Minarik RG25U, RG51UA User Manual

RG Series

Models:

RG25U

RG51UA

SCR, Adjustable-Speed

Regenerative Drives

for DC Brush Motors

User’s Manual

Copyright 1998 by

Minarik Corporation

All rights reserved. No part of this manual may be reproduced or transmitted in

any form without written permission from Minarik Corporation. The information

and technical data in this manual are subject to change without notice. Minarik

Corporation and its Divisions make no warranty of any kind with respect to this

material, including, but not limited to, the implied warranties of its merchantability

and fitness for a given purpose. Minarik Corporation and its Divisions assume no

responsibility for any errors that may appear in this manual and make no

commitment to update or to keep current the information in this manual.

Printed in the United States of America.

m Safety Warnings

• This symbol m denotes an important safety tip or warning.

Please read these sections carefully prior to performing any of

the instructions contained in that section.

• Have a qualified electrical maintenance technician install,

adjust and service this equipment. Follow the National

Electrical Code and all other applicable electrical and safety

codes, including the provisions of the Occupational Safety

and Health Act (OSHA), when installing equipment.

• Reduce the chance of an electrical fire, shock, or explosion by

proper grounding, over-current protection, thermal protection,

and enclosure. Follow sound maintenance procedures.

• It is possible for a drive to run at full speed as a result of a

component failure. Please ensure that a master switch has

been placed in the AC line to stop the drive in an emergency.

• This drive is isolated from earth ground. Circuit potentials

are at 115 VAC above earth ground. Avoid direct contact with

the printed circuit board or with circuit elements to prevent the

risk of serious injury or fatality. Use a non-metallic screwdriver

for adjusting the calibration trimpots.

ii

Contents

Specifications 1

Dimensions 2

Regenerative Drives 4

Installation 6

Mounting drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Line fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Screw terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Spade lugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Speed adjust potentiometer installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

RG25U Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

AC line and motor connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Speed adjust potentiometer connections . . . . . . . . . . . . . . . . . . . . . .11

RG51UA Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

AC line, motor, and field connections . . . . . . . . . . . . . . . . . . . . . . . . .12

Speed adjust potentiometer connections . . . . . . . . . . . . . . . . . . . . . .13

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Operation 16

Before applying power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Line starting and line stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Automatic restart upon power restoration . . . . . . . . . . . . . . . . . . . . . . . . .17

Regenerative deceleration (RG25U) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Regenerative deceleration (RG51UA) . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Calibration 19

MAX SPD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

FWD TQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

REV TQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

IR COMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

DB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Application Notes 23

RG25U/RG51UA Connections to other Minarik devices . . . . . . . . . . . . . .23

Optional speed adjust potentiometer connections . . . . . . . . . . . . . . . . . . .24

Troubleshooting 29

Replacement Parts 32

CE Compliance for RG51UA 33

Limited Warranty inside back cover

iii

Illustrations

Fig Description Page

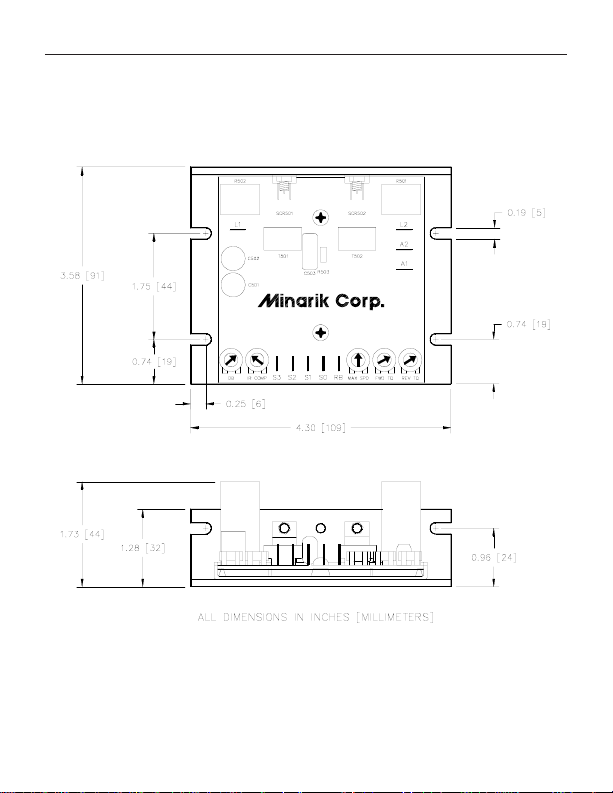

1. RG25U Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

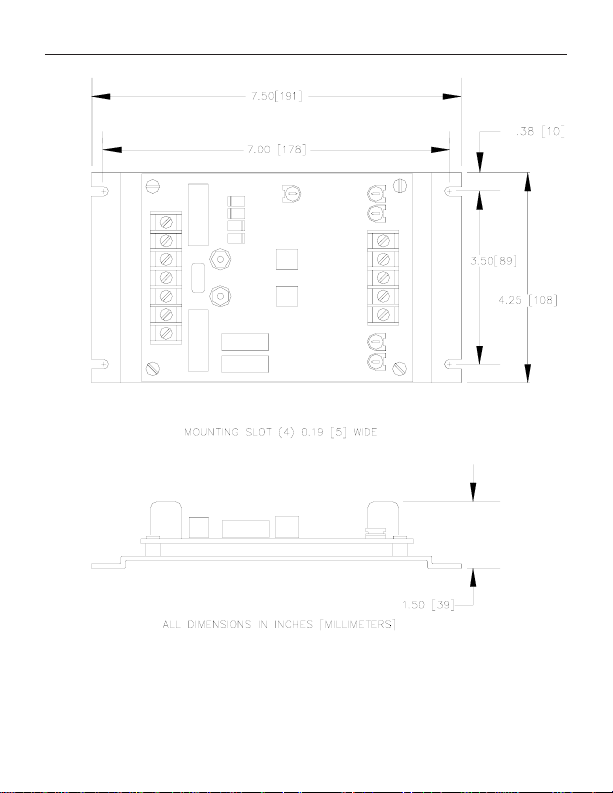

2. RG51UA Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

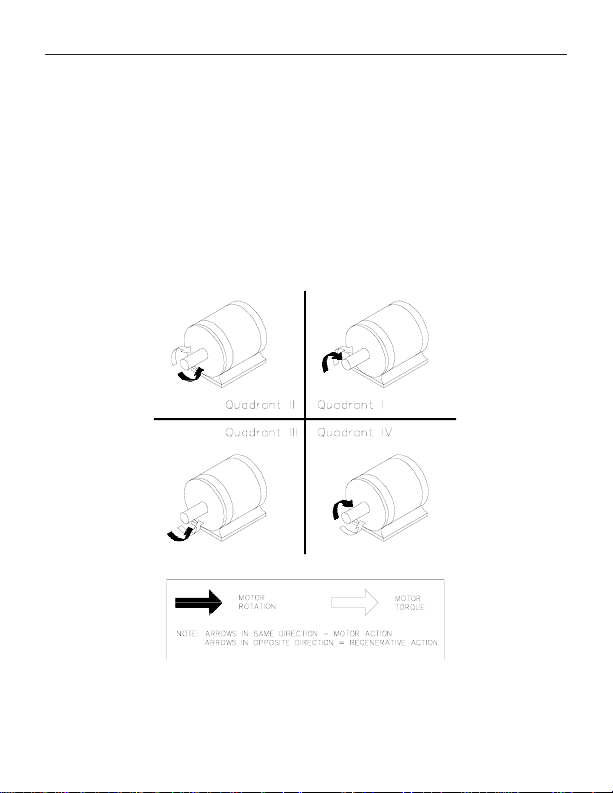

3. Four-Quadrant Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4. Screw Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

5. Speed Adjust Potentiometer Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .9

6. RG25U AC Line and Motor Connections . . . . . . . . . . . . . . . . . . . . . . . . . .10

7a. RG25U Connection for Unidirectional Operation . . . . . . . . . . . . . . . . . . . .11

7b. RG25U Connection for Bidirectional Operation . . . . . . . . . . . . . . . . . . . . .11

8. RG51UA AC Line, Motor and Field Connections . . . . . . . . . . . . . . . . . . . .12

9a. RG51UA Connection for Unidirectional Operation . . . . . . . . . . . . . . . . . . .13

9b. RG51UA Connection for Bidirectional Operation . . . . . . . . . . . . . . . . . . . .13

10. RG25U/RG51UA Series Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . .14

11. RG25U Regenerative Deceleration Switch . . . . . . . . . . . . . . . . . . . . . . . .17

12. RG51UA Regenerative Deceleration Switch . . . . . . . . . . . . . . . . . . . . . . .18

13. Typical FWD TQ, REV TQ and IR COMP Settings . . . . . . . . . . . . . . . . . . .21

14. Deadband Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

15. RG25U/RG51UA Connection to Other Minarik Devices . . . . . . . . . . . . . . .23

16. Forward-Reverse Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

17. Forward-Stop-Reverse Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

18. Independent Adjustable Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

19. Independent Forward and Reverse Speeds . . . . . . . . . . . . . . . . . . . . . . . .27

20. Independent Forward and Reverse Speeds with FWD-STOP-REV Switch .28

Tables

Fig Description Page

1. Line Fusing for RG Series Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2. Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

3. AC Line Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4. Armature Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

vvi1

Specifications

Max.

Armature HP Range

Model (Amps DC) Applied

RG25U 5.0 1/8–1/2

RG51UA 5.0 1/8–1/2

AC Line Voltage 115 VAC, ±10%, 50/60 Hz, single phase

Peak Current Limit 9 ADC

Maximum Armature Voltage Range at 115 VAC Input 60–75 VDC

Form Factor 1.77 at base speed

Acceleration Time (with load) 1 second

Deceleration Time (with load) 1 second

Speed Adjust Potentiometer 50KΩ

Analog Input Voltage Range (isolated; S1 to S2) 0–10 VDC

Input Impedance (S0 to S2) RG25U 200KΩ

Load Regulation at Base Speed 3%

Speed Range 50:1

Weight - RG25U .50 lb (227 grams)

Weight - RG51UA .75 lb (340 grams)

Ambient Temperature Range 10°C–55°C

Vibration 0.5g max (0 – 50 Hz)

RG51UA ONLY

Field Voltage (F1 to F2) 100 VDC

Maximum Field Current 1 ADC

Current with 115 VAC

RG51UA 100KΩ

0.1g max (above 50 Hz)

2

Dimensions

Figure 1. RG25U Dimensions

Dimensions

3

Figure 2. RG51UA Dimensions

4

Regenerative Drives

Most non-regenerative, variable speed, DC drives control

current flow to a motor in one direction. The direction of

current flow is the same direction as the motor rotation.

Non-regenerative drives operate in Quadrant 1, and also in

Quadrant 3 if the drive is reversible (Figure 3). Motors must

stop before reversing direction. Unless dynamic braking is

used, non-regenerative drives cannot oppose an overhauling

load, and cannot decelerate a load faster than coasting to a

lower speed.

Regenerative drives operate in two additional quadrants:

Quadrant 2 and Quadrant 4. In these quadrants, motor torque

is in the opposite direction of motor rotation.

Regenerative drives can reverse a motor without contactors,

switches, brake resistors, and inhibit plugs. They can also

control an overhauling load and decelerate a load faster than it

would take to coast to a lower speed.

The RG25U and the RG51UA are regenerative drives. They

are uncased chassis model drives and designed to be installed

in original equipment. The drives are the same electrically.

The physical layout and size of these drives are different (see

Dimensions section). The RG51UA includes a field supply for

shunt wound motors.

The RG25U and the RG51UA are half wave rectified DC

regenerative drives. Therefore the maximum armature voltage

Regenerative Drives

of these drives is 75 VDC. This means that a 90 VDC motor

will only run at about 83% of rated nameplate speed.

The form factor of the RG25U and the RG51UA is 1.77. This

will cause a higher-than-normal heating in the motor

armature. To prevent a shorter-than-normal motor life,

Minarik recommends that the horsepower rating of the motor

for a given application be at least 50% greater than the

required horsepower.

5

Figure 3. Four Quadrant Operation

6

Installation

ASSUMPTIONS: Minarik drives supply motor voltage from

A1 (or A+) and A2 (or A–) terminals. It is assumed

throughout this manual that, when A1 (or A+) is positive with

respect to A2 (or A–), the motor will rotate clockwise (CW)

while looking at the output shaft protruding from the front of

the motor. If this is opposite of the desired rotation, simply

reverse the wiring of A1 (or A+) and A2 (or A–) with each

other.

Mounting drives

Drive components are sensitive to electrostatic fields. Avoid

contact with the circuit board directly. Hold the drive by the

chassis only.

Protect the drive from dirt, moisture, and accidental contact.

Provide sufficient room for access to the terminal block and

calibration trimpots.

Mount the drive away from other heat sources. Operate

the drive within the specified ambient operating temperature

range.

Prevent loose connections by avoiding excessive vibration

of the drive.

Installation

Mount the drive with its board in either a horizontal or

vertical plane. The RG25U has six 0.188 inch (4.8 mm) wide

slots in the chassis that accept #8 pan head screws. Fasten

either the large base or the narrow flange of the chassis to the

subplate. The RG51UA has four 0.188 inch (4.8mm) wide

slots in the base of the chassis that accept #8 pan head screws.

The chassis must be earth grounded for noise suppression. To

ground the RG51UA chassis, connect earth ground to the

GND terminal on the seven position terminal block.

To ground the RG25U use a star washer beneath the head of at

least one of the mounting screws to penetrate the anodized

chassis surface and to reach bare metal.

Line fusing

The National Electrical Code requires the installation of a

circuit breaker or fuse on the incoming AC line voltage. Use a

circuit breaker or fast acting fuse rated for 8 amps or less.

With an 115VAC line voltage fuse the hot leg of the AC line

that connects to L1 and leave L2 unfused. Use 250VAC fuses.

See Table 1 for recommended line fuse sizes.

Table 1. Recommended Line Fuse Sizes

90 VDC Maximum Armature Fuse

Motor HP Current Rating

1/8 1.5 3

1/4 2.6 5

1/3 3.5 8

1/2 5.0 8

7

Loading...

Loading...