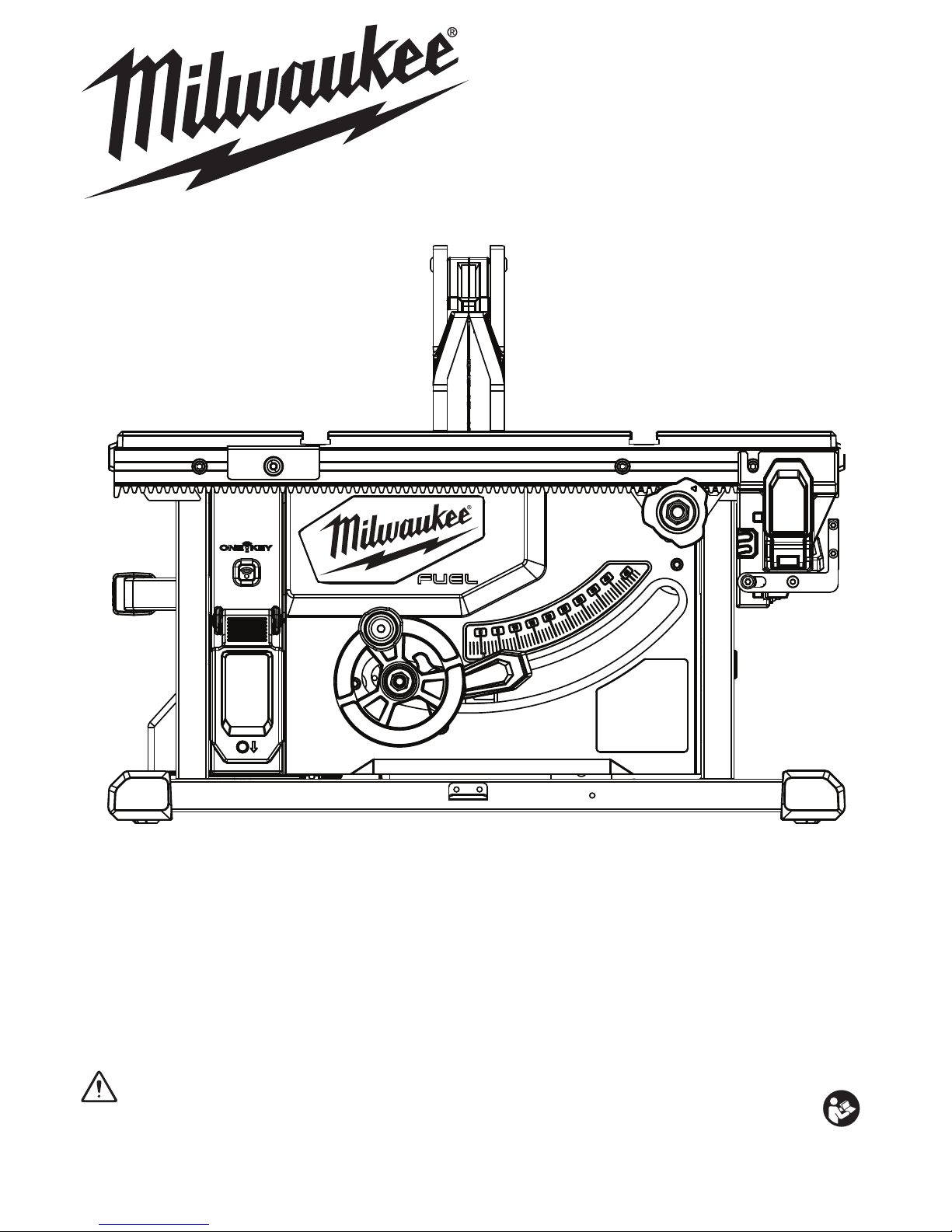

Milwaukee M18 FUEL FTS210 Operator's Manual

Cat. No.

M18 FTS210

M18™ FUEL™ 210mm (8 1/4") TABLE SAW W/ ONE-KEY™

OPERATOR'S MANUAL

To reduce the risk of injury, user must read and understand operator's manual.

WARNING

2

GENERAL POWER TOOL

SAFETY WARNINGS

WARNING

Read all safety warnings, instruc-

-

tions provided with this power tool. Failure to

follow all instructions listed below may result in

Save all

warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated (cordless) power tool.

WORK AREA SAFETY

Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

Do not operate power tools in explosive atmo-

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

Keep children and bystanders away while operat-

ing a power tool. Distractions can cause you to lose

control.

ELECTRICAL SAFETY

Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools.

reduce risk of electric shock.

Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the

risk of electric shock.

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

PERSONAL SAFETY

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

A

moment of inattention while operating power tools

may result in serious personal injury.

Use personal protective equipment. Always

wear eye protection. Protective equipment such

as a dust mask, non-skid safety shoes, hard hat or

hearing protection used for appropriate conditions

will reduce personal injuries.

Prevent unintentional starting. Ensure the switch

source and/or battery pack, picking up or carrying

the tool.

the switch or energising power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action can

cause severe injury within a fraction of a second.

POWER TOOL USE AND CARE

Do not force the power tool. Use the correct power

tool for your application. The correct power tool

will do the job better and safer at the rate for which

it was designed.

Do not use the power tool if the switch does not

Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

Disconnect the plug from the power source and/

or remove the battery pack, if detachable, from

the power tool before making any adjustments,

changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition that

have the power tool repaired before use. Many

accidents are caused by poorly maintained power

tools.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

result in a hazardous situation.

Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

BATTERY TOOL USE AND CARE

Recharge

manufacturer. A charger that is suitable for one type

with another battery pack.

battery packs. Use of any other battery packs may

If operating a power tool in a damp location is

unavoidable, use a residual current device

(RCD) protected supply. Use of a RCD reduces

the risk of electric shock.

3

When battery pack is not in use, keep it away

from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects,

that can make a connection from one terminal

to another. Shorting the battery terminals together

Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation

or burns.

Do not use a battery pack or tool that is dam-

explosion or risk of injury.

excessive temperature. -

perature above 130°C (265°F) may cause explosion.

Follow all charging instructions and do not charge

the battery pack or tool outside the temperature

Charging

range may damage the battery and increase the risk

SERVICE

Have

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

Never service damaged battery packs. Service

of battery packs should only be performed by the

manufacturer or authorised service providers.

SPECIFIC SAFETY RULES FOR

TABLE SAWS

Guarding related warnings

Keep guards in place. Guards must be in working

order and be properly mounted. A guard that is

loose, damaged, or is not functioning correctly must

be repaired or replaced.

Always use saw blade guard, riving knife and

anti-kickback device for every through–cutting

operation. For through-cutting operations where the

saw blade cuts completely through the thickness of

the workpiece, the guard and other safety devices

help reduce the risk of injury.

Immediately reattach the guarding system after

completing an operation (such as rabbeting,

dadoing or resawing cuts) which requires removal

of the guard, riving knife and/or anti-kickback

device. The guard, riving knife, and anti-kickback

device help to reduce the risk of injury.

Make sure the saw blade is not contacting the

guard, riving knife or the workpiece before the

switch is turned on. Inadvertent contact of these

items with the saw blade could cause a hazardous

condition.

Adjust the ri

ving

knife as described in this

instruction manual. Incorrect spacing, positioning

in reducing the likelihood of kickback.

For the riving knife and anti-kickback device to

work, they must be engaged in the workpiece.

The riving knife and anti-kickback device are ineffective when cutting workpieces that are too short to

be engaged with the riving knife and anti-kickback

device. Under these conditions a kickback cannot be

prevented by the riving knife and antikickback device.

Use the appropriate saw blade for the riving

knife. For the riving knife to function properly, the

saw blade diameter must match the appropriate

riving knife and the body of the saw blade must be

thinner than the thickness of the riving knife and the

cutting width of the saw blade must be wider than

the thickness of the riving knife.

Cutting procedures warnings

DANGER

in the vicinity or in line with the

saw blade. A moment of inattention or a slip could

direct your hand towards the saw blade and result

in serious personal injury.

Feed the workpiece into the saw blade or cutter

only against the direction of rotation. Feeding the

workpiece in the same direction that the saw blade is

rotating above the table may result in the workpiece,

and your hand, being pulled into the saw blade.

Never use the mitre gauge to feed the workpiece

when ripping and do not use the rip fence as a

length stop when cross cutting with the mitre

gauge. Guiding the workpiece with the rip fence

and the mitre gauge at the same time increases the

likelihood of saw blade binding and kickback.

When ripping, always apply the workpiece feed-

ing force between the fence and the saw blade.

Use a push stick when the distance between the

fence and the saw blade is less than 150 mm,

and use a push block when this distance is less

than 50 mm. “Work helping” devices will keep

your

hand at a safe distance from the saw blade.

Use only the push stick provided by the manu-

facturer or constructed in accordance with the

instructions.

distance of the hand from the saw blade.

Never use a damaged or cut push stick. A damaged

push stick may break causing your hand to slip into

the saw blade.

Do not perform any operation “freehand”. Always

use either the rip fence or the mitre gauge to

position and guide the workpiece. “Freehand”

means using your hands to support or guide the

workpiece, in lieu of a rip fence or mitre gauge.

Freehand sawing leads to misalignment, binding

and kickback.

Never reach around or over a rotating saw blade.

Reaching for a workpiece may lead to accidental

contact with the moving saw blade.

Provide auxiliary workpiece support to the rear

and/or sides of the saw table for long and/or

wide workpieces to keep them level. A long and/

or wide workpiece has a tendency to pivot on the

table’s edge, causing loss of control, saw blade

binding and kickback.

Feed workpiece at an even pace. Do not bend or

twist the workpiece. If jamming occurs, turn the

the jam. Jamming the saw blade by the workpiece

can cause kickback or stall the motor.

Do

the saw is running. The material may become

trapped between the fence or inside the saw blade

blade stops before removing material.

Use an auxiliary fence in contact with the table

top when ripping workpieces less than 2 mm

thick. A thin workpiece may wedge under the rip

fence and create a kickback.

4

Never leave the table saw running unattended.

to a complete stop. An unattended running saw is

an uncontrolled hazard.

Locate the table saw in a well-lit and level area

where you can maintain good footing and balance.

It should be installed in an area that provides

enough room to easily handle the size of your

workpiece. Cramped, dark areas, and uneven

Frequently clean and remove sawdust from

under the saw table and/or the dust collection

device. Accumulated sawdust is combustible and

may self-ignite.

The table saw must be secured. A table saw that

is not properly secured may move or tip over.

Remove tools, wood scraps, etc. from the table

before the table saw is turned on. Distraction or

a potential jam can be dangerous.

Always use saw blades with correct size and

shape (diamond versus round) of arbour holes.

Saw blades that do not match the mounting hardware

of the saw will run

Never use damaged or incorrect saw blade

washers, bolts or nuts. These mounting means were

specially designed for your saw, for safe operation

and optimum performance.

Never stand on the table saw, do not use it as

a stepping stool. Serious injury could occur if the

tool is tipped or if the cutting tool is accidentally

contacted.

Make sure that the saw blade is installed to rotate

in the proper direction. Do not use grinding

wheels, wire brushes, or abrasive wheels on a

table saw. Improper saw blade installation or use of

accessories not recommended may cause serious

injury.

Always use common sense and be cautious when

using tools. It is not possible to anticipate every

situation that could result in a dangerous outcome.

Do not use this tool if you do not understand these

operating instructions or you feel the work is beyond

your capability; contact Milwaukee Tool or a trained

professional for additional information or training.

WARNING

Some dust created by power sanding,

sawing, grinding, drilling, and other

construction activities contains chemicals known to

cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

lead from lead-based paint

crystalline silica from bricks and cement and other

masonry products, and

arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to

Kickback causes and related warnings

Kickback is a sudden reaction of the workpiece due

to a pinched, jammed saw blade or misaligned line of

cut in the workpiece with respect to the saw blade or

when a part of the workpiece binds between the saw

frequently during kickback, the workpiece is lifted from

the table by the rear portion of the saw blade and is

propelled towards the operator. Kickback is the result

of saw misuse and/or incorrect operating procedures

or conditions and can be avoided by taking proper

precautions as given below.

Never stand directly in line with the saw blade.

Always position your body on the same side of

the saw blade as the fence. Kickback may propel

the workpiece at high velocity towards anyone

standing in front and in line with the saw blade.

Never reach over or in back of the saw blade

to pull or to support the workpiece. Accidental

contact with the saw blade may occur or kickback

Never hold and press the workpiece that is being

Pressing

will create a binding condition and kickback.

Align the fence to be parallel with the saw blade.

A misaligned fence will pinch the workpiece against

the saw blade and create kickback.

Use a featherboard to guide the workpiece against

the table and fence when making non-through

cuts such as rabbeting, dadoing or resawing

cuts. A featherboard helps to control the workpiece

in the event of a kickback.

Use extra caution when making a cut into blind

areas of assembled workpieces. The protruding

saw blade may cut objects that can cause kickback.

Support large panels to minimise the risk of saw

blade pinching and kickback. Large panels tend

to sag under their own weight. Support(s) must be

placed under all portions of the panel overhanging

the table top.

Use extra caution when cutting a workpiece that

is twisted, knotted, warped or does not have a

straight edge to guide it with a mitre gauge or

along the fence. A warped, knotted, or twisted

workpiece is unstable and causes misalignment of

the kerf with the saw blade, binding and kickback.

Never cut more than one workpiece, stacked

vertically or horizontally. The saw blade could

pick up one or more pieces and cause kickback.

When restarting the saw with the saw blade in

the workpiece, centre the saw blade in the kerf so

that the saw teeth are not engaged in the material.

If the saw blade binds, it may lift up the workpiece

and cause kickback when the saw is restarted.

Keep

set. Never use warped saw blades or saw blades

with cracked or broken teeth. Sharp and properly set

saw blades minimise binding, stalling and kickback.

Table saw operating procedure warnings

T

cord when removing the table insert, changing

the saw blade or making adjustments to the

riving knife, antikickback device or saw blade

guard, and when the machine is left unattended.

Precautionary measures will avoid accidents.

Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE

®

service facility for a

replacement.

5

SYMBOLOGY

Volts

Direct Current

No Load Revolutions per Minute (RPM)

Read operator’s manual

Wear eye protection. Use hearing

and respiratory protection.

Keep hands and body out of the path

of the saw blade.

Match kerf width of blade (>1.8 mm)

and blade body thickness (<1.55 mm)

with the marking on the riving knife to

reduce the risk of kickback.

Only use 210 mm (8 1/4") saw blades

Match the arrow direction on the saw

blade with the arrow direction on the

riving knife.

SPECIFICATIONS

Cat. No. ..............................................M18 FTS210

Volts............................................................18V DC

Battery Type .................................................M18™

Charger Type................................................M18™

Recommended Ambient

Operating Temperature ......................-17°C to 51°C

No Load RPM ..................................................6300

Blade Arbour.................................................30 mm

Blade Diameter ...............................210 mm (8-1/4")

Blade Tilt .................................................. -3° to 47°

Mitre gauge angle.........................60° Right or Left

Cutting Depth, 0° Bevel .......................63 mm (2.5")

Cutting Depth, 45° Bevel ...................44 mm (1.75")

Blade Kerf ................................ ..>1.8 mm minimum

.................................<2.2 mm maximum

Blade body thickness..............<1.55 mm maximum

Riving knife thickness ....................1.6 mm (0.063")

ADDITIONAL BATTERY SAFETY RULES

WARNING

To reduce the risk of fire, personal

injury, and product damage due to a short circuit,

never immerse your inflator, battery pack or

charger in fluid or allow a fluid to flow inside them.

Corrosive or conductive fluids, such as seawater,

certain industrial chemicals, and bleach or

bleach-containing products, etc., can cause a short

circuit.

Regulatory Compliance mark (RCM).

This product meets applicable

regulatory requirements.

6

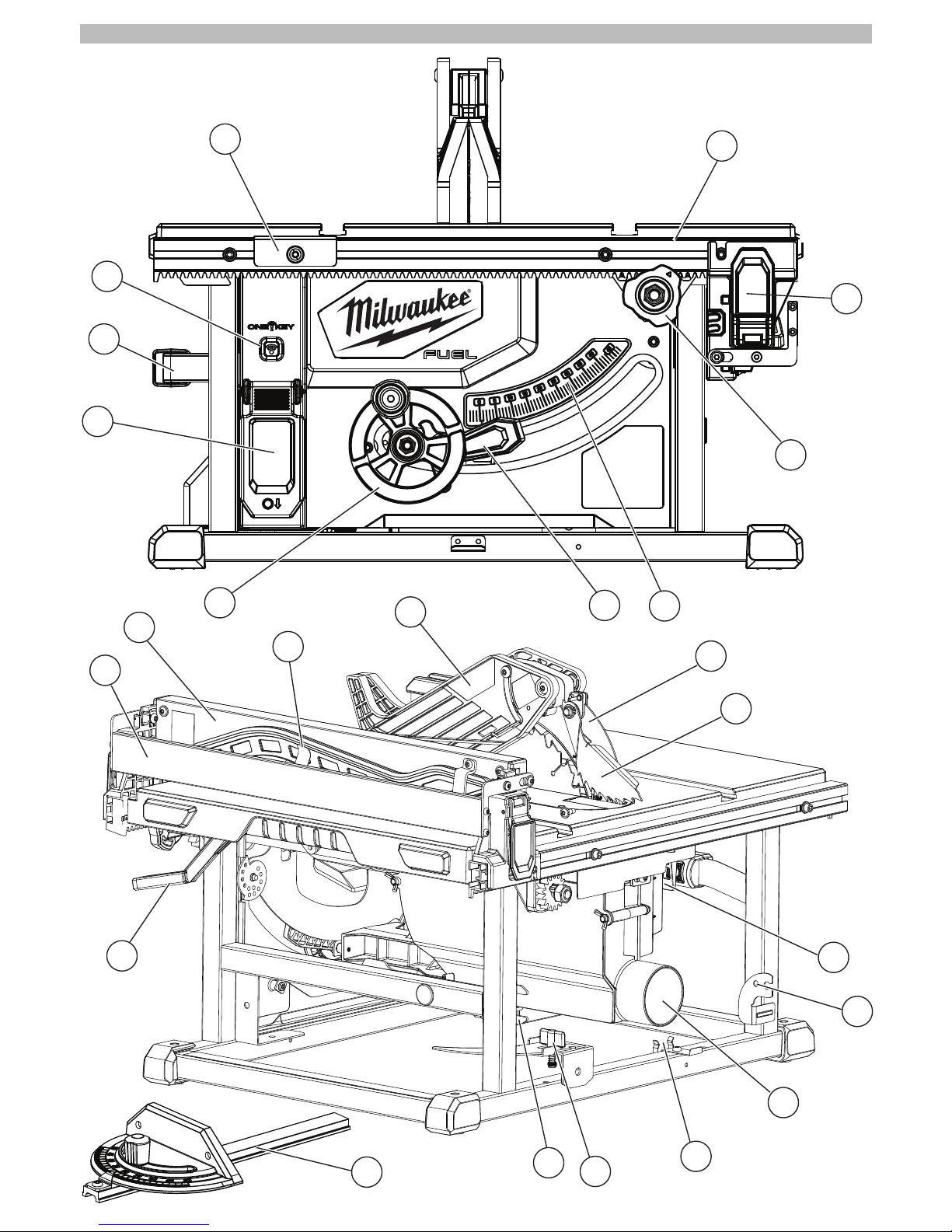

FUNCTIONAL DESCRIPTION

13

9

3

11

2

10

5

4

6

7

8

1

12

14

15

16

18

17

21

20

22

23

19

24

7

1. Rip scale indicator

2. Rip scale

3. Fence latch

4. Fence adjusting knob

5. Bevel scale

6. Bevel locking lever

7. Height adjusting wheel

8. Switch cover

9. Carrying handle

10. ONE-KEY

TM

indicator

11. Extending rip fence

12. Rip fence

13. Push stick

14. Blade guard

15. Riving knife and blade guard assembly

16. Anti-kickback pawls

17. Riving knife release lever

18. Anti-kickback pawl storage

19. Dust chute

20. Mitre gauge storage

21. Riving knife without guard / riving knife storage

22. Blade wrench / blade wrench storage

23. Mitre gauge

24. Fence lock

WARNING

recommended for this tool. Others

may be hazardous.

Unpacking

This product requires assembly.

Carefully lift saw from the carton and place it on a

level work surface.

NOTE: This tool is heavy. To avoid back injury, keep

your knees bent and lift with your legs, not your back,

and get help when needed.

If tool is shipped with a battery installed, remove

the battery pack.

Remove any packaging and zip ties.

Inspect the tool carefully to make sure no breakage

or damage occurred during shipping.

Mounting the Table Saw

WARNING

Ensure the saw is on a stable,

level surface before use.

For extra stability, mount the table saw to workbench

using the mounting holes in the in the frame. Insert

screws at an angle through the table saw frame.

Understanding the Table Saw

Before adjusting or operating the saw, have a basic

understanding of table saw use and terminology.

The upper portion of the blade projects up through the

table and is surrounded by an insert called the throat

plate. The height of the blade is set with a wheel on

the front of the cabinet. The rip fence is used to position work for lengthwise cuts. A rip fence scale on the

front rail shows the distance between the rip fence

and the blade. It is very important to use the riving

knife with blade guard and anti-kickback pawls for

all through-sawing operations. Use the mitre gauge

for all cross-cut operations.

Detailed instructions are provided in this manual

for making adjustments and basic cuts: cross cuts,

mitre cuts, bevel cuts, and compound cuts. This table

saw is designed to cut wood and wood composition

products only. Do not cut metal. Do not cut plastics.

Understand these instructions before continuing.

ASSEMBLY

WARNING

Recharge only with the charger

-

manual supplied with your charger and battery.

Removing/Inserting the Battery

To remove the battery, push in the release buttons

and pull the battery pack away from the tool.

WARNING

Always remove battery pack before

changing or removing accessories.

To insert the battery, slide the pack into the body

of the tool. Make sure it latches securely into place.

If any parts are damaged or missing, do not

operate this tool until the parts are replaced.

Use of this product with damaged or missing

parts could result in serious personal injury.

Do not attempt to modify this tool or create

accessories not recommended for use with this

tool.

Any such alteration or modification is misuse

and could result in a hazardous condition

leading to possible serious personal injury.

Do not insert to battery pack until assembly is

complete. Failure to comply could result in

accidental starting and possible serious

personal injury

.

Do not lift the saw without help. Hold it close to

your body. Keep your knees bent and lift with

your legs, not your back. Ignoring these precautions can result in back injury.

Do not discard the packing material until you have

carefully inspected the tool, identified all loose

parts, and satisfactorily operated the tool.

The MILWAUKEE

®

Table Saw Stand can also be

used.

8

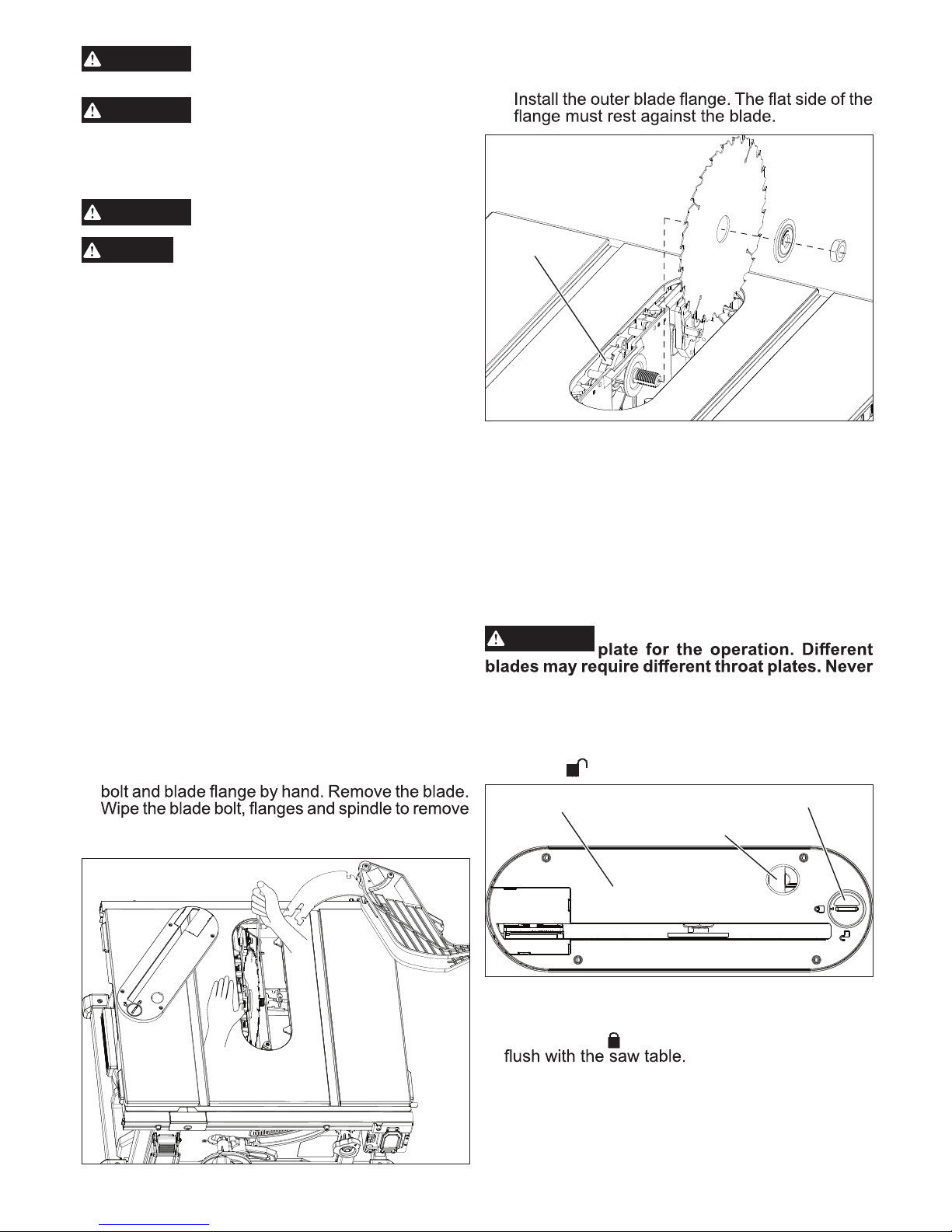

Selecting, Installing, and Changing Blades

WARNING

Do not use blades rated less than

the speed of this tool. Failure to

heed this warning could result in personal injury.

WARNING

Use the appropriate saw blade for

the riving knife. Match kerf width

of blade (>1.8 mm) and blade body thickness

(<1.55 mm) with the marking on the riving knife

to reduce the risk of kickback. Failure to heed

this warning could result in personal injury.

WARNING

Blades are sharp. Wear work gloves

when handling blades.

NOTICE

To work properly, the saw blade teeth

must point down toward the front of

the saw. Failure to heed this warning could cause

damage to the saw blade, the saw, or the workpiece.

Blade kerf width and blade body thickness must be

within the limits stamped on the riving knife. Do not

use metal-cutting blades. Do not cut plastics.

The blade wrench should be stored on the table

saw frame (see "Functional Description" for storage

location).

NOTE: To replace the blade with an accessory blade,

follow the instructions provided with the accessory.

To change the saw blade:

1. Remove the battery pack.

2. Set the blade angle (bevel) to 0° and lock it in

place.

3. Raise the blade by turning the height adjusting

wheel clockwise.

4. Remove the riving knife.

5. Remove the throat plate.

6. Press in the spindle lock and rotate the spindle/

blade until the lock engages.

7. Use the blade wrench to loosen the blade bolt

counterclockwise. Carefully remove the blade

dust and debris. Inspect the parts for damage.

Replace if needed.

8. Match the arrow direction on the replacement saw

blade with the arrow direction on the riving knife.

The teeth should point toward the front of the table

saw. Slide the blade onto the spindle.

9.

Spindle lock

10. Hand-thread the blade bolt. Once the spindle

starts to spin, press in the spindle lock and rotate

the blade until the lock engages. Securely tighten

clockwise with the blade wrench.

11. Reinstall the appropriate throat plate, riving knife,

and anti-kickback pawls for the application.

12. Check blade guard and anti-kickback pawls move

freely before starting the saw. Ensure the blade

teeth match the direction of rotation indicated on

the riving knife.

Changing the Throat Plate

WARNING

Always use the appropriate throat

operate the saw without a throat plate in place.

1. Remove the battery pack.

2. Lower the blade by turning the height adjusting

wheel counterclockwise.

3. To remove a throat plate, turn the throat plate

latch to

unlocked.

Throat plate

Lift hole

Throat plate latch

4. Use the hole to lift the throat plate out.

5. To install a throat plate, slide the back end into the

slot and drop the front into place. Turn the throat

plate latch to

locked. The throat plate must be

Always use clean, sharp blades. Dull blades tend

to overload the tool, bind, and cause pinching. Use

only 210mm (8-1/4") table saw blades rated at

least 6300 RPM.

The blade provided with the saw is a high-quality

combination blade suitable for ripping and cross

cut operations.

Loading...

Loading...