Page 1

CT224

12-Channel Temperature Monitor

Installation and Operating Instructions

Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com

Page 2

This page left blank intentionally.

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 2

Page 3

Table Of Contents

1. Introduction

2. Pre-Installation

3. Installation

A. Mounting

B. Wiring

1.) Controller Power

2.) Inputs

3.) Outputs

4.) Serial Communications

4. Programming Configuration

A. Using the CT224

1.) Modes / Buttons

B. Entering the Program Settings

C. Setup Worksheet

5. Communications

A. Function Codes

B. Memory Map

6. Specifications

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 3

Page 4

1. Introduction

The CT224 is a universal 12-channel monitor capable of monitoring inputs for any combination of

RTDs, Thermocouples, and 4-20mA loop inputs. The CT224 has 5 outputs, 4 of the outputs can be

used for warning or shutdown signals, the other output is dedicated to signaling alarm conditions.

One internal audible alarm is also present. RS485 or RS232 Serial Communications is also included

on the CT224 and allows use of the Modbus Protocol to communicate data with another device.

MincoSoft CT224 Software is also provided to allow easy communication with the CT224 by using a

computer.

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 4

Page 5

2. Pre-Installation

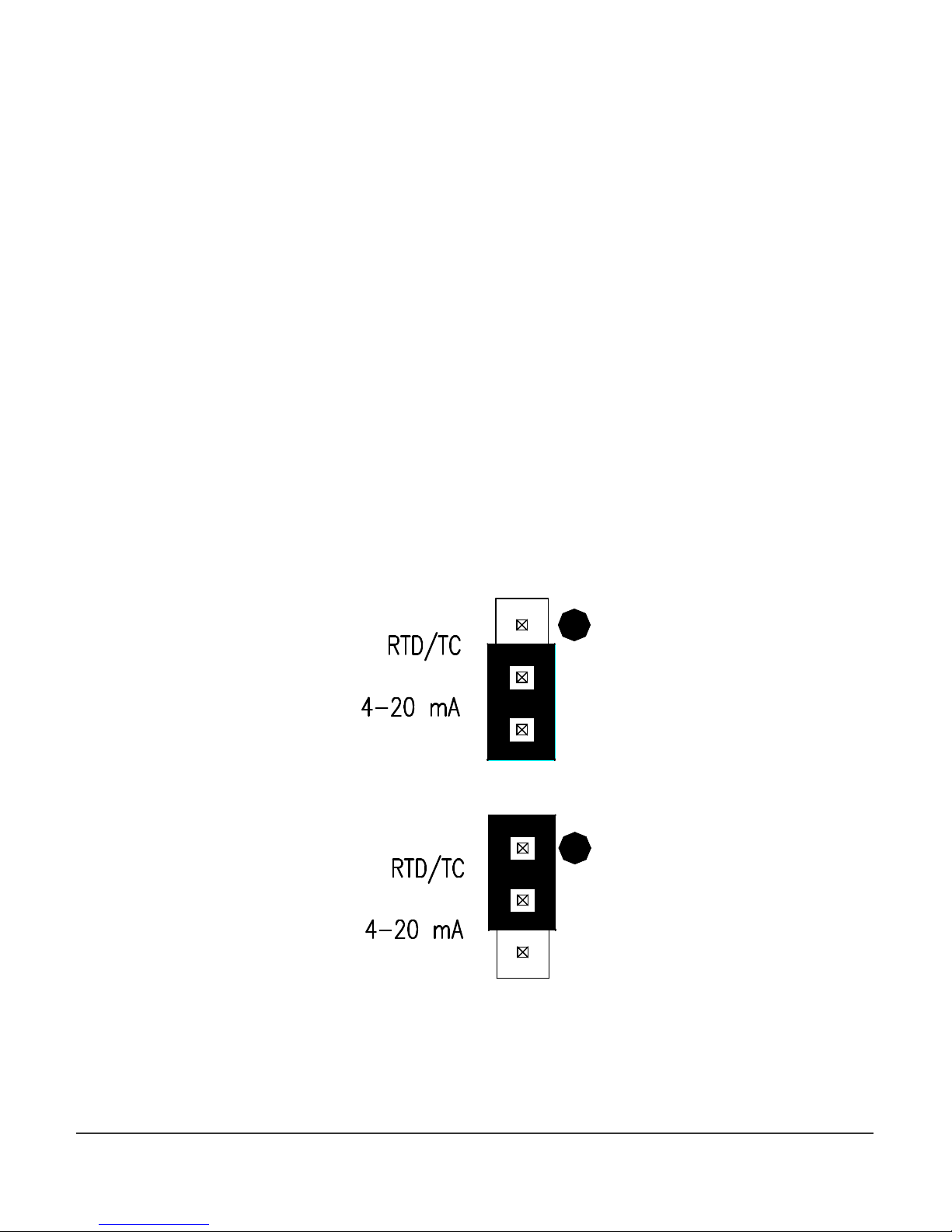

Figure 1

– Jumper

in position for 4

-

20mA Inputs

The first step before installing the CT224 is to determine the input types that will be used. If analog

4-20mA signals will be used as inputs, jumpers under the rear cover will need to be changed. When

received, the jumpers are set to allow RTD and thermocouple inputs on all input channels. Analog

inputs require that the jumpers be moved to the 4-20mA setting. Follow the simple steps below to

allow 4-20mA loop inputs:

1. Remove the 4 screws that hold the rear cover on. (Do not remove the other 4 screws

that go directly through the board.)

2. Set the rear cover aside.

3. Look at the top of the CT224. There is one jumper for each channel located next to the

corresponding channels terminal block. For all of the channels that will be used for 420mA inputs, set the jumper to the position away from the dot. Figure 1 shows a

jumper in the position to allow 4-20mA loops. Leave the jumpers for the other

channels that will be used for RTDs and thermocouples in the dot position. Figure 2

shows a jumper in the position for RTD and Thermocouple inputs.

4. Replace the rear cover and screws.

The CT224 is now ready to accept 4-20mA inputs on the channels that are set like the jumper shown

in Figure 1.

Figure 2 – Jumper in position for RTD or Thermocouple Inputs

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 5

Page 6

3. Installation

A. Mounting

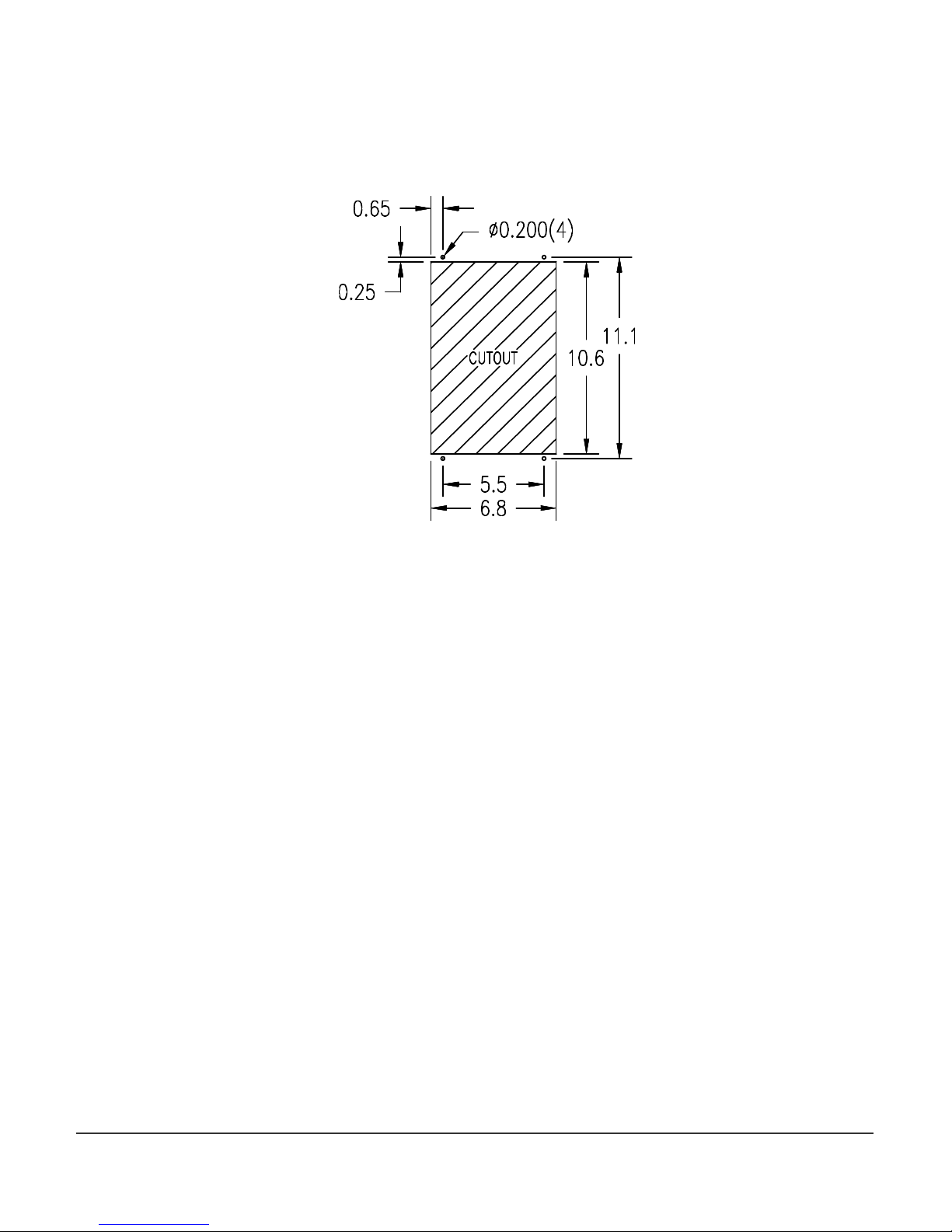

Make a rectangular cut out in the panel where the CT224 will be located. The cutout should

be made according to Figure 3.

Slide the CT224 into the cut out, drill holes for the screws or bolts that will fasten the unit to

the panel. Be sure that the gasket around the CT224 is compressed between the front cover

and the panel so that liquid and debris cannot get behind and inside of the panel.

Figure 3 – Panel Cutout

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 6

Page 7

B. Wiring

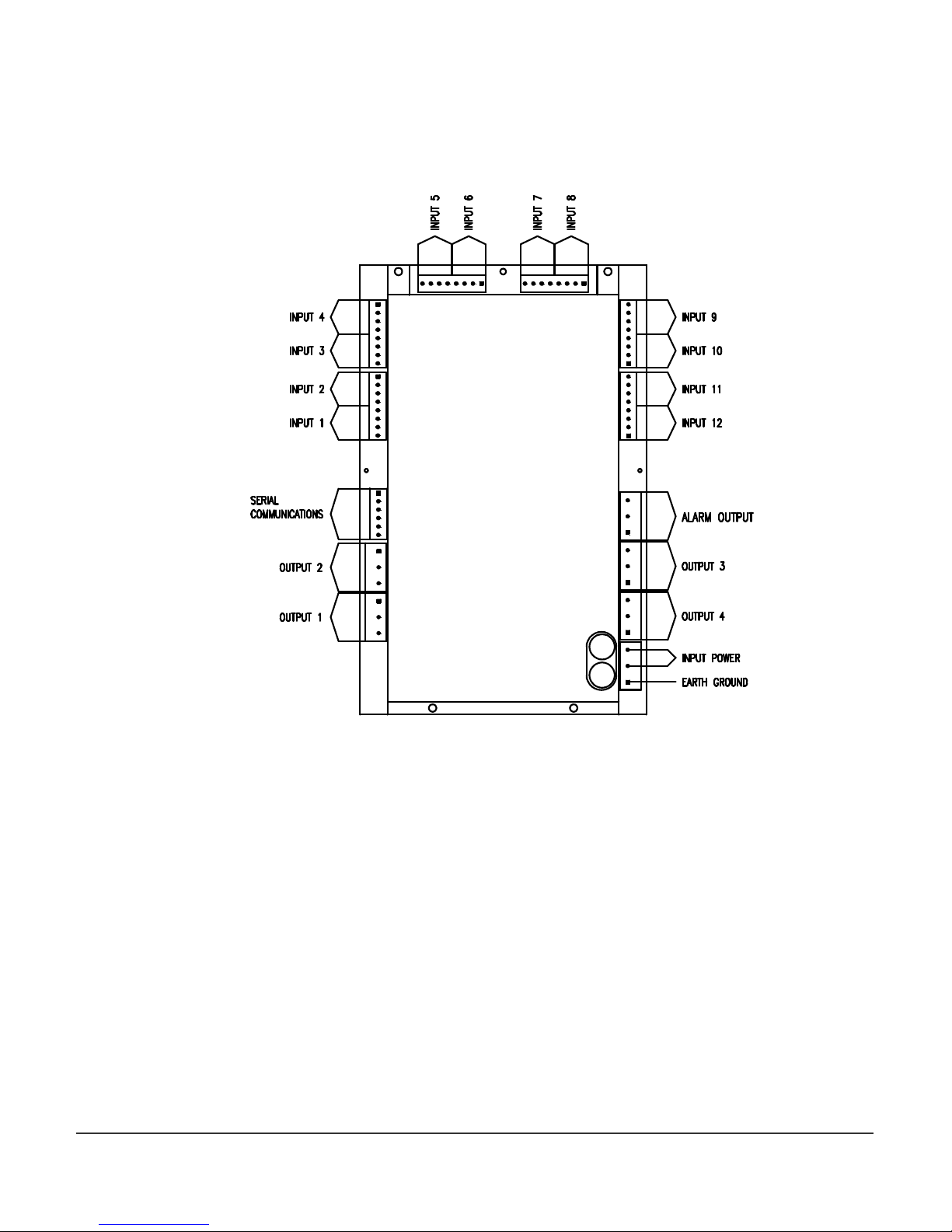

The locations of the connections on the CT224 are shown in Figure 4. The rear cover of the

CT224 also shows the connections for each terminal. More detail for each of the connections

is given in the following sections.

Figure 4 – Wiring Connection Locations

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 7

Page 8

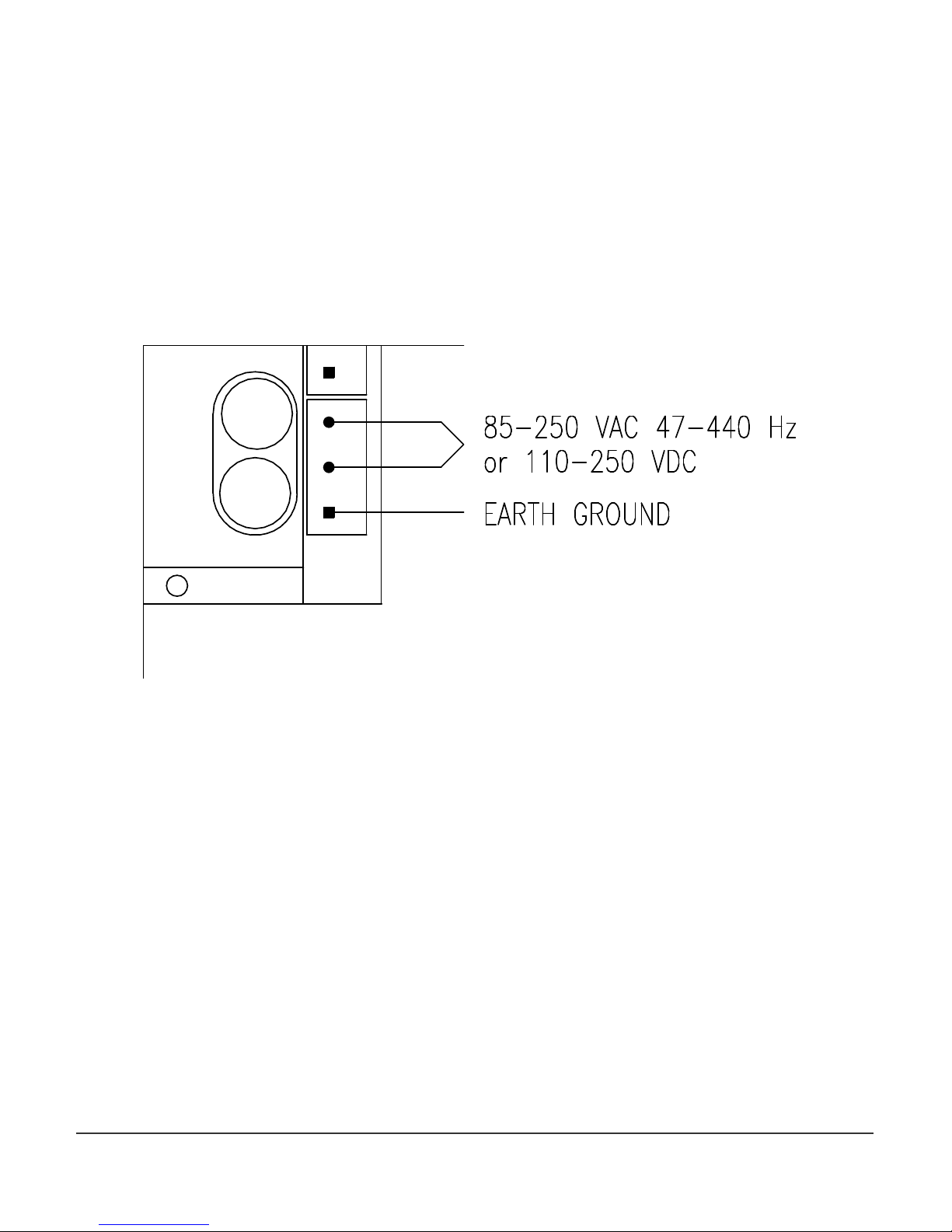

1. Controller Power

The CT224 Power connections will vary depending on which type of power is use.

AC

On AC models, the Line and Neutral will be connected to the terminal block in the lower right

hand corner on the rear of the CT224. See Figure 5. The lower terminal on the terminal block

is used for ground. It is important to connect earth ground to the lower terminal if shielded

cable is used for sensors. This connection is how a grounding connection is made to the

shields of the RTDs. Connecting to earth ground also provides a path for current to flow in

the event of an electrical failure and helps to protect the operator from possible electrocution

in such an event.

Fuse

Fuse

Figure 5 – AC Power Connections

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 8

Page 9

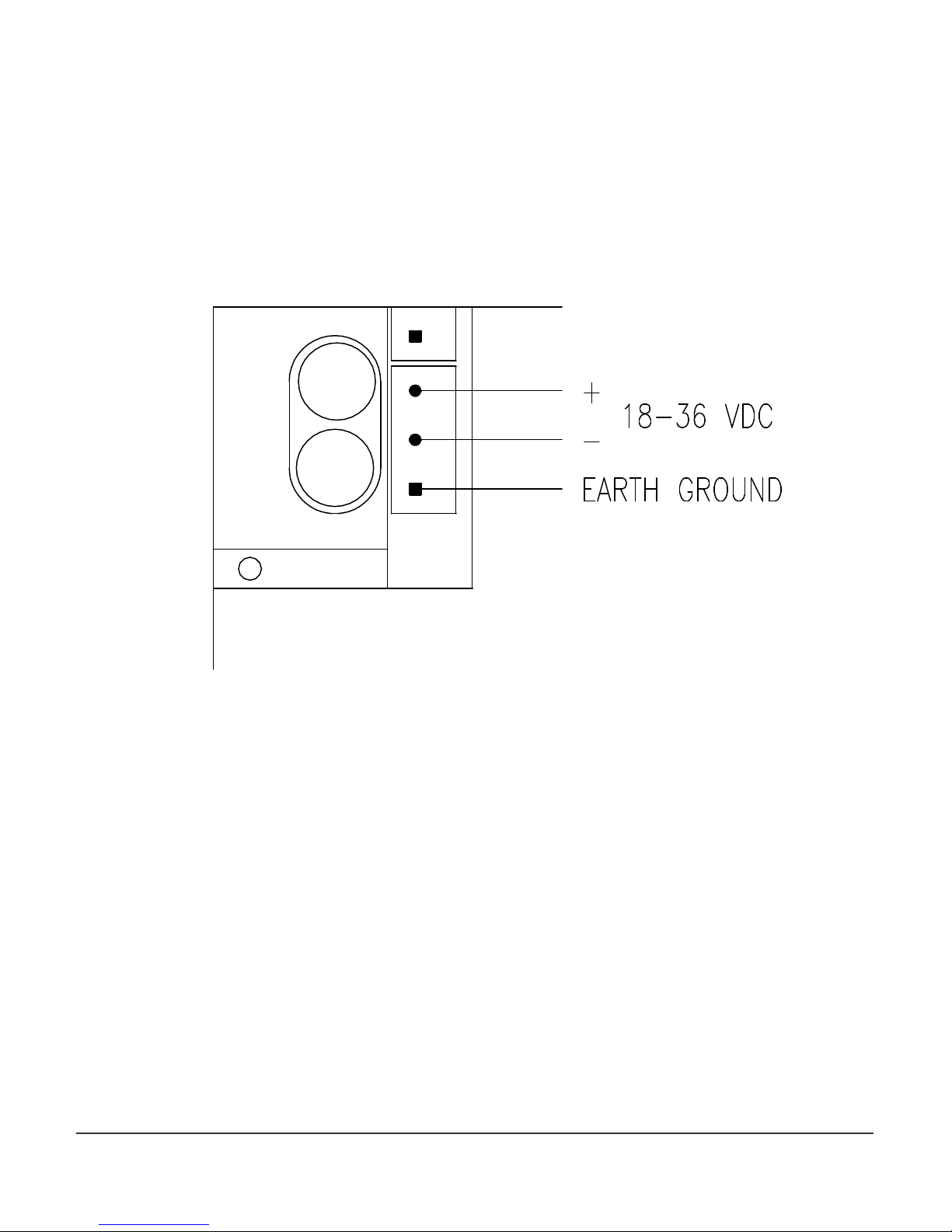

DC

On DC models, the DC voltage is connected to the upper terminals and the terminal block in

the lower right corner on the rear of the CT224. See Figure 6. The upper terminal on the

control power terminal block is connected to the positive supply voltage, between 18 and

36Vdc. The lower terminal on the terminal block is used for ground. It is important to

connect earth ground to the lower terminal if shielded cable is used for sensors. This

connection is how a grounding connection is made to the shields of the RTDs. Connecting to

earth ground also provides a path for current to flow in the event of an electrical failure and

helps to protect the operator from possible electrocution in such an event.

Fuse

Fuse

Figure 6 – DC Power Connections

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 9

Page 10

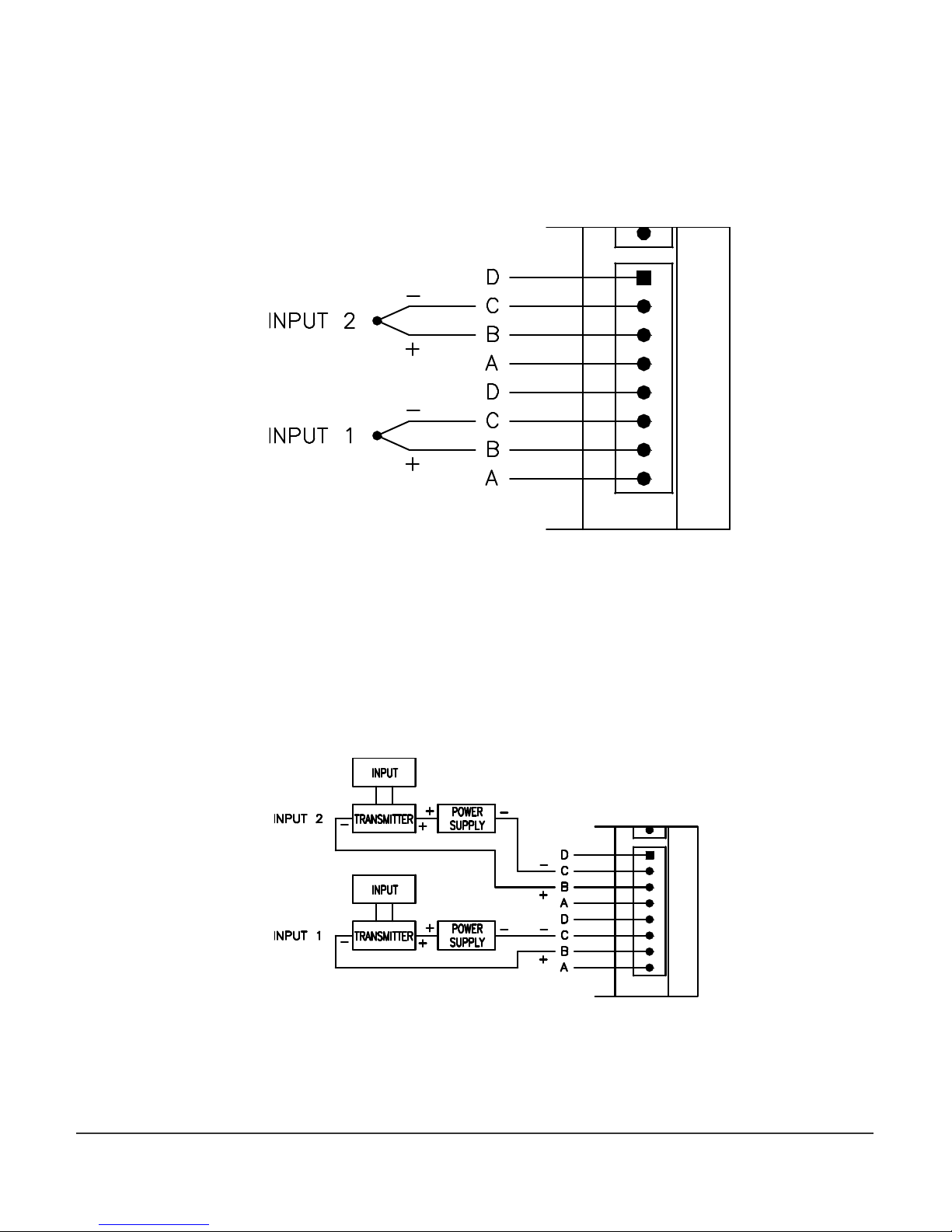

2. Inputs

Maximum Length for

The CT224 can accept any combination of the input types specified in Section 6 at the end of

this document. These may include RTDs, thermocouples, and 4-20mA transmitter loops.

However, some care must be taken when using multiple inputs so that a safe environment is

created for personnel and equipment. For instance, a CT224 should monitor sensors from

only one piece of equipment, especially if high voltage is present. Using this approach,

damage to other devices is greatly reduced, if a circuit fault should occur.

The CT224 does not have channel to channel isolation. This means that grounded

thermocouples cannot be used directly with the CT224. Ungrounded thermocouples may be

used. If grounded thermocouples are used, a device such a Thermocouple Isolator can be

utilized as a means to break ground loops and provide proper inputs to the CT224.

Another consideration due to not having channel to channel isolation is that when using 420mA inputs, all loops will share the same return path. Keep this in mind when planning the

system to ensure that it is safe to wire all loops together. It is the system designer’s

responsibility to ensure that good safety measures are used. If unsure about the safety

aspects of a system, call Minco for assistance.

Each input channel has 3 input terminals and a common earth ground terminal. The

terminals are labeled as A, B, C and D. Terminal D is connected to earth ground, when earth

ground is connected to the terminal block as described in Section 1, Controller Power. Input

wiring for the different input types is shown in Figures 7, 8, 9, and 10.

RTDs - RTDs Use three terminals per channel. Care should be taken to not exceed 30 ohms of

lead wire resistance. Chart 1 shows maximum lead wire length per lead of an RTD so as not to

exceed the 30 ohms maximum lead wire resistance. Leadwire for RTDs should be twisted and

shielded, this will reduce fluctuations in the readings due to noise.

3-wire RTD: The odd colored wire must be connected to terminal A of the input channel.

The other two wires can be placed in either order in B and C. If the RTD has a shield, place it

into terminal D. When adding leadwire to the RTD, be sure to use the same length and gauge

for each lead. The CT224 is able to provide very good compensation for leadwire resistance

as long as each lead has the same resistance. Recommended Extension Leadwire: Belden

1031A or any other wire that is twisted and shielded is a good choice.

Leadwire

(AWG)

Ohms/Foot at

25ºC

18 .0065 4615

20 .0103 2912

22 .0165 1818

24 .0262 1145

26 .0418 717

28 .0666 450

30 ohms of

Resistance

Chart 1 – Leadwire Resistance per lead

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 10

Page 11

Figure 7

– 3-

Wire RTD Wiring

2-wire RTD: One of the leads should be placed in terminal A for the input channel. The

other lead should be placed in either B or C. A jumper wire must be placed between B and C

in order to complete the input circuit. If the RTD has a shield, connect it to terminal D.

Recommended Extension Leadwire: Belden 1030A or any other wire that is twisted and

shielded is a good choice.

The 2-wire RTD will exhibit some error due to the inability to compensate for lead wire

resistance. This can be partially compensated by using the Zone Offset feature as shown later

in the manual under the Programming Configuration section. Chart 2 shows lead wire

resistance based on wire gauge. The desired offset value can be calculated using the chart,

length of leadwire, and by visiting www.minco.com and using the “Sensor Calc” program to

determine the affect of the leadwire. By using this information it is possible to reduce the

leadwire error by adjusting the offset.

Figure 8 – 2-Wire RTD Wiring

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 11

Page 12

Thermocouples – Thermocouples use terminals B and C. The positive lead on the

thermocouple should be connected to the B terminal and the negative lead to the C terminal.

On a thermocouple the red lead is usually negative (–) and the other lead is usually positive

(+). Figure 9 shows how to wire the Thermocouple to the CT224.

Figure 9 – Thermocouple Wiring

4-20mA – 4-20mA inputs use terminals B and C. The loop positive should be connected to

the B terminal and the loop negative should be connected the C terminal. When configuring

the CT224 for 4-20mA loops, you must set the jumpers located on the top part of the PCB to

the position with out the dot. This is shown in Figure 1 in the Pre-Installation Instruction

section.

Figure 10

– 4-20mA Wiring Diagram

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 12

Page 13

3. Outputs

Two types of outputs are available on the CT224, relays or logic. The output type is

determined by the options that were ordered.

There are three terminals for each output. All three terminals are used when relays are the

output type. When logic outputs are installed, only two of the terminals are used. The

terminals are labeled as A, B, C. Caution: The terminal positions are A, B, C on the left side of

the unit reading from top to bottom, but they are labeled as C, B, A on the right side of the

unit.

The CT224 has 5 outputs. Four of the outputs are used for signals and can be configured to

trip and untrip in several different ways. The different methods are covered in section

4. Program Configuration part B) Entering The Program Settings. The Alarm Output

differs from the other 4 outputs in several ways. The Alarm Output will use the hysteresis

value for the channel that caused it to trip as it’s untrip value. If the alarm is configured to

sound with a channel that is set to latch another output on a trip, the alarm will continue to

sound until a key is pressed. The Alarm Output cannot be configured for reverse acting, it is

always direct acting.

Relay outputs: Relays are SPDT, they have terminals for both normally open (NO) and

normally closed (NC) contacts. The NO contact is between terminals B and C and the NC

contacts are between terminals A and B.

Logic outputs: Logic outputs use terminals A and B, with B as the reference ground. Logic

outputs are not isolated from the controller supply. Caution must be taken when using logic

outputs since several devices may be sharing the same reference ground when they are

connected.

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 13

Page 14

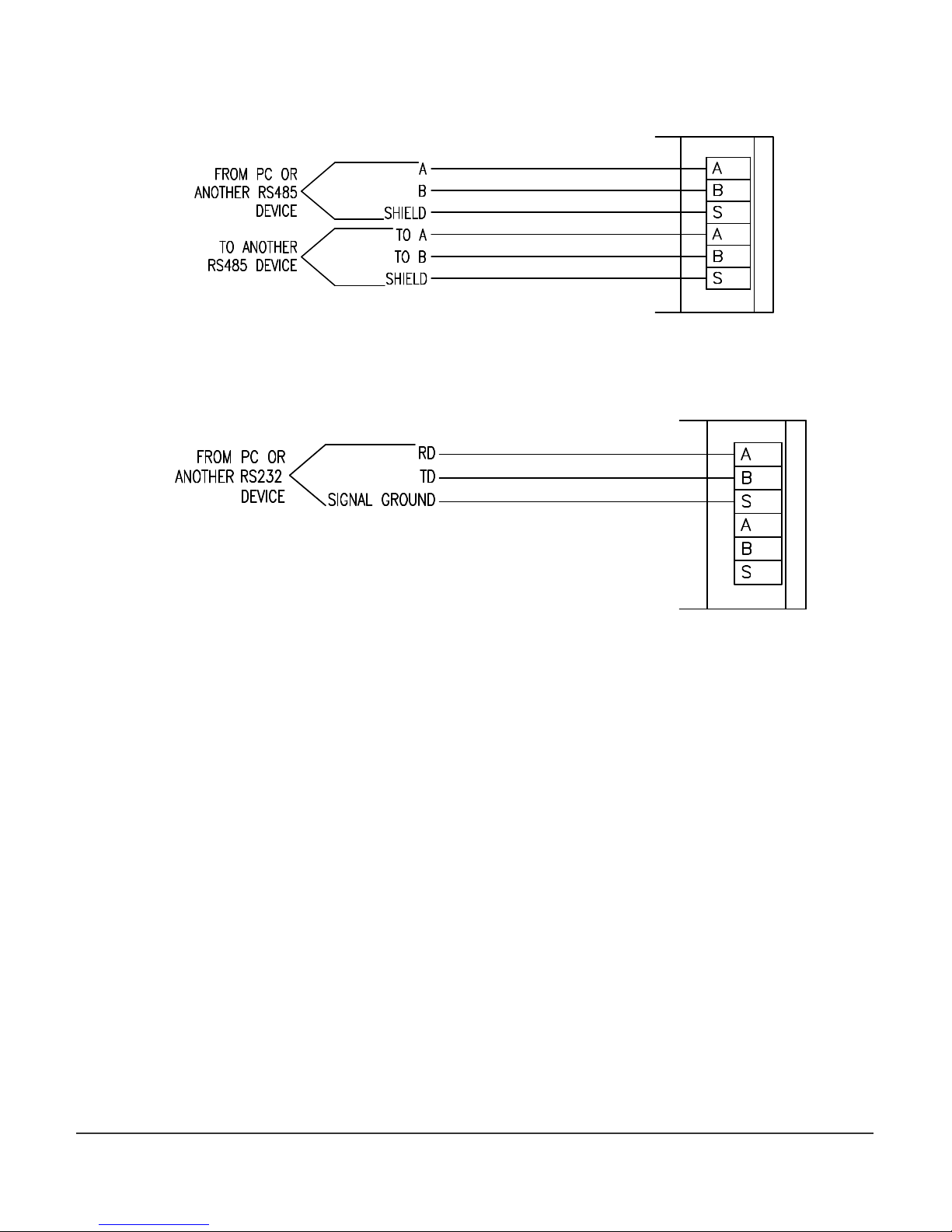

4. Serial Communications

Modbus protocol is used to communicate between the CT224 and other device (PC or PLC).

Two physical interface options are available for serial communications. They are RS232 and

RS485. The CT224 is always a slave device.

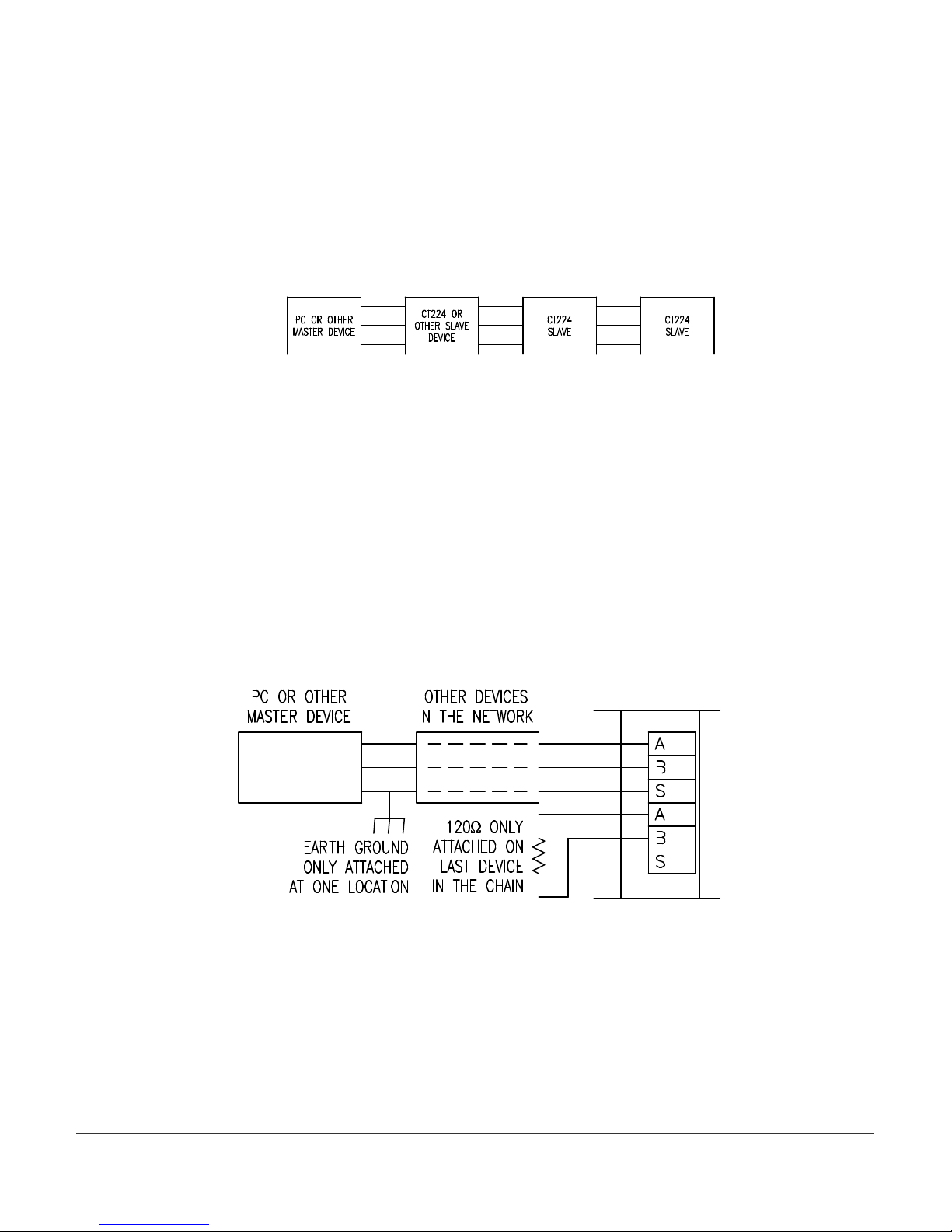

RS485

RS485 allows for multiple devices to be connected to one network. Up to 128 CT224 can be

connected to a network. The RS485 standard allows up to 32 nodes to be connected on a

half-duplex network. However, each CT224 accounts for only ¼ of a node, so 128 CT224 can

be connected to the network when RS485 is used as the medium.

The connections on the CT224 are labeled as A, B, and S. The two signal wires are A and B.

The A terminal should be connected to the A terminal on the RS232 to RS485 converter. The

B terminal should be connected to the B terminal on the RS232 to RS485 converter. The S

terminal should be connected to the shield. The shield wire should be connected to ground

in one location only, to avoid ground loops, which can cause erratic communications. Refer

to Figure 11 for a wiring diagram.

RS232

Terminal A is the Transmit Data (TD) connection, terminal B is the Receive Data (RD)

connection, and terminal S is the Signal Ground (SG) connection on the CT224. RS232 devices

require Terminal A connected to Receive Data from the master device, Terminal B to Transmit

Data from the master device, and terminal S to Signal Ground. For a 9-pin D-Sub connector

on a PC, connect A to pin2, B to pin 3, and S to pin 5. Caution should be taken when using

RS232, as it is not isolated. This could cause ground loops through devices, which could

cause damage to the CT224 and / or other devices. Refer to Figure 11 for a wiring diagram.

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 14

Page 15

RS485

RS232

Figure 11

– Wiring diagrams for RS232 and RS485

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 15

Page 16

Connecting Multiple CT224

A network of CT224’s should be wired so that the CT224’s are in a chain. However, only

devices using RS485 can be connected in this manner. RS232 will only allow one (1) device to

be connected to a port, so RS232 devices cannot be used in a network. A star or ring

configuration is not appropriate for RS485. Each CT224 should only be connected to at most

2 other CT224. Figure 12 shows the basic wiring for a chain configuration. Like terminals on

the CT224’s should be connected together in the chain, A to A, B to B, S to S.

Figure 12 – Master Slave Chain

End devices (Master and last Slave) on an RS485 network should be terminated to achieve

error-free communications. The termination should match the characteristic impedance of

the network. Normally this value is about 120ohms. Figure 13 shows how to easily apply a

termination resistor to the last CT224 in a chain. Do not use more than 2 termination resistors

on the network. There are many other methods for terminating an RS485 network. If

interested in trying a different termination approach, consult the Internet for various other

configurations. In most applications, terminating with 120ohm resistors will provide errorfree communications.

Figure 13 – Termination of RS485 Network

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 16

Page 17

4. Program Configuration

A. Using the CT224

The CT224 has two main modes of operation, Monitoring Mode and Menu Mode. When the

CT224 is powered up it will enter Monitoring Mode. Initially the message “Initializing Inputs”

will be shown on the display. The CT224 is evaluating the inputs and initializing the outputs

based on the program configuration that has been stored in the device. After a few seconds

the screen will change and display an input reading.

1. Modes / Buttons

The CT224 has 4 buttons. The user interface has been designed to offer quick modifications

to many parameters in an easy to use manner. Buttons have different purposes depending on

the Mode of the CT224.

Monitoring Mode

Most of the time the unit will be in Monitoring Mode. In Monitoring Mode, all zones

that are configured for input (including the Cold Junction Compensation value), are

scanned and the program settings are used to adjust the outputs.

When in Monitoring Mode, the Back and Right arrow buttons display the next lower

input zone while the Enter and Up arrow buttons move to the next higher input zone.

When customized zone names are used, they will be displayed. The name given to

input zone 1 will be displayed in place of the default name “ZONE 1”. Entering a

custom zone name can be done by entering Menu Mode, selecting Options, Rename

Zones.

Menu Mode

To enter Menu Mode from Monitoring Mode, press and hold any key for 3 seconds. A

beep will sound and the main menu will be shown. There are many different menus

that can be accessed in the Menu Mode. While in Menu Mode, the inputs are not read

and outputs are not adjusted. A 60-second countdown is started each time a key is

pressed when in Menu Mode. If 60 seconds passes without pressing a key, the CT224

will reset and enter Monitoring Mode and continue to evaluate inputs and outputs.

The buttons in Menu Mode are used for different purposes based on which area is

entered. The Back and Right arrow buttons move the cursor up one line and the Enter

and Up arrow move the cursor down one line when making a selection from a list.

When a selection is made which prompts the user for input, then the buttons take on

different tasks. When prompted to enter a value, the Up arrow is used to change the

value of the character or the selection where the cursor is located. Once the desired

character has been set at the current cursor position, pressing the right arrow will

move the cursor to the next position and the Up arrow can be used to adjust that

character. Pressing Enter will accept (and save) the current setting and advance to the

next step in the configuration process. The Back button is used to move back to the

previous step in the configuration process or exit the section that is currently being

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 17

Page 18

modified. To quickly exit an area where configuration is being done, hold the Enter

Key for 3 seconds and the mode will be exited. All parameters that were modified and

saved by pressing Enter will be saved.

The first menu shown when Menu Mode is entered is the Main Menu. It allows the

following choices:

1. Monitor Zones

2. Setup

3. Manual Reset

4. Options

1. Monitor Zones

Select this option to return to Monitoring Mode to read and evaluate the inputs and

outputs.

2. Setup Menu

The Configuration Menu may require a password to enter, by default no password is

required. The Configuration Menu contains the following options.

1. Change Passwords

2. Change Settings

3. Modify Offsets

4. Comm Settings

1. Change Passwords - Select the password to change. A message asking

if you would like to change a password will be shown. Choose ‘Yes’ to change a

password or ‘No’ to exit the Change Passwords option. By setting a password

to 0000, the password will be deactivated. The valid range for a password is

0000 to 9999. If a password is already entered, the user will be required to

enter the existing password in order to change it. If you forget your password,

the master password can be used, it is found on the last page of this manual.

Available selections are:

1. Program Password

2. Unlatch Password

1. Program Password – Changes the password that is used to

protect the Change Program option.

2. Unlatch Password – Changes the password that is used to

protect Manual Reset of the Outputs.

2. Change Settings - This section is used to configure all inputs and

outputs. (May be password protected.) When this section is exited, either due

to the 60-second timeout or exited by the user, the CT224 will automatically

reset and start scanning with the new program settings. The CT224 will also

reset when program settings are changed via the communications link using

MincoSoft’s CT224 Software. This is the main section of the CT224

configuration process and has a full section below covering its use. See section

4B, Entering the Program Settings, for more information.

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 18

Page 19

3. Modify Offsets - Adjust the offset for each input zone. The offsets are

used to improve accuracy of the readings. This could be useful if a 2-wire RTD

is used or a particular value is crucial in a process. The offset can be used so

that less error is present. The units for the offset are Tenths. So, if the reading

is off by -1 degree (or 1 unit in any other measurement), the number that

should be entered for the offset value is 10, because this will raise the value by

10 tenths or +1 degree.

4. Comm Settings – This selection steps through setting the monitor

address and the baud rate for the serial communications. The settings chosen

must match the settings selected by the master device that will be

communicating with the CT224. The first screen requests the user to enter the

Modbus address. The valid range of addresses is from 1 to 247. If 0 is selected,

the CT224 will not monitor the communication lines. Each CT224 is factory set

to a default Modbus address of 1. If communications are not used, it is

acceptable to leave the default address at 1. If multiple CT224 are to be used,

the addresses should be changed to prevent communication errors. The next

screen will request setting the baud rate. Valid baud rates are: 600, 1200, 2400,

4800, 9600, and 19200.

3. Manual Reset - Use this option to reset the outputs if a trip has occurred and

Manual Reset Only was selected when configuring the outputs. (May be password

protected.)

4. Options – Options Menu allows the user to personalize the zone names and

exercise the relays.

1. Rename Zones

2. Exercise Relays

3. Freeze Outputs

1. Rename Zones – This option is used to personalize the display. Up to

16 characters can be entered to describe the input location. Capital letters (AZ), numbers (0-9), and spaces are allowed.

2. Exercise Relays – This option can be used to trip the outputs for test

purposes. This can be helpful to verify that wiring is correct and that

connections are secure. When selected and relays are in tripped condition, the

unit will keep the outputs tripped until another key is pressed.

3. Freeze Outputs – Selecting this option will disable the program from

changing the state of any output. The message “Outputs are Frozen” is

displayed on the screen when this selection is active and the CT224 is in

Monitor Mode. To unfreeze the outputs, choose this option again and the

Freeze Outputs option will be disabled.

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 19

Page 20

B) Entering the Program Settings

The first step to take when configuring the CT224 is to decide how you would like the device

configured. Configuration is best performed using MincoSoft CT224 Software. If you do not

have a computer available for configuration you may also use the keypad on the CT224 to

enter the settings. If using the keypad to configure the CT224, use the Setup Worksheet to

speed up the process and reduce errors. Due to the 60-second timeout in the CT224, it is best

to fill out the Setup Worksheet before configuring the unit. This will also allow you to have

record of the settings that are programmed into the unit for future reference.

A description for each of the configuration options is give on the following pages.

Reverse acting outputs? - Choose the outputs you would like to configure for reverse action.

N – Relay: Normally Open (NO) contact will be open and the Normally Closed (NC)

contact will be closed.

Logic: Output will be low (0V) in untripped state.

Y – Relay: NO contact will be closed and the NC contact will be open in the untripped

state. The Logic: Output will be high (+5V) in untripped state.

Temperature Scale: Choose the temperature scale that the CT224 should use. RTDs and

thermocouples will use this temperature scale for display. Options are F, Fahrenheit and C,

Celsius.

Zone to be displayed during normal operation: Choose how the input readings should be

displayed.

The user can always adjust the displayed reading by pressing keys, after 5 seconds the CT224

will resume it’s process of displaying the High, Low or Scanning through inputs.

High – Highest input reading is displayed, regardless of input type.

Low – Lowest input reading is displayed, regardless of input type.

Any – Display will stay on the zone that the user has set it to.

Minutes of alarm silence when a key is pressed: Set the amount of time to wait until the

alarm will resound, if the alarm condition is still present. Valid range is 1 to 100 minutes or

Stays Off. This setting only resounds the alarm, it will not re-trip an output. It is designed to

remind personnel that there is still a trip condition in affect.

If an input fails: This setting allows the user to determine what action the CT224

should take if a broken sensor is detected.

Sound alarm – Alarm will sound if input fails. Alarm will resound according to the

“Minutes of alarm silence when a key is pressed” set in the previous step.

Trip output(s) associated with failed input – All outputs configured to trip on the

channel that has a failed input will trip.

Ignore – Continue operating like the input is still functioning properly.

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 20

Page 21

Choose input type: Select the input type for this zone. Options are:

Resistance

Type

Sensor Range

RTD Inputs

Material

at 0ºC in ohms

TCR

Sensor Range

Platinum (PA) 100 .00392 -200 to 700ºC (-328 to 1292ºF)

Platinum (PB) 100 .00391 -200 to 700ºC (-328 to 1292ºF)

Platinum (PD or PE)

100 .00385 -200 to 850ºC (-328 to 1562ºF)

Platinum (PF) 1000 .00385 -200 to 600ºC (-328 to 1112ºF)

Nickel (NA) 120 .00672 -80 to 260ºC (-112 to 500ºF)

Copper (CA)

9.035 (10 Ω at 25°C)

.00427 -100 to 260ºC (-148 to 500ºF)

Thermocouple Inputs

E -270 to 1000ºC (-454 to 1832ºF)

J -200 to 1200ºC (-328 to 2192ºF)

K -270 to 1150ºC (-454 to 2102ºF)

T -270 to 400ºC (-454 to 752ºF)

4-20mA Transmitters: Output proportional to process variable for Pressure PSI, Pressure Bar,

% Relative Humidity, Process Variable mA, Process Variable Vdc, Vibration G, Temperature ºC,

Temperature ºF.

Enter Low End of Transmitter Range: This setting will only be displayed if a 4-20mA input is

selected in the previous step. All ranges for RTDs and thermocouples are fixed. The valid

input range is between -999 and 9999.

Enter High End of Transmitter Range: This setting is also only available when a 4-20mA

input is selected. The valid input range is between –999 and 9999. The high end of the

transmitter range must be higher than the low end.

Zone X Trip 1: Set the trip value for this zone. When Trip 2 is displayed it will correspond to

the second trip value for the zone. Valid temperature ranges are shown in the charts found

under “Choose input type:”. If a value not within the range for the sensor is entered, a

warning will be displayed and a new, valid setting should be entered.

Trip Over or Under? – This setting determines when the outputs will trip.

Over – Outputs for the zone will trip when the reading is higher than the trip value.

Under – Outputs for the zone will trip when the reading is lower than the trip value.

Sound Alarm on Trip? –Yes will cause the alarm to sound and alarm output to trip when the

reading passes the trip value. Selecting No will not sound the alarm when the outputs are

tripped.

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 21

Page 22

Outputs to trip:

Output1__ Output2__

Output3__ Output4__ - A Y after the output indicates to trip the output when the reading

passed the trip value. An N after the output indicates the output should not be tripped.

Untrip Outputs by: - This setting will determine how the outputs associated with this trip will

be untripped.

Manual Reset Only – This setting causes the outputs to latch. In addition,

temperature display will show highest reading since the trip event. The outputs can

only be reset by entering the Main Menu and selecting Manual Reset. This will also

return temperature display to normal operation. (A password may be necessary to

reset the relays.)

Pressing Enter – The outputs will untrip when Enter is pressed.

Using Hysteresis – The outputs will untrip when the input value exits the hysteresis

(deadband) limit.

Note: The order of precedence for the methods of untrip is Manual Reset Only,

Pressing Enter, and then Using Hysteresis. This means that if at any time an output is

tripped and configured by an zone to untrip using Manual Reset Only, the only way to

untrip that zone is using the Manual Reset.

Note: When any zone causes a trip for an output, all zones that have caused a trip on

that output will be refreshed. This means that if an output has been tripped and then

cleared by pressing Enter and another zone causes that output to retrip, the output

will act as though both trips have reoccurred at the same time to cause the output to

trip. So, if the second trip were to reset by dropping below the programmed

hysteresis value, the output will still be tripped, due to the first zone, which caused the

trip. To reset the output again, Enter would need to be pressed.

Set Hysteresis: - Hysteresis is the amount that the reading must move past the trip value

before the outputs will reset. For example, the system is configured to trip at 100ºF, has a

10ºF hysteresis and will trip Output 1 on an over temperature reading. The reading increases

to 100ºF, so Output 1 trips. The reading will need to go below 90ºF before Output 1 will reset.

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 22

Page 23

C. Setup Worksheet

Prompt

Description

Selection

Reverse acting

Choose which outputs should be

Output 1

__ Output 2__

Temperature Scale:

Choose the temperature scale to

Degrees _____

Zone t

o be

Choose how input readings

High

Minutes of alarm

Set the amount of time that

________

Minutes

If an input fails:

Choose action to take if input fails.

Sound Alarm

Zone X Trip 1:

Choose the type of input that is

Zone 1 _____ Zone 6_____

Zone X Trip 1:

For 4

-

20mA current loops, enter

Zone 1 ____

_ Zone 6_____

outputs?

displayed during

normal operation:

silence when a key

is pressed:

Choose input type:

in an active state, before a trip

condition occurs.

which the CT224 should be

configured.

should be displayed.

should pass before the alarm will

resound due to an alarm

condition.

attached.

Output 3__ Output 4__

Low

Any

Trip Output(s)

Ignore

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Enter Low End of

Transmitter Range:

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 23

the low end of the range of the

input. These settings will not be

used for RTD and Thermocouple

inputs. The range for RTD and

Thermocouples are not

changeable. See Specifications in

the rear of the manual for the

range of RTD and Thermocouples.

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Page 24

Prompt

Description

Selection

Zone X Trip 1:

Enter High End of

For 4

-

20mA current loops, enter

Zone 1 _____ Zone 6_____

Zone X Trip 1:

Set the trip value.

Zone X Trip 1:

Set the input condition for when

Zone 1 _____ Zone 6_____

Zone X Trip 1:

Set to alarm when an output is

Zone 1 _____ Zone 6_____

Transmitter Range:

the high end of the range of the

input.

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Zone 1 _____ Zone 6_____

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Trip Over or Under?

Sound Alarm on

Trip?

the output(s) should trip.

tripped.

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 24

Page 25

Prompt

Description

Selection

Zone X T

rip 1:

Outputs to trip:

Choose outputs to trip when trip

Zone 1 Trip 1: Zone 7 Trip 1:

Zone X Trip 1:

Choose the preferred method

to

Zone 1 _____ Zone 6_____

Zone X Trip 1:

Set the hysteresis (deadband)

Zone 1 _____ Zone 6_____

Output1__

Output2__

Output3__

Output4__

value is observed.

Output1__ Output2__ Output1__ Output2__

Output3__ Output4__ Output3__ Output4__

Zone 2 Trip 1: Zone 8 Trip 1:

Output1__ Output2__ Output1__ Output2__

Output3__ Output4__ Output3__ Output4__

Zone 3 Trip 1: Zone 9 Trip 1:

Output1__ Output2__ Output1__ Output2__

Output3__ Output4__ Output3__ Output4__

Zone 4 Trip 1: Zone 10 Trip 1:

Output1__ Output2__ Output1__ Output2__

Output3__ Output4__ Output3__ Output4__

Zone 5 Trip 1: Zone 11 Trip 1:

Output1__ Output2__ Output1__ Output2__

Output3__ Output4__ Output3__ Output4__

Zone 6 Trip 1: Zone 12 Trip 1:

Output1__ Output2__ Output1__ Output2__

Output3__ Output4__ Output3__ Output4__

Untrip Outputs by:

Set Hysteresis:

untrip the outputs.

value. Hysteresis is the amount

that the input value must pass

beyond the trip value before the

output will untrip.

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 25

Page 26

Prompt

Description

Selection

Zone X Trip 2:

Choose input type:

Choose the type of input that is

Zone

1 _____ Zone 6_____

Zone X Trip 2:

Enter the low end of the range of

Zone 1 _____ Zone 6_____

Zone X Trip 2:

Enter the high end of the range of

Zone 1 _____ Zone 6_____

Zone X Trip 2:

Set the trip value.

Zone 1 _____ Zone 6_____

attached.

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Enter Low End of

Transmitter Range:

(4-20mA inputs

only, if another

input type is

selected, this option

will not be

displayed.)

Enter High End of

Transmitter Range:

(4-20mA inputs

only, if another

input type is

selected, this option

will not be

displayed.)

the input.

the input.

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 26

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Page 27

Prompt

Description

Selection

Zone X Trip 2:

Trip Over or Under?

Set the condition when the

Zone 1 _____ Zone 6_____

Zone X Trip 2:

Set to alarm when an output is

Zone 1 _____

Zone 6_____

Zone X Trip 2:

Choose outputs to trip when trip

Zone 1 Trip 1: Zone 7 Trip 1:

outputs should trip.

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Sound Alarm on

Trip?

Outputs to trip:

Output1__

Output2__

Output3__

Output4__

tripped.

value is observed.

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Output1__ Output2__ Output1__ Output2__

Output3__ Output4__ Output3__ Output4__

Zone 2 Trip 1: Zone 8 Trip 1:

Output1__ Output2__ Output1__ Output2__

Output3__ Output4__ Output3__ Output4__

Zone 3 Trip 1: Zone 9 Trip 1:

Output1__ Output2__ Output1__ Output2__

Output3__ Output4__ Output3__ Output4__

Zone 4 Trip 1: Zone 10 Trip 1:

Output1__ Output2__ Output1__ Output2__

Output3__ Output4__ Output3__ Output4__

Zone 5 Trip 1: Zone 11 Trip 1:

Output1__ Output2__ Output1__ Output2__

Output3__ Output4__ Output3__ Output4__

Zone 6 Trip 1: Zone 12 Trip 1:

Output1__ Output2__ Output1__ Output2__

Output3__ Output4__ Output3__ Output4__

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 27

Page 28

Zone X Trip 2:

Choose the preferred method to

Zone 1 _____ Zone 6_____

Zone X

Trip 2:

Set the hysteresis (deadband)

Zone 1 _____ Zone 6_____

Untrip Outputs by:

Set Hysteresis:

untrip the outputs.

value. Hysteresis is the amount

that the input value must pass

beyond the trip value before the

output will untrip.

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Zone 2 _____ Zone 7_____

Zone 3 _____ Zone 8_____

Zone 4 _____ Zone 9_____

Zone 5 _____ Zone 10_____

Zone 6 _____ Zone 11_____

Zone 7 _____ Zone 12_____

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 28

Page 29

5. Communications

The CT224 uses Modbus protocol to communicate over an RS485 bus. RTU transmission

mode is supported by the CT224. ASCII transmission mode is not supported. Data transfer

must adhere to the following data format: 1 start bit, 8 data bits and 1 stop bit. Supported

data rates are: 600, 1200, 2400, 4800, 9600, and 19200 baud. Supported function codes are

0x03, 0x04, and 0x10. These instructions allow the program settings to be read and modified

and access to the input readings on the monitor. The communications are limited to 41

characters per transmission, including header information and checksum. A character is

defined as hexadecimal 0 … 9, A … F. Modbus addresses are allowed in the range from 1 to

247. If the CT224 is set to a Modbus address of 0, the unit will ignore all signals on the

communication inputs.

The CT224 supports half-duplex operation. This means that only two signal wires are required

to send and receive signals. Using half-duplex operation helps to minimize wiring and still

provides the long distance communications allowed while using RS485. Wire lengths up to

4000 ft. are allowed with RS485 as compared to only 50 ft. using RS232.

Using a PC for RS485 Communications

Minco offers an accessory package (AC102734) that contains an isolated RS232 to RS485

converter, power supply to power the converter, and a DB25 to DB9 adapter. These parts

have been thoroughly tested and have been found to work properly with the CT224 and

MincoSoft CT224 software. MincoSoft CT224 software is configured to use a converter that

requires DTR to be active all of the time and RTS to be active when transmitting and inactive

when receiving. Other converters that have the same requirements will work with the

MincoSoft CT224 software. More information about CT224 Communications can be found in

the MincoSoft CT224 Software Manual. Minco does not guarantee that any other RS232 to

RS485 converter will work with the CT224.

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 29

Page 30

A) Function Codes

Function Code 0x03 – Read program settings

The 0x03 function code is used to read the program settings in the CT224. Program settings

are shown in the memory map later in this section. The maximum number of data bytes that

can be sent from the CT224 is 32. This is due to the 41 byte limit set for communications.

Therefore, the maximum value that can be used as the number of memory locations to read is

16.

To request data from 3 memory locations starting at location 0x20, the proper data string to

use, assuming the monitor address is 1, would be:

0103002000030104

01 Monitor Address

03 Function Code

00 High byte of starting memory location

20 Low byte of starting memory location

00 High byte of the number of memory locations to read

03 Low byte of the number of memory locations to read

0104 The checksum for the string that is being sent

The response from the CT224 would look like the following:

01030600010002000374FD

01 Monitor Address

03 Function Code

06 Number of data bytes returned

000100020003 Data bytes returned starting at memory location 0x20

74FD The checksum for the string that was sent

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 30

Page 31

Function Code 0x04 – Read current inputs

The 0x04 function code is used to retrieve the current input readings.

To request data from 4 memory locations starting at location 0x10, the proper data string to

use, assuming the monitor address is 1, would be:

010400100003CEB1

01 Monitor Address

04 Function Code

00 High byte of starting memory location

10 Low byte of starting memory location

00 High byte of the number of memory locations to read

04 Low byte of the number of memory locations to read

0CF0 The checksum for the string that was sent

The response from the CT224 would look something like the following: (Returned data bytes

will obviously vary, depending on the values at those locations.)

0104060001000200030004AEF0

01 Monitor Address

04 Function Code

06 Number of data bytes returned

0001000200030004 Data returned, 4 – 16 bit words

AEF0 The checksum for the string that was sent

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 31

Page 32

Function Code 0x10 – Write program settings

The 0x10 function code is used to write program settings to the CT224. When sending the

Write Program Settings command, the hexadecimal number 10 will be used. Program

settings are shown in the memory map later in this section. The maximum number of data

bytes that can be sent to the CT224 is 32. This is due to the 41 byte limit set for

communications. Therefore, the maximum value that can be used as the number of memory

locations to write is 16.

To store settings to 3 memory locations starting at location 0x20, the proper data string to

use, assuming the monitor address is 1, would be:

011000200003AABBCCDDEEFF5B39

01 Monitor Address

10 Function Code

00 High byte of starting memory location

20 Low byte of starting memory location

00 High byte of the number of memory locations to write

03 Low byte of the number of memory locations to write

AABB First word of data to send

CCDD Second word of data to send

EEFF Third word of data to send

5B39 The checksum for the string that was sent

The response from the CT224 would look something like the following:

011006C2AD

01 Monitor Address

10 Function Code

06 Number of data bytes received

C2AD The checksum for the string that was sent

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 32

Page 33

B) Memory Map

Explanation of the Value Format can be found after the chart Current Values for Inputs and

Outputs.

Program Settings are stored according to the chart below:

Register Address Description Value Format

0000 Reverse Acting Relays / Temperature Scale A

0001 Zone to be displayed B

0002 Length of Silence C

0003 Action to take on failed input D

0004 Zone 1 Trip 1 – Input Type E

0005 - Low end of input range F

0006 - High end of input range G

0007 - Trip Value H

0008 - Trip Over or Under I

0009 - Sound Alarm / Outputs to trip J

000A - Output Reset / Hysteresis Value K

000B Zone 1 Trip 2 – Trip Value H

000C - Trip Over or Under I

000D - Sound Alarm / Outputs to trip J

000E - Output Reset / Hysteresis Value K

000F Zone 2 Trip 1 – Input Type E

0010 - Low end of input range F

0011 - High end of input range G

0012 - Trip Value H

0013 - Trip Over or Under I

0014 - Sound Alarm / Outputs to trip J

0015 - Output Reset / Hysteresis Value K

0016 Zone 2 Trip 2 – Trip Value H

0017 - Trip Over or Under I

0018 - Sound Alarm / Outputs to trip J

0019 - Output Reset / Hysteresis Value K

001A Zone 3 Trip 1 – Input Type E

001B - Low end of input range F

001C - High end of input range G

001D - Trip Value H

001E - Trip Over or Under I

001F - Sound Alarm / Outputs to trip J

0020 - Output Reset / Hysteresis Value K

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 33

Page 34

0021 Zone 3 Trip 2 – Trip Value H

0022 - Trip Over or Under I

0023 - Sound Alarm / Outputs to trip J

0024 - Output Reset / Hysteresis Value K

0025 Zone 4 Trip 1 – Input Type E

0026 - Low end of input range F

0027 - High end of input range G

0028 - Trip Value H

0029 - Trip Over or Under I

002A - Sound Alarm / Outputs to trip J

002B - Output Reset / Hysteresis Value K

002C Zone 4 Trip 2 – Trip Value H

002D - Trip Over or Under I

002E - Sound Alarm / Outputs to trip J

002F - Output Reset / Hysteresis Value K

0030 Zone 5 Trip 1 – Input Type E

0031 - Low end of input range F

0032 - High end of input range G

0033 - Trip Value H

0034 - Trip Over or Under I

0035 - Sound Alarm / Outputs to trip J

0036 - Output Reset / Hysteresis Value K

0037 Zone 5 Trip 2 – Trip Value H

0038 - Trip Over or Under I

0039 - Sound Alarm / Outputs to trip J

003A - Output Reset / Hysteresis Value K

003B Zone 6 Trip 1 – Input Type E

003C - Low end of input range F

003D - High end of input range G

003E - Trip Value H

003F - Trip Over or Under I

0040 - Sound Alarm / Outputs to trip J

0041 - Output Reset / Hysteresis Value K

0042 Zone 6 Trip 2 – Trip Value H

0043 - Trip Over or Under I

0044 - Sound Alarm / Outputs to trip J

0045 - Output Reset / Hysteresis Value K

0046 Zone 7 Trip 1 – Input Type E

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 34

Page 35

0047 - Low end of input range F

0048 - High end of input range G

0049 - Trip Value H

004A - Trip Over or Under I

004B - Sound Alarm / Outputs to trip J

004C - Output Reset / Hysteresis Value K

004D Zone 7 Trip 2 – Trip Value H

004E - Trip Over or Under I

004F - Sound Alarm / Outputs to trip J

0050 - Output Reset / Hysteresis Value K

0051 Zone 8 Trip 1 – Input Type E

0052 - Low end of input range F

0053 - High end of input range G

0054 - Trip Value H

0055 - Trip Over or Under I

0056 - Sound Alarm / Outputs to trip J

0057 - Output Reset / Hysteresis Value K

0058 Zone 8 Trip 2 – Trip Value H

0059 - Trip Over or Under I

005A - Sound Alarm / Outputs to trip J

005B - Output Reset / Hysteresis Value K

005C Zone 9 Trip 1 – Input Type E

005D - Low end of input range F

005E - High end of input range G

005F - Trip Value H

0060 - Trip Over or Under I

0061 - Sound Alarm / Outputs to trip J

0062 - Output Reset / Hysteresis Value K

0063 Zone 9 Trip 2 – Trip Value H

0064 - Trip Over or Under I

0065 - Sound Alarm / Outputs to trip J

0066 - Output Reset / Hysteresis Value K

0067 Zone 10 Trip 1 – Input Type E

0068 - Low end of input range F

0069 - High end of input range G

006A - Trip Value H

006B - Trip Over or Under I

006C - Sound Alarm / Outputs to trip J

006D - Output Reset / Hysteresis Value K

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 35

Page 36

006E Zone 10 Trip 2 – Trip Value H

006F - Trip Over or Under I

0070 - Sound Alarm / Outputs to trip J

0071 - Output Reset / Hysteresis Value K

0072 Zone 11 Trip 1 – Input Type E

0073 - Low end of input range F

0074 - High end of input range G

0075 - Trip Value H

0076 - Trip Over or Under I

0077 - Sound Alarm / Outputs to trip J

0078 - Output Reset / Hysteresis Value K

0079 Zone 11 Trip 2 – Trip Value H

007A - Trip Over or Under I

007B - Sound Alarm / Outputs to trip J

007C - Output Reset / Hysteresis Value K

007D Zone 12 Trip 1 – Input Type E

007E - Low end of input range F

007F - High end of input range G

0080 - Trip Value H

0081 - Trip Over or Under I

0082 - Sound Alarm / Outputs to trip J

0083 - Output Reset / Hysteresis Value K

0084 Zone 12 Trip 2 – Trip Value H

0085 - Trip Over or Under I

0086 - Sound Alarm / Outputs to trip J

0087 - Output Reset / Hysteresis Value K

0088 Input Offset – Zone 1 L

0089 - Zone 2 L

008A - Zone 3 L

008B - Zone 4 L

008C - Zone 5 L

008D - Zone 6 L

008E - Zone 7 L

008F - Zone 8 L

0090 - Zone 9 L

0091 - Zone 10 L

0092 - Zone 11 L

0093 - Zone 12 L

0094 Reserved

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 36

Page 37

0095 Reserved

0096 Reserved

0097 Reserved

0098 Zone 1 Name - Characters 1, 2 M

0099 - Characters 3, 4 M

009A - Characters 5, 6 M

009B - Characters 7, 8 M

009C - Characters 9, 10 M

009D - Characters 11, 12 M

009E - Characters 13, 14 M

009F - Characters 15, 16 M

00A0 Zone 2 Name - Characters 1, 2 M

00A1 - Characters 3, 4 M

00A2 - Characters 5, 6 M

00A3 - Characters 7, 8 M

00A4 - Characters 9, 10 M

00A5 - Characters 11, 12 M

00A6 - Characters 13, 14 M

00A7 - Characters 15, 16 M

00A8 Zone 3 Name - Characters 1, 2 M

00A9 - Characters 3, 4 M

00AA - Characters 5, 6 M

00AB - Characters 7, 8 M

00AC - Characters 9, 10 M

00AD - Characters 11, 12 M

00AE - Characters 13, 14 M

00AF - Characters 15, 16 M

00B0 Zone 4 Name - Characters 1, 2 M

00B1 - Characters 3, 4 M

00B2 - Characters 5, 6 M

00B3 - Characters 7, 8 M

00B4 - Characters 9, 10 M

00B5 - Characters 11, 12 M

00B6 - Characters 13, 14 M

00B7 - Characters 15, 16 M

00B8 Zone 5 Name - Characters 1, 2 M

00B9 - Characters 3, 4 M

00BA - Characters 5, 6 M

00BB - Characters 7, 8 M

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 37

Page 38

00BC - Characters 9, 10 M

00BD - Characters 11, 12 M

00BE - Characters 13, 14 M

00BF - Characters 15, 16 M

00C0 Zone 6 Name - Characters 1, 2 M

00C1 - Characters 3, 4 M

00C2 - Characters 5, 6 M

00C3 - Characters 7, 8 M

00C4 - Characters 9, 10 M

00C5 - Characters 11, 12 M

00C6 - Characters 13, 14 M

00C7 - Characters 15, 16 M

00C8 Zone 7 Name - Characters 1, 2 M

00C9 - Characters 3, 4 M

00CA - Characters 5, 6 M

00CB - Characters 7, 8 M

00CC - Characters 9, 10 M

00CD - Characters 11, 12 M

00CE - Characters 13, 14 M

00CF - Characters 15, 16 M

00D0 Zone 8 Name - Characters 1, 2 M

00D1 - Characters 3, 4 M

00D2 - Characters 5, 6 M

00D3 - Characters 7, 8 M

00D4 - Characters 9, 10 M

00D5 - Characters 11, 12 M

00D6 - Characters 13, 14 M

00D7 - Characters 15, 16 M

00D8 Zone 9 Name - Characters 1, 2 M

00D9 - Characters 3, 4 M

00DA - Characters 5, 6 M

00DB - Characters 7, 8 M

00DC - Characters 9, 10 M

00DD - Characters 11, 12 M

00DE - Characters 13, 14 M

00DF - Characters 15, 16 M

00E0 Zone 10 Name - Characters 1, 2 M

00E1 - Characters 3, 4 M

00E2 - Characters 5, 6 M

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 38

Page 39

00E3 - Characters 7, 8 M

00E4 - Characters 9, 10 M

00E5 - Characters 11, 12 M

00E6 - Characters 13, 14 M

00E7 - Characters 15, 16 M

00E8 Zone 11 Name - Characters 1, 2 M

00E9 - Characters 3, 4 M

00EA - Characters 5, 6 M

00EB - Characters 7, 8 M

00EC - Characters 9, 10 M

00ED - Characters 11, 12 M

00EE - Characters 13, 14 M

00EF - Characters 15, 16 M

00F0 Zone 12 Name - Characters 1, 2 M

00F1 - Characters 3, 4 M

00F2 - Characters 5, 6 M

00F3 - Characters 7, 8 M

00F4 - Characters 9, 10 M

00F5 - Characters 11, 12 M

00F6 - Characters 13, 14 M

00F7 - Characters 15, 16 M

00F8 Modbus Address N

00F9 Baud Rate Indicator O

00FA Reserved

00FB Reserved

00FC Simulation Mode / Wait Mode / Reset P

00FD Password for entering programming menu Q

00FE Password for allowing manual reset R

00FF Reserved

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 39

Page 40

Current Values for Inputs and Outputs:

Register Address

Description

Value Format

0000 Input Reading for Zone 1 – Upper 16 bits S

0001 – Lower 16 bits S

0002 Input Reading for Zone 2 – Upper 16 bits S

0003 – Lower 16 bits S

0004 Input Reading for Zone 3 – Upper 16 bits S

0005 – Lower 16 bits S

0006 Input Reading for Zone 4 – Upper 16 bits S

0007 – Lower 16 bits S

0008 Input Reading for Zone 5 – Upper 16 bits S

0009 – Lower 16 bits S

000A Input Reading for Zone 6 – Upper 16 bits S

000B – Lower 16 bits S

000C Input Reading for Zone 7 – Upper 16 bits S

000D – Lower 16 bits S

000E Input Reading for Zone 8 – Upper 16 bits S

000F – Lower 16 bits S

0010 Input Reading for Zone 9 – Upper 16 bits S

0011 – Lower 16 bits S

0012 Input Reading for Zone 10 – Upper 16 bits S

0013 – Lower 16 bits S

0014 Input Reading for Zone 11 – Upper 16 bits S

0015 – Lower 16 bits S

0016 Input Reading for Zone 12 – Upper 16 bits S

0017 – Lower 16 bits S

0018 Input Reading for CJC – Upper 16 bits S

0019 – Lower 16 bits S

001A Output Status T

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 40

Page 41

Value Format Chart:

Value

Format Explanation

A

This 16 bit word is used for two parameters. The upper 8 bits set which

outputs are used as reverse acting or direct acting. The lower 8 bits set the

temperature scale.

Reverse or Direct acting outputs:

A 0 indicates Normal output operation and a 1 indicates Reverse acting. The

format is as follows: 0000 4321, where bit location 4 represents output 4, bit

location 3 represents output 3, etc.

Temperature Scale:

0 indicates using degrees C and a 1 indicates using degrees F

The format is as follows: 0000 000X, where X will be a 0 or 1 indicating the

scale

Example:

Set Output 1 and 2 as reverse acting and the temperature scale to F:

The 16 bits to send would be: 0000 0011 0000 0001 = 0x0301

B

C

This 16 bit word sets the zone to be displayed.

0000 0000 0000 00XX, where XX is 00 for High zone, 01 for Low zone, or 10 for

‘Any’. The ‘Any’ option will stay on the zone that was last viewed by the user.

Example:

Set option ‘Any’:

The 16 bits to send would be: 0000 0000 0000 0010 = 0x0002

This 16 bit word sets the length of silence before the alarm will resound if a

trip condition still exists after the alarm has been silenced. To set the alarm so

that it will not resound, a value greater than 100 should be.

Example:

Set the silence time to 5 minutes:

The 16 bits to send would be: 0000 0000 0000 0101 = 0x0005

To disable the alarm from resounding, set the value to 101:

The 16 bits to send would be: 0000 0000 01101 0101 = 0x0065 (101 decimal)

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 41

Page 42

Hex value

Input Type

D

This 16 bit word sets the zone to be displayed.

0000 0000 0000 00XX, where XX is 00 for Sound Alarm, 01 for Trip Outputs, or

10 for Ignore.

Example:

Set option Trip Outputs:

The 16 bits to send would be: 0000 0000 0000 0001 = 0x0001

E

This 16 bit word sets the input type.

0000 0000 000X XXXX, where X XXXX is assigned in the chart below.

0x00 Input Off

0x01 PA

0x02 PB

0x03 PD or PE

0x04 PF

0x05 NA

0x06 CA

0x07 E Thermocouple

0x08 J Thermocouple

0x09 K Thermocouple

0x0A T Thermocouple

0x0B 4-20mA Pressure, PSI

0x0C 4-20mA Pressure, Bar

0x0D 4-20mA % Humidity

0x0E 4-20mA Process Variable, mA

0x0F 4-20mA Process Variable, Vdc

0x10 4-20mA Vibration, G

0x11 4-20mA Temperature, C

0x12 4-20mA Temperature, F

Example:

Set the input to a PF (1000 ohm platinum) RTD.

The 16 bits to send would be: 0000 0000 0000 0100 = 0x0004

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 42

Page 43

Input Type

Low End , °F

Low End, °C

Input Type

High End , °F

High End, °C

F This 16 bit word sets the low end of the input range. The valid input range is

between -999 and 9999. If using a temperature input, the low end of the

range is shown in the following chart, choose the low end for °F, if the

temperature scale is set to °F or choose the low end for °C, if the temperature

scale is set to °C. The low and high end of the range must be entered for the

given sensor input or errant operation may result. The low end of the range

must also be lower than the high end of the range.

PA -328 -200

PB -328 -200

PD or PE -328 -200

PF -328 -200

NA -112 -80

CA -148 -100

E Thermocouple -470 -279

J Thermocouple -346 -210

K Thermocouple -454 -270

T Thermocouple -454 -270

4-20mA (All) -999 to 9999 -999 to 9999

Example:

Set the low end of the range for a PF sensor when the temperature scale is set

to F.

The 16 bits to send would be: 1111 1110 1011 1000 = 0xFEB8 (-328 decimal)

G This 16 bit word sets the high end of the input range. The valid input range is

between -999 and 9999. If using a temperature input, the low end of the

range is shown in the following chart, choose the low end for °F, if the

temperature scale is set to °F or choose the low end for °C, if the temperature

scale is set to °C. The low and high end of the range must be entered for the

given sensor input or errant operation may result. The high end of the range

must also be higher than the low end of the range.

PA 1292 700

PB 1292 700

PD or PE 1562 850

PF 1166 630

NA 500 260

CA 500 260

E Thermocouple 1832 1000

J Thermocouple 2192 1200

K Thermocouple 2500 1370

T Thermocouple 752 400

4-20mA (All) -999 to 9999 -999 to 9999

Example:

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 43

Page 44

Set the high end of the range for a PF sensor when the temperature scale is

set to F.

The 16 bits to send would be: 0000 0100 1000 1110 = 0x048E (1166 decimal)

H This 16 bit word sets the Trip Value. The value must be set between the low

and high end of the range for proper operation. If the value is set higher that

the high end of the range, the input will be turned Off. If the second trip point

is used for an input, the first trip point must also be used. The second trip

point cannot be set and used without setting the first trip point, it will be

ignored.

Example:

Set the Trip Value to 100.

The 16 bits to send would be: 0000 0000 0110 0100 = 0x0064 (100 decimal)

Set the input to Off for an input using a PF sensor with temperature scale set

to F.

The 16 bits to send would be: 0000 0100 1000 1111 = 0x048F (1167 decimal)

I This 16 bit word sets whether to trip on an input reading that is Over or Under

the trip point.

0000 0000 0000 000X, where X is 0 for Over or 1 for Under.

Example:

Set the outputs to trip on an Over reading:

The 16 bits to send would be: 0000 0000 0000 0000 = 0x0000

J This 16 bit word is used for two parameters. The upper 8 bits set whether to

trip the alarm output and sound the alarm. The lower 8 bits set the outputs to

trip.

Trip alarm output and sound alarm:

A 0 indicates that the alarm output and alarm buzzer will not be activated

when a trip condition occurs on the specified input. A 1 indicates that the

alarm output and alarm buzzer will be activated when a trip condition occurs

on the specified input.

The format is as follows: 0000 000X, where X will be a 0 or 1

Outputs to Trip:

A 0 indicates not to trip and a 1 indicates to trip when a trip condition occurs.

The format is as follows: 0000 4321, where bit location 4 represents output 4,

bit location 3 represents output 3, etc.

Example:

Set the alarm to trip when a trip condition occurs and trip output 2 and 3:

The 16 bits to send would be: 0000 0001 0000 0110 = 0x0106

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 44

Page 45

Hex

ASCII

K This 16 bit word is used for two parameters. The upper 8 bits set the type of

action that will be taken to untrip the output(s) when a trip has occurred. The

lower 8 bits set the hysteresis value that will be used, if applicable.

Action to take to untrip the output(s):

0 indicates that a Manual Reset will be used to untrip the output(s). 1

indicates that Hysteresis will be used to untrip the output(s). 2 indicates that

the output(s) can be untripped by pressing Enter.

The format is as follows: 0000 00XX, where XX will be a 00, 01, or 10

Hysteresis:

Hysteresis can be any value between 0 and 20. The units for the hysteresis are

determined by the units used for the input type.

Example:

Set the output(s) to untrip using Manual Reset:

The 16 bits to send would be: 0000 0000 0000 0000 = 0x0000

Se the output(s) top untrip using the hysteresis value. Set the hysteresis value

to 10.

The 16 bits to send would be: 0000 0001 0000 1010 = 0x010A

L This 16 bit word is used to set the offset to add to the input reading to

compensate for some error in the sensor input. The offset is .1 x value. This

means that if the decimal number 10 is stored for the offset, the actual offset

is 1 unit (units are the same as the unit for the input type for the given input).

The valid range for offsets is -999 to 9999.

Example:

Set the offset to 1.2 units.

The 16 bits to send would be: 0000 0000 0000 1100 = 0x000C (12 decimal)

M This 16 bit word holds 2 ASCII character codes. The characters are used in the

name for the input.

The ASCII character code chart for characters understood by the CT224 is

shown below.

Code

Character

0x20

0x30 0

0x31 1

0x32 2

0x33 3

0x34 4

0x35 5

0x36 6

0x37 7

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 45

Page 46

0x38 8

0x39 9

0x41 A

0x42 B

0x43 C

0x44 D

0x45 E

0x46 F

0x47 G

0x48 H

0x49 I

0x4A J

0x4B K

0x4C L

0x4D M

0x4E N

0x4F O

0x50 P

0x51 Q

0x52 R

0x53 S

0x54 T

0x55 U

0x56 V

0x57 W

0x58 X

0x59 Y

0x5A Z

Example:

Set two characters to be ‘R5’ in the name for a zone.

The 16 bits to send would be: 0101 0010 0011 0101 = 0x5235

N This 16 bit word sets the Modbus Address for the controller. The valid range

for addresses is 1 to 247.

Example:

Set the address to 20:

The 16 bits to send would be: 0000 0000 0001 0100 = 0x0014 (20 decimal)

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 46

Page 47

Hex Code

Baud Rate

O This 16 bit word sets the Baud Rate for the CT224 according to the chart

below.

0 600

1 1200

2 2400

3 4800

4 9600

5 19200

Example:

Set the Baud Rate to 4800:

The 16 bits to send would be: 0000 0000 0000 0011 = 0x0003

P This 16 bit word sets the mode of operation for the CT224.

0x0000 - Normal Operation. The CT224 will have 0x0000 in this location when

it is operating in a normal fashion.

0x0001 – Reset. If 0x0001 is placed in this register, the CT224 will reset itself.

0x0505 – Wait Mode. If 0x0505 is placed into this register, the CT224 will not

read any inputs and will not trip any outputs. It is recommended that Wait

Mode be entered before updating any program settings. This will prevent

erratic trips caused by only partially configured inputs. If Wait Mode is not

existed within 2 minutes, the CT224 will automatically exit Wait Mode and

return to Normal Operation. Wait Mode is normally exited by writing 0x0001

(Reset) to the register. This will cause the CT224 to reset and begin using the

new settings.

Example:

Unit is reading inputs and updating the outputs (operating in Normal Mode).

Update the program settings and return to normal operation.

The first step should be to enter Wait Mode. Do this by sending 0x0505 to the

register. Then, update the settings that are to be updated. After updates

have been made, send 0x0001 to the register. The CT224 will reset and clear

any trips that may have been in place due to the old settings. The CT224 will

monitor inputs after reset and use the new settings.

Q This 16 bit word is used to store the password needed to enter the

Configuration Menu. Valid range for inputs is from 0 to 9999. 0 is used to

disable the password.

Example:

Set the password for entering the Configuration Menu to 3456.

The 16 bits to send would be: 0000 1101 1000 0000 = 0x0D80 (3456 decimal)

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 47

Page 48

R This 16 bit word is used to store the password needed to Manual Reset the

CT224. Valid range for inputs is from 0 to 9999. 0 is used to disable the

password.

Example:

Set the password for entering the Configuration Menu to 1234.

The 16 bits to send would be: 0000 0100 1101 0010 = 0x04D2 (1234 decimal)

S This 16 bit word contains part of an input reading. The Input Reading is

comprised of 2, 16 bit words. When the upper and lower words are combined

into one 32 bit word, the result will yield the true reading for the input x .1 .

This means that if the input reads 1234, the true input reading is 123.4 .

If the upper 16 bit word is 0x7FFF, this indicates that the input is Off.

If the upper 16 bit word is 0x0001, this indicates that the input has Failed.

The valid range for inputs is determined by the low and high input ranges.

Example:

If the full 32 bit reading is 0x00000800, the true input is 204.8

If the full 32 bit reading is 0xFFFFFFF0, the true input is -1.6

If the full 32 bit reading is 0x7FFFFFFF, the input is Off

If the full 32 bit reading is 0x000186A0 (100,000 decimal), the input has Failed.

T This 16 bit word contains the current status of the outputs. The upper 8 bits

hold the status of the outputs. The lower 8 bits are undetermined.

The upper 8 bits have the format 00054321. Where bit number 5 indicates the

status of the alarm, 0 not tripped or 1 tripped. Bit number 4 indicates the

status of output 4, 0 not tripped or 1 tripped. Bit number 3 indicates the

status for output 3, etc.

Example:

The 16 bit value read in was 0000 0101 1000 1000

The lower 8 bits can be discarded. Use the upper 8 bits 0000 0101. 1’s

indicate that outputs 1 and 3 are tripped and 0’s indicate that outputs 2, 4 and

the alarm output are not tripped.

Important Message Regarding Communications: The memory in the CT224 should

not be used in a way that parameters are being changed often. All settings are stored in

EEPROM. Repeated programming of EEPROM will cause the memory to fail. Under normal

use, reprogramming of memory will not be a problem. However, if an automated routine is

used to constantly change the settings, the limit of programming cycles can be quickly

overcome.

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 48

Page 49

Specifications:

Input:

1 to 12 RTDs (2 or 3

-

wire), Thermocouples, or 4

-

20 mA current loop.

Input Scan Rate:

Less than 1.5 seconds.

Outputs

Relays: Form C, SPDT 10 A @250 VAC/24 VDC resistive load; 10 A

Display:

20x4 line backlit LCD. 0.1°F or 0.1°C.

Keyboard:

4 membrane type keys wi

th audible and tactile feedback.

Accuracy:

2°C (3°F) in 0 to 60°C (32 to 158°F) ambient, over entire input range.

Power Supply:

Option A:

85 to 240 VAC @ 50/60 Hz. Or 110 to 250 VDC, 5 Watts

Replacement Fuses:

5x20mm, 250V, 500 mA.

Communication Interface:

RS485 or RS232 (Modbus protocol).

Enclosure:

Steel case; NEMA 4 front panel.

Ambient

T

emperature R

ating

: 0 to 60°C (32 to 158°F).

Connections:

Terminal blocks at rear accept wires to AWG 12.

Dimensions:

7.5” x 11.5” x 2”.

Mounting:

Panel mount enclosure. See cutout drawing.

Weight:

3.8 lbs.

Approvals:

UL 508

,

CSA C22.2 No. 14

-

M91

Standard Input Types:

RTD:

-200 to 700°C: PA (100 Ω/0.00392 Ω/Ω/°C)

-200 to 700°C: PB (100 Ω/0.00391 Ω/Ω/°C)

-200 to 850°C: PD/PE (100 Ω/0.00385 Ω/Ω/°C)

-200 to 600°C: PF (1000 Ω/0.00385 Ω/Ω/°C)

-80 to 260°C: NA (120 Ω/0.00672 Ω/Ω/°C)

-100 to 260°C: CA (10 Ω/0.00427 Ω/Ω/°C)

Thermocouple: (Ungrounded only)

-270 to 1000°C: Type E

-200 to 1200°C: Type J

-270 to 1150°C: Type K

-270 to 400°C: Type T

4-20 mA current loop:

Pressure (PSI, Bar), Humidity (%), Temperature (°F, °C),

Process Variable (mA, Vdc), and Vibration G. Must be linear

with respect to process variable to be measured.

make current; 2500 VA breaking capacity, ¼ HP at 120 VAC

motor load.

Logic: 5V DC output, 20 mA.

max.

Option B: 18 to 36 VDC, 6 Watts max.

UL File No: E252736

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 49

Page 50

This page left blank intentionally.

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 50

Page 51

This page left blank intentionally.

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 51

Page 52

How to Order

Worldwide Headquarters

European Headquarters

Asia Pacific Headquarters

ISO 9001:2000

/ AS9100B

CT224 Model Number: CT224

A Power Supply:

A= 85-240 VAC @ 50/60 HZ / 110-250 VDC

B = 18-36 VDC

1 Output:

1 = Relays

2 = Logic (5V)

A Communication Interface:

A = RS232

B = RS485

CT224A1A ← Sample Part Number

CT224 Master Password is: 9821

7300 Commerce Lane

Minneapolis, MN 55432 USA

Tel: 1.763.571.3121

Fax: 1.763.571.0927

sales@minco.com

www.minco.com

Usine et Service

Commercial, Z.I.

09310 Aston, France

Tel: (33) 5 61 03 24 01

Fax: (33) 5 61 03 24 09

Minco Tel: 763.571.3121 • Fax: 763.571.0927 • www.minco.com 52

20 Science Park Road

#02-31 Teletech Park

Singapore Science Park II

Singapore 117674

Tel: (65) 6511 3388

Fax: (65) 6511 3399

F:\MOD\CT224\LIT\1007MN.DOC

Minco 2012

Stock # 360-00099(D) 02/29/12

Flex Circuits

Thermofoil™ Heaters

Sensors

Instruments

Loading...

Loading...