Page 1

Instrument Manual

Sartorius Mechatronics T&H GmbH, Meiendorfer Str. 205, 22145 Hamburg, Germany

Tel: +49.40.67960.303 Fax: +49.40.67960.383

Process Controller Maxxis 4

PR 5500

Instrument Manual 9499 050 55000 Edition 2 24.07.2015

for PR 5500 Release 2.20

Page 2

Please note

Any information in this document is subject to change without notice and does not represent a commitment

on the part of SARTORIUS INTEC unless legally prescribed. This product should be operated only by trained and

qualified personnel. In correspondence concerning this product the type, name and release number as well as

all license numbers in relation to the product have to be quoted.

Important

This product is partly copyrighted. It may not be modified or copied and may not be used without purchasing

or written authority from the copyright owner (SARTORIUS INTEC). By using this product, you agree to be

bound by the terms stated herein.

Page 3

PR 5500 Instrument Manual Table of Contents

Table of Contents

1 Introduction.........................................................................................................................................................................1

2 Safety Information ............................................................................................................................................................. 2

2.1 Electrical Protective Class............................................................................................................................................................................2

2.2 Intended Use ....................................................................................................................................................................................................2

2.3 Initial Inspection ............................................................................................................................................................................................2

2.4 Before Commissioning ..................................................................................................................................................................................3

2.4.1 Installation ............................................................................................................................................................................................3

2.4.2 Opening the Instrument ...................................................................................................................................................................4

2.4.3 Mains Connection and Protective Grounding Conductor for PR 5500 .............................................................................4

2.5 RF Interference Suppression .......................................................................................................................................................................6

2.6 Failure and Excessive Stress ........................................................................................................................................................................6

2.7 Important Note ...............................................................................................................................................................................................6

2.8 Repairs and Maintenance ............................................................................................................................................................................6

2.8.1 Static Sensitive Components ...........................................................................................................................................................6

2.8.2 Replacing Fuses ...................................................................................................................................................................................6

3 Process Controller ............................................................................................................................................................... 7

3.1 General Information .....................................................................................................................................................................................7

3.2 Overview of the Instrument .......................................................................................................................................................................7

3.3 Housing .............................................................................................................................................................................................................9

3.3.1 Housing dimensions ...........................................................................................................................................................................9

3.3.2 Housing Dimensions with Strain Relief and Reinforcing frame ....................................................................................... 10

3.3.3 Control Panel Cut-Out ................................................................................................................................................................... 11

3.4 Display and Control Panel ........................................................................................................................................................................ 12

3.4.1 Overview ............................................................................................................................................................................................. 12

3.4.2 Display ................................................................................................................................................................................................. 13

3.4.3 Operating Elements ......................................................................................................................................................................... 15

3.4.4 Operation using the VNC Program ............................................................................................................................................. 19

3.5 Overview of Connections ......................................................................................................................................................................... 20

3.5.1 Plug-in Cards ..................................................................................................................................................................................... 21

3.5.2 Application Licenses ........................................................................................................................................................................ 23

3.6 Instrument Versions ................................................................................................................................................................................... 24

3.6.1 Combinatorics for the Options .................................................................................................................................................... 24

Sartorius EN-I

Page 4

Table of Contents PR 5500 Instrument Manual

4 Device Installation ............................................................................................................................................................27

4.1 General Information .................................................................................................................................................................................. 27

4.2 Mechanical Preparation ............................................................................................................................................................................ 28

4.3 Hardware Construction ............................................................................................................................................................................. 30

4.3.1 Main Board ........................................................................................................................................................................................ 30

4.3.2 Network Port ..................................................................................................................................................................................... 31

4.3.3 USB Connection ............................................................................................................................................................................... 32

4.3.4 SD Card Slot ....................................................................................................................................................................................... 36

4.3.5 RS-232 Interface (built-in) ........................................................................................................................................................... 37

4.4 Accessories .................................................................................................................................................................................................... 42

4.4.1 PR 5500/04 2x RS-485 Interface ................................................................................................................................................ 42

4.4.2 PR 5500/32 2x RS-232 Interface ................................................................................................................................................ 52

4.4.3 PR 5500/07 Analog Inputs and Outputs ................................................................................................................................... 57

4.4.4 PR 5500/10 Weighing Electronics Board .................................................................................................................................. 59

4.4.5 PR 5500/12 Digital Inputs and Outputs ................................................................................................................................... 69

4.4.6 PR 5500/13 Digital Inputs and Outputs ................................................................................................................................... 76

4.4.7 PR 5500/17 Digital Inputs and Outputs ................................................................................................................................... 83

4.4.8 PR 1721/61 ProfiBus-DP................................................................................................................................................................ 91

4.4.9 PR 1721/64 DeviceNet ................................................................................................................................................................... 94

4.4.10 PR 1721/65 CC-Link ........................................................................................................................................................................ 98

4.4.11 PR 1721/66 ProfiNet I/O .............................................................................................................................................................. 101

4.4.12 PR 1721/57 EtherNet-IP .............................................................................................................................................................. 104

5 Commissioning ............................................................................................................................................................... 107

5.1 Power Failure/Data Protection/Warm Start/Cold Start ................................................................................................................107

5.1.1 General Information .....................................................................................................................................................................107

5.1.2 Power Failure ...................................................................................................................................................................................107

5.1.3 Warm Start ......................................................................................................................................................................................107

5.1.4 Cold Start .........................................................................................................................................................................................108

5.1.5 Overwrite Protection ....................................................................................................................................................................109

5.2 Switching on the Device ......................................................................................................................................................................... 111

5.3 Switching off the Device ........................................................................................................................................................................ 113

5.4 Warm-up Time ........................................................................................................................................................................................... 113

5.5 Configuring and Calibrating via the Front Keys/PC Keyboard ................................................................................................... 113

5.6 Configuring and Calibrating via a Notebook/PC ............................................................................................................................114

5.6.1 Connecting the Device to the Network and Determining the IP Address ................................................................... 114

5.6.2 Activating the ‘DHCP’ Network ................................................................................................................................................. 116

5.6.3 Searching for Devices in the Network using ‘IndicatorBrowser’ .................................................................................... 118

5.6.4 Operation using the VNC Client Program .............................................................................................................................. 119

5.6.5 Operation via a Web Browser .................................................................................................................................................... 120

5.6.6 Resetting Network ......................................................................................................................................................................... 123

5.7 Help Function ............................................................................................................................................................................................. 124

5.8 Selecting the Operating Language ...................................................................................................................................................... 124

EN-II Sartorius

Page 5

PR 5500 Instrument Manual Table of Contents

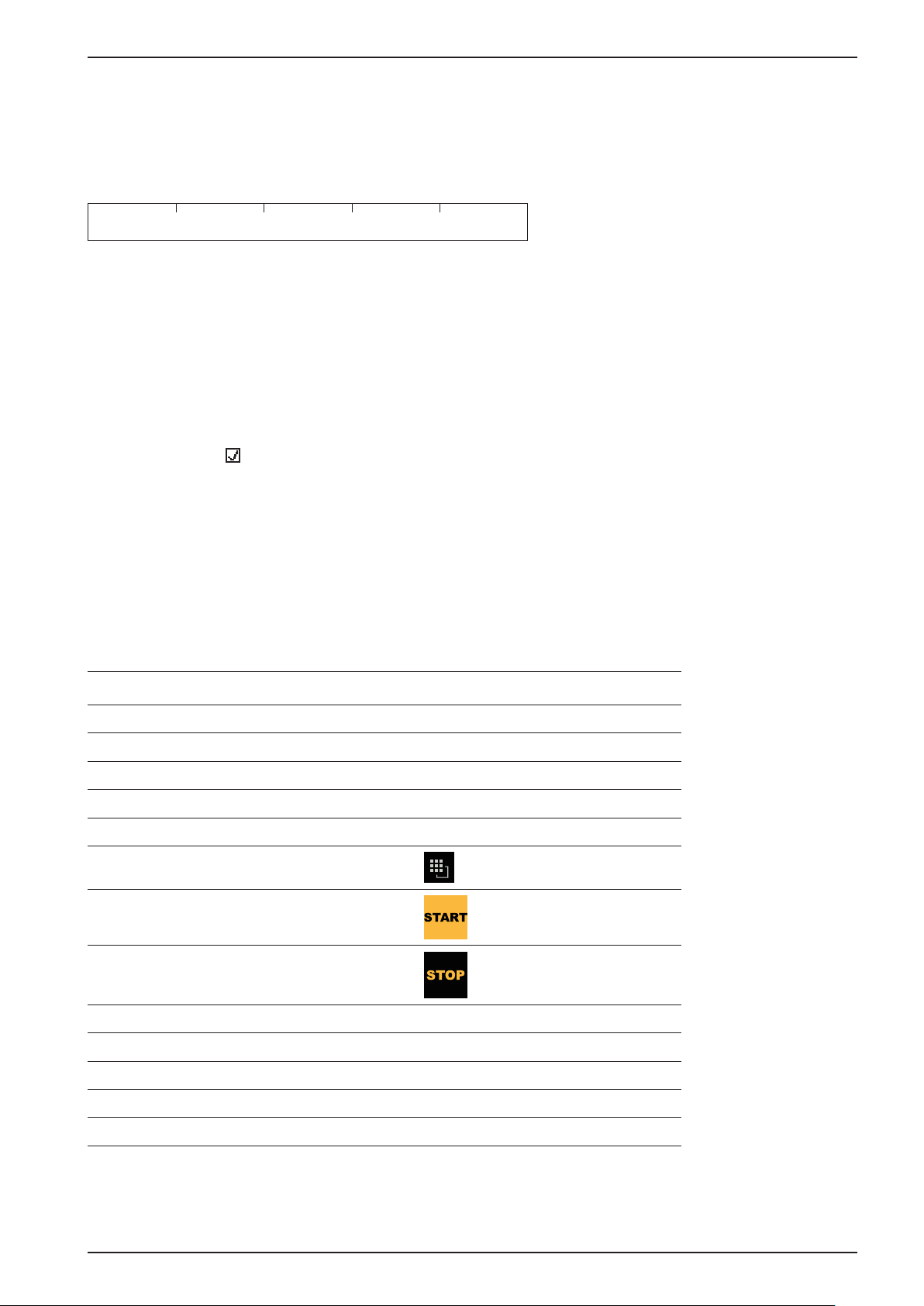

5.9 User Management.....................................................................................................................................................................................125

5.9.1 General Information .....................................................................................................................................................................125

5.9.2 Activating User Management .................................................................................................................................................... 125

5.9.3 Deactivating User Management................................................................................................................................................133

5.9.4 User Login/Logout..........................................................................................................................................................................134

5.10 System Menu .............................................................................................................................................................................................. 135

5.10.1 System Setup: Connected Devices ............................................................................................................................................135

5.10.2 System setup: Date & Time ......................................................................................................................................................... 136

5.10.3 System setup: Operating parameters ...................................................................................................................................... 137

5.10.4 System setup: Network parameters ......................................................................................................................................... 138

5.10.5 System setup: Network share connections ............................................................................................................................ 139

5.10.6 System setup: Fieldbus parameters .......................................................................................................................................... 140

5.10.7 System setup: Weighing point – Weighing point A ........................................................................................................... 140

5.10.8 System setup: Weighing point: Weighing point A: Internal weighing point ............................................................. 141

5.10.9 System setup: Weighing point: Weighing point A: xBPI scale ........................................................................................ 143

5.10.10 System setup: Weighing point: Weighing point A: SBI scale .......................................................................................... 144

5.10.11 System setup: Weighing point: Weighing point A: Pendeo Truck ................................................................................. 145

5.10.12 System setup: Weighing point: Weighing point A: Pendeo Process ............................................................................. 148

5.10.13 System setup: Weighing point: Weighing point A: PR-Net Weighing Point ..............................................................151

5.10.14 System setup: Weighing point: Weighing point A: Mettler-Scale .................................................................................151

5.10.15 System setup: Weighing point: Weighing point A: SMA scale .......................................................................................152

5.10.16 System setup: Display settings ..................................................................................................................................................152

5.10.17 System setup: License settings ..................................................................................................................................................152

5.10.18 System setup: User management ............................................................................................................................................. 153

5.11 Calibrating the Internal Weighing Point ........................................................................................................................................... 154

5.11.1 General Information .....................................................................................................................................................................154

5.11.2 Showing the Calibration Data ................................................................................................................................................... 155

5.11.3 Increased Resolution (10-fold) .................................................................................................................................................. 156

5.11.4 Selecting the Calibration Mode ................................................................................................................................................157

5.11.5 Determining the Maximum Capacity [Max] .......................................................................................................................... 159

5.11.6 Determining the Scale Interval [Scale interval] ................................................................................................................... 162

5.11.7 Determining the Dead Load [Dead load at] ........................................................................................................................... 163

5.11.8 Calibrating with Weight [Max at] ............................................................................................................................................165

5.11.9 Calibrating with mV/V [Max at] ................................................................................................................................................ 167

5.11.10 Calibrating the Scale with Load Cell Data (Smart Calibration) [by data] .................................................................... 168

5.11.11 Subsequent Dead Load Correction ........................................................................................................................................... 169

5.11.12 Linearity ............................................................................................................................................................................................ 170

5.11.13 Saving the Calibration ..................................................................................................................................................................172

5.11.14 Canceling Calibration ................................................................................................................................................................... 172

5.11.15 Display Units .................................................................................................................................................................................... 173

5.11.16 Parameter Input ............................................................................................................................................................................. 175

Sartorius EN-III

Page 6

Table of Contents PR 5500 Instrument Manual

5.12 Configuring a xBPI Scale ........................................................................................................................................................................ 182

5.12.1 General Information .....................................................................................................................................................................182

5.12.2 xBPI Parameter Input for Serial Interface .............................................................................................................................182

5.12.3 xBPI Parameter Input for Scale Function...............................................................................................................................183

5.12.4 Setting up an xBPI Platform ......................................................................................................................................................185

5.12.5 Setting the xBPI Dead Load ........................................................................................................................................................ 189

5.12.6 xBPI Calibration with the User Weight ................................................................................................................................... 190

5.12.7 xBPI Calibration with Automatic Weight Detection ..........................................................................................................192

5.12.8 xBPI Calibration with Default Weight .....................................................................................................................................193

5.12.9 xBPI Calibration with Internal Weight .................................................................................................................................... 194

5.12.10 xBPI Linearization .......................................................................................................................................................................... 196

5.12.11 xBPI Display Units .......................................................................................................................................................................... 198

5.13 Setting the SBI Scale ...............................................................................................................................................................................199

5.13.1 General Information .....................................................................................................................................................................199

5.13.2 Parameter for Serial Interface ................................................................................................................................................... 199

5.13.3 Parametereingabe .......................................................................................................................................................................... 200

5.14 Calibrating Digital Weighbridge Load Cell ‚Pendeo® Truck‘ ........................................................................................................ 201

5.14.1 General Information .....................................................................................................................................................................201

5.14.2 Parameter Input for Serial Interface ....................................................................................................................................... 201

5.14.3 Calibration Sequence .................................................................................................................................................................... 202

5.14.4 Search for load cells and set dead load .................................................................................................................................. 202

5.14.5 Search for Load Cells .................................................................................................................................................................... 203

5.14.6 View and Assign Load Cells ......................................................................................................................................................... 204

5.14.7 Calibrating Load Cells ................................................................................................................................................................... 207

5.14.8 Assign Load Cell Name ................................................................................................................................................................. 210

5.14.9 Service Function ............................................................................................................................................................................. 210

5.14.10 Corner Correction .......................................................................................................................................................................... 212

5.14.11 Parameter input ............................................................................................................................................................................. 214

5.14.12 Subsequent Dead Load Correction ........................................................................................................................................... 217

5.15 Calibrating Digital Precision Compression Load Cell ‘Pendeo® Process’ ................................................................................. 218

5.15.1 General Information .....................................................................................................................................................................218

5.15.2 Parameter Input for Serial Interface ....................................................................................................................................... 218

5.15.3 Calibration Sequence .................................................................................................................................................................... 219

5.15.4 Search for load cells and set dead load .................................................................................................................................. 219

5.15.5 Search for Load Cells .................................................................................................................................................................... 220

5.15.6 View and Assign Load Cells ......................................................................................................................................................... 221

5.15.7 Calibrating Load Cells ................................................................................................................................................................... 224

5.15.8 Assign Load Cell Name ................................................................................................................................................................. 227

5.15.9 Service Function ............................................................................................................................................................................. 227

5.15.10 Corner Correction .......................................................................................................................................................................... 229

5.15.11 Parameter input ............................................................................................................................................................................. 230

5.15.12 Subsequent Dead Load Correction ........................................................................................................................................... 233

EN-IV Sartorius

Page 7

PR 5500 Instrument Manual Table of Contents

5.16 PR-Net Weiging Point ............................................................................................................................................................................. 234

5.16.1 General Information .....................................................................................................................................................................234

5.16.2 Parameter Input ............................................................................................................................................................................. 234

5.17 Mettler-Scale ..............................................................................................................................................................................................236

5.17.1 General Information .....................................................................................................................................................................236

5.17.2 Parameter Input in Mettler-Scale Menu ................................................................................................................................ 236

5.17.3 Parameter Input for Serial Interface ....................................................................................................................................... 236

5.17.4 Parameters Input for Scale Function ....................................................................................................................................... 238

5.18 Setting the SMA Scale ............................................................................................................................................................................. 240

5.18.1 General Information .....................................................................................................................................................................240

5.18.2 Parameter for Serial Interface ................................................................................................................................................... 240

5.18.3 Parametereingabe .......................................................................................................................................................................... 241

5.19 General Parameter Settings ................................................................................................................................................................... 242

5.19.1 Equipment Settings ....................................................................................................................................................................... 242

5.19.2 Setting the Date and Time .......................................................................................................................................................... 253

5.19.3 Setting the Operating Parameters ...........................................................................................................................................255

5.19.4 Network Parameters .....................................................................................................................................................................260

5.19.5 Network Share Connections ....................................................................................................................................................... 262

5.19.6 Fieldbus Parameters ...................................................................................................................................................................... 266

5.19.7 Display Settings .............................................................................................................................................................................. 271

5.19.8 License Settings .............................................................................................................................................................................. 272

5.20 System Information ..................................................................................................................................................................................274

5.20.1 Showing the Version ..................................................................................................................................................................... 274

5.20.2 Showing the Status ....................................................................................................................................................................... 275

5.20.3 Showing Alarm information .......................................................................................................................................................276

5.20.4 Showing Hardware Options ........................................................................................................................................................ 277

5.20.5 ModBus-TCP IO Modules ............................................................................................................................................................. 278

5.20.6 Browsing the Alibi Memory ........................................................................................................................................................ 279

5.20.7 Showing Calibration Check Numbers ...................................................................................................................................... 279

5.20.8 Showing Pendeo data ...................................................................................................................................................................279

5.20.9 Displaying Event Log ..................................................................................................................................................................... 282

5.20.10 Printing Out Configuration Settings ....................................................................................................................................... 283

Sartorius EN-V

Page 8

Table of Contents PR 5500 Instrument Manual

6 Extended Functions ....................................................................................................................................................... 284

6.1 System Maintenance ................................................................................................................................................................................284

6.1.1 General Information .....................................................................................................................................................................284

6.1.2 Saving to selected Media (Backup) .......................................................................................................................................... 284

6.1.3 Restoring Backup Data from External Media .......................................................................................................................289

6.1.4 Exporting to selected Media ......................................................................................................................................................295

6.1.5 Importing Data from External Media ...................................................................................................................................... 298

6.1.6 Alibi Memory Maintenance ........................................................................................................................................................ 303

6.1.7 SD Card Maintenance ................................................................................................................................................................... 314

6.1.8 Creating a Service Report ...........................................................................................................................................................316

6.1.9 Switching Off the Device ............................................................................................................................................................317

6.1.10 Updating the Software ................................................................................................................................................................318

6.1.11 Resetting the Device to the Factory Settings ....................................................................................................................... 329

6.1.12 Hardware Test .................................................................................................................................................................................330

6.1.13 Functions via the WEB Site ......................................................................................................................................................... 338

6.2 Alibi Memory .............................................................................................................................................................................................. 346

6.2.1 General Information .....................................................................................................................................................................346

6.2.2 Erasing the Alibi Memory ............................................................................................................................................................ 346

6.2.3 Browsing the Alibi Memory ........................................................................................................................................................ 348

6.2.4 Exporting and Printing Alibi Data Records ............................................................................................................................ 351

6.3 BIOS Menu ..................................................................................................................................................................................................352

6.3.1 General Information .....................................................................................................................................................................352

6.3.2 Accessing the BIOS Menu............................................................................................................................................................352

6.3.3 Troubleshooting Menu ................................................................................................................................................................. 354

EN-VI Sartorius

Page 9

PR 5500 Instrument Manual Table of Contents

7 ModBus Protocol ........................................................................................................................................................... 356

7.1 General Description .................................................................................................................................................................................. 356

7.2 ModBus-RTU ............................................................................................................................................................................................... 357

7.3 ModBus-TCP/UDP......................................................................................................................................................................................358

7.4 Functions .....................................................................................................................................................................................................359

7.5 Error Messages ........................................................................................................................................................................................... 364

7.6 Word Addresses .........................................................................................................................................................................................365

8 EW Com Protocol ........................................................................................................................................................... 366

8.1 Weight Function Commands ................................................................................................................................................................. 366

8.2 Other Commands ......................................................................................................................................................................................367

8.3 SPM Commands ......................................................................................................................................................................................... 368

8.4 Error Messages for EW Com Commands............................................................................................................................................369

9 Repairs and Maintenance ............................................................................................................................................. 370

9.1 Battery for Date/Time .............................................................................................................................................................................. 370

9.2 Rechargeable Battery for Voltage Supply ......................................................................................................................................... 370

9.3 Solder Work ................................................................................................................................................................................................370

9.4 Cleaning ....................................................................................................................................................................................................... 371

10 Disposal ........................................................................................................................................................................... 372

11 Error Messages ............................................................................................................................................................... 373

11.1 Error Messages in Measuring Circuit .................................................................................................................................................. 373

11.2 Error Messages with xBPI Scales .......................................................................................................................................................... 375

11.2.1 Error Messages ................................................................................................................................................................................ 375

11.2.2 Error during "Set zero" and "Set tare" .................................................................................................................................... 376

11.3 Error Messages with Pendeo® Load Cells ..........................................................................................................................................377

11.4 Error messages with PR-Net Weighing Point ..................................................................................................................................378

11.5 Error messages with Type ‚Mettler-Scale‘ Weighing Point .......................................................................................................... 378

11.6 Error Messages during Calibration ...................................................................................................................................................... 379

11.6.1 Determining the Maximum Capacity (MAX) ......................................................................................................................... 379

11.6.2 Determining the Scale Interval .................................................................................................................................................380

11.6.3 Determining the Dead Load........................................................................................................................................................381

11.6.4 Calibrating with Weight .............................................................................................................................................................. 382

Sartorius EN-VII

Page 10

Table of Contents PR 5500 Instrument Manual

12 Specifications ................................................................................................................................................................. 383

12.1 Note on Using ‘Free Software’ .............................................................................................................................................................. 383

12.2 Decoding the Serial Number ................................................................................................................................................................. 383

12.3 General Data ............................................................................................................................................................................................... 383

12.3.1 Battery for Date/Time ................................................................................................................................................................... 383

12.3.2 Rechargeable Battery for Voltage Supply .............................................................................................................................. 383

12.3.3 Display ............................................................................................................................................................................................... 383

12.3.4 Power Connection 230 V AC ...................................................................................................................................................... 383

12.3.5 Power Connection 24 V DC.........................................................................................................................................................384

12.4 Effect of Ambient Conditions ............................................................................................................................................................... 384

12.4.1 Ambient Conditions ......................................................................................................................................................................384

12.4.2 Electromagnetic Compatibility (EMC) ..................................................................................................................................... 384

12.4.3 RF Interference Suppression .......................................................................................................................................................385

12.5 Mechanics .................................................................................................................................................................................................... 385

12.5.1 Design ................................................................................................................................................................................................ 385

12.5.2 Dimensions ....................................................................................................................................................................................... 385

12.5.3 Weights ............................................................................................................................................................................................. 385

12.6 Documentation on the Enclosed CD ................................................................................................................................................... 385

13 Appendix ......................................................................................................................................................................... 386

13.1 Configuration Printout ...........................................................................................................................................................................386

13.2 Test Printout ............................................................................................................................................................................................... 388

13.3 Alibi Printout .............................................................................................................................................................................................. 389

13.4 LEDs ............................................................................................................................................................................................................... 390

13.5 Terminal Coding ........................................................................................................................................................................................391

13.6 Exchanging the Plug-In Cards .............................................................................................................................................................. 392

13.6.1 Safety Information ........................................................................................................................................................................ 392

13.6.2 Optional and Fieldbus Cards ....................................................................................................................................................... 392

13.7 Replacing the Device ...............................................................................................................................................................................393

13.8 Replacing the SD Card ............................................................................................................................................................................. 395

EN-VIII Sartorius

Page 11

PR 5500 Instrument Manual Introduction

1 Introduction

tt Please read all the instructions carefully and completely before using the instrument.

tt Read the safety precautions carefully.

tt These instructions are part of the product. Keep them in a safe and easily accessible location.

Symbols and Signs

The following symbols are used in this manual:

Warning of dangerous electrical voltage.

DANGER indicates death or severe, irreversible personal injury which will occur if the

corresponding safety measures are not observed.

!

Danger

Warning of a hazard area.

WARNING indicates that death or severe, irreversible injury may occur if the corresponding

safety measures are not observed.

!

Warning

Warning of personal injury and/or property damage.

CAUTION indicates that minor, reversible injury or damage to property may occur if the

corresponding safety measures are not observed.

!

Caution

Note

tt Indicates a required action

ty Describes the result of an action

- Indicates an item in a list

User tips, useful information, and notes.

[ ] Encloses menu items and soft keys

Hotline

Phone: +49.40.67960.444

Fax: +49.40.67960.474

E-mail: technical.support@sartorius.com

Sartorius EN-1

Page 12

Safety Information PR 5500 Instrument Manual

2 Safety Information

2.1 Electrical Protective Class

Warning!

This instrument has been built and tested in compliance with the safety regulations

for measuring and control instrumentation for protective class I (protective grounding

!

Warnung

2.2 Intended Use

This instrument is only intended for use in weighing and metering systems, and is especially well-suited for tank

and container scales, weigh bridges, platform weighers, crane weighers, dispensing systems and as a weighing

indicator in intelligent control systems. Product operation, commissioning and maintenance must be performed

by trained and qualified personnel who are aware of and able to deal with the related hazards and take suitable

measures for self-protection.

The instrument reflects the state of the art. No warranty is given that the product is free of faults, especially not

in conjunction with third-party software and hardware components required for operation.

The manufacturer does not accept any liability for damage caused by other system components or due to

incorrect use of the product. The use of this product signifies recognition of the stipulations listed above.

conductor) according to IEC 1010/EN 61010 or VDE 0411. The instrument was in

perfect condition with regard to safety features when it left the factory. To maintain

this condition and to ensure safe operation, the operator must follow the instructions

and observe the warnings in this manual.

2.3 Initial Inspection

Check the contents of the consignment for completeness. Check the contents visually to determine whether any

damage has occurred during transport. If there are grounds for rejection of the goods, a claim must be filed with

the carrier immediately. The Sartorius Intec sales or service organization must also be notified.

EN-2 Sartorius

Page 13

PR 5500 Instrument Manual Safety Information

2.4 Before Commissioning

Visual inspection!

Before commissioning as well as after storage or transport, inspect the device visually for

signs of mechanical damage.

2.4.1 Installation

Design Protection class Installation

Control cabinet housing IP 65, back IP 20 Control Panel Cut-Out

To ensure proper cooling of the instrument, make sure air circulation around the instrument is not blocked.

Avoid exposing the instrument to excessive heat; e.g., from direct sunlight. Ambient conditions must be taken

into account at all times.

With outdoor mounting, make sure that adequate weather protection is provided (for temperatures,

see Chapter 12.4.1).

Sartorius EN-3

Page 14

Safety Information PR 5500 Instrument Manual

2.4.2 Opening the Instrument

High Voltage!

Working on the instrument while it is switched on may have life-threatening

consequences.

!

Danger

This instrument contains electrostatically sensitive components. For this reason, an equipotential bonding

conductor must be connected when working on the open instrument (antistatic protection).

Disconnect the instrument from the supply voltage.

When removing covers or parts using tools, live parts or terminals may be exposed.

Please note that capacitors in the instrument may still be charged even after

disconnecting the device from all voltage sources.

2.4.3 Mains Connection and Protective Grounding Conductor for PR 5500

2.4.3.1 Version 230 V AC

Mains connection

Safe interruption of both supply voltage conductors must be provided for, either by

disconnecting the power connector or using a separate switch.

The instrument is protected via two fuses (see Chapter 12.3.4) on the back of the

device (primary side).

The instrument is equipped with a wide range power supply and covers AC systems

with a frequency of 50 Hz/60 Hz and a voltage range of 100 V AC to 240 V AC

+10%/-15 % automatically (without manual selection).

The power supply is protected against short circuits and overloads, and disconnects

automatically in case of a fault.

If the electrical protection has triggered:

- Disconnect the device from all power sources and wait at least 1 minute.

- Determine and eliminate the cause of the error.

- Reconnect the device to the supply voltage.

Protective grounding conductor

The instrument must be connected to a protective ground via a protective grounding

conductor (PE) in the power connector.

The power cable contains a protective grounding conductor which must not be

interrupted inside or outside the device. The protective grounding conductor is

connected to the back of the housing inside the instrument.

EN-4 Sartorius

Page 15

PR 5500 Instrument Manual Safety Information

2.4.3.2 Version 24 V DC

Mains connection

This version is designed for 24 V direct current.

The supply is established via three spring clamp terminals (+ PE -). The

instrument is protected against incorrect polarity.

Protective grounding conductor

The protective grounding must be connected to the central

terminal (PE).

Fuse

The instrument is protected in the + line via a fuse (see Chapter 12.3.5)

inside the device (primary side).

Sartorius EN-5

Page 16

PR 5500 Instrument Manual Safety Information

2.5 RF Interference Suppression

The device is intended for use in the industrial sector and can cause RF interference if used in residential areas

(see Chapter 12.4.3). In this case, the operator may be required to put suitable countermeasures in place.

2.6 Failure and Excessive Stress

If there is any reason to assume that safe operation of the instrument is no longer ensured, shut it down and

make sure it cannot be used. Safe operation is no longer ensured if any of the following is true:

- The instrument is physically damaged.

- The instrument does not function.

- The instrument has been subjected to stresses beyond the tolerance limits (e.g., during storage or transport).

2.7 Important Note

Make sure that the construction of the instrument is not altered to the detriment of safety. In particular,

leakage paths, air gaps (of live parts) and insulating layers must not be reduced. Sartorius Intec cannot be held

responsible for personal injury or property damage caused by an instrument repaired incorrectly by an operator

or installer.

2.8 Repairs and Maintenance

Repairs are subject to inspection and must be carried out at Sartorius Intec. In case of defect or malfunction,

please contact your local Sartorius Intec dealer or service center for repair. When returning the instrument for

repair, please include a precise and complete description of the problem.

Maintenance work must be carried out only by a trained technician aware of the involved hazards, whereby the

relevant precautions must be taken in account.

2.8.1 Static Sensitive Components

This instrument contains electro-statically sensitive components. Therefore, potential equalization must be

provided when working on the device (antistatic protection).

2.8.2 Replacing Fuses

Warning!

The use of repaired fuses and bypassing the fuse holder is prohibited.

Only the fuses specified in Chapter 12.3 are allowed.

!

Warning

Sartorius EN-5

Page 17

PR 5500 Instrument Manual Process Controller

3 Process Controller

3.1 General Information

This instrument is equipped with a TFT color display, and a function/alphanumeric keypad. With the

corresponding application, this device is a powerful system for managing/documenting weighing and dosing

processes. It combines the functions of a user-friendly interface as well as a weighing and dosing instrument,

PLC and interfaces.

The instrument is programmable according to the IEC 61131-3 standard (requires the PR 1750/60 development

tool accessory).

3.2 Overview of the Instrument

- Accuracy 10.000 d at 0,5 µV/d for the weighing electronics

- High-speed conversion with response times from 5 msec

- Weight display with status and weight unit on a TFT color display

- Housing for installation in a control cabinet. Protection type front IP 65, else IP 20

- Integrated LAN connection (10/100 Mbps) for data transmission

- USB 2.0 connection (Type A, i = 200 mA), integrated for printer, USB stick, PC keyboard, barcode scanner,

external splitter (hub)

- SD card slot (incl. SD card)

- Integrated RS-232 interface, e.g. for connecting a PC, printer or remote display

- Can be expanded using the following plug-in cards:

- 2x RS-485 interface card PR 5500/04

- Analog E/A interface card PR 5500/07

- Weighing electronics board PR 5500/10 (W1)

- Digital E/A interface card PR 5500/12

- Digital E/A interface card PR 5500/13

- Digital E/A interface card PR 5500/17

- 2x RS-232 interface card PR 5500/32

- Fieldbus cards PR 1721/6x

- Wide range power supply for 100 to 240 V AC, protection class I (protective grounding conductor)

- Version for 24 V direct current

- Plug-in connections on the rear side of the device for load cells, inputs/outputs, LAN connection, serial

interfaces

- Alternative operation using PC tool (Browser/VNC)

- Calibration using weights, by entering mV/V values, or directly, using load cell data (Smart Calibration)

- Software configuration of the interface cards, e.g. for remote display or printer

- Analog test for the weighing electronics

- Overwrite protection:

- via a max. of 3 CAL switches (two on the main board and one on the weighing electronics board)

- via software

Sartorius EN-7

Page 18

Process Controller PR 5500 Instrument Manual

Communication Protocols

For the internal RS-232: Fieldbus slave (accessories):

- Remote display protocol - PR 1721/61 ProfiBus DP

- Printer - PR 1721/64 DeviceNet

- ModBus protocol - PR 1721/65 CC Link

- xBPI protocol - PR 1721/66 ProfiNet I/O

- SBI protocol - PR 1721/67 EtherNet IP

- EW-Com protocol

For the internal LAN interface:

- ModBus-TCP

- Ethernet-TCP/IP

- OPC

EN-8 Sartorius

Page 19

PR 5500 Instrument Manual Process Controller

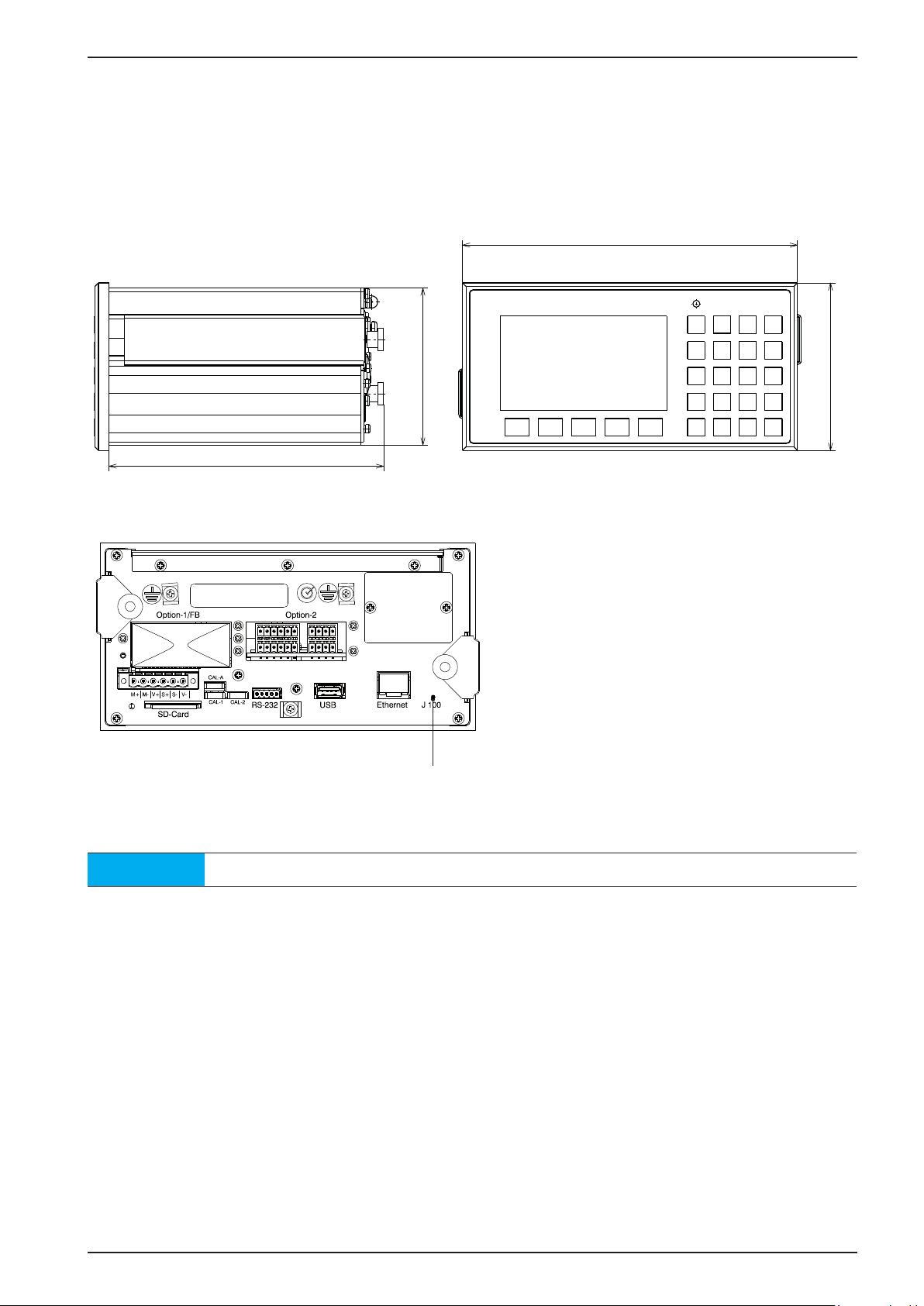

3.3 Housing

192

3.3.1 Housing dimensions

The keypad and the display form one unit with the front. A rectangular cut-out is required for the installation.

Cable connections are made at the back of the housing.

90

157

Front view Side view

Reset key

Back view

96

Note

All dimensions in mm.

Sartorius EN-9

Page 20

Process Controller PR 5500 Instrument Manual

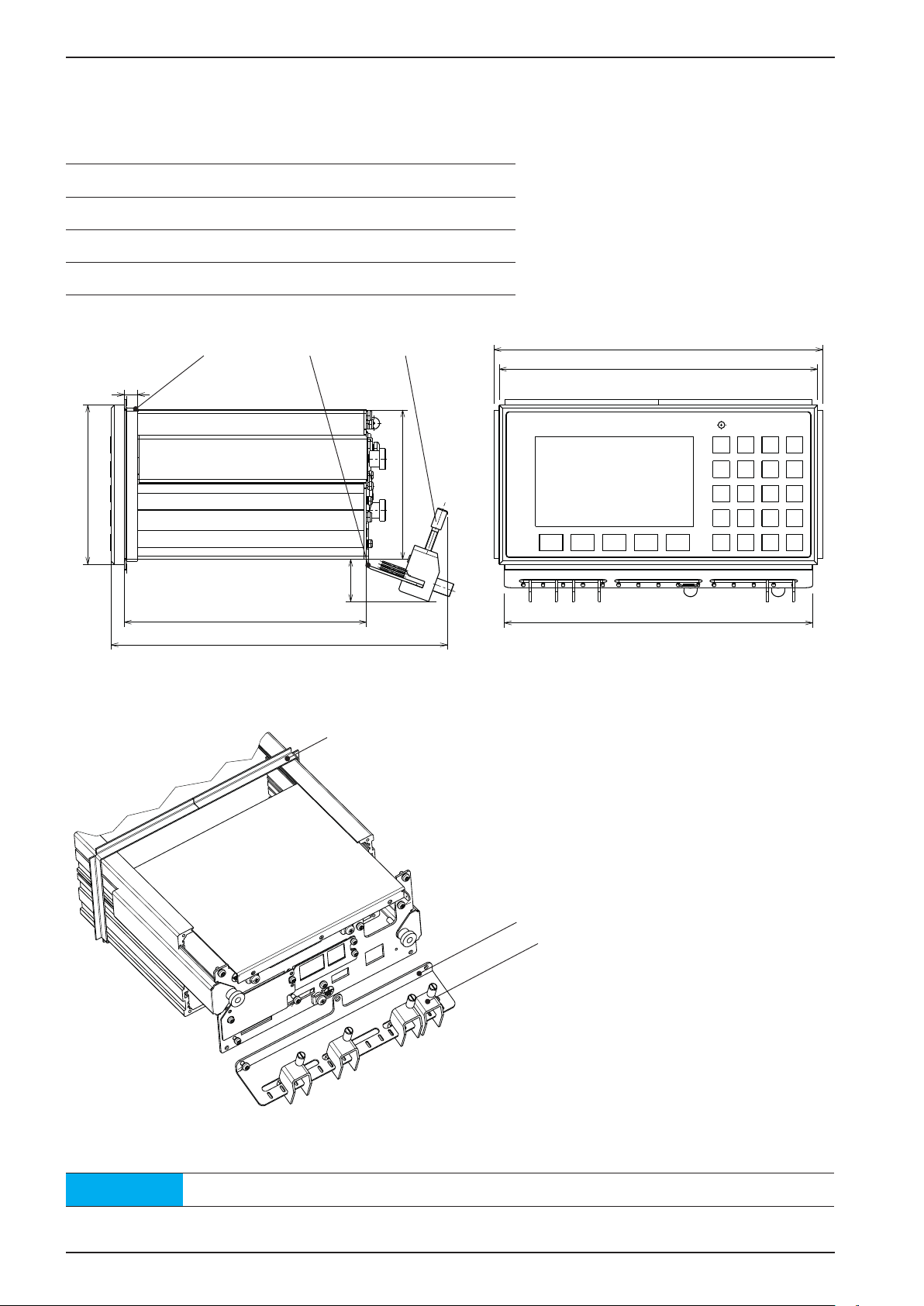

3.3.2 Housing Dimensions with Strain Relief and Reinforcing frame

96

199

The dimensions with the following options must be observed for installation:

Pos. Designation

1 Reinforcing frame

2 Screen clamping rail

3 Cable clamps

1 2 3

8

90

25

146 186

203

Side view Front view

1

192

2

3

Back view

Note

All dimensions in mm.

EN-10 Sartorius

Page 21

PR 5500 Instrument Manual Process Controller

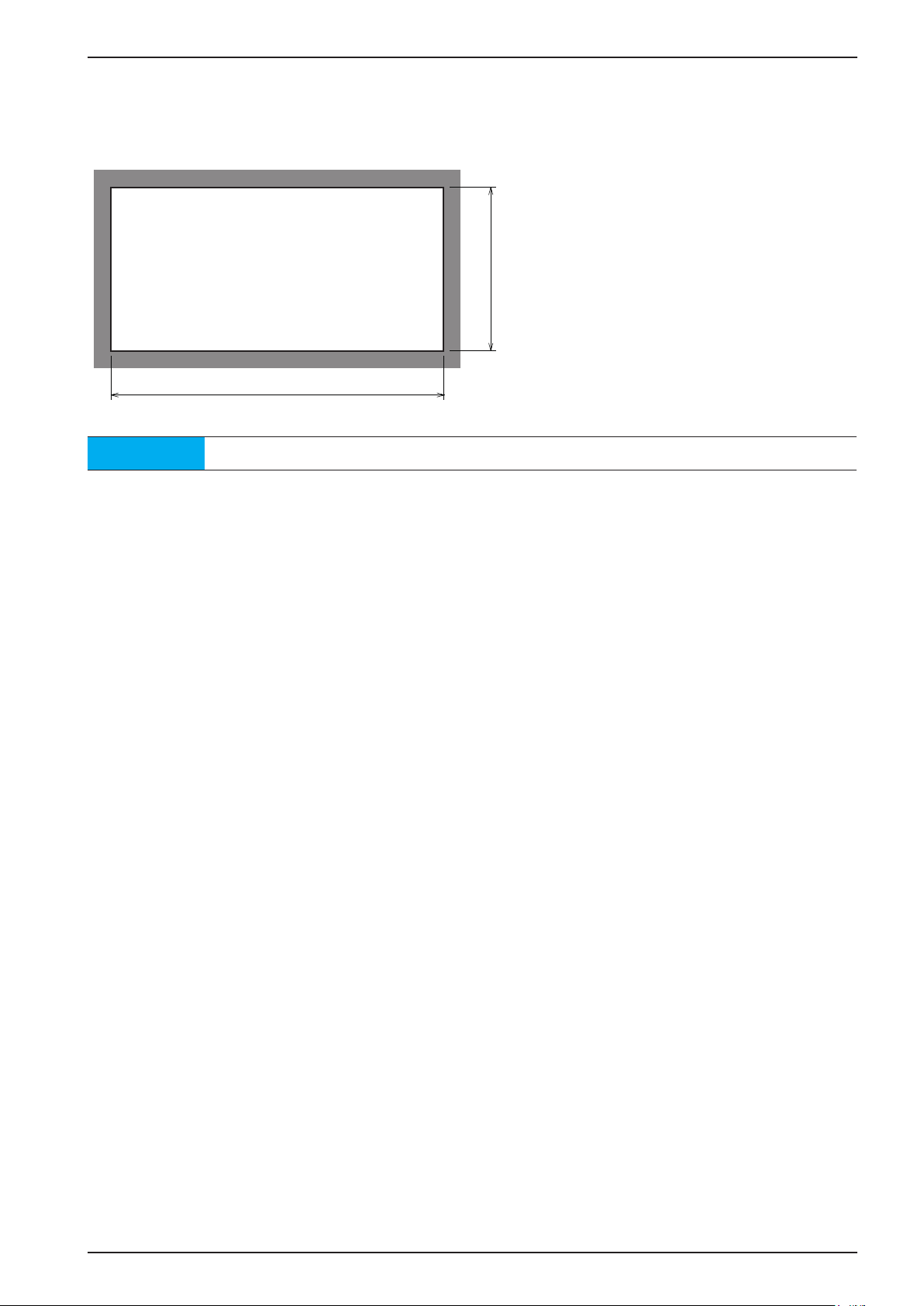

3.3.3 Control Panel Cut-Out

The control panel cut-out must be made before installing the unit.

+0.5

91

+0.5

187

Note

All dimensions in mm.

Sartorius EN-11

Page 22

Process Controller PR 5500 Instrument Manual

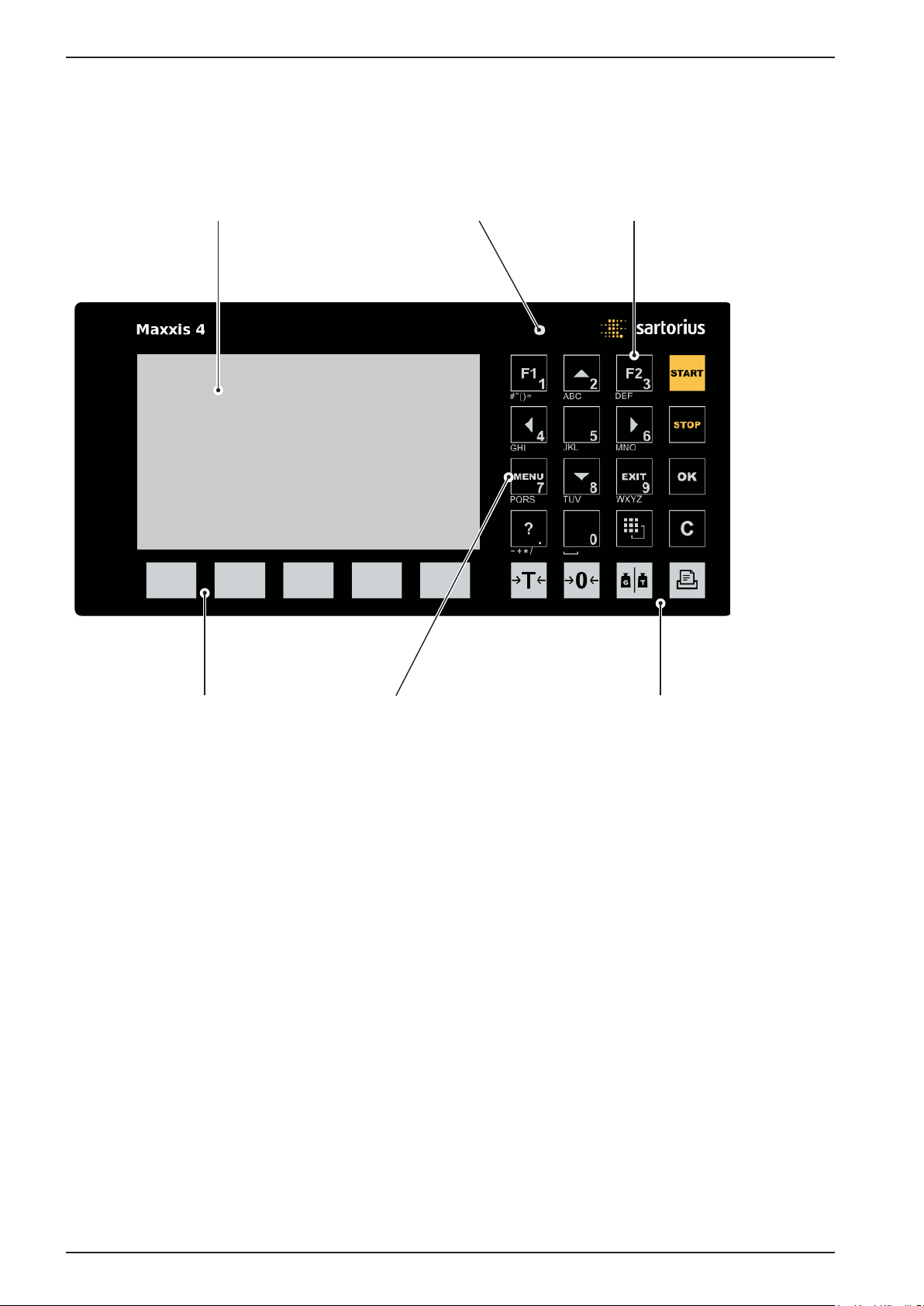

3.4 Display and Control Panel

3.4.1 Overview

4.3” color display LED Alphanumeric/function keys

Softkeys Navigation/Menu keys Indicator keys

EN-12 Sartorius

Page 23

PR 5500 Instrument Manual Process Controller

3.4.2 Display

The TFT display shows weight values of up to 7 digits with a decimal point and a plus or minus sign. Available

weight units are t, kg, g, mg, lb and oz.

The current weight value is displayed under the weight display as a bar graph in relation to the maximum

capacity. When the maximum capacity (Max) reaches 100 %, the bar graph is located on the right.

Bargraph Weight type/polarity sign/Standstill Status display Weight value Symbols/Mass unit

info line

Sartorius EN-13

Page 24

Process Controller PR 5500 Instrument Manual

Value type/Polarity sign Zero/Standstill/Dosing/Monitor. Symbols Mass unit

B

G

NET

T

PT

no indication

User

Setp

Diff

Gross weight Weight value

standstill

Gross weight in NTEP or

NSC mode

Net weight

(Net = gross - tare)

Tare weight

Preset tare

not tared

- Test value

- Gross, not tared

additional weight value,

application-specific

function

U

The gross weight

value is within ±¼ d

of zero

Filling mode:

flashes when filling is

“held”; rapid flashing

indicates “error”

Pendeo load cells:

plausibility monito-

ring; average value

deviation of each load

cell

Pendeo load cells:

Temperature control;

1…n load cells are

above/below the permissible temperature

!

R1

R2

R3

WP-A

Max

Min

t

kg

g

mg

lb

oz

Value not permissible in

legal metrology (e.g. 10-fold

resolution, deactived load cell)

Range 1

Range 2

Range 3

Weighing point A

Maximum capacity

(weighing range)

Minimum weight

+

–

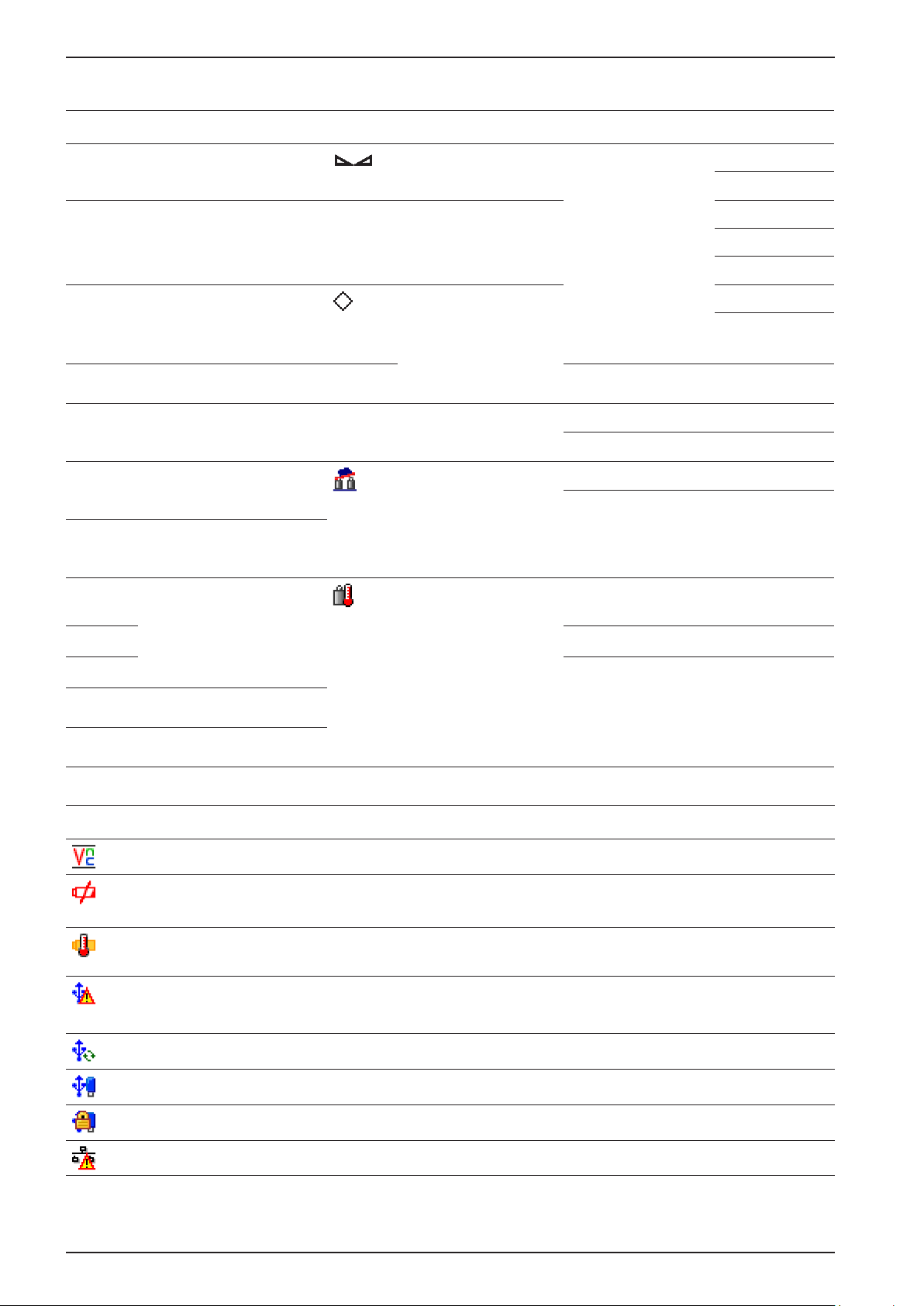

Status icons in the info line

Icon Description

Positiv value

Negativ value

Remote control via VNC (Virtual Network Computing) is active.

- The clock battery is empty.

- The standby battery is empty.

The standby battery is too hot and is not charging. If this does not go away, then the ambient

temperature must be checked, see Chapter 3.4.3.2.

- A USB device has been connected that is not supported.

- The max. current of i

Check newly connected devices.

USB stick recognized and ready for use.

Stick is in use and may not be removed.

IP address conflict in network settings

= 200 mA has been exceeded.

max

EN-14 Sartorius

Page 25

PR 5500 Instrument Manual Process Controller

3.4.3 Operating Elements

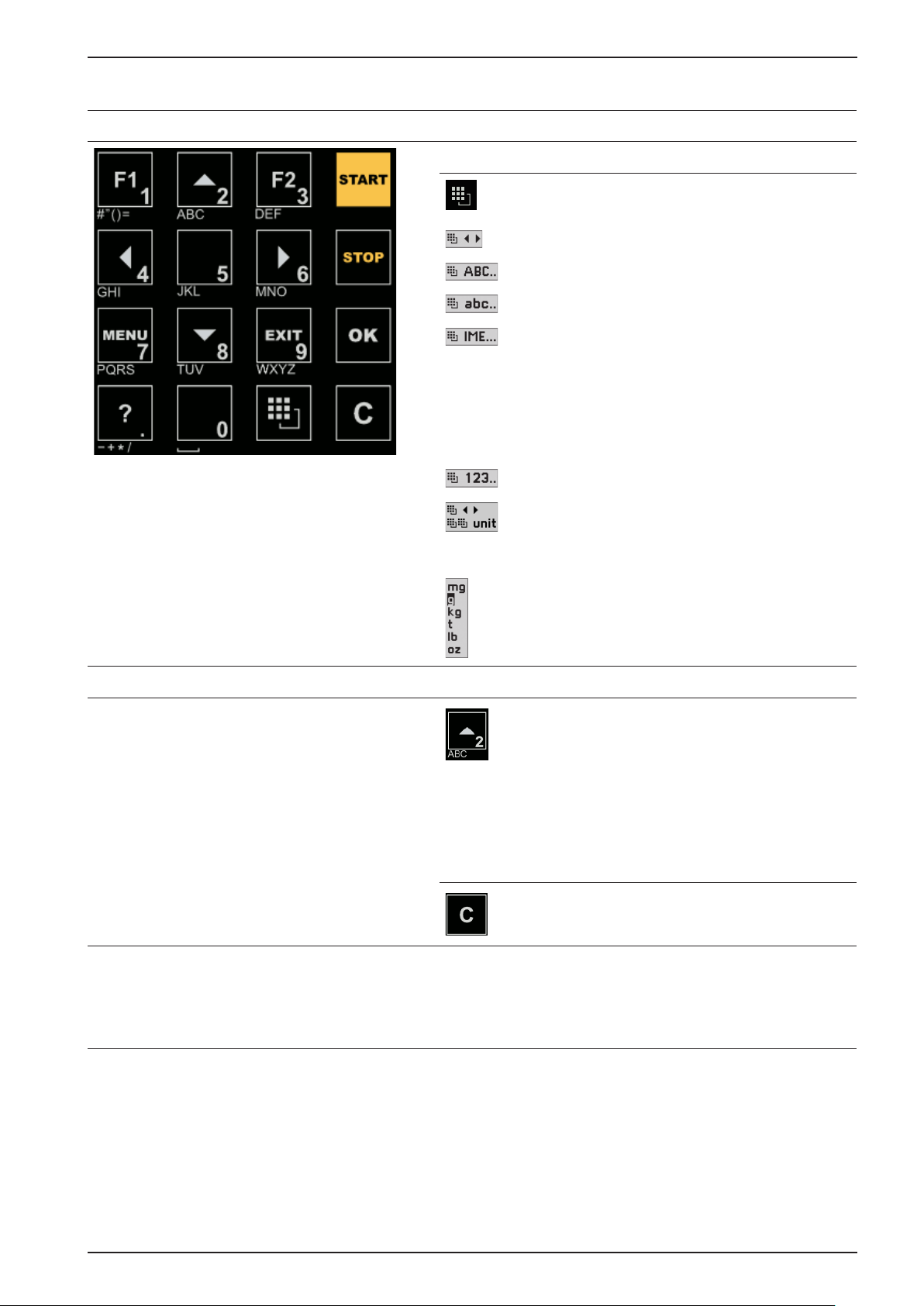

3.4.3.1 Front keys

The following table shows the basic meanings of symbols for the front keys. The keys could have additional

meanings depending on the applications used.

Indicator keys

Tare

The current gross weight is stored in

the tare memory if

- the weight value is stable

- the device is not in error status

(function dependent on

configuration)

Sets gross weight to zero if

- the weight value is stable

- the weight is within the zero

(function dependent on

configuration)

Application keys

Starts an application-specific

printout.

Display gross/tare weight

You switch to the next weight by

pressing the key (only tared scale).

During calibration, pressing this key

switches the weight to a 10-fold

resolution for 5 seconds.

setting range

Sartorius EN-15

Page 26

Process Controller PR 5500 Instrument Manual

Navigation/menu keys

Function keys

F1

F2

Scroll up in the menu

Scroll down in the menu

- Cursor moves to the left

- Selection

- Exit the menu window

- Cursor moves to the right.

- Selection

- Confirm entry/selection

Assign with a defined function

(Operating parameters menu).

Assign with a defined function

(Operating parameters menu).

OK

EXIT

C

Soft key

1… 5

MENU

Confirm entry/selection

- Cancel entry/selection (after a

security prompt), without saving

the change.

- Exit the parameter/menu

window

Pressing the Delete key deletes

individual characters (within an

entry) or entire character sections,

see also page 17.

Select corresponding menu

functions, see also Chapter 3.4.3.2.

Switches to the Operating menu.

Starts an application-specific

function.

Stops an application-specific

function.

?

LED

Operating state Color LED status

Normal operation turned off

Power failure <5 seconds red flashing slowly After 5 seconds, the unit will

Power failure >5 seconds red flashing quickly The device performs a data

After backup the power failure is still

existing

Power voltage is on turned off The device performs a warm start,

Displays the corresponding Help

window.

continue normally.

backup. Is then the power on,

the unit returns to the normal

operation (LED turned off).

turned off The unit turns off.

see Chapter 5.1.3.

EN-16 Sartorius

Page 27

PR 5500 Instrument Manual Process Controller

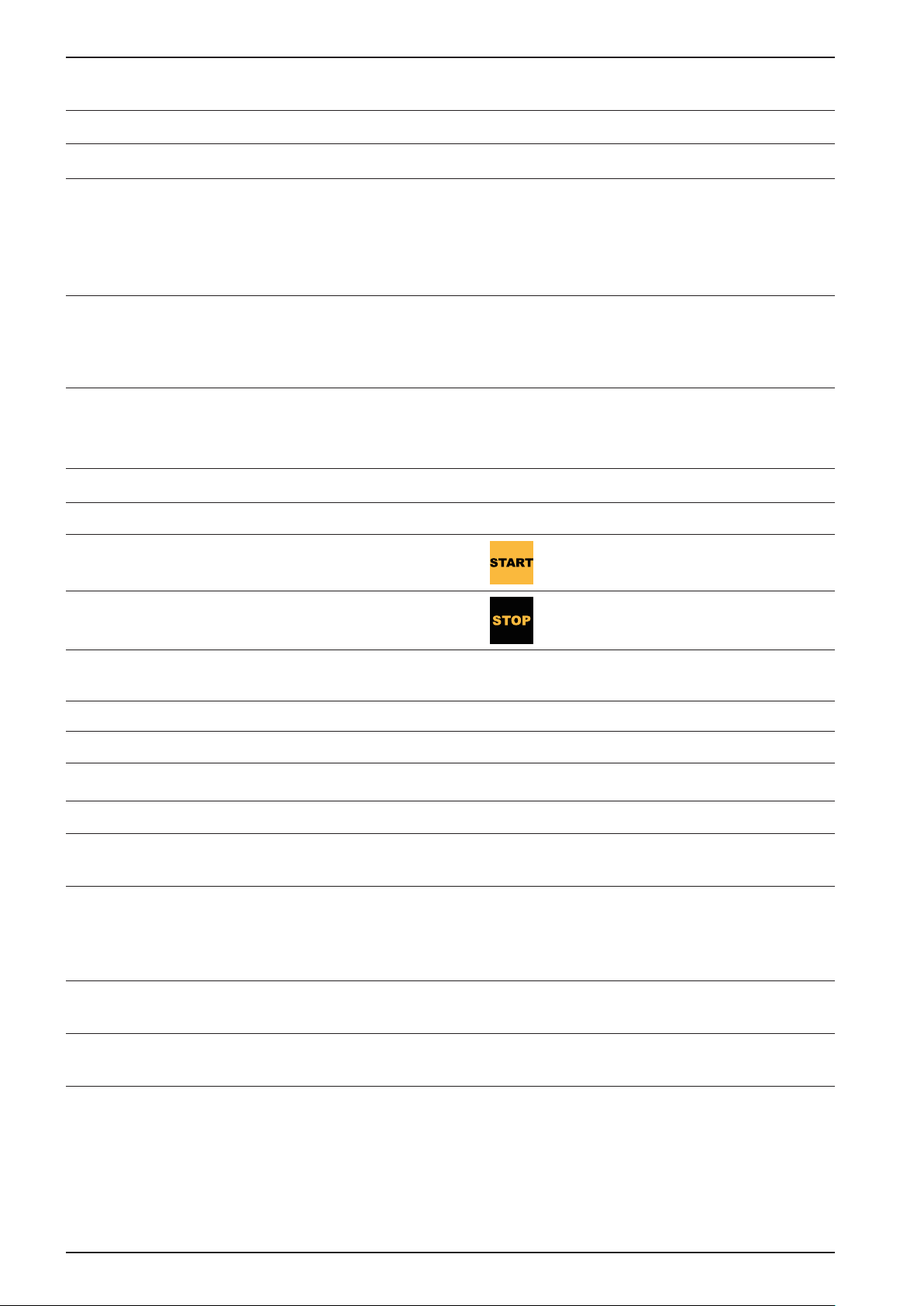

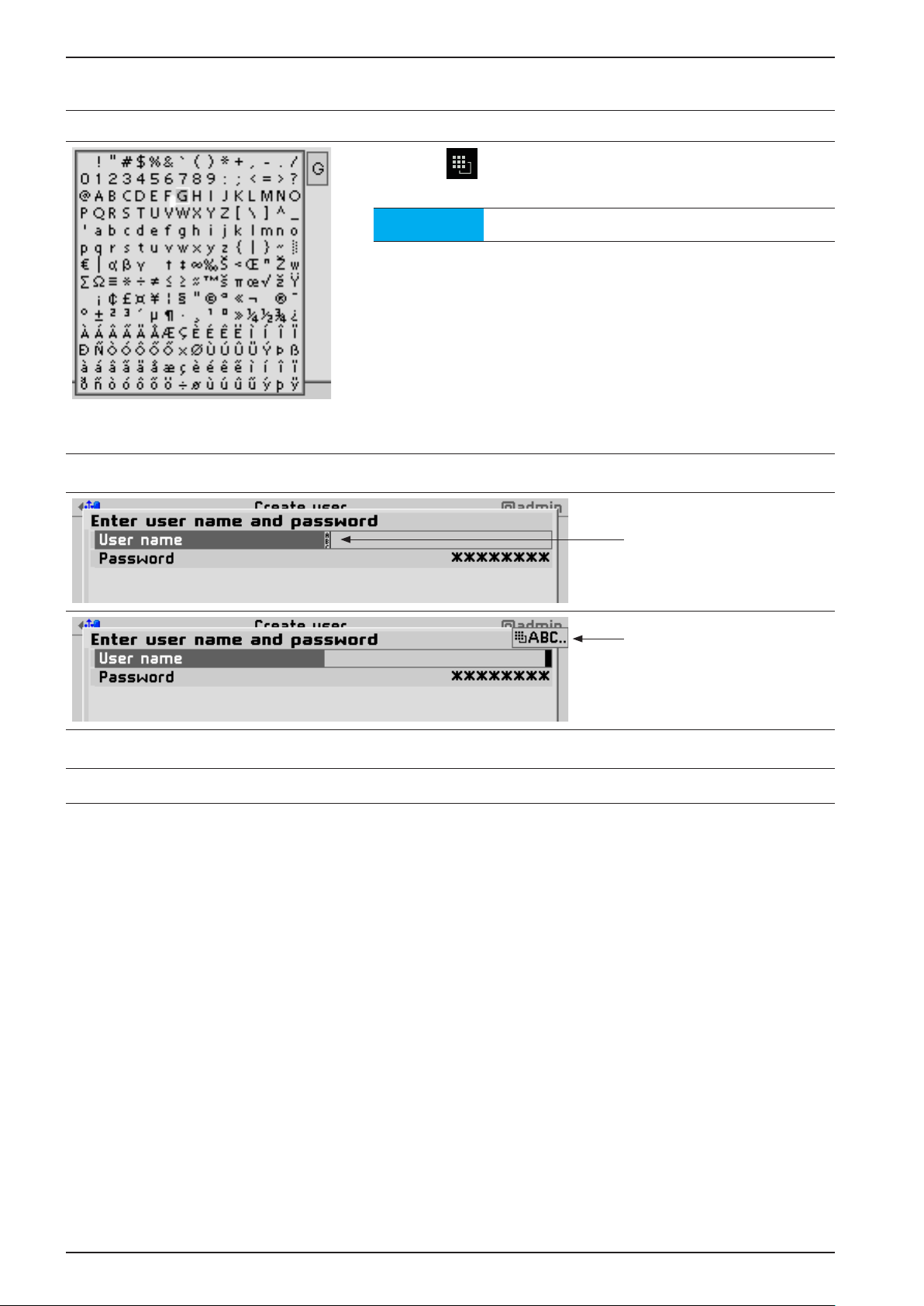

Alphanumeric keypad

Toggle key

Pressing this will toggle between the following

input modes:

- Cursor

- Uppercase letters

- Lowercase letters

- Pinyin

When Chinese was selected or set under

[Operating parameters] - [Input method].

- Hepburn

When Japanese was selected or set under

[Operating parameters] - [Input method].

- Numbers

- Units

Double-click on the toggle key opens a small

selection window.

Select the unit with cursor keys / and

confirm with

Input without character table

Pressing this once will display the first character,

e.g. 'A' in the cursor position. Pressing it twice

will display 'B' in the cursor position and threetimes will display 'C.'

Waiting approx. 2 seconds will complete the

character entry.

If only numeric values are required for input,

letters are not enabled.

You can delete the character to the left of the

cursor by pressing the Delete key C during entry.

Numerical value input (e.g. weight value):

Delete the content of the input field by pressing

the Delete key

OK.

C.

Sartorius EN-17

Page 28

Process Controller PR 5500 Instrument Manual

Input with character table

Double-clicking the key displays the character

table.

Input field

Note

The toggle function is turned off.

Procedure

tt Select the desired character with the cursor.

ty The selected character is shown magnified in

the field at the top right.

tt Press the

the input field.

tt Another double-click on the toggle key and

other characters can be input as described

previously.

OK key to enter the character in

Left of the input field is

displayed whether numeric

and/or alphabetical

characters can be entered.

The respective setting is

displayed.

Keyboard shortcuts

STOP

+

EXIT

Trigger a cold start, see also Chapter 5.19.3.

EN-18 Sartorius

Page 29

PR 5500 Instrument Manual Process Controller

3.4.3.2 Operation Using Soft Keys

The functions of the five soft keys below the graphic display are indicated in the bottommost text line of the

display. In the descriptions of operating sequences which entail the use of soft keys, the soft key function to be

selected is shown in square brackets; the soft key symbol is not displayed, e.g. [Save].

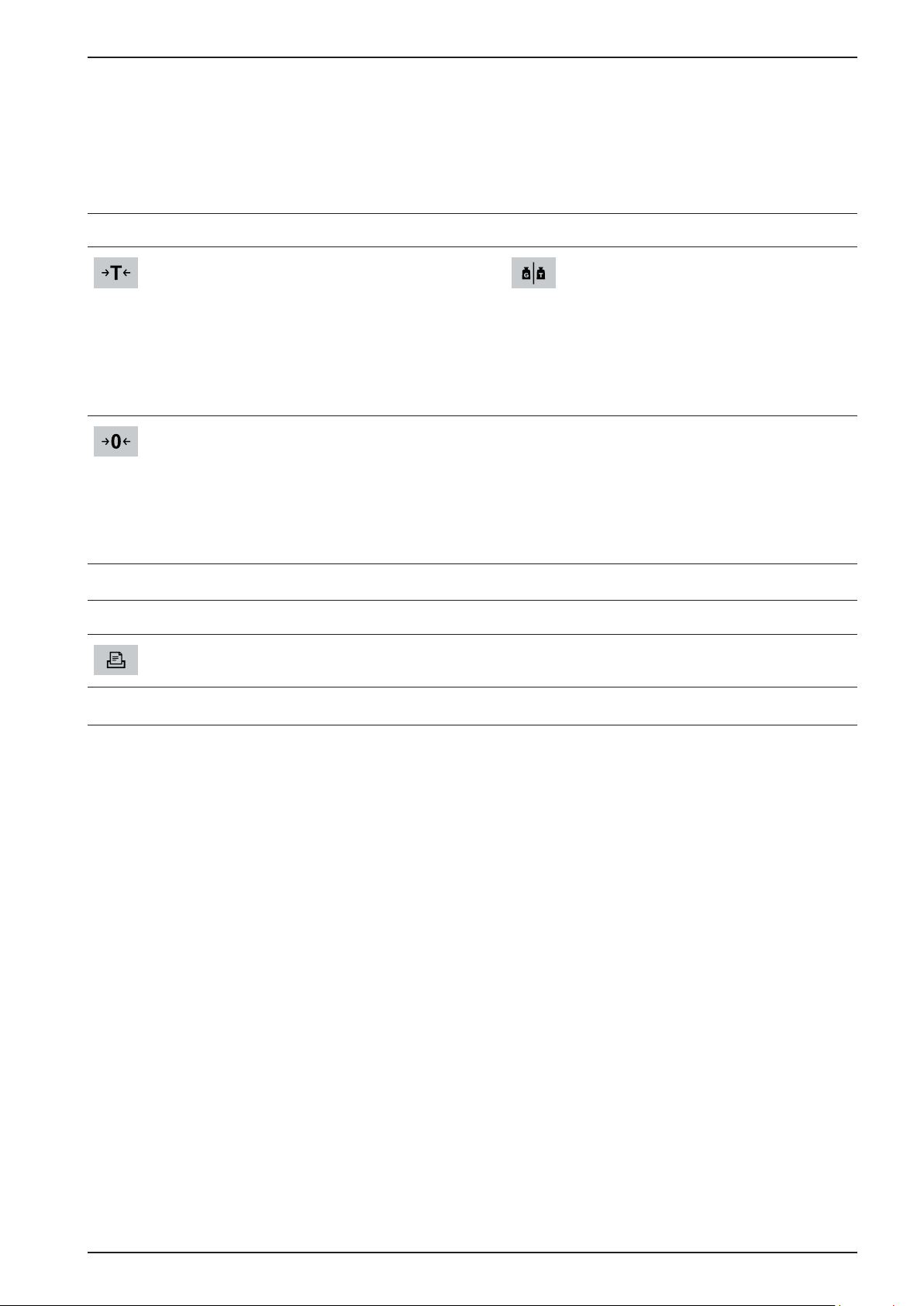

Standard Save

3.4.3.3 Selection using the Navigation Keys

Menu

You can navigate menus using the cursor keys, the

Parameters

Individual parameters are selected using the / keys.

The required values/texts are entered via the alphanumeric keys.

Checkmarks are set using the OK key.

If the list of parameters is long, a vertical bar graph on the left (black/gray) shows which part of the list is

displayed.

Available selection lists are indicated by the following arrow .

The parameter is selected in the selection list via the

3.4.3.4 PC Keys

The device can also be operated via a PC keyboard. The corresponding key assignments can be viewed in the

following table, see also Chapter 4.3.3.2.

PC keyboard Front keypad

F1 F1

F2 F2

F3 ?

OK key and the EXIT key.

OK key.

F4 MENU

F5 to F9 Soft key 1 to 5

F10

F11

F12

ESC

Cursor keys: , , , , , ,

ENTER

Backspace

Numeric keypad Alphanumeric keypad

EXIT

OK

C

3.4.4 Operation using the VNC Program

User interface, see Chapters 3.4.1, 3.4.2 and 3.4.3.1.

Sartorius EN-19

Page 30

Process Controller PR 5500 Instrument Manual

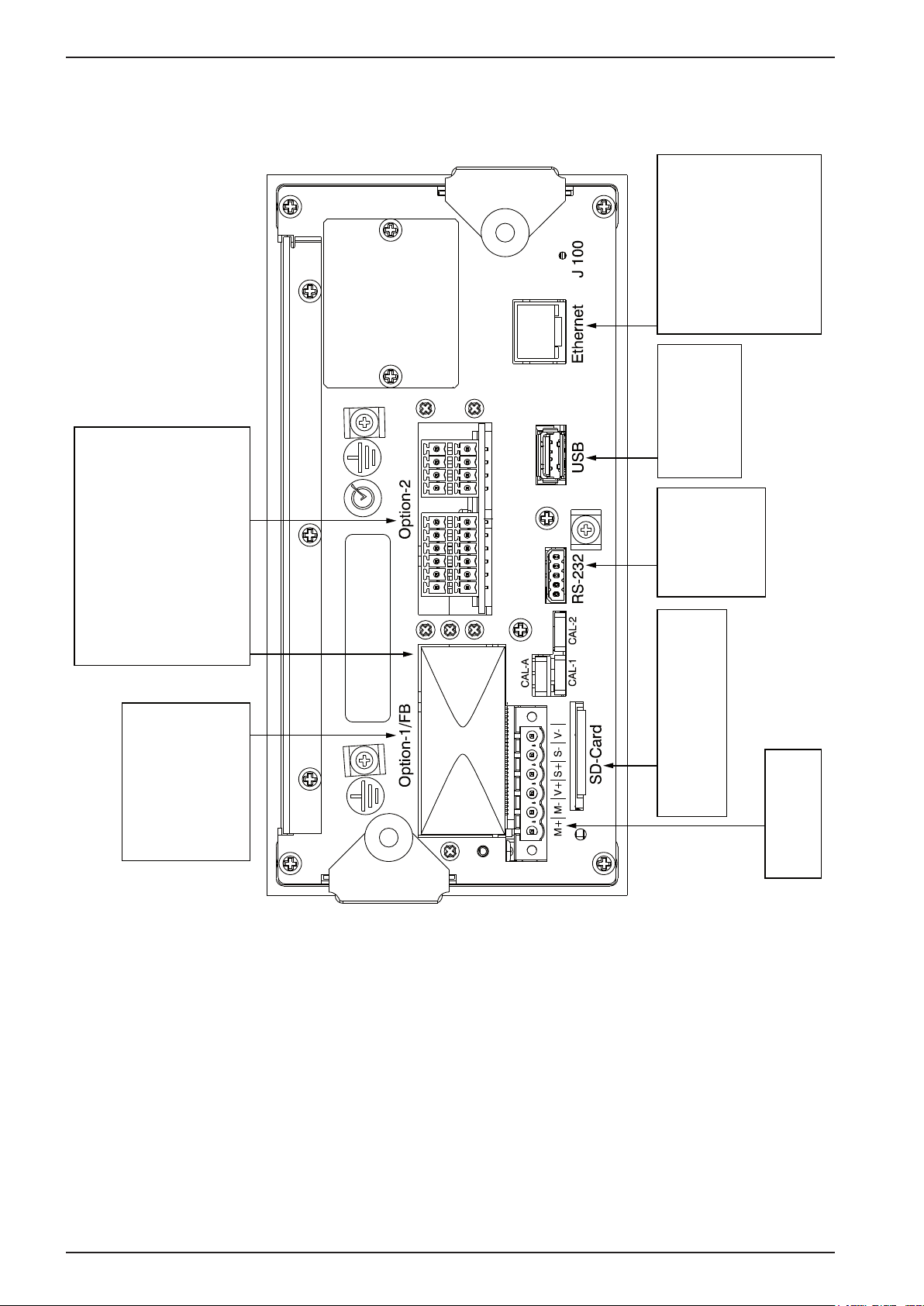

3.5 Overview of Connections

or

24 V DC

100…240 V AC

LAN port

(builtin) for

- remote access via VNC

- software flash

- communication/data exchange:

OPC, ModBus-TCP

USB 2.0 port

(builtin) for

USB stick, USB keyboard,

USB barcode scanner,

USB printer

- external I/O devices:

ModBus-TCP

- printer

Interfaces

- Option-1 and/or Opton-2:

Serial ports RS-485 (2x) PR 5500/04 and

Serial ports RS-232 (2x) PR 5500/32

One channel can be used to connect

an IS-platform without external

power supply.

Option-FB

Fieldbus interfaces

one option only

- ProfiBus-DP PR 1721/61

- Option-1 and/or Option-2:

Analogue I/O PR 5500/07

- Option-1 and/or Option-2:

Digital I/O PR 5500/12, ../13, ../17

or

- DeviceNet PR 1721/64

- CC-Link PR 1721/65

- ProfiNet I/O PR 1721/66

- EtherNet-IP PR 1721/67

Serial port RS-232

(builtin)

for

- printer

- remote display

- external scales

SD card port (builtin)

SD card will be used as memory

extension, not to transport data.

WP A

Internal weighing point

PR 5500/10 (W1)