Milwaukee 8940-20 Operator's Manual

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Catalog No.

No de Cat.

Catálogo No.

8940-20

HEAVY-DUTY COMMERCIAL VACUUM CLEANER

EXTRA ROBUSTE ASPIRATEUR COMMERCIAL

HEAVY-DUTY ASPIRADORA COMMERCIAL

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN COMPRENDRE LE

MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL MANUAL DEL

OPERADOR.

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below, may result in

electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS.

To reduce the risk of fire, electric shock or injury:

1. Do not leave appliance when plugged in. Unplug from outlet

when not in use and before servicing.

2. Do not expose vacuum cleaner to rain. Store indoors.

3. Do not allow to be used as a toy. Close attention is necessary

when used by or near children.

4. Use only as described in this manual. Use only manufacturer’s

recommended attachments.

5. Do not use with damaged cord or plug. If appliance is not

working as it should, has been dropped, damaged, left outdoors, or

dropped into water, return it to a service center.

6. Do Not: pull or carry by cord, use cord as a handle, close a

door on cord, or pull cord around sharp edges or corners.

Do not run appliance over cord. Keep cord away from heated

surfaces.

7. Do not unplug by pulling on cord. To unplug, grasp the plug not

the cord.

8. Do not handle plug or appliance with wet hands.

9. Do not put any object into openings. Do not use with any

openings blocked; keep free of dust, lint, hair, and anything else that

may reduce air flow.

10. Keep hair, loose clothing, fingers, and all parts of body away

from openings and moving parts.

11. Turn off all controls before unplugging.

12. Use extra care when cleaning on stairs.

13. Use special care when emptying heavily loaded tanks.

14. Do not leave the cord lying on the floor once you have

finished the cleaning job. It can become a tripping hazard.

15. Do not pick up anything that is burning or smoking such as

cigarettes, matches, or hot ashes.

16. Do not use to pick up flammable or combustible liquids

such as gasoline or use in areas where they may be present.

17. Do not use in the presence of explosive liquids or vapors.

18. Vacuum cleaners have motors and other parts that can pro-

duce sparks during normal use. Do not use within 30 feet of

areas where explosive gases may be present (such as gasoline

pumps and places where liquids like paint thinners, cleaners, solvents, etc. are stored).

19. Do not use where oxygen or anesthetics are used.

20. To avoid spontaneous combustion, empty tank after each use.

21. Do not use your vacuum cleaner as a sprayer of flammable

liquids such as oil based paints, lacquers, household cleaners,

etc.

22. Connect to a properly grounded outlet only. See grounding

instructions.

23. Unplug power cord whenever motor head is removed from

tank.

24. Do not use without dust bag and filter in place.

25. Do not pick up wood or coal ash, soot, cement, plaster or

drywall dust without full cloth filter or collection bag in place.

These are very fine particles that may pass through the foam and

disc filters and affect the performance of the motor or be exhausted

back into the air. Full cloth filters and additional collection filter bags

are available.

26. To reduce the risk of health hazards from vapors or dust, do

not vacuum toxic, carcinogenic or other hazardous materials such

as asbestos, arsenic, barium, berylium, lead, pesticides or other

health endangering materials.

27. Always wear safety goggles when operating vacuum.

28. STAY ALERT. Watch what you are doing and use common sense.

Do not use vacuum cleaner when you are tired, distracted or under

the influence of drugs, alcohol or medication causing diminished

control.

29. Wear electrically insulated footwear, such as rubber boots,

when vacuuming wet material.

30. WARNING! Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known

to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specifically designed

to filter out microscopic particles.

page 2

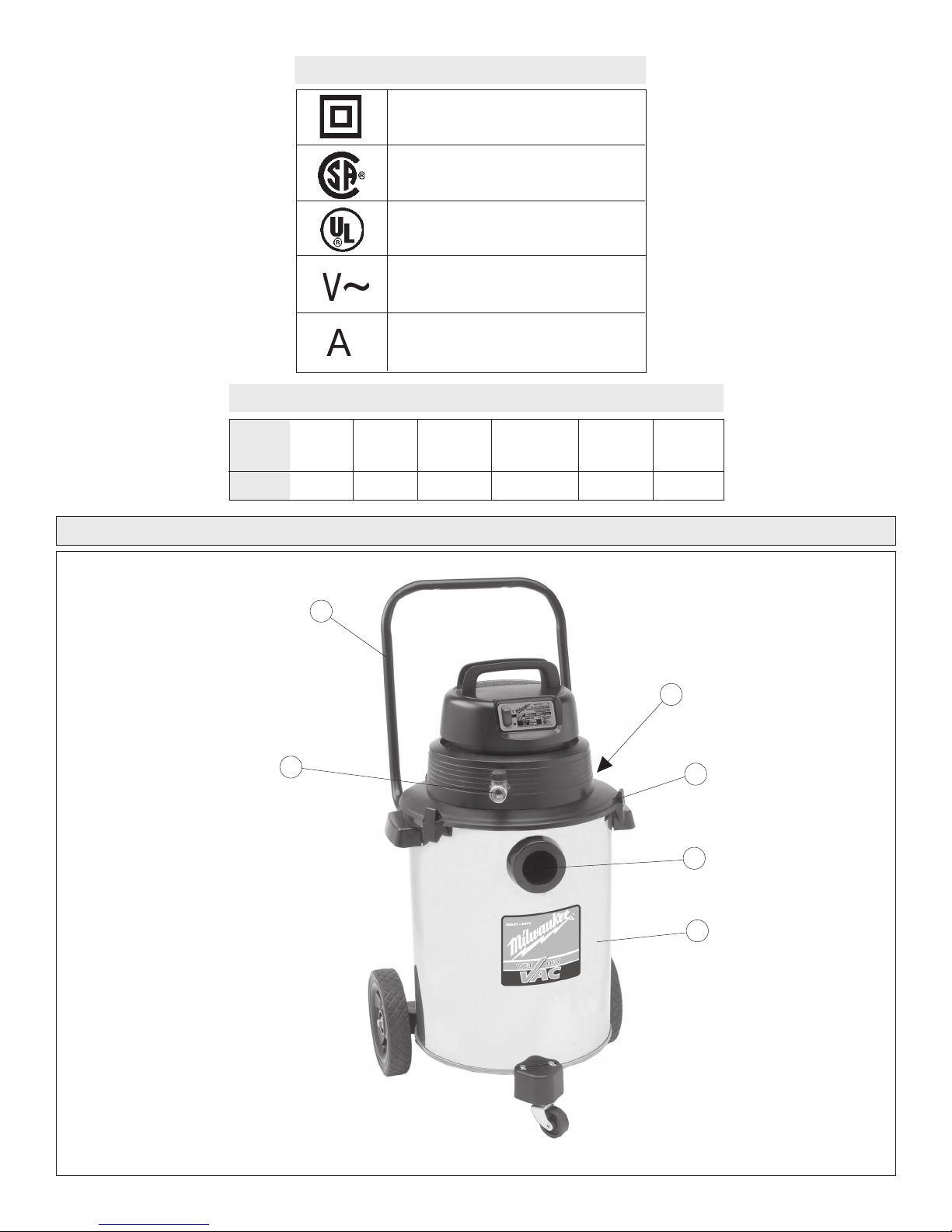

Symbology

Double Insulated

Canadian Standards Association

Underwriters Laboratories, Inc.

Volts Alternating Current

Amps

Specifications

1. Handle

2. Exhaust port

3. Tank latch

4. Intake port

5. Tank

6. Shut-off assembly

Catalog

No.

8940-20

6

Volts

AC

120

1

Amps

11.5

Tank

Capacity

(gallons)

8

Air Flow

(cubic feet

per minute)

140

FUNCTIONAL DESCRIPTION

Sealed

Suction in

Water

60"

For

Materials

Wet or Dry

2

3

4

5

page 3

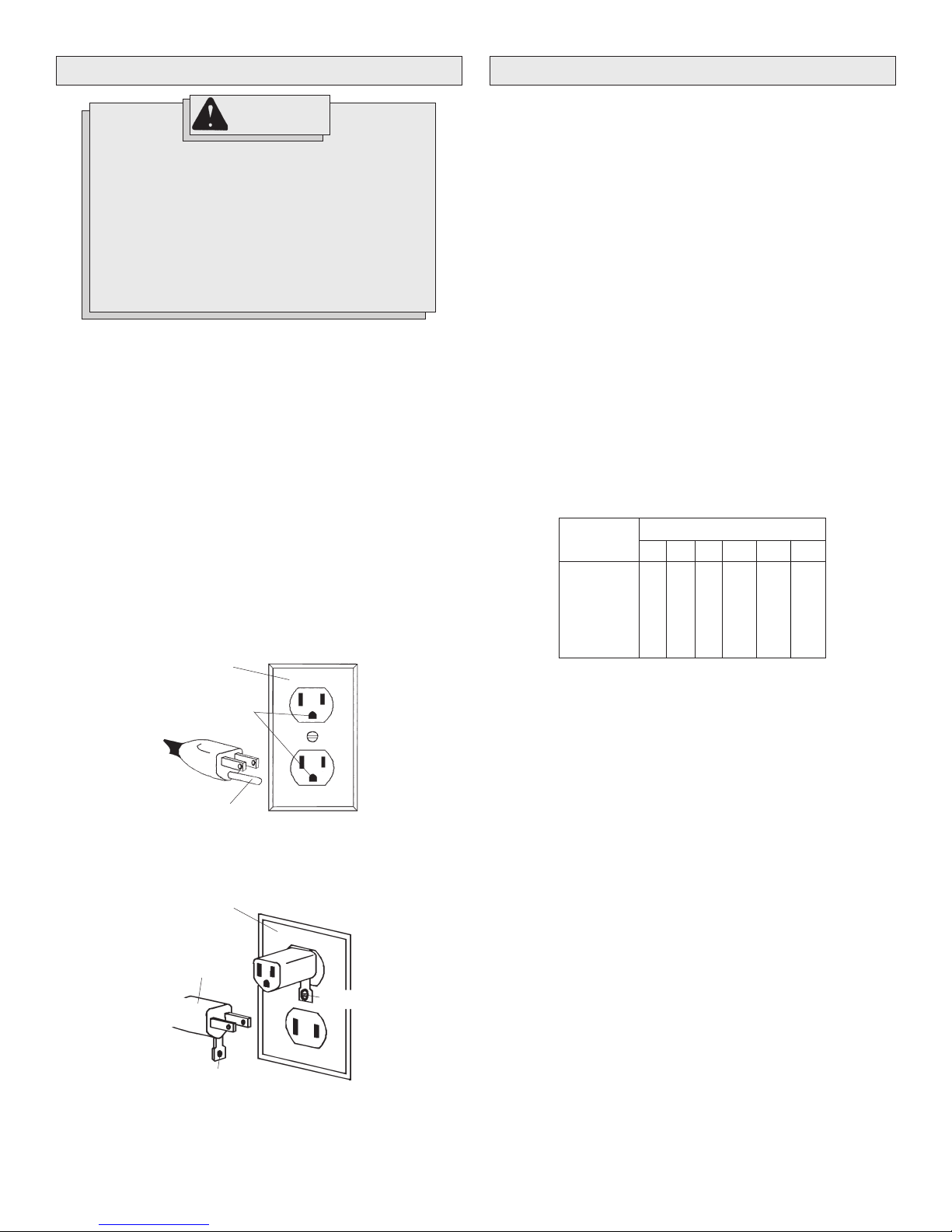

GROUNDING EXTENSION CORDS

WARNING!

Improperly connecting the grounding wire can

result in the risk of electric shock. Check with a

qualified electrician if you are in doubt as to

whether the outlet is properly grounded. Do not

modify the plug provided with the tool. Never

remove the grounding prong from the plug. Do not

use the tool if the cord or plug is damaged. If

damaged, have it repaired by a

service facility before use. If the plug will not fit the

outlet, have a proper outlet installed by a qualified

electrician.

MILWAUKEE

Grounded tools require a three wire extension cord. Double insulated

tools can use either a two or three wire extension cord. As the distance

from the supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes

a serious drop in voltage, resulting in loss of power and possible tool

damage. Refer to the table shown to determine the required minimum

wire size.

The smaller the gauge number of the wire, the greater the capacity of the

cord. For example, a 14 gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension cord to make up the

total length, be sure each cord contains at least the minimum wire size

required. If you are using one extension cord for more than one tool, add

the nameplate amperes and use the sum to determine the required minimum wire size.

This vacuum cleaner must be grounded. If it should malfunction or break

down, grounding provides a path of least resistance for electric current

to reduce the risk of electric shock. This vacuum cleaner is equipped

with a cord having an equipment grounding conductor and grounding

plug. The plug must be inserted into an appropriate outlet that is properly

installed and grounded in accordance with all local codes and ordinances.

This vacuum cleaner is for use on a nominal 120-volt circuit, and has a

grounded plug that looks like the plug illustrated in Figure A. A temporary

adaptor that looks like the adaptor illustrated in Figure B may be used to

connect this plug to a 2-pole receptacle as shown in Figure B if a properly grounded outlet is not available. The temporary adaptor should be

used only until a properly grounded outlet (Figure A) can be installed by

a qualified electrician. The green colored rigid ear, lug, or the like

extending from the adaptor must be connected to a permanent ground

such as a properly grounded outlet box cover. Whenever the adaptor is

used, it must be held in place by a metal screw.

The Canadian Electrical Code prohibits the use of temporary adapters.

Cover of

grounded outlet

box

Outlet ground

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors, be sure it is marked

with the suffix “W-A” (“W” in Canada) to indicate that it is acceptable

for outdoor use.

• Be sure your extension cord is properly wired and in good electrical

condition. Always replace a damaged extension cord or have it

repaired by a qualified person before using it.

• Protect your extension cords from sharp objects, excessive heat

and damp or wet areas.

Recommended Minimum Wire Gauge

Nameplate

Amperes

8.1 - 12

12.1 - 15

15.1 - 20

* Based on limiting the line voltage drop to five

volts at 150% of the rated amperes.

for Extension Cords*

25'

0 - 5

5.1 - 8

16

16

14

12

10

Extension Cord Length

100'

50'

16

16

14

12

10

75'

16

14

12

10

10

14

12

10

10

150'

12

10

--

--

--

--

200'

12

--

--

--

--

READ AND SAVE ALL INSTRUCTIONS FOR

FUTURE USE.

Grounding

prong

Cover of

grounded outlet

box

Temporary

adapter

Green grounding

ear

Fig. A

Screw

Fig. B

page 4

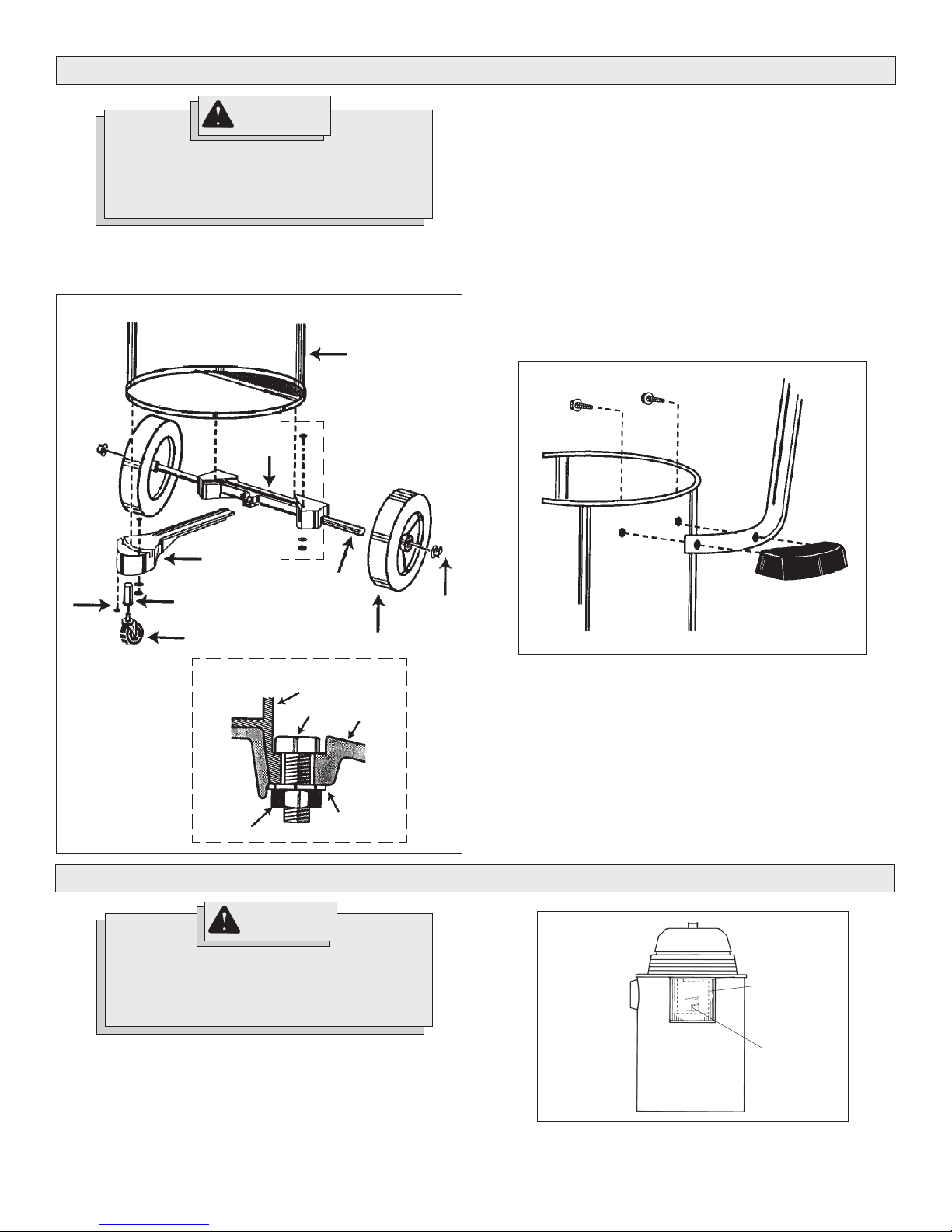

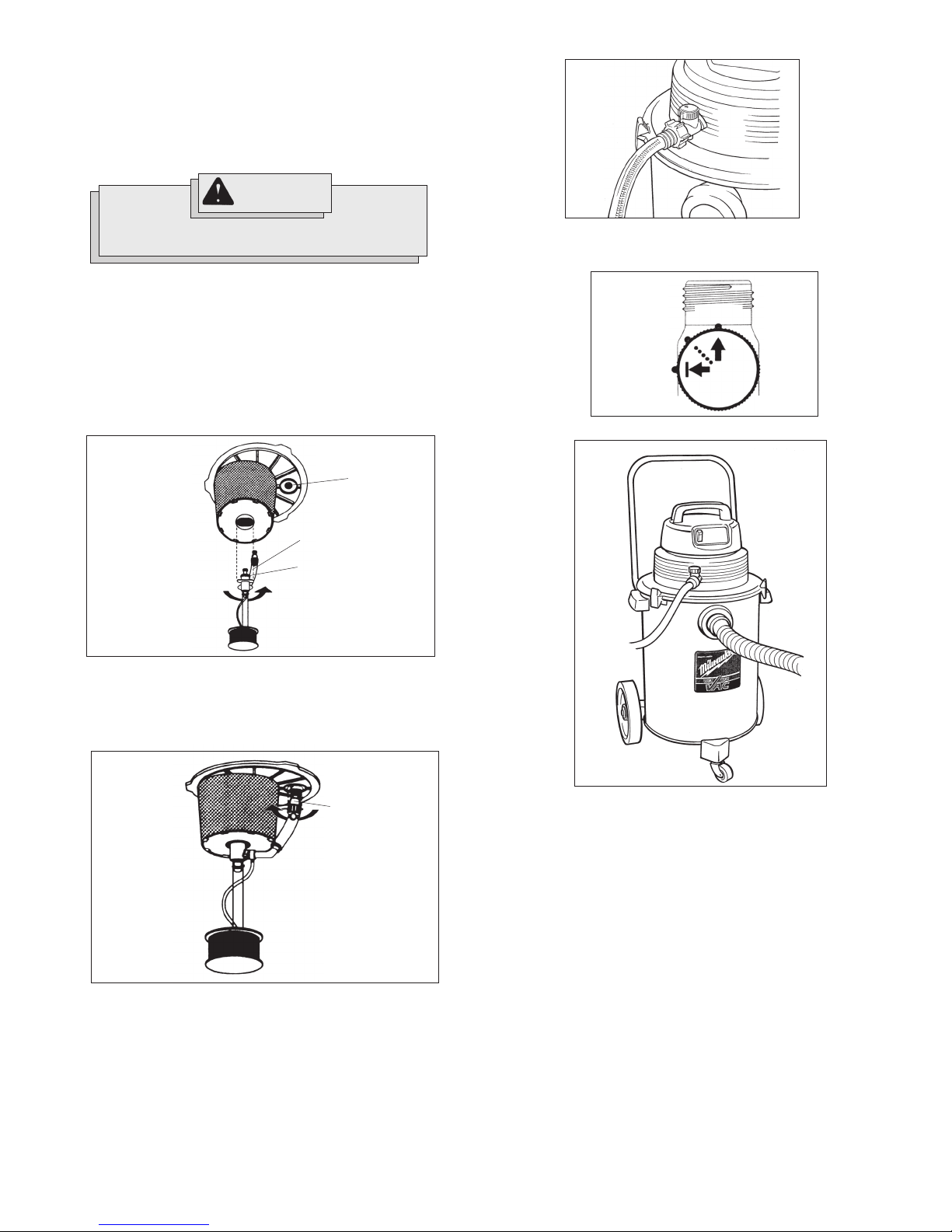

TOOL ASSEMBLY

WARNING!

To reduce the risk of injury, always unplug vacuum

cleaner before attaching or removing accessories

or making adjustments. Use only specifically

recommended accessories. Others may be

hazardous.

Assembling Dolly (Fig. 1)

Assemble as shown in the diagram. You will need a hammer and a

Phillips screwdriver.

Fig. 1

A

B

F

C

I

G

E

1. Place wheels on rear frame (B) by tapping in the axle (C), fitting the

wheel (D) on the axle and tapping a cap nut (E) on with a hammer.

2. Insert caster socket (G) into front frame (F) and secure it with the

phillips screw (I).

3. Align front frame (F) and rear frame (B) so that they fit together and

fit lip of tank (J) into the grooves in front and rear frames.

4. Secure frame (B and F) to the tank by placing the hex bolts (K)

through the holes in dolly and securing them with nut (N) and washer

(M) as shown.

5. Insert caster (H) into caster socket (G) and push down until caster

snaps into place.

Installing Handle (Fig. 2)

You will need either a flat blade screwdriver or a socket driver and a

wrench or a pair of pliers.

Fig. 2

H

J

K

N

D

L

M

OPERATION

WARNING!

If the float is clean and moves freely and the

suction does not shut off when tank is filled (you

will be able to see water in the exhaust port),

send motorhead to the nearest

service facility for repair.

Vacuuming Wet Materials (Fig. 3)

When vacuuming wet materials, either the filter cartridge or the

foam sleeve is required. Remove all dry pick-up filters. A float valve

shuts off suction when the tank is full (Fig. 3). If you are vacuuming a

large amount of liquid, the filter cartridge can become saturated and a

mist can appear from the exhaust port. If this happens, dry the filter by

running the vacuum (without picking up anything) for 10

minutes.

MILWAUKEE

1. Place dolly handle between tank and side handle on either side of

the tank.

2. Fasten tightly with slotted hex head screws.

Fig. 3

float cage

float

page 5

Starting and Stopping Vacuum Cleaner

1. To turn vacuum cleaner on, turn the ON/OFF switch to the ON

position.

2. To turn vacuum cleaner off, turn the ON/OFF switch to the OFF

position.

NOTE: Switch will automatically return to the neutral position.

WARNING!

Fig. 6

To reduce the risk of electric shock, do not direct

discharge stream at vacuum cleaner.

Vacuuming Wet Materials Using Pump (Fig. 4 - 8)

1. Always unplug vacuum cleaner before removing the tank cover.

2. Remove the tank cover and dry pick-up filters. Tank should be cleaned

of any dirt or debris.

3. Make sure the foam sleeve is properly installed for wet vacuuming

(see “When Vacuuming Wet Materials”).

4. Insert the pump pick-up assembly's inlet fitting into the bottom of the

motor housing on the tank cover. Rotate until the discharge hose

lines up with the plug on the bottom of the tank cover (Fig. 4).

Fig. 4

plug

discharge hose

inlet fitting

8. Before starting the pumping operation, check to see that the shut-off

valve is in the OFF position (Fig. 7).

Fig. 7

ON

PRIMED

OFF

9. Attach the 1-1/4" vacuum hose to the tank inlet (Fig. 8).

Fig. 8

5. Remove plug from discharge hole. Insert the discharge fitting and

rotate clockwise to lock into place (Fig. 5).

NOTE: Do not cut the security loop which fastens the plug to the lid

cage. The plug must be used for vacuuming dry materials.

Fig. 5

discharge fitting

6. Replace tank cover and secure with lid latches to the tank.

7. Connect a standard garden hose (not supplied) to the shut-off valve

(Fig. 6).

page 6

10. Plug in vacuum cleaner. Turn ON/OFF switch to ON position.

NOTE: Switch will automatically return to the neutral position.

11. Start wet pick-up.

NOTE: To start the pumping feature, you will need approximately 4"

of water in the bottom of the tank. At that time you can start the

pump or continue with the standard wet pick-up until the tank has

reached capacity. The vacuum cleaner will automatically shut off

when full.

Removing Liquid from the Vacuum Cleaner Tank Using Pump

1. To empty a full tank by pumping, remove the vacuum hose from the

liquid. The ON/OFF switch must be manually held in the ON position

with the shut-off valve in the priming position.

NOTE: The vacuum hose must be attached to the vacuum cleaner in

order to prime.

NOTE: If the vacuum cleaner fails to prime, restrict airflow to the

vacuum by capping the end of hose.

2. Once the liquid begins to flow through the garden hose, the shut-off

valve should be turned to the full ON position to achieve the maximum flow. You will have to manually hold the ON/OFF switch in the

ON position for approximately 10-15 seconds. This will allow the

water level to reduce significantly. Pumping will continue automati-

cally. The vacuum cleaner will continue to discharge liquid until

there is about 4" left in the tank.

NOTE: The vacuum cleaner is capable of wet vacuuming while

pumping. If the vacuum cleaner should shut off, the pick-up volume

may be greater than the discharge volume. Repeat steps 1 and 2.

3. After wet vacuuming and pumping has been completed, the remaining liquid should be emptied from the tank and the pump pick-up

assembly should be removed and cleaned.

NOTE: Keep shut-off valve in the OFF position when not pumping.

Removing Liquid from the Vacuum Cleaner Tank Without Pump

1. Unplug vacuum cleaner.

2. Remove motor head and set aside.

3. Block wheels.

4. Carefully dump contents into a drain. Do not dump through intake

tube.

5. Rinse and dry tank.

NOTE: Do not store vacuum cleaner with liquid in tank. Run the

vacuum cleaner for about 10 minutes without picking up anything to

dry the inside of the tank and the filter cartridge.

Vacuuming Dry Materials

When vacuuming dry materials, either the filter cartridge or the foam

sleeve AND the cloth filter are required. The reusable dry disc filter

should always be in position over the foam sleeve for dry pick up. There

are other filters that can be used with the required filters to provide

additional filtration when vacuuming dry material. Follow the instructions

included with these filters. Empty tank and clean filter frequently. Be

sure filters are dry before using the vacuum cleaner to pick up dry

material. Dry material will clog wet filters and make them difficult to clean.

Starting and Stopping Vacuum Cleaner

1. To turn vacuum cleaner on, turn the ON/OFF switch to the ON

position.

2. To turn vacuum cleaner off, turn the ON/OFF switch to the OFF

position.

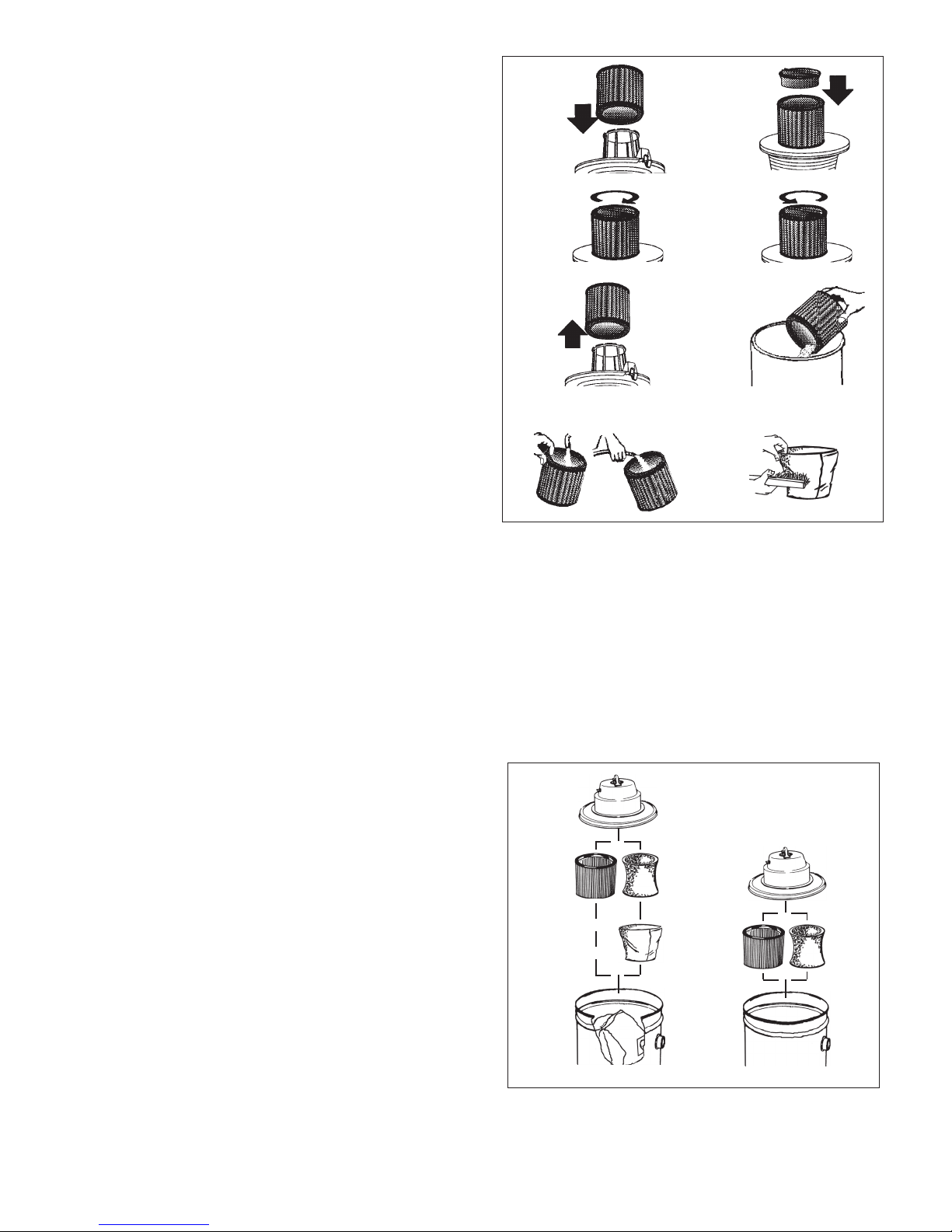

Filter Cleaning and Changing (Fig. 9)

To install filter:

1. Slide cartridge filter down over filter cage (Fig. 9A).

2. Insert filter retainer into top of cartridge filter (Fig. 9B).

3. Hold base of lid cage with one hand and turn retainer clockwise to

tighten (Fig. 9C).

4. To remove filter for cleaning, hold base of lid cage with one hand and

turn retainer counterclockwise to loosen (Fig. 9D).

5. Slide filter off filter cage (Fig. 9E).

6. Clean dry filter by tapping filter on side of waste can (Fig. 9F).

Clean wet filter by rinsing from the inside (Fig. 9G).

Clean cloth filters by shaking off loose material and brushing the filter

with a soft bristle brush (Fig. 9H).

NOTE: When wet (to prevent mold and/or mildew build-up), the car-

tridge filter should be removed and allowed to air dry for a 24-hour

period before being re-installed back into the filter cage.

Fig. 9A

Fig. 9C

Fig. 9E Fig. 9F

Fig. 9G Fig. 9H

Installing Filters (Fig. 10)

1. Unplug vacuum cleaner.

2. Remove motor head and set aside.

3. Attach cartridge filter or foam sleeve to motor head (Fig. 10).

• If you plan to vacuum dry material into a filter bag, expand the

paper filter bag and fit cardboard collar onto the intake tube as

far as possible.

• If you plan to vacuum dry material and you are using the foam

sleeve, you must also use the cloth filter.

CAUTION: Use care when handling motor head. Dropping motor

head may cause permanent damage.

4. Replace motor head and snap down tank latches.

Fig. 10

Fig. 9B

Fig. 9D

dry materials wet materials

page 7

ACCESSORIES

• Electrical inspection (switch, cord, armature, etc.)

• Testing to assure proper mechanical and electrical operation

WARNING!

To reduce the risk of injury, always unplug the

tool before attaching or removing accessories.

Use only specifically recommended accessories. Others may be hazardous.

For a complete listing of accessories refer to your

Tool catalog or go on-line to www.mil-electric-tool.com. To obtain a catalog, contact your local distributor or a service center listed on the back

cover of this operator’s manual.

Wet/Dry Cartridge Filter

Catalog No. 49-90-1830

Foam Sleeve

Catalog No. 49-90-0770

High Efficiency Filter Bags (package of 5)

Catalog No. 49-90-0445

10' x 1-1/4" Plastic Hose

Catalog No. 49-90-0110

1-1/4" Diameter Extension Wand

Catalog No. 49-90-2100

Wand connects to 1-1/4" ID hose.

12" Squeegee Insert

Catalog No. 49-90-2120

MILWAUKEE

Electric

WARNING!

To reduce the risk of injury, electric shock and damage

to the tool, never immerse your tool in liquid or allow a

liquid to flow inside the tool.

Cleaning

Clean dust and debris from vents. Keep the tool handles clean, dry and

free of oil or grease. Use only mild soap and a damp cloth to clean your

tool since certain cleaning agents and solvents are harmful to plastics

and other insulated parts. Some of these include: gasoline, turpentine,

lacquer thinner, paint thinner, chlorinated cleaning solvents, ammonia

and household detergents containing ammonia. Never use flammable or

combustible solvents around tools.

Repairs

If your tool is damaged, return the entire tool to the nearest service

center listed on the back cover of this operator’s manual.

12" Floor Nozzle

Catalog No. 49-90-2110

12" Brush Insert

Catalog No. 49-90-2130

MAINTENANCE

WARNING!

To reduce the risk of injury, always unplug your tool

before performing any maintenance. Never disassemble the tool or try to do any rewiring on the tool's

electrical system. Contact a

for ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a regular maintenance program. Before use, examine the general condition of your tool. Inspect

guards, switches, tool cord set and extension cord for damage. Check

for loose screws, misalignment, binding of moving parts, improper mounting, broken parts and any other condition that may affect its safe operation. If abnormal noise or vibration occurs, turn the tool off immediately

and have the problem corrected before further use. Do not use a damaged tool. Tag damaged tools “DO NOT USE” until repaired

(see “Repairs”).

Under normal conditions, relubrication is not necessary until the motor

brushes need to be replaced. After six months to one year, depending

on use, return your tool to the nearest

the following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears, spindles, bearings,

housing, etc.)

page 8

MILWAUKEE

MILWAUKEE

service facility

service facility for

TWO YEAR TOOL LIMITED WARRANTY

Every

MILWAUKEE

ranted to be free from defects in material and workmanship.

will repair or replace (at

tool (including battery chargers) which examination proves to be defective in material or workmanship from two (2) years after the date of

purchase. Return the tool and a copy of the purchase receipt or other

proof of purchase to a

Branch location or

paid and insured. This warranty does not cover damage from repairs

made or attempted by other than

abuse, normal wear and tear, lack of maintenance, or accidents.

Battery Packs, Flashlights, and Radios are warranted for one (1) year

from the date of purchase.

THE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN ARE

EXCLUSIVE. IN NO EVENT SHALL

INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES, INCLUDING

LOSS OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, OR CONDITIONS, WRITTEN OR ORAL, EXPRESSED OR IMPLIED FOR

MERCHANTABLILITY OR FITNESS FOR PARTICULAR USE OR PURPOSE.

This warranty gives you specific legal rights. You may also have other

rights that vary from state to state and province to province. In those

states that do not allow the exclusion of implied warranties or limitation

of incidental or consequential damages, the above limitations or exclusions may not apply to you. This warranty applies to the United States,

Canada, and Mexico only.

tool is tested before leaving the factory and is war-

MILWAUKEE

MILWAUKEE

MILWAUKEE

MILWAUKEE

’s discretion), without charge, any

Factory Service/Sales Support

Authorized Service Station, freight pre-

MILWAUKEE

MILWAUKEE

authorized personnel,

BE LIABLE FOR ANY

Loading...

Loading...