Page 1

Cat. No.

No de Cat.

Cat. No.

5337-20, 5337-21

5339-20, 5339-21

5340-20, 5340-21

5342-20, 5342-21

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

HEAVY-DUTY ROTARY HAMMERS AND DEMOLITION HAMMERS

EXTRA ROBUSTES MARTEAUX ROTATIFS ET MARTEAU DE DÉMOLISSEUR

ROTOMARTILLOS Y MARTILLOS PERFORADORES DE

DEMOLICIÓN HEAVY-DUTY

TO REDUCE THE RISK OF INJURY, USER MUST READ OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER EL MANUAL DEL OPERADOR.

Page 2

page 2

Page 3

GENERAL SAFETY RULES — FOR ALL POWER TOOLS

WARNING

Failure to follow all instructions listed below may result in electric shock, fi re and/or serious injury. The term "power tool" in all of the

warnings listed below refers to your mains-operated (corded) power tool or battery-opearted (cordless) power tool.

SAVE THESE INSTRUCTIONS

READ ALL INSTRUCTIONS

WORK AREA SAFETY

1. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

2. Do not operate power tools in explosive atmospheres, such as

in the presence of fl ammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

3. Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

4. Power tool plugs must match the outlet. Never modify the plug in

any way. Do not use any adapter plugs with earthed (grounded)

power tools. Unmodifi ed plugs and matching outlets will reduce risk

of electric shock.

5. Avoid body contact with earthed or grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is earthed or grounded.

6. Do not expose power tools to rain or wet conditions. Water entering

a power tool will increase the risk of electric shock.

7. Do not abuse the cord. Never use the cord for carrying, pulling, or

unplugging the power tool. Keep cord away from heat, oil, sharp

edges, or moving parts. Damaged or entangled cords increase the

risk of electric shock.

8. When operating a power tool outdoors, use an extension cord suit-

able for outdoor use. Use of a cord suitable for outdoor use reduces

the risk of electric shock.

PERSONAL SAFETY

9. Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired

or under the infl uence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in serious personal

injury.

10. Use safety equipment. Always wear eye protection. Safety equip-

ment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

11. Avoid accidental starting. Ensure the switch is in the off-position

before plugging in. Carrying tools with your fi nger on the switch or

plugging in power tools that have the switch on invites accidents.

12. Remove any adjusting key or wrench before turning the power

tool on. A wrench or a key left attached to a rotating part of the power

tool may result in personal injury.

13. Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

14. Dress properly. Do not wear loose clothing or jewellery. Keep your

hair, clothing and gloves away from moving parts. Loose clothes,

jewellery, or long hair can be caught in moving parts.

15. If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used.

Use of these devices can reduce dust-related hazards.

16. Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at

the rate for which it was designed.

17. Do not use the power tool if the switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

18. Disconnect the plug from the power source and/or the battery pack

from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the tool accidentally.

19. Store idle power tools out of the reach of children and do not al-

low persons unfamiliar with the power tools or these instructions

to operate power tools. Power tools are dangerous in the hands of

untrained users.

20. Maintain power tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the

power tool's operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly maintained power

tools.

21. Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier to

control.

22. Use the power tool, accessories and tool bits etc., in accordance

with these instructions and in the manner intended for the particular type of power tool, taking into account the working conditions

and the work to be performed. Use of the power tool for operations

different from those intended could result in a hazardous situation.

23. Have your power tool serviced by a qualifi ed repair person using

only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

1. Hold power tools by insulated gripping surfaces when performing

an operation where the cutting tool may contact hidden wiring or

its own cord. Contact with a “live” wire will make exposed metal parts

of the tool “live” and shock the operator.

2. Maintain labels and nameplates. These carry important information.

If unreadable or missing, contact a MILWAUKEE service facility for a

free replacement.

3. WARNING! Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry products,

and

• arsenic and chromium from chemically-treated lumber.

Y our risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals: work

in a well ventilated area, and work with approved safety equipment,

such as those dust masks that are specifi cally designed to fi lter out

microscopic particles.

4. Wear ear protectors. Exposure to noise can cause hearing loss.

5. Use auxiliary handles supplied with the tool. Loss of control can

cause personal injury.

POWER TOOL USE AND CARE

SERVICE

SPECIFIC SAFETY RULES

page 3

Page 4

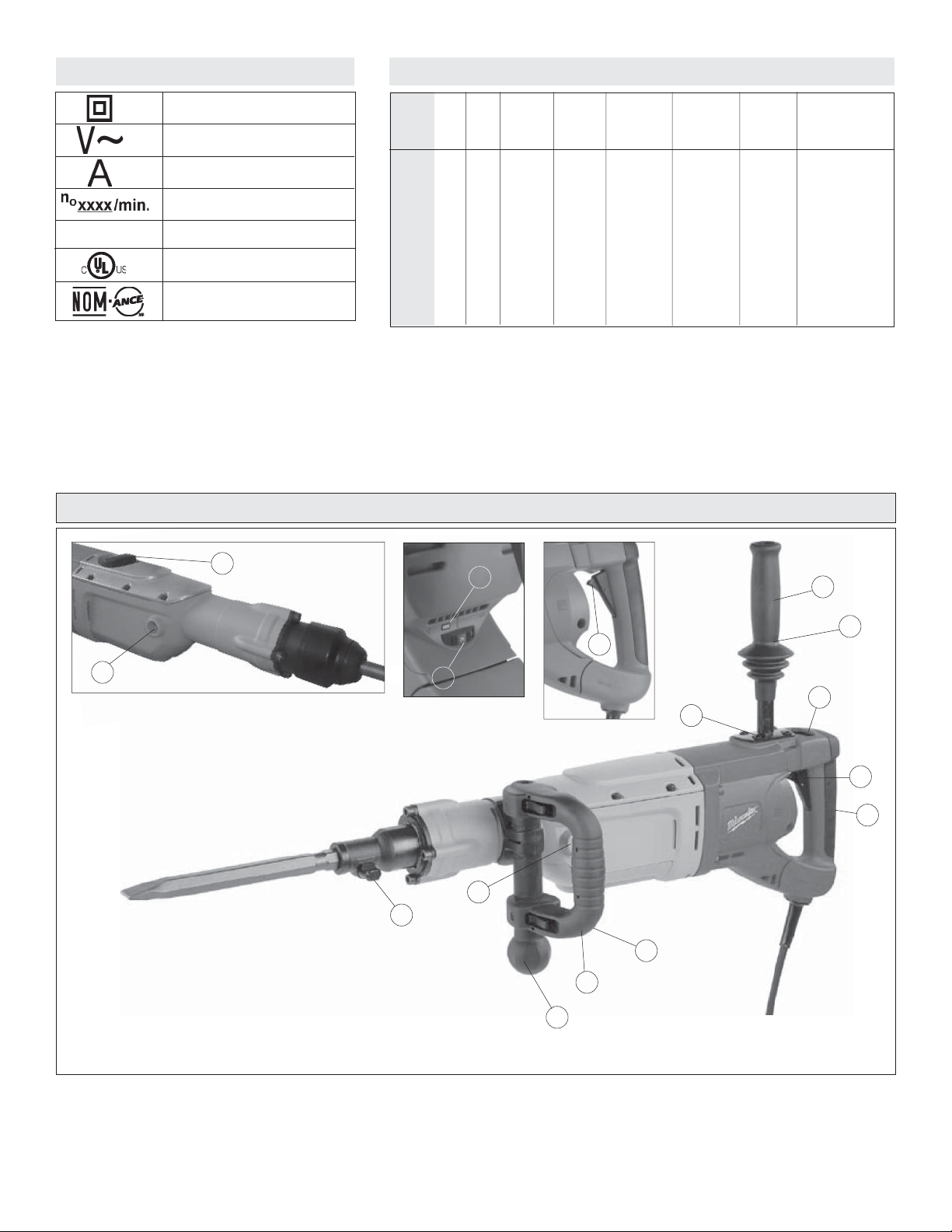

Symbology

Specifi cations

BPM

Double Insulated

Volts Alternating Current

Amps

No Load Revolutions per

Minute (RPM)

Blows per Minute (BPM)

Underwriters Laboratories, Inc.

Mexican Approvals Marking

Max

Percussion

Core Bit

Diameter

--

--

--

--

†

6"

†

6"

†

6"

†

6"

†

Chisels

"Chiseling

Chipping"

See

and

Chisel Shank

Type

3/4" Hex

3/4" Hex

SDS-Max

SDS-Max

3/4" Hex with

21/32" Round

3/4" Hex with

21/32" Round

SDS-Max

SDS-Max

Cat.

No.

5337-20

5337-21

5339-20

5339-21

5340-20

5340-21

5342-20

5342-21

Volts

AC

120

120

120

120

120

120

120

120

Amps

14

14

14

14

15

15

15

15

No Load

RPM *

--

--

--

--

125 - 250

125 - 250

125 - 250

125 - 250

Blows/

Minute

975-1950*

975-1950*

975-1950*

975-1950*

975-1950*

975-1950*

975-1950*

975-1950*

Max

Percussion

Drill Bit

Diameter

--

--

--

--

2" Spline

2" Spline

2" SDS-Max

2" SDS-Max

* EFCC - The Electronic Feedback Control Circuit maintains constant speed under varying

load conditions.

† Use MILWAUKEE core bits Cat. No. 48-20-5125 through 48-20-5165. Do not use LHS

(Large Hole System) Components with rotary hammers 5340-20 and 5342-20. The bits

could fail, breaking apart at the threaded stud and causing injury and property damage.

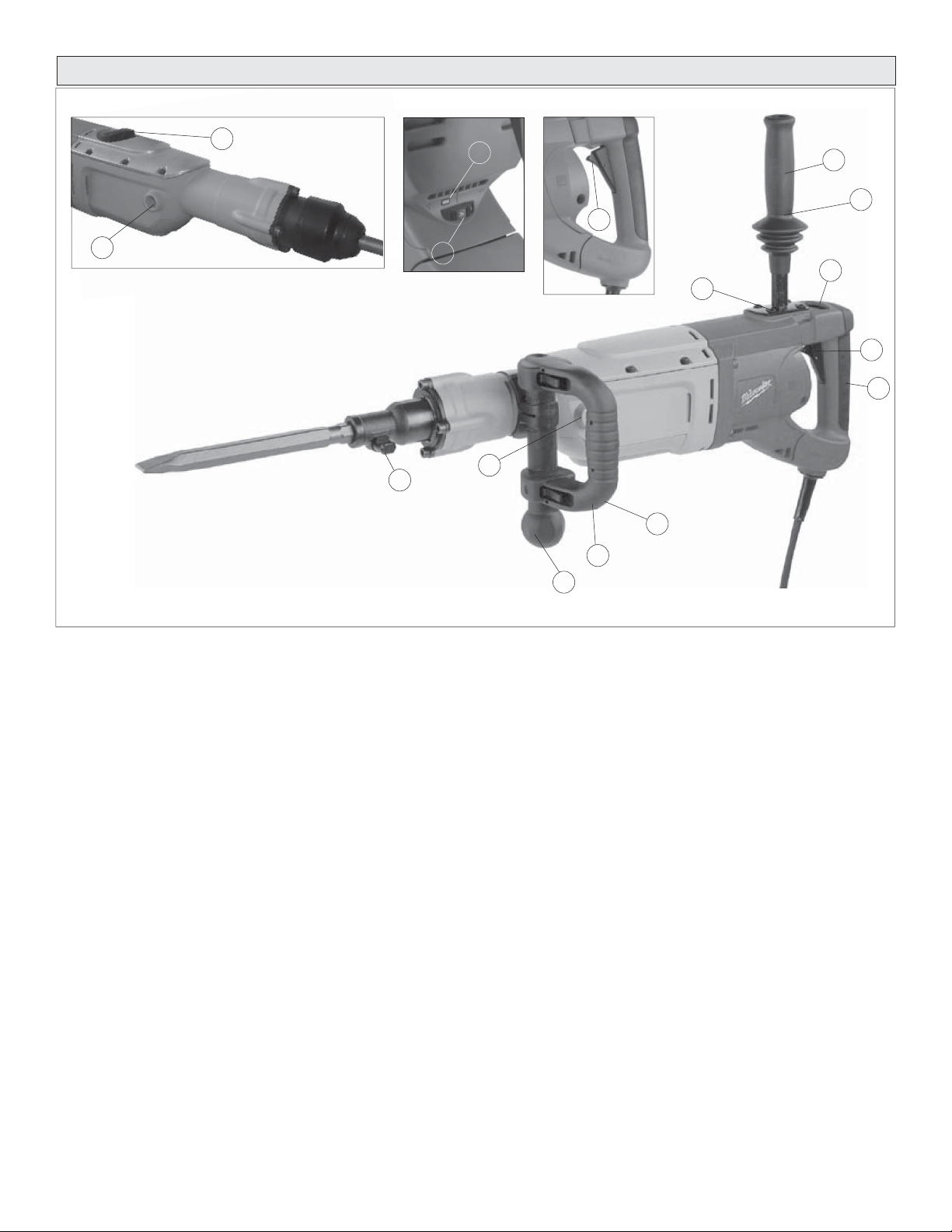

FUNCTIONAL DESCRIPTION

12

11

Cat. No. 5342-20

5

1. Vibration isolation system

2. On/Off trigger switch

3. Soft grip handle

4. Service indicator light

5. Speed control dial

6. Lock-on button (Cat. Nos. 5337-20, 5339-20 only)

9

7. Spade side handle (Cat. Nos. 5337-20, 5339-20 only)

8. Spade side handle adjusting knob (Cat. Nos. 5337-20, 5339-20 only)

9. Bit lock (Cat. Nos. 5337-20, 5340-20 only)

10. Straight side handle (must be used when hammering with rotation)

11. Straight side handle mounting positions (3 locations)

12. Action selector (Cat. No. 5339-20, 5342-20 only)

4

1

10

6

1

11

2

3

11

Cat. No. 5337-20

7

1

8

page 4

Page 5

GROUNDING EXTENSION CORDS

WARNING

Improperly connecting the grounding wire can result in the risk of

electric shock. Check with a qualifi ed electrician if you are in doubt

as to whether the outlet is properly grounded. Do not modify the

plug provided with the tool. Never remove the grounding prong

from the plug. Do not use the tool if the cord or plug is damaged. If

damaged, have it repaired by a MILWAUKEE service facility before

use. If the plug will not fi t the outlet, have a proper outlet installed

by a qualifi ed electrician.

Grounded tools require a three wire extension cord. Double insulated tools

can use either a two or three wire extension cord. As the distance from the

supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a serious drop in

voltage, resulting in loss of power and possible tool damage. Refer to the

table shown to determine the required minimum wire size.

The smaller the gauge number of the wire, the greater the capacity of the

cord. For example, a 14 gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension cord to make up the total

length, be sure each cord contains at least the minimum wire size required. If

you are using one extension cord for more than one tool, add the nameplate

amperes and use the sum to determine the required minimum wire size.

Grounded Tools:

Tools with Three Prong Plugs

Tools marked “Grounding Required”

have a three wire cord and three

prong grounding plug. The plug must

be connected to a properly grounded

outlet (See Figure A). If the tool should

electrically malfunction or break down,

grounding provides a low resistance

path to carry electricity away from

the user, reducing the risk of electric

shock.

The grounding prong in the plug is connected through the green wire inside

the cord to the grounding system in the tool. The green wire in the cord must

be the only wire connected to the tool's grounding system and must never

be attached to an electrically “live” terminal.

Y our tool must be plugged into an appropriate outlet, properly installed and

grounded in accordance with all codes and ordinances. The plug and outlet

should look like those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked “Double Insulated” do

not require grounding. They have a

special double insulation system which

satisfies OSHA requirements and

complies with the applicable standards

of Underwriters Laboratories, Inc., the

Canadian Standard Association and

the National Electrical Code. Double

Insulated tools may be used in either

of the 120 volt outlets shown in Figures

B and C.

Fig. A

Fig. B

Fig. C

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors, be sure it is marked with

the suffi x “W-A” (“W” in Canada) to indicate that it is acceptable for

outdoor use.

• Be sure your extension cord is properly wired and in good electrical

condition. Always replace a damaged extension cord or have it repaired

by a qualifi ed person before using it.

• Protect your extension cords from sharp objects, excessive heat and

damp or wet areas.

Recommended Minimum Wire Gauge

Nameplate

Amperes

5.1 - 8

8.1 - 12

12.1 - 15

15.1 - 20

* Based on limiting the line voltage drop to fi ve

volts at 150% of the rated amperes.

for Extension Cords*

25'

0 - 5

16

16

14

12

10

Extension Cord Length

100'

14

12

10

10

150'

12

10

--

--

--

--

50'

16

16

14

12

10

75'

16

14

12

10

10

200'

12

--

--

--

--

READ AND SAVE ALL INSTRUCTIONS

FOR FUTURE USE.

page 5

Page 6

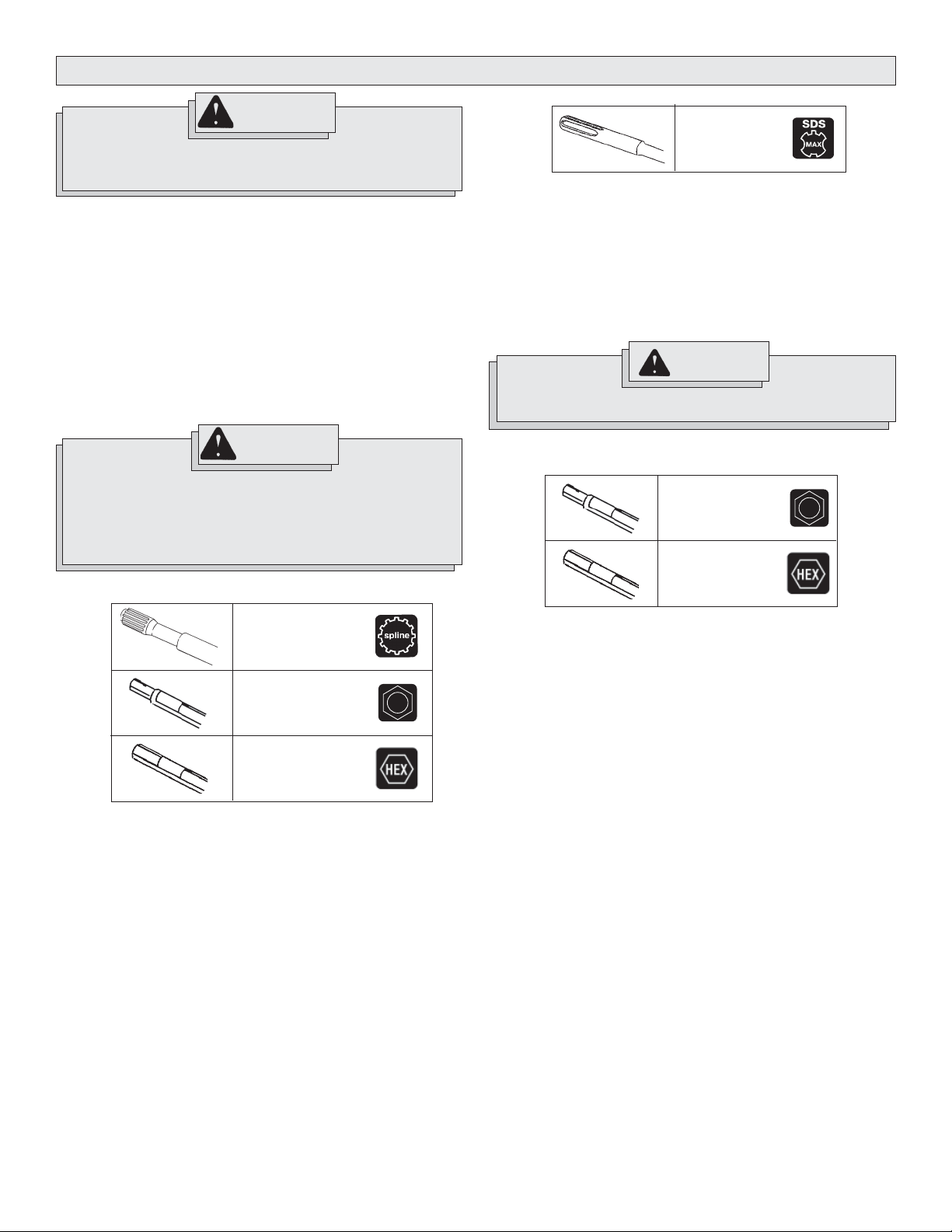

TOOL ASSEMBLY

WARNING

To reduce the risk of injury, always unplug tool before attaching

or removing accessories or making adjustments. Use only specifi -

cally recommended accessories. Others may be hazardous.

Adjusting the Spade Side Handle (Cat. No. 5337-20, 5339-20 only)

The spade side handle is provided on demolition hammers only. Do not use

the spade side handle on Rotary Hammers.

1. Slightly loosen the spade side handle by turning the spade side handle

adjusting knob counterclockwise.

2. Rotate the spade side handle to the desired position. The handle can be

moved to the left or right of the tool, as well as forward or backward.

3. Securely tighten the spade side handle adjusting knob.

Adjusting the Straight Side Handle

Screw the straight side handle into one of three positions (top, left side, or

right side). Tighten securely.

WARNING

To reduce the risk of injury when hammering with rotation, always

use the straight side handle when using this tool. Always brace

or hold securely.

To reduce the risk of injury when hammering with or without rotation, wear safety goggles or glasses with side shields.

Installing Bits and Chisels

SDS Max shank

Cat. No. 5339-20,

5342-20

1. Clean and grease the bit or chisel shank.

2. Insert the bit or chisel into the nose of the tool.

3. Rotate the bit or chisel slowly until it aligns with the locking mechanism.

4. Push the bit or chisel into the tool until it locks (Fig. 2).

5. Pull on the bit or chisel to verify that it is locked into place.

6. To remove, pull the bit release collar toward the rear of the tool and

remove the bit or chisel.

WARNING

To reduce the risk of injury, use only specifi cally recommended

MILWAUKEE hammer chisels. Others may damage tool.

Installing Hammer Chisels

Round hex shank

(Cat. No. 5340-20)

Hex shank

(Cat. No. 5337-20)

Spline shank

Cat. No. 5340-20 only

Round hex shank

Cat. No. 5340-20 only

Hex shank

Cat. No. 5337-20 only

NOTE: To reduce the risk of damage to the bit lock, do not use round hex

shank bits in the 5337-20. Only use hex shank bits in this tool.

1. Clean and grease the bit or chisel shank.

2. Pull out the bit lock and rotate it 180°.

3. Insert the bit or chisel into the nose of the tool (Fig. 1)

NOTE: When using hex (on cat. no. 5337-20) or hex/round (on cat. no.

5340-20) bits or chisels, the notch in the shank must face toward the

bottom of the nosepiece of the tool.

4. Lock the bit or chisel by pulling out the bit lock and rotating it 180°.

5. Pull on the bit or chisel to verify that it is locked into place.

6. To remove, rotate the bit lock 180° and remove the bit or chisel.

NOTE: Use caution when handling hot bits and chisels.

Always clean and grease the chisel shank before inserting the chisel into the

tool. Inspect the shank to make sure it is not "mushroomed", as described

in "Maintaining Hammer Chisels". Always make sure that the chisel is in

good working condition before use.

page 6

Page 7

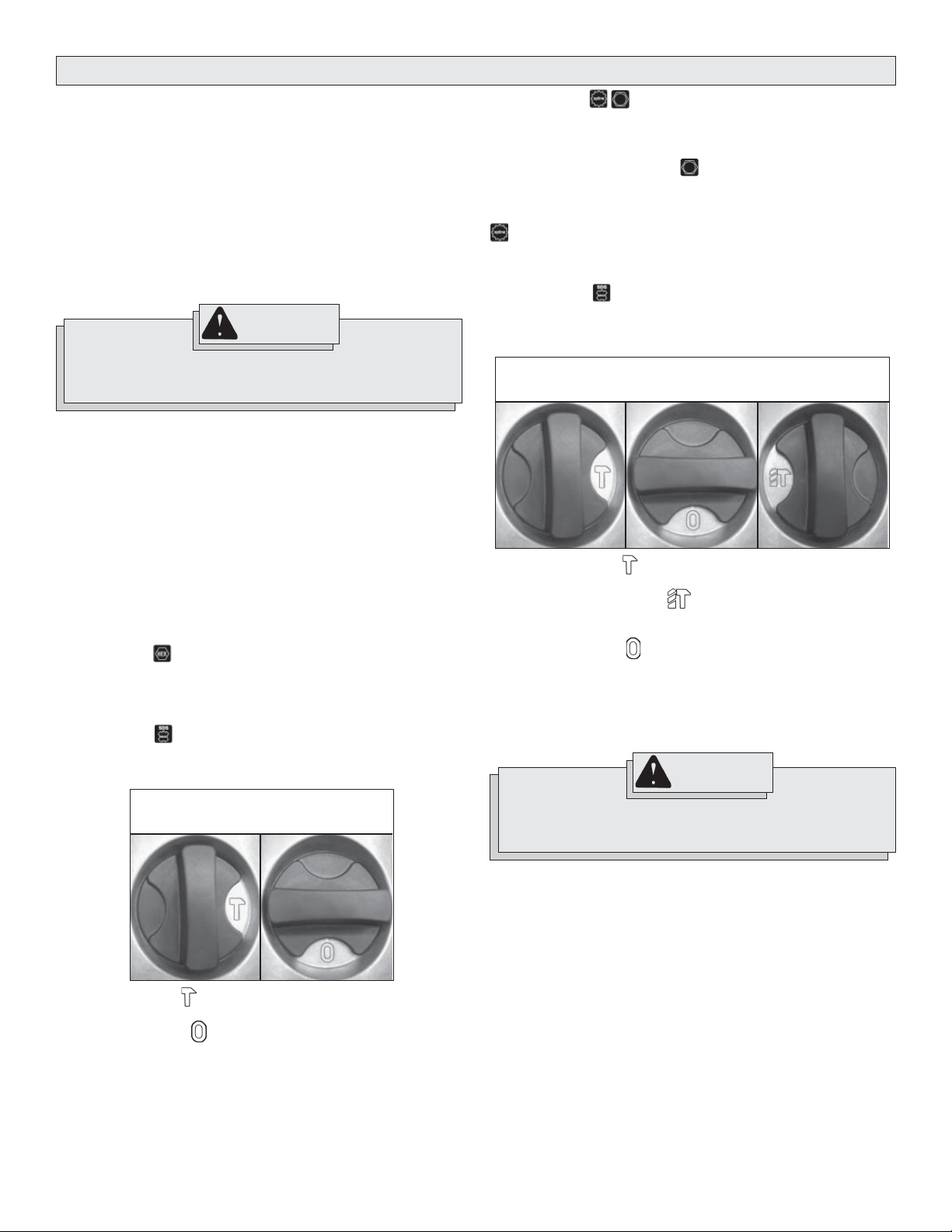

OPERATION

Electronic Feedback Control Circuit

These hammers have an Electronic Feedback Control Circuit (EFCC) which

helps improve the operation and life of the tool.

Feedback Control

The electronic speed control circuit allows the tool to maintain constant

speed and torque between no-load and load conditions.

Soft Start

The Soft-Start feature reduces the amount of torque reaction to the tool and

the user. This feature gradually increases the motor speed up from zero to

the speed set by the speed control dial.

WARNING

To reduce the risk of injury, wear safety goggles or glasses with

side shields. Unplug the tool before changing accessories or

making adjustments.

Selecting Speed

The speed control dial on these hammers allows the user to adjust the

rotating speed (RPM) and the impact rate (BPM) of the tool.

To change the speed, set the speed control dial to the desired setting.

• Lower speeds provide more control when starting holes and reduce

'spalling' on breakthrough. Spalling occurs when pieces of material chip

off around the drilled hole on breakthrough. When chiseling in soft or

brittle materials, use lower speeds to reduce damage to surrounding

areas of the material.

• Higher speeds provide faster penetration when drilling and chiseling in

demolition work.

Selecting Action

Cat. No. 5337-20

The cat. no. 5337-20 demolition hammer is for "hammering-only". No rotation is available. Only chisels and other "hammering-only" accessories

should be used.

Cat. No. 5339-20 (Fig. 3)

The cat. no. 5339-20 demolition hammer is for "hammering-only". No rotation

is available. The action selector is used to select the action:

Cat. No. 5340-20

The cat. no. 5340-20 rotary hammer has "hammering-only" and "hammering

with rotation", depending on the type of shank inserted into the tool.

For "hammering-only": Insert a chisel or other "hammering-only" accessory

with a 3/4" Hex with 21/32" Round shank into the nose of the tool (see

"Inserting Bits and Chisels"). The rotational drive mechanism will run but not

engage with the chisel, resulting in "hammering-only" action.

For "hammering with rotation": Insert a drill or coring bit with a spline

xxx shank into the nose of the tool (see "Inserting Bits and Chisels"). The

rotational drive mechanism engages with the bit, resulting in "hammering

with rotation" action.

Cat. No. 5342-20 (Fig. 4)

Cat. no. 5342-20 rotary hammer has "hammering-only", "hammering with

rotation", and "chisel adjustment" settings. The action selector is used to

select the action:

Fig. 4

Hammering Only

1. Hammering only. For use with "hammering only" accessories.

Use this setting for chiseling.

2. Hammering with rotation. Use this setting for drilling holes with

drill bits. Do not use "hammering with rotation" when using chisels or

other "hammering-only" accessories.

3. Chisel adjustment. Use this setting to adjust the angle of the chisel

blade in relation to the tool. With a chisel mounted in the tool, twist

the chisel to the desired angle. Then, rotate the action selector to the

Hammering only setting for use.

NOTE: To engage the hammering mechanism, maintain pressure on the

bit/chisel. When pressure is released, hammering stops.

Chisel Adjustment

Hammering with

Rotation

WARNING

Fig. 3

Hammering Only Chisel Adjustment

1. Hammering only . For use with "hammering only" accessories. Use

this setting for chiseling.

2. Chisel adjustment. Use this setting to adjust the angle of the chisel

blade in relation to the tool. With a chisel mounted in the tool, twist

the chisel to the desired angle. Then, rotate the action selector to the

"hammering only" setting for use.

NOTE: To engage the hammering mechanism, maintain pressure on the

bit/chisel. When pressure is released, hammering stops.

To reduce the risk of injury, when using chisels or other hammering-only accessories in cat. no. 5342-20, the action selector must

be set to the "hammering only" position.

Starting and Stopping the Tool

1. To start the tool, pull the trigger.

2. To stop the tool, release the trigger.

Locking the Trigger (Cat. No. 5337-20, 5339-20 only)

The lock button on the demolition hammers holds the trigger in the "On"

position for continuous use.

1. To lock the trigger, hold in the lock button while pulling the trigger.

Release the trigger.

2. To unlock the trigger, pull the trigger and release. The lock button will

pop out.

page 7

Page 8

Cold Hammering

If the hammer is stored for a long period of time or at cold temperatures,

the lubrication may become stiff and the tool may not hammer initially or

the hammering may be weak. If this happens:

1. Insert a chisel into the tool.

2. Pull the trigger and apply the chisel against a scrap piece of concrete.

3. Turn the tool On and Off every few seconds. After 15 seconds to 2

minutes, the tool will start hammering normally. The colder the hammer

is, the longer it will take to warm up.

Operator Force

These hammers feature the Vibration Isolation System to provide the operator with comfort without sacrifi cing power or performance. The motor housing

is suspended independently from the switch handle. Insulating elements

absorb vibration when hammering and drilling.

Ideal operator force compresses the handle slightly and allows the tool to

work aggressively while the handle provides maximum vibration dampening.

Excessive operator force compresses the handle too far and reduces the

vibration dampening. Users will be able to feel the difference and should

adjust the force to the handle accordingly.

WARNING

Applying greater pressure does not increase the tool's effectiveness. If the applied working pressure is too high, the shock

absorber will be pushed together making vibration to the handle

noticeably stronger.

WARNING

To reduce the risk of injury, hold or brace securely. Always be

prepared for drill reaction when bit binds, when hole becomes

clogged, when striking embedded materials, and during hole

breakthrough.

4. Pull the trigger. Always hold the tool securely using the straight handle

and trigger handle and maintain control.

5. Use only enough pressure to hold the tool in place, engage the hammering mechanism, and prevent the tip of the bit from wandering. This

tool has been designed to achieve top performance with only moderate

pressure. Let the tool do the work.

When pressure is released, hammering stops.

6. When drilling deep holes, the speed may begin to drop off. Pull the bit

partially out of the hole while the tool is running to help clear dust.

NOTE: Do not use water to settle the dust since it will clog the bit fl utes

and tend to make the bit bind in the hole.

If a bit binds:

If the bit should bind, a built in, nonadjustable slip clutch prevents the bit

from turning when the tool is held or braced securely. If this occurs

1. Turn off and unplug the tool.

2. Free the bit from the workpiece.

3. Clear debris from the hole.

4. Begin drilling again.

WARNING

Hammering Only

1. Insert a chisel or other "hammering only" accessory into the tool (see

"Installing Bits and Chisels").

2. Position the tool on the workpiece.

3. Grasp both handles fi rmly (trigger handle and either the spade handle

or straight handle).

4. Pull the trigger. Always hold the tool securely using two handles and

maintain control.

5. Use only enough pressure to hold the tool in place, engage the hammering mechanism, and prevent the tip of the chisel from wandering.

This tool has been designed to achieve top performance with only

moderate pressure. Let the tool do the work.

NOTE: To engage the hammering mechanism, maintain pressure on

the bit/chisel. When pressure is released, hammering stops.

6. When chiseling or chipping, hold the tool at an angle to the work area.

For best performance, work from a corner or close the edge of the work

and break off a small area at a time.

If a hammer iron gets stuck:

1. Unplug the tool.

2. Pull out bit lock and rotate it 180°.

3. Pull the tool off of the stuck accessory.

4. Remove the accessory from the workpiece.

Hammering with Rotation

1. Insert a drill or coring bit into the tool (see "Installing Bits and Chisels").

2. Position the tool on the workpiece.

3. Grasp both handles fi rmly (trigger handle and straight handle).

Use MILWAUKEE core bits Cat. No. 48-20-5125 through 48-20-5165.

Do not use LHS (Large Hole System) Components with rotary hammers 5340-20 and 5342-20. The bits could fail, breaking apart at the

threaded stud and causing injury and property damage.

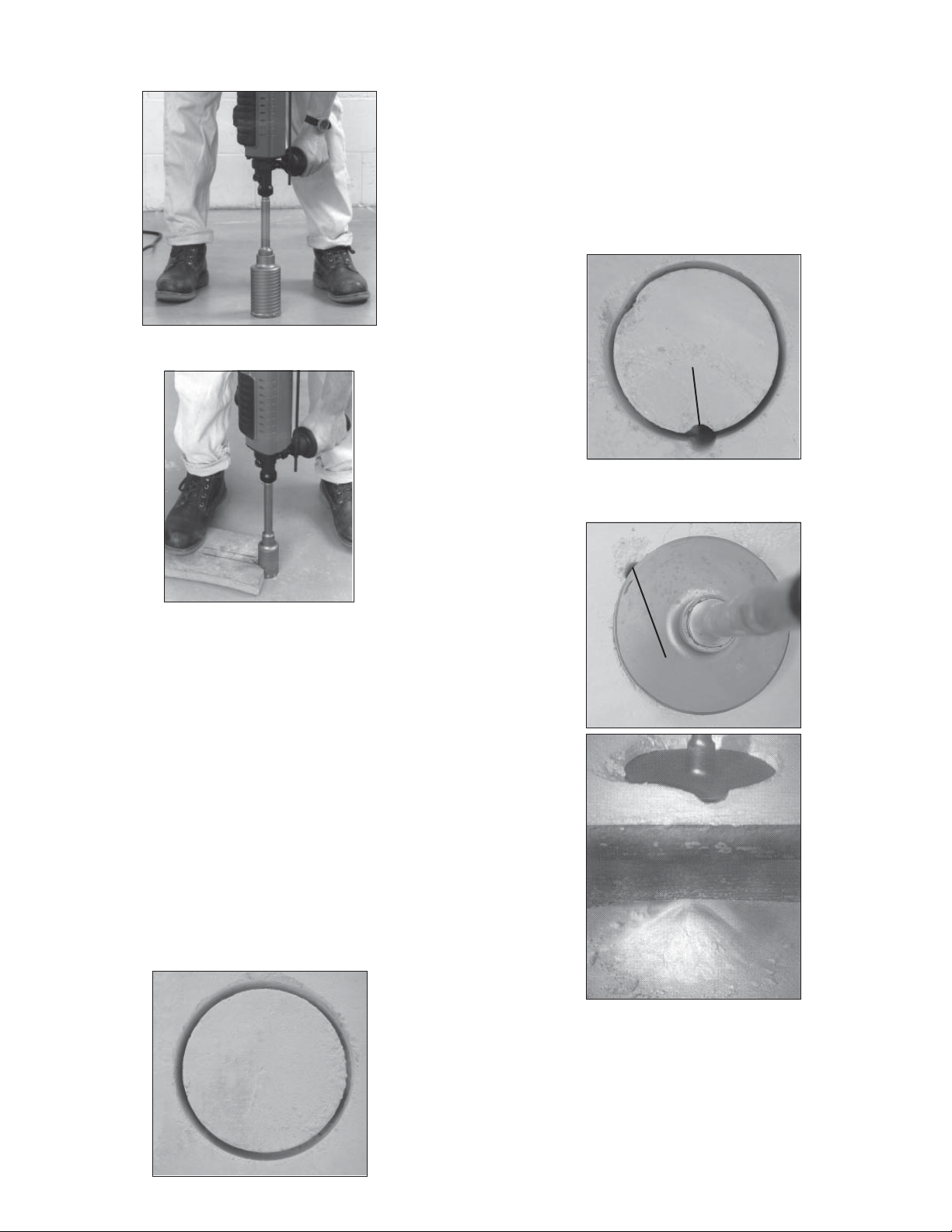

Using Rotary Percussion Core Bits (Fig. 5 - 7)

Core bits are useful for drilling larger holes for conduit and pipe.

MILWAUKEE Heavy-Duty Core Bits have heat-treated steel bodies with

durable carbide tips. These core bits are specially designed for fast, accurate

drilling with combined hammering and rotary action.

1. Clean and lubricate the threads on the adapter and core bit to make

later removal easier. Screw the threaded end of the adapter into the

rear of the core bit.

2. Push the guide plate onto the pointed end of the center pin. Insert the

center pin and guide plate assembly into the core bit. Be sure the small

end of the center pin is securely placed into the hole in the center of

the core bit (Fig. 5).

Fig. 5

3. Insert the adapter into the nose of the tool (see “Installing Bits and

Chisels”. Set the action selector to the hammering-with-rotation

setting.

page 8

Page 9

4. Press the center pin fi rmly against your center mark, hold the tool fi rmly

and pull the trigger (Fig. 6).

Fig. 6

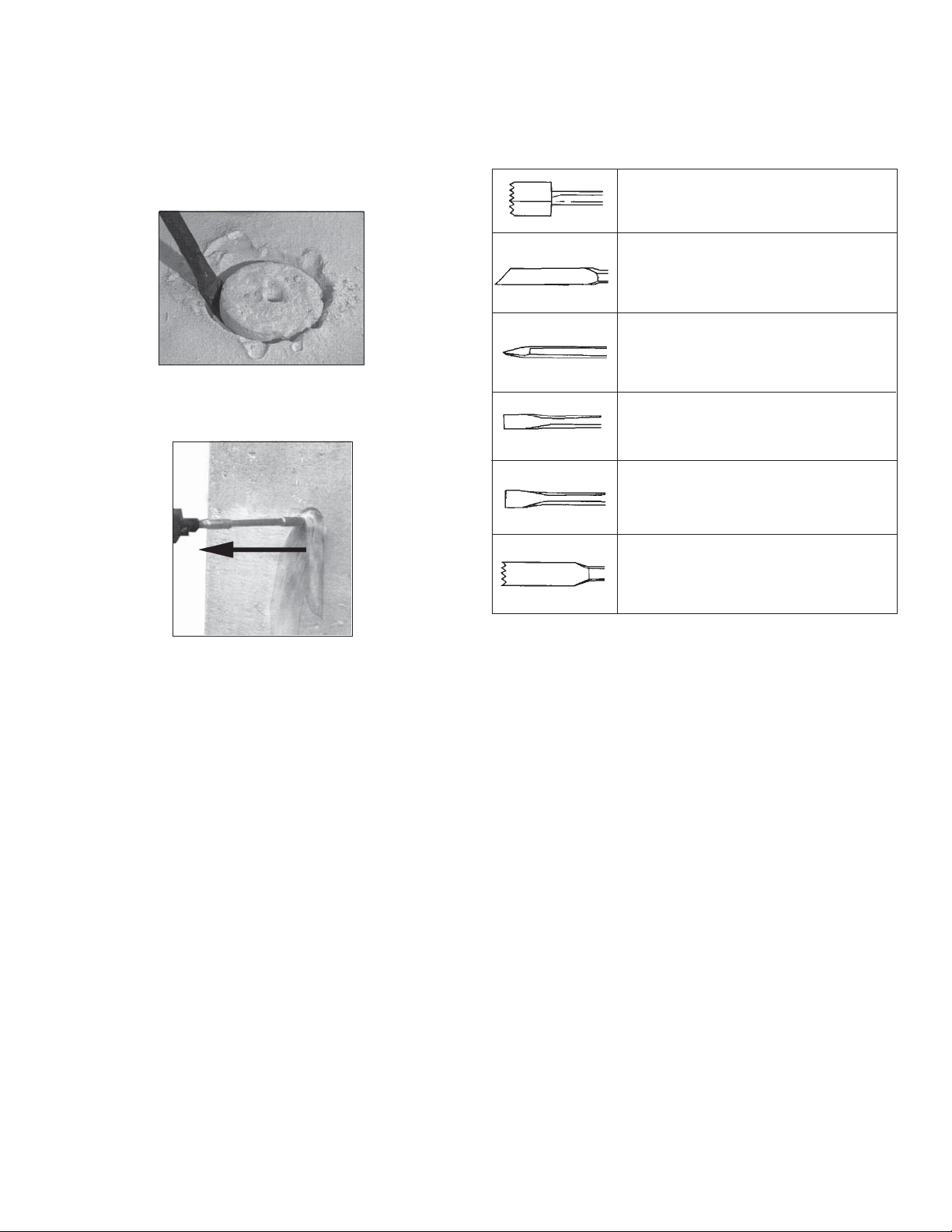

3. Remove the bit from the tool.

4. Install a standard fl uted bit, approximately 7/8" in diameter, onto the

tool.

5. Drill a perpendicular hole through the kerf of the large hole (Fig. 9).

• Depending on the location of the work, the hole should either break

through the other side of the hole/fl oor or extend 4"-5" past the end of

the workpiece (such as into the dirt below a concrete slab).

• If dust builds up in the hole, vacuum it out and continue drilling.

• If drilling through a wall, the hole for dust should be drilled on the lowest

part of the large hole kerf (Fig. 9) as the dust will fall there when drilling

and can be evacuated more easily.

Fig. 9

NOTE: If a center pin and guide plate are not available, use a template

or notched board to start the hole (Fig. 7).

Fig. 7

5. After drilling to about the depth of the core bit teeth, remove the center

pin and guide plate from the core bit. Resume drilling.

6. To change the core bit, hold the tool upwards, pointing it away from

your body, and run the tool allowing rotation and impacting for about

fi ve seconds to loosen the core bit from the adapter shank.

NOTE: To make deeper holes, remove the core bit, break and remove

the core. Resume drilling. When drilling long or deep holes, after each

inch of penetration pull the bit partially out of the hole while the tool is

running, to help clear dust from the bit fl utes. Dust can clog the bit fl utes

and can make the bit bind in the hole. If this occurs, stop the tool, free

the bit and begin again.

Drill a hole through

the work.

6. Reinstall the core bit and continue drilling (Fig. 10 & 11). Dust and debris

will fall through the hole and optimize the cutting ability of the bit.

Fig. 10

Dust and debris

will fall through

the hole.

Top view

Fig. 11

Drilling Large Diameter Holes with Core Bits (Fig. 8-13)

When drilling holes with large diameter core bits, dust may build up in the

cut and can cause the tool to stall, bind, or cut slowly. By creating an opening for the dust to escape, drilling time, bit stress, and tool stress can be

reduced.

1. Start the cut as normal.

2. Once the bit is fi rmly established in the cut (about 1/4" deep), remove

the bit from the cut (Fig. 8).

Fig. 8

Cut approximately

1/4" deep with a core

bit.

Side view

of slab

page 9

Page 10

7. For core bits, once the maximum core bit depth is drilled, the core must

be broken and removed.

• Install a chisel bit.

• Place the chisel into the hole kerf (Fig. 12).

• Chisel down into the kerf at several points until the core is loose or

broken.

• Remove the core and vacuum/remove any remaining dust and debris.

• Install the core bit and continue the cut.

Fig.

NOTE: If unable to drill a hole in the kerf, pull back on the bit with the ham-

mer running (Fig. 13). This will remove some of the dust and debris from

the cut. Repeat this for every inch of drilling. If necessary, vacuum dust and

debris from the cut and surrounding area.

Fig. 13

Pull bit out as far

as possible once

or twice per inch

drilled.

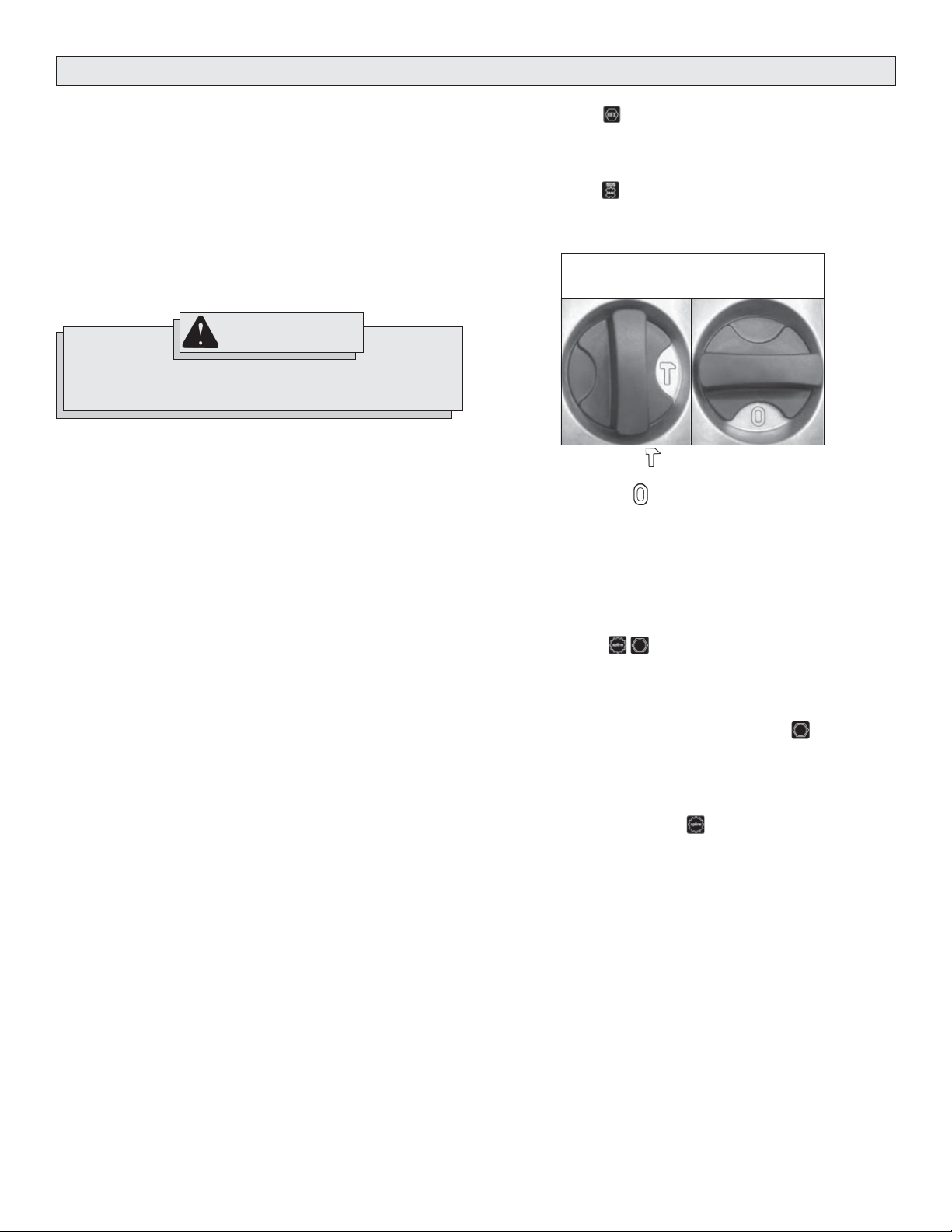

Chiseling and Chipping

These MILWAUKEE Hammers may be used for chipping and chiseling.

When chiseling, hold the tool at an angle to the workpiece. Work from a

corner or close to the edge of the workpiece, breaking off one small area

at a time rather than attempting too large an area.

A variety of accessories are available.

Bushing Tools

Used to surface concrete.

Mortar Cutting Chisels (Seam Tools)

For removing old mortar for tuck pointing or

caulking.

Bull Points

For demolition work and starting holes in

concrete slabs.

Flat Chisels

For edging, chipping or channeling.

Scaling Chisels

For removing weld spatter or scale and cutting straight lines.

Slotting Chisel

For slotting and cutting between drilled holes

in concrete and masonry.

page 10

Page 11

MAINTENANCE

ACCESSORIES

WARNING

To reduce the risk of injury, always unplug your tool before performing any maintenance. Never disassemble the tool or try to do

any rewiring on the tool's electrical system. Contact a MILW AUKEE

service facility for ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a regular maintenance program. Before use, examine the general condition of your tool. Inspect

guards, switches, tool cord set and extension cord for damage. Check

for loose screws, misalignment, binding of moving parts, improper

mounting, broken parts and any other condition that may affect its safe

operation. If abnormal noise or vibration occurs, turn the tool off immediately and have the problem corrected before further use. Do not

use a damaged tool. Tag damaged tools “DO NOT USE” until repaired

(see “Repairs”).

Under normal conditions, relubrication is not necessary until the motor

brushes need to be replaced. After six months to one year, depending on

use, return your tool to the nearest MILWAUKEE service facility for the

following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears, spindles, bearings,

housing, etc.)

• Electrical inspection (switch, cord, armature, etc.)

• Testing to assure proper mechanical and electrical operation

Maintaining Hammer Chisels

Through normal use, the shank of the chisel can "mushroom" over and cause

the chisel to become stuck inside the hammer. To prevent this from happening, periodically remove the chisel from the tool and inspect the shank. If the

shank starts to "mushroom", have the chisel refurbished or replaced.

WARNING

To reduce the risk of injury, always unplug the tool before attaching or removing accessories. Use only specifi cally recommended

accessories. Others may be hazardous.

For a complete listing of accessories refer to your MILWAUKEE Electric Tool catalog or go on-line to www.milwaukeetool.com. To obtain a

catalog, contact your local distributor or a service center.

Thick Wall Carbide-Tipped Core Bits

Core body with Guide Plate and Centering Pin

Diameter Drilling Depth Cat.No.

1-1/2" 4-1/16" 48-20-5125

1-3/4" 4-1/16" 48-20-5130

2" 4-1/16" 48-20-5135

2-1/2" 4-1/16" 48-20-5140

3" 4-1/16" 48-20-5145

3-1/2" 4-1/16" 48-20-5150

4" 4-1/16" 48-20-5155

5" 4-1/16" 48-20-5160

6" 4-1/16" 48-20-5165

NOTE: Use MILWAUKEE core bits Cat. No. 48-20-5125 through 48-20-5165.

Do not use LHS (Large Hole System) Components with rotary hammers

5340-20 and 5342-20. The bits could fail, breaking apart at the threaded

stud and causing injury and property damage.

Brush Replacement

These MILWAUKEE hammers are will automatically shut off when the

brushes need to be replaced. Return your tool to the nearest MILWAUKEE

service facility for repairs.

Service Indicator Light

These MILWAUKEE Hammers feature a service indicator light. When the

red light turns on, the tool is in need of servicing. Return your tool to the

nearest MILWAUKEE service facility for service.

NOTE: When the service light comes on, the tool will continue to run for a

few hours and then the motor will shut off.

WARNING

To reduce the risk of injury, electric shock and damage to the tool,

never immerse your tool in liquid or allow a liquid to fl ow inside

the tool.

Cleaning

Clean dust and debris from vents. Keep the tool handles clean, dry and

free of oil or grease. Use only mild soap and a damp cloth to clean your

tool since certain cleaning agents and solvents are harmful to plastics and

other insulated parts. Some of these include: gasoline, turpentine, lacquer

thinner, paint thinner, chlorinated cleaning solvents, ammonia and household detergents containing ammonia. Never use fl ammable or combustible

solvents around tools.

Repairs

If your tool is damaged, return the entire tool to the nearest service center.

FIVE YEAR TOOL LIMITED WARRANTY

Every MILWAUKEE tool is tested before leaving the factory and is warranted to be free from defects in material and workmanship. MILWAUKEE

will repair or replace (at MILWAUKEE’s discretion), without charge, any

tool (including battery chargers) which examination proves to be defective

in material or workmanship from fi ve (5) years after the date of purchase.

Return the tool and a copy of the purchase receipt or other proof of purchase to a MILWAUKEE Factory Service/Sales Support Branch location or

MILWAUKEE Authorized Service Station, freight prepaid and insured. This

warranty does not cover damage from repairs made or attempted by other

than MILWAUKEE authorized personnel, abuse, normal wear and tear, lack

of maintenance, or accidents.

Battery Packs, Flashlights, and Radios are warranted for one (1) year from

the date of purchase.

THE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN ARE

EXCLUSIVE. IN NO EVENT SHALL MILWAUKEE BE LIABLE FOR ANY

INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES, INCLUDING

LOSS OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, OR CONDITIONS, WRITTEN OR ORAL, EXPRESSED OR

IMPLIED FOR MERCHANTABLILITY OR FITNESS FOR PARTICULAR

USE OR PURPOSE.

This warranty gives you specifi c legal rights. You may also have other rights

that vary from state to state and province to province. In those states that

do not allow the exclusion of implied warranties or limitation of incidental

or consequential damages, the above limitations or exclusions may not

apply to you. This warranty applies to the United States, Canada, and

page 11

Page 12

RÈGLES GÉNÉRALES DE SÉCURITÉ POUR LES OUTILS ÉLECTRIQUE

AVERTISSEMENT

LIRE SOIGNEUSEMENT TOUTES LES INSTRUCTIONS

Le non respect des instructions ci-après peut entraîner des chocs électriques, des

incendies et/ou des blessures graves. Le terme «outil électrique» fi gurant dans les

avertissements ci-dessous renvoie à l’outil électrique à alimentation par le réseau

(à cordon) ou par batterie (sans fi l).

CONSERVER CES INSTRUCTIONS

SÉCURITÉ DU LIEU DE TRAVAIL

1. Maintenir la zone de travail propre et bien éclairée. Les zones

encombrées ou mal éclairées sont favorables aux accidents.

2. Ne pas utiliser d’outil électrique dans une atmosphère explosive,

telle qu’en en présence de liquides, de gaz ou de poussières in-

fl ammables. Les outils électriques génèrent des étincelles qui peuvent

enfl ammer les poussières ou les fumées.

3. Tenir les enfants et les personnes non autorisées à l’écart pendant

le fonctionnement d’un outil électrique. Un manque d’attention de

l’opérateur risque de lui faire perdre le contrôle de l’outil.

SÉCURITÉ ÉLECTRIQUE

4. La fiche de l’outil électrique doit correspondre à la prise

d’alimentation. Ne jamais modifi er la fi che d’une manière quel-

conque. Ne pas utiliser d’adaptateur avec les outils électriques

mis à la terre (à la masse). Des fi ches non modifi ées et des prises

d’alimentation assorties réduisent le risque de choc électrique.

5. Éviter tout contact corporel avec des surfaces reliées à la masse ou

à la terre telles que tuyaux, radiateurs, cuisinières et réfrigérateurs.

Un risque de choc électrique plus élevé existe si le corps est relié à la

masse ou à la terre.

6. Ne pas exposer les outils électriques à la pluie ou à l’humidité. Le

risque de choc électrique augmente si de l’eau s’infi ltre dans un outil

électrique.

7. Prendre soin du cordon. Ne jamais utiliser le cordon pour trans-

porter, tirer ou débrancher l’outil électrique. T enir le cordon à l’écart

de la chaleur, des huiles, des arêtes coupantes ou des pièces en

mouvement. Un cordon endommagé ou emmêlé présente un risque

accru de choc électrique.

8. Se procurer un cordon d’alimentation approprié en cas

d’utilisation d’un outil électrique à l’extérieur. L’utilisation d’un

cordon d’alimentation pour usage extérieur réduit le risque de choc

électrique.

SÉCURITÉ INDIVIDUELLE

9. Être sur ses gardes, être attentif et faire preuve de bon sens en

utilisant un outil électrique. Ne pas utiliser un outil électrique en

cas de fatigue ou sous l’infl uence de drogues, d’alcool ou de

médicaments. Un instant d’inattention lors de l’utilisation d’un outil

électrique peut entraîner des blessures graves.

10. Utiliser un équipement de sécurité. Toujours porter des lunettes de

protection. Un équipement de sécurité comprenant masque anti-poussière, chaussures de sécurité anti-dérapantes, casque ou dispositif de

protection anti-bruit peut, dans les circonstances appropriées, réduire

le risque de blessure.

11. Éviter tout démarrage accidentel de l’outil. S’assurer que le com-

mutateur est en position OFF (Arrêt) avant de brancher l’outil. Le

port de l’outil avec un doigt sur le commutateur ou son branchement

avec le commutateur en position ON (Marche) sont favorables aux

accidents.

12. Retirer toute clé de réglage avant de mettre l’outil sous tension.

Une clé laissée attachée sur une pièce mobile de l’outil électrique peut

entraîner des blessures.

13. Ne pas travailler à bout de bras. Bien garder un bon équilibre à tout

instant. Ceci permet de mieux préserver la maîtrise de l’outil électrique

dans des situations imprévues.

page 12

14. Porter des vêtements adéquats. Ne pas porter de vêtements amples

ni de bijoux. Ne pas approcher les cheveux, vêtements et gants

des pièces en mouvement. Les vêtements amples, les bijoux ou les

cheveux longs risquent d’être happés par les pièces en mouvement.

15. Si des dispositifs sont prévus pour l’extraction et la récupération

des poussières, vérifi er qu’ils sont connectés et utilisés correcte-

ment. L’utilisation de ces dispositifs peut réduire les risques liés aux

poussières.

UTILISA TION ET ENTRETIEN DE L’OUTIL ÉLECTRIQUE

16. Ne pas forcer l’outil électrique. Utiliser l’outil électrique approprié

à l’application considérée. L’outil électrique adapté au projet consi-

déré produira de meilleurs résultats, dans des conditions de sécurité

meilleures, à la vitesse pour laquelle il a été conçu.

17. Ne pas utiliser l’outil électrique si le commutateur ne le met pas

sous ou hors tension. Tout outil électrique dont le commutateur de

marche-arrêt est inopérant est dangereux et doit être réparé.

18. Débrancher la fi che de la prise d’alimentation et/ou la batterie

de l’outil électrique avant d’effectuer des réglages, de changer

d’accessoires ou de ranger l’outil. De telles mesures de sécurité

préventive réduisent le risque de mettre l’outil en marche accidentellement.

19. Ranger les outils électriques inutilisés hors de la portée des

enfants et ne pas laisser des personnes qui connaissent mal les

outils électriques ou ces instructions utiliser ces outils. Les outils

électriques sont dangereux dans les mains d’utilisateurs non formés à

leur usage.

20. Entretien des outils électriques. S’assurer de l’absence de tout

désalignement ou de grippage des pièces mobiles, de toute rupture

de pièce ou de toute autre condition qui pourrait affecter le bon

fonctionnement de l’outil électrique. En cas de dommages, faire

réparer l’outil avant de l’utiliser de nouveau. Les outils électriques

mal entretenus sont à la source de nombreux accidents.

21. Garder les outils de coupe affûtés et propres. Les outils de coupe

correctement entretenus et bien affûtés risquent moins de se gripper

et sont plus faciles à manier.

22. Utiliser cet outil électrique, les accessoires, les mèches, etc.

conformément à ces instructions et de la façon prévue pour ce

type particulier d’outil électrique, tout en prenant en compte les

conditions de travail et le type de projet considérés. L’utilisation de

cet outil électrique pour un usage autre que l’usage prévu peut créer

des situations dangereuses.

ENTRETIEN

23. Faire effectuer l’entretien de l’outil électrique par un technicien

qualifi é qui n’utilisera que des pièces de rechange identiques. La

sécurité d’utilisation de l’outil en sera préservée.

RÈGLES DE SÉCURITÉ PARTICULIÈRE

1. Tenir l’outil par les surfaces de prise isolées si, au cours des

travaux, l’outil de coupe risque d’entrer en contact avec des fi ls

cachés ou avec son propre cordon. Le contact avec un fi l sous ten-

sion met les parties métalliques exposées de l’outil sous tension, ce

qui infl igera un choc électrique à l’opérateur.

2. Entretenez les étiquettes et marqies di fabricant. Les indications

qu'elles contiennent sont précieuses. Si elles deviennent illisibles ou

se détachent, faites-les remplacer gratuitement à un centre de service

MILWAUKEE accrédité.

Page 13

3. AVERTISSEMENT! La poussière degage par perçage, sclage, perçage

et autres travaux de construction contient des substances chimiques

reconnues comme pouvant causer le cancer, des malformations congénitales ou d’autres troubles de reproduction. Voici quelques exemples

de telles substances

• Le plomb contenu dans la peinture au plomb.

• Le silice cristallin contenu dans la brique, le béton et divers produits de

maçonnerie.

• L’arsenic et le chrome servant au traitement chimique du bois.

Les risque associés à l’exposition à ces substances varient, dépendant

de la fréquence des travaux. Afi n de minimiser l’exposition à ces sub-

stances chimiques, assurez-vous de travailler dans un endroit bien aéré

et d’utiliser de l’equipement de sécurité tel un masque antipoussière

spécifi quement conçu pour la fi ltration de particules microscopiques.

4. Porter des protège-oreilles. Une exposition au bruit peut provoquer

une perte auditive.

5. Utiliser les poignées auxiliaires fournies avec l’outil. Une perte de

contrôle peut provoquer des blessures.

Specifi cations

No de

cat.

5337-20

5337-21

5339-20

5339-21

5340-20

5340-21

5342-20

5342-21

Volts

CA

120

120

120

120

120

120

120

120

Amps

14

14

14

14

15

15

15

15

T/Min à

vide

--

--

--

--

125 - 250

125 - 250

125 - 250

125 - 250

Coups/

975-1 950*

975-1 950*

975-1 950*

975-1 950*

975-1 950*

975-1 950*

975-1 950*

975-1 950*

Diamètre maxi de la

mèche de perçage à

Min.

Cannelure de 51 mm

Cannelure de 51 mm

SDS-Max de 51 mm

SDS-Max de 51 mm

percussion

--

--

--

-(2")

(2")

(2")

(2")

* EFCC - Le circuit électronique de contrôle de la rétroaction maintient une vitesse constante quelles que

soient les variations de la charge.

†

Utiliser les trépans carottiers MILWAUKEE No de cat. 48-20-5125 à 48-20-5165. Ne pas utiliser les com-

posants LHS (systèmes pour grands orifi ces) avec les marteaux rotatifs 5340-20 et 5342-20. Les mèches

Diamètre maxi du

trépan carottier à

percussion

152 mm† (6")

152 mm† (6")

152 mm† (6")

152 mm† (6")

†

--

--

--

--

Ciseaux

Voir

« Cisèlement

et

burinage »

Type de queue

de ciseau

Hexagonal de 3/4 po

Hexagonal de 3/4 po

SDS-Max

SDS-Max

Hexagonal de 3/4 po

et rond de 21/32 po

Hexagonal de 3/4 po

et rond de 21/32 po

SDS-Max

SDS-Max

DESCRIPTION FONCTIONNELLE

12

No de cat. 5342-20

4

BPM

Pictographie

Double Isolation

Courant alternatif

Ampères

Tours-minute à

vide (RPM)

Coups/Min.

Underwriters

Laboratories, Inc.

Inscription mexicaine

d’approbation

1

10

11

1. Système d’isolation contre les vibrations

2. Gâchette marche/arrêt

3. Poignée

4. Témoin lumineux de fonctionnement

5. Cadran de réglage de la vitesse

6. Bouton de blocage (No de cat. 5337-20, 5339-20

uniquement)

9

7. Poignée latérale courbe (No de cat. 5337-20, 5339-20 uniq.)

8. Molette de réglage de la poignée latérale (No de cat. 5337-20,

5339-20 uniquement)

9. Mandrin (No de cat. 5337-20, 5340-20 uniquement)

10. Poignée latérale droite (à utiliser avec le martelage rotatif)

11. Positions de montage de la poignée latérale droite (3 positions)

12. Sélecteur de mode (No de cat. 5339-20, 5342-20 uniquement)

6

5

1

11

2

3

11

No de cat. 5337-20

7

1

8

page 13

Page 14

MISE À LA TERRE

CORDONS DE RALLONGE

AVERTISSEMENT

Si le fi l de mise à la terre est incorrectement raccordé, il peut en

résulter des risques de choc électrique. Si vous n’êtes pas certain que la prise dont vous vous servez est correctement mise à

la terre, faites-la vérifi er par un électricien. N’altérez pas la fi che

du cordon de l’outil. N’enlevez pas de la fi che, la dent qui sert à

la mise à la terre. N’employez pas l’outil si le cordon ou la fi che

sont en mauvais état. Si tel est le cas, faites-les réparer dans un

centre-service MILWAUKEE accrédité avant de vous en servir. Si

la fi che du cordon ne s’adapte pas à la prise, faites remplacer la

prise par un électricien.

Outils mis à la terre :

Outils pourvus d’une fi che de cordon à trois dents

Les outils marqués « Mise à la terre

requise » sont pourvus d’un cordon à

trois fi ls dont la fi che a trois dents. La

fi che du cordon doit être branchée sur

une prise correctement mise à la terre

(voir Figure A). De cette façon, si une

défectuosité dans le circuit électrique

de l’outil survient, le relais à la terre

fournira un conducteur à faible résistance pour décharger le courant et

protéger l’utilisateur contre les risques

de choc électrique.

La dent de mise à la terre de la fi che est reliée au système de mise à la

terre de l’outil via le fi l vert du cordon. Le fi l vert du cordon doit être le seul fi l

raccordé à un bout au système de mise à la terre de l’outil et son autre extrémité ne doit jamais être raccordée à une borne sous tension électrique.

Votre outil doit être branché sur une prise appropriée, correctement installée et mise à la terre conformément aux codes et ordonnances en vigueur.

La fi che du cordon et la prise de courant doivent être semblables à celles

de la Figure A.

Outils à double isolation :

Outils pourvus d’une fi che de cordon à deux dents

Les outils marqués « Double

Isolation » n’ont pas besoin d’être

raccordés à la terre. Ils sont pourvus

d’une double isolation conforme eux

exigences de l’OSHA et satisfont aux

normes de l’Underwriters Laboratories, Inc., de l’Association canadienne

de normalisation (ACNOR) et du

« National Electrical Code » (code

national de l’électricité). Les outils à

double isolation peuvent être branchés

sur n’importe laquelle des prises à 120

volt illustrées ci-contre Figure B et C.

Fig. A

Fig. B

Fig. C

Si l’emploi d’un cordon de rallonge est nécessaire, un cordon à trois fi ls doit

être employé pour les outils mis à la terre. Pour les outils à double isolation,

on peut employer indifféremment un cordon de rallonge à deux ou trois fi ls.

Plus la longueur du cordron entre l’outil et la prise de courant est grande,

plus le calibre du cordon doit être élevé. L’utilisation d’un cordon de rallonge

incorrectement calibré entraîne une chute de voltage résultant en une perte

de puissance qui risque de détériorer l’outil. Reportez-vous au tableau cicontre pour déterminer le calibre minimum du cordon.

Moins le calibre du fi l est élevé, plus sa conductivité est bonne. Par exemple,

un cordon de calibre 14 a une meilleure conductivité qu’un cordon de calibre 16. Lorsque vous utilisez plus d’une rallonge pour couvrir la distance,

assurez-vous que chaque cordon possède le calibre minimum requis. Si

vous utilisez un seul cordon pour brancher plusieurs outils, additionnez le

chiffre d’intensité (ampères) inscrit sur la fi che signalétique de chaque outil

pour obtenir le calibre minimal requis pour le cordon.

Directives pour l’emploi des cordons de rallonge

• Si vous utilisez une rallonge à l’extérieur, assurez-vous qu’elle est

marquée des sigles « W-A » (« W » au Canada) indiquant qu’elle est

adéquate pour usage extérieur.

• Assurez-vous que le cordon de rallonge est correctement câblé et

en bonne condition. Remplacez tout cordon derallonge détérioré ou

faites-le remettre en état par une personne compétente avant de vous

en servir.

• Tenez votre cordon de rallonge à l’écart des objets ranchants, des

sources de grande chaleur et des endroits humides ou mouillés.

Calibres minimaux recommandés pour les

Fiche

signalétique

Ampères

0 - 5,0

5,1 - 8,0

8,1 - 12,0

12,1 - 15,0

15,1 - 20,0

* Basé sur sur une chute de voltage limite de 5

volts à 150% de l’intensité moyenne de courant.

cordons de rallonge*

Longueur du cordon de rallonge (m)

30,4

14

12

10

10

45,7

60,9

12

10

--

--

--

--

7,6

16

16

14

12

10

15,2

16

16

14

12

10

22,8

16

14

12

10

10

12

--

--

--

--

LISEZ ATTENTIVEMENT CES INSTRUCTIONS

ET CONSERVEZ-LES POUR LES

CONSUL TER AU BESOIN.

page 14

Page 15

MONTAGE DE L'OUTIL

AVERTISSEMENT

Pour minimiser les risques de blessures, débranchez toujours

l’outil avant d’y faire des réglages, d’y attacher ou d’en enlever

les accessoires. L’usage d’accessoires autres que ceux qui

sont spécifi quement recommandés pour cet outil peut com-

porter des risques.

Réglage de la poignée latérale courbe (No de cat. 5337-20,

5339-20 uniquement)

Seuls les marteaux de démolition sont équipés d’une poignée latérale

courbe. N’utilisez pas la poignée latérale avec marteaux rotatifs.

1. Desserrez légèrement la poignée latérale en faisant tourner la molette

de réglage de la poignée dans le sens anti-horaire.

2. Faites tourner la poignée latérale jusqu’à la position désirée. Vous

pouvez déplacer la poignée vers la gauche, vers la droite, vers l’avant

ou vers l’arrière de l’outil.

3. Resserrez la molette de réglage de la poignée latérale.

Réglage de la poignée latérale droite

Visser la poignée latérale droite sur une des trois positions (supérieure,

latérale gauche ou latérale droite). Resserrez fermement.

AVERTISSEMENT

Pour minimiser les risques de blessures lors du martelage

avec rotation, veuillez toujours utiliser la poignée latérale droite

lorsque vous utilisez cet outil. Maintenez-le fermement.

Pour minimiser les risques de blessures lors du martelage avec

ou sans rotation, portez des lunettes étanches ou des lunettes

à protection latérale.

Installation des mèches et ces ciseaux

Queue SDS Max

No de cat. 5339-20,

5342-20

1. Nettoyez et graissez la queue de la mèche ou du ciseau.

2. Introduisez la mèche ou le ciseau dans l’embout de l’outil.

3. Faites tourner lentement la mèche ou le ciseau jusqu’à ce qu’il soit

aligné avec le mécanisme de blocage.

4. Enfoncez la mèche ou le ciseau jusqu’à ce qu’ils s’enclenchent dans

l’outil (Fig. 2).

5. Tirez sur la mèche ou sur le ciseau pour vérifier qu’il est

fermement bloqué.

6. Pour les retirer, tirez sur le collier de déblocage de la mèche vers l’arrière

de l’outil, puis enlevez la mèche ou le ciseau.

AVERTISSEMENT

Pour minimiser les risques de blessures, utilisez les ciseaux pour

marteaux spécialement recommandés par MILWAUKEE. Les cis-

eaux d’autres marques pourraient endommager l’outil.

Installation des ciseaux pour marteau

Queue hexagonale

arrondie

(No de cat. 5340-20)

Queue hexagonale

(No de cat. 5337-

Queue cannelée

No de cat. 5340-20

uniquement

Queue hexagonale

arrondie

No de cat. 5340-20

uniquement

Queue hexagonale

No de cat. 5337-20

uniquement

N.B. : Pour minimiser les risques d’endommagement du mandrin, n’utilisez

pas de mèches à queue hexagonale arrondie sur le 5337-20. Sur cet outil,

n’utilisez que des mèches à queue hexagonale.

1. Nettoyez et graissez la queue de la mèche ou du ciseau.

2. Tirez sur le mandrin et faites-le tourner de 180°.

3. Introduisez la mèche ou le ciseau dans l’embout de l’outil (Fig. 1).

N.B. : Lors de l’utilisation de mèches ou de ciseaux hexagonaux

(sur la No de cat. 5337-20) ou hexagonaux/ronds (sur le No de cat.

5340-20), l’encoche de la queue doit être orientée vers l’embout

de l’outil.

4. Serrez la mèche ou le ciseau en tirant sur le mandrin et en le faisant

tourner de 180°.

5. Tirez sur la mèche ou sur le ciseau pour vérifi er qu’il est fermement

bloqué.

6. Pour les retirer, tournez le mandrin de 180° et retirez la mèche

ou le ciseau.

NOTA : Soyez prudent lors de la manipulation de mèches et de ciseaux

chauds.

Nettoyez et graissez toujours la queue du ciseau avant de l’introduire

dans l’outil. Examinez la queue pour vous assurer qu’elle ne présente pas

une forme de champignon tel que décrit sous la rubrique « Entretien des

ciseaux pour marteau ». Assurez-vous toujours que le ciseau est en bon

état avant de l’utiliser.

page 15

Page 16

MANIEMENT

Circuit de contrôle électronique de la rétroaction

Ces marteaux disposent d’un circuit électronique de contrôle de la

rétroaction (EFCC) qui permet d’améliorer l’utilisation et la durée de

service de l’outil.

Contrôle de la rétroaction

Le circuit électronique de contrôle de la vitesse maintient une vitesse et un

couple constants de l’outil, avec ou sans charge.

Démarrage sans à-coups

La fonction de démarrage sans à-coups réduit le couple appliqué sur l’outil

et subi par l’utilisateur. Cette fonction augmente progressivement la vitesse

du moteur de zéro jusqu’à la vitesse sélectionnée sur le cadran de réglage

de la vitesse.

AVERTISSEMENT

Pour minimiser les risques de blessures, portez des lunettes à

coques latérales. Débranchez l’outil avant de changer les accessoires ou d’effectuer des réglages.

Sélection de la vitesse

Le cadran de réglage de la vitesse de ces marteaux permet à l’utilisateur

de régler la vitesse de rotation (tr/mn) et la vitesse d’impact (coups par

minute) de l’outil.

Pour modifi er la vitesse, réglez le cadran de réglage de la vitesse selon

vos besoins.

• Une vitesse réduite garantit un meilleur contrôle lorsque vous commencez un orifi ce et elle réduit l’effet d’écaillage. L’écaillage se produit

lorsque des morceaux de matériau s’émiettent autour de l’orifi ce perforé.

Lors du burinage de matériaux fragiles et cassants, réduisez la vitesse

pour éviter d’endommager les zones adjacentes.

• Une grande vitesse permet de perforer et buriner plus rapidement lors

des travaux de démolition.

Sélection du mode de travail

No de cat. 5337-20

Le marteau de démolition No de cat. 5337-20 est conçu pour

« martelage uniquement ». La rotation n’est pas disponible. N’utilisez que

des ciseaux ou d’autres accessoires pour « martelage uniquement ».

No de cat. 5339-20 (Fig. 3)

Le marteau de démolition No de cat. 5339-20 est conçu pour « martelage

uniquement ». La rotation n’est pas disponible. Utilisez le sélecteur de mode

pour choisir le type d’opération :

Fig. 3

Martelage

uniquement

1. Martelage uniquement. Pour l’utilisation des accessoires pour « mar-

telage uniquement ». Utilisez cette confi guration pour le burinage.

2. Réglage du ciseau. Utilisez ce mode pour régler l’angle du tranchant du ciseau par rapport à l’outil. Le ciseau monté sur l’outil, orientez

le ciseau selon l’angle désiré. Puis, placez le sélecteur de mode sur

« martelage uniquement » avant de l’utiliser.

N.B.: Pour enclencher le mécanisme de martelage, faites pression sur

la mèche ou sur le ciseau. Lorsque la pression est annulée, le martelage

s’arrête.

No de cat. 5340-20

Le marteau rotatif de No de cat. 5340-20 fonctionne en mode « martelage

uniquement » et en mode « martelage avec rotation » en fonction du type

de queue introduit dans l’outil.

Pour le « martelage uniquement » : Introduisez un ciseau ou un autre accessoire pour « martelage uniquement » à queue ronde de 21/32 pouce

et hexagonale de 3/4 pouce dans l’embout de l’outil (voir « Installation des

mèches et des ciseaux »). Le mécanisme d’entraînement rotatif fonctionne

mais il n’enclenche pas le ciseau et, par conséquent, l’outil travaille en mode

« martelage uniquement ».

Pour le « martelage avec rotation » : Introduisez une mèche de perçage

ou de carottage à queue cannelée dans l’embout de l’outil (voir « Installation des mèches et des ciseaux »). Le mécanisme d’entraînement

rotatif s’enclenche avec la mèche pour fonctionner en mode « martelage

avec rotation ».

Réglage du ciseau

page 16

Page 17

No de cat. 5342-20 (Fig. 4)

Le marteau rotatif No de cat. 5342-20 présente les modes « martelage

uniquement », « martelage avec rotation » et « réglage du ciseau ». Utilisez

le sélecteur de mode pour choisir le type d’opération :

Fig. 4

Martelage unique-

ment

1. Martelage uniquement. Pour l’utilisation des accessoires pour « mar-

telage uniquement ». Utilisez cette confi guration pour le burinage.

2. Martelage avec rotation. Utilisez ce mode pour percer des orifi ces à l’aide mèches de perçage. N’utilisez pas le mode « martelage

avec rotation » lors de l’utilisation de ciseaux ou d’autres accessoires

de « martelage uniquement ».

3. Réglage du ciseau. Utilisez ce mode pour régler l’angle du tran-

chant du ciseau par rapport à l’outil. Le ciseau monté sur l’outil, orientez

le ciseau selon l’angle désiré. Puis, placez le sélecteur de mode sur

« martelage uniquement » avant de l’utiliser.

N.B. : Pour enclencher le mécanisme de martelage, faites pression sur

la mèche ou sur le ciseau. Lorsque la pression est annulée, le martelage

s’arrête.

Réglage du ciseau

Martelage avec

rotation

AVERTISSEMENT

Pour minimiser les risques de blessures lors de l’utilisation de

ciseaux ou d’autres accessoires pour « martelage uniquement »

sur le No de cat. 5342-20, placez le sélecteur sur le mode « martelage uniquement ».

Mise en marche/arrêt de la l’outil

1. Pour mettre en marche l’outil, tirez sur la gâchette.

2. Pour arrêter l’outil, relâchez la gâchette.

Blocage de la gâchette (No de cat. 5337-20, 5339-20 uniquement)

Le bouton de blocage des marteaux de démolition maintient la gâchette en

position « Marche » afi n de garantir une vitesse de travail constante.

1. Pour bloquer la gâchette, maintenez le bouton de blocage en tirant

sur la gâchette. Relâchez la gâchette.

2. Pour débloquer la gâchette, tirez sur la gâchette et relâchez-la. Le

bouton de blocage ressort.

Martelage à froid

Si vous n’utilisez pas l’outil durant une longue période ou si vous le conservez

à basses températures, la lubrifi cation peut durcir et l’outil peut présenter

peu de force lors du martelage. Dans ce cas :

1. Introduisez un ciseau dans l’outil.

2. Tirez sur la gâchette et posez le ciseau contre un morceau de béton.

3. Mettre en marche et arrêter l’outil toutes les 2 secondes. Au bout de

15 secondes à 2 minutes, l’outil commence à marteler correctement.

Plus l’outil est froid, plus le réchauffement est long.

Force de l’utilisateur

Ces marteaux offrent un système d’isolation contre les vibrations afi n

d’assurer le confort de l’utilisateur sans réduire le rendement de l’outil. Le

logement du moteur est indépendant de la poignée. Les éléments d’isolation

absorbent les vibrations lors du martelage ou du perçage.

Pour obtenir la force de travail idéale, serrez légèrement la poignée. Ce

faisant, le marteau travaille à plein régime tandis que la poignée amortit les

vibrations au maximum.

Une force excessive appliquée sur la poignée réduit l’amortissement des

vibrations. Les utilisateurs remarqueront facilement la différence et devront

régler la force en conséquence.

AVERTISSEMENT

Une pression plus élevée n’augmente pas le rendement de l’outil.

Si vous appliquez une pression excessive, l’amortisseur de

chocs vibre également et transmet les vibrations à la poignée.

page 17

Page 18

Martelage uniquement

1. Introduisez un ciseau ou un autre accessoire « martelage uniquement »

dans l’outil (voir « Installation des mèches et des ciseaux »).

2. Placez l’outil sur la zone de travail.

3. Saisissez fermement les deux poignées (la poignée de la gâchette et

la poignée courbe ou la poignée latérale).

4. Tirez sur la gâchette. Maintenez toujours l’outil fermement à l’aide des

deux poignées.

5. Utilisez la force nécessaire pour maintenir l’outil en place, enclenchez

le mécanisme de martelage et évitez le tremblement du bout du ciseau.

Cet outil a été conçu pour fournir le meilleur rendement avec une pression modérée. Ne forcez pas l’outil : laissez-le travailler.

N.B.: Pour enclencher le mécanisme de martelage, faites pression sur

la mèche ou sur le ciseau. Lorsque la pression est annulée, le martelage

s’arrête.

6. Lors du ciselage ou du burinage, formez un angle entre l’outil et

la zone de travail. Pour optimiser le fonctionnement, placez-vous

dans un coin ou au bord de la zone de travail et travaillez morceau

par morceau.

Si le marteau se coince :

1. Débranchez l’outil.

2. Tirez sur le mandrin et faites-le tourner de 180°.

3. Séparez l’outil de l’accessoire coincé.

4. Libérez l’accessoire.

AVERTISSEMENT

Utiliser les trépans carottiers MILW AUKEE No de cat. 48-20-5125

à 48-20-5165. Ne pas utiliser les composants LHS (systèmes pour

grands orifi ces) avec les marteaux rotatifs 5340-20 et 5342-20.

Les mèches peuvent se casser au niveau du goujon fi leté et

causer des blessures et des dommages.

Utilisation des trépans carottiers à percussion rotatifs (Fig. 5 - 7)

Les trépans carottiers sont utiles pour percer des orifi ces plus larges

pour les conduits ou les tubes. Les trépans carottiers extra robustes

de MILWAUKEE sont constituées d’un corps en acier traité thermiquement et d’une pointe robuste en carbure. Ces trépans carottiers

sont spécialement conçus pour un perçage rapide et précis avec un

marteau rotatif.

1. Nettoyez et lubrifi ez les fi lets de l’adaptateur et du trépan carottier

pour faciliter son extraction. Vissez l’extrémité fi letée de l’adaptateur à

l’arrière du trépan carottier.

2. Poussez la plaque de guidage sur l’extrémité pointue de la broche

centrale. Introduisez la broche centrale et la plaque de guidage dans

le trépan carottier. Assurez-vous que la petite extrémité de la broche

centrale est fermement fi xée dans l’orifi ce central du trépan carottier

(Fig. 5).

Fig. 5

Martelage avec rotation

1. Introduisez une mèche ou une tarière dans l’outil (voir « Installation des

mèches et des ciseaux »).

2. Placez l’outil sur la zone de travail.

3. Saisissez fermement les poignées (la poignée de la gâchette et la

poignée latérale).

AVERTISSEMENT

Pour minimiser les risques de lésion, tenez fermement l’outil.

Soyez toujours prêt à compenser la réaction de la mèche

lorsqu’elle se bloque, lorsque le trou se bouche, lors du martèlement de matériaux encastrés et lors du perçage du trou.

4. Tirez sur la gâchette. Maintenez toujours fermement l’outil à l’aide de

la poignée droite et de la poignée à gâchette.

5. Utilisez la force nécessaire pour maintenir l’outil en place, enclenchez

le mécanisme de martelage et évitez le tremblement du bout du ciseau.

Cet outil a été conçu pour fournir le meilleur rendement avec une pression modérée. Ne forcez pas l’outil : laissez-le travailler.

Lorsque la pression est annulée, le martelage s’arrête.

6. Lors du forage de trous profonds, la vitesse peut se réduire progressivement. Extrayez légèrement la mèche de l’orifi ce pour éliminer les

poussières.

N.B.: N’utilisez pas d’eau car les poussières pourraient s’agglomérer,

obstruer les cannelures de la mèche et provoquer son coincement.

3. Introduisez l’adaptateur dans l’embout de l’outil (voir « Installation des

mèches et des ciseaux »). Placez le sélecteur de mode sur « martelage

avec rotation ».

4. Poussez la broche centrale contre la marque centrale, maintenez

fermement l’outil et tirez sur la gâchette (Fig. 6).

Fig. 6

Si la mèche se coince :

Si la mèche se coince, un limiteur de couple intégré, non réglable, permet

d’éviter la rotation de la mèche lorsque l’outil est fermement saisi. Dans

ce cas :

1. Arrêtez et débranchez l’outil.

2. Libérez la mèche.

3. Retirez les débris du trou.

4. Recommencez le perçage.

page 18

Page 19

N.B.: Si une broche centrale et une plaque de guidage ne sont pas disponibles, utilisez un gabarit ou une plaque crantée pour commencer le

trou (Fig. 7).

Fig. 7

5. Après avoir percé à une profondeur approximativement égale à la taille

de la dent du trépan carottier, retirez la broche centrale et la plaque de

guidage du trépan carottier. Terminez le perçage.

6. Pour remplacer le trépan carottier, orientez l’outil vers le haut (pas vers

vous) et faites-le fonctionner durant cinq secondes en mode « martelage avec rotation » jusqu’à ce que le trépan carottier se desserre de

l’adaptateur.

N.B.: Pour percer des orifi ces plus profonds, enlevez le trépan carottier,

cassez et retirez le noyau. Terminez le perçage. Lors du perçage

d’orifi ces profonds, retirez partiellement le trépan carottier tous les 25,4

mm (1 pouce) de l’orifi ce tout en maintenant l’outil en fonctionnement

afi n d’éliminer les poussières des cannelures du trépan carottier. Les

poussières peuvent obstruer les cannelures et coincer le trépan carottier

dans l’orifi ce. Dans ce cas, arrêtez l’outil, libérez le trépan carottier et

recommencez.

Perçage de gros trous avec des trépans carottiers (Fig. 8-13)

Lors du perçage de trous avec des trépans carottiers de grand diamètre, de

la poussière peut s’accumuler dans la coupe et l’outil peut caler, se coincer

ou couper lentement. En créant une ouverture pour laisser la poussière

s’échapper, le temps de perçage et les contraintes de l’outil et carottier

sont réduites.

1. Commencer la coupe normalement.

2. Une fois la mèche fermement en place dans la coupe (à une profondeur

d’environ 6,4 mm (1/4 pouce), retirer la mèche de la coupe (Fig. 8).

Fig. 8

Couper à une profondeur d’environ

6,4 mm (1/4") avec

un trépan carottier.

3. Retirer le trépan de l’outil.

4. Installer une mèche à goujure standard, d’un diamètre approximatif de

22,2 mm (7/8 pouce), sur l’outil.

5. Percer un trou perpendiculaire par la saignée du gros trou (Fig. 9).

• Selon l’emplacement de l’ouvrage, le trou doit déboucher de l’autre

côté du trou/plancher ou dépasser de 101,6 mm à 127,0 mm (4 à 5

pouces) l’extrémité de la pièce travaillée (dans la terre sous une dalle

de ciment par exemple).

• Si de la poussière s’accumule dans le trou, l’aspirer et continuer à

percer.

• En cas de perçage à travers un mur, le trou pour la poussière doit être

percé sur la partie la plus basse de la saignée du gros trou (Fig. 9), la

poussière tombant à cet emplacement lors du perçage et pouvant être

plus facilement évacuée.

Fig. 9

Percer un trou par

l’ouvrage.

page 19

Page 20

6. Installer le trépan carottier et continuer à percer (Fig. 10 et 11). La

poussière et les débris tombent par le trou, ce qui optimise la capacité

de coupe du trépan ou de la mèche.

Fig. 10

La poussière et les

débris tombent par

le trou.

Vue du haut

Cisellement et burinage

Les marteaux MlLWAUKEE employés pour le burinage et le cisellement.

Pour buriner, tenez l’outil à angle de la surface de travail. Commencez par

un coin ou en bordure de la surface et ciselez une petite partie de la surface

à la fois plutôt que d’en prendre trop grand.

Plusieurs genres d’accessoires sont offerts :

Boucharde

Employée pour les surfaces en béton.

Ciseau à mortier

Servant à enlever le vieux mortier avant de jointoyer ou de calfeutrer.

Fig. 11

Vue latérale de la dalle

7. Pour le trépan carottier, une fois la profondeur maximale du trépan

carottier percée, la carotte doit être cassée et retirée.

• Installer une mèche burin.

• Placer le burin dans la saignée du trou (Fig. 12).

• Buriner dans la saignée en divers points jusqu’à ce que la carotte soit

détachée ou cassée.

• Retirer la carotte et aspirer/retirer toute la poussière et tous les débris

restants.

• Installer le trépan carottier et continuer la coupe.

Fig.

Ciseau à pointe robuste

Employé pour les légers travaux de démolition

et pour commencer le forage d’un trou dans une

dalle de béton.

Ciseau à plat

Employé pour cisailler les bords, rainurer et

dégrossir les surfaces.

Ciseau à détartrer

Servant à enlever le tartre et les éclaboussures

de soudage ou couper en ligne droite.

Ciseau à fendre

Pour faire des fentes et découper entre les trous

pratiqués dans le béton ou la maçonnerie.

N.B. : En cas d’impossibilité de percer un trou dans la saignée, tirer le trépan

en arrière avec le marteau en marche (Fig. 13). Cela doit retirer un peu

de poussière et de débris de la coupe. Répéter cette opération à chaque

pouce percé. Si nécessaire, aspirer la poussière et les débris de la coupe

et de la zone environnante.

Fig. 13

Extraire le trépan

aussi loin que possible une ou deux fois

par pouce percé.

page 20

Page 21

MAINTENANCE

ACCESSOIRES

AVERTISSEMENT

Pour minimiser les risques de blessures, débranchez toujours

l’outil avant d’y effectuer des travaux de maintenance. Ne faites

pas vous-même le démontage de l’outil ni le rebobinage du système électrique. Consultez un centre de service MILWAUKEE

accrédité pour toutes les réparations.

Entretien de l’outil

Gardez l’outil en bon état en adoptant un programme d’entretien ponctuel.

Avant de vous en servir, examinez son état en général. Inspectez-en la

garde, interrupteur, cordon et cordon de rallonge pour en déceler les défauts.

Vérifi ez le serrage des vis, l’alignement et le jeu des pièces mobiles, les

vices de montage, bris de pièces et toute autre condition pouvant en rendre

le fonctionnement dangereux. Si un bruit ou une vibration insolite survient,

arrêtez immédiatement l’outil et faites-le vérifi er avant de vous en servir de

nouveau. N’utilisez pas un outil défectueux. Fixez-y une étiquette marquée

« HORS D’USAGE » jusqu’à ce qu’il soit réparé (voir « Réparations »).

Normalement, il ne sera pas nécessaire de lubrifi er l’outil avant que le temps

ne soit venu de remplacer les balais. Après une période pouvant aller de

6 mois à un an, selon l’usage, retournez votre outil à un centre de service

MILWAUKEE accrédité pour obtenir les services suivants :

• Lubrifi cation

• Inspection et remplacement des balais

• Inspection et nettoyage de la mécanique (engrenages, pivots, coussinets, boîtier etc.)

• Inspection électrique (interrupteur, cordon, induit etc.)

• Vérifi cation du fonctionnement électromécanique

Entretien des ciseaux pour marteau

Assurez-vous que la queue pour vous assurer qu’elle ne présente pas une

forme de champignon. Retirez la mèche ou le ciseau. Voir que la pièce-outil

est en bonne condition.

Remplacement des balais