Page 1

Tel: 763. 571.3121 • Fax: 763. 571.0927 • www.minco.com

TT115/TT155/TT165/TT297 TemptranTM

2-wire Temperature Transmitter for RTD Thermometers

Installation and Operating Instructions

Page 2

Minco Tel: 763. 571.3121 • Fax: 763. 571.0927 • www.minco.com 2

Description

Designed for use in room air applications, model TT115/TT155/TT165 is a 2-wire temperature

transmitter for RTD (Resistance Temperature Detector) thermometers. The TemptranTM

converts the RTD's signal into a 4 to 20 mA DC current. The current changes according to the

range in which the Temptran is calibrated: 4 mA at the lowest temperature of the range, rising

to 20 mA at the top of the range. The leads that supply power also carry the current signal.

Note: Transmitter circuit board only, Room Air housing and RTD sold separately.

Specifications

Sensing Element:

100 ohm platinum RTD, 0.00392 ohm/ohm/°C TCR,

100 ohm platinum RTD, 0.00391 ohm/ohm/°C TCR,

100 ohm platinum RTD, 0.00385 ohm/ohm/°C TCR,

1000 ohm platinum RTD, 0.00385 ohm/ohm/°C TCR

1000 ohm platinum RTD, 0.00375 ohm/ohm/°C TCR

Output:

4 to 20 mA DC over specified range, limited to 30mA maximum.

Calibration Accuracy:

± 0.1% of Span

Transmitter Linearity:

± 0.1% of Span.

Physical:

Printed circuit board designed to mount inside the S470 series

thermostat housing with RTD

Operating Environment:

32° to 122°F (0° to 50°C), non-condensing.

Storage Environment:

-67° to 212°F (-55° to 100°C), non-condensing.

Ambient Temperature

Effects:

± 0.007% Span/°F (± 0.014% Span/°F for Spans < 100°F)

Warm-up Drift:

± 0.1% of Span max., assuming Vsupply = 24 VDC and Rloop =

250 ohms. Stable within 30 minutes.

Supply Voltage:

8.5 to 35 volts DC, non-polarized.

Input Voltage Effect:

± 0.001% of span per volt from 8.5 to 35 VDC.

Maximum Load

Resistance:

The maximum allowable resistance of the signal-carrying loop,

including extension wires and load resistance, is given by this

formula: Rloop max = (Vsupply-8.5)/.02 amps. For example, if

the supply voltage is 24 VDC, the loop resistance must be less

than

775 .

System Integration:

Output “High” (22-28mA) with sensor open. Output “Low”

(3.3-3.7mA) with sensor shorted.

Zero and Span

Adjustment:

Non-interacting, Zero and Span ±5%.

Maximum Output

Current:

30 mA.

Power Connections:

Screw terminals, non-polar (connect either way).

Sensor Connections:

Screw terminals, non-polar (connect either way).

Page 3

Minco Tel: 763. 571.3121 • Fax: 763. 571.0927 • www.minco.com 3

Installation

Locate the Temptran near the RTD, in an area where the ambient temperature stays between

the temperature range of the output.

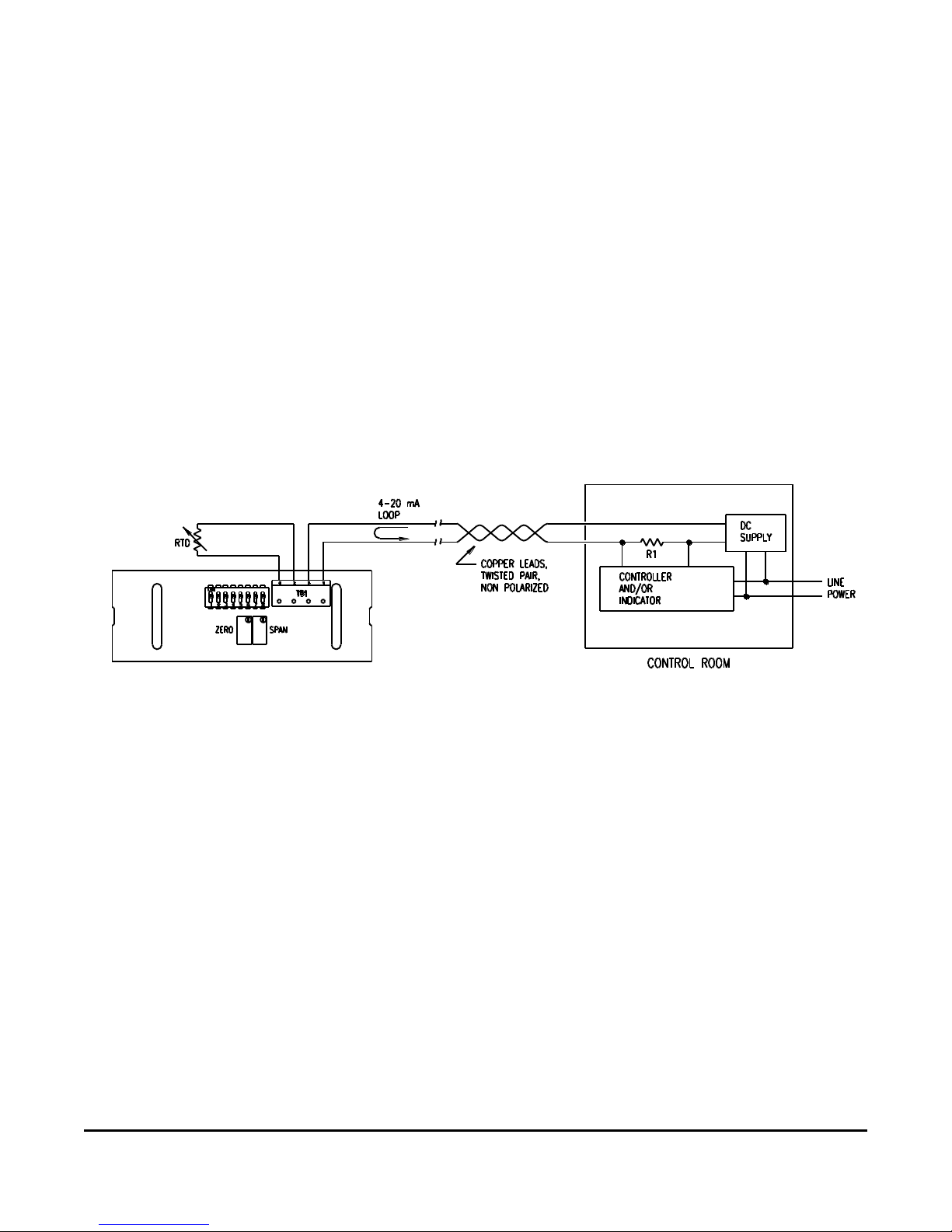

Connect the Temptran as shown in the wiring diagram below. The transmitter’s power and RTD

connections are designed for non-polar hook-up, so polarity is not important. The maximum

DC supply should not exceed 35 VDC. For the RTD, good connections are a must, a few ohms

of resistance in the connection could cause an error of several degrees.

The Temptran has been factory-calibrated to its marked temperature range or to a specific

RTD, do not change its Zero or Span adjustments.

Wiring Diagram

Figure 1

Power Supply

DC power supply requirements are determined by the transmitter’s minimum voltage

requirement and voltage drop across the load resistor and installation lead wires.

Example: The transmitter requires 8.5 Volts minimum. A typical 250 ohm load resistor drops 5.0

Volts @ 20 mA. Allowing a margin of 0.5 Volts for the supply permits 25 ohms of lead wire

resistance for remote installation. Totaling these, we get a minimum power supply requirement

of 14 VDC.

Using a 24 VDC power supply will take care of nearly all installations, but the transmitter will

operate at voltages up to 35 VDC.

Page 4

Minco Tel: 763. 571.3121 • Fax: 763. 571.0927 • www.minco.com 4

Calibration Procedure

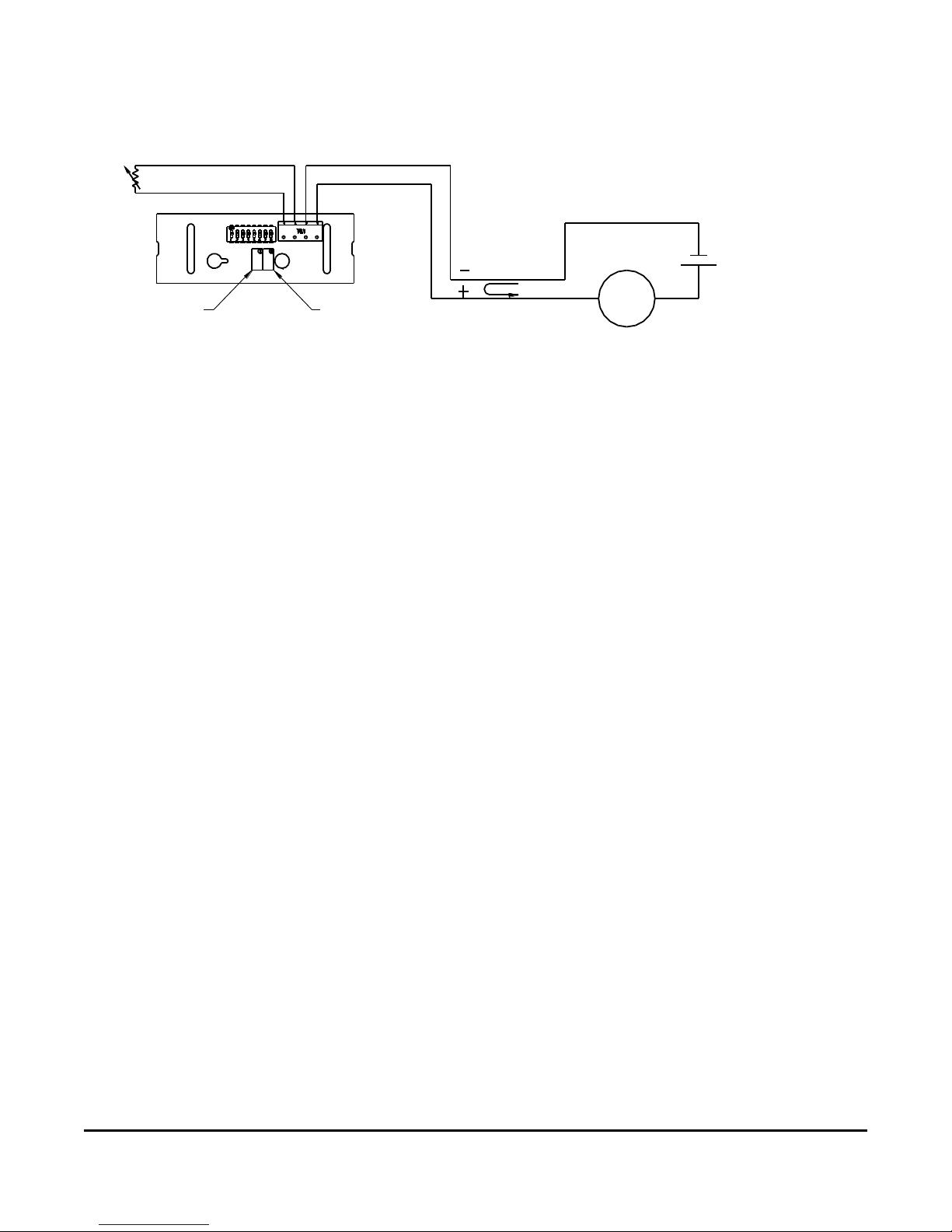

1. Connect the equipment as shown below (Figure 2) substituting a resistance decade box,

with resolution of at least 0.01 ohm, in place of the RTD.

DECADE

BOX

SPAN ADJ.

ZERO ADJ.

4-20 mA

LOOP

mA

INDICATOR

24 VDC

POWER SUPPLY

Figure 2

2. Determine sensor resistance corresponding to the lower and upper temperature range of

the transmitter from Tables 3 and 4 (page 6). Using “RTD Calc” a more complete resistance

vs. temperature chart can be printed; Download it from Minco’s web site, www.minco.com.

3. Set the decade box to the resistance value corresponding to the lower temperature. Adjust

the Zero pot until the milliammeter reads 4.0 mA +/- 0.016 mA.

4. Set the decade box to the resistance value corresponding to the upper temperature. Adjust

the Span pot until the milliammeter reads 20.0 mA +/- 0.016 mA.

5. Set the decade box to the resistance value corresponding to the lower temperature and

verify that the milliammeter still reads 4.0 mA +/- 0.016 mA. Correct if necessary, then

repeat steps 4 and 5.

Transmitter Ranging

The transmitter is initially calibrated to a specific temperature range, as shown on the label

attached to the housing. Unless a different range is desired, ranging is not necessary. If the

temperature range is changed, recalibrate the transmitter as described in the section,

Calibration Procedure.

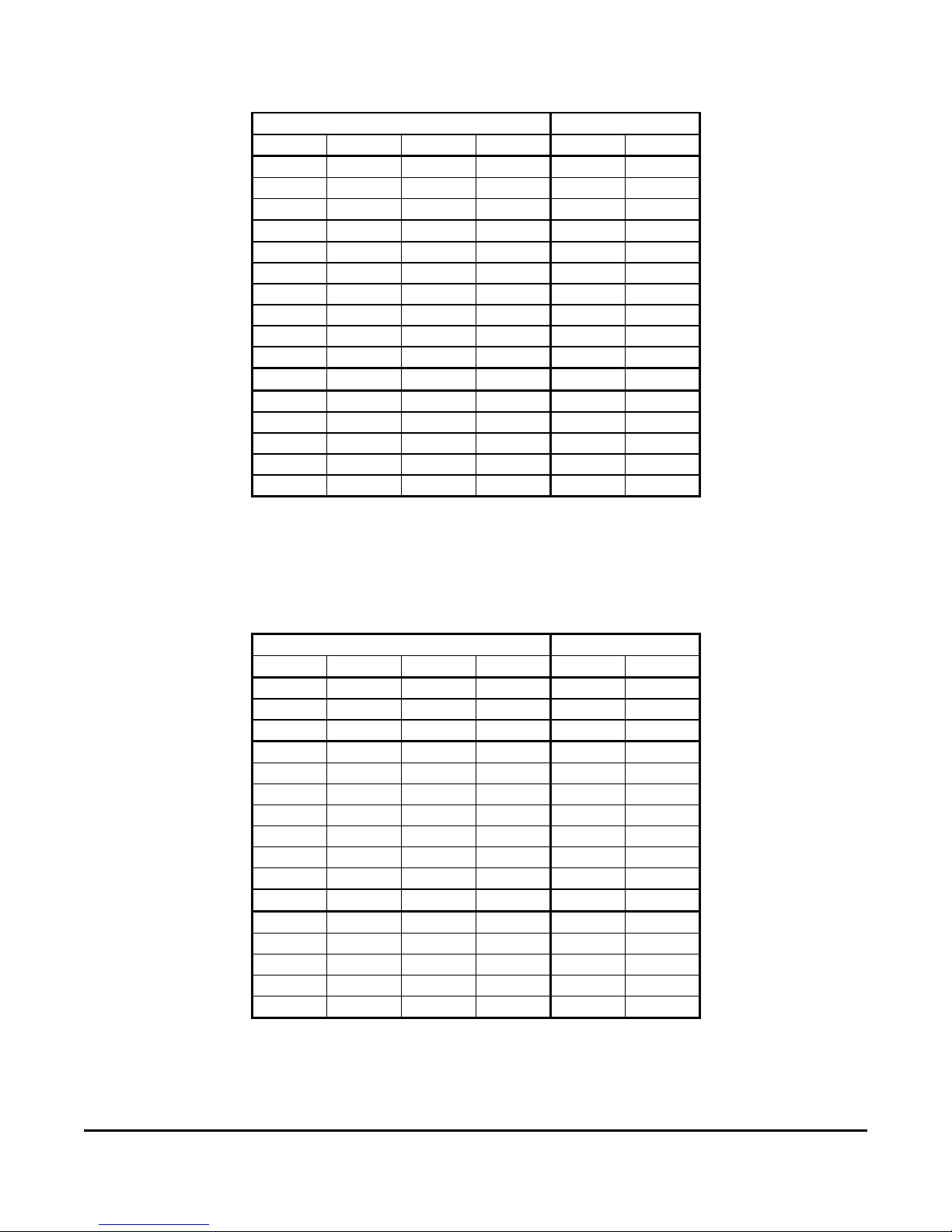

When a different temperature range is desired, Tables 1, 2, 3, and 4 (Pages 5 and 6) provide

range switch settings corresponding to the various temperature ranges. Switches 1 to 4 set the

lower temperature limit (Zero) of the transmitter. Switches 5 to 8 set the upper minus lower

temperature (Span) of the transmitter.

For example, a temperature range of 30 to 90°F has a Zero of 30°F and a Span of 60°F (90-30).

Table 1 shows the closest Zero range is 30°F with switches 1 through 4, respectively, in the OFF,

ON, ON, and OFF positions. Likewise, Table 2 shows the closest Span range is 58°F with

switches 5 through 8, respectively, in the ON, ON, OFF, and ON positions. Once the switches

are set, the Zero and Span trim pots should provide sufficient adjustments to calibrate the

transmitter.

Page 5

Minco Tel: 763. 571.3121 • Fax: 763. 571.0927 • www.minco.com 5

In the event that the trim pots do not have sufficient adjustments, the switch settings should

then be changed. In the above example, if the Zero trim pot cannot adjust the transmitter

current down to 4mA with the 30°F Zero switch settings, then the Zero switch settings should

then be changed to 39°F (OFF, ON, OFF and ON) which is the next higher range. Likewise if the

Span trim pot does not have sufficient adjustment, then the Span switch settings should be

changed.

Page 6

Minco Tel: 763. 571.3121 • Fax: 763. 571.0927 • www.minco.com 6

Zero Switch Settings for 100 Ohm PT Elements

Table 1

Span Switch Settings for 100 Ohm PT Elements

(Upper Minus Lower Temperature Limits)

Table 2

* Span = Upper - Lower Temperature. Zero ranges overlap next adjacent range.

Switch Settings

Center Point

1 2 3 4 °F

°C

ON

ON

ON

ON

-71

-57

ON

ON

ON

OFF

-62

-52

ON

ON

OFF

ON

-53

-47

ON

ON

OFF

OFF

-44

-42

ON

OFF

ON

ON

-33

-36

ON

OFF

ON

OFF

-24

-31

ON

OFF

OFF

ON

-15

-26

ON

OFF

OFF

OFF

-6

-21

OFF

ON

ON

ON 3 -16

OFF

ON

ON

OFF

14

-10

OFF

ON

OFF

ON

23

-5

OFF

ON

OFF

OFF

32

0

OFF

OFF

ON

ON

41

5

OFF

OFF

ON

OFF

52

11

OFF

OFF

OFF

ON

61

16

OFF

OFF

OFF

OFF

73

23

Switch Settings

Center Point

5 6 7 8 °F

°C

ON

ON

ON

ON

43

24

ON

ON

ON

OFF

52

29

ON

ON

OFF

ON

63

35

ON

ON

OFF

OFF

74

41

ON

OFF

ON

ON

85

47

ON

OFF

ON

OFF

94

52

ON

OFF

OFF

ON

103

57

ON

OFF

OFF

OFF

113

63

OFF

ON

ON

ON

124

69

OFF

ON

ON

OFF

135

75

OFF

ON

OFF

ON

144

80

OFF

ON

OFF

OFF

153

85

OFF

OFF

ON

ON

164

91

OFF

OFF

ON

OFF

175

97

OFF

OFF

OFF

ON

184

102

OFF

OFF

OFF

OFF

193

107

Page 7

Minco Tel: 763. 571.3121 • Fax: 763. 571.0927 • www.minco.com 7

Zero Switch Settings for 1000 Ohm PT Elements

Table 3

Span Switch Settings for 1000 Ohm PT Elements

(Upper Minus Lower Temperature Limits)

Table 4

* Span = Upper - Lower Temperature. Zero ranges overlap next adjacent range.

Switch Settings

Center Point

1 2 3 4 °F

°C

ON

ON

ON

ON

-71

-57

ON

ON

ON

OFF

-62

-52

ON

ON

OFF

ON

-53

-47

ON

ON

OFF

OFF

-44

-42

ON

OFF

ON

ON

-33

-36

ON

OFF

ON

OFF

-24

-31

ON

OFF

OFF

ON

-15

-26

ON

OFF

OFF

OFF

-6

-21

OFF

ON

ON

ON 3 -16

OFF

ON

ON

OFF

14

-10

OFF

ON

OFF

ON

23

-5

OFF

ON

OFF

OFF

32

0

OFF

OFF

ON

ON

41

5

OFF

OFF

ON

OFF

52

11

OFF

OFF

OFF

ON

61

16

OFF

OFF

OFF

OFF

73

23

Switch Settings

Center Point

5 6 7 8 °F

°C

ON

ON

ON

ON

43

24

ON

ON

ON

OFF

52

29

ON

ON

OFF

ON

63

35

ON

ON

OFF

OFF

74

41

ON

OFF

ON

ON

85

47

ON

OFF

ON

OFF

94

52

ON

OFF

OFF

ON

103

57

ON

OFF

OFF

OFF

113

63

OFF

ON

ON

ON

124

69

OFF

ON

ON

OFF

135

75

OFF

ON

OFF

ON

144

80

OFF

ON

OFF

OFF

153

85

OFF

OFF

ON

ON

164

91

OFF

OFF

ON

OFF

175

97

OFF

OFF

OFF

ON

184

102

OFF

OFF

OFF

OFF

193

107

Page 8

Minco (Main Office) Customer Service/ Minco S.A.

7300 Commerce Lane Order Desk: Usine et Service

Minneapolis, MN Tel: 1.763.571.3123 Commercial, Z.I.

55432 Fax: 1.763.571.0942 09310 Aston, France

USA custserv@minco.com Tel: (33) 5 61 03 24 01

Tel: 1.763.571.3121 www.minco.com Fax: (33) 5 61 03 24 09 Stock # 360-00092(B) 103395

Fax: 1.763.571.0927

www.minco.com

How to Order

TT115

Model Number:

TT115 = Nominally calibrated transmitter

TT155 = Calibrated with thermometers so output tracks temperature within

±0.75% of temperature Span

TT165 = Calibrated with thermometers so output tracks temperature within

±0.50% of temperature Span

TT297 = Calibrated with thermometers so output tracks temperature within

±0.20% of temperature Span

PD

Resistance thermometer type: RTD Temptran

PA = 100 Platinum (.00392)

PB = 100 Platinum (.00391)

PD = 100 Platinum (.00385)

PE = 100 Platinum (.00385)

PF = 1000 Platinum (.00385)

PW = 1000 Platinum (.00375)

1

4-20 mA DC Output

H

Temperature Range (4 mA Temp/20 mA Temp):

H = 40 to90°F ( 4 to32°C)

Consult factory for current list of available ranges.

TT115PD1H Sample part number

Warranty

Items returned within three years from the date of sale, transportation prepaid, which Minco

Products, Inc. (the “seller”) reasonably determines to be faulty by reason of defective materials

or faulty workmanship will be replaced or repaired at the seller’s discretion, free of charge.

This remedy is to be the sole and exclusive remedy available to the buyer in the event of a

breach by the seller. Items that show evidence of mishandling or misapplication may be

returned by the seller at the customer’s expense.

Furthermore, the seller is not to be held responsible for consequential damages caused by this

product except as required under Minnesota Statutes, Section 336.1-719 (3).

This warranty is in lieu of any other expressed warranty or implied warranty of merchantability

or fitness for a particular purpose, and of any other obligations or liability of the seller or its

employees or agent.

Loading...

Loading...