Milwaukee 6370-20 User Manual [en, es, fr]

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Catalog No.

No de Cat.

Catálogo No.

6370-20

6370-21

8" METAL CUTTING SAW

SCIE À MÉTAUX 203 mm (8")

SIERRA DE 203 mm (8") PARA CORTAR METAL

TO REDUCE THE RISK OF INJURY, USER MUST READ OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER EL MANUAL DEL OPERADOR.

page 2

GENERAL SAFETY RULES — FOR ALL POWER TOOLS

WARNING

Failure to follow all instructions listed below may result in electric shock, fi re and/or serious injury. The term "power tool" in all of the

warnings listed below refers to your mains-operated (corded) power tool or battery-opearted (cordless) power tool.

SAVE THESE INSTRUCTIONS

READ ALL INSTRUCTIONS

WORK AREA SAFETY

1. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

2. Do not operate power tools in explosive atmospheres, such as

in the presence of fl ammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

3. Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

4. Power tool plugs must match the outlet. Never modify the plug in

any way. Do not use any adapter plugs with earthed (grounded)

power tools. Unmodifi ed plugs and matching outlets will reduce risk

of electric shock.

5. Avoid body contact with earthed or grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is earthed or grounded.

6. Do not expose power tools to rain or wet conditions. Water entering

a power tool will increase the risk of electric shock.

7. Do not abuse the cord. Never use the cord for carrying, pulling, or

unplugging the power tool. Keep cord away from heat, oil, sharp

edges, or moving parts. Damaged or entangled cords increase the

risk of electric shock.

8. When operating a power tool outdoors, use an extension cord suit-

able for outdoor use. Use of a cord suitable for outdoor use reduces

the risk of electric shock.

PERSONAL SAFETY

9. Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired

or under the infl uence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in serious personal

injury.

10. Use safety equipment. Always wear eye protection. Safety equip-

ment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

11. Avoid accidental starting. Ensure the switch is in the off-position

before plugging in. Carrying tools with your fi nger on the switch or

plugging in power tools that have the switch on invites accidents.

12. Remove any adjusting key or wrench before turning the power

tool on. A wrench or a key left attached to a rotating part of the power

tool may result in personal injury.

13. Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

14. Dress properly . Do not wear loose clothing or jewellery . Keep your

hair, clothing and gloves away from moving parts. Loose clothes,

jewellery, or long hair can be caught in moving parts.

15. If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used.

Use of these devices can reduce dust-related hazards.

16. Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at

the rate for which it was designed.

17. Do not use the power tool if the switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

18. Disconnect the plug from the power source and/or the battery pack

from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the tool accidentally.

19. Store idle power tools out of the reach of children and do not al-

low persons unfamiliar with the power tools or these instructions

to operate power tools. Power tools are dangerous in the hands of

untrained users.

20. Maintain power tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the

power tool's operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly maintained power

tools.

21. Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier to

control.

22. Use the power tool, accessories and tool bits etc., in accordance

with these instructions and in the manner intended for the particular type of power tool, taking into account the working conditions

and the work to be performed. Use of the power tool for operations

different from those intended could result in a hazardous situation.

23. Have your power tool serviced by a qualifi ed repair person using

only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

POWER TOOL USE AND CARE

SERVICE

page 3

SPECIFIC SAFETY RULES - FOR METAL CUTTING SAWS

1. DANGER!:

Keep hands away from cutting area and blade. Keep your second

hand on auxiliary handle or motor housing. If both hands are holding

the saw, they cannot be cut by the blade.

Do not reach underneath the workpiece. The guard cannot protect

you from the blade below the workpiece.

Adjust the cutting depth to the thickness of the workpiece. Less

than a full tooth of the blade teeth should be visible below the workpiece.

NEVER hold piece being cut in your hands or across your leg.

Secure the workpiece to a stable platform. It is important to support

the work properly to minimize body exposure, blade binding, or loss of

control.

Hold power tool by insulated gripping surfaces when performing

an operation where the cutting tool may hidden wiring or its own

cord. Contact with a “live” wire will also make exposed metal parts of

the tool “live” and shock the operator.

When ripping always use a rip fence or straight edge guide. This

improves the accuracy of cut and reduces the chance of blade binding.

Always use blades with correct size and shape (diamond versus

round) of arbor holes. Blades that do not match the mounting hardware

of the saw will run eccentrically, causing loss of control.

Never use damaged or incorrect blade washers or bolts. The blade

washers and bolts were specially designed for your saw, for optimum

performance and safety of operation.

2. Causes and Operator Prevention of KICKBACK:

KICKBACK is a sudden reaction to a pinched, bound or misaligned saw

blade, causing an uncontrolled saw to lift up and out of the workpiece

toward the operator.

When the blade is pinched or bound tightly by the kerf closing down, the

blade stalls and the motor reaction drives the unit rapidly back toward

the operator.

If the blade becomes twisted or misaligned in the cut, the teeth at the

back edge of the blade can dig into the top surface of the wood causing

the blade to climb out of the kerf and jump back toward operator.

KICKBACK is the result of saw misuse and/or incorrect operating pro-

cedures or conditions and can be avoided by taking proper precautions

as given below:

Maintain a fi rm grip with both hands on the saw and position your

arms to resist kickback forces. Position your body to either side of the

blade, but not in line with the blade. Kickback could cause the saw to

jumb backwards, but kickback forces can be controlled by the operator,

if proper precautions are taken.

When blade is binding, or when interrupting a cut for any reason,

release the trigger and hold the saw motionless in the material

until the blade comes to a complete stop. Never attempt to remove

the saw from the work or pull the saw backward while the blade

is in motion or kickback may occur. Investigate and take corrective

actions to eliminate the cause of blade binding.

When restarting a saw in the workpiece, center the saw blade in

the kerf and check that saw teeth are not engaged into the material.

If saw blade is binding, it may walk up or kickback from the workpiece

as the saw is restarted.

Support large panels to minimize the risk of blade pinching and

kickback. Large panels tend to sag under their own weight. Supports

must be placed under the panel on both sides, near the line of cut and

near the edge of the panel.

Do not use dull or damaged blade. Unsharpened or improperly set

blades produce narrow kerf causing excessive friction, blade binding

and kickback.

Blade depth and bevel adjusting locking levers must be tight and

secure before making cut. If blade adjustment shifts while cutting, it

may cause binding and kickback.

Use extra caution when making a "plunge cut" (or pocket cut) into

existing walls or other blind areas. The protruding blade may cut

objects that can cause kickback.

page 4

3. Check lower guard for proper closing before each use. Do not op-

erate saw if lower guard does not move freely and close instantly.

Never clamp or tie the lower guard into the open position. If saw is

accidentally dropped, lower guard may be bent. Raise the lower guard

with the lower guard lever and make sure it moves freely and does not

touch the blade or any other part, in all angles and depths of cut.

Check the operation of the lower guard spring. If the guard and the

spring are not operating properly, they must be serviced before

use. Lower guard may operate sluggishly due to damaged parts, gummy

deposits, or a buildup of debris.

Lower guard should be retracted manually only for special cuts

such as "plunge cuts" ("pocket cuts") and "compound cuts". Raise

lower guard by lower guard lever and as soon as blade enters the

material, the lower guard must be released. For all other sawing,

the lower guard should operate automatically.

Always observe that the lower guard is covering the blade before

placing saw down on bench or fl oor. An unprotected, coasting

blade will cause the saw to walk backwards, cutting whatever is in its

path. Be aware of the time it takes for the blade to stop after switch is

released.

4. Maintain labels and nameplates. These carry important information.

If unreadable or missing, contact a

free replacement.

5. WARNING! Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry products,

and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals: work in

a well ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to fi lter out microscopic

particles.

6. Do not touch material immediately after it has been cut. Use caution; cut material may be hot and sharp.

7. Do not use cutting oil. The use of cutting oil may cause a fi re.

8. Do not use tool near fl ammable material. Sparks may cause fi re.

9. Chip container cover may be hot after use. Use caution when empty-

ing chip container or changing the blade.

10. Do not start the blade when in contact with workpiece. Wait for

blade to reach full speed before beginning cut.

MILWAUKEE service facility for a

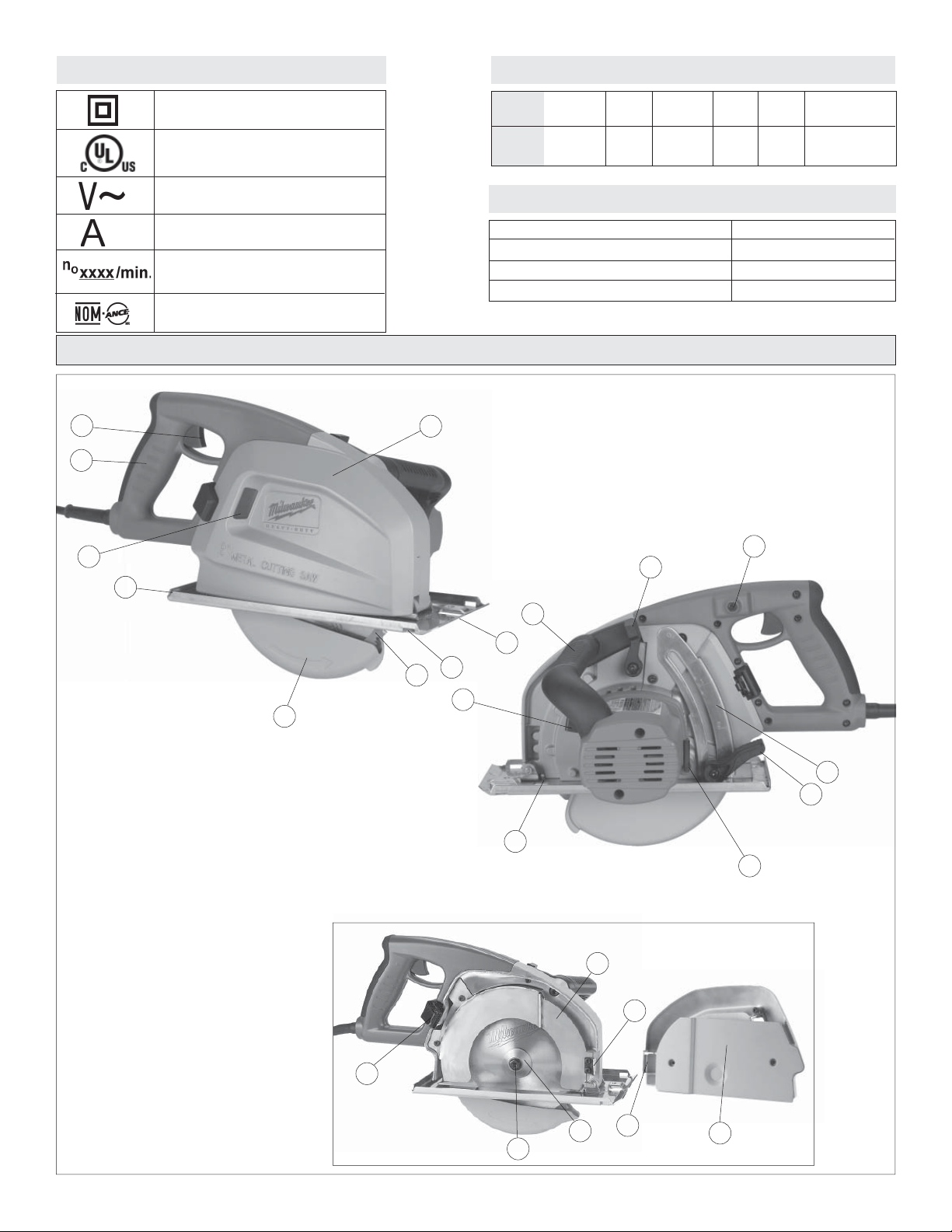

Symbology

Double Insulated

Underwriters Laboratories, Inc.

Cat.

No.

6370-20

6370-21

Volts

AC Only

120

120

Specifi cations

No Load

Amps

13

13

RPM

3700

3700

Blade

Size

8"

8"

Round

Arbor

5/8"

5/8"

Depth of Cut

0 to 2-9/16"

0 to 2-9/16"

Volts Alternating Current

Amperes

No Load Revolutions per Minute (RPM)

Mexican Approvals Marking

2

1

9

8

1. Handle

2. Trigger

3. Chip container

4. Sight line

5. Rip fence slot

6. Blade

7. Lower guard

8. Shoe

9. Chip viewing window

10. Spindle lock button

11. Front handle

12. Lower guard lever

13. Overload protector

14. Depth setting gauge

15. Depth adjusting lever

16. Hex wrench

17. Contact window

18. Latch

19. Upper guard

20. Tab

21. Tab pin

22. Outer blade fl ange

23. Blade bolt

Capacities

Materials *

Steel Studs, Steel Decking, Roofi ng Panels

Steel Plate

Angle Iron

* See "Applications" for requirements when cutting thicker materials.

6370-20 and 6370-21

10 gauge, up to 2-9/16" thick

1/4" thick

2-1/2" x 2-1/2" x 1/4"

FUNCTIONAL DESCRIPTION

3

13

12

11

4

5

6

10

7

14

15

17

16

19

20

18

22

23

21

3

page 5

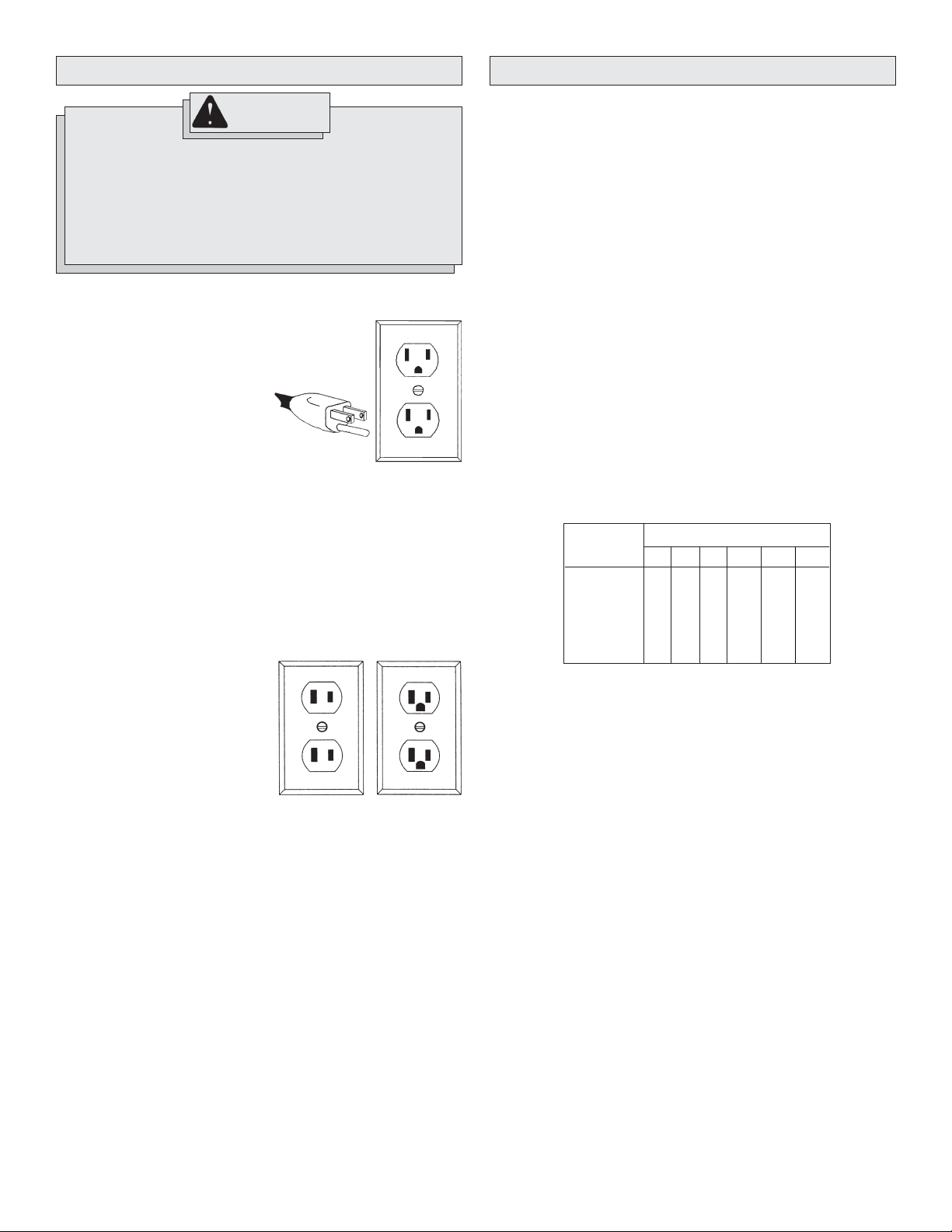

GROUNDING EXTENSION CORDS

WARNING

Improperly connecting the grounding wire can result in the risk of

electric shock. Check with a qualifi ed electrician if you are in doubt

as to whether the outlet is properly grounded. Do not modify the

plug provided with the tool. Never remove the grounding prong

from the plug. Do not use the tool if the cord or plug is damaged. If

damaged, have it repaired by a MILWAUKEE service facility before

use. If the plug will not fi t the outlet, have a proper outlet installed

by a qualifi ed electrician.

Grounded tools require a three wire extension cord. Double insulated tools

can use either a two or three wire extension cord. As the distance from the

supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a serious drop in

voltage, resulting in loss of power and possible tool damage. Refer to the

table shown to determine the required minimum wire size.

The smaller the gauge number of the wire, the greater the capacity of the

cord. For example, a 14 gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension cord to make up the total

length, be sure each cord contains at least the minimum wire size required. If

you are using one extension cord for more than one tool, add the nameplate

amperes and use the sum to determine the required minimum wire size.

Grounded Tools:

Tools with Three Prong Plugs

Tools marked “Grounding Required”

have a three wire cord and three

prong grounding plug. The plug must

be connected to a properly grounded

outlet (See Figure A). If the tool should

electrically malfunction or break down,

grounding provides a low resistance

path to carry electricity away from

the user, reducing the risk of electric

shock.

The grounding prong in the plug is connected through the green wire inside

the cord to the grounding system in the tool. The green wire in the cord must

be the only wire connected to the tool's grounding system and must never

be attached to an electrically “live” terminal.

Y our tool must be plugged into an appropriate outlet, properly installed and

grounded in accordance with all codes and ordinances. The plug and outlet

should look like those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked “Double Insulated” do

not require grounding. They have a

special double insulation system which

satisfies OSHA requirements and

complies with the applicable standards

of Underwriters Laboratories, Inc., the

Canadian Standard Association and

the National Electrical Code. Double

Insulated tools may be used in either

of the 120 volt outlets shown in Figures

B and C.

Fig. A

Fig. B

Fig. C

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors, be sure it is marked with

the suffi x “W-A” (“W” in Canada) to indicate that it is acceptable for

outdoor use.

• Be sure your extension cord is properly wired and in good electrical

condition. Always replace a damaged extension cord or have it repaired

by a qualifi ed person before using it.

• Protect your extension cords from sharp objects, excessive heat and

damp or wet areas.

Recommended Minimum Wire Gauge

Nameplate

Amperes

5.1 - 8

8.1 - 12

12.1 - 15

15.1 - 20

* Based on limiting the line voltage drop to fi ve

volts at 150% of the rated amperes.

for Extension Cords*

25'

0 - 5

16

16

14

12

10

Extension Cord Length

100'

14

12

10

10

150'

12

10

--

--

--

--

50'

16

16

14

12

10

75'

16

14

12

10

10

200'

12

--

--

--

--

READ AND SAVE ALL INSTRUCTIONS

FOR FUTURE USE.

page 6

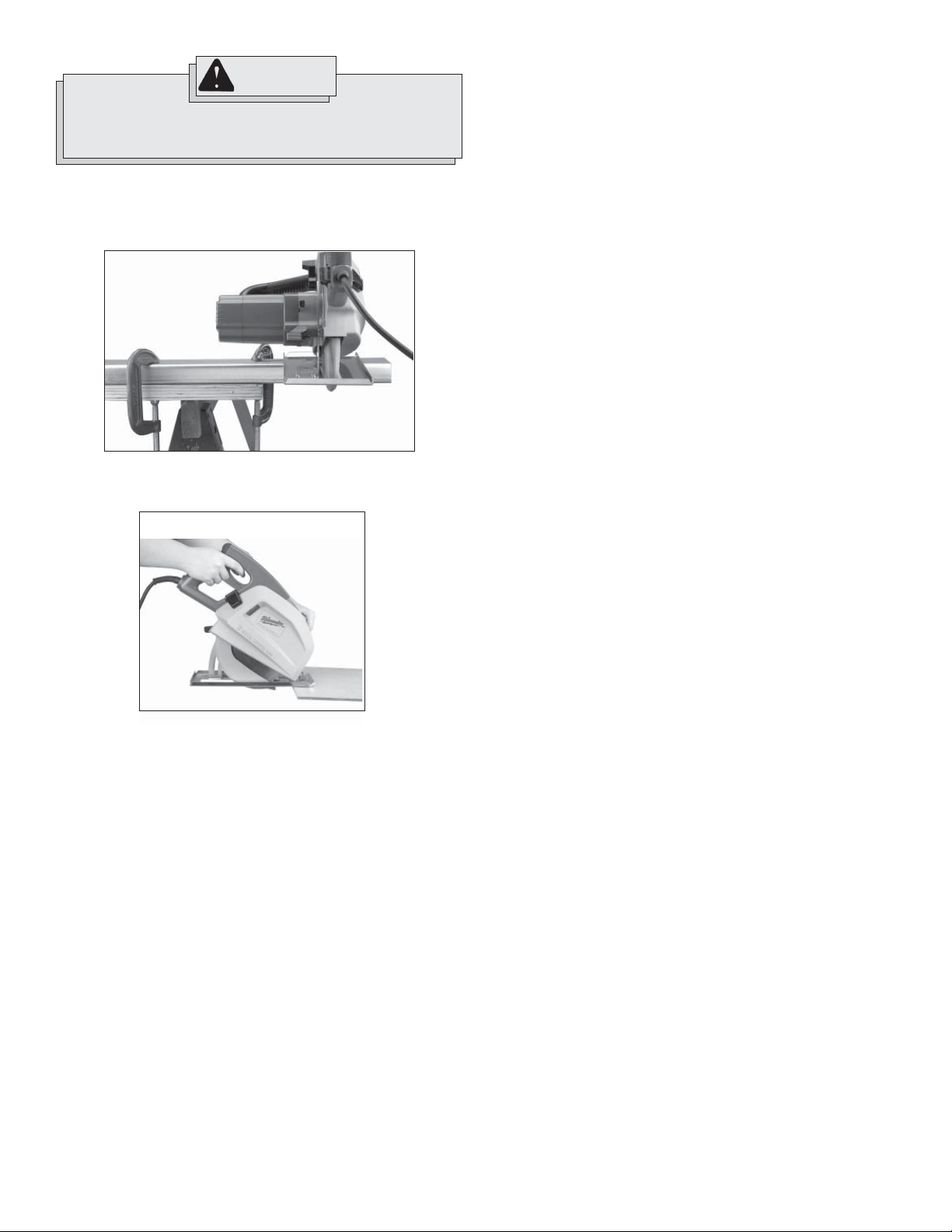

TOOL ASSEMBLY

WARNING

To reduce the risk of injury, always unplug tool before attaching

or removing accessories or making adjustments. Use only specifi -

cally recommended accessories. Others may be hazardous.

Selecting Blade

Select a blade appropriate for your application. Refer to the “Accessories”

section for a list of blades for this tool.

Always use sharp blades. Dull blades tend to overload the tool and increase

the chance of KICKBACK. Only use blades with a maximum safe operating

speed greater than the no load RPM marked on the tool's nameplate. Read

the blade manufacturer's instructions before use. Do not use any type of

abrasive cut-off wheel or dry diamond cutting blades. Use the correct blade

type for your application. Using the wrong blade may result in reduced

performance or damage to the blade. Do not use blades that are cracked

or have broken teeth.

Checking the Operation of the Lower Guard

Check the operation and condition of the lower guard lever. If the guard and

the lever are not operating properly, they must be serviced before use. Lower

guard may operate sluggishly due to damaged parts, gummy deposits, or

a buildup of debris.

1. Unplug tool before checking the lower guard.

2. Place the tool on its side (Fig. 1).

NOTE: This procedure will not show proper lower guard operation if

the tool is not on its side.

3. Grasp the lower guard by the sides and push it all the way back into

the blade housing.

4. Release the lower guard.

• If the guard immediately springs back into place, it is working correctly

and you may continue with use.

• If the guard does not immediate spring back into place, clean the upper

and lower guards to remove all chips and debris. Then, check

the operation again by starting with step 1.

• If the guard still does not immediately spring back into place, contact a

MILWAUKEE service facility for repairs.

Removing and Installing Chip Container

WARNING

• NEVER operate tool when guards and chip container are not

installed. Serious injury may occur.

• To reduce the risk of injury, wear safety goggles or glasses

with side shields when removing the chip container. Chips and

debris may fl y up into the face.

Installing and Removing Blades (Figs. 1 & 2)

Fig. 1

Spindle lock

button

1. Unplug tool before installing or removing blades.

2. Remove the chip container (see "Removing and Installing Chip Container").

3. Place the saw on a fl at surface with the blade facing up (Fig. 1). To

remove the blade bolt from the spindle, push in the spindle lock button

and hold. Using the wrench provided with the tool, turn the blade bolt

counterclockwise. Remove the blade bolt and outer blade fl ange. Do

not remove the inner blade fl ange.

4. Remove the blade from the spindle. Always clean the spindle, upper

guard, lower guard, and blade fl anges to remove any chips and de-

bris.

5. To install a blade, place the blade on the spindle with the teeth

pointing in the same direction as the arrow on the lower guard

(Fig. 2).

Fig. 2

6. Place the blade fl ange on the spindle and hand tighten the blade

bolt.

7. While holding in the spindle lock button, use the wrench to turn the

blade bolt clockwise and tighten securely.

8. Replace the chip container (see "Removing and Installing Chip Con-

To remove, turn

counterclockwise

1. Unplug tool before removing or installing chip container.

2. To remove the chip container , open the latch and pull the chip container

off of the tab.

3. To install the chip container, fi t the tab pin onto the tab, position the

chip container, and secure the latch.

page 7

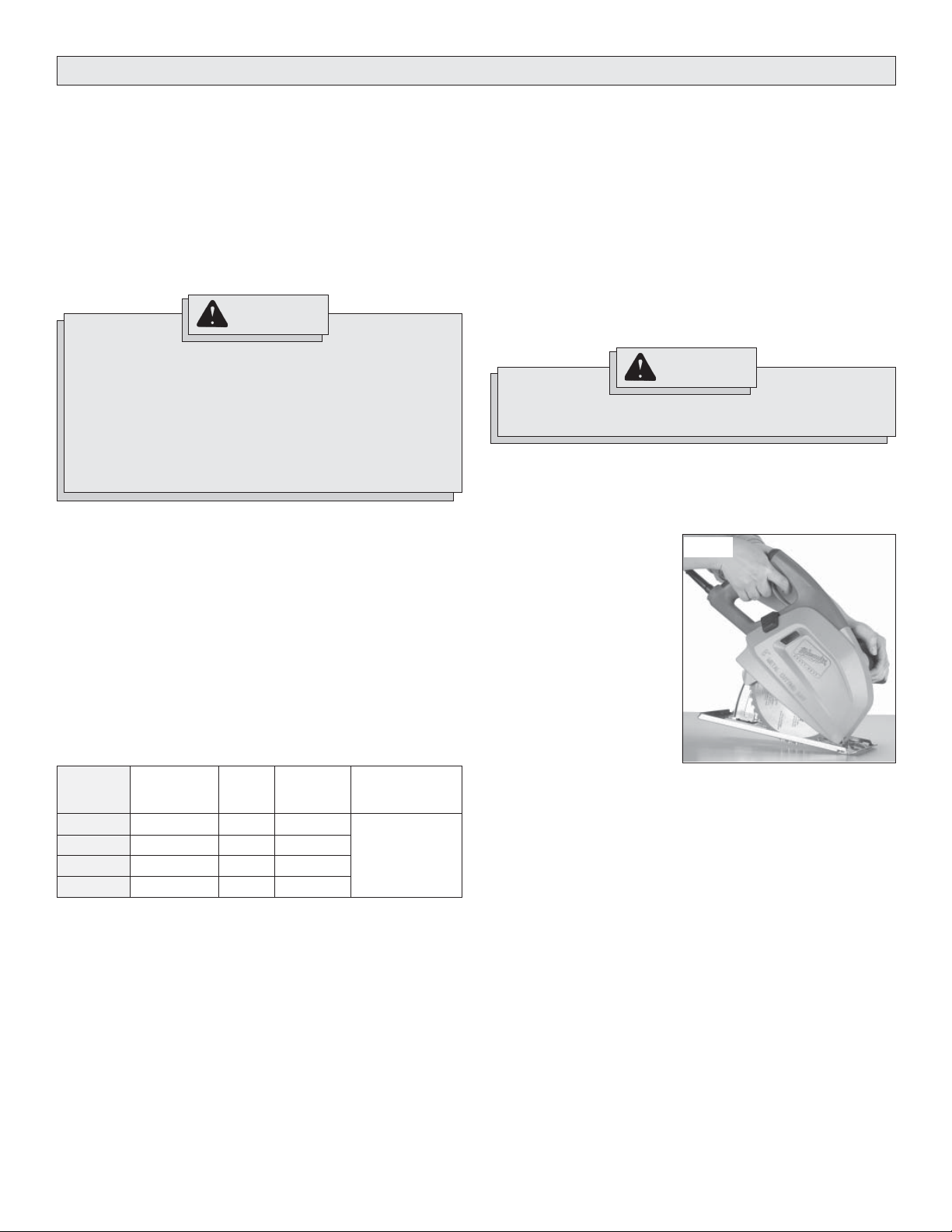

Adjusting Depth (Figs. 3 & 4)

1. Unplug tool before adjusting blade depth.

2. To adjust the depth of the cut, hold the saw by the handle and

loosen the depth adjusting lever by pulling it up, away from the shoe

(Fig. 3).

Fig. 3

3. Raise or lower the shoe to the desired position. For the proper depth

setting, the blade should extend no more than 1/4” below the material

being cut (Fig. 4).

4. Push the depth adjusting lever down to secure the shoe position.

Fig. 4

1/4"

Emptying the Chip Container

Chips and other debris from the workpiece are collected inside the chip container, which needs to be emptied to ensure proper functioning of the tool.

1. Unplug tool.

2. Remove the chip container (see "Removing and Installing Chip Container") and empty. Use a brush to ensure all chips and debris have

been removed.

3. Remove all chips and debris from upper guard, blade, and housing.

4. Replace the chip container (see "Removing and Installing Chip Container").

OPERATION

Causes and Operator Prevention of KICKBACK:

KICKBACK is a sudden reaction to a pinched, bound or misaligned saw

blade, causing an uncontrolled saw to lift up and out of the workpiece

toward the operator.

When the blade is pinched or bound tightly by the kerf, or cutting slot, closing

down, the blade stalls and the motor reaction drives the unit rapidly back

toward the operator.

If the blade becomes twisted or misaligned in the cut, the teeth at the back

edge of the blade can dig into the top surface of the wood causing the blade

to climb out of the kerf and jump back toward operator.

KICKBACK is the result of tool misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as

given below:

1. Maintain a fi rm grip with both hands on the saw and position your

body and arm to allow you to resist KICKBACK forces. KICKBACK

forces can be controlled by the operator, if proper precautions are

taken.

2. When blade is binding, or when interrupting a cut for any reason,

release the trigger and hold the saw motionless in the material

until the blade comes to a complete stop. Never attempt to remove

the saw from the work or pull the saw backward while the blade is

in motion or KICKBACK may occur. Investigate and take corrective

actions to eliminate the cause of blade binding.

3. When restarting a saw in the workpiece, center the saw blade in

the kerf, or cut, and check that saw teeth are not engaged into the

material. If saw blade is binding, it may walk up or KICKBACK from

the workpiece as the saw is restarted.

4. Support large panels to minimize the risk of blade pinching and

KICKBACK. Large panels tend to sag under their own weight. Supports

must be placed under the panel on both sides, near the line of cut and

near the edge of the panel.

5. Do not use dull or damaged blades. Unsharpened or improperly set

blades produce narrow kerf causing excessive friction, blade binding

and KICKBACK.

6. Depth adjusting lever must be tight and secure before making

cut. If blade adjustment shifts while cutting, it may cause binding and

KICKBACK.

7. Use extra caution when making a “Pocket Cut” into existing walls

or other blind areas. The protruding blade may cut objects that can

cause KICKBACK.

8. Set the depth of cut for no more than 1/4" greater than the thick-

ness of the stock. The less blade exposed, the less chance of binding

and KICKBACK. Before cutting, be sure depth and bevel adjustments

are tight.

9. Stay alert. Any distraction can cause twisting or binding. Repetitive

cuts may lull the user into careless movements.

page 8

WARNING

To reduce the risk of injury , everyone in the work area should wear

safety goggles or glasses with side shields. Unplug the tool before

changing accessories or making adjustments.

General Operation (Figs. 5 & 6)

Always clamp the workpiece securely on a saw horse or bench

(Fig. 5). See “Applications” for the correct way to support your work in different situations.

Fig. 5

1. Draw a cutting line. Place the front of the shoe on the edge of the

workpiece without making blade contact. Hold the trigger handle with

one hand and the front handle with the other (Fig. 6).

Fig. 6

4. While cutting, keep the shoe fl at against the workpiece and maintain a

fi rm grip. Do not force the saw through the workpiece. Forcing a saw

can cause KICKBACK. Use a light, continuous pressure to make the

cut while following the cut line through the sight line.

5. If making a partial cut, restarting in mid-cut or correcting direction, allow

the blade to come to a complete stop. To resume cutting, center the

blade in the kerf, back the saw away from cutting edge a few inches,

pull the trigger and re-enter the cut slowly.

6. If the saw binds and stalls, maintain a fi rm grip and release the trigger

immediately. Hold the saw motionless in the workpiece until the blade

comes to a complete stop.

7. After fi nishing a cut, be sure the lower guard closes and the blade comes

to a complete stop before setting the saw down.

Overload Protector

The overload protector automatically turns off the tool when the motor is

overloaded. The tool can become overloaded when using a dull blade,

cutting material that is too thick, cutting materials too quickly, or cutting

hard metals such as stainless steel. To prevent the overload protector from

activating, always use a sharp blade and follow the cutting instructions

under the "Applications" section. Do not attempt to defeat or override the

overload protector.

If the tool turns off automatically:

1. Release the trigger and unplug the tool.

2. Remove the blade from the workpiece.

3. Allow the tool to rest for a miniumum of two minutes.

4. Reset the overload protector by pushing in the button.

5. Allow the tool to run under no load to ensure the tool has properly

cooled.

6. Resume the cut. When restarting a saw in the workpiece, center the

saw blade in the kerf, or cut, and check that saw teeth are not engaged

into the material. If saw blade is binding, it may walk up or KICKBACK

from the workpiece as the saw is restarted.

2. Line up the sight line with your cutting line. Position your arms and body

to resist KICKBACK.

3. Pull the trigger and allow the motor to reach full speed before beginning

cut.

page 9

APPLICATIONS

This tool is intended for cutting unhardened ferrous metal and non-ferrous

metal. Refer to the “Accessories” section for a list of blades to be used for

the proper applications of this tool. The following precautions must be followed to reduce the risk of injury:

• Do not cut stacked materials. Cut one piece at a time.

• Do not cut hardened steel.

• Cut materials with the wider edge of the shoe over the clamped side of

the material.

• Do not touch the blade, workpiece, chips, or chip container with bare

hands immediately after cutting; they may be hot and could burn

skin.

Cutting Materials Thicker than 1/4" (3/4" Maximum Thickness)

CAUTION!

To reduce the risk of damage to the tool or blade, do not exceed

the Feed Rate and Maximum Cut Time for materials thicker than

1/4", as charted below.

Between Maximum Cut Times, allow the tool to cool down for 6

minutes of running with no load or 60 minutes switched off.

Cutting too fast or too long in heavy material will damage the tool

if the tool is not allowed to cool.

Cutting too slow will cause excessive wear on the blade.

When cutting materials over 1/4", certain guidelines must be followed to avoid

serious damage to the tool and/or blade. The correct combination of the

following factors will allow for a sucessful cut through thicker materials:

1. Material Thickness (do not cut materials thicker than 3/4")

NOTE: If the material thickness is not shown in the chart below , round

up to the nearest thickness listed in the chart and follow those guidelines.

2. Maximum Length of Cut (the length of material in inches through which

the saw moves between cool down periods)

3. Feed Rate (the speed at which the saw moves through the material in

seconds per inch)

4. Maximum Cutting Time (the total amount of time that the saw can be

under load between cool down periods.

5. Cool Down Period (6 minutes running with no load or 60 min. switched

off.)

Material

Thickness

3/8"

1/2"

5/8"

3/4"

Maximum

Cutting Time

(seconds)

30 - 45

18 - 36

18 - 30

20 - 25

Max

Length

of Cut

15"

9"

6"

5"

Feed Rate

(sec./inch)

2 - 3

2 - 4

3 - 5

4 - 5

Cool Down

Period

6 min. of running

with no load

or 60 min.

switched off

Cutting Thin or Corrugated Materials

Cut thin and corrugated materials at least 1" from the edge of the workpiece

to avoid injury or damage to the tool caused by thin strips of metal being

pulled into the upper guard.

Cutting Large Sheets

Large sheets sag or bend if they are not correctly supported. If you attempt

to cut without leveling and properly supporting the workpiece, the blade will

tend to bind, causing KICKBACK.

Support large sheets. Be sure to set the depth of the cut so that you only

cut through the workpiece, not through the supports.

When cutting widths greater than 4", clamp 1" lumber to workpiece and use

the inside edge of the shoe as a guide.

Pocket Cutting (Fig. 7)

WARNING!

To reduce the risk of electric shock, check work area for hidden

pipes and wires before making pocket cuts.

Pocket cuts are made in the middle of the workpiece when it can not be cut

from an edge. We recommend using a Sawzall® reciprocating saw or jig

saw for this type of cut. However, if you must use a circular saw to make

a pocket cut, USE EXTREME CAUTION. To maintain control of the saw

during pocket cutting, keep both hands on the saw (Fig. 7).

1. Beginning at a corner, line up

the sight line with your cutting

line. Tilt the saw forward,

fi rmly fi xing the front of the

shoe on the workpiece. The

blade should be just above

cutting line, but not touching

it. Raise the lower guard using the lower guard lever.

2. Pull the trigger and allow the

motor to reach full speed

before beginning cut. Using

the front of the shoe as a

hinge point, gradually lower

the back end of the saw into

the workpiece. Release the

lower guard lever.

3. When the shoe rests fl at against workpiece, advance the saw to the far

corner. Release the trigger and allow the blade to come to a complete

stop before removing it from workpiece. Repeat the above steps for

each side of the opening. Use a Sawzall® reciprocating saw, jig saw

or small hand saw to fi nish the corners if they are not completely cut

through.

Troubleshooting

If the blade does not follow a straight line:

• Teeth are dull. This is caused by hitting a hard object, dulling teeth on

one side. The blade tends to cut to the side with the sharpest teeth.

• Shoe is out of line or bent

• Blade is bent

If the blade binds, smokes or turns blue from friction:

• Blade is dull

• Blade is on backwards

• Blade is bent

• Blade is dirty

• Workpiece is not properly supported

• Incorrect blade is being used

Fig. 7

page 10

Loading...

Loading...