Cat. No. / No de cat.

2633-20

M18

TM

FORCELOGICTM 2" - 3" PROPEX® EXPANSION TOOL

OUTIL D'EXTENSION PROPEX® DE 50,8 mm - 76,2 mm (2" - 3")

M18TM FORCELOGIC

TM

HERRAMIENTA DE EXPANSIÓN PROPEX® FORCELOGICTM

M18TM DE 50,8 mm - 76,2 mm (2" - 3")

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

WARNING To reduce the risk of injury, user must read and understand operator's manual.

AVERTISSEMENT An de réduire le risque de blessures, l'utilisateur doit lire et bien

comprendre le manuel.

ADVERTENCIA Para reducir el riesgo de lesiones, el usuario debe leer y entender el manual.

2

GENERAL POWER TOOL

SAFETY WARNINGS

WARNING

Read all safety warnings, instructions, illustrations and specifica-

tions provided with this power tool. Failure to follow

all instructions listed below may result in electric shock,

re and/or serious injury. Save all warnings and instructions for future reference. The term "power tool"

in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

WORK AREA SAFETY

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• Do not operate power tools in explosive atmo

-

spheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Un

-

modied plugs and matching outlets will reduce risk

of electric shock.

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet condi

-

tions. Water entering a power tool will increase the

risk of electric shock.

• Do not abuse the cord. Never use the cord for car

rying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk

of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric

shock.

• If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of an GFCI reduces

the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use a power tool while you are tired or under the

inuence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result

in serious personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as a dust

mask, non-skid safety shoes, hard hat or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the switch

is in the o-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your nger on the

switch or energizing power tools that have the switch

on invites accidents.

• Remove any adjusting key or wrench before turn

-

ing the power tool on. A wrench or a key left attached

to a rotating part of the power tool may result in per

-

sonal injury.

• Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry or long hair can

be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust col

-

lection can reduce dust-related hazards.

• Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action can

cause severe injury within a fraction of a second.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

• Do not use the power tool if the switch does not

turn it on and o. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source and/

or remove the battery pack, if detachable, from

the power tool before making any adjustments,

changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting

the power tool accidentally.

• Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

• Maintain power tools and accessories. Check for

misalignment or binding of moving parts, breakage

of parts and any other condition that may aect the

power tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are caused

by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly main

-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

dierent from those intended could result in a hazard

-

ous situation.

• Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles

and grasping surfaces do not allow for safe handling

and control of the tool in unexpected situations.

BATTERY TOOL USE AND CARE

• Recharge only with the charger specied by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of re when used with

another battery pack.

• Use power tools only with specically designated

battery packs. Use of any other battery packs may

create a risk of injury and re.

• When battery pack is not in use, keep it away from

other metal objects, like paper clips, coins, keys,

nails, screws or other small metal objects, that can

make a connection from one terminal to another.

Shorting the battery terminals together may cause

burns or a re.

3

• Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact ac

cidentally occurs, ush with water. If liquid contacts eyes, additionally seek medical help. Liquid

ejected from the battery may cause irritation or burns.

• Do not use a battery pack or tool that is damaged or

modied. Damaged or modied batteries may exhibit

unpredictable behavior resulting in re, explosion or

risk of injury.

• Do not expose a battery pack or tool to re or ex

-

cessive temperature. Exposure to re or temperature

above 265°F (130°C) may cause explosion.

• Follow all charging instructions and do not charge

the battery pack or tool outside the temperature

range specied in the instructions. Charging im

-

properly or at temperatures outside the specied range

may damage the battery and increase the risk of re.

SERVICE

• Have your power tool serviced by a qualied repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

• Never service damaged battery packs. Service of

battery packs should only be performed by the manu

-

facturer or authorized service providers.

SPECIFIC SAFETY RULES FOR

EXPANDERS

• Use tool only to expand PEX-a material. Other

materials may split or crack, causing leaking.

• Store tool with expander head installed to protect

expander cone from damage.

• Keep ngers away from expander head during use.

When expander head contracts or expands, pinching

can occur.

• Maintain labels and nameplates. These carry im

-

portant information. If unreadable or missing, contact

a MILWAUKEE service facility for a free replacement.

•

WARNING

Some dust created by power sanding,

sawing, grinding, drilling, and other

construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to

lter out microscopic particles.

SPECIFICATIONS

Cat. No. ..................................................... 2633-20

Volts.............................................................. 18 DC

Battery Type .................................................M18™

Charger Type................................................M18™

Recommended Ambient

Operating Temperature ...................... 0°F to 125°F

Max PEX-A Diameter...................................2" to 3"

DN40 to DN75

Expander Heads 2"-3" MILWAUKEE M18 ProPEX

®

DN40 to DN75 MILWAUKEE M18 ProPEX

®

Lubricant ............ ProPEX® Expander Cone Grease

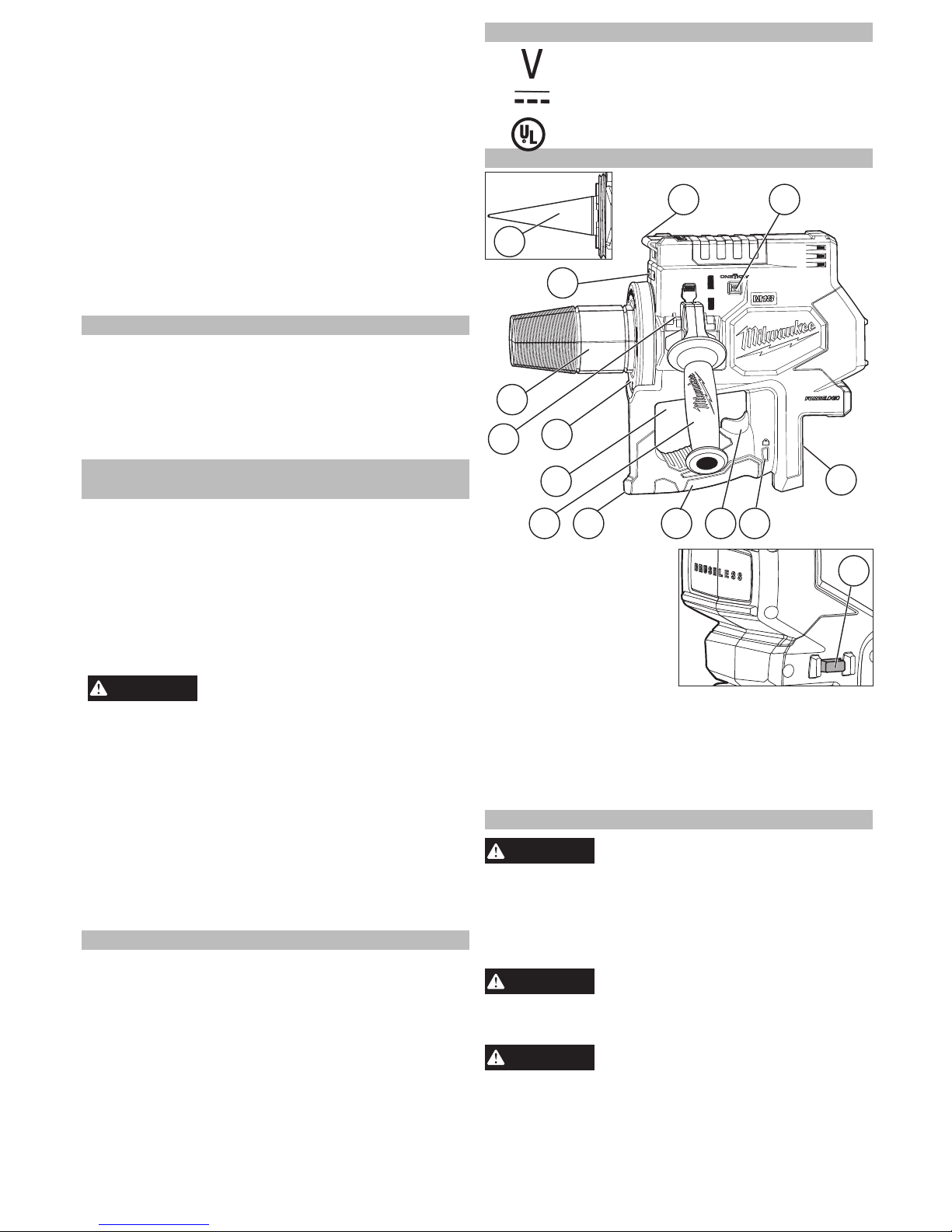

SYMBOLOGY

Volts

Direct Current

C

US

UL Listing for Canada and U.S.

FUNCTIONAL DESCRIPTION

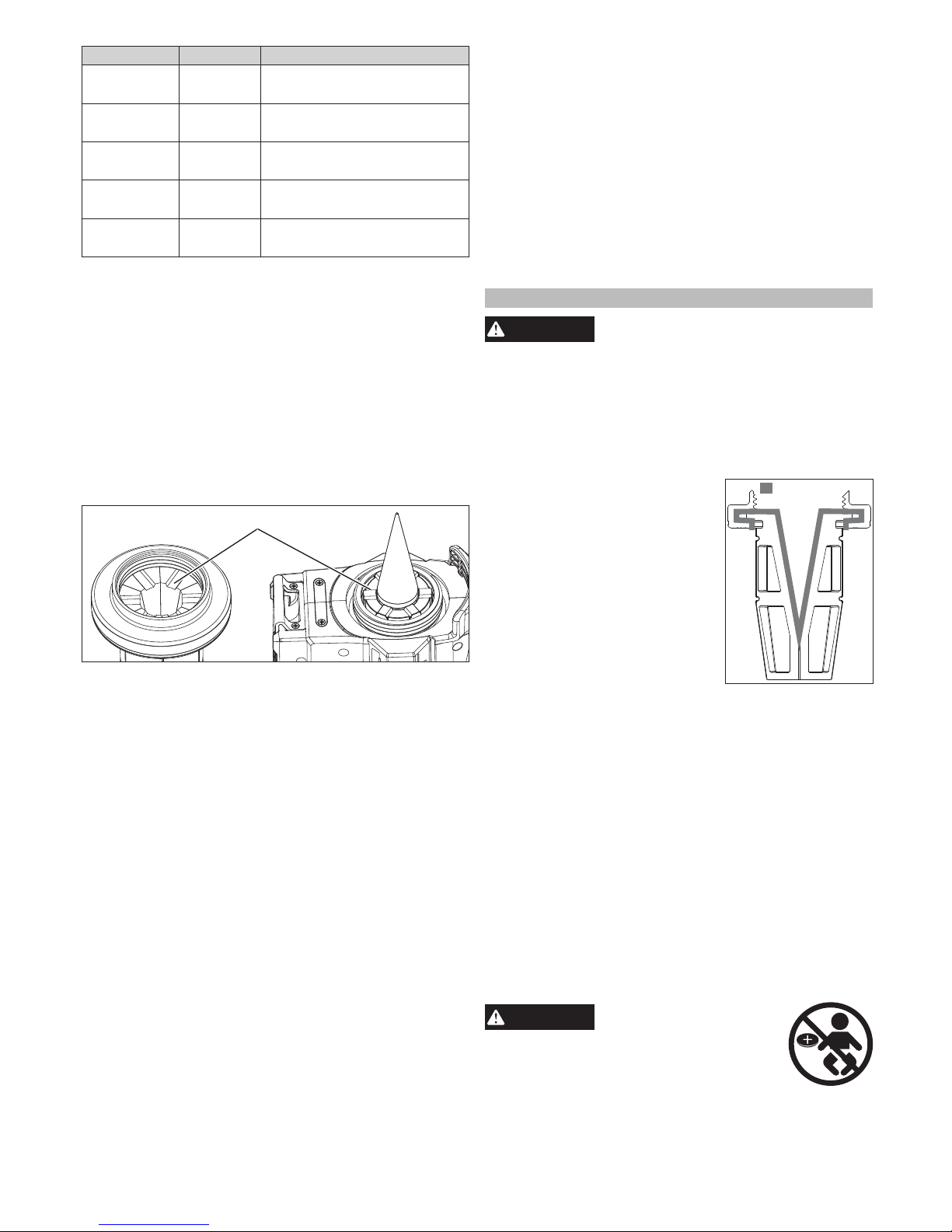

1. Expander cone

2. Hanger

3. ONE-KEY™

indicator

4. Battery bay

5. Trigger lock

6. Trigger

7. Trigger handle

8. LED worklight

9. Side handle

10. Status indicator

11. Rotate collar

15

5

1

2

13

89 7 6

12

14

3

4

10

11

12. Side handle positions

(both sides)

13. Expander head

14. Coin cell battery door

15. Manual release button

ASSEMBLY

WARNING

Recharge only with the charger

specied for the battery. For specic charging instructions, read the operator’s

manual supplied with your charger and battery.

Removing/Inserting the Battery

To remove the battery, push in the release buttons

and pull the battery pack away from the tool.

WARNING

Always remove battery pack before

changing or removing accessories.

To insert the battery, slide the pack into the body

of the tool. Make sure it latches securely into place.

WARNING

Only use accessories specically

recommended for this tool. Others

may be hazardous.

4

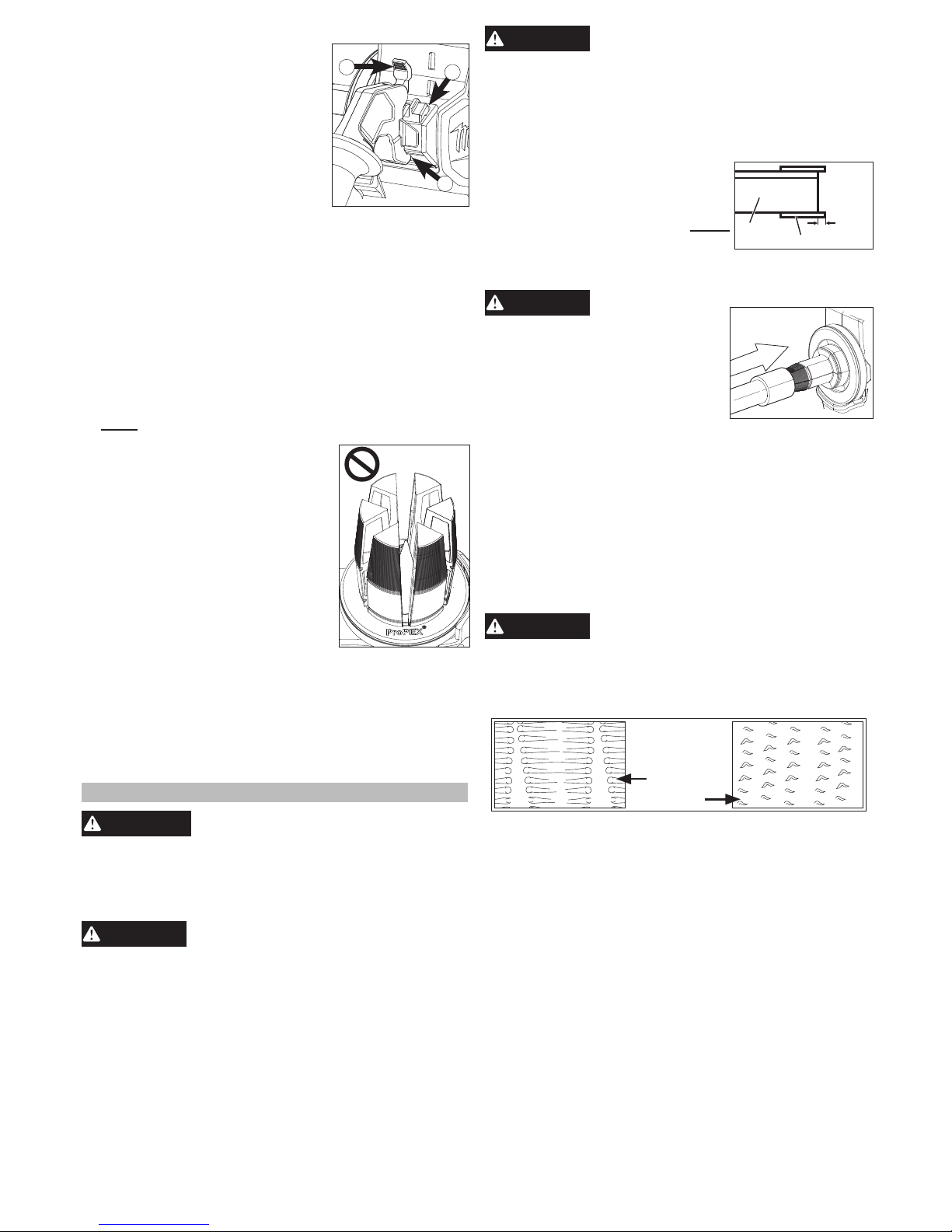

CAUTION

Improper lubrication (too much or

too little) may result in faulty con-

nections, which could result in property damage.

• Do not expand tubing beyond the tool's capacity

(3" / DN75).

1. Cut the PEX tubing to the needed length. Use only

cutters designed for plastic tubing. Make sure the

cut is perpendicular to the length of the tubing.

2. Slide the ProPEX

®

Ring over

ring

1/16"

tubing

the end of the tubing until it

butts aginst the ring stop.

3. With expander head NOT

inserted in the tubing, pull and

hold the trigger to initiate the

rotation of the expander head.

CAUTION

Do not force the tubing onto the

expander head.

4. When the green indicator light

turns on and/or the white work

light flashes, insert the expander head into the PEX

tubing and release the trigger.

5. The expander head will con-

tinue to expand. When the expander reaches

maximum diameter it will automatically retract.

NOTE: To cancel quickly, pull and release trigger.

6. Tool will be fully retracted when green indicator

light blinks 3 times. The next expansion can be

started.

7. Continue expanding until the tubing reaches the

shoulder of the expander head. Then expand 1 to

2 more times, depending on the room temperature

(the warmer the temperature, the more expansions

are necessary).

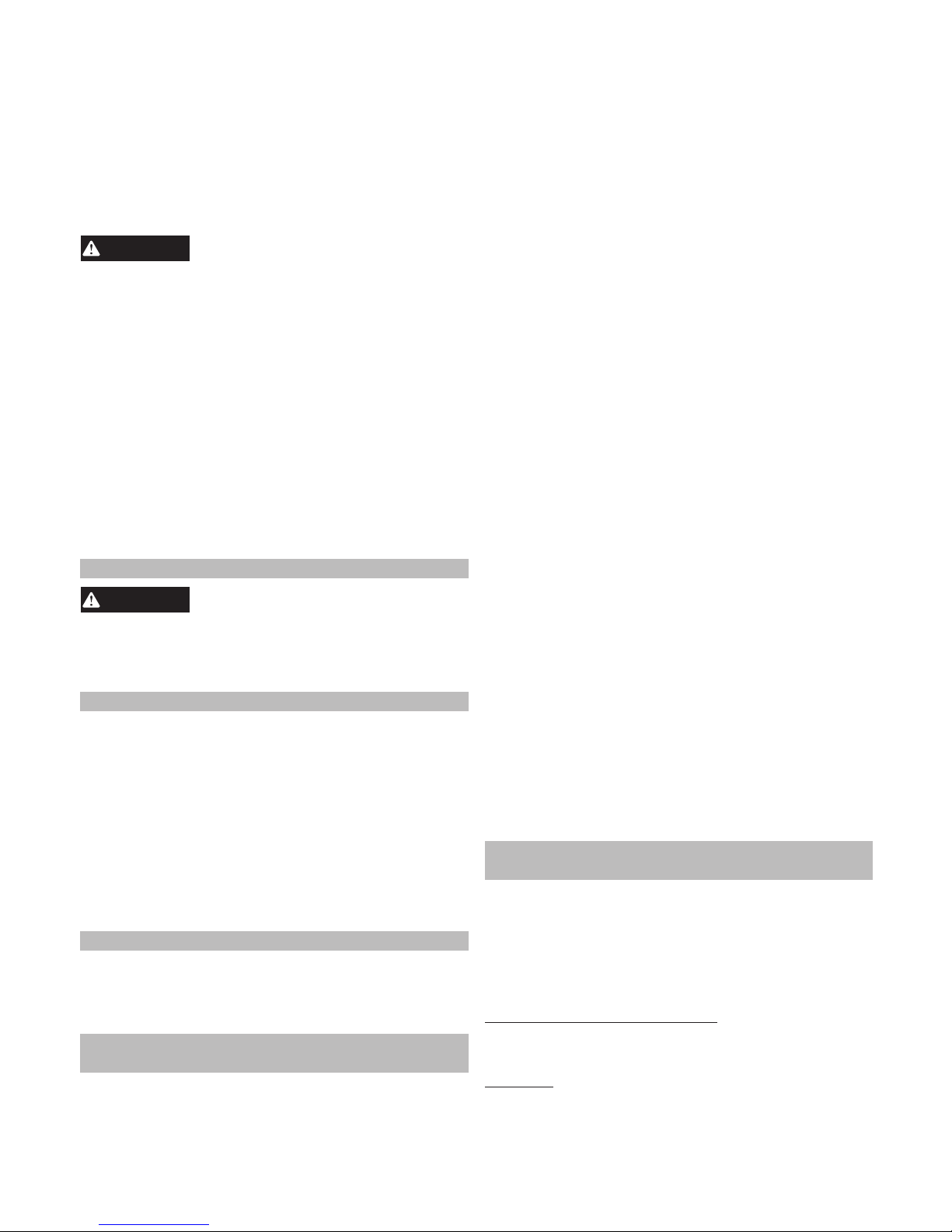

CAUTION

Ensure the expander head rotates

at the beginning of each stroke to

ensure creation of even, smooth expansion

marks. If the head is not rotating, the expander

head may cause deep grooves in the tubing and

faulty connections, which could result in a leak.

Expansion

markings

inside tubing

Incorrect

Correct

8. Remove tubing when the segments are contracted.

9. Slide the tubing over the tting until it is ush with

the tting shoulder. If unable to slide tubing over

the tting, remove from tting and expand one

additional time. Important! You should feel some

resistance as the tting goes into the tubing If you

do not feel any resistance, the tubing may be over

expanded and will require additional time to shrink

over the tting .

10.Tubing should t tightly against the tting shoul-

der. If more than 1/16" gap between tubing and

shoulder, cut 3"-5" (3" for 2" PEX and 5" for 2.5"

and 3" PEX) o the end of the tubing and restart

the procedure with a new ProPEX

®

Ring.

Attaching the Side Handle

1. Attach the side handle clamping

3

2

1

collar onto the tool by rst

hooking the upper jaw, then the

lower jaw.

2. Press down on the clamp lever

to secure the clamping collar

assembly.

Changing Expander Heads

To remove an expander head:

1. Remove the battery pack.

2. Place the tool with the head pointing up and un-

screw the head (counterclockwise).

To install an expander head:

1. Remove the battery pack.

2. Place the tool with the head pointing up.

3. Verify that the expander cone is fully retracted.

4. Screw the head onto tool (clockwise). Hand tighten

securely. Do not over tighten. The expander head

must t tightly against the tool.

5. Check installation:

a. Ensure the head segments

Flowering

segments

do not “ower”.

b. Rotate the six expander

segments in the clockwise

direction. The head will rotate

freely. The head should not

rotate counterclockwise.

c. The expander head collar will

t ush against the tool.

d. Correct installation by loos-

ening the head slightly and

rotating the segments until

they engage in the cogs. Re-tighten the head.

ONE-KEY™

To learn more about the ONE-KEY™ functionality

for this tool, please reference the Quick Start guide

included with this product or go to milwaukeetool.

com/One-Key. To download the ONE-KEY app, visit

the App Store or Google Play from your smart device.

OPERATION

WARNING

Always remove battery pack before

changing or removing accesso-

ries. Only use accessories specically recommended for this tool. Others may be hazardous.

To reduce the risk of injury, wear safety goggles

or glasses with side shields.

CAUTION

Use only MILWAUKEE M18™ ProPEX® expander heads. The use of

incorrectly sized expansion heads may result in

faulty connections, which could result in property damage.

Making PEX Tubing Connections

To ensure a proper connection:

• Remove the expander head and remove any dirt

and debris.

• Use a clean, lint-free cloth to apply a thin coat of

ProPEX

®

Expander Cone Grease to the expander

cone. Do not over or under-lubricate. Wipe excess

grease from inside collar and cone before expand-

ing tubing.

5

Status Indicator

LED Indicates Action

Flashing

White

Rotation

complete

Insert into tubing and release

the trigger

Solid Green Expansion

in progress

Tool will continue to expand to

maximum diameter

Flashing

Green

Expansion

complete

Start process for next

expansion

Flashing Red Expansion

error

Correct the error and restart

the expansion process

Flashing Red

and Green

Service

required

Contact a MILWAUKEE

service facility for ALL repairs.

Cold-weather Use

Colder weather (<40°F/4°C) requires a longer contraction time and fewer expansions.

Troubleshooting ProPEX® Connections

If ttings will not seal, check for the following:

• Is the expander head screwed on tightly? Tighten

the head securely. Ensure the head is tight against

the tool.

• Are the expander head segments bent or mis-

aligned? Replace expander head.

• Are the expander head segments failing to contract

between expansions? Clean the head and lubricate

the cone. Ensure cogs are engaged.

Cogs

•Is the expander cone over or under lubricated?

Clean and lubricate.

•Isthettingdamaged? Replace tting.

• Is the expander cone bent or damaged? Return to

a MILWAUKEE service facility for repair.

• Was the expander head held in the expanded posi-

tion before tubing was removed? Cut 3"-5" (3" for 2"

PEX and 5" for 2.5" and 3" PEX) o the end of the

tubing and restart the procedure with a new ProPEX

®

Ring.

• Was the tubing rotated slightly after each expan-

sion? Cut 3"-5" (3" for 2" PEX and 5" for 2.5" and

3" PEX) o the end of the tubing and restart the

procedure with a new ProPEX

®

Ring.

• Are the tubing and ProPEX

®

Ring clean and dry?

Wipe dry.

• Is grease getting into the tubing from the expander

head? Wipe grease from tubing. Clean the expander

head, ensuring excessive amounts of grease are not

present on the head.

If ProPEX

®

Ring slides during expansion:

• Are the tubing and ProPEX

®

Ring clean and dry?

Wipe clean.

• Are your hands clean and dry? Wipe dry — oils from

your hands can lubricate the tubing and ProPEX

®

Ring.

• Are you holding the ring in place? Place your thumb

against the ring and hold in place during rst couple

of expansions.

If expander head does not expand when trigger is

pulled:

• Verify that the expander head is fully retracted.

• Set tool on a work surface with the cone pointing up.

Pull the trigger and hold until the green light indicates

that the press cycle has started. Release the trigger

and then press and hold the manual retract button un-

til the motor stops (up to 1 minute). Repeat if expander head still does not expand when trigger is pulled.

If the head does not fully retract at the end of an

expansion:

• Press the manual release button to fully retract the

expander cone

• Remove the expander head from the tool and rein-

stall, verifying proper installation.

MAINTENANCE

WARNING

To reduce the risk of injury, always

unplug the charger and remove the

battery pack from the charger or tool before

performing any maintenance. Never disassemble

the tool, battery pack or charger. Contact a

MILWAUKEE service facility for ALL repairs.

Maintaining Tool

Keep your tool, battery pack and charger in good

repair by adopting a regular maintenance program.

Each month:

• Remove the expander head and

Lubrication

areas

soak in degreasing agent to

remove grease from between

expander segments. Re-lubricate head (expander head

collar groove, expander cone

mating surface).

• Wipe expander cone and rotate

collar with clean, dry, lint-free

cloth. Re-lubricate when complete.

After six months to one year,

depending on use, return the tool, battery pack and

charger to A MILWAUKEE service facility for:

• Lubrication

• Mechanical inspection and cleaning (gears, spin-

dles, bearings, housing, etc.)

• Electrical inspection (battery pack, charger, motor)

• Testing to assure proper mechanical and electrical

operation

If the tool does not start or operate at full power with

a fully charged battery pack, clean the contacts on

the battery pack. If the tool still does not work properly, return the tool, charger and battery pack, to a

MILWAUKEE service facility for repairs.

ONE-KEY™

Refer to the ONE-KEY App for information regarding

necessary servicing, such as internal battery life and

crimp count.

WARNING

Chemical Burn Hazard.

This device contains a

lithium button/coin cell battery. A new

or used battery can cause severe internal burns and lead to death in as

little as 2 hours if swallowed or enters the body.

Always secure the battery cover. If it does not

close securely, stop using the device, remove the

batteries, and keep it away from children. If you

think batteries may have been swallowed or

entered the body, seek immediate medical atten-

tion.

6

Internal Battery

An internal battery is used to facilitate full ONE-KEY™

functionality.

To replace the battery:

1. Remove the battery pack.

2. Remove the screw and open the battery door.

3. Remove the old battery, keep it away from children,

and dispose of it properly.

4. Insert the new battery (3V CR2032), with the positive side facing up.

5. Close the battery door and tighten the screw

securely.

WARNING

To reduce the risk of personal injury and damage, never immerse

your tool, battery pack or charger in liquid or

allow a liquid to ow inside them.

Cleaning

Clean dust and debris from charger and tool vents.

Keep tool handles clean, dry and free of oil or grease.

Use only mild soap and a damp cloth to clean the

tool, battery pack and charger since certain cleaning

agents and solvents are harmful to plastics and other

insulated parts. Some of these include gasoline,

turpentine, lacquer thinner, paint thinner, chlorinated

cleaning solvents, ammonia and household deter-

gents containing ammonia. Never use ammable or

combustible solvents around tools.

Repairs

For repairs, return the tool, battery pack and charger

to the nearest service center.

ACCESSORIES

WARNING

Always remove battery pack before

changing or removing accesso-

ries. Only use accessories specically recommended for this tool. Others may be hazardous.

For a complete listing of accessories, go online to

www.milwaukeetool.com or contact a local distributor.

SERVICE - UNITED STATES

1-800-SAWDUST (1.800.729.3878)

Monday-Friday, 7:00 AM - 6:30 PM CST

or visit www.milwaukeetool.com

Contact Corporate After Sales Service Technical

Support with technical, service/repair, or warranty

questions.

Email: metproductsupport@milwaukeetool.com

Become a Heavy Duty Club Member at

www.milwaukeetool.com to receive important

notications regarding your tool purchases.

SERVICE - CANADA

Milwaukee Tool (Canada) Ltd

1.800.268.4015

Monday-Friday, 7:00 AM - 4:30 PM CST

or visit www.milwaukeetool.ca

LIMITED WARRANTY

USA & CANADA

Every MILWAUKEE power tool* (see exceptions below) is warranted

to the original purchaser only to be free from defects in material and

workmanship. Subject to certain exceptions, MILWAUKEE will repair

or replace any part on an electric power tool which, after examination,

is determined by MILWAUKEE to be defective in material or workman-

ship for a period of ve (5) years** after the date of purchase unless

otherwise noted. Return of the power tool to a MILWAUKEE factory

Service Center location or MILWAUKEE Authorized Service Station,

freight prepaid and insured, is required. A copy of the proof of purchase

should be included with the return product. This warranty does not

apply to damage that MILWAUKEE determines to be from repairs

made or attempted by anyone other than MILWAUKEE authorized

personnel, misuse, alterations, abuse, normal wear and tear, lack of

maintenance, or accidents.

Normal Wear: Many power tools need periodic parts replacement and

service to achieve best performance. This warranty does not cover

repair when normal use has exhausted the life of a part including,

but not limited to, chucks, brushes, cords, saw shoes, blade clamps,

o-rings, seals, bumpers, driver blades, pistons, strikers, lifters, and

bumper cover washers.

*This warranty does not cover Air Nailers & Staplers; Airless Paint

Sprayer; Cordless Battery Packs; Gasoline Driven Portable Power

Generators; Hand Tools; Hoist – Electric, Lever & Hand Chain; M12™

Heated Gear; Reconditioned Product; and Test & Measurement

Products. There are separate and distinct warranties available for

these products.

**The warranty period for Job Site Radios, M12™ Power Port, M18™

Power Source, Jobsite Fan and Trade Titan™ Industrial Work Carts is

one (1) year from the date of purchase. The warranty period for the

Drain Cleaning Cables is two (2) years from the date of purchase. The

warranty period for the M18™ Compact Heat Gun and the 8 Gallon

Dust Extractor is three (3) years from the date of purchase. The warranty period for the LED in the LED Work Light and the LED Upgrade

Bulb for the Work Light is the lifetime of the product subject to the

limitations above. If during normal use the LED or LED Bulb fails, the

part will be replaced free of charge.

Warranty Registration is not necessary to obtain the applicable war-

ranty on a MILWAUKEE power tool product. The manufacturing date

of the product will be used to determine the warranty period if no proof

of purchase is provided at the time warranty service is requested.

ACCEPTANCE OF THE EXCLUSIVE REPAIR AND REPLACEMENT

REMEDIES DESCRIBED HEREIN IS A CONDITION OF THE CON-

TRACT FOR THE PURCHASE OF EVERY MILWAUKEE PRODUCT.

IF YOU DO NOT AGREE TO THIS CONDITION, YOU SHOULD NOT

PURCHASE THE PRODUCT. IN NO EVENT SHALL MILWAUKEE

BE LIABLE FOR ANY INCIDENTAL, SPECIAL, CONSEQUENTIAL

OR PUNITIVE DAMAGES, OR FOR ANY COSTS, ATTORNEY FEES,

EXPENSES, LOSSES OR DELAYS ALLEGED TO BE AS A CONSEQUENCE OF ANY DAMAGE TO, FAILURE OF, OR DEFECT IN ANY

PRODUCT INCLUDING, BUT NOT LIMITED TO, ANY CLAIMS FOR

LOSS OF PROFITS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT

APPLY TO YOU. THIS WARRANTY IS EXCLUSIVE AND IN LIEU

OF ALL OTHER EXPRESS WARRANTIES, WRITTEN OR ORAL.

TO THE EXTENT PERMITTED BY LAW, MILWAUKEE DISCLAIMS

ANY IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR USE OR PURPOSE; TO THE EXTENT SUCH

DISCLAIMER IS NOT PERMITTED BY LAW, SUCH IMPLIED WARRANTIES ARE LIMITED TO THE DURATION OF THE APPLICABLE

EXPRESS WARRANTY AS DESCRIBED ABOVE. SOME STATES

DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO

YOU, THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS,

AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM

STATE TO STATE.

This warranty applies to product sold in the U.S.A. and Canada only.

Please consult the ‘Service Center Search’ in the Parts & Service sec-

tion of MILWAUKEE’s website www.milwaukeetool.com or call 1.800.

SAWDUST (1.800.729.3878) to locate your nearest service facility for

warranty and non-warranty service on a Milwaukee electric power tool.

LIMITED WARRANTY - MEXICO,

CENTRAL AMERICA & CARIBBEAN

TECHTRONIC INDUSTRIES' warranty is for 5 years since the original

purchase date.

This warranty card covers any defect in material and workmanship

on this Product.

To make this warranty valid, present this warranty card, sealed/

stamped by the distributor or store where you purchased the product,

to the Authorized Service Center (ASC). Or, if this card has not been

sealed/stamped, present the original proof of purchase to the ASC.

Call toll-free1 01 (800) 030-7777 to nd the nearest ASC, for service,

parts, accessories or components.

Procedure to make this warranty valid

Take the product to the ASC, along with the warranty card sealed/

stamped by the distributor or store where you purchased the product,

and any faulty piece or component will be replaced without cost for

you. We will cover all freight costs relative with this warranty process.

Exceptions

This warranty is not valid in the following situations

a) When the product is used in a dierent manner from the end-user

guide or instruction manual.

b) When the conditions of use are not normal.

c) When the product was modied or repaired by people not authorized

by TECHTRONIC INDUSTRIES.

Note: If cord set is damaged, it should be replaced by an Authorized

Service Center to avoid electric risks.

Loading...

Loading...