Milwaukee M18 2648-20 Operator's Manual

Cat. No. / No de cat.

2648-20

M18™ RANDOM ORBIT SANDER

PONCEUSE À MOUVEMENTS ORBITAUX ASYNCHRONES M18™

LIJADORAS DE ÓRBITA ALEATORIA M18™

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

WARNING To reduce the risk of injury, user must read and understand operator's manual.

AVERTISSEMENT An de réduire le risque de blessures, l'utilisateur doit lire et bien

comprendre le manuel.

ADVERTENCIA Para reducir el riesgo de lesiones, el usuario debe leer y entender el manual.

2

GENERAL POWER TOOL

SAFETY WARNINGS

WARNING

Read all safety warnings, instructions, illustrations and specica-

tions provided with this power tool. Failure to

follow all instructions listed below may result in

electric shock, re and/or serious injury. Save all

warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-oper-

ated (cordless) power tool.

WORK AREA SAFETY

• Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while operating a power tool. Distractions can cause you to lose

control.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodied plugs and matching outlets will

reduce risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

• If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of an GFCI reduces

the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the inuence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

• Use personal protective equipment. Always

wear eye protection. Protective equipment such

as a dust mask, non-skid safety shoes, hard hat or

hearing protection used for appropriate conditions

will reduce personal injuries.

• Prevent unintentional starting. Ensure the switch

is in the o-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your nger on

the switch or energizing power tools that have the

switch on invites accidents.

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

• Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

• If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

• Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action can

cause severe injury within a fraction of a second.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct power

tool for your application. The correct power tool

will do the job better and safer at the rate for which

it was designed.

• Do not use the power tool if the switch does not

turn it on and o. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source and/

or remove the battery pack, if detachable, from

the power tool before making any adjustments,

changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

• Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

• Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition that

may aect the power tool’s operation. If damaged,

have the power tool repaired before use. Many

accidents are caused by poorly maintained power

tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations dierent from those intended could

result in a hazardous situation.

• Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

BATTERY TOOL USE AND CARE

• Recharge only with the charger specied by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of re when used

with another battery pack.

• Use power tools only with specically designated

battery packs. Use of any other battery packs may

create a risk of injury and re.

3

• When battery pack is not in use, keep it away

from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects,

that can make a connection from one terminal

to another. Shorting the battery terminals together

may cause burns or a re.

• Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation

or burns.

• Do not use a battery pack or tool that is damaged or modied. Damaged or modied batteries

may exhibit unpredictable behavior resulting in re,

explosion or risk of injury.

• Do not expose a battery pack or tool to re or

excessive temperature. Exposure to re or temperature above 265°F (130°C) may cause explosion.

• Follow all charging instructions and do not charge

the battery pack or tool outside the temperature

range specied in the instructions. Charging

improperly or at temperatures outside the specied

range may damage the battery and increase the risk

of re.

SERVICE

• Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

• Never service damaged battery packs. Service

of battery packs should only be performed by the

manufacturer or authorized service providers.

SPECIFIC SAFETY RULES

FOR SANDERS

• Collected sanding dust from sanding surface coatings

such as polyurethanes, linseed oil, etc. can self-ignite

in the sander dust box or elsewhere and cause re. To

reduce the risk of re always empty the dust box frequently

(10-15 minutes) while sanding and never store or leave a

sander without totally emptying its dust box. Also follow

the recommendations of the coatings manufacturers.

• Maintain labels and nameplates. These carry important

information. If unreadable or missing, contact a MILWAU

-

KEE service facility for a free replacement.

•

WARNING

Some dust created by power sanding,

sawing, grinding, drilling, and other

construction activities contains chemicals known to cause

cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on

how often yo

u do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to

lter out microscopic particles.

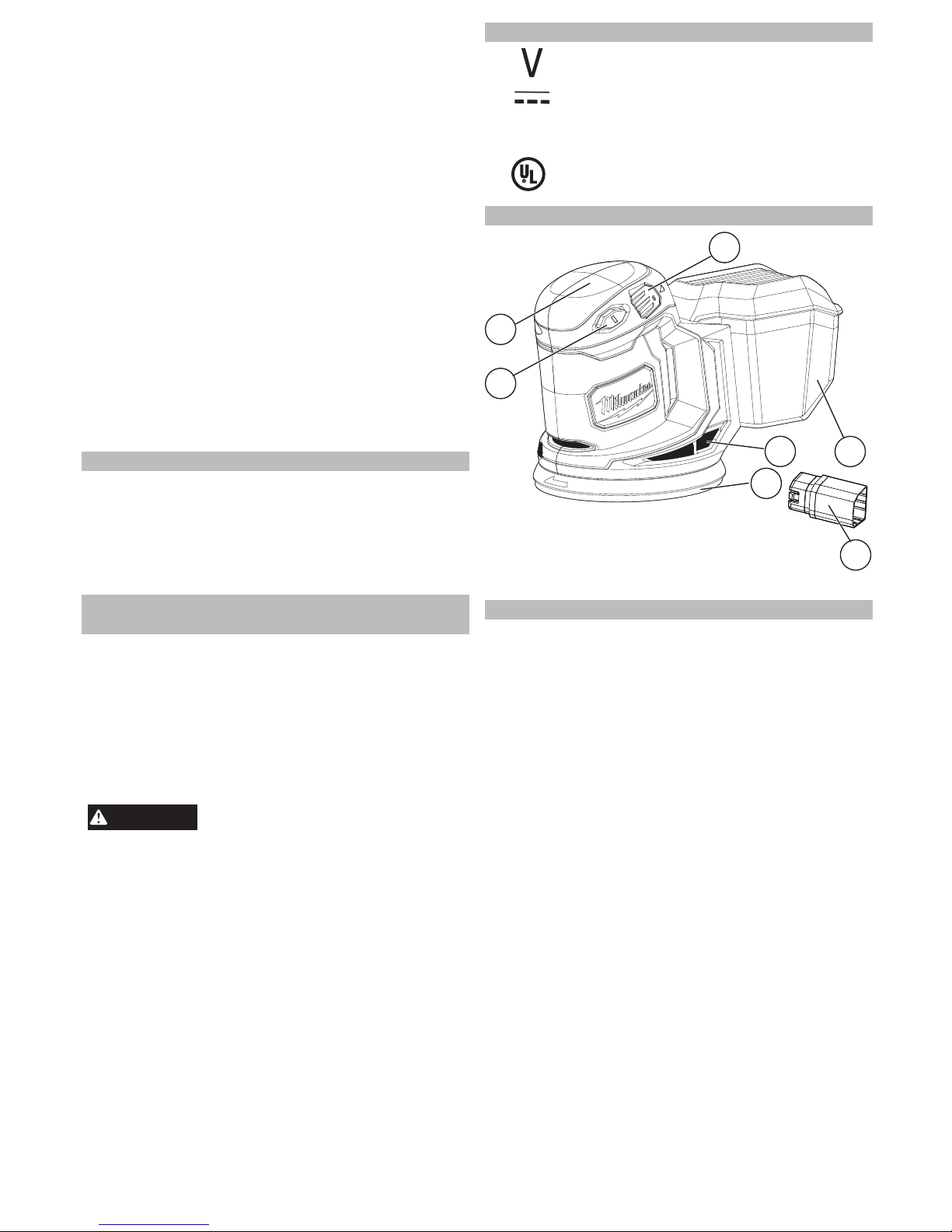

SYMBOLOGY

Volts

Direct Current

OPM

Orbits per Minute (OPM)

C

US

UL Listing for Canada and U.S.

FUNCTIONAL DESCRIPTION

1. On/O switch

2. Hand grip

3. Variable speed dial

4. Dust box

1

2

4

3

5. Air vents

6. Backing pad

7. Extender

5

6

7

SPECIFICATIONS

Cat. No. ..................................................... 2648-20

Volts.............................................................. 18 DC

Orbits Per Min.................................... 7,000-12,000

Paper Size .................................................... 5" dia.

Battery Type ................................................. M18™

Charger Type................................................M18™

Recommended Ambient

Operating Temperature ......................0°F to 125°F

4

Attaching Hook-and-Loop Sanding Discs

1. Remove the battery pack.

2. Align holes in hook-and-loop type sanding disc

with holes in pad, then carefully press fuzzy side

of sanding disc against pad as tightly as possible.

NOTE: Hook-and-loop type sanding discs can

be reused for the life of the sanding abrasive. It

is recommended that you keep the sanding disc

backing pad clean to provide for best adhesion.

Clean occasionally by brushing lightly with a small

brush.

Changing the Backing Pad

The sander comes assembled

with the hook-and-loop pad.

To attach a pressure sensitive

adhesive (PSA) pad (not in-

cluded), rst remove the hookand-loop pad. Inspect backing

pad before installing. Do not

use if broken or defective.

1. Remove the battery pack.

2. Remove the four screws

that hold the hook-and-loop

pad in place.

3. Remove the hook-and-loop

pad.

4. Clean dust particles from the

pad brake.

5. Apply a thin layer of light-

weight grease to the back

of the pad.

6. Align the holes in the pres-

sure sensitive adhesive

(PSA) pad with the four

screw holes in the sander.

7. Replace the four screws

securely.

Attaching PSA Sanding Discs

1. Remove the battery pack.

2. Carefully peel paper backing from the pressure

sensitive adhesive type sanding disc.

3. Align holes in sanding disc with holes in backing

pad, then carefully press sticky side of disc against

pad as tightly as possible.

NOTE: Holes in sanding disc must line up with

holes in the backing pad in order for the dustless

feature of the sander to function properly.

NOTE: It is recommended that you clean backing

pad occasionally by brushing lightly with a small

brush. Dust buildup on backing pad could cause

sanding disc not to stick properly.

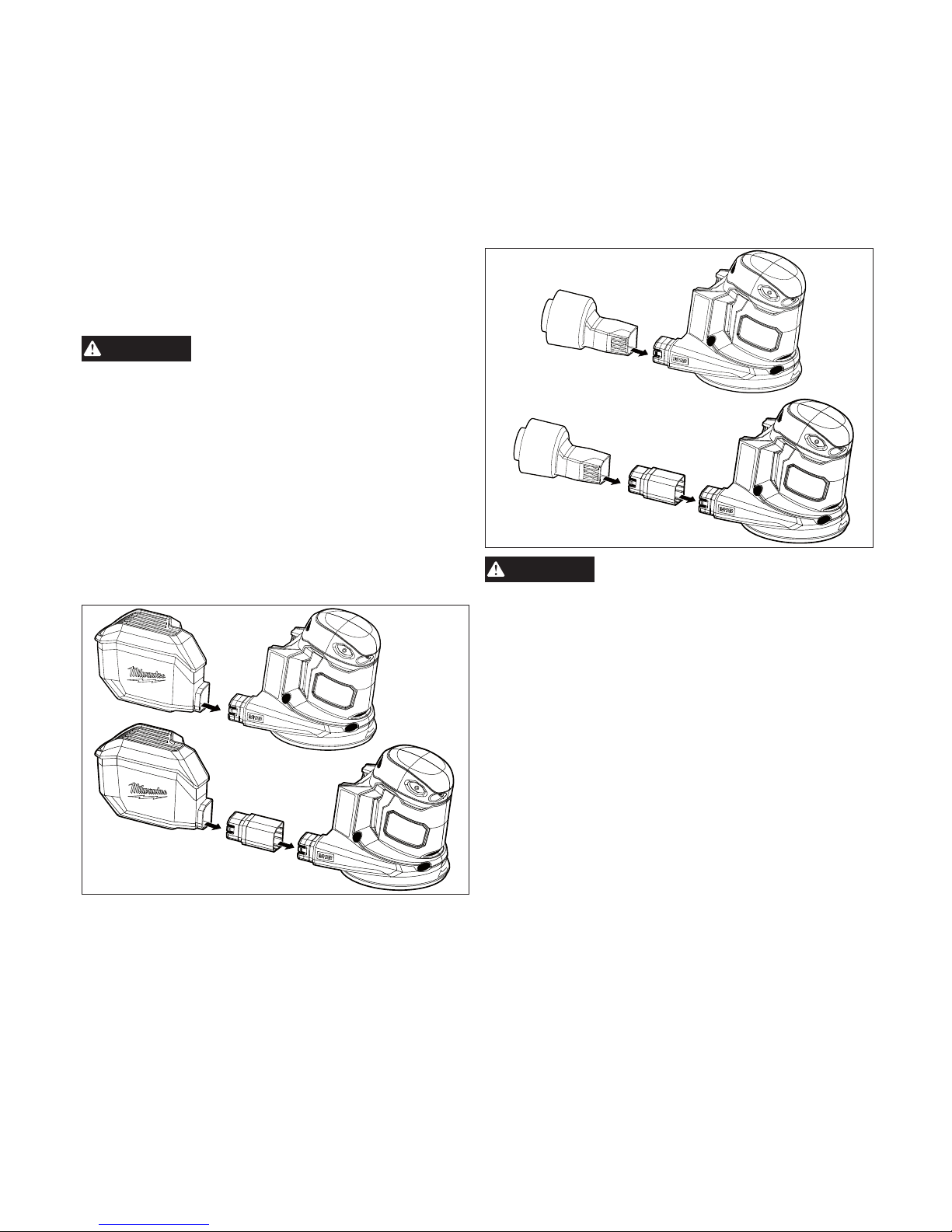

ASSEMBLY

WARNING

Recharge only with the charger

specied for the battery. For specic charging instructions, read the operator’s

manual supplied with your charger and battery.

Removing/Inserting the Battery

To remove the battery, push in the release buttons

and pull the battery pack away from the tool.

WARNING

Always remove battery pack before

changing or removing accessories.

To insert the battery, slide the pack into the body

of the tool. Make sure it latches securely into place.

WARNING

Only use accessories specically

recommended for this tool. Others

may be hazardous.

Selecting Sandpaper and Grits

Sandpaper can be made from various grit materials

and these should be selected according the material

to be sanded. The guidelines below list materials and

grit materials that should be used with them.

• Fine woodwork – garnet or aluminum oxide

• Rough woodwork – aluminum zirconia or ceramic

aluminum oxide

• Manufactured wood products (particleboard,

medium density ber board, etc.) – silicon carbide

or aluminum oxide

• Solid surface materials (Corian

®

, quartz, granite,

etc.) – silicon carbide or aluminum oxide

• Metals – emery or aluminum oxide

Sandpaper is also graded by coarseness. Start your

work with an abrasive grit just coarse enough to remove high spots and excessive roughness. Follow

with a second sanding using a grit one or two grades

ner. Continue with successively ner grits until you

obtain the desired nish.

Do not switch from a coarse grit to a very ne grit in

one step because it may be dicult to remove the

marks made by the coarse grit abrasive. Use the

nest grits practical for the roughing operation, and

nish by using successively ner grits.

Grit Type Typical Application

60

80

Course

Ideal for initial sanding on

rougher surfaces. For fast stock

removal. Rough sanding and

stripping of painted and rusted

surfaces.

100

120

Medium

For intermediate sanding and

removal of minor surface imper-

fections.

150

180

220

Fine

Ideal for ne sanding prior to

straining, priming, or sealing.

5

Remove PSA Sanding Disc Before Storage

Do not store the sander with the sanding disc in-

stalled. Heat generated from sanding causes the

pressure sensitive adhesive to ow and form a tight

bond between the backing pad and sanding disc.

Removing the sanding disc soon after you have n-

ished a sanding operation avoids letting the adhesive

set up. If the sanding disc is left on the backing pad

for an extended period of time after use, the adhesive

will set up and cause the sanding disc to become

dicult to remove.

It may also tear when removing. When this situation

occurs, it becomes dicult to clean the backing pad

for the next sanding disc.

NOTE: If you forget to remove the sanding disc after

a sanding operation, sand for a few minutes to soften

the adhesive backing before attempting to remove

sanding disc.

WARNING

Collected sanding dust from sand-

ing surface coatings such as

polyurethanes, linseed oil, etc. can self-ignite in

the sander dust box or elsewhere and cause re.

To reduce the risk of re always empty the dust

box frequently (10-15 minutes) while sanding and

never store or leave a sander without totally

emptying its dust box. Also follow the recommendations of the coatings manufacturers.

Dust Box with Filter

The dust box provides a dust collection and air ltration system for the sander. Sanding dust is drawn up

through the holes of the sanding pad and collected

in the dust box during sanding. To use the dust box:

1. Remove the battery pack.

2. To insert, slide the dust box chute into the sander's

dust port. Ensure the dust box vents are facing

up and push sander and dust box together rmly.

Use the extender when using larger M18™ battery

packs

3. To remove, grasp the sander and dust box rmly

and pull apart.

4. To empty, using the tabs, pull o the dust box lid.

Empty dust from the dust box and tap lter clean.

Do not clean lter with water or compressed air.

Replace lter when necessary (Cat. No. 43-31-

0105). Reinstall the lid and ensure it snaps into

place.

For more ecient operation, empty the dust box

when it is no more than half full. This will permit air

to ow through the box better. Always empty and

clean the dust box thoroughly upon completion of

a sanding operation and before storing the sander.

Universal Hose Adapter

Use the universal hose adapter to attach the sander

to a vacuum hose.

1. Remove the battery pack.

2. Remove the dust box from the sander.

3. To insert, slide the adapter into the sander's dust

port. Push sander and adapter together rmly.

Connect the vacuum hose to the adapter, twisting

together to secure.

NOTE: For extra length, use the extender.

4. To remove, disconnect the vacuum hose from the

adapter. Then, grasp the sander and adapter rmly

and pull apart.

WARNING

When sander is not connected to

vacuum, always reinstall dust box

assembly back onto sander. Failure to do so

could cause sanding dust or foreign objects to

be thrown into your face or eyes which could

result in possible serious injury.

6

OPERATION

WARNING

To reduce the risk of injury, always

remove battery pack before chang-

ing or removing accessories or making adjust-

ments. Only use accessories specically recommended for this tool. Others may be hazardous.

To reduce the risk of injury, always wear safety

goggles or glasses with side shields.

Starting and Stopping the Tool

To start the sander, press the ON (I) button.

To stop sander, press the OFF (O) button.

Speed Dial

The speed dial allows the sander to operate at variable

speeds - from low speed (1) to high speed (6).

1. To increase sanding disc speed, turn the dial to a

higher setting.

2. To decrease sanding disc speed, turn the dial to a

lower setting.

WARNING

Finish sanding can produce clouds

of ne dust that could ignite in the

presence of sparks or open ame. Always wear a

suitable dust mask or respirator and use your

sander in a well-ventilated area.

To reduce the risk of injury, inspect for and remove

all raised nails and fasteners from workpiece

before sanding. Striking a fastener while sanding

could cause loss of control.

General Sanding with Random Orbit Sanders

When using random orbit sanders there are a few

things to keep in mind:

• Unlike most sanders, random orbit sanders should

be placed on the workpiece BEFORE the tool is

started. If the sander is started before it is placed on

the workpiece, the free oating pad may be spinning

at a speed that can cause scratches when it is nally

placed on workpiece.

• Unlike most sanders, random orbit sanders can be

moved across the workpiece in any direction (in the

case of wood, regardless of the direction of the grain).

• Varying pressure applied to the sander will aect its

rotating speed. A light pressure is recommended for

ne work, moderate pressure for rough work. Excessive pressure does not allow the pad to rotate enough.

• Keep sanding pad at on the workpiece. Tipping the

sander or using the edges of the pad may produce

an uneven nish, and reduce pad life.

• Keep sander moving in broad even strokes across the

workpiece. Sanding in one spot too long can cause

gouging and uneven results.

• Check the workpiece frequently, random orbit sanders

work more aggressively than simple orbital sanders.

WARNING

Properly secure workpiece before

sanding. Unsecured work could be

thrown towards the operator causing injury.

Do not wear loose clothing or jewelry when op-

erating sander. They could get caught in moving

parts causing serious injury. Keep head away from

sander and sanding area. Hair could be drawn into

sander causing serious injury.

1. Place sander on the workpiece and turn on the

sander.

2. Keep the sanding disc at against the workpiece,

keep the sander moving across the workpiece, and

use long, sweeping strokes.

3. Begin sanding with a coarse grit sandpaper and

gradually use ner and ner grits of sandpaper until

the desired nish is reached. For example when

using the sander on wood, begin with an 80 grit

followed by a 120 grit, then a 180 grit and so on.

Removing Paint or Varnish

1. When removing several layers of paint or varnish,

remove as much as possible with a paint solvent or

varnish remover.

2. Scrape away the residue with a putty knife or other

scraping tool and allow the surface to cool and dry

before applying sander to the workpiece.

WARNING

To reduce the risk of re and explosion, paint solvents and varnish

removers must be removed from the workpiece

and the workpiece must be completely dry before

sanding.

3. Select a coarse grit sandpaper disc to help prevent

the sandpaper from clogging.

4. Keep the sander moving over new areas to avoid heat

-

ing and softening the old coating (paint or varnish).

5. Work in wide, overlapping strokes to produce a

uniform nish.

6. As the workpiece begins to show through the old

coating, switch to a medium grit sandpaper disc

to avoid scratching the surface of the workpiece.

Gradually switch to a ne grit sandpaper until you

achieve the desired nish.

MAINTENANCE

WARNING

To reduce the risk of injury, always

unplug the charger and remove the

battery pack from the charger or tool before performing any maintenance. Never disassemble the

tool, battery pack or charger. Contact a MILWAUKEE

service facility for ALL repairs.

Maintaining Tool

Keep your tool, battery pack and charger in good

repair by adopting a regular maintenance program.

Inspect your tool for issues such as undue noise,

misalignment or binding of moving parts, breakage of

parts, or any other condition that may aect the tool

operation. Return the tool, battery pack, and charger

to a MILWAUKEE service facility for repair. After six

months to one year, depending on use, return the tool,

battery pack and charger to a MILWAUKEE service

facility for inspection.

If the tool does not start or operate at full power with a

fully charged battery pack, clean the contacts on the

battery pack. If the tool still does not work properly,

return the tool, charger and battery pack, to a MIL

-

WAUKEE service facility for repairs.

WARNING

To reduce the risk of personal injury and damage, never immerse

your tool, battery pack or charger in liquid or allow

a liquid to ow inside them.

Cleaning

Clean dust and debris from vents. Keep handles clean,

dry and free of oil or grease. Use only mild soap and

a damp cloth to clean, since certain cleaning agents

and solvents are harmful to plastics and other insulated

parts. Some of these include gasoline, turpentine,

lacquer thinner, paint thinner, chlorinated cleaning

solvents, ammonia and household detergents contain

-

ing ammonia. Never use ammable or combustible

solvents around tools.

Repairs

For repairs, return the tool, battery pack and charger

to the nearest service center.

Loading...

Loading...