Page 1

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Catalog No.

No de Cat.

Catálogo No.

6497

10" MAGNUM® SLIDE COMPOUND MITER SAW

SCIE À ONGLETS COMBINÉE COULISSANTE MAGNUM® 254 mm (10")

SIERRA ANGULAR DE DISCOS DE CORTE COMPUESTO MAGNUM®, DE

254 mm (10") DE DIÁMETRO

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN COMPRENDRE LE

MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL MANUAL DEL

OPERADOR.

Page 2

page 2

Page 3

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below, may result in

electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

1. Keep work area clean and well lit. Cluttered, dark work areas

invite accidents.

2. Avoid dangerous environments. Do not use your power tool in

rain, damp or wet locations or in the presence of explosive atmospheres (gaseous fumes, dust or flammable materials). Remove

materials or debris that may be ignited by sparks.

3. Keep bystanders away. Children and bystanders should be kept

at a safe distance from the work area to avoid distracting the operator and contacting the tool or extension cord.

4. Protect others in the work area from debris such as chips and

sparks. Provide barriers or shields as needed.

5. Make workshop child proof with padlocks, master switches, or

by removing starter keys.

ELECTRICAL SAFETY

6. Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify the plug

in any way. Do not use any adaptor plugs. Check with a qualified

electrician if you are in doubt as to whether the outlet is properly

grounded. If the tool should electrically malfunction or break down,

grounding provides a low resistance path to carry electricity away

from the user.

7. Double insulated tools are equipped with a polarized plug

(one blade is wider than the other). This plug will fit in a

polarized outlet only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet. Do not change

the plug in any way. Double insulation eliminates the need for

the three wire grounded power cord and grounded power supply

system.

8. Guard against electric shock. Prevent body contact with

grounded surfaces such as pipes, radiators, ranges and refrigerators. When making blind or plunge cuts, always check the work area

for hidden wires or pipes. Hold your tool by insulated nonmetal

grasping surfaces. Use a Ground Fault Circuit Interrupter (GFCI) to

reduce shock hazards.

9. Do not expose to rain or use in damp locations.

10. Do not abuse the cord. Never use the cord to carry the tools

or pull the plug from an outlet. Keep cord away form heat,

oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

PERSONAL SAFETY

11. Know your power tool. Read this manual carefully to learn your

power tools applications and limitations as well as potential hazards associated with this type of tool.

12. Stay alert, watch what you are doing, and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A mo-

ment of inattention while operating power tools may result in serious

personal injury.

13. Dress properly. Do not wear loose clothing or jewelry. Wear a

protective hair covering to contain long hair. These may be caught in

moving parts. When working outdoors, wear rubber gloves and

insulated non-skid footwear. Keep hands and gloves away from

moving parts.

14. Reduce the risk of unintentional starting. Be sure your tool is

turned off before plugging it in. Do not use a tool if the power switch

does not turn the tool on and off. Do not carry a plugged-in tool with

your finger on the switch.

15. Remove all adjusting keys and wrenches. Make a habit of

checking that adjusting keys, wrenches, etc. are removed from the

tool before turning it on.

16. Do not overreach. Maintain control. Keep proper footing and

balance at all times. Maintain a firm grip. Use extra care when using

tool on ladders, roofs, scaffolds, etc.

17. Use safety equipment. Everyone in the work area should wear

safety goggles or glasses with side shields complying with

current safety standards. Everyday eyeglasses only have impact

resistant lenses. They are not safety glasses. Wear hearing protection during extended use and a dust mask for dusty operations. Hard

hats, face shields, safety shoes, etc. should be used when specified or necessary. Keep a fire extinguisher nearby.

18. Keep guards in place and in working order.

19. Never stand on tool. Serious injury could occur if the tool is tipped

or if the cutting tool is unintentionally contacted.

20. Keep hands away from all cutting edges and moving parts.

TOOL USE AND CARE

21. Secure work. Use a clamp, vise or other practical means to hold

your work securely, freeing both hands to control the tool.

22. Do not force tool. Your tool will perform best at the rate for which

it was designed. Excessive force only causes operator fatigue,

increased wear and reduced control.

23. Use the right tool. Do not use a tool or attachment to do a job for

which it is not recommended. For example, do not use a circular

saw to cut tree limbs or logs. Do not alter a tool.

24. Unplug tool when it is not in use, before changing accessories or

performing recommended maintenance.

25. Store idle tools. When not in use, store your tool in a dry, secured

place. Keep out of reach of children.

26. Never leave the tool running unattended. Turn power off. Do

not leave the tool until it comes to a complete stop.

27. Check for damaged parts. Inspect guards and other parts before use. Check for misalignment, binding of moving parts, improper

mounting, broken parts and any other conditions that may affect

operation. If abnormal noise or vibration occurs, turn the tool off

immediately and have the problem corrected before further use. Do

not use a damaged tool. Tag damaged tools DO NOT USE until

repaired. A guard or other damaged part should be properly repaired

or replaced by a MILWAUKEE service facility. For all repairs, insist

on only identical replacement parts.

page 3

Page 4

28. Use proper accessories. Consult this manual for recommended

accessories. Using improper accessories may be hazardous. Be

sure accessories are properly installed and maintained. Do not defeat a guard or other safety device when installing an accessory or

attachment.

29. Maintain tools carefully. Keep handles dry, clean and free from

oil and grease. Keep cutting edges sharp and clean. Follow instructions for lubricating and changing accessories. Periodically inspect

tool cords and extension cords for damage. Have damaged parts

repaired or replaced by a MILWAUKEE service facility.

30. Maintain labels & nameplates. These carry important information. If unreadable or missing, contact a MILWAUKEE service facility for a free replacement.

SPECIFIC SAFETY RULES

SERVICE

31. Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified per-

sonnel may result in a risk of injury.

32. When servicing a tool, use only identical replacement parts.

follow instructions in the maintenance section of this

manual. Use of unauthorized parts or failure to follow maintenance

instructions may create a risk of shock or injury.

1. WARNING! Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known

to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

lead from lead-based paint

crystalline silica from bricks and cement and other masonry

products, and

arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specifically designed

to filter out microscopic particles.

2. Always keep hands away from the path of the saw blade.

3. Do not defeat the guards of operate the tool without the

guards in place.

4. Always support work properly. Use the fence, support blocks,

auxiliary work support or clamps to keep workpiece secure. Always support the free end of the workpiece and support all small

workpieces. Workpieces that bow and pinch the blade may result in

kick back. Do not perform any operations freehand (unsupported).

5. Never reach around, under or across blade.

6. Check guards for smooth operation before each use.

7. Avoid kick back. Kick back is a violent reaction to a pinched or

binding blade, which throws the saw head upward and towards

the operator. Proper workpiece selection and support, proper blade

selection and maintenance, and even feed rate are essential to

reduce the risk of kick back.

8. Always wait for the blade to stop completely before changing positions, retrieving a cut-off piece, or preparing the next cut.

Unplug the tool before tightening blade screw, servicing, making

adjustments, transporting or moving the saw to another location.

9. Be sure the clamp handle and the bevel adjustment lever

are tightened securely before making cuts.

10. Do not use abrasive wheels with the miter saw.

11. Use the right blade. Use only recommended blade types and

sizes with proper mounting holes, rated at least 5500 RPM. Follow

the rotation arrow on the blade to be sure you install it properly.

Keep saw blades sharp to help prevent cracking and grabbing.

Never use defective or incorrect washers or bolts.

12. Do not lock the trigger in the on position.

13. Wait for the blade to reach full speed before lowering the

saw head to make a cut.

14. Keep the cord away from the cutting area and position it so that

it will not be tripped over or caught on the workpiece while you are

cutting.

15. Do not place hands under the saw motor or in the path of

the blade. Do not retrieve a piece of material that is cut off while the

blade is rotating. Never place hands or fingers behind or in front of

the saw blade.

16. Keep blades clean and sharp. An unsharpened or improperly

sharpened blade produces a narrow kerf and is likely to be pinched

by the workpiece. A dull blade produces excessive friction which

can cause the blade to warp or bind. Be sure the blade screw is

tight to prevent slipping or loosening during operation.

17. Restarting in mid-cut. If you stop the saw in mid-cut, allow the

blade to stop, then raise the saw out of the cut. Then restart the

saw.

18. If the blade stalls, do not turn the switch on and off. A dull

blade or excess pressure may cause stalling. Release the switch

immediately if the blade binds or the saw stalls and remove the saw

from the cut.

19. Avoid cutting nails. Inspect for and remove all nails before cutting.

20. Thin material tends to warp or sag and must be well-supported

over its entire length to avoid pinching the blade.

21. Position fence properly. The flip fence can be adjusted for compound cuts and miter cuts. Always make sure the fence is adjusted

for the intended cut. Never operate the saw without the fence in

place.

22. Lock the saw head down and lock the sliding mechanism

before transporting.

23. Push the saw through the workpiece. Do not pull the saw

through the workpiece. To make a cut, raise saw head and pull it

out OVER the workpiece WITHOUT cutting, start the motor, wait a

few seconds for the blade to reach full speed, press down on saw

head, and push saw head through the cut.

page 4

Page 5

Symbology

Specifications

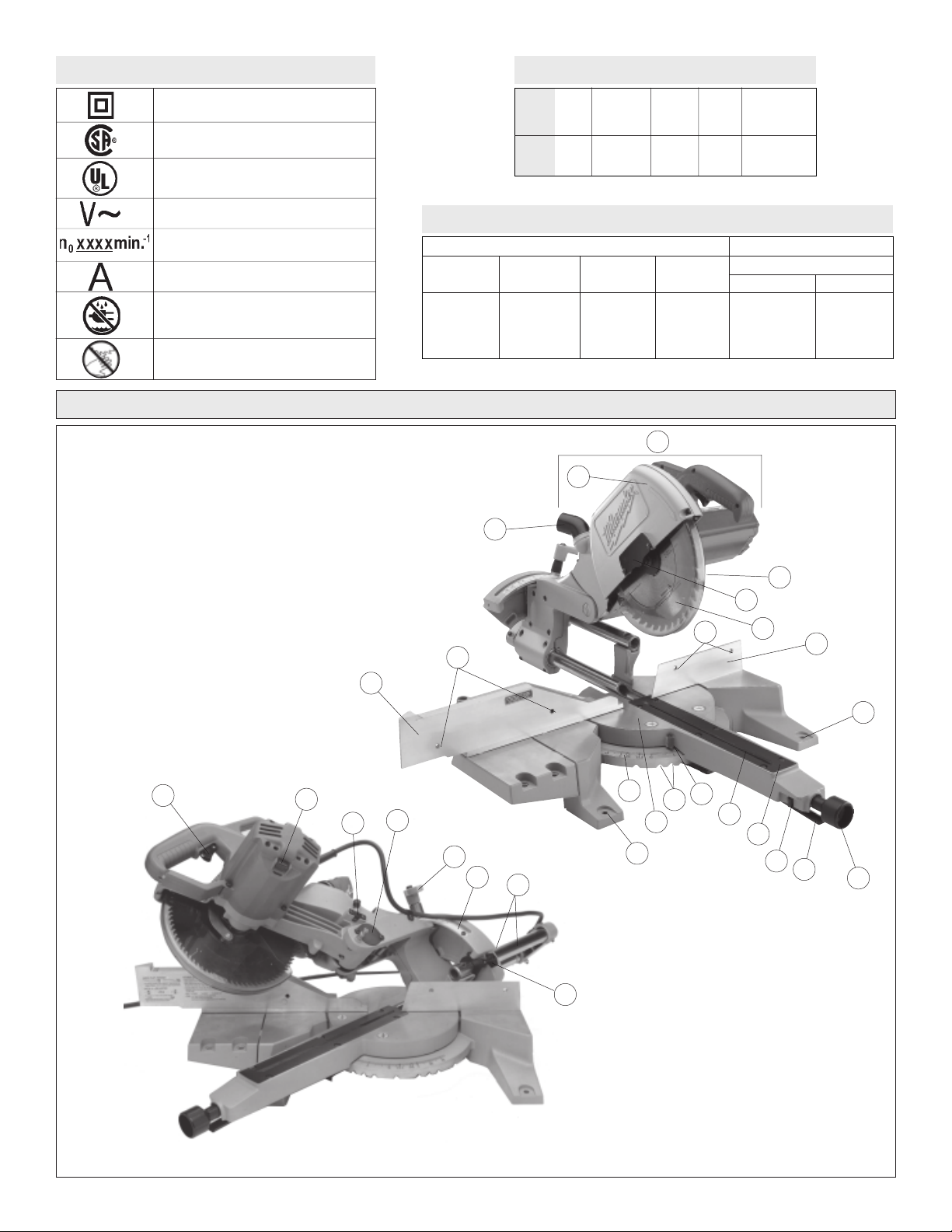

1. Saw head

2. Upper guard

3. Lower guard

4. Blade screw guard

5. Blade

6. Fence

7. Clamp handle

8. Detent override lever

9. Detent override lock

10. Kerf plate

11. Kerf plate slot

12. Pointer

13. Positive angle stops

14. Turntable

15. Miter angle scale

16. Mounting holes (4)

Double Insulated

Canadian Standards

Association

Underwriters

Laboratories, Inc.

Volts Alternating Current

No Load Revolutions

per Minute (RPM)

Amperes

Do not expose to rain or use in

damp locations.

Always keep hands away from

the path of the saw blade.

FUNCTIONAL DESCRIPTION

17. Flip fence

18. Face board mounting holes (4)

19. Dust ejection port

20. Trigger

21. Spindle lock

22. Depth adjustment set screw

23. Lock pin

24. Bevel adjustment lever

25. Bevel angle scale

26. Slide rails

27. Slide rail lock

17

Max Height

at 90°

3-29/32" H

at 8-1/2" W

19

18

Catalog

Number

6497

Volts

AC

120

Amps

15

No Load

RPM

4800

Arbor

Size

5/8"

Blade

Size

10"

Capacities

Miter Cuts Compound Cuts

Max Height

at 45°

3-29/32" H at

6" W

2

Max Width

at 90°

12-3/8" W at

3-7/16" H

Max Width

at 45°

8-3/4" W at

3-7/16" H

1

45° Miter and 45° Bevel

Max Height

2-3/8" W at

7-9/16" H

3

4

18

5

Max Width

8-3/4" W at

2-1/8" H

6

16

20

21

22

23

24

25

26

27

15

16

14

13

12

11

10

9

8

7

page 5

Page 6

GROUNDING EXTENSION CORDS

WARNING!

Improperly connecting the grounding wire can result in the

risk of electric shock. Check with a qualified electrician if

you are in doubt as to whether the outlet is properly

grounded. Do not modify the plug provided with the tool.

Never remove the grounding prong from the plug. Do not

use the tool if the cord or plug is damaged. If damaged, have

it repaired by a MILWAUKEE service facility before use. If the

plug will not fit the outlet, have a proper outlet installed by

a qualified electrician.

Grounded Tools:

Tools with Three Prong Plugs

Tools marked Grounding Required

have a three wire cord and three

prong grounding plug. The plug must

be connected to a properly grounded

outlet (See Figure A). If the tool should

electrically malfunction or break

down, grounding provides a low resistance path to carry electricity

away from the user, reducing the risk

of electric shock.

The grounding prong in the plug is connected through the green wire

inside the cord to the grounding system in the tool. The green wire in the

cord must be the only wire connected to the tool's grounding system and

must never be attached to an electrically live terminal.

Your tool must be plugged into an appropriate outlet, properly installed

and grounded in accordance with all codes and ordinances. The plug

and outlet should look like those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked Double Insulated do

not require grounding. They have a

special double insulation system

which satisfies OSHA requirements

and complies with the applicable

standards of Underwriters Laboratories, Inc., the Canadian Standard

Association and the National Electrical Code. Double Insulated tools may

be used in either of the 120 volt outlets shown in Figures B and C.

Fig. A

Fig. B

Fig. C

Grounded tools require a three wire extension cord. Double insulated

tools can use either a two or three wire extension cord. As the distance

from the supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a

serious drop in voltage, resulting in loss of power and possible tool

damage. Refer to the table shown to determine the required minimum

wire size.

The smaller the gauge number of the wire, the greater the capacity of the

cord. For example, a 14 gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension cord to make up the

total length, be sure each cord contains at least the minimum wire size

required. If you are using one extension cord for more than one tool, add

the nameplate amperes and use the sum to determine the required minimum wire size.

Guidelines for Using Extension Cords

If you are using an extension cord outdoors, be sure it is marked

with the suffix W-A (W in Canada) to indicate that it is acceptable

for outdoor use.

Be sure your extension cord is properly wired and in good electrical

condition. Always replace a damaged extension cord or have it

repaired by a qualified person before using it.

Protect your extension cords from sharp objects, excessive heat

and damp or wet areas.

Recommended Minimum Wire Gauge

Nameplate

Amperes

8.1 - 12

12.1 - 15

15.1 - 20

* Based on limiting the line voltage drop to five

volts at 150% of the rated amperes.

for Extension Cords*

25'

0 - 5

5.1 - 8

16

16

14

12

10

Extension Cord Length

100'

50'

16

16

14

12

10

75'

16

14

12

10

10

14

12

10

10

150'

12

10

--

--

--

--

200'

12

--

--

--

--

READ AND SAVE ALL INSTRUCTIONS

FOR FUTURE USE.

page 6

Page 7

TOOL ASSEMBLY

WARNING!

To reduce the risk of injury, always unplug tool before

attaching or removing accessories or making adjustments.

Use only specifically recommended accessories. Others

may be hazardous.

Mounting the Miter Saw

To prevent the tool from sliding, falling or tipping during operation, the

saw can be mounted to a supporting surface such as a level, sturdy

work table or bench. Position the saw and workbench to allow adequate

room for cross-cutting long workpieces. To mount the saw, insert fasteners through the four holes in the base of the saw.

Installing the Clamp Handle

The clamp handle locks the selected miter angle. The tool is shipped with

the handle unassembled. To install the handle, thread it clockwise into

the tool. To tighten the handle and lock the angle, turn the handle clockwise. To loosen and unlock, turn it counterclockwise.

Installing Dust Bag or Vacuum Hose

A dust bag is provided to collect sawdust. To install the dust bag, push

the dust bag onto the dust ejection port. This port is also designed to

accept a standard workshop vacuum hose. To collect sawdust directly

into a vacuum cleaner, attach the vacuum cleaner hose to the dust

ejection port and turn it on before cutting.

Raising and Lowering the Saw Head

The saw head locks down for transporting and storing the tool. The tool

is shipped with the saw head locked down. To unlock it, press and hold

down the saw head and simultaneously pull out the lock pin. To lock the

saw head, press and hold down the saw head and then push in the lock

pin.

Locking and Unlocking the The Sliding Mechanism

Lock the sliding mechanism to transport and store the tool. To unlock it,

loosen the slide rail lock by turning it counterclockwise. To lock it, tighten

the slide rail lock by turning it clockwise. Always lock the sliding mechanism before transporting the saw.

Lock-Off

There is a hole in the trigger through which a padlock will fit to lock the

tool when it is not in use. Use a padlock with a 1/4" shackle and always

unplug the tool before installing it (padlock not supplied with tool).

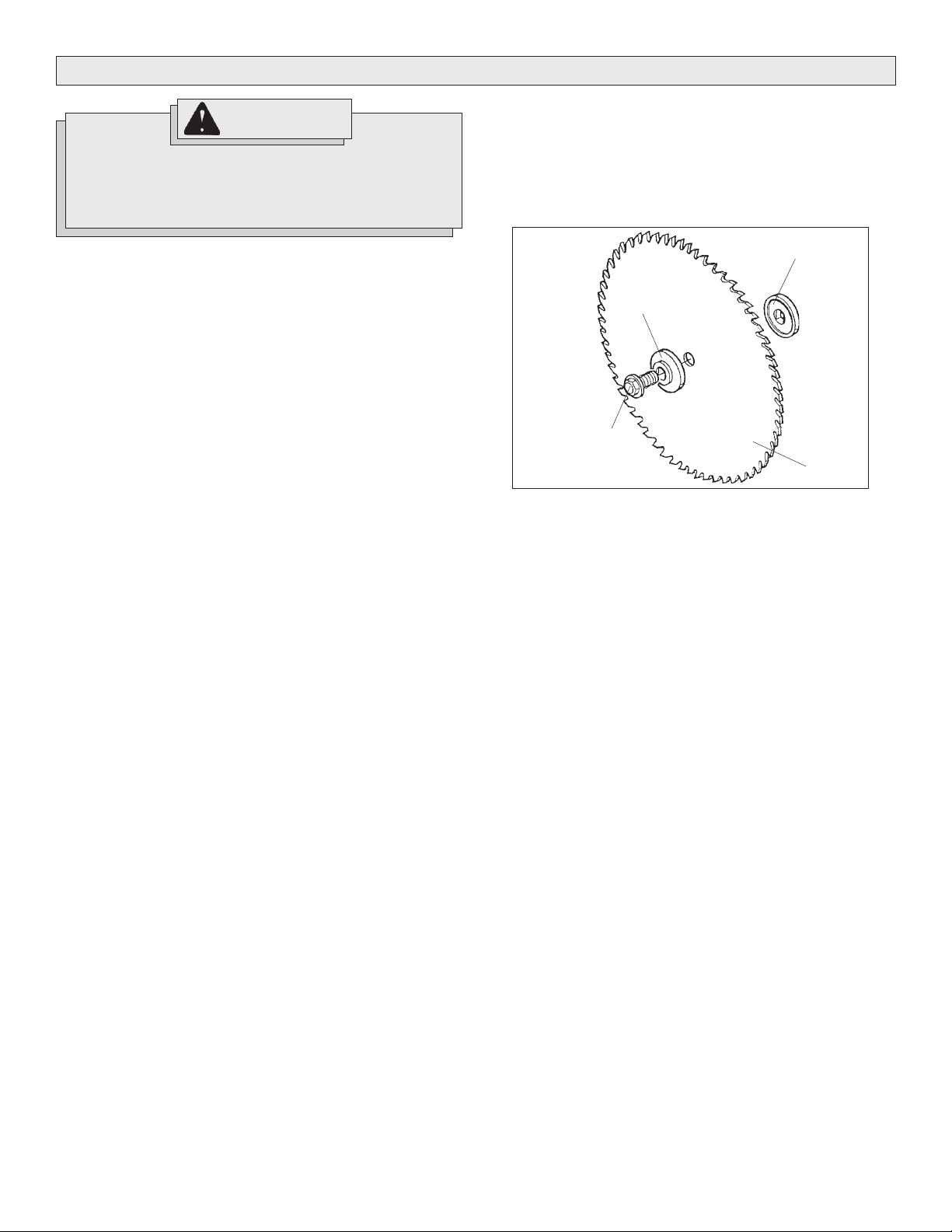

Installing and Changing Blades (Fig. 1)

MILWAUKEE offers a full line of carbide-tipped Miter Saw blades. Always use clean, sharp blades because dull blades tend to overload the

tool, bind and cause pinching. Use only 10" blades rated at least 5500 RPM.

Fig. 1

Outer flange

Blade screw

1. To install a blade, unplug the tool.

2. Raise the saw head.

3. Loosen (do not remove) the two screws on the blade screw guard

counterclockwise.

4. Rotate blade screw guard to expose blade screw.

5. Press in the spindle lock and rotate the spindle until the lock engages.

6. Use the wrench supplied with the tool to loosen and remove the lefthand thread blade screw clockwise (wrench is stored behind the

right fence in wrench holder).

7. Lift and hold up the lower guard.

8. Remove the outer blade flange, blade (if present), and the inner

blade flange. Wipe the flanges and spindle to remove dust and

debris.

9. Install the inner blade flange as shown.

10. Match the arrow on the blade with the arrow on the tool casting.

Install the selected blade by sliding the blade between the gap in the

fence and then lifting the blade up to the spindle.

11. Install the outer blade flange.

12. Press in the spindle lock and rotate the blade until lock engages

while replacing and securely tightening the blade screw counterclockwise with supplied wrench.

13. Rotate the blade screw guard into position and securely tighten the

two screws clockwise. Return the wrench to the wrench holder.

14. Lower the saw head and check the clearance between the blade

and the turntable. The blade should rotate freely.

NOTE: If you are installing the blade for the first time, be aware that

kerf plates (which come uncut) need to be cut before use. See

"Cutting the Kerf Plate Slot".

Inner flange

Blade

A Note About Kerf Plates

The purpose of the kerf plate is to eliminate tear-out (splintering along the

cut) by providing edge support for the workpiece. Because saw blades

can vary in width, to get the best possible edge support and alignment

and to reduce tear-out, each blade (or width of blade) should have its

own kerf plate.

page 7

Page 8

OPERATION

WARNING!

To reduce the risk of injury, wear safety goggles or glasses

with side shields. Always wait for the blade to stop completely and unplug the tool before changing accessories or

making adjustments. Do not defeat the guards.

Collecting Dust

For dust collection, MILWAUKEE recommends using either Dust Bag No.

48-09-1025 or a MILWAUKEE Vacuum Cleaner. The dust tube is de-

signed to accept a standard vacuum hose and swivels for convenience.

Using Face Boards

There are face board mounting holes in the fences for attaching face

boards. Face boards place distance between the fence and the

workpiece, providing improved support for some workpieces. For example, as the width of the face board increases, the height of the

workpiece which can be cut increases slightly (but the width capacity

decreases slightly). Similarly, if you place a face board on the saw table

and place a workpiece on top of the face board, you can cut a workpiece

with greater width (but with less height).

Guards

The tool is shipped with both the upper and lower guard installed. The

lower guard should cover the blade when the saw head is up and it

should open automatically as the saw head is lowered into the workpiece.

If the lower guard appears loose or if it does not move to cover the blade

when the saw head is up, take the saw to an authorized service center

for repairs. Do not attempt to open the guard further than the automatic

action permits. The tool is designed so that when the guard is opened

with the saw head in the up position, the saw head cannot be lowered.

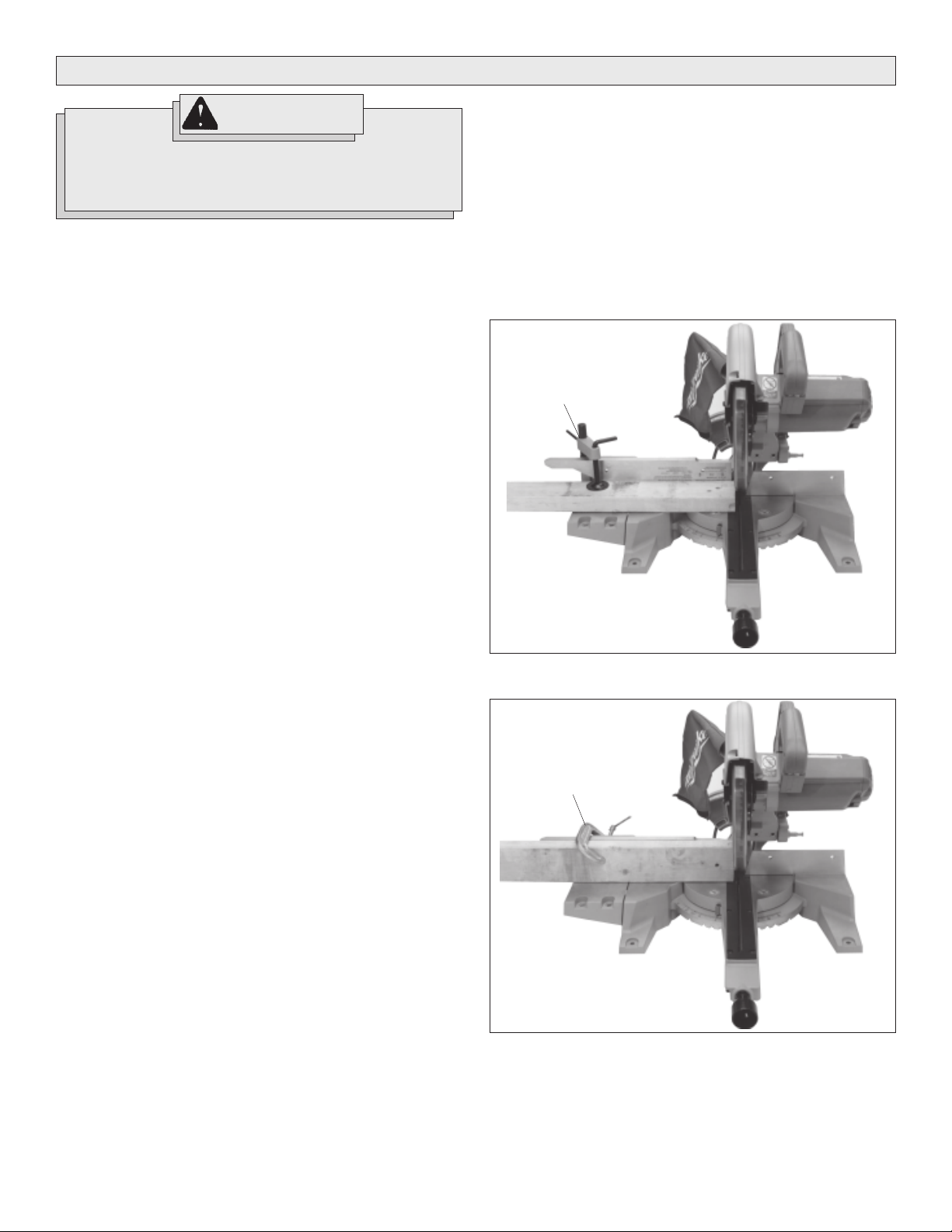

Support the Workpiece Properly (Figs. 2 & 3)

Always support the workpiece during operation. Otherwise, the

workpiece may pull up and into the saw. While there are many ways to

support and secure workpieces, MILWAUKEE advises using one of the

following three methods.

1. Use the Fence: Align the workpiece flush against the fence as

shown to provide a straight path for the saw blade. This will help

eliminate the tendency for the blade teeth to bind. The fence can be

used as a support for miter, bevel and compound cuts.

2. Use Vise No. 49-52-0310: Clamp the workpiece to the base using

the MILWAUKEE vise (Fig. 2). The vise fits into the slot on the back

of the left fence.

Fig. 2

Vise

Select the Workpiece Carefully

Be cautious of pitchy, knotty, wet or warped workpieces. These materials are likely to create pinching conditions. Workpieces that bow and

pinch may result in kick back. Inspect for and remove nails before cutting. Always keep blades clean and sharp; otherwise the blade produces a narrow kerf and is likely to be pinched by the workpiece. This

tool is not recommended for cutting ferrous metals such as iron and

steel. See Applications for a more complete list of materials.

3. Use a C-clamp: Clamp the workpiece to the fence with a C-clamp

(Fig. 3).

Fig. 3

C-clamp

Support of Longer Workpieces

Longer workpieces need support along their length. If you are using the

saw on a level work bench, prop up the workpiece with a small piece of

2x4 on its edge. (The saw base surface is 3 1/2" (the width of a 2x4)

from the bottom of the saw feet.) There are also many aftermarket work

tables specifically designed for miter saws that provide supports for all

types of workpieces.

page 8

Page 9

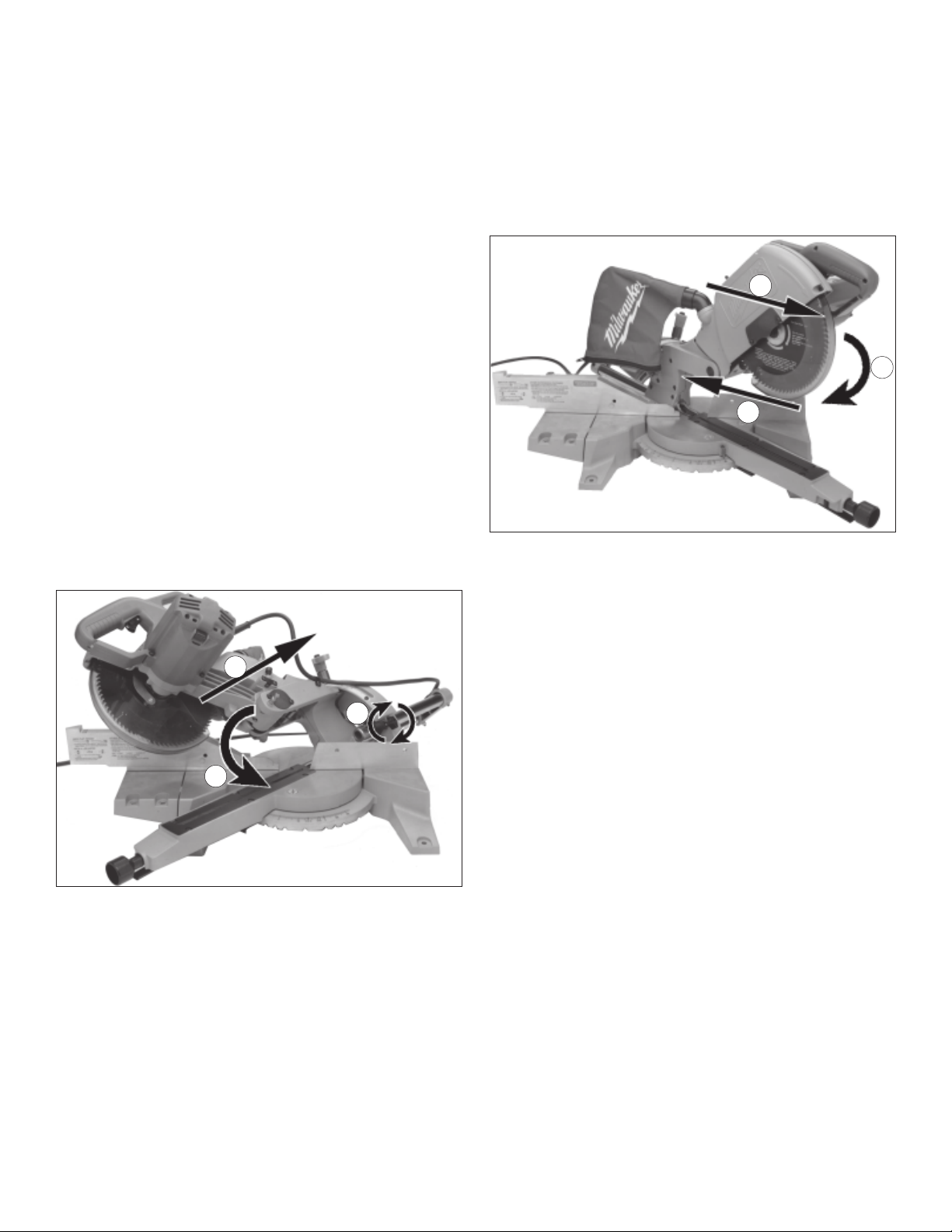

Adjusting the Miter Angle

®

The miter mechanism on the MILWAUKEE Magnum

Slide Compound

Miter Saw has detent settings for commonly cut angles (0°, 15°, 22.5°

30°, and 45°). These detents make for quick, accurate set up of common

angles. In addition to the spring-loaded detents there is also a detent

override. The detent override, when engaged, allows the turntable to

smoothly rotate to any miter angle. The turntable can be easily locked at

any miter angle. The detent override is especially useful when making

small adjustments near 0°, 15°, 22.5° 30°, and 45°.

The saw cuts miter angles from 51° on the left to 59° on the right. Angle

markings appear on the scale that runs along the perimeter of the base.

1. To select a positive angle stop, loosen the clamp handle.

Pull the detente override lever and rotate the turntable to the desired

angle.

Tighten the clamp handle.

2. To select other angles, use the override mechanism, which allows

quick and accurate adjustments at any angle.

Pull up on the detent override lever and lock it by pushing in the

detent override lock.

Rotate the turntable to the desired angle.

Tighten the clamp handle securely clockwise.

Adjusting the Bevel Angle

The bevel mechanism has two positive sping-loaded stops: one at 0°

and one at 45°. The mechanism can be adjusted to any angle in between

by using the bevel angle scale. The bevel mechanism also has several

degrees of overtravel on both the left and right; the saw can be adjusted

to 48° on the left and to negative 3° on the right. To obtain the overtravel,

apply several pounds of force on the saw handle to override the springloaded stops. Do not attempt to exceed the stated overtravel.

1. To adjust the bevel angle, place one hand on the front handle for

better control. Using the other hand, loosen the bevel adjustment

lever counterclockwise

2. Pull or push the saw handle to desired position, using the bevel

angle scale as a guide.

3. Tighten the bevel adjustment lever clockwise securely.

Adjusting the Depth of Cut (Fig. 4)

A hex cap screw with a lock nut controls the depth of cut. This cut can

be adjusted when cutting grooves, rabbets, or other operations

Fig. 4

Socket

head cap

screw

locknut

Using the Flip Fence (Fig. 5, 6, & 7)

The quick-change flip fence can be positioned for simple miter cuts

(Fig. 5) and for bevel and compound cuts (Fig. 6). This helps to provide

superior support for both types of cuts.

Fig. 5

For miter cuts

Fig. 6

For bevel and

compound cuts

1. To adjust the fence, loosen the fence lock lever (counterclockwise)

(Fig. 7). When the fence lock lever is parallel with the fence slot, pull

the fence away from the saw. A firm detent must be overridden to

accomplish this.

Fig. 7

Fence lock lever

Fence slot

2. Position the fence for the desired cut. Always position the fence

properly for maximum work support.

3. With the fence lock lever parallel to the fence, insert the fence lock

lever through the fence slot. Turn the fence lock lever clockwise to

secure the fence to the tool.

NOTE: The clamp on the mechanism must be rotated to a vertical

position, 90° to the slot. This position is required for proper clamping.

Starting and Stopping the Tool

Always hold the handle firmly because the starting and stopping action

of the motor may cause the handle to move up or down slightly. Always

secure the turntable by tightening the clamp handle when setting miter

angles. Always make sure the spindle lock is released so the blade is

free to rotate.

1. To start the motor, pull the trigger.

2. To stop the motor, release the trigger.

1. Unplug the tool.

2. Loosen the lock nut by turning counterclockwise.

3. To set the saw for maximum depth of cut, unscrew the hex cap

screw so that it doesn't extend from the bottom of the saw arm.

To limit the depth of cut, screw the hex cap screw through the saw

arm. The more the screw is driven through the shallower the cut is.

4. Securely tighten the lock nut.

5. Make a sample cut and adjust as necessary.

page 9

Page 10

WARNING!

To reduce the risk of injury, do not rely on the brake as a

safety feature. Always wait until the blade stops completely

before allowing anything near the blade.

Electric Brake

The electric brake engages when the trigger is released, causing the

blade to stop and allowing you to proceed with your work. Generally the

saw blade stops in four to five seconds. However, there may be a delay

between the time the trigger is released and the time the brake engages.

Occasionally the brake may miss completely. If the brake misses frequently, the saw needs servicing by an authorized MILWAUKEE ser-

vice station. The brake is not a substitute for the guards, so it is essential

to always wait for the blade to stop completely before removing the

blade from the kerf. The correct brush grade must be used for proper

operation of the brake. Use only identical MILWAUKEE replacement

brushes when servicing the tool.

Cutting the Kerf Plate Slot

The tool is shipped with the kerf plate installed; never attempt to make a

cut without the plate installed. The kerf plate is NOT factory-cut, so the

first cut you make with the tool will be to create a kerf slot. The angle of

the kerf slot for compound cuts is different than that for miter cuts.

Therefore, it is necessary to cut new kerf slots for each type of angle.

Generally, it is best to cut a kerf slot before cutting a workpiece.

When cutting a kerf slot, be sure to use the blade you intend to use for

your work since blades have different widths that affect the kerf. When

changing from a thick blade to a thinner one, you may want to purchase

a new kerf plate and cut a new kerf slot. Also, bevel cuts require a

different kerf slot than miter cuts, so always be sure to cut a new slot for

bevel cuts. Cut the kerf slot following the procedure below.

1. Make sure that the slide rail lock is loose and that the saw head

moves freely back and forth on the slide rails.

2. Raise saw head and pull it out OVER the kerf plate WITHOUT cutting.

3. Start the motor. Wait a few seconds for the blade to reach full

speed.

4. Press down on the saw head. To help prevent damaging the kerf

plate, gently and slowly lower the saw head to the full depth of cut

(the point where the saw head will not lower any further). When the

cut is complete, release the trigger. WAIT FOR THE BLADE TO STOP

COMPLETELY before gently raising the saw head.

5. Push saw through the cut.

1. Slide the saw head back on the slide rails so that the blade is closest

to the fence (1).

2. Tighten the slide rail lock (2).

3. Plug in the tool. Raise the saw head completely.

4. Select the desired angles following the steps in "Adjusting the Miter

Angle" and "Adjusting the Bevel Angle".

5. Place the workpiece on the turntable and line up the cut.

6. Support the workpiece using any of the methods described in "Support the Workpiece Properly".

7. Start the motor. Wait a few seconds for the blade to reach full

speed. Then gently lower the saw head into the workpiece all the

way through the cut (3).

8. Always allow the saw to do the work. Forcing the tool may stall or

overheat the motor.

9. After the cut is complete, release the trigger and wait for the blade

to stop completely. Then gently raise the saw head and remove the

workpiece. Always unplug the tool before retrieving loose cut-off

pieces from inside the guard area.

Making a Sliding Cut (Fig. 9)

Cut workpieces with chop cuts whenever possible. A chop cut is always faster and easier to make than a sliding cut. Cut wider workpieces

using the sliding mechanism.

Fig. 9

1

2

3

Making a Chop Cut (Fig. 8)

The Magnum® Slide Compound Miter saw can be used to make chop cuts

(cuts not requiring the use of the slide mechanism). Cut workpieces with

chop cuts whenever possible. A chop cut is always faster and easier to

make than a sliding cut.

Fig. 8

1

2

3

page 10

1. Make sure that the slide rail lock is loose and that the saw head

moves freely back and forth on the slide rails.

2. Select the desired angle following the steps in "Adjusting the Miter

Angle" and "Adjusting the Bevel Angle".

3. Place the workpiece on the turntable and line up the cut.

4. Raise saw head and pull it out OVER the workpiece WITHOUT cutting (1).

5. Start the motor. Wait a few seconds for the blade to reach full

speed.

6. Press down on saw head (2).

7. Push saw through the cut (3).

8. After the cut is complete, release the trigger and wait for the blade

to stop completely. Then gently raise the saw head and remove the

workpiece. Always unplug the tool before retrieving loose cut-off

pieces from inside the guard area.

Page 11

APPLICATIONS

Recommended Materials and Applications

The following materials can be cut with the slide compound miter saw.

There are many types of saw blades available. Always use the proper

blade for the particular material and application.

Wood

solid wood, plywood, particle board, MDF (medium density fiberboard), HDF (high density fiberboard), melamine laminated particle

board, formica laminates, hardboard (masonite).

Plastics

PVC, CPVC, ABS, solid surfacing materials (such as Corian®), and

other plastic materials.

Nonferrous Metals

aluminum, brass, copper, and other non-ferrous materials.

WARNING!

Do not cut stone, brick, concrete, or ferrous metals (iron,

steel, stainless steel, or alloys of these metals) with this

saw.

Do not use abrasive wheels with this saw.

Dust created by cutting these materials and/or using abra-

sive cut-off wheels can jam the blade guard and possibly

cause personal injury.

Cutting Non-Square Materials

Cutting Round (Cylindrical) Materials

"V" shaped blocks can be used to support round materials like closet rod

and plastic pipe.

Cutting Compound Miters (Fig. 11)

The chart below identifies miter and bevel settings for various types of

crown molding for 90° corners. Note that these are ideal settings and

may vary because many moldings have slightly different spring angles

and some walls are not perfectly square. Fig. 11 illustrates the relationship between the spring angle, the ceiling, the wall and the molding.

Type of Crown

(spring angle)

30°

35°

38°

40°

45°

52°

* Wood is positioned flat on the miter saw table.

Fig. 11

Wall

Spring

angle

Miter

(angle of table)

26.6°

29.8°

31.6°

32.7°

35.3°

38.2°

Ceiling

Bevel

(tilt of blade)

37.8°

35.4°

33.9°

32.8°

30°

25.8°

Aluminum Sash and Other Channel Type and Materials (Fig. 10)

Aluminum sash material can be supported with blocks to prevent it from

deforming while it is being cut (Fig. 10).

Fig. 10

Fence

Base

Clamp

Wood support block

Aluminum material

Wood support block

page 11

Page 12

MAINTENANCE

ACCESSORIES

WARNING!

To reduce the risk of injury, always unplug your tool before

performing any maintenance. Never disassemble the tool or

try to do any rewiring on the tool's electrical system. Contact

a MILWAUKEE service facility for ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a regular maintenance program. Before use, examine the general condition of your tool. Inspect

guards, switches, tool cord set and extension cord for damage. Check

for loose screws, misalignment, binding of moving parts, improper mounting, broken parts and any other condition that may affect its safe operation. If abnormal noise or vibration occurs, turn the tool off immediately

and have the problem corrected before further use. Do not use a damaged tool. Tag damaged tools DO NOT USE until repaired

(see Repairs).

Under normal conditions, relubrication is not necessary until the motor

brushes need to be replaced. After six months to one year, depending on

use, return your tool to the nearest MILWAUKEE service facility for the

following:

Lubrication

Brush inspection and replacement

Mechanical inspection and cleaning (gears, spindles, bearings,

housing, etc.)

Electrical inspection (switch, cord, armature, etc.)

Testing to assure proper mechanical and electrical operation

WARNING!

To reduce the risk of injury, always unplug the tool before

attaching or removing accessories. Use only specifically

recommended accessories. Others may be hazardous.

For a complete listing of accessories refer to your MILWAUKEE Electric

Tool catalog or go on-line to www.milwaukeetool.com. To obtain a

catalog, contact your local distributor or a service center.

Vise

Cat. No. 49-52-0310

Secures workpiece to the miter saw base.

Dust Bag

Cat. No. 48-09-1025

Collects dust to help keep the work area clean.

Kerf Plate

Cat. No. 49-52-0405

Same as supplied with the tool. Use a new kerf plate when changing

from a thick to a thinner blade or if the kerf slot enlarges due to blade

deflection.

Guide Rod Assembly

Cat. No. 49-52-0110

Fasten guide rods to the miter saw base to provide added support for

longer workpieces.

WARNING!

To reduce the risk of injury, electric shock and damage to the

tool, never immerse your tool in liquid or allow a liquid to flow

inside the tool.

Cleaning

Clean dust and debris from vents. Keep the tool handles clean, dry and

free of oil or grease. Use only mild soap and a damp cloth to clean your

tool since certain cleaning agents and solvents are harmful to plastics

and other insulated parts. Some of these include: gasoline, turpentine,

lacquer thinner, paint thinner, chlorinated cleaning solvents, ammonia

and household detergents containing ammonia. Never use flammable or

combustible solvents around tools.

Repairs

If your tool is damaged, return the entire tool to the nearest service

center.

page 12

FIVE YEAR TOOL LIMITED WARRANTY

Every MILWAUKEE tool is tested before leaving the factory and is warranted to be free from defects in material and workmanship. MILWAUKEE

will repair or replace (at MILWAUKEEs discretion), without charge, any

tool (including battery chargers) which examination proves to be defective in material or workmanship from five (5) years after the date of

purchase. Return the tool and a copy of the purchase receipt or other

proof of purchase to a MILWAUKEE Factory Service/Sales Support

Branch location or MILWAUKEE Authorized Service Station, freight pre-

paid and insured. This warranty does not cover damage from repairs

made or attempted by other than MILWAUKEE authorized personnel,

abuse, normal wear and tear, lack of maintenance, or accidents.

Battery Packs, Flashlights, and Radios are warranted for one (1) year

from the date of purchase.

THE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN ARE

EXCLUSIVE. IN NO EVENT SHALL MILWAUKEE BE LIABLE FOR ANY

INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES, INCLUDING

LOSS OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, OR CONDITIONS, WRITTEN OR ORAL, EXPRESSED OR IMPLIED FOR

MERCHANTABLILITY OR FITNESS FOR PARTICULAR USE OR PURPOSE.

This warranty gives you specific legal rights. You may also have other

rights that vary from state to state and province to province. In those

states that do not allow the exclusion of implied warranties or limitation

of incidental or consequential damages, the above limitations or exclusions may not apply to you. This warranty applies to the United States,

Canada, and Mexico only.

Page 13

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT!

VOUS DEVEZ LIRE ET COMPRENDRE TOUTES LES INSTRUCTIONS

Le non-respect, même partiel, des instructions ci-après entraîne un risque de choc

électrique, d'incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS

AIRE DE TRAVAIL

1. Conservez votre lieu de travail propre et bien éclairé. Les

endroits sombres et encombrés sont propices aux accidents.

2. Évitez les milieux dangereux. Ne vous servez pas de votre outil

électrique sous la pluie ou dans les endroits mouillés ou humides, les

atmosphères propices aux explosions (émanations de gaz, poussière

ou substances inflammables). Faites disparaître les matériaux qui

risquent dêtre enflammés par les étincelles.

3. Éloignez les spectateurs. Les enfants et les spectateurs devraient

être tenus à distance du lieu de travail, afin de ne pas déranger

lutilisateur et être à labri de tout contact avec loutil et le cordon de

rallonge.

4. Protégez ceux qui se trouvent sur les lieux des éclats et des

étincelles. Installez des barrières ou des écrans protecteurs si

nécessaire.

5. Faites de votre atelier un lieu sécuritaire pour les enfants

on installant des cadenas, un interrupteur principal et en retirant les

clés de démarrage.

SÉCURITÉ ÉLECTRIQUE

6. Les outils mis à la terre doivent être branchés dans une

prise de courant correctement installée et mise à la terre

conformément à tous les codes et règlements pertinents.

Ne modifiez jamais la fiche de quelque façon que ce soit,

par exemple en enlevant la broche de mise à la terre.

Nutilisez pas dadaptateur de fiche. Si vous nêtes pas cer-

tain que la prise de courant est correctement mise à la

terre, adressez-vous à un électricien qualifié. En cas de

défaillance ou de défectuosité électrique de loutil, une mise à la

terre offre un trajet de faible résistance à lélectricité qui autrement

risquerait de traverser lutilisateur.

7. Les outils à double isolation sont équipés dune fiche

polarisée (une des lames est plus large que lautre),

qui ne peut se brancher que dune seule façon dans une

prise polarisée. Si la fiche nentre pas parfaitement dans la

prise, inversez sa position ; si elle nentre toujours pas

bien, demandez à un électricien qualifié dinstaller

une prise de courant polarisée. Ne modifiez pas la fiche de

loutil. La double isolation élimine le besoin dun cordon

dalimentation à trois fils avec mise à la terre ainsi que dune prise de

courant mise à la terre.

8. Protégez-vous des chocs électriques. Evitez tout contact avec

les surfaces mises à la terre tels les radiateurs, cuisinières et

réfrigérateurs. Lorsque vous enfoncez loutil à laveuglette au travers

dun matériau assurez-vous dabord quil ny pas de câbles électriques

ou de tuyaux. Tenez loutil par ses parties isolées non métalliques.

Employez un coupe-circuit relié à la masse (GFCI) pour réduire les

risques de choc.

9. N'exposez pas l'outil aux intempéries et ne vous en servez

pas dans les endroits humides.

10. Ne maltraitez pas le cordon. Ne transportez pas loutil par

son cordon et ne débranchez pas la fiche en tirant sur le

cordon. Nexposez pas le cordon à la chaleur, à des huiles, à

des arêtes vives ou à des pièces en mouvement. remplacez

immédiate-ment un cordon endommagé. Un cordon

endommagé augmente le risque de choc électrique.

SÉCURITÉ DES PERSONNES

11. Famiiliarisez-vous avec votre outil électrique. Lisez

attentivement ce manual pour apprendre les applications, limitations

et risues inhérent au maniement de ce genre doutil.

12. Restez alerte, concentrez-vous sur votre travail et faites

preuve de jugement. Nutilisez pas un outil électrique si

vous êtes fatigué ou sous linfluence de drogues, dalcool

ou de médicaments. Un instant dinattention suffit pour entraîner

des blessures graves.

13. Habillez-vous correctement. Ne portez ni vêtements amples ni

bijoux. Portez un casque protecteur pour contenir les longs cheveux

et les empêcher de se prendre dans les pièces en mouvement. Si

vous travaillez à lextérieur, portez des gants de caoutchouc et des

chaussures à semelles antidérapantes. Tenez vos mains ou vos

gants à lécart des pièces en mouvement.

14. Réduisez les risques de démarrage accidentel. Assurez-vous

que votre outil est à la position darrêt « OFF » avant de le brancher.

Nutilisez pas un outil dont linterrupteur ne fonctionne pas

normalement. Ne transportez pas un outil branché en gardant les

doigts sur la détente.

15. Retirez les clés de réglage. Prenez lhabitude de vérifier si les

clés de réglage et autres outils sont retirés de loutil avant de le

mettre en marche.

16. Ne dépassez pas les limites, contrôlez loutil. Gardez les

pieds bien en place et assurez votre équilibre. Tenez loutil fermement.

Soyez très prudent si vous utilisez loutil dans une échelle, sur un

toit, un échafaud, etc.

17. Employez de léquipement de sécurité. Toutes les personnes

présentes dans laire de travail devraient porter des lunettes de

protection ou à coques latérales conformes aux normes de

sécurité en vigueur. Les lunettes ordinaires peuvent être pourvues

de verres résistants, mais elles ne sont pas sécuritaires. Portez des

protecteurs doreilles pour les tâches prolongées et un masque

facial contre la poussière. Un casque rigide, un masque facial, des

chaussures de sécurité, etc. devraient être utilisés lorsque la situation lexige. Gardez un extincteur dincendie à portée de la main.

18. Maintenez les gardes en place et en bon état.

19. Ne vous appuyez jamais sur l'outil. De graves blessures

pourraient résulter du renversement de l'outil ou de son démarrage

accidentel.

20. Tenez les mains à lécart des arêtes tranchantes et des

pièces en mouvement.

UTILISATION ET ENTRETIEN DES OUTILS

21. Assujettissez louvrage. Employez une fixation, pince-étau ou

autre dispositif approprié pour maintenir solidement louvrage et libérer

vos deux mains pour le maniement de loutil.

22. Ne forcez pas loutil. Votre outil fournira un meilleur rendement si

vous lemployez comme il doit lêtre. Un usage excessif, en plus de

fatiguer lutilisateur, augmentera lusure de loutil et rendra son

maniement plus difficile.

23. Employez loutil approprié. Nutilisez pas un outil ou un accessoire

non approprié à la tâche. Par exemple, on ne doit pas employer une

scie circulaire pour tailler un arbre ou scier des bûches. Naltérez

pas loutil.

24. Débranchez loutil lorsque vous ne vous en servez pas ou avant

den changer les accessoires ou den effectuer lentretien.

page 13

Page 14

25. Rangez les outils que vous n'utilisez pas au sec dans un

endroit sûr, hors de la portée des enfants.

26. Ne laissez jamais l'outil en marche sans surveillance. Avant

de vous en éloigner, coupez le courant et attendez qu'il soit

complètement arrêté.

27. Décelez les pièces défectueuses. Avant de vous servir de

loutil, inspectez les gardes et les autres pièces. Vérifiez lalignement

et le jeu des pièces mobiles, les vices de montage, bris de pièces et

toute autre condition pouvant nuire au bon fonctionnement de loutil.

Si un bruit ou une vibration insolite survient, arrêtez immédiatement

loutil et faites-le vérifier avant de vous en servir de nouveau.

Nutilisez pas un outil défectueux. Fixez-y une étiquette marquée

« HORS DUSAGE » jusquà ce quil soit réparé. Si une garde ou une

autre pièce est défectueuse, elle devrait être réparée ou remplacée

dans un centre de service MILWAUKEE accrédité. Insistez pour

obtenir des pièces de rechange identiques.

28. Employez les accessoires appropriés. Consultez ce manuel

pour connaître quels accessoires utiliser. Lemploi daccessoires

autres que ceux qui sont recommandés peut comporter des risques.

Assurez-vous que les accessoires sont correctement installés et

entretenus. Ne dérangez pas un garde ou autre dispositif de sécurité

lorsque vous installez un accessoire.

RÈGLES DE SÉCURITÉ PARTICULIÈRE

29. Prenez soin de loutil. Gardez les poignées propres, sèches et

exemptes dhuile ou de graisse. Maintenez les tranchants propres et

vifs. Suivez les instructions de graissage et dinstallation des

accessoires. Inspectez périodiquement le cordon de loutil et le cordon de rallonge. Faites réparer ou remplacer les pièces défectueuses

à un centre de service MILWAUKEE accrédité.

30. Entretenez les étiquettes et marques du fabricant. Les indications quelles contiennent sont précieuses. Si elles deviennent

illisibles ou si elles se détachent, faites-les remplacer gratuitement à

un centre de service MILWAUKEE accrédité.

RÉPARATION

31. La réparation des outils électriques doit être confiée à un

réparateur qualifié. Lentretien ou la réparation dun outil électrique

par un amateur peut avoir des conséquences graves.

32. Pour la réparation dun outil, nemployez que des pièces de

rechange dorigine. Suivez les directives données à la

section « réparation » de ce manuel. Lemploi de pièces non

autorisées ou le non-respect des instructions dentretien peut créer

un risque de choc électrique ou de blessures.

1. AVERTISSEMENT! La poussière degage par perçage, sclage,

perçage et autres travaux de construction contient des substances

chimiques reconnues comme pouvant causer le cancer, des malformations congénitales ou dautres troubles de reproduction. Voici

quelques exemples de telles substances :

Le plomb contenu dans la peinture au plomb.

Le silice cristallin contenu dans la brique, le béton et divers

produits de maçonnerie.

Larsenic et le chrome servant au traitement chimique du bois.

Les risque associés à lexposition à ces substances varient,

dépendant de la fréquence des travaux. Afin de minimiser lexposition

à ces substances chimiques, assurez-vous de travailler dans un

endroit bien aéré et dutiliser de lequipement de sécurité tel un masque

antipoussière spécifiquement conçu pour la filtration de particules

microscopiques.

2. Tenez toujours les mains à l'écart de la ligne de coupe.

3. Ne faussez pas les gardes et n'employez pas l'outil si les

gardes ne sont pas en place.

4. Supportez correctement le matériau. Servez-vous du réglet,

de blocs dappui, de fixations ou autres auxiliaires pour assujettir le

matériau à couper. Supportez toujours le tronçon du morceau à

couper et les morceaux de petite dimension. Un matériau qui se plie

et coince la lame peut provoquer un mouvement de recul. Ne faites

pas de coupe en tenant le matériau avec les mains, sans appui.

5. Nallongez jamais les mains autor, en dessous ou en travers

de la lame.

6. Vérifiez si les gardes fonctionnent bien avant chaque tâche.

7. Évitez le mouvement de recul. Le mouvement de recul est une

réaction violente de loutil vers le haut ou larrière lorsque la lame

reste coincée durant la coupe. Une bonne maîtrise de loutil est

essentielle pour contrer le mouvement de recul.

8. Attendez toujours l'arret complet de la lame avant de changer

de position, de retirer un tronçon ou de préparer la coupe suivante.

Débranchez loutil pour serrer la vis de lame, faire de lentretien ou

des réglages, déplacer la scie ou la transporter.

9. Assurez-vous que la poignée de réglage d'angle et le levier

régleur de biseau sont serrés à fond avant defaire une

coupe.

10. Nemployez pas une meule abrasive aec la scie à onglets.

11. Utilisez une lame appropriée. Nutilisez que des lames de type et

de dimension recommandés, dont le trou darbre est conforme et le

calibre adéquat pour une rotation dau moins 5 500 t/min. Observez

la flèche indiquant le sens de la rotation sur la lame et installez celleci correctement. Gardez les lames de scie bien aiguisées pour éviter

de les craqueler ou de les gripper. Nemployez jamais une rondelle

ou un boulon incorrects ou en mauvais état.

12. Ne calez pas la détente en position de marche.

13. Attendez que la lame ait atteint son plein régime avant

d'abaisser la scie pour faire une coupe.

14. Tenez le cordon à lécart de la ligne de coupe et placez-le pour

quil ne nuise pas et quil ne semmêle pas avec le matériau.

15. Ne placez pas les mains sous le moteur de la scie, ni en

travers de la ligne de coupe. Nessayez pas de retirer un tronçon

de matériau pendant que la lame tourne encore. Ne placez jamais les

mains ou les doigts derrière la lame.

16. Gardez les lames propres et bien affûtées. Une lame émoussée

ou mal aiguisée produit un trait étroit et risque de rester coincée

dans le matériau. Une lame émoussée produit une friction excessive

qui peut causer le gauchissement ou le coincement. Assurez-vous

que la vis de lame est bien serrée pour éviter que la lame ne se

relâche ou ne glisse durant la coupe.

17. Démarrage à mi-coupe. Si vous devez arrêter la scie durant la

coupe, laissez la lame sarrêter complètement et retirez la scie de

lentaille. Ensuite, remettez loutil en marche pour continuer la coupe.

18. Si la lame reste coincée, n'essayez pas de remettre la scie

en marche en jouant avec la détente. Une lame émoussée ou

une trop grande pression sur loutil peuvent causer le coincement de

la lame dans le matériau. Si cela se produit, relâchez immédiatement

la détente et retirez la scie de lentaille.

19. Évitez les clous. Inspectez le matériau et enlevez-en les clous

avant de commencer la coupe.

20. Les matériaux minces ont tendance à plier ou à saffaisser. Ils

doivent être bien supportés sur toute leur étendue pour éviter que la

lame de la scie reste coincée dans le matériau durant la coupe.

21. Placez correctement le réglet. Le réglet à bascule peut être

ajusté pour des coupes combinées ou en biseau. Assurez-vous

toujours quil est correctement placé pour chaque genre de coupe.

Ne vous servez jamais de la scie sans que le réglet ne soit en place.

22. Avant de déplacer l'outil, abaissez la tête de scie, verrouillez-

la et verrouillez aussi le mécanisme à glissière.

23. Poussez la scie en travers du matériau. Ne la tirez pas à

reculons. Pour faire une coupe, relevez la tête de la scie et tirez-la

PAR-DESSUS le matériau sans scier. Mettez le moteur en marche,

attendez quelques secondes que la lame atteigne son plein régime,

abaissez la tête de la scie, et tête de scie de poussée par la coupe.

page 14

Page 15

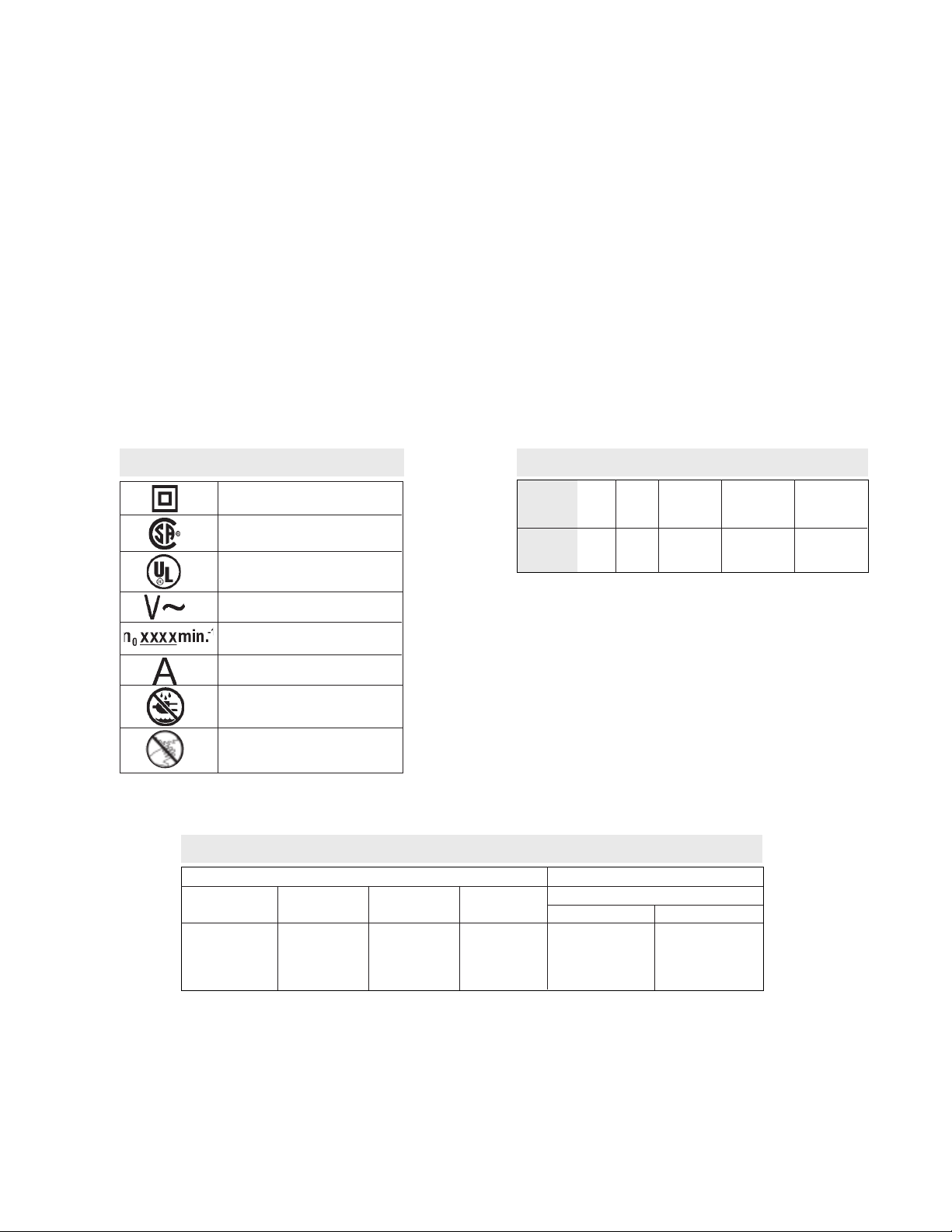

Pictographie

Spécifications

Double Isolation

lAssociation canadienne

de normalisation (ACNOR)

Underwriters

Laboratories, Inc.

Couvant alternatif

Tours-minute á vide (RPM)

Ampères

N'exposez pas l'outil aux intempéries

et ne vous en servez pas dans les

endroits humides.

Tenez toujours les mains à l'écart de

la ligne de coupe.

1. Tête de scie

2. Garde supérieur

3. Garde-lame inférieur

4. Garde-vis de lame

5. Lame

6. Réglet

7. La poignée de réglage

d'angle

8. Positionneur à crabots

9. Verrou du positionneur

à crabots

10. Plaque d'entaille

11. Fente d'entaille

12. Indicateur

13. Réglage d'angles à

crabots

14. Table tournante

15. Échelle d'onglets

16. Trous de montage (4)

DESCRIPTION FONCTIONNELLE

17. Réglet à bascule

18. Planche d'appui trous de

montage(4)

19. Capteur de poussière

20. Détente

21. Verrou du pivot

22. Vis de calage du réglage de

profondeur

23. Goujon de blocage

24. Levier régleur de bisseau

25. Échelle d'angles

26. Glissière

27. Verrou de glissière

17

Hauteur

max. à 90°

100 mm H à

216 mm L

(3-29/32" H à

8-1/2" L)

18

No de

Cat.

6497

Volts

CA

120

Ampères

15

T/Min.

à vide

4 800

Dim.

pivot

5/8"

Calibre de

lame

254 mm

(10")

Capacité

Coupes en onglet Coupes combinées

Hauteur

max. à 45°

100 mm H à

152 mm L

(3-29/32" H

19

à 6" L)

Lageur

max. à 90°

315 mm L à

87 mm H

(12-3/8" L à

3-7/16" H)

2

Lageur

max. à 45°

222 mm L à

87 mm H

(8-3/4" L à

3-7/16" H)

1

45° onglet x 45° biseau

Hauteur max.

60 mm L à

192 mm H

(2-3/8" L à

7-9/16" H)

3

4

18

5

Lageur max.

222 mm L à

54 mm H

(8-3/4" L à

2-1/8" H)

6

16

20

21

22

23

24

25

26

27

15

16

14

13

12

11

10

9

8

7

page 15

Page 16

MISE À LA TERRE

CORDONS DE RALLONGE

AVERTISSEMENT!

Si le fil de mise à la terre est incorrectement raccordé, il peut

en résulter des risques de choc électrique. Si vous nêtes

pas certain que la prise dont vous vous servez est

correctement mise à la terre, faites-la vérifier par un

électricien. Naltérez pas la fiche du cordon de loutil.

Nenlevez pas de la fiche, la dent qui sert à la mise à la terre.

Nemployez pas loutil si le cordon ou la fiche sont en

mauvais état. Si tel est le cas, faites-les réparer dans un

centre-service MILWAUKEE accrédité avant de vous en

servir. Si la fiche du cordon ne sadapte pas à la prise, faites

remplacer la prise par un électricien.

Outils mis à la terre :

Outils pourvus dune fiche de cordon à trois dents

Les outils marqués « Mise à la terre

requise » sont pourvus dun cordon

à trois fils dont la fiche a trois dents.

La fiche du cordon doit être branchée

sur une prise correctement mise à la

terre (voir Figure A). De cette façon,

si une défectuosité dans le circuit

électrique de loutil survient, le relais

à la terre fournira un conducteur à

faible résistance pour décharger le

courant et protéger lutilisateur contre

les risques de choc électrique.

La dent de mise à la terre de la fiche est reliée au système de mise à la

terre de loutil via le fil vert du cordon. Le fil vert du cordon doit être le seul

fil raccordé à un bout au système de mise à la terre de loutil et son autre

extrémité ne doit jamais être raccordée à une borne sous tension

électrique.

Votre outil doit être branché sur une prise appropriée, correctement

installée et mise à la terre conformément aux codes et ordonnances en

vigueur. La fiche du cordon et la prise de courant doivent être semblables

à celles de la Figure A.

Outils à double isolation :

Outils pourvus dune fiche de

cordon à deux dents

Les outils marqués « Double

Isolation » nont pas besoin dêtre

raccordés à la terre. Ils sont pourvus

dune double isolation conforme eux

exigences de lOSHA et satisfont aux

normes de lUnderwriters Laboratories, Inc., de lAssociation canadienne

de normalisation (ACNOR) et du

« National Electrical Code » (code national de lélectricité). Les outils à

double isolation peuvent être

branchés sur nimporte laquelle des

prises à 120 volt illustrées ci-contre

Figure B et C.

Fig. A

Fig. B

Fig. C

Si lemploi dun cordon de rallonge est nécessaire, un cordon à trois fils

doit être employé pour les outils mis à la terre. Pour les outils à double

isolation, on peut employer indifféremment un cordon de rallonge à deux

ou trois fils. Plus la longueur du cordron entre loutil et la prise de courant

est grande, plus le calibre du cordon doit être élevé. Lutilisation dun

cordon de rallonge incorrectement calibré entraîne une chute de voltage

résultant en une perte de puissance qui risque de détériorer loutil.

Reportez-vous au tableau ci-contre pour déterminer le calibre minimum

du cordon.

Moins le calibre du fil est élevé, plus sa conductivité est bonne. Par

exemple, un cordon de calibre 14 a une meilleure conductivité quun

cordon de calibre 16. Lorsque vous utilisez plus dune rallonge pour

couvrir la distance, assurez-vous que chaque cordon possède le calibre minimum requis. Si vous utilisez un seul cordon pour brancher

plusieurs outils, additionnez le chiffre dintensité (ampères) inscrit sur la

fiche signalétique de chaque outil pour obtenir le calibre minimal requis

pour le cordon.

Directives pour lemploi des cordons de rallonge

Si vous utilisez une rallonge à lextérieur, assurez-vous quelle est

marquée des sigles « W-A » (« W » au Canada) indiquant quelle est

adéquate pour usage extérieur.

Assurez-vous que le cordon de rallonge est correctement câblé et

en bonne condition. Remplacez tout cordon derallonge détérioré ou

faites-le remettre en état par une personne compétente avant de

vous en servir.

Tenez votre cordon de rallonge à lécart des objets ranchants, des

sources de grande chaleur et des endroits humides ou mouillés.

Calibres minimaux recommandés pour

signalétique

12,1 - 15,0

15,1 - 20,0

* Basé sur sur une chute de voltage limite de 5

volts à 150% de lintensité moyenne de courant.

les cordons de rallonge*

Fiche

Ampères

0 - 5,0

5,1 - 8,0

8,1 - 12,0

Longueur du cordon de rallonge (m)

7,6

15,2

16

16

14

12

10

16

16

14

12

10

22,8

16

14

12

10

10

30,4

14

12

10

10

--

45,7

12

10

--

--

--

60,9

12

--

--

--

--

LISEZ ATTENTIVEMENT CES INSTRUCTIONS

ET CONSERVEZ-LES POUR LES

CONSULTER AU BESOIN.

page 16

Page 17

MONTAGE DE L'OUTIL

AVERTISSEMENT!

Pour minimiser les risques de blessures, débranchez

toujours loutil avant dy faire des réglages, dy attacher ou

den enlever les accessoires. Lusage daccessoires autres

que ceux qui sont spécifiquement recommandés pour cet

outil peut comporter des risques.

Montage de la scie à onglets

Pour empêcher la scie de glisser, tomber ou basculer durant le travail,

elle peut être montée sur une surface de soutien solide et de niveau, une

table, un banc ou un établi. Placez la scie et la table de travail de façon à

laisser assez despace pour la coupe transversale des longs morceaux.

Pour monter la scie, insérez des boulons de fixation dans les quatre

trous de la base.

Installation de la poignée de réglage dangle

La poignée de réglage dangle sert à bloquer le réglage à longlet désiré.

Cet outil nest pas monté lorsque la scie est livrée. Pour linstaller, vissez

la poignée dans loutil en sens horaire, tel quindiqué. Pour serrer la

poignée et bloquer le réglage, tournez la poignée en sens horaire. Pour

desserrer la poignée et déverrouiller le réglage, tournez la poignée en

sens inverse-horaire.

Installation du sac à poussière ou du boyau daspiration

Un sac à poussière pour capter la sciure de bois. Pour installer le sac, il

suffit den pousser le col sur le capteur de poussière. Le capteur de

poussière est aussi conçu pour être raccordé au boyau standard dun

aspirateur datelier. Il suffit alors de raccorder le boyau de laspirateur au

capteur de poussière de la scie et de mettre laspirateur en marche au

moment de la coupe.

Relèvement et abaissement de la tête de scie

La tête de la scie se verrouille en position abaissée pour le transport et

le rangement. Au moment de la livraison, la tête est verrouillée en position

basse, pour la déverrouiller, appuyez légèrement sur la tête et en même

temps, tirez sur le goujon de verrouillage. Pour verrouiller la tête, pressezla et retenez-la vers le bas et poussez à fond le goujon de verrouillage.

Verrouillage et déverrouillage du mécanisme coulissant

Pour transporter ou ranger loutil, on peut en verrouiller le mécanisme

coulissant. Pour le déverrouiller, desserrez le verrou de la glissière en le

tournant en sens inverse-horaire. Pour verrouiller, serrez le verrou de la

glissière en le vissant en sens horaire. Verrouillez toujours le mécanisme

coulissant avant de transporter la scie.

Verrouillage de loutil

La détente est pourvue dun trou pour accueillir un cadenas pour verrouiller

loutil lorsquil ne sert pas. Utilisez un cadenas à étrier de 6 mm (1/4") et

débranchez loutil avant de linstaller. (Le cadenas nest pas fourni avec

loutil).

Installation et changement de lames (Fig. 1)

MILWAUKEE offre une gamme complète de lames de scie à onglets à

dents carburées. Employez toujours des lames propres et bien affûtées,

car les lames émoussées causent une surcharge à loutil et sont à risque

de coincement. Nemployez que des lames de 254 mm (10") calibrées

pour au moins 5 500 t/min.

Fig. 1

Bride extérieure

Vis de lame

1. Pour installer une lame, débranchez loutil.

2. Relevez la tête de la scie.

3. Dévissez (sens inverse-horaire), sans les retirer, les deux vis du

garde-vis de lame.

4. Faites tourner sur lui-même le garde-vis pour exposer la vis de lame.

5. Appuyez sur le verrou du pivot et tournez la lame jusquà ce que le

verrou senclenche.

6. À laide de la clé de lame qui accompagne loutil, dévissez et retirez

la vis de lame à filetage gaucher et la tournant en sens horaire. La

clé de lame se trouve dans le porte-clé derrière le réglet gauche.

7. Relevez et retenez le garde inférieur.

8. Retirez la bride de lame extérieure, la lame (sil y a lieu), puis la bride

de lame intérieure. Essuyez les brides et le pivot pour en enlever la

sciure et les rognures.

9. Installez la bride intérieure, tel quindiqué.

10. Alignez la flèche apparaissant sur la lame sur celle qui apparaît sur

loutil. Ensuite, installez la lame choisie en la faisant glisser par

louverture dans le réglet pour la relever jusquau pivot.

11. Mettez la bride extérieure en place sur le pivot.

12. Appuyez sur le verrou du pivot et faites tourner la lame jusquà ce

que le verrou senclenche, tandis que vous revissez la vis de lame

en sens inverse-horaire à laide de la clé.

13. Replacez le garde-vis de lame à sa position initiale et vissez les

deux vis en sens horaire. Replacez ensuite la clé dans le porte-clé.

14. Abaissez la tête de la scie et vérifier la clairance entre la lame et la

table tournante. La lame devrait passer librement.

N.B. Si vous installez une lame pour la première fois, rappelez-vous

que la plaque dentaille (livrée sans entaille) doit être entaillée avant

usage. Voir « Coupe du gabarit d'entaille ».

Bride intérieure

Lame

À-propos des plaques dentailles

Lutilité dune plaque dentaille est déviter léclatement du bois autour de

la coupe en soutenant les bords du matériau. Étant donné que les lames

de scie peuvent varier en épaisseur, il est nécessaire de se munir dune

plaque à lentaille de chaque lame pour protéger le bois de léclatement

lors de la coupe.

page 17

Page 18

MANIEMENT

AVERTISSEMENT!

Pour minimiser les risques de blessures, portez toujours

des lunettes de protection. Attendez l'arrêt complet de la

lame avant de procéder à des réglages ou des travaux de

maintenance de l'outil. Ne faussez pas les gardes.

Captage de la poussière

Pour capter la poussière, MILWAUKEE recommande dutiliser le sac à

poussière No 48-09-1025 (voir rubrique «Accessoires»), ou un aspirateur

MILWAUKEE. Le capteur de poussière pivotant est conçu pour être

raccordé à un boyau daspirateur standard.

Utilisation dune planche dappui

Le réglet est pourvu de trous pour y fixer une planche dappui. La planche

dappui sert à distancer le réglet du matériau et à fournir un plus grand

appui pour certains morceaux volumineux. Par exemple, si la largeur de

la planche dappui augmente, la hauteur du morceau à tailler pourra être

augmentée légèrement, tandis que la capacité de coupe en largeur

diminuera légèrement. De la même façon, si vous placez une planche

dappui sur la table de scie et quensuite vous placez un morceau à

couper sur la planche, vous pourrez faire une coupe plus large mais

moins haute.

Gardes

À la livraison, loutil est pourvu dun garde supérieur et dun garde inférieur

montés. Le garde inférieur devrait recouvrir la lame lorsque la tête est

relevée et il devrait se rétracter automatiquement lorsque la tête est

abaissée progressivement dans le matériau. Si le garde inférieur paraît

lâche ou sil ne recouvre pas la lame lorsque la tête est relevée, faites

corriger le défaut à un centre de service MILWAUKEE accrédité.

Nessayez pas de forcer la rétraction du garde au delà de sa rétraction

automatique. Loutil est conçu de telle façon que si le garde ne couvre

pas la lame en position relevée, il sera impossible dabaisser la tête de la

scie.

Choisissez soigneusement le matériau

Prenez garde aux matériaux goudronneux, humides, gondolés ou pleins

de noeuds, ces matériaux comportent un risque de coincement de la

lame. Les matériaux qui saffaissent et pincent la lame peuvent provoquer

un mouvement de recul de la scie. Décelez et enlevez les clous avant la

coupe. Gardez toujours la lame propre et tranchante, autrement, elle

produira un trait trop étroit qui favorisera le coincement dans le matériau.

Cet outil nest pas recommandé pour la coupe des métaux ferreux tels le

fer et lacier.

Supportez correctement le matériau (Figs. 2 & 3)

Le morceau à tailler doit toujours être supporté durant la coupe. Si le

matériau nest pas adéquatement appuyé, il aura tendance à se soulever

vers la scie. Il y a plusieurs façons de supporter et dassujettir les

matériaux, MILWAUKEE conseille les trois méthodes suivantes :

1. Servez-vous du réglet . Alignez le matériau sur le réglet, tel quindiqué,

afin de laisser une ligne de coupe droite à la lame. Ce procédé

éliminera la tendance des lames de scie à se coincer. Le réglet peut

servir de support pour une coupe en onglet, en biseau ou une coupe

combinée.

2. Utilisez létau No 49-52-0300. Fixez le matériau à la table à laide de

létau MILWAUKEE, tel quindiqué (Fig. 2). Létau sadapte dans la

fente au dos du réglet gauche.

Fig. 2

L'étau

3. Servez-vous dune presse à main. Fixez le matériau au réglet à

laide dune presse à main, tel quindiqué (Fig. 3).

Fig. 3

Presse à main

page 18

Soutien des matériaux longs

Les matériaux longs doivent être soutenus sur toute leur étendue. Si

vous sciez sur un établi de niveau, il suffira de soutenir le bout du

matériau à laide dun petit morceau de 2X4 (la surface de la base de la

scie est à 90 mm (3-1/2")(de hauteur, ce qui égale la largeur dun 2X4). Il

y a également sur le marché des tables douvrage, conçues spécialement

pour les scies à onglets, qui offrent le soutien nécessaire pour tout

genre de matériaux.

Page 19

Réglage de langle donglet

®

La scie à onglets combinée coulissante MILWAUKEE Magnum

est

pourvue dun mécanisme à onglets qui permet des réglages de crabots

aux angles les plus fréquemment utilisés (0°, 15°, 22,5°, 30° et 45°. Ce

mécanisme permet de faire, avec rapidité et exactitude, les coupes

angulaires les plus courantes. En outre,le mécanisme permet aussi

doutrepasser les réglages des crabots à ressorts permettant à la table

de tourner librement et dêtre bloquée à nimporte quel angle de coupe

autour des angles préréglés de 0°, 15°, 22,5°, 30° et 45°.

La scie coupe des angles donglet entre 51° à gauche et 59° à droite. Les

degrés dangles sont marqués sur léchelle apparaissant le long du

périmètre de la base.

1. Pour sélectionner un angle à butée fixe, assurez-vous que la

poignée de réglage dangle est desserrée.

Tirez sur le levier de blocage dangle et faites tourner la table jusquà

langle désiré. Serrez la poignée de réglage dangle.

2. Pour sélectionner dautres angles, la scie est pourvue dun

positionneur à crabots qui permet de faire des réglages rapides et

précis à nimporte quel angle.

Pour utiliser le positionneur, relevez le levier du positionneur et

verrouillez-le en enfonçant le verrou du positionneur. Ensuite, faites

tourner la table à langle désiré. Serrez la poignée de réglage en la

tournant à fond en sens horaire. Cette caractéristique est

particulièrement utile pour faire de petits réglages autour des angles

préréglés.

Réglage de langle de biseau

Le mécanisme de biseau est pourvu de deux réglages à ressort; lun à la

position 0° et lautre à 45°. Le mécanisme peut être ajusté à nimporte quel

angle intermédiaire à laide de léchelle dangles de biseau illustrée à

droite. Le mécanisme de biseau est pourvu de plusieurs degrés de