Milwaukee M18 FORCE LOGIC 750 MCM Operator's Manual

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Cat. No. / No de cat.

2779-20

M18™ FORCE LOGIC™ 750 MCM CRIMPER

SERTISSEUR UTILITAIRE 750 MCM M18™ FORCE LOGIC™

CRIMPADORA 750 MCM UTILITARIA M18™ FORCE LOGIC™

WARNING To reduce the risk of injury, user must read and understand operator's manual.

AVERTISSEMENT An de réduire le risque de blessures, l'utilisateur doit lire et bien

comprendre le manuel.

ADVERTENCIA Para reducir el riesgo de lesiones, el usuario debe leer y entender el manual.

GENERAL POWER TOOL

WARNING

SAFETY WARNINGS

Read all safety warnings, instruc-

tions provided with this power tool. Failure to

follow all instructions listed below may result in

electric shock, re and/or serious injury. Save all

warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-oper-

ated (cordless) power tool.

tions, illustrations and specica-

WORK AREA SAFETY

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not operate power tools in explosive atmo

spheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while operat

ing a power tool. Distractions can cause you to lose

control.

-

-

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodied plugs and matching outlets will

reduce risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet condi

tions. Water entering a power tool will increase the

risk of electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

• If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of an GFCI reduces

the risk of electric shock.

-

PERSONAL SAFETY

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the inuence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as a dust

mask, non-skid safety shoes, hard hat or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your nger on the

switch or energizing power tools that have the switch

on invites accidents.

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result

in personal injury.

• Do not overreach. Keep proper footing and bal

ance at all times. This enables better control of the

power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust

collection can reduce dust-related hazards.

• Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action

can cause severe injury within a fraction of a second.

-

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it was designed.

• Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source and/

or remove the battery pack, if detachable, from

the power tool before making any adjustments,

changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

• Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

• Maintain power tools and accessories. Check for

misalignment or binding of moving parts, break

age of parts and any other condition that may

affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many

accidents are caused by poorly maintained power

tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

different from those intended could result in a hazard

ous situation.

• Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles

and grasping surfaces do not allow for safe handling

and control of the tool in unexpected situations.

-

-

BATTERY TOOL USE AND CARE

• Recharge only with the charger specied by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of re when used

with another battery pack.

• Use power tools only with specically designated

battery packs. Use of any other battery packs may

create a risk of injury and re.

2

• When battery pack is not in use, keep it away

WARNING

WARNING

WARNING

WARNING

from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects,

that can make a connection from one terminal to

another. Shorting the battery terminals together may

cause burns or a re.

• Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact ac

cidentally occurs, ush with water. If liquid con-

tacts eyes, additionally seek medical help. Liquid

ejected from the battery may cause irritation or burns.

• Do not use a battery pack or tool that is dam

aged or modied. Damaged or modied batteries

may exhibit unpredictable behavior resulting in re,

explosion or risk of injury.

• Do not expose a battery pack or tool to re or

excessive temperature. Exposure to re or tem

perature above 265°F (130°C) may cause explosion.

• Follow all charging instructions and do not

charge the battery pack or tool outside the

temperature range specied in the instructions.

Charging improperly or at temperatures outside the

specied range may damage the battery and increase

the risk of re.

SERVICE

• Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

• Never service damaged battery packs. Service

of battery packs should only be performed by the

manufacturer or authorized service providers.

SPECIFIC SAFETY RULES FOR

CRIMPER

• Use tool only as directed. Only trained personnel

should operate tool.

•

damage, do not use on live electrical lines.

Tool is NOT insulated. Contact with a live

circuit could result in severe injury or death.

Turn off power before making a crimp.

• Use tool only with MILWAUKEE "U" dies and

connectors for which they are rated. Jaws, dies,

and connectors must be used in an APPROVED

COMBINATION to achieve a successful operation.

Improper combinations can result in a faulty crimp.

Electric shock, re, explosion, and property damage

could occur.

• Keep hands away from crimping jaws while tool

is in use. Fingers could be crushed.

•To reduce the risk of injury, wear safety goggles

or glasses with side shields when operating or

servicing the tool.

• Inspect and discard workpieces with cracks or

wear before use. Materials may crack or shatter.

• Follow connector manufacturers' installation

instructions. Other uses may cause damage to the

tool, accessories, and workpiece.

• Always use common sense and be cautious when

using tools. It is not possible to anticipate every

situation that could result in a dangerous outcome.

Do not use this tool if you do not understand these

operating instructions or you feel the work is beyond

your capability; contact Milwaukee Tool or a trained

professional for additional information or training.

To reduce the risk of explosion,

electric shock and property

• Maintain labels and nameplates. These carry im-

portant information. If unreadable or missing, contact

a MILWAUKEE service facility for a free replacement.

•

construction activities contains chemicals known to

cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

-

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated lum

-

ber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to

lter out microscopic particles.

Some dust created by power sanding,

sawing, grinding, drilling, and other

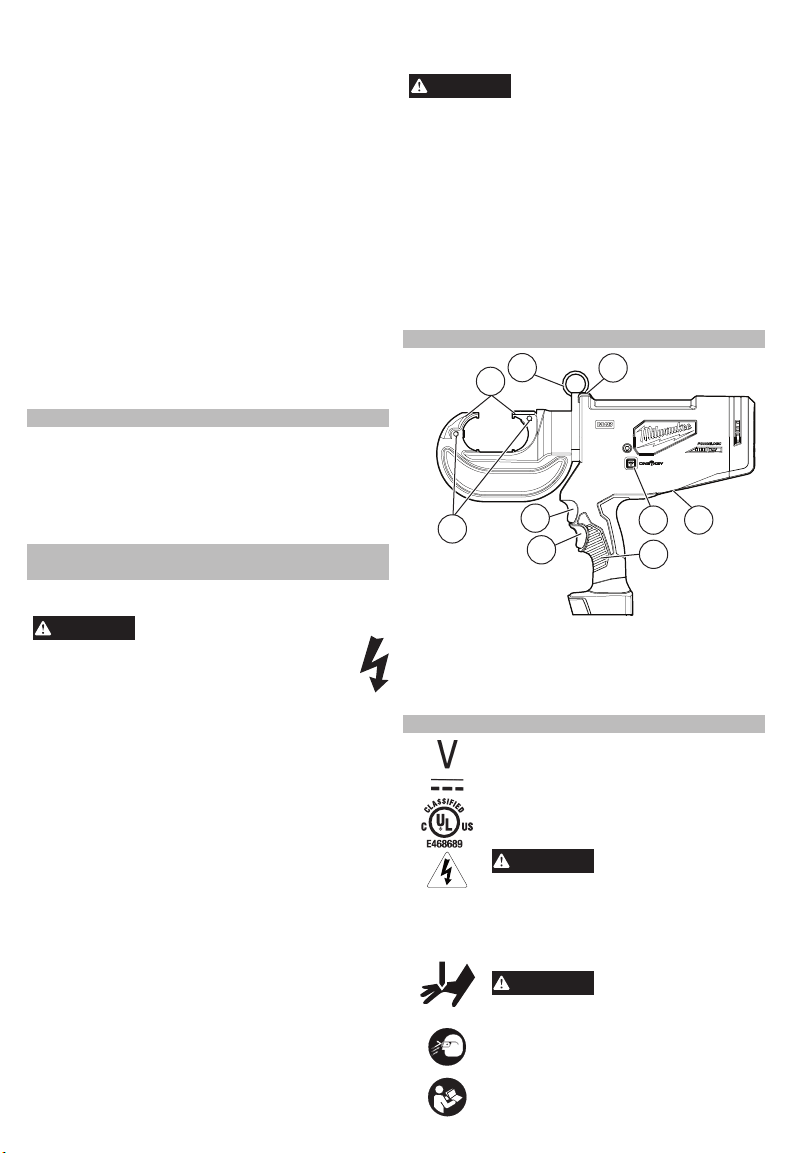

FUNCTIONAL DESCRIPTION

2

1

9

1. Crimping jaws

2. Lift ring

3. LEDs/Crimping

indicator

4. Internal battery

8

7

3

4

5

6

5. ONE KEY indicator

6. Handle

7. Reverse trigger

8. Trigger

9. Die release pins

SYMBOLOGY

Volts

Direct Current

Underwriters Laboratories, Inc.

United States and Canada

3

and property damage, do not use on live

electrical lines. Tool is NOT insulated.

Contact with a live circuit could result in

severe injury or death. Turn off power

before making a crimp.

is in use. Fingers could be crushed.

To reduce the risk of injury, wear safety

goggles or glasses with side shields

when operating or servicing the tool.

Read operator's manual.

To reduce the risk of

explosion, electric shock

Keep hands away from

crimping jaws while tool

-

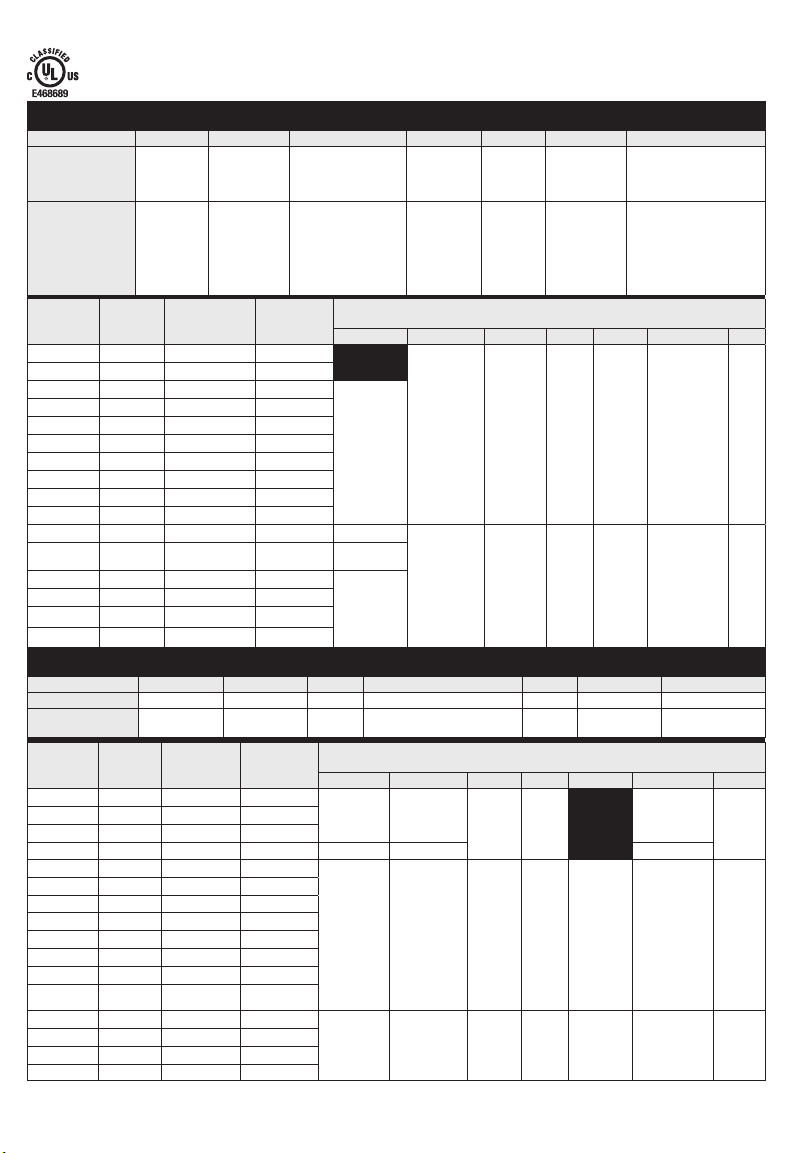

Connections made with this tool (2779-20) and combination of die and connector part

numbers in the charts below produce cULus Classied crimps according to the UL 486A-B

classication standards.

Copper Short & Long Barrel Lugs & Splices

Table A

Anderson Blackburn® Burndy ILSCO Panduit Penn-Union T&B

Splice

Model #'s

Lug

Model #'s

Wire

Size

VHS,

VHSS

VHCL,

VHCS

Die

Color Cat. No.

CSP,

CU

CTL,

CTL-2,

CTL-L,

LCN

YA, YAZ, YA-L,

YA-2L, YA-2LN,

YA-L-NT,

YA-L-2NT,

YA-L-TC,

YA-L-2TC, YA-2N,

YA-TC, YA-2TC

Die

Indentation

Mark

YS,

YS-L,

YS-T

CT,

CTL

CLN, CLW,

CRA,CRB,

CRA-L,

CRB-L,

CRA-2L,

CRB-2L,

CSW

Anderson Blackburn

SCH,

SCL,

SCS,

SCSS

LCA,

LCAS,

LCB,

LCC,

LCD

Lugs: Total # of Crimps

Splices: # of Crimps per Side

®

Burndy ILSCO Panduit Penn-Union T&B

BBCU,

BCU

BBLU,

BLU

54504-54523-TB,

54804-54823

54104-54123-TB,

54204-54223,

54850BE-54880BE,

54930BE-54923BE

#8 AWG RED 49-12-U008C 8

#6 AWG BLUE 49-12-U006C 6

#4 AWG GRAY 49-12-U004C 4

#2 AWG BROWN 49-12-U002C 2

#1 AWG GREEN 49-12-U001C 1

1/0 AWG PINK 49-12-U01AC 1/0

2/0 AWG BLACK 49-12-U02AC 2/0

1

1 1 1 1 1 1

3/0 AWG ORANGE 49-12-U03AC 3/0

4/0 AWG PURPLE 49-12-U04AC 4/0

250 MCM YELLOW 49-12-U250C 250

300 MCM WHITE 49-12-U300C 300 2

350 MCM RED 49-12-U350C 350

400 MCM BLUE 49-12-U400C 400

500 MCM BROWN 49-12-U500C 500

600 MCM GREEN 49-12-U600C 600

Lugs: 2

Splices:

2

N/A

2 2 2 2 2 2

750 MCM BLACK 49-12-U750C 750

Dual Rated Lugs & Splices

Splice Model #'s

Lug Model #'s

Wire

Size

#8 AWG BLUE 49-12-U008 8

#6 AWG GRAY 49-12-U006 6

#4 AWG GREEN 49-12-U004 4

#2 AWG PINK 49-12-U002 2 1 1 1

#1 AWG GOLD 49-12-U001 1

1/0 AWG TAN 49-12-U01A 1/0

2/0 AWG OLIVE 49-12-U02A 2/0

3/0 AWG RUBY 49-12-U03A 3/0

4/0 AWG WHITE 49-12-U04A 4/0

250 MCM RED 49-12-U250 250

300 MCM BLUE 49-12-U300 300

350 MCM BROWN 49-12-U350 350

400 MCM GREEN 49-12-U400 400

500 MCM PINK 49-12-U500 500

600 MCM BLACK 49-12-U600 600

750 MCM YELLOW 49-12-U750 750

Number of crimps is a minimum. Additional crimps would not negatively affect the integrity of the connection so long as they are uniformly

placed between the intended crimp area of the connector, typically outlined with color bands or knurls. For the latest listing of approvals,

visit milwaukeetool.com. For technical or service assistance, contact Milwaukee Customer Service at 1-800-729-3878.

Anderson Blackburn® Burndy ILSCO Panduit Penn-Union T&B

VACS ASP YS-A AS,ASN SA BCUA 60501-60578

VACL ATL YA-A,

Die

Color Cat. No.

Die

Indentation

Mark

ACL, ACN,ALND, ALNS,

YA-ATN

2ACL, 2ACN

Anderson Blackburn

Lugs: N/A

Splices:

1

Lugs: 1

Splices:

LAA,

LAB

Lugs: Total # of Crimps

Splices: # of Crimps per Side

®

Burndy ILSCO Panduit Penn-Union T&B

N/A

1 1

BLUA 60101-60178,

2 2 2 2 2 2 2

3 3 3 3 3 3 3

4

60230-60278

Lugs: 1

Splices: N/A

1

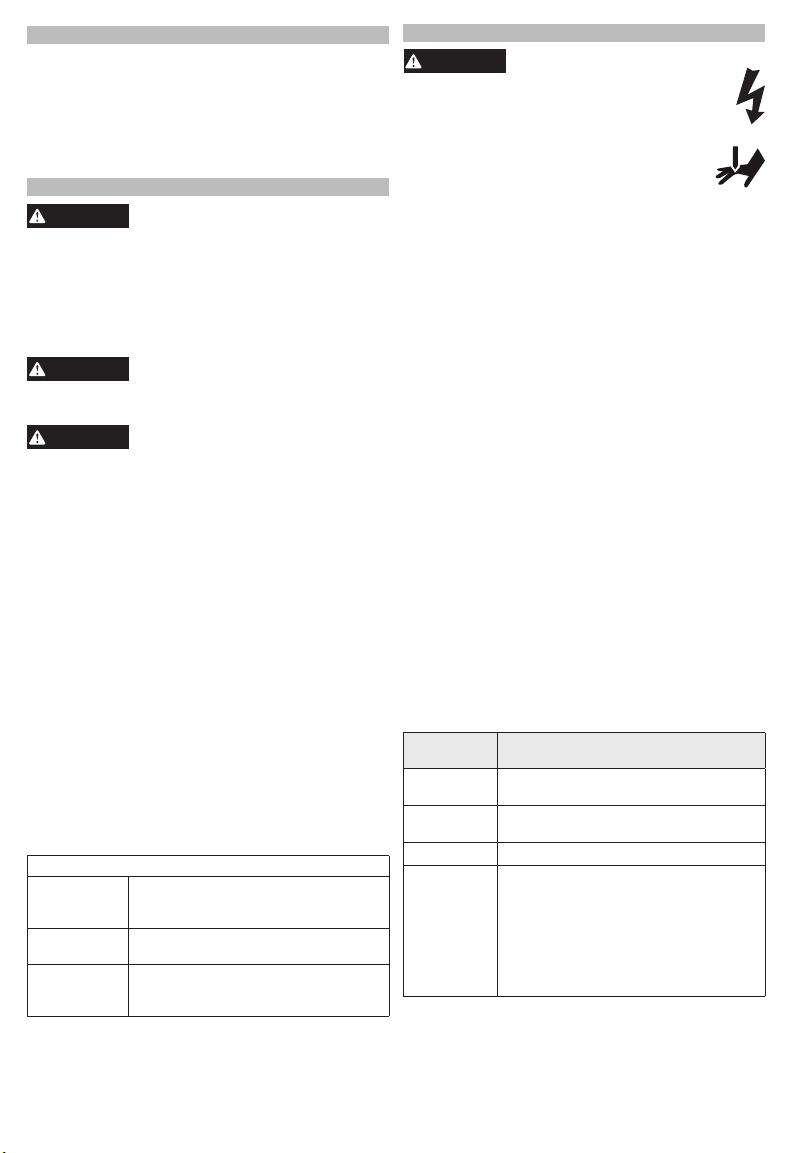

Cat. No. ..................................................... 2779-20

WARNING

WARNING

WARNING

WARNING

Volts .............................................................. 18 DC

Battery Type .................................................M18™

Charger Type ................................................M18™

Recommended Ambient

Operating Temperature ......................0°F to 125°F

Force ..........................................................12 Tons

Capacity................................... #8AWG - 750 MCM

ASSEMBLY

Recharge only with the charger

SPECIFICATIONS

cic charging instructions, read the operator’s

manual supplied with your charger and battery.

To remove the battery, push in the release buttons

and pull the battery pack away from the tool.

To insert the battery, slide the pack into the body

of the tool. Make sure it latches securely into place.

ries. Only use accessories specically recommended for this tool. Others may be hazardous.

MILWAUKEE "U" dies and connectors for which

they are rated. Jaws, dies, and connectors must

be used in an approved combination to achieve

a successful operation. Improper combinations

can result in a faulty crimp. Electric shock, re,

explosion, and property damage could occur.

Inspect dies and connectors before use. Only use

properly matched dies and connectors for the crimp-

ing jaws. Refer to Specications for die/connector

compatibility.

1. Remove the battery pack.

2. Snap the appropriate dies into each side of the

crimping jaws.

3. To remove, press the release button for each side

of the crimping jaws. Pull dies out from crimping

jaws.

To learn more about the ONE-KEY™ function-

ality for this tool, please reference the Quick

Start guide included with this product or go to

milwaukeetool.com/One-Key. To download the

ONE-KEY™ app, visit the App Store or Google Play

from your smart device.

Solid Blue Wireless mode is active and ready

Blinking Blue Tool is actively communicating with

Blinking Red Tool is in security lockout and can

specied for the battery. For spe-

Inserting/Removing the Battery

Always remove battery pack before

changing or removing accesso-

An incomplete or faulty crimp could

cause a re. Use tool only with

Changing the Dies

ONE-KEY™

ONE-KEY™ Indicator

to be congured via the ONE-KEY™

app.

the ONE-KEY™ app.

be unlocked by the owner via the

ONE-KEY™ app.

OPERATION

To reduce the risk of explosion,

damage, do not use on live electrical lines.

Tool is NOT insulated. Contact with a live

circuit could result in severe injury or death.

Turn off power before making a crimp.

Keep hands away from crimping jaws

while tool is in use. Fingers could be

crushed.

Always remove battery pack before changing

or removing accessories. Only use accessories

specically recommended for this tool. Others

may be hazardous.

To reduce the risk of injury, always wear proper

eye protection marked to comply with ANSI Z87.1.

Before crimping:

•

Inspect the jaws and dies for cracks or other damage. Do not use damaged jaws or dies. Contact a

MILWAUKEE

•

Ensure dies are properly installed.

•

Jaws, dies, connectors, and cables must

an APPROVED COMBINATION

tions can result in a faulty crimp.

•

Inspect and discard workpieces with cracks or wear

before use. Materials may crack or shatter.

•Follow installation specications as specied in

Table A using an Approved Combination of jaws,

dies, connectors and cables as indicated. Other

uses may cause damage to the tool, accessories,

and workpiece.

1. Install the dies.

2. Insert battery pack.

3. Rotate the jaws to the desired angle. Hold tool

securely. Press and hold the trigger.

4. When the cycle is complete the tool will switch

off and the indicator will light. Release the trigger.

Press and hold the reverse trigger to manually

return the crimping jaws.

NOTE: After the cycle reaches a certain point, the

crimp may automatically nish, even if the trigger

is released.

LED

Indicator Denition

Solid Green Tool completed the operation and

Solid Red Tool completed the operation but did NOT

Flashing Red Tool did NOT complete the operation.

Flashing

Red/Green

(after Solid

Green or

Solid Red)

5. Continue crimping according to the instructions in

Table A.

• Crimps should be uniformly placed on the barrel

of the connector.

• Crimps should be reasonably placed within the

color bands or knurled area of the connector.

• For splices, begin crimping in the center, working

outward while alternating sides.

5

electric shock and property

Crimping

service facility.

. Improper combina-

reached full crimping pressure.

reach full crimping pressure.

Tool has reached its service interval

(20,000 crimps). Red/Green flashing

will begin after the solid Red or Green

indicator for the operation is displayed.

MILWAUKEE

tool be inspected and preventative

maintenance completed. Return tool to

a

MILWAUKEE service facility.

recommends that the

be used in

• For lugs, begin crimping near the pad, working

WARNING

WARNING

WARNING

WARNING

towards the barrel.

6. An LED will light the workpiece when the trigger

is pulled.

7. The die identier is pressed into the connector

during the crimp.

MAINTENANCE

To reduce the risk of injury, always

battery pack from the charger or tool before

performing any maintenance. Never disassemble

the tool, battery pack or charger. Contact a

MILWAUKEE service facility for ALL repairs.

Keep your tool, battery pack and charger in good repair by adopting a regular maintenance program. After six months to one year, depending on use, return

the tool, battery pack and charger to a MILWAUKEE

service facility for:

• Lubrication

• Mechanical inspection and cleaning (gears, spin-

dles, bearings, housing, etc.)

• Electrical inspection (battery pack, charger, motor)

• Testing to assure proper mechanical and electrical

operation

If the tool does not start or operate at full power with

a fully charged battery pack, clean the contacts on

the battery pack. If the tool still does not work properly, return the tool, charger and battery pack, to a

MILWAUKEE service facility for repairs.

lithium button/coin cell battery. A new

or used battery can cause severe internal burns and lead to death in as

little as 2 hours if swallowed or enters the body.

Always secure the battery cover. If it does not

close securely, stop using the device, remove the

batteries, and keep it away from children. If you

think batteries may have been swallowed or

entered the body, seek immediate medical atten-

tion.

An internal battery is used to facilitate full ONE-KEY™

functionality.

To replace the battery:

1. Remove the battery pack.

2. Remove the screw(s) and open the battery door.

3. Remove the old battery, keep it away from children,

and dispose of it properly.

4. Insert the new battery (3V CR2032), with the posi-

tive side facing up.

5. Close the battery door and tighten the screw

securely.

your tool, battery pack or charger in liquid or

allow a liquid to ow inside them.

Clean dust and debris from vents. Keep handles

clean, dry and free of oil or grease. Use only mild

soap and a damp cloth to clean, since certain cleaning agents and solvents are harmful to plastics and

other insulated parts. Some of these include gasoline,

turpentine, lacquer thinner, paint thinner, chlorinated

unplug the charger and remove the

Maintaining Tool

ONE-KEY™

Chemical Burn Hazard.

This device contains a

Internal Battery

To reduce the risk of personal injury and damage, never immerse

Cleaning

cleaning solvents, ammonia and household deter-

gents containing ammonia. Never use ammable or

combustible solvents around tools.

For repairs, return the tool, battery pack and charger

to the nearest service center.

Repairs

ACCESSORIES

Use only recommended accesso-

For a complete listing of accessories, go online to

www.milwaukeetool.com or contact a distributor.

ries. Others may be hazardous.

SERVICE - UNITED STATES

1-800-SAWDUST (1.800.729.3878)

Monday-Friday, 7:00 AM - 6:30 PM CST

or visit www.milwaukeetool.com

Contact Corporate After Sales Service Technical

Support with technical, service/repair, or warranty

questions.

Email: metproductsupport@milwaukeetool.com

Become a Heavy Duty Club Member at

www.milwaukeetool.com to receive important

notications regarding your tool purchases.

SERVICE - CANADA

Milwaukee Tool (Canada) Ltd

Monday-Friday, 7:00 AM - 4:30 PM CST

Every MILWAUKEE power tool* (see exceptions below) is warranted

to the original purchaser only to be free from defects in material and

workmanship. Subject to certain exceptions, MILWAUKEE will repair

or replace any part on an electric power tool which, after examination,

is determined by MILWAUKEE to be defective in material or workman-

ship for a period of ve (5) years** after the date of purchase unless

otherwise noted. Return of the power tool to a MILWAUKEE factory

Service Center location or MILWAUKEE Authorized Service Station,

freight prepaid and insured, is required. A copy of the proof of purchase

should be included with the return product. This warranty does not

apply to damage that MILWAUKEE determines to be from repairs

made or attempted by anyone other than MILWAUKEE authorized

personnel, misuse, alterations, abuse, normal wear and tear, lack of

maintenance, or accidents.

Normal Wear: Many power tools need periodic parts replacement and

service to achieve best performance. This warranty does not cover

repair when normal use has exhausted the life of a part including,

but not limited to, chucks, brushes, cords, saw shoes, blade clamps,

o-rings, seals, bumpers, driver blades, pistons, strikers, lifters, and

bumper cover washers.

*This warranty does not cover Air Nailers & Staplers; Airless Paint

Sprayer; Cordless Battery Packs; Gasoline Driven Portable Power

Generators; Hand Tools; Hoist – Electric, Lever & Hand Chain; M12™

Heated Gear; Reconditioned Product; and Test & Measurement

Products. There are separate and distinct warranties available for

these products.

**The warranty period for Job Site Radios, M12™ Power Port, M18™

Power Source, Jobsite Fan and Trade Titan™ Industrial Work Carts

is one (1) year from the date of purchase. The warranty period for

the Drain Cleaning Cables is two (2) years from the date of purchase.

The warranty period for the LED in the LED Work Light and the LED

Upgrade Bulb for the Work Light is the lifetime of the product subject

to the limitations above. If during normal use the LED or LED Bulb

fails, the part will be replaced free of charge.

Warranty Registration is not necessary to obtain the applicable warranty on a MILWAUKEE power tool product. The manufacturing date

of the product will be used to determine the warranty period if no proof

of purchase is provided at the time warranty service is requested.

ACCEPTANCE OF THE EXCLUSIVE REPAIR AND REPLACEMENT

REMEDIES DESCRIBED HEREIN IS A CONDITION OF THE CONTRACT FOR THE PURCHASE OF EVERY MILWAUKEE PRODUCT.

IF YOU DO NOT AGREE TO THIS CONDITION, YOU SHOULD NOT

PURCHASE THE PRODUCT. IN NO EVENT SHALL MILWAUKEE

BE LIABLE FOR ANY INCIDENTAL, SPECIAL, CONSEQUENTIAL

OR PUNITIVE DAMAGES, OR FOR ANY COSTS, ATTORNEY FEES,

6

1.800.268.4015

or visit www.milwaukeetool.ca

LIMITED WARRANTY

USA & CANADA