Page 1

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Catalog No.

No de Cat.

Catálogo No.

6016

6017

HEAVY-DUTY ORBITAL FINISHING SANDER

EXTRA ROBUSTE PONCEUSES ORBITALES DE FINITION

HEAVY-DUTY LIJADORA PARA ACABADOS

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN COMPRENDRE LE

MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL MANUAL DEL

OPERADOR.

Page 2

GENERAL SAFETY RULES — FOR ALL POWER TOOLS

WARNING!

Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury. The term "power tool" in

all of the warnings listed below refers to your mains-operated (corded) power tool or battery-opearted (cordless) power tool.

SAVE THESE INSTRUCTIONS

READ ALL INSTRUCTIONS

WORK AREA SAFETY

1. Keep work area clean and well lit. Cluttered or dark areas invite

accidents.

2. Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which may ignite the dust or fumes.

3. Keep children and bystanders away while operating a power

tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

4. Power tool plugs must match the outlet. Never modify the

plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and matching outlets

will reduce risk of electric shock.

5. Avoid body contact with earthed or grounded surfaces such

as pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is earthed or grounded.

6. Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

7. Do not abuse the cord. Never use the cord for carrying,

pulling, or unplugging the power tool. Keep cord away from

heat, oil, sharp edges, or moving parts. Damaged or entangled

cords increase the risk of electric shock.

8. When operating a power tool outdoors, use an extension

cord suitable for outdoor use. Use of a cord suitable for outdoor

use reduces the risk of electric shock.

PERSONAL SAFETY

16. Do not force the power tool. Use the correct power tool for

your application. The correct power tool will do the job better and

safer at the rate for which it was designed.

17. Do not use the power tool if the switch does not turn it on

and off. Any power tool that cannot be controlled with the switch is

dangerous and must be repaired.

18. Disconnect the plug from the power source and/or the bat-

tery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting the tool accidentally.

19. Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tools or these

instructions to operate power tools. Power tools are danger-

ous in the hands of untrained users.

20. Maintain power tools. Check for misalignment or binding of

moving parts, breakage of parts and any other condition

that may affect the power tool's operation. If damaged, have

the power tool repaired before use. Many accidents are caused

by poorly maintained power tools.

21. Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier

to control.

22. Use the power tool, accessories and tool bits etc., in accor-

dance with these instructions and in the manner intended

for the particular type of power tool, taking into account the

working conditions and the work to be performed. Use of

the power tool for operations different from those intended could

result in a hazardous situation.

POWER TOOL USE AND CARE

SERVICE

9. Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use a power tool while

you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating power tools

may result in serious personal injury.

10. Use safety equipment. Always wear eye protection. Safety

equipment such as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions will reduce personal injuries.

11. Avoid accidental starting. Ensure the switch is in the off-

position before plugging in. Carrying tools with your finger on

the switch or plugging in power tools that have the switch on invites

accidents.

12. Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating part of

the power tool may result in personal injury.

13. Do not overreach. Keep proper footing and balance at all

times. This enables better control of the power tool in unexpected

situations.

14. Dress properly. Do not wear loose clothing or jewellery.

Keep your hair, clothing and gloves away from moving parts.

Loose clothes, jewellery, or long hair can be caught in moving parts.

15. If devices are provided for the connection of dust extrac-

tion and collection facilities, ensure these are connected

and properly used. Use of these devices can reduce dust-re-

lated hazards.

page 2

23. Have your power tool serviced by a qualified repair person

using only identical replacement parts. This will ensure that

the safety of the power tool is maintained.

Page 3

SPECIFIC SAFETY RULES

1. Hold power tools by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden

wiring or its own cord. Contact with a “live” wire will make exposed metal parts of the tool “live” and shock the operator.

2. Maintain labels and nameplates. These carry important information. If unreadable or missing, contact a MILWAUKEE service facility for a free

replacement.

3. WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause

cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in

a well ventilated area, and work with approved safety equipment, such as those dust masks that are specifically designed to filter out

microscopic particles.

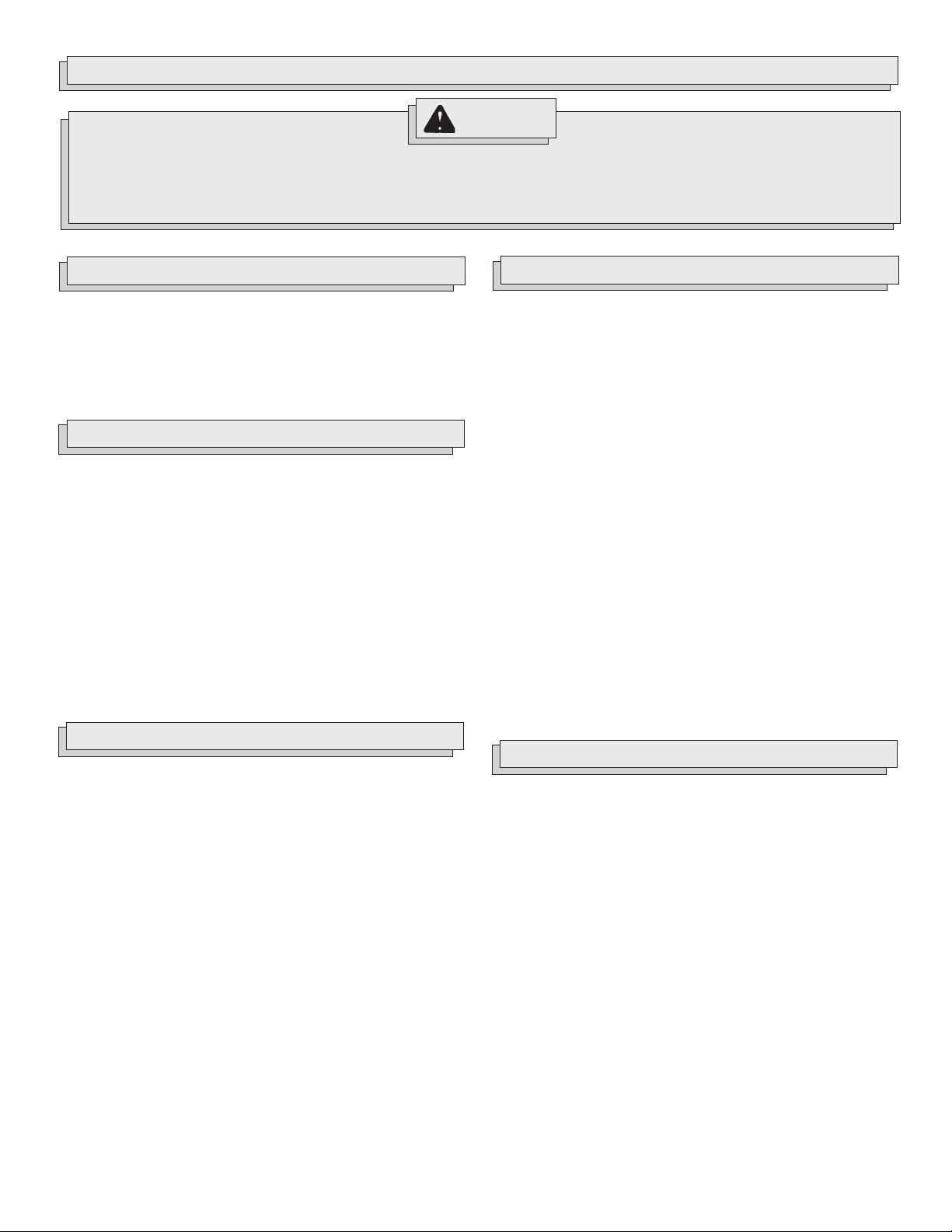

OPM

1. Vents

2. Cord

3. Dust bag (Cat. No. 6017 only)

4. Pad

5. Clamp lever

6. Clamp grip

7. Handle

8. On/Off switch

9. Punch plate (Cat. No. 6017 only)

Symbology

Canadian Standards

Association

Underwriters

Laboratories, Inc.

Volts Alternating Current

Orbits

per Minute (OPM)

Amps

Double Insulated

FUNCTIONAL DESCRIPTION

Specifications

Cat.

Volts

No.

6016

6017

8

7

AC

Amps

115

1.8

115

1.8

1

Orbits

per Minute

13,000

13,000

2

Pad Size

4-3/8" - 4"

4-3/8" - 4"

3

9

6

4

5

page 3

Page 4

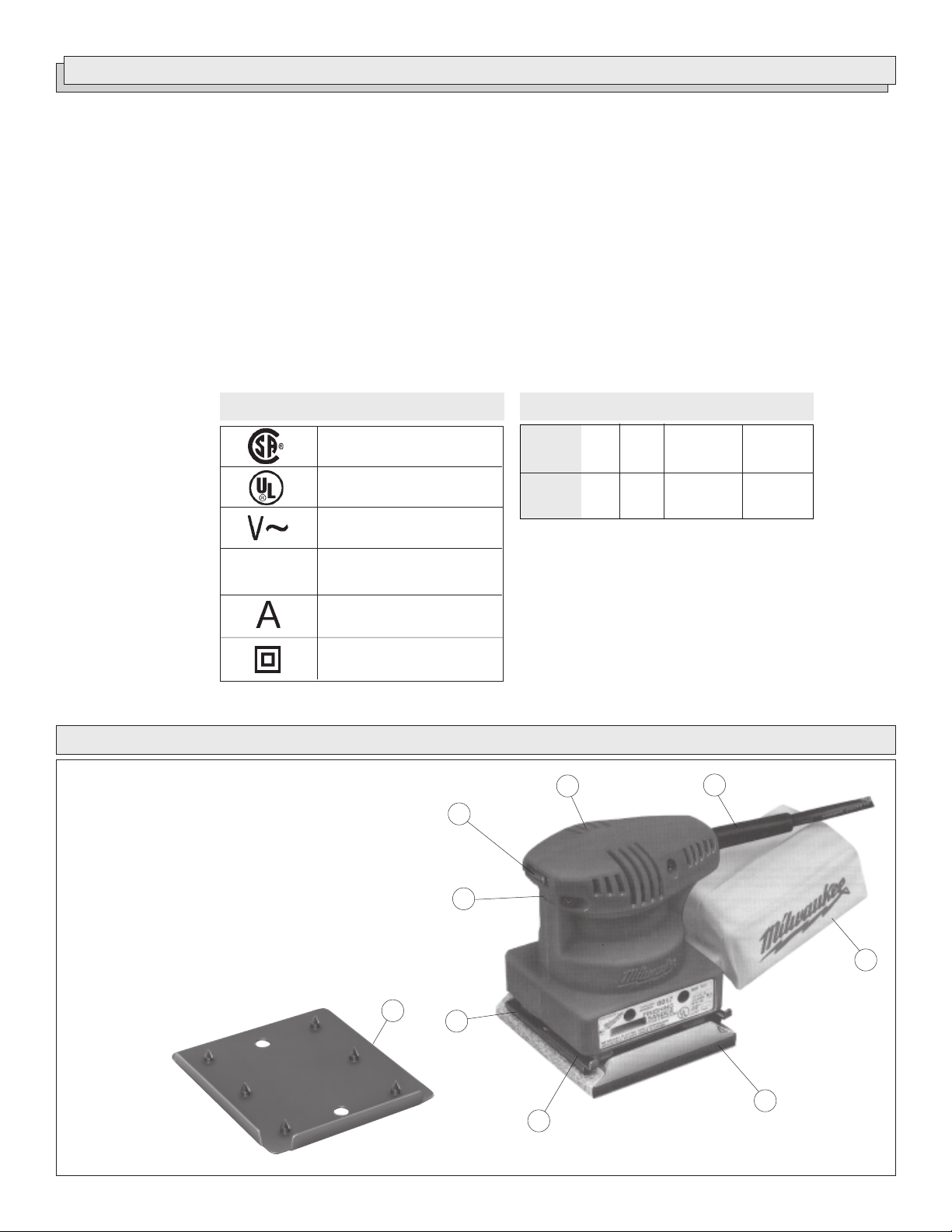

GROUNDING EXTENSION CORDS

WARNING!

Improperly connecting the grounding wire can result in the

risk of electric shock. Check with a qualified electrician if

you are in doubt as to whether the outlet is properly

grounded. Do not modify the plug provided with the tool.

Never remove the grounding prong from the plug. Do not

use the tool if the cord or plug is damaged. If damaged, have

it repaired by a MILWAUKEE service facility before use. If

the plug will not fit the outlet, have a proper outlet installed

by a qualified electrician.

Grounded Tools:

Tools with Three Prong Plugs

Tools marked “Grounding Required”

have a three wire cord and three

prong grounding plug. The plug must

be connected to a properly grounded

outlet (See Figure A). If the tool should

electrically malfunction or break

down, grounding provides a low resistance path to carry electricity

away from the user, reducing the risk

of electric shock.

The grounding prong in the plug is connected through the green wire

inside the cord to the grounding system in the tool. The green wire in the

cord must be the only wire connected to the tool's grounding system and

must never be attached to an electrically “live” terminal.

Your tool must be plugged into an appropriate outlet, properly installed

and grounded in accordance with all codes and ordinances. The plug

and outlet should look like those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked “Double Insulated” do

not require grounding. They have a

special double insulation system

which satisfies OSHA requirements

and complies with the applicable

standards of Underwriters Laboratories, Inc., the Canadian Standard

Association and the National Electrical Code. Double Insulated tools may

be used in either of the 120 volt outlets shown in Figures B and C.

Fig. A

Fig. B

Fig. C

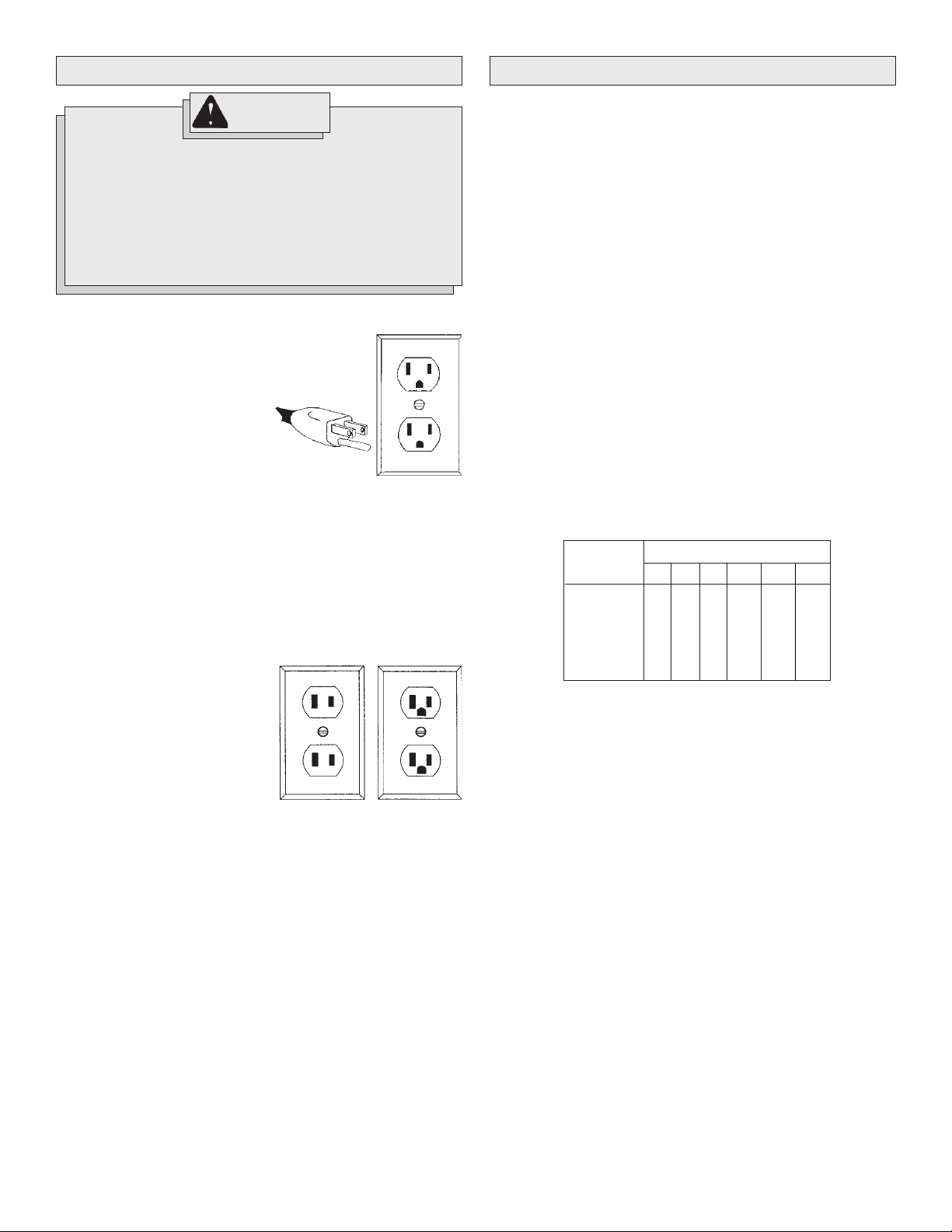

Grounded tools require a three wire extension cord. Double insulated

tools can use either a two or three wire extension cord. As the distance

from the supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a

serious drop in voltage, resulting in loss of power and possible tool

damage. Refer to the table shown to determine the required minimum

wire size.

The smaller the gauge number of the wire, the greater the capacity of the

cord. For example, a 14 gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension cord to make up the

total length, be sure each cord contains at least the minimum wire size

required. If you are using one extension cord for more than one tool, add

the nameplate amperes and use the sum to determine the required minimum wire size.

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors, be sure it is marked

with the suffix “W-A” (“W” in Canada) to indicate that it is acceptable

for outdoor use.

• Be sure your extension cord is properly wired and in good electrical

condition. Always replace a damaged extension cord or have it

repaired by a qualified person before using it.

• Protect your extension cords from sharp objects, excessive heat

and damp or wet areas.

Recommended Minimum Wire Gauge

Nameplate

Amperes

8.1 - 12

12.1 - 15

15.1 - 20

* Based on limiting the line voltage drop to five

volts at 150% of the rated amperes.

for Extension Cords*

25'

0 - 5

5.1 - 8

16

16

14

12

10

Extension Cord Length

100'

50'

16

16

14

12

10

75'

16

14

12

10

10

14

12

10

10

150'

12

10

--

--

--

--

200'

12

--

--

--

--

READ AND SAVE ALL INSTRUCTIONS

FOR FUTURE USE.

page 4

Page 5

TOOL ASSEMBLY

WARNING!

To reduce the risk of injury, always unplug tool before

attaching or removing accessories or making adjustments.

Use only specifically recommended accessories. Others

may be hazardous.

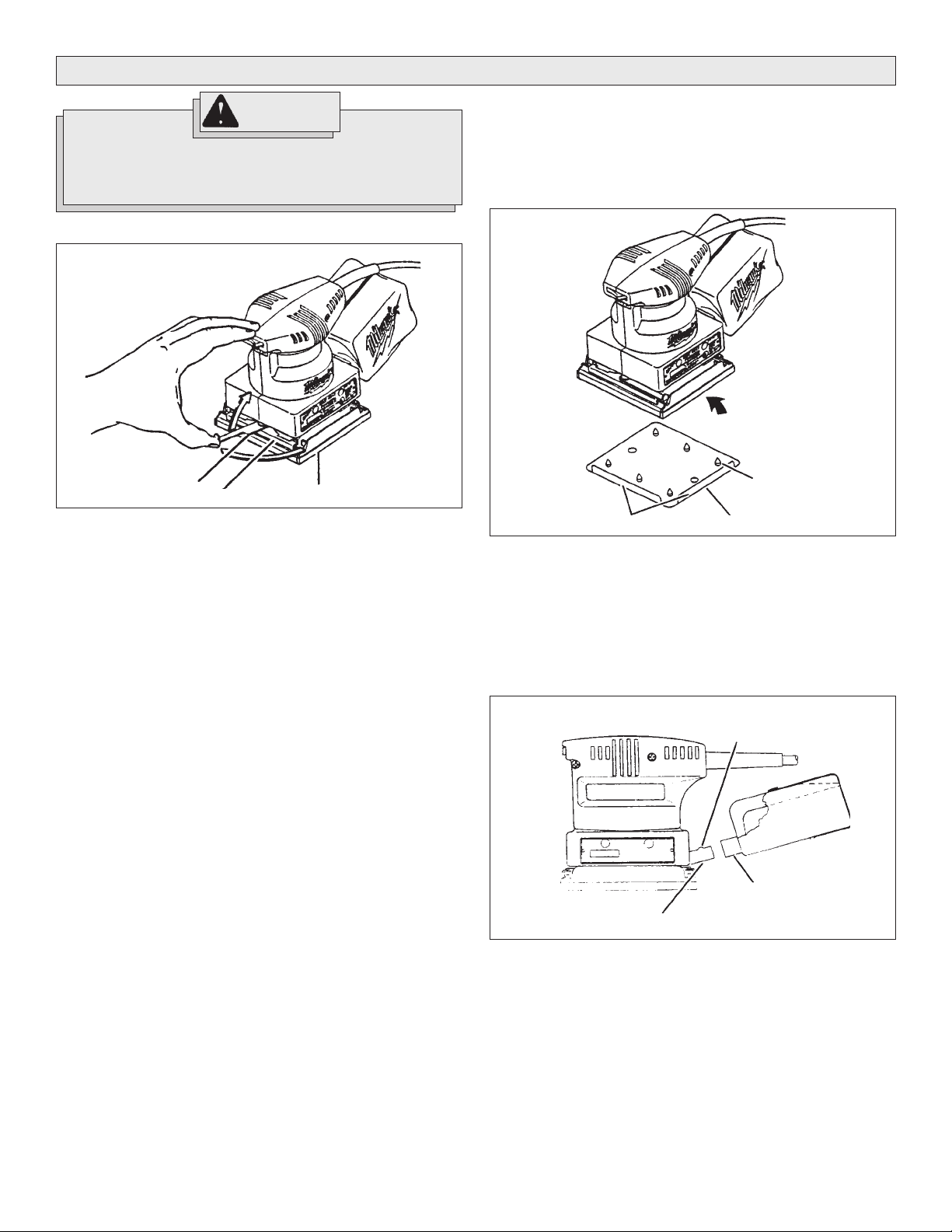

Attaching Sandpaper (Fig. 1)

Fig. 1

Clamp lever

Clamp grip

1. Unplug sander.

2. Use 1/4 sheet of sandpaper (4-1/2" x 5-1/2") (see “Selecting Sandpaper and Grits”).

3. To open clamp grip, pull out clamp lever.

4. With grit side out, place sandpaper between clamp grip and base

plate while aligning edges of sandpaper with pad edges.

5. To secure sandpaper, release clamp grip and return it to its original

position.

6. Wrap sandpaper around length of pad and attach free end of sheet

under opposite clamp as above. Pre-folding sandpaper will make

attachment easier.

NOTE: Sandpaper must be drawn as tight as possible for best

results.

Pad

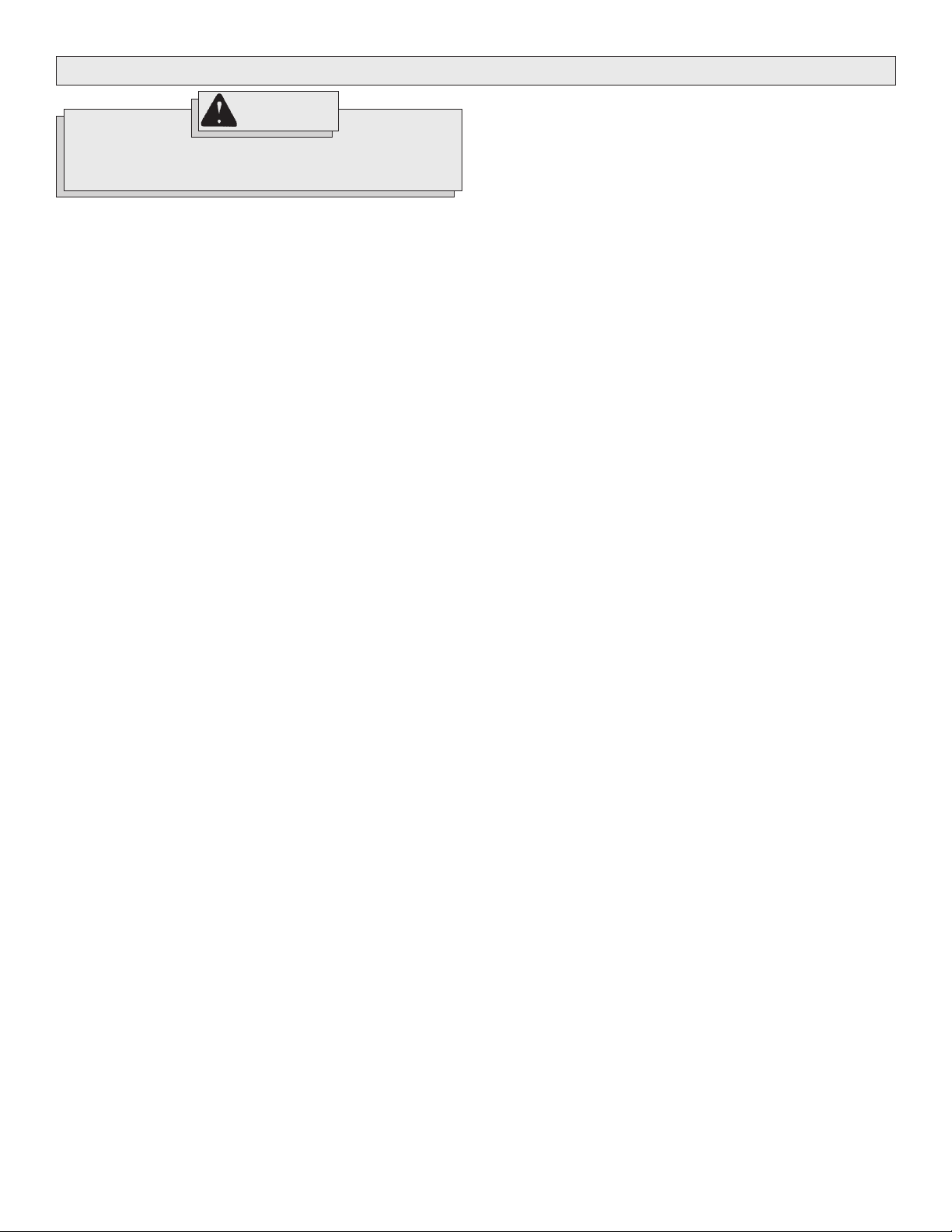

Punch Plate (Cat. No. 6017 only) (Fig. 2)

Cat. No. 6017 is equipped with a punch plate which punctures holes in

sandpaper. These holes allow dust to be removed from work surface

and vacuumed into the dust bag. It may be necessary to re-punch holes

with punch plate during Sander operation to keep the dust pick-up system working efficiently.

Fig. 2

Spikes

Bent edges

To use punchplate:

1. Align bent edges of plate with edges of sandpaper so sandpaper is

completely covered by plate.

2. Puncture holes in sandpaper by firmly pressing punch plate spikes

through sandpaper.

Dust Bag (Cat. No. 6017 only) (Fig. 3)

Cat. No. 6017 is equipped with a dust bag for easy dust pickup.

Fig. 3

Punch plate

Detent

Entry port

Dust exit spout

To attach dust bag, slide bag’s entry port over sander’s dust exit spout

until detent engages with hole in entry port.

To remove dust bag, gently twist entry port and pull it away from dust

exit spout.

For best results, empty dust bag when it is no more than half full. To

empty dust bag, remove bag from sander. Unzip bag and gently tap to

remove dust.

page 5

Page 6

OPERATION

WARNING!

To reduce the risk of injury, wear a dust mask and safety

glasses with side shields. Unplug the tool before changing

accessories or making adjustments.

Selecting Sandpaper and Grits

Aluminum oxide, silicon carbide or other synthetic abrasives are recommended for power sanding. A garnet sandpaper is acceptable, but has a

short life.

Start your work with an abrasive grit just coarse enough to remove high

spots and excessive roughness. Follow with a second sanding using a

grit one or two grades finer. Continue with successively finer grits until

you obtain the desired finish.

Do not switch from a coarse grit to a very fine grit in one step because

it may be impossible to remove the swirl marks made by the coarse grit

abrasive. Use the finest grits practical for the roughing operation, and

finish by using successively finer grits.

General Sanding

1. To prevent rough action due to starting under load, turn ON/OFF

Switch ON before applying sander to workpiece.

2. Work in slow, overlapping strokes parallel to grain. Your Finishing

Sander is designed for even weight distribution. Excessive pressure may damage workpiece and motor as well as cause premature

sandpaper wear.

3. Repeat operation using successively finer grits of sandpaper until

desired finish is obtained. Example: 60 Coarse, 100 Medium, 150

Fine.

Removing Paint and Varnish

1. If you use liquid removers or heaters to speed your work, be sure

surface is cool and dry. Before applying sander, remove excess

material with putty knife or other suitable scraping tool.

2. Use coarse, open coat abrasive to avoid usual clogging of abrasive

surface.

3. To avoid heating and softening of material being removed, keep

Finishing Sander moving over new areas.

4. Work in wide, overlapping arcs for uniform finish. Do not concentrate on small areas

Cabinets and Doors

Because your Finishing Sander works with circular movements, you

may sand joining pieces in any direction regardless of grain. Properly

changing from coarse to fine grit abrasives, will result in an excellent

finish.

page 6

Page 7

MAINTENANCE

ACCESSORIES

WARNING!

To reduce the risk of injury, always unplug your tool before

performing any maintenance. Never disassemble the tool or

try to do any rewiring on the tool's electrical system. Contact

a MILWAUKEE service facility for ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a regular maintenance program. Before use, examine the general condition of your tool. Inspect

guards, switches, tool cord set and extension cord for damage. Check

for loose screws, misalignment, binding of moving parts, improper mounting, broken parts and any other condition that may affect its safe operation. If abnormal noise or vibration occurs, turn the tool off immediately

and have the problem corrected before further use. Do not use a damaged tool. Tag damaged tools “DO NOT USE” until repaired

(see “Repairs”).

Under normal conditions, relubrication is not necessary until the motor

brushes need to be replaced. After six months to one year, depending on

use, return your tool to the nearest MILWAUKEE service facility for the

following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears, spindles, bearings,

housing, etc.)

• Electrical inspection (switch, cord, armature, etc.)

• Testing to assure proper mechanical and electrical operation

WARNING!

To reduce the risk of injury, always unplug the tool before

attaching or removing accessories. Use only specifically

recommended accessories. Others may be hazardous.

For a complete listing of accessories refer to your MILWAUKEE Electric

Tool catalog or go on-line to www.milwaukeetool.com. To obtain a

catalog, contact your local distributor or a service center.

Dust Bag Assembly

Cat. No. 48-09-0310

Punch Plate Assembly

Cat. No. 49-80-2050

Cat. No. 48-09-0310

Cleaning

Clean dust and debris from vents. Keep the tool handles clean, dry and

free of oil or grease. Use only mild soap and a damp cloth to clean your

tool since certain cleaning agents and solvents are harmful to plastics

and other insulated parts. Some of these include: gasoline, turpentine,

lacquer thinner, paint thinner, chlorinated cleaning solvents, ammonia

and household detergents containing ammonia. Never use flammable or

combustible solvents around tools.

WARNING!

To reduce the risk of injury, electric shock and damage to the

tool, never immerse your tool in liquid or allow a liquid to flow

inside the tool.

Repairs

If your tool is damaged, return the entire tool to the nearest service

center.

Cat. No. 49-80-2050

FIVE YEAR TOOL LIMITED WARRANTY

Every MILWAUKEE tool is tested before leaving the factory and is warranted to be free from defects in material and workmanship. MILWAUKEE

will repair or replace (at MILWAUKEE’s discretion), without charge, any

tool (including battery chargers) which examination proves to be defective in material or workmanship from five (5) years after the date of

purchase. Return the tool and a copy of the purchase receipt or other

proof of purchase to a MILWAUKEE Factory Service/Sales Support

Branch location or MILWAUKEE Authorized Service Station, freight pre-

paid and insured. This warranty does not cover damage from repairs

made or attempted by other than MILWAUKEE authorized personnel,

abuse, normal wear and tear, lack of maintenance, or accidents.

Battery Packs, Flashlights, and Radios are warranted for one (1) year

from the date of purchase.

THE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN ARE

EXCLUSIVE. IN NO EVENT SHALL MILWAUKEE BE LIABLE FOR ANY

INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES, INCLUDING

LOSS OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, OR CONDITIONS, WRITTEN OR ORAL, EXPRESSED OR IMPLIED FOR

MERCHANTABLILITY OR FITNESS FOR PARTICULAR USE OR PURPOSE.

This warranty gives you specific legal rights. You may also have other

rights that vary from state to state and province to province. In those

states that do not allow the exclusion of implied warranties or limitation

of incidental or consequential damages, the above limitations or exclusions may not apply to you. This warranty applies to the United States,

Canada, and Mexico only.

page 7

Page 8

RÈGLES GÉNÉRALES DE SÉCURITÉ POUR LES OUTILS ÉLECTRIQUE

AVERTISSEMENT!

LIRE SOIGNEUSEMENT TOUTES LES INSTRUCTIONS

Le non respect des instructions ci-après peut entraîner des chocs

électriques, des incendies et/ou des blessures graves. Le terme «outil

électrique» figurant dans les avertissements ci-dessous renvoie à l’outil

électrique à alimentation par le réseau (à cordon) ou par batterie (sans fil).

CONSERVER CES INSTRUCTIONS

SÉCURITÉ DU LIEU DE TRAVAIL

1. Maintenir la zone de travail propre et bien éclairée. Les zones

encombrées ou mal éclairées sont favorables aux accidents.

2. Ne pas utiliser d’outil électrique dans une atmosphère ex-

plosive, telle qu’en en présence de liquides, de gaz ou de

poussières inflammables. Les outils électriques génèrent des

étincelles qui peuvent enflammer les poussières ou les fumées.

3. Tenir les enfants et les personnes non autorisées à l’écart

pendant le fonctionnement d’un outil électrique. Un manque

d’attention de l’opérateur risque de lui faire perdre le contrôle de

l’outil.

SÉCURITÉ ÉLECTRIQUE

4. La fiche de l’outil électrique doit correspondre à la prise

d’alimentation. Ne jamais modifier la fiche d’une manière

quelconque. Ne pas utiliser d’adaptateur avec les outils

électriques mis à la terre (à la masse). Des fiches non modifiées

et des prises d’alimentation assorties réduisent le risque de choc

électrique.

5. Éviter tout contact corporel avec des surfaces reliées à la

masse ou à la terre telles que tuyaux, radiateurs, cuisinières

et réfrigérateurs. Un risque de choc électrique plus élevé existe

si le corps est relié à la masse ou à la terre.

6. Ne pas exposer les outils électriques à la pluie ou à

l’humidité. Le risque de choc électrique augmente si de l’eau s’infiltre

dans un outil électrique.

7. Prendre soin du cordon. Ne jamais utiliser le cordon pour

transporter, tirer ou débrancher l’outil électrique. Tenir le

cordon à l’écart de la chaleur, des huiles, des arêtes

coupantes ou des pièces en mouvement. Un cordon

endommagé ou emmêlé présente un risque accru de choc électrique.

8. Se procurer un cordon d’alimentation approprié en cas

d’utilisation d’un outil électrique à l’extérieur. L’utilisation d’un

cordon d’alimentation pour usage extérieur réduit le risque de choc

électrique.

SÉCURITÉ INDIVIDUELLE

9. Être sur ses gardes, être attentif et faire preuve de bon

sens en utilisant un outil électrique. Ne pas utiliser un outil

électrique en cas de fatigue ou sous l’influence de drogues,

d’alcool ou de médicaments. Un instant d’inattention lors de

l’utilisation d’un outil électrique peut entraîner des blessures graves.

10. Utiliser un équipement de sécurité. Toujours porter des

lunettes de protection. Un équipement de sécurité comprenant

masque anti-poussière, chaussures de sécurité anti-dérapantes,

casque ou dispositif de protection anti-bruit peut, dans les

circonstances appropriées, réduire le risque de blessure.

11. Éviter tout démarrage accidentel de l’outil. S’assurer que le

commutateur est en position OFF (Arrêt) avant de brancher

l’outil. Le port de l’outil avec un doigt sur le commutateur ou son

branchement avec le commutateur en position ON (Marche) sont

favorables aux accidents.

12. Retirer toute clé de réglage avant de mettre l’outil sous

tension. Une clé laissée attachée sur une pièce mobile de l’outil

électrique peut entraîner des blessures.

13. Ne pas travailler à bout de bras. Bien garder un bon équilibre

à tout instant. Ceci permet de mieux préserver la maîtrise de l’outil

électrique dans des situations imprévues.

14. Porter des vêtements adéquats. Ne pas porter de vêtements

amples ni de bijoux. Ne pas approcher les cheveux,

vêtements et gants des pièces en mouvement. Les vêtements

amples, les bijoux ou les cheveux longs risquent d’être happés par

les pièces en mouvement.

15. Si des dispositifs sont prévus pour l’extraction et la

récupération des poussières, vérifier qu’ils sont connectés

et utilisés correctement. L’utilisation de ces dispositifs peut

réduire les risques liés aux poussières.

UTILISATION ET ENTRETIEN DE L’OUTIL ÉLECTRIQUE

16. Ne pas forcer l’outil électrique. Utiliser l’outil électrique

approprié à l’application considérée. L’outil électrique adapté

au projet considéré produira de meilleurs résultats, dans des conditions de sécurité meilleures, à la vitesse pour laquelle il a été conçu.

17. Ne pas utiliser l’outil électrique si le commutateur ne le met

pas sous ou hors tension. Tout outil électrique dont le

commutateur de marche-arrêt est inopérant est dangereux et doit

être réparé.

18. Débrancher la fiche de la prise d’alimentation et/ou la batterie

de l’outil électrique avant d’effectuer des réglages, de

changer d’accessoires ou de ranger l’outil. De telles mesures

de sécurité préventive réduisent le risque de mettre l’outil en marche

accidentellement.

19. Ranger les outils électriques inutilisés hors de la portée

des enfants et ne pas laisser des personnes qui

connaissent mal les outils électriques ou ces instructions

utiliser ces outils. Les outils électriques sont dangereux dans les

mains d’utilisateurs non formés à leur usage.

20. Entretien des outils électriques. S’assurer de l’absence de

tout désalignement ou de grippage des pièces mobiles, de

toute rupture de pièce ou de toute autre condition qui

pourrait affecter le bon fonctionnement de l’outil électrique.

En cas de dommages, faire réparer l’outil avant de l’utiliser

de nouveau. Les outils électriques mal entretenus sont à la source

de nombreux accidents.

21. Garder les outils de coupe affûtés et propres. Les outils de

coupe correctement entretenus et bien affûtés risquent moins de se

gripper et sont plus faciles à manier.

22. Utiliser cet outil électrique, les accessoires, les mèches,

etc. conformément à ces instructions et de la façon prévue

pour ce type particulier d’outil électrique, tout en prenant

en compte les conditions de travail et le type de projet

considérés. L’utilisation de cet outil électrique pour un usage autre

que l’usage prévu peut créer des situations dangereuses.

ENTRETIEN

23. Faire effectuer l’entretien de l’outil électrique par un

technicien qualifié qui n’utilisera que des pièces de

rechange identiques. La sécurité d’utilisation de l’outil en sera

préservée.

page 8

Page 9

RÈGLES DE SÉCURITÉ PARTICULIÈRE

1. Tenir l’outil par les surfaces de prise isolées si, au cours des travaux, l’outil de coupe risque d’entrer en contact avec des fils

cachés ou avec son propre cordon. Le contact avec un fil sous tension met les parties métalliques exposées de l’outil sous tension, ce qui

infligera un choc électrique à l’opérateur.

2. Entretenez les étiquettes et marqies di fabricant. Les indications qu'elles contiennent sont précieuses. Si elles deviennent illisibles ou se

détachent, faites-les remplacer gratuitement à un centre de service MILWAUKEE accrédité.

3. AVERTISSEMENT! La poussière degage par perçage, sclage, perçage et autres travaux de construction contient des substances chimiques

reconnues comme pouvant causer le cancer, des malformations congénitales ou d’autres troubles de reproduction. Voici quelques exemples de

telles substances :

• Le plomb contenu dans la peinture au plomb.

• Le silice cristallin contenu dans la brique, le béton et divers produits de maçonnerie.

• L’arsenic et le chrome servant au traitement chimique du bois.

Les risque associés à l’exposition à ces substances varient, dépendant de la fréquence des travaux. Afin de minimiser l’exposition à ces

substances chimiques, assurez-vous de travailler dans un endroit bien aéré et d’utiliser de l’equipement de sécurité tel un masque antipoussière

spécifiquement conçu pour la filtration de particules microscopiques.

Pictographie

l’Association canadienne

de normalisation (ACNOR)

Underwriters

Laboratories, Inc.

Couvant alternatif

Double Insulated

OPM

1. Èvents

2. Cordon

3. Sac ramasse-poussière (No de cat. 6017)

4. Tampon

5. Levier de fixation

6. Pince de fixation

7. Poignée

8. Interrupteur ON/OFF

9. Plaque-poiçon (No de cat. 6017)

Orbites / Minute (OPM)

Ampères

Cat.

Volts

CA

115

115

No de

6016

6017

DESCRIPTION FONCTIONNELLE

1

8

7

Specifications

Orbites /

Ampères

1,8

1,8

Minute

13 000

13 000

Dim. papier

110 mm - 100 mm

(4-3/8" - 4")

110 mm - 100 mm

(4-3/8" - 4")

2

3

9

6

4

5

page 9

Page 10

MISE À LA TERRE

CORDONS DE RALLONGE

AVERTISSEMENT!

Si le fil de mise à la terre est incorrectement raccordé,

il peut en résulter des risques de choc électrique. Si

vous n’êtes pas certain que la prise dont vous vous

servez est correctement mise à la terre, faites-la

vérifier par un électricien. N’altérez pas la fiche du

cordon de l’outil. N’enlevez pas de la fiche, la dent qui

sert à la mise à la terre. N’employez pas l’outil si le

cordon ou la fiche sont en mauvais état. Si tel

est le cas, faites-les réparer dans un centre-service

MILWAUKEE accrédité avant de vous en servir. Si la

fiche du cordon ne s’adapte pas à la prise, faites

remplacer la prise par un électricien.

Outils mis à la terre :

Outils pourvus d’une fiche de cordon à trois dents

Les outils marqués « Mise à la terre

requise » sont pourvus d’un cordon

à trois fils dont la fiche a trois dents.

La fiche du cordon doit être branchée

sur une prise correctement mise à la

terre (voir Figure A). De cette façon,

si une défectuosité dans le circuit

électrique de l’outil survient, le relais

à la terre fournira un conducteur à

faible résistance pour décharger le

courant et protéger l’utilisateur contre

les risques de choc électrique.

La dent de mise à la terre de la fiche est reliée au système de mise à la

terre de l’outil via le fil vert du cordon. Le fil vert du cordon doit être le seul

fil raccordé à un bout au système de mise à la terre de l’outil et son autre

extrémité ne doit jamais être raccordée à une borne sous tension

électrique.

Votre outil doit être branché sur une prise appropriée, correctement

installée et mise à la terre conformément aux codes et ordonnances en

vigueur. La fiche du cordon et la prise de courant doivent être semblables

à celles de la Figure A.

Outils à double isolation :

Outils pourvus d’une fiche de

cordon à deux dents

Les outils marqués « Double

Isolation » n’ont pas besoin d’être

raccordés à la terre. Ils sont pourvus

d’une double isolation conforme eux

exigences de l’OSHA et satisfont aux

normes de l’Underwriters Laboratories, Inc., de l’Association canadienne

de normalisation (ACNOR) et du

« National Electrical Code » (code national de l’électricité). Les outils à

double isolation peuvent être

branchés sur n’importe laquelle des

prises à 120 volt illustrées ci-contre

Figure B et C.

Fig. A

Fig. B

Fig. C

Si l’emploi d’un cordon de rallonge est nécessaire, un cordon à trois fils

doit être employé pour les outils mis à la terre. Pour les outils à double

isolation, on peut employer indifféremment un cordon de rallonge à deux

ou trois fils. Plus la longueur du cordron entre l’outil et la prise de courant

est grande, plus le calibre du cordon doit être élevé. L’utilisation d’un

cordon de rallonge incorrectement calibré entraîne une chute de voltage

résultant en une perte de puissance qui risque de détériorer l’outil.

Reportez-vous au tableau ci-contre pour déterminer le calibre minimum

du cordon.

Moins le calibre du fil est élevé, plus sa conductivité est bonne. Par

exemple, un cordon de calibre 14 a une meilleure conductivité qu’un

cordon de calibre 16. Lorsque vous utilisez plus d’une rallonge pour

couvrir la distance, assurez-vous que chaque cordon possède le calibre minimum requis. Si vous utilisez un seul cordon pour brancher

plusieurs outils, additionnez le chiffre d’intensité (ampères) inscrit sur la

fiche signalétique de chaque outil pour obtenir le calibre minimal requis

pour le cordon.

Directives pour l’emploi des cordons de rallonge

• Si vous utilisez une rallonge à l’extérieur, assurez-vous qu’elle est

marquée des sigles « W-A » (« W » au Canada) indiquant qu’elle est

adéquate pour usage extérieur.

• Assurez-vous que le cordon de rallonge est correctement câblé et

en bonne condition. Remplacez tout cordon derallonge détérioré ou

faites-le remettre en état par une personne compétente avant de

vous en servir.

• Tenez votre cordon de rallonge à l’écart des objets ranchants, des

sources de grande chaleur et des endroits humides ou mouillés.

Calibres minimaux recommandés pour

signalétique

12,1 - 15,0

15,1 - 20,0

* Basé sur sur une chute de voltage limite de 5

volts à 150% de l’intensité moyenne de courant.

les cordons de rallonge*

Fiche

Ampères

0 - 5,0

5,1 - 8,0

8,1 - 12,0

Longueur du cordon de rallonge (m)

7,6

15,2

16

16

16

16

14

14

12

12

10

10

22,8

16

14

12

10

10

30,4

14

12

10

10

--

45,7

12

10

--

--

--

60,9

12

--

--

--

--

LISEZ ATTENTIVEMENT CES INSTRUCTIONS

ET CONSERVEZ-LES POUR LES

CONSULTER AU BESOIN.

page 10

Page 11

MONTAGE DE L'OUTIL

AVERTISSEMENT!

Pour minimiser les risques de blessures, débranchez

toujours l’outil avant d’y faire des réglages, d’y attacher ou

d’en enlever les accessoires. L’usage d’accessoires

autres que ceux qui sont spécifiquement recommandés

pour cet outil peut comporter des risques.

Installation du papier abrasif (Fig. 1)

Fig. 1

Levier de

fixation

Pince de fixation

1. Débranchez la ponceuse

2. Emploient 1/4 de feuille de papier abrasif (115 mm x 140 mm) (4-1/2"

x 5-1/2") (voir “Choix du papier abrasif et du calibre de grains”).

3. Pour ouvrir la pince de fixation, tirez le levier de fixation, tel qu’indiqué.

4. Placez un bout de la feuille de papier, face abrasive tournée vers

l’extérieur, entre la pince de fixation et la semelle de la ponceuse et

alignez-la sur le tampon.

5. Pour maintenir la feuille en place, relâchez la pince de fixation vers

sa position originale.

6. Étendez la feuille de papier abrasif sur le tampon et fixez-en le bout

dans la pince de fixation à l’autre extrémité de la semelle, tel qu’indiqué

précédemment. Pour faciliter l’insertion de la feuille, pliez-en les bouts

d’avance.

N.B. Pour un meilleur ponçage, la feuille de papier abrasif doit être

tendue le plus possible sur le tampon.

Tampon

Plaque-poinçon (No de cat. 6017) (Fig. 2)

La ponceuse No. 6017 est pourvue d’une plaque-poinçon servant à

perforer le papier abrasif. Les trous ainsi percés servent à l’évacuation

de la poussière de ponçage qui est aspirée dans le sac ramassepoussière. Il peut devenir nécessaire, en cours de ponçage, de poinçonner

de nouveau les trous afin d’assurer l’efficacité du système d’évacuation.

Fig. 2

Pointes

Bords recourbés

1. Alignez les côtés recourbés de la plaque sur les bords de la feuille

de papier abrasif, de façon à la couvrir entièrement.

2. Appuyez fermement pour que les pointes de la plaque-poinçon

perforent le papier abrasif.

Sac ramasse-poussière (No de cat. 6017) (Fig. 3)

La ponceuse No 6017 est pourvue d’un sac pour aspirer efficacement la

poussière de ponçage.

Fig. 3

Plaque-poinçon

Détente

Col du sac

goulot d’évacuation

Pour installer le sac ramasse-poussière, glissez le col du sac sur le

goulot d’évacuation de la ponceuse jusqu’à ce que la détente, sur le

goulot, s’enclenche dans le col du sac.

Pour retirer le sac ramasse-poussière, tournez légèrement le col du

sac en le retirant du goulot.

Pour obtenir de meilleurs résultats, videz le sac ramasse-poussière

lorsqu’il est à moitié plein. Pour vider le sac, retirez-le du goulot de la

ponceuse. Ensuite, ouvrez-en la fermeture-éclair et tapotez-le légèrement

pour en faire sortir la poussière.

page 11

Page 12

MANIEMENT

AVERTISSEMENT!

Pour minimiser les risques de blessures, portez

des lunettes à coques latérales. Débranchez l’outil

avant de changer les accessoires ou d’effectuer des

réglages.

Choix du papier abrasif et du calibre de grains

Le corindon, le carbure de silicium et d’autres abrasifs synthétiques sont

recommandés pour poncer à outils électriques. Un papier abrasif grenat

est acceptable mais non durable.

Commencez à poncer avec un papier dont le grain est assez gros pour

enlever bosses et rugosités. Ensuite, changez pour un papier d’un ou

deux degrés plus fin. Continuez à poncer à l’aide d’un papier graduellement

plus fin jusqu’à obtention du résultat désiré.

Ne passez pas directement d’un papier à grains grossiers à un papier à

grains très fins, il pourrait alors être impossible de faire disparaître les

sillons laissés par les grains grossiers. Commencez toujours à poncer

avec un papier à grains aussi fins que possible, compte tenu de l’état de

la surface, et continuez à poncer avec du papier à grains graduellement

plus fins.

Ponçage général

1. Pour éviter que la ponceuse ne démarre par soubresauts, placez

l’interrupteur ON/OFF à la position “ON” avant de la poser sur la

surface à poncer.

2. Poncez lentement en faisant chevaucher vos mouvements dans le

sens du grain du bois. Le design de la ponceuse de finition en

répartit également le poids sur toute la semelle, une pression excessive pourra endommager la pièce à poncer, surcharger le moteur de

la ponceuse et user prématurément le papier abrasif.

3. Recommencez le ponçage, en utilisant successivement un papier

abrasif à grains graduellement plus fins, jusqu’à ce que le fini désiré

soit obtenu. Par exemple, un papier à grains grossiers, calibre 60,

suivi d’un papier à grains moyens de calibre 100 et finalement un

papier à grains fins, calibre 150.

Décapage de peintures et vernis

1. Si vous utilisez un décapant liquide ou un chalumeau pour accélérer

le décapage, laissez la surface sécher ou refroidir. Enlevez l’enduit

avec un couteau à mastiquer ou une autre forme de grattoir avant

d’utiliser la ponceuse.

2. Employez un papier abrasif à grains espacés pour éviter

l’encrassement du papier.

3. Pour prévenir le ramollissement et la surchauffe de l’enduit, gardez

la ponceuse de finissage en mouvement sur toute la surface à

décaper.

4. Pour obtenir un fini uniforme, poncez en faisant chevaucher de

larges mouvements arqués. Ne concentrez pas le ponçage sur des

espaces restreints.

Armoires et portes

Grâce aux mouvements circulaires de votre ponceuse de finissage,

vous pouvez poncer les parties adjacentes sans égard au sens du

grain. En alternant les calibres d’abrasif de gros à fin, vous obtiendrez

un beau fini.

page 12

Page 13

MAINTENANCE

ACCESSOIRES

AVERTISSEMENT!

Pour minimiser les risques de blessures,

débranchez toujours l’outil avant d’y effectuer des

travaux de maintenance. Ne faites pas vous-même

le démontage de l’outil ni le rebobinage du système

électrique. Consultez un centre de service

MILWAUKEE accrédité pour toutes les réparations.

Entretien de l’outil

Gardez l’outil en bon état en adoptant un programme d’entretien ponctuel.

Avant de vous en servir, examinez son état en général. Inspectez-en la

garde, interrupteur, cordon et cordon de rallonge pour en déceler les

défauts. Vérifiez le serrage des vis, l’alignement et le jeu des pièces

mobiles, les vices de montage, bris de pièces et toute autre condition

pouvant en rendre le fonctionnement dangereux. Si un bruit ou une

vibration insolite survient, arrêtez immédiatement l’outil et faites-le vérifier

avant de vous en servir de nouveau. N’utilisez pas un outil défectueux.

Fixez-y une étiquette marquée « HORS D’USAGE » jusqu’à ce qu’il soit

réparé (voir « Réparations »).

Normalement, il ne sera pas nécessaire de lubrifier l’outil avant que le

temps ne soit venu de remplacer les balais. Après une période pouvant

aller de 6 mois à un an, selon l’usage, retournez votre outil à un centre de

service MILWAUKEE accrédité pour obtenir les services suivants :

• Lubrification

• Inspection et remplacement des balais

• Inspection et nettoyage de la mécanique (engrenages, pivots,

coussinets, boîtier etc.)

• Inspection électrique (interrupteur, cordon, induit etc.)

• Vérification du fonctionnement électromécanique

AVERTISSEMENT!

Pour minimiser les risques de blessures,

débranchez toujours l’outil avant d’y installer ou

d’en enlever les accessoires. L’emploi

d’accessoires autres que ceux qui sont

expressément recommandés pour cet outil peut

présenter des risques.

Pour une liste complète des accessoires, prière de se reporter au catalogue MILWAUKEE Electric Tool ou visiter le site internet

www.mil-electric-tool.com. Pour obtenir un catalogue, il suffit de contacter

votre distributeur local ou l'un des centres-service énumérés sur la page

de couverture de ce manuel.

Sac ramasse-poussière

No de cat. 48-09-0310

Plaque-poinçon

No de cat. 49-80-2050

No de cat. 48-09-0310

Nettoyage

Débarrassez les évents des débris et de la poussière. Gardez les

poignées de l’outil propres, à sec et exemptes d’huile ou de graisse. Le

nettoyage de l’outil doit se faire avec un linge humide et un savon doux.

Certains nettoyants tels l’essence, la térébenthine, les diluants à laque

ou à peinture, les solvants chlorés, l’ammoniaque et les détergents

d’usage domestique qui en contiennent pourraient détériorer le plastique

et l’isolation des pièces. Ne laissez jamais de solvants inflammables ou

combustibles auprès des outils.

AVERTISSEMENT!

Pour minimiser les risques de blessures, choc

électrique et dommage à l'outil, n'immergez jamais

l'outil et ne laissez pas de liquide s'y infiltrer.

Réparations

Si votre outil doit être réparé, retournez-le en entier au centre-service le

plus près selon la liste apparaissant à la dernière page de ce manuel.

No de cat. 49-80-2050

GARANTIE LIMITÉE DE L’OUTIL DE CINQ ANS

Tous les outils MILWAUKEE sont testés avant de quitter l’usine et sont

garantis exempts de vice de matériau ou de fabrication. MILWAUKEE

réparera ou remplacera (à la discrétion de MILWAUKEE), sans frais,

tout outil (y compris les chargeurs de batterie) dont l’examen démontre le

caractère défectueux du matériau ou de la fabrication dans les cinq (5)

ans suivant la date d’achat. Retourner l’outil et une copie de la facture ou

de toute autre preuve d’achat à une branche Entretien usine/Assistance

des ventes de l’établissement MILWAUKEE ou à un centre d’entretien

agréé par MILWAUKEE, en port payé et assuré. Cette garantie ne couvre

pas les dommages causés par les réparations ou les tentatives de

réparation par quiconque autre que le personnel agréé par MILWAUKEE,

les utilisations abusives, l’usure normale, les carences d’entretien ou les

accidents.

Les batteries, les lampes de poche et les radios sont garanties pour un

(1) an à partir de la date d’achat.

LES SOLUTIONS DE RÉPARATION ET DE REMPLACEMENT DÉCRITES

PAR LES PRÉSENTES SONT EXCLUSIVES. MILWAUKEE NE SAURAIT

ÊTRE RESPONSABLE, EN AUCUNE CIRCONSTANCE, DES DOMMAGES

ACCESSOIRES, SPÉCIAUX OU INDIRECTS, Y COMPRIS LES MANQUES À

GAGNER.

CETTE GARANTIE EST EXCLUSIVE ET REMPLACE TOUTES LES AUTRES

GARANTIES OU CONDITIONS, ÉCRITES OU ORALES, EXPRESSES OU

TACITES DE QUALITÉ MARCHANDE OU D’ADAPTATION À UNE

UTILISATION OU UNE FIN PARTICULIÈRE.

Cette garantie vous donne des droits particuliers. Vous pouvez aussi

bénéficier d’autres droits variant d’un état à un autre et d’une province à

une autre. Dans les états qui n’autorisent pas les exclusions de garantie

tacite ou la limitation des dommages accessoires ou indirects, les limitations ou exclusions ci-dessus peuvent ne pas s’appliquer. Cette garantie

s’applique aux États-Unis, au Canada et au Mexique uniquement.

page 13

Page 14

REGLAS DE SEGURIDAD GENERALES PARA HERRAMIENTAS ELÉCTRICAS

¡ADVERTENCIA!

Si no se siguen todas las siguientes instrucciones se puede provocar una

LEA TODAS LAS INSTRUCCIONES

descarga eléctrica, un incendio y/o lesiones graves. El término “herramienta

eléctrica” en todas las advertencias incluidas más abajo se refiere a su

herramienta operada por conexión (cable) a la red eléctrica o por medio de

una batería (inalámbrica).

GUA0RDE ESTAS INSTRUCCIONES

SEGURIDAD EN EL ÁREA DE TRABAJO

1. Mantenga limpia y bien iluminada el área de trabajo. Las

áreas desordenadas u oscuras contribuyen a que se produzcan

accidentes.

2. No utilice herramientas eléctricas en atmósferas explosivas,

como en la presencia de líquidos, gases o polvo inflamables.

Las herramientas eléctricas crean chispas que pueden incendiar el

polvo o las emanaciones.

3. Mantenga a los niños y otras personas alejadas mientras

utiliza una herramienta eléctrica. Las distracciones pueden

hacerle perder el control.

SEGURIDAD ELÉCTRICA

4. Los enchufes de las herramientas eléctricas deben ser del

mismo tipo que el tomacorrientes. Nunca realice ningún

tipo de modificación en el enchufe. No use enchufes

adaptadores con herramientas eléctricas con conexión a

tierra. Se reducirá el riesgo de descarga eléctrica si no se modifican

los enchufes y los tomacorrientes son del mismo tipo.

5. Evite el contacto corporal con superficies con conexión a

tierra, como tuberías, radiadores, estufas y refrigeradores.

El riesgo de descarga eléctrica aumenta si su cuerpo está conectado

a tierra.

6. No exponga la herramientas eléctricas a la lluvia o a

condiciones de humedad. El agua que entra en una herramienta

eléctrica aumenta el riesgo de descarga eléctrica.

7. No abuse del cable. Nunca use el cable para transportar la

herramienta eléctrica, tirar de ella o desenchufarla.

Mantenga el cable alejado del calor, los bordes afilados o

las piezas en movimiento. Los cables dañados o enmarañados

aumentan el riesgo de descarga eléctrica.

8. Cuando se utiliza una herramienta eléctrica en el exterior,

use una extensión que sea apropiada para uso en el exterior. El uso de un cable apropiado para el exterior reduce el riesgo

de descarga eléctrica.

SEGURIDAD PERSONAL

9. Manténgase alerta, ponga cuidado a lo que está haciendo y

use el sentido común cuando utilice una herramienta eléctrica.

No use una herramienta eléctrica cuando está cansado o bajo

la influencia de drogas, alcohol o medicinas. Despistarse un

minuto cuando se utiliza una herramienta eléctrica puede tener como

resultado lesiones personales graves.

10. Use equipo de seguridad. Lleve siempre protección ocular.

Llevar equipo de seguridad apropiado para la situación, como una

máscara antipolvo, zapatos de seguridad antideslizantes casco o

protección auditiva, reducirá las lesiones personales.

11. Evite los arranques accidentales. Asegúrese de que el

interruptor esté en la posición de apagado antes de enchufar

la herramienta. Mover herramientas con el dedo en el interruptor

o enchufar herramientas con el interruptor en la posición de encendido

contribuye a que se produzcan accidentes.

12. Quite todas las llaves de ajuste antes de encender la

herramienta. Una llave que esté acoplada a una pieza giratoria de

la herramienta puede provocar lesiones personales.

page 14

13. No se estire demasiado. Mantenga los pies bien asentados y

el equilibrio en todo momento. Esto permite tener mejor control

de la herramienta eléctrica en situaciones inesperadas.

14. Vístase de manera apropiada. No lleve ropa suelta ni joyas.

Mantenga el cabello, la ropa y los guantes lejos de la piezas

en movimiento. La ropa floja, las joyas o el cabello largo pueden

quedar atrapados en las piezas en movimiento.

15. Si se proporcionan dispositivos para la conexión de

sistemas de recolección y extracción de polvo, asegúrese

de que estén conectados y se usen apropiadamente. El uso

de estos dispositivos puede reducir los peligros relacionados con el

polvo.

USO Y CUIDADO DE LAS HERRAMIENTAS

ELÉCTRICAS

16. No fuerce la herramienta eléctrica. Use la herramienta eléctrica

correcta para la aplicación. La herramienta eléctrica correcta

funcionará mejor y de manera más segura a la velocidad para la que

se diseñó.

17. No use la herramienta eléctrica si el interruptor no la

enciende ni la apaga. Cualquier herramienta eléctrica que no se

pueda controlar con el interruptor es peligrosa y se debe reparar.

18. Desconecte el enchufe de la toma de alimentación y/o la

batería de la herramienta eléctrica antes de realizar cualquier

ajuste, cambiar accesorios o almacenar las herramientas

eléctricas. Dichas medidas preventivas de seguridad reducen el

riesgo de que la herramienta se prenda accidentalmente.

19. Almacene las herramientas eléctricas fuera del alcance de

los niños y no permita que personas no familiarizadas con

ellas o estas instrucciones las utilicen. Las herramientas

eléctricas son peligrosas en las manos de usuarios no capacitados.

20. Mantenimiento de las herramientas eléctricas. Revise que

no haya piezas móviles que estén desalineadas o que se

atasquen, piezas rotas ni ninguna otra condición que pueda

afectar el funcionamiento de la herramienta eléctrica. Si se

encuentran daños, haga que le reparen la herramienta antes de usarla. Las herramientas mal mantenidas son la causa de

muchos accidentes.

21. Mantenga las herramientas de corte limpias y afiladas. Es

menos probable que se atasquen las herramientas de corte con

filos afilados que se mantienen de manera apropiada y también son

más fáciles de controlar.

22. Use la herramienta eléctrica, los accesorios y las brocas,

etc. siguiendo estas instrucciones y de la manera para la

que dicha herramienta eléctrica en particular fue diseñada,

teniendo en cuenta las condiciones de trabajo y la tarea que

se va a realizar. El uso de la herramienta eléctrica para operaciones

diferentes de aquellas para las que se diseño podría resultar en una

situación peligrosa.

MANTENIMIENTO

23. Haga que un técnico calificado realice el mantenimiento de la

herramienta eléctrica utilizando solamente piezas de repuesto

idénticas. Esto asegurará que se mantiene la seguridad de la

herramienta eléctrica.

Page 15

REGLAS ESPECIFICAS DE SEGURIDAD

1. Agarre la herramienta por los asideros aislados cuando realice una operación en la que la herramienta de corte pueda entrar

en contacto con cables ocultos o con su propio cable. El contacto con un cable “con corriente” hará que las partes de metal expuesto de

la herramienta pasen la corriente y produzcan una descarga al operador.

2. Guarde las etiquetas y placas de especificaciones. Estas tienen información importante. Si son ilegibles o si no se pueden encontrar,

póngase en contacto con un centro de servicio de MILWAUKEE para una refacción gratis.

3. ¡ADVERTENCIA! Algunas partículas de polvo resultantes del lijado mecánico, aserrado, esmerilado, taladrado y otras actividades relacionadas

a la construcción, contienen sustancias químicas que se saben ocasionan cáncer, defectos congénitos u otros daños al aparato reproductivo.

A continuación se citan algunos ejemplos de tales sustancias químicas:

• plomo proveniente de pinturas con base de plomo

• sílice cristalino proveniente de ladrillos, cemento y otros productos de albañilería y

• arsénico y cromo provenientes de madera químicamente tratada.

El riesgo que usted sufre debido a la exposición varía dependiendo de la frecuencia con la que usted realiza estas tareas. Para reducir la

exposición a estas sustancias químicas: trabaje en un área bien ventilada, y utilice equipo de seguridad aprobado como, por ejemplo, máscaras

contra el polvo que hayan sido específicamente diseñadas para filtrar partículas microscópicas.

Simbología

Canadian Standards

Association

Underwriters

Laboratories, Inc.

Volts de corriente alterna

Double Isolation

OPM

1. Ventilas

2. Cable

3. Saco recolector de polvo (Cat. No. 6017)

4. Base

5. Palanca de las uñas sujetadoras de la lija

6. Uñas sujetadoras

7. Empuñadura

8. Interruptor ON - OFF

9. Base perforadora (Cat. No. 6017)

Orbitas por minuto (OPM)

Amperios

Cat.

Volts

No.

6016

6017

DESCRIPCION FUNCIONAL

1

8

7

Especificaciones

ca

115

115

Orbitas por

A

1,8

1,8

minuto

13 000

13 000

Tamaño lija

110 mm - 100 mm

(4-3/8" - 4")

110 mm - 100 mm

(4-3/8" - 4")

2

3

9

6

4

5

page 15

Page 16

TIERRA

EXTENSIÓNES ELÉCTRICAS

¡ADVERTENCIA!

Puede haber riesgo de descarga eléctrica si se conecta el

cable de conexión de puesta a tierra incorrectamente.

Consulte con un electricista certificado si tiene dudas

respecto a la conexión de puesta a tierra del tomacorriente.

No modifique el enchufe que se proporciona con la

herramienta. Nunca retire la clavija de conexión de puesta a

tierra del enchufe. No use la herramienta si el cable o el

enchufe está dañado. Si está dañado antes de usarlo, llévelo

a un centro de servicio MILWAUKEE para que lo reparen. Si

el enchufe no se acopla al tomacorriente, haga que un

electricista certificado instale un tomacorriente adecuado.

Herramientas con conexión a tierra:

Herramientas con enchufes de tres clavijas

Las herramientas marcadas con la

frase “Se requiere conexión de

puesta a tierra” tienen un cable de

tres hilo y enchufes de conexión de

puesta a tierra de tres clavijas.

El enchufe debe conectarse a

un tomacorriente debidamente

conectado a tierra (véase la

Figura A). Si la herramienta se

averiara o no funcionara

correctamente, la conexión de puesta a tierra proporciona un trayecto

de baja resistencia para desviar la corriente eléctrica de la trayectoria

del usuario, reduciendo de este modo el riesgo de descarga eléctrica.

La clavija de conexión de puesta a tierra en el enchufe está conectada

al sistema de conexión de puesta a tierra de la herramienta a través del

hilo verde dentro del cable. El hilo verde debe ser el único hilo conectado

al sistema de conexión de puesta a tierra de la herramienta y nunca se

debe unir a una terminal energizada.

Su herramienta debe estar enchufada en un tomacorriente apropiado,

correctamente instalado y conectado a tierra según todos los códigos y

reglamentos. El enchufe y el tomacorriente deben asemejarse a los de la

Figura A.

Herramientas con doble aislamiento:

Herramientas con clavijas de dos patas

Las herramientas marcadas con

“Doble aislamiento” no requieren

conectarse “a tierra”. Estas

herramientas tienen un sistema

aislante que satisface los

estándares de OSHA y llena los

estándares aplicables de UL (Underwriters Laboratories, Inc.), de la

Asociación Canadiense de

Estándares (CSA) y el Código

Nacional de Electricidad. Las

herramientas con doble aislamiento

pueden ser usadas en cualquiera de

los toma corriente de 120 Volt

mostrados en las Figuras B y C.

Fig. A

Fig. B

Fig. C

Las herramientas que deben conectarse a tierra cuentan con clavijas de

tres patas y requieren que las extensiones que se utilicen con ellas sean

también de tres cables. Las herramientas con doble aislamiento y clavijas

de dos patas pueden utilizarse indistintamente con extensiones de dos a

tres cables. El calibre de la extensión depende de la distancia que exista

entre la toma de la corriente y el sitio donde se utilice la herramienta. El

uso de extensiones inadecuadas puede causar serias caídas en el

voltaje, resultando en pérdida de potencia y posible daño a la herramienta.

La tabla que aquí se ilustra sirve de guía para la adecuada selección de

la extensión.

Mientras menor sea el número del calibre del cable, mayor será la

capacidad del mismo. Por ejemplo, un cable calibre 14 puede transportar

una corriente mayor que un cable calibre 16. Cuando use mas de una

extensión para lograr el largo deseado, asegúrese que cada una tenga

al menos, el mínimo tamaño de cable requerido. Si está usando un cable

de extensión para mas de una herramienta, sume los amperes de las

varias placas y use la suma para determinar el tamaño mínimo del cable

de extensión.

Guías para el uso de cables de extensión

• Si está usando un cable de extensión en sitios al aire libre, asegúrese

que está marcado con el sufijo “W-A” (“W” en Canadá) el cual indica

que puede ser usado al aire libre.

• Asegúrese que su cable de extensión está correctamente cableado

y en buenas condiciones eléctricas. Cambie siempre una extensión

dañada o hágala reparar por una persona calificada antes de volver

a usarla.

• Proteja su extensión eléctrica de objetos cortantes, calor excesivo

o areas mojadas.

Calibre mínimo recomendado para

cables de extensiónes eléctricas*

Amperios

(En la placa)

0 - 5,0

5,1 - 8,0

8,1 - 12,0

12,1 - 15,0

15,1 - 20,0

* Basado en limitar la caída en el voltaje a 5

volts al 150% de los amperios.

Largo de cable de Extensión en (m)

30,4

14

12

10

10

45,7

60,9

12

12

10

--

--

--

--

7,6

16

16

14

12

10

15,2

16

16

14

12

10

22,8

16

14

12

10

10

--

--

--

--

LEA Y GUARDE TODAS LAS INSTRUCCIONES

PARA FUTURAS REFERANCIAS.

page 16

Page 17

ENSAMBAJE DE LA HERRAMIENTA

¡ADVERTENCIA!

Para reducir el riesgo de lesiones, desconecte siempre la

herramienta antes de fijar o retirar accesorios, o antes de

efectuar ajustes. Utilice sólo los accesorios específicamente

recomendados. El uso de otros accesorios puede ser

peligroso.

Colocación del papel de lija (Fig. 1)

Fig. 1

Palanca de

las uñas

Uñas sujetadoras

1. Desconecte la lijadora.

2. Usan 1/4 de pliego de lija 115mm x 140 mm (4-1/2" x 5-1/2") (vea

“Selección del papel de lija y el grano adecuado).

3. Para abrir las uñas sujetadoras, jale la palanca de las uñas como se

ilustra.

4. Con la superficie abrasiva hacia afuera, coloque la lija entre las

uñas sujetadoras y la base, alineando las orillas de la lija con las

orillas de la base.

5. Para asegurar la lija, suelte las uñas sujetadoras y regréselas a sus

posición original.

6. Pase la lija por la base y asegure el extremo libre a las uñas

sujetadoras del lado contrario. Se recomienda predoblar el papel de

las lijas para hacer su colocación más fácil.

NOTA: Para mejores resultados, la lija debe quedar lo más

ajustada posible.

Base

Plato perforador (Cat. No. 6017) (Fig. 2)

El Cat. No. 6017 está equipado con un plato perforador que permite

hacerle las perforaciones necesarias al papel de lija. Estas perforaciones

permitirán absorver el polvo de la superficie y aspirarlo hasta el saco

recolector. En ocasiones es necesario reperforar la lija varias veces

durante la operación para permitir que el sistema de recolección y

aspiración del polvo funcione adecuadamente.

Fig. 2

Cortadores

Orillas dobladas

1. Alinie las orillas dobladas del plato con las de la lija, de tal manera

que la lija quede cubierta totalmente por el plato perforador.

2. Perfore la lija presionando firmemente el plato perforador através de

la lija.

Saco recolector de polvo (Cat. No. 6017) (Fig. 3)

La Lijadora Cat. No. 6017 está equipada con un saco recolector de polvo

para su fácil recolección.

Fig. 3

Hoja perforadora

Tope

Entrada del

saco

Salda del polvo

Para colocar el saco recolector, deslice la entrada del saco sobre las

salida del polvo de la lijadora hasta que quede firmemente unido.

Para retirar el saco, gire suavemente las uniones y deslícelo de la

salida del polvo recolector del polvo.

Para óptimos resultados, vacíe el saco cuando esté solamente medio

lleno. Para vaciarlo, desmóntelo de la lijadora. Abra el zipper del saco y

vacíelo suavemente.

page 17

Page 18

OPERACION

¡ADVERTENCIA!

Para reducir el riesgo de lesiones, use siempre lentes de

seguridad o anteojos con protectores laterales. Desconecte

la herramienta antes de cambiar algún accesorio o de hacerle

algún ajuste.

Selección de la hoja de lija y su tipo de grano

Para lijados poderosos se recomiendan lijas de óxido de aluminio, carburo

de silicio y otros abrasivos sintéticos. Otros tipos de lija pueden ser

usados pero su vida será muy corta.

Empiece el trabajo con un grano abrasivo lo suficientemente áspero

para remover las impurezas grandes y la rudeza excesiva. La segunda

lijada hágala con lija de uno o dos grados más fina. Continúe cada vez

con granos más finos hasta alcanzar el terminado deseado.

No cambie de un grano muy áspero a uno muy fino en una sola operación,

porque puede ser imposible quitar las marcas que causará el grano

áspero. Use el grano más fino posible para las lijadas de superficies

ásperas y dé el acabado deseado usando sucesivamente granos cada

vez más finos.

Lijado en general

1. Para evitar maltratar la superficie al encender la lijadora, coloque el

interruptor en ON antes de colocar la lijadora sobre la superficie de

trabajo.

2. Trabaje con movimientos lentos y repetidos, siempre en paralelo a

las vetas de la madera. Su lijadora está diseñada con el peso en

forma balanceada. Si se presiona demasiado, se puede dañar la

superficie y el motor al igual que desgastar muy rápidamente la lija.

3. Repita las operaciones usando cada vez granos más finos hasta

lograr el acabado deseado. Por ejemplo: Inicie con grano # 60 para

el lijado áspero, siga con grano # 100 para el lijado medio y termine

con grano # 150 para el lijado fino.

Remoción de pinturas y barniz

1. Si se van a usar removedores líquidos o pistolas de calor para

acelerar el trabajo, asegúrese que la superficie esté fría y seca.

Antes de operar la lijadora, remueva el material sobrante con un

cuchillo o espátula.

2. Use granos ásperos, abiertos, para evitar que se “tape” la superficie

de la lija.

3. Para evitar que se afloje o caliente el material de la superficie lijada,

mantenga la lijadora en movimiento por nuevas areas.

4. Trabaje y lije en arcos amplios y repetidos. No se concentre en

areas pequeñas.

Gabinetes y puertas

Dado que su lijadora orbital para acabados trabaja a base de movimientos

circulares, se pueden lijar uniones en cualquier dirección, sin importar la

dirección de la veta. Si se va cambiando de lija pasando de granos

ásperos a finos, se puede lograr una acabado excelente.

page 18

Page 19

MANTENIMIENTO

ACCESORIOS

¡ADVERTENCIA!

Para reducir el riesgo de lesiones, desconecte siempre la

herramienta antes de darle cualquier mantenimiento. Nunca

desarme la herramienta ni trate de hacer modificaciones en

el sistema eléctrico de la misma. Acuda siempre a un Centro

de Servicio MILWAUKEE para TODAS las reparaciones.

Mantenimiento de las herramientas

Adopte un programa regular de mantenimiento y mantenga su herramienta

en buenas condiciones. Antes de usarla, examine las condiciones generales de la misma. Inspeccione guardas, interruptores, el cable de la

herramienta y el cable de extensión. Busque tornillos sueltos o flojos,

defectos de alineación y dobleces en partes móviles, así como montajes

inadecuados, partes rotas y cualquier otra condición que pueda afectar

una operación segura. Si detecta ruidos o vibraciones anormales, apague

la herramienta de inmediato y corrija el problema antes de volver a usarla.

No utilice una herramienta dañada. Colóquele una etiqueta que diga “NO

DEBE USARSE” hasta que sea reparada (vea “Reparaciones”).

Bajo condiciones normales, no se requiere lubricación hasta que haya

que cambiar los carbones. Después de 6 meses a un año, dependiendo

del uso dado, envíe su herramienta al Centro de Servicio MILWAUKEE

más cercano para que le hagan:

• Lubricación

• Inspección y cambio de carbones

• Inspección mecánica y limpieza (engranes, flechas, baleros,

carcarza, etc.)

• Inspección eléctrica (interruptor, cable, armadura, etc.)

• Probarla para asegurar una operación mecánica y eléctrica

adecuada.

¡ADVERTENCIA!

Para reducir el riesgo de lesiones, desconecté siempre su

herramienta antes de colocar o retirar un accesorio. Use

solo accesorios recomendados específicamente. Otros

puenden peligrosos.

Para una lista completa de accessorios, refiérase a su catálogo

MILWAUKEE Electric Tool o visite nuestro sitio en Internet:

www.milwaukeetool.com. Para obtener un catálogo, contacte su

distribuidor local o uno de los centros.

Saco recolector de polvo

Cat. No. 48-09-0310

Plato perforador de la lija

Cat. No. 49-80-2050

Cat. No. 48-09-0310

Cat. No. 49-80-2050

¡ADVERTENCIA!

Para reducir el riesgo de lesiones, descarga eléctrica o daño

a la herramienta, nunca la sumerja en líquidos ni permita que

estos fluyan dentro de la misma.

Limpieza

Limpie el polvo y suciedad de las ventilas. Mantenga las empuñaduras

de la herramienta limpias, secas y libres de aceite y grasa. Use sólo

jabón neutro y un trapo húmedo para limpiar su herramienta ya que

algunas substancias y disolventes limpiadores pueden ocasionar daños

a materiales plásticos y partes aislantes. Algunos de estos incluyen:

gasolina, trementina, diluyente para barniz, diluyente para pintura,

disolventes limpiadores clorados, amoníaco, y detergentes caseros que

contengan amoníaco.

Reparaciones

Si su instrumento se daña, vuelva el instrumento entero al más cercano

centro de reparaciones.

GARANTÍA LIMITADA DE CINCO AÑOS

Todas las herramientas MILWAUKEE se prueban antes de abandonar la

fábrica y se garantiza que no presentan defectos ni en el material ni de

mano de obra. En el plazo de cinco (5) años a partir de la fecha de

compra MILWAUKEE reparará o reemplazará (a discreción de

MILWAUKEE), sin cargo alguno, cualquier herramienta (cargadores de

baterías inclusive) cuyo examen determine que presenta defectos de

material o de mano de obra. Devuelva la herramienta, con gastos de

envío prepagados y asegurada, y una copia de la factura de compra, u

otro tipo de comprobante de compra, a una sucursal de reparaciones/

ventas de la fábrica MILWAUKEE o a un centro de reparaciones

autorizado por MILWAUKEE. Esta garantía no cubre los daños

ocasionados por reparaciones o intentos de reparación por parte de

personal no autorizado por MILWAUKEE, abuso, desgaste y deterioro

normal, falta de mantenimiento o accidentes.

Las baterías, linternas y radios tienen una garantía de un (1) año a partir

de la fecha de compra.

LOS DERECHOS A REPARACIÓN Y REEMPLAZO DESCRITOS EN EL

PRESENTE DOCUMENTO SON EXCLUSIVOS. MILWAUKEE NO SERÁ EN

NINGÚN CASO RESPONSABLE DE DAÑOS INCIDENTALES, ESPECIALES

O CONSECUENTES, INCLUYENDO LA PÉRDIDA DE GANANCIAS.

ESTA GARANTÍA ES EXCLUSIVA Y SUSTITUYE A TODA OTRA GARANTÍA,

O CONDICIONES, ESCRITAS U ORALES, EXPRESAS O IMPLÍCITAS DE

COMERCIALIZACIÓN O IDONEIDAD PARA UN USO O FIN DETERMINADO.

Esta garantía le proporciona derechos legales específicos. Es posible

que usted tenga otros derechos que varían de estado a estado y de

provincia a provincia. En aquellos estados que no permiten la exclusión

de garantías implícitas o la limitación de daños incidentales o

consecuentes, las limitaciones anteriores pueden que no apliquen. Esta

garantía es válida solamente en los Estados Unidos, Canadá y México.

page 19

Page 20

UNITED STATES

CANADA

MILWAUKEE Service

MILWAUKEE prides itself in producing a

premium quality product that is

N

OTHING BUT HEAVY DUTY

Your satisfaction with our products is

very important to us!

If you encounter any problems with the

operation of this tool, or you would like to

locate the factory Service/Sales Support Branch

or authorized service station nearest you,

please call...

®

.

1-800-SAWDUST

(1.800.729.3878)

NATIONWIDE TOLL FREE

Monday-Friday • 8:00 AM - 4:30 PM • Central Time

or visit our website at

www.milwaukeetool.com

For service information, use the 'Service Center

Search' icon found in the 'Parts & Service' section.

Service MILWAUKEE

MILWAUKEE est fier de proposer un produit de

première qualité NOTHING BUT HEAVY DUTY®. Votre

satisfaction est ce qui compte le plus!

En cas de problèmes d’utilisation de l’outil ou

pour localiser le centre de service/ventes ou le

centre d’entretien le plus proche, appelez le...

416.439.4181

fax: 416.439.6210

Milwaukee Electric Tool (Canada) Ltd

755 Progress Avenue

Scarborough, Ontario M1H 2W7

Notre réseau national de distributeurs agréés se tient

à votre disposition pour fournir l’aide technique,

l’outillage et les accessoires nécessaires. Composez

le 416.439.4181 pour obtenir les noms et adresses

des revendeurs les plus proches ou bien consultez

la section «Où acheter» sur notre site web à l’adresse

www.milwaukeetool.com

Additionally, we have a nationwide network of

authorized Distributors ready to assist you with your

tool and accessory needs. Check your “Yellow Pages”

phone directory under “Tools-Electric” for the names

& addresses of those nearest you or see the

'Where To Buy' section of our website.

Corporate After Sales Service - Technical Support

Brookfield, Wisconsin USA

•Technical Questions •Service/Repair Questions •Warranty

1-800-SAWDUST

(1.800.729.3878)

fax:1.800.638.9582

email: metproductsupport@milwaukeetool.com

Monday-Friday • 8:00 AM - 4:30 PM • Central Time

MEXICO

Servicios de MILWAUKEE

Milwaukee Electric Tool

Blvd. Abraham Lincoln no. 13

Colonia Los Reyes Zona Industrial

Tlalnepantla, Edo. México C.P. 54073

Tel. 55 5565-1414 Fax: 55 5565-6874

Adicionalmente, tenemos una red nacional de

distribuidores autorizados listos para ayudarle con

su herramienta y sus accesorios. Por favor, llame

al 55 5565-1414 para obtener los nombres y

direcciones de los más cercanos a usted, o consulte

la sección ‘Where to buy’ (Dónde comprar) de

nuestro sitio web en

www.milwaukeetool.com

MILWAUKEE ELECTRIC TOOL CORPORATION

13135 West Lisbon Road • Brookfield, Wisconsin, U.S.A. 53005

58-14-3370d7 10/04 Printed in Taiwan

page 20

Loading...

Loading...