Page 1

DIGITAL INDICATOR

CSD-903-EX

Instruction Manual

EN294-1492-H

Page 2

IV

Page 3

FOREWORD

Thank you very much for your purchasing the digital Indicator CSD-903-EX.

This manual is provided to explain installation procedures and check points in operation. We

would like you to read through this instruction manual with much care for the best use of our

product to avoid malfunctions.

We also would like you to deliver the manual to end user surely to keep it at hand.

Marks and references described in this manual

The following marks are placed for the matters that indicate “Don’t do this”, “Caution”, and “For

reference”. Please be sure to read following descriptions with marks.

When you are operating the instrument, you have to pay cautions or restrictions related with this

description.

Be sure to read to prevent from malfunction.

Descriptions that may cause injury or physical damage to operators and such as occurrences of

physical damage.

When you are operating the instrument, you have to pay cautions or restrictions related with this

description.

Be sure to read to prevent from malfunction.

Warning

Caution

I

Page 4

For safe operation

Be sure to read this manual before operation.

1. Location of installation

Use the Instrument under the following conditions.

Caution

● Environmental temperature : -10 ℃ ~ 50 ℃ (Preservation : -20 ℃ ~ 60 ℃)

※The temperature span of JIS B 7611-2 conformity is -10 ℃ ~ 40 ℃.

● Environmental humidity : Less than 85 % R.H.(Non condensing)

Do not install the Instrument in following places. It may cause damage to the Instrument.

Caution

(1) Place to be avoided.

● Places exposed to direct sunlight and/or places in the high temperature.

● Places in a high humid area.

● Places where the instrument is directly affected by vibrations or mechanical shocks.

● Environments containing of corrosive gas or salt, etc.

● Environments with rapid change in temperature and/or humidity.

● Near the devices which generate magnetism or electromagnetic waves.

● Environments vulnerable to radioactivity or radioactivity rays.

● Environments where chemical reaction may take place such a laboratory.

II

Page 5

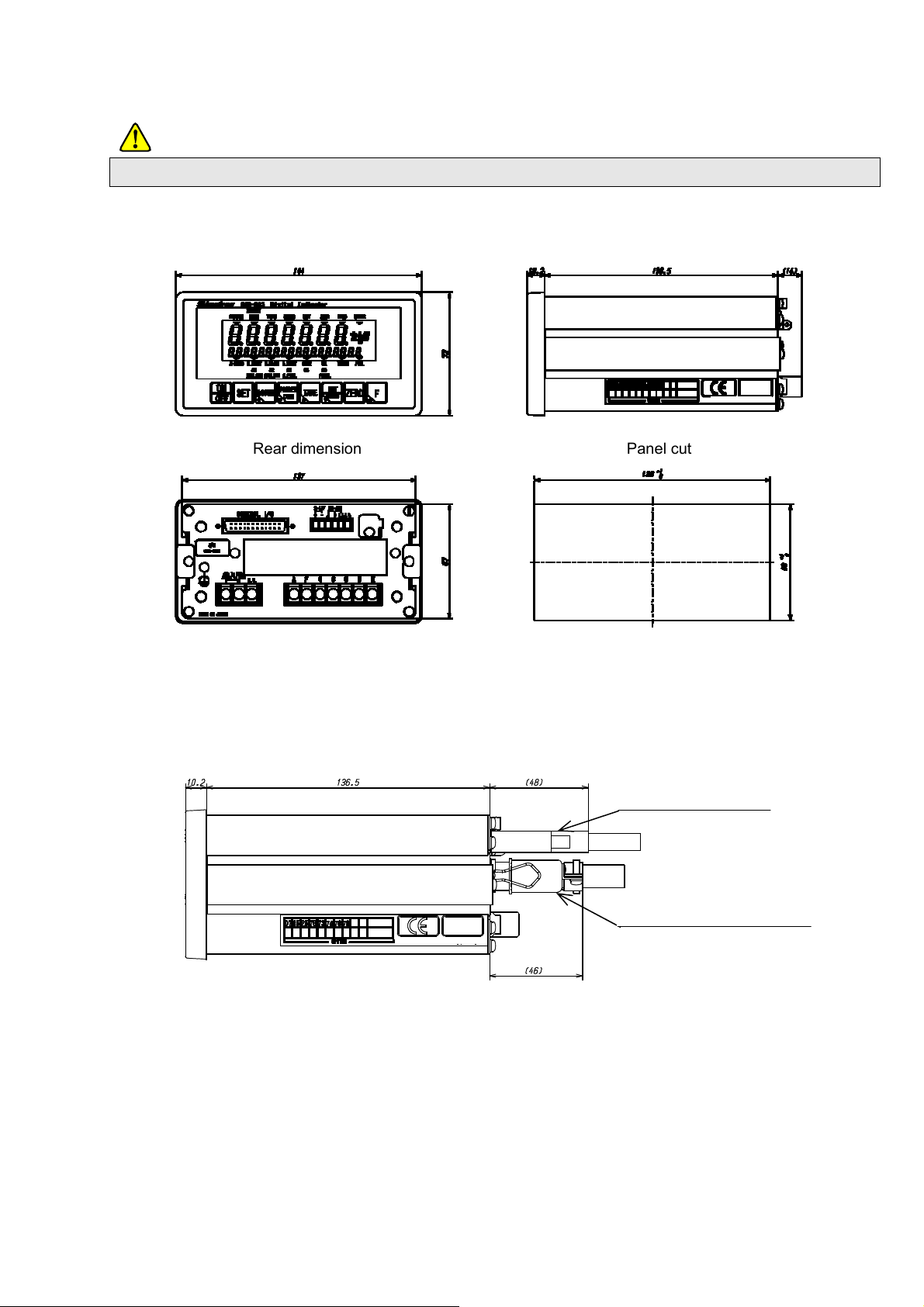

(2) Installing the Instrument

Please secure and set up the spaces between CSD-903 and the dev i ces.

Caution

Followings are the dimensions of the Instrument and for environmental spaces required:

Front Side

Rear dimension Panel cut

unit: mm

The side view when BCD connector is installed. (The I/O connector for external control attached is

the same dimension as a BCD connector.)

unit: mm

Control I/O Connector

BCD out connector (Option)

III

Page 6

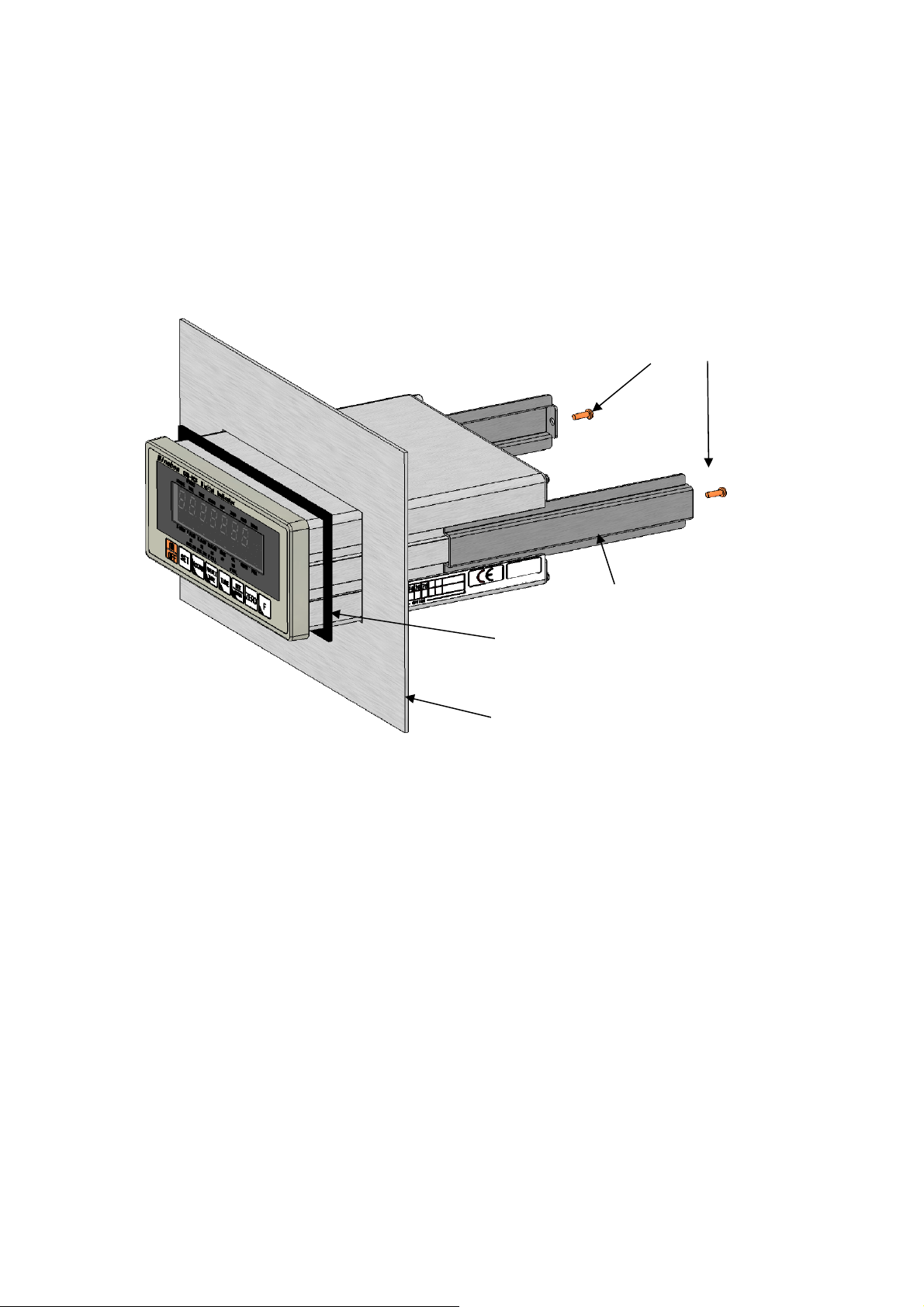

(3) Applicable environment

Warning: The instrument may subject to use in a highly humid area or in full of powder dust.

In such a case, use the instrument by inserting the panel mount gasket attached between the control

panel (cabinet) and the main body.

By inserting the panel mount gasket, the front panel section becomes IP65 (International Protection

Code) or equivalent in dust-proof and water-proof construction.

* Care should be taken when handling the panel mount gasket.

2.

Screw (M3×10 bind)

Panel mounting metal

Panel mount gasket

(Dust proof・Water proof)

Control board (cabinet)

IV

Page 7

Power supply

Be sure to check that power supply is OFF when installing each cable. If an operator works with power

ON, he/she may have an electric shock or the instrument may be destroyed.

Before supplying power, check the indication of power voltage/specifications to be identical with

supplied power. If they are not identical, contact with us. Without checking the above, operation may

cause damage to the instrument or electric shock.

Be sure to ground a grounding wire. If a grounding wire is not grounded, it may cause malfunction of

the instrument or an electric shock to an operator.

Warning

Warning

Caution

3. Instructions for use

Before using a new instrument, or when exchanging a strain gage applied transducer fo r a new one, be

sure to make calibration. If neglected, it may cause incorrect results in measurement or malfunction in

the instrument and moreover may cause damage to peripheral equipments. When similar trouble

occurs after calibration, be sure to make calibration again, even if calibration has completed.

When using the instrument, check that wires are connected properly. If neglected, correct

measurement cannot be obtained and it may cause malfunction in the instrument or cause dama ge to

peripheral devices or a critical accident.

Caution

Caution

Improper change of setting during operation may cause incorrect measurement or malfunction, or

cause damage to peripheral equipments.

Do not give the instrument such a shock as throwing something at it.

It may cause damage or destroy electrical circuits and even have loose resistance to environment or

operability.

Do not remove the cover of the case of the instrument, nor peel off the panel sheet nor take th e

instrument into pieces. If neglected, it may cause damage to the case and the panel sheet and even

have the possibility of damage to resist to environments or operational performances.

At the time of shipment from the factory, the instrument has been plated with a clear sheet on the panel

sheet for protective purpose. In case of application, use the instrument after removing the clear sheet

first.

Do not push the panel sheet on the instrument with the excessive strong force nor push it with sharp

edge object such as a driver. If neglected, it may cause damage to the panel switch and even have the

possibility of damage to resist to environments or operational performances.

Caution

Caution

Caution

V

Page 8

4. Conformity standard

This instrument has suited the following standard.

EN61326:2006

[Electrical equipment for measurement, control, and laboratory use - EMC requirements]

[Immunity test requirements for equipment intended for use in industrial locations]

EN61010-1:2001

[Safety requirements for electrical equipment for measurement, control and laboratory use

- Part 1:General requirement]

Annex C (Performance level H) of JIS B 7611-2:2009

[Non-automatic weighing instruments – Metrological and technical requirements and tests

- Part 2:Measuring instruments used in transaction or certification]

The instrument with the software ver.2.100 or later conforms to the JIS standard.

Please observe the following conditions strictly when this instrument suits the below if neglected, it

may not conform to the above standard.

Caution

Caution

(1) Shield processing

- Use the shielded cable other than the power cable.

- Refer to relative notes, for method of shielding process.

(2) Grounding

- The ground of this instrument shall apply the individual ground by using the protective ground

terminal.

VI

Page 9

Please observe the following conditions strictly when this instrument suits the JIS standard.

If neglected, there is a possibility of not suiting the above-mentioned standard.

Caution

(3) Setting Functions

As for the details of the function of the value of C Function and Function,

please refer the paragraph 5-2 and 7-2.

CF-03 [Condition of over display] shall be applied the value of 2.

CF-08 [Net weight sign inversion] shall be applied the value of 0.

CF-11 [Effective range of zero set] shall be applied with less than the value of 02.

CF-13 [Data width of zero tracking] shall be applied with less than 4% of weighing capacity.

CF-20 [Set the stability detection in condition display while the set mode 2 or set of preset tare]

shall be applied the value of 0.

CF-21 [Set the unit display in sub-display section while the set mode 2 or set of preset tare] shall

be applied the value of 0.

F-01 [Setting of digital filter] shall be applied with more than the value of 016.

F-02 [Setting of analog filter] shall be applied with less than the set value of 01.

F-05 [Setting of stabilization filter] shall be applied with more than the value of 092.

F-06 [Data width of stabilization filter] shall be applied with less than the set value of 020.

F-07 [Time width of stabilization filter] shall be applied with more than the value of 05.

F-10 [Stability detection data width] shall be applied with the set value of more than 20.

F-11 [Stability detection time width] shall be applied with more than the value of 10.

F-15 [Operating condition of the preset tare weight cancellation] shall be applied the value of 0

or 1.

[OL] is appeared in the load date section at the over load. [-OL] is appeared in the load data section at

the condition of gross value is minus

VII

Page 10

Divisional history

Data Manual NO. Revision reason(content)

2010/10 DRW. NO. EN294-1492

2011/2 DRW. NO. EN294-1492A

2011/10 DRW. NO. EN294-1492B

2011/12 DRW. NO. EN294-1492C

2012/12 DRW. NO. EN294-1492-D

VIII

First edition VER. 1. 000

Due to ECN No.FN10-02182A,FN11-02001

ROM Ver.2.100 or later

- Addition –

Preface 4.[JIS B 7611-2 : 2009] conformity standard.

4-3-1. addition of procedure

6-5. [System using the zener barrier] is added.

6-11. [Setting while set mode 2 or set of preset tare]

6-11-1.[Operation for stability detection]

6-11-2.[Operation for unit display in sub-display section]

Clause 6 and item number correction

12.[EzCTS mode] is added to [Check mode].

12-2.[EzCTS mode]

Clause 12 and item number correction

16-3-12.[Reading out ROM version] is added command.

25.[CF-20] or [CF-21] is added to [Setting table for

functions].

Additional correction of contents.

- CorrectionPreface 4.[EN61326:2009] → [EN61326:2006]

14-3-4.[Delay time of RS-485 return data]

16-3-10.[DE-9S-N(JAE)] → [DE-9S-NR by JAE or

equivalent.]

18-4.Power consumption [Approx. 8 VA] → [Approx 10

VA]

Due to ECN No.FN11-02123

ROM Ver.2.200 or later

- CorrectionPreface 1. Change picture of front view and panel

mounting view.

9. Correct the numbers of reference clause and

mistakes.

9-3-2. Correct the drawing of simple comparison

discharging mode.

16-1-5. Correct the graph for scaling of analog output.

- Addition-

1-1. Add the contents of the each function for condition

display section 2.

9-2-1. Add the contents of condition display section in the

measurement comparison value 1 setting mode.

- Deletion16-2-9. Delete the notes sentence・If set value of CF-03

is 2 and fross value is minus, BCD output shall be data

over condition.

Due to ECN No.FN11-02123

- Deletion6-9-1. Delete the notes sentence・The tare weight

cancellation is not accepted when gross value is below

the zero.

Due to ECN No.FN12-02088

-CorrectionChange of Minebea’s Logo.

- Addition2-3. Add the applicable connector.

2-4. Add the applicable connector and note.

2-5. Add the applicable connector and note.

Page 11

Data Manual NO. Revision reason(content)

Due to ECN No.FN12-02095

-Correction7-2., 8-5., 16-3-12.(12) change the explanation of key

lock.

7-2., 16-2-2., 16-3-12(12) change the explanation of

stream mode.

16-3-14. Correct the explanation of procedure for

communications.

-Addition4-3-8. Add the note.

16-3-14. Add the explanation for calibration procedure.

6-2., 7-1., 8-14., 9-2-1., 9-2-2., 9-8., 10-18., 11-3.,

16-2-13(9), (10), (12).

Add the note,and correction of error in writing.

Due to ECN NO.FN12-02097-A

-Correction1-1. Change the clause in the explanation of ZERO from

[Gross value or Net value] to [displayed].

4-3-6. Change the displayed number of dight for load cell

output voltage at zero calibration.

4-3-7. Change the displayed number of digit for load cell

output voltage at span calibration.

5-2. Change the number of digit for CF-93. and CF-94.

12-7. Change the number of digit for load cell output

voltage.

16-3-3. Change the explanation of when RS-422/485 is

used.

2012/12 DRW. NO. EN294-1492-D

16-3-4. Change the explanation, title and note.

16-3-12. Command list for reading and writing the set

value.

16-3-13. (1)Change explanation title.

(2)Change explanation title.

-Addition7-2. Add F-18/48/49. Add the set value of F-19/47.

Add the contents of item of F-41.

8-9. Add the target of hold to holding explanation.

8-9-2. Add the detailed information of holding target.

8-10-1. Add the selection item of sub display.

14-3-1. Add the stream mode and note.

14-3-6. Add the explanation of output target in stream

mode.

16-3-12. Add F-17., F-18., F-48., F-49., to the command

list for reading and writing the set value.

Add the set value 9 ~ 15 of F-19 and 2 of F-47.

16-3-14. (7) 2) Add the registration command for zero of

the fifth decimal point digit.

(10) 2) Add the registration command for span

of the fifth decimal point digit.

25. Add the F-18.,F-48., and F-49 to the table of function

settting.

Add the setting of 9 ~ 15 to the setting table of sub

display (F-19).

Due to ECN No.FN12-02119

-Addition16-1-1. Add the resolution.

16-1-2. Add the resolution.

18-3. Add the resolution.

Due to ECN No.FN13-02078

2013/05 DRW. NO. EN294-1492-E

- Addition-

15. Add a sentence to the configuration table.

IX

Page 12

Data Manual NO. Revision reason(content)

Due to ECN NO.FN15-02117

< Correction >

Cover : Change [MINEBEA] logo

Foreword, Ⅶ. Change the setting amount for operating

condition of Preset tare weight cancellation

7-2., 8-10., 16-3-12. Change the combination including

[Brand].

8-11. Change the display range of accumulating

operation.

8-11-2. Correct the note of accumulating operation.

25.Setting table for functions

<Additional>

Foreword, Ⅶ. Add the setting value of net weight sign

inversion.

3-1. Add the accumulation display mode.

5-2., 6-6.Add the net weight sign inversion and

explanation.

7-2. Add the preset tare weight cancellation operating

condition, comparator brand setting target, operating

mode of RS-232C interface, brand switch target, brand

2015/07 DRW. NO. EN294-1492-F

2016/05 DRW. NO. EN294-1492-G

number, and external control input.

8-7-3. Add the explanation of net weight offset operation.

8-11. Add the explanation of accumulation value clear

and accumulation time clear.

8-12. Add the explanation of brand switch target.

8-14. Add all brand accumulation clear, brand-1, brand-2,

and brand-4.

9-2. Add the explanation of brand number setting

method.

9-5., 9-6. Add the explanation of set value of 4-steps

comparator mode.

9-9. Add the batch/discharge brand setting and all brand

accumulation clear.

10-11. Add the explanation of batch/discharge brand

setting target.

14-3. Add the explanation of operating mode.

15. Add the explanation of command and calibration by

communication.

16-3-12. Add the accumulation amount (10 digits),

effective brand number, setting brand number,

comparator brand setting target, all brand accumulation

clear, RS-232C operating mode external control input.

Due to ECN FN16-02057

- DeletionDelete ‘Minebea Co., LTD. Measuring Components

Business Unit’ from the front cover.

2017/08 DRW. NO. EN294-1492-H

Due to ECN FN17-02017

・Delete the company name in the contents.

X

Page 13

Contents

FOREWORD ............................................................................................................................................................ I

MARKS AND REFERENCES DESCRIBED IN THIS MANUAL ............................................................................. I

FOR SAFE OPERA TION ........................................................................................................................................ II

1. LOCA TION OF INSTALLATION ...................................................................................................................... II

2. POWER SUPPLY ............................................................................................................................................ V

3. INSTRUCTIONS FOR USE ............................................................................................................................ V

4. CONFORMITY STANDARD .......................................................................................................................... VI

DIVISIONAL HISTOR Y ....................................................................................................................................... VIII

1. NAME AND FUNCTION OF EACH POINT ..................................................................................................... 1

1-1. FRONT PANEL .............................................................................................................................................. 1

1-2. REAR PANEL ................................................................................................................................................ 3

1-3. SIDE ........................................................................................................................................................... 4

2. CONNECTING WIRES .................................................................................................................................... 5

2-1. NOTES FOR CONCERNING CONNECTING WIRES .............................................................................................. 5

2-2. CONNECTION WITH STRAIN GAGE APPLIED TRANSDUCER ................................................................................ 6

2-3. CONNECTION OF EXTERNAL CONTROL I/O ................................................................................................... 11

2-4. CONNECTION OF STANDARD RS-485 INTERFACE ......................................................................................... 12

2-5. CONNECTION WITH 2-WIRES SERIAL INTERFACE .......................................................................................... 13

2-6. CONNECTION WITH POWER SUPPLY AND GROUND ........................................................................................ 14

3. OPERA TION .................................................................................................................................................. 15

3-1. CHANGEOVER OF MODE ............................................................................................................................. 15

4. CALIBRATION ............................................................................................................................................... 17

4-1. SET ITEMS REQUIRED IN THE CALIBRATION .................................................................................................. 17

4-2. PROCEDURE SET IF NECESSARY AFTER CALIBRATION ................................................................................... 17

4-3. CALIBRATION PROCEDURES ....................................................................................................................... 18

4-4. FINE ADJUSTMENT OF ZERO AND SPAN ........................................................................................................ 24

4-5. DIGITAL LINEARIZE. .................................................................................................................................... 27

4-6. CALIBRATION ONLY OF ZERO POINT ............................................................................................................. 30

4-7. LOCK OF CALIBRATION .............................................................................................................................. 32

5. C FUNCTION MODE ..................................................................................................................................... 33

5-1. SETTING METHOD OF C FUNCTION DATA ...................................................................................................... 33

5-2. FUNCTION OF C FUNCTION DATA ................................................................................................................. 34

6. VARIOUS FUNCTIONS BY C FUNCTION DAT A ......................................................................................... 37

6-1. SETTING OF DECIMAL POINT DISPLAY POSITION ............................................................................................ 37

6-2. A/D SAMPLING RATE .................................................................................................................................. 37

6-3. CONDITION OF OVER DISPLAY ( OR DISPLAY) ............................................................................... 37

6-4. UNIT ......................................................................................................................................................... 37

XI

Page 14

6-5.

EXCITATION .............................................................................................................................................. 37

6-6. NET WEIGHT SIGN INVERSION .................................................................................................................... 38

6-7. ZERO SET ................................................................................................................................................. 38

6-8. ZERO TRACKING ....................................................................................................................................... 39

6-9. POWER ON ZERO ...................................................................................................................................... 40

6-10. TARE WEIGHT CANCELLATION ..................................................................................................................... 40

6-11. CLEAR AT POWER ON ................................................................................................................................. 41

6-12. SETTING WHILE SET MODE 2 OR SET OF PRESET TARE ................................................................................. 41

6-13. GRAVITY ACCELERATION COMPENSATION .................................................................................................... 41

6-14. AUTOMATIC RANGE SWITCH ....................................................................................................................... 43

6-15. SETTING OF THE STABILITY DETECTION TIME WIDTH IN CALIBRATION ............................................................. 44

6-16. DIGITAL LINEARIZE CLEAR .......................................................................................................................... 44

6-17. MEMORY CLEAR ........................................................................................................................................ 45

7. FUNCTION MODE ........................................................................................................................................ 46

7-1. SETTING METHOD OF THE FUNCTION MODE ................................................................................................. 46

7-2. FUNCTION OF THE FUNCTION DATA ............................................................................................................. 47

8. VARIOUS FUNCTIONS BY FUNCTION DATA ............................................................................................ 54

8-1. DIGITAL FILTER .......................................................................................................................................... 54

8-2. ANALOG FILTER ......................................................................................................................................... 54

8-3. DISPLAY FREQUENCY ................................................................................................................................ 54

8-4. STABILIZATION FILTER ................................................................................................................................ 54

8-5. KEY LOCK FUNCTION ................................................................................................................................. 56

8-6. STABILITY DETECTION ............................................................................................................................... 56

8-7. INPUT OF THE PRESET TARE WEIGHT CANCELLATION .................................................................................... 57

8-8. PRINT COMMAND ...................................................................................................................................... 58

8-9. HOLD ....................................................................................................................................................... 58

8-10. SUB DISPLAY SECTION ............................................................................................................................... 59

8-11. ACCUMULATION ........................................................................................................................................ 60

8-12. BRANDS ................................................................................................................................................... 61

8-13. SETTING OF F KEY .................................................................................................................................... 61

8-14. SETTING OF EXTERNAL CONTROL I/O ......................................................................................................... 62

8-15. MEMORY CLEAR ........................................................................................................................................ 63

9. MEASUREMENT MODE ............................................................................................................................... 64

9-1. SETTING METHOD OF THE MEASUREMENT MODE ......................................................................................... 66

9-2. MEASUREMENT COMPARISON VALUE SETTING MODE ................................................................................... 67

9-3. SIMPLE COMPARISON MODE ....................................................................................................................... 72

9-4. SEQUENTIAL MODE ................................................................................................................................... 76

9-5. 4 STEPS COMPARATOR MODE 1 .................................................................................................................. 83

9-6. 4 STEPS COMPARATOR MODE 2 .................................................................................................................. 89

9-7. SQ FUNCTION MODE ................................................................................................................................. 92

9-8. SETTING METHOD OF THE SQ FUNCTION MODE ........................................................................................... 92

9-9. FUNCTION OF SQ FUNCTION DATA .............................................................................................................. 93

XII

Page 15

10.

VARIOUS FUNCTIONS BY SQ FUNCTION DATA ................................................................................... 95

10-1. WEIGHING MODE ....................................................................................................................................... 95

10-2. CONTROL MODE ........................................................................................................................................ 95

10-3. COMPARISON SIGNAL OPERATION ............................................................................................................... 95

10-4. NEAR ZERO (ZERO BAND) COMPARISON OPERATION ................................................................................. 95

10-5. FULL COMPARATIVE OPERATION .................................................................................................................. 95

10-6. BATCH MONITORING TIMER ........................................................................................................................ 95

10-7. SETTING FOR OPERATION AT THE TIME BATCH START .................................................................................... 96

10-8. F-FLOW COMPARE STOP TIMER ................................................................................................................... 96

10-9. M-FLOW COMPARE STOP TIMER .................................................................................................................. 96

10-10. D-FLOW COMPARE STOP TIMER ................................................................................................................... 96

10-11. FLOW/DISCHARGE BRAND SETTING TARGET ................................................................................................ 97

10-12. AUTOMATIC FREE FALL COMPENSATION ....................................................................................................... 97

10-13. JUDGE CONDITION ..................................................................................................................................... 97

10-14. WAITING TIME FOR JUDGE .......................................................................................................................... 97

10-15. SETTING FOR THE OPERATION OF COMPENSATION FLOW .............................................................................. 98

10-16. SETTING FOR THE OPERATION OF MEASURING FINISH OUTPUT ...................................................................... 98

10-17. SETTING FOR DISCHARGE OPERATION AFTER MEASURING FINISH .................................................................. 99

10-18. ACCUMULATION CLEAR ............................................................................................................................ 100

10-19. SQ FUNCTION CLEAR ............................................................................................................................... 100

11. STORED PLACE OF SETTING DATA .................................................................................................... 101

11-1. DATA RECORDED IN RAM ......................................................................................................................... 101

11-2. DATA RECORDED IN EEPROM ................................................................................................................. 101

11-3. DATA CAN BE CHANGED SAVING LOCATION ................................................................................................. 101

12. CHECK MODE ......................................................................................................................................... 102

12-1. SETTING METHOD OF CHECK MODE .......................................................................................................... 103

12-2. EZCTS MODE ......................................................................................................................................... 104

12-3. CONFIRMATION OF ROM VERSION ............................................................................................................ 104

12-4. CONFIRMATION OF OPTIONS ..................................................................................................................... 105

12-5. CONFIRMATION OF EXTERNAL CONTROL INPUT .......................................................................................... 105

12-6. CONFIRMATION OF EXTERNAL CONTROL OUTPUT ....................................................................................... 106

12-7. CONFIRMATION OF LOAD CELL OUTPUT VOLTAGE ....................................................................................... 107

12-8. CONFIRMATION OF BCD OUTPUT (WHEN BCD OUTPUT IS APPLIED.) .......................................................... 107

12-9. CONFIRMATION OF ANALOG OUTPUT (WHEN THE ANALOG OUTPUT IS APPLIED.) ........................................... 108

13. 2 WIRE SERIAL INTERF ACE(S-I/F) ................................................................................................ ....... 109

13-1. INTERFACE SPECIFICATION ....................................................................................................................... 109

13-2. DATA FOR M AT .......................................................................................................................................... 109

13-3. FORMAT DATA EXPLANATION ..................................................................................................................... 110

13-4. EXPLANATION OF OUTPUT TYPE ................................................................................................................ 110

14. ST ANDARD RS-485 COMMUNICA TION ................................................................................................ 111

14-1. SPECIFICATIONS FOR STANDARD RS-485 COMMUNICATION ........................................................................ 111

XIII

Page 16

14-2.

DATA FORM AT .......................................................................................................................................... 111

14-3. ITEM OF STANDARD RS-485 COMMUNICATION SETTING .............................................................................. 111

14-4. CONNECTING METHOD ............................................................................................................................. 11 3

15. MODBUS COMMUNICATION ................................................................................................................. 115

15-1. CALIBRATION BY TRANSMISSION THROUGH MODBUS INTERFACE ................................................................ 123

16. OPTIONS ................................................................................................................................................. 135

16-1. ANALOG OUTPUT .................................................................................................................................... 135

16-2. BCD OUTPUT ......................................................................................................................................... 140

16-3. RS-232C AND RS-422/485 INTERFACE ................................................................................................... 145

17. TROUBLE SHOOTING............................................................................................................................ 182

17-1. EXECUTE TROUBLE SHOOTING ................................................................................................................. 182

18. SPECIFICATIONS ................................................................................................................................... 196

18-1. ANALOG SPECIFICATIONS ........................................................................................................................ 196

18-2. SPECIFICATIONS FOR DIGITAL ................................................................................................................... 196

18-3. INTERFACE ............................................................................................................................................. 197

18-4. GENERAL SPECIFICATIONS ....................................................................................................................... 199

18-5. STANDARD SPECIFICATIONS AT THE TIME OF SHIPMENT .............................................................................. 199

18-6. ACCESSORIES ........................................................................................................................................ 199

19. ERROR DISPLAY .................................................................................................................................... 200

19-1. ERROR LOAD DISPLAY ............................................................................................................................. 200

19-2. ERROR SUB DISPLAY ............................................................................................................................... 201

20. DISPLAY OF SEQUENCE ERROR ......................................................................................................... 201

21. WARRANTY ...................................................................................................................... ...................... 202

21-1. WARRANTY ............................................................................................................................................. 202

21-2. REPAIR ................................................................................................................................................... 202

22. LIFETIME OF USED PARTS ................................................................................................................... 202

22-1. DISPLAY MODULE .................................................................................................................................... 202

22-2. EEPROM .............................................................................................................................................. 202

22-3. ELECTROLYTIC CAPACITOR ...................................................................................................................... 202

22-4. BATTERY ................................................................................................................................................ 202

23. EXCHANGE OF FUSES .......................................................................................................................... 203

23-1. EXCHANGE PROCEDURE OF FUSE ............................................................................................................ 203

24. DISPLAY CHARACTER PATTERN ......................................................................................................... 204

25. SETTING TABLE FOR FUNCTIONS ...................................................................................................... 205

XIV

Page 17

y

y

y

y

1. Name and function of each point

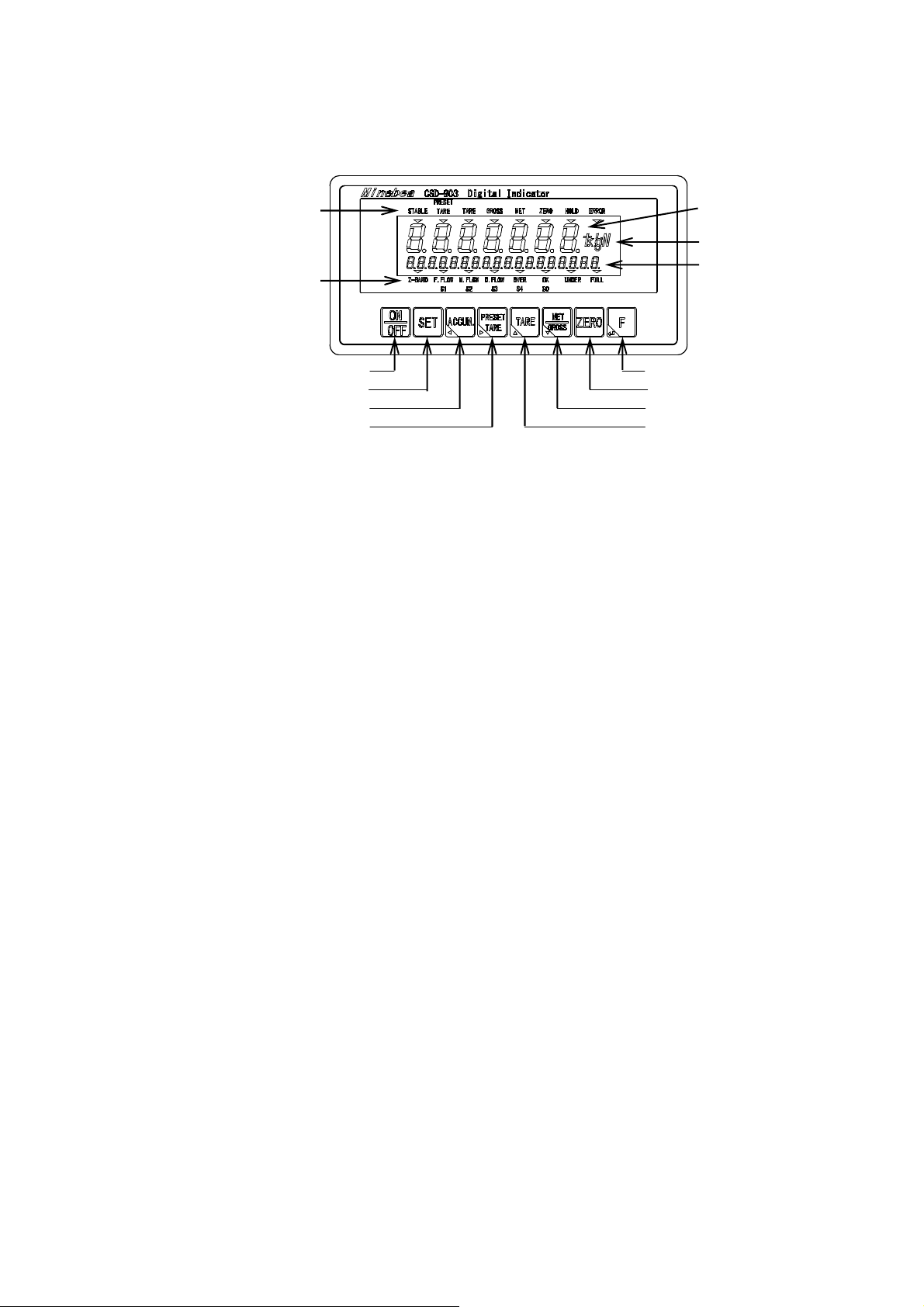

1-1. Front panel

(3) Condition display section 1

(4) Condition display section 2

(9) PRESET TARE ke

(1) Unit display section

The set measuring unit is displayed.

[○] lights at the unit display section at the stand-by condition (The load display has been turned off

while energized)

(2) Load display section

It displays [Gross/Net value], [Over] and [Error].

Also it displays the condition or the setting value in preceding the various setting.

(3) Condition display section 1

It displays the condition of CSD-903.

STABLE It lights when the measured data is steady.

PRESET TARE It blinks while setting a preset tare weight cancellation.

It lights when a preset tare weight cancellation is set.

TARE It lights when the tare weight cancellation is executed.

GROSS It lights when the load display is gross value.

NET It lights when the load display is net value.

ZERO It lights when the displayed load value is zero, and within ±1/4 of a scale interval.

HOLD It lights when HOLD function is active.

ERROR It lights when the output of ERROR signal outputs.

(6) ON/OFF ke

(7) SET ke

(8) ACCUM. ke

(2) Load display section

(1) Unit display section

(5) Sub display section

(13) F key

(12) ZERO key

(11) NET/GROSS key

(10) TARE key

1

Page 18

(4) Condition display section 2

Z-BAND It lights when a gross or net load value is under the value set as near zero.

It also blinks during setting and selecting the Z-BAND.

F.FLOW/S1 It lights when an output signal of full flow is ‘ON’ status in the sequential mode.

/PRELIM2 Also when an output signal S1 is ‘ON’ status in 1 or 2 of comparator mode.

It also blinks during setting and selecting the PRELIM2.

M.FLOW/S2 It lights when an output signal of medium flow is ‘ON’ status in sequential mode.

/PRELIM1 Also when an output signal S2 is ‘ON’ status in 1 or 2 of comparator mode.

It also blinks during setting and selecting the PRELIM1.

D.FLOW/S3 It lights when an output signal of dribble flow is ‘ON’ status in sequential mode.

/F.FALL Also when an output signal S3 is ‘ON’ status in 1 or 2 of comparator mode.

It also blinks during setting and selecting the F.FALL.

OVER/S4 It lights when the judgment condition becomes over in sequential mode.

Also when an output signal S4 is ‘ON’ status in 1 or 2 of comparator mode.

It also blinks during setting and selecting the OVER.

OK/S0 It lights when the judgment condition becomes ok in sequential mode.

/FINAL Also when an output signal S0 is ‘ON’ status in 1 or 2 of comparator mode.

It also blinks during setting and selecting the FINAL.

UNDER It lights when the judgment condition becomes under in sequential mode.

It also blinks during setting and selecting the UNDER.

FULL It lights when the judgment condition becomes full in sequential mode.

It also blinks during setting and selecting the FULL.

(5) Sub display

It displays a setting value of an accumulation value, an accumulation count and a sequence

operation. Please refer ‘8-10 Sub display section’ as for the details.

(6) key

This key turns the display on and off. When the display is turning off, the electric power is supplied to

the inside of the indicator and the measuring section. The display becomes the stand-by condition at

the time of turning off.

(7) key

Change to the function mode. Change each status to the former status set in advance.

(8) key

It is used for the load value to accumulate, and also it carries up the set digit when the value is set.

(9) key

It is used when the setting of the preset tare weight cancellation is executed.

And also it carries down the set digit when the value is set.

(10) key

The tare weight cancellation is executed.

And one value of the selected digit is raised when the value is set.

(11) key

It switches the gross value and net value of the displayed data.

And one value of the selected digit is lowered when the value is set.

(12) key

It memorizes a present load value as a zero point, and makes the display a zero.

(13) key

2

Execute function set in F key.

(Selectable from None, Print, Hold, Start of flow, Emergency stop, Zero clear, Tare weight bear,

Accumulation bear, Shift to the setting mode of weighing comparative mode or Forced batch finish)

Otherwise, decide the various data input and memorize the setting value in internal memory.

Page 19

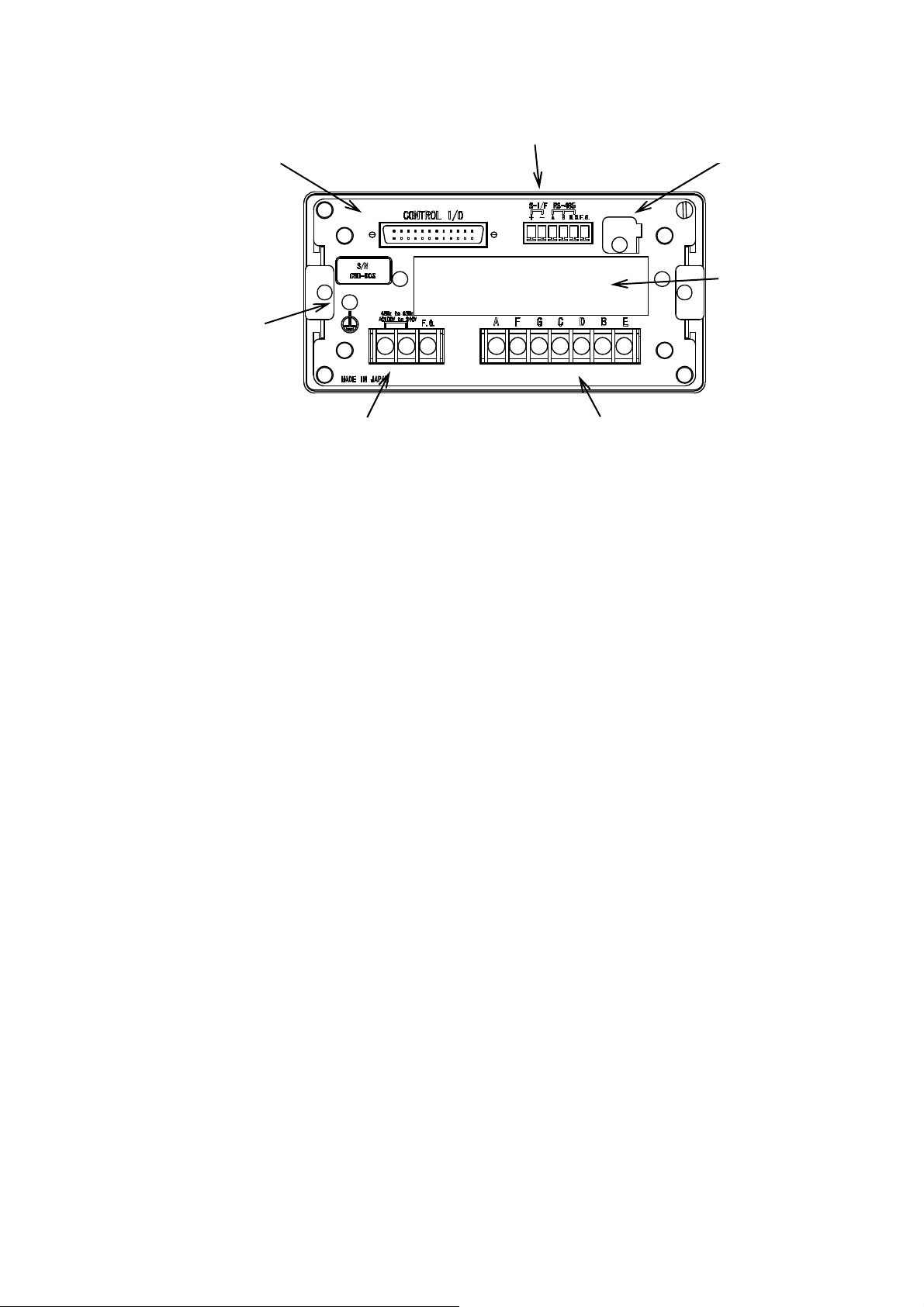

1-2. Rear panel

(6) External control I/O

(7) Protected earth

terminals

(1) Power supply terminals

It connects with power supply and ground.

(2) Load cell terminals

The signal line of the weighing part (load cell) is connected.

Up to 6 pieces of strain gage based transducer scan 350 Ω be connected when the bridge power

supply is DC10 V.

(3) Optional parts mounting section

One point either of analog electric current output, analog voltage output, BCD output, CC-Link,

RS-232C or RS-422/485 is installed.

(4) Calibration LOCK switch section

Calibration LOCK switch can be operated by removing the cover.

(5) RS-485 and 2-wires method serial interface terminals

RS-485 interface terminals connect with a host computer, etc., and the 2 wires method serial

interface terminal connects with a printer, an external display unit, etc.

(6) External control I/O connector

It uses to connect with the external control unit.

Up to 9 input and up to 13 output in available to use.

(7) Protected earth terminals

Grounding wire should be connected to prevent the influence of noise such as static electricity.

Do not connect it other than the grounding.

F.G. of the power supply terminals is common internally.

(5) RS-485 and 2-wires method serial interface terminals

(1) Power supply terminals

(4) Calibratin LOCK switch

(3) Optional parts

mounting section

(2) Load cell terminals

3

Page 20

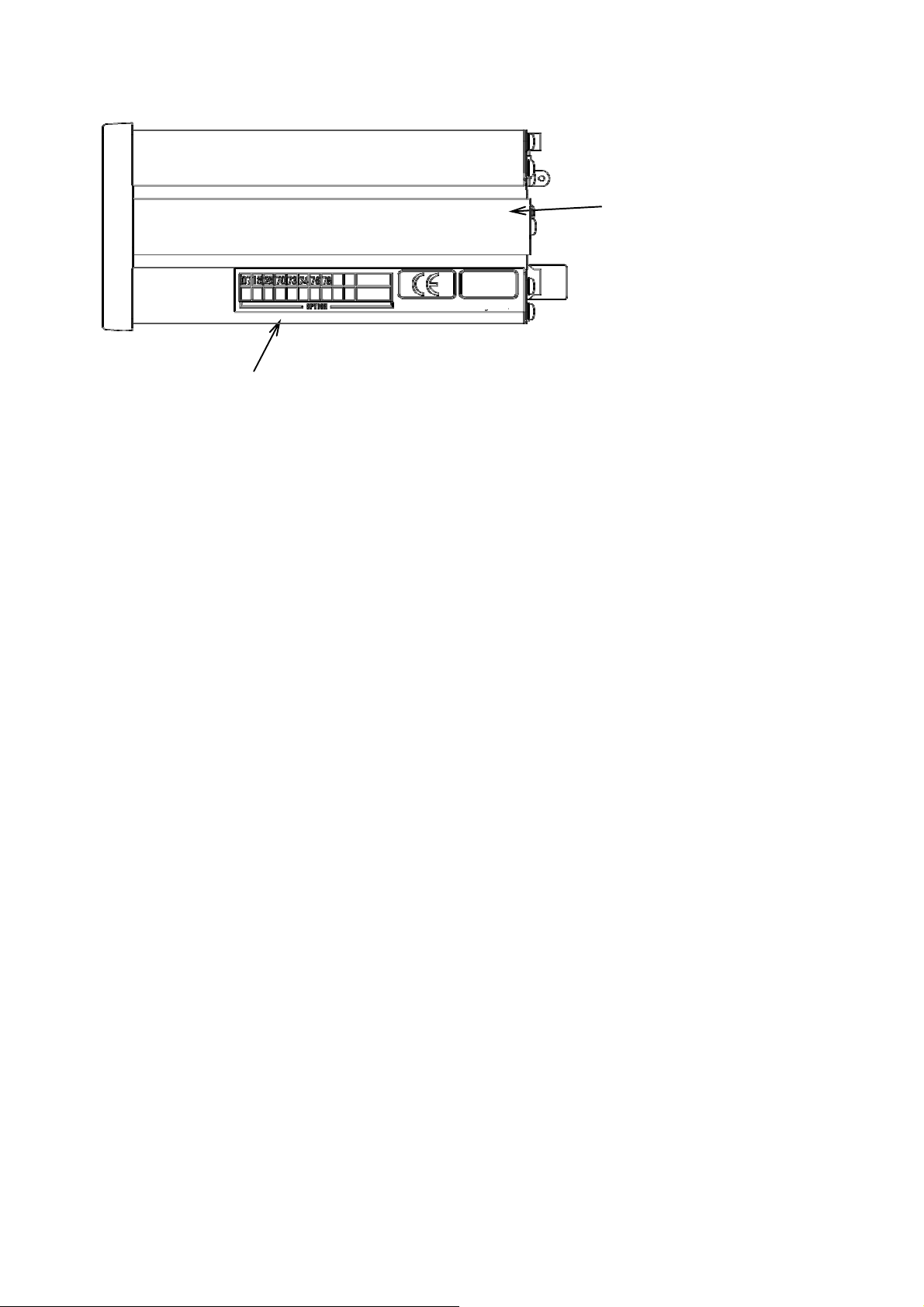

1-3. Side

(1) Model instructions seal

(2) Panel mounting metal

(2) Panel mounting metal

(1) Model instruction seal

It shows a model number.

Use when CSD-903 is mounted to the control panel.

4

Page 21

2. Connecting wires

2-1. Notes for concerning connecting wires

● When connecting with wires, make sure it was turning off the power supply without fail.

● Do not supply the AC power supply until the installation is completed. There is no switch that

switches ON/OFF of power supply in the main body.

● Do not drop the instrument, and do not give a strong impact because the terminal board of the panel

is made of resin.

● Be sure to install and use an acrylic cover of the attachment for the terminal board.

● The tightening torque of terminal screws on the terminal board is as shown in the table below.

Terminal board

Power supply terminal board

Loading cell terminal board

The solder less terminal that suits the terminal board of this terminal is as shown in the table as

below.

Terminal stand

Power supply terminal board

Loading cell terminal board

● The cable connected with the main body should be separated from the noise source such as I/O for

the control, power supply line as possible.

● The Conduit wiring should be the type for exclusive use. Avoid sharing it with other lines.

● Be sure to ground a grounding wire with exclusive use of D-type single grounding. Do not share it

with other groundings for power supply.

● The shield cable line is used for the connection of the external control I/O, and the shield with F.G

terminal of the power supply terminals

Terminal board screw

tightening torque

0.6 N・m

Width of solder less

terminal

6.2 mm or less

Acceptable Oki

solder less terminal

O type 1.25-3 or Y

type 1.25-3.5

5

Page 22

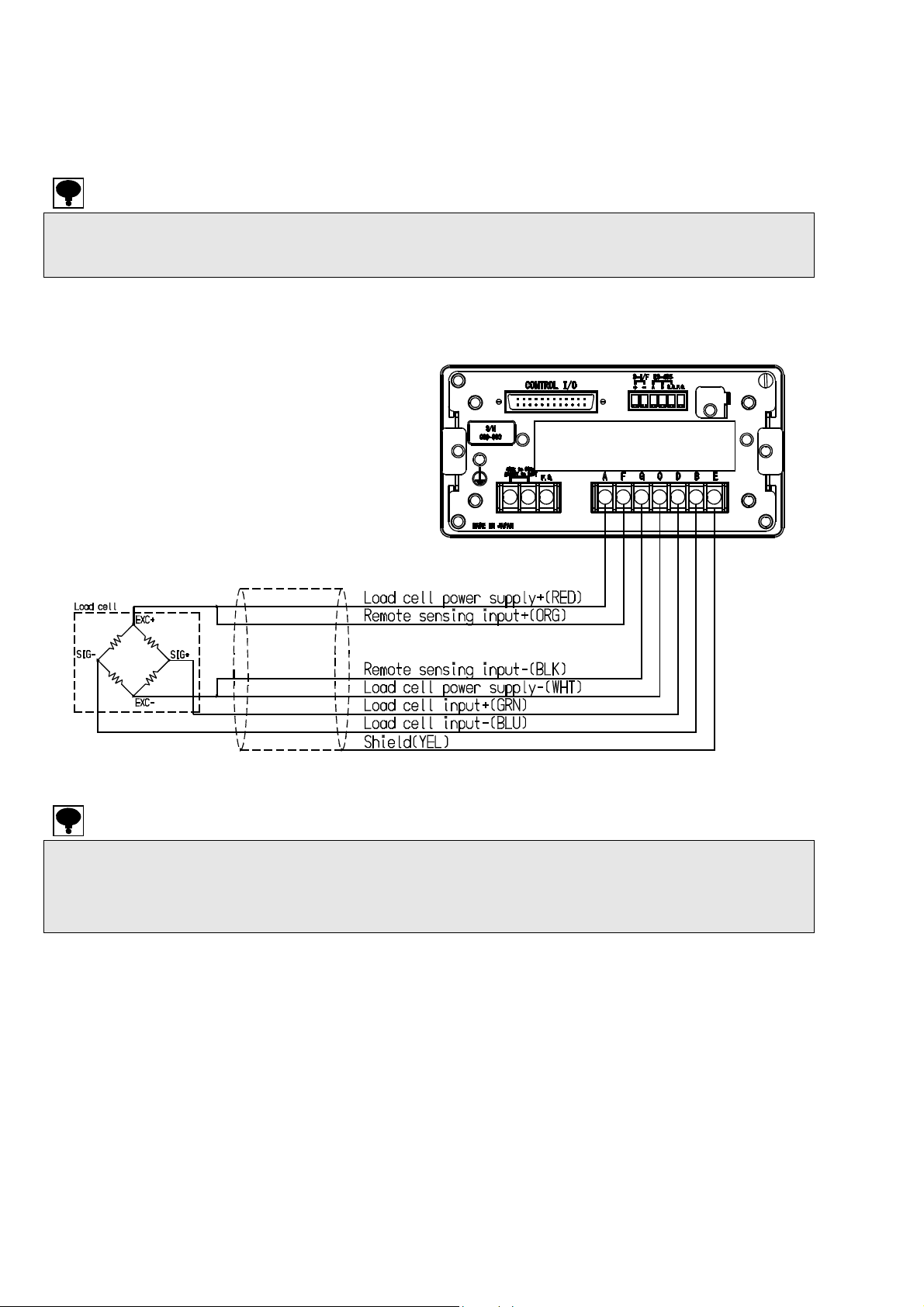

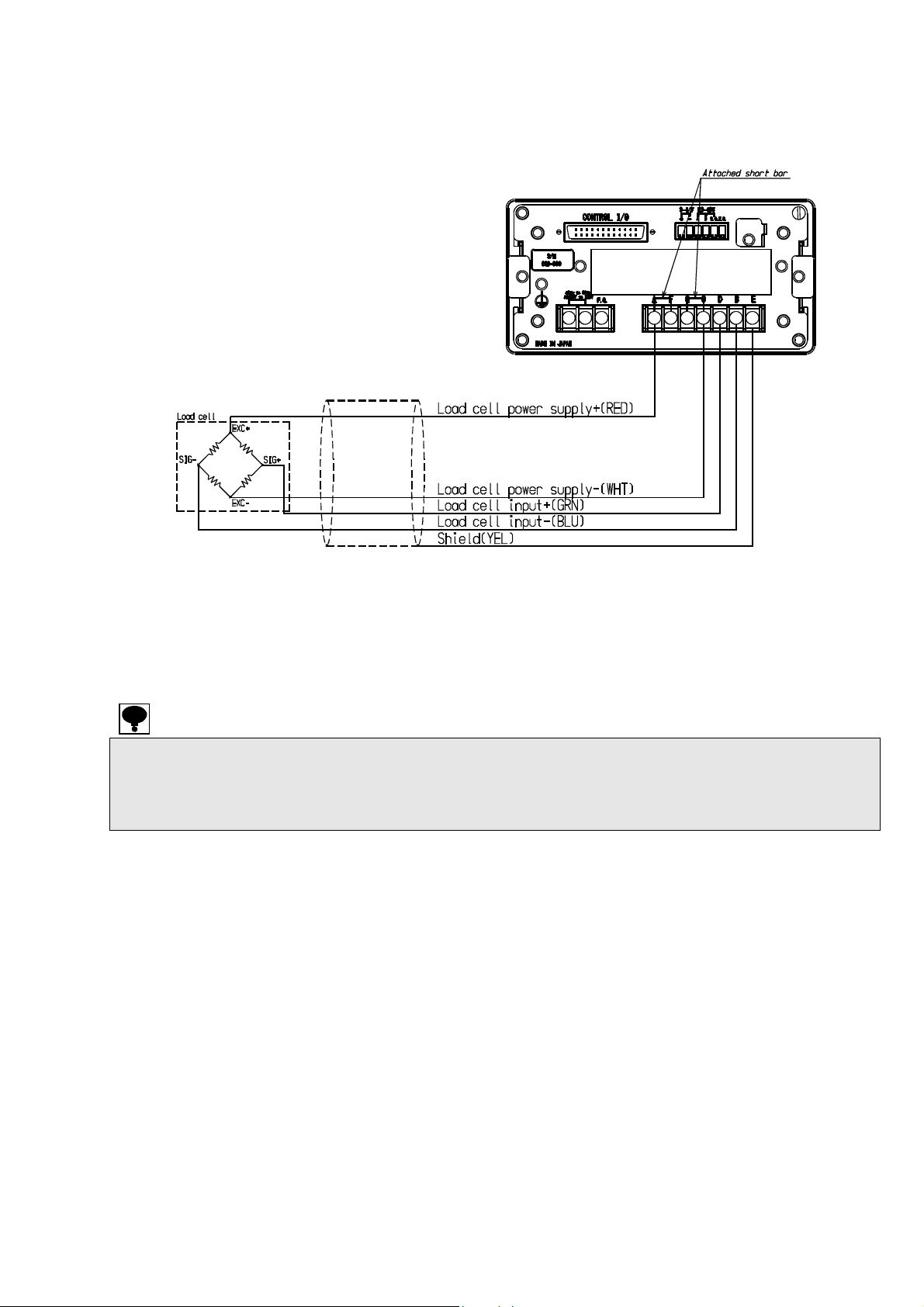

2-2. Connection with strain gage applied transducer

The instrument can connect with the strain gage applied transducers, such as load cells, pressure

sensors, etc. Here, we describe the example of connection with load cells, so that the connection

with another type of strain gage applied transducers shall be preceded in the same way.

When the tension is applied with the use of tension type or universal (tension/compression) type load

cell, and display of (+) direction is required, connect the input (+) of the load cell to the terminal B and

the input (-) of the load cell to the terminal D individually.

(1) Case 6-wires type connection cable

・ When the length of CAB-501 (our standard cable) is more than 100 m totally, there may have the

・ Shorten the remote sensing input + and remote sensing input – near the main body of load cell.

case that accuracy is out of warranty as the remote sensing function of the instrument does not

work enough due to the resistance of the cable.

However, when the short is made near the instrument, it will not work as the six-wire type.

6

Page 23

(2) Case 4-wire type connection cable

・ As using the 4-wire cable, shorten the load cell terminals A - F and C - G with the attached shor t bar.

・ When the length of CAB-502 (our standard cable) is more than 30 m totally, there may have the case

CSD-903 does not work in normal operation when the terminal F and G is in the open status.

that the accuracy is out of warranty due to the resistance of cable, the input voltage of the

instrument will be decreased.

7

Page 24

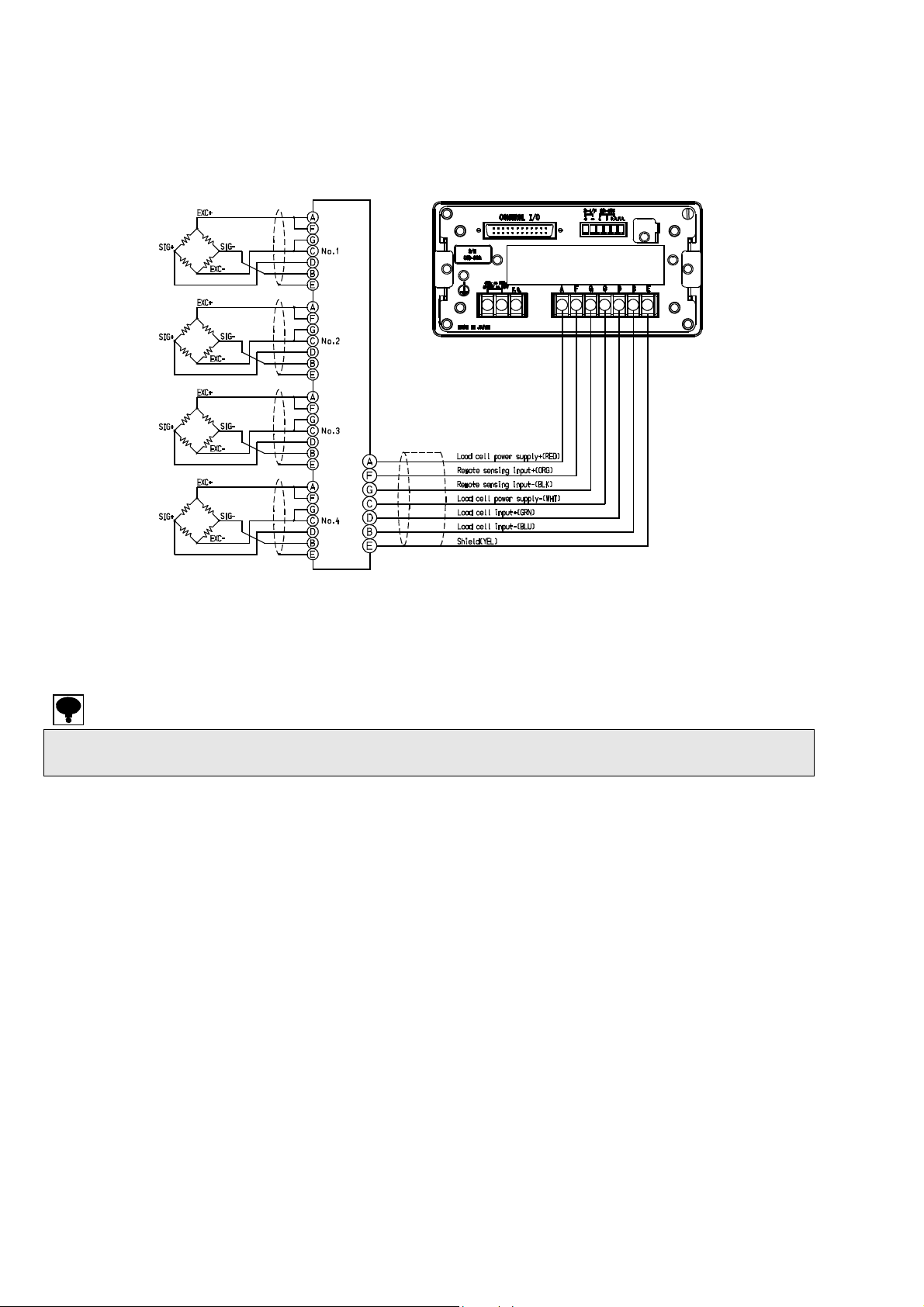

(3) Case connection of the load cells in parallel

The hopper scale, the track scale, etc, have the case to connect with several pieces of the load cells

in parallel. The parallel connections can be easily executed by using optional SB-310 and SB-320

(Summing type junction box).

CSD-903 can make up to 6 parallel connections when the load cell is 350 ohm type. Please consult us

as for a method over 5 parallel connections.

8

Page 25

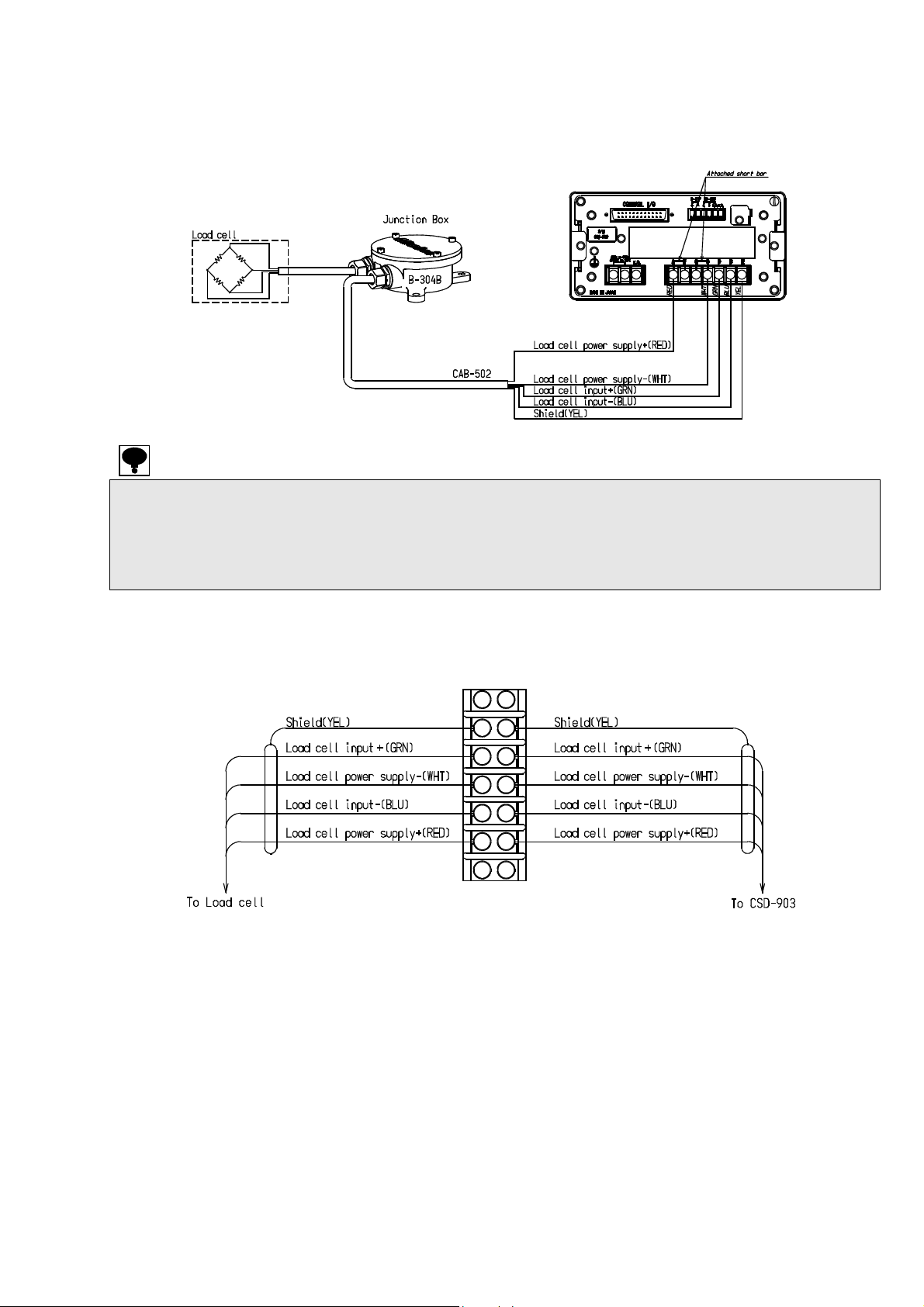

(4) Connecting with load cell, Junction box B-304B for extension, and CSD-903

1) When you use CAB-502 (4 core cable)

・ When you use it with 4 wires method, be sure to make a short-circuited between A-F and between

・ There is the possibility of the descent of the input voltage of the instrument at the time of total 30m

C-G of the load cell terminal board. When terminal F and terminal G are used with opening status,

CSD-903 cannot make normal operation.

or more in length of CAB-502 (our standard cable) and also the possibility of outside of accuracy

due to the resistance of the cable.

B-304B internal terminal connection

9

Page 26

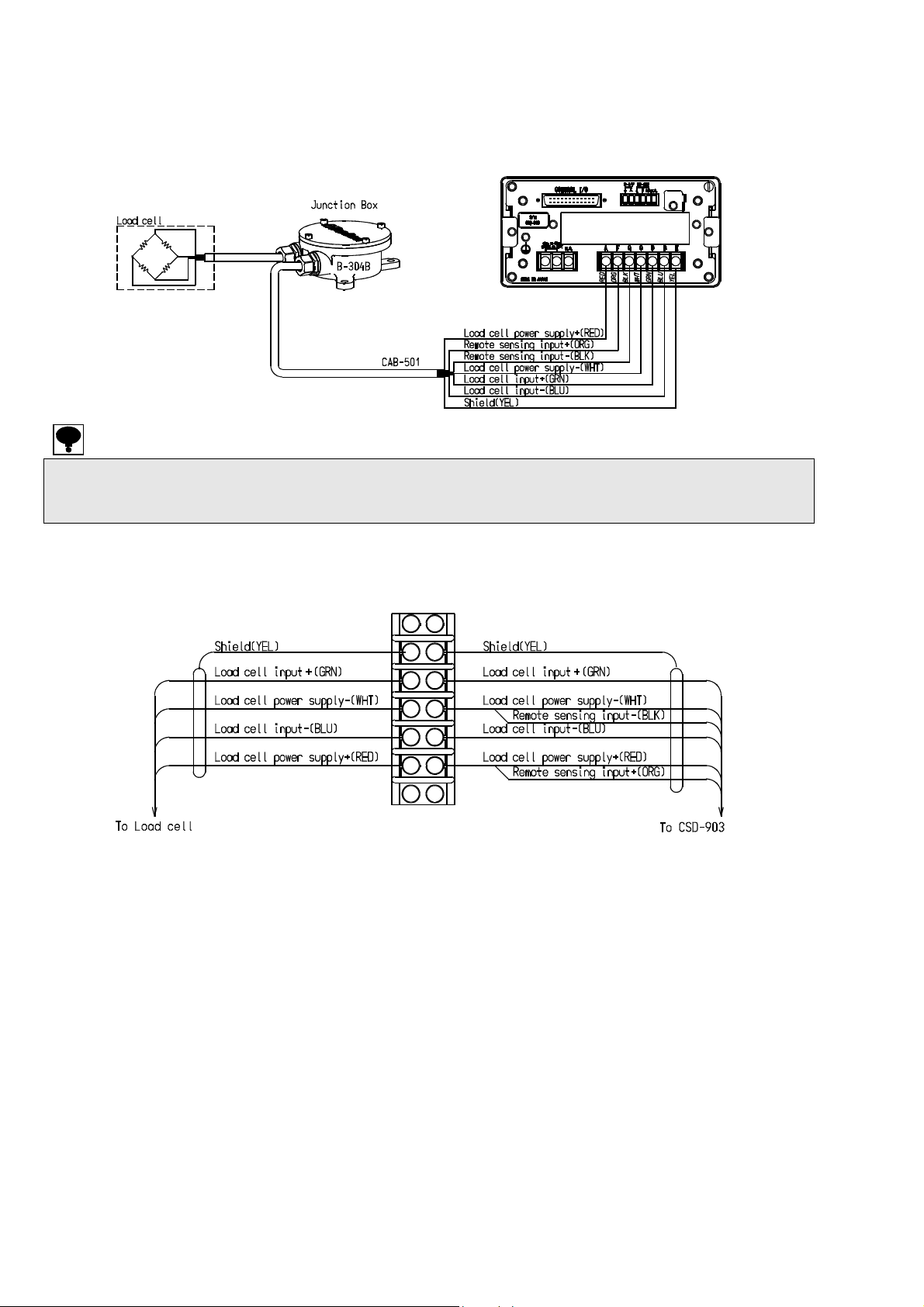

2) When you use CAB-501(6 core cable)

The remote sensing function of the instrument does not function enough due to the resistance of the

cable at the time of total 100m or more in length of CAB-501 (our standard cable), and there may have

the possibility of outside the accuracy guarantee.

B-304B internal terminal connection chart

10

Page 27

r

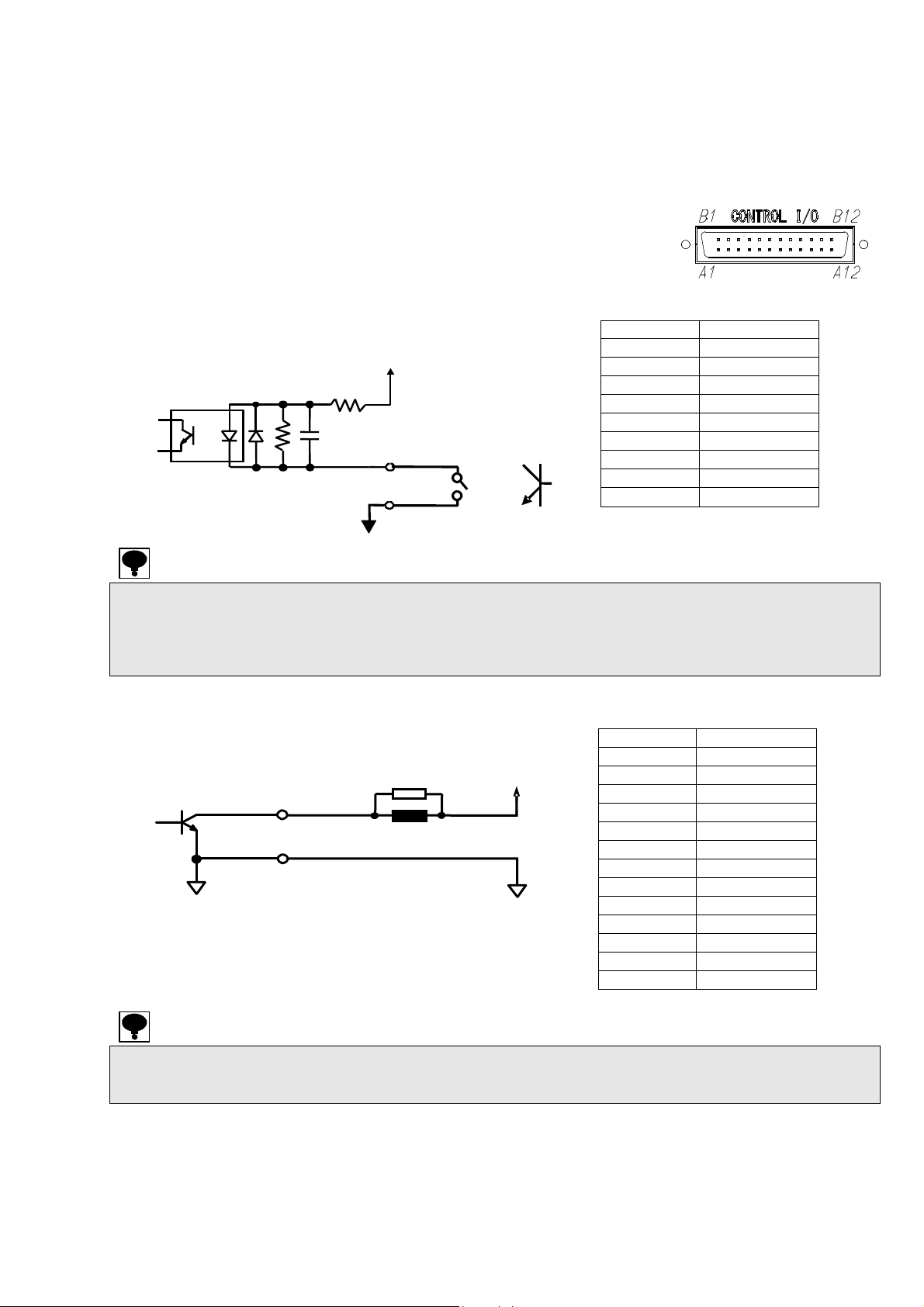

2-3. Connection of external control I/O

The function can be controlled from the outside with the external control I/O connector on the rear

panel.

The external control input is executed by shortening each input and COM.1 with a contact point or

open collector after wiring the connector.

The external control output is executed by open collector output.

(Open collector rated: V

The right figure is an external control I/O connector.

The upper line from A1 to A9 is for input signal, and the lower line

from B1 to B12 and A12 is for output signal.

(1) Connection for input

430ohm

・ There are a pulse input and a level input in the recognition of the external control input signal

depending on setting items.

・ Refer to [8-13-1.Seting method of the external control input] for the details.

・ The common of the external control input and the common of the 2 wire serial interface circuit are

common.

(2) Connection for output

B1 to B12, A12

A11

COM.2

Open collector rated:

=DC35V IC=DC40mA

V

CE

= DC35 V, IC = DC40 mA at maximum.)

CE

Approx. 12V

2.2 k-ohms

0.047μF

A1 to A9

A10

COM.1

Surge elimination device

Load

o

Applicable connector :

Connector FCN-361J024-AU,

Connector cover FCN-360C024-B (made by Fujitsu)

V

CE

A1 Input1

A2 Input2

A3 Input3

A4 Input4

A5 Input5

A6 Input6

A7 Input7

A8 Input8

A9 Input9

A10 COM. 1

B1 Output1

B2 Output2

B3 Output3

B4 Output4

B5 Output5

B6 Output6

B7 Output7

B8 Output8

B9 Output9

B10 Output10

B11 Output11

B12 Output12

A12 Output13

A11 COM. 2

・ The common of the external control output is insulated from the other commons.

・ Refer to [8-13-2. Setting method of the external control output] for the details.

・ Connect a suitable serge elimination device for load for protection from external control output.

11

Page 28

A

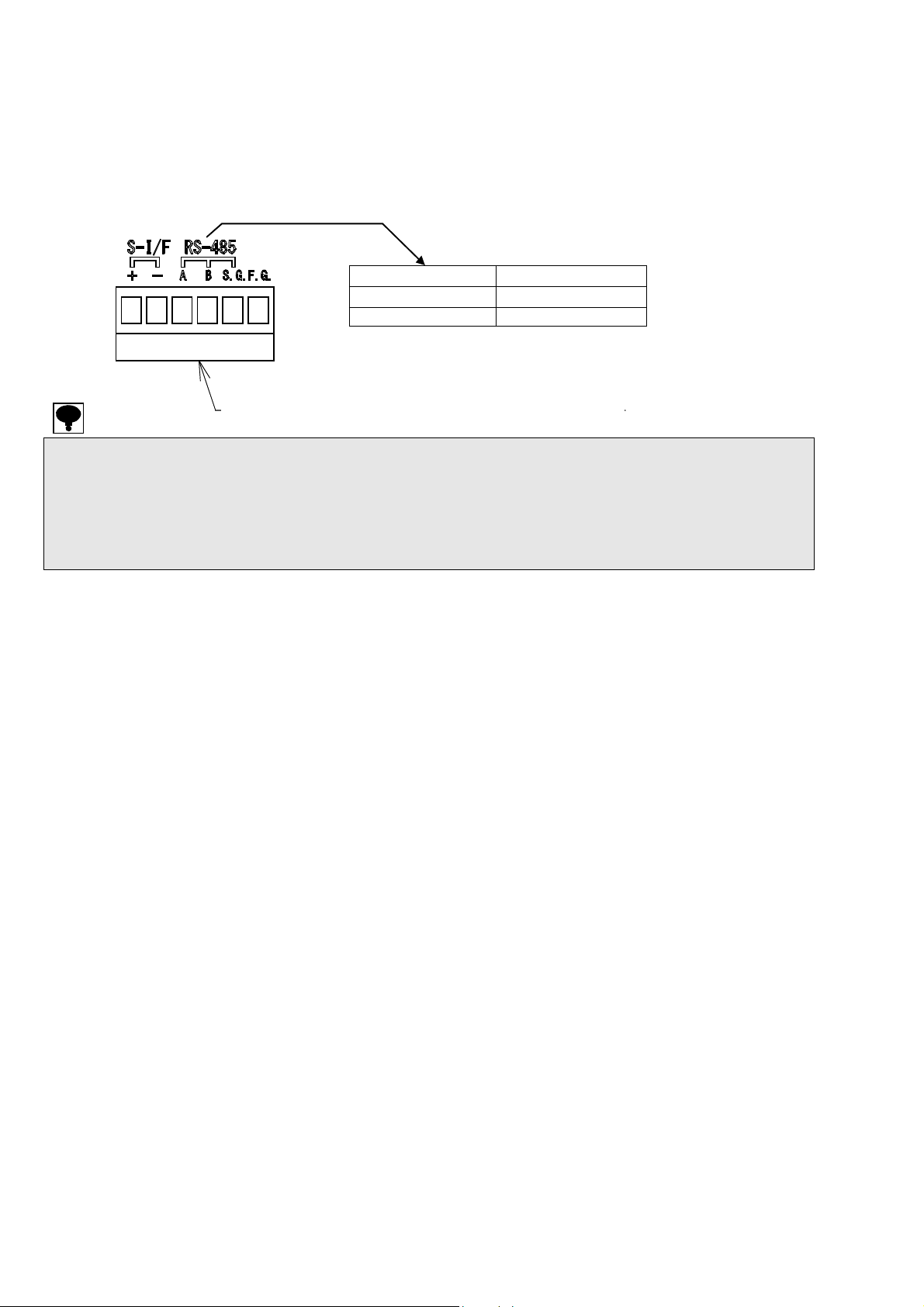

2-4. Connection of standard RS-485 interface

Connect with A, B and S.G. on the output terminals for RS-485 interface and the 2 wire serial

interface showing as below figure. Refer to [14-4.Connecting method] as to the connection.

With the standard RS-485, either the command mode or the protocol conforming to the Modbus is

selectable.

(Refer to [15.Modbus communication] as to the Modbus communication.)

・ Stripped length of electrical cable tip is 7 mm.

・ The tightening torque of terminal screws on the terminal block is 0.6 N・m.

・ Please use AWG28 ~ AWG16 for connecting cable.

・ The signal ground of standard RS-485 interface and internal common are connected.

・ Please connect the shield with F.G. terminal of RS-485 interface / 2-wires method serial interface

terminal by using the shielded cable when CSD-903 complies with the CE conformity or applied JIS

standard.

Screw side of terminals

A

B

S.G. Signal ground

pplicable Plug : XW4B-06B-H1.made by OMRON.

Differential I/O (+)

Differential I/O (-)

12

Page 29

A

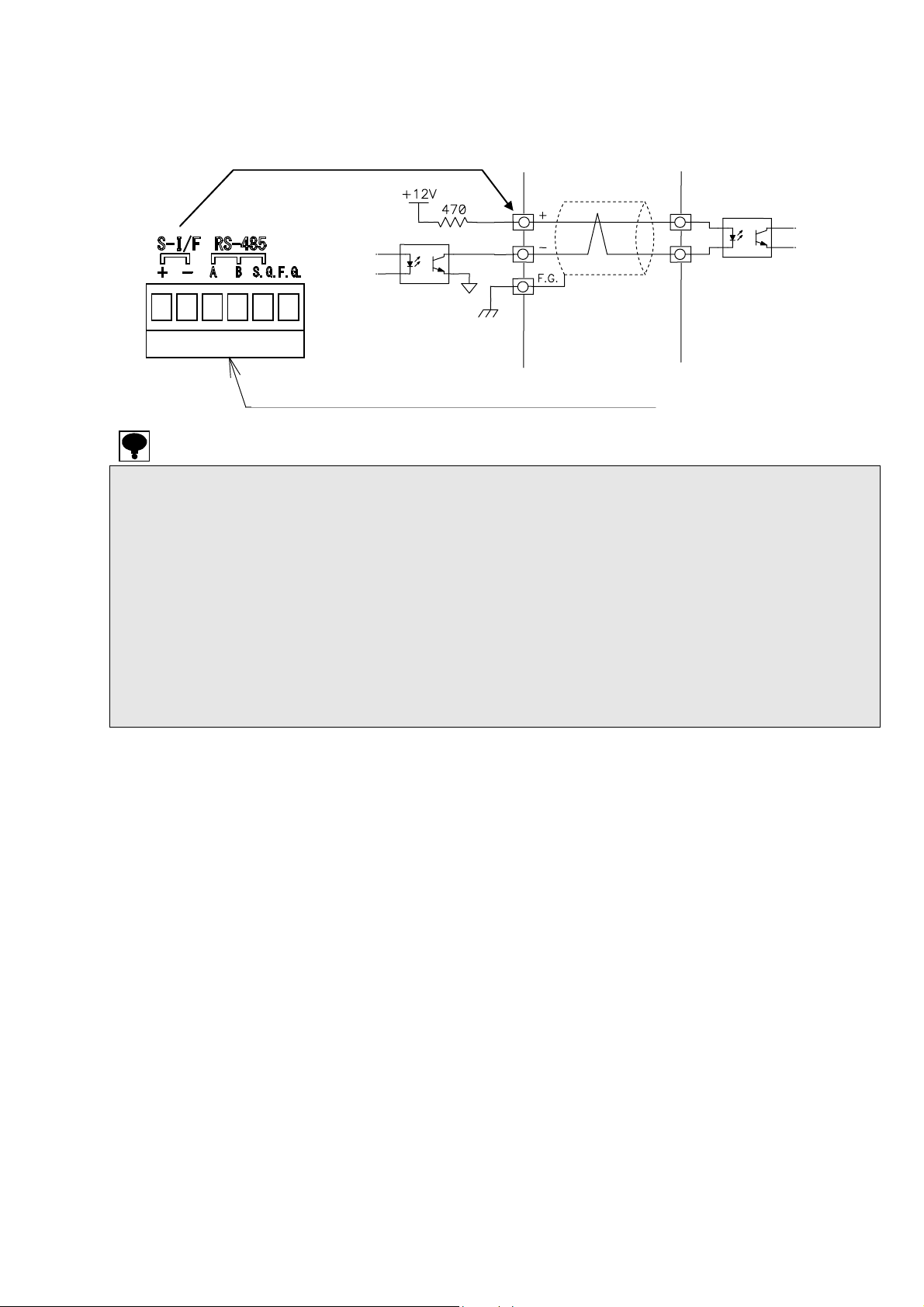

2-5. Connection with 2-wires Serial interface

This is the 2-wires method serial interface to connect with a printer, an external display unit, etc.

The 2-wires serial interface is connected with +, - and F.G. shown in the below figure.

CSD-903Internal

equivalent circuit

・ Stripped length of electrical cable tip is 7 mm.

・ The tightening torque of terminal screws on the terminal block is 0.6 N・m.

・ Please use AWG28 ~ AWG16 for connecting cable.

・ There are M252B, etc., made by UNIPULSE as the equipment for the 2-wires method serial interface.

・ The cable must use two cores shielded cable as much as possible and connect the shield with F.G.

・ The equipment for 2-wires method serial interface can be connected up to three in parallel.

・ The commons of the external control input and the 2-wires method serial interface are connected.

・ This internal circuit and photocoupler are insulated.

・ Please connect the shield with F.G. terminal of RS-485 interface/2-wires method serial interface

terminal. Please twist the cable when you don’t use the shielded cable.

(The applicable cable length is up to 100 m with shield, and up to 20 m without shield.)

(Maximum output current : Approx. DC20 mA)

terminal by using the shielded cable when CSD-903 complies with the CE conformity or applied JIS

standard.

Screw side of terminals

pplicable plug : XW4B-06B-H1 (made by OMRON)

Serial interface corresponding equipment

13

Page 30

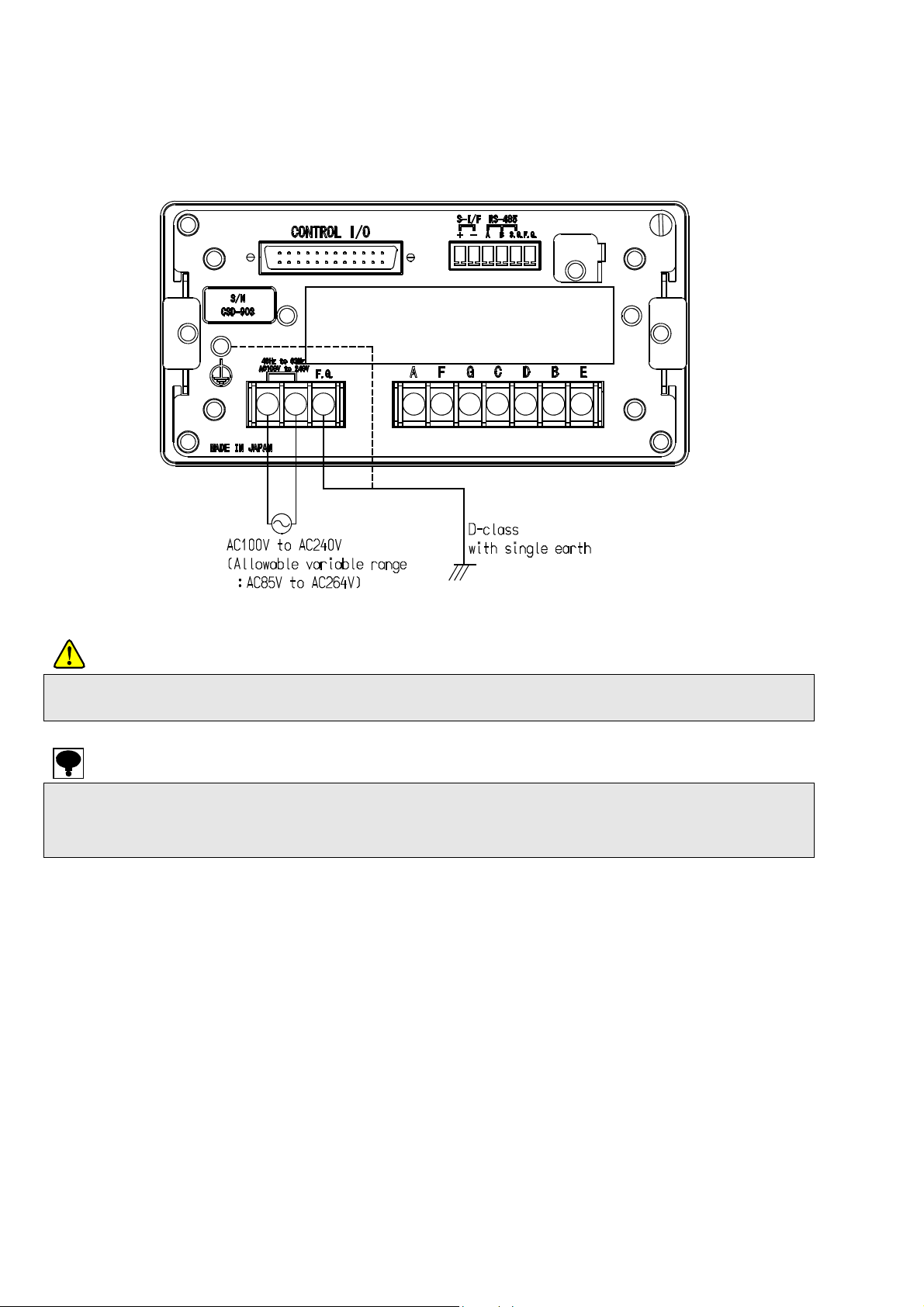

2-6. Connection with power supply and ground

Connect the power supply with the power supply terminal board on the rear panel of the instrument

shown as below figure.

Grounding should be the D class with the single earth.

Connection with the power supply and the earth should be made surely according to the figures, and

also within the specified power supply condition.

・ The grounding of the instrument should be the D-class with single earth.

・ When suiting the instrument with the CE conformity standard or JIS standard, please make the

Warning

It may cause an unexpected malfunction due to the effects of noise from other equipments.

single earth with a protective ground terminal.

14

Page 31

y

3. Operation

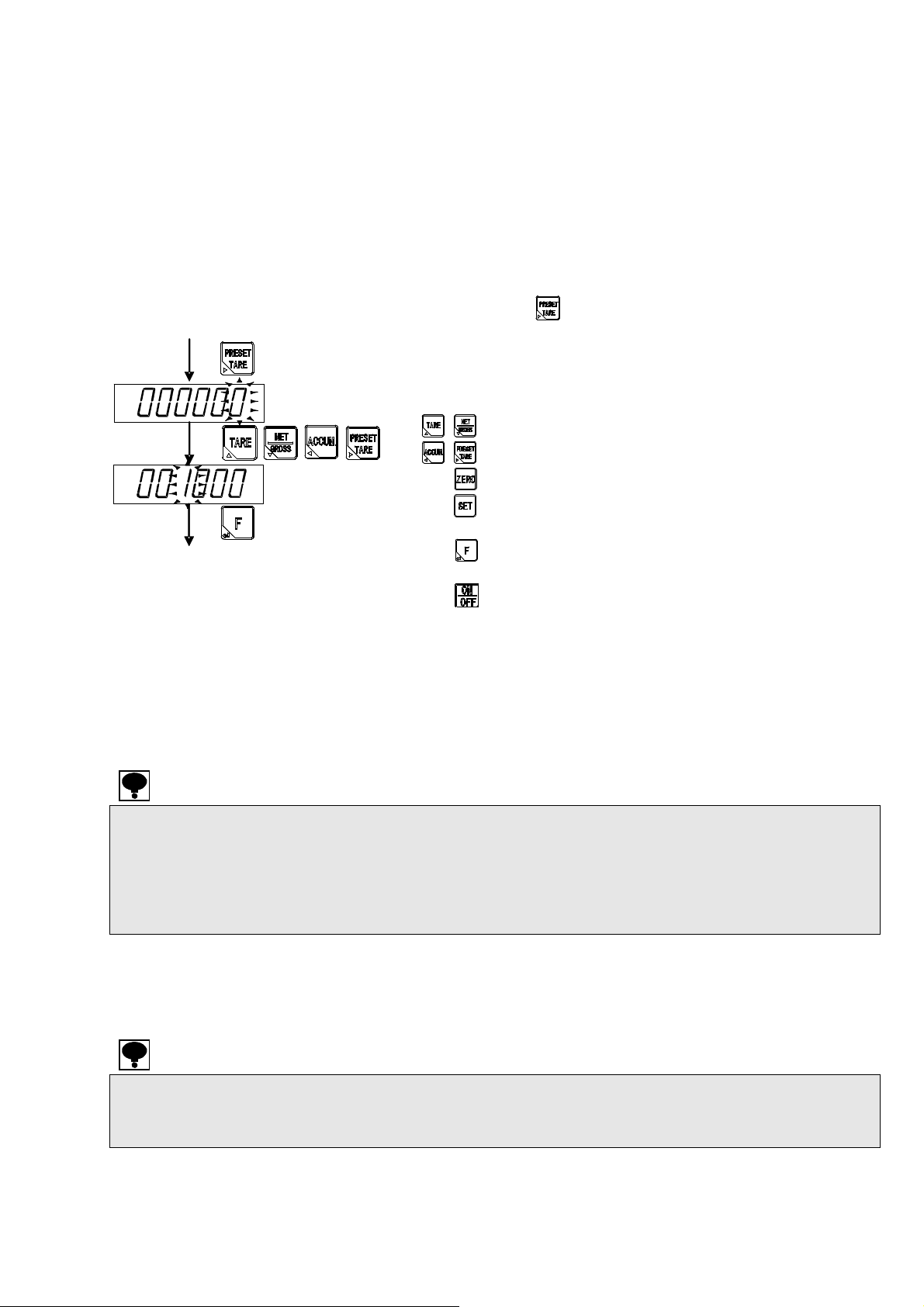

3-1. Changeover of mode

This unit has various modes according to the operating situation.

Change the mode by the key operation.

Stand-by condition

(Light off the measuring value

Set mode 1

Display of

Display of

Display of

Set mode 2

Display of

Display of

Displa

Display of

of

Power ON

Display check

(All light on)

Mesurement mode

(Display measuring value)

+

①Refer to the C function mode

②Refer to the Calibration mode

③Refer to the Check mode

④Refer to the Function mode

⑤Refer to the SQ Function mode

⑥Refer to the setting mode of

weighing comparative value

⑦Refer to the Accumulation

display mode

When the load cell output exceeds ±10 % of weighing capacity in the condition that power-on-zero is

valid after checking the display, the display becomes the error indication of [ ‐‐‐‐‐‐ ]. At this time, if

the key is pressed, the display compulsorily becomes a load display. Refer to the paragraph [6-8.

Power on zero].

15

Page 32

(1) C function mode ( )

Various functions which relate to calibration by setting C function data become effective.

(2) Calibration mode ( )

By setting the calibration data, the calibration is executed to display the electric signal from the

measuring section (load cell) as an accurate load.

(3) Check mode ( )

The ROM version, the each input/output operation, the monitor of load cell output value, the BCD

output and the analog output can be confirmed by the check mode.

(4) Function mode ( )

Various functions become effective because of setting the function data.

(5) SQ function mode ( )

The setting of SQ function data makes various functions related to the sequence operation effective.

(6) Weighing comparative mode ( )

Execute the setting of comparison value of various weighing in the sequence weighing and

comparison operation.

(7) Accumulation display mode ( )

The accumulation value and accumulation times can be confirmed for each brand.

Pressing the key clears the accumulation value and accumulation times displayed.

16

Page 33

4. Calibration

To be able to display the electrical signal from the measuring section (load cell) as an accurate

weight, the operation to match the display of the instrument with the weight loaded on the

measuring section is called a calibration.

For example to adjust the display of this instrument to 100.00 accurately when the weight of 100

kg is loaded on the measuring section is said.

4-1. Set items required in the calibration

(1) Scale interval ( , , , , , )

It is the minimum unit of the measuring value the value to be set is [1], [2], [5], [10], [20] or [50].

The value of {Weighing capacity/Scale interval} is the display resolution.

(2) Weighing capacity ( )

It is the maximum weight to be able to measure by the measuring section (load cell).

(3) Mass of weight used at the span calibration ( )

The span calibration can be executed with the arbitrary weight. The same setting as the weighing

capacity is executed when there is a weight for weighing capacity.

Please give setting here as 2/3 or more of weighing capacity to reduce the calibration error.

(4) Calibration at zero ( )

It is a procedure of the calibration to become the zero point of the measurement when nothing is put

on the measuring section (status of an initial load). There are [Method by the weighing data (status of

an initial load)] and [Method by a numeric input of the load cell output voltage] as a calibration

method.

(5) Calibration at span ( )

It is a procedure by which execute the calibration of the change in the electric signal of the load cell

when the weight is put on the measuring section to become the display of a correct weighing value.

There are [Method with weight] and [Method by a numeric input of the load cell output voltage] as a

calibration method.

4-2. Procedure set if necessary after calibration

(1) Display position of decimal point (C function : )

The decimal point is put on the load display of this unit.

(2) Unit (C function : )

The unit is put on the load display of this unit.

(3) Digital linearize ( )

It is a function the compensation of three points or less except the zero and span, and to reduce the

measurement error. Refer to the paragraph 4-5. Digital linearization.

(4) Automatic range switch (C function : ~ )

It is the setting of the second range or the third range for [Multi scale interval scale]. The boundary

value and the scale interval within the each range are set. Refer to the [6-13.Automatic range switch].

(5) Gravity acceleration compensation (C function: , )

It is a function for the compensation of the span error by setting the gravity acceleration of the two

different districts with a calibration place and a place to be used. Refer to [6-11.Gravity acceleration

compensation].

・ Please execute the calibration if necessary when the environment to be used changes .

・ The display resolution that the performance becomes effective is 10 000 or less.

・ The mass of the weight used in the span calibration must use the one of 2/3 or more of weighing

The display resolution is a value into which weighing capacity is divided by the scale interval of the

first range.

capacity to reduce the calibration error.

17

Page 34

4-3. Calibration procedures

4-3-1. Flow of calibration

Step1 Connect the load cell with this instrument.

Step2 Please energize.

Step3 Please set the bridge power supply.

Step4 To stabilize this unit and the measuring section (load cell); please

make the instrument to the status of energizing for about 10 min.

Step5 Please switch the mode to the calibration mode.

Step6 Please set the scale interval.

Step7 Please set weighing capacity.

Step8 Please set the mass of the weight put on the measuring section.

Step9 Please execute the calibration of the zero point with nothing put on

the measuring section, or by setting the output voltage value of the

zero point of the load cell.

Step10 Please executes the calibration of span by putting the weight on the

measuring section, or by setting the output voltage value of the

span point of the load cell.

Step11 Please quit from the calibration mode. Process the setting since

step 12 showing as follows if necessary.

Connection with load cell

Energizing power supply

Paragraph 6-5

Set the bridge power supply.

Energy for 10 min after

power is turned on.

Paragraph 4-3-2

Switch to the calibration

mode

Paragraph 4-3-3

Set the scale interval

Paragraph 4-3-4

Set the weighing capacity

Paragraph 4-3-5

Set the mass of the weight

Paragraph 4-3-6

Calibration at zero point

Paragraph 4-3-7

Calibration at span

Paragraph 4-3-8

Quit the calibration

Step12

to Paragraph 6-1

Set the display

position of

decimal point

Step13 Step14 Step15

to Paragraph 6-4

Set of the unit

to Paragraph 4-5

Digital linearize

to Paragraph 6-12

Automatic range

switch

Step16

to Paragraph 6-11

Gravity

acceleration

18

Page 35

4-3-2. Switch to the calibration mode

Stand-by condition

Change from the standard measurement mode to the

stand-by condition by the key.

+

Calibration mode

Move to the setting of the scale interval.

4-3-3. Set of the scale interval

Pressing the key with the key pressed, it

displays .

Press the key here.

displays.

Press the here.

displays and it enters into the calibration

mode.

When key is pressed twice from

display, is displayed.

[ ] is the scale interval being memorized now.

Please select the scale interval from 1, 2, 5, 10, 20 or 50.

: Selects the scale interval.

: Setting is interrupted and returns to CCAL

display.

The scale interval to

be used

: The displayed value is memorized, and proceed

to the next step.

Move to set weighing capacity

Press the key after the set.

19

Page 36

g

p

p

4-3-4. Set weighing capacity

Memorized weighing

Memorized weighing

ca

acity

When key is pressed from display,

is displayed.

When the weighing capacity has already been changed, the

weighing capacity being memorized now is displayed.

Here, please set the weighing capacity.

Changed weighing

Changed weighing

acity

ca

Move to setting the mass

of the weight.

4-3-5. Setting the mass of the weight

Mass amount equal to

ひょう量分の分銅値

wei

hing capacity

Weight value put on

measurement section.

: The value of changed digit is changed.

: Changed digit is selected.

: The value is changed to [0].

: Setting is interrupted and display returns to CCAL.

: The display value is memorized, and it proceed to the

next step.

After the setting, press the key.

When key is pressed from display

****

****

[ ] is the amount of weighing capacity.

is displayed.

Please set the mass of the weight actually put on the measuring

section here.

The same setting as the weighing vcapacity is executed when

there is a weight for weighing capacity.

: The value of changed digit is changed.

: Changed digit is selected.

: The value is changed to [0].

: Setting is interrupted and display returns to CCAL.

: The display value is memorized, and it proceed to the

next step.

Move to the calibration

of zero point

After the setting, press the key.

20

Page 37

V/VmV/V

4-3-6. Calibration of zero point

When the zero calibration starts, is displayed.

Please select the zero calibration method.

(1) Method by the measuring data (status of initial load) ⇒ Press the key, and execute the

operation of a).

Execute the calibration of zero with nothing put on the measuring section.

(2) Method by the numeric input of the load cell output voltage. ⇒ Press the key, and execute the

operation of b).

Execute the calibration of zero with inputting the output voltage value of the load cell when nothing is

put on the measuring section.

Press the

key,

with nothing on

the measuring

section.

a) Method by the measuring data (status of

initial load)

Please make that nothing is put on the

measuring section.

Press the key when

display blinks, and the STABLE mark lights. The

zero point is memorized, and is

displayed.

b) Method by the numeric input of load cell

output voltage.

Under the

calibration

of zero.

Press the

key,

after STABLE

mark lights on.

Error display in the calibration of zero point

Memorized load cell output voltage.

Set output voltage of the load cell.

Move to the calibration of span.

m

When key setting is pressed,

is displayed, and when

key is pressed, is displayed also.

[ ] is the memorized output voltage

of the load cell. Please set the load cell output

voltage in mV/V scale which correspond to the

zero point of the measurement.

: The value of changed digit is

changed.

: Changed digit is selected.

: The displayed value is changed to [0].

: Setting is interrupted and display

returns to CCAL.

: The display value is memorized, and

it proceed to the next step.

After the setting, press the key.

: The display blinks for about two seconds when the output of the load cell is

-2.5 mV/V or less. (Refer to the paragraph 19. Error display)

: The display blinks for about two seconds when the output of the load cell is

2.5 mV/V or more. (Refer to the paragraph 19. Error display)

21

Page 38

M

/

/

der

4-3-7. Calibration of span

When the span calibration starts, is displayed.

Please select the span calibration method.

(1) Method by the measuring ⇒ data Press the key, and execute the operation of a).

Execute the span calibration with weight put on the measuring section.

(2) Method by the numeric output of the load cell output ⇒Press the key, and execute the

operation b).

Execute the span calibration by inputting the value which subtracts the output voltage of the load cell

to zero point of measurement set in paragraph 4-3-6. From the output voltage corresponding to the

mass of the weight set in paragraph 4-3-5.

key is

pressed with

the weight put

on the

measurement

section.

a) Method with weight

Please put the weight corresponds to mass set

in the paragraph 4-3-5 on the measuring

section.

Please press the key when

display blinks, and the STABLE

mark lights. Span is memorized and

is displayed.

b) Method by the numeric input of load cell

output voltage.

When key is pressed, is

the

Un

calibration of

span.

Press the

key

after the

STABLE mark

lights on.

emorized output

voltage of the loa d ce ll.

is displayed also.

[ ] is the memorized output voltage

displayed, and when key is pressed,

mV

V

of the load cell. Please set the value in mV/V

scale which subtracts the output voltage of the

load cell to zero point of measurement from the

output voltage corresponding to the mass of the

Se t outpu t vo ltage of

the load cell.

weighing capacity.

: The value of changed digit is

changed.

mV

V

: Changed digit is selected.

: The displayed value is changed to

zero.

: Setting is interrupted and display

returns to CCAL.

: The display value is memorized, and

it proceeds to the next step.

After the setting, press the key.

Error display in the calibration of span

: The display blinks for about two seconds when ([Load cell output voltage at span]-

[Load cell output voltage at zero point]) ≦ 0.0 mV/V.

(Refer to the paragraph 19. Error display)

: The display blinks for about two seconds when load cell output is 3.1 mV/V or more.

(Refer to the paragraph 19. Error display)

22

Page 39

4-3-8. Quit the calibration

Stand-by condition

Please set the fine adjustment of ZERO and SPAN, digital linearize, ZERO set and Tare weight

cancellation after the finish of calibration. Those data is cleared if you process the calibration again.

Press the key to quit the calibration mode.

The display becomes , and the set data is

memorized internally.

Press the to set to the stand-by condition.

The calibration mode is completed.

is displayed when span calibration is completed.

23

Page 40

p

4-4. Fine adjustment of zero and span

It is the function to make the fine adjustment of zero and span when there is a difference between

the actual measuring value and the weight.

4-4-1. Changeover to zero and span fine adjustment mode

Measurement mode

Stand-by condition

+

Fine adjustment mode of

zero and span

Press the key, and move from a usual measurement

mode to the stand-by condition.

When key is pressed with key, is

displayed.

Press the key here.

By pressing the key, is displayed, then it

enters into the fine adjustment mode of zero and span.

is displayed, then key is pressed.

is displayed.

Move to the fine

adjustment mode of

zero and s

an.

24

Page 41

4-4-2. Fine adjustment of zero and span

When key pressed from display,

is displayed.

In executing the zero fine adjustment, proceeds the operation of

a).

In case of executing the span adjustment only, press key,

and proceed the operation of b) after displaying .

a) Fine adjustment of Zero

Press the key. Display becomes .

[ ] is the present measuring value, and it can be displayed

up to 1/10 digit.

Ex. Without a decimal point 0 ~ 6000 -> 0.0 ~ 6000.0

With a decimal point 0.0 ~ 600.0 -> 0.00 ~ 600.00

Please set the display to [zero] after the condition which nothing is

put on the measuring point.

: Increase the measuring value.

Increase continuously by keeping the key pressed.

: Decrease the measuring value.

Decrease continuously by keeping the key pressed.

: Interrupts the setting, and returns to

display.

: Memorizes the display value, and proceed to the next

step.

After the zero fine adjustment, press the key.

Display becomes . in case of executing the fine

adjustment of span, precedes the operation of b).

Otherwise, press the key, and proceed the operation of c)

after displaying .

b) Fine adjustment of span

Put the weight which can be put on the measuring section under

the weighing capacity.

is displayed by pressing the key.

[ ] is the present measuring value, and it can be

displayed up to 1/10 digit.

Please set the display to become the same value with the weight

put on the measuring section.

After the fine adjustment of span, proceeds the operation of c)

after the display by pressing key.

[A]

[B]

25

Page 42

[A]

[B]

c) End of fine adjustment mode

Press the key to quit the fine adjustment mode of zero and

span.

the internal memory.

Press the key, and move to the stand-by condition.

The fine adjustment mode of zero and span is completed.

displayed, and the setting data is memorized to

26

Page 43

p

p

4-5. Digital linearize.

After the calibration, the measurement error of some scale interval levels might be caused between

the zero and span (weighing capacity) by the influence of the measuring section etc.

The digital linearization function executes the compensation of three points or less except the zero

and span, and to reduce the measurement error.

D

i

s

p

l

a

y

Error

0

Zero

Before linearization

4-5-1. Changeover to digital linearization mode

Measurement mode

Span

Weight value

D

i

s

p

l

a

y

0

Zero

Correction

Correction

After linearization

oint 1

Span

Correction point 3

oint 2

Wheight value

Make the condition from the normal measurement

mode to the stand-by condition by pressing the

Stand-by condition

+

Digital linearization mode

Move to the digital linearization mode.

key.

Press the key with pressing the key,

is displayed.

Press the key after pressing the key ,

is displayed.

is displayed after pressing the

key twice, and enter into the digital

linearization mode.

27

Page 44

4-5-2. Setting of the digital linearization

Put the weights.

By pressing the key twice from

display, is displayed. As the display

Becomes → by

pressing the key, please select the numbers of

points which wants to compensate linearization, and

press the key

: compensation by 1 point

: compensation by 2 point

: compensation by 3 point

Please put the weight of the point which should be the

compensation after the display becomes

on the measuring section and press the key.

As the measuring value blinks, press the key

after confirming the stability mark (▼) lighting on.

As the 100 digit of the measuring value blinks, set to

Confirm the stability mark

lighting on.

the same value with the weights put on the measuring

section.

:Increase the measuring value.

:Decrease the measuring value.

When P-1 is selected.

:The displayed value is memorized, and proceed

to the next step.

Put the weights.

:The setting is interrupted, and return to the

display of .

The display becomes when

Confirm the stability mark

lighting on.

compensation of the second point.