Page 1

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Cat. No.

No de cat.

7100-20

ROUND HEAD FRAMING NAILER

CLOUEUSE À BANDE POUR CHARPENTE

CLAVADORA DE CABEZA REDONDA

TO REDUCE THE RISK OF INJURY, USER MUST READ OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LES RISQUES DE BLESSURES, L’UTILISATEUR DOIT LIRE

LE MANUEL DE L’OPÉRATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER EL MANUAL

DEL OPERADOR.

Page 2

GENERAL SAFETY INSTRUCTIONS

DANGER

IMPORTANT SAFETY INSTRUCTIONS. SAVE THESE

INSTRUCTIONS PERTAINING TO A RISK OF INJURY OR DEATH

WARNING

WHEN USING TOOLS, BASIC PRECAUTIONS SHOULD

ALWAYS BE FOLLOWED, INCLUDING THE FOLLOWING:

GENERAL

1. To reduce the risk of injury, read all

instructions before using the tool.

WORK AREA

2. Keep the work area clean and well

lighted. Cluttered benches and dark

areas increase the risk of injury.

3.

Do not operate the tool in explosive

atmospheres, such as in the presence

of fl ammable liquids, gases, or dust.

The tool is able to create sparks resulting

in the ignition of the dust or fumes.

4. Keep bystanders, children, and visi-

tors away while operating the tool.

Distractions are able to result in the loss

of control of the tool.

5. Know what is behind your workpiece.

A fastener could travel through the workpiece and out the other side, striking a

bystander and causing serious injury.

6. DANGER: Avoid performing opera-

tions where the fastener may contact

hidden wiring. Contact with a “live”

wire will make exposed metal parts of

the tool “live” and shock the operator,

resulting in serious injury or death.

Contact a qualifi ed electrician to ensure

a safe work environment exists.

PERSONAL SAFETY

7. Stay alert. Watch what you are doing

and use common sense when operating

the tool. Do not use the tool while tired

or under the infl uence of drugs, alcohol,

or medication. A moment of inattention

while operating the tool increases the

risk of injury to persons.

8. Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

Keep hair, clothing, and gloves away

from moving parts. Loose clothes,

jewelry, or long hair increases the risk

of injury to persons as a result of being

caught in moving parts.

9. Avoid unintentional starting. Remove

fi nger from the trigger when not driving fasteners. Be sure the trigger is not

pulled before connecting to the air supply. Do not carry the tool with your fi nger

on the trigger or connect the tool to the

air supply with the trigger pulled.

10. Do not overreach. Keep proper footing

and balance at all times. Proper footing

and balance enables better control of

the tool in unexpected situations.

11.

Use safety equipment. A dust mask,

non-skid safety shoes and a hard hat

used for appropriate conditions will reduce

personal injuries.

12. The operator and other people in the

work area must wear eye protection

in accordance with ANSI Z87.1. Eye

protection does not fi t all operators in the

same way. Make sure the eye protection

chosen has side shields or provides

protection from fl ying debris both from

the front and sides. The employer is

responsible for enforcing the use of eye

protection by the operator and other

people in the work area. When required,

wear head protection in accordance with

ANSI Z89.1.

13. Always wear ear protectors when

using the tool for extended periods.

Prolonged exposure to high intensity

noise is able to cause hearing loss.

14. Do not carry an air hose or a tool con-

nected to an air hose when climbing

ladders, rigging or scaffolding. Do

not attach an air hose or tool connected to an air hose to your body

when working at elevated heights. At-

tach the hose to the structure to reduce

the risk of loss of balance and injury if

the hose shifts.

15. Always assume that the tool contains

fasteners. Do not point the tool toward

yourself or anyone whether it contains

fasteners or not.

16. Do not nail on top of another nail. This

can cause the nail to be defl ected and

hit someone, or cause the tool to react

and result in a risk of injury to persons.

TOOL USE AND CARE

17. Use clamps or another practical way

to secure and support the workpiece

to a stable platform. Holding the work

by hand or against the body is unstable

and is able to lead to loss of control.

18. Do not force the tool. Use the correct

tool for the application. The correct tool

will do the job better and safer at the rate

for which the tool is designed.

19. Do not use the tool if the trigger does

not turn the tool on or off. Any tool that

cannot be controlled with the trigger is

dangerous and must be repaired.

Disconnect the tool from the air source,

20.

then empty the magazine before making

adjustments, doing tool maintenance,

clearing jams, touching the workpiece

contact or leaving work area. Verify the

tool is empty and there is no residual pressure in the tool prior to performing these

actions. Such precautionary measures

reduce the risk of injury to persons.

21. Store idle tools out of reach of chil-

dren and other untrained persons.

A tool is dangerous in the hands of

untrained users.

22. Maintain the tool with care. A properly

maintained tool reduces the risk of injury.

If the tool has been dropped, received a

sharp blow, been run over , etc., perform

the "Required Daily Testing" before

further use.

23. Check for misalignment or binding

of moving parts, breakage of parts,

and any other condition that affects

the tool’s operation. If damaged, have

the tool serviced before using. Many accidents are caused by poorly maintained

tools. There is an increased risk of the

tool bursting if the tool is damaged.

24. Use only those fasteners specifi cally

recommended. Fasteners not identifi ed

for use with this tool by the tool manufacturer are able to result in a risk of injury

to persons or tool damage when used

in this tool. See the "Specifi cations"

section for fastener requirements.

25. Use only accessories that are identi-

fi ed by the manufacturer for the specifi c tool model. Use of an accessory

not intended for use with the specifi c

tool model, increases the risk of injury

to persons.

SERVICE

26. a) Tool service must be performed

only by qualifi ed repair personnel.

b) The wrench provided is for tighten-

ing screws during "Required Daily

Testing".

c) Use only identical replacement

parts recommended by the manufacturer.

27. Use only the air tool lubricants supplied

with the tool or specifi ed by the manu-

facturer. Do not use other lubricants;

they will damage the tool. See "Acces-

sories" for a list of recommended air tool

lubricants.

2 3

Page 3

AIR SOURCE

TERMINOLOGY

28. DANGER: Do not use oxygen, combustible gases or bottled gases as a

power source for this tool. The tool will

explode and cause death or serious

injury.

29. Never connect to an air source that

is capable of exceeding 200 psi. Over

pressurizing the tool may result in bursting, abnormal operation, breakage of the

SPECIFIC SAFETY INSTRUCTIONS

1. Use air supply hoses with a minimum

working pressure rating of 200 psi.

2. Use pressure regulators to limit the

air pressure supplied to the tool. Set

the regulators to no more than 120

psi.

3. Install only hose couplings that will

allow all pressure to be removed from

tool when disconnected from the

source. If the wrong fi tting is installed,

pressure may remain in the tool after

disconnection, allowing it to drive a

fastener, possibly causing injury.

4. Prior to each use, check workpiece

contact and trigger for correct operation. Do not disassemble or clamp

parts of the workpiece contact, trigger,

or driving mechanism. This will cause

unexpected actuation, resulting in serious injury.

5. Never point the discharge area of the

tool at any body parts or at other people. Always assume the tool is loaded

and capable of driving a fastener.

6. Do not actuate the tool into free

space. Do not engage in horseplay.

The discharged fasteners are projectiles

capable of causing serious injury.

7. When using the tool, ensure the

workpiece contact is securely placed

on the workpiece. Hold the tool fi rmly

and be prepared for the recoil.

tool or serious injury to persons. Use

only clean, dry, regulated compressed

air at the rated pressure or within the

Actuate

T o cause movement of the tool component(s)

intended to drive a fastener.

rated pressure range as marked on the

tool. Prior to using the tool, always verify

that the air source has been adjusted to

the rated air pressure or within the rated

air-pressure range. Air compressors

should comply with ANSI B19.3.

Actuation System

The use of a trigger, workpiece contact

and/or other operating control, separately

or in some combination or sequence, to

actuate the tool.

• Single sequential actuation

An actuation system that requires the

workpiece contact and then the trigger

8. Do not remove, tamper with, or

otherwise cause the tool operating

controls to become inoperable. This

will cause unexpected actuation, resulting in serious injury.

9. Do not operate a tool if any portion of

the tool operating controls is inoperable, disconnected, altered, or not work-

ing properly. This will cause unexpected

actuation, resulting in serious injury.

10. Always keep hands and body away

from discharge area of the tool. Never

attempt to clear a jammed workpiece

contact by grasping the discharge area

of the tool. Fasteners discharged from

tool can cause serious injury if they

to be activated in a specifi c sequence

to drive a fastener. Additional actuation

can occur when the trigger is released

and reactivated.

• Contact actuation

An actuation system that requires the

workpiece contact and the trigger to be

activated in any sequence to drive a

fastener. Additional actuation can occur

when either the workpiece contact or the

trigger is released and reactivated.

• Selective actuation

An actuation system that allows selec-

tion of actuation systems: single sequential actuation or contact actuation.

contact hands or body.

11. Do not drive fasteners close to the

edge of the workpiece. Fasteners can

slip off corners and edges or penetrate

through thin material, making them

projectiles capable of causing serious

injury.

12. Use the tool only for the intended

purpose. Do not abuse the tool. Do

not use as a hammer, stamp or engrave

information onto parts, drop or impact

the tool or otherwise apply excess force

to the tool in use. Do not mount the

tool to stands or modify it for stationary

use.

13. Do not carry tool by the air hose. Only

carry the tool by the handle with your

Specifi cations

fi nger off of the trigger.

14. Do not use this tool without the

safety warning label in place. If the

label is damaged or missing, contact

MILWAUKEE for a free replacement.

Cat.

7100-20

No.

Operating

Pressure

min. 70 PSI

max. 120 PSI

Fastener

Length

min. 2"

max. 3.5"

Collation

Angle

22°

4 5

Fastener

A staple, pin, brad, nail, or other fastening

device which is designed and manufactured

for use in the tools.

Jam

An obstruction in the feed or drive areas of

the tool.

Workpiece Contact

An operating control element on the tool

intended to be activated by the workpiece

to be fastened.

Symbology

Read the Operator's Manual

Wear Eye Protection

Keep hands away

Fastener Size

(Diameter)

min. .113"

max. .148"

Air

Consumption

3

.16 ft

/cycle at

100 psi

Air

Inlet

3/8 in.

NPT

Magazine

Capacity

64-72 nails

Page 4

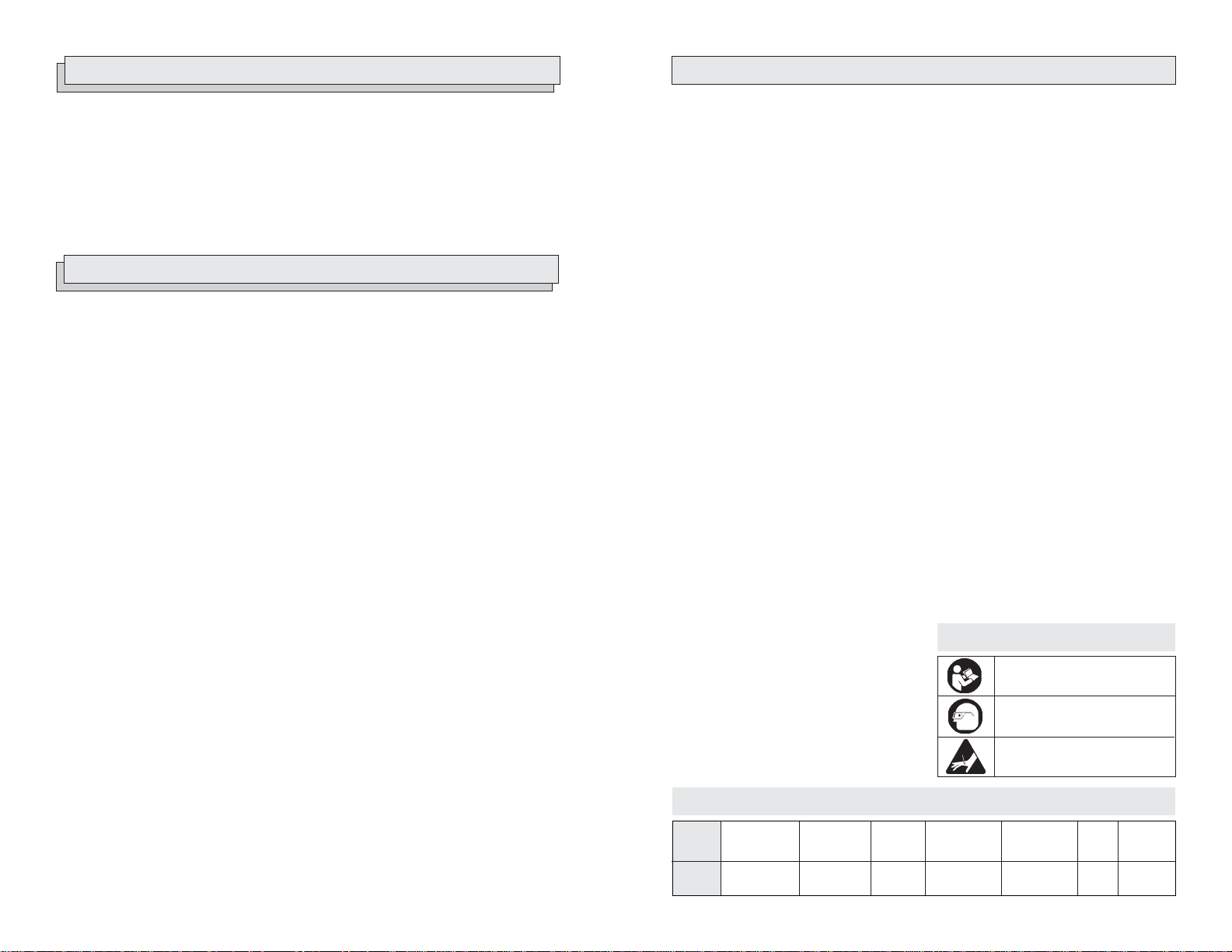

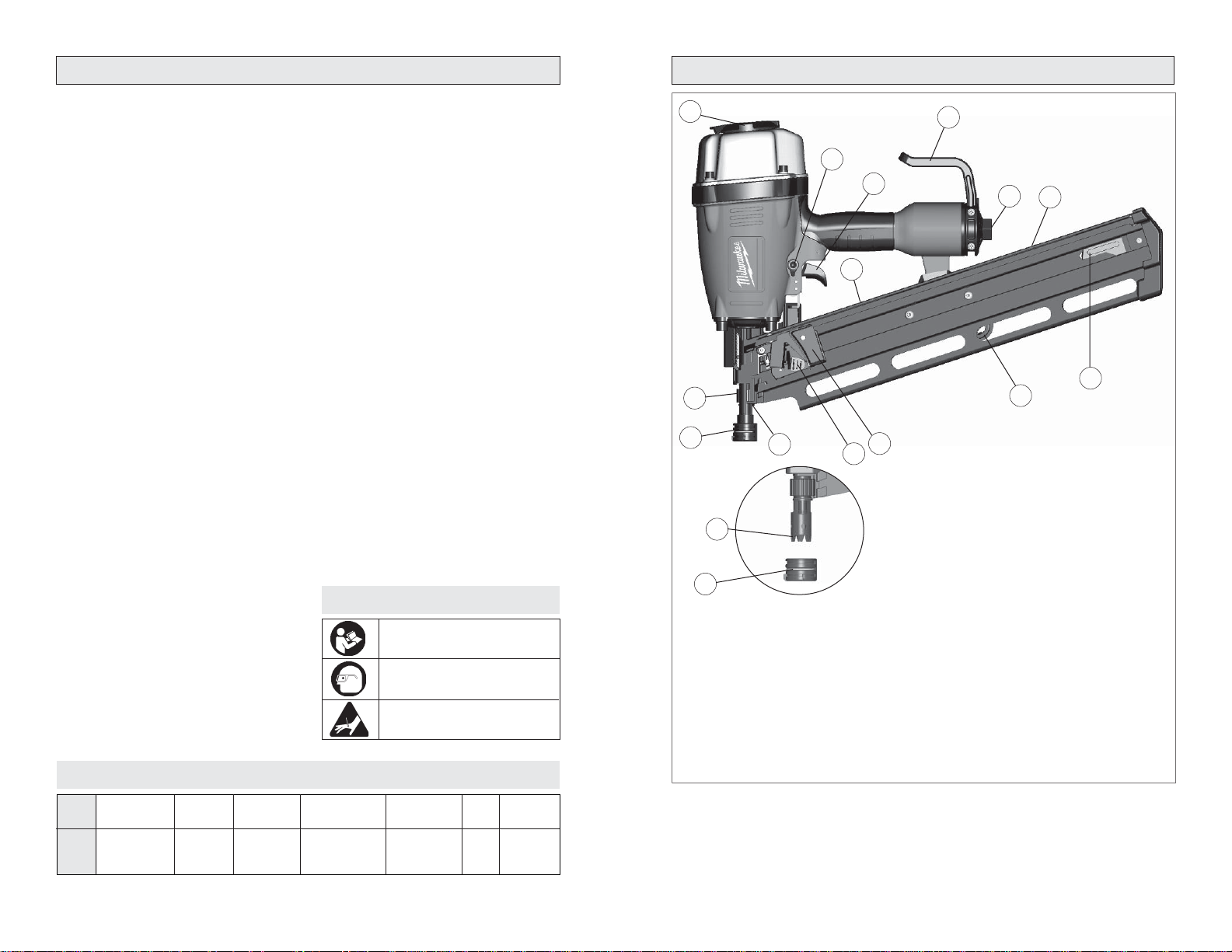

FUNCTIONAL DESCRIPTION

ASSEMBLY

5

6

7

13

8

Disconnect the air supply from the

tool and remove fastener strips

before changing or removing acces-

9

10

sories. Only use accessories specifi cally recommended for this tool

by the manufacturer. Others may be

hazardous.

The operator and other people in the

work area must wear eye protection

in accordance with ANSI Z87.1. Eye

protection does not fi t all operators

in the same way. Make sure the eye

protection chosen has side shields or

provides protection from fl ying debris

both from the front and sides.

11

4

3

16

15

2

1

1. No-mar pad

2. Toe-nail claw

3. Workpiece contact

14

4. Depth of drive adjustment

5. Exhaust defl ector

6. Actuation selector

7. Trigger

8. Rafter hook

9. Air inlet

10. Nameplate (on top of magazine)

11. Nail stop tab

12. Extra no-mar pad storage

(on back of magazine)

13. Warning label (on top of magazine)

14. Pusher

15. Pusher release button

16. Nail guide

12

No-Mar Pad

The No-Mar Pad on the nose of the tool

protects the workpiece when the workpiece

contact is compressed during actuation. The

pad can be removed and replaced.

1. Before removing or replacing no-mar

2. To remove the pad, pull the pad open

3. Storage for an additional pad is available

4. To replace the pad, fi t it into place over

Exhaust

The exhaust cap can be adjusted to direct

the exhaust as desired. Turn the exhaust cap

to the desired locking position.

WARNING

pads, disconnect the air supply from the

tool and remove fastener strips.

and away from the toe-nailing claw.

on the magazine of the tool.

the points of the claw.

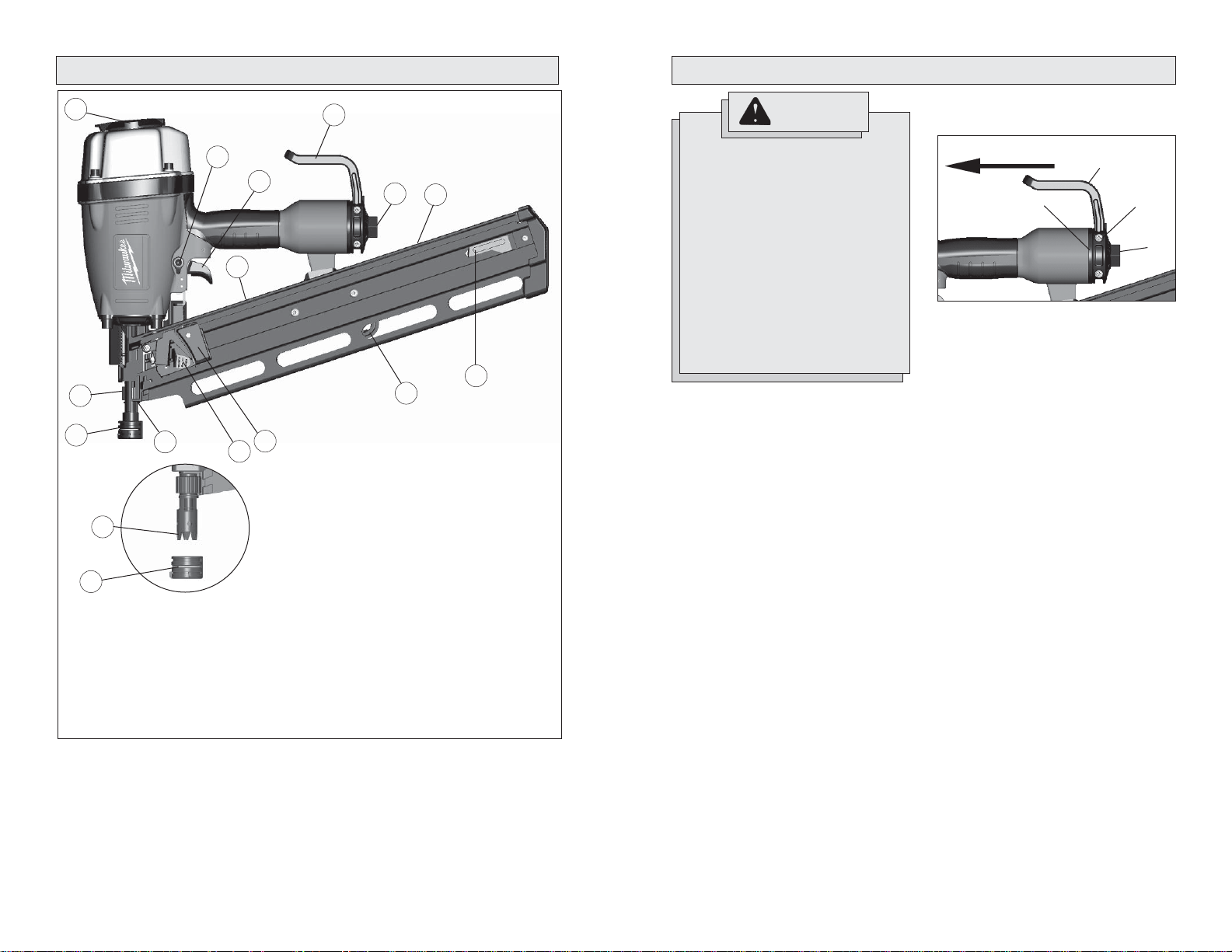

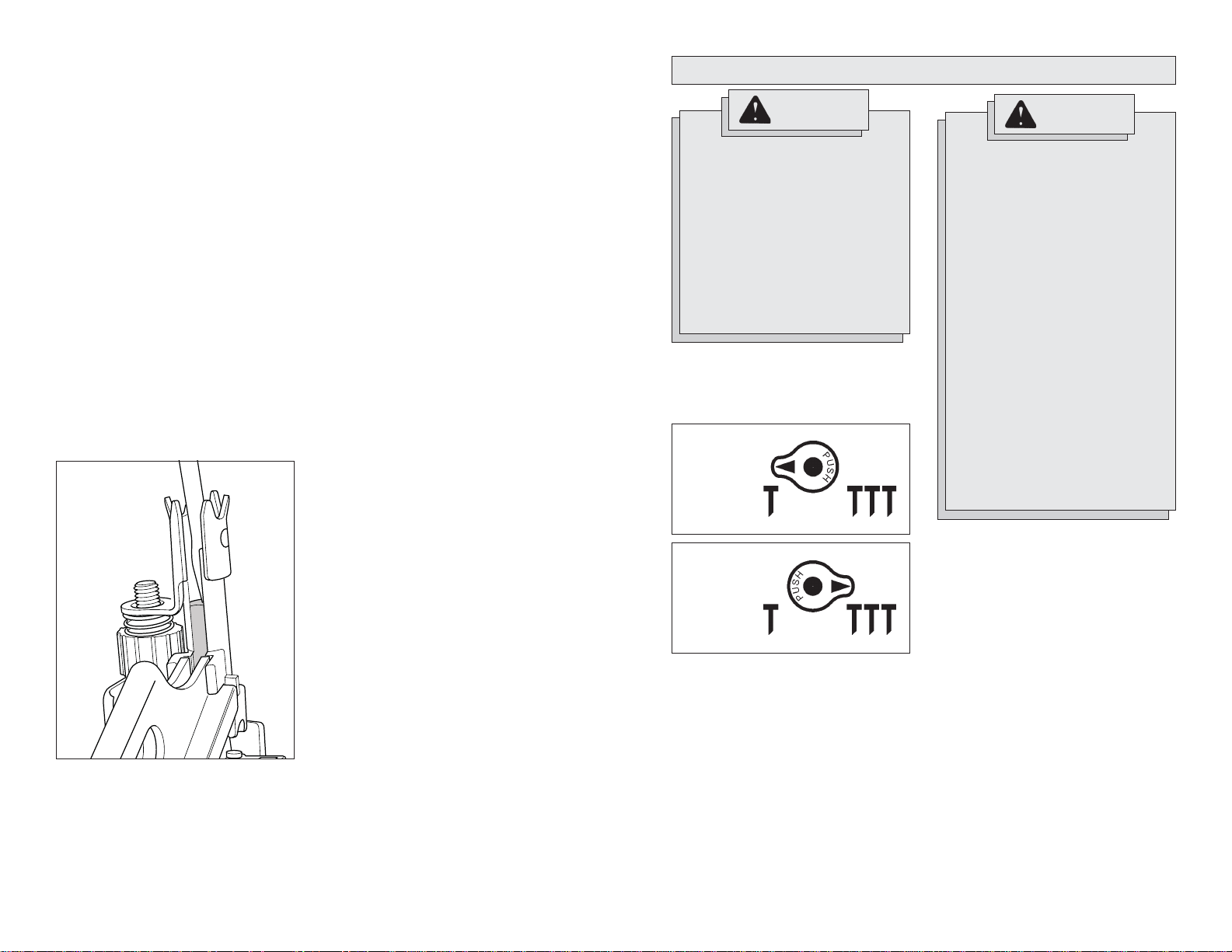

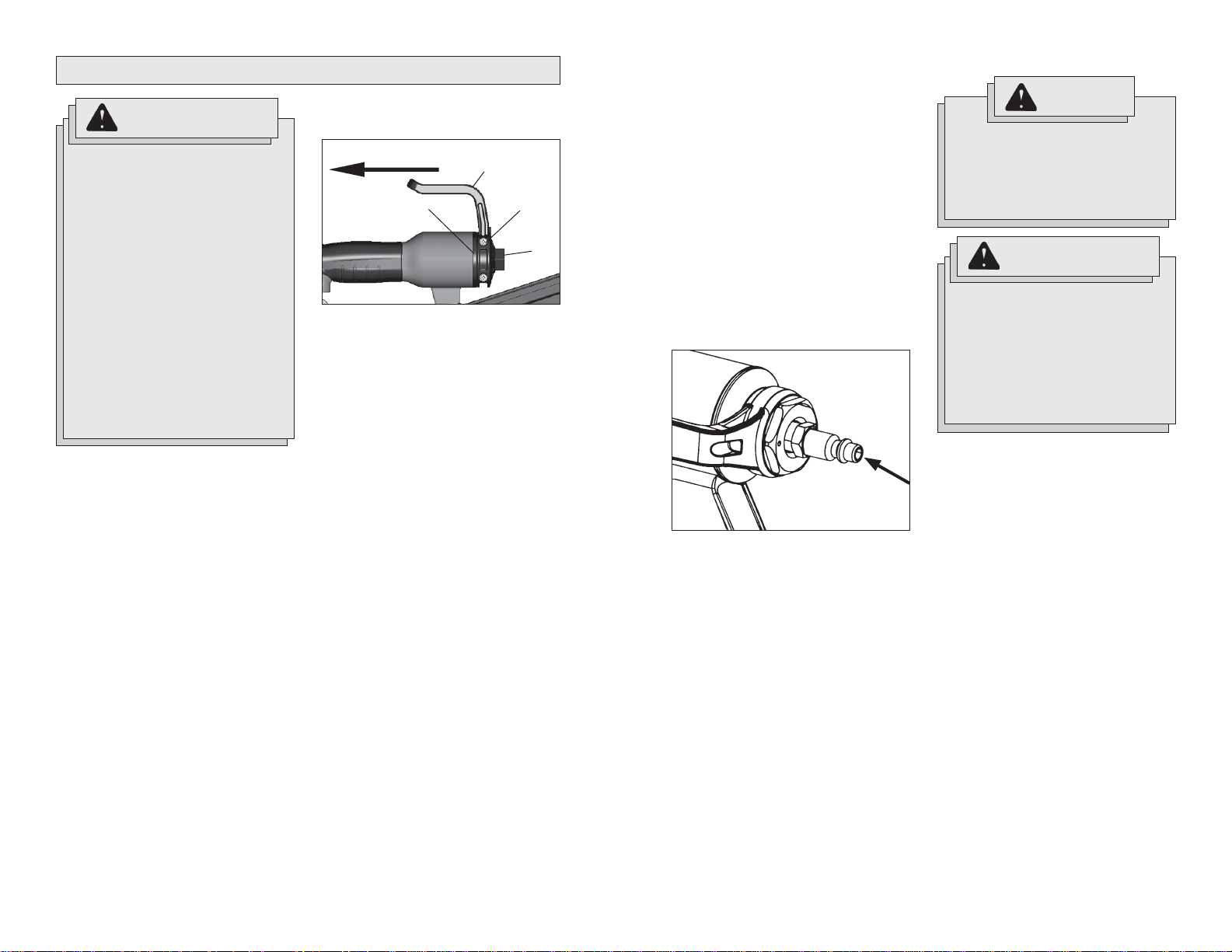

Removing and Installing the Rafter Hook

Fig. 1

Front of tool

End cap

To remove the hook:

1. Rotate the hook until it snaps into one of

the preset positions.

2. Remove the two mounting screws using

the wrench provided.

3. Pull the hook off the rear of the tool.

To install the hook:

1. Align the spring-loaded post on the hook

with a slot on the rear of the tool.

2. Slide the hook onto the tool, making sure

the hook points toward the front of the

tool. Push the hook up against the end

cap.

3. Install the two mounting screws using

the wrench provided. Tighten securely.

4. V erify that the hook is installed correctly

by fi rmly pulling the hook toward the air

inlet. It must not move.

Rafter hook

Screw

(2)

Air

inlet

6 7

Page 5

Lubricating the Tool

Lubricate the tool with air tool lubricant

before connecting the air supply. Under low

use, lubricate once a day. Under heavy use,

lubricate twice a day. Use only a few drops

of oil at a time. Using too much oil will cause

it to collect in the tool and be noticeable

in the exhaust. Do not use detergent oil,

WD-40, transmission fl uid, motor oil, or other

lubricants not specifi cally designated as air

tool lubricant. These lubricants will cause

accelerated wear to the seals, o-rings and

bumpers in the tool, resulting in poor tool

performance and frequent maintenance.

Fig. 2

3/8" NPT quick

connector

2-3

drops of

air tool

lubricant

DANGER

Do not use oxygen, combustible gases or bottled gases as a power source

for this tool. The tool will explode and

cause death or serious injury.

WARNING

Always use a coupling that discharges all the compressed air in the tool at

the time the fi tting or hose coupling is

disconnected. Using a coupling that

does not discharge the compressed

air could cause unintended operation

and serious injury.

Use only clean, dry compressed air with a

maximum pressure of 200 psi. Before connecting the tool to the air supply, check the

air compressor regulator gauge to be sure it

is functioning properly, with a range between

70-120 psi. Air pressure higher than 120 psi

could cause injury and property damage. The

correct pressure is the lowest pressure that

will do the job.

To connect the air supply:

1. Remove the plastic plug from the tool air

inlet.

2. Insert a 3/8" NPT quick connector into

the tool air inlet.

NOTE: To improve the seal between

the connector and the tool, and to help

protect against oxidation, apply a PTFE

tape or paste to the connector threads

before insertion.

3. Lubricate the quick connector with 2-3

drops air tool lubricant.

4. Snap the air hose onto the quick connector.

5. Check for air leakage.

Installing Fastener Strips

WARNING

Always point the tool away from

yourself and others when installing

fasteners. Failure to do so could

result in injury.

Always make sure the tool's magazine is EMPTY before connecting to

the air supply. The tool may actuate

when the tool is fi rst connected to the

air supply. Always connect the tool

to the air supply before loading nails

to prevent injury from unintended

actuation.

Never install fasteners with the

workpiece contact or trigger activated. Failure to do so could result

in injury.

Use only recommended fasteners

of the correct size, length, collation

angle and head type, as indicated

on the tool's nameplate. Refer to the

"Accessories" section for information on recommended fasteners.

Other fasteners could result in tool

malfunction, leading to injury.

1. Verify that the magazine is empty and

then connect the air supply to the tool.

2. Lay the tool on its side and point the

nose of the tool away from yourself and

others.

Feed fastener strips into the magazine and

3.

over the nail stop tab. Be sure the point of

the fasteners is pointed downward.

NOTE: Use only recommended fasten-

ers of the correct size, length, collation

angle and head type as indicated on the

tool's nameplate.

4. Slide the pusher to the rear of the magazine and over the nail stop tab.

5. Gently allow the pusher to slide forward,

pushing the fasteners toward the driving

mechanism. The pusher will stop when

it rests against the end of the fastener

strip.

NOTE: The fasteners must be aligned

with the nose of the tool for the fasteners

to be installed correctly.

Removing Fastener StripsConnecting the Air Supply

WARNING

To avoid serious injury, disconnect

the tool from the air supply before

removing fastener strips or clearing

a jammed fastener.

Keep fi ngers clear of fastener track

of magazine. Pusher could pinch

fi ngers, causing injury.

1. Lay the tool on its side and point the

nose of the tool away from yourself and

others.

2.

Disconnect the air supply from the tool.

3.

To remove fasteners, press the pusher

release button on the pusher and gently

slide the pusher forward toward the driving

mechanism.

4. Slide the nails back until they stop.

5. Press down on the fastener stop tab

near the end of the magazine and slide

the fasteners over the tab.

6. Remove fastener strip from the tool.

7. Reload according to "Installing Fastener

Strips".

8 9

Page 6

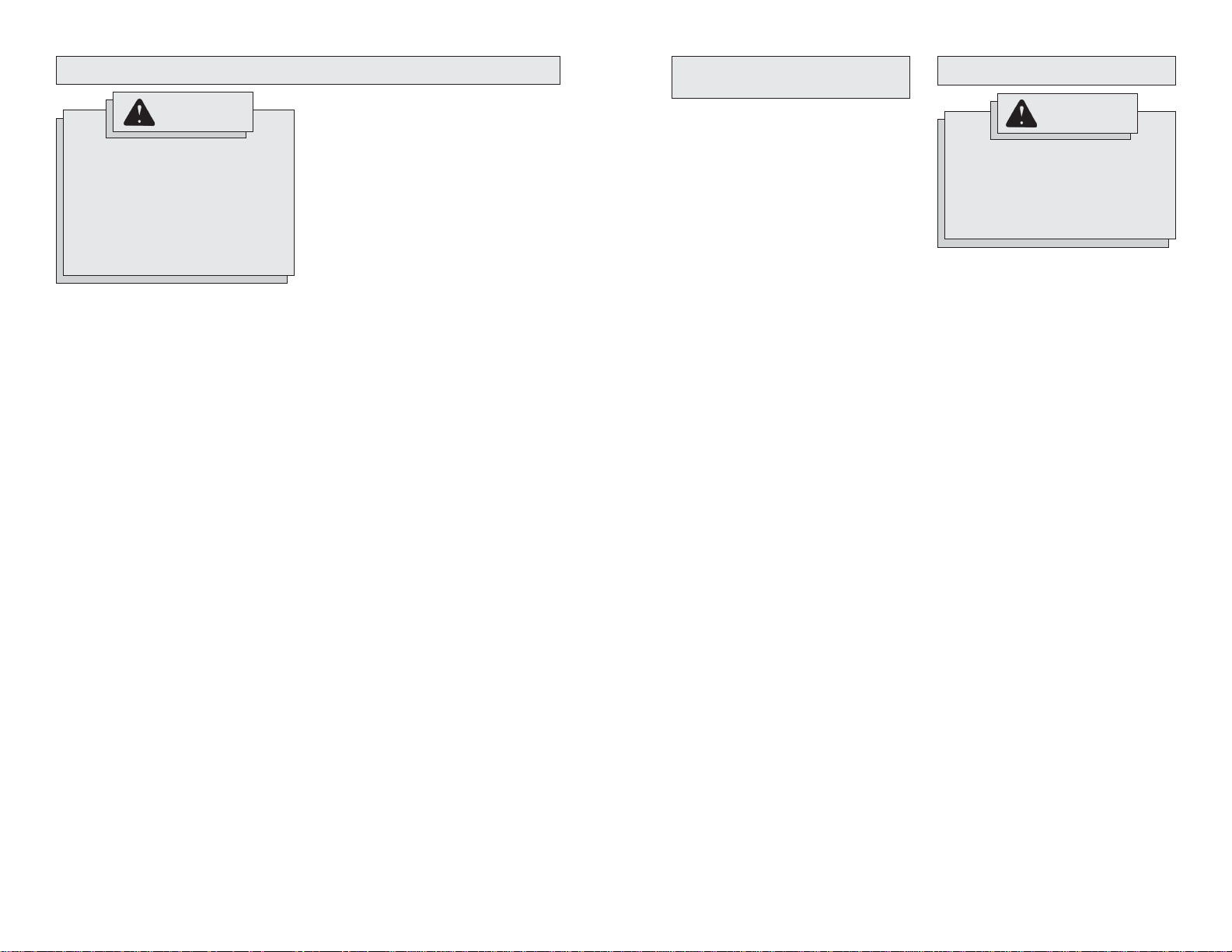

Clearing a Jammed Fastener

Most jams are caused by a fastener or part

of a fastener wedging between the driver

blade and the nail guide. Fastener strips

with an incorrect collation angle or the

wrong fastener type (such as clipped head

fasteners) may cause continuous jamming.

To clear the jam:

1. Lay the tool on its side and point the

nose of the tool away from yourself and

others.

2. Disconnect the air supply from the tool

and remove fastener strip.

3. Insert a screwdriver into the end of the

nail guide. The tip of the screwdriver

should contact the tip of the driver

blade.

4. Tap the screwdriver gently with a hammer. The screwdriver will push the driver

blade back, freeing the jam.

5. Remove the fastener and other debris

(use needle-nose pliers if necessary).

6. Follow the steps under "Required Daily

Testing" before restarting the work.

Fig. 3

T ap screwdriver

to free fastener

OPERATION

WARNING

The operator and other people in the

work area must wear eye protection

in accordance with ANSI Z87.1. Eye

protection does not fi t all operators

in the same way. Make sure the eye

protection chosen has side shields or

provides protection from fl ying debris

both from the front and sides. The

employer is responsible for enforcing

the use of eye protection by the operator and other people in the work area.

When required, wear head protection

in accordance with ANSI Z89.1.

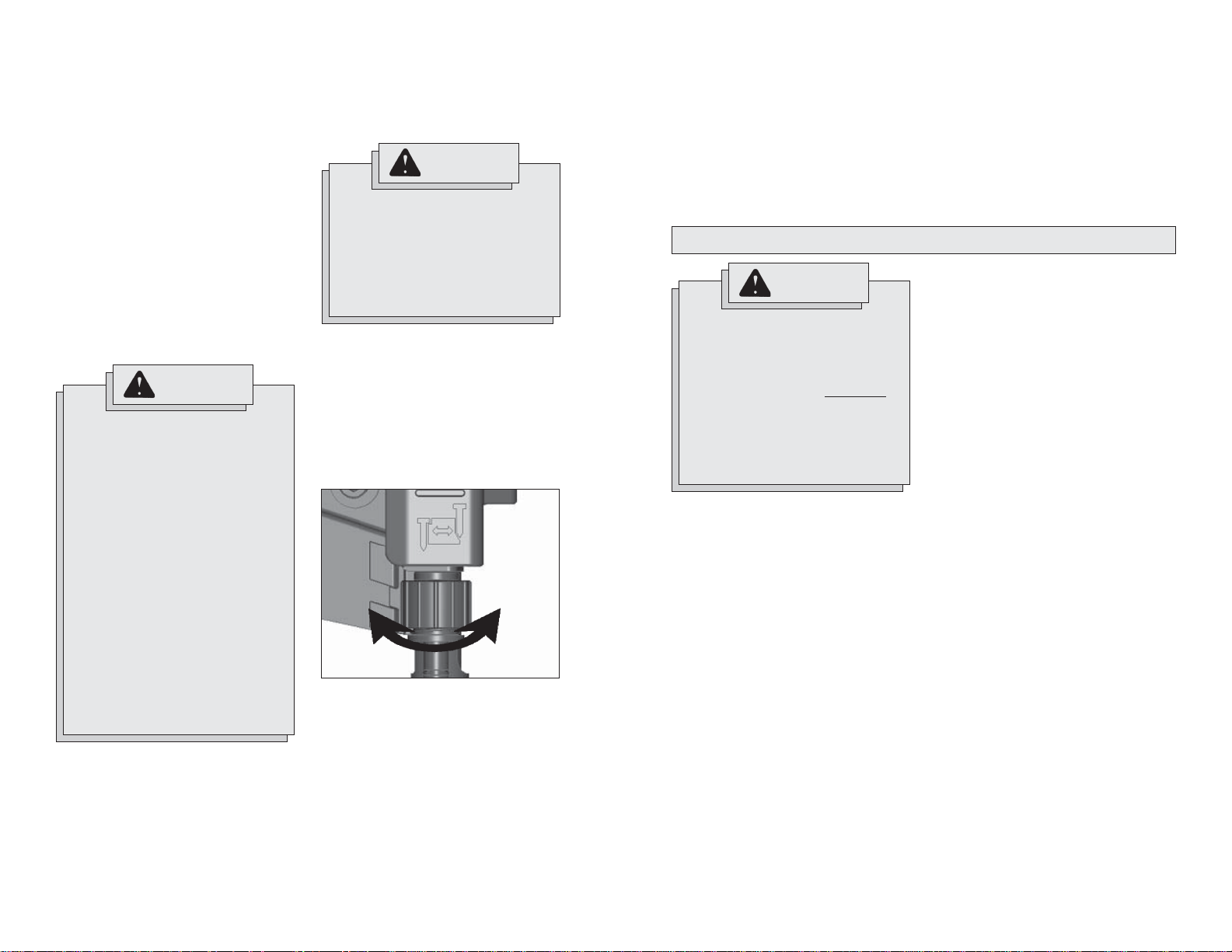

Selecting Actuation Mode

The selectable trigger can be set to either

Single Sequential Actuation mode or Contact

Actuation mode.

Fig. 4

Single

Sequential

Actuation

Fig. 5

Contact

Actuation

1. Push in and hold the Actuation

Selector.

2. Rotate the Selector to Single Sequential Actuation (T) or Contact Actuation

(TTT).

3. Release the Actuation Selector.

NOTE: Be sure the selector is snapped

into position. Understand the actuation

process before use.

WARNING

To reduce the risk of injury to yourself and others, test the tool before

beginning work each day according to

the "Required Daily Testing" section.

Do not use the tool unless you thoroughly understand the actuation

operation selected.

Disconnect the air supply from the

tool and remove fastener strips

before leaving the work area, moving the tool to another location, or

handing the tool to another person.

Failure to do so could result in serious injury.

Do not carry an air hose or a tool connected to an air hose when climbing

ladders, rigging or scaffolding. Do

not attach an air hose or tool connected to an air hose to your body

when working at elevated heights.

Attach the hose to the structure to

reduce the risk of loss of balance and

injury if the hose shifts.

Single Sequential Actuation Operation

1. Grip the handle fi rmly.

2. Position the nose of the tool on the work

surface.

3. Push the tool against the work surface,

compressing the workpiece contact.

4. Pull the trigger to drive the fastener . The

tool will recoil away from the workpiece

as the fastener is driven.

5. Remove your fi nger from the trigger and

remove the tool from the workpiece.

NOTE: If the tool is not removed from

the workpiece, another fastener may be

driven if the trigger is pulled again.

10 11

Page 7

Contact Actuation Operation

1. Grip the handle fi rmly.

2. Pull and hold the trigger.

3. Push the tool against the work surface,

compressing the workpiece contact to

drive the fastener. The tool will recoil

away from the workpiece as the fastener

is driven.

NOTE: Contact Actuation will also work by

fi rst compressing the workpiece contact, then

pulling the trigger.

Reload Indicator

To indicate that the magazine is almost

empty of fasteners (about 4-5 left), the workpiece contact will not compress, preventing

operation under usual pressure. Install more

fasteners to continue working.

WARNING

NEVER wedge or hold back the workpiece contact mechanism during

operation of the tool. Never attempt

to clear a jammed workpiece contact

by grasping the discharge area of the

tool. Doing so could result in serious

injury.

To avoid serious injury , do not attempt

to prevent the recoil by holding the

tool too fi rmly against the work. Keep

face and body away from the tool.

During normal use, the tool will recoil

immediately after driving a fastener.

This is a normal function of the tool.

Restriction to the recoil can result

in a second fastener being driven

when the tool is in Contact Actuation

mode. Grip the handle fi rmly, let the

tool do the work, and do not place

a second hand on top of the tool or

near exhaust.

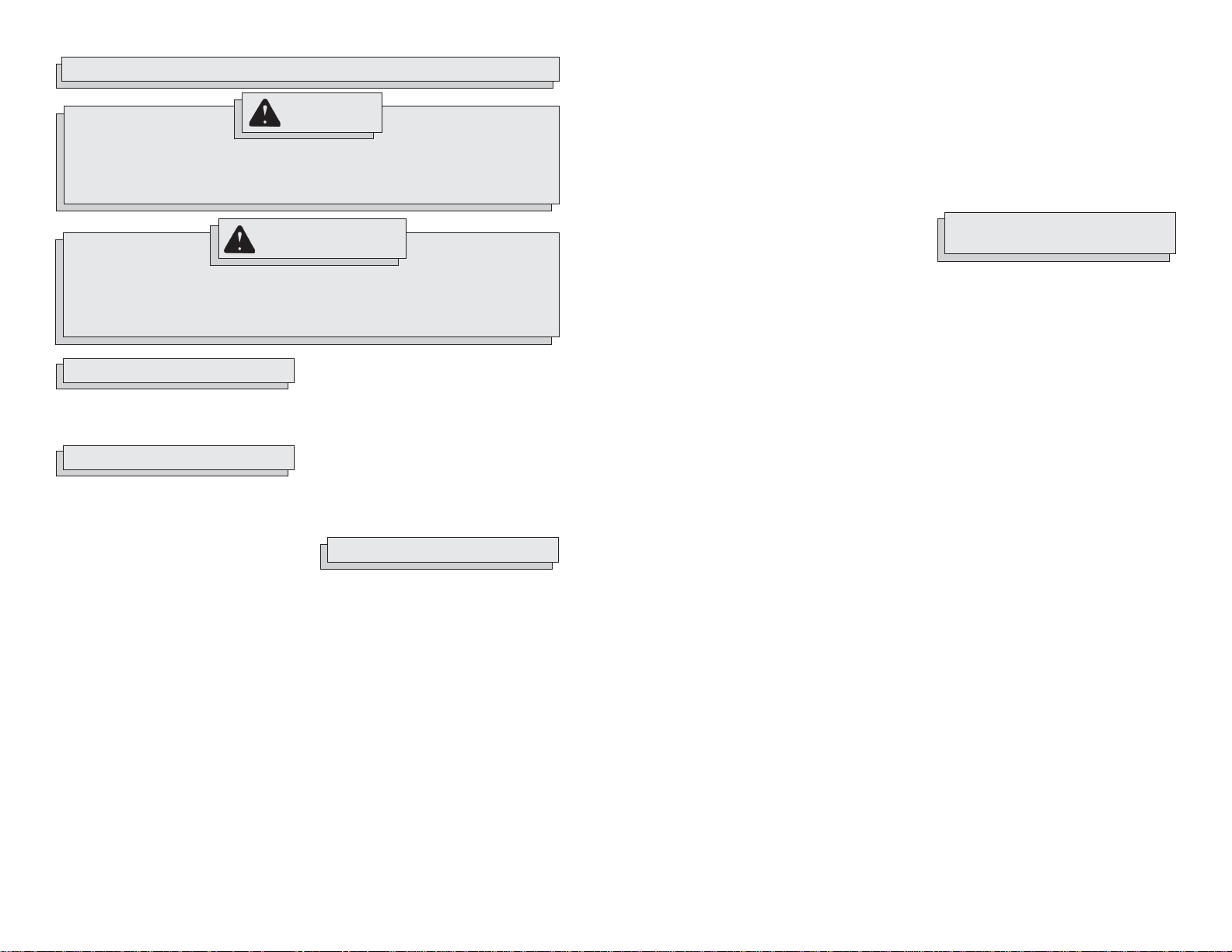

Setting the Air Pressure and Depth of

Drive

The amount of air pressure required will

depend on the size of the fastener and the

workpiece material.

WARNING

Know what is behind your workpiece.

A fastener could travel through the

workpiece and out the other side,

striking a bystander and causing serious injury. Lower the air pressure

and/or depth of drive to prevent the

fastener from being pushed all the

way through the workpiece.

1. Lay the tool on its side and point the

nose of the tool away from yourself and

others.

2. Disconnect the air supply from the tool

and remove fastener strip.

3. Set the depth of drive adjustment to the

middle of its range.

4. Reload fastener strip according to "Installing Fastener Strips".

Fig. 6

Set to

middle of

range

5. Begin testing the depth of drive by driving a test fastener into the same type of

workpiece material used for the actual

job using an air pressure of 90-95 psi.

6. Raise or lower the air pressure to fi nd the

lowest setting that will drive the fastener

consistently. Do not exceed 120 psi.

NOTE: It may be possible to achieve the

desired depth with air pressure adjustments alone. If fi ner adjustments are

needed, use the depth of drive adjustment.

7. To fi ne-tune the depth of drive, discon-

nect the air supply and lay the tool on

its side and point the nose of the tool

away from yourself and others. Remove

fastener strip. Turn the depth selector

left or right to increase or decrease the

driving depth.

REQUIRED DAILY TESTING

WARNING

To reduce the risk of injury to yourself and others, test the tool before

beginning work each day or if the

tool is dropped, received a sharp

blow, been run over, etc. Complete

the following checklist IN ORDER. If

the tool does not work as it should,

contact a MILWAUKEE service facil-

ity immediately.

Always point tool away from yourself

and others.

1. Disconnect the air supply from the tool

and remove fastener strip.

2. Check all screws, bolts, nuts, and pins

on the tool. Any loose fasteners must be

tightened.

3. Pull back the fastener pusher on the

magazine (to override the Reload Indicator) and press the workpiece contact

against a workpiece. It must move

smoothly.

4. With the workpiece contact pressed

against the workpiece, pull the trigger.

It must move smoothly.

5. Connect the air supply (at 70 psi) to the

tool. DO NOT load a fastener strip.

6. Select the Single Sequential Actuation

Operation. Air must not leak from the

tool.

Without pulling the trigger, pull back

the fastener pusher on the magazine

(to override the Reload Indicator) and

press the workpiece contact against a

workpiece. The tool must not operate.

8. Reload fastener strip according to "Installing Fastener Strips".

9. Drive a test fastener and repeat step 7

and 8 until desired depth is reached.

Holding the workpiece contact away

from the workpiece, pull back the

fastener pusher on the magazine (to

override the Reload Indicator). Pull and

hold the trigger for 5 seconds. The tool

must not operate.

Continue to pull and hold the trigger and

push the workpiece contact against a

workpiece. The tool must not operate.

Without pulling the trigger, pull back

the fastener pusher on the magazine

(to override the Reload Indicator) and

press the workpiece contact against a

workpiece. Pull the trigger. The tool must

operate.

Release the trigger. The driver must

move up.

7. Select the Contact Actuation Operation.

Holding the workpiece contact away

from the workpiece, pull back the

fastener pusher on the magazine (to

override the Reload Indicator) and pull

the trigger. The tool must not operate.

Continue to pull and hold the trigger and

push the workpiece contact against a

workpiece. The tool must operate.

8. If all previous tests work properly, set the

tool for your work. Select the operation

and load fastener strips.

9. Set the depth of drive according to the

"Setting the Air Pressure and Depth of

Drive" section.

10. If all tests operate properly, the tool is

ready for use. Repeat these tests before

use each day or if the tool is dropped,

received a sharp blow, been run over,

jammed, etc.

12 13

Page 8

MAINTENANCE

WARNING

To reduce the risk of injury, use only

identical replacement parts recommended by the manufacturer. Tool

service must be performed only by

qualifi ed repair personnel. Always

wear safety goggles or glasses with

side shields when servicing tools.

Disconnect tool from air supply before servicing.

Cleaning

Clean dust and debris from tool vents.

Keep tool handles clean, dry and free of oil

or grease. Use only mild soap and a damp

cloth to clean the tool, since certain cleaning

agents and solvents are harmful to plastics

and other parts. Some of these include gasoline, turpentine, lacquer thinner, paint thinner ,

chlorinated cleaning solvents, ammonia and

household detergents containing ammonia.

Never use fl ammable or combustible sol-

vents around tools.

Lubrication

Frequent, but not excessive, lubrication is

required for best performance. Oil added

through the air line connection will lubricate

the internal parts. Do not use detergent oil,

WD-40, transmission fl uid, motor oil, or other

lubricants not specifi cally designated as air

tool lubricant. These lubricants will cause

accelerated wear to the seals, o-rings and

bumpers in the tool, resulting in poor tool

performance and frequent maintenance.

Cold Weather Operation

For cold weather operation, near and below

freezing, the moisture in the air line may

freeze and prevent tool operation. Use an

air tool lubricant or permanent antifreeze as

a cold weather lubricant in the air line.

Do not store tools in a below-freezing environment. Ice or frost could form on the tools'

operating valves and mechanisms, causing

tool failure.

Air Supply-Pressure and Volume

Air volume is as important as air pressure.

The air volume supplied to the tool may be inadequate because of undersized fi ttings and

hoses, or from the effects of dirt and water in

the system. Restricted air fl ow will prevent

the tool from receiving an adequate volume

of air, even though the pressure reading is

high. The results will be slow operation or

reduced driving power. Before evaluating tool

problems for these symptoms, trace the air

supply from the tool to the supply source for

restrictive connectors, low points containing

water and anything else that would prevent

full volume fl ow of air to the tool.

FIVE YEAR TOOL

LIMITED WARRANTY

Every MILWAUKEE tool is tested before leaving

the factory and is warranted to be free from defects

in material and workmanship. MILWAUKEE will

repair or replace (at MILWAUKEE’s discretion),

without charge, any tool (including battery chargers) which examination proves to be defective

in material or workmanship for fi ve (5) years after

the date of purchase. Return the tool and a copy

of the purchase receipt or other proof of purchase

to a MILWAUKEE Factory Service/Sales Support

Branch location or MILWAUKEE Authorized

Service Station, freight prepaid and insured. This

warranty does not cover damage from repairs

made or attempted by other than MILWAUKEE

authorized personnel, misuse, alterations, abuse,

normal wear and tear, lack of maintenance, or accidents. Certain parts of certain tools, such as but

not limited to o-rings, seals, bumpers, and driver

blades for MILWAUKEE nailers and stapling tools,

are considered normal wear and tear items not

covered by this warranty.

The warranty period for Li-Ion Battery Packs is two

(2) years from the date of purchase. The warranty

period for Ni-Cd Battery Packs, Flashlights, Radios,

and Professional Hoists (lever, chain, and electric)

is one (1) year from the date of purchase.

THE REPAIR AND REPLACEMENT REMEDIES

DESCRIBED HEREIN ARE EXCLUSIVE. IN NO

EVENT SHALL MILWAUKEE BE LIABLE FOR ANY

INCIDENTAL, SPECIAL, OR CONSEQUENTIAL

DAMAGES OR FOR ANY EXPENSES, LOSSES

OR DELAYS INCIDENTAL TO ANY DAMAGE TO,

FAILURE OF, OR DEFECT IN ANY PRODUCT,

INCLUDING BUT NOT LIMITED TO LOSS OF

PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU

OF ALL OTHER W ARRANTIES, OR CONDITIONS,

WRITTEN OR ORAL, EXPRESS OR IMPLIED.

WITHOUT LIMITING THE GENERALITY OF

THE FOREGOING, MILWAUKEE DISCLAIMS

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

USE OR PURPOSE AND ALL OTHER IMPLIED

WARRANTIES.

This warranty gives you specifi c legal rights. You

may also have other rights that vary from state to

state and province to province. In those states that

do not allow the exclusion of implied warranties or

limitation of incidental or consequential damages,

the above limitations or exclusions may not apply

to you. This warranty applies to the United States,

Canada, and Mexico only.

ACCESSORIES

WARNING

Always disconnect the air supply

from the tool and remove fastener

strips before changing or removing

accessories. Only use accessories

specifi cally recommended for this

tool. Others may be hazardous.

For a complete listing of accessories refer to

your MILWAUKEE Electric Tool catalog or go

on-line to www.milwaukeetool.com. To obtain

a catalog, contact your local distributor or a

service center.

Use MILWAUKEE fasteners with the

following specifi cations:

Length: 2" to 3.5"

Collation Angle: 22°

Size (diameter): 0.113" to 0.148"

Air Tool Oil

Synthetic formula for all season

performance

4 oz bottle Cat. No. 49-32-7100

16 oz bottle Cat. No. 49-32-7105

Quick Connectors

14 15

Page 9

INSTRUCTIONS D’ENTRETIEN GÉNÉRALES

DANGER

CONSIGNES DE SÉCURITÉ IMPORTANTES. CONSERVER

CES INSTRUCTIONS RELATIVES À UN RISQUE

DE BLESSURES GRAVES, VOIRE MORTELLES.

AVERTISSEMENT

LORS DE L’UTILISATION D’OUTILS, DES PRÉCAUTIONS

DE BASE DOIVENT TOUJOURS ÊTRE SUIVIES, Y

COMPRIS LES SUIVANTES:

GÉNÉRALITÉS

1. Pour limiter les risques de blessures,

lire toutes les instructions fi gurant dans

ce document avant d’utiliser l’outil.

AIRE DE TRAVAIL

2. Maintenir l’aire de travail dans un

bon état de propreté générale et

bien éclairé. Le risque de blessures

est d’autant plus important sur les

établis encombrés et dans les zones

sombres.

3.

Ne pas utiliser l’outil dans des environnements explosifs, tels qu’en

présence de liquides, de gaz et de

poussières inflammables. L’outil

pourrait provoquer des étincelles qui

risqueraient d’enfl ammer les poussières

ou les fumées.

4. Veiller à ce que personne, visiteur ou

enfant, ne se tienne à proximité de

l’aire de travail pendant l’utilisation

de l’outil. Des distractions pourraient

entraîner une perte de contrôle de

l’outil.

5. Bien savoir ce qui se trouve derrière

la pièce sur laquelle l’opération est

réalisée. Une attache pourrait traverser

la pièce et ressortir de l’autre côté, risquant ainsi de blesser grièvement une

personne qui se tiendrait à proximité.

6. DANGER. Éviter toute opération au

cours de laquelle l’attache pourrait

entrer en contact avec un câblage

caché. T out contact avec un fi l sous ten-

sion aurait un effet conducteur avec les

parties métalliques exposées de l’outil

qui risquerait de provoquer un choc à

l’opérateur et de causer ainsi des blessures graves, voire mortelles. S’assurer

de la sécurité de l’environnement de

travail; pour ce faire, contacter un électricien.

SÉCURITÉ INDIVIDUELLE

7. Se tenir sur ses gardes. Lors de

l’utilisation de l’outil, ne pas le quitter

des yeux et faire preuve de bon sens.

Ne pas l’utiliser sous l’effet de la fatigue

ou sous l’infl uence de drogues, d’alcool

ou de médicaments. Tout moment

d’inattention décuple les risques de

blessures pour les personnes se tenant

aux alentours.

8. Porter une tenue appropriée. Ne pas

porter de vêtements amples ou de bijoux pendants. S’attacher les cheveux

s’ils sont longs. Ne pas approcher les

cheveux, les vêtements, les bijoux et

les gants des pièces en mouvement.

Pris dans les pièces en mouvement, ils

décuplent le risque de blessures possible.

9. Éviter tout démarrage accidentel.

Sauf pour enfoncer une attache, ne

jamais laisser le doigt sur la gâchette.

Avant de brancher l’outil à la prise d’air,

s’assurer que la gâchette n’est pas

activée. Ne pas transporter l’outil en

laissant le doigt sur la gâchette et ne

pas le connecter à la prise d’air si la

gâchette est activée.

10. Ne pas se pencher de manière ex-

cessive. Garder un bon équilibre et

une bonne posture à tout instant afi n

de bénéfi cier d’un meilleur contrôle de

l’outil en cas de situation imprévue.

11. Utiliser un équipement de sécurité.

Lorsque les conditions l’exigent, le port

d’un masque de protection contre la

poussière, de chaussures de sécurité

antidérapantes et d’un casque de chantier réduit le risque de blessures.

12. L’opérateur et toutes les personnes

se tenant dans l’aire de travail doivent porter un masque de protection

conformément à la norme ANSI Z87.1.

Le masque de protection ne s’adapte

pas de la même façon sur tous les

opérateurs. Veiller à ce que la protection

choisie dispose de protections latérales

et soit en mesure de parer les débris

volants projetés à l’avant ou sur les

côtés. Il incombe à l’opérateur de veiller

à ce que l’opérateur et les autres personnes présentes dans l’aire de travail

se munissent d’un masque. Lorsque la

situation l’exige, porter un casque de

protection conformément à la norme

ANSI Z89.1.

13. En cas d’utilisation prolongée

de l’outil, toujours se munir d’un

casque auditif. De longues périodes

d’exposition à des bruits haute intensité

pourraient entraîner une perte auditive.

14. Lors de l’ascension d’échelles ou

d’échafaudages, ne pas transporter

de conduite d’air ni d’outil relié à

une conduite d’air. Lors d’opérations

réalisées en altitude, ne pas attacher

contre soi de conduite d’air ou d’outil

relié à une conduite d’air. La fi xer à

la structure métallique afi n de réduire

les risques de perte d’équilibre et les

blessures causées par le mouvement

éventuel de la conduite.

15. Toujours présumer que l’outil con-

tient des attaches. Ne pas pointer

l’outil vers soi ou vers quiconque, qu’il

contienne des attaches ou non.

16. Ne pas enfoncer de clou sur un

autre clou. Ceci pourrait provoquer la

déviation du clou et blesser quelqu’un

ou entraîner une réaction de l’outil qui

risquerait de blesser l’opérateur ou les

personnes se tenant à proximité.

UTILISATION CORRECTE

DE L’OUTIL

17. Utiliser des pinces ou d’autres moyens appropriés pour fi xer et soutenir

la pièce de travail sur une plate-forme

stable. Un maintien de la structure à

la main ou contre soi, en plus d’être

instable, risquerait de provoquer une

perte de contrôle.

18. Ne pas forcer l’outil. Utiliser l’outil

adapté à l’application. Il permettra de

mieux réaliser le travail et ce, de façon

plus sûre et à la vitesse prévue pour

l’outil.

19. Ne pas utiliser l’outil si la gâchette

ne l’active ou ne le désactive pas.

Considérer comme dangereux tout outil

dont la gâchette n’assure pas le contrôle

et le faire réparer.

20.

Déconnecter l’outil de la prise d’air et

vider le réservoir avant d’effectuer tout

réglage, de réaliser l’entretien de l’outil,

de dégager toute pièce bloquée, de

toucher le point de contact sur la pièce

de bois ou de quitter l’aire de travail.

Avant de réaliser ces opérations, vérifi er

que l’outil est vide et que toute pression

a été dissipée afi n de réduire les risques

de blessures possibles.

21. Ranger les outils hors de portée

des enfants et d’autres personnes

inexpérimentées. Tout outil constitue

un danger entre les mains d’utilisateurs

non formés.

22. Effectuer régulièrement et soigneuse-

ment l’entretien de l’outil. Un entretien

correct permet de minimiser le risque

de blessures causées par l’outil. En

cas de chute, de coup, d’écrasement,

etc. de l’outil, réaliser la procédure de

«Tests quotidiens requis» avant de le

réutiliser.

16 17

Page 10

23. Vérifi er que les pièces en mouve-

ment sont correctement alignées et

qu’elles ne grippent pas, qu’aucune

pièce n’est cassée et qu’il n’existe

aucun élément susceptible d’affecter

le fonctionnement de l’outil. S’il est

endommagé, effectuer l’entretien de

l’outil avant de le réutiliser. De nombreux

accidents sont provoqués par des outils

dont l’entretien n’a pas été effectué correctement. Les dommages subis par un

outil augmentent le risque d’explosion

de ce dernier.

24. Utiliser uniquement les attaches re-

commandées. L’utilisation d’attaches

non recommandées pour cet outil par

son fabriquant risquerait de provoquer

des blessures ou d’endommager l’outil.

Voir la section «Spécifi cations» pour les

exigences applicables aux attaches.

25. Utiliser uniquement des acces-

soires spécifiés par le fabriquant

pour le modèle d’outil en question.

L’utilisation d’un accessoire non recommandé pour un modèle particulier

pourrait décupler le risque de blessures

éventuelles.

ENTRETIEN

26. a) L’entretien de l’outil doit être réalisé uniquement par un personnel

de réparation qualifi é.

b) La clé fournie sert à serrer les vis

pendant « l’essai quotidien obligatoire ».

c) N’utiliser que des pièces de rem-

placement identiques recommandées

par le fabricant.

27. N’utiliser que les lubrifi ants fournis

avec l’outil ou spécifi és par le fab-

riquant. Ne pas utiliser d’autres lubrifi -

ants pour ne pas endommager l’outil.

Consulter la liste des lubrifi ants pour

outils pneumatiques dans la section

« Accessoires ».

PRISE D’AIR

28. DANGER: Ne pas utiliser d’oxgygène,

de gaz combustibles ou de gaz en

bouteille pour faire fonctionner cet outil.

Ceci provoquera l’explosion de l’outil et

provoquera des blessures graves, voire

mortelles.

29. Ne jamais connecter l’outil à une prise

d’air pouvant dépasser 13,8 BAR.

Une pressurisation excessive de l’outil

pourrait entraîner l’éclatement, un fonctionnement anormal ou une défaillace

de l’outil, et pourrait blesser l’opérateur

ainsi que les personnes se tenant à

proximité. Utiliser uniquement de l’air

comprimé propre, sec et régulé à la

pression nominale ou dans la plage de

pression nominale indiquée sur l’outil.

Avant d’utiliser l’outil, toujours vérifi er

que la prise d’air a été ajustée à la

pression d’air nominale ou qu’elle est

comprise dans dans la plage de pression d’air nominale. Les compresseurs

pneumatiques doivent être conformes à

la norme ANSI B19.3.

INSTRUCTIONS D’ENTRETIEN SPÉCIFIQUES

1. Utiliser des conduites de prise d’air

d’une pression nominale minimale de

13,8 BAR.

2. Limiter la pression de l’air dirigée

vers l’outil à l’aide de régulateurs

de pression réglés à 8,3 BAR maximum.

3. Installer uniquement des raccords

qui permettront de dissiper toute

la pression de l’outil une fois celui-ci déconnecté de la prise d’air.

L’installation d’un mauvais raccord pourrait laisser une pression résiduelle dans

l’outil une fois déconnecté, et permettre

ainsi l’introduction d’une attache, risquant ainsi de causer des blessures.

4. Avant chaque utilisatioin, vérifi er que

l’élément de contact avec la pièce

de bois et la gâchette fonctionnent

correctement. Ne pas démonter ou

fi xer des éléments de contact, de la

gâchette ou du mécanisme d’insertion.

Ceci causerait un fonctionnement inattendu, causant de graves blessures.

5. Ne jamais diriger la zone de décharge

de l’outil vers une partie du corps ou

ou vers quelqu’un. T oujours présumer

que l’outil est chargé et capable de

libérer une attache.

6. Ne pas actionner l’outil à l’air libre. Ne

pas se chamailler ni jouer avec l’outil.

Les attaches qu’il décharge consituent

des projectiles capables de causer de

graves blessures.

7. Avant d’actionner l’outil, s’assurer

que l’élément de contact avec la

pièce de bois est bien appuyé contre

cette dernière. Maintenir fermement

l’outil et s’apprêter à contrer la force de

retour.

8. Ne pas retirer les commandes de

fonctionnement, interférer avec

celles-ci ou les empêcher de toute

autre façon de fonctionner correctement. Ceci causerait un fonctionnement

inattendu, causant de graves blessures.

9. Ne pas utiliser l’outil si la moindre de

ses commandes de fonctionnement

ne fonctionne pas correctement, est

déconnectée, modifi ée ou défectueuse.

Ceci causerait un fonctionnement inattendu, causant de graves blessures.

10. Ne jamais approcher les mains et

le corps de la zone de décharge de

l’outil. Ne jamais déblocage d’une élé-

ment de commande de fonctionnement

en tenant la zone de décharge de l’outil.

Les attaches déchargées par l’outil

peuvent causer de graves blessures si

elles touchent les mains ou le corps.

11. Ne pas enfoncer d’attache près du

bord de la pièce de bois. Les attaches

peuvent glisser et ressortir des coins et

des rebords ou pénétrer à travers des

matériaux très fi ns, en faisant des pro-

jectiles capables de causer de graves

blessures.

12. Utiliser l’outil uniquement à ses fi ns

prévues. S’en servir correctement.

Ne pas s’en servir comme d’un marteau,

graver ou estampiller d’informations sur

les pièces, le faire tomber ou le soumettre à des chocs, ou appliquer une

force excessive de toute autre nature

sur l’outil utilisé. Ne pas monter l’outil

sur des cales ou le modifi er afi n de le

rendre stationnaire.

13. Ne pas transporter l’outil en le tenant

par la conduite d’air. Le transporter

uniquement par la poignée, avec le doigt

HORS de la gâchette.

14. Ne pas utiliser cet outil si l’étiquette

de sécurité n’est pas en place. Si

l’étiquette est endommagée ou manquante, contacterMILWAUKEE pour

obtenir gratuitement un exemplaire de

rechange.

18 19

Page 11

TERMINOLOGIE

Actionner

Provoquer le mouvement du ou des

composant(s) de l’outil permettant d’insérer

une attache.

Dispositif d’actionnement

Utilisation d’une gâchette, d’un élément de

contact avec la pièce de bois et/ou d’une

commande de fonctionnement, de façon

séparée, combinée ou successive, en vue

d’actionner l’outil.

• Actionnement en séquence

Un fonctionnement du système qui

nécessite l’activation de l’élément de

contact puis de la gâchette dans une

séquence particulière pour insérer une

attache. L’outil peut être actionné à nouveau lorsque la gâchette est relâchée

puis réactivée.

• Activation par contact

Un fonctionnement du système qui

nécessite l’activation de l’élément de

contact et de la gâchette dans n’importe

quelle séquence pour insérer une attache. L’outil peut être actionné à nouveau lorsque l’élément de contact ou la

gâchette est relâché(e) et réactivé(e).

• Actionnement par sélection

Dispositif d’actionnement permettant la

sélection des dispositifs d’actionnement

en séquence ou par contact.

Spécifi cations

Attache

Une agraphe, une broche, un clou, une

pointe ou un autre type d’attache conçu

et fabriqué pour une utilisation avec ces

outils.

Blocage

Obstruction dans les zones d’alimentation

ou d’insertion de l’outil.

Elément de contact avec la pièce de

bois

Un élément de commande de fonctionnement

de l’outil activé par la pièce de bois à solidariser.

Pictographie

Lire le manuel de l’opérateur

Porter un masque de

protection

Ne pas approcher les

mains

DESCRIPTION FONCTIONNELLE

5

6

7

13

4

1. Patin caoutchouté ne faisant pas de marques

3

16

15

2

1

2. Attache pour clouage en biais

14

3. Elément de contact avec la pièce de bois

4. Réglage de la profondeur d’insertion

5. Défl ecteur d’échappement

6. Commande d’actionnement

7. Gâchette

8. Crochet de chevron

9. Arrivée d’air

10. Plaque signalétique

(sur la partie supérieure du réservoir)

11. Butée de clou

12. Rangement du patin caoutchouté

13. Étiquette d’avertissement

(sur la partie supérieure du réservoir)

14. Pousseur

15. Bouton de libération du pousseur

16. Guide de clou

8

9

10

11

12

supplémentaire (au dos du réservoir)

No

de cat.

7100-20

Pression de

fonctionnement

4,8 BAR min.

8,3 BAR max.

Longueur

de l’attache

50,8 mm min.

88,9 mm max.

Angle

d’assemblage

22 °

Taille de l’attache

(Diamètre)

2,9 mm min.

3,8 mm max.

Consommation

d’air

4,53 L/cycle à

6,9 BAR

Prise

d’air

3/8

pouce

NPT

Contenance

du réservoir

64 à 72

clous

20 21

Page 12

MONTAGE

AVERTISSEMENT

Déconnecter la prise d’air de l’outil

et enlever les bandes d’attaches

avant de remplacer ou d’enlever les

accessoires. N’utiliser que les accessoires spécifi quement recommandés

pour cet outil par son fabriquant. Les

autres accessoires peuvent présenter

des dangers.

L’opérateur et toutes les personnes

se tenant dans l’aire de travail doivent porter un masque de protection

conformément à la norme ANSI Z87.1.

Le masque de protection ne s’adapte

pas de la même façon sur tous les

opérateurs. Veiller à ce que la protection choisie dispose de protections

latérales et soit en mesure de parer

les débris volants projetés à l’avant

ou sur les côtés.

Patin caoutchouté

Le patin anti-marques présent sur l’embout

de l’outil protège la pièce de bois lorsque le

contact avec la pièce de bois est compressé

lors du fonctionnement. Ce patin peut être

retiré et remplacé.

1. Avant d’enlever ou de remplacer les

coussinets antimarques, déconnecter la

prise d’air de l’outil et enlever les bandes

d’attaches.

2. Pour retirer le patin, tirer dessus pour

l’ouvrir et l’écarter de l’attache pour

clouage en biais.

3. Le réservoir de l’outil dispose d’un

espace de rangement pour un patin

supplémentaire.

4. Pour remplacer le patin, l’insérer cor-

rectement sur les points de l’attache.

Échappement

Le bouchon d’échappement peut être réglé

pour diriger l’échappement comme souhaité.

Tourner le bouchon d’échappement jusqu’à

la position de verrouillage voulue.

Retrait et installation du crochet à chevron

Fig. 1

Avant de l’outil

Embout

Retrait du crochet:

1. Faire tourner le crochet jusqu’à ce qu’il

s’enclenche dans une des positions

préréglées.

2. Retirer les deux vis de montage en

utilisant la clé fournie.

3. Extraire le crochet de l’arrière de

l’outil.

Installation du crochet:

1. Aligner le montant sous pression de

ressort sur le crochet avec une fente

sur l’arrière de l’outil.

2. Faire glisser le crochet sur l’outil, en

s’assurant que le crochet est orienté

vers l’avant de l’outil. Pousser le crochet

vers le haut contre l’embout.

3. Installer les deux vis de montage en utilisant la clé fournie. Serrer fermement.

4. Vérifier que le crochet est correctement installé en tirant fermement le

crochet vers l’arrivée d’air. Il ne doit pas

bouger.

Crochet

Vis (2)

Arrivée

d’air

Graissage de l’outil

Avant de le connecter à la prise d’air, graisser

l’outil avec un lubrifi ant spécialement conçu

pour outils pneumatiques. En cas de faible

utilisation, lubrifi er une fois par jour. En cas

d’utilisation intensive, lubrifi er deux fois par

jour. N’ajouter que quelques gouttes d’huile

à la fois. Une quantité d’huile excessive

s’accumulera dans l’outil et se fera ressentir au niveau de l’échappement. Ne pas

utiliser d’huile détergente, deWD-40, d’huile

de transmission, d’huile moteur ou d’autre

lubrifi ant n’étant pas expressément destiné

à la lubrifi cation d’outils pneumatiques. Ces

lubrifi ants entraîneront l’usure précoce des

joints d’étanchéité, des joints toriques et

des amortisseurs de l’outil, affectant ainsi

les performances de l’outil et la fréquence

d’entretien requise.

Fig. 2

Connecteur rapide

3/8 pouce NPT

2 à 3

gouttes de

lubrifi ant pour outils

pneumatiques

Connexion de la prise d’air

DANGER

Ne pas utiliser d’oxgygène, de gaz

combustibles ou de gaz en bouteille

pour faire fonctionner cet outil. Ceci

provoquera l’explosion de l’outil,

qui entraînera des blessures graves,

voire mortelles.

AVERTISSEMENT

Toujours utiliser un raccord dissipant tout l’air comprimé présent

dans l’outil lors de la déconnexion

du raccord ou de l’accouplement de

la conduite. L’utilisation d’un raccord ne répondant pas à de telles

spécifi cations pourrait provoquer un

fonctionnement accidentel et causer

de graves blessures.

Utiliser uniquement de l’air comprimé sec et

propre sous une pression maximale de 13,8

BAR. Avant de raccorder l’outil à la prise

d’air, vérifi er que la jauge du régulateur du

compresseur pneumatique fonctionne correctement, dans une plage comprise entre

4,8 et 8,3 BAR. Une pression pneumatique

supérieure à 8,3 BAR peut causer des blessures et des dommages matériels. La pression correcte est la pression la plus basse

qui permettra de réaliser l’opération.

Pour connecter la prise d’air:

1. Retirer le bouchon en plastique de la

prise d’air de l’outil.

2. Insérer un raccord rapide de 3/8 pouce

NPT dans la prise d’air de l’outil.

3. Graisser le raccord rapide en lui appliquant 2 à 3 gouttes de lubrifi ant pour

outils pneumatiques.

4. Rattacher la conduite d’air au raccord

rapide.

5. Vérifi er l’absence de fuites d’air.

REMARQUE: Pour améliorer la qualité du

joint entre le raccord et l’outil et empêcher

la formation de rouille, appliquer du ruban

ou une pâte PTFE sur le fi letage du raccord

avant de l’insérer.

22 23

Page 13

Installation des bandes d’attaches

AVERTISSEMENT

Toujours veiller à ce que le réservoir

de l’outil soit VIDE avant de le raccorder à la prise d’air. L ’outil pourrait

être actionné lors de la connexion de

l’outil à la prise d’air. Toujours connecter l’outil à la prise d’air avant de

charger des clous afi n d’éviter toute

blessure causée par un enclenchement accidentel.

Lors de l’installation des attaches,

toujours diriger l’outil en direction

opposée à soi et aux personnes se

tenant à proximité. Le non-respect de

cette précaution pourrait provoquer

des blessures.

Ne jamais installer d’attaches lorsque

l’élément de contact avec la pièce

de bois ou la gâchette est activé(e).

Le non-respect de cette précaution

pourrait provoquer des blessures.

N’utiliser que des attaches de taille,

de longueur et d’angle d’assemblage

corrects, comme indiqué sur la

plaque signalétique de l’outil.Pour

de plus amples informations concernant les attaches recommandées,

consulter la section «Accessoires».

L’utilisation d’autres attaches pourrait provoquer le mauvais fonctionnement de l’outil et causer des

blessures.

1. S’assurer que le réservoir est vide puis

brancher la prise d’air à l’outil.

2. Coucher l’outil sur le côté et diriger

l’embout de l’outil dans la direction opposée à soi et aux autres personnes se

tenant à proximité.

Insérer une bande d’attaches dans le

3.

réservoir, par-dessus la butée de clous.

Veiller à ce que la pointe des attaches soit

orientée vers le bas.

REMARQUE: N’utiliser que des at-

taches de taille, de longueur et d’angle

d’assemblage corrects, comme indiqué

sur la plaque signalétique de l’outil.

4. Faire coulisser le pousseur vers l’arrière

du réservoir, par-dessus la butée de

clous.

5. Laisser le pousseur glisser doucement vers l’avant, tout en poussant

les bandes d’attaches vers le mécanisme d’entraînement. Une fois qu’il

repose contre l’extrémité de la bande

d’attaches, le pousseur se bloque.

REMARQUE: Lorsqu’elles sont cor-

rectement installées, les attaches

doivent être alignées avec l’embout de

l’outil.

Retrait des bandes d’attaches

AVERTISSEMENT

Pour éviter toute blessure grave, déconnecter l’outil de la prise d’air avant

de retirer les bandes d’attaches ou de

dégager une attache bloquée.

Ne pas approcher les doigts de la sortie du réservoir. Le pousseur pourrait

provoquer des blessures par pincement au niveau des doigts.

1. Coucher l’outil sur le côté et diriger

l’embout de l’outil dans la direction opposée à soi et aux autres personnes se

tenant à proximité.

2. Débrancher la prise d’air de l’outil.

3. Pour enlever les bandes d’attaches,

enfoncer le bouton de déclenchement

du pousseur et faire glisser ce dernier

doucement vers l’avant, en direction du

mécanisme d’entraînement.

4. Faire glisser les clous vers l’arrière

jusqu’à la butée.

5. Appuyer sur la butée du pousseur située

près de l’extrémité du réservoir et faire

glisser les attaches sur la butée.

6. Retirer la bande d’attaches de l’outil.

7. Recharger selon la procédure indiquée

à la section «Installation des bandes

d’attaches».

Déblocage d’une attache

La plupart des blocages sont causés par une

attache se coinçant en totalité ou en partie

entre la lame du pilote et le guide de clous

(embout). Des bandes d’attaches à angle

d’assemblage incorrect ou un type incorrect

d’attaches (telles des attaches à tête ronde)

peuvent causer un enrayage continu. Pour

débloquer l’outil:

1. Coucher l’outil sur le côté et diriger

l’embout de l’outil dans la direction opposée à soi et aux autres personnes se

tenant à proximité.

2. Débrancher la prise d’air de l’outil et

retirer la bande d’attaches.

3. Introduire un tournevis dans l’extrémité

du guide de clous. L’embout du tournevis doit être en contact avec l’embout

de la lame du pilote.

4. Taper doucement sur le tournevis

à l’aide d’un marteau. Le tournevis

poussera la lame du pilote vers l’arrière

et libérera l’obstruction.

5. Retirer l’attache (en utilisant une pince

à becs fi ns si nécessaire) et les autres

débris.

6. Avant de recommencer à travailler,

suivre la procédure de «T ests quotidiens

requis».

Fig. 3

Taper doucement

sur le tournevis

pour libérer

l’attache

24 25

Page 14

FONCTIONNEMENT

AVERTISSEMENT

L’opérateur et toutes les personnes

se tenant dans l’aire de travail doivent porter un masque de protection conformément à la norme ANSI

Z87.1. Le masque de protection ne

s’adapte pas de la même façon sur

tous les opérateurs. Veiller à ce que

la protection choisie dispose de protections latérales et soit en mesure

de parer les débris volants projetés

à l’avant ou sur les côtés. Il incombe

au responsable de veiller à ce que

l’opérateur et les autres personnes

présentes dans l’aire de travail se

munissent d’un masque. Lorsque la

situation l’exige, porter un casque de

protection conformément à la norme

ANSI Z89.1.

Sélection du mode d’actionnement

La gâchette peut être réglée en mode

d’actionnement en séquence ou en mode

d’actionnement par contact.

Fig. 4

Actionnement

en séquence

AVERTISSEMENT

Pour réduire le risque de blessures

pour soi-même comme pour les

autres, vérifi er l’outil tous les jours

avant de commencer à travailler, selon

les instructions fi gurant à la section

«Tests quotidiens requis».

Ne pas utiliser l’outil sans avoir auparavant compris en détail le mode

d’actionnement sélectionné.

Avant de quitter l’aire de travail, de

déplacer l’outil ou de passer l’outil

à quelqu’un d’autre, déconnecter

l’outil de la prise d’air. Le non-respect

de cette précaution pourrait provoquer des blessures graves.

Lors de l’ascension d’échelles ou

d’échafaudages, ne pas transporter

de conduite d’air ni d’outil relié à

une conduite d’air. Lors d’opérations

réalisées en altitude, ne pas attacher

contre soi de conduite d’air ou d’outil

relié à une conduite d’air. La fi xer à la

structure métallique afi n de réduire

les risques de perte d’équilibre et les

blessures causées par le mouvement

éventuel de la conduite.

Mode d’actionnement en séquence

1. Tenir fermement le manche.

2. Positionner l’embout de l’outil sur la

surface de travail.

3. Presser l’outil contre la surface de travail. L’élément de contact de la pièce de

bois est ainsi comprimé.

4. Appuyer sur la gâchette pour insérer

l’attache. Lors de l’insertion de l’attache,

l’outil dégagera une force de résistance

émise par la pièce de bois.

5. Retirer le doigt de la gâchette et éloigner

l’outil de la pièce de bois.

REMARQUE : Si l’outil n’est pas enlevé

de la pièce à travailler, une autre bande

peut être entraînée si la gâchette est

déclenchée à nouveau.

Mode de fonctionnement par contact

1. Tenir fermement le manche.

2. Appuyer sur la gâchette et la maintenir

enfoncée.

3. Presser l’outil contre la surface de travail. L’élément de contact de la pièce

de bois est ainsi comprimé et l’attache

est introduite. Lors de l’insertion de

l’attache, l’outil dégagera une force de

résistance émise par la pièce de bois.

REMARQUE: L’actionnement par contact

pourra également être réalisé en comprimant

d’abord l’élément de contact contre la pièce

de bois, puis en appuyant sur la gâchette.

AVERTISSEMENT

NE JAMAIS bloquer ou reternir le

mécanisme d’élément de contact

de la pièce de bois pendant le fonctionnement de l’outil. Ne jamais dé-

blocage d’une élément de commande

de fonctionnement en tenant la zone

de décharge de l’outil. Ceci pourrait

causer de graves blessures.

Pour éviter toute blessure grave,

ne pas chercher à contenir la force

de retour en maintenant l’outil trop

fermement contre la pièce de bois.

Maintenez le visage et le corps

partis de l’outil. En fonctionnement

normal, l’outil excercera une force

de retour immédiatement après

l’insertion de l’attache. Il s’agit

d’une réaction normale de l’outil. La

prévention de la force de retour peut

entraîner l’insertion d’une deuxième

attache lorsque l’outil est en mode

d’actionnement par contact. Tenir

fermement le manche et laisser l’outil

agir. Ne pas poser une deuxième

main sur l’appareil ou à proximité de

l’échappement.

Fig. 5

Actionnement

par contact

1. Enfoncer la commande d’actionnement

et la maintenir enfoncée.

2. Placer la commande en position

d’actionnement en séquence (T) ou

en position d’actionnement par contact

(TTT).

3. Relâcher la commande d’actionnement.

REMARQUE: S’assurer que la com-

mande est bien enclenchée en position. Avant d’utiliser les différents

modes, bien comprendre le processus

d’actionnement.

Indicateur de recharge

Pour indiquer que le magasin ne contient

presque plus de bandes d’attaches (4 ou

5 seulement),le contact de la pièce de

bois ne se comprime pas, empêchant le

fonctionnement sous la pression normale.

Installer plus d’attaches pour continuer à

travailler.

26 27

Page 15

Réglage de la pression d’air et de la profondeur d’insertion

La pression d’air requise dépend de la taille

de l’attache et du matériau de la pièce de

bois.

AVERTISSEMENT

Bien savoir ce qui se trouve derrière

la pièce sur laquelle l’opération est

réalisée. Une attache pourrait traverser la pièce et ressortir de l’autre

côté, risquant ainsi de blesser grièvement une personne qui se tiendrait

à proximité. Pour empêcher que

l’attache ne soit insérée complètement au travers de la pièce de bois,

réduire la pression d’air et/ou la profondeur d’insertion.

1. Coucher l’outil sur le côté et diriger

l’embout de l’outil dans la direction opposée à soi et aux autres personnes se

tenant à proximité.

2. Débrancher la prise d’air de l’outil et

retirer la bande d’attaches.

3. Régler ensuite la profondeur d’insertion

à mi-course.

4. Recharger la bande d’attaches selon la

procédure indiquée à la section «Installation des bandes d’attaches».

Fig. 6

Réglé à

mi-course

5. Vérifi er la profondeur d’insertion en in-

troduisant une attache de test dans une

pièce de bois fabriquée dans le même

matériau que celle qui sera utilisée pour

l’opération réelle, sous une pression de

6,2-6,6 BAR.

6. Régler la pression d’air afi n de déter-

miner le réglage minimum permettant

d’introduire correctement l’attache. Ne

pas dépasser 8,3 BAR.

REMARQUE: La profondeur désirée

peut être obtenue en réalisant uniquement des réglages de pression d’air.

Pour réaliser des réglages plus précis,

ajuster la profondeur d’insertion.

7. Pour ajuster la profondeur d’insertion,

déconnecter la prise d’air, coucher

l’outil sur le côté et diriger l’embout

en direction opposée à soi et aux autres personnes se tenant à proximité.

Enlever la bande d’attaches. Tourner

la commande de profondeur vers la

gauche ou la droite pour augmenter ou

réduire la profondeur d’insertion.

8. Recharger la bande d’attaches selon la

procédure indiquée à la section « Installation des bandes d’attaches ».

9. Insérer une attache d’essai et répéter

les étapes 7 et 8 jusqu’à obtenir la profondeur désirée.

TESTS QUOTIDIENS REQUIS

AVERTISSEMENT

Pour réduire le risque de blessures

pour soi comme pour les personnes

se tenant à proximité, tester l’outil

tous les jours avant de commencer

à travailler ou en cas de chute, de

coup, d’écrasement, etc. de l’outil.

Réaliser les vérifi cations suivantes

DANS L’ORDRE INDIQUÉ. Si l’outil

ne fonctionne pas correctement,

contacter immédiatement un agent

de réparation MILWAUKEE.

Toujours diriger l’outil en direction

opposée à soi et aux autres.

1. Débrancher la prise d’air de l’outil et

retirer la bande d’attaches.

2. Vérifi er toutes les vis et tiges de même

que tous les boulons et écrous sur l’outil.

Visser toutes les attaches lâches.

3. Tirer le pousseur d’attaches du réservoir vers l’arrière (afi n de contourner

l’indicateur de recharge) et presser

l’élément de contact contre la pièce

de bois. Le mouvement doit se faire

naturellement.

4. Le contact étant appuyé contre la pièce

à travailler, appuyer sur la gâchette.

Le mouvement doit se faire naturellement.

5. Connecter la prise d’air (à 4,8 BAR)

à l’outil. NE PAS charger de bande

d’attaches.

6. Sélectionner le mode d’actionnement en

séquence. Aucune quantité d’air ne doit

s’échapper de l’outil.

Sans appuyer sur la gâchette, tirer le

pousseur d’attaches du réservoir vers

l’arrière (afi n de contourner l’indicateur

de recharge) et presser l’élément de

contact contre la pièce de bois. L’outil

ne doit pas fonctionner.

Tout en maintenant l’élément de con-

tact de la pièce de bois à l’écart de

la pièce de bois, tirer sur le pousseur

d’attache du réservoir (pour contourner

l’indicateur de recharge). Tirer et maintenir la gâchette pendant 5 secondes.

L’outil ne doit pas fonctionner.

Continuer à tirer sur la gâchette et

pousser l’élément de contact contre la

pièce de bois. L’outil ne doit pas fonctionner.

Sans appuyer sur la gâchette, tirer le

pousseur d’attaches du réservoir vers

l’arrière (afi n de contourner l’indicateur

de recharge) et presser l’élément de

contact contre la pièce de bois. Tirer sur

la gâchette. L’outil doit fonctionner.

Relâcher la gâchette. Le pilote doit se

relever.

7. Sélectionner le mode d’actionnement

par contact.

Tout en maintenant l’élément de contact

à l’écart de la pièce de bois, tirer sur le

pousseur d’attache du réservoir (pour

contourner l’indicateur de recharge) et

appuyer sur la gâchette. L’outil ne doit

pas fonctionner.

Continuer à tirer sur la gâchette et

pousser l’élément de contact contre la

pièce de bois. L’outil doit fonctionner.

8. Si tous les tests ci-dessus indiquent

un fonctionnement correct, régler l’outil

pour l’opération à réaliser. Sélectionner le mode et charger les bandes

d’attache.

9. Régler la profondeur d’insertion conformément aux instructions de la section

«Réglage de la pression de l’air et de la

profondeur d’insertion».

10. Si tous les tests indiquent un fonctionnement correct, l’outil est prêt à être

utilisé. Répéter ces tests tous les jours

avant d’utiliser l’outil ou en cas de chute,

de coup, d’écrasement, d’enrayage, etc.

de l’outil.

28 29

Page 16

ENTRETIEN

AVERTISSEMENT

Pour réduire le risque de blessures,

utiliser uniquement des pièces de

rechanges identiques recommandées par le fabriquant. L’entretien

de l’outil doit être réalisé uniquement par un personnel de réparation

qualifi é. Lors de l’entretien des out-

ils, toujours porter des lunettes de

sécurité ou un masque de protection

doté de protections latérales. Avant

d’effectuer l’entretien, déconnecter

l’outil de la prise d’air.

Nettoyage

Nettoyer la poussière et les débris des

évents de l’outil. Maintenir les poignées

de l’outil propres, sèches et exemptes de

graisse ou d’huile. Nettoyer l’outil uniquement à l’aide d’un savon doux et d’un chiffon

humide car certains agents et solvents de

nettoyage sont nocifs pour le plastique et

les autres pièces, notamment: essence, essence de térébenthine, diluant pour vernis,

diluant pour peintures, solvant chloré, ammoniaque et détergents ménagers contenant de l’ammoniaque. Ne jamais utiliser de

solvants infl ammables ou combustibles à

proximité d’outils.

Lubrifi cation

Un graissage fréquent mais pas excessif

est crucial pour assurer un fonctionnement

optimal de l’outil. Pour lubrifi er les pièces

internes, ajouter quelques gouttes d’huile

dans le raccord de la conduite d’air. Ne pas

utiliser d’huile détergente, deWD-40, d’huile

de transmission, d’huile moteur ou d’autre

lubrifi ant n’étant pas expressément destiné

à la lubrifi cation d’outils pneumatiques. Ces

lubrifi ants entraîneront l’usure précoce des

joints d’étanchéité, des joints toriques et

des amortisseurs de l’outil, affectant ainsi

les performances de l’outil et la fréquence

d’entretien requise.

Fonctionnement par temps froid

Par temps froid, en cas de gel ou de températures avoisinantes, l’humidité contenue dans

la conduite d’air pourrait geler et empêcher

le fonctionnement de l’outil. Pour graisser

l’outil par temps froid, verser du lubrifi ant

pour outil pneumatique ou un antigel toutes

saisons dans la conduite d’air.

Ne pas remiser d’outils dans un endroit

dont la température est inférieure au point

de gel. Du givre ou de la glace pourrait se

former sur les soupapes et les mécanismes

de fonctionnement des outils et provoquer

la défaillance des outils.

Prise d’air - Pression et volume

Le volume d’air est aussi important que la

pression. Des raccords et des conduites

inadaptés, l’effet de la saleté ou la présence

d’eau dans le système peuvent entraîner

une arrivée d’air en volume inadéquat. Une

restriction du débit d’air empêchera l’outil

de recevoir le volume d’air adéquat, même

si la jauge de pression indique une pression

élevée. Ceci ralentira le fonctionnement et

affectera la puissance d’insertion. Avant

d’évaluer les problèmes éventuels pouvant

causer de tels symptômes au niveau de

l’outil, vérifi er que la conduite reliant la prise

d’air à l’outil ne présente aucun des éléments

suivants: connecteurs bouchés, présence

d’eau à certains endroits et tout autre élément pouvant restreindre le débit d’air en

direction de l’outil.

ACCESSOIRES