Page 1

MINEBEA Co., Ltd.

INSTRUCTION MANUAL

Digital indicator with CC−Link interface

CSD−815B−73

Note : Please read this Instruction Manual carefully before use.

Be sure to follow the items that require attention described in the manual.

Keep the manual at hand so that you can pick it up and read it as soon as

necessity requires.

EN294−1435

Page 2

Forwards

Thank you very much for your purchasing Minebea’s Digital Indicator with CC−Link

interface CSD−815B−73. This manual explains installation procedures and connecting

method and also operating method for the Digital Indicator with CC−Link interface

CSD−815B−73. When you will use this instrument as the specification with CC−Link

interface, make use of it properly after reading through the manual carefully.

Be sure to deliver the manual to the end user. Moreover, the end user should keep the

manual at hand after reading it over.

This manual is intended for the technical experts to read. When you read this instruction

manual, the program basic knowledge of a Mitsubishi general−purpose sequencer and the

basic knowledge of CC−LINK interface are needed.

●CC−LINK is an abbreviation of “Control & Communication Link”

●The contents of the manual may subject to change for improvement without notice.

I

Page 3

Marks and arrangements used in this manual

The following marks are attached to the explanation on the matters that indicate “Don’t do

this.”, “Take care.” and “For reference”.

Be sure to read these items where these marks are attached.

Warning ● Warning may cause injury or accident that may harm to the operator.

Do not do these things described here.

● Caution during operation and working.

Be sure to read the item to prevent malfunction.

About the view of this book

In this instruction manual, the connection method and use of the CC−Link interface

specification of the option for CSD−815B are explained. Please see the CSD−815B

instruction manual about other main body functions and a basic method of handling and

notes.

D CSD−815B instruction manual(DRW NO.EN294−1435*)

Moreover, please refer to the instruction manual on sequencer and sequencer side

CC−LINK interface for the sequencer program and CC−LINK.

II

Page 4

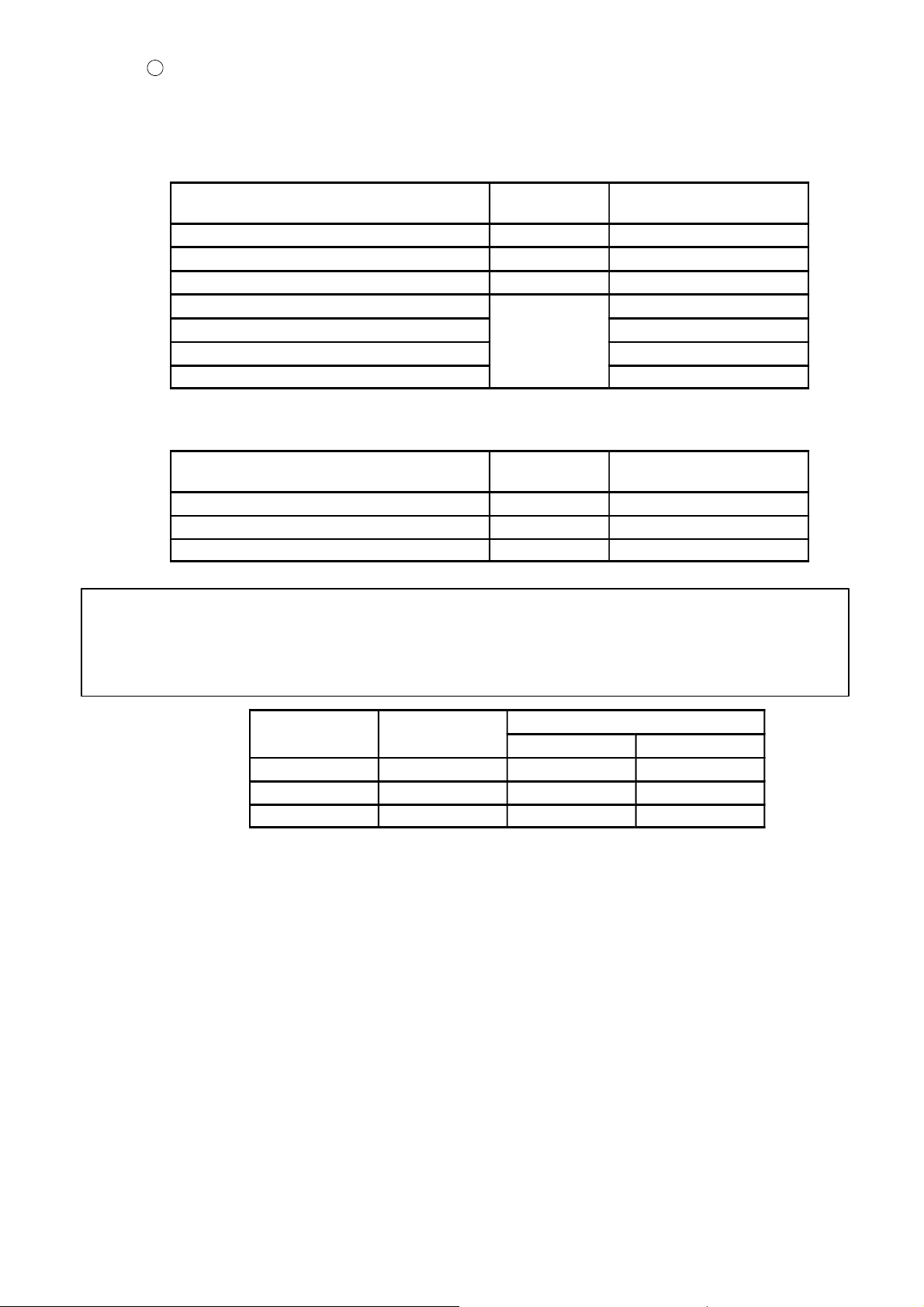

History of revision

Date Instruction Manual No. Details of revised point

Nov. 2010

DRW. NO. EN294−1435

First version

CSD−815B main body Ver.1.200 or later CC−Link

interface CARD Ver.04 or later

III

Page 5

CONTENTS

Forwards Ⅰ....................................................................

Marks and arrangements used in this manual Ⅱ....................................

About the view of this book Ⅱ....................................................

History of revision Ⅲ............................................................

1. General 1.................................................................

1−1. Features 1............................................................

2. Name and function of each point 2..........................................

2−1. Rear panel CC−Link I/F point 2..........................................

3. Connecting method 4......................................................

3−1. Connector pin configuration for communication 4...........................

3−2. Cable length 4.........................................................

3−3. Connection 4..........................................................

3−4. Notes fo connection 5..................................................

4. Setting of CC−Link connecting 6............................................

4−1. Detail of CC−Link setting 6..............................................

4−2. Setting of the station(Function F−85) 6....................................

4−3. Setting of baud rate(F−86

4−4. 32 bits data expression method(F−87) 7..................................

) 6.............................................

5. PCL memory explanation 8.................................................

5−1. Address 8.............................................................

5−2. Address map 9........................................................

5−2−1.Data detail 9..........................................................

5−2−2.Relay zone 14..........................................................

6. Operation method 22.......................................................

6−1. Writing the set value (Special data area) 22.................................

6−2. Writing/Reading by general command 23...................................

6−3. Shift to status where it is possible to communicate 25........................

6−4. CPU normal operation signal 25...........................................

7. Specifications of interface 26................................................

7−1. CC−Link interface spec 26...............................................

7−2. Accessory 26...........................................................

Page 6

1. General

This unit is a remote device station of CC−LINK Ver.1.10.

This unit can be connected with the mastering station of CC−LINK Ver.1.10.

1−1. Features

Main features for CSD−815B−73 are as follows :

(1) Because this unit can be controlled by using remote I/O and a remote register of the sequencer,

the program volume of the sequencer can be reduced.

(2) Wiring with the sequencer can be reduced.

1

Page 7

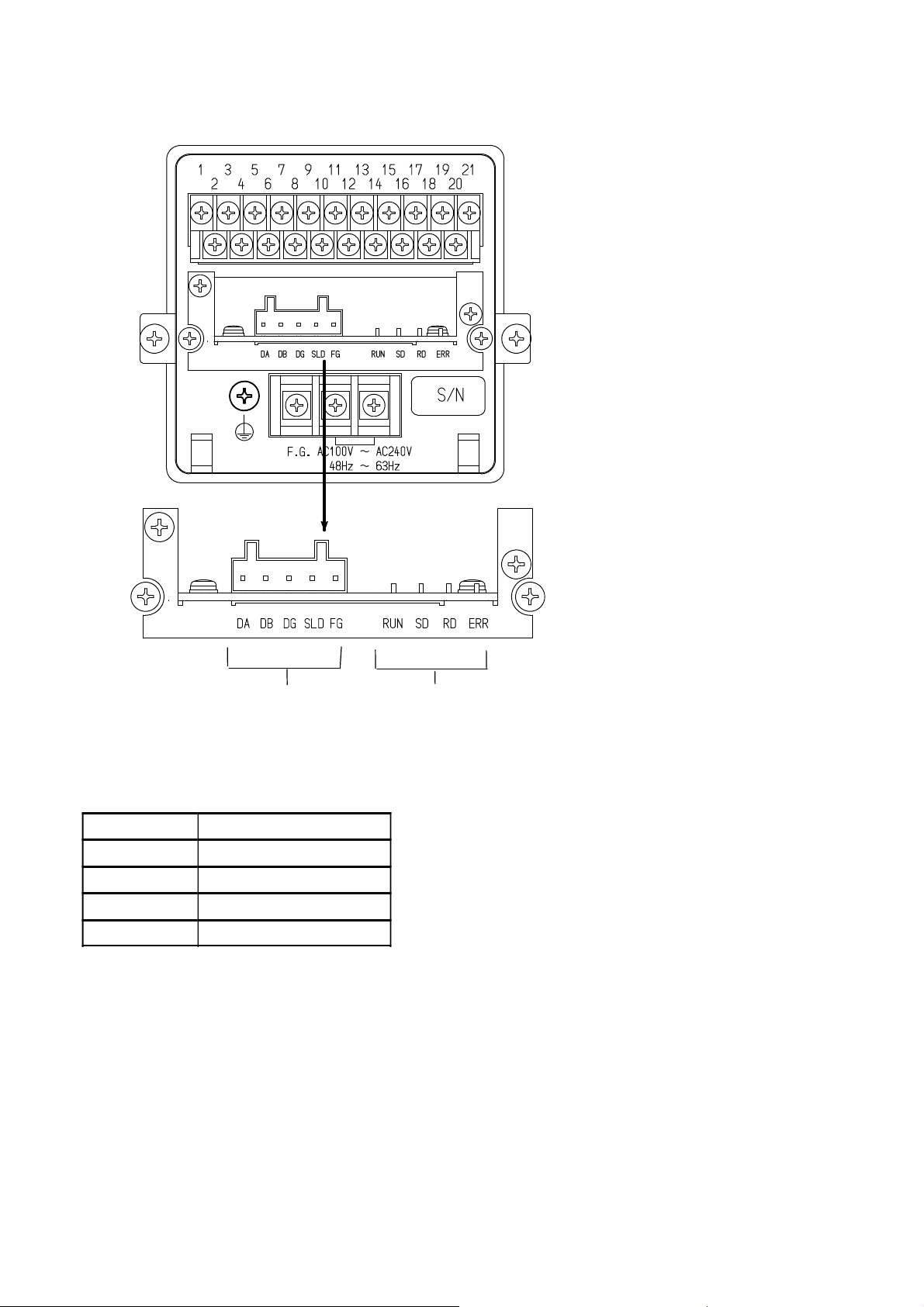

2. Name and function of each point

2−1. Rear panel CC−Link I/F point

Connector for communication

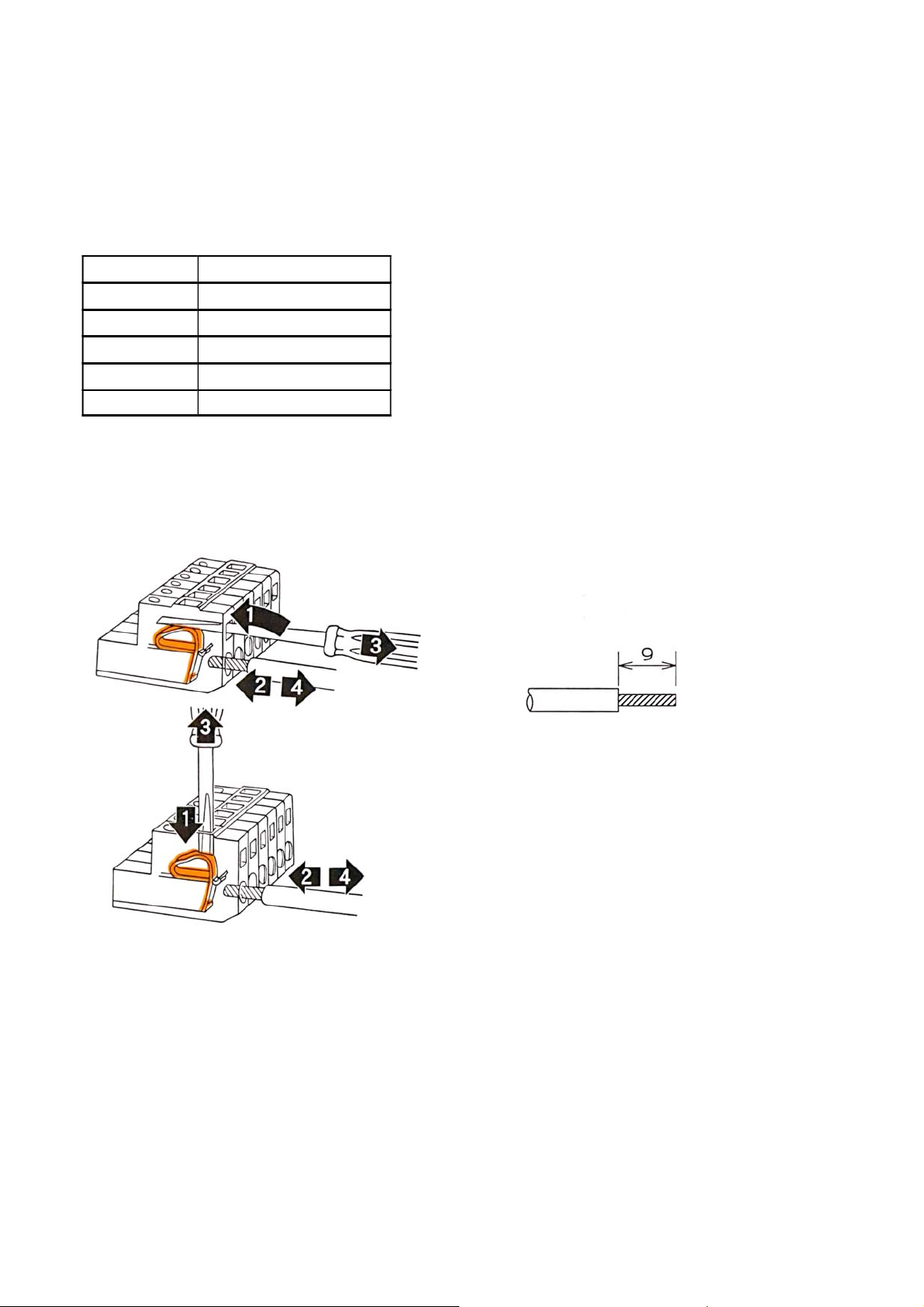

(1) Connector for communication terminal block

Connector type terminal block for CC−LINK interface.

Connector type terminal block pin configuration is as follows.

DA

DB Signal cable DB side

DG Signal cable ground

SLD Shield

FG Frame ground

Suitable plug:721−105/037−000 (WAGO) ※to be attached.

“SLD” and “FG” are connected in the instrument.

The internal circuit and photo coupler are insulated.

Signal cable DA side

Status LED

2

Page 8

(2) Status LED

The communication status is expressed with four LED.

LED Name

RUN ・Normal ・In the reset

SD ・Sending − −

RD ・Receiving − −

ERR ・Abnormal setting

・CRC error occurs.

・Trouble

Light on Light off Light on/off

・unavailable to

communication

・Normal ・When setting changes

−

3

Page 9

3. Connecting method

3−1. Connector pin configuration for communication

Refer to “2−1. Rear panel(1) Connector for communication terminal block”.

3−2. Cable length

Relation of baud rate and total extension length as follows.

Baud rate

156 kbps 1 200 m or less

625 kbps 600 m or less

2.5 Mbps 200 m or less

5 Mbps 150 m or less

10 Mbps 100 m or less

Cable length

3−3. Connection

Please follow the instruction of connecting wires on the sequencer instruction manual about

connecting wires.

Striped electrical cable length

1) Put in the driver minus type.

2) Insert the electrical cable.

3) Pull out the driver minus type.

4) Confrim wire connection by a few tension.

4

Page 10

3−4. Notes of Connection

・When the wiring, be sure to the instrument power supply is OFF.

・Do not supply the AC power until complete the installation. This instrument does not have

power switch (ON/OFF).

・Do not fell or make a strong impact on this instrument rear pannel terminal block because it is

made of resin.

・

Striped electrical cable tip length is 9 mm.

・Cables which connecting this instrument isolate from noise sources, for example, power supply

line and I/O for control’s as much as possible.

・Be sure to connect the ground wire must be D single ground. Do not common the

ground with a kind of power supply.

・For CC−link cable connection, use twist pear cable wire with shield(Cable for CC−link) and

connect the shield in terminal block’s SLD terminal or F.G.terminal.

●Connect the termination to the CC−Link connector to electrical

termination which is far from PLC as possible.

●Use the connecting cable for CC−Link.

5

Page 11

4. Setting of CC−Link connecting

Please set the following in the function mode when you use CC−LINK interface.

Please refer to clause 8−1 of the CSD−815B instruction manual for ”Method of setting the function”.

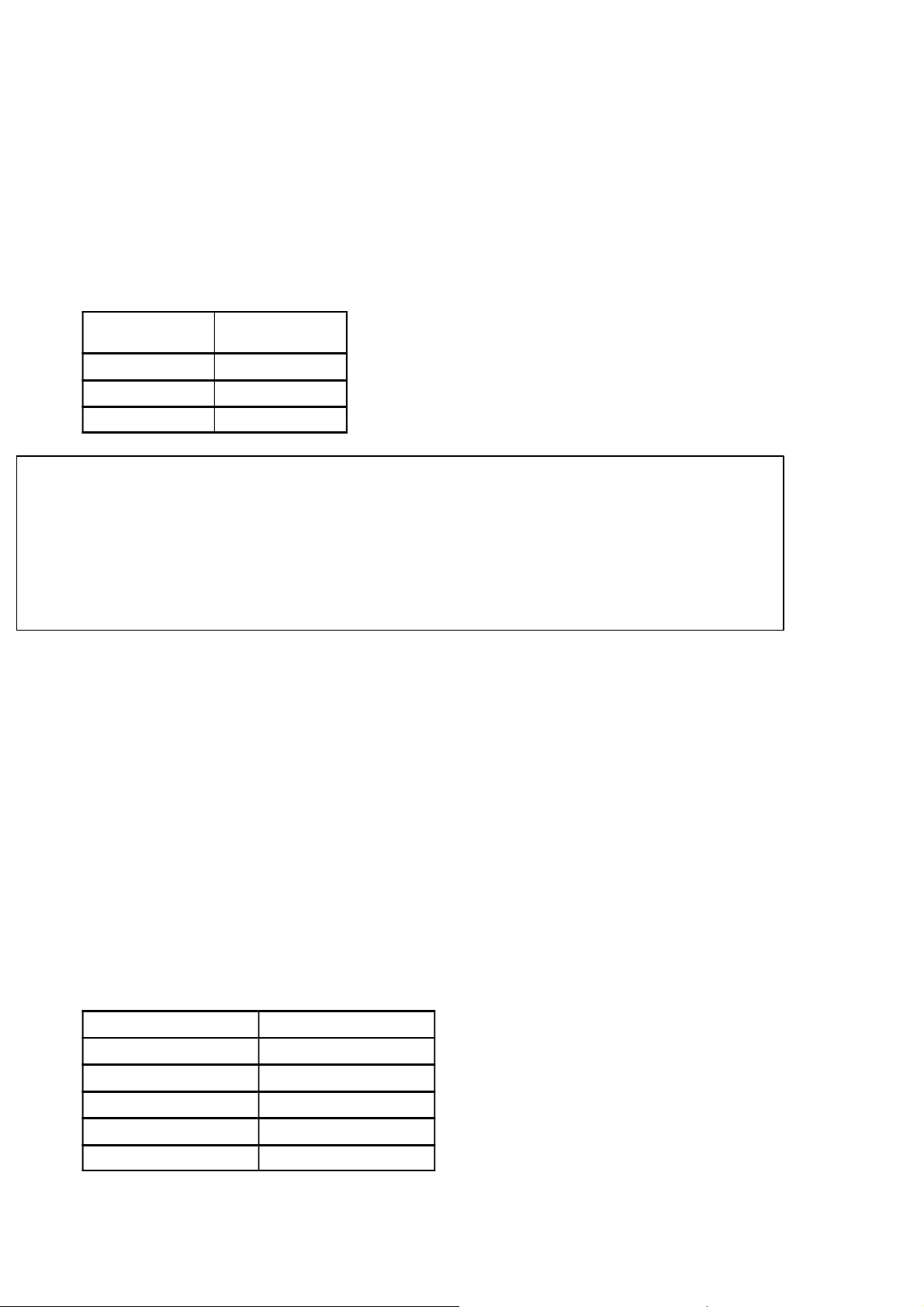

4−1. Detail of CC−Link setting

Setting of the station(Function F−84)

The station of CC−LINK is set.

The range which can be set is “0”−“2”.

Default is set as [2].

F−84

0 1 station

1 2 stations

2 4 stations

Occupied

stations No.

●Setting changes for occupied stations No is corresponding to this

software after ROM Ver. 1200 and after CC−Link I/F CARD software

ROM Ver. 04.

Before ROM Ver. 1.100 and Ver. 03 is fixed 4 station occupied station

No.

4−2. Setting of the station(Function F−85)

Excute the setting of the station.

When it is 1 occupied station: selectable from station No 01 to 64.

When it is 2 occupied station: selectable from station No 01 to 63.

When it is 4 occupied station: selectable from station No 01 to 61.

The occupied station of this instrument is 1., 2, 4 stations.

For example, when the station number is assumed to 1 station and station No is set as 01, 01 to 04

stations are occupied. Therefore, the station number must not overlap.

Default is set as [01].

4−3. Setting of baud rate(F−86)

Excute the setting baud rate (unit: bps).

The range which can be set is from [0] to [4].

Default is set as [0]. Each setting value for baud rate is as fallow.

F−86 setting value

0 156 kbps

1 625 kbps

2 2.5 Mbps

3 5 Mbps

4 10 Mbps

Baud rate

6

Page 12

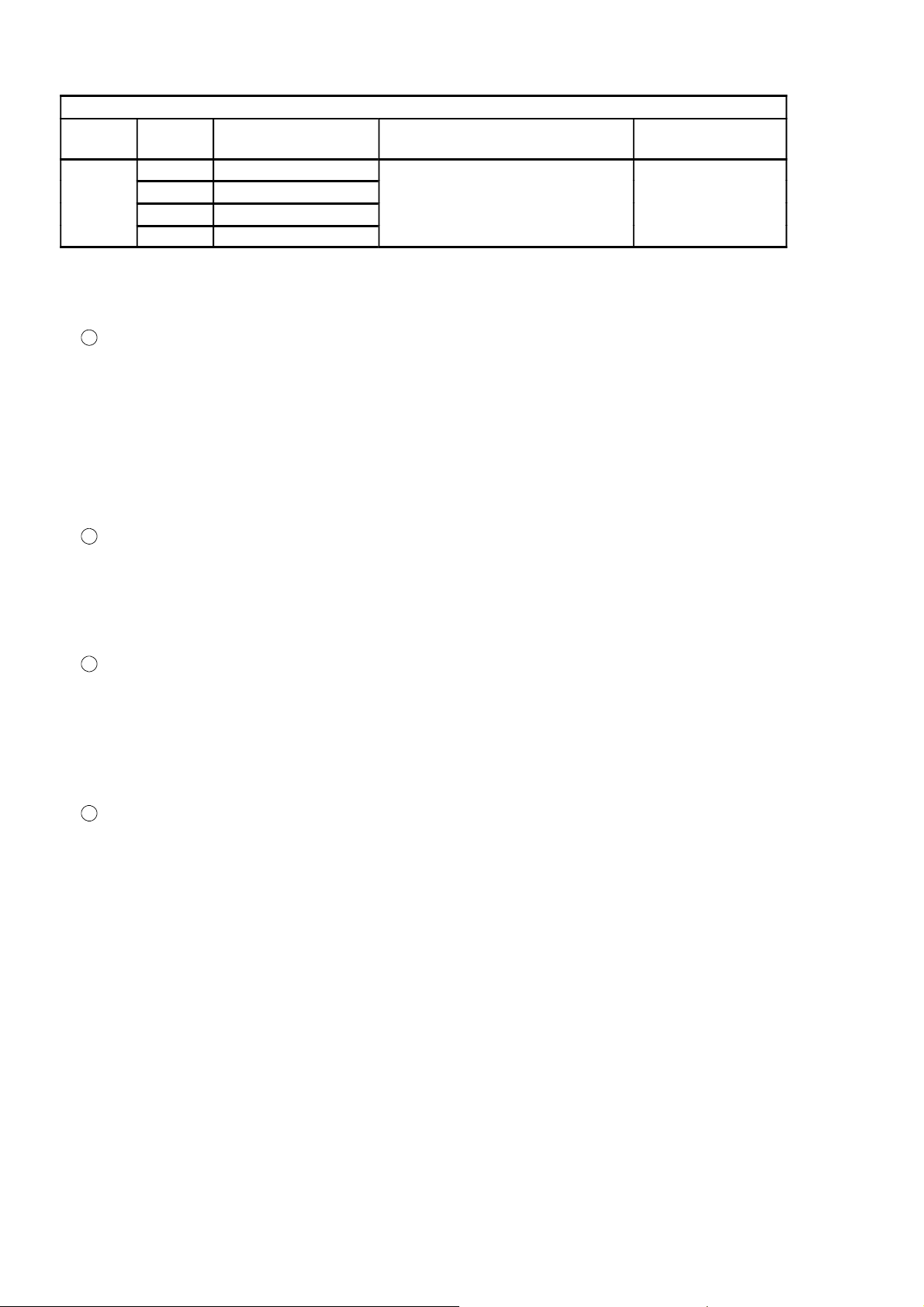

4−4. 32 bits data expression method(F−87)

Excute the setting of 32 bits data expression method.

The range which can be set is [0] or [1].

Default is set as [0]. Each setting value for 32 bits data expression method is as fallow.

F−87 setting value

0 Expression of standard binary

1 Highest bit sign

Load value F−87 Lower 16 bit Upper 16 bit

−1

−10

−99999

32 bits data expression method

0 FFFFH FFFFH

1 8000H 0001H

0 FFFFH FFF6H

1 8000H 000AH

0 FFFEH 7961H

1 8001H 869FH

Setting value is valid when the power rebooting. In case of changing the

setting, excute the power rebooting.

7

Page 13

5. PLC memory explanation

i

a

g

Station

R

emote

R

emote

R

3

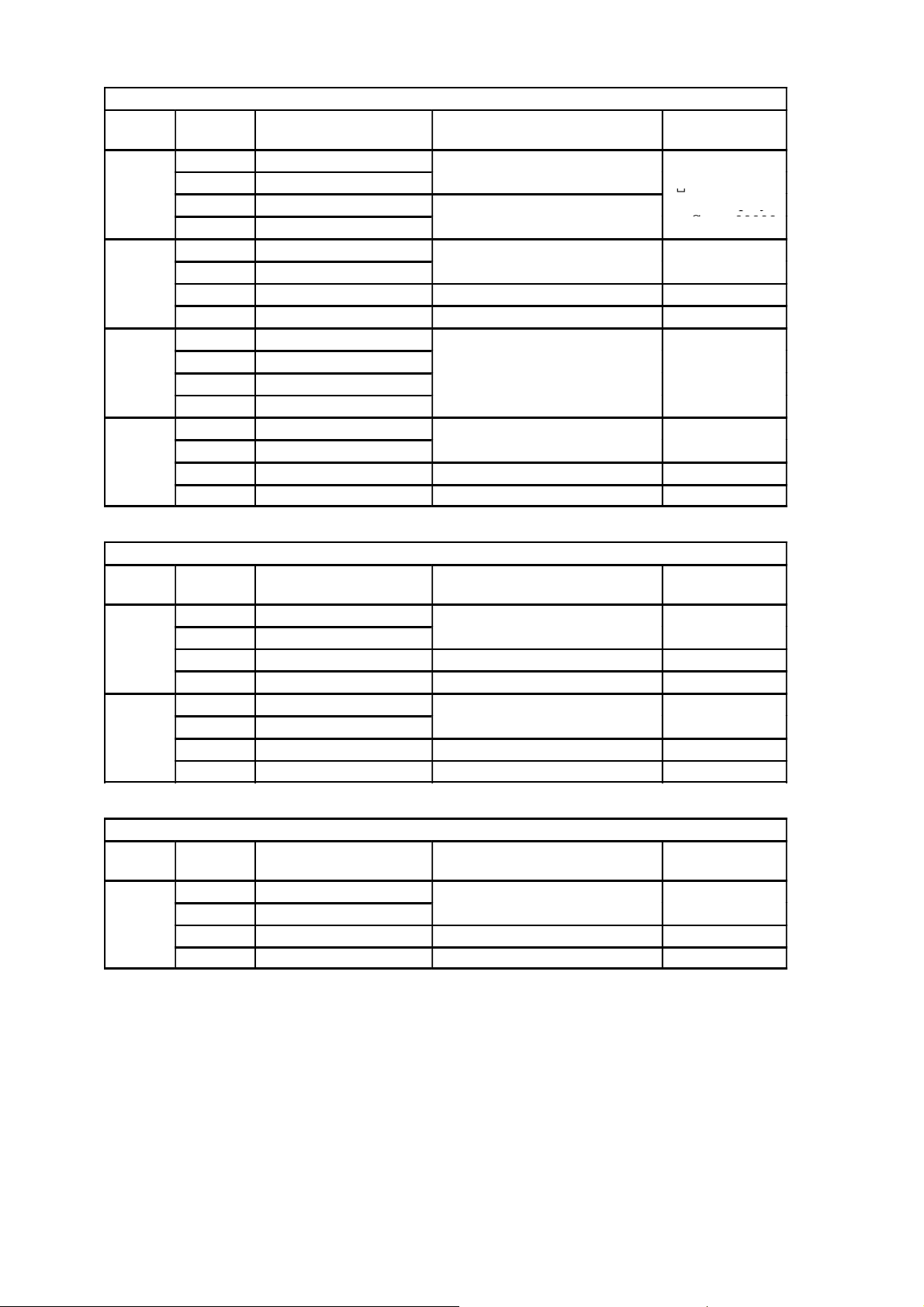

5−1. Address

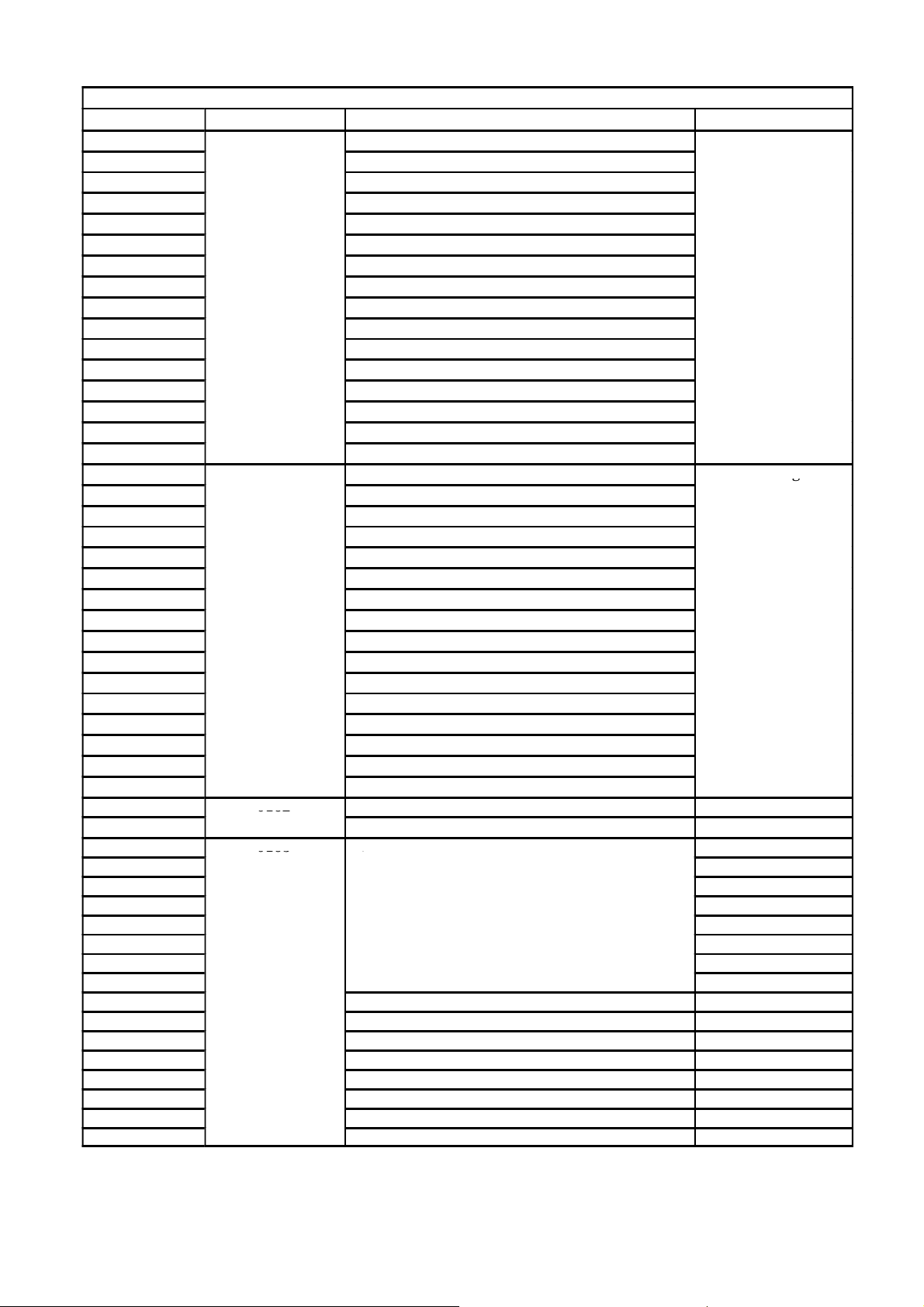

A remote I/O(RX/RY:Bit handling register) and a remote register(RWw/RWr:Word handling register)

secures the zone in the master station depends on the occupied station number. As shown in the table

below in case of this unit.

Occupied station number

Type

Remote input 128 points 64 points 32 points

Remote output 128 points 64 points 32 points

Remote

register

The address number of the remote station allocated to the mastering station is as shown in the table

below.

Station

No.

0

1

2

Master→

Remote

Remote→

Master

Remote Remote

input

− − − −

RX0000 RY0000 RWw0000 RWr0000

00E0 0160 01E0 02E0

RX0020 RY0020 RWw0004 RWr0004

00E2 0162 01E4 02E4

RX0040 RY0040 RWw0008 RWr0008

00E4 0164 01E8 02E8

Occupies 4

stations

16 points 8 points 4 points

16 points 8 points 4 points

output

Occupies 2

stations

Remote register

Master→Remote Remote→Master

Occupies 1

station

Remarks

I/O for each 16 points

s occupiedas

system area.

emarks

Specify the master station

〜

10

〜

64

RX0120 RY0120 RWw0024 RWr0024

00F2 0172 0204 0304

RX07E0 RY07E0 RWw00FC RWr00FC

015E 01DE 02DC 03DC

8

Page 14

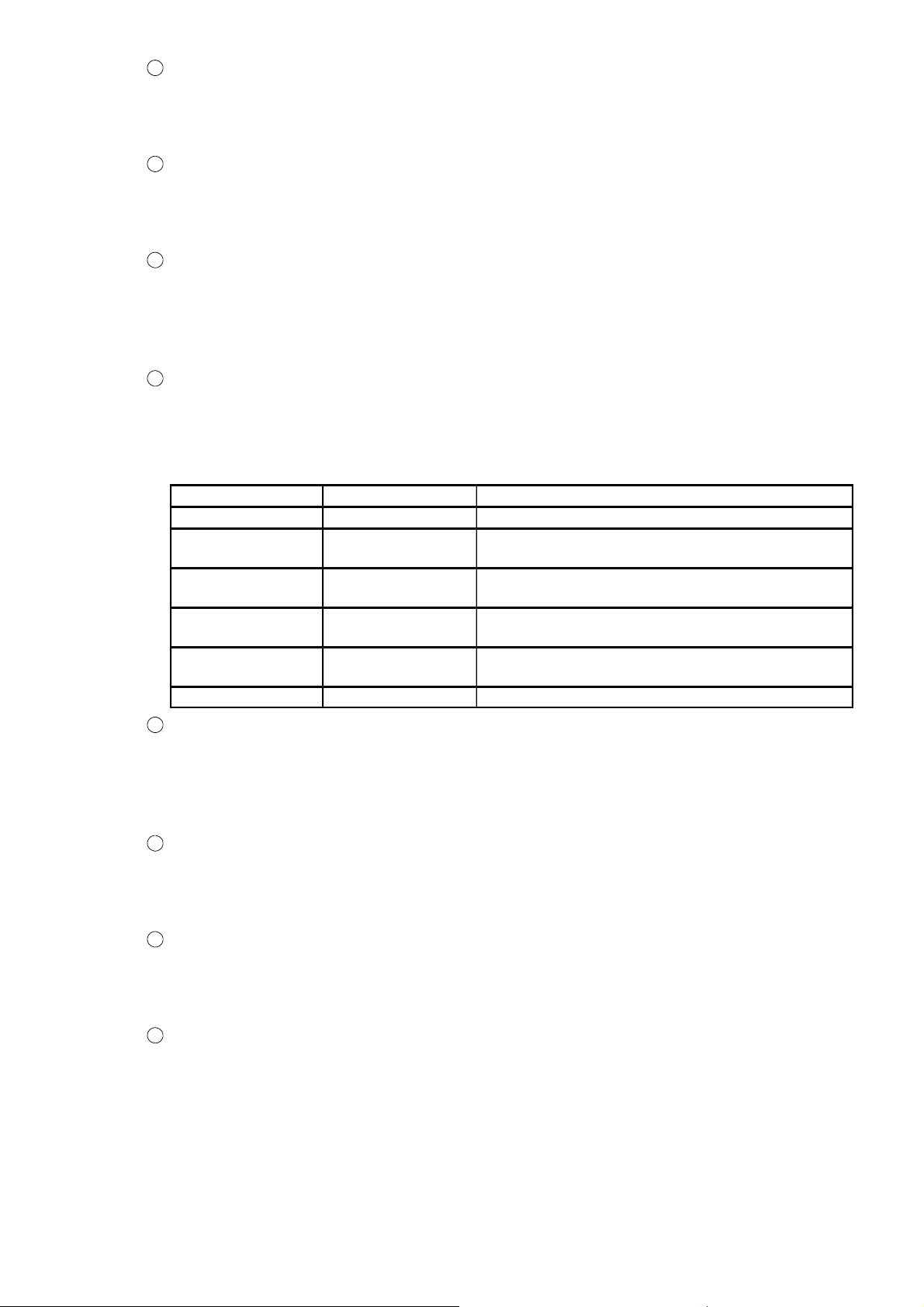

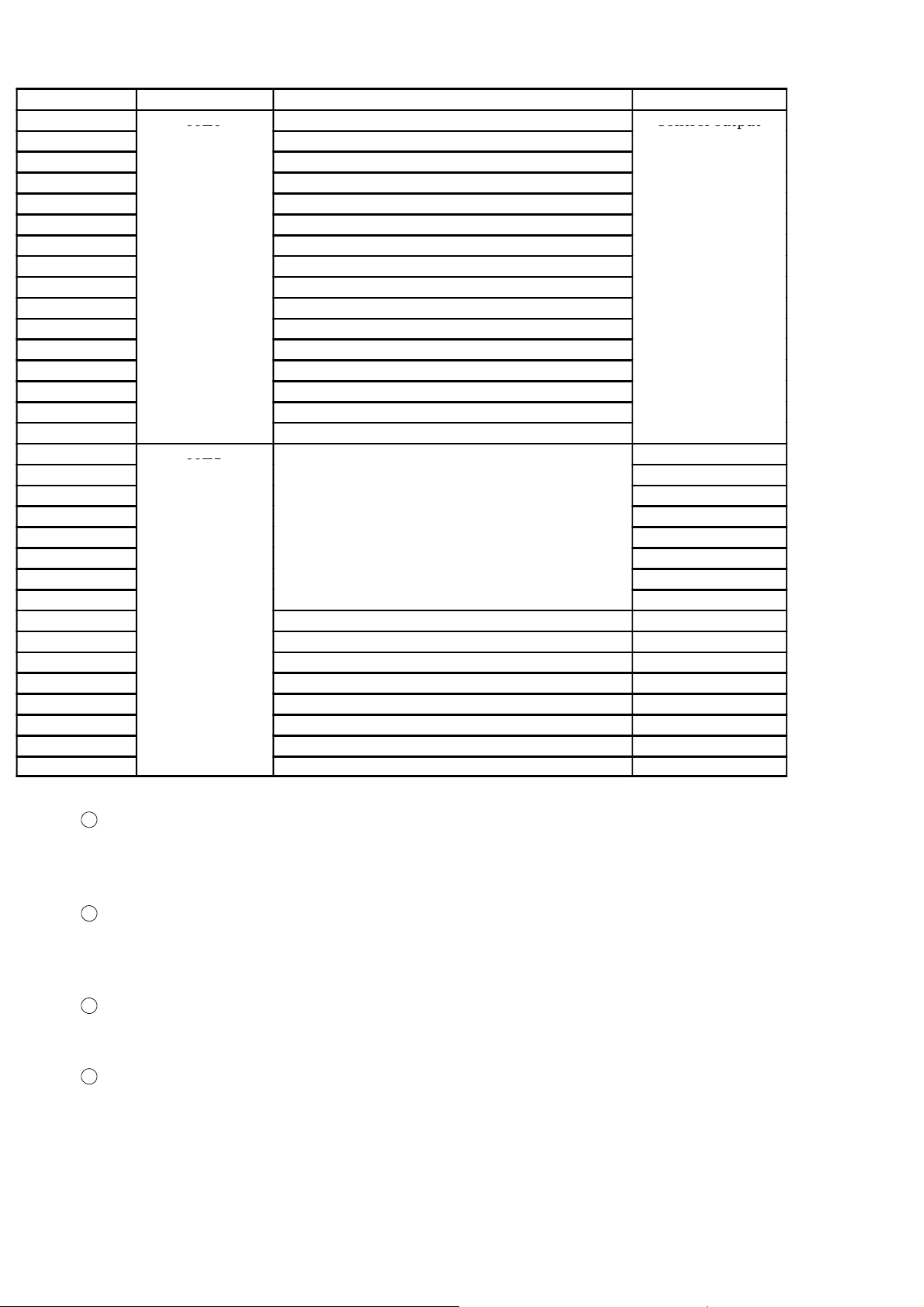

5−2. Address map

①

S

32bi

①

S

32bi

①

S

32bi

S

l

data

a

Undefined

32bi

Undefined

32bit3

Undefined

32bi

②

G

l

data

a

32bi

①

S

32bi

S

l

data

a

①

S

32bi

②

G

l

data

a

32bi

In this paragraph, the address of “Remote input”, “Remote output”, and

“Remote register” when the station Number of [1] is set. Please note

that the address is different when you set the station number except

No.[1].

5−2−1.Data detail

(1) Remote register(Master→This instrument)

Occupies 4 stations

Station

1

2

4

Buffer

Address

01E0 RWw0000

01E1 RWw0001

01E2 RWw0002

01E3 RWw0003

01E4 RWw0004

01E5 RWw0005

01E6 RWw0006

01E7 RWw0007

01E8 RWw0008

01E9 RWw0009

01EA RWw000A

01EB RWw000B

01EC RWw000C

01ED RWw000D

01EE RWw000E ③Command No.(Return) 8 bit

01EF RWw000F ④Operating mode(Return) 8 bit

Register

Master→CSD−815B

Contents Remarks

0 set value

1 set value

2 set value

enera

are

t

t

t

pecia

t

t

t

are

Station

1

2

Occupies 2 stations

Buffer

Address

01E0 RWw0000

01E1 RWw0001

01E2 RWw0002

01E3 RWw0003

01E4 RWw0004

01E5 RWw0005

01E6 RWw0006 ③Command No.(Return) 8 bit

01E7 RWw0007 ④Operating mode(Return) 8 bit

Register

Master→CSD−815B

9

Contents Remarks

0 set value

1 set value

enera

t

t

are

pecia

t

are

Page 15

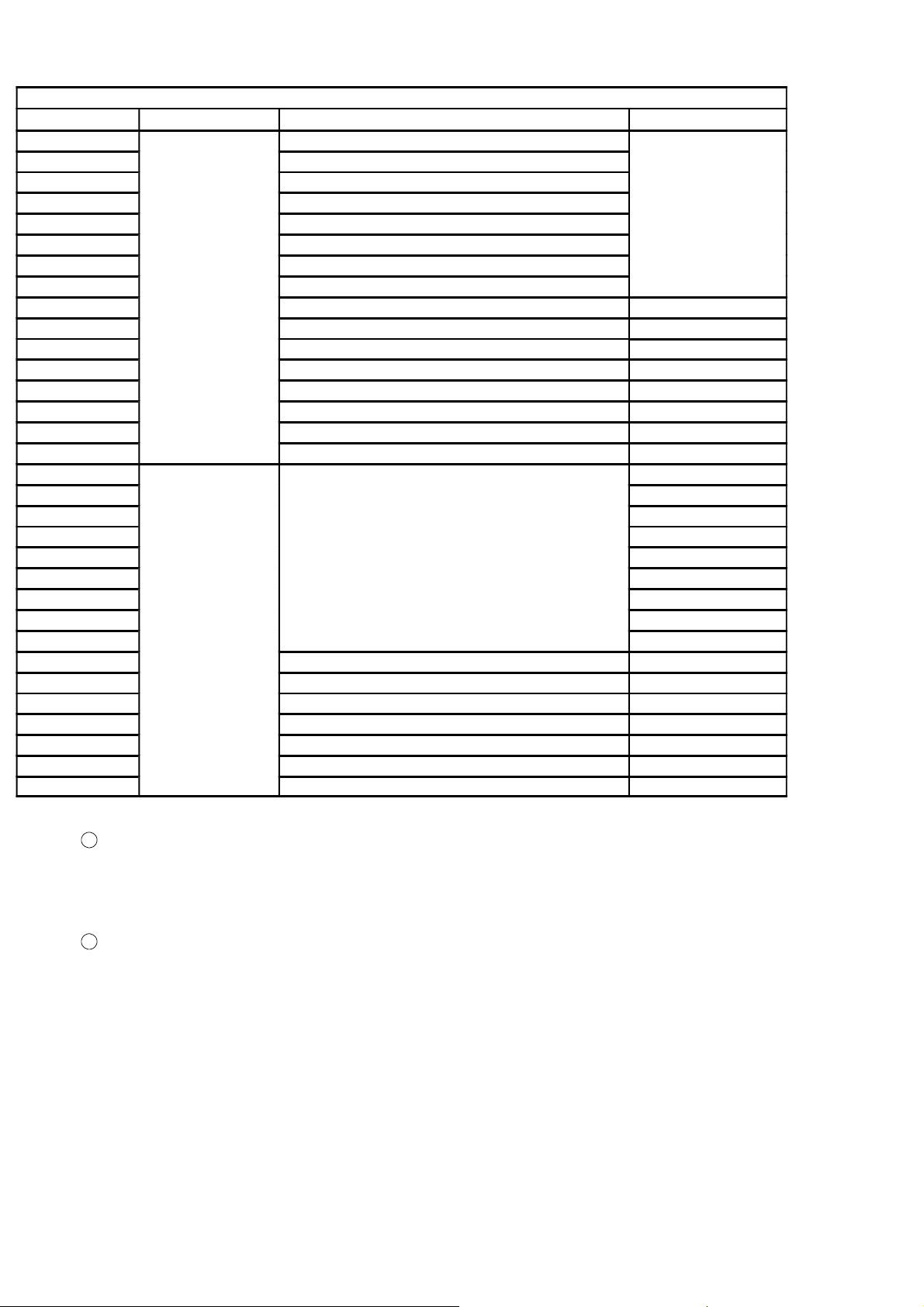

Occupies 1 station

U

d

S

l

data

a

Station

Buffer

Address

Register

Master→CSD−815B

Contents Remarks

01E0 RWw0000

01E1 RWw0001

1

01E2 RWw0002

nuse

64bit

pecia

01E3 RWw0003

Remote register(Master station→This instrument)

1

Special data area(4 stations ,2 stations )

When the set value is registered by using the set value writing request (request 1), the set value

is set in each area.

Details of each set value are shown as follow,

set value from S0 to S2

Execute the setting of the comparative data.

Data type :32 bits binary with + or −

Setting range :−99 999〜99 999

2

General data area(4 stations ,2 stations )

When the command order is executed by using the general command request (request 2), the

set value or the operating order code is set in this area.

Data type :32 bits binary with + or −

Range of setting value:−99 999〜99 999

are

3

Command No.(4 stations ,2 stations )

When the command order is executed by using the general command request (request 2), the

command No. is set in this area.

The content of the general data area is set depending on the command set in this command No.

Data type :8 bits binary

Range of setting value :0〜255

4

Operation mode(4 stations ,2 stations )

When the operation mode is a changeover and is gotten by using the operation mode

changeover request (request 3), the mode number is set in this area. Mode only [0] corresponds

in the current state, and write [0] only.

Data type :8 bits binary

Range of setting value :0〜255 (However, [0] only corresponds in the current status.)

10

Page 16

5

Decimal

a

Commands list(4 stations ,2 stations )

When the command order is executed by using the general command request (request 2), the

value set in command No. and the general data area is indicated as follows;

Writing the set value and operation request (Writing/Reading out selection=Writing [OFF])

Setting value or command request

S0 10 −99 999〜99 999

S1 11 −99 999〜99 999

S2 12 −99 999〜99 999

Tare weight cancellation ON(A/Z ON) 14

Tare weight cancellation OFF(A/Z OFF)

Zero set ON(ZERO)

Reset of sequence error 36

Reading out the setting value(Selection of writing/Reading out=Reading out[ON])

Setting value or Command request

S0 10 −99 999〜99 999

S1 11 −99 999〜99 999

S2 12 −99 999〜99 999

Command No.

(RWw000E)

0

Command No.

(RWw000E)

General data area

(RWw000C〜RWw000D)

15

16

General data area

(RWw000C〜RWw000D)

Numeric representation of a remote register is as shown in the table

below as a rule. However, the negative numeric expression is different

according to setting F−87. Please refer to the paragraph 4−1.

Decimal

number

0 0000H 0000H 0000H

1 0001H 0000H 0001H

10 000AH 0000H 000AH

16bitsdat

Upper position Lower position

32 bits data

11

Page 17

(2) Remote register(Instrument→Master)

OLdisplay

①

N

OL

display

:

Set

99999

②

G

py

Undefined

3

Undefined

⑤

G

l

data

a

g

⑧

Indicate

value(NET

weight

⑤

G

l

data

a

g

⑧

Indicate

value(NET

weight

Station

Buffer

Address

Register

Master→Instrument

02E0 RWr0000

02E1 RWr0001

1

02E2 RWr0002

02E3 RWr0003

02E4 RWr0004

02E5 RWr0005

2

02E6 RWr0006 ③Error code

02E7 RWr0007

02E8 RWr0008

02E9 RWr0009

02EA RWr000A

02EB RWr000B

02EC RWr000C

02ED RWr000D

4

02EE RWr000E ⑥Command No.(Response)

02EF RWr000F ⑦Operation mode(Response)

Occupies 4 stations

et weightvalue

ross weightvalue

④Error assistance code

enera

Contents Remarks

:Set 99999

−OL display

:Set −99999

are

Station

1

2

Station

1

Occupies 2 stations

Buffer

Address

02E0 RWr0000

02E1 RWr0001

Register

Master→Instrument

Contents Remarks

⑧Indicate value(NET wei

value/ GROSS weight value)

02E2 RWr0002 ③Error code

02E3 RWr0003

④Error assistance code

02E4 RWr0004

02E5 RWr0005

enera

are

02E6 RWr0006 ⑥Command No.(Response)

02E7 RWr0007 ⑦Operation mode(Response)

Occupies 1 station

Buffer

Address

02E0 RWr0000

02E1 RWr0001

Register

Master→Instrument

Contents Remarks

⑧Indicate value(NET wei

value/ GROSS weight value)

02E2 RWr0002 ③Error code

02E3 RWr0003

④Error assistance code

ht

ht

12

Page 18

1

Net weight value(4 stations ,2 stations )

Area for displaying the net weight value

Data type :32 bits binary with + or −

Range of setting value :−99 999〜99 999

2

Gross weight value(4 stations )

Area for displaying the gross weight value

Data type :32 bits binary with s+ or −

Range of setting value :−99 999〜99 999

3

Error code(4 stations ,2 stations ,1 station )

Refer to below table of ④ error assistance code too.

Area for displaying the error No. generating in the main body of the indicator.

Data type :16 bits binary

Range of setting value :0〜255

4

Error assistance code(4 stations ,2 stations ,1 station )

Data type :16 bits binary

Range of setting value :0〜255

Error code

Error support code Error contents

0 0 No error

99 0

1 1

1 2

1 13

In case of setting the unspecified data in

command No.

In case of the instrument is “Calibration mode”,

“Check mode” and “Monitor mode”.

In case of setting the ZERO or A/Z at the

prohibition condition,

In case of the data setting other than specification

in general data area,

1 14 In case of connecting error of internal

5

General data area(4 stations ,2 stations )

When the setting value reading out command is ordered by using the general command

request (Request 2), this area displays the setting value.

Data type :32 bits binary with + or −.

Range of setting value :−99 999〜99 999

6

Command No.(Response)(4 stations ,2 stations )

When the command order is executed by the general command request (Request 2), this area

displays that command No.

Data type :8 bits binary

7

Operation mode (Response)(4 stations ,2 stations )

When the changeover of the operation by the operation mode changeover request (Request 3),

this area displays the mode.

Data type :8 bits binary

8

Indicate value(NET weight/ GROSS weight) (2 stations ,1 station )

It is area which showing the GROSS weight value or NET weight value.

Data type :32 bits binary with + or −

Range of setting value :−99 999〜99 999

13

Page 19

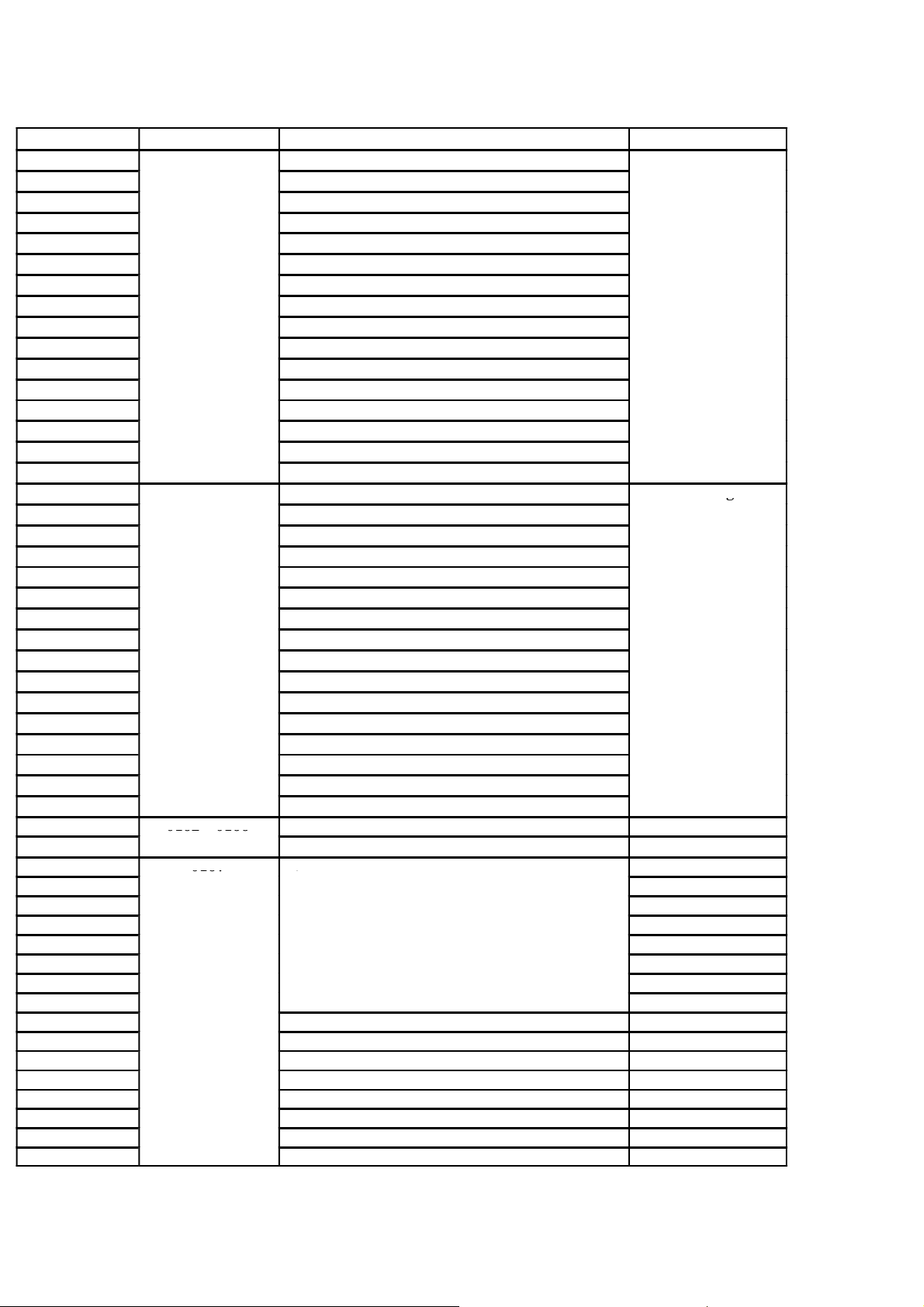

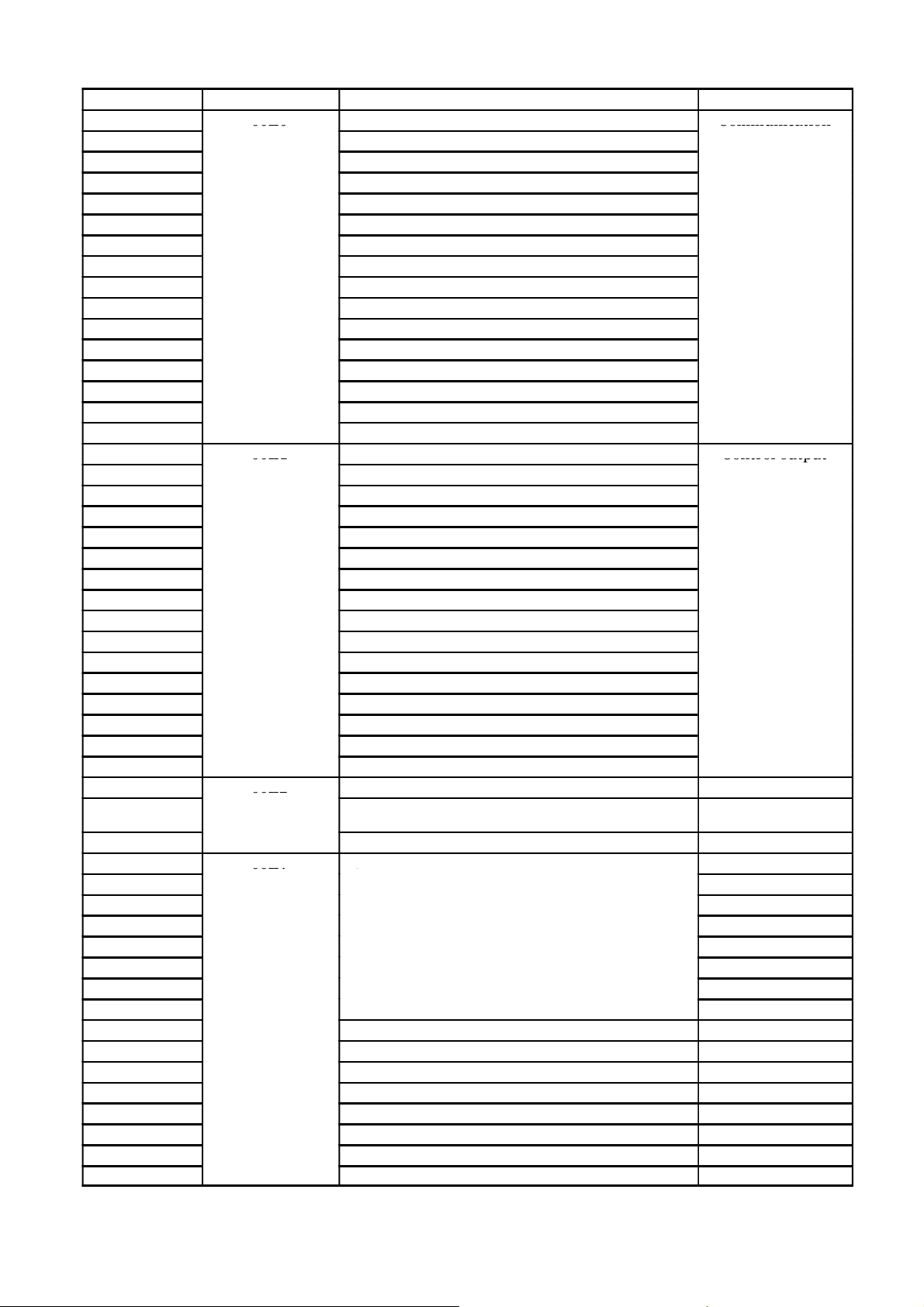

5−2−2.Relay zone

g

0162

0166

0167

y

(1) Remote input (Master→This instrument) Occupies 4 stations

Device NO. Buffer address Contents Classification

RY0000

RY0001

RY0002

RY0003

RY0004

RY0005

RY0006

RY0007

RY0008

RY0009

RY000A

RY000B

RY000C

RY000D

RY000E

RY000F

RY0010

RY0011

RY0012

RY0013

RY0014

RY0015

RY0016

RY0017

RY0018

RY0019

RY001A

RY001B

RY001C

RY001D

RY001E

RY001F

・

RY006F

RY0070

RY0071

RY0072

RY0073

RY0074

RY0075

RY0076

RY0077

RY0078

RY0079

RY007A

RY007B

RY007C

RY007D

RY007E

RY007F

0160

0161

0162〜0166

0167

①Setting value writing request (Request 1)

②General command request (Request 2)

③Selection of writing/Reading out. (R/W)

④Operation mode changeover request (Request 3)

⑤ZERO

⑥A/Z ON

⑦A/Z OFF

System reservation zone

⑧Initial data proseccing complete flag

⑨Initialed data set request flag

⑩Error reset request flag

Communication

Control signal

14

Page 20

Occupies 2 stations

g

0162

0163

y

Device NO. Buffer address Contents Classification

RY0000

RY0001

RY0002

RY0003

RY0004

RY0005

RY0006

RY0007

RY0008

RY0009

RY000A

RY000B

RY000C

RY000D

RY000E

RY000F

RY0010

RY0011

RY0012

RY0013

RY0014

RY0015

RY0016

RY0017

RY0018

RY0019

RY001A

RY001B

RY001C

RY001D

RY001E

RY001F

・

RY002F

RY0030

RY0031

RY0032

RY0033

RY0034

RY0035

RY0036

RY0037

RY0038

RY0039

RY003A

RY003B

RY003C

RY003D

RY003E

RY003F

0160

0161

0162

0163

①Setting value writing request (Request 1)

②General command request (Request 2)

③Selection of writing/Reading out. (R/W)

④Operation mode changeover request (Request 3)

⑤ZERO

⑥A/Z ON

⑦A/Z OFF

⑪Select NET weight value/GROSS weight value

System data zone

⑧Initial data proseccing complete flag

⑨Initialed data set request flag

⑩Error reset request flag

Communication

Control signal

15

Page 21

Occupies 1 station

Device NO. Buffer address Contents Classification

RY0000

RY0001

RY0002

RY0003

RY0004

RY0005

RY0006

RY0007

RY0008

RY0009

RY000A

RY000B

RY000C

RY000D

RY000E

RY000F

RY0010

RY0011

RY0012

RY0013

RY0014

RY0015

RY0016

RY0017

RY0018

RY0019

RY001A

RY001B

RY001C

RY001D

RY001E

RY001F

0160

0161

⑤ZERO

⑥A/Z ON

⑦A/Z OFF

⑪Select NET weight value/GROSS weight value

System data zone

⑧Initial data proseccing complete flag

⑨Initialed data set request flag

⑩Error reset request flag

Communication

1

Setting value writing request (Request 1)

Requests writing of the data set in special data area. (RWw0000−RWw000B).

ON :In the request of writing

OFF :After confirming “Setting value writing response (Response 1)” of remote input.

2

General command request (Request 2)

Writing/Reading out by the command order is requested.

Please use together with writing/reading out selection (R/W).

ON :In the request of writing/reading out

OFF :After confirming “Setting value writing response (Response 2)” of remote input.

16

Page 22

3

Selection of writing or reading out(R/W)

Select writing or reading out by the command order.

Writing the data set in general−purpose data area (RWw000C−RWw000D) by command NO.

(RWw000E) is ordered for writing.

Reading out the data set in general−purpose data area (RWw000C−RWw000D) by command

NO. (RWw000E) is ordered for reading out.

ON :Reading out

OFF :Writing

4

Operation mode changeover request (Request 3)

Requests the writing of the data set in operation mode (RWw000F).

ON :In the request of writing request.

OFF :After confirming “Operation mode changeover response (Response 3)” of remote

input.

5

ZERO

Execute the zero set.

ON :In requesting the execution of zero set.

OFF :Normal

6

A/Z ON

Start an automatic zero.

ON :In the request of starting the automatic zero.

OFF :Normal

7

A/Z OFF

Clear the automatic zero.

ON :In the request of A/Z clear.

OFF :Normal

8

Initial proseccing complete flag

Send the initial proseccing complete flag when it will recive [RX078] command,

ON :Data clear request

OFF :Normal

9

Initial data setting request flag

Request the initialization of the instrument.

ON :In the request of default setting.

OFF :Normal

10

Error re−set requesting flag

When the error generation is notified with error condition command [RX007A], request the

release of the error.

ON :In the request of clear

OFF :Normal

11

Indicate value NET weight value/GROSS weight value comunand(2 stations, 1station)

Select the indication valiue [NET] or [GROSS] in remote resistor area when the station

occupies 1 or 2,

ON :NET weight value (Same value of remote resistor at the occupies 4 stations)

OFF :GROSS weight value (Same value of remote resistor at the occupies 4 stations)

17

Page 23

(2) Remote output(Master→Instrument) Occupies 4 stations

00E0

Communication

00E1

Control

output

00E2

00E7

y

Device NO.

RX0000

RX0001

RX0002

RX0003

RX0004

RX0005

RX0006

RX0007

RX0008

RX0009

RX000A

RX000B

RX000C

RX000D

RX000E

RX000F

RX0010

RX0011

RX0012

RX0013

RX0014

RX0015

RX0016

RX0017

RX0018

RX0019

RX001A

RX001B

RX001C

RX001D

RX001E

RX001F

RX0020

・

RX006F

RX0070

RX0071

RX0072

RX0073

RX0074

RX0075

RX0076

RX0077

RX0078

RX0079

RX007A

RX007B

RX007C

RX007D

RX007E

RX007F

Buffer address Contents Classification

00E0

00E1

①Setting value writing request (Response 1)

②General command response (Response 2)

③Writing/reading out selection response (R/W response)

④Operation mode changeover response(Response 3)

⑤CPU normal operation

⑥Decimal point position 1

⑥Decimal point position 2

⑥Decimal point position 4

⑦S0

⑦S1

⑦S2

⑧In the holding

⑨Abnormal load value

Communication

Control output

00E2

〜00E6

00E7

System reservation zone

⑩Initial data setting request flag

⑪Error reset request flag

⑫Remote ready

18

Page 24

Occupies 2 stations

00E0

Communication

00E1

Control

output

00E2

00E7

y

Device NO.

RX0000

RX0001

RX0002

RX0003

RX0004

RX0005

RX0006

RX0007

RX0008

RX0009

RX000A

RX000B

RX000C

RX000D

RX000E

RX000F

RX0010

RX0011

RX0012

RX0013

RX0014

RX0015

RX0016

RX0017

RX0018

RX0019

RX001A

RX001B

RX001C

RX001D

RX001E

RX001F

RX0020

・

・

RX006F

RX0030

RX0031

RX0032

RX0033

RX0034

RX0035

RX0036

RX0037

RX0038

RX0039

RX003A

RX003B

RX003C

RX003D

RX003E

RX003F

Buffer address Contents Classification

00E0

00E1

①Setting value writing request (Response 1)

②General command response (Response 2)

③Writing/reading out selection response (R/W response)

④Operation mode changeover response(Response 3)

⑤CPU normal operation

⑥Decimal point position 1

⑥Decimal point position 2

⑥Decimal point position 4

⑦S0

⑦S1

⑦S2

⑧In the holding

⑨Abnormal load value

Communication

Control output

00E2

00E7

System reservation zone

⑩Initial data setting request flag

⑪Error reset request flag

⑫Remote ready

19

Page 25

Occupies 1 station

00E0

Control

output

00E1

Device NO.

RX0000

RX0001

RX0002

RX0003

RX0004

RX0005

RX0006

RX0007

RX0008

RX0009

RX000A

RX000B

RX000C

RX000D

RX000E

RX000F

RX0010

RX0011

RX0012

RX0013

RX0014

RX0015

RX0016

RX0017

RX0018

RX0019

RX001A

RX001B

RX001C

RX001D

RX001E

RX001F

Buffer address Contents Classification

00E0

⑦S0

⑦S1

⑦S2

⑧In the holding

⑨Abnormal load value

Control output

00E1

⑩Initial data setting request flag

⑪Error reset request flag

⑫Remote ready

1

Setting value writing response (Response 1)

The end of writing by the set value writing request (request 1) is notified.

ON :In completion of writing

OFF :After confirming OFF of “Setting value writing request(Request 1)”

2

General command response (Response 2)

The end of the command instruction by the general command request (request 2) is notified.

ON :In the completion of command instruction

OFF :After confirming OFF of the general command request (Request 2)

3

Writing/Reading out selecting response (R/W response)

Notify the status of write/reading out by the command instruction when notifying by the

general command response (response 2).

4

Operating mode changeover response(Response 3)

Notify that the end of the operation mode changeover by the operation mode changeover

request (request 3(RY0004)).

ON :In the completion of the changeover

OFF :After confirming the OFF of the operation mode changeover request(Request 3)

20

Page 26

5

CPU normal operation

Notify that CC−LINK interface is operating normally. Reverse the status of ON/OFF in 0.5

seconds.

6

Decimal point position 1, 2, 3 or 4

Notify the decimal point position of the load value by the binary value of three points. This

output is updated by turning on the power supply, and initialed data set request flag (RY0079).

0 :No decimal point

0

2

3

4

digit

digit

digit

digit

7

S0〜S2

1 :10

2 :10

3 :10

4 :10

Notify the condition of S0〜S2. The same condition with S0〜S2 of the indicator

8

Holding

Notified whether the load value is holding.

ON :Holding

OFF :Free running

9

Abnormal load value

Notifies when the load value is “OL” or “−OL”.

ON :When abnormality occurs

OFF :Normal

10

Initialed data set completion flag

Notify the end of initialization when there is a request with initialed data set request flag

(RY0079).

ON :In the completion of set

OFF :Normal

11

Error condition flag

Notify when the error occurs in the indicator. After the error is released, it is reset with error

reset request flag (RY007A).

ON :In the occurrence of error

OFF :Normal

12

Remote ready

Notified to be able to complete initialization and to communicate.

ON :Possible to communicate

OFF :In the initialization

21

Page 27

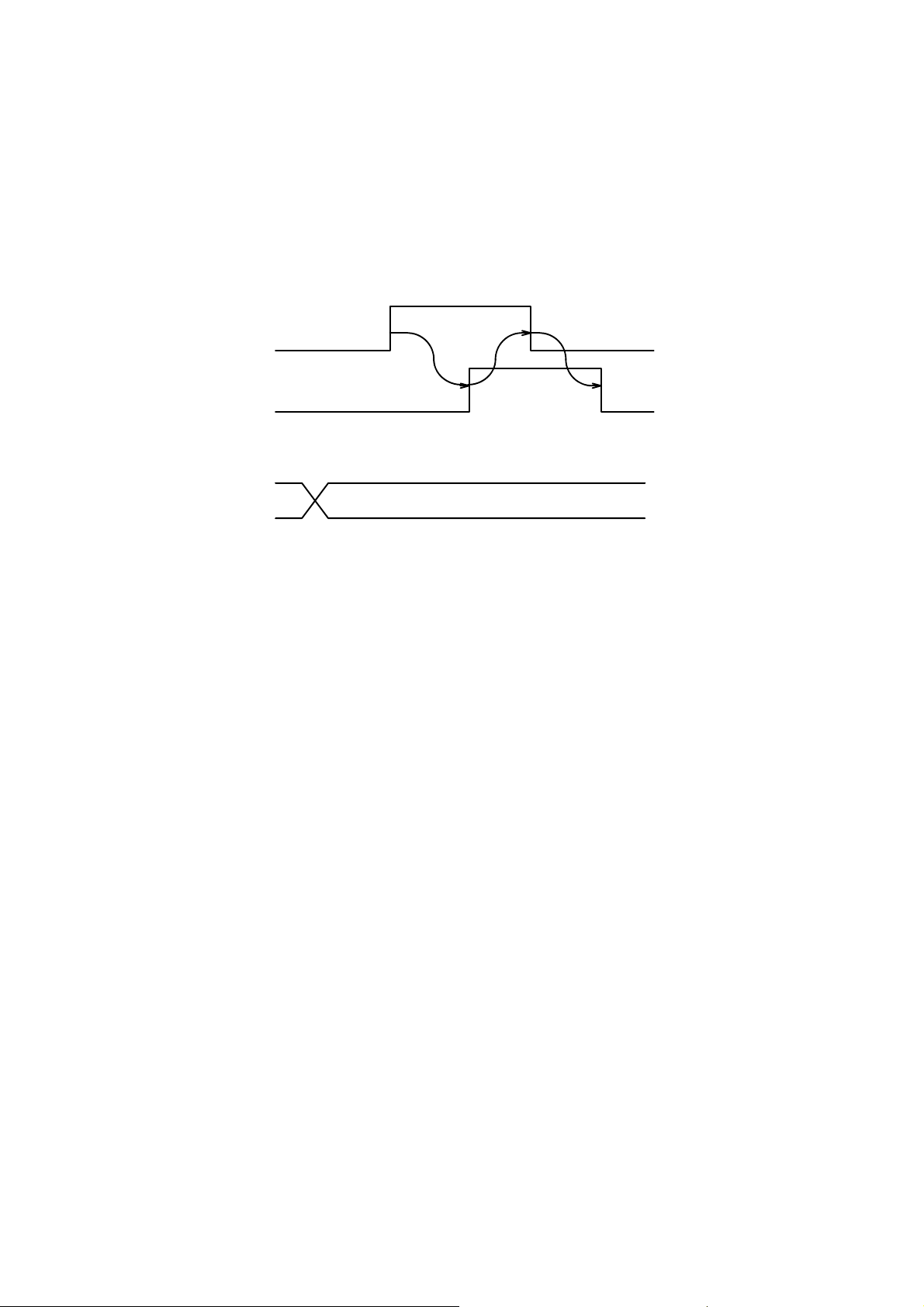

6. Operation method

6−1. Writing the set value (Special data area)

The set value is set in the special data area.

The instrument recognizes that “Set writing request (request 1) RY0000” was turned on, and it

writes the data set in “Special data area (RW0000−RW0009)” into the indicator.

It responds to the master station by “Set value writing response RX0000 (response 1)” after

writing is completed.

Time chart

Set value writing request (Request 1)

(RY0000)

Set value writing response(Response 1)

(RX0000)

Special data

(RWw0000)

〜

(RWw0009)

22

Page 28

6−2. Writing/Reading by general command

Data is set in the general data area and command No. is set in the command No. area.

The instrument recognize that “General command request RY0002 (Request 2)”, and it execute to

write the data set in “General data area (RWr000C〜000D)” by “Selection of writing/reading out

(RY0003)” or “Command No.(RWw000E)”, or to reading the data into “General data area

(RWw000C〜000E)” to the instrument.

It responds to the master station by ”General command response RX0000 (response 2)” after

writing is completed.

1

Writing request

General command request (Request 1)

(RY0002)

General command response (Response 1)

(RX0000)

Selection of writing or reading

(RY0003)

General data

(RWw000C)

〜

(RWw000D)

Command NO.

(RWw000E)

Command No.(Response)

(RWr010E)

Selection response of writing or

reading out

(RX0003)

23

Page 29

2

Reading out request

General command request (Request 1)

(RY0002)

General command response (Response 1)

(RX0000)

Selection of writing or reading out

(RY0003)

Command No.

(RWw000E)

General data

(RWw000C)

〜

(RWw000D)

Command No.(Response)

(RWr010E)

Selection response of writing

or reading out

(RX0003)

24

Page 30

6−3. Shift to status where it is possible to communicate

“Remote READY (RX007B)” is turned on along with the power supply turning on after

initialization (set initialing) completion is done and it is assumed the status where it is possible to

communicate.

Moreover, remote READY is turned off when ”Set initial request (RY0079)” transmitted by the

master station is turned on, and initialization is executed. It responds to the master station after

initialization is completed by turning on ”Set initial response (RX0079)”.

That the master station recognizes turning on ”Set initial response (RX0079)”, and ”Set initial

response (RX0079)” is turned off makes that ”Set initial request (RY0079)” is turned off, and

remote ready is turned on.

Set initial request

(RY0079)

Set initial response

(RX0079)

Remote ready

(RX007B)

Power supply turning on

6−4. CPU normal operation signal

When the instrument operates normally, the condition of ”CPU normal operating signal

(RX0006)” is reversed at 0.5 seconds interval.

CPU normal operation

(RX0006)

0.5 s

25

Page 31

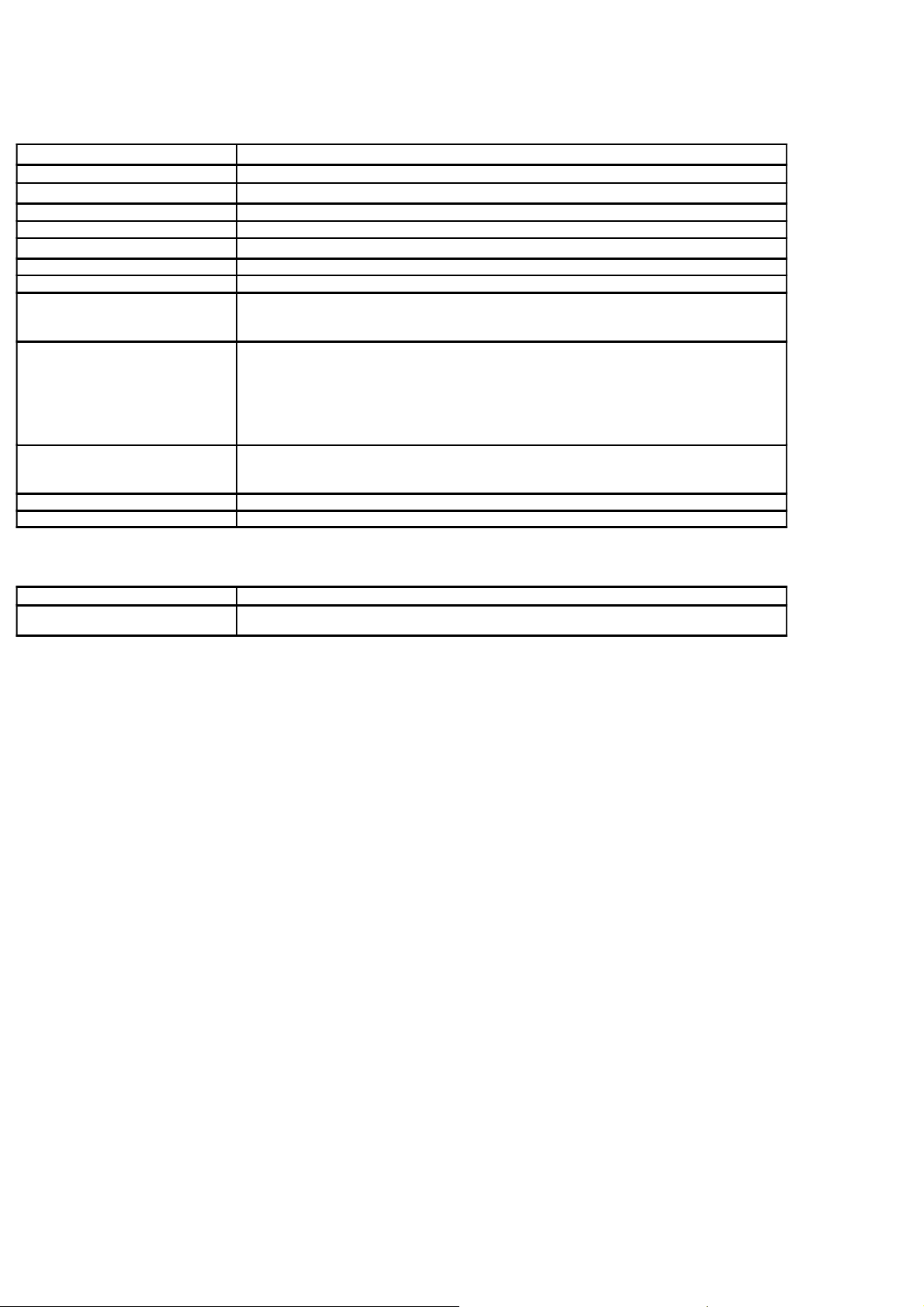

7. Specifications of interface

7−1. CC−Link interface spec

Specifications

Version of CC−LINK Ver.1.10

Occupied stations No.

Communication method Polling method

Synchronous method Bit synchronization method

Contents

Selectable from 1,2 or 4 stations.

Baud rate Selectable from 156 kbps, 625 kbps, 2.5 Mbps, 5 Mbps or 10 Mbps

Transmission path form RS.485 bus

Transmission format HDLC conforming

Remote station number In the case of 1 station occupied,Noʼs. 01 to 64 can be selectable.

Cable length Baud rate(bps) Total extensiondistance(m)

Numbers of connection In the case of 1 station occupied, 64 units at maximum.

Termination Resistance externally attached

Status LED The status of communication is expressed with four LED.RUN, SD, RD or ERR

In the case of 2 stations occupied,Noʼs. 01 to 63 can be selectable.

In the case of 4 stations occupied,Noʼs. 01 to 61 can be selectable.

156 kbps 1 200m or less

625 kbps 600m or less

2.5 Mbps 200m or less

5 Mbps 150m or less

10 Mbps 100m or less

In the case of 2 stations occupied, 32 units at maximum.

In the case of 4 stations occupied, 16 units at maximum.

7−2. Accessory

Instruction manual or CC−LINK 1 piece

Connector pin configuration for

CC−LINK

1 piece attached(721−105/037−000 WAGO)

26

Page 32

D The contents of this manual may subject to change without notice.

HEAD QUARTER : MINEBEA CO., LTD.

4106−73 Miyota, Miyota−machi, Kitasakugun, Nagano−ken 389−0293, Japan

0267−32−2200 .0267−31−1350

Measuring Components Business Unit

FUJISAWA PLANT 1−1−1, Katase, Fujisawa−shi Kanagawa−ken, 251−8531 Japan

0466−22−7151 .0466−22−1701

KARUIZAWA PLANT 4106−73 Miyota, Miyota−machi, Kitasakugun, Nagano−ken 389−0293, Japan

0267−31−1309 .0267−31−1350

HOMEPAGE ADDRESS http://www.minebea−mcd.com

Loading...

Loading...