Milwaukee Tool 8977-20 User Manual [en, es, fr]

Cat. No.

No de cat.

8975-6

8977-20

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

HEAT GUNS

PISTOLETS À DÉCAPER

PISTOLAS DE CALOR

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S

MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN

COMPRENDRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL

MANUAL DEL OPERADOR.

GENERAL POWER TOOL SAFETY WARNINGS

WARNING READ ALL SAFETY WARNINGS AND ALL INSTRUCTIONS. Failure to

follow the warnings and instructions may result in electric shock, fi re and/or serious injury. Save

all warnings and instructions for future reference. The term “power tool” in the warn-

ings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

WORK AREA SAFETY

• Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of fl ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

ELECTRICAL SAFETY

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodifi ed plugs and matching outlets will

reduce risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use

of a cord suitable for outdoor use reduces the risk

of electric shock.

• If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

PERSONAL SAFETY

• Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the infl uence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

• Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

• Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your fi nger on the switch or energising power tools

that have the switch on invites accidents.

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

• Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

• Dress properly . Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

• If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

• Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

• Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such pre-

ventive safety measures reduce the risk of starting

the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

• Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits

etc., in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

SERVICE

• Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

2

IMPORTANT SAFETY INSTRUCTIONS

HEAT GUNS

READ THESE INSTRUCTIONS

• Know your work environment. Hidden areas such

as behind walls, ceilings, fl oors, soffi t boards and

other panels may contain fl ammable materials that

may ignite when using the heat gun in these locations. Ignition of these materials may not be readily

apparent and could result in property damage and

personal injury. Check these areas before applying

heat. If in doubt, use an alternate method. Pausing

or lingering in one spot may ignite the panel or the

material behind it. Keep heat gun moving to avoid

excessive temperatures.

• Do not direct the heat gun air airfl ow at clothing,

hair or other body parts. Do not use as a hair

dryer. Heat guns can produce 1100°F (593°C) or

more of fl ameless heat at the nozzle. Contact with

the air stream could result in personal injury.

• Do not use near fl ammable liquids or in explosive

atmospheres, such as in the presence of fumes,

gases or dust. The fl ameless heat from the heat

gun may ignite the dust or fumes. Remove materials

or debris that may become ignited from work area.

• Shield materials around the heated area to prevent property damage or fi re.

• Keep a fi re extinguisher nearby. Heat guns may

ignite fl ammable materials left in the work area.

• WARNING! Hot Surfaces. Always hold the heat

gun by the plastic enclosure. Do not touch

nozzle, accessory tips or store heat gun until

the nozzle has cooled to room temperature. The

metal nozzle requires approximately 20 minutes

to cool before it can be touched. Contact with the

nozzle or accessory tip could result in personal

injury. Place the heat gun in a clear area away from

combustible materials while cooling to prevent fl am-

mable materials from igniting.

• Do not cut off airfl ow by placing nozzle too close

to workpiece. Keep intake vents clean and clear of

obstructions. Restricting airfl ow may cause the heat

gun to overheat.

• Place the heat gun on a stable, level surface

when not hand held. Use the support pads or

support stand. Place cord in a position that won’t

cause the heat gun to tip over.

• Do not leave the heat gun unattended while running or cooling down. Inattention invites accidents.

• Store indoors in a dry location. Do not expose to

rain or moisture.

• Do not direct airfl ow directly on glass. The glass

may crack and could result in property damage or

personal injury.

• Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE Service facility for a free

replacement.

• WARNING Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to fi lter out microscopic particles.

IMPORTANT SAFETY INSTRUCTIONS

FOR REMOVING PAINT

WARNING Use extreme care when

stripping paint. Peelings, residue and vapors of

paint may contain lead, which is POISONOUS.

Pre-1977 paint may contain lead and paint

made before 1950 is likely to contain lead.

Hand to mouth contact with paint peelings or

residue from pre-1977 paint may result in lead

ingestion. Exposure to even low levels of lead

can cause irreversible brain and nervous

system damage. Y oung and unborn children are

especially vulnerable to lead poisoning. DO NOT

REMOVE LEAD-BASED PAINT WITH A HEAT

GUN. Before beginning your work, determine

whether the paint you are removing contains

lead. A local health department or a professional

who uses a paint analyzer can check the paint for

lead content. LEAD-BASED PAINT SHOULD BE

REMOVED ONL Y BY A PROFESSIONAL.

PERSONS REMOVING PAINT SHOULD

FOLLOW THESE GUIDELINES:

• W ork in a well ventilated area. If possible, move the

workpiece outdoors. If working indoors, open windows

and place an exhaust fan in a window. Be sure the fan

is moving air from inside to outside. Proper ventilation

will reduce the risk of inhaling chemicals found in the

fumes or dust created by using a heat gun.

• Remove or cover any carpets, rugs, furniture,

clothing, cooking utensils and air ducts to prevent

property damage from the paint peelings.

• Place drop cloths in the work area to catch paint

scrapings. Wear protective clothing such as hats,

extra work shirts and overalls. Paint scrapings may

contain chemicals that are hazardous.

• Work in one room at a time. Remove furnishings

or cover them and place in the center of the room.

Seal doorways with drop cloths to seal work area

from the rest of the building.

• Children, pregnant or potentially pregnant

women, and nursing mothers should not be near

work area until all work is completed and work area

is cleaned thoroughly.

• Wear a dust respirator mask or a dual filter

(dust and fume) respirator mask which has been

approved by the Occupational Safety and Health Administration (OSHA), the National Institute of Safety

and Health (NIOSH), or the United States Bureau

of Mines. These masks and replaceable fi lters are

readily available at major hardware stores. Be sure

the mask fi ts. Beards and facial hair may keep masks

from sealing properly. Change fi lters often. DISPOS-

ABLE PAPER MASKS ARE NOT ADEQUATE.

3

• Use caution when operating the heat gun. Keep

the heat gun moving to prevent excessive temperatures. Excessive heat can cause paint and other

materials to burn and cause fumes, which may be

inhaled by the operator.

• Keep work environment clean. Keep food and

drink away from work area. Wash hands, arms and

face and rinse mouth before eating and drinking. Do

not smoke, or chew gum or tobacco in the work area.

Paint scrapings and dust created from removing

paint may contain chemicals that are hazardous.

• Clean up all paint scraping and dust. DO NOT

SWEEP , DR Y DUST OR V ACUUM. Wet mop fl oors.

Use a wet cloth to clean all walls, sills and other sur-

GROUNDING

WARNING Improperly connecting the

grounding wire can result in the risk of electric

shock. Check with a qualifi ed electrician if you

are in doubt as to whether the outlet is properly

grounded. Do not modify the plug provided

with the tool. Never remove the grounding

prong from the plug. Do not use the tool if the

cord or plug is damaged. If damaged, have

it repaired by a MILWAUKEE service facility

before use. If the plug will not fi t the outlet,

have a proper outlet installed by a qualifi ed

electrician.

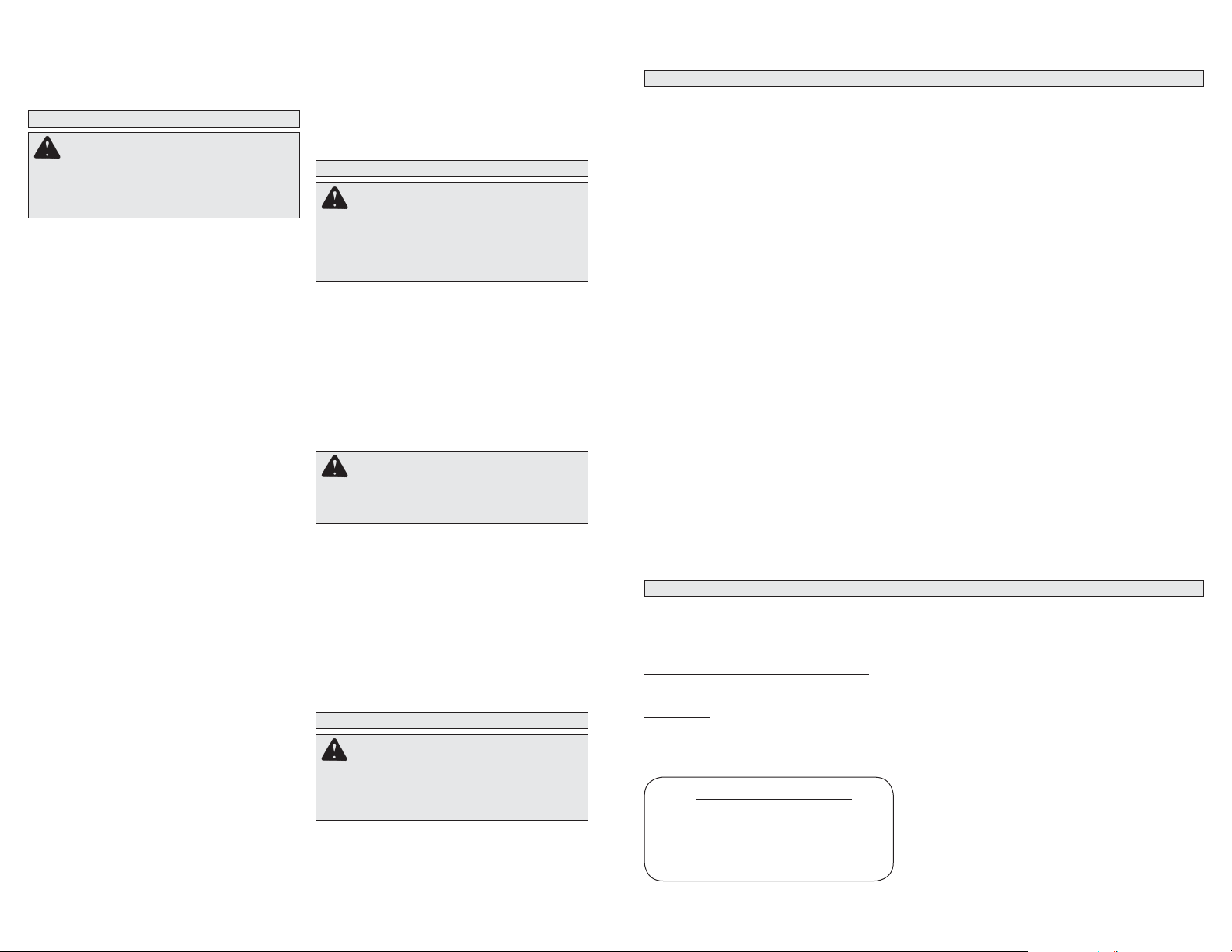

Grounded Tools: Tools with Three Prong Plugs

Tools marked “Grounding Required” have a three

wire cord and three prong grounding plug. The plug

must be connected to a properly grounded outlet (See

Figure A). If the tool should electrically malfunction

or break down, grounding provides a low resistance

path to carry electricity away from the user, reducing

the risk of electric shock.

The grounding prong in the plug is connected through

the green wire inside the cord to the grounding system

in the tool. The green wire in the cord must be the

only wire connected to the tool's grounding system

and must never be attached to an electrically

“live” terminal.

Your tool must be plugged into an

appropriate outlet, properly installed

and grounded in accordance with

all codes and ordinances. The plug

and outlet should look like those in

Figure A.

Double Insulated Tools: T ools with Two Prong Plugs

Tools marked “Double Insulated”

do not require grounding. They

have a special double insulation

system which satisfies OSHA requirements and complies with the

applicable standards of Underwriters Laboratories, Inc., the Canadian

Standard Association and the National Electrical Code. Double Insulated tools may

be used in either of the 120 volt outlets shown in

Figures B and C.

Fig. A

Fig. B

Fig. C

faces where paint and dust have accumulated. Use

a high phosphate detergent, trisodium phosphate

(TSP), or a trisodium phosphate substitute to clean

and mop the work area.

• Dispose of paint scrapings properly. Following

each work session, place paint scrapings in a double

plastic bag, close it with tape or twist ties and dispose.

• Remove protective clothing and work shoes

in the work area to avoid transferring dust to

other parts of the building. Wash work clothes

separately. Wipe shoes of f with a wet rag that is then

washed with the work clothes. Wash hair and body

thoroughly with soap and water.

SAVE THESE INSTRUCTIONS

EXTENSION CORDS

Grounded tools require a three wire extension cord.

Double insulated tools can use either a two or three

wire extension cord. As the distance from the supply

outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately

sized wire causes a serious drop in voltage, resulting

in loss of power and possible tool damage. Refer to

the table shown to determine the required minimum

wire size.

The smaller the gauge number of the wire, the greater

the capacity of the cord. For example, a 14 gauge

cord can carry a higher current than a 16 gauge cord.

When using more than one extension cord to make

up the total length, be sure each cord contains at

least the minimum wire size required. If you are using

one extension cord for more than one tool, add the

nameplate amperes and use the sum to determine

the required minimum wire size.

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors, be sure

it is marked with the suffi x “W-A” (“W” in Canada) to

indicate that it is acceptable for outdoor use.

• Be sure your extension cord is properly wired and in

good electrical condition. Always replace a damaged

extension cord or have it repaired by a qualifi ed

person before using it.

• Protect your extension cords from sharp objects,

excessive heat and damp or wet areas.

Recommended Minimum Wire Gauge

For Extension Cords*

Extension Cord Length

Nameplate Amps

0 - 2.0

2.1 - 3.4

3.5 - 5.0

5.1 - 7.0

7.1 - 12.0

12.1 - 16.0

16.1 - 20.0

* Based on limiting the line voltage drop to fi ve volts at

150% of the rated amperes.

25' 50' 75' 100' 150'

18

18

18

18

18

18

18

16

14

12

18

18

16

14

12

10

18

16

14

12

10

--

16

14

12

10

16

14

12

12

--

--

--

--

--

READ AND SAVE ALL

INSTRUCTIONS FOR FUTURE USE.

4

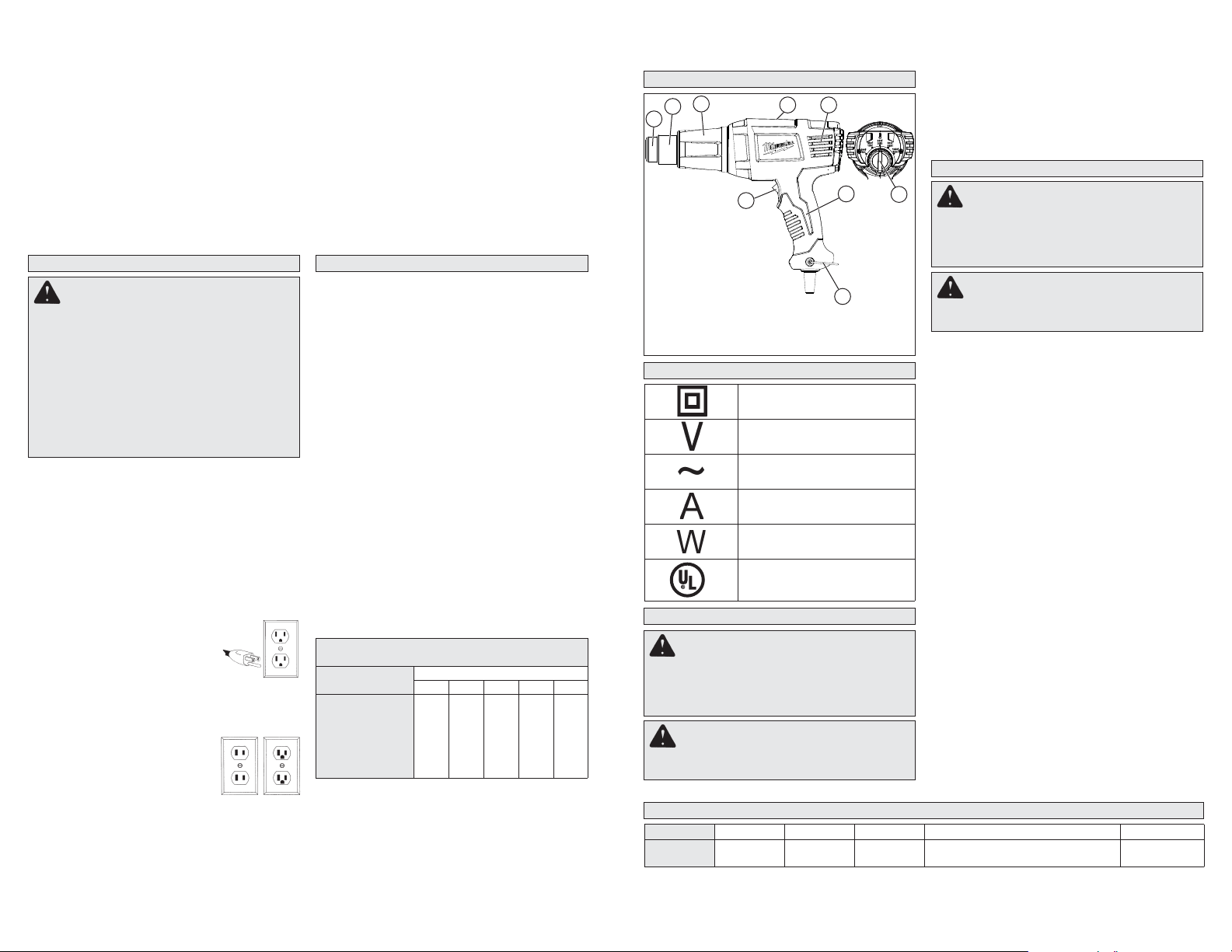

FUNCTIONAL DESCRIPTION

3

2

1

4

5

Installing/Removing Nozzles

1. To install, slide the nozzle onto the heat gun

nose.

2. Adjust heat, distance and length of application

as necessary.

3. To remove, allow tool to cool to room temperature, then pull nozzle away from tool.

OPERATION

1. Accessory

attachment area

2. Nozzle

3. Front cover

4. Nameplate (on back)

5. Intake vents

6. Handle

7. Support stand

8. High/Low switch (8975-6)

Heat/Cool-down mode switch (8977-20)

9. Variable temperature dial

(8977-20 only)

8

6

7

SYMBOLOGY

Double Insulated

Volts

Alternating Current

Amps

Watts

Underwriters Laboratories, Inc.

US

C

United States and Canada

ASSEMBLY

WARNING To reduce the risk of injury,

always unplug tool before attaching or removing accessories or making adjustments. Use

only specifi cally recommended accessories.

Others may be hazardous.

WARNING To reduce the risk of injury,

do not remove or attach accessory tips until

tool has cooled to room temperature.

9

WARNING To reduce the risk of injury,

always unplug tool before attaching or removing accessories or making adjustments. Use

only specifi cally recommended accessories.

Others may be hazardous.

WARNING To reduce the risk of in-

jury, wear safety goggles or glasses with side

shields.

Selecting Temperature

The proper amount of heat for each application

depends on the temperature selected, distance

between the nozzle and workpiece, and the length

of time heat is applied. Experiment with scrap

materials and start with the lowest temperature.

Be cautious when working until the proper combination of heat, distance and time of application

has been obtained. Use a back and forth motion

when applying heat unless concentrated heat is

desirable. When done, place the tool upright on a

fl at surface, snap the support stand into the center

notched position, and place the cord so the heat

gun won’t tip to allow the nozzle to cool.

High/Low Switch (Cat. No 8975-6)

1. For Low Temperature (570°F), move the switch

to the middle position.

2. For High Temperature (1000°F), press in the

bottom of the switch.

3. For OFF, press in the top of the switch.

Variable Temperature Dial (Cat. No. 8977-20)

1. For ON, push the switch to the (II) position.

2. Rotate the variable temperature dial to increase

or decrease the temperature (up to 1040°F)

3. To cool the tool before storage, push the switch

to the (I) position.

4. For OFF, push the switch to the (0) position.

Hands-Free Use

The heat guns can be positioned upright on a

stable surface, leaving both hands free for the application. Always place tool on a fl at surface, snap

the support stand into the center notched position,

and place the cord so the heat gun won’t tip. The

rear vent openings are designed to allow air fl ow

SPECIFICATIONS

Cat. No. Volts AC Max. Amps Max. Watts Temperature Airfl ow CFM*

8975-6

8977-20

120

120

11.6

11.6

1400

1400

570° F / 1000° F (300°C / 540°C)

100° F / 1040° F (38°C / 560°C)

5

15

20

* Cubic feet per minute

even when the tool is resting on the end cap. Do

not cover the vents with foreign materials such as

clothing or rags.

APPLICATIONS

WARNING To reduce the risk of heat

damage and personal injury, shield combustible materials and areas adjacent to workpiece.

Protect yourself from hot paint scrapings and

dust.

Types of Nozzles

• Hook Nozzle - Surrounding heat for thin pipe welding, soft soldering copper pipes, tube shaping and

shrinking of shrink tubes.

• Air Reduction Nozzle - Intensifi ed, spot directed

heat for corners, plexiglas bending and soldering.

• Defl ector Nozzle - Defl ected heat protects glass

window panes when removing paint and putty.

• Air Spreader Nozzle - Directs heat over large

areas for drying, removing paint, fl oor coverings,

and vinyl tops.

Removing Paint

Read safety instructions for removing paint before

proceeding with paint removal.

1. Begin work with low temperature setting.

2. Place nozzle approximately 1" away from work

surface.

3. Pass nozzle back and forth over a small area of

workpiece.

4. Gradually increase heat until paint starts to

blister, then remove heat.

5. Remove paint using a sharp-edged putty knife.

Creating Bends

Both variable temperature and dual temperature

heat guns are ideal for creating bends in plexiglas

that is used for guards and fi xtures.

1. T o form a bend, use either a low or high tempera-

ture setting. When using a low temperature, hold

the heat gun close to the workpiece and pass the

nozzle back and forth slowly. When using a high

temperature, hold the heat gun further away

from the workpiece and pass the nozzle back

and forth rapidly.

2. Pass the nozzle over entire length of the surface

to be bent. Applying heat to only part of the

surface will make bending uneven.

Soldering

1. Attach the air reduction or hook nozzle to the

heat gun.

2. De-burr the pipe and joint using sandpaper or

steel wool.

3. T o solder with either lead or non-lead solder , coat

the tip on both the copper pipe and the joint with

fl ux. Then slip the joint over the pipe.

4. Slip the accessory nozzle around the joint. With

the heat gun at a high temperature setting, apply

heat to the joint.

5. When the fl ux bubbles, add solder and position

heat gun so excess solder does not drip into the

heat gun.

Heat Shrinking

1. Attach the air reduction or hook nozzle to the

heat gun.

2. To heat shrink tubing, use a low temperature

setting. Apply heat to the workpiece using a side

to side motion until tubing has shrunk. Remove

heat immediately.

MAINTENANCE

WARNING To reduce the risk of

injury, always unplug your tool before performing any maintenance. Never disassemble the tool or try to do any rewiring

on the tool’s electrical system. Contact a

MILWAUKEE service facility for ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a regular

maintenance program. Before use, examine the

general condition of your tool. Inspect guards,

switches, tool cord set and extension cord for

damage. Check for loose screws, misalignment,

binding of moving parts, improper mounting, broken parts and any other condition that may affect

its safe operation. If abnormal noise or vibration

occurs, turn the tool off immediately and have the

problem corrected before further use. Do not use a

damaged tool. T ag damaged tools “DO NOT USE”

until repaired (see “Repairs”).

WARNING To reduce the risk of injury ,

electric shock and damage to the tool, never

immerse your tool in liquid or allow a liquid to

fl ow inside the tool.

Cleaning

Clean dust and debris from vents. Keep the tool

handles clean, dry and free of oil or grease. Use

only mild soap and a damp cloth to clean your tool

since certain cleaning agents and solvents are

harmful to plastics and other insulated parts. Some

of these include: gasoline, turpentine, lacquer thinner, paint thinner, chlorinated cleaning solvents,

ammonia and household detergents containing

ammonia. Never use fl ammable or combustible

solvents around tools.

Repairs

If your tool is damaged, return the entire tool to the

nearest service center.

ACCESSORIES

WARNING To reduce the risk of injury ,

always unplug the tool before attaching or

removing accessories. Use only specifi cally

recommended accessories. Others may be

hazardous.

For a complete listing of accessories refer to your

MILWAUKEE Electric Tool catalog or go on-line

to www.milwaukeetool.com. To obtain a catalog,

contact your local distributor or a service center.

6

LIMITED WARRANTY - USA AND CANADA

Every MILWAUKEE power tool (including cordless product – tool, battery pack(s) - see separate & distinct

CORDLESS BATTERY PACK LIMITED WARRANTY statements & battery charger and Work Lights*) is warranted to the original purchaser only to be free from defects in material and workmanship. Subject to certain

exceptions, MILWAUKEE will repair or replace any part on an electric power tool which, after examination, is

determined by MILWAUKEE to be defective in material or workmanship for a period of fi ve (5) years* after the

date of purchase unless otherwise noted. Return of the power tool to a MILWAUKEE factory Service Center

location or MILWAUKEE Authorized Service Station, freight prepaid and insured, is required. A copy of the

proof of purchase should be included with the return product. This warranty does not apply to damage that

MILWAUKEE determines to be from repairs made or attempted by anyone other than MILWAUKEE authorized

personnel, misuse, alterations, abuse, normal wear and tear, lack of maintenance, or accidents.

*The warranty period for, Job Site Radios, M12™ Power Port, M18™ Power Source, and T rade T itan™ Industrial Work Carts is one (1) year from the date of purchase. The warranty period for a LED Work Light and LED

Upgrade Bulb is a limited LIFETIME warranty to the original purchaser only, if during normal use the LED bulb

fails the Work Light or Upgrade Bulb will be replaced free of charge.

*This warranty does not cover Air Nailers & Stapler, Airless Paint Sprayer, Cordless Battery Packs, Gasoline

Driven Portable Power Generators, Hand Tools, Hoist – Electric, Lever & Hand Chain, M12™ Heated Jackets,

Reconditioned product and Test & Measurement products. There are separate and distinct warranties available for these products.

Warranty Registration is not necessary to obtain the applicable warranty on a MILWAUKEE power tool product.

The manufacturing date of the product will be used to determine the warranty period if no proof of purchase is

provided at the time warranty service is requested.

ACCEPTANCE OF THE EXCLUSIVE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN IS A

CONDITION OF THE CONTRACT FOR THE PURCHASE OF EVERY MILWAUKEE PRODUCT . IF YOU DO NOT

AGREE TO THIS CONDITION, YOU SHOULD NOT PURCHASE THE PRODUCT. IN NO EVENT SHALL MIL-

WAUKEE BE LIABLE FOR ANY INCIDENTAL, SPECIAL, CONSEQUENTIAL OR PUNITIVE DAMAGES, OR FOR

ANY COSTS, ATTORNEY FEES, EXPENSES, LOSSES OR DELA YS ALLEGED T O BE AS A CONSEQUENCE

OF ANY DAMAGE TO, FAILURE OF, OR DEFECT IN ANY PRODUCT INCLUDING, BUT NOT LIMITED T O, ANY

CLAIMS FOR LOSS OF PROFITS. SOME STA TES DO NOT ALLOW THE EXCLUSION OR LIMIT A TION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMIT A TION OR EXCLUSION MA Y NOT APPL Y

TO YOU. THIS W ARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS WARRANTIES, WRITTEN

OR ORAL. TO THE EXTENT PERMITTED BY LAW, MILWAUKEE DISCLAIMS ANY IMPLIED WARRANTIES,

INCLUDING WITHOUT LIMIT A TION ANY IMPLIED W ARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PAR TICULAR USE OR PURPOSE; TO THE EXTENT SUCH DISCLAIMER IS NOT PERMITTED BY LAW , SUCH

IMPLIED WARRANTIES ARE LIMITED TO THE DURATION OF THE APPLICABLE EXPRESS WARRANTY AS

DESCRIBED ABOVE. SOME ST A TES DO NOT ALLOW LIMITA TIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU, THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

This warranty applies to product sold in the U.S.A. and Canada only.

Please consult the ‘Service Center Search’ in the Parts & Service section of MILWAUKEE’s website www.mil-

waukeetool.com or call 1.800.SAWDUST (1.800.729.3878) to locate your nearest service facility for warranty

and non-warranty service on a Milwaukee electric power tool.

LIMITED WARRANTY - MEXICO, CENTRAL AMERICA AND CARIBBEAN

TECHTRONIC INDUSTRIES' warranty is for 5 year since the original purchase date.

This warranty card covers any defect in material and workmanship on this Power Tool.

To make this warranty valid, present this warranty card, sealed/stamped by the distributor or store where you purchased the product, to the Authorized Service Center (ASC). Or , if this card has not been sealed/stamped, present the

original proof of purchase to the ASC.

Call toll-free 1 800 832 1949 to fi nd the nearest ASC, for service, parts, accessories or components.

Procedure to make this warranty valid

Take the product to the ASC, along with the warranty card sealed/stamped by the distributor or store where you purchased the product, and there any faulty piece or component will be replaced without cost for you. We will cover all

freight costs relative with this warranty process.

Exceptions

This warranty is not valid in the following situations:

a) When the product is used in a different manners from the end-user guide or instruction manual.

b) When the conditions of use are not normal.

c) When the product was modifi ed or repaired by people not authorized by TECHTRONIC INDUSTRIES.

Note: If cord set is damaged, it should be replaced by an Authorized Service Center to avoid electric risks.

SERVICE AND ATTENTION CENTER

Model:

Av Presidente Mazarik 29 Piso 7, 11570 Chapultepec Morales

Miguel Hidalgo, Distrito Federal, Mexico

Date of Purchase:

Ph. 52 55 4160-3547

Distributor or Store Stamp:

IMPORTED AND COMMERCIALIZED BY:

TECHTRONIC INDUSTRIES MEXICO, .S.A. DE C.V.

Av Presidente Mazarik 29 Piso 7, 11570 Chapultepec Morales

Miguel Hidalgo, Distrito Federal, Mexico

7

Loading...

Loading...