Milwaukee M18 FUEL 48105601, M18 FUEL 48105602 Operator's Manual

OPERATOR'S MANUAL

Cat. No.Cat. No.

M18 FTR, 48105601, 48105602

M18 FUEL™ LAMINATE TRIMMER

WARNING

To reduce the risk of injury, user must read and understand operator's manual.

GENERAL POWER TOOL

SAFETY WARNINGS

WARNING

tions provided with this power tool. Failure to

follow all instructions listed below may result in

warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated (cordless) power tool.

Read all safety warnings, instruc-

Save all

WORK AREA SAFETY

• Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

Do not operate power tools in explosive atmo-

•

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

Keep children and bystanders away while operat-

•

ing a power tool. Distractions can cause you to lose

control.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools.

reduce risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

•

If operating a power tool in a damp location is

unavoidable, use a residual current device

(RCD) protected supply. Use of a RCD reduces

the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

moment of inattention while operating power tools

may result in serious personal injury.

• Use personal protective equipment. Always

wear eye protection. Protective equipment such

as a dust mask, non-skid safety shoes, hard hat or

hearing protection used for appropriate conditions

will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch

source and/or battery pack, picking up or carrying

the tool.

the switch or energising power tools that have the

switch on invites accidents.

A

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

-

• Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

• If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

• Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action can

cause severe injury within a fraction of a second.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct power

tool for your application. The correct power tool

will do the job better and safer at the rate for which

it was designed.

• Do not use the power tool if the switch does not

controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source and/

or remove the battery pack, if detachable, from

the power tool before making any adjustments,

changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

• Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

• Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition that

have the power tool repaired before use. Many

accidents are caused by poorly maintained power

tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

result in a hazardous situation.

• Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

Any power tool that cannot be

BATTERY TOOL USE AND CARE

manufacturer. A charger that is suitable for one type

with another battery pack.

battery packs. Use of any other battery packs may

2

• When battery pack is not in use, keep it away

from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects,

that can make a connection from one terminal

to another. Shorting the battery terminals together

• Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact acciden-

eyes, additionally seek medical help. Liquid

ejected from the battery may cause irritation or burns.

• Do not use a battery pack or tool that is dam-

explosion or risk of injury.

•

Do not expose a battery pack or tool to fire or

excessive temperature. Exposure to fire or

temperature above 130°C (265°F) may cause explosion.

• Follow all charging instructions and do not charge

the battery pack or tool outside the temperature

Charging im-

SERVICE

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

• Never service damaged battery packs. Service

of battery packs should only be performed by the

manufacturer or authorised service providers.

SPECIFIC SAFETY RULES FOR

LAMINATE TRIMMER

•

Use clamps or another practical way to secure

and support the workpiece to a stable platform.

Holding the work by your hand or against the body

leaves it unstable and may lead to loss of control.

•

ing the start-up. The reaction torque of the motor,

as it accelerates to full speed, can cause the tool

to twist.

• -

sition your body and arm to allow you to resist

kickback forces. The operator can control kick-

back forces, if proper precautions are taken.

• Some woods contain preservatives that can be

toxic. Take extra care to prevent inhalation and

skin contact when working with these materials.

Request, and follow, any safety information available from your material supplier.

•

Never hold the workpiece in one hand and the

tool in the other hand when using the tool. Never

place hands near or below cutting surface.

Clamping the material and guiding the tool with

both hands is safer.

•

Never use dull or damaged bits. Sharp bits

must be handled with care. Damaged bits can

break during use. Dull bits require more force to

push the tool, which could cause the bit to break.

Damaged bits can throw carbide pieces and burn

the workpiece.

•

After changing the bit or making any adjust-

ments, make sure the collet nut and any other

adjustment devices are securely tightened.

Loose adjustment devices can unexpectedly shift,

causing loss of control. Loose rotating components

will be violently thrown. Watch for vibration or wobbling that could indicate an improperly installed bit.

• Never start the tool when the bit is in contact

with the material. The bit cutting edge may grab

the material causing loss of control of the tool.

• Never lay the tool down until the bit has come

to a complete stop. The spinning bit can grab the

surface and pull the tool out of your control.

• Never touch the bit during or immediately after

use. After use the bit, collet, and collet nut may be

hot enough to burn bare skin.

• Never clamp the workpiece to a hard surface,

such as concrete or stone. Contact with the bit

could cause the tool to jump and loss of control.

•

Only operate the trimmer when held. Do not

clamp or secure the trimmer to a surface and hold

the workpiece by hand.

• Never use bits larger than the smallest of the

openings in the base, sub-base, or dust collection

port.

• Do not loosen or remove the plunge base caps.

Internal springs are under pressure. If loosened or

removed, the plunge base caps and internal springs

will become projectiles, which could cause injury.

•

WARNING

appropriate respiratory protection or use an

OSHA compliant dust extraction solution.

Always use common sense and be cautious

•

when using tools. It is not possible to anticipate

every situation that could result in a dangerous

outcome. Do not use this tool if you do not

understand these operating instructions or you feel

the work is beyond your capability; contact

MILWAUKEE

additional information or training.

Maintain labels and nameplates. These carry

•

important information. If unreadable or missing,

contact a MILWAUKEE® service facility for a

replacement.

•

WARNING

-

construction activities contains chemicals known to

cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to

To reduce the risk of injury, when

working in dusty situations, wear

®

Tool or a trained professional for

Some dust created by power sanding,

sawing, grinding,

drilling, and other

ADDITIONAL BATTERY SAFETY RULES

WARNING

a short circuit, never immerse your tool, battery

pack or charger in fluid or allow a fluid to flow inside

them. Corrosive or conductive fluids, such as

seawater, certain industrial chemicals, and bleach

or bleach-containing products, etc., can cause a

short circuit.

3

To reduce the risk of fire, personal

injury , and product damage due to

Cat. No. ................................................... M18 FTR

SPECIFICATIONS

Volts............................................................ 18V DC

Battery Type .................................................M18™

Charger Type................................................M18™

No Load RPM ................................ 10,000 - 31,000

Maximum Bit Size ............................. 38mm (1-1/2")

Collet Size ........................... 6.35mm (1/4") & 6mm

Recommended Ambient

Operating Temperature ................... -17°C to 51°C

Plunge Base Cat. No. ........................... 48105601

Offset Base Cat. No. ............................ 48105602

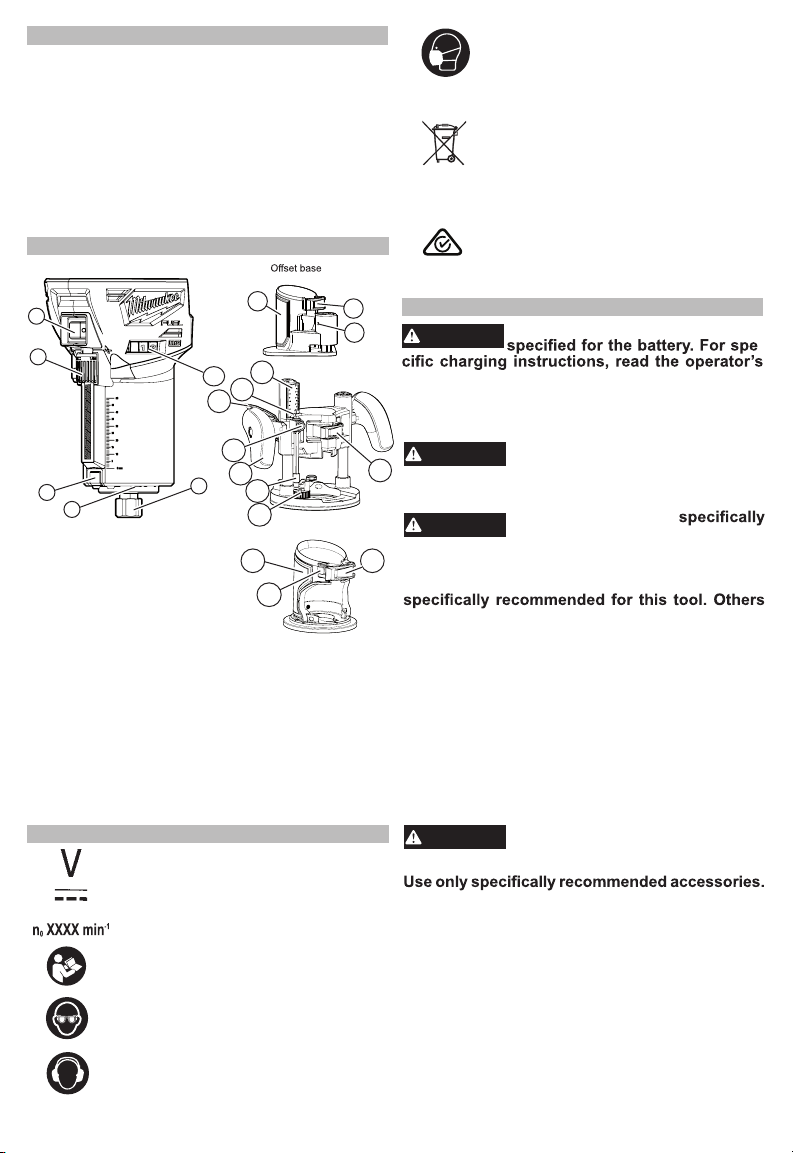

FUNCTIONAL DESCRIPTION

Cat. No. M18 FTR

Wear dust mask.

Do not dispose of electric tools

together with household waste

material. Electric tools and electronic

equipment that have reached the end

of their life must be collected

separately and returned to an

environmentally compatible recycling

facility.

Regulatory Compliance Mark (RCM).

This product meets applicable

regulatory requirements.

1

6

5

4

1. ON/OFF switch

2. Speed control dial

3. Collet / collet nut

4. LED (not shown)

5. Spindle lock

6. Micro adjustment dial

7. Quick release lever

8. Macro adjustment

button

9. Gripping surface

SYMBOLOGY

Volts

Direct Current

No Load Revolutions per Minute (RPM)

Read Operator's Manual

Wear eye protection.

Wear hearing protection.

9

16

2

15

14

13

12

3

11

10

9

8

7

17

Plunge base

Fixed base

10. Depth turret

11. Micro adjustment

sleeve

12. Handles

13. Depth gauge knob

14. Plunge release lever

15. Depth gauge indicator

16. Depth gauge

17. Shaft / housing hole

ASSEMBLY

WARNING

manual supplied with your charger and battery.

To remove the battery, push in the release buttons

and pull the battery pack away from the tool.

WARNING

7

To insert the battery, slide the pack into the body

of the tool. Make sure it latches securely into place.

WARNING

may be hazardous.

7

Always remove battery from tool before changing

or removing accessories. Only use accessories

may be hazardous.

The collet must be attached to the collet nut before

installing the collet assembly to the tool. Be sure

that the collet size matches the size of the bit shank,

otherwise the collet may break.

1. To assemble, place collet on an even surface, and

place the nut over the collet.

2. Press down on the nut to snap the nut and collet

together.

3. To disassemble, use a rod to push the collet out

of the nut.

WARNING

accessories or making adjustments.

Others may be hazardous.

Never use bits larger than the smallest of the

openings in the base, sub-base, or dust shroud.

The use of larger bits can result in loss of control

and possible serious personal injury.

Do not tighten the collet nut without inserting the

bit. The collet may break.

Never touch the bit during or immediately after

use. After use the bit, collet, and collet nut may

be hot enough to burn bare skin.

Recharge only with the charger

Removing/Inserting the Battery

Always remove battery pack before

changing or removing accessories.

Only use

reco

accessorie

mmended

for this s tool. Others

Installing Collets

Installing/Removing Bits

Al

ways

tool

remove

before

battery

attaching

or

from

the

removing

-

4

Loading...

Loading...