Milwaukee 6497 Operator's Manual

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Catalog No.

No de Cat.

Catálogo No.

6497

10" MAGNUM® SLIDE COMPOUND MITER SAW

SCIE À ONGLETS COMBINÉE COULISSANTE MAGNUM® 254 mm (10")

SIERRA ANGULAR DE DISCOS DE CORTE COMPUESTO MAGNUM®, DE

254 mm (10") DE DIÁMETRO

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN COMPRENDRE LE

MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL MANUAL DEL

OPERADOR.

page 2

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below, may result in

electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

1. Keep work area clean and well lit. Cluttered, dark work areas

invite accidents.

2. Avoid dangerous environments. Do not use your power tool in

rain, damp or wet locations or in the presence of explosive atmospheres (gaseous fumes, dust or flammable materials). Remove

materials or debris that may be ignited by sparks.

3. Keep bystanders away. Children and bystanders should be kept

at a safe distance from the work area to avoid distracting the operator and contacting the tool or extension cord.

4. Protect others in the work area from debris such as chips and

sparks. Provide barriers or shields as needed.

5. Make workshop child proof with padlocks, master switches, or

by removing starter keys.

ELECTRICAL SAFETY

6. Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify the plug

in any way. Do not use any adaptor plugs. Check with a qualified

electrician if you are in doubt as to whether the outlet is properly

grounded. If the tool should electrically malfunction or break down,

grounding provides a low resistance path to carry electricity away

from the user.

7. Double insulated tools are equipped with a polarized plug

(one blade is wider than the other). This plug will fit in a

polarized outlet only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet. Do not change

the plug in any way. Double insulation eliminates the need for

the three wire grounded power cord and grounded power supply

system.

8. Guard against electric shock. Prevent body contact with

grounded surfaces such as pipes, radiators, ranges and refrigerators. When making blind or plunge cuts, always check the work area

for hidden wires or pipes. Hold your tool by insulated nonmetal

grasping surfaces. Use a Ground Fault Circuit Interrupter (GFCI) to

reduce shock hazards.

9. Do not expose to rain or use in damp locations.

10. Do not abuse the cord. Never use the cord to carry the tools

or pull the plug from an outlet. Keep cord away form heat,

oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

PERSONAL SAFETY

11. Know your power tool. Read this manual carefully to learn your

power tool’s applications and limitations as well as potential hazards associated with this type of tool.

12. Stay alert, watch what you are doing, and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A mo-

ment of inattention while operating power tools may result in serious

personal injury.

13. Dress properly. Do not wear loose clothing or jewelry. Wear a

protective hair covering to contain long hair. These may be caught in

moving parts. When working outdoors, wear rubber gloves and

insulated non-skid footwear. Keep hands and gloves away from

moving parts.

14. Reduce the risk of unintentional starting. Be sure your tool is

turned off before plugging it in. Do not use a tool if the power switch

does not turn the tool on and off. Do not carry a plugged-in tool with

your finger on the switch.

15. Remove all adjusting keys and wrenches. Make a habit of

checking that adjusting keys, wrenches, etc. are removed from the

tool before turning it on.

16. Do not overreach. Maintain control. Keep proper footing and

balance at all times. Maintain a firm grip. Use extra care when using

tool on ladders, roofs, scaffolds, etc.

17. Use safety equipment. Everyone in the work area should wear

safety goggles or glasses with side shields complying with

current safety standards. Everyday eyeglasses only have impact

resistant lenses. They are not safety glasses. Wear hearing protection during extended use and a dust mask for dusty operations. Hard

hats, face shields, safety shoes, etc. should be used when specified or necessary. Keep a fire extinguisher nearby.

18. Keep guards in place and in working order.

19. Never stand on tool. Serious injury could occur if the tool is tipped

or if the cutting tool is unintentionally contacted.

20. Keep hands away from all cutting edges and moving parts.

TOOL USE AND CARE

21. Secure work. Use a clamp, vise or other practical means to hold

your work securely, freeing both hands to control the tool.

22. Do not force tool. Your tool will perform best at the rate for which

it was designed. Excessive force only causes operator fatigue,

increased wear and reduced control.

23. Use the right tool. Do not use a tool or attachment to do a job for

which it is not recommended. For example, do not use a circular

saw to cut tree limbs or logs. Do not alter a tool.

24. Unplug tool when it is not in use, before changing accessories or

performing recommended maintenance.

25. Store idle tools. When not in use, store your tool in a dry, secured

place. Keep out of reach of children.

26. Never leave the tool running unattended. Turn power off. Do

not leave the tool until it comes to a complete stop.

27. Check for damaged parts. Inspect guards and other parts be-

fore use. Check for misalignment, binding of moving parts, improper

mounting, broken parts and any other conditions that may affect

operation. If abnormal noise or vibration occurs, turn the tool off

immediately and have the problem corrected before further use. Do

not use a damaged tool. Tag damaged tools “DO NOT USE” until

repaired. A guard or other damaged part should be properly repaired

or replaced by a MILWAUKEE service facility. For all repairs, insist

on only identical replacement parts.

page 3

28. Use proper accessories. Consult this manual for recommended

accessories. Using improper accessories may be hazardous. Be

sure accessories are properly installed and maintained. Do not defeat a guard or other safety device when installing an accessory or

attachment.

29. Maintain tools carefully. Keep handles dry, clean and free from

oil and grease. Keep cutting edges sharp and clean. Follow instructions for lubricating and changing accessories. Periodically inspect

tool cords and extension cords for damage. Have damaged parts

repaired or replaced by a MILWAUKEE service facility.

30. Maintain labels & nameplates. These carry important informa-

tion. If unreadable or missing, contact a MILWAUKEE service facility for a free replacement.

SPECIFIC SAFETY RULES

SERVICE

31. Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified per-

sonnel may result in a risk of injury.

32. When servicing a tool, use only identical replacement parts.

follow instructions in the maintenance section of this

manual. Use of unauthorized parts or failure to follow maintenance

instructions may create a risk of shock or injury.

1. WARNING! Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known

to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specifically designed

to filter out microscopic particles.

2. Always keep hands away from the path of the saw blade.

3. Do not defeat the guards of operate the tool without the

guards in place.

4. Always support work properly. Use the fence, support blocks,

auxiliary work support or clamps to keep workpiece secure. Always support the free end of the workpiece and support all small

workpieces. Workpieces that bow and pinch the blade may result in

kick back. Do not perform any operations freehand (unsupported).

5. Never reach around, under or across blade.

6. Check guards for smooth operation before each use.

7. Avoid kick back. Kick back is a violent reaction to a pinched or

binding blade, which throws the saw head upward and towards

the operator. Proper workpiece selection and support, proper blade

selection and maintenance, and even feed rate are essential to

reduce the risk of kick back.

8. Always wait for the blade to stop completely before changing positions, retrieving a cut-off piece, or preparing the next cut.

Unplug the tool before tightening blade screw, servicing, making

adjustments, transporting or moving the saw to another location.

9. Be sure the clamp handle and the bevel adjustment lever

are tightened securely before making cuts.

10. Do not use abrasive wheels with the miter saw.

11. Use the right blade. Use only recommended blade types and

sizes with proper mounting holes, rated at least 5500 RPM. Follow

the rotation arrow on the blade to be sure you install it properly.

Keep saw blades sharp to help prevent cracking and grabbing.

Never use defective or incorrect washers or bolts.

12. Do not lock the trigger in the on position.

13. Wait for the blade to reach full speed before lowering the

saw head to make a cut.

14. Keep the cord away from the cutting area and position it so that

it will not be tripped over or caught on the workpiece while you are

cutting.

15. Do not place hands under the saw motor or in the path of

the blade. Do not retrieve a piece of material that is cut off while the

blade is rotating. Never place hands or fingers behind or in front of

the saw blade.

16. Keep blades clean and sharp. An unsharpened or improperly

sharpened blade produces a narrow kerf and is likely to be pinched

by the workpiece. A dull blade produces excessive friction which

can cause the blade to warp or bind. Be sure the blade screw is

tight to prevent slipping or loosening during operation.

17. Restarting in mid-cut. If you stop the saw in mid-cut, allow the

blade to stop, then raise the saw out of the cut. Then restart the

saw.

18. If the blade stalls, do not turn the switch on and off. A dull

blade or excess pressure may cause stalling. Release the switch

immediately if the blade binds or the saw stalls and remove the saw

from the cut.

19. Avoid cutting nails. Inspect for and remove all nails before cutting.

20. Thin material tends to warp or sag and must be well-supported

over its entire length to avoid pinching the blade.

21. Position fence properly. The flip fence can be adjusted for com-

pound cuts and miter cuts. Always make sure the fence is adjusted

for the intended cut. Never operate the saw without the fence in

place.

22. Lock the saw head down and lock the sliding mechanism

before transporting.

23. Push the saw through the workpiece. Do not pull the saw

through the workpiece. To make a cut, raise saw head and pull it

out OVER the workpiece WITHOUT cutting, start the motor, wait a

few seconds for the blade to reach full speed, press down on saw

head, and push saw head through the cut.

page 4

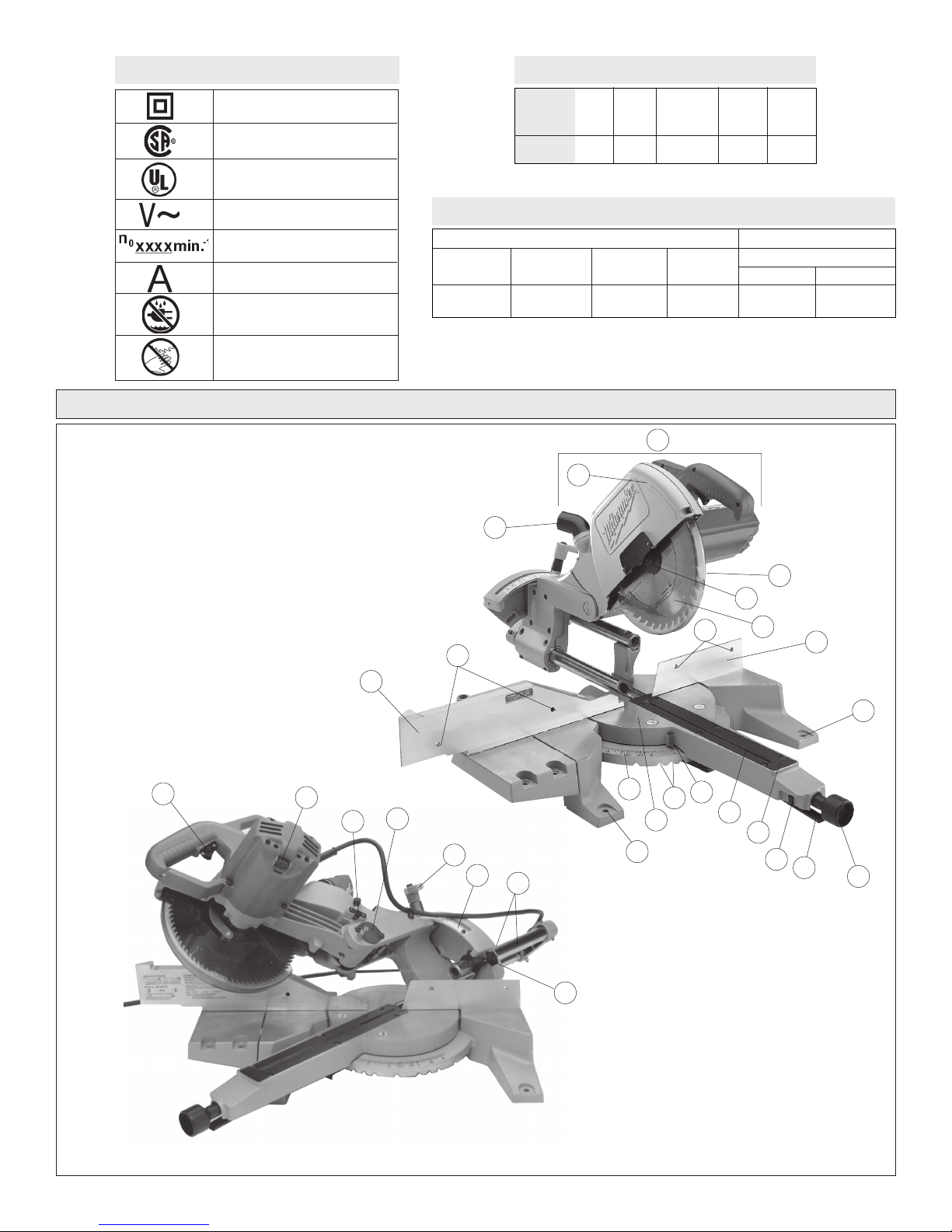

Symbology

Specifications

1. Saw head

2. Upper guard

3. Lower guard

4. Blade screw guard

5. Blade

6. Fence

7. Clamp handle

8. Detent override lever

9. Detent override lock

10. Kerf plate

11. Kerf plate slot

12. Pointer

13. Positive angle stops

14. Turntable

15. Miter angle scale

16. Mounting holes (4)

Double Insulated

Canadian Standards

Association

Underwriters

Laboratories, Inc.

Volts Alternating Current

No Load Revolutions

per Minute (RPM)

Amperes

Do not expose to rain or use in

damp locations.

Always keep hands away from

the path of the saw blade.

FUNCTIONAL DESCRIPTION

17. Flip fence

18. Face board mounting holes (4)

19. Dust ejection port

20. Trigger

21. Spindle lock

22. Depth adjustment set screw

23. Lock pin

24. Bevel adjustment lever

25. Bevel angle scale

26. Slide rails

27. Slide rail lock

17

Max Height

at 90°

3-29/32" H

at 8-1/2" W

19

18

Catalog

Number

6497

Volts

AC

120

Amps

15

No Load

RPM

4800

Arbor

Size

5/8"

Blade

Size

10"

Capacities

Miter Cuts Compound Cuts

Max Height

at 45°

3-29/32" H at

6" W

2

Max Width

at 90°

12-3/8" W at

3-7/16" H

Max Width

at 45°

8-3/4" W at

3-7/16" H

1

45° Miter and 45° Bevel

Max Height

2-3/8" W at

7-9/16" H

3

4

18

5

Max Width

8-3/4" W at

2-1/8" H

6

16

20

21

22

23

24

25

26

27

15

16

14

13

12

11

10

9

8

7

page 5

GROUNDING EXTENSION CORDS

WARNING!

Improperly connecting the grounding wire can

result in the risk of electric shock. Check with a

qualified electrician if you are in doubt as to

whether the outlet is properly grounded. Do not

modify the plug provided with the tool. Never

remove the grounding prong from the plug. Do

not use the tool if the cord or plug is damaged. If

damaged, have it repaired by a MILWAUKEE

service facility before use. If the plug will not fit

the outlet, have a proper outlet installed by a

qualified electrician.

Grounded tools require a three wire extension cord. Double insulated

tools can use either a two or three wire extension cord. As the distance

from the supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a

serious drop in voltage, resulting in loss of power and possible tool

damage. Refer to the table shown to determine the required minimum

wire size.

The smaller the gauge number of the wire, the greater the capacity of the

cord. For example, a 14 gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension cord to make up the

total length, be sure each cord contains at least the minimum wire size

required. If you are using one extension cord for more than one tool, add

the nameplate amperes and use the sum to determine the required minimum wire size.

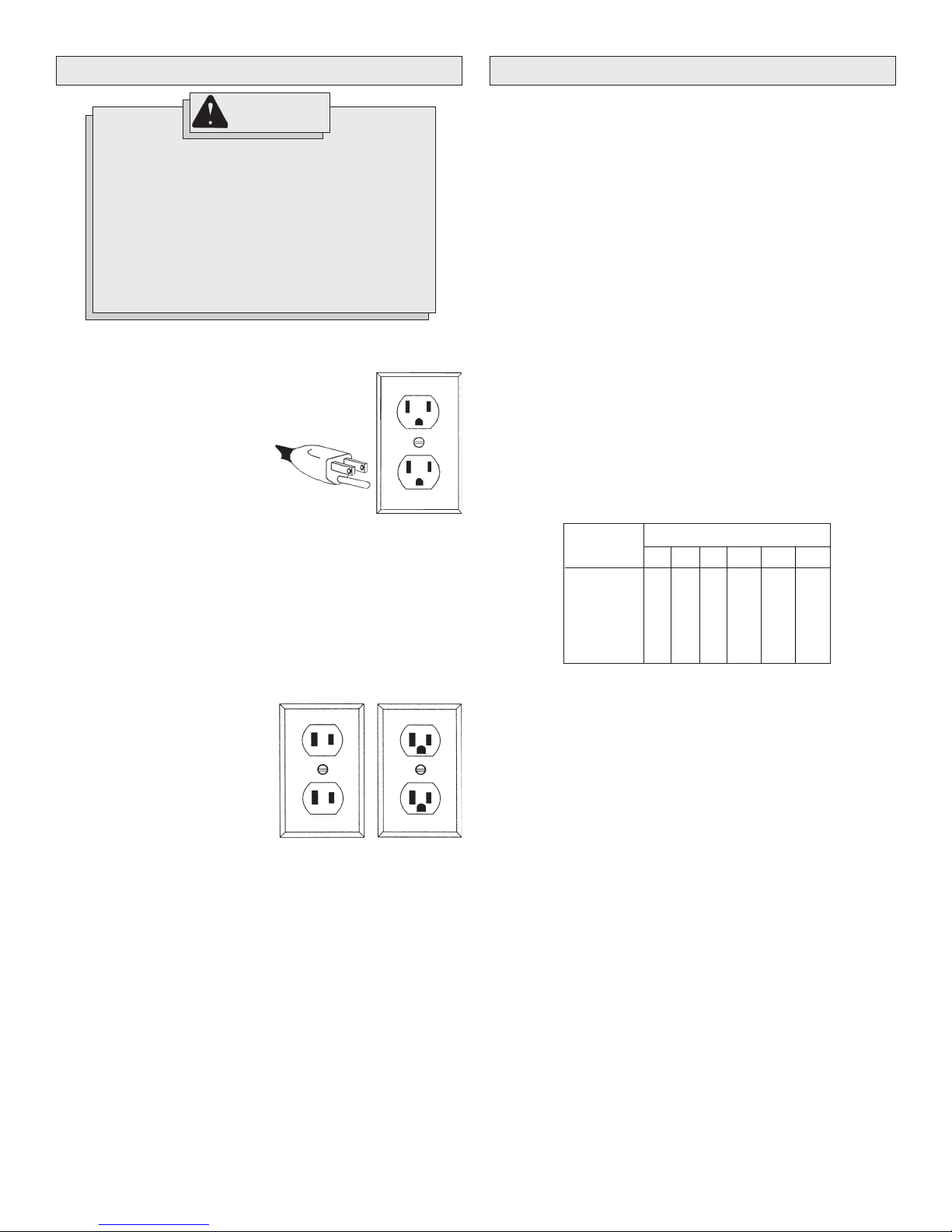

Grounded Tools:

Tools with Three Prong Plugs

Tools marked “Grounding Required”

have a three wire cord and three

prong grounding plug. The plug must

be connected to a properly grounded

outlet (See Figure A). If the tool should

electrically malfunction or break

down, grounding provides a low resistance path to carry electricity

away from the user, reducing the risk

of electric shock.

The grounding prong in the plug is connected through the green wire

inside the cord to the grounding system in the tool. The green wire in the

cord must be the only wire connected to the tool's grounding system and

must never be attached to an electrically “live” terminal.

Your tool must be plugged into an appropriate outlet, properly installed

and grounded in accordance with all codes and ordinances. The plug

and outlet should look like those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked “Double Insulated” do

not require grounding. They have a

special double insulation system

which satisfies OSHA requirements

and complies with the applicable

standards of Underwriters Laboratories, Inc., the Canadian Standard

Association and the National Electrical Code. Double Insulated tools may

be used in either of the 120 volt outlets shown in Figures B and C.

Fig. A

Fig. B

Fig. C

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors, be sure it is marked

with the suffix “W-A” (“W” in Canada) to indicate that it is acceptable

for outdoor use.

• Be sure your extension cord is properly wired and in good electrical

condition. Always replace a damaged extension cord or have it

repaired by a qualified person before using it.

• Protect your extension cords from sharp objects, excessive heat

and damp or wet areas.

Recommended Minimum Wire Gauge

Nameplate

Amperes

8.1 - 12

12.1 - 15

15.1 - 20

* Based on limiting the line voltage drop to five

volts at 150% of the rated amperes.

for Extension Cords*

25'

0 - 5

5.1 - 8

16

16

14

12

10

Extension Cord Length

100'

50'

16

16

14

12

10

75'

16

14

12

10

10

14

12

10

10

150'

12

10

--

--

--

--

200'

12

--

--

--

--

READ AND SAVE ALL INSTRUCTIONS

FOR FUTURE USE.

page 6

Loading...

Loading...