Milwaukee 6527, 6527-21, 6537-22, 6528, 6537-75 Operating Instructions Manual

Removing and Replacing the Quik-Lok® Cord

Select Models (Fig. 1)

1. To remove the Quik-Lok® Cord, turn the cord nut 1/4 turn

to the left and pull it out.

2. To replace the Quik-Lok® Cord, align the connector keyways and push the connector in as far as it will go. Turn the

cord nut 1/4 turn to the right to lock.

Selecting a Blade

Use MILWAUKEE Sawzall Blades for best performance.

When selecting a blade, choose the right type and length.

Many types of blades are available for a variety of applications: cutting metal, wood, nail-embedded wood, scroll cutting, roughing-in, and contours.

Many lengths are also available. Choose a length long

enough to extend beyond the shoe and your work throughout

the stroke. Do not use blades less than 3-112" long since

they won't extend beyond the shoe throughout the stroke.

For best performance and longest life, see "Accessories" to

select the best blade for the job.

IInstalling and Removing Blades

Blade Clamp Select Models (Fig. 2)

Unplug the tool before changing blades. Be sure the spindle

and blade clamp area are clean. Metal chips and sawdust may

prevent the blade clamp screw from clamping securely.

1. Depending on the job, the blade may be inserted with the

teeth facing upward or downward.

To install a blade, loosen the blade clamp screw, turning it

counterclockwise. Insert the blade until the tang butts against

the spindle.

NOTE: The blade must be inserted all the way into the spindle so that the tang on the blade seats firmly in the blade

clamp.

Insert the hex key into the blade clamp screw, turning it

clockwise. Tighten securely.

2. To remove a blade, insert hex key into the blade clamp

screw and turn it counterclockwise 1 full turn as shown. Then

slide the blade out of the spindle. Be careful when handling

hot blades.

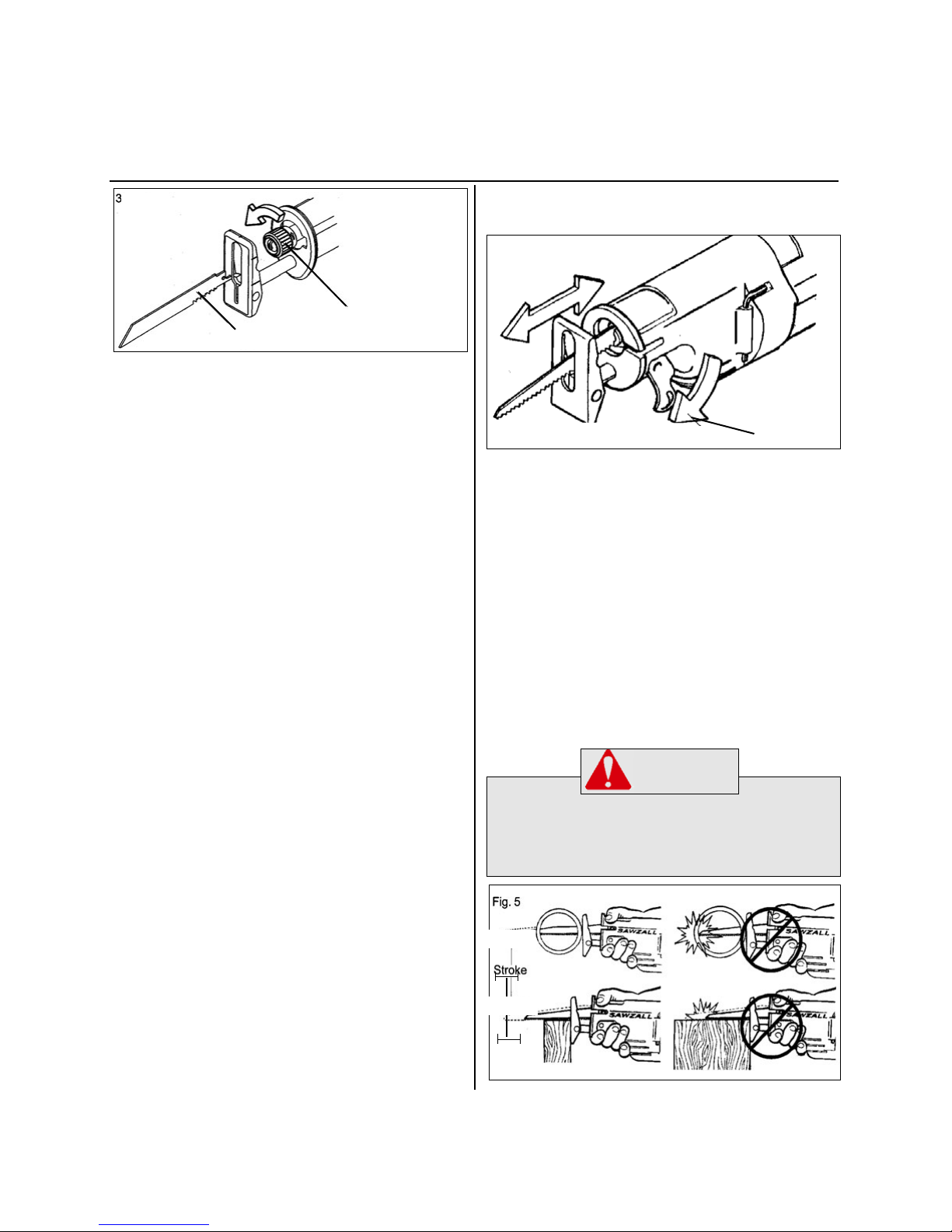

Quik-Lok° Blade Clamp - Select Models (Fig. 3)

Unplug the toot before changing blades. Be sure spindle and

blade clamp areas are clean. Metal chips and sawdust may

prevent Quik-Lok® Blade Clamp from clamping securely.

Milwaukee Tool

Super Sawzall®

Model Numbers: 6527, 6527-21, 6528, 6537-22, 6537-75

Operating Instructions

Page 1

RenTrain INC

RenTrain INC

To reduce the risk of injury, always unplug tool

before attaching or removing accessories. Use

only specifically recommended accessories.

Others may be hazardous.

WARNING!

Fig 1.

TOOL ASSEMBLY

Hex Key

Blade Clamp Screw

Fig 2.

1. Depending on the job, the blade may be inserted with the

teeth facing up or down. To install a blade, twist collar in the

direction of the arrow while inserting the blade into the

clamp until the tang butts against the collar.

2. Release collar and the spring loaded mechanism will clamp

the blade firmly in place.

3. Twist collar in the opposite direction of the arrow to ensure

that the blade is locked into the clamp.

4. Tug on blade to make sure it is securely locked in place.

5. To remove a blade, twist collar in the direction of the

arrow while pulling on the blade. Be careful when handling

hot blades.

Quik-Lok® Blade Clamp Maintenance

Periodically clean dust and debris from the Quik-Lok®

Blade Clamp with dry compressed air.

If the collar resists twisting, twist the collar back and

forth to shake debris loose.

Periodically lubricate Quik-Lok® Blade Clamp with a dry

lubricant such as graphite.

Removing broken blades from the

Quik-Lok® Blade Clamp

Unplug the tool before removing blades. Broken blades can

be removed by the following methods.

Point the tool downward, twist the collar, and shake the

tool up and down. (DO NOT turn the tool on while your fingers are holding the blade clamp open). The shank of the broken blade should drop out of the clamp.

If shaking the tool doesn't work...In most cases, a corner

of the broken blade will extend beyond the blade clamp.

Simply twist the collar and pull the broken blade out of the

clamp by this corner.

If the broken stub doesn't extend far enough to be grabbed

by its corner, use a thin blade with small teeth (such as a

metal cutting blade) to hook the blade that is jammed in the

clamp while twisting the collar and pull it out.

Adjustable Pivot Shoe (Fig. 4)

The shoe can be adjusted forward or backward to three positions to take advantage of the unused portion of the blade or

for special jobs requiring low blade clearance.

1. To adjust the shoe, pull the shoe release lever down 1/4

turn and slide the shoe forward or backward to the desired

position.

2. To lock shoe in position, push the shoe release lever up.

3. After adjusting the shoe, slowly pull the trigger to be sure

the blade always extends beyond the shoe and your work

throughout the stroke.

DO NOT OPERATE SAWZALL WITHOUT SHOE.

STRIKING THE SPINDLE AGAINST WORK MAY

DAMAGE THE RECIPROCATING MECHANISM.

Operating Instructions (continued)

Page 2

RenTrain INC

RenTrain INC

Blade

Collar

Fig 2.

Fig 4.

To reduce the risk of injury, be sure the blade

always extends beyond the shoe and work

throughout the stroke. Blades may shatter if

they impact the work or shoe (Fig 5).

WARNING!

Fig 5.

Stroke

1/4 Turn

Loading...

Loading...