Milwaukee 8911, 8945, 8925, 8912, 8926 Operator's Manual

...

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S

MANUAL.

OPERATOR'S MANUAL

Cat. No.

8911

8912

8925

8926

8945

8965

HEAVY-DUTY COMMERCIAL VACUUM

2

3

* Based on limiting the line voltage drop to fi ve volts at

150% of the rated amperes.

Recommended Minimum Wire Gauge

For Extension Cords*

Extension Cord Length

Nameplate

Amperes

25' 50' 75' 100' 150'

0 - 2.0

2.1 - 3.4

3.5 - 5.0

5.1 - 7.0

7.1 - 12.0

12.1 - 16.0

16.1 - 20.0

18

18

18

18

16

14

12

18

18

18

16

14

12

10

18

18

16

14

12

10

--

18

16

14

12

10

--

--

16

14

12

12

--

--

--

WARNING - TO REDUCE THE

RISK OF FIRE, ELECTRIC SHOCK OR INJURY:

• Do not leave appliance when plugged in. Unplug

from outlet when not in use and before servicing.

Connect to a properly grounded outlet only. See

Grounding Instructions.

• Do not expose to rain – store indoors.

• Do not allow to be used as a toy. Close attention

is necessary when used by or near children.

• Use only as described in this manual. Use only

manufacturer’s recommended attachments.

• Do not use with damaged cord or plug. If appliance is not working as it should, has been

dropped, damaged, left outdoors, or dropped

into water, return it to a service center.

• Do not pull or carry by cord, use cord as a handle,

close a door on cord, or pull cord around sharp

edges or corners. Do not run appliance over cord.

Keep cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug

grasp the plug not the cord.

• Do not handle plug or appliance with wet hands.

• Do not put any object into openings. Do not use

with any opening blocked; keep free of dust, lint,

hair, and anything else that may reduce air fl ow.

• Keep hair, loose clothing, fi ngers, and all parts

of body away from openings and moving parts.

• Do not pick up anything that is burning or smoking such as cigarettes, matches, or hot ashes.

• Do not use without dust bag and/or fi lters in

place.

• Turn off all controls before unplugging.

• Use extra care when cleaning on stairs.

• Do not use to pick up fl ammable or combustible

liquids such as gasoline or use in areas where

they may be present.

• Vacuum cleaners have motors and other parts

that can produce arcs or sparks during normal

use. Do not use within 20 feet of areas where

explosive gases may be present (such as gasoline pumps and places where liquids like paint

thinners, cleaners, solvents, etc. are stored).

• Unplug power cord whenever motor head is

removed from tank.

• Do not use in the presence of explosive liquids

or vapors.

• To reduce the risk of health hazards from

vapors or dust, do not vacuum toxic, carcinogenic or other hazardous materials such as

asbestos, arsenic, barium, berylium, lead, pesticides or other health endangering materials.

• Do not use where oxygen or anesthetics are used.

• Wear electrically insulated footwear, such as

rubber boots, when vacuuming wet material.

• Maintain labels and nameplates. These carry im-

portant information. If unreadable or missing, contact

a MILWAUKEE service facility for a free replacement.

• WARNING! Do NOT use this vacuum cleaner to

vacuum lead paint debris because this maydisperse

fi ne lead particles into the air. This vacuum cleaner is

not intended for use under EPA Regulation 40 CFR

Part 745 for lead paint material cleanup.

• WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treatedlumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to fi lter out microscopic particles.

IMPORTANT SAFETY INSTRUCTIONS

WARNING Failure to follow the warnings and instructions may result

in electric shock, fi re and/or serious injury. When using an electrical appliance,

basic precautions should always be followed, including the following: READ ALL

INSTRUCTIONS BEFORE USING THIS APPLIANCE.

READ AND

SA VE ALL

INSTRUCTIONS

FOR FUTURE USE

GROUNDING

INSTRUCTIONS

WARNING Improper

connection of the equipment-grounding conductor can result in a risk of

electric shock. Check with a qualifi ed electrician or service person if

you are in doubt as to whether the

outlet is properly grounded. Do not

modify the plug provided with the

appliance - If it will not fi t the outlet,

have a proper outlet installed by a

qualifi ed electrician.

This appliance must be grounded. If it should malfunction or breakdown, grounding provides a path

of least resistance for electric current to reduce the

risk of electric shock. This appliance is equipped

with a cord having an equipment-grounding conductor and grounding plug. The plug must be inserted

into an appropriate outlet that is properly installed

and grounded in accordance with all local codes

and ordinances.

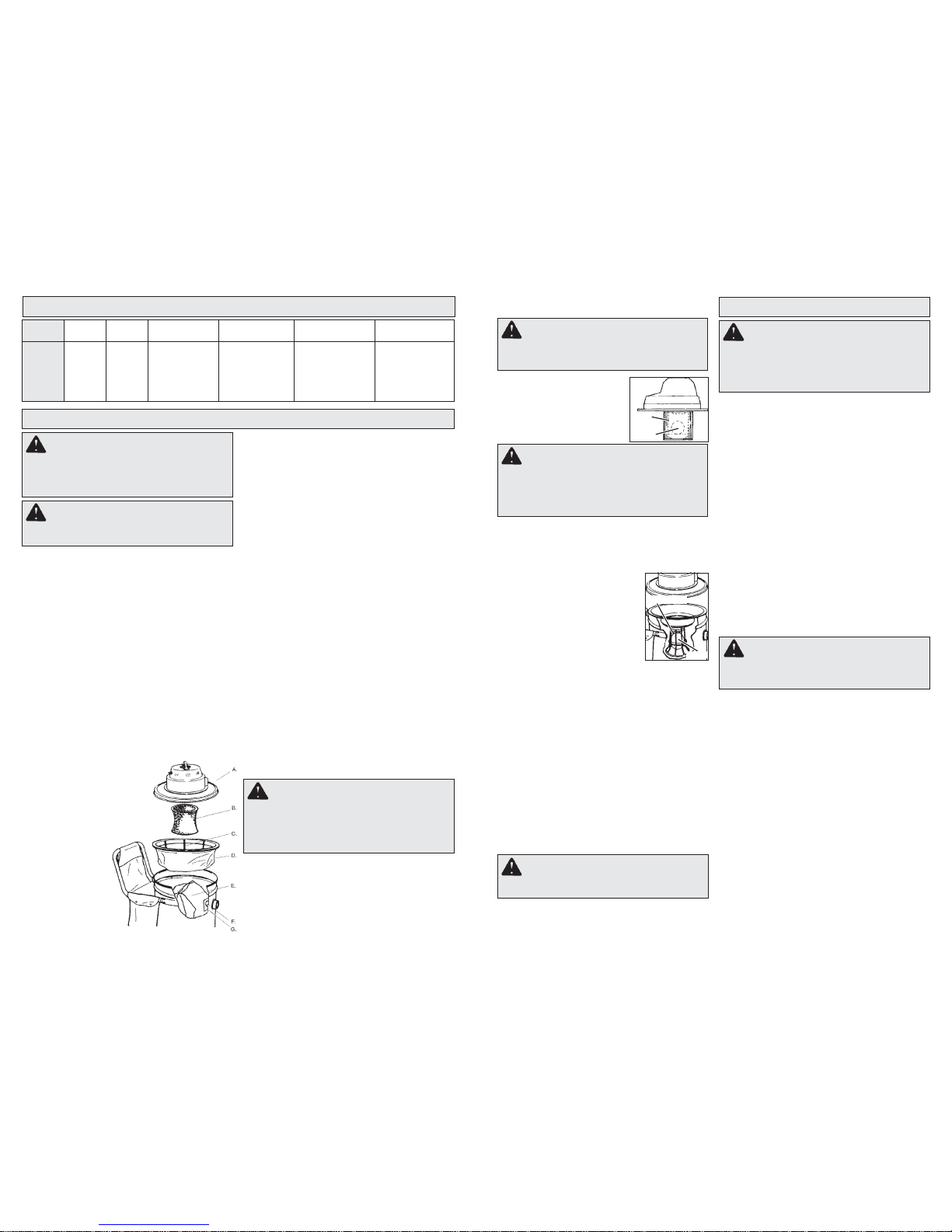

This appliance is for use on a nominal 120-volt

circuit, and has a grounded plug that looks like the

plug illustrated in sketch A. A temporary adaptor

that looks like the adaptor illustrated in sketches

B and C may be used to connect this plug to a

2-pole receptacle as shown in sketch B if a properly grounded outlet is not available. The temporary adaptor should be used only until a properly

grounded outlet (sketch A) can be installed by a

qualifi ed electrician. The green colored rigid ear, lug

or the like extending from the adaptor must be connected to a permanent ground such as a properly

grounded outlet box cover. Whenever the adaptor

is used, it must be held in place by a metal screw.

IN CANADA, THE USE OF A TEMPORARY ADAPTOR IS NOT PERMITTED BY THE CANADIAN

ELECTRICAL CODE. Make sure that the appliance is connected to an outlet having the same

confi guration as the plug. No adaptor should be

used with this appliance.

Grounded tools require a three wire extension cord.

As the distance from the supply outlet increases,

you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire

causes a serious drop in voltage, resulting in loss

of power and possible tool damage. Refer to the

table shown to determine the required minimum

wire size.

The smaller the gauge number of the wire, the

greater the capacity of the cord. For example, a 14

gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension

cord to make up the total length, be sure each cord

contains at least the minimum wire size required.

If you are using one extension cord for more than

one tool, add the nameplate amperes and use the

sum to determine the required minimum wire size.

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors, be

sure it is marked with the suffi x “W-A” (“W” in

Canada) to indicate that it is acceptable for outdoor

use.

• Be sure your extension cord is properly wired

and in good electrical condition. Always replace a

damaged extension cord or have it repaired by a

qualifi ed person before using it.

• Protect your extension cords from sharp objects,

excessive heat and damp or wet areas.

EXTENSION

CORDS

FUNCTIONAL

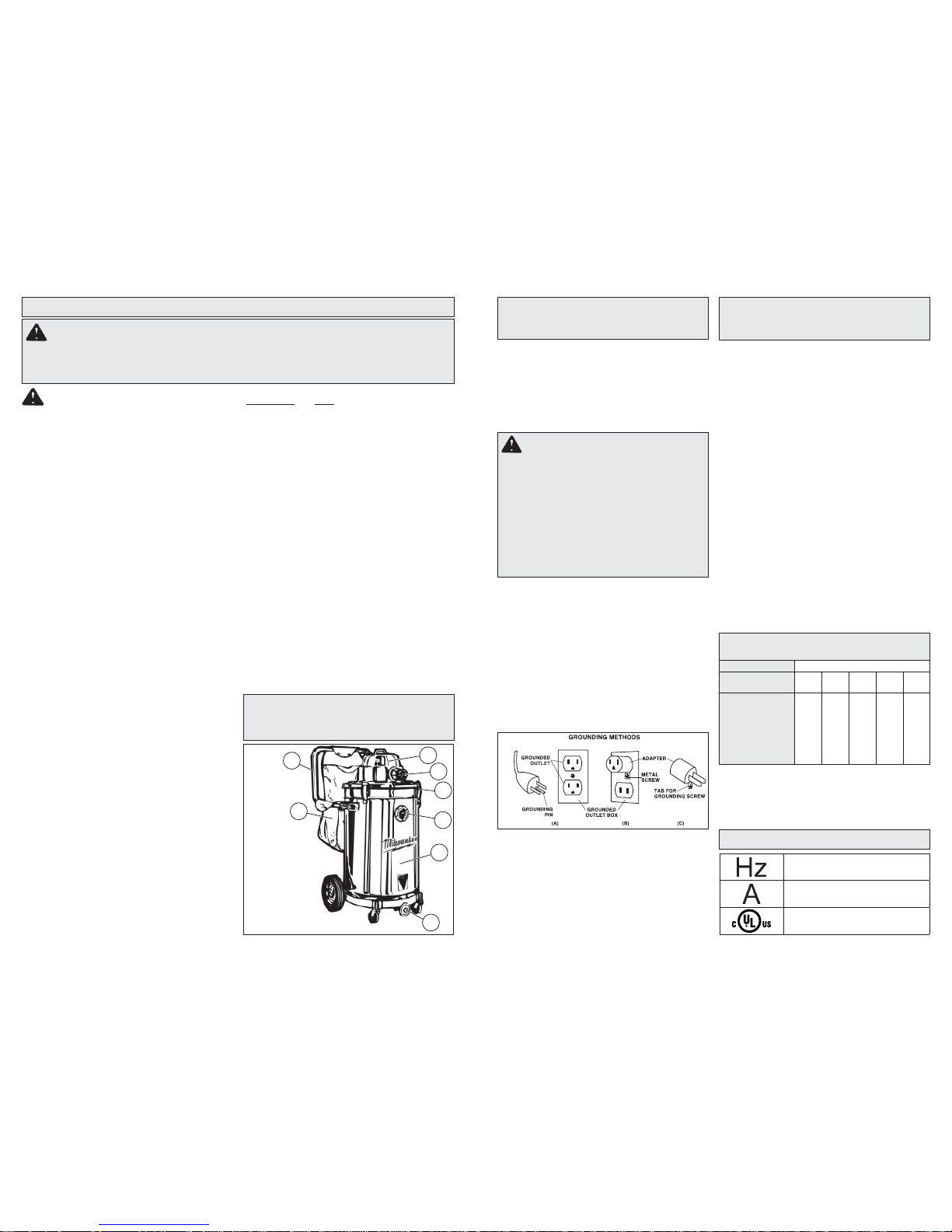

DESCRIPTION

1. Motor head

handle

2. Exhaust port

3. Tank latch

4. Intake port

5. Tank

6. Drain valve

7. Accessory storage pouch

8. Handle

7

2

1

5

4

3

8

6

Hertz

Amps

Underwriters Laboratories, Inc.

United States and Canada

SYMBOLOGY

4

5

Cat. No.

Volts

AC Amps For Materials

Tank Capacity

Gallons

Air Flow Cubic

Feet per Minute

Sealed Suction

in Water

8911

8912

8925

8926

8945

8965

120

120

120

120

120

120

7.5

9.2

9.2

9.2

9.2

6.2

Wet or Dry

Wet or Dry

Wet or Dry

Wet or Dry

Wet or Dry

Wet or Dry

11

11

15

21

no tank

10

94

92

92

92

92

133

84"

130"

130"

130"

130"

49"

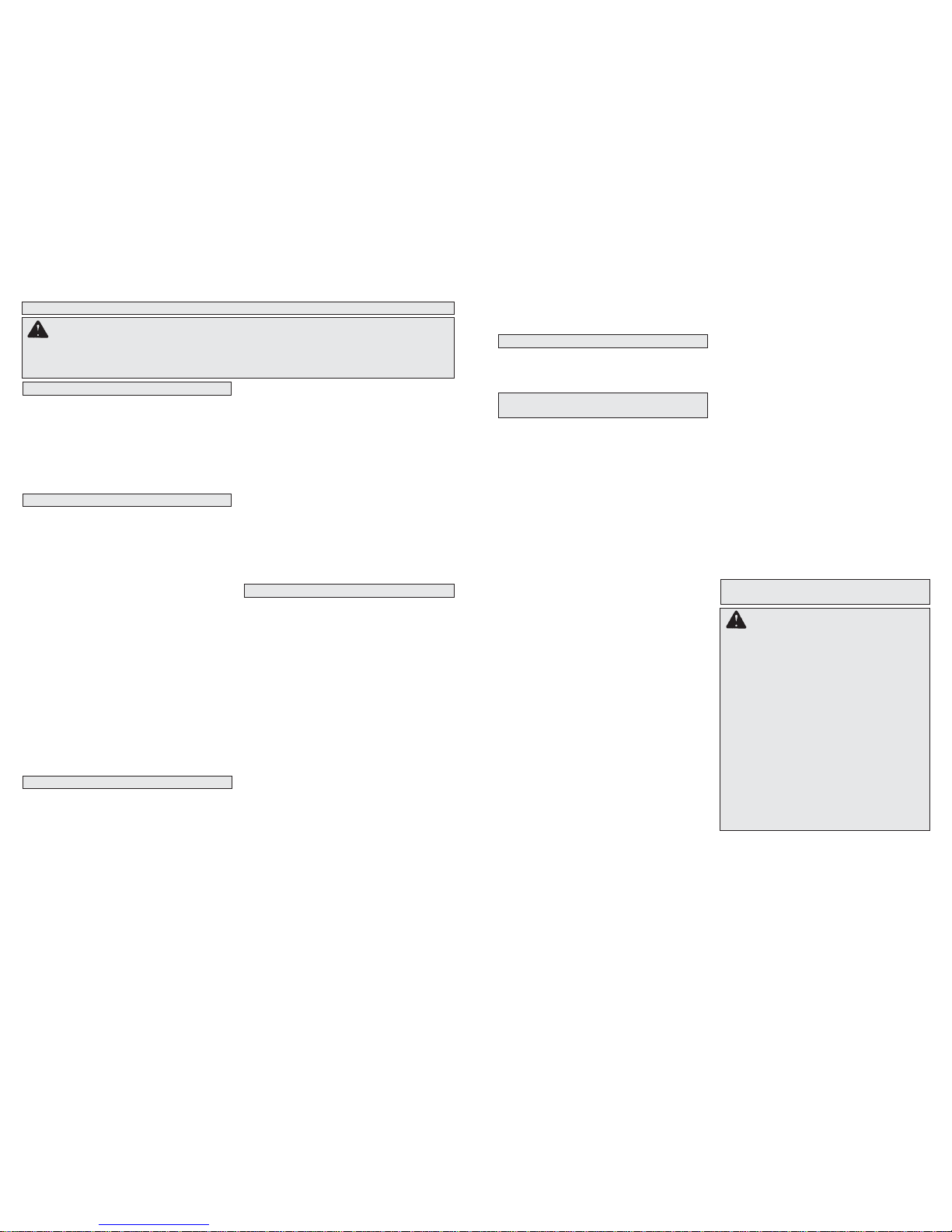

Using the Vacuum Cleaner To Pick Up Wet

Materials:

A fl oat valve shuts off suction

when the tank is full. Be sure

the fl oat is clean and moves

freely in the fl oat cage to ensure

that the fl oat valve works.

Float

cage

Float

SPECIFICATIONS

WARNING To reduce

the risk of injury, always unplug tool before

changing or removing accessories. Only use

accessories specifi cally recommended for

this tool. Others may be hazardous.

OPERATION

WARNING To reduce the

risk of injury, wear safety goggles or glasses

with side shields.

WARNING To reduce the

risk of fi re, electric shock, injury, and damage

to the tool: Do not plug any tool or appliance rated over 5 amps into the outlet on the

vacuum cleaner. Check nameplate on the tool

for the amp rating.

WARNING To reduce the

risk of electric shock, DO NOT pick up wet materials unless the vacuum cleaner is properly

set up to pick up wet materials.

Starting and Stopping Vacuum Cleaner

To turn on the vacuum cleaner, set the ON/OFF

switch to the ON position.

To turn off the vacuum cleaner, set the ON/OFF

switch to the OFF position.

Using the Vacuum Cleaner To Pick Up Dry Materials:

Make sure that the tank is dry before using the

vacuum cleaner to pick up dry materials. If the

vacuum cleaner tank is wet, run the vacuum cleaner

for about 5 minutes (without picking up anything) to

dry the inside of the tank.

4. Attach

cloth fi lter (D) to fi lter frame (D).

5. Set fi

lter frame and cloth fi

lter assembly (C and

D)

onto tank.

6. Replace motor head and snap down tank

latches.

Changing Paper Filter Bag and Cleaning Cloth

Filter

1. Remove motor head and set aside.

2.

Clean the cloth fi lter each time the tank is emptied

by shaking off loose material and brushing the

fi lter with a soft bristle brush. Do not wash cloth

fi lter with water. Washing can shrink the fi lter and

damage the gasket.

3. Pull bag out of the tank using care not the tear bag

on intake tube. Seal bag with cardboard fl aps and

discard.

Using the Vacuum Cleaner To Collect Dust Created By Tools:

Many tools (such as sanders) are designed so they

can be used with vacuum cleaners. The vaccum

cleaners collect the dust that these tools create

before it gets into the air or onto the fl oor. Vacuum

cleaners with the AUTO setting are ideal for collecting

dust because they can be set up to turn on and off

automatically using the tool’s AUTO/ON/OFF switch.

Vacuum cleaners without an AUTO setting can still

collect dust. The operator will simply have to turn the

vacuum on and off.

Using a Vacuum Cleaner without an Automatic

Switch as a Dust Collection Device for a Tool

1. Connect vaccum hose to the tool’s dust collection

port.

2. Turn on the vacuum cleaner.

3. Turn on tool.

Installing Filters

1.

Remove motor head (A) and set aside.

Caution: Use care when handling motor head.

Dropping motor head may cause permanent

damage.

2.

If you are using Cat. No. 8965, place foam fi lter

sleeve (B) over fl oat value cage.

3.

Install only one of the following fi lters:

If you plan to vacuum dry material into a fi lter bag,

expand the paper fi lter bag

(E) and fi

t cardboard collar

(G) onto the intake tube (F)

as far as possible.

If you plan to vacuum medium fi ne to coarse, sharp

dry material directly into the

tank without a fi lter

bag, fi t a

dacron fi lter onto

the cloth fi lter as-

sembly (C and D).

If you plan to vacuum extremely fi ne

material directly

into the tank without a fi lter bag, fi t

a paper fi lter onto

the tank.

Using a Vacuum Cleaner with an Automatic

Switch as a Dust Collection Device for a Tool

1. Connect vacuum hose to the tool.

2. Plug the tool into the electrical outlet on the

vacuum cleaner’s motor head.

3. Set the AUTO/ON/OFF switch to the AUTO position.

4. Turn on the tool and the vacuum cleaner will start

automatically within a few seconds.

Float cage

Float

Cat. No. 8965 does not need a wet adapter for picking

up wet materials. The safety valve is already built in

to the 8965 vaccum cleaner. Do not remove the foam

fi lter sleeve. It is designed to be used with both wet

and dry materials.

Installing Wet Adapter

1. Remove motorhead and set

aside.

2.

Set wet adapter into tank.

3. Replace motorhead and snap

down tank latches.

Removing Liquid from the Vacuum

Tank on Vacuum Cleaners with

Drain Valves

1. Center drain valve over fl oor drain.

2. Open drain valve.

For Cat. No. 8925, open drain valve by turning the

drain valve handle counter clockwise. To closedrain valve trun clockwise.

For Cat. No. 8924 and 8926, open drain valve by

pulling up on the handle. To close push down on

handle.

3. Drain.

4. Rinse, dry tank and close drain valve.

Removing Liquid from the Vacuum Tank on

Vacuum Cleaners without Drain Valves

1. Remove motorhead and wet adapter and set aside.

2. Block

wheels.

3.

Carefully dump contents into fl oor drain.

4.

Rinse and dry tank.

Do not store vacuum cleaner with liquid in tank. Run

the vacuum for about 5 minutes without picking up

anything to dry the inside of the tank.

WARNING If the fl oat is

clean, moves freely and the suction does not

shut off when the tank is fi lled (you will be

able to see water in the exhaust port), send

the motorhead to the nearest MILWAUKEE

service facility for repair.

Using the Vacuum as a Blower

1. Attached hose exhaust port on the motorhead.

2. Attach the appropriate accessory to the hose.

3. Turn the vacuum on.

W ARNING T o reduce the risk

of injury: wear safety glasses and a dustmask

when using the vacuum cleaner as a blower.

Maintaining Tools

Keep your tool in good repair by adopting a regular

maintenance program. Before use, examine the

general condition of your tool. Inspect guards,

switches, tool cord set and extension cord for

damage. Check for loose screws, misalignment,

binding of moving parts, improper mounting, broken parts and any other condition that may affect

its safe operation. If abnormal noise or vibration

occurs, turn the tool off immediately and have the

problem corrected before further use. Do not use a

damaged tool. T ag damaged tools “DO NOT USE”

until repaired (see “Repairs”).

Under normal conditions, relubrication is not necessary until the motor brushes need to be replaced.

After six months to one year, depending on use,

return your tool to the nearest MILWAUKEE service

facility for the following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears, spindles, bearings, housing, etc.)

• Electrical inspection (switch, cord, armature, etc.)

• Testing to assure proper mechanical and electrical

operation

WARNING To reduce the

risk of injury, electric shock and damage to

the tool, never immerse your tool in liquid or

allow a liquid to fl ow inside the tool.

WARNING To reduce

the risk of injury, always unplug your tool

before performing any maintenance. Never

disassemble the tool or try to do any rewiring on the tool’s electrical system. Contact a

MILWAUKEE service facility for ALL repairs.

Cleaning

Clean dust and debris from vents. Keep the tool

handles clean, dry and free of oil or grease. Use

only mild soap and a damp cloth to clean your

tool since certain cleaning agents and solvents

are harmful to plastics and other insulated parts.

Some of these include: gasoline, turpentine, lacquer

thinner, paint thinner , chlorinated cleaning solvents,

ammonia and household detergents containing

ammonia. Never use fl ammable or combustible

solvents around tools.

Storage

Before storing the vacuum cleaner, always empty

and clean the tank. Never allow debris to sit in

the tank for any extended period of time. The

vacuum cleaner should be stored indoors.

MAINTENANCE

Cat. No.

8975

8977

8978

8986-20

8988-20

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S

MANUAL.

OPERATOR'S MANUAL

HEAVY-DUTY HEAT GUNS

PERSONAL SAFETY

GENERAL POWER TOOL SAFETY WARNINGS

WORK AREA SAFETY

ELECTRICAL SAFETY

• Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of fl ammable

liquids, gases or dust. Power tools create

sparks which may ignite the dust or fumes.

• Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodifi ed plugs and matching outlets will

reduce risk of electric shock.

• Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. W ater entering a power tool will increase

the risk of electric shock.

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

• When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

• If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your fi nger on the switch or energising power

tools that have the switch on invites accidents.

• Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

• Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewellery. Keep your hair , clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

• If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

WARNING READ ALL SAFETY WARNINGS AND INSTRUCTIONS.

Failure to follow the warnings and instructions may result in electric shock, fi re and/or

serious injury. Save all warnings and instructions for future reference

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

POWER TOOL USE AND CARE

• Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

• Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

• Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

• Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

• Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

• Use the power tool, accessories and tool bits

etc., in accordance with these instructions,

taking into account the working conditions

• Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the infl uence of drugs, alcohol or medi-

cation. A moment of inattention while operating

power tools may result in serious personal injury.

• Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

• Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

IMPORT ANT SAFETY INSTRUCTIONS

HEAT GUNS

and the work to be performed. Use of the power

tool for operations different from those intended

could result in a hazardous situation.

SERVICE

• Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

READ THESE INSTRUCTIONS

• Know your work environment. Hidden areas

such as behind walls, ceilings, fl oors, soffi t boards

and other panels may contain fl ammable materials

that may ignite when using the heat gun in these

locations. Ignition of these materials may not be

readily apparent and could result in property damage and personal injury. Check these areas before

applying heat. If in doubt, use an alternate method.

Pausing or lingering in one spot may ignite the

panel or the material behind it. Keep heat gun

moving to avoid excessive temperatures.

• Do not direct the heat gun air airfl ow at clothing,

hair or other body parts. Do not use as a hair

dryer. Heat guns can produce 1000°F (540°C) or

more of fl ameless heat at the nozzle. Contact with

the air stream could result in personal injury.

• Do not use near fl ammable liquids or in ex-

plosive atmospheres, such as in the presence

of fumes, gases or dust. The fl ameless heat

from the heat gun may ignite the dust or fumes.

Remove materials or debris that may become

ignited from work area.

• Shield materials around the heated area to

prevent property damage or fi re.

• Keep a fi re extinguisher nearby . Heat guns may

ignite fl ammable materials left in the work area.

• WARNING! Hot Surfaces. Always hold the heat

gun by the plastic enclosure. Do not touch

nozzle, accessory tips or store heat gun until

the nozzle has cooled to room temperature.

The metal nozzle requires approximately 20

minutes to cool before it can be touched. Contact

with the nozzle or accessory tip could result in

personal injury. Place the heat gun in a clear area

away from combustible materials while cooling to

prevent fl ammable materials from igniting.

• Do not cut off airfl ow by placing nozzle too

close to workpiece. Keep intake vents clean

and clear of obstructions. Restricting airfl ow may

cause the heat gun to overheat.

• Place the heat gun on a stable, level surface

when not hand held. Use the support pads or

support stand. Place cord in a position that won’t

cause the heat gun to tip over.

• Do not leave the heat gun unattended while

running or cooling down. Inattention invites

accidents.

PERSONS REMOVING PAINT SHOULD

FOLLOW THESE GUIDELINES:

• Work in a well ventilated area. If possible, move

the workpiece outdoors. If working indoors, open

windows and place an exhaust fan in a window. Be

sure the fan is moving air from inside to outside.

Proper ventilation will reduce the risk of inhaling

chemicals found in the fumes or dust created by

using a heat gun.

• Store indoors in a dry location. Do not expose

to rain or moisture.

• Do not direct airfl ow directly on glass. The

glass may crack and could result in property

damage or personal injury.

• Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE Service facility for a free

replacement.

• WARNING Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals:

work in a well ventilated area, and work with

approved safety equipment, such as those dust

masks that are specially designed to fi lter out

microscopic particles.

IMPORT ANT SAFETY INSTRUCTIONS

FOR REMOVING PAINT

WARNING Use extreme care when

stripping paint. Peelings, residue

and vapors of paint may contain lead,

which is POISONOUS. Pre-1977 paint

may contain lead and paint made

before 1950 is likely to contain lead. Hand to

mouth contact with paint peelings or residue

from pre-1977 paint may result in lead

ingestion. Exposure to even low levels of lead

can cause irreversible brain and nervous

system damage. Young and unborn children

are especially vulnerable to lead poisoning.

DO NOT REMOVE LEAD-BASED PAINT WITH

A HEAT GUN. Before beginning your work,

determine whether the paint you are removing

contains lead. A local health department or

a professional who uses a paint analyzer

can check the paint for lead content. LEADBASED PAINT SHOULD BE REMOVED ONL Y

BY A PROFESSIONAL.

Loading...

Loading...