Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

INSTRUCTION MANUAL

FOR

CSD-801 DIGITAL INDICATOR

MINEBEA CO., LTD.

SHINKOH COMMUNICATION DIVISION

DRW.NO. 294-1011-A

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

§1.

OUTLINE

CONTENTS

CSD-801 DIGITAL INDICATOR

Page

1

§2.

§3.

§4.

§5.

§6.

FEATURES

NAME OF EACH PART

3-1 Front panel

3-2

Rear panel 3

INSTALLATION

CONNECTION METHOD 5

5-1

5-2

Terminal board for power and transducer

Terminal board for digital control 5

5-3 BCD-OUT connector 6

5-4 Precautions for connection 8

HANDLING PROCEDURE

10

6-1 Connection 11

6-2 Power ON

11

1

2

2

4

5

6-3

6-4

Actual load calibration-I 12

Actual load calibration-II

6-5 Actual load calibration-III

6-6

Electric calibration-I

6-7 Electric calibration-II 20

6-8 Registration of each function by SET MODE 21

6-9 Start of measurement 21

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

16

17

19

Page 5

§7. FUNCTION IN MEASUREMENT MODE 22

7-1 Zero set function 22

7-2 AUTO ZERO, AUTO ZERO OFF function 23

7-3 Comparative setting function (Comparator) 25

7-4 CENTER ZERO function 27

§8. FUNCTION BY SET MODE (INITIAL SETTING FUNCTION) 28

8-i Required switch for SET MODE 29

8-2 ZERO TRACKING 30

8-3 Minimum effective digit setting function 34

8-4 Multiplication function 38

8-5 Pre-set cancellation function 40

8-6 Comparative setting condition

changeover function 43

8-7 Judgment function 46

8-8 Dummy 0 indication 49

8-9 Decimal point indication 51

8-10. Sign inversion function 53

8-11 Sign transfer function 55

8-12 BCD-OUT true conversion 57

8-13 Unit indication changeover 58

8-14 Manual Z/S function 59

8-15 Back-up Data Clear 60

§9. SELF-CHECK FUNCTION 61

§10. ERROR INDICATION 61

§11. SET MODE SETTING VALUE TABLE 65

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

§12. ANALOG ADJUSTMENT 67

§13.

12-1

12-2

12-3

12-4

12-5

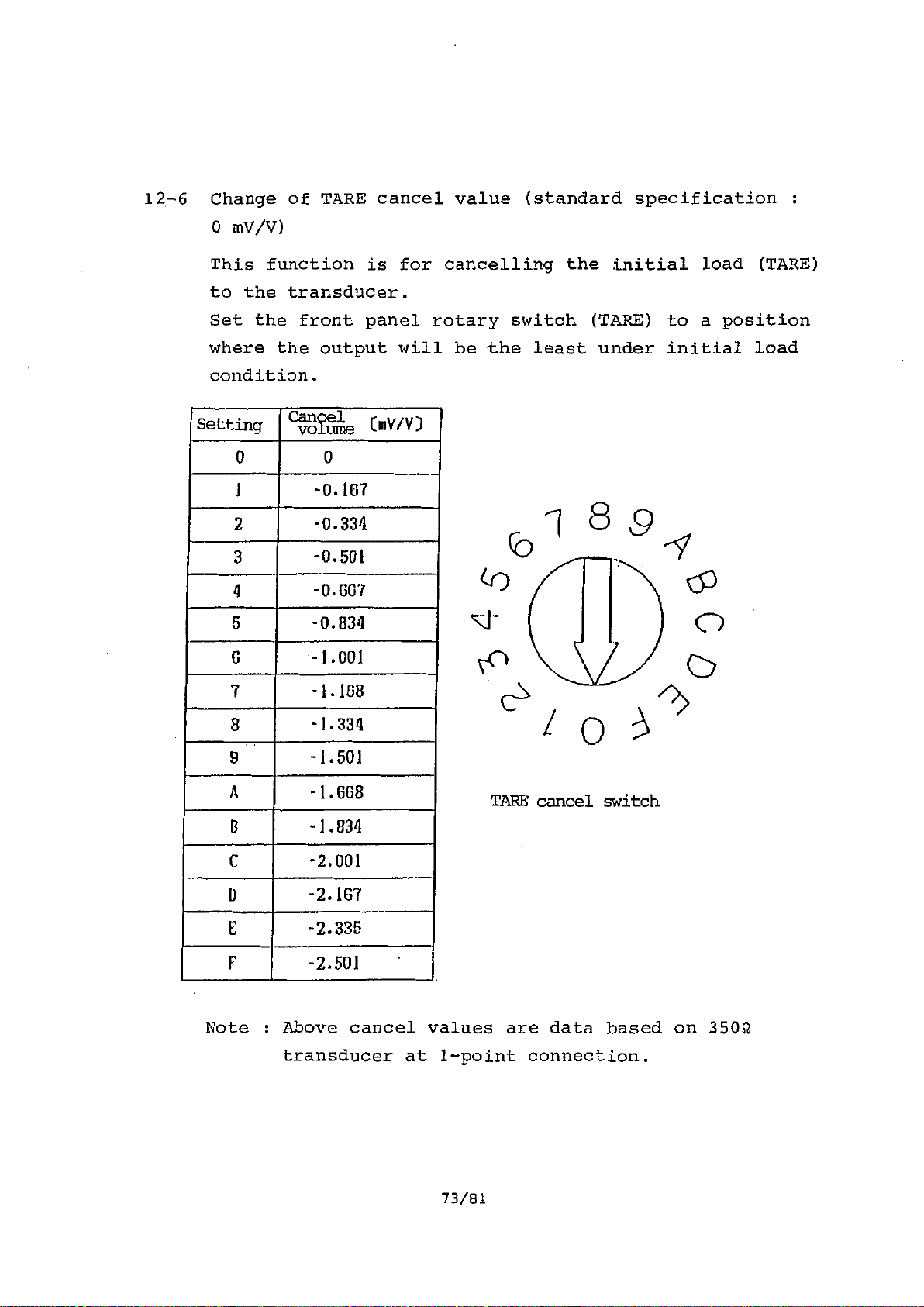

12-6

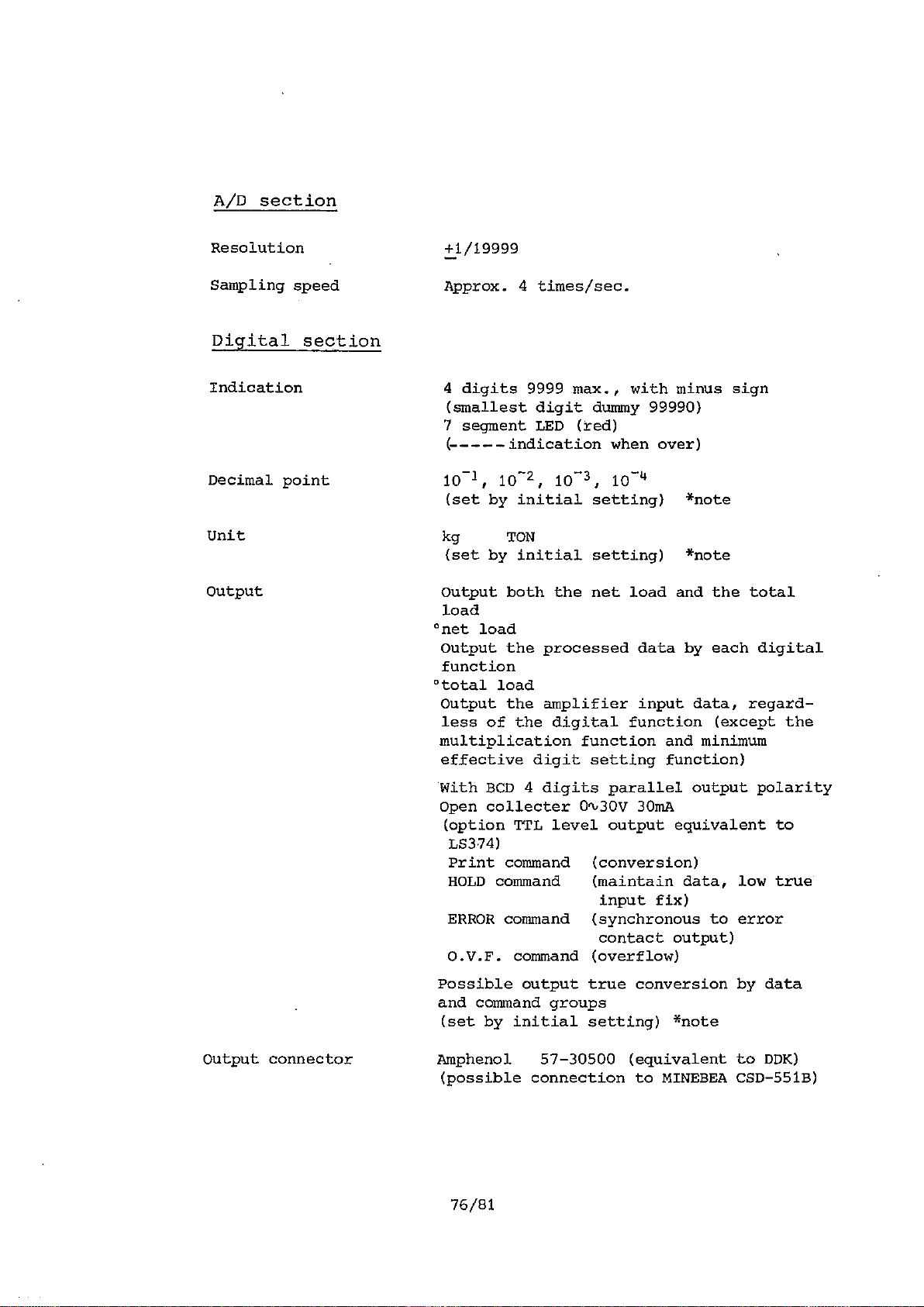

SPECIFICATION

13-1

13-2

Standard parts adjustment

Layout of adjustment parts 68

Adjustment of bridge voltage 69

GAIN adjustment

Change of CHECK value

Change of TARE cancel value

General specification 75

Block Diagram

13-3 Appearance Drawing

§14. ACCESSORIES

67

69

71

73

75

78

80

81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

§1. OUTLINE

The equipment is CPU mounted digital indicator for

instrumentation.

§2. FEATURES

o Remote setting function is provided to the converter

(transducer) power, and the error from cable length

will be cancelled.

o Flying capacitor is adopted at signal amplifier input

step. In common mode noise reduction ratio is set at

120dB.

o Drift at the signal amplifier is reduced as much as

possible by chopper amplifier.

o Maximum indication is 9999, with multi (multiplying)

function and, at dumy (-)0, indication up to (+)199980

is possible.

o Provided with BCD parallel-out output (open collector),

which can simultaneously output the total load and

net load.

o Setter is provided with 5-digits 2-steps digital switch,

as well as pre-set cancellation and judgment functions.

It can also be connected to MINEBEA digital setter

CSD-551B by using BCD parallel out connector.

o By its zero tracking function, secular change in zero-

point of the converter and the like will be cancelled.

1/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

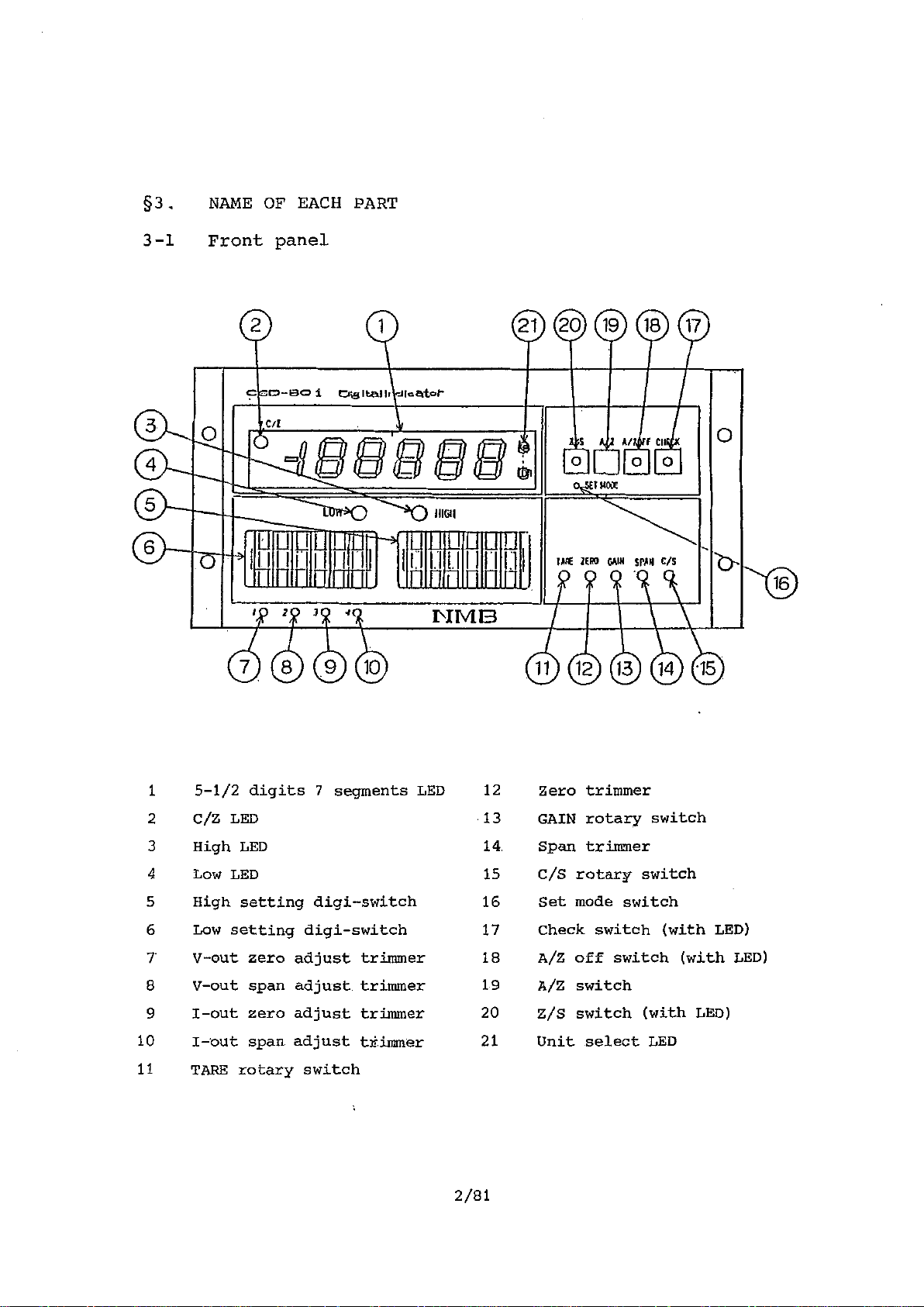

§ 3 -

3 -I Front panel

NAME OF EACH PART

M--sao 11 G;51 Ital IF meettnlO

C i

IIii

9

• WO I117 tali 0 rt 41

11

woo

fillrillini

0 CO igi IN Li

mum

1E1111

11

,

L'o

A*2

"I r0e I

0s

o�sEi

voce

lArE ZERO GAIN SPAN C/S

9 1F 35? , NINTH

1 5-1/2 digits 7 segments LED 12 Zero trimmer

2 C/Z LED

3 High LED

4

Low LED 15

5

High setting digi-switch

13

14

16 Set mode switch

GAIN rotary switch

Span trimmer

C/S rotary switch

]

6

Low setting digi-switch

7' V-out zero adjust trimmer

8 V-out span adjust trimmer 19 A/Z switch

9

I -out zero adjust trimmer

10

11 TA RE rotary switch

I -out span adjust trimmer

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

17

18

20 Z/S switch (with LED)

21

2/81

Check switch (with LED)

A/Z off switch (with LED)

Unit select LED

Page 10

§4. INSTALLATION

For the safe and complete operation of the instrument,

it is important that equipment is installed properly

in a suitable location. Ideally, a dry room with

uniform temperature environment will be the most

suitable location.

(1) When installing, select a location where mechanical

vibration and corrosive gas are minimal, with small

temperature change near the normal temperature.

(temperature compensated range i 0 % 50°C)

(2) The equipment is panel-mount type. When mounting to

a panel, prepare square holes at designated positions.

(Refer to panel outline drawing and panel cut

dimensions.)

4/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

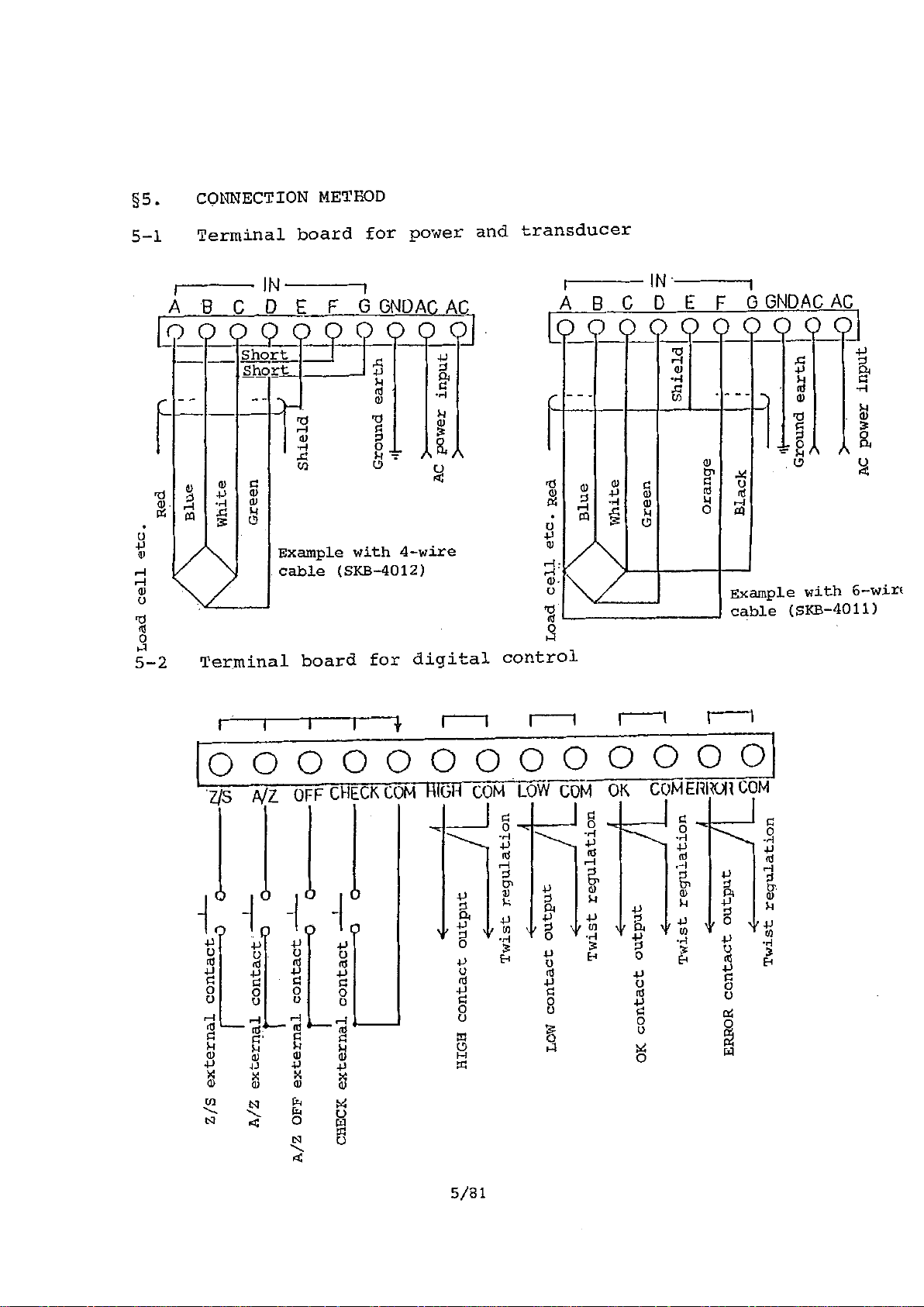

Z/S external contact--

I 0

A/2 external contact —I

A/Z OFF external contact --1-- C

CHECK external

HIGH contact output

contact ----

-0 0

Twist regulation --

LOW contact output //

0 -Zt

0 0--

<

r-

Cil

IN

11

A

11-0

0

0

0

-r-

rn

0

7t

0

0

0

7- 0

0 n

ulLoad cell etc.

Red

Blue

1-3

White

5

H.

o

tr

0

ct

0

0

h Load cell etc. Red

K

0

(r, tcs

1--•

IQ

Green

•

I

Shield

Ground earth

II

AC power input

Twist regulation -71:0

OK contact output

Twist

ERROR contact output

Twist regulation X

regulation rrIM

0

0

O

0

AC power input

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

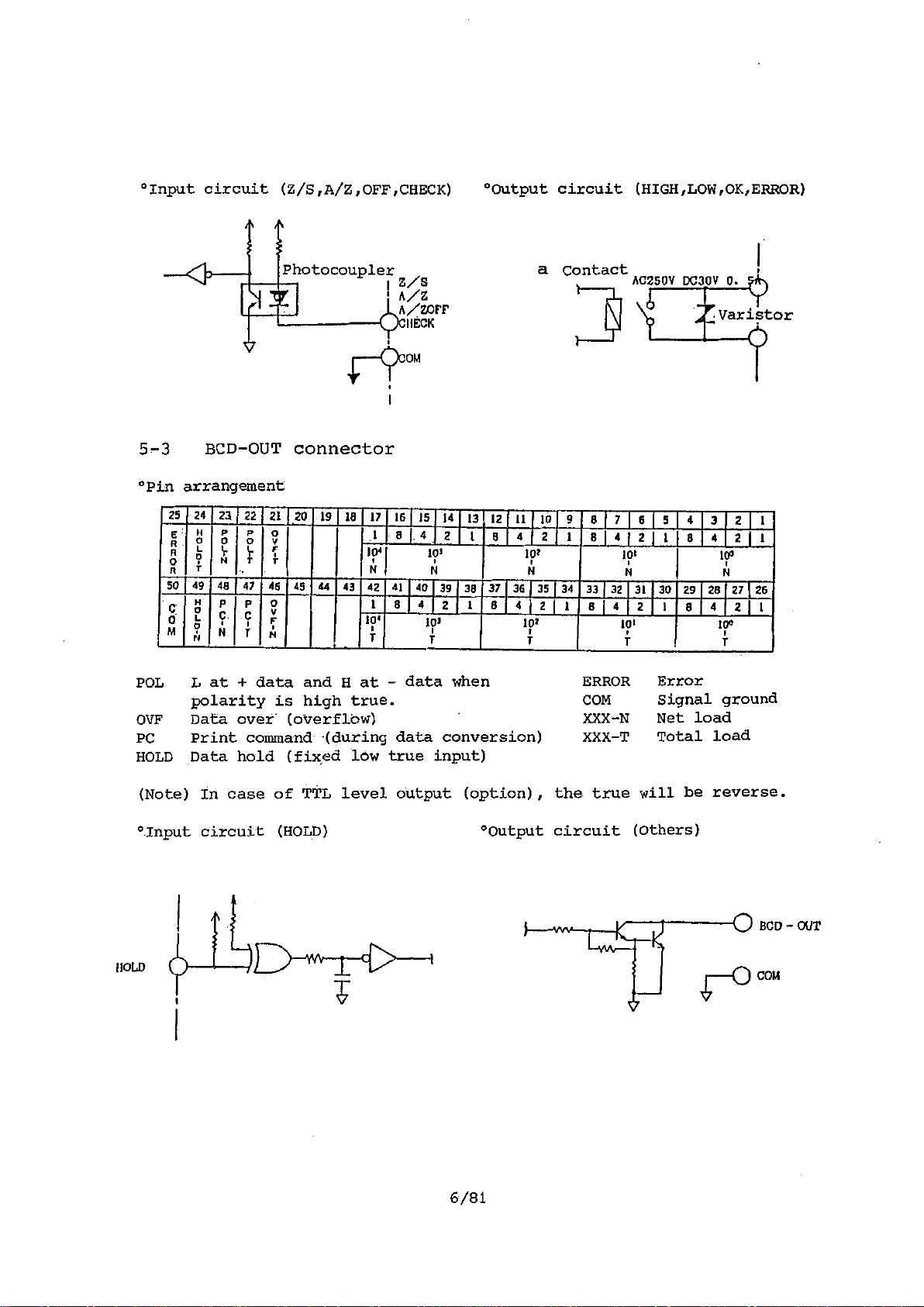

°Input circuit (Z/S,A/Z,OFF,CHECK)

°Output circuit (HIGH,LOW,OK,ERROR)

Photocoupler

z/s

a Contact

n/z

A/'7,10fF

IIECK

OM

5-3 BCD-OUT connector

°Pin arrangement

25 24 23

HP

Roev

o

ton

4r‘,"4

ft

r

50 49 48

o H

C

0

I.

M

.

N

POL

L at + data and H at - data when

polarity is high true.

OVF Data over (overflow) XXX-N

PC

Print command -(during data conversion) XXX-T

HOLD Data hold (fixed low true input)

221 21120

47

p

C

C

N

P

0

I

T

46 49 44

0

P

v

f

T 1

N

19 1 18 [17 16 15

1

8 1.4

1041 103

14 1 N

43

42 41

10'

i

- 4

40

I

8

4

101

T

39

14

2

2

38

13

1

1

12 11

8

37

36) 35 1 34

8

10

4 2

103

N

4 1 2 1 1

101

i

9 8 [

1

81 4 1 2 1 1

33 1 32

8 1

ERROR

COM

7 16

4 2 1 8

AC250V DC30V 0.

1 5 4

101

N

31

10'

f

8 4 2 1

30 29 28 27 1

Error

Signal ground

Net load

Total load

Naristor

3 2 1 1

1

100

N

26

4 2 1

10°

T

1

(Note) In case of TTL level output (option),

the true will be reverse.

°.Input circuit (HOLD) °Output circuit (Others)

HOLD

6/81

BCD — OUT

COM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

Timing Chart (When data command is high true output)

°Normal

0,2mS

270m8

DATA

ML

P. C.

°Hold signal input

HOLD

DATA

POL

P. C.

°Data over (overflow)

DATA

POL

60••••••••=.•••

ML

L

H

P. C.

O. V. F.

DATA

POL

P. C.

4RMDR

°Error

7/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

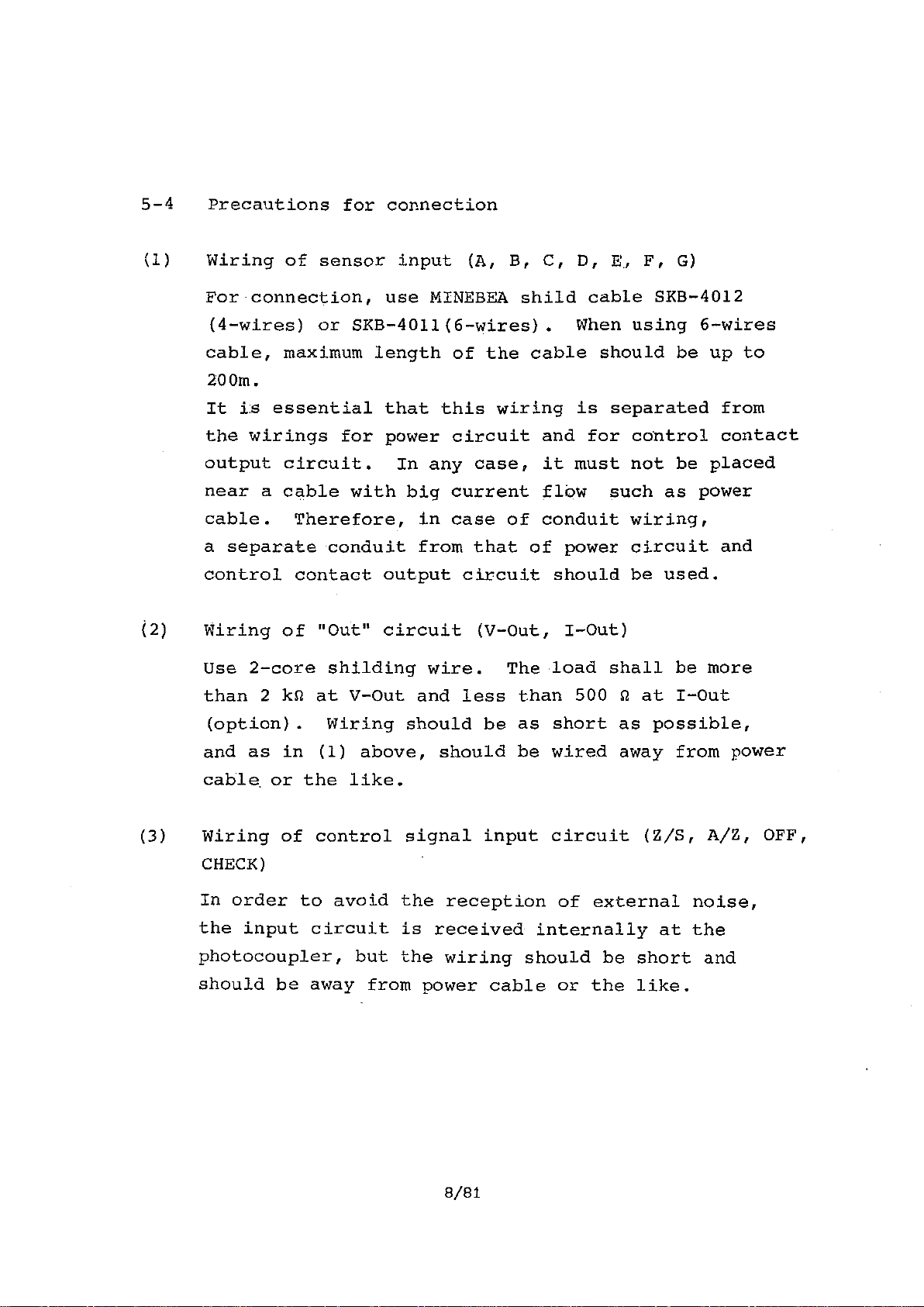

5-4 Precautions for connection

(1) Wiring of sensor input (A, B, C, D, E, F, G)

For connection, use MINEBEA shild cable SKB-4012

(4-wires) or SKB-4011(6-wires). When using 6-wires

cable, maximum length of the cable should be up to

200m.

It is essential that this wiring is separated from

the wirings for power circuit and for control contact

output circuit. In any case, it must not be placed

near a cable with big current flow such as power

cable. Therefore, in case of conduit wiring,

a separate conduit from that of power circuit and

control contact output circuit should be used.

(2) Wiring of "Out" circuit (V-Out, I-Out)

Use 2-core shilding wire. The load shall be more

than 2 k0 at V-Out and less than 500 0 at I-Out

(option). Wiring should be as short as possible,

and as in (1) above, should be wired away from power

cable. or the like.

(3) Wiring of control signal input circuit (Z/S, A/Z, OFF,

CHECK)

In order to avoid the reception of external noise,

the input circuit is received internally at the

photocoupler, but the wiring should be short and

should be away from power cable or the like.

8/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

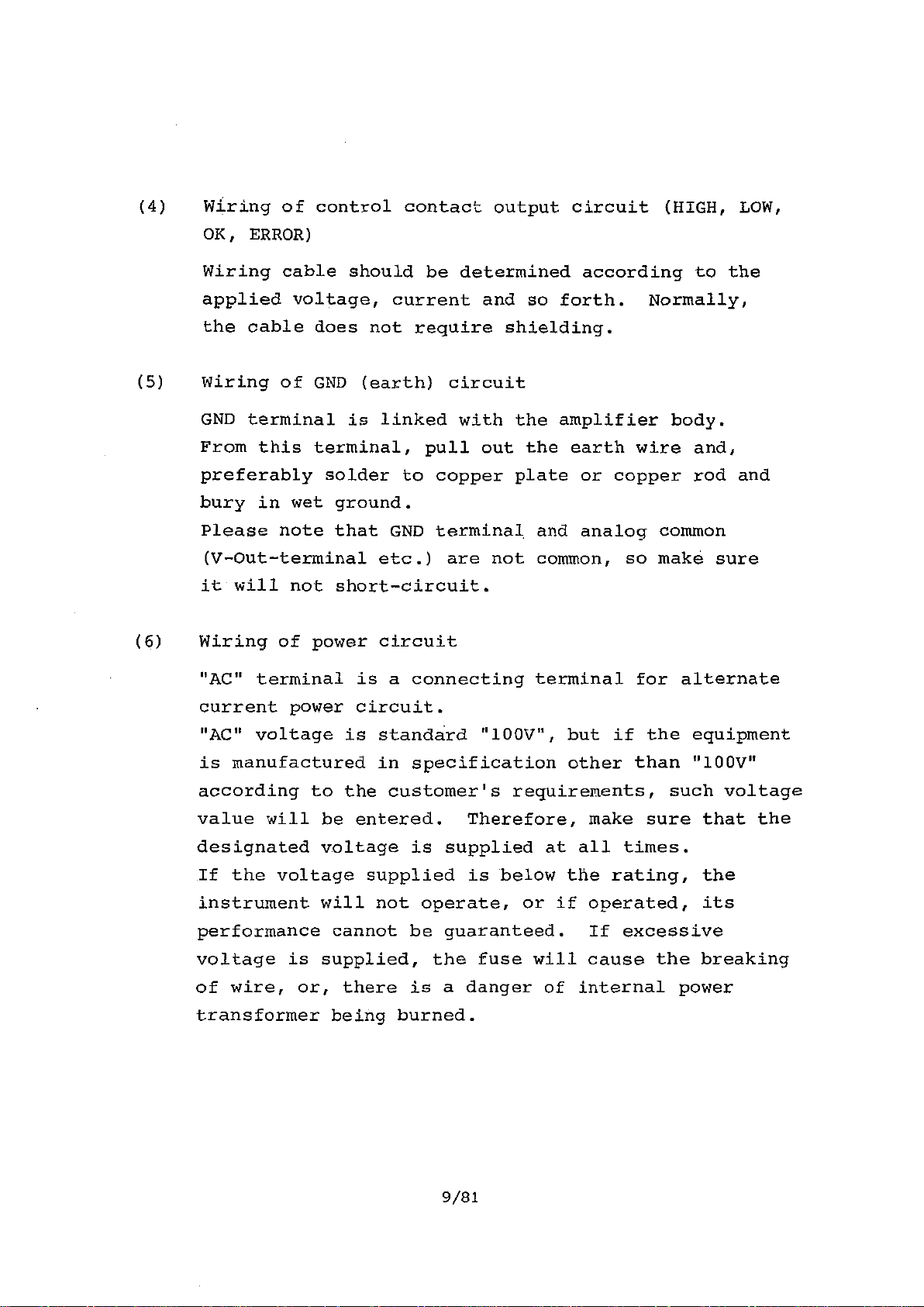

(4) Wiring of control contact output circuit (HIGH, LOW,

OK, ERROR)

Wiring cable should be determined according to the

applied voltage, current and so forth. Normally,

the cable does not require shielding.

(5) Wiring of GND (earth) circuit

GND terminal is linked with the amplifier body.

From this terminal, pull out the earth wire and,

preferably solder to copper plate or copper rod and

bury in wet ground.

Please note that GND terminal and analog common

(V-Out-terminal etc.) are not common, so make sure

it will not short-circuit.

(6) Wiring of power circuit

"AC" terminal is a connecting terminal for alternate

current power circuit.

"AC" voltage is standard "100V", but if the equipment

is manufactured in specification other than "100V"

according to the customer's requirements, such voltage

value will be entered. Therefore, make sure that the

designated voltage is supplied at all times.

If the voltage supplied is below the rating, the

instrument will not operate, or if operated, its

performance cannot be guaranteed. If excessive

voltage is supplied, the fuse will cause the breaking

of wire, or, there is a danger of internal power

transformer being burned.

9/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

HANDLING PROCEDURE

§6.

In order to utilize the various functions of CSD-801 effectively, adjustments shall be made

according to the following procedure.

In case of changing our standard adjusted product

to the customer's specification or changing the

specification of previously adjusted product.

Using digital output only

6-1

(Connection)

6 -2

(Power on)

6-3

(Actual load

calibration I)

4,

Combined use of

analog output

Basically, adjustment

in our factory will be

required.

Please contact our

sales representative.

In case the product has been shipped from

our factory, with adjustment required by

the customer's specification already completed.

Using digital output

only

6-1

(Connection)

6-2

(Power on)

6-4 6-6

(Actual load

calibration II•

Electric

calibration I)

6 -B

(Function' registration`

by set mode)

6 -9

(Start measurement)

6-8

(Function registration

by set mode)

4.

6-9

(Start measurement)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

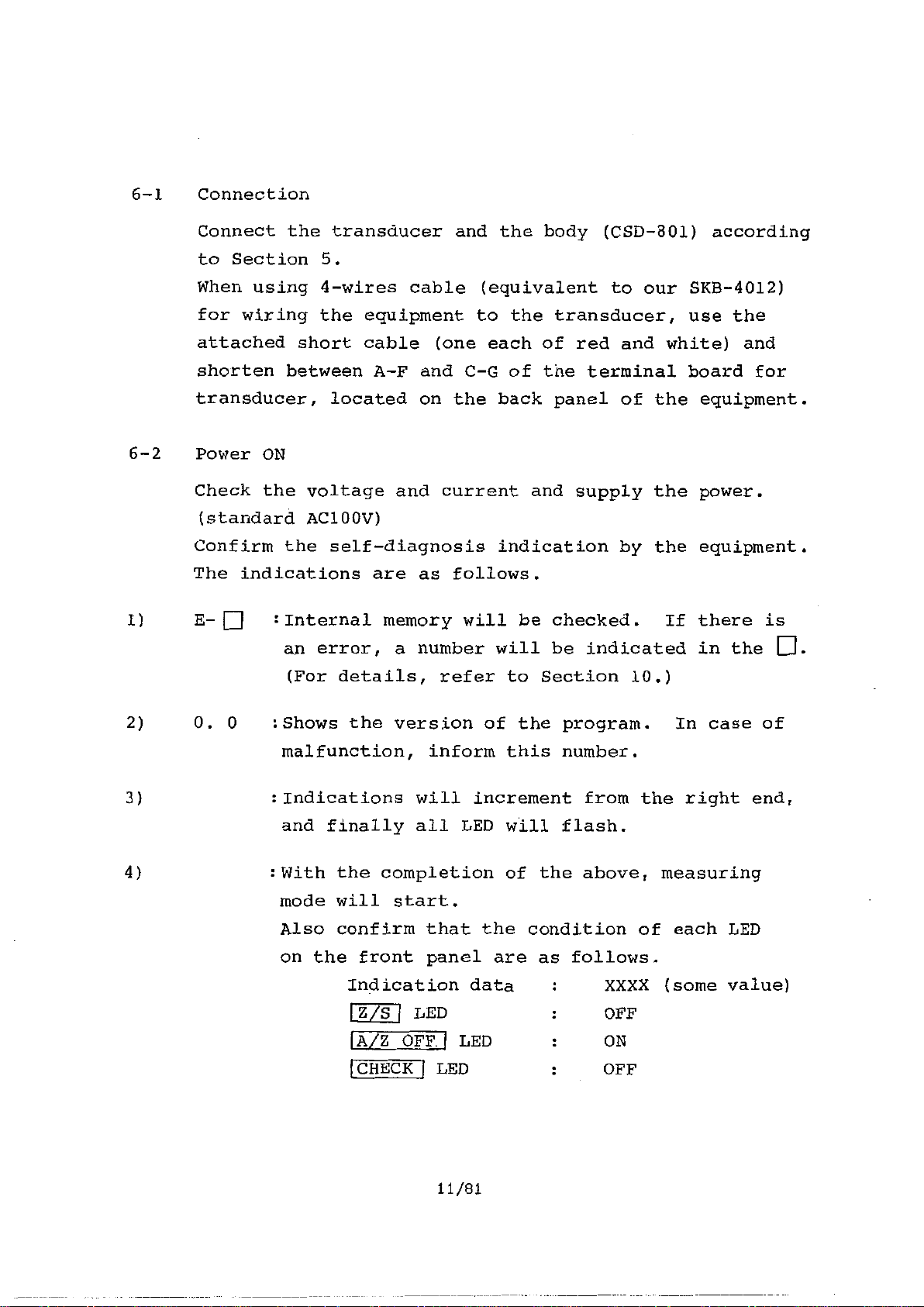

6-1 Connection

Connect the transducer and the body (CSD-801) according

to Section 5.

When using 4-wires cable (equivalent to our SKB-4012)

for wiring the equipment to the transducer, use the

attached short cable (one each of red and white) and

shorten between A-F and C-G of the terminal board for

transducer, located on the back panel of the equipment.

6-2 Power ON

Check the voltage and current and supply the power.

(standard AC100V)

Confirm the self-diagnosis indication by the equipment.

The indications are as follows.

1) E- 0 :Internal memory will be checked. If there is

an error, a number will be indicated in the ❑ .

(For details, refer to Section 10.)

2) 0. 0 :Shows the version of the program. In case of

malfunction, inform this number.

3) :Indications will increment from the right end,

and finally all LED will flash.

4) :With the completion of the above, measuring

mode will start.

Also confirm that the condition of each LED

on the front panel are

Indication data

Lz/s

[A/z OFF.

'CHECK

LED

LED ON

LED OFF

as follows.

XXXX (some value)

OFF

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

6-3 Actual load calibration-I (for changing specification,

no analog output)

(1) Maintain the condition with initial load on transducer.

(2) Adjust the TARE rotary switch (coarse adjustment) and

ZERO trimmer (fine adjustment) of the equipment, and

confirm that the indication will be 0 (zero).

(3) Apply maximum load on the transducer.

(4) What is the maximum indication required under the

condition of (3) above.

1) less than 999 4- to (5)

2) less than 1999 to (6)

3) less than 4999 to (7)

4) less than 9999 4- to (8)

5) more than 10000 to (9)

(5) Multiply the required indication by 10 times (x 10)

Eg,) If the maximum indication is 800, then

800 x 10 = P1500I

To obtain the calculated value, adjust the

'GAIN'

rotary switch and ISPANI trimmer on the front panel

with the attached micro-driver.

If the adjustment cannot be made, change the bridge

voltage by referring to 12-3 in page 69, and repeat

the same adjustment.

If the adjustment still cannot be made, proceed to (6).

12/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

If the adjustment is completed, set mode (refer to

Section 8) will start, and by utilizing the minimum

effective digit setting function (Section 8-3, page 34)

cut the 108 digit.

After completion, pass through the set mode and proceed

to (10).

(6) Multiply the required indication by 5 times (x 5)

Eg.) If the maximum indication is 1500, then

1500 x 5 = 1 7500 1

To obtain the calculated value, adjust the IGAIN1

rotary switch and SPAN trimmer on the front panel

with the attached micro-driver.

If the adjustment cannot be made, change the bridge

voltage by referring to 12-3 in page 69, and repeat

the same adjustment.

If the adjustment still cannot be made, proceed to (7).

If the adjustment is completed, set mode (refer to

Section 8) will start, and by utilizing the multipli-

cation function (Section 8-4, page 38), set the

indication data at 1/5.

After completion, pass through the set mode and

proceed to (10).

(7) Multiply the required indication by 2 times (x 2)

Eg.) If the maximum indication is 3000, then

3000 x 2 = 60001

To obtain the calculated value, adjust the

rotary switch and

(SPAN

trimmer on the front panel

!GAIN]

with the attached micro-driver.

13/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

If the adjustment cannot be made, change the bridge

voltage by referring to 12-3 in page 69, and repeat

the same adjustment.

If the adjustment still cannot be made, proceed to (8).

If the adjustment is completed, set mode (refer to

Section 8) will start, and by utilizing the multipli-

cation function (Section 8-4, page 38), set the

indication data at 1/2.

After completion, pass through the set mode and proceed

to (10).

(8) To obtain the required indication value, adjust the

GAIN

rotary switch and SPAN trimmer on the front

panel with the attached micro-driver.

If the adjustment cannot be made, change

voltage by referring to 12-3 in page 69,

the bridge

and repeat

the same adjustment.

If the adjustment still cannot be made, it

that it is out of the specification of the

is possible

equipment.

Please contact our sales representative.

If the adjustment is completed, proceed to

(10) .

(9) Multiply the required indication by 1/2 time (x 1/2)

Eg.) If the maximum indication is 16000, then

16000 x 1/2 =

To obtain the calculated value, adjust the

8000

GAIN

rotary switch and (SPAN trimmer on the front panel

with the attached micro-driver.

If the adjustment cannot be made, change the bridge

voltage by referring to 12-3 in page 69, and repeat

the same adjustment.

14/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

If the adjustment still cannot be made, it is possible

that it is out of the specification of the equipment.

Please contact our sales representative.

If the adjustment is completed, set mode (refer to

Section 8) will start, and by utilizing the multipli-

cation function (Section 8-4, page 38), set the

indication data by x 2. After completion, pass through

the set mode and proceed to (10).

(10) Remove the load and confirm that the indication is 0

(zero) and that C/Z LED is lighted. If it cannot be

confirmed, adjust the front panel zero trimmer which

should give 0 (zero) indication.

Once again, provide maximum load and adjust the

trimmer to obtain the required indication.

Repeat the above operation several times.

(11) Remove the load and turn on the front panel

CHECK I

switch.

(12) Suitably turn the front panel rotary switch,

and adjust so that the indication will be at about

80% of the required maximum indication. Record the

indicated value. Hereafter, electric calibration

can be made by this value.

By turning on the CHECK switch again, check value

will be released.

SPAN)

15/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

6-4 Actual load calibration•-II (for detection, no analog

output)

(1)

(2)

Apply initial load on the transducer.

Adjust the TARE rotary switch (coarse adjustment) and

ZERO trimmer, and confirm that the indication becomes

0 (zero).

(3)

(4) Adjust the

Apply maximum load on transducer.

,SPAN

trimmer to obtain required indication

at (3) condition.

(5) Remove the load and confirm that the indication is 0

(zero) and that C/Z LED is lighted. If it does not

work properly, adjust the ZERO trimmer, and the

indication will be 0 (zero). Apply the maximum load

again and adjust the SPAN] trimmer to obtain required

indication. Repeat the above operation several times.

(6) Remove the load and turn on the front panel (CHECK

switch. Check value will be indicated, and such value

should be recorded.

Hereafter, electric calibration will be possible with

this value.

By turning on the !CHECK switch again, the check

value will be released.

16/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 23

6-5 Actual load calibration-III (for detection, with

analog output)

(1) Apply initial load on the transducer.

(2) Turn the front panel TARE rotary switch and adjust

so that the indication will be nearest to 0 (zero).

(3) Further, turn the front panel jZEROJ trimmer so that

the indication will be 0 (zero) and that "C/Z" LED

will be lighted.

(4) In case there is a voltage output (V-Out), separate

zero adjustment should be done. By adjusting the

trimmer No.1, located at the lower left side of the

front panel, V-Out should be 0.000 V when the indica-

tion is 0 (zero).

(5) In case there is an isolation output (I-Out), by

similaly adjusting trimmer No.3, I-Out should be

4.00 mA when the indication is 0 (zero).

(6) Apply maximum load on the transducer.

(7) Adjust the[SPANjtrimmer to obtain the required indi-

cation at (6) condition.

(8) If there are further analog output, adjust to obtain

required analog value with the following trimmer.

Front panel lower left side trimmer No.2 V-Out SPAN

Front panel lower left side trimmer No.4 I-Out SPAN

17/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

(9) Remove the load and repeat the above (3)q,(8) several

times.

Note: ZERO, SPAN adjustment (trimmer No.liA) of analog

output are not interlocked with the indication.

Therefore, adjustments should be made by confirm-

ing the output of V-Out or I-Out with digital

multi-meter or the like.

(10) Remove the load and turn on the front panel

switch. Record the indication and analog value.

Hereafter, electric calibration will be possible with

this value.

(11) Hereafter, ZERO and SPAN adjustment of the indication

and analog output should be made by IZEROI and

trimmer, located at lower right of the front panel.

If, for some reason, there should be a gap between the

proportion of the indication and voltage output, adjust

the trimmer No.1"4.

ICHECKI

SPAN I

18/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

6-6 Electric calibration-1 (for detection, no analog output)

(1) Apply initial load on the transducer.

(2) Adjust the TARE rotary switch (coarse adjustment) and

ZERO trimmer (fine adjustment), and confirm that the

indication will be 0 (zero).

(3) Turn on the front panel

will be given. Then, adjust the 1SPANJ trimmer so that

the value will be the same as the CHECK value in the

test report sheet, attached to the equipment.

(If there is no report sheet, adjust with the CHECK

value recorded at the time of actual load inspection.)

(4) Turn on the

will be 0 (zero). If it does not become 0 (zero),

adjust the front panel ZERO trimmer (fine adjustment),

and after confirming that the indication is 0 (zero),

then carry out (3) above.

CHECK

switch again and the indication

LCHECK1

switch. An indication

19/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

6-7 Electric calibration-II

(for detection, with

analog output)

(1) Apply initial load on the transducer.

(2) With the front panel

0 (zero) indication as well as "C/Z" IJED light.

(If adjustment cannot be made, jointly use the

rotary switch.)

Also, adjust the trimmer No.1 (V-Out) or trimmer No.3

(I-Out), so that voltage output will be 0.000 V or

current output will be 4.00 mA when the indication is

0 (zero).

(3) Turn on the front panel

and analog output will be shown.

In the attached test report sheet, indicated value and

analog value are noted as the check values.

First, adjust the

SPAN

value will be the same.

Then, adjust trimmer No.2 (V-Out) or trimmer No.4

(I-Out) so that the analog value will be the same.

ZERO]

trimmer, adjust to obtain

'TARE'

CHECK

switch. Indication

trimmer so that the indicated

(4) By turning on the ICHECK switch again, the indication

will be 0 (zero). If it does not become 0 (zero),

repeat the above (2) and (3) several times.

20/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 27

6-8 Registration of each function by set mode

By referring to Section 8. (page 28), register each

function.

Eg.) 1) Setting of decimal point

2) Changeover of the unit

3) Changeover of BCD-OUT true

etc.

ry

6-9 Start-of ,measurement

Turn on the

'Z/S

switch and start the measurement.

As required, set the value of comparative setter.

21/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

§7. FUNCTION IN MEASUREMENT MODE

This function is a function which can be carried out

during normal measurement. Condition at the time of

power supply to this equipment is in this mode.

7-1 Zero set function (Digital tare cancel, hereinafter

abbreviated as Z/S)

A function to make the indication 0 (zero) regardless

of the analog output.

It can be used for tare cancel and the like.

At the time of Z/S function OFF, it will beYY

(Indication data) = (BCD output: Total load) =

(BCD output: Net load) = (a)

But with the Z/S function ON, it will be

(Indication data) = (BCD output: Netload)

Z/S cancel data is the total load data

function is turned ON.

Also, by turning ON the Z/S function, it will be

possible to use AUTO ZERO function and ZERO TRACKING

function.

(1) Z/S ON

By turning ON the front panel Z/S switch, red LED in

the Z/S switch will be lighted, and the total load

value at such time will be memorized and the indication

will be 0 (zero).

Thereafter, the indication will be made according to

formula (b).

(Total—MIT- Z

(hATAgt,

(b)

when the Z/S

22/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

(2) Z/S OFF

By repeating the same operation as above (1), red LED

in the Z/S switch will be put out and the total load

value at such time will be indicated.

Thereafter, the indication will be made according to

formula (a). (However, this function is effective

only when the LED in the A/Z OFF switch is lighted.)

7-2 AUTO ZERO, AUTO ZERO OFF Function

(hereinafter, AUTO ZERO will be abbreviated as A/Z)

As in Z/S function, this function indicates 0 (zero)

regardless of the analog output.

While the Z/S function is a function to determine the

basis of indication (indication 0), A/Z function is

a function for easy understanding of the changed

amount of the data, which will give optional value a

0 (zero), and can indicate 0 repeatedly.

In case of A/Z function OFF, indication will be made

according to the formula (a) or (b) shown in Z/S

function.

In case of A/Z function ON, it will be

(Indication data) = (BCD output: Net load) =

a a celdata) (c)

— cpb,cia,.. — Ar t CA,K tga— c.tcoreA. )

A/Z cancel data means (Total load - Z/S cancel data)

when the A/Z function is turned ON.

A/Z function can be used only when the Z/S function

ON, and not at Z/S function OFF.

23/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

(1) A/Z ON

By turning ON the front panel A/Z switch, red colored

LED in the A/Z OFF switch will be put out.

(Total load - Z/S cancel data) at such time will be

memorized and the indication will be 0 (zero).

Hereafter, indication will be made according to formula

(c).

Also, it is possible to turn ON the A/Z function

repeatedly without turning OFF the A/Z function. With

A/Z function ON, Z/S function will be locked and Z/S

function OFF will not be accepted.

(2) A/Z OFF

By turning ON the front panel A/Z OFF switch, red

colored LED in the A/Z OFF switch will be lighted,

and thereafter indicate according to formula (b).

Also, with A/Z function OFF, locked condition of Z/S

function will be released and Z/S function OFF will be

possible.

24/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

7-3 Comparative setting function (comparator)

This is a function which will turn ON the rear contact

at above or below the setting value against the indica-

tion.

There are two setting points, HIGH and LOW, and each

can be set at high or low limits. Also, it will output

signals to show that, by setting, it is within the

range of two (2) settings. (OK)

(1) Setting of comparative value

Set the setting values of each 2 points at\the front

panel digital switch. The set values include the sign,

so if rear contact ON is desired at indicated value "+",

set the sign at "+", and if rear contact ON is desired

at indicated value "-", then 6.et the sign at "-".

(2) Setting of comparative conditions

When in standard specification or in back-up data clear,

both HIGH and LOW points will be set at high limits,

and whew-the- indic-ated- -va-lu-e---1-8- above the set value of

9 front panel digital switch, rear contact output will

be ON.

To change the condition, setting contents exchange

function of initial setting will be used.

Also, in case the condition of HIGH is at low limit

and condition of LOW is at high limit, and if setting

value of HIGH a indicated value setting value of

LOW, then contact output of OK will be ON in addition

to contacts of HIGH and LOW. This OK contact can be

controlled by the judgement function of initial setting.

(For the above, refer to initial setting function.)

25/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

(3) Output of comparative results

If the indicated value satisfies the conditions of (2)

against the setting of (1), then contact output will

be ON and front panel LED (color : red) will be ON.

Note : If the indicated value is unsteady in the

vicinity of the set value, contact output will

similary be unsteady.

Eg.1 LOW=high limit setting HIGH high limit setting

indication

HIGH setting value

LOW setting value

a.

HIGH contact

LOW contact oii

OK contact ON

Eg.2

indication

HIGH setting value

LOW setting value

HIGH contact OOFFN

LOW contact OcFF° ON

OK contact ow

ON

OFF

OFF

OFF

LOW=high limit setting HIGH=low limit setting

26/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

7-4 CENTER ZERO function

Turn on the front panel C/Z LED (color: red) when both

the indication is 0 (zero) and the total load value is

less than + 1/2 of 1 digit.

Example 1

Tota l load

Value

+ 1000.0

+ 1000.0

+ 1000.0

+ 1000.0

+ 0.5

+ 0.0

+ 0.0

+ 0.0

+ 0.3

0.3

Z/S cancel Z/S cancel

data data

OFF

+ 1000.0

+ 500.0

— 1000.0

OFF

+ 1000.0

+ 1000.0

OFF

OFF

- 0.3

+ 500.0 + 0 OFF

+ 2000.0 + 0 OFF

— 1000.0 + 0 ON

OFF + 1000.0 OFF

OFF + 0 OFF

OFF + 0 OFF

OFF — 1000.0 OFF

OFF + 0 ON

OFF + 0 ON

OFF + 0 ON

Indcation C/Z

27/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

§8. FUNCTION BY SET MODE (INITIAL SETTING FUNCTION)

This function is for carrying out the various functions

of this equipment and to set required data for such

functions.

Using the attached micro-driver, press the hole located

at front panel SET MODE. Then, SET MODE switch will be

ON, indication will be "P" and will be in SET MODE.

Normal measurement (Measurement Mode) will not be made

while indication is "P". To achieve measurement mode,

turn ON the SET MODE again.

Functions which can be registered by SET MODE are as

follows.

1) ZERO TRACKING

2) Minimum effective digit setting

3) Multiplication

4) Pre-set (weight) cancellation

5) Setting contents exchange

6) Judgment

7) Dummy 0 indication

8) Decimal point indication

9) Sign inversion

10) Sign transfer

11) Unit indication changeover

12) Manual. Z/S function

13) Back-up data clear

Each of the above functions will be registered under

the condition of SET MODE (indication "P").

28/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 35

8-1 Required switches for SET MODE

During the SET MODE (indication "P" lighted), each

switch on the front panel will have a different meaning

from that in Measurement Mode.

(1) Digital switch (LOW)

Setting function Nos.

(2) Digital switch (HIGH)

Data setting

Set the data per each function set by digital switch(LOW).

(3) Z/Sj switch

Function data register

Contents set by digital switches (HIGH/LOW) will be

registered in internal memory. While this switch is

pressed, indication will show the contents of digital

switch (HIGH). If the switch is released, the

indication will be "P".again.

(4) A/Zj or

Memory dump

Will indicate the data, presently registered within the

function set by digital switch (LOW).

Data will be indicated while the switch is pressed,

and indication will be "P" if switch is released.

(5)

CHECK switch

Self-check

Similar self-check as in initial power feed.

A/Z OFF

switch

29/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

8-2 ZERO TRACKING (Z/T)

While the indication is 0 (zero), it will cancel the

changing indication, due to drift of input data caused

by internal and external reasons.

Z/T will indicate 0 (zero) when the data, with the

exception of 0 (zero), is within a certain width and

time, and the data out of such position will be added

to Z/S cancel value (see 7-1).

Note : This function will be effective by Z/S switch ON

during Measurement Mode, after Set Mode register.

Registration Procedure

(1) Yes or no of Z/T execution will be set at the front

panel, digital switch.

Note 1.

Digital switch LOW

Digital switch HIGH +/-

*1 : For minimum effective digit setting (see 8-3)

*2 : For pre-set (weight) cancellation function (see 8-5)

*3 : For multiplication (see 8-4)

Note 1. : + or - both possible

+/-

Note 1.

0 0

*1

0 x

*2

0 0

0

*3

-- 0: Z/T ineffective

-- 1: Z/T effective

-- 2'b9: Error (E-3)

(Function No.)

(Data)

30/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 37

(2) Turn ON the WS switch and register the set value at

to internal memory.

(1)

(While the [Z/S1 switch is. ON, value set by digital

switch HIGH will be indicated, and when the switch is

released, "P" will be indicated. "E--3" will be

indicated when there is an error in digital switch

setting. In this case, data set at digital switch

will not be registered. Reconfirm the contents of

the digital switch.)

31/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 38

(3) Set the data required for Z/T to digital switch

Note 1

Digital switch LOW

Digital switch HIGH + / -

Note 1 : + or - both possible

+/- 0 0 0 0

Note 1

1

0

0

X

0

X (Data)

(Function No.)

'VT

time width setting

— 0 0 sec.

— 1 : 1 sec.

-- 2 : 2.5 sec.

-- 3 : 4 sec.

-- 4 6 sec.

-- 5 : 8 sec.

-- 6%9: Error (E-3)

• Data width to be

zero cancelled

0 0 (Z/T ineffective)

-- 1 1 count or below

r- 2 : 1.5 count or below

— 3 3 count or below

4%9: Error (E-3)

Data

--0

See the following graph for the relation between time width and

data width.

t

Time

t : Time width

d : Data width

32/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 39

(4) Turn ON the Z/S switch and register the set value at

(3) to internal memory.

(While the Z/S switch is ON, value set by digital

switch HIGH will be indicated, and when the switch is

released, "P" will be indicated. "E-3" will be

indicated when there is an error in digital switch

setting. In this case, data set at digital switch

will not be registered. Reconfirm the contents of

the digital switch.)

33/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

8-3 Minimum effective digit setting function

This function is for setting the minimum digit of

indication, and to determine the increment (indication

change) of such digit.

Also, it is possible to select whether to cut and close

to the right or to leave as 0 (zero), such digits below

the set digit.

(Example)

- Normal increment

- When minimum digit is

0 and increment is 2

10

- When minimum digit is

below to be cut and

increment is 1

} 1992 ± 1994 ÷ 1994 -÷ 1996 1996

101,

.9- 1994 a 1995

1993

199 199 + 200

+1996

a 200

(Note)

This function is effective for BCD output data as

well, but close to the right function will, in BCD

output, become leave as 0 (zero).

-0- 1997

+ 200

34/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 41

Registration Procedure

(1) Yes or no to execute minimum effective digit setting

will be set.

Note 1

Digital switch LOW I +1-

00 TO 10A (Function No.)

Note 1 *1 *2 *3

'Digital switch HIGH +/- 0 I X iXTh. X (Data)

- 0

- 1

*1 : For pre-set (weight) cancellation function (see 8-5)

*2 : For multiplication (see 8-4)

*3 : For Z/T (see 8-2)

Note 1 : or - both possible.

: minimum effective digit

settingtqffective

: minimum effective digit

setting **effective

: Error (E-3)

(2) Turn ON the Z/S

at (1) to internal memory.

(While the Z/S switch is ON, value set by digital

switch HIGH will be indicated, and when the switch is

released, "P" will be indicated. "E-3" will be

indicated when there is an error in digital switch

setting. In this case, data set at digital switch

will not be registered. Reconfirm the contents of

the digital switch.)

switch and register the set value

35/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 42

(3) Set the data required for minimum effective digit

setting function.

Note 1

Digital switch LOW

Note 1

Digital switch HIGH

Note 1 : or - both possible

/

(Function No.)

(Data)

• Minimum effective

digit setting

--o : 100

- -1 : 101

- -2 : 102

- : Error (E-3)

'Indication below

minimum digit

—0 : leave zero

- -1 : blank (close to

right)

— 2"9 : Error (E-3)

• Indication increment of

minimum digit

36/81

—0 : 0,1,2,3,4,5,6,7,8,9

—1 : 0,2,4,6,8

—2 : 0,5

- : Error (E-3)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 43

(4) Turn ON thelZ/S switch and register the set value

at (3) to internal memory.

(While the Z/Slswitch is ON, value set by digital

switch HIGH will be indicated, and when the switch is

released, "P" will be indicated. "E-3" will be

indicated when there is an error in digital switch

setting. In this case, data set at digital switch

will not be registered. Reconfirm the contents of

the digital switch.)

37/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 44

8-4 Multiplication function

This function will indicate the data multiplied by

constant and BCD output.

According to the constant, maximum indication and

maximum setting value of digital switch will change.

Constant Maximum indication (or set value)

X 2

X 1

X .1/2

X 1/5

+/-

+/-

+/-

+/-

19998

9999

4999

1999

In standard specification and after back-up data clear

the constant will be at (X1).

Note : If the

transfer from measurement mode

the constant cannot be changed

Be sure to register under

Z/S, switch is ON just prior to the

to set mode,

in this function.

Z S

switch off

condition.

38/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 45

Registration Procedure

(1) Set the multiplication constant

Note 1

Digital switch LOW

Digital switch HIGH

▪ /

Note 1 *1 *2

0 0

+/-

0

0

0

*3

X

• Multiplication

constant

(Function No.)

(Data)

0 : x 1

1 x 1/2

"-2 : X 1/5

3 : X 2

4.1,9 : Error (.E-3)

*1 : For minimum effective digit setting function (see 8-3)

*2 : For pre-set (weight) cancellation function (see 8-5)

*3 : For Z/T (see 8-2)

Note 1 : or - both possible

(2) Turn ON the

at (1) to internal memory.

(While the Z/5) switch is ON, value set by digital

switch HIGH will be indicated, and when the switch is

released, "P" will be indicated. "E-3" will be

indicated when there is an error in digital switch

setting. In this case, data set at digital switch

will not be registered. Reconfirm the contents of

the digital switch.)

Z/S' switch and register the set value

39/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 46

8-5 Pre-set (weight) cancellation function

This function is for comparative setting, with a

method where a reference point (quantitative point)

is established on digital switch HIGH and to set the

excess and deficiency data (cancel portion) against

such point on digital switch LOW.

Eg.) When HIGH contact ON at quantitative 1000 kg,

and LOW contact ON at pre-quantitative 200 kg

(indication 800 kg), then,

• Method to date :

Digital switch HIGH setting

+01000

Digital switch LOW setting

+00800

• By using pre-set (weight) cancellation function:

Digital switch HIGH setting 4- +01000

Digital switch LOW setting -00200

Note 1) Consider polarity when setting digital switch

LOW.

If set as +00200, contact on LOW side will be

ON at indication +01200.

40/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 47

1Registration Procedure

(1) Set yes or no to execute pre-set (weight) cancellation

function

Digital switch LOW

*1 : For minimum effective digit setting function (see 8-3)

*2 : For multiplication function (see 8-4)

*3 : For Z/T (see 8-2)

Note 2 : + or - both possible

0 0 0 0 0

: Pre-set (weight)

1 : Pre-set (weight)

2'%,9 : Error (E-3)

(Function No.)

(Data)

cancellation function

ineffective

cancellation function

effective

41/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 48

(2) Turn ON the

Z/s switch and register the set value

at (1) to internal memory.

(While the 'Z/S switch is ON, value set by digital

switch HIGH will be indicated, and when the switch

is released, "P" will be indicated. When there is an

error in digital switch setting, data set at digital

switch will not be registered. Reconfirm the contents

of digital switch.)

(3) When registration is finished and measurement mode

is carried out, LED for contact monitor on th front

surface will be green.

(4) Refer to preceeding example and select the set value.

42/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 49

8-6 Comparative setting condition changeover function

Can select comparative condition of setting points

for HIGH and LOW each.

Comparative condition is a condition to turn ON the

relay contact, according to the size relation of

setting value and indication value, and will be as

the following figure.

\\\\

\ Contact ON

f. 1

Setting point

High Limit Setting

+F.S.-

Setting point

Low Limit Setting

43/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 50

Therefore, as this equipment is incorporated with

2 points of setting points, 4 points of setting methods

are possible as shown below. Furthermore, with the

setting method (3), output of OK contact can be obtained

in addition to 2 points of contacts HIGH and LOW.

IGH

Low contact ON field

\-\\\.\

High contact ON field

(1) High high limit setting

(2) Low low limit setting

.s.

(3) High low limit setting

HIGH

LOW

(4) Low high limit setting

IGH

F.S.

44/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 51

Registration Procedure'

(1) Set HIGH and LOW each of comparative setting conditions.

Note 1

Digital switch LOW

Digital switch HIGH

*1 : For judgment function (see 8-7)

Note 1 : + or - both possible

+1 -

Note 1 *1

0

+/-

0 I 0

2

0

•Comparative condition

—0 : High limit setting

—1 : Low limit setting

- : Error (E-3)

•Comparative condition for

digital switch HIGH

—0 : High limit setting

—1 : Low limit setting

: Error (E-3)

(Function No.)

(Data)

for digital switch LOW

(2) Turn ON the Z /S

(1) to internal memory.

(While the 1Z/S1 switch is ON, value set by digital

switch HIGH will be indicated, and when the switch

is released, "P" will be indicated. "E-3" will be

indicated when there is an error in digital switch

setting. In this case, data set at digital switch

will not be registered. Reconfirm the contents of

the digital switch.)

switch and register the set value at

45/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 52

8-7 Judgment function

As described in 8-6, if the comparative conditions of

comparative setting function are set as

I) HIGH

2) LOW

low limit setting

high limit setting

and the indication value satisfies the condition of

setting value of LOW Indication value g setting value of HIGH ... (1)

then it is possible to output OK contact in addition

to 2 contacts of HIGH and LOW.

This function is to further control such OK contact

output by external signal, with

CHECK switch used

for the external signal.

Operationally, normally there will be no OK contact

output when the indication value is satisfying the

condition of formula (1), but will output by turning

CHECK'ON the (CHECK( switch. By putting the switch

ON again, output will be OFF. Once the OK contact is

ON, the condition will be maintained unless input of

switch is made again, so even if the conditionCHECK

of the indication value no longer satisfies the

conditions of formula (1), OK contact output will

continue to be in output.

Relationship between data fluctuation and input/output

signal will be as follows.

46/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 53

HIGH

setting value

LOW

sett3_ng valu

Data fluctuation by time

HIGH

contact

contact

CHECK

input

Ott

OFF

Olt

OFF

Oil

OFF -

OH

OK

contact OFF

Remarks : 1 -' judgement ON

2 - judgement OFF

Note : By executing this function, conventional CAL

function by !CHECK' switch cannot be carried out.

47/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 54

Registration Procedure'

(1) Set yes or no of judgment function execution

Note 1

Digital switch LOW

Digital switch HIGH

*1 : For comparative setting condition changeover function

(see 8-6)

Note 1 : + or - both possible

+ / -

Note 1

+/- 0

0

0

0

*1 *1

0

X X X

0 : Judgment function

1 : Judgment function

- 2,k,9 : Error (E-3)

2

0

ineffective

effective

(Function No.)

(Data)

(2) Turn ON the 1Z/S1 switch and register the set value at

(1) to internal memory.

(While the Z/S switch is ON, value set by digital

switch HIGH will be indicated, and when the switch is

released, "P" will be indicated. "E-3" will be

indicated when there is an error in digital switch

setting. In this case, data set at digital switch

will not be registered. Reconfirm the contents of

the digital switch.)

48/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 55

8-8 Dummy 0 indication

Normally, dummy 0 (leave 0) will be lighted at the

right end of 4 digits indication.

Registration Procedure

(1)

Note : This function cannot be registered if

switch is ON in the measurement mode, just prior

to set mode ON ("P" indication). ("E-3" will be

indicated at the time of registration in set

mode.)

Be sure to enter set mode after Z/S switch OFF.

Set yes or no of dummy

Note

Digital switch LOW

Digital switch HIGH

+/-

Note 1 *1

+ / -

0 indication

1

of

0

0

x x

0

*2 *3

4

0

x x

o : dummy 0

-- 1 : dummy 0

2q,9 : Error (E-3)

z/s1

(Function No.)

(Data)

ineffective

effective

*1 : For sign transfer indication function (see 8-11)

*2 : For sign inversion function (see 8-10)

*3 : For decimal point indication (see 8-9)

Note 1 : + or - both possible

49/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 56

(2) Turn ON the

at (1) to internal memory.

(While the Z/S switch is ON, value set by digital

switch HIGH will be indicated, and when the switch is

released, "P" will be indicated. "E-3" will be

indicated when there is an error in digital switch

setting. In this case, data set at digital switch

will not be registered. Reconfirm the contents of

the digital switch.)

ZIS

switch and register the set value

50/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 57

8-9 Decimal point indication

Add decimal point to indication data

Registration procedure

Note : This function cannot be registered if

switch is ON in the measurement mode, just prior

to set mode ON ("P" indication). ("E-3" will be

indicated at the time of registration in set mode)

Be sure to enter set mode after jZ/SI switch OFF.

(1) Set necessary digits of decimal point

Note 1

Digital switch LOW

Digital switch HIGH

/ -

Note 1 *1 *2

/ -

0 0 0 0

0

1 . g . . 9 - £3

104 103 102 10'

— 1 : 101

— 2 : 102

— 3 : 103

- - 4 : 104

5'1,9 : Error (E-3)

lz/s1

4

*3

• Decimal point

indication digit

0 : OFF (No decimal

(Function No.)

(Data)

point)

*1 : For sign transfer indication (see 8-11)

*2 : For sign inversion function (see 8-10)

*3 : For dummy 0 indication (see 8-8)

Note 1 : +1- both possible

51/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 58

(2) Turn ON the Z/S switch and register the set value

at (1) to internal memory..

(While the Z/S switch is ON, value set by digital

switch HIGH will be indicated, and when the switch is

released, "P" will be indicated. "E-3" will be

indicated when there is an error in digital switch

setting. In this case, data set at digital switch

will not be registered. Reconfirm the contents of

the digital switch.)

52/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 59

8-10 Sign inversion function

Will invert the sign of indication and BCD output.

Therefore, it will be (-) indication at (+) data and

(+) indication at (-) data.

Registration Procedure

Note : This function cannot be registered if IZ/S[switch

is ON in the measurement mode, just prior to

set mode ON ("P" indication). ("E-3" will be

indicated at the time of registration in set mode)

Be sure to enter set mode after [Z/S switch OFF.

(1) Register yes or no of sign inversion function execution.

Note 1

Digital switch LOW

Digital switch HIGH

*1 : For sign transfer indication (see 8-11)

*2 : For decimal point indication (see 8-9)

*3 : For dummy 0 indication (see 8-8)

Note 1 : +/- both possible

/ -

Note 1 *1 *2 *3

/ -

0 0

-.a

0 X

0 0

4

0 : Sign inversion function

ineffective

1 : Sign inversion function

effective

2q,9 : Error (5-3)

(Function No.)

(Data)

53/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 60

(2) Turn ON the Z/S switch and register the set value

at (1) to internal memory.

(While the Z/S switch is ON, value set by digital

switch HIGH will be indicated, and when the switch is

released, "P" will be indicated. "E-3" will be

indicated when there is an error in digital switch

setting. In this case, data set at digital switch

will not be registered. Reconfirm the contents of the

digital switch.)

54/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 61

8-11 Sign transfer function

Normally, ( ) sign is fixed at the left end of the

front panel indicator, but with this function, (-)

sign will transfer to left/right according to the

digit of indication.

Registration Procedure

Note : This function cannot be registered if LZ/SI switch

is ON in the measurement mode, just prior to set

mode ON ("P" indication). ("E-3" will be

indicated at the time of registration in set mode)

Be sure to enter set mode after WS' switch OFF.

(1) Register yes or no of sign transfer function execution.

Note 1

Digital switch LOW

Digital switch HIGH

*1 : For indication of sign inversion (see 8-10)

*2 : For decimal point indication (see 8-9)

*3 : For dummy 0 indication (see 8-8)

Note 1 : +/- both possible

+ / -

Note 1

+ / -

0 0 0

*1 *2

0

x

0 : Sign transfer function

1 : Sign transfer function

2q9 : Error (E-3)

4

0

*3

ineffective

effective

(Function No.)

(Data)

55/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 62

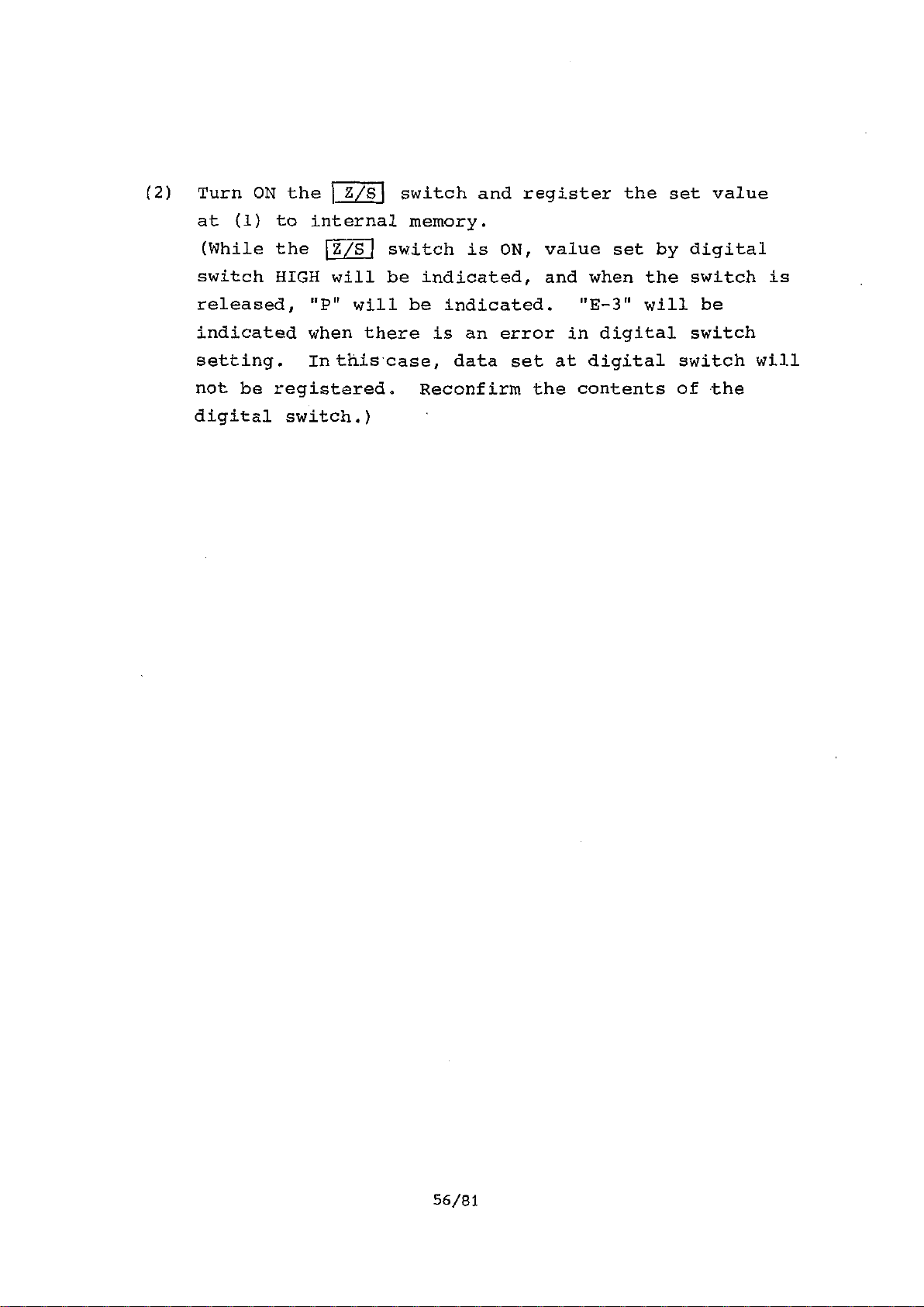

(2) Turn ON the 1 Z/S1 switch and register the set value

at (1) to internal memory.

(While the

Z/S switch is ON, value set by digital

switch HIGH will be indicated, and when the switch is

released, "P" will be indicated. "E-3" will be

indicated when there is an error in digital switch

setting. Inthis case, data set at digital switch will

not be registered. Reconfirm the contents of the

digital switch.)

56/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 63

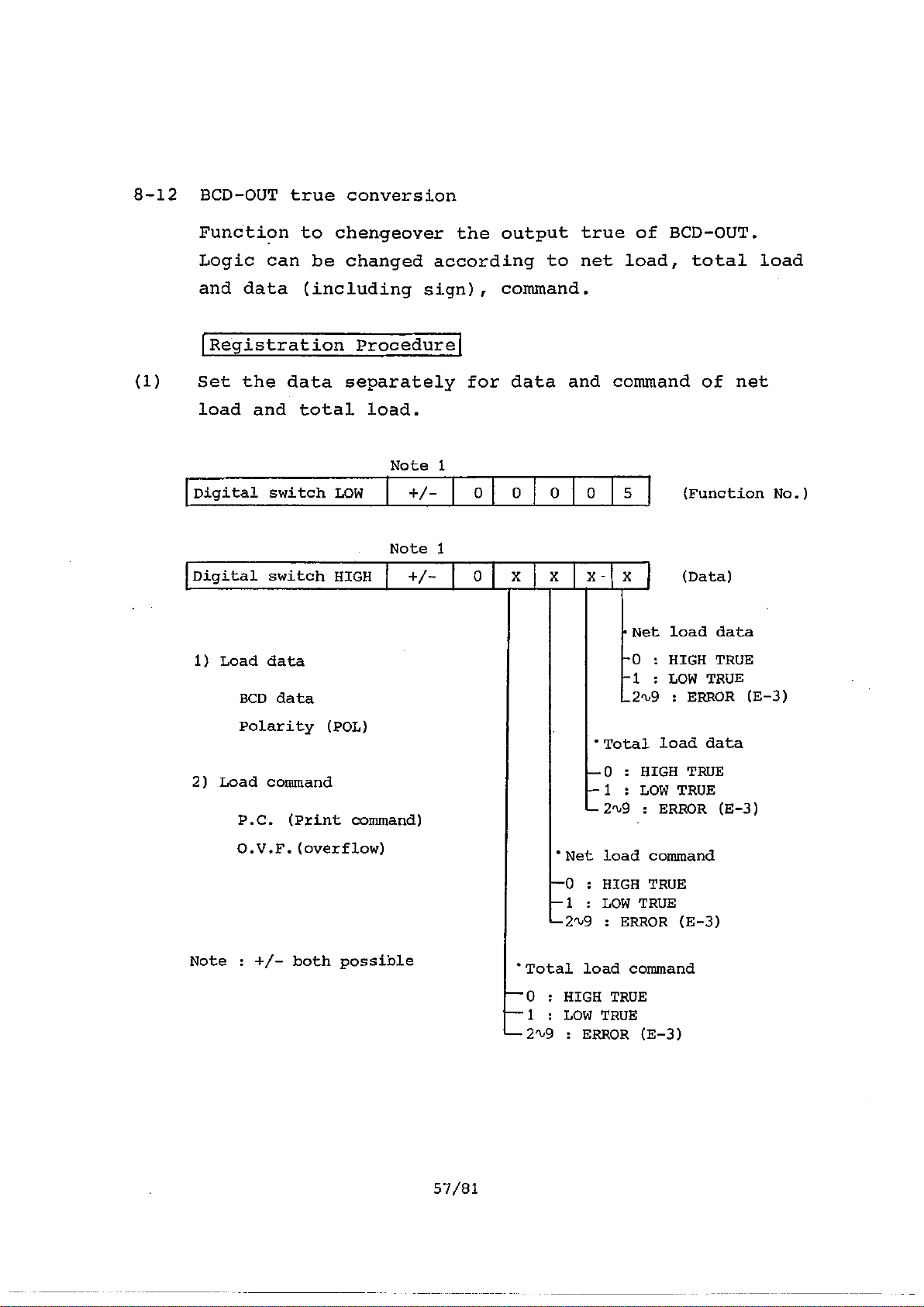

8-12 BCD-OUT true conversion

Function to chengeover the output true of BCD-OUT.

Logic can be changed according to net load, total load

and data (including sign), command.

Registration Procedure

(1) Set the data separately for data and command of net

load and total load.

Note 1

Digital switch LOW + / -

Note 1

Digital switch HIGH + / -

1) Load data

BCD data

Polarity (POL)

2) Load command

P. C . (Print command)

0.V.F.(overflow)

0 0

0 0

'Net load command

—0 : HIGH TRUE

--1 : LOW TRUE

—2'1)9 : ERROR (E-3)

5

•Net load data

-0 : HIGH TRUE

-1 : LOW TRUE

_2ru9 : ERROR (E-3)

'Total load data

--0 : HIGH TRUE

--1 : LOW TRUE

(Function No.)

(Data)

: ERROR (E-3)

Note : +/- both possible

57/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

'Total load command

--O : HIGH TRUE

--1 : LOW TRUE

: ERROR (E -3)

Page 64

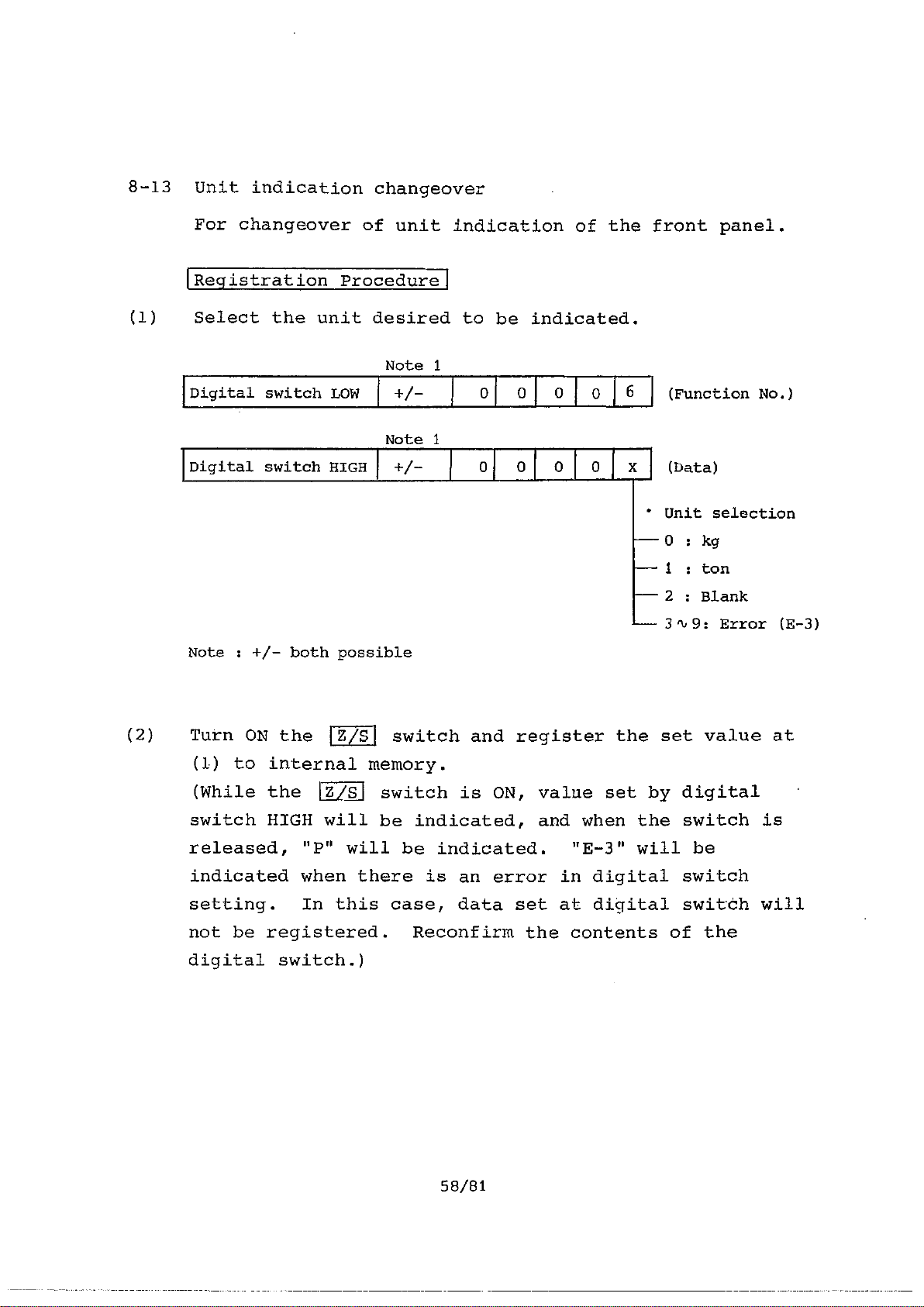

8-13 Unit indication changeover

For changeover of unit indication of the front panel.

Registration Procedure

(1) Select the unit desired to be indicated.

Note 1

Digital switch LOW

Digital switch HIGH I +/-

Note : +/- both possible

(2) Turn ON the

(1) to internal memory.

(While the Z/S switch is ON, value set by digital

switch HIGH will be indicated, and when the switch is

Z/S

6

+/-

Note 1

0

0 0

0

0 0 0 0 x

(Function No.)

(Data)

• Unit selection

- -- 0 : kg

--- 1 : ton

- -- 2 : Blank

3 '1,9: Error (E-3)

switch and register the set value at

released, "P" will be indicated. "E-3" will be

indicated when there is an error in digital switch

setting. In this case, data set at digital switch will

not be registered. Reconfirm the contents of the

digital switch.)

58/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 65

8-14 Manual Z/S function

This is a function to confirm the Z/S cancellation

value in Z/S function (7-1).

Registration Procedure

(1) Set the function No.

Note 1

Digital switch LOW +/- 0

Note : + or - both possible

0 0

0

(Function No.)

8

(2) By turning ON IA/Z switch or IA/Z OFF switch, Z/S

cancellation value will be indicated while it is ON.

Use for confirmation of Z/S cancellation value.

59/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 66

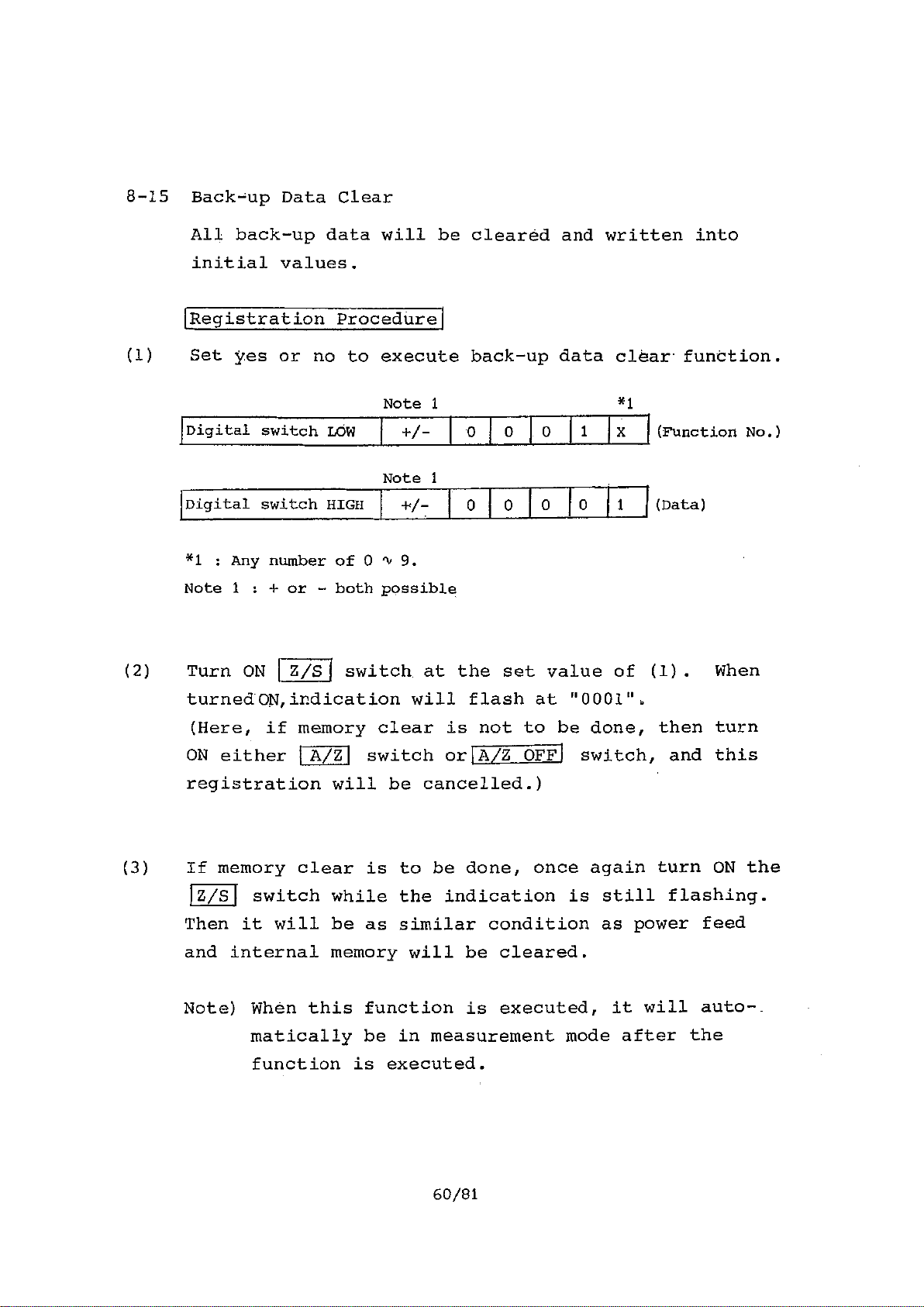

8-15 Back-up Data Clear

All back-up data will be cleared and written into

initial values.

Registration Procedure

(1) Set yes or no to execute back-up data clear function.

Note 1

Digital switch LOW

Digital switch HIGH

*1 : Any number of 0 9.

Note 1 : + or - both possible

+ / -

Note 1

+/:

0

0 0

0 0

*1

1

(Function No.)

(Data)

1

(2) Turn ON Z/S switch at the set value of (1). When

turnedON,indication will flash at "0001".

(Here, if memory clear is not to be done, then turn

ON either A/Z switch or

IA/Z OFF

switch, and this

registration will be cancelled.)

(3) If memory clear is to be done, once again turn ON the

Z/S

switch while the indication is still flashing.

Then it will be as similar condition as power feed

and internal memory will be cleared.

Note) When this function is executed, it will auto-

matically be in measurement mode after the

function is executed.

60/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 67

§9.

SELF-CHECK FUNCTION

At the time of power feed or by front panel

switch ON during set mode ("P" indication), self-check

can be made.

As the contents of self-check, followings will be done.

1) ROM check

2) RAM check

3) Back-up check

4) A/D check

5) Indication check

§10. ERROR INDICATION

When the following various errors should occur, each

[CHECK]

Program check

Memory check

Back-up check

Operation check of internal

A/D converter

Check abnormal indication

( 1 )

will be indicated and rear panel ERROR contact will

be ON. Also, the bit of BCD-OUT connector No.25 pin

(ERROR) will be ON.

Data over

Will be indicated when input data exceeds indication

maximum value. Normally, indication maximum value is

9999, but when multiplication function (see 8-4) is

used, it will be 4999 at x 1/2, 1999 at x 1/4 and

19998 at x 2.

61/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 68

(2)

E - 0

ROM error

Will be indicated when error is discovered during self-

check per Section 9. When this error is indicated, the

program will stop. Cut off the power then refeed.

If "E-0" is still indicated, please contact our sales

representative.

(3)

(4)

E - 1

RAM error

Will be indicated when error is discovered during self-

check per Section 9. When this error is indicated, the

program will stop. Cut off the power then refeed.

If "E-1" is still indicated, please contact our sales

representative.

E - 2

Back-up data error

Will be indicated when error is discovered during self-

check per Section 9. It will light and indicate for

about 1 second and then proceed to next operation.

When this indication is given, it will be judged that

there is abnormality in the back-up data, and all data

registered per Sections 7 and 8 will be cancelled, and

will be in standard specification condition. Therefore,

all digital functions should be registered again.

Normally, back-up data will remain memorized for about

1 month, even when the power is cut off.

If "E-2" indication is repeated many times, please

contact our sales representative.

62/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 69

(5)

E - 3

Key operation error

Will be indicated when a wrong digital switch is set,

(6)

(7)

while

Also,

mode, it could be indicated if

prior to turning the

mode).

Digital switch setting value error

Will be indicated when the setting value of digital

switch during measurement mode should exceed the

indication maximum value.

Reconfirm the setting value.

X XX X X

A/D error

Will be indicated if abnormality in internal A/D

registering the data in set mode of Section 8.

depending on the registration function during set

switch is ON just

E - 4

1SET MODE

Z/S1

switch ON (measurement

converter is discovered when self-check in set mode

is made.

Method of checking A/D converter is, first, input REF.

voltage of 1V to A/D and confirm if digital output is

within 10000 ± 10 count. In all, digital output

should be confirmed 10 times.

If more than ± 10 count is detected, its value and

number of confirmation order

Eg.) If the 5th confirmation

Indication will be

63/81

will be indicated.

is 9876,

98765

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 70

This indication will be released by

!CHECK

switch ON.

If there is no error thereafter, it will move to

indication check.

If error indication is repeated several times,

please contact our sales representative.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 71

§11, SET MODE SETTING VALUE TABLE

Switch (HIGH) for setting the contents are expressed

as follows.

4/- 00000

10°

101

102

103

104

+/-

Data (HIGH)

Function Na (LOW)

+1- 00000

digit

10"

value Setting contents

0

1

ZIT OFF

ON

+1- 00001

+/- 00002

101

102

103

10" 0

lot

1O

101

102

0

Multiplication constant X 1/2

2

3

0

Preset (weight) cancellation OFF

1

0

Minimum effective digit setting OFF

1

X ..1

X 1/5

X 2

ON

ON

Z/T OFF Approx. 1 sec.

I

2

3

4

5

0

1

2

3

0

1

0

1

0

1

Z/Talme width Approx. 2.5 sec.

Approx. 4 sec.

Approx. 6 sec.

Approx. 8 sec.

Z/T OFF Less than 1

Z/T Data width

Less than 1.5

Less than 3

Comparative setting condition High limit

(LW) Inv/ limit

Comparative setting condition High limit

Low limit

Judgement fucntion OFF

ON

65/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 72

+/-

00003

10"

0

Minimum effective digit

1

2

10"

10'

102

00004

+/-

+/- 00005

10' 0

102

10"

10'

102

I0'

10" 0

101

102

0

0

0

2

0

1

0

1

2

:3

4

0

1

0

1

1

1

1

Below minimum effective 0 display

1

digit indication

Minimum 0,1,2,3,4,5,0,7,8,9

1

effective digit 0,2,4,6,8

indication 0,5

Dummy 0 ON

Decimal point 10-1

Sign inversion ON

Sign trnasfer OFF

BCD output logic,Net load data

BCD output logic,Total load dataHigh true

BCD output logic, Net load CaatriandHigh true

OFF

10-2

10-3

10-a

OFF

ON

High true

Irm true

I. true

Ta w true

+/-

+/-

00000

00007

103

10"

10'

°

1 command Lcw true

0

1

2

0

BCD output logic, To load High true

Unit TON

blank

Unused

1

2

9

+/-

00008

10" --

0 --

Z/S camel data

104

+I- .

+/-

0001X

10'

0

1

Ineffective

Back-up data clear _

Note 1 : Cannot register if IZ/SI switch is ON just prior to

turning on the set mode switch.

1

66/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 73

§12. ANALOG ADJUSTMENT

Although standard internal adjustments have been made

at the time of shipment from the factory, changes can

be made by the following procedure, if various changes

are required.

12-1 Standard parts adjustment

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

Bridge voltage

GAIN

Sensitivity

TARE cancel

CHECK value

Indication

Unit

Power voltage

BCD-OUT

(10) ZERO TRACKING

(11) Multiplication

(12) Comparative setting

DC5V

X2000 times

10V output at 1 mV/V input

0 mV/V

approx. 8V

10000 indication at 10V output

(in conversion)*

Select kg *

AC 100V ± 10% 50/60 Hz

Open collector

True

Total load data/command ... High true

Net load data/command ... High true *

Time width 0, data width 0

(no execution)

Constant 1

HIGH/LOW high limit setting *

Pre-set (weight) cancellation,

judgment function (no execution)*

(13) Minimum effective

digit setting

loe digit *

0,1,2,3,4,5,6,7,8,9

indication *

*: Can be changed by initial setting function

67/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 74

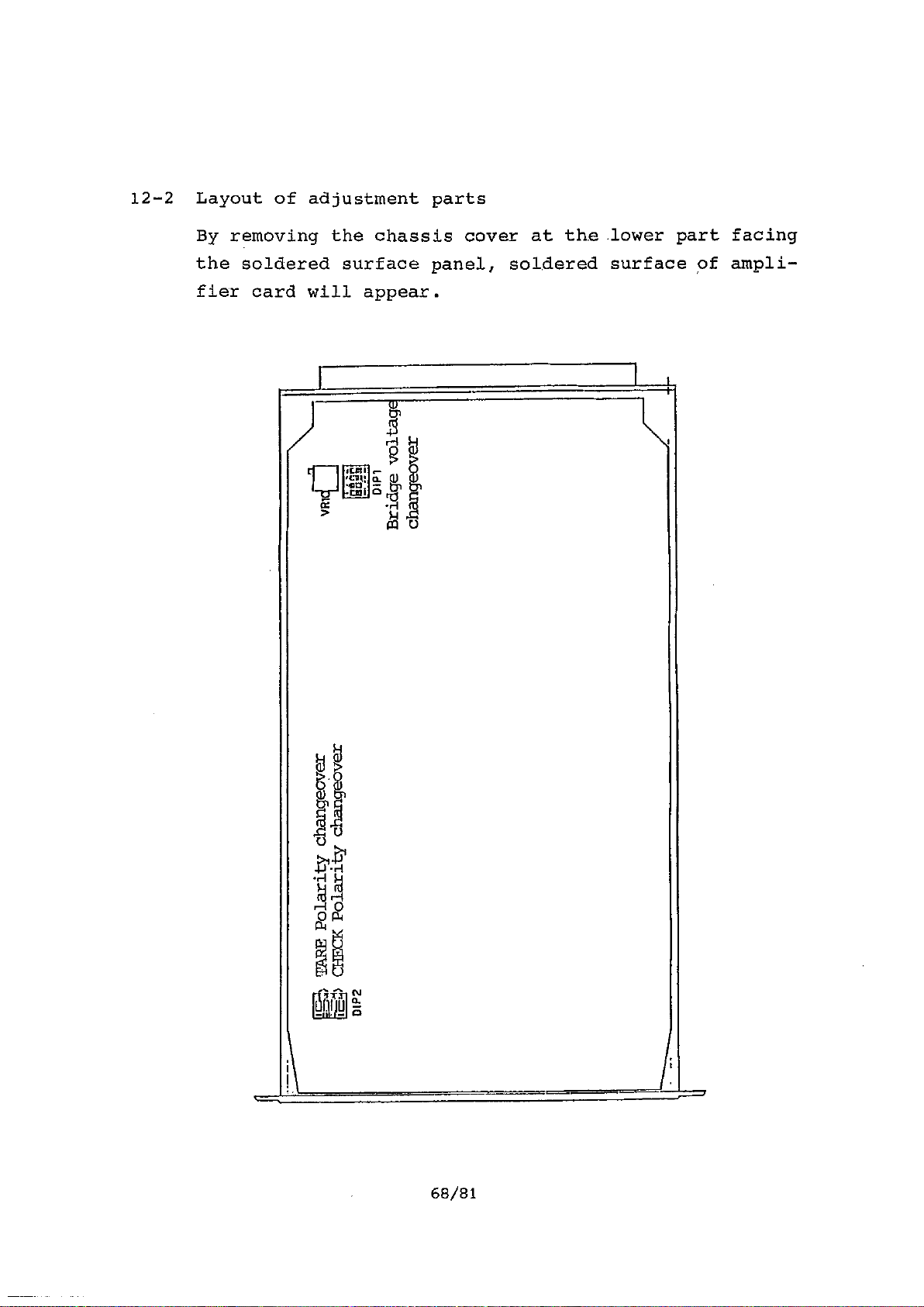

12-2 Layout of adjustment parts

By removing the chassis cover at the lower part facing

the soldered surface panel, soldered surface of ampli-

fier card will appear.

68/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 75

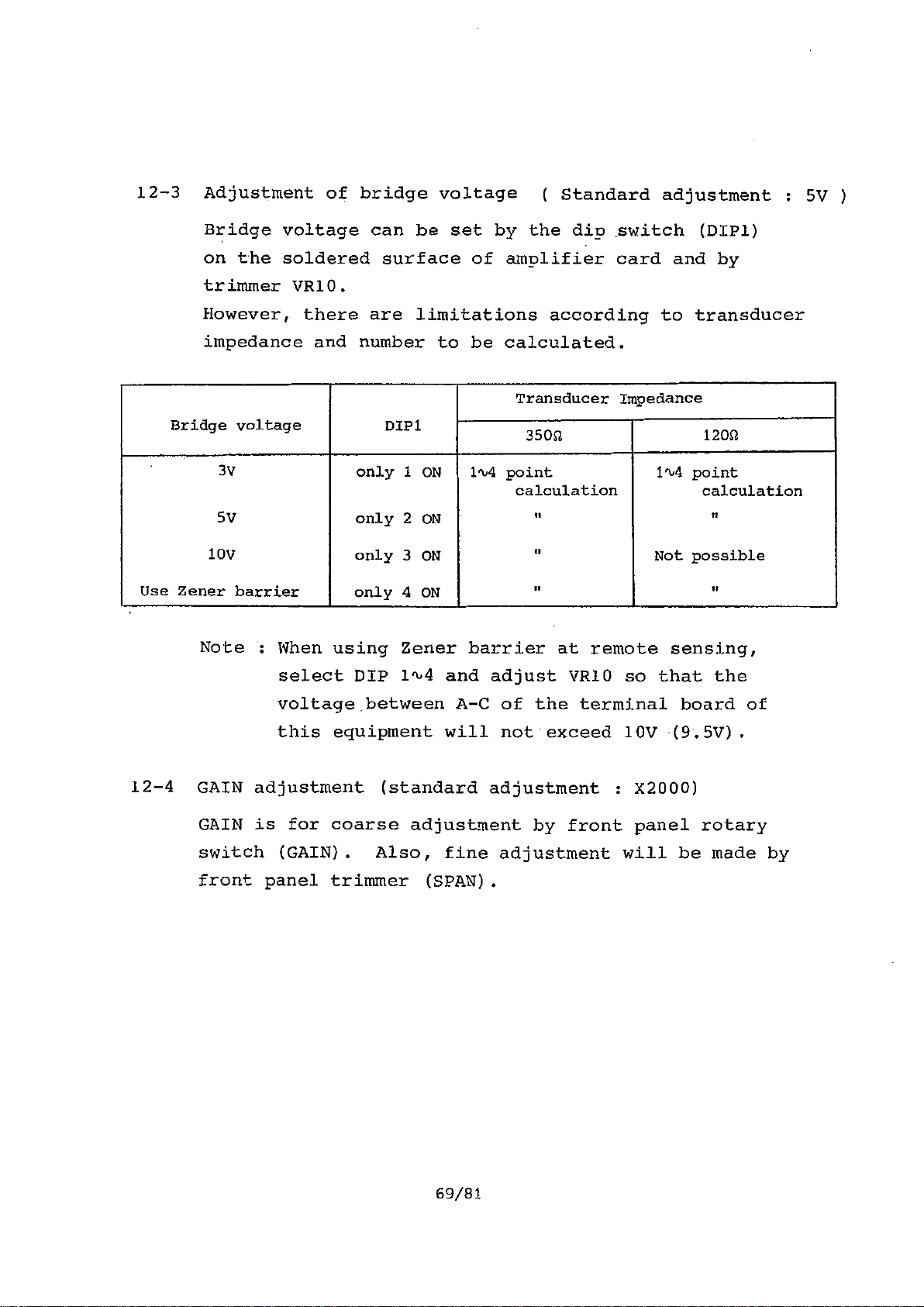

12-3 Adjustment of bridge voltage ( Standard adjustment : 5V )

Bridge voltage can be set by the dip switch (DIP1)

on the soldered surface of amplifier card and by

trimmer VR10.

However, there are limitations according to transducer

impedance and number to be calculated.

Transducer Impedance

Bridge voltage

DIP1

35012

120g

3V

5V

10V

Use Zener barrier

only 1 ON

only 2 ON

only 3 ON

only 4 ON

1'4 point

calculation

il

it

II

1"4 point

Not possible

Note : When using Zener barrier at remote sensing,

select DIP 1'4 and adjust VRIO so that the

voltage between A-C of the terminal board of

this equipment will not exceed 10V (9.5V).

12-4 GAIN adjustment (standard adjustment : X2000)

GAIN is for coarse adjustment by front panel rotary

switch (GAIN). Also, fine adjustment will be made by

front panel trimmer (SPAN).

calculation

ti

11

69/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 76

Required GAIN (G) can be obtained by the following

formula.

VA

G

Where,

Bridge voltage : Vb [V]

Output of used transducer (actual output) : E [mV/V]

Required output voltage Ve [mV]

Required GAIN : G [times]

Related formula of GAIN rotary switch setting and GAIN

are as the following table.

Vb X E

Setting

GAIN.

5

0

1

2

3 1275

4

5 765

6 510

7

8

9

For SPAN adjustment, adjust 1/1,‘,3/4 against each of

the above GAIN value.

2040

1785

1530

1020

255

2040

1785

0

GAIN setting switch

Note : GAIN values in this section are based on analog

output (V-Out).

Indicated data will be 1/10 values.

70/81

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 77

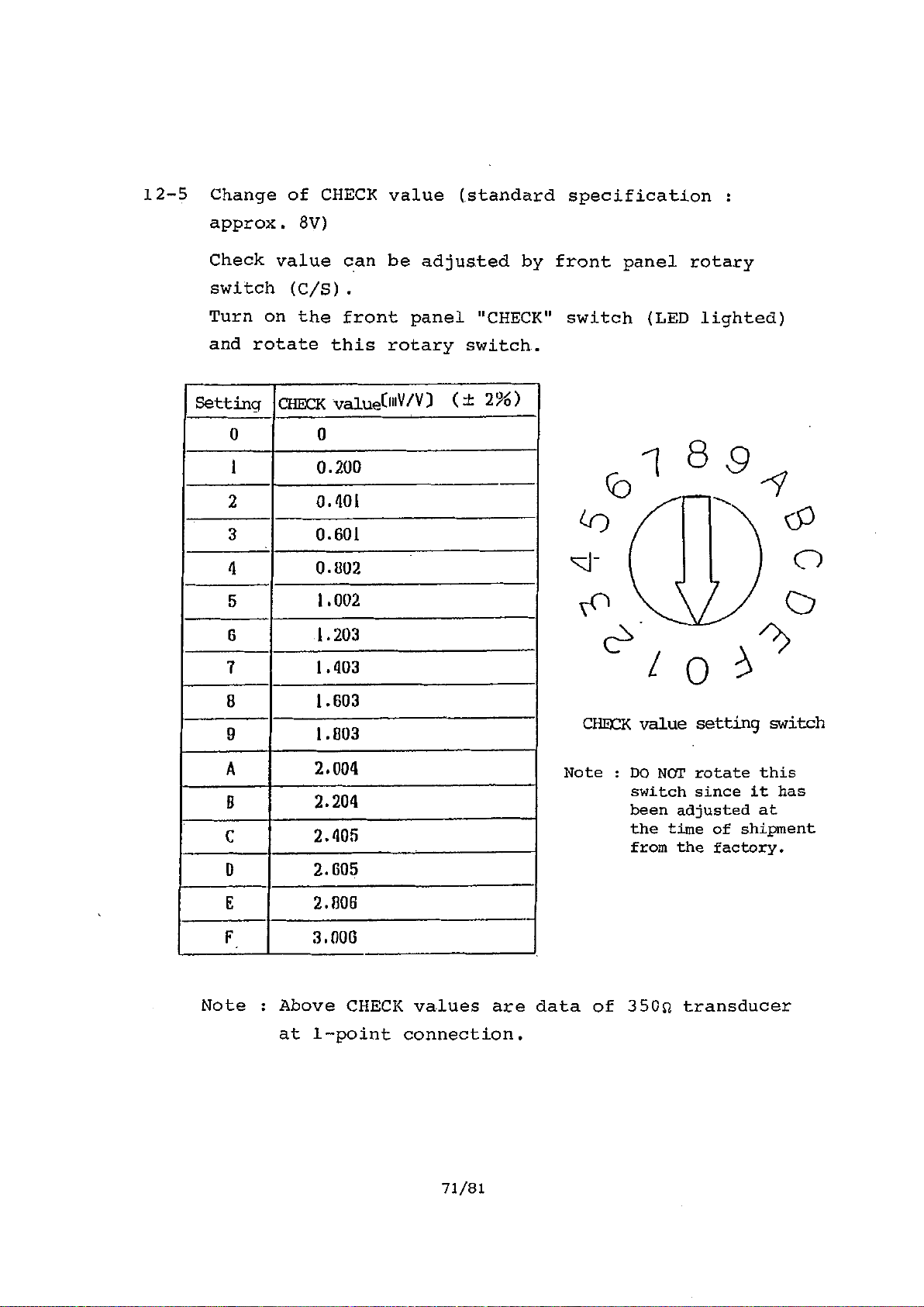

12-5 Change of CHECK value (standard specification :

approx. 8V)

Check value can be adjusted by front panel rotary

switch (C/S).

Turn on the front panel "CHECK" switch (LED lighted)

and rotate this rotary switch.

Setting

0 0

1

2 0.401

3

4

5

6

7

8

9

A

8

C

0

CHECK value(mV/V) (-± 2%)

0.200

0.601

0.1302

1.002

1.203

1.403

1.603

1.803

2.004

2.204

2.405

2.605

1 8 9 -1

cP

Z

CHECK value setting switch

Note : DO NOT rotate this

switch since it has