Page 1

1

DIGITAL TRANSMITTER

OPT-563B

Quick Instruction Manual

Minebea Co., Ltd.

Measuring Components Business Unit

EN294-1723

Page 2

2

Page 3

I

Introduction

Thank you for purchasing the Minebea OPT-563B Digital Transmitter for flange type torque

transducers using optical transmission.

This instruction manual is a [quick] instruction manual primarily intended to describe the procedure for

calibration by inputting numerical torque values.

For detailed instructions on how to use the OPT-563B, refer to Instruction Manual EN294-1596*.

Note that handling or operating the device incorrectly may result in malfunctions. Read the instruction

manual EN294-1596* thoroughly before use for safety and optimal results.

The guaranteed accuracy when calibrating by inputting numerical torque values will be approximately

1/500 (±0.2% RO).

Note also that symmetry correction cannot be adjusted using numerical input.

Keep this instruction manual in a location where it is readily accessible to end users.

Pictograms and conventions used in this manual

This manual uses the following pictograms to indicate actions to avoid at all times, aspects requiring

caution, and other noteworthy matters.

Be sure to read the descriptions provided alongside these pictograms.

WARNING

This indicates circumstances in which incorrect handling may result in death or serious injury to

users.

Avoid the actions described here at all times.

CAUTION

This indicates circumstances in which incorrect handling may result in injury to users or damage to

property.

This indicates operating or procedural precautions or restrictions.

Always read the details included here to avoid malfunctioning.

Page 4

II

Revision History

Date Manual No. Revision reason (details)

2015/12 DRW. No.EN294-1723 1st issue

Page 5

III

Contents

INTRODUCTION ...................................................................................................................................................... I

PICTOGRAMS AND CONVENTIONS USED IN THIS MANUAL ........................................................................... I

REVISION HISTORY ............................................................................................................................................... II

CONTENTS ............................................................................................................................................................ III

1. P A RT NAMES AND FUNCTIONS ................................................................................................................... 5

1-1. Front Panel .......................................................................................................................................................................................... 5

1-2. Rear Panel ............................................................................................................................................................................................ 7

2. OPERATING INSTRUCTIONS ........................................................................................................................ 8

2-1. Key ................................................................................................................................................................................................. 8

2-1-1. When Operated in Measurement Mode ........................................................................................... 8

2-2. Key ................................................................................................................................................................................................. 8

2-2-1. When Operated in Measurement Mode ........................................................................................... 8

2-2-2. When Operated in Other Modes ....................................................................................................... 8

2-3. Key ................................................................................................................................................................................................. 8

2-3-1. When Operated in Measurement Mode ........................................................................................... 8

2-3-2. When Operated in Other Modes ....................................................................................................... 8

2-4. Key .................................................................................................................................................................................................. 8

2-4-1. When Operated in Measurement Mode ........................................................................................... 8

2-4-2. When Operated in Other Modes ....................................................................................................... 9

2-5. Key .................................................................................................................................................................................................. 9

2-5-1. When Operated in Measurement Mode ........................................................................................... 9

2-5-2. When Operated in Other Modes ....................................................................................................... 9

2-6. Key .................................................................................................................................................................................................. 9

2-6-1. When Operated in Measurement Mode ........................................................................................... 9

2-6-2. When Operated in Other Modes ....................................................................................................... 9

2-7. Key .................................................................................................................................................................................................. 9

3. CALIBRATION ............................................................................................................................................... 10

3-1. Settings Required for Calibration ............................................................................................................................................. 10

Page 6

IV

3-2. Settings to be Altered As Necessary After Calibration ................................................................................................. 10

3-3. Calibration Procedure ................................................................................................................................................................... 11

3-3-1. Calibration in Measurement Mode .................................................................................................. 11

3-3-2. Selecting Calibration Mode ............................................................................................................ 12

3-3-3. Minimum Scale Division Setting ..................................................................................................... 12

3-3-4. Torque Setting ................................................................................................................................ 13

3-3-5. Actual Torque Setting ..................................................................................................................... 14

3-3-6. Zero Calibration .............................................................................................................................. 15

3-3-7. Span Calibration ............................................................................................................................. 16

3-3-8. Calibration End ............................................................................................................................... 17

3-4. Zero/Span Fine Adjustment Function ................................................................................................................................... 18

3-4-1. Selecting Zero Point Fine-adjustment Mode .................................................................................. 18

3-4-2. Selecting Span Point Fine-adjustment Mode ................................................................................. 19

4.

FUNCTION MODE ......................................................................................................................................... 20

4-1. Selecting Function Mode ............................................................................................................................................................. 20

4-2. Function List .................................................................................................................................................................................... 21

Page 7

5

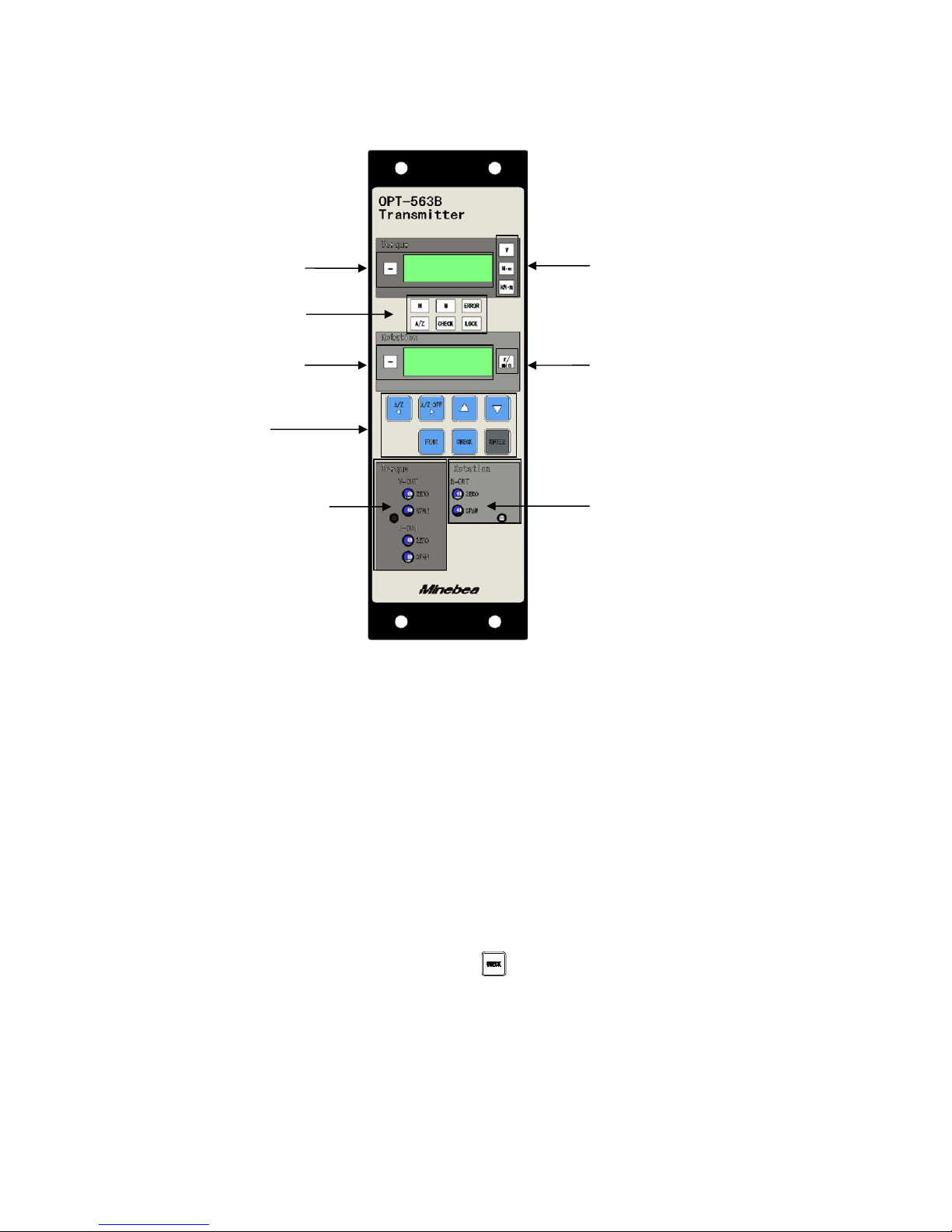

1. Part Names and Functions

1-1. Front Panel

(1) Torque units display

Displays the measurement units set.

(2) Torque display

Displays the torque reading and [OL] (for over limit).

(3) Status display

Indicates the OPT-563B status.

H : Illuminates when the torque meter light level is normal.

M : Illuminates when the torque meter light level is low.

Note that [M] does not illuminate if used in conjunction with the DBX-001 power

supply box.

A/Z : Illuminates when the A/Z function operates.

CHECK : Illuminates when the key is pressed to turn CHECK on.

LOCK : Illuminates when external control input LOCK to COM1 is short-circuited.

ERROR : Illuminates when an error signal is output.

(4) Rotation speed units display

Displays the rotation speed units.

(4) Rotation speed units

display

(2) Torque display

(1) Torque units display

(3) Status display

(6) ~ (12) Key

switches

(13) Torque analog output

trimmer section

(14) Rotation speed analog

output trimmer section

(5) Rotation speed

display

Page 8

6

(5) Rotation speed display

Displays the rotation speed and [OS] (for overspeed).

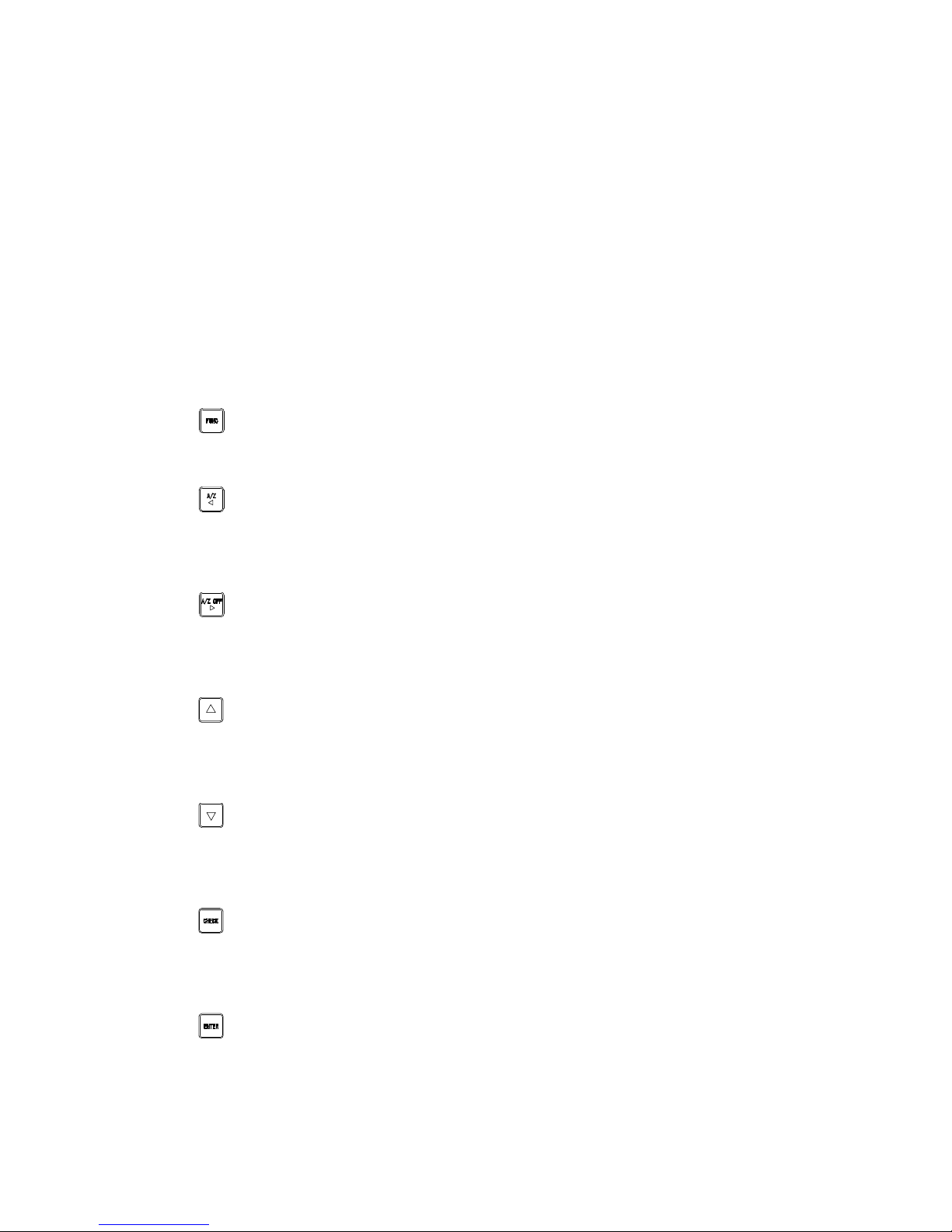

(6) key

Turns on the A/Z function. Also moves the setting digit to the left when setting numerical values.

(7) key

Turns off the A/Z function. Also moves the setting digit to the right when setting numerical values.

(8) key

Increments the digit selected when setting numerical values.

(9) key

Decrements the digit selected when setting numerical values.

(10) key

Used to select function mode. Also used to return to measurement mode without entering the value

when setting. Depress for at least 2 seconds to select function mode.

(11) key

Used to turn the CHECK value on or off. Depress for at least 2 seconds to turn on the CHECK value.

(12) key

Used for registering settings.

(13) Torque analog output trimmer section

Torque analog output (VOUT and IOUT) zero point and span point trimmer adjustment (fine

adjustment) section

(14) Rotation speed analog output trimmer section

Rotation speed analog output (ROUT) zero point and span point adjustment (fine adjustment) section

Page 9

7

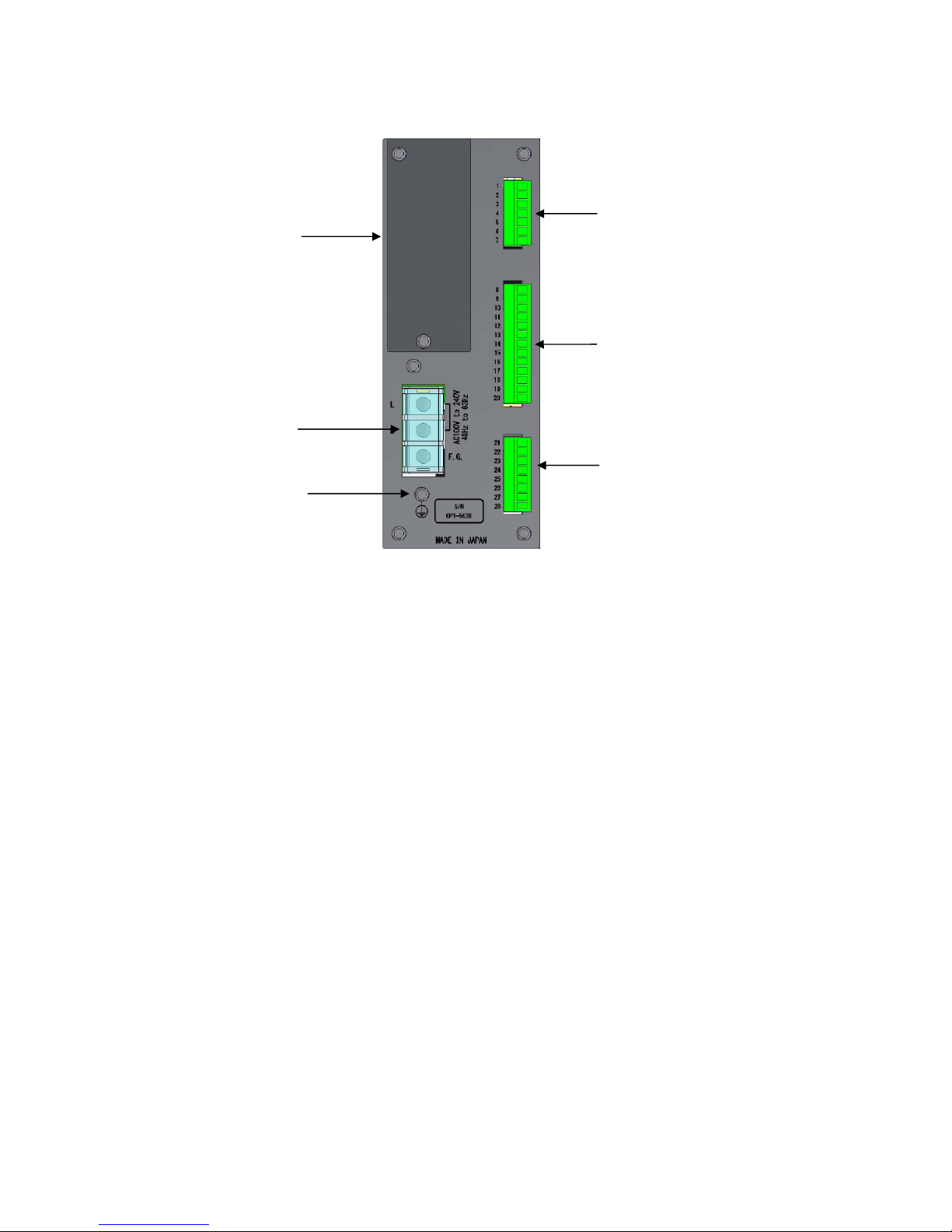

1-2. Rear Panel

(1) Power supply terminal board

Connected to the AC power supply and grounding wire.

(2) Protective ground terminal

Connect this to ground to eliminate noise effects such as static electricity. Do not connect any wires

other than the grounding wire.

This connector is internally linked to F.G. on the power supply terminal board.

(3) External control input/output connector

Used to connect the external control device.

(4) Torque transducer/rotation speed detector connector

Connect the signal cable to the torque transducer/rotation speed detector (MP-9820).

(5) Analog output connector

Connect the signal cable to the analog input device.

(6) Optional part mounting section

One optional part (RS-232C, RS-422/485, PROFIBUS, or CANopen) can be mounted.

(1) Power supply

terminal board

(2) Protective

ground terminal

(6) Optional part

mounting section

(3) External control

input/output connector

(4) Torque transducer/rotation speed

detector connector

(5) Analog output connector

Page 10

8

2. Operating Instructions

This section describes how to operate the equipment using the keys on the front panel.

CAUTION

Stop measuring before operating the keys. There is a risk of malfunctioning if the keys are operated

while measurement is in progress.

Key operations in measurement mode are enabled by depressing for approximately 1 second.

2-1. Key

2-1-1. When Operated in Measurement Mode

This selects function mode and is displayed on the setting display.

Function setting or other modes can be selected in this mode.

2-2. Key

2-2-1. When Operated in Measurement Mode

Pressing this button activates the auto-zero function and zeros the torque reading if the value displayed

on the torque display is 10% or less of the maximum value. [A/Z] is also displayed on the status display.

2-2-2. When Operated in Other Modes

Pressing the key when a setting is displayed causes the flashing digit to move to the left in the

sequence 10

1

, 102, 103, 104. (Note that the range of movement will vary depending on the number of

digits and sign displayed.)

2-3. Key

2-3-1. When Operated in Measurement Mode

This cancels the auto-zero function, and [A/Z] disappears on the status display.

2-3-2. When Operated in Other Modes

Pressing the key when a setting is displayed causes the flashing digit to move to the right in the

sequence 10

4

, 103, 102, 101. (Note that the range of movement will vary depending on the number of

digits and sign displayed.)

2-4. Key

2-4-1. When Operated in Measurement Mode

This has no effect.

Page 11

9

2-4-2. When Operated in Other Modes

Setting increment

Pressing the key when a setting is displayed increments the value in sequence from 0 to 9, and

then back to 0.

Fine adjustment increment

Pressing the key for fine adjustment of the zero point, span point, asymmetry correction,

linearization correction, or analog output increments the corresponding value.

2-5. Key

2-5-1. When Operated in Measurement Mode

This has no effect.

2-5-2. When Operated in Other Modes

Setting decrement

Pressing the key when a setting is displayed decrements the value in sequence from 0 to 1, and

then back to 0.

Fine adjustment decrement

Pressing the key for fine adjustment of the zero point, span point, asymmetry correction,

linearization correction, or analog output decrements the corresponding value.

2-6. Key

2-6-1. When Operated in Measurement Mode

[CHECK] illuminates on the status display, and the value (CHECK value) set in function mode F-20 is

output from the torque analog output (V-OUT/I-OUT). For further details, refer to Section 9-2.

2-6-2. When Operated in Other Modes

This has no effect.

2-7. Key

Pressing the key registers the setting altered within the system.

Page 12

10

3. Calibration

Calibration refers to the process of adjusting the display reading to match the torque acting on the

torque transducer in order to ensure that the electrical signal from the torque transducer is

displayed as an accurate torque figure.

For example, this adjustment ensures that an accurate reading of 1000.0 N·m is given when a

torque of 1,000 N·m acts on the torque transducer.

The equipment must always be calibrated before using for the first time or after replacing a torque

transducer.

When calibrating the equipment before using for the first time, calibrate by entering the numerical

values, referring to the calibration certificate sheet provided when the torque transducer was

purchased.

When calibrating the equipment after replacing a torque transducer, calibrate by entering the

numerical values, referring to the calibration certificate sheet provided with the torque transducer

purchased.

3-1. Settings Required for Calibration

(1) Minimum scale division

The minimum measurement interval. The available settings are [1], [2], [5], and [10].

The value set for [SPAN value/MIN. SCALE DIVISION] will form the display resolution.

(2) SPAN value

The maximum torque value that can be measured by the torque transducer.

(3) ZERO calibration

The setting to be calibrated to ensure that the equipment torque reading is zero when no torque is

applied to the torque transducer (initial torque state). This can be calibrated either using the torque

value (initial torque state) or by entering the torque transducer output value.

(4) SPAN calibration

The setting to be calibrated to ensure that the variations in the electrical signal from the torque

transducer are displayed on the equipment correctly as the torque when a torque is applied to the

torque transducer. This can be calibrated either using the torque value (span torque state) or by

entering the torque transducer output value.

(5) Calibration data selection

The equipment can save up to four sets of calibration data. Select the location for saving the

calibration data by selecting Calibration Data 1 to 4 before calibrating using F-59. If the equipment is

jointly calibrated at Minebea, the calibration data will be stored to [Calibration Data 1].

3-2. Settings to be Altered As Necessary After Calibration

For details of the setting instructions, refer to Instruction Manual EN294-1596*.

(1) Symmetry correction

This function corrects torsional span errors in the clockwise and counter-clockwise directions.

(2) Linearization correction

This function minimizes measuring errors by correcting up to five points, excluding zero and span.

(3) Change polarity

This function inverts the polarity of the torque transducer output.

(4) Decimal place

Sets the decimal place for the torque reading on the equipment.

(5) Units

Adds units to the torque reading on the equipment.

Recalib rate as necessary if the usage environment changes.

The maximum readout resolution for valid performance is 10,000.

In span calibration, use a value of at least 2/3 of the span to minimize calibration errors.

Page 13

11

3-3. Calibration Procedure

3-3-1. Calibration in Measurement Mode

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

Step 9

Connect the torque transducer to the equipment.

Turn on and wait for approximately 10 minutes for the torque

transducer and equipment to stabilize.

Select calibration mode.

Select the minimum torque units.

Select the minimum torque units.

Set the maximum torque value that can be measured by the

torque transducer.

Calibrate the zero point with the torque transducer at the initial

torque state or by setting the zero point torque for the torque

transducer.

Calibrate the span point with the span torque acting on the torque

transducer or by setting the span point torque for the torque

transducer.

Calibration is complete. Perform steps 10 onward as described

below where necessary.

Steps 4 to 9 must be carried out in sequence. The calibration results will not be updated if the proced ure is not

completed up to step 9.

The A/Z function is canceled once calibration is completed (up to step 9).

The A/Z function is canceled if step 10, 11, or 12 is performed.

For details of steps 11 to 15, refer to Instruction Manual EN294-1596*.

Section 3-3-3

Minimum scale

division setting

Section 3-3-4

Torque setting

Step 11

Ste

p

12 Step 13

Ste

p

14

Section 3-3-5

Actual torque setting

Section 3-3-7

Span calibration

Section 3-3-6

Zero calibration

Step 15

After turning on powe

r

Calibration mode

selection

End of calibration

Decimal place

setting

Units setting

Symmetry

correction

function

Linearization

correction

function

Polarity change

function

Step 10

Section 3-4

Zero/span fine

adjustment

function

Torque transducer

connection

Page 14

12

3-3-2. Selecting Calibration Mode

Calibration mode can be selected from measurement mode as follows.

appears in the upper part when the key

is depressed for approximately 2 seconds in measurement

mode.

The upper display reads when the key

is pressed.

The upper display reads and

flashes on the lower display, indicating

calibration mode has been selected when the key is

pressed.

(If the equipment has been previously calibrated, the

minimum scale division registered at that time will be

displayed.)

3-3-3. Minimum Scale Division Setting

Set the minimum scale division for torque.

Use the or key to set the required minimum scale

division on the lower display. Select from [1], [2], [5], or [10].

* Enter value (1) on the calibration certificate sheet. (No

decimal point)

For example, if the minimum digit is 100.00 N·m, set to [d-01].

: Selects the minimum scale division.

: Cancels the setting and returns to

measurement mode.

: Registers the value displayed and proceeds

to the next step.

Press the key after setting. (If the equipment has been

previously calibrated, the torque value registered at that time

will be displayed.)

The maximum readout resolution for valid performance is 10,000.

Measurement

mode

To minimum scale

division setting

Registered minimum

scale division

Registered minimum

scale division

Minimum scale

division used

To torque setting

Registered torque

value

Page 15

13

3-3-4. Torque Setting

Set the maximum torque displayed.

Use the keys to change the torque

on the lower display to the required value.

* Enter value (2) on the calibration certificate sheet. (No

decimal point)

For example, if the maximum indication is 100.00 N·m,

set to [10000].

: Alters the value of the digit to be

altered.

: Selects the digit to be altered.

: Cancels the setting and returns to

measurement mode.

: Registers the value displayed and

proceeds to the next step.

Press the key after setting.

New torque value

To actual torque

setting

Registered torque

value

New torque value

Page 16

14

3-3-5. Actual Torque Setting

Set actual torque acting on the torque transducer (or torque transducer output).

When calibrating by entering numerical values, set the same value as set in "3-3-4 Torque Setting".

* Enter value (3) on the calibration certificate sheet. (No decimal point)

For example, if the maximum indication is 100.00 N·m, set to [10000].

Use the keys to change the torque on

the lower display to the required value.

: Alters the value of the digit to be altered.

: Selects the digit to be altered.

: Cancels the setting and returns to

measurement mode.

: Registers the value displayed and

proceeds to the next step.

Press the key after setting.

Actual torque value

or torque meter output

To zero calibration

New torque value

Page 17

15

3-3-6. Zero Calibration

Register the input at the zero point.

To calibrate by entering the torque value for the torque transducer, press the key and then press

the key.

Calibrate zero by entering the zero point torque (frequency) for the torque transducer.

Calibration by entering the torque value for the torque

transducer

Press the key to display in the

lower display, and then press the key to display the

value.

The value displayed will be the output frequency for the

torque transducer at the initial torque state previously

registered.

Set the torque value (frequency) corresponding to the zero

point in 1 Hz intervals.

* Enter the torque calibration value zero frequency

included on the calibration certificate sheet for the torque

transducer.

* Enter value (4) on the calibration certificate sheet. (No

decimal point)

For example, if the torque calibration value (zero) is

9.957 kHz, set to [9957].

: Alters the value of the digit to be altered.

: Selects the digit to be altered.

: Cancels the setting and returns to

measurement mode.

: Registers the value displayed and

proceeds to the next step.

Press the key after setting.

Zero calibration error display

: The display flashes for approximately 2 seconds when the torque transducer

frequency output is less than 9,500 Hz or if the value entered is less than 9,500 Hz.

: The display flashes for approximately 2 seconds when the torque transducer

frequency output exceeds 10,500 Hz or if the value entered exceeds 10,500 Hz.

To span calibration

Hz

Registered torque transducer output

value

Hz

Set torque transducer output value

Page 18

16

3-3-7. Span Calibration

Register the input at the span point.

To calibrate by entering the torque value for the torque transducer, press the key and then press

the key.

Calibrate span by entering the span point torque (frequency) for the torque transducer.

Calibration by entering the torque value for the torque

transducer

Press the key to display in the

lower display, and then press the key to display

. The value displayed will be the output

frequency for the torque transducer at the span point

previously registered. Set the torque value (frequency)

corresponding to the span point in 1 Hz intervals.

* Enter the torque calibration value span frequency

included on the calibration certificate sheet for the torque

transducer.

* Enter value (5) on the calibration certificate sheet. (No

decimal point)

For example, if the torque calibration value (span) is

14.913 kHz, set to [14913].

: Alters the value of the digit to be altered.

: Selects the digit to be altered.

: Cancels the setting and returns to

measurement mode.

: Registers the value displayed and

proceeds to the next step.

Press the key after setting.

Span calibration error display

: The display flashes for approximately 2 seconds when [span point torque transducer

output frequency or span point torque transducer value entered] - [zero point torque

transducer output frequency or zero point torque transducer value entered] ≤ 0 or when

the torque transducer output frequency is less than 14,500 Hz or if the value entered is

less than 14,500 Hz.

: The display flashes for approximately 2 seconds when the torque transducer output

frequency exceeds 15,500 Hz or if the value entered exceeds 15,500 Hz.

In span calibration, use a torque value of at least 2/3 of the display torque to minimize calibration

errors.

Hz

Registered torque transducer

output value

Hz

Set torque transducer output value

Page 19

17

3-3-8. Calibration End

Displays after span calibration ends.

Press the key to exit calibration mode.

The system switches to measurement mode and the data set is registered.

Th e calib ration values (zero point and span) will not be entered unless the procedure is performe d in sequence

up to this step.

Calibration can be performed only in the counter-clockwise torsional direction.

The A/Z function is canceled once calibration is completed.

Measurement

mode

Page 20

18

3-4. Zero/Span Fine Adjustment Function

This function fine-adjusts the zero point and span point if there are discrepancies between the actual

torque and the reading displayed.

3-4-1. Selecting Zero Point Fine-adjustment Mode

Zero point fine-adjustment mode can be selected from measurement mode as follows.

appears in the upper part when the key is

depressed for approximately 2 seconds in measurement mode.

The upper display reads when the key is

pressed twice.

The upper display reads and the reading on the

lower display flashes, indicating zero point fine-adjustment mode

has been selected when the key is pressed. The lower display

displays the torque value currently entered. Set the torque

transducer to the initial torque state, and adjust the display to

[ZERO].

: Increments the torque.

Hold down the key to increment the torque continuously.

: Decrements the torque.

Hold down the key to decrement the torque continuously.

: Cancels the setting and returns to measurement mode.

: Registers the value displayed and proceeds to the next

step.

Press the key after setting.

is displayed after zero point fine-adjustment.

Press the key to exit zero point fine-adjustment mode. The

system switches to measurement mode and the data set is

registered.

Measurement

mode

Current

torque value

(twice)

Measurement

mode

Page 21

19

3-4-2. Selecting Span Point Fine-adjustment Mode

Span point fine-adjustment mode can be selected from measurement mode as follows.

.

appears in the upper part when the key

is depressed for approximately 2 seconds in measurement

mode.

The upper display reads when the key

is pressed three times.

The upper display reads and the reading on

the lower display flashes, indicating span point fine-adjustment

mode has been selected when the key is pressed. The

lower display displays the torque value currently entered. Apply

an actual torque to the torque transducer, and adjust the

display to [actual torque value].

: Increments the torque.

Hold down the key to increment the torque

continuously.

: Decrements the torque.

Hold down the key to decrement the torque

continuously.

: Cancels the setting and returns to measurement

mode.

: Registers the value displayed and proceeds to the

next step.

Press the key after setting.

is displayed after span point fine-adjustment.

Press the key to exit span point fine-adjustment mode.

The system switches to measurement mode and the data set is

registered.

The change polarity setting will be temporarily canceled for zero/span fine-adjustment. (Restored after

adjustment)

The A/Z function is canceled once the zero/span fine-adjustment function ends.

Measurement

mode

Current torque

value

(3 times)

Measurement

mode

Page 22

20

4. Function Mode

4-1. Selecting Function Mode

Function mode can be selected from measurement mode as follows.

appears in the upper part when the

key is depressed for approximately 2 seconds in

measurement mode.

The upper display reads when the

key is pressed.

Use the keys to select the required

function number on the upper display.

: Alters the value of the digit to be altered.

: Selects the digit to be altered.

: Cancels the setting and returns to

measurement mode.

: Registers the value displayed and

proceeds to the next step.

Press the key after setting.

The lower display changes to display the function

details.

Use the keys to select the required

function number on the lower display.

The upper display reads when the

key is pressed, indicating that function registration

is complete.

Press the key to exit function mode and return to

measurement mode.

Measurement mode

Value set

Value registered

To measurement mode

Value set

Page 23

21

4-2. Function List

Function No. Item

Setting

value

Details

F-01 Decimal place

●0 No decimal point

1 1000.0

2 100.00

3 10.000

4 1.0000

F-02 Torque display units

●0 N·m

1 kN·m

2 V

F-04 Display cycles

0 4 cycles/s

●1 20 cycles/s

F-05 Torque analog filter

0 1 Hz

1 10 Hz

2 30 Hz

3 50 Hz

4 100 Hz

5 300 Hz

6 500 Hz

●7 1 kHz

F-06 Torque digital filter

00~88

No. of moving-average samples = 2

m+2n

m: 101 setting, n: 100 setting

●00

F-07 Rotation speed analog filter

0 1 Hz

●1 10 Hz

F-08 Rotation speed digital filter

00~88

No. of moving-average samples = 2

m+2n

m: 101 setting, n: 100 setting

●00

F-09

Torque stabilization filter

No. of averaging

0 No. of moving-average samples: 1

1 No. of moving-average samples: 2

2 No. of moving-average samples: 4

3 No. of moving-average samples: 8

4 No. of moving-average samples: 10

5 No. of moving-average samples: 12

●6 No. of moving-average samples: 14

7 No. of moving-average samples: 16

8 No. of moving-average samples: 32

F-10

Torque stabilization filter

Time width setting

000~999

Unit: 10 ms

000: Torque stabilization filter off

●000

F-11

Torque stabilization filter

Data width setting

00~99

Unit: DIGIT

00: Torque stabilization filter off

●20

Page 24

22

Function No. Item

Setting

value

Details

F-15

Rotation speed stabilization

filter

No. of averaging

0 No. of moving-average samples: 1

1 No. of moving-average samples: 2

2 No. of moving-average samples: 4

3 No. of moving-average samples: 8

4 No. of moving-average samples: 10

5 No. of moving-average samples: 12

●6 No. of moving-average samples: 14

7 No. of moving-average samples: 16

8 No. of moving-average samples: 32

F-16

Rotation speed stabilization

filter

Time width setting

000~999

Unit: 10 ms

000: Rotation speed stabilization filter off

●000

F-17

Rotation speed stabilization

filter

Data width setting

00~99

Unit: DIGIT

00: Rotation speed stabilization filter off

●20

F-18 Key lock

0000

~1111

●0000

0: Off

1: On

10

0

digit:

10

1

digit:

10

2

digit:

10

3

digit:

F-19 Polarity change

●0

Torque in counter-clockwise direction is

positive.

1 Torque in clockwise direction is positive.

F-20 CHECK value

0~20

Refer to Section 9-2-3.

●16

F-21

Torque analog output

Max. display value

1~99 999

Unit: DIGIT

●10 000

F-22

Rotation speed analog output

Max. display value

1~27 500

Unit: DIGIT

●25 000

F-23 Rotation direction polarity

● 0 +

1 -

F-24

Rotation detection input signal

format

● 0 Off

1 Measured using 2 rotation detectors

2

Measured using 1 rotation detector.

Rotation direction detected using external

input signal

3

Measured using 1 rotation detector.

Rotation direction cannot be detected.

Page 25

23

Function No. Item

Setting

value

Details

F-25 No. of rotation detection gears

●0 120

1 240

2 360

F-26

Selecting A/Z data save

destination

●0 RAM

1 EEPROM

F-30 RS-232C operating mode

●0 Command mode

1 Stream mode

F-31 RS-232C stream output target

●0 Torque display data

1 Input torque A/D data

2 Rotation speed display data

3 Frequency data

F-32

RS-232C/RS-422/RS-485

Baud rate

0 1,200 bps

1 2,400 bps

2 4,800 bps

●3 9,600 bps

4 19,200 bps

5 38,400 bps

6 57,600 bps

7 115,200 bps

F-33

RS-232C/RS-422/RS-485

Data bit length

●0 7 bit

1 8 bit

F-34

RS-232C/RS-422/RS-485

Parity bit

0 None

●1 Odd

2 Even

F-35

RS-232C/RS-422/RS-485

Stop bit

●0 1 bit

1 2 bit

F-36

RS-232C/RS-422/RS-485

Terminator

0 CR

●1

CR+LF

F-37

RS-232C/RS-422/RS-485

Decimal point

●0 No

1 Yes

F-38 RS-422/485 address

00~31

●00

F-39 RS-422/485 selection

●0 RS-422

1 RS-485

F-40 RS-485 data delay time

000~999

Unit: 10 ms

Can be set in range 0~9.99 s.

●001

Page 26

24

Function No. Item

Setting

value

Details

F-41

PROFIBUS

Station No.

000~125

●000

F-42

CANopen

Node ID

001~127

●001

F-43

CANopen

Baud rate

0 10 kbps

1 20 kbps

2 50 kbps

3 100 kbps

4 125 kbps

5 250 kbps

6 500 kbps

7 800 kbps

●8 1 Mbps

F-45

CANopen

PDO output frequency

0~100

0: Off

Unit: 1 ms

●100

F-50 Maintenance 1 00000 0~99 999 (Do not use)

F-51 Maintenance 2 00000 0~99 999 (Do not use)

F-55 Calibration prohibited 0000

0: Calibration permitted

1: Calibration prohibited

10

0

digit: Calibration data 1

10

1

digit: Calibration data 2

10

2

digit: Calibration data 3

10

3

digit: Calibration data 4

F-56 Symmetry correction clear 0

Clear data corrected using symmetry

correction function.

F-57

Clearing counter-clockwise

linearization correction

0

Clear data corrected using linearization

correction function. (Counter-clockwise

direction)

F-58

Clearing clockwise linearization

correction

0

Clear data corrected using linearization

correction function. (Clockwise direction)

F-59 Calibration data selection

●0 Calibration data 1

1 Calibration data 2

2 Calibration data 3

3 Calibration data 4

F-60 Calibration 1 Increment 1 Datum value (initial value)

F-61

Calibration 1 Maximum display

value

10000 Datum value (initial value)

F-62

Calibration 1 Actual torque

value

10000 Datum value (initial value)

F-63 Calibration 1 ZERO A/D 0x1FFFF Datum value (initial value)

F-64 Calibration 1 +SPAN A/D 0x3AAAA Datum value (initial value)

F-65 Calibration 1 -SPAN A/D 0x5555 Datum value (initial value)

F-66

Calibration 1 ZERO frequency

conversion value

10000 Datum value (initial value)

F-67

Calibration 1 +SPAN frequency

conversion value

15000 Datum value (initial value)

F-68

Calibration 1 -SPAN frequency

conversion value

5000 Datum value (initial value)

Page 27

25

Function No. Item

Setting

value

Details

F-70 Calibration 2 Increment 1 Datum value (initial value)

F-71

Calibration 2 Maximum display

value

10000 Datum value (initial value)

F-72

Calibration 2 Actual torque

value

10000 Datum value (initial value)

F-73 Calibration 2 ZERO A/D 0x1FFFF Datum value (initial value)

F-74 Calibration 2 +SPAN A/D 0x3AAAA Datum value (initial value)

F-75 Calibration 2 -SPAN A/D 0x5555 Datum value (initial value)

F-76

Calibration 2 ZERO frequency

conversion value

10000 Datum value (initial value)

F-77

Calibration 2 +SPAN frequency

conversion value

15000 Datum value (initial value)

F-78

Calibration 2 -SPAN frequency

conversion value

5000 Datum value (initial value)

F-80 Calibration 3 Increment 1 Datum value (initial value)

F-81

Calibration 3 Maximum display

value

10000 Datum value (initial value)

F-82

Calibration 3 Actual torque

value

10000 Datum value (initial value)

F-83 Calibration 3 ZERO A/D 0x1FFFF Datum value (initial value)

F-84 Calibration 3 +SPAN A/D 0x3AAAA Datum value (initial value)

F-85 Calibration 3 -SPAN A/D 0x5555 Datum value (initial value)

F-86

Calibration 3 ZERO frequency

conversion value

10000 Datum value (initial value)

F-87

Calibration 3 +SPAN frequency

conversion value

15000 Datum value (initial value)

F-88

Calibration 3 -SPAN frequency

conversion value

5000 Datum value (initial value)

F-90 Calibration 4 Increment 1 Datum value (initial value)

F-91

Calibration 4 Maximum display

value

10000 Datum value (initial value)

F-92

Calibration 4 Actual torque

value

10000 Datum value (initial value)

F-93 Calibration 4 ZERO A/D 0x1FFFF Datum value (initial value)

F-94 Calibration 4 +SPAN A/D 0x3AAAA Datum value (initial value)

F-95 Calibration 4 -SPAN A/D 0x5555 Datum value (initial value)

F-96

Calibration 4 ZERO frequency

conversion value

10000 Datum value (initial value)

F-97

Calibration 4 +SPAN frequency

conversion value

15000 Datum value (initial value)

F-98

Calibration 4 -SPAN frequency

conversion value

5000 Datum value (initial value)

F-99 Memory clear -

Returns function settings to default

settings.

Page 28

26

SAMPLE

(1)

(2)(3)

(4)

(5)

Page 29

.

Page 30

D The contents of this manual may subject to change without notice.

HEAD QUARTER : MINEBEA CO., LTD.

4106−73 Miyota, Miyota−machi, Kitasakugun, Nagano−ken 389−0293, Japan

0267−32−2200 .0267−31−1350

Measuring Components Business Unit

FUJISAWA PLANT 1−1−1, Katase, Fujisawa−shi Kanagawa−ken, 251−8531 Japan

0466−22−7152 .0466−22−1701

KARUIZAWA PLANT 4106−73 Miyota, Miyota−machi, Kitasakugun, Nagano−ken 389−0293, Japan

0267−31−1309 .0267−31−1350

HOMEPAGE ADDRESS http://www.minebea−mcd.com

Loading...

Loading...