................................................................................. 202

12.3.1 Write window (input area).......................................................................................................................... 202

12.3.2 Read window (output area) ....................................................................................................................... 202

12.3.3 Indicator functions...................................................................................................................................... 202

12.3.4 Filling functions........................................................................................................................................... 202

12.3.5 Setup of the eldbus interface ................................................................................................................. 204

13 SPM .................................................................................................................................................. 211

13.1 General information................................................................................................................................................ 211

13.2 Elementary data types............................................................................................................................................211

13.3 Addressing............................................................................................................................................................... 212

13.4 System data............................................................................................................................................................. 212

14 Repairs and maintenance ..................................................................................................................217

14.1 Repairs...................................................................................................................................................................... 217

14.2 Maintenance............................................................................................................................................................ 217

EN-5 Minebea Intec

Transmitter Series PR 5220 Table of contents

14.3 Soldering work........................................................................................................................................................ 217

14.4 Cleaning ................................................................................................................................................................... 217

15 Disposal ........................................................................................................................................... 218

16 Error messages .................................................................................................................................219

16.1 Error messages measuring circuit........................................................................................................................ 219

16.2 Weight error status................................................................................................................................................ 220

16.3 Error messages for xBPI scales............................................................................................................................ 220

16.4 Error messages for Pendeo® load cells.............................................................................................................. 221

16.5 Error messages during calibration.......................................................................................................................222

16.6 Error numbers @ "LAST_ERROR" ........................................................................................................................224

16.6.1 Weighing point error ...................................................................................................................................224

16.6.2 Error in the "EasyFill" application..............................................................................................................224

17 Specications .................................................................................................................................. 226

17.1 Note on using "Free Software" .............................................................................................................................226

17.2 Decoding the serial number..................................................................................................................................226

17.3 General data ............................................................................................................................................................226

17.3.1 Supply voltage..............................................................................................................................................226

17.4 Eect of ambient conditions ................................................................................................................................226

17.4.1 Ambient conditions .....................................................................................................................................226

17.4.2 Electromagnetic Compatibility (EMC).......................................................................................................227

17.4.3 RF interference suppression ......................................................................................................................227

17.5 Weighing electronics..............................................................................................................................................227

17.5.1 Load cells.......................................................................................................................................................227

17.5.2 Principle.........................................................................................................................................................228

17.5.3 Accuracy and stability .................................................................................................................................228

17.5.4 Sensitivity......................................................................................................................................................228

17.5.5 Connecting cables........................................................................................................................................228

17.6 Mechanics ................................................................................................................................................................229

17.6.1 Design............................................................................................................................................................229

17.6.2 Weights..........................................................................................................................................................229

17.7 Documentation on the enclosed CD....................................................................................................................229

18 Appendix .........................................................................................................................................230

18.1 Spare parts.............................................................................................................................................................. 230

18.2 Test connector........................................................................................................................................................ 230

Minebea Intec EN-6

1 Introduction Transmitter Series PR 5220

1 Introduction

1.1 Read the manual

- Please read this manual carefully and completely before using the product.

- This manual is part of the product. Keep it in a safe and easily accessible location.

1.2 This is what instructions look like

1. - n. are placed before steps that must be done in sequence.

is placed before a step.

describes the result of a step.

1.3 This is what lists look like

- indicates an item in a list.

1.4 This is what menus and soft keys look like

[ ] frame menu items and soft keys.

Example:

[Start]- [Applications]- [Excel]

1.5 This is what safety instructions look like

Signal words indicate the severity of the danger involved when measures for preventing

hazards are not followed.

DANGER

Warning of personal injury

DANGER indicates that death or severe, irreversible personal injury will occur if

appropriate safety measures are not observed.

Take appropriate safety measures.

WARNING

Warning of potential health risk or risk of personal injury!

WARNING indicates that death or severe, irreversible injury may occur if appropriate

safety measures are not observed.

Take appropriate safety measures.

CAUTION

Warning of personal injury and/or property damage.

CAUTION indicates that minor, reversible injury or damage to property may occur if

appropriate safety measures are not observed.

Take appropriate safety measures.

EN-7 Minebea Intec

Transmitter Series PR 5220 1 Introduction

NOTICE

Warning of property and/or environmental damage.

ATTENTION indicates that damage to property and/or the environment may occur if

appropriate safety measures are not observed.

Take appropriate safety measures.

Note:

User tips, useful information and notes.

1.6 Hotline

Phone: +49.40.67960.444

Fax: +49.40.67960.474

E-mail: help@minebea-intec.com

Minebea Intec EN-8

2 Safety instructions Transmitter Series PR 5220

2 Safety instructions

2.1 General information

CAUTION

Warning of personal injury.

The product was in perfect condition with regard to safety features when it left the

factory.

To maintain this condition and to ensure safe operation, the user must follow the

instructions and observe the warnings in this manual.

2.2 Intended use

The device is intended for use as an indicator for weighing functions.

Product operation, commissioning and maintenance must be performed by trained and

qualied personnel who are aware of and able to deal with the related hazards and take

suitable measures for self-protection.

The device reects the state of the art.

The manufacturer does not accept any liability for damage caused by third-party system

components or due to incorrect use of the product. The use of this product signies

recognition of the stipulations listed above.

2.3 Incoming goods inspection

The shipment must be checked for completeness. A visual inspection must be performed

to determine if the shipment has been damaged. If there are grounds for a complaint, this

must be brought to the attention of the delivery company immediately. A Minebea Intec

sales or service point must be informed.

2.4 Before operational startup

NOTICE

Perform visual inspection!

Before operational startup as well as after storage or transport, inspect the device

visually for signs of mechanical damage.

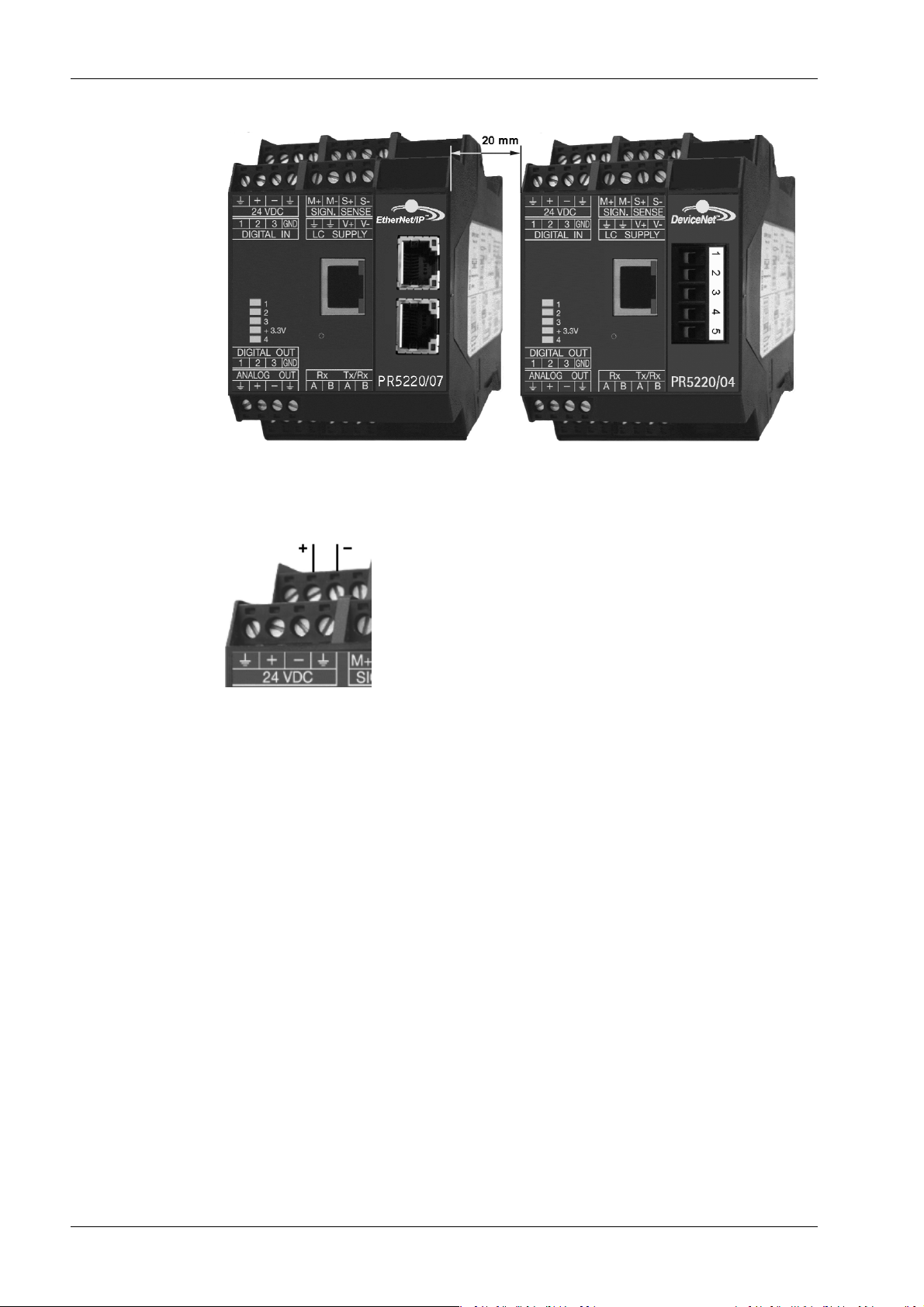

2.4.1 Installation

The device is designed for mounting rail installation (35 mm as per DIN 46277).

NOTICE

Excessive heat may reduce the device lifetime.

When mounting on the rail, make sure that the distance from other instruments left

and right of the device is at least 20 mm.

EN-9 Minebea Intec

Transmitter Series PR 5220 2 Safety instructions

The device has to be installed in an EMC-compliant manner, see Chapter 4.3.

2.4.2 Supply voltage connection

The supply voltage is 24 V DC ±20%.

Max. power consumption:

- PR 5220/00: 6.5 W

- PR 5220/01: 8.5 W

- PR 5220/04: 8.5 W

- PR 5220/06: 8.5 W

- PR 5220/07: 8.5 W

For connection to 230/115 V AC, an external power supply (e.g., Minebea Intec PR 1624/

00 or Phoenix Mini Power) is required.

2.4.3 Protective conductor connection

The protective conductor is connected via the mounting rail.

2.5 RF interference suppression

The device is designed for operation in the industrial sector and can cause

RF interferences in a residential environment, see Chapter 17.4.3. In this case, the

operator can be required to carry out the appropriate measures.

2.6 Failure and excessive stress

If there is any reason to assume that safe operation of the device is no longer ensured,

shut it down and make sure it cannot be used.

Minebea Intec EN-10

2 Safety instructions Transmitter Series PR 5220

Safe operation is no longer ensured if any of the following is true:

- The device is physically damaged.

- The device does not function.

- The device has been subjected to stresses beyond the tolerance limits (e.g., during

storage or transport).

2.7 Important note

Make sure that the construction of the device is not altered to the detriment of safety. In

particular, leakage paths, air gaps (of live parts) and insulating layers must not be

reduced.

Minebea Intec cannot be held responsible for personal injury or property damage caused

by a device repaired incorrectly by an operator or installer.

2.8 Repairs and maintenance

2.8.1 General information

Repairs are subject to inspection and must be carried out at Minebea Intec.

In case of defect or malfunction, please contact your local Minebea Intec dealer or service

center for repair.

When returning the device for repair, please include a precise and complete description of

the problem.

Maintenance work may only be carried out by a trained technician with expert knowledge

of the hazards involved and the required precautions.

2.8.2 Electrostatically sensitive parts

This device contains electro-statically sensitive components. Therefore, potential

equalization must be provided when working on the device (antistatic protection).

2.8.3 Replacing fuses

The device has no replaceable fuse.

The load cell supply voltage is protected against short circuit.

On failure of load cell supply voltage the device must be disconnected from the power

supply; determine and eliminate the cause . Then the supply voltage can be switched on

again.

EN-11 Minebea Intec

Transmitter Series PR 5220 3 Device description

3 Device description

3.1 Transmitter versions

3.1.1 General information

The transmitter of the PR 5220 series exists in 5 versions. A later extension of the version

is not possible. Each type is clearly xed by the corresponding number. The front overlays

are adapted to the corresponding type.

PR 5220/00 PR 5220/01 PR 5220/04

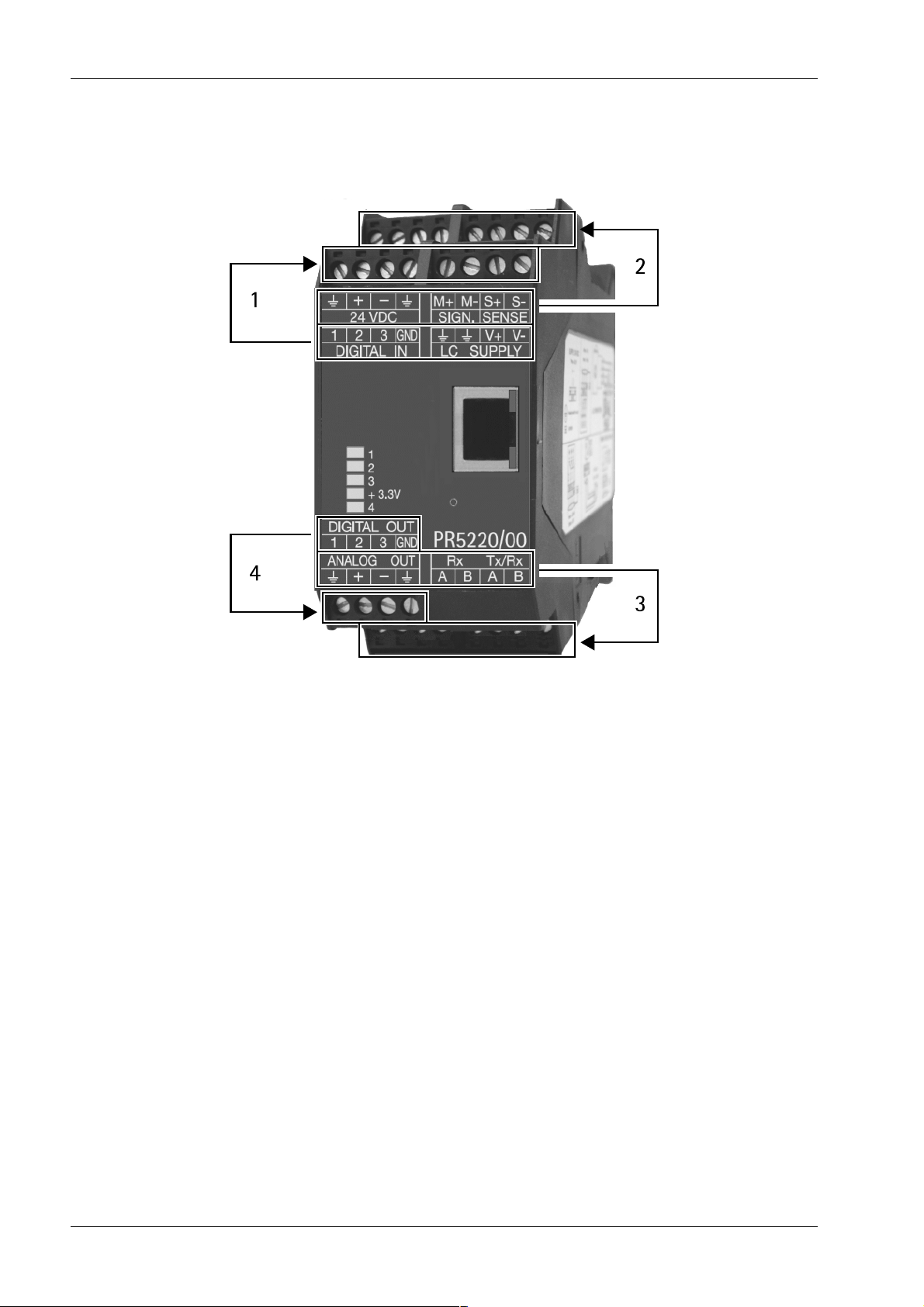

3.1.2 PR 5220/00

PR 5220/06 PR 5220/07

This type has digital inputs and outputs as well as one analog output and a LAN-Adapter

for conguring and operating of the device. At the serial output e.g. a remote display can

be connected.

3.1.3 PR 5220/01 ProBus DP

In addition to PR 5220/00, the instrument is provided with a ProBus port.

Minebea Intec EN-12

3 Device description Transmitter Series PR 5220

3.1.4 PR 5220/04 DeviceNet

Additionally to the PR 5220/00 this instrument has a DeviceNet connection.

3.1.5 PR 5220/06 ProNet I/O

In addition to PR 5220/00, the instrument is provided with two ProNet I/O ports.

3.1.6 PR 5220/07 EtherNet IP

In addition to PR 5220/00, the instrument is provided with EtherNet-IP ports.

3.2 General information

The device contains two applications:

- Standard

- EasyFill

Most functions are supported by both applications.

Some functions depend on the application.

3.3 Overview of the device

- Precision 10.000 e according to OIML R76

- Internal resolution 7.5 million counter steps

- Linearity <0.002%

- Measure rate is congurable: 6100/sec

- Digital lter with adjustable characteristic line

- Electrically isolated interfaces

- 3 programmable pairs of limits

- 24 V DC supply voltage connection

- Connection via plug-in terminal blocks

- Socket for LAN adapter

- The device is snapped to a mounting rail.

- 5 Status LEDs for power supply, communication, error detection

- The "EasyFill" application allows for quick and reliable lling and emptying of

containers (for functional description, see Chapter 6.1).

The menu-guided calibration and conguration of the device are carried out on a

notebook/PC.

- Calibration using weights according to the mV/V method or using load cell data

(smart calibration)

- Analog output 0/420 mA, congurable for gross/net weight

- Analog value via eldbus

- 3 digital inputs, electrically isolated

- 3 digital outputs, electrically isolated

EN-13 Minebea Intec

Transmitter Series PR 5220 3 Device description

3.3.1 Communication protocols

For the internal RS-485:

- Remote display protocol

- ModBus-RTU (slave)

- SMA protocol

- xBPI protocol

Feldbus (slave):

- PR 5220/01 ProBus-DP

- PR 5220/04 DeviceNet

- PR 5220/06 ProNet I/O

- PR 5220/07 EtherNet-IP

For the internal LAN:

- ModBus-TCP

3.4 Housing

3.4.1 Sticker

- Ethernet-TCP/IP

- OPC

The connection diagram is located on the side of the housing.

Minebea Intec EN-14

3 Device description Transmitter Series PR 5220

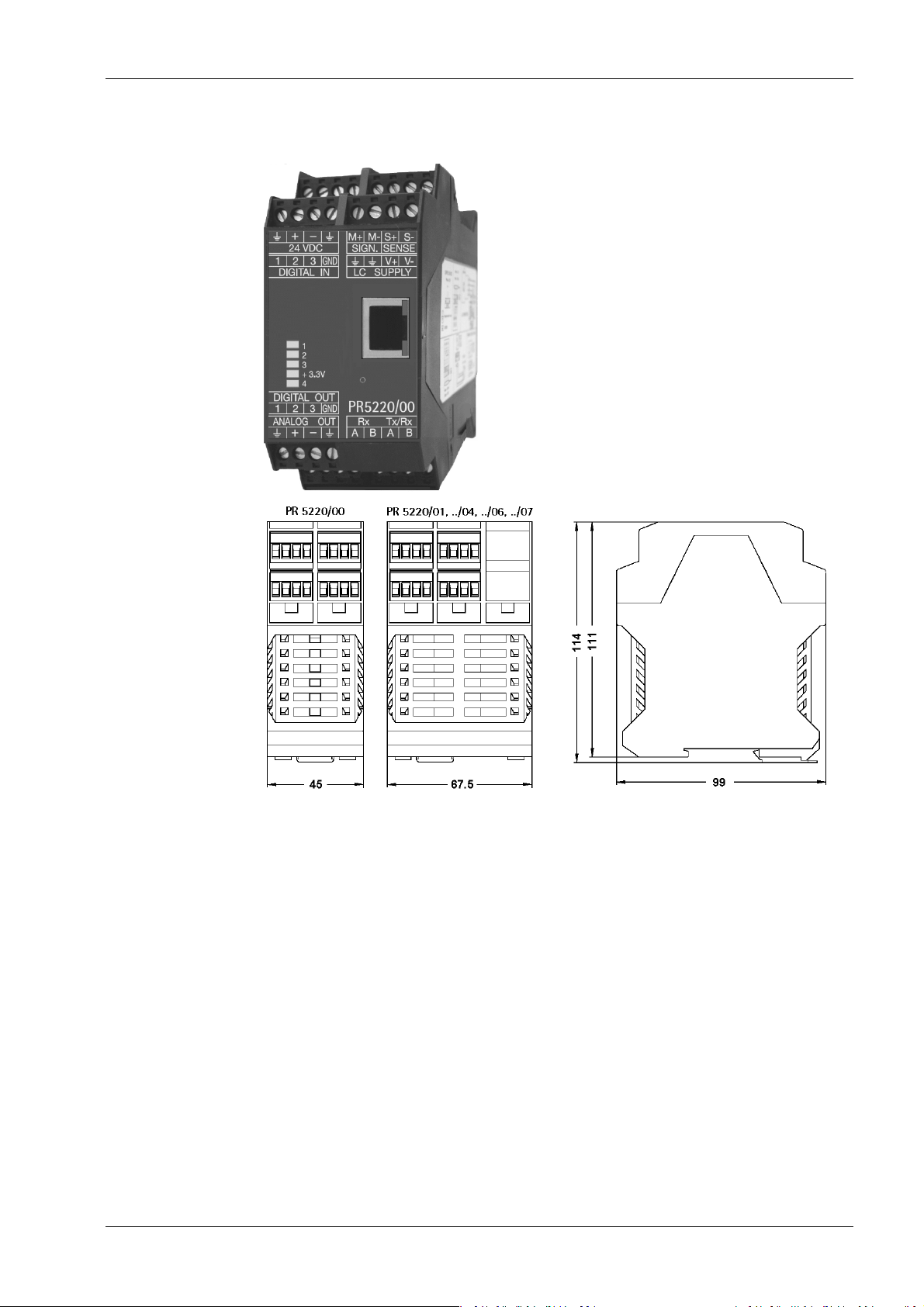

3.4.2 Dimensions

all dimensions in mm

3.5 Display and control panel

3.5.1 General information

The transmitter of the PR 5220 series can only be operated by Notebook/PC.

- VNC viewer (see Chapters 3.5.4.4 and 7.9) or

- WEB browser (see Chapter 7.10)

EN-15 Minebea Intec

Transmitter Series PR 5220 3 Device description

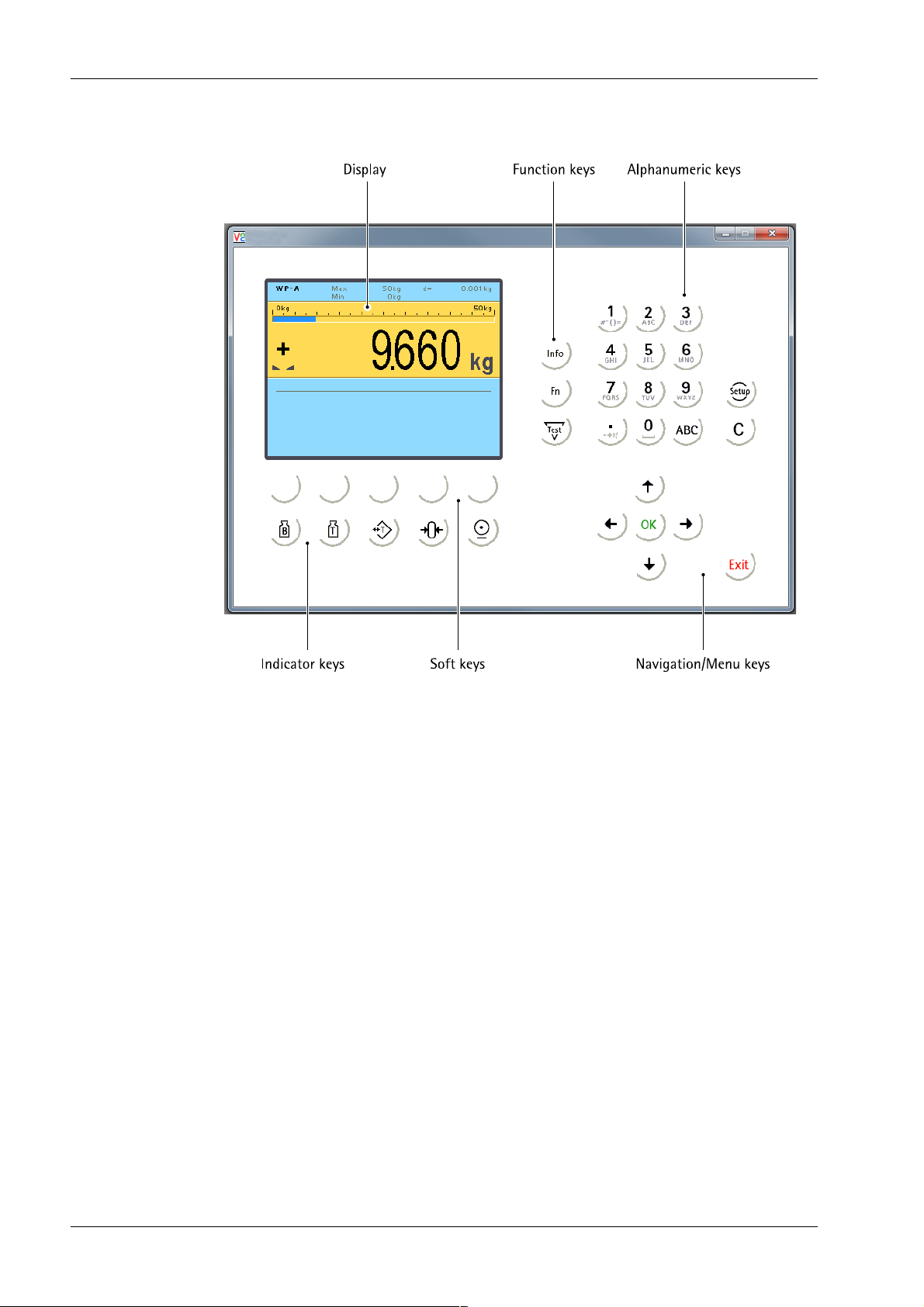

3.5.2 Overview

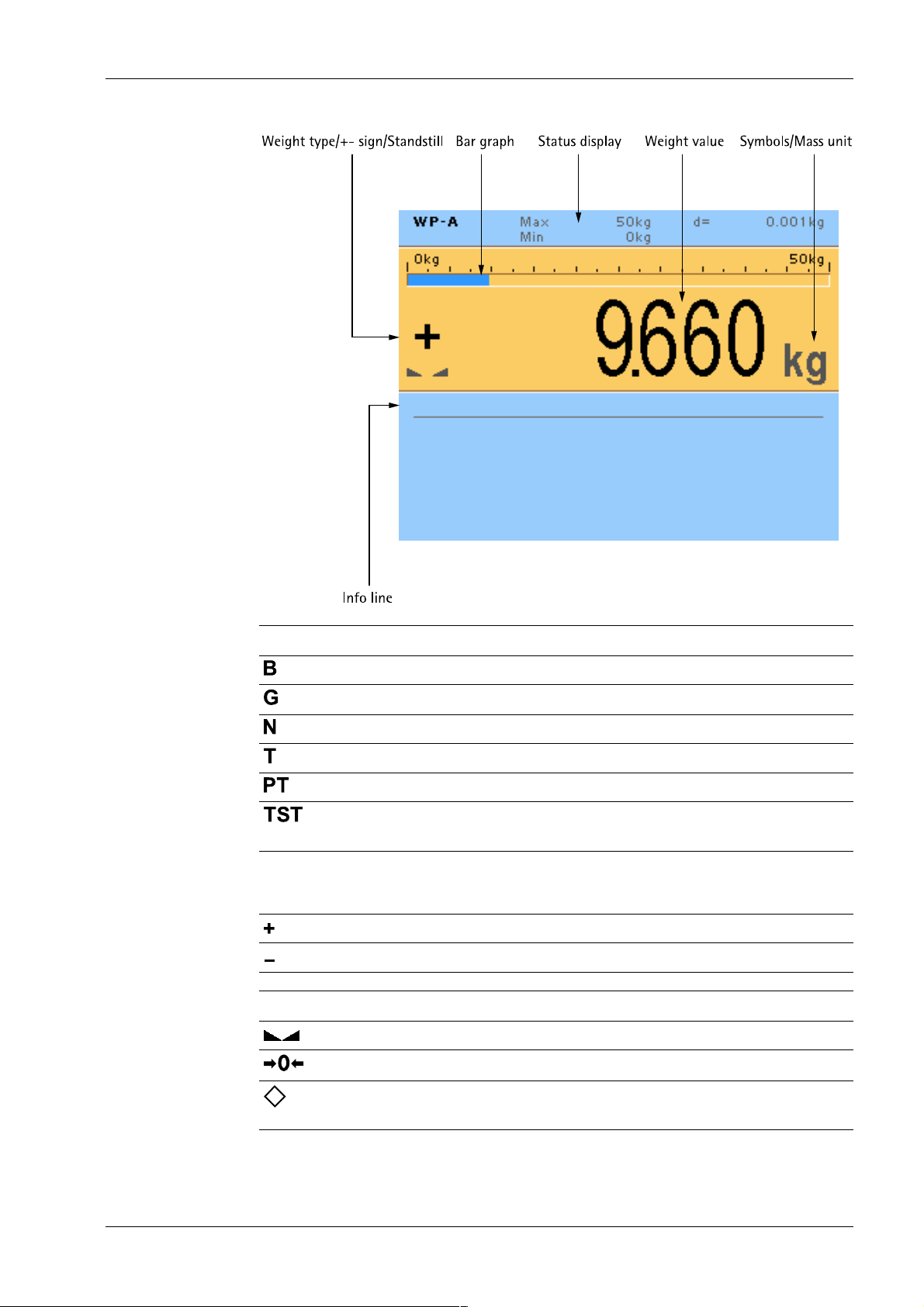

3.5.3 Display

3.5.3.1 User interface

The display of the user interface shows weight values of up to 7‑digits with decimal point

and plus or minus sign.

Available weight units are t, kg, g, mg, lb or oz.

Above the weight display of the user interface, the currently displayed weight is shown as

a bar graph in relation to the maximum load (Max). When Max reaches 100%, the bar

graph is located on the right.

Minebea Intec EN-16

3 Device description Transmitter Series PR 5220

Weight type/plus or minus sign Description

Gross weight

Gross weight in NTEP or NSC mode

Net weight (Net = gross - tare)

Tare weight

Preset tare

The display shows the test value without weight

unit.

No display - Test value

- Gross, not tared

Positive value

Negative value

Standstill/Zero Description

Weight value standstill

The gross weight value is within ±¼ d of zero.

Filling mode; ashes when batching is stopped; ashes rapidlyto indicate error.

EN-17 Minebea Intec

Transmitter Series PR 5220 3 Device description

Symbols/mass unit Description

Value not permissible in legal metrology

(e.g.,10-fold resolution, deactivated load cell).

R1 Range 1

R2 Range 2

R3 Range 3

WP A Weighing point A

Max Maximum load (weighing range)

Min Minimum weight

t, kg, g, mg, lb, oz These weight units are available.

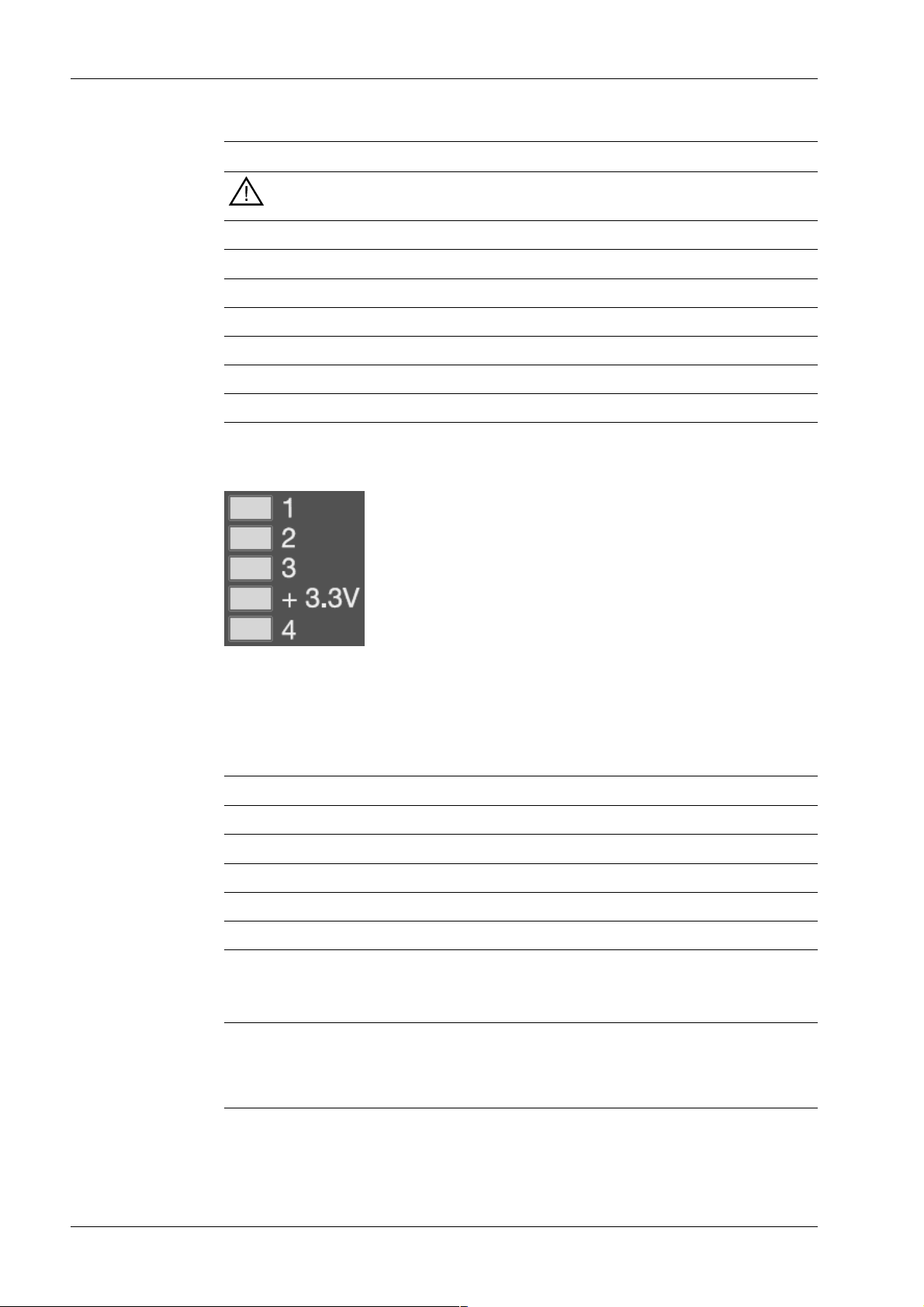

3.5.3.2 LEDs

The device has 5 green LEDs for the following status displays:

- Operational status

- Error status

Power supply, bus connection

LED Power on Bus Bus connection not provided

1

2

3

+3.3V lit

4 lit* ashing 1 Hz

* The LED for bus activity (PR 5220/01 and PR 5220/04) lights up as soon as there is a

connection.

Note:

The LED remains lit, even if there is no communication or the physical connection is

interrupted.

Minebea Intec EN-18

3 Device description Transmitter Series PR 5220

Weight status

LED Standstill ± Null < Null or > FSD

1 lit

2 lit

3 lit

+3.3V

4

Note:

For weight error status, see Chapter 16.2.

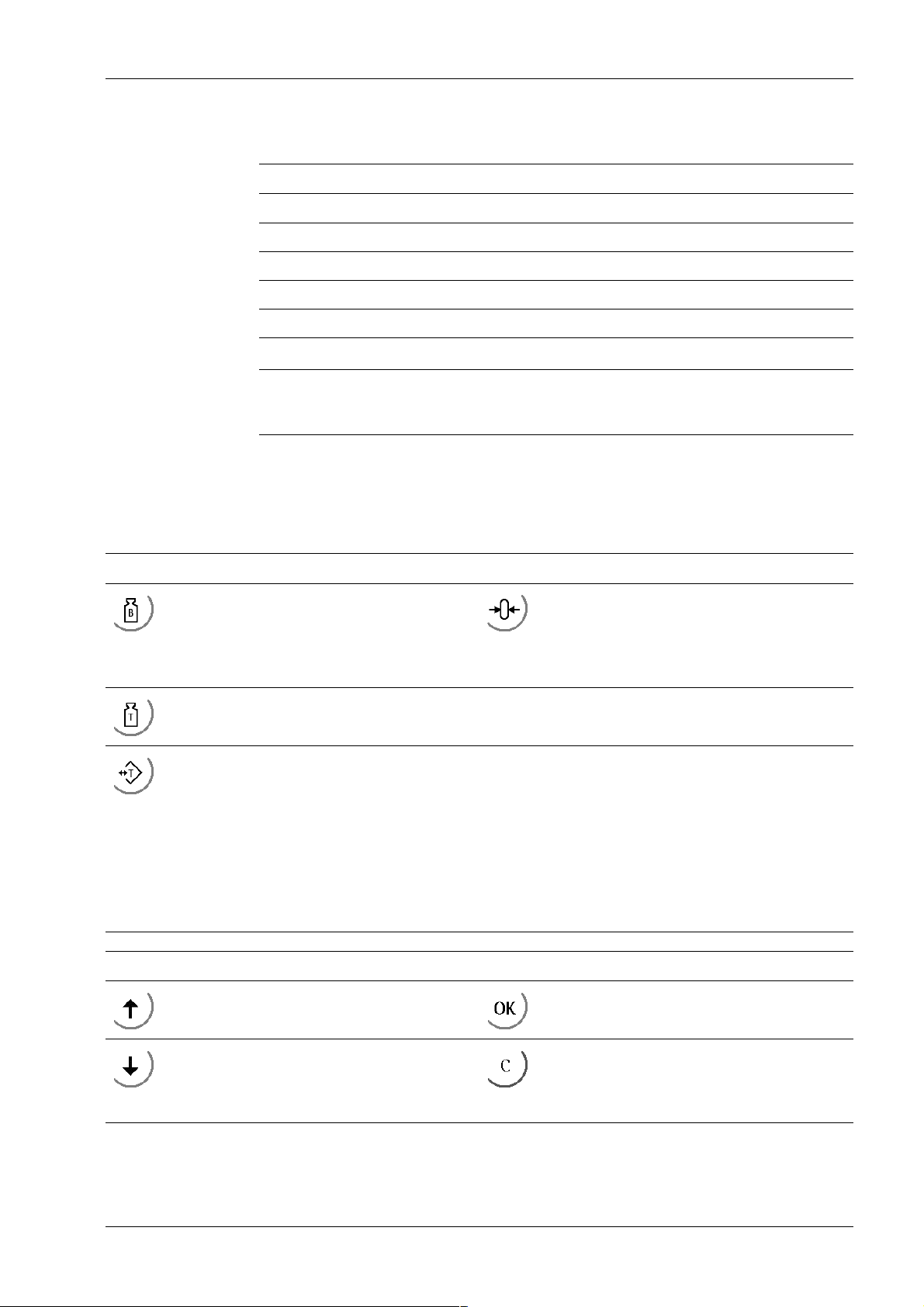

3.5.4 Operating elements

3.5.4.1 User interface

Indicator keys

Display gross weight Sets gross weight to zero, provided that

Display tare weight.

Taring

The current gross weight is stored in

the tare memory, provided that

- weight value is stable;

- the instrument is not in error sta-

tus.

This function depends on the conguration.

Navigation/menu keys

The following tables show the basic meanings of symbols on the operator interface.

- weight value is stable;

- weight is within zero setting range.

This function depends on the conguration.

Scroll up in the menu. Conrm input/selection.

Scroll down in the menu. - Backspace

- Pressing the delete key deletes indivi-

dual characters (within an entry).

EN-19 Minebea Intec

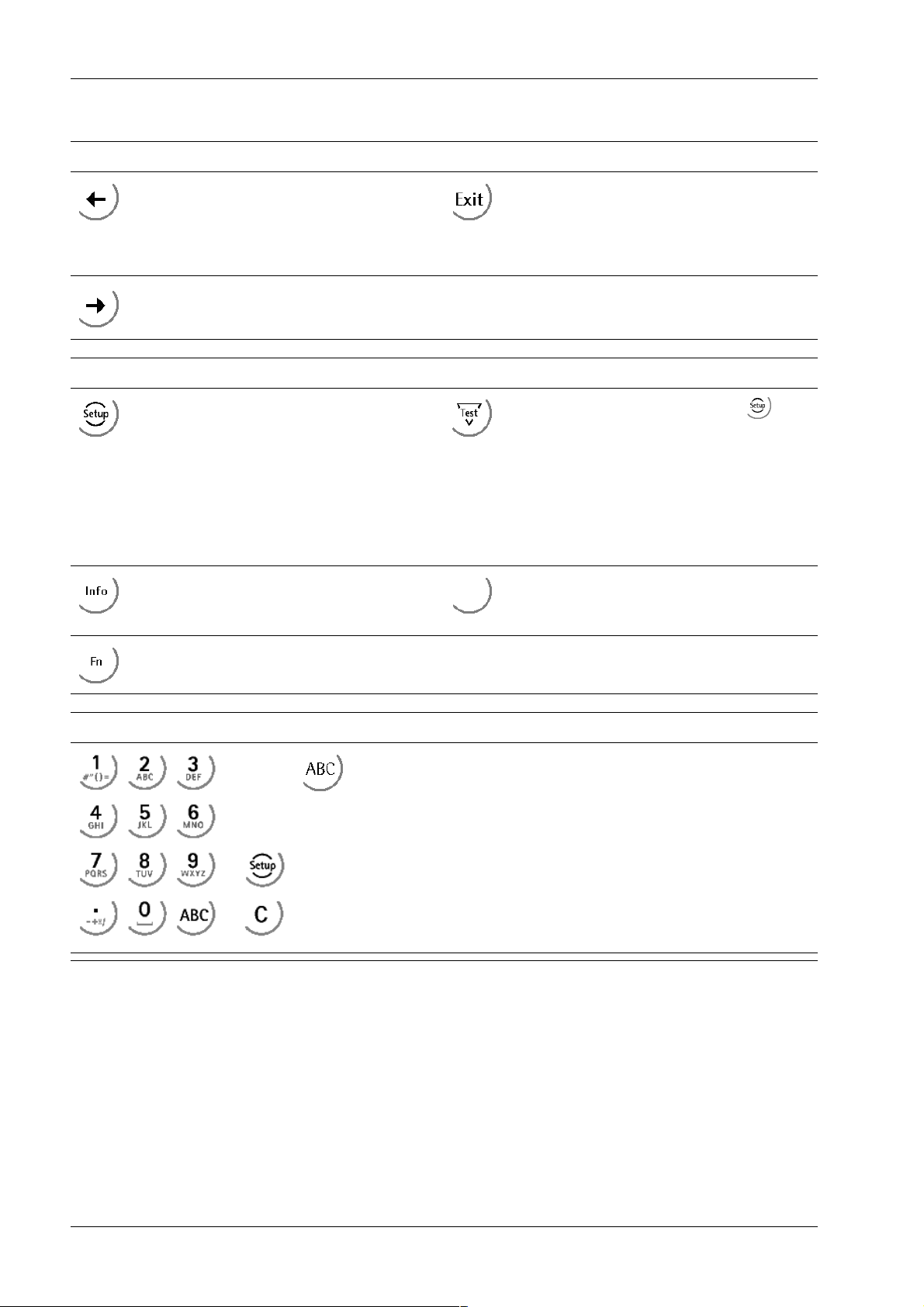

Transmitter Series PR 5220 3 Device description

Navigation/menu keys

- Cursor to the left

- Selection

- Cursor to the right

- Selection

Function keys/softkeys

Access the Setup menu.

Information on version number, tted

hardware, 10-fold resolution

- Cancel entry/selection (after a conr-

mation prompt) without saving the change.

- Exit parameters/menu window.

Depending on the settings under

-[Weighingpoint]- [Calib]- [Param]- [Test

mode] the following is displayed by calling

the test with the key later on:

- with "Absolute" the maximum load

- with "Relative" the deviation from test

value.

Softkeys 1…5

Select appropriate menu function, see also

Chapter 3.5.4.2.

No function

Alphanumeric keypad

Toggle key

Toggle by pressing:

- between alpha and numerical mode

- during conguration between weight units

Minebea Intec EN-20

3 Device description Transmitter Series PR 5220

Alphanumeric keypad

Pressing once displays the corresponding rst character, e.g.,"A",

at the cursor position. After pressing twice, "B" is displayed at the

cursor position and after pressing three times, "C" is displayed.

Press the cursor key to nish entering a character or wait

approx. 2 seconds.

If only numeric values are required for input, letters are not enabled.

Press the cursor key within an entry to return to the previous

character.

Press the cursor key within an entry to select the next character.

Within an input, pressing the delete key deletes the character

to the left of the cursor.

Input eld

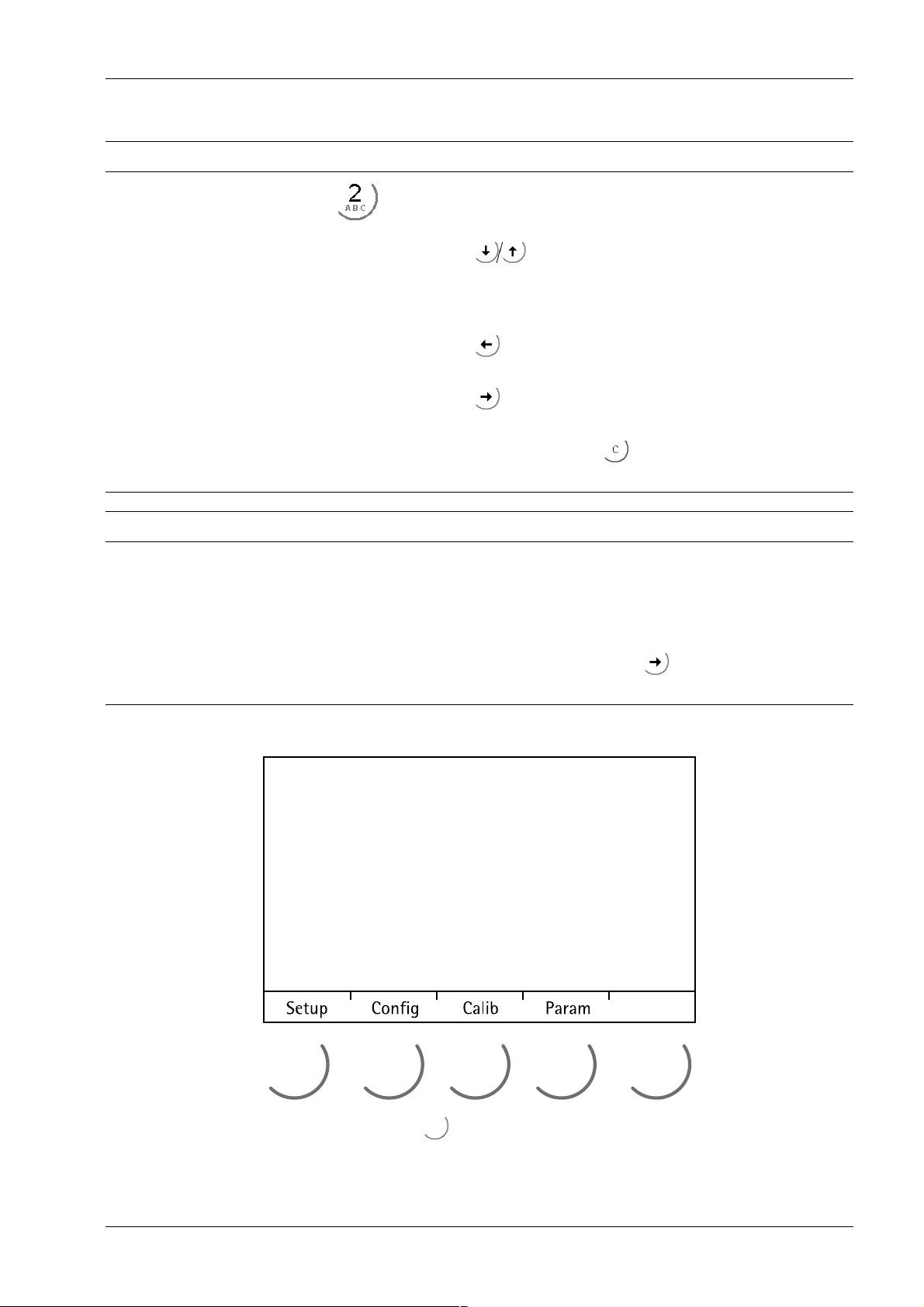

3.5.4.2 Operation using soft keys

In principle

If alphanumeric characters are already present in the input eld of

the selected line, they will be completely overwritten after immediate entry.

If alphanumeric characters are already present in the input eld of

the selected line, you can press the cursor key to select the

characters to be overwritten and overwrite them.

The functions of the ve soft keys below the graphic display are indicated in the

bottommost text line of the display. Soft key functions shown in gray cannot be selected

at the active menu level or with the current access privileges.

EN-21 Minebea Intec

Transmitter Series PR 5220 3 Device description

In the descriptions of operating sequences which entail the use of soft keys, the soft key

function to be selected is shown in square brackets; the soft key symbol is not displayed;

example: [Calib].

3.5.4.3 Navigation key operation

Menu

The cursor keys, the and keys are used to navigate through the menus.

Parameters

Use the cursor keys to select the individual parameters.

Use the key to conrm the selection.

The required values | texts are entered via the alphanumeric keys.

The key is used to check the ☑ box.

If the list of parameters is long, a vertical bar graph on the left (black and gray) shows

which part of the list is displayed.

An arrow in front of a menu item indicates that there are menu sublevels.

Possible settings and an available selection list is indicated by double arrows.

The parameter is selected using the key.

3.5.4.4 Operation using VNC

User interface, see Chapters 3.5.2, 3.5.3.1 and 3.5.4.1.

Minebea Intec EN-22

3 Device description Transmitter Series PR 5220

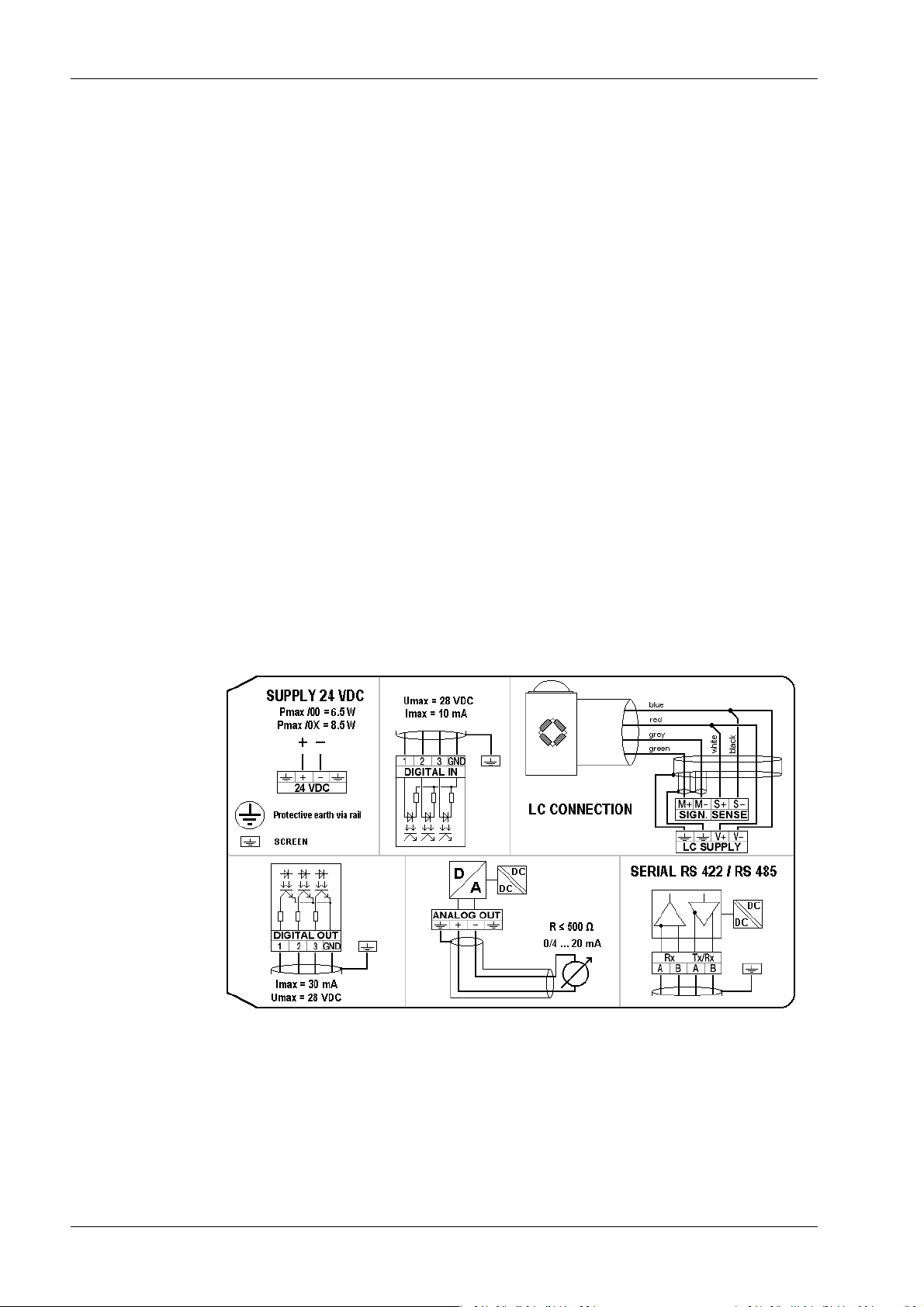

3.6 Overview of connections

EN-23 Minebea Intec

Transmitter Series PR 5220 4 Device installation

4 Device installation

4.1 General information

Before starting work, please read Chapter 2 and follow all instructions.

Note:

For use in UL-regulated applications:

The PR 5220 transmitter must be installed in an NTRL end-enclosure.

WARNING

Warning of a hazard area and/or risk of personal injury

All cable connections must be protected against damage.

Note:

- Measurement cables should be kept away from power equipment.

- Signal cables and measurement cables should be installed separately from electric

power lines.

- It is recommended to lay measurement cables in separate cable conduits.

- Data cables should be crossed at right angles.

Further procedures:

- Check the consignment: make sure that all components are present.

- Safety check: inspect all components for damage.

- Make sure that the on-site installation is correct and complete including cables, e.g.

power cable fuse protection, load cells, junction box, data cables, console/cabinet,

etc.

- Follow all device installation instructions related to application, safety, ventilation,

sealing and environmental inuences.

- Connect the cable from the junction box or platform/load cell.

- If applicable: connect other data cables, power cables, etc.

- Connect to power supply.

- Check the installation.

4.2 Mechanical preparation

4.2.1 Control cabinet units

Have all required parts, technical documents and tools at hand for installation.

Other procedures:

- Install device.

- Secure the cable at the place of installation; e.g., using cable ties.

Minebea Intec EN-24

4 Device installation Transmitter Series PR 5220

- Remove the insulation from the cable ends and keep the strands short.

- Connect the screens to the screen clamping rail using cable clamps, see Chapter 4.3.

- Establish equipotential bonding between instruments/system modules (mandatory

for Ex-applications.)

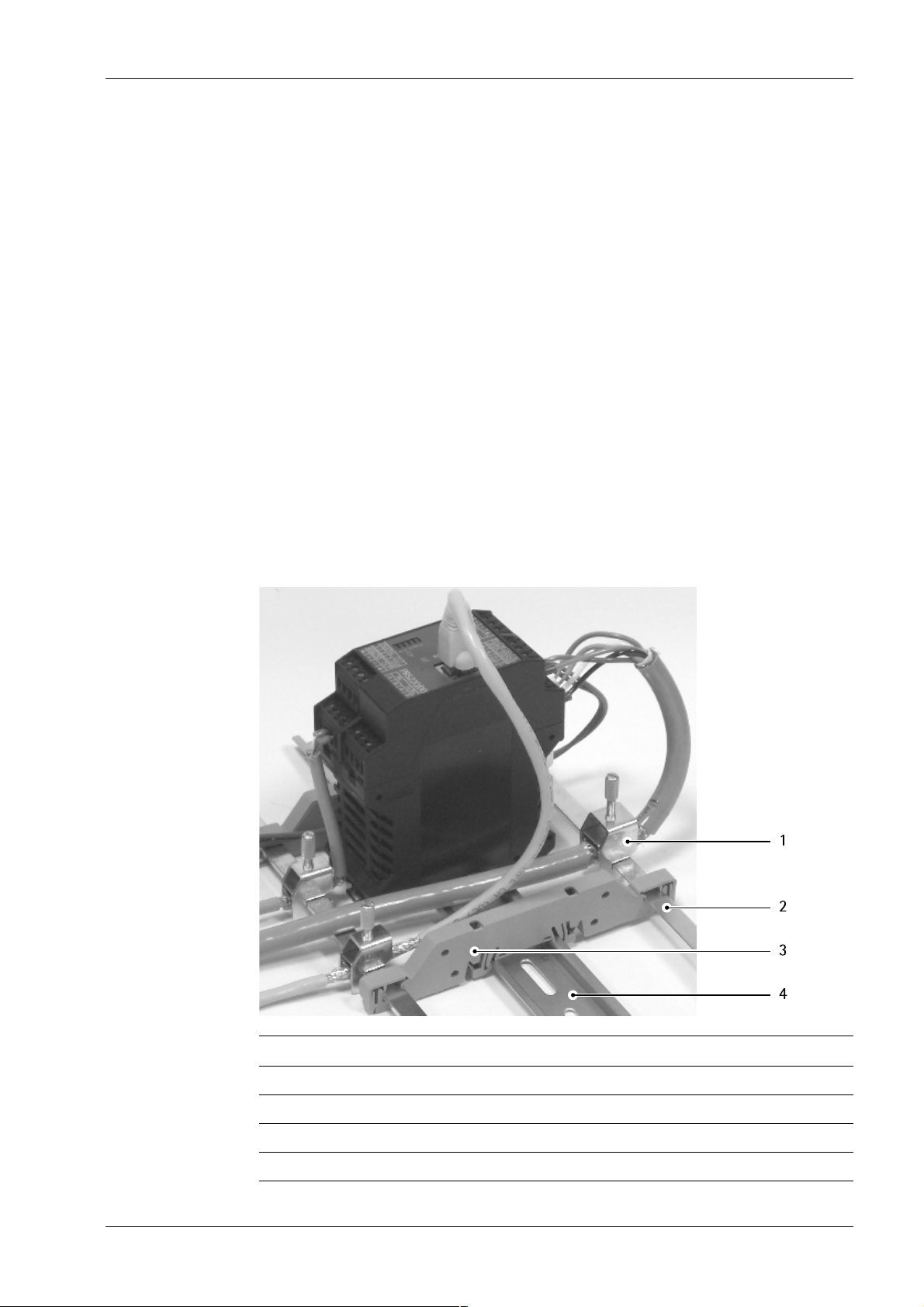

4.3 EMC-compliant installation

- Use only screened data cables.

- Connect screens on both sides to ground.

- Keep non-screened cable ends short.

- Make equipotential bonding conductor connections between screen clamping rail

and cabinet/housing.

- Use metal or metalized connector casings.

- Establish equipotential bonding between instruments/system modules (mandatory

for Ex-applications.

- Use standard reference potential.

- Connect mounting rail to protective earth.

- Install measure and data cables separately from power cables.

No. Description

1 Screen clamp (e.g. Phoenix SK8-D)

2 Screen rail (e.g. Phoenix NLS-CU 3/10)

3 Rail connector bracket (e.g. Phoenix AB-SK 65D)

4 Mounting rail (35 mm)

EN-25 Minebea Intec

Transmitter Series PR 5220 4 Device installation

4.4 Hardware construction

4.4.1 Notes for connection

The labels on the front side of the transmitter are assigned to the clamps as follows:

- Lower line to the front clamps (1)

- Upper line to the back clamps (2)

- Lower line to the back clamps (3)

- Upper line to the front clamp (4)

4.4.2 Network port

The device has an internal Ethernet port.

4.4.2.1 Ethernet port

The Ethernet port contains a powerful TCP/IP interface connection with transfer rates of

10 or 100 Mbit/s.

Function tests can be made via the LEDs (green and yellow) in the RJ-45 socket.

Minebea Intec EN-26

4 Device installation Transmitter Series PR 5220

Specications

Description Data

Connection RJ-45 socket on the device front

Transmission rates 10 Mbit/s, 100 Mbit/s, full/half duplex, auto-detection

Connection mode Point to point

Potential isolation Yes

Cable type CAT 5 patch cable, twisted pair, screened

Cable impedance

Cable length max. 115 m

4.4.2.2 Notebook/PC connection

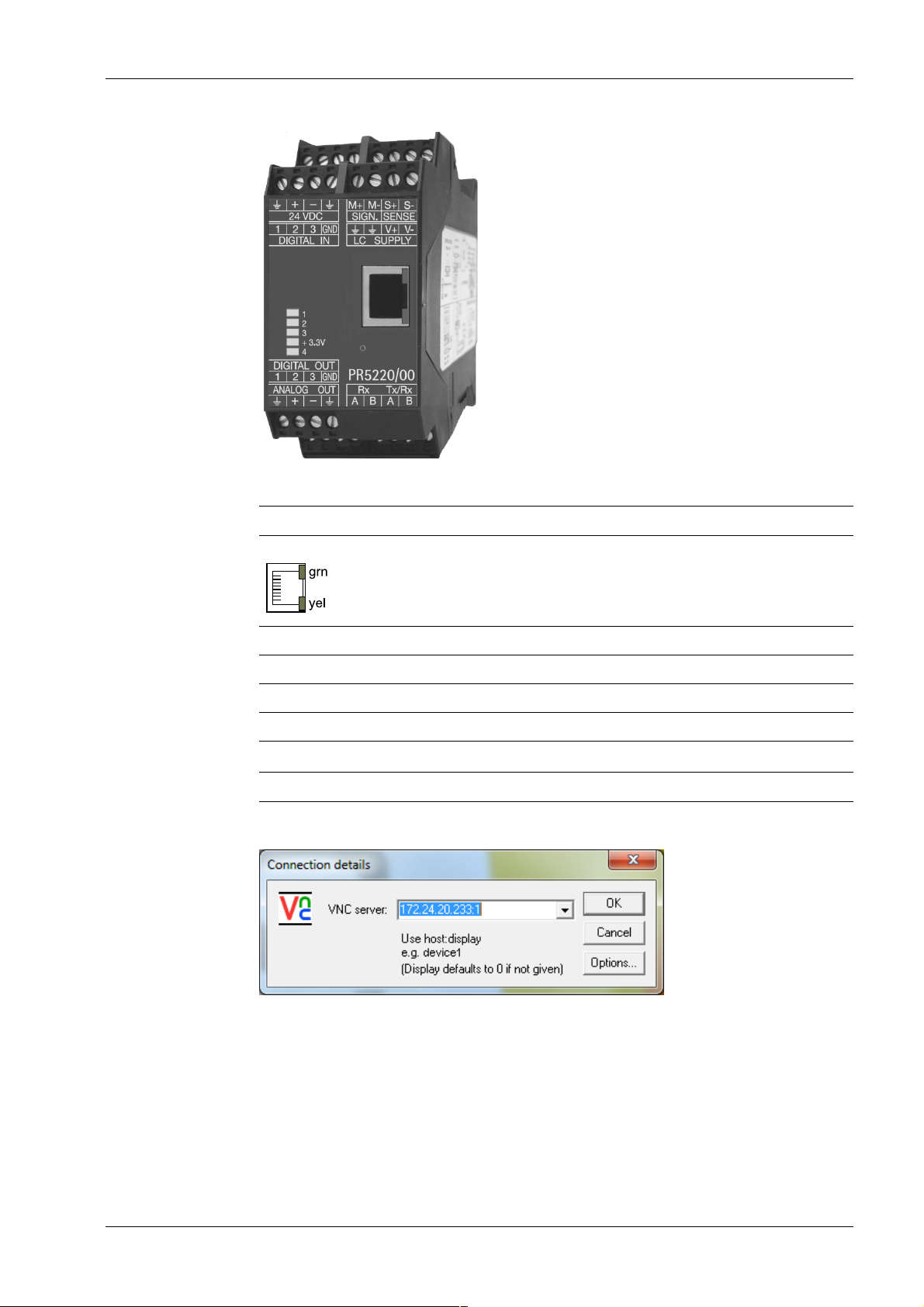

green (grn): ashing on data trac (activity)

Yellow (yel): lights up when there is an existing connection

(link)

150

Remote operation of the device from a notebook/PC is possible (install VNC software

version 3.3.7* on the notebook/PC).

For the network address see Chapter7.7.

* Minebea Intec guarantees the functionality only if this version is used.

EN-27 Minebea Intec

Loading...

Loading...