Page 1

MINEBEA CO., LTD.

INSTRUCTION MANUAL

DIGITAL INDICATOR

CSD−701B

Note : Please read this Instruction Manual carefully before use.

Be sure to follow the items that require attention described in the manual.

Keep the manual at hand so that you can pick it up and read it as soon as

necessity requires.

EN294−1127−K

Page 2

Forwards

Thank you very much for your purchasing Minebea’s Digital Indicator CSD−701B.

This manual explains installation procedures and connecting method and also operating

method for the Digital Indicator CSD−701B. Make use of it properly after reading through

the manual carefully.

Be sure to deliver the manual to the end user. Moreover, the end user should keep the

manual at hand after reading it over.

This manual is intended for the technical experts to read.

●The contents of the manual may subject to change for improvement without notice.

I

Page 3

Marks and arrangements used in this manual

The following marks are attached to the explanation on the matters that indicate “Don’t do

this.”, “Take care.” and “For reference”.

Be sure to read these items where these marks are attached.

Warning ● Warning may cause injury or accident that may harm to the operator.

Don’t do these things described here.

● Caution during operation and working.

Be sure to read the item to prevent malfunction.

Mark during operation.

● Press the switch.

II

Page 4

For safe operation

Be sure to read this instruction manual before use.

1. Installation place

● Use the instrument where the temperature/humidity specifies with

the range as follows:

Environmental temperature :−10 ℃ to 50 ℃

Environmental humidity :Less than 85 %R.H. (Non condensing)

(1) Location where installation is not allowed.

Warning ● Don’t locate the instrument on the places as follows :

It may cause an unexpected faulty in the instrument.

・ Don’t locate the instrument in direct and/or high temperature area.

・ Don’t use the instrument in a high humid area.

・ Don’t install the instrument where there are vibrations and shocks.

・ Don’t use the instrument where there is excess of dusts and fine particles.

・ Don’t use the instrument where there are corrosive gas and salt and like

that.

・ Don’t install the instrument where there is rapid change of temperature

and humidity.

・ Don’t install the instrument near the devices that are magnetized or

generate an electromagnetic field.

・ Don’t install the instrument where the instrument may be affected by

radioactivity or radial rays.

・ Avoid the location where chemical reaction may take place such as in a

laboratory, or like that.

III

Page 5

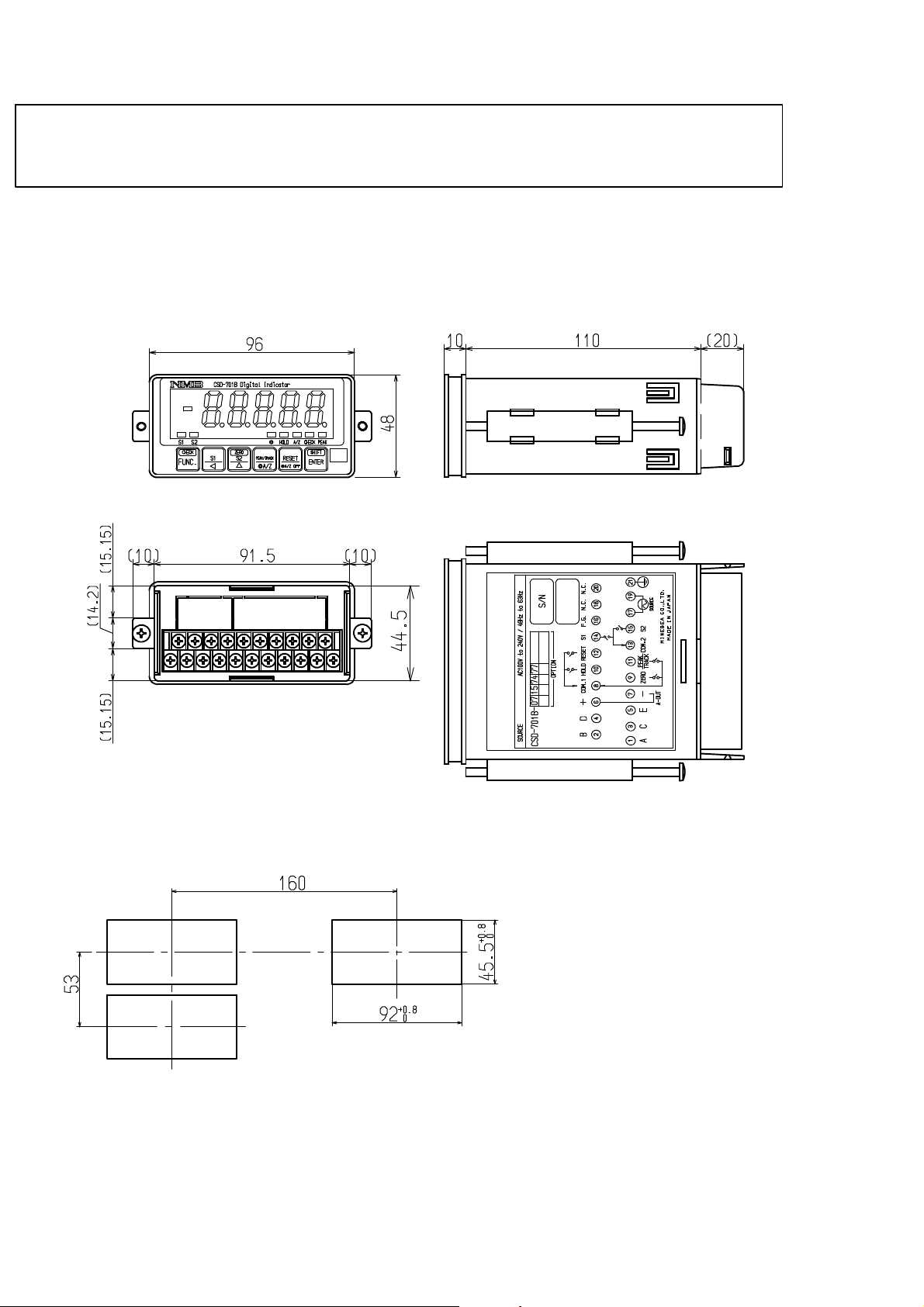

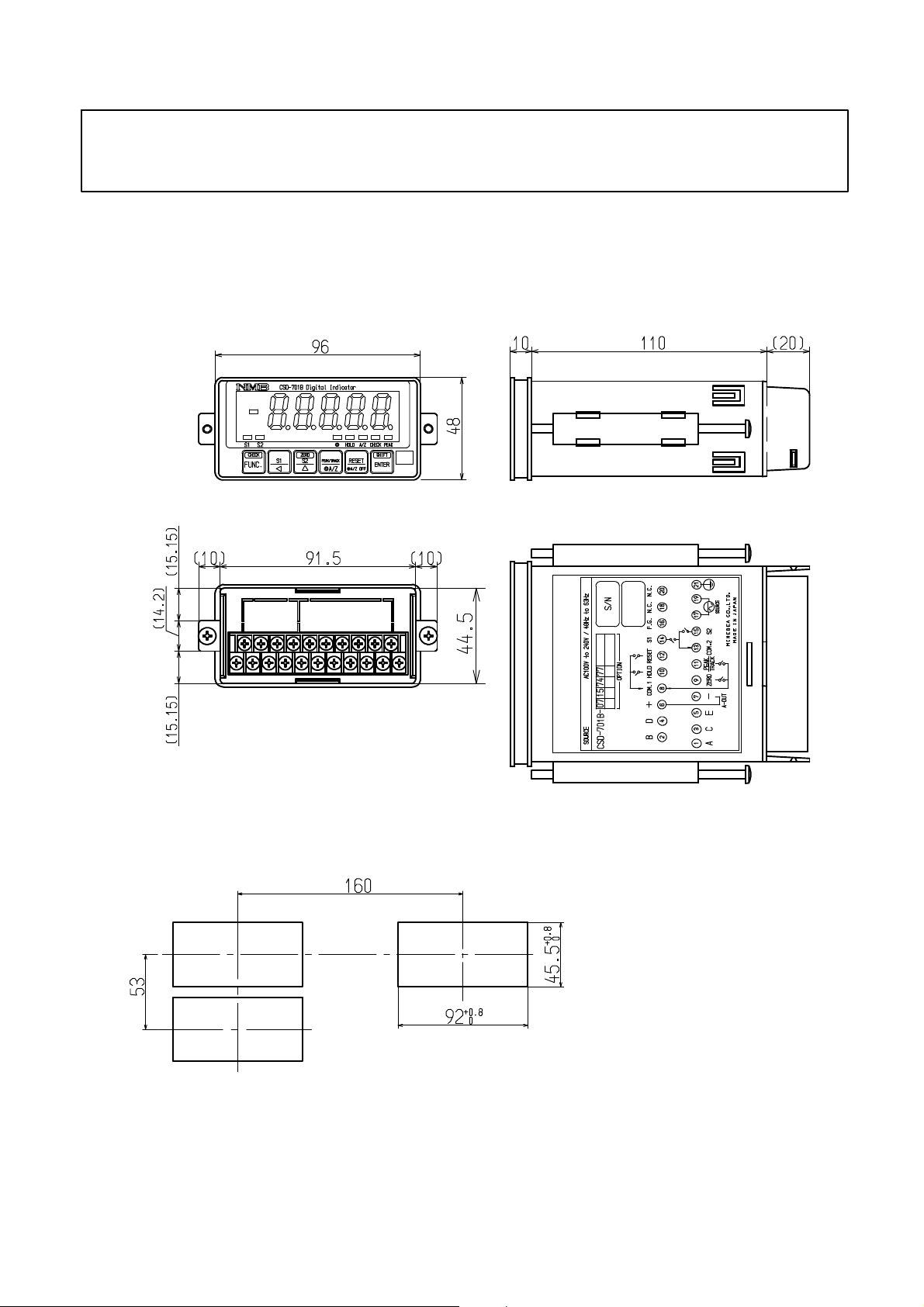

(2) Installation

● When installing the instrument, install as referring to the following

figures and secure the space around the instrument.

Each dimensions of the instrument and required dimensions for the environmental

spaces are as follows:

Outline dimensions

Front

Rear

Side

Upper

Panel cut size

Unit:mm

IV

Page 6

2. Power supply

Warning ● Be sure to check that the power supply is off in connecting each cable.

If the work is done while the power is on, there may have the case that

electric shock to the operator or even may have damage to the

instrument.

● Before supplying the power, check that the indication of power supply

voltage/specifications for the instrument and the power going to

supply should be the same.

If they are not equal, contact with Minebea.

If you use the instrument without checking them, it may cause a

damage in the instrument or electric shock to the operator.

● Earth wire should be grounded securely.

When earth wire is not connected, it may cause a malfunction of the

instrument or electric shock to the operator.

3. Application note

Warning ● Before using a new instrument or exchanging the strain gage applied

transducer for a new one, be sure to make calibration. If calibration

will not be made, the correct measuring results may not be obtained

nor which may cause malfunction in the instrument and there may

exist damage in peripheral equipments.

Besides, even though calibration has been made, there may occur the

similar case when the results are not correct, so make calibration,

again.

Warning ● In case of using the instrument, check that the connections are

executed properly. If not connected properly, the correct measuring

result will not be obtained, nor it may cause malfunctions of the

instrument, damage to the peripheral equipments or even more

serious accidents.

V

Page 7

Warning ● When change of setting is made carelessly on the instrument during

measurement, correct measured results may not be obtained and it

may cause malfunction in the instrument and even have the

possibility of damage in peripheral instruments.

Warning ● Do not shock the instrument such as throwing something on it.

If neglected, it may cause destruction of the parts and damage to the

electrical circuits.

Warning ● Do not push the panel sheet on the instrument with the excessive

strong force nor push it with sharp edge object such as a driver.

If neglected, it may cause a damage to the panel switch and even have

the possibility of damage to resist to environments or operational

performances.

Warning ● Don’t remove the cover of the case of the instrument, nor peel off the

panel sheet nor take the instrument into pieces.

If neglected, it may cause a damage to the case and the panel sheet

and even have the possibility of damage to resist to environments or

operational performances.

● At the time of shipment from the factory, the instrument has been

plated with a clear sheet on the panel sheet for protective purpose.

In case of application, use the instrument after removing the

clearsheet first.

VI

Page 8

History of revision

Date Instruction Manual No. Details of revised point

Dec. 2000

Mar. 2001

Mar. 2001

DRW.NO.EN294−1127 First Version ROM Ver. 1.000 or later

ECN No.FN01−02042

− Correction −

P.49 7−1−1. Input signal for external control

“During the holding operation, it is reset condition by short

DRW.NO.EN294−1127−A

DRW.NO.EN294−1127−B

circuit.”→“During the peak hold operation, reset condition

is made by short circuit.”

P.91 9−2−6 Output condition at Positive logic

Output data “Yes”→Condition of transistor “OFF”

Output data “No”→Condition of transistor “ON”

ECN No.FN01−02041 ROM Ver.1.300 or later

− Correction −

5−2−1. 6th step.

Add the clause “

5−2−3. 12th step.

Change the display of “SP−L” and “SP−H”

11−1. Specifications for analog Input filter

“2 Hz”→ “1 Hz(At the “0” setting of the digital filter and

stabilized filter)”

− Change −

7−13. “Key lock”→ “Lock of key function”,

According to this change, following sentence is corrected.

8−2. F−06 “Setting key lock”

→ “Setting the lock of key function”

According to this change, following setence is also

corrected.

It can be increased 〜”

Jun. 2001

Jul. 2001

Sep. 2001

May. 2003

Aug. 2003

DRW.NO.EN294−1127−C

DRW.NO.EN294−1127−D

DRW.NO.EN294−1127−E

DRW.NO.EN294−1127−F

DRW.NO.EN294−1127−G

ECN No.FN01−02085

− Correction ‐

Change the outline dimensions (upper part)

− Additions ‐

9−6−2., 9−7−2, 11−11−6. add the “Power consumption”.

−Correction−

9−2−4.

(1)Equivalent circuit of input section “COM.1”→ “COM.”

(2)Equivalent circuit of output section “▼”→ “▽”

Due to ECN No.FN01−02134

−Changeー

Operating temperature range

“0 ℃ to 50 ℃”→ “−10 ℃ to 50 ℃”

Due to ECN No.FN03−02040

−Correction−

4−3−5.(2) “4mA to 20mA” to “DC4mA to 20mA”

7−2−4., (1), 7−15−4., 6−2., 9−1−1., 9−2−1., 9−2−2.

9−3−1., 11−7., “Display interlock”→“PEAK/Net weight”

Due to ECN No.FN03−02118

− Correction −

11−2. Specifications for digital section

Display range “−99 999”→ “9 999”

VII

Page 9

Date

Apr. 2005

Nov. 2007

Instruction Manual No. Details of revised point

Due to ECN No.FN05−02035

− Addition −

DRW.NO.EN294−1127−H

DRW.NO.EN294−1127−I

At the warning column in the wiring section, the clause of “

As there is a case which standard wiring color is different,

please confirm the inspection data sheet of the load cell

being used.” is added.

Due to ECN No.FN07−02126

− Correction −

9−2−3. “DC−37P−N made by JAE”

to “Equivalent to DC−37P−NR made by JAE”

9−3−4. “DE−9S−N (JAE)”

to “Equivalent to DE−9S−NR made by JAE”

May, 2010

Oct. 2010

DRW.NO.EN294−1127−J

DRW.NO.EN294−1127−K

Due to ECN No.FN10−01019A

− Addition −

11−10.Accessories panel mounting gasket is added.

Due to ECN No.FN10−02140

− Change −

Minebea logo is changed.

VIII

Page 10

INDEX

Forwards Ⅰ.......................................................

Marks and arrangements used in this manual Ⅱ....................................

For safe operation Ⅲ............................................................

1. Installation place Ⅲ.........................................................

2. Power supply Ⅴ............................................................

3. Application note Ⅴ.........................................................

History of revision Ⅶ............................................................

1. General 1.................................................................

1−1. Features 1............................................................

2. Name and function of each point 2..........................................

2−1. Front panel 2.........................................................

2−2. Rear panel 3..........................................................

3. Installation procedures 4...................................................

3−1. Installation place 4....................................................

3−2. Location where installation is not allowed. 4.............................

3−3. Installation 5.........................................................

3−4. Applicable environment 6..............................................

4. Connecting method 7......................................................

4−1. Layout of the terminal boards 7.........................................

4−2. Note on connection 8..................................................

4−3. Connection 9..........................................................

4−3−1. Connection with strain gage applied transducers 9..................

4−3−2. Connection with external control inputs 13..........................

4−3−3. Connection with contact outputs 14.................................

4−3−4. Connection with the power supply and the earth 15...................

4−3−5. Connection with analog outputs 16.................................

5. Calibration procedures 18...................................................

5−1. Preparations 18........................................................

5−2. Calibration procedures 18...............................................

5−2−1. Calibration method to register the output of strain gage applied transducer

at the time of maximum display after setting the load to zero 19........

5−2−2. Calibration procedures to register the output of strain gage applied

transducer at the time of zero and the maximum display 24............

5−2−3. Calibration method to register by reading output value of

strain gage applied transducer in the conditions of

zero/actual load application individually 29..........................

5−2−4. Zero fine adjustment 35............................................

5−2−5. Span fine adjustment 37...........................................

5−2−6. Calibration procedure to apply registration again for zero point only 39

5−3. Selection of calibration methods on each condition 41......................

5−3−1. In case of executing the calibration on the instrument newly. 41.......

5−3−2. When the calibration is executed again. 45...........................

5−4. Setting the prohibition against calibration 45..............................

6. Operation procedure 46.....................................................

6−1.

key 46............................................................

6−1−1. Operations in Measurement mode 46...............................

6−2.

key 46............................................................

Page 11

6−2−1. When operating in the measurement mode 46........................

6−2−2. Operation is made in another mode 47..............................

6−3.

key 47............................................................

6−3−1. When operated in the Measurement mode. 47........................

6−3−2. When operated in another modes 48................................

6−4.

key 48............................................................

6−4−1. When operated in the Measurement mode. 48........................

6−4−2. When operated in another modes 48................................

6−5.

key 49............................................................

6−5−1. When operated in the Measurement mode 49........................

6−5−2. When operated in another modes. 49................................

6−6.

key 49............................................................

7. Function and operation 50...................................................

7−1. External control input signal and contact output signal 50..................

7−1−1. Input signal for external control 50.................................

7−1−2. Contact output signal 51...........................................

7−1−3. Equivalent circuit 51..............................................

7−2. Comparator 52.........................................................

7−2−1. ON/OFF of comparator S1 and S2 52................................

7−2−2. Change of set value 52.............................................

7−2−3. Operation on comparator S1 and S2 54..............................

7−2−4. Comparative target for comparator S1 and S2 55.....................

7−2−5. Hysteresis on comparator 56.......................................

7−3. How to use the filter 58.................................................

7−3−1. Digital filter 58...................................................

7−4. Zero tracking 58........................................................

7−4−1. What is zero tracking? 58..........................................

7−4−2. Setting related with zero tracking. 59...............................

7−4−3. Cancellation for compensation by zero tracking 59...................

7−5. Stabilized filter 60

7−5−1. What is the Stabilized filter? 60.....................................

7−5−2. Setting related with the Stabilized filter. 60..........................

7−6. Change of Peak function and A/Z function 61..............................

7−7. How to use the peak hold. 62.............................................

7−8. Various functions concerning display 63..................................

7−8−1. Selection of target of display 63.....................................

7−8−2. Selection of position of decimal point display 63......................

7−8−3. Load display range 63.............................................

7−9. Selection the target for HOLD 63.........................................

7−10. Change of bridge power supply voltage 64.................................

7−11. Tare weight cancellation (A/Z) 64........................................

7−12. Zero set 64.............................................................

7−13. Lock of key function 65.................................................

7−14. CHECK value 65.......................................................

7−15. How to use the analog output 66.........................................

7−15−1. Scaling of analog output 66........................................

7−15−2. Fine adjustment 1 on analog output 67..............................

7−15−3. Fine adjustment 2 on analog output 70..............................

......................................................

Page 12

7−15−4. Selection of the target of analog output 72...........................

7−16. Memory location for setting data and so on 72.............................

7−17. Prohibition of calibration 72.............................................

7−18. Check mode 73.........................................................

7−18−1. Operating procedure for the check mode 73..........................

7−19. Monitor mode 78.......................................................

8. Function mode 80..........................................................

8−1. Setting method for function mode 80.....................................

8−2. Function of Function data 82............................................

9. Options 88.................................................................

9−1. Current output 88......................................................

9−1−1. Related functions 88..............................................

9−1−2. Specifications for the current output 88.............................

9−2. BCD output 89.........................................................

9−2−1. Related function 89...............................................

9−2−2. Specifications for BCD output 89...................................

9−2−3. Pin configurations for the BCD output connector 89..................

9−2−4. Equivalent circuit for input/output 90...............................

9−2−5. Timing chart 91..................................................

9−2

−6. Output condition 92...............................................

9−2−7. Selection of output logic for P.C.(Print command),

and selection of its width 93........................................

9−3. RS−232C interface 94..................................................

9−3−1. Related function 94...............................................

9−3−2. Specifications for interface 94......................................

9−3−3. Procedures of data transfer 95......................................

9−3−4. Pin configurations for connector pin 96.............................

9−3−5. Data format 97...................................................

9−3−6. Communication error process 100...................................

9−4. RS−422 interface 101....................................................

9−4−1. Related functions 101..............................................

9−4−2. Specifications on interface 102......................................

9−4−3. Procedure of data transmission 102..................................

9−4−4. Pin layout and wiring of Connector 103..............................

9−4−5. Data format 104...................................................

9−4−6. Process of communication error 106.................................

9−5. Serial interface 107......................................................

9−

5−1. Related function 107...............................................

9−5−2. Specifications for Interface 107......................................

9−5−3. Connecting method and internal equivalent circuit 108................

9−5−4. Data format 109...................................................

9−5−5. Explanation of format data 110......................................

9−5−6. Explanation of output type 110......................................

9−6. Power supply voltage DC12 V(CSD701B−P66) 111........................

9−6−1. Layout of the terminal boards 111...................................

9−6−2. Connection with the power supply and the earth 112...................

9−7. Power supply voltage DC24 V(CSD701B−P67) 113........................

9−7−1. Layout of the terminal boards 113...................................

9−7−2. Connection with the power supply and the earth 114...................

10. Trouble shooting 115........................................................

Page 13

10−1. Execute trouble shooting 116.............................................

10−2. Optional check 125......................................................

10−3. Error display 131........................................................

11. Specifications 132...........................................................

11−1. Specifications for analog section 132.......................................

11−2. Specifications for digital section 132.......................................

11−3. Front panel sheet key function 133........................................

11−4. External control function 133.............................................

11−5. Comparator function 134.................................................

11−6. Contact output signal 134................................................

11−7. Various kinds of functions 134............................................

11−8. General specifications 134................................................

11−9. Standard specifications at the shipment 135................................

11−10. Accessories 135..........................................................

11−11. Options 135.............................................................

11−11−1. Current output 135................................................

11−11−2. BCD output 135...................................................

11−11−3. RS−232C interface 135.............................................

11−11−4. RS−422 interface 137..............................................

11−11−5. Serial interface 137................................................

11−11−

11−12. Outline dimensions 138..................................................

6. Power supply voltage 137...........................................

12. Warranty 139................................................................

12−1. Warranty 139...........................................................

12−2. Repair 139..............................................................

13. Appendix 140................................................................

13−1. Replacement of fuse 140..................................................

13−2. Character’s pattern for display 142........................................

13−3. Setting table for functions 143............................................

Page 14

1. General

The instrument is a digital indicator for the application of strain gage applied transducer.

1−1. Features

Main features for CSD−701B are as follows :

(1) Compact size and light weight

48 mm×96 mm×120 mm Approx.0.3 kg (Without any options)

(2) The A/Z function and the peak holding function can be used by the selection.

1

Page 15

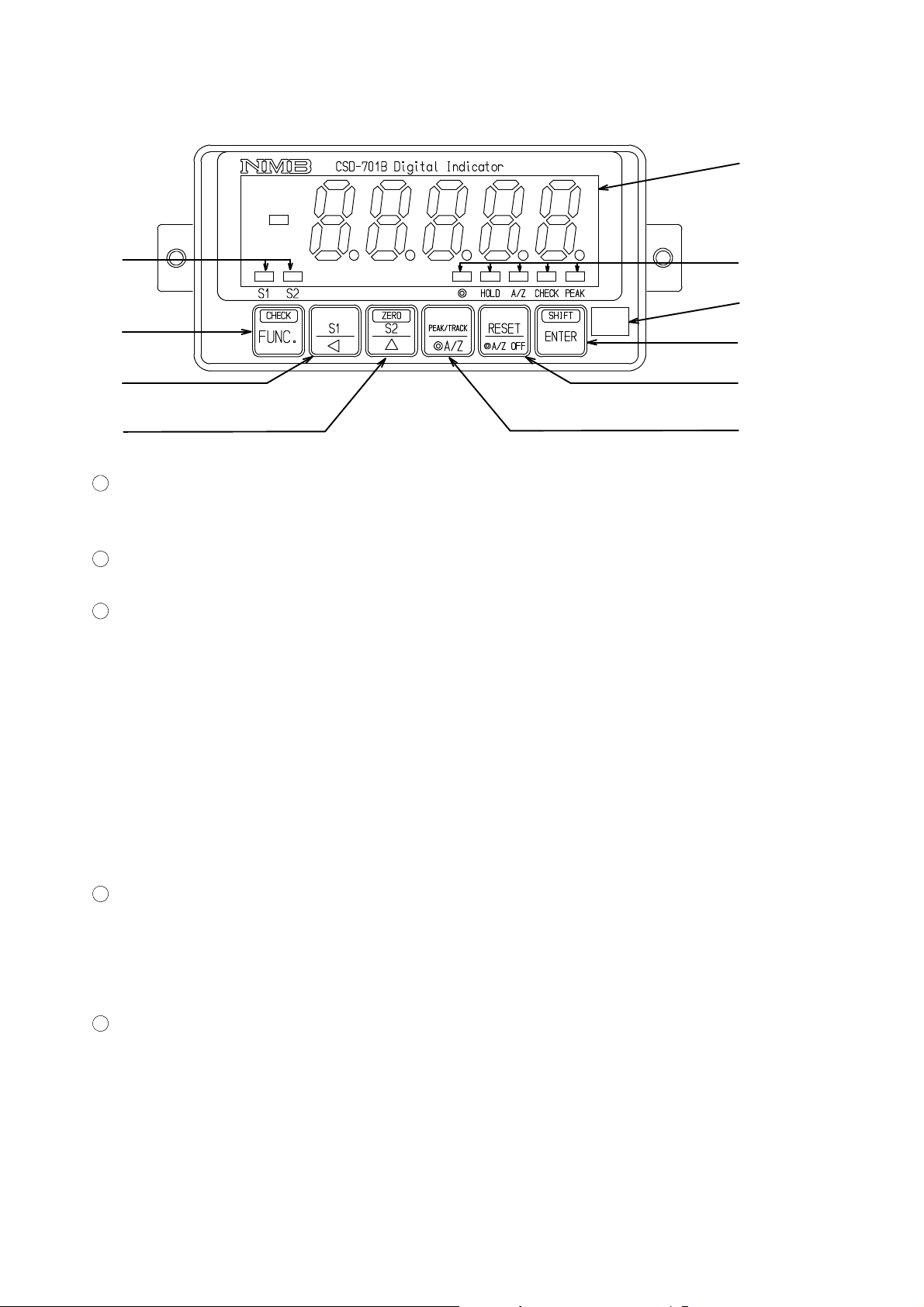

2. Name and function of each point

2−1. Front panel

①

②

④

⑤

⑥

1

Load display section

The load data is shown in the Measurement mode, and status or set value is shown in various

kinds of Calibration mode and Setting mode.

2

Judgement display

Compared results by comparator function can be displayed.

3

Status display

◎ Lights up when selecting A/Z or A/Z OFF function in the Function mode.

In the same way, light off when selecting Peak hold function in the Function

mode.

HOLD Lights up when between the HOLD and COM.1 at the external control input is

shorted.

A/Z Lights up at the time of executing Tare weight cancellation(A/Z ON).

Lights off with the tare weight cancellation clear.

(Effective when selecting the A/Z or A/Z OFF function in the function mode.)

CHECK Lights up when the CHECK is ON.

PEAK Lights up when selecting the Peak mode.

③

⑩

⑨

⑧

⑦

4

key

Used when shifting to the Function mode.

Also, by pressing this key and the

turned on and off

5

key

Used when calling the S1 set value changeover mode, or carrying digit at the time of various

kinds of settings.

key together, it is used when the CHECK value is

2

Page 16

6

key

Used when calling the S2 set value changeover mode, or for the increment of values at the time

of various kinds of settings.

Also, by pressing this key and the

zero adjustment).

7

key

Used for making the changeover mode of Peak/Track, or executing the Tare weight

cancellation (A/Z ON).

(Changeover of Peak hold function and A/Z function depends on the setting of Function mode.)

8

key

Used for the reset of Peak value, or for Tare weight cancellation clear(A/Z OFF).

(Changeover of Peak hold function and A/Z function depends on the setting of Function mode.)

9

key

Used for registering set values at the time of various kinds of settings.

Also, by pressing this key and the

turned on and off.

Also, by pressing this key and

adjustment).

key together, it will execute the set of zero(One−touch

key together, it is used when the CHECK value is

key together, it will execute the set of zero(One−touch zero

10

Position of pasting the Unit seal

As necessity requires, paste the Unit seal attached.

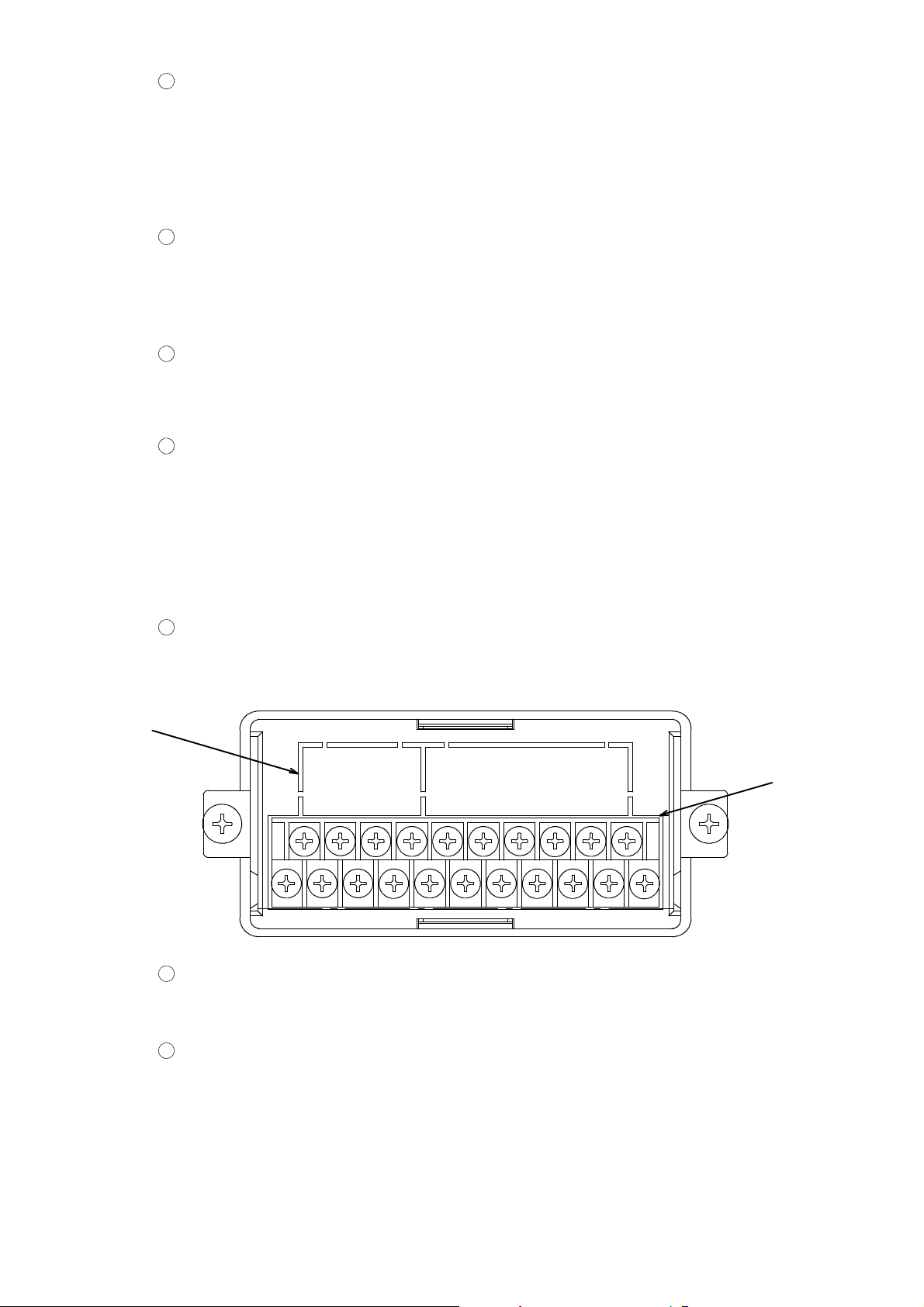

2−2. Rear panel

②

1

Terminal board

Connects with external control input, contact output, various kinds of strain gage applied

transducer such as load cell, analog output, AC power supply, and a grounding wire.

2

Installing section for options

Whichever one can be installed from the optional BCD−OUT, RS−232C, RS−422 or serial

interface.

①

3

Page 17

3. Installation procedures

3−1. Installation place

● Use the instrument where the temperature/humidity specifies within

the range as follows:

Environmental temperature :−10 ℃ to 50 ℃

Environmental humidity :85 %RH or less(Non condensing.)

3−2. Location where installation is not allowed.

Warning ● Don’t locate the instrument on the places such as follows:

It may cause an unexpected faulty in the instrument.

D Do n ot expose the instrument in direct sunlight and/or high temperature area.

D Do n ot use the instrument in a high humid area.

D Do n ot install the instrument where there is high mechanical vibrations and shock.

D Do n ot use the instrument where there are excess of dusts and fine particles.

D Do n ot install the instrument where there include any corrosive gas or any salty

atmosphere.

D Do not install the instrument where there is rapid change of temperature and humidity.

D Do n ot install the instrument near the devices that are magnetized or generate an

electromagnetic field.

D Do n ot install the instrument where there may suffer radioactivity or radioactive rays.

D Avoid the location where chemical reaction may take place such as in a laboratory, or like

that.

4

Page 18

3−3. Installation

● When installing the instrument, install as the following figures and

secure the space around the instrument.

Each dimensions of the instrument and required dimensions for the environmental spaces are as

follows:

Outline dimensions

Front

Side

Rear

Panel cut size

Upper

Unit:mm

5

Page 19

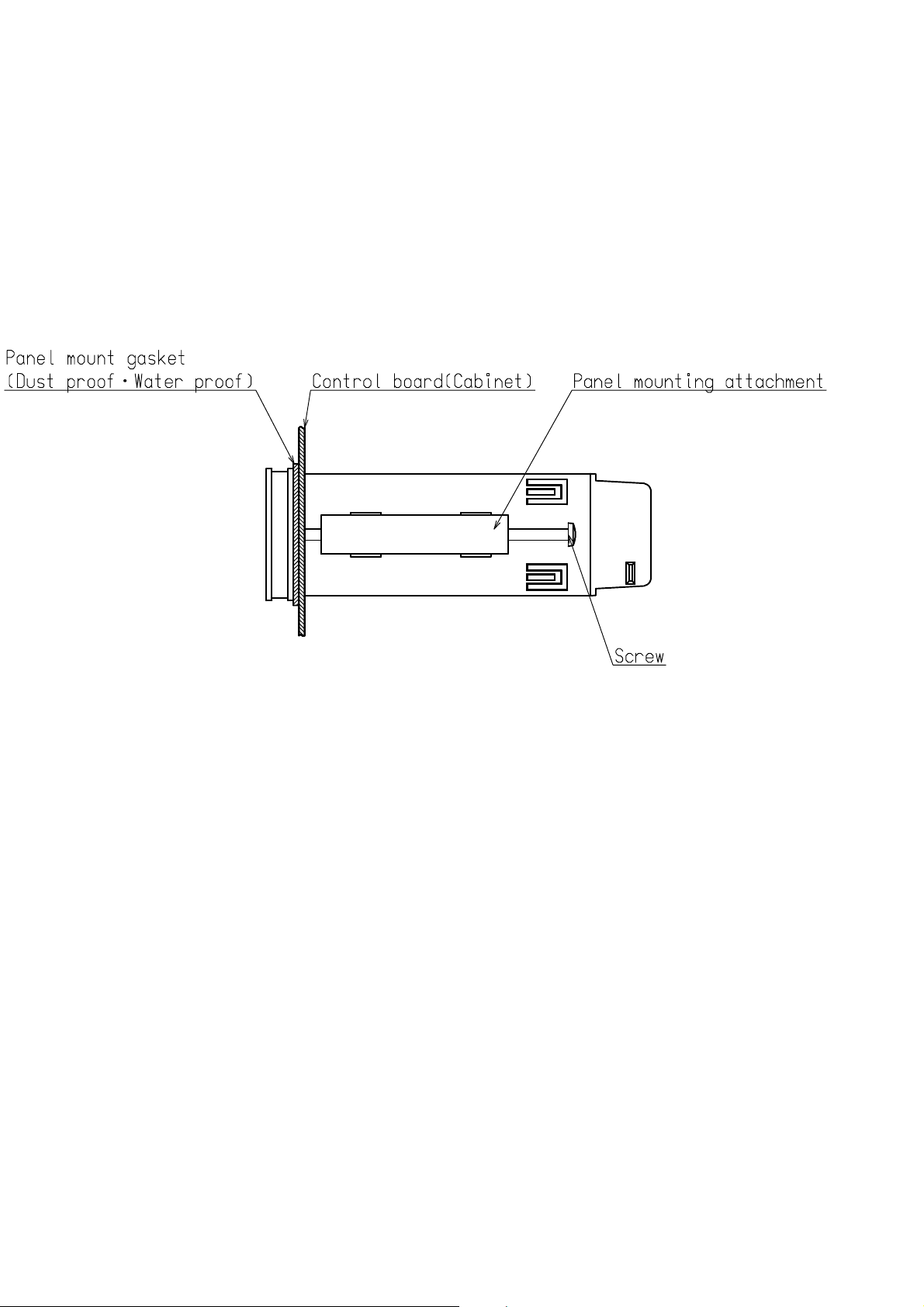

3−4. Applicable environment

Warning: The instrument may subject to use in a highly humid area or in full of powder dust.

In such a case, use the instrument by inserting the panel mount gasket attached between the con-

trol panel (cabinet) and the main body

.

By inserting the panel mount gasket, the front panel section becomes IP65 (Inter-

national Protection Code) or equivalent in dust−proof and water−proof construc-

tion.

* Care should be taken when handling the panel mount gasket, since there are up

and down directions.

6

Page 20

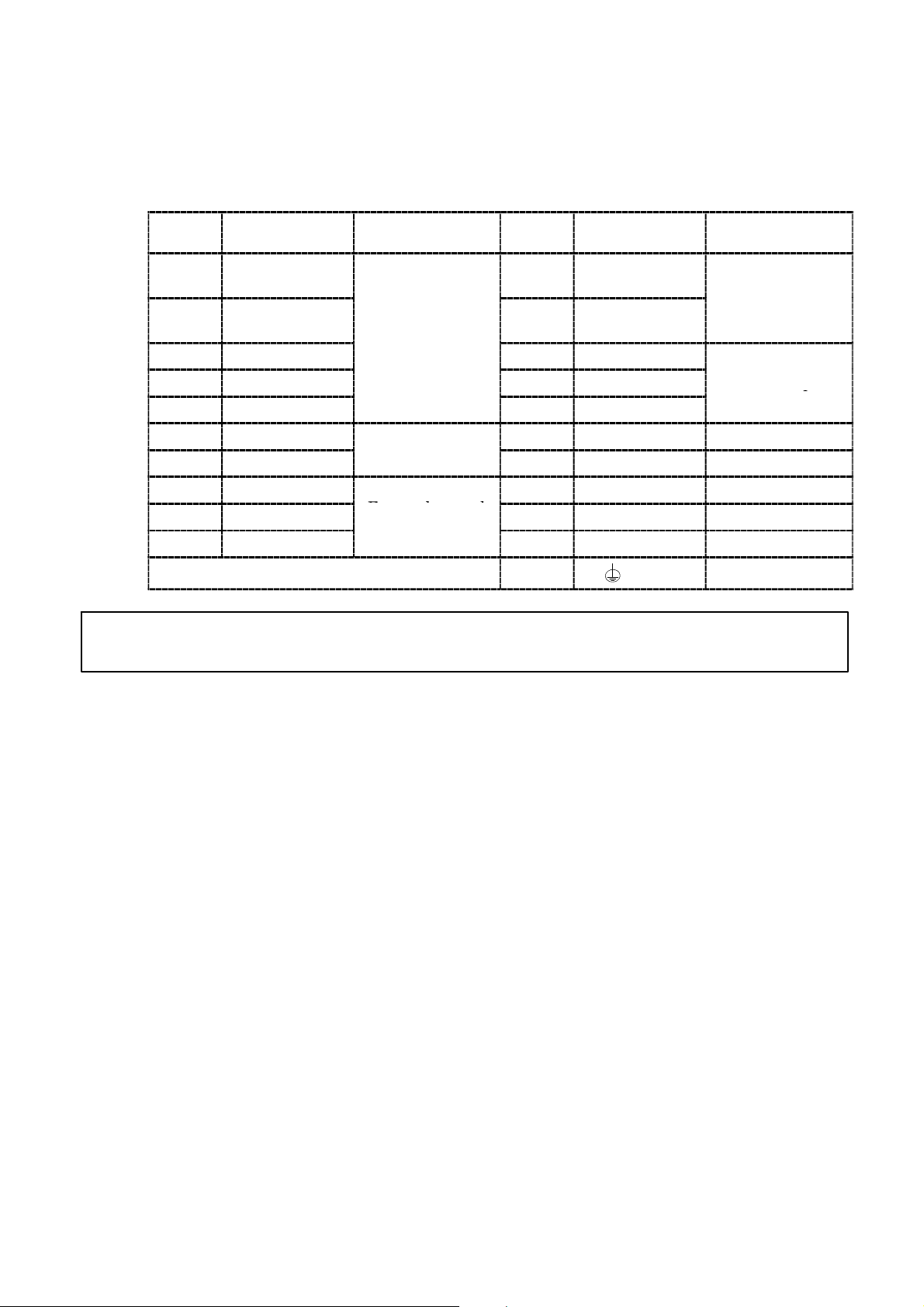

4. Connecting method

External

control

applied

p

Anal

input

4−1. Layout of the terminal boards

There is one terminal board containing 21 point of terminals in the panel.

Layout of terminal boards are shown in the following figure.:

Termin

al No.

1 A 11

2 B Strain gage

3 C

4 D 14 S1

5 E 15 S2

6 A−OUT +

7 A−OUT −

8 COM.1

9 ZERO

10 HOLD

Descriptions Applications

transducer

og output

External control

Termin

al No.

12

13 COM.2

16 F. G Frame ground

17 SOURCE AC power supply

18 N.C.

19 SOURCE AC power supply

20 N.C.

21 Ground

Descriptions Applications

PEAK/TRACK

or A/Z

RESET or A/Z

OFF

External control

input

Contact output

● The COM.1(Terminal No.8) and COM.2(Terminal No.13) are isolated.

7

Page 21

4−2. Note on connection

Warning ● In case of connection with the instrument, keep strictly to the

following items. If neglected, it may cause an unexpected failure

or a damage to the instrument.

D Be sure to set the power supply to OFF, when the connection will be made.

D Since the terminal boards at rear side of the instrument is made of resin, take care not to

drop it down or not to apply strong impact.

D Recommended torque to tighten the terminal screws for terminal board should be as

follows:

Torque to tighten

the terminal screws

Terminal board 0.6 N・m

D The suitable crimp type terminal lugs for the terminal board are as follows:

Width of crimp

type terminal lugs

Terminal board 6.2 mm or less 1.25−3 or Y type 1.25−3.5

D Connecting cable with the instrument should be away from the noise source such as power

supply line and/or I/O line for control and so on as far as possible.

D Conduit wiring should be the type of exclusive one, and avoid using with another line

together.

D All of the connections should be executed securely by referring to the Instruction manual

for the instrument.

Suitable crimp type

terminal lugs

8

Page 22

4−3. Connection

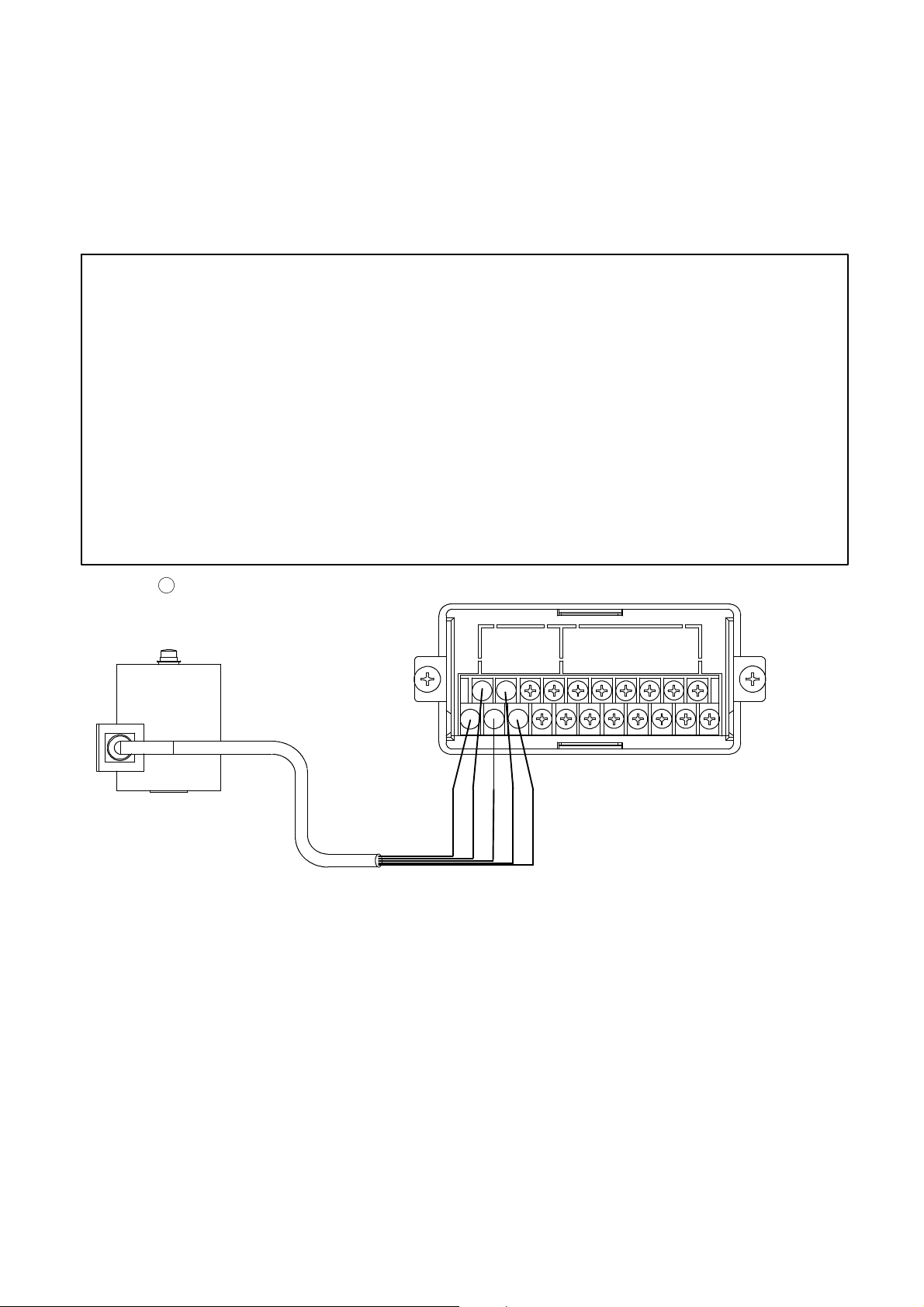

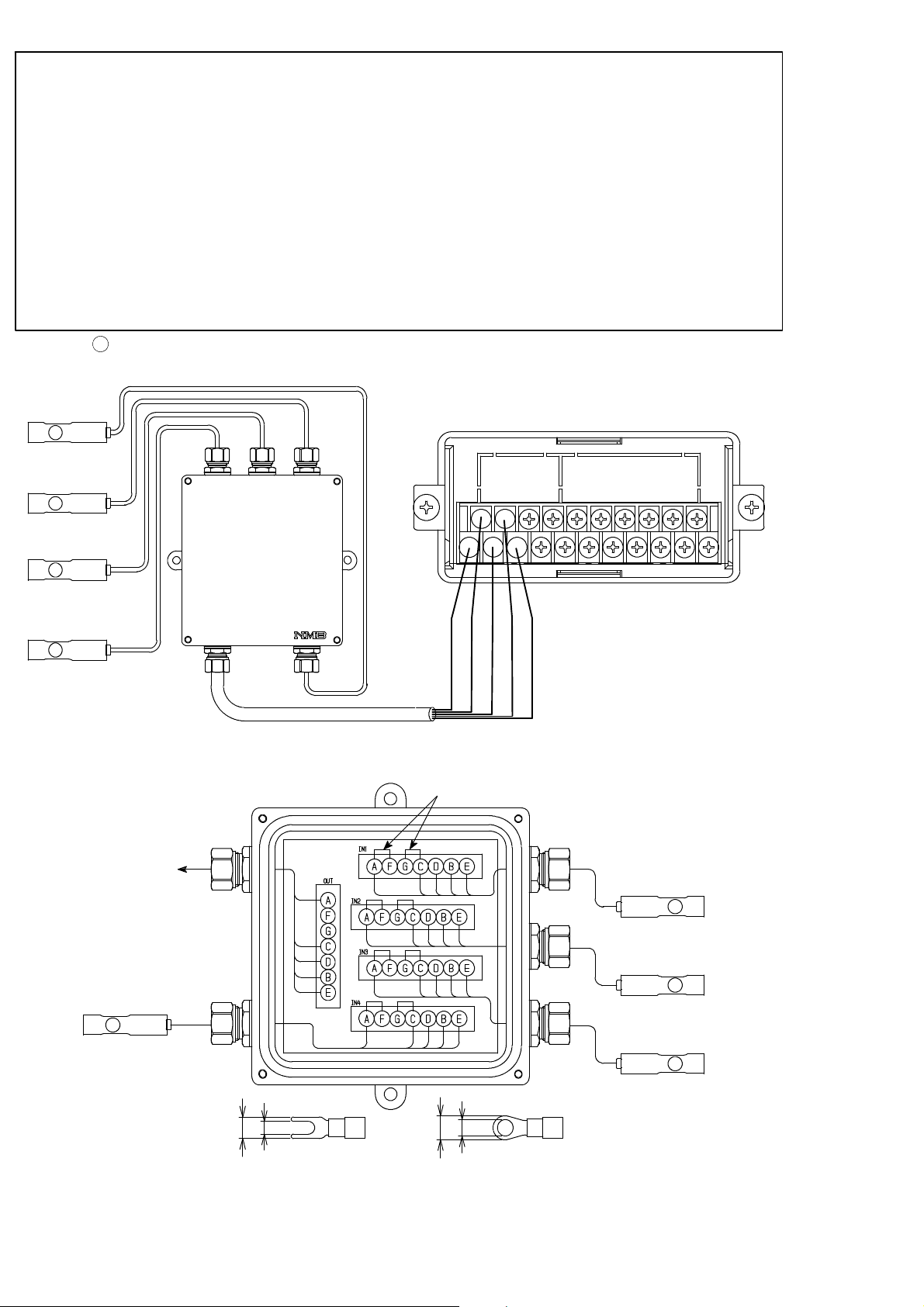

4−3−1. Connection with strain gage applied transducers

The instrument can connect with strain gage applied transducers, such as load cell, pressure

transducer and so on. Here, we will describe the example of connections with load cell, so the

connection with other type of strain gage applied transducers shall be proceeded in the same

way.

※1 When tension is applied with the application of tension type or

universal(compression/tension) type of load cell, and display of “+”

direction is required, connect “Green” with Terminal No.2 and

“Blue” with Terminal No.4 individually. As there is a case which

standard wiring color is different, please confirm the inspection data

sheet of the load cell being used.

※2 When the length of CAB−502 is more than 30 m totally, there may

have the case that the accuracy is out of warranty because the

resistance of cable makes the input voltage of the instrument

decreased.

1

Connection with 1 piece of load cell and CSD−701B

3m

※1※

1

RED

WHT

BLU

GRN

Shield

9

Page 23

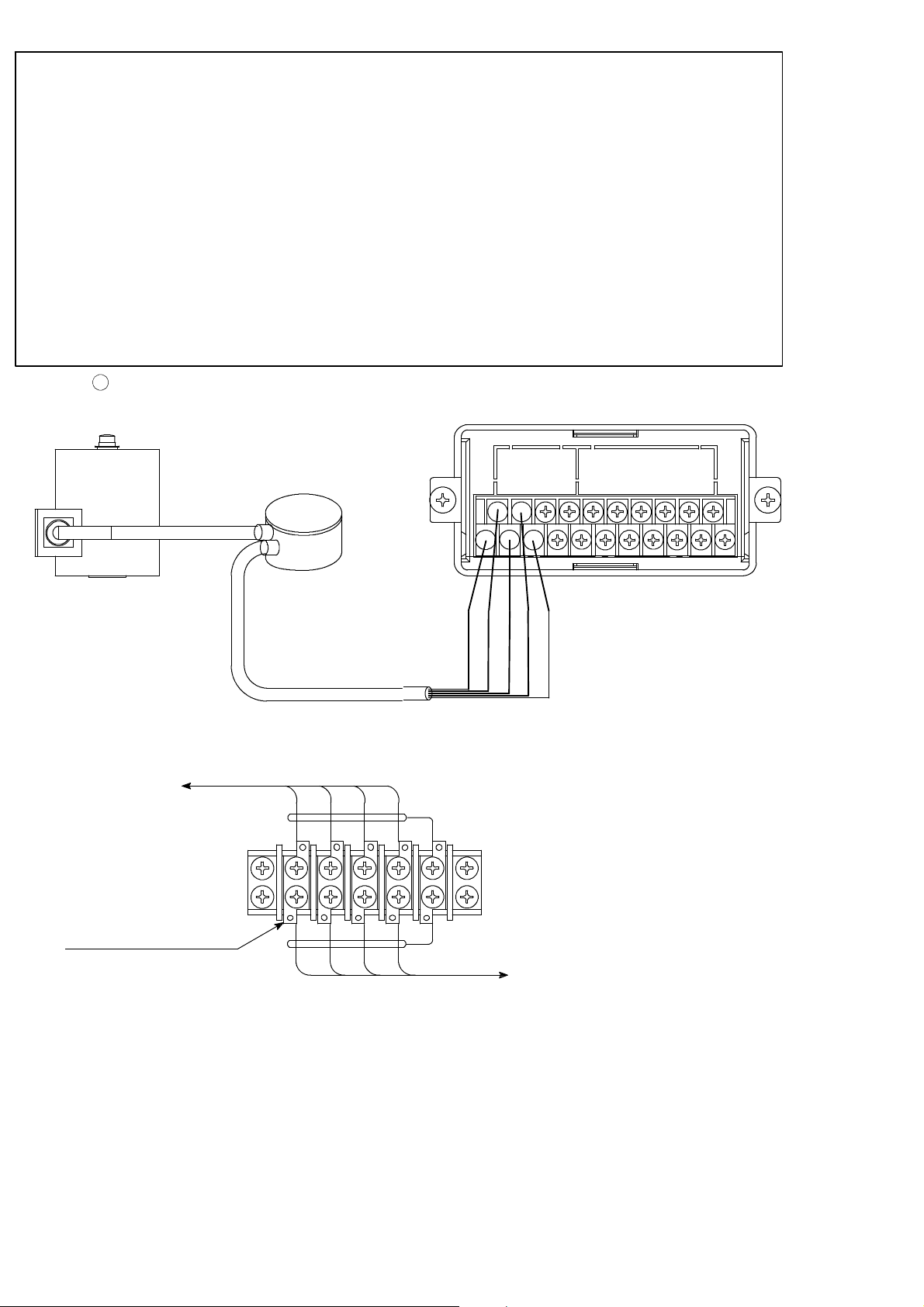

※1 When tension is applied with the application of tension type or

universal(compression/tension) type of load cell, and display of “+”

direction is required, connect “Green” with Terminal No.2 and

“Blue” with Terminal No.4 individually. As there is a case which

standard wiring color is different, please confirm the inspection data

sheet of the load cell being used.

※2 When the length of CAB−502 is more than 30 m totally, there may

have the case that the accuracy is out of warranty because the

resistance of cable makes the input voltage of the instrument

decreased.

2

Connection with 1 piece of load cell and Junction box for extension use(B−304) and

CSD−701B.

Junction box

3m

※2 (Total length of CAB−502 is within 30 m)

Internal wiring diagram of B−304

to load cell

Terminal pitch 9.5 mm

B−304

CAB−502

RED WHTBLU

RED WHTBLU

※1※

RED

BLU

GRN YEL(Shield)

Suitable crimp type terminal lugs

:1.25−4or2−4

YEL(Shield)

GRN

1

WHT

GRN

Shield

to CSD−701B

10

Page 24

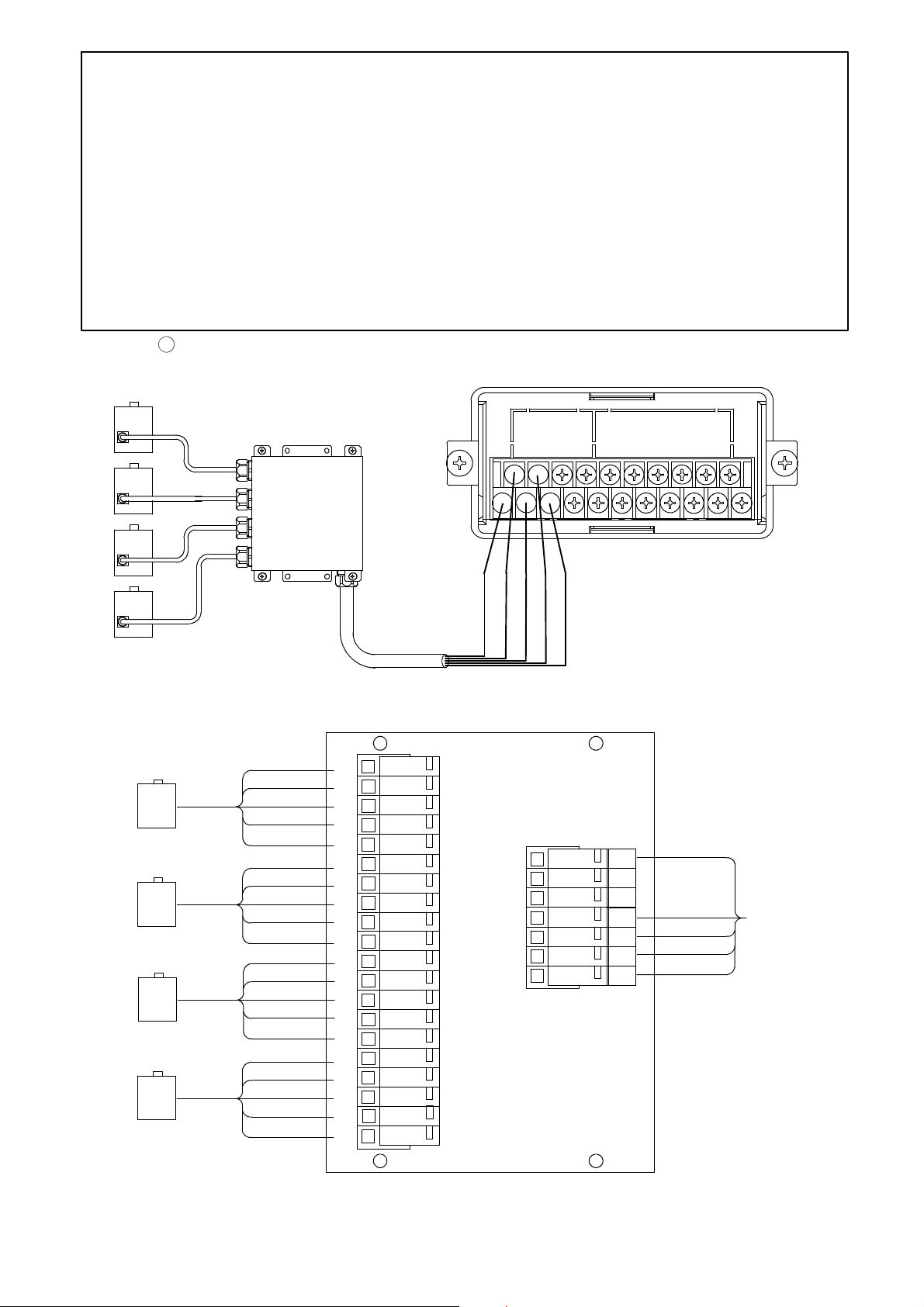

※1 When tension is applied with the application of tension type or

universal(compression/tension) type of load cell, and display of “+”

direction is required, connect “Green” with Terminal No.2 and

“Blue” with Terminal No.4 individually. As there is a case which

standard wiring color is different, please confirm the inspection data

sheet of the load cell being used.

※2 When the length of CAB−502 is more than 30 m totally, there may

have the case that the accuracy is out of warranty because the

resistance of cable makes the input voltage of the instrument

decreased.

3

Connection with 2 to 4 pieces of load cells, Summing type junction box(B−307) and

CSD−701B.

Junction box

B−307

CAB−502

※2 (Total length of CAB−502 is within 30 m)

Internal wiring diagram of B−307

WHT

RED

GRN

BLU

YEL(Shield)

WHT

RED

GRN

BLU

YEL(Shield)

WHT

RED

GRN

BLU

YEL(Shield)

WHT

RED

GRN

BLU

YEL(Shield)

1W

1R

1G

1B

1Y

2W

2R

2G

2B

2Y

3W

3R

3G

3B

3Y

4W

4R

4G

4B

4Y

※1※

RED

BLU

1

WHT

GRN

Shield

RED

RD

OR

BK

WHT

WH

GN

BL

YE

GRN

BLU

YEL(Shield)

to CSD−701B

11

Page 25

※1 When tension is applied with the application of tension type or

universal(compression/tension) type of load cell, and display of “+”

direction is required, connect “Green” with Terminal No.2 and

“Blue” with Terminal No.4 individually. As there is a case which

standard wiring color is different, please confirm the inspection data

sheet of the load cell being used.

※2 When the length of CAB−502 is more than 30 m totally, there may

have the case that the accuracy is out of warranty because the

resistance of cable makes the input voltage of the instrument

decreased.

4

Connection with 2 to 4 pieces of load cells, Summing type junction box(SB−310) and

CSD−701B.

SB−310

CAB−502

※2 (Total length of CAB−502 is within 30 m)

Internal wiring diagram of SB−310

Output port

to CSD−701B

RD

WH

GR

Input port

No.4

BL

YE

※1※

RED

BLU

Short bar

YERD WH BLGR

YERD WH BLGR

YERD WH BLGR

YERD WH BLGR

1

WHT

GRN

Shield

Input port No.1

Input port No.2

Input port No.3

Suitable crimp type

terminal lugs:

A

B

or

φB

φA

A:3.2 mm or less

B:7 mm or less

・Y type ・Round type

12

Page 26

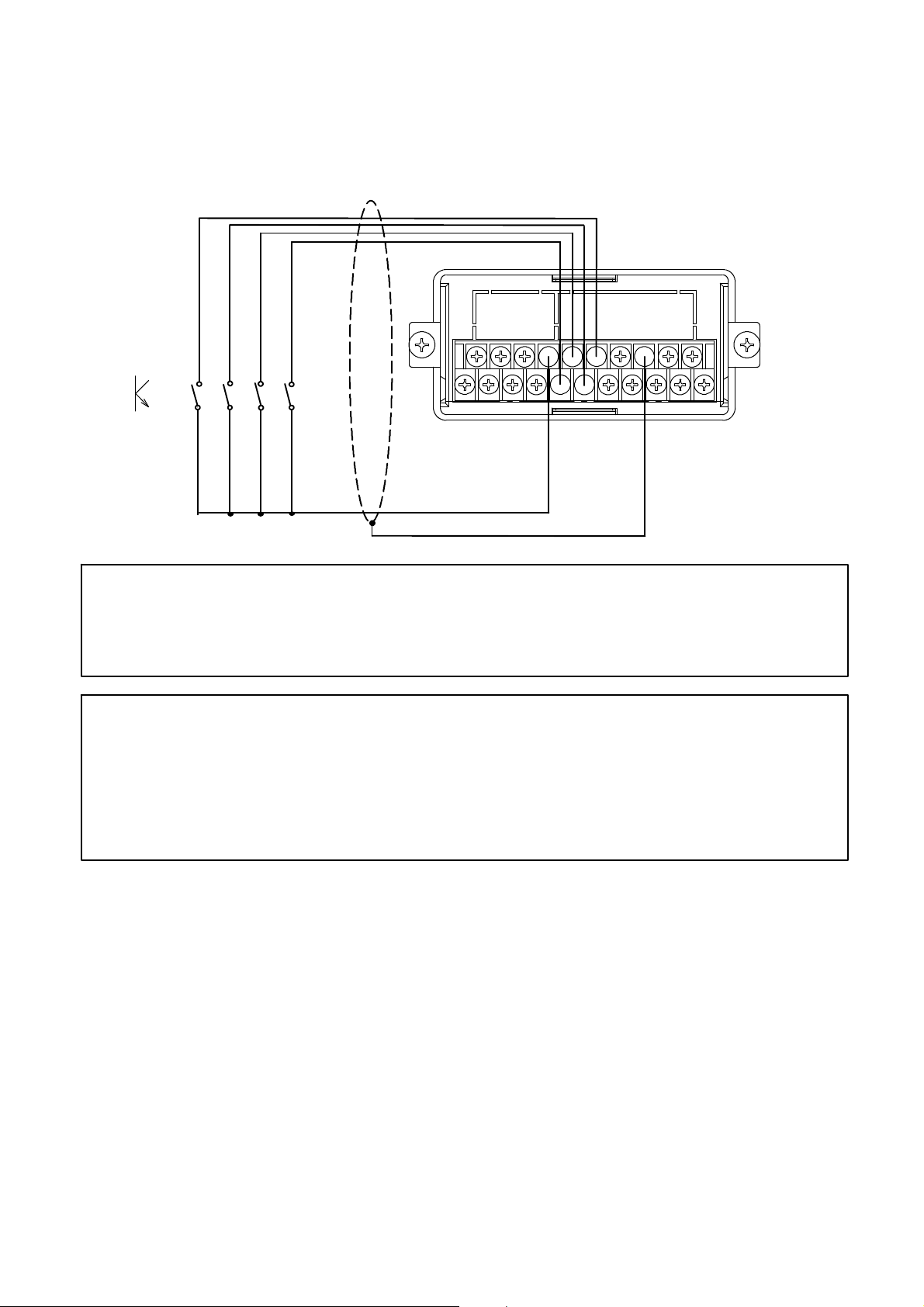

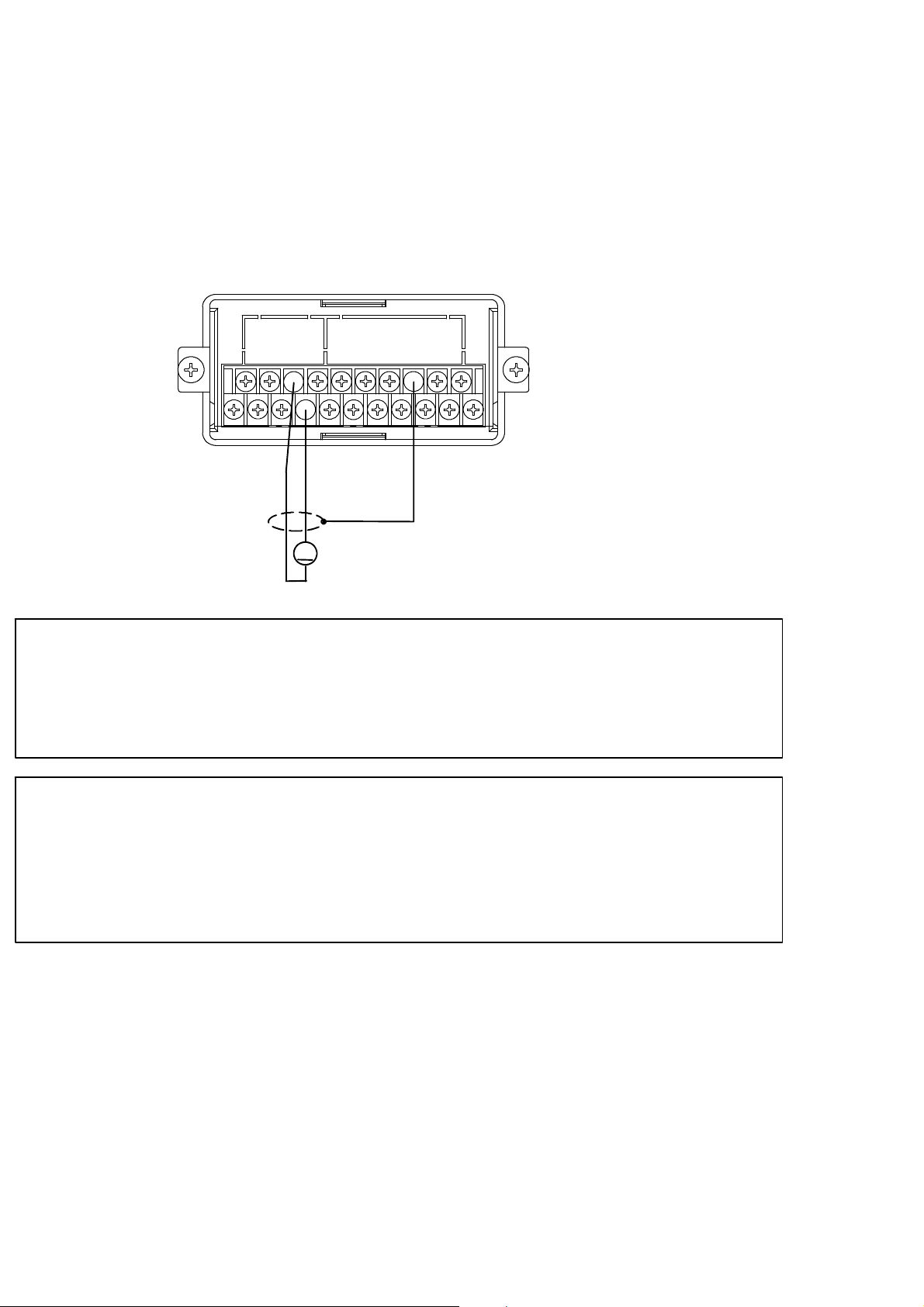

4−3−2. Connection with external control inputs

Connections with external control input “ZERO”,“HOLD”, “PEAK/TRACK” and “RESET”

should be made according to the below figures by using a contact point or an open collector

between the each terminal and terminal No. 8 at “COM.1”

Refer to the paragraph 7−1 for the function of each input.

or

Shield

Warning ● Connections with external control outputs should be made securely

according to the figures. If neglected, it may cause an unexpected

failure and/or malfunction to the instrument.

● For the connections with external control inputs, be sure to apply

shielded cable, and the shielded cable should be connected with GND

terminal of the instrument.(Terminals No.16)

If not connected, it may cause malfunction due to the effects from

external noises and so on.

13

Page 27

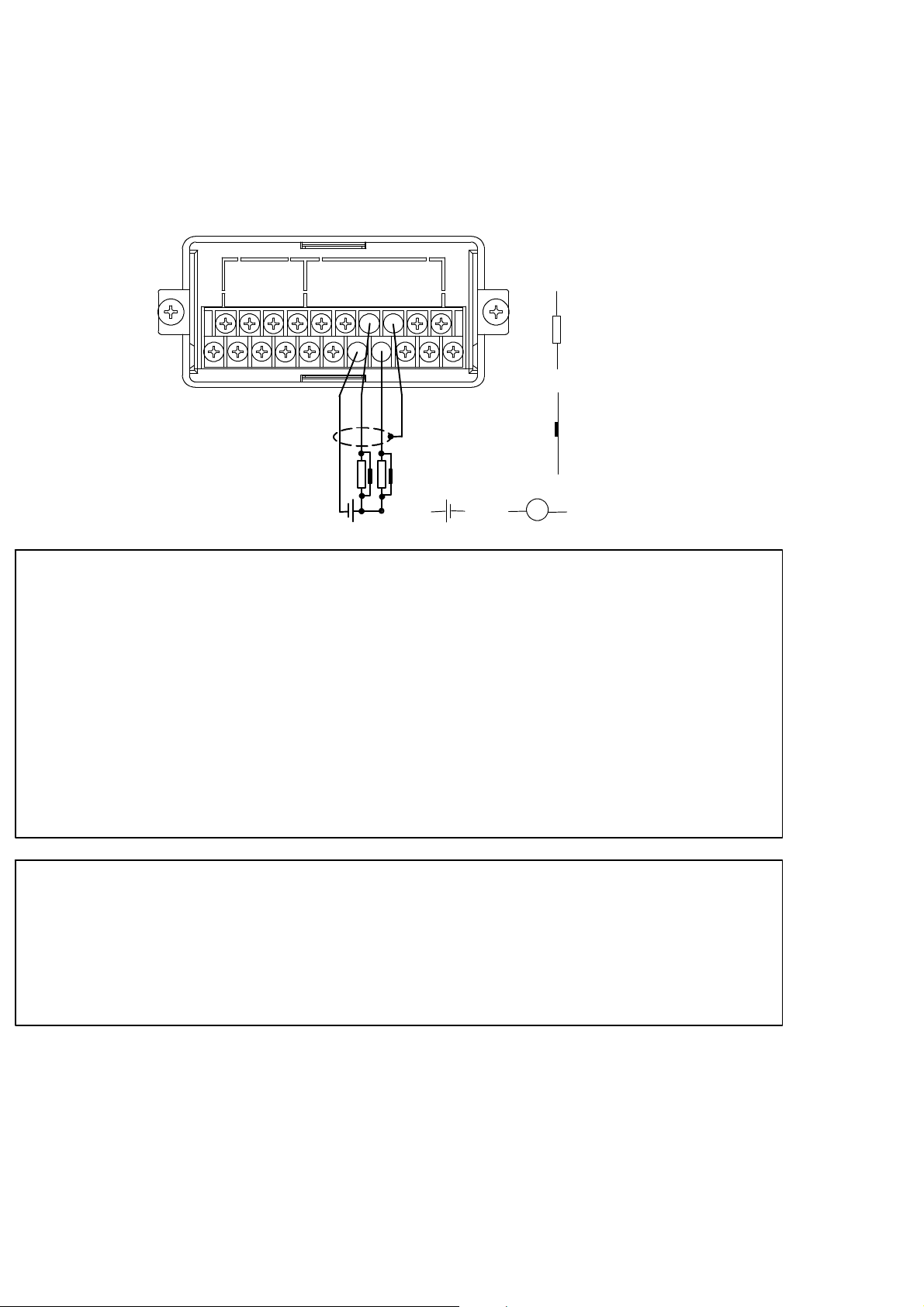

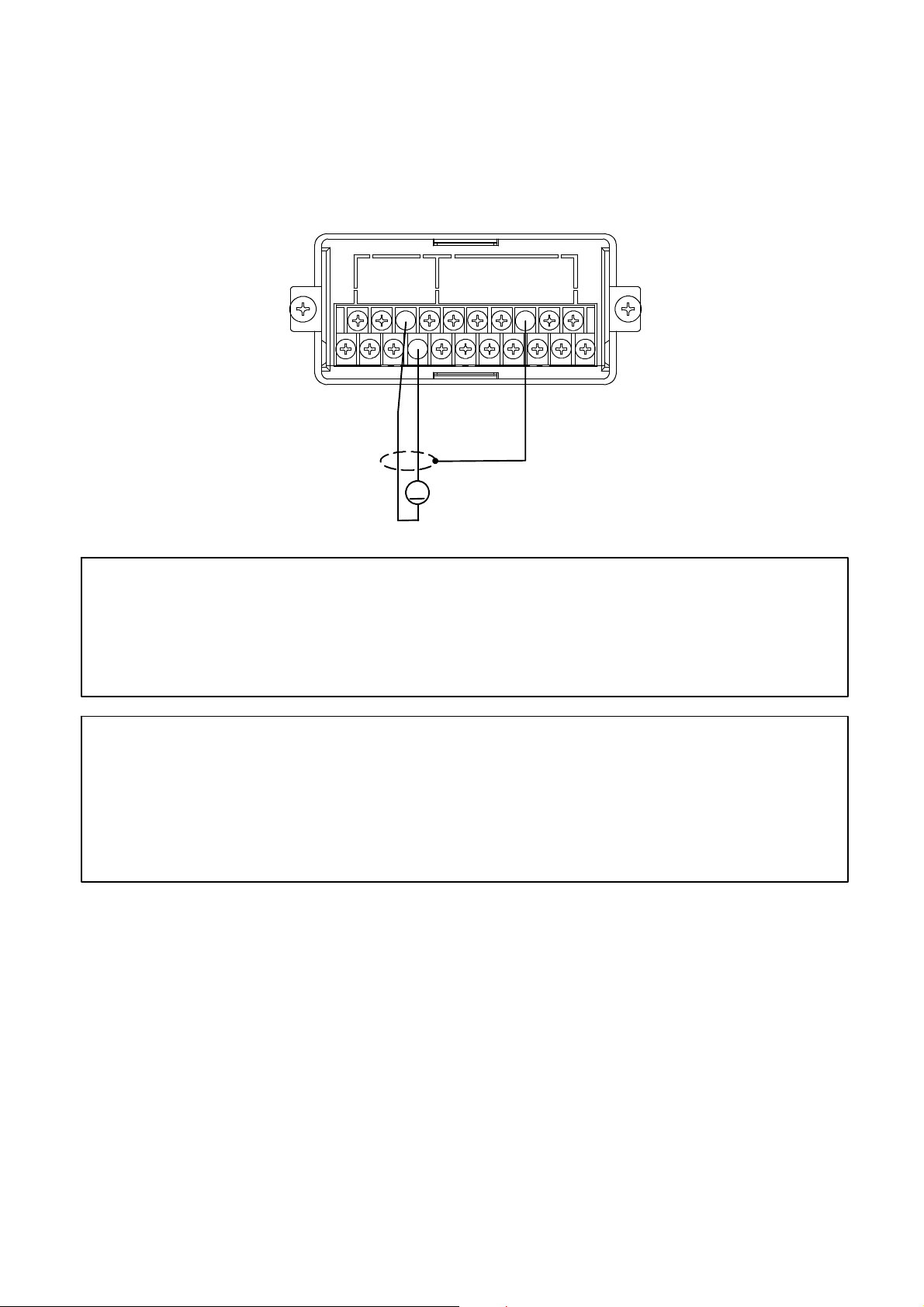

4−3−3. Connection with contact outputs

Connections with contact outputs “S1” and “S2” and external load should be made by using

each terminal and terminal No. 13 at “COM.2”.

At the same time, take care that the load should not exceed the rated load of contact output.

Rated load of contact output AC125 V 0.1 A (Resistance load)

DC30 V 0.5 A (Resistance load)

load

Surge preventive element

〜

or

Shield

or

Warning ● Connections with contact outputs should be made securely according

to the figures and also within the rated capacity of the instrument. If

neglected, it may cause an unexpected failure and/or malfunction to

the instrument.

● For the protection from the contact of the instrument, connect the

surge preventive element that satisfies the characteristics of external

load to connect. If neglected, it may cause unexpected failure and/or

malfunction due to the effects from damage/melt down of the contact

and so on.

● For the connections with contact outputs, be sure to apply shielded

cable, and the shielded cable should be connected with GND terminal

of the instrument.(Terminal No.16)

If not connected, it may cause malfunction due to the effects from

external noises and so on.

14

Page 28

4−3−4. Connection with the power supply and the earth

Connections with the power supply and the earth should be made as the following figure.

Grounding should be the D class with single earth.

Power supply voltage AC100 V to AC240 V

(Allowable variable range:AC85 V to AC264 V)

Frequency for power supply 50/60 Hz

Power consumption Approx.11 VA at maximum. (at AC100 V)

D class with single earth

〜

AC100 V to AC240 V

(Allowable variable range

:AC85 V to AC264 V)

Warning ● Connections with the power supply and the earth should be made

securely according to the figures and also within the rated capacity of

the instrument. If neglected, it may cause an unexpected cause of

failure.

● Grounding should be the D class with single earth.

If neglected, it may cause an unexpected malfunction due to the

effects of noise from other equipments.

15

Page 29

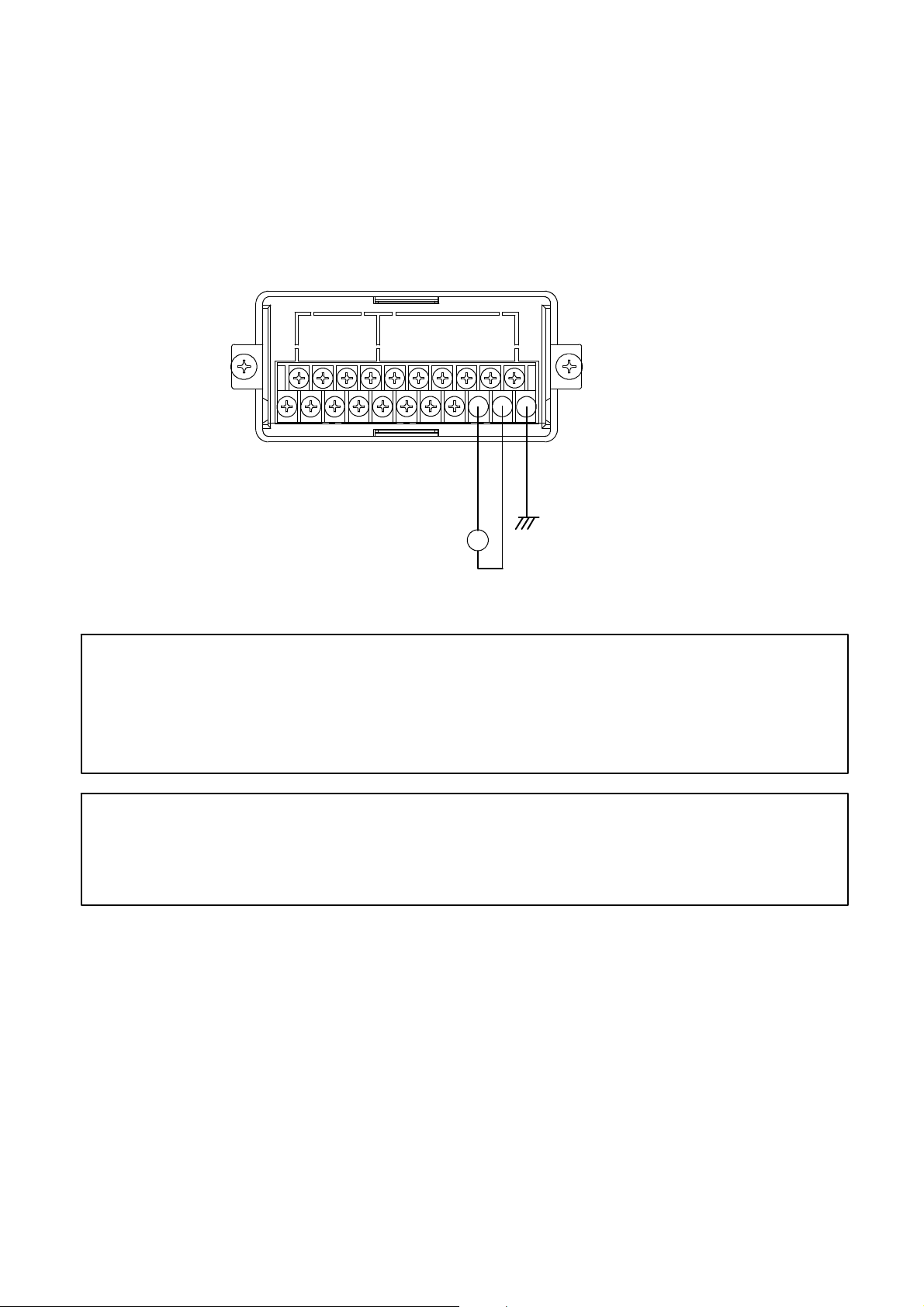

4−3−5. Connection with analog outputs

(1) In case of standard instrument (voltage output)

The instrument prepares output voltage for analog outputs as a standard.

Connections with voltage output should be made as the following figure.

Voltage output DC0 V to 5 V

Over−range At “−OL” display Approx.−1.25 V

At “OL” display Approx.6.25 V

Load resistance 5 kΩ or more

Shield

−

V

+

Warning ● Connections with voltage outputs should be made securely according

to the figures and also within specified load resistance.

If neglected, it may cause an unexpected failure and/or malfunction to

the instrument.

● For the connections with voltage outputs, be sure to apply shielded

cable, and the shielded cable should be connected with the F.G.

terminal of the instrument(Terminal No.16).

If not connected, it may cause malfunction due to the effects from

external noises and so on.

16

Page 30

(2) In case of option (current output)

Connections with current output should be made as the following figure.

Current output DC4 mA to 20 mA

Over−range At “−OL” display Approx.0 mA

At “OL” display Approx.24 mA

Load resistance 260 Ω or less

Shield

−

A

+

Warning ● Connections with current outputs should be made securely according

to the figures and also within the specified load resistance.

If neglected, it may cause an unexpected failure and/or malfunction to

the instrument.

● For the connections with current outputs, be sure to apply shielded

cable, and the shielded cable should be connected with the F.G.

terminal of the instrument.(Terminal No.16)

If not connected, it may cause malfunction due to the effects from

external noises and so on.

17

Page 31

5. Calibration procedures

Warning ● Before using the new instrument or after exchanging the strain gage

applied transducer with a new one, be sure to make calibration.

If calibration is not made, correct measured results may not be

obtained, or it may cause malfunction to the instrument and it may

damage the peripheral equipment.

Moreover, even if calibration has made, there may occur the similar

case as above when the result is not correct. So make precise

calibration again.

● The calibration for the instrument and “Display value at the time of

minimum analog output”(F−21) and “Display value at the time of

maximum analog output” (F−22) are not interlocked. In due course,

make check on the setting for F−21 and F−22 securely.

If neglected, correct outputs may not be obtained, or it may cause

malfunction to the instrument and it may damage the peripheral

equipment.

5−1. Preparations

According to the Chapter 4. Connecting method, connect the instrument and the strain gage

applied transducer properly, then supply the power.

5−2. Calibration procedures

Load calibration procedures for the instrument are as follows:

1

Calibration method to register the output (conversion with mV/V) of strain gage applied

transducer at the time of maximum display (weighing capacity) after setting the load to zero

(Initial load condition with tare weight).

2

Calibration method (Automatic calibration for Zero and Span) to register the output of strain

gage applied transducer (conversion with mV/V) at the time of zero load(Initial load

application with tare) at the optional load condition, and also to register the output

(conversion with mV/V) of strain gage applied transducer at the time of maximum display

(weighing capacity).

3

Calibration method (Actual load calibration) to register by the reading output of strain gage

applied transducer, when setting in the condition of zero load applied (Initial load application

with tare) and in the condition of actual load applied individually.

4

Fine adjustment on Zero

5

Fine adjustment on Span

6

Calibration procedures to apply registration again for zero point only(Tare weight

cancellation).

18

Page 32

● The accuracy of calibration obtained from ① and ② is 1/1 000 or so.

If more than the accuracy 1/1 000 is required, make calibration of ③

type.

In the following paragraphs, we will describe each calibration procedure by showing the

examples with load cell applied.

5−2−1. Calibration method to register the output of strain gage applied transducer at the time

of maximum display after setting the load to zero.

Warning ● Before using a new instrument or exchanging the strain gage applied

transducer for a new one, be sure to make calibration.

If calibration shall not be made, correct measured results may not be

obtained nor it may cause malfunction in the instrument and there

may exist damage to the peripheral equipment.

Besides, even though the calibration has been made, there may occur

the similar case when the result is not correct, so make calibration

again.

● During the calibration is executing, be sure to set Tare weight

cancellation clear, and to make cancellation (Execution of F−98) for

compensated data on zero set and set the OFF position of Zero

tracking(Setting “00000” on F−07 and F−08), and also set the OFF

position o Peak.

● During calibration procedures, press the key in case of

interrupting the calibration is required. The calibration data will be

kept as they are before entering the calibration and then returns to

the Measurement mode.

● Every time the

the display will change as the following arrow marks. However, every

time the

direction of the following arrow marks.

key is pressed, the display will change as the reverse

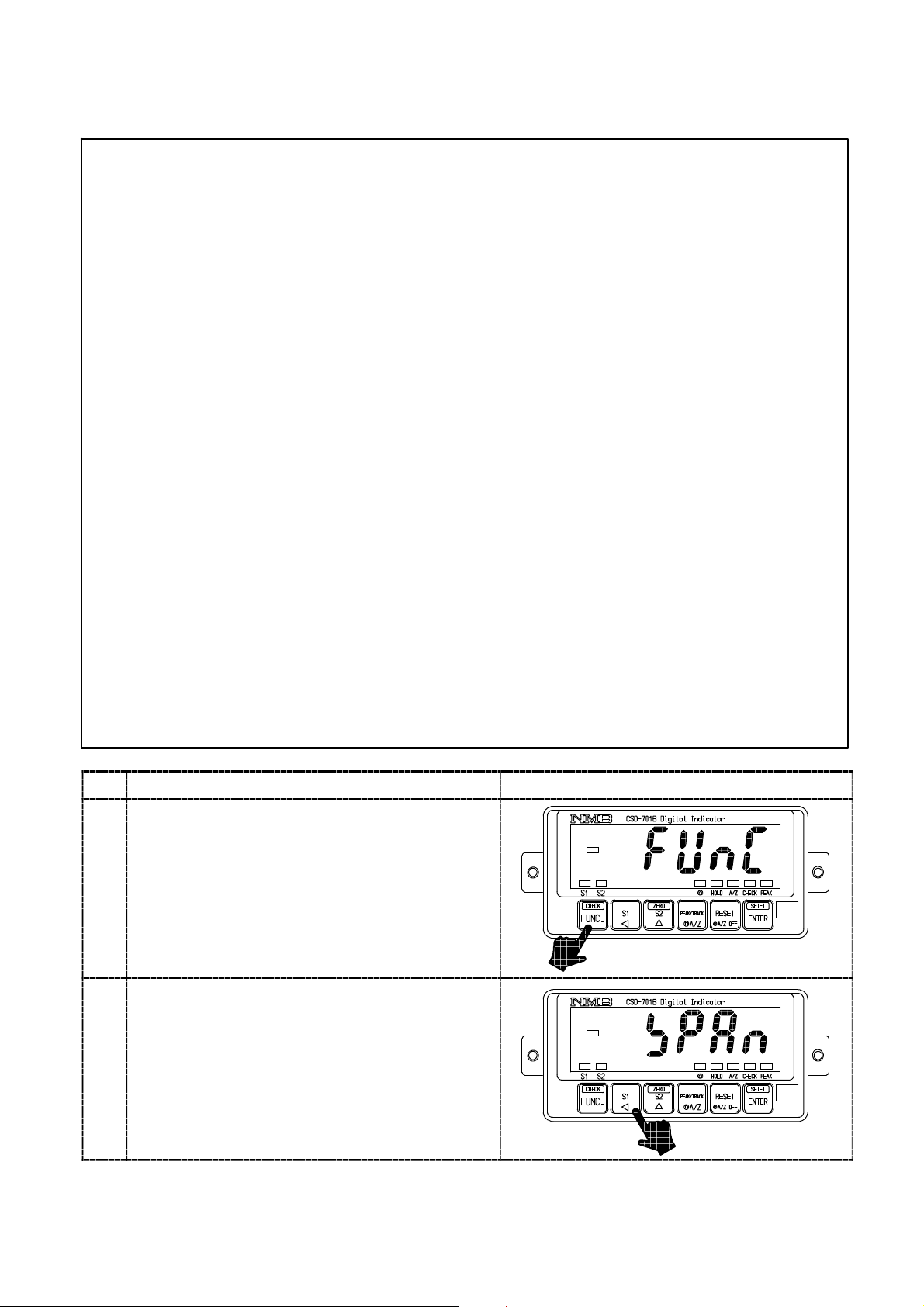

key is pressed with the load display of ”FUNC”,

“FUNC”→“CCAL”→“ACAL”→“LCAL”→“ZERO”→“SPAN”→

“TARE”→“TARE”→“CHEK”→“MONT”→“VCAL”→“VADJ”→

“FUNC”→“CCAL”→・・・・・ (Hereinafter, it will repeat.)

19

Page 33

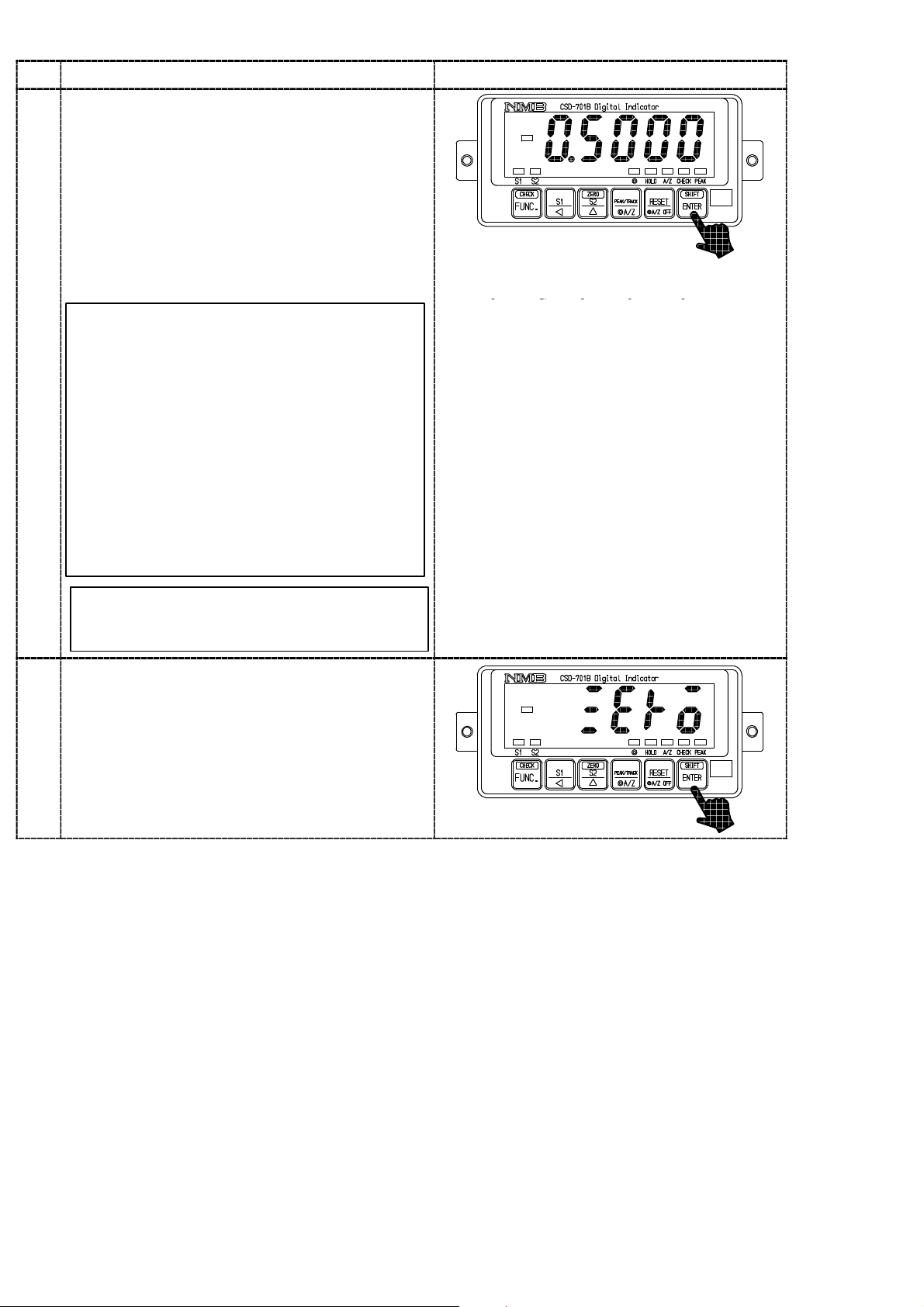

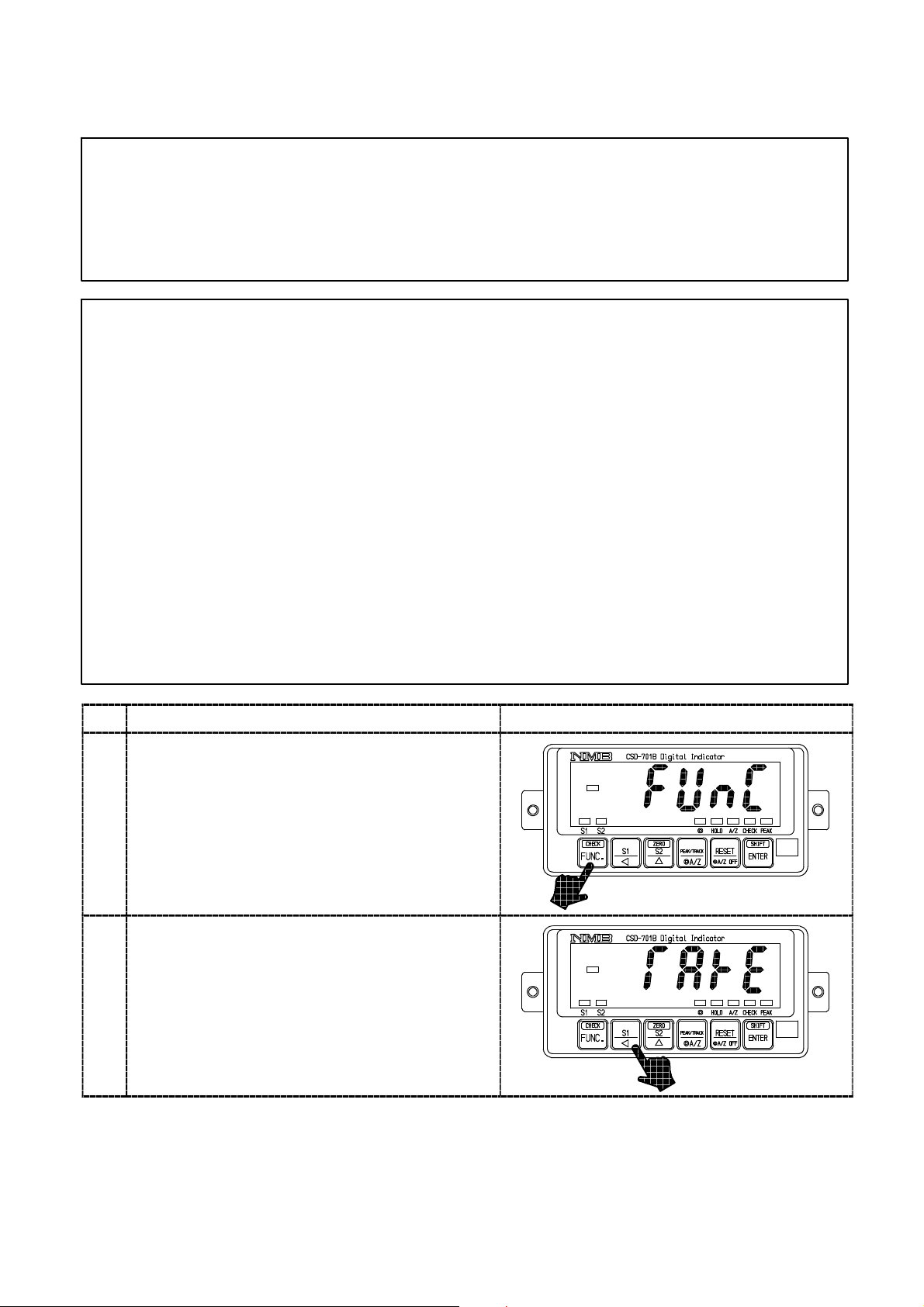

Procedures

Press the key for approx. one second.

The load display will show “FUNC”.

1

Press the key once.

The load display will show “CCAL”.

2

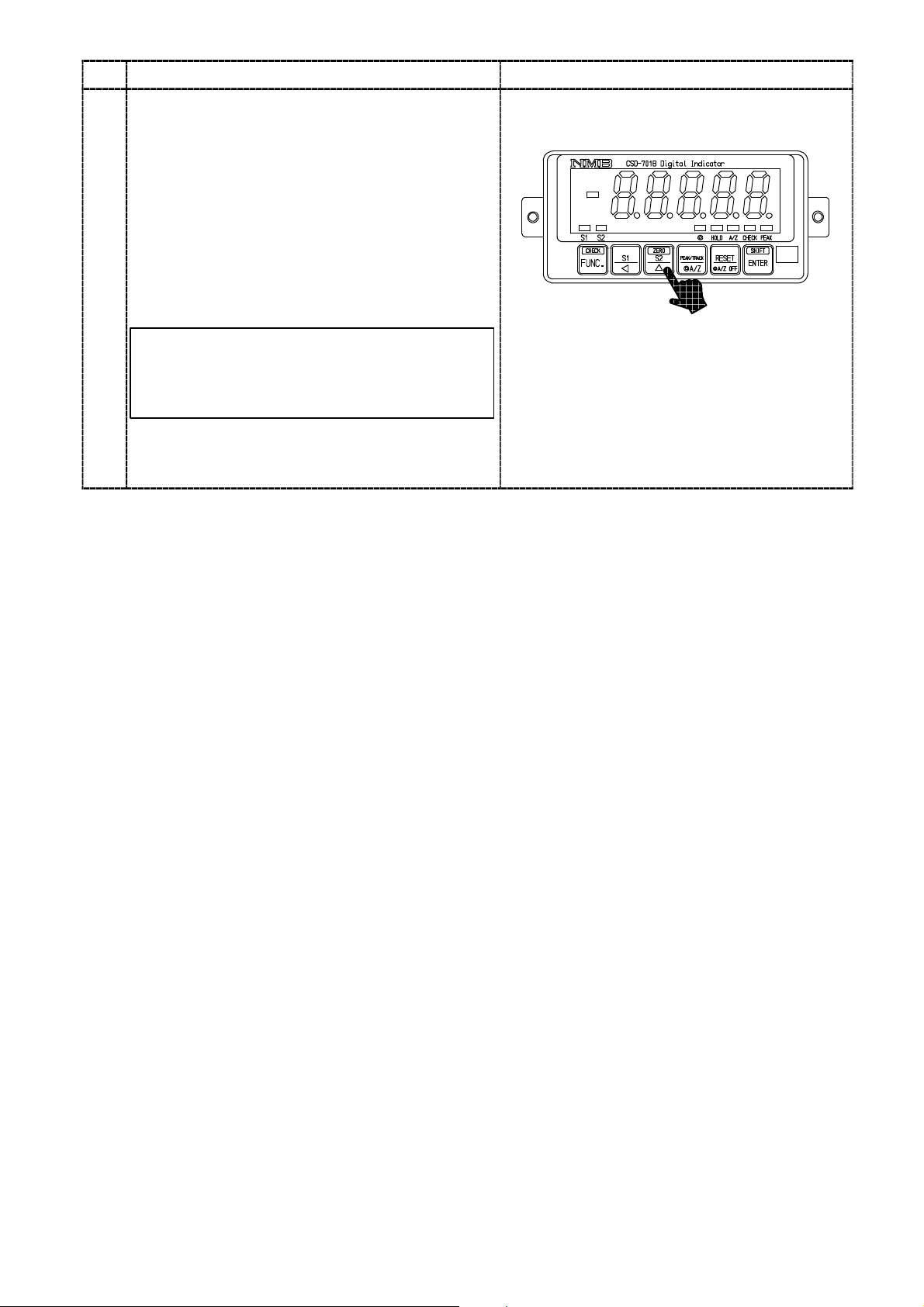

Press the key.

“CCAL” mode can be entered, then the load

display will show “SCAL”.

3

Press the key.

The load display shows “D−01” and it will flash

on and off.

When the calibration has completed already, the

set value of minimum scale registered at that

4

time will be displayed.

Set the minimum scale with the right keys.

Setting value for the minimum scale will be 4

(four) as follows:

1, 2, 5, 10

Press the key.

The load display will show “DISP”.

5

key :Set value inclement key

20

Page 34

Procedures

Press the key.

The load display will show “2000”, and the digit

of minimum display will flash on and off.

When the calibration has completed already, the

registered value of maximum display at that time

will be displayed.

By the setting of minimum scale, the digit

of minimum display that flashes on and off

will be as follows:

The minimum scale 1, 2, 5 10

The minimum scale 10 10

Set the maximum display value with the right

keys. Setting range for the maximum display

value will be (the minimum scale×100)〜99 990.

In order to make effective use of the performance,

6

set within the following ranges.

When setting is made over the range as below,

there may have a possibility of unstable display

and so on.

Setting range for the

maximum display value

100〜10 000

200〜20 000

500〜50 000

1 000〜99 990

The minimum scale

1

2

5

10

It can be increased continuously by the

continuity press of the key.

0

1

digit

digit

key :Set value carry key

key :Set value inclement key

key :Set value initialization key

Press the key.

The load display will show “S MV”.

7

21

Page 35

Procedures

Press the key.

The load display will show “0.5000”, and the

digit of 10

In case that calibration has completed already,

the registered output value of load cell at that

time will be displayed.

Set the given value with the right keys, which is

subtracted the output value of load cell at the

time of initial load application from the output

value of load cell corresponding to the maximum

display value set in the step 6.

0

will flash on and off.

Though the number of digits has not

prepared in the “Inspection data” for load

8

cell so many as shown in the right figure,

extra digits are necessary for the

compensation with the standard point at

internal of the instrument.

In case of actual setting, insert “0”, into the

extra digits.

As for the value for extra digit, when tare

compensation and fine adjustment on load

are applied, it will be rewritten as a

compensated value automatically.

Setting range for the output of load cell is

from 0.400 0 mV/V to 3.100 0 mV/V.

key :Set value carry key

key :Set value inclement key

key :Set value initialization key

It can be increased continuously by the

continuity press of the key.

Press the key.

The load display will show “ZERO”.

Here, set the instrument with initial load

application.

9

22

Page 36

Procedures

Press the key.

The load display will show “ZERO” with lighting

display on and off, then zero adjustment can be

started.

Warning :At the same time, take care not

to apply load variation due to vibration and

so on. When load variation is applied, there

10

will be possibilities that zero point is

unstable, and precise reading of zero will

not be obtained.

After completed, the load display will become

“END”.

However, when the initial load is not entered

within the range from −0.3 mV/V to 2.4 mV/V,

the error code shown in the right figure will

show for about 2 seconds, then load display will

show “ZERO” and return to step 9.

TE−L :Zero point −OVER

TE−H :Zero point +OVER

Press the key.

After “CCAL” mode is over, the load display will

showthepresent load.

11

Error Code

Error Code

23

Page 37

5−2−2. Calibration procedures to register the output of strain gage applied transducer at the

time of zero and the maximum display

(1) Procedure by key operation

Warning ● Before using a new instrument or exchanging the strain gage applied

transducer for a new one, be sure to make calibration.

If calibration shall not be made, correct measured results may not be

obtained nor may cause malfunction in the instrument and there may

exist damage in peripheral equipments.

Besides, even though calibration has been made, there may occur the

similar case when the result is not correct, so make calibration again.

● During the calibration is executing, be sure to set Tare weight

cancellation clear, and to make cancellation (Execution of F−98) for

compensated data on zero set and set the OFF position of Zero

tracking(Setting “00000” on F−07 and F−08), and also set the OFF

position of Peak.

If neglected, correct measured results may not be obtained.

● During calibration procedures, press the key in case of

interrupting the calibration is required. The calibration data will be

kept as they are before entering the calibration and then returns to

the Measurement mode.

● Every time the key is pressed with the load display of “FUNC”,

the display will change as the following arrow marks. However, every

time the

direction of the following arrow marks.

“FUNC”→“CCAL”→“ACAL”→“LCAL”→“ZERO”→“SPAN”→

“TARE”→“CHEK”→“MONT”→“VCAL”→“VADJ”→“FUNC”→

“CCAL”→・・・・・ (Hereinafter, it will repeat.)

is pressed, the display will change as the reverse

24

Page 38

Procedures

Press the key for about one second

The load display will show “FUNC”.

1

Press the key twice.

It will make the load display proceed as

“FUNC”→“CCAL”→“ACAL”.

2

Press the key.

“ACAL” mode can be entered, then the load

display will show “SCAL”.

3

Press the key.

The load display shows “D−01”.

When the calibration has completed already, the

set value of minimum scale which has registered

at that time will be displayed.

4

Set the minimum scale with the right keys.

Setting value for the minimum scale will be 4

(four) as follows:

1, 2, 5, 10

Press the key.

The load display will show “DISP”.

5

key :Set value inclement key

25

Page 39

Procedures

Press the key.

The load display shows “2000” and the minimum

display digit will flash on and off.

When the calibration has completed already, the

maximum display value which has registered at

that time will be displayed.

By the setting of minimum scale, the digit

of minimum display that flashes on and off

will be as follows:

The minimum scale 1,2,5 10

The minimum scale 10 10

Set the maximum display value with the right

keys. Setting range for the maximum display

value will be (the minimum scale×100)〜99 990.

In order to make effective use of the performance,

6

set within the following ranges.

When setting is made over the range as below,

there may have a possibility of unstable display

and so on.

Setting range for the

maximum display value

100〜10 000

200〜20 000

500〜50 000

The minimum scale

1

2

5

0

digit

1

digit

key :Set value carry key

key :Set value inclement key

key :Set value initialization key

1 000〜99 990

It can be increased continuously by the

continuity press of the key.

Press the key.

The load display will show “Z MV”.

7

10

26

Page 40

Procedures

y

:

y

8

extra

digits

are

necessary

for

the

key:Set

value

initialization

key

Press the key.

The load display will show “0.0000”, and the

digit of 10

calibration has completed already, the registered

output value of load cell at that time will be

displayed.

Set the output value for load cell with the initial

load application with the right keys.

0

will flash on and off. In case that

Though the number of digits has not

prepared in the ”Inspection data” for load

cell so many as shown in the right figure,

compensation with the standard point at

internal of the instrument.

In case of actual setting, insert “0”, into the

extra digits.

As for the value for extra digit, when tare

compensation and fine adjustment on load

are applied, it will be rewritten as a

compensated value automatically.

Setting range for the output of load cell is

from −0.3 mV/V to 2.400 0 mV/V.

key :Set value carry key

key :Set value inclement key

ke

Setvalue initialization ke

It can be increased continuously by the

continuity press of the key.

Press the key.

The load display will show “S MV”.

9

27

Page 41

Procedures

yyy

Press the key.

The load display will show “0.5000” and the digit

0

will flash on and off.

at 10

In case that calibration has completed already,

the registered output value of load cell at that

time will be displayed.

The output value of the load cell which

corresponds to the maximum indicated value set

according to the procedure 8 is set with the right

keys.

key :Set value carry key

The set value to be set here should be

0.4 mV/V or more than the set value in the

step 8.

10

Though the number of digits has not

prepared in the Inspection data for load cell

as many as the digits in the right figure,

extra digits are necessary for the

compensation for the internal standard

point of the instrument.

In case of actual setting, insert “0” into the

extra digits.

As for the value of extra digits, when tare

compensation and fine adjustment on load

are applied, it will be written as a

compensated value automatically.

It can be increased continuously by the

continuity press of the key.

Press the key.

The load display will show the “END”.

11

key :Set value inclement key

key :Set value initialization key

Press the key.

After “ACAL” mode is over, the load display will

show the present load.

12

28

Page 42

5−2−3. Calibration method to register by reading output value of strain gage applied

transducer in the conditions of zero/actual load application individually.

(1) Procedures by the key operation

Warning ● Before using a new instrument or exchanging the strain gage applied

transducer for a new one, be sure to make calibration.

If calibration shall not be made, correct measured results may not be

obtained nor may cause malfunction in the instrument and there may

exist damage in peripheral equipments.

Besides, even though calibration has been made, there may occur the

similar case when the result is not correct, so make calibration again.

● During the calibration is executing, be sure to set Tare weight

cancellation clear, and to make cancellation (Execution of F−98) for

compensated data on zero set and set the OFF position of Zero

tracking(Setting “00000” on F−07 and F−08), and also set the OFF

position of Peak.

● During calibration procedures, press the key in case of

interrupting the calibration is required. The calibration data will be

kept as they are before entering the calibration and then returns to

the Measurement mode.

● Every time the key is pressed with the load display of “FUNC”,

the display will change as the following arrow marks. However, every

time the is pressed, the display will change as the reverse

direction of the following arrow marks.

“FUNC”→“CCAL”→“ACAL”→“LCAL”→“ZERO”→“SPAN”→

“TARE”→“CHEK”→“MONT”→“VCAL”→“VADJ”→“FUNC”→

“CCAL”→・・・・・ (Hereinafter, it will repeat.)

29

Page 43

Procedures

Press the key for about one second.

The load display will show “FUNC”.

1

Press the key three times.

It will make the load display proceed as

“FUNC”→“CCAL”→“ACAL”→“LCAL”.

2

Press the key.

“LCAL” mode can be entered, then the load

display will show “SCAL”.

3

Press the key.

The load display shows “D−01”.

When the calibration has completed already, the

set value of minimum scale registered at that

time will be displayed.

4

Set the minimum scale with the right keys.

Setting value for the minimum scale will be 4

(four) as follows:

1, 2, 5, 10

Press the key.

The load display will show “DISP”.

5

key :Set value inclement key

30

Page 44

Procedures

Press the key.

The load display shows “2000” and the minimum

display digit will flash on and off.

When the calibration has completed already, the

maximum display value which has registered at

that time will be displayed.

By the setting of minimum scale, the digit

of minimum display that flashes on and off

will be as follows:

The minimum scale 1,2,5 10

The minimum scale 10 10

0

1

digit

digit

key :Set value carry key

key :Set value inclement key

Set the maximum display value with the right

keys. Setting range for the maximum display

value will be (the minimum scale×100)〜99 990.

In order to make effective use of the performance,

6

set within the following ranges.

When setting is made over the range as below,

there may have a possibility of unstable display

and so on.

Setting range for the

maximum display value

100〜10 000

200〜20 000

500〜50 000

1 000〜99 990

The minimum scale

1

2

5

10

It can be increased continuously by the

continuity press of the key.

Press the key.

The load display will show “LOAD”.

key :Set value initialization key

7

31

Page 45

Procedures

pp

The

load

value

applied

on

the

load

cell

should

be

key:Setvalueinitializati

y

Press the key.

The load display will show “2000”, and the digit

0

will flash on and off.

of 10

In case that calibration has completed already,

the registered output value of load cell at that

time will be displayed.

By thesettingof minimum scale, thedigit

of minimum display that flashes on and off

will be as follows:

The minimum scale 1,2,5 10

8

The minimum scale 10 10

0

digit

1

digit

key :Set value carry key

Set the actual load value going to apply on the

load cell with the right keys.

The load value a

less than the maximum display value set in the

step 6 and should be the maximum load that can

apply on the load cell with the range of (the

minimum scale ×100)〜99 999 as well.

lied on theload cell shouldbe

It can be increased continuously by the

continuity press of the key.

Press the key.

The load display will show “ZERO”.

Here, set the initial load application.

9

key :Set value inclement key

onke

32

Page 46

Procedures

e

Press the key.

The “ZERO” on load display will flash on and

off, and zero adjustment can be started.

Warning :Take care not to apply load

variations due to vibrations and so on.

If load variation is applied, the zero point

will not stabilized, in due course there is a

possibility that correct reading of zero

won’t be obtained.

When completed, the display on the load display

will show “SPAN”.

However, when the initial load is not entered the

10

range of −0.3 mV/V to 2.4 mV/V, the right Error

code will be shown for about 2 seconds, then the

display on the load display section will be shown

as “ZERO”, and then the procedure 9 can be

entered.

TE−L:Zero point −OVER

TE−H:Zero point +OVER

Error code

Apply thesame load on theload cell as setin th

11

step 8.

Error code

33

Page 47

12

Procedures

Press the key.

The “SPAN” on the load display will flash on

and off, and span adjustment can be started.

Warning :Take care not to apply load

variations due to vibrations and so on.

If load variation is applied, the span will

not stabilized, in due course there is a

possibility that correct reading of span

won’t be obtained.

When completed, the display on the load display

will show “END”.

However, when the value corresponding to the

maximum display value does not satisfy the

range from 0.4 mV/V to 3.1 mV/V, the right

Error code will light up for about 2 seconds, then

the display on the load display section will show

“SPAN”, and then returns to the step 10.

SP−L:Span − Over

SP−H:Span + Over

Error code

Press the key.

After “LCAL” mode is over, the load display will

showthepresent load.

13

Error code

34

Page 48

5−2−4. Zero fine adjustment

(1) Procedures by key operation

● During the Tare weight cancellation(A/Z) or Zero set is executed, and

also during effective for Zero tracking and Peak ON, Zero fine

adjustment mode can’t be entered into. (Displays ER−5.)

The Zero fine adjustment can be entered after Tare weight

cancellation clear(A/Z OFF), cancellation of the Compensated data at

Zero set (Execution of F−98), set OFF the Zero tacking (Set the

F−08 and F−09 to “00000”.) and set the Peak OFF.

● During the calibration procedure, press the key to interrupt the

calibration. The calibration data will keep the same condition as it is

entered before, then returns to the Measurement mode.

● When the key is pressed with the load display of “FUNC”, the

display will change as the following arrow marks indicate at every

time the key is pressed. However, every time the is pressed, the

display will change as the reverse direction of the following arrow

marks.

“FUNC”→“CCAL”→“ACAL”→“LCAL”→“ZERO”→“SPAN”

→“TARE”→“CHEK”→“MONT”→“VCAL”→“VADJ”→“FUNC”

→“CCAL”→・・・・・(Hereinafter, it will repeat.)

Procedures

Press the key for about one second.

The load display will show “FUNC”.

1

Press the key four times.

It will make the load display proceeded as

“FUNC”→“CCAL”→“ACAL”→“LCAL”

→“ZERO”.

2

Here, set the initial load application.

35

Page 49

Procedures

5

Press the key.

Zero fine adjustment mode can be entered, then

the display on load display will show the present

load value and lights on and off. At the same

time, set the present load value to “0” with the

right keys.

It can be increased continuously by the

3

continuity press of the key.

key :Zero fine adjustment

display decreasing key

The variation of load value for one push of

the right key is less than 1 digit of display.

Therefore, a few pushes of these keys are

required to get the change of 1 digit of

display value.

Press the key.

The indication of load display will show “END”.

4

Press the key.

After quitting from zero fine adjustment mode,

the load display will show the present load value.

key :Zero fine adjustment

display increasing key

36

Page 50

5−2−5. Span fine adjustment

(1) Procedures by key operation

● During the Tare weight cancellation(A/Z) or Zero set is executed, and

also during effective for Zero tracking and Peak ON, Span fine

adjustment mode can’t be entered into. (Displays ER−5.)

The Span fine adjustment can be entered after Tare weight

cancellation clear(A/Z OFF), cancellation of the Compensated data at

Zero set (Execution of F−98), set OFF the Zero tacking (Set the F−08

and F−09 to “00000”.) and set the Peak OFF.

● During the calibration procedure, press key to interrupt the

calibration. The calibration data will keep the same condition as it is

entered before, then returns to the Measurement mode.

● When the key is pressed with the load display of “FUNC”, the

display will change as the following arrow marks indicate at every

time the key is pressed. However, every time the is pressed, the

display will change as the reverse direction of the following arrow

marks.

“FUNC”→“CCAL”→“ACAL”→“LCAL”→“ZERO”→“SPAN”

→“TARE”→“CHEK”→“MONT” →“VCAL”→“VADJ”→“FUNC”

→“CCAL”→・・・・・(Hereinafter, it will repeat.)

Procedures

Press the key for about one second.

The load display will show “FUNC”.

1

Press the key five times.

It will make the load display proceeded as

“FUNC”→“CCAL”→“ACAL”→“LCAL”

→“ZERO”→“SPAN”.

2

Please give the maximum load which can be

applied to the load cell here below the maximum

indicated value.

37

Page 51

Procedures

5

Press the key.

Span fine adjustment mode can be entered, then

the display on load display will show the present

load value and lights on and off. At the same

time, adjust the present load value to be the same

load applied on the load cell with the right keys.

It can be increased continuously by the

3

continuity press of the key.

The variation of load value for one push of

the right key is less than 1 digit of display.

Therefore, a few pushes of these keys are

required to get the change of 1 digit of

display value.

Press the key.

The indication of load display will show “END”.

4

key :Span fine adjustment

display decreasing key

key :Span fine adjustment

display increasing key

Press the key.

After quitting from zero Span fine adjustment

mode, the load display will show the present load

value.

38

Page 52

5−2−6. Calibration procedure to apply registration again for zero point only

(1) Procedures by key operation

Warning ● During the execution of calibration, be sure to set the Tare weight

cancellation clear, cancellation of the Compensated data at Zero set

(Execution of F−98), and set OFF the Zero tacking (Set the F−08 and

F−09 to “00000”.) and set the Peak OFF.

● During the calibration procedure, press the key to interrupt the

calibration. The calibration data will keep the same condition as it is

entered before, then returns to the Measurement mode.

● When the key is pressed with the load display of “FUNC”, the

display will change as the following arrow marks indicate at every

time the key is pressed. However, every time the is pressed, the

display will change as the reverse direction of the following arrow

marks.

“FUNC”→“CCAL”→“ACAL”→“LCAL”→“ZERO”→“SPAN”

→“TARE”→“CHEK”→“MONT” →“VCAL”→“VADJ”→“FUNC”

→“CCAL”→・・・・・(Hereinafter, it will repeat.)

Procedures

Press the key for about one second.

The load display will show “FUNC”.

1

Press the key six times.

It will make the load display proceeded as

“FUNC”→“CCAL”→“ACAL”→“LCAL”

→“ZERO”→“SPAN”→“TARE”.

2

Here, set the initial load application.

39

Page 53

Procedures

Press the key.

The “TARE” mode can be entered.

The display on the load display section will show

“ZERO”.

3

Press the key.

The display of “ZERO” on the load display

section will flash on and off, and Tare weight

cancellation will be entered.

Warning :At the same time, care should

be taken not to apply load variation due to

vibration and so on.

If load variation is applied, zero point

becomes unstable, so there is a possibility

that correct zero can’t be read.

When completed, the indication of load

display will show “END”.

However, when the initial load isn’t entered

4

within the range of −0.3 mV/V and 2.4 mV/V,

the error code in the right will be shown for

about 2 seconds, then the display on the load

display will show “TARE”, and returns to the

step 2.

TE−L:Zero point −OVER

TE−H:Zero point +OVER

Press the key.

After quitting from the “TARE” mode, the load

display will showthepresent load value.

5

Error code

Error code

40

Page 54

5−3. Selection of calibration methods on each condition

The instrument prepares calibration methods shown in the paragraph in **タグなし**.

Calibration procedures, we’ll explain some conditions to execute actual calibration here.

(1) When executing calibration on the new instrument.

(In case that Combined Inspection at Minebea has not executed.)

D When load condition and output condition of load cell are clarified.

(Required accuracy is less than 1/1 000 or so.)

→Proceed to the paragraph 5−3−1(1)

D When load condition and output condition of load cell are clarified.

(Required accuracy is more than 1/1 000 or so.)

→Proceed to the paragraph 5−3−1(2)

D When load condition is clarified, but output condition of load cell is unclear.

→Proceed to the paragraph 5−3−1(3)

D When exchanging with existing CSD−701B is required.

→Proceed to the paragraph 5−3−1(4)

(2) When making calibration again.

D When calibration only for tare weight is required.

(In case that the combined Inspection at Minebea has already executed, and the calibration

only for tare weight is required.)

D When fine adjustment on zero and span is required.

5−3−1. In case of executing the calibration on the instrument newly.

When the new instrument is purchased or reuse is desired with the new specific conditions,

execute the calibration with whichever procedure as follows:

(1) When the load condition and the output condition of load cell are clarified.

(In case of desired accuracy is less than 1/1000 or so.)

Warning ● The calibration accuracy obtained in this procedure is less than

1/1 000 or so. When precise accuracy more than 1/1 000 is necessary,

make calibration with actual load according to the paragraph 5−3−1

(2).

Besides, the accuracy described here is a combined accuracy of the

instrument and the strain gage applied transducer connected.

If there may exist another factors of error such as mechanical

elements and so on, it will become out of warranty, so care should be

taken fully.

● The rated output value for load cell applicable by the calculation

should be assumed as the value described on the “Inspection data”

individually.

41

Page 55

5−2−1For example, we will show the calibration procedures as follows, that is, 3 points of load

cells with 3 mV/V of rated output and 5 t of rated capacity.

Tare weight 1.5 t

Weighing capacity 5 t

Maximum display 5 000

1

Calculate the output of load cell at maximum display from the above conditions. Check that

the calculated value should be within the range from 0.4 mV/V to 3.1 mV/V. If the value is out

of the range, calibration can’t be executed.

(Output of load cell at maximum display)

(Rated output)+(Rated output)+(Rated output)

=

3 mV/V+3 mV/V+3 mV/V

=

1 mV/V

=

2

After making the load cell to the initial load condition (tare weight), execute the calibration

according to the paragraph 5−2−1. In this case, input “5000” in the step 6, and input “1.0000”

in the step 8 individually.

3

If necessity requires, apply zero/span fine adjustment according the paragraph 5−2−4, and

5−2−5.

(2) When the both conditions of load and the output of load cell are clarified.

(In case that required accuracy is more than 1/1 000 or so.)

Number of load cells

3 points

×

3 points×5t

5t

×

(No. of load cells)×(Rated load)

Weighing capacity

Warning ● The accuracy obtained through the procedures of this calibration

consists from combined accuracy with the instrument and combined

strain gage applied transducer, the accuracy of weight used during the

calibration, error factors on mechanical and also error factors on

calibration works, that is, the total accuracy of these. If high accuracy

is required, full considerations should be made on each factor. If

neglected, there will be a case that desired accuracy may not be

obtained, so care should be taken fully.

When high accuracy is required, actual load calibration by using the weight and so on are

required.

For example, we’ll show the calibration procedures in the following conditions, that is, 3 points

of load cell with 3 mV/V of rated output and 5 t of rated capacity.

Tare weight 1.5 t

Weighing capacity 5 t

Maximum display 5 000

42

Page 56

1

Calculate the output of load cell at the maximum display from the above conditions.

Check that the calculated value at this point is within the range from 0.4 mV/V to 3.1 mV/V.

If the value is out of the range, calibration cant’ be executed.

(Output of load cell at maximum display)

(Rated output)+(Rated output)+(Rated output)

=

Number of load cells

3 mV/V+3 mV/V+3 mV/V

=

1 mV/V

=

2

After making the load cell to the initial load condition (tare weight), execute the calibration

3 points

×

5t

3 points×5t

×

Weighing capacity

(No. of load cells)×(Rated load)

according to the paragraph 5−2−3. In this case, input “5000” in the step 6, and input the load

value applied on the load cell in the step 8 individually.

3

If necessity requires, apply zero/span fine adjustment according the paragraph 5−2−4, and

5−2−5.

(3) When the load condition is clarified but the output condition of load cell is not clarified.

In the case of using the existing load detecting section, and adopting the new digital indicator

only, it is necessary to execute calibration after checking the output of load cell when its

output is not clarified.