Page 1

Catalog No.

No de Cat.

Número de Catálogo

6266

6276

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

JIG SAW

SCIE SAUTEUSE

SIERRA CALADORA

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN COMPRENDRE LE

MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL MANUAL DEL

OPERADOR.

Page 2

GENERAL SAFETY RULES

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below, may result in

electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

1. Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

2. Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away while operat-

ing a power tool. Distractions can cause you to lose control.

Protect others in the work area from debris such as chips and

sparks. Provide barriers or shields as needed.

ELECTRICAL SAFETY

4. Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify

the plug in any way. Do not use any adaptor plugs. Check

with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools should electrically

malfunction or break down, grounding provides a low resistance

path to carry electricity away from the user.

5. Double Insulated tools are equipped with a polarized plug

(one blade is wider than the other). This plug will fit in a

polarized outlet only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet. Do not change

the plug in any way. Double insulation eliminates the need for

the three wire grounded power cord and grounded power supply

system.

6. Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is grounded.

7. Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

8. Do not abuse the cord. Never use the cord to carry the tools

or pull the plug from an outlet. Keep cord away from heat,

oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

9. When operating a power tool outside, use an outdoor

extension cord marked W-A or W. These cords are rated

for outdoor use and reduce the risk of electric shock.

PERSONAL SAFETY

10. Stay alert, watch what you are doing, and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A

moment of inattention while operating power tools may result in

serious personal injury.

11. Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

12. Avoid accidental starting. Be sure switch is off before

plugging in. Carrying tools with your finger on the switch or

plugging in tools with the switch on invites accidents.

13. Remove adjusting keys or wrenches before turning the

tool on. A wrench or a key that is left attached to a rotating part of

the tool may result in personal injury.

14. Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the tool

in unexpected situations.

15. Use safety equipment. Always wear eye protection. Dust

mask, non-skid safety shoes, hard hat, or hearing protection must

be used for appropriate conditions.

TOOL USE AND CARE

16. Use clamps or other practical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body is unstable and may lead to loss of control.

17. Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for which

it is designed.

18. Do not use tool if switch does not turn it on or off. Any tool

that cannot be controlled with the switch is dangerous and must be

repaired.

19. Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the tool.

Such preventive safety measures reduce the risk of starting the tool

accidentally.

20. Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

21. Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools with sharp cutting edge are less likely to

bind and are easier to control. Do not use a damaged tool. Tag

damaged tools Do not use until repaired.

22. Check for misalignment or binding of moving parts, break-

age of parts, and any other condition that may affect the

tools operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

23. Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for

one tool, may become hazardous when used on another tool.

SERVICE

24. Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified per-

sonnel could result in a risk of injury.

25. When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this

manual. Use of unauthorized parts or failure to follow Maintenance

Instructions may create a risk of electric shock or injury.

page 2

Page 3

SPECIFIC SAFETY RULES

1. Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its

own cord. Contact with a live wire will make exposed metal parts of the tool live and shock the operator.

2. Keep hands away from all cutting edges and moving parts.

3. Maintain labels and nameplates. These carry important information. If unreadable or missing, contact a MILWAUKEE Service facility for a

free replacement.

4. WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause

cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

lead from lead-based paint

crystalline silica from bricks and cement and other masonry products, and

arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

Symbology

Double Insulated

Volts Alternating Current

Amps

No Load Revolutions per Minute

(RPM)

Underwriters Laboratories, Inc.

Canadian Standards Association

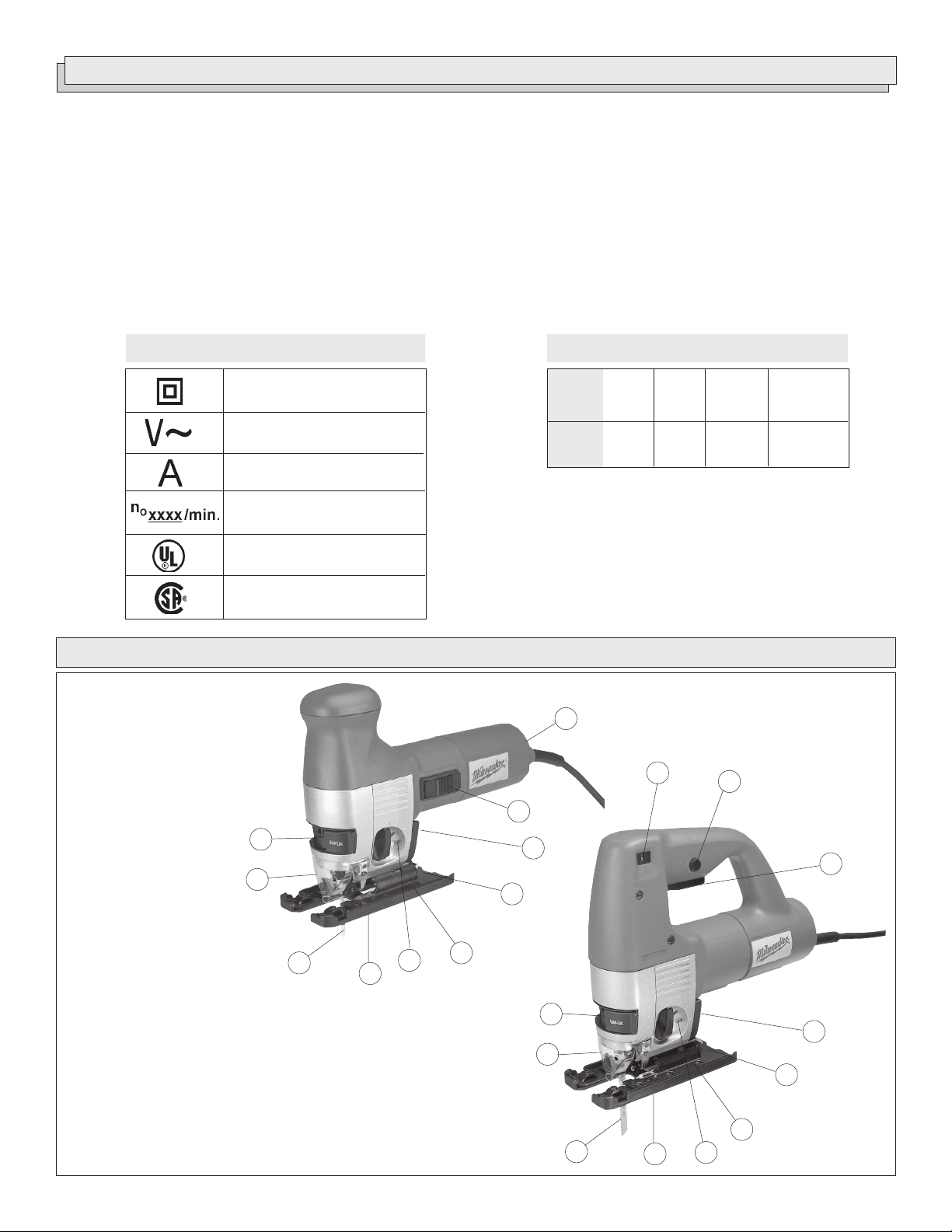

FUNCTIONAL DESCRIPTION

Cat No. 6276

Cat.

No.

6266

6276

11

Specifications

Volts

AC

Only

Amps

120

120

11

5.7

5.7

Length

of

Stroke

1"

1"

10

Strokes

per

minute

450- 3100

450-3100

2

1. Quik-Lok tension lever

2. Transparent blade cover

3. Blade

4. Shoe

5. Orbital action selector lever

6. Tilt angle scale

7. Hex key

8. Vacuum manifold

9. On/Off switch

10. Lock button

11. Speed control dial

9

1

3

5

4

6

8

7

1

2

3

4

5

Cat No. 6266

9

8

7

6

page 3

Page 4

GROUNDING EXTENSION CORDS

WARNING!

Improperly connecting the grounding wire can

result in the risk of electric shock. Check with a

qualified electrician if you are in doubt as to

whether the outlet is properly grounded. Do not

modify the plug provided with the tool. Never

remove the grounding prong from the plug. Do

not use the tool if the cord or plug is damaged. If

damaged, have it repaired by a MILWAUKEE

service facility before use. If the plug will not fit

the outlet, have a proper outlet installed by a

qualified electrician.

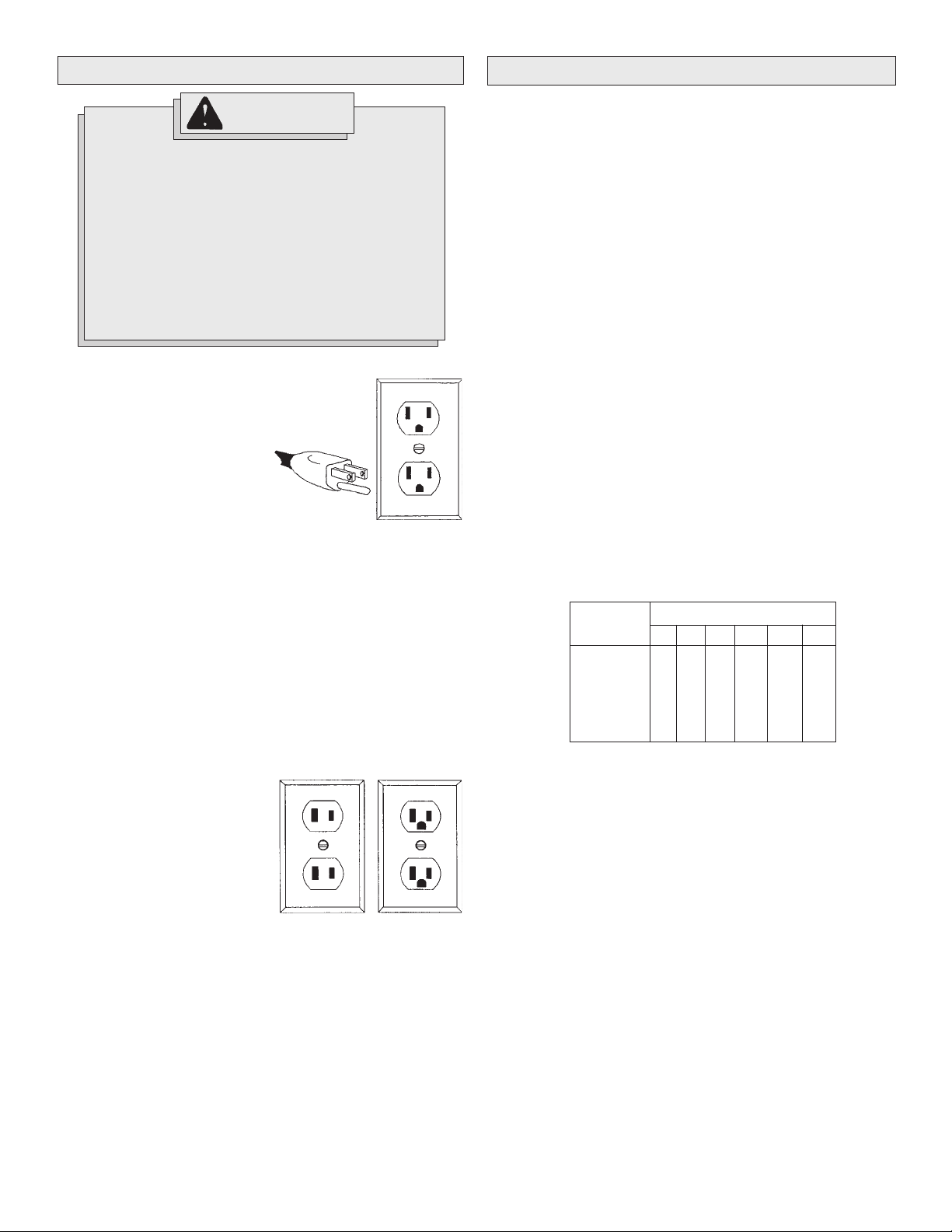

Grounded Tools:

Tools with Three Prong Plugs

Tools marked Grounding Required

have a three wire cord and three

prong grounding plug. The plug must

be connected to a properly grounded

outlet (See Figure A). If the tool should

electrically malfunction or break

down, grounding provides a low resistance path to carry electricity

away from the user, reducing the risk

of electric shock.

The grounding prong in the plug is connected through the green wire

inside the cord to the grounding system in the tool. The green wire in the

cord must be the only wire connected to the tool's grounding system and

must never be attached to an electrically live terminal.

Your tool must be plugged into an appropriate outlet, properly installed

and grounded in accordance with all codes and ordinances. The plug

and outlet should look like those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked Double Insulated do

not require grounding. They have a

special double insulation system

which satisfies OSHA requirements

and complies with the applicable

standards of Underwriters Laboratories, Inc., the Canadian Standard

Association and the National Electrical Code. Double Insulated tools may

be used in either of the 120 volt outlets shown in Figures B and C.

Fig. A

Fig. B

Fig. C

Grounded tools require a three wire extension cord. Double insulated

tools can use either a two or three wire extension cord. As the distance

from the supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a

serious drop in voltage, resulting in loss of power and possible tool

damage. Refer to the table shown to determine the required minimum

wire size.

The smaller the gauge number of the wire, the greater the capacity of the

cord. For example, a 14 gauge cord can carry a higher current than a 16

gauge cord. When using more than one extension cord to make up the

total length, be sure each cord contains at least the minimum wire size

required. If you are using one extension cord for more than one tool, add

the nameplate amperes and use the sum to determine the required minimum wire size.

Guidelines for Using Extension Cords

If you are using an extension cord outdoors, be sure it is marked

with the suffix W-A (W in Canada) to indicate that it is acceptable

for outdoor use.

Be sure your extension cord is properly wired and in good electrical

condition. Always replace a damaged extension cord or have it

repaired by a qualified person before using it.

Protect your extension cords from sharp objects, excessive heat

and damp or wet areas.

Recommended Minimum Wire Gauge

Nameplate

Amperes

8.1 - 12

12.1 - 15

15.1 - 20

* Based on limiting the line voltage drop to five

volts at 150% of the rated amperes.

for Extension Cords*

25'

0 - 5

5.1 - 8

16

16

14

12

10

Extension Cord Length

100'

14

12

10

10

150'

12

10

--

--

--

--

50'

16

16

14

12

10

75'

16

14

12

10

10

200'

12

--

--

--

--

READ AND SAVE ALL INSTRUCTIONS FOR

FUTURE USE.

page 4

Page 5

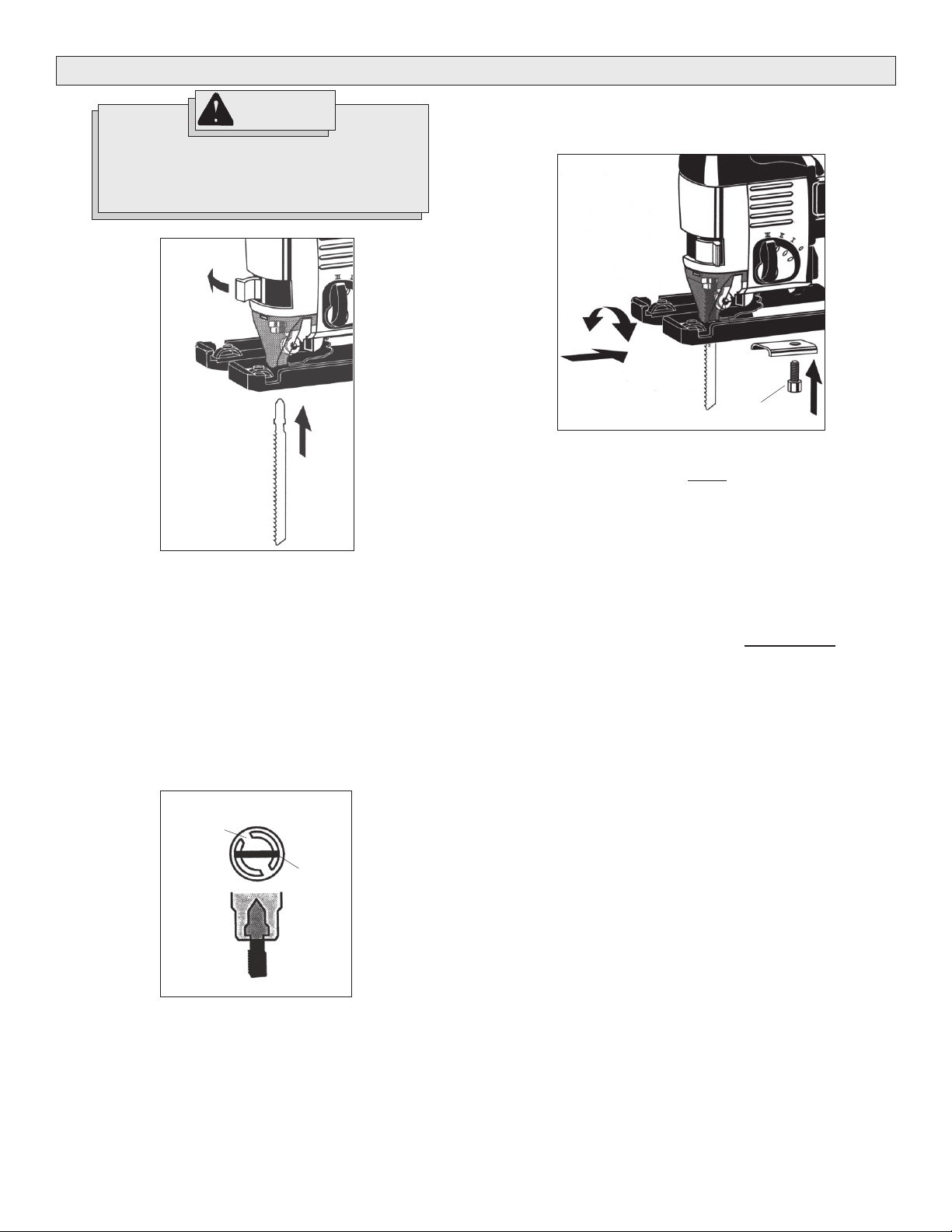

TOOL ASSEMBLY

WARNING!

To reduce the risk of injury, always unplug

tool before attaching or removing accessories

or making adjustments. Use only specifically

recommended accessories. Others may be

hazardous.

Fig. 1

Installing saw blades

This tool uses only T-Shank jig saw blades.

1. Unplug the tool.

2. Push the Quik-Lok tension lever as far as it will go and hold it in

position (Fig. 1).

3. Fit the saw blade into the groove in the support roller and push it

firmly into the plunger as far as it will go; the lug of the saw blade

must be in the plunger.

4. Release the Quik-Lok tension lever and the saw blade is automatically held.

5. Check that the saw blade is held firmly; the slot in the plunger will be

at an angle to the saw (Fig. 2).

Fig. 2

Slot

Adjusting the shoe (Fig. 3)

The shoe may be tilted up to 45° in either direction and moved forward or

backward.

Fig. 3

Shoe screw

1. To set a tilt angle for angle cuts and bevels, loosen the shoe

screw, pull the base backward

longer engaged. Tilt to the required preset angle (15°, 30°, or 45°) as

read on the tilt angle scale. Push back into the retaining lugs and

tighten the shoe screw. If angles other than the presets are required, set the desired angle and tighten the shoe screw without

engaging the retaining lugs.

If very exact angles are needed it is recommended that a test cut

and subsequent adjustment be made.

2. To move the shoe back for plunge cuts or cuts in corners,

loosen the shoe screw and pull the shoe

screw will fit into a slot to hold the shoe at 0°.

Using the Shoe Cover

The non-marring shoe cover is used to prevent marring and scratching

of the workpiece surface. To attach the shoe cover, hook the front of the

cover over the steel shoe. Next, snap the rear of the shoe cover to the

steel shoe. Be sure both sides are snapped in place.

When the shoe cover is not needed, remove it by pulling the tabs on rear

of the shoe cover outward from the steel shoe. Unhook the front of the

shoe cover and remove.

slightly until the retaining lugs are no

all the way back. The shoe

Blade

page 5

Page 6

OPERATION

WARNING!

To reduce the risk of injury, wear safety goggles

or glasses with side shields. Unplug the tool

before changing accessories or making

adjustments.

The 6266 and 6276 Orbital Action jig saws can cut a wide variety of

materials including metal, wood and plastic. Cuts may be straight lines,

bevels, curves or internal cut-outs. Notable features of these jig saws

include:

Rapid blade change without tools with the Quik-Lok blade change

system.

Adjustable Orbital Action blade stroke cuts faster by pressing the

blade against the work only during the upstroke. This is particularly

effective when rough cutting thick wooden boards.

Electronic dial speed control maintains the pre-set speed during the

cut.

Adjustable shoe can be tilted by up to 45 degrees in either direction

for bevel cuts.

Non-marring shoe cover to protect the surface of workpiece from

marring and scratching.

Sawdust blower removes the sawdust ahead of the cut for im-

proved visibility.

Built in manifold for vacuum assisted dust collection (hose is op-

tional).

Transparent blade cover improves dust extraction.

Vibration dampened mechanism permits quieter, smoother running.

Starting and stopping the tool

For Model No. 6266

1. To start the tool, press the On/Off switch.

2. To stop the tool, release the On/Off switch.

For Model No. 6276

1. To start the tool, push the On/Off switch forward until I is visible.

2. To stop the tool, push the On/Off switch backwards until 0 is

visible.

Locking the On/Off Switch

The lock button holds the trigger in the ON position for continuous use.

(Model No. 6266 only)

1. To lock the On/Off switch, hold the lock button in while pressing the

On/Off switch. Then release the On/Off switch.

2. To unlock the On/Off switch, press the On/Off switch and release.

The lock button will pop out.

Adjusting stroke per minute

The strokes per minute may be adjusted with the speed control dial. The

numbers 1 through 7 are printed on the dial with 1 being the slowest

speed and 7 the highest speed. Recommended cutting speeds for various materials are listed below. Optimum cutting speeds should be determined by the user for specific cutting requirements. Strokes per minute

may be adjusted when the tool is running or stopped.

Material Recommended saw speed

Wood

Metal

Plastic

7

4-5

2

Adjusting the orbital action

The amount of orbital action may be adjusted with the orbital action

selector lever. In general, a large orbital action (III) should be used with

soft materials and a small orbital action (0) should be used with hard

materials. When a smooth cut is required no orbit (0) should be used.

Recommended orbit settings for different material compositions are presented below. The optimum orbital action should be determined by the

user for their specific cutting requirements. Orbital action may be adjusted when the tool is running or stopped.

Material Orbital action

Wood

Metal

Plastic

Smooth Cut

Making the Cut

1. Set the stroke and orbital action according the material to be cut.

2. Position the tool with the front part of the shoe on the workpiece and

switch on.

3. Hold the machine firmly against the workpiece and guide it along the

desired cutting line. Do not feed into the work too hard, light pressure on the saw blade will achieve the optimum cutting speed.

Special Cutting Techniques

1. Straight cuts To obtain a perfectly straight cut, clamp a strip of

wood as a guide along the workpiece or use the parallel guide

(accessory).

2. Cutting at a bevel angle adjust the shoe to the correct angle (see

Adjusting the Shoe).

3. Cutting close to obstacles move the shoe backward to provide

greater clearance (see Adjusting the Shoe).

4. Cutting Sheet Metal sheet metal may vibrate when being cut. To

minimize this vibration clamp the workpiece to a wood base.

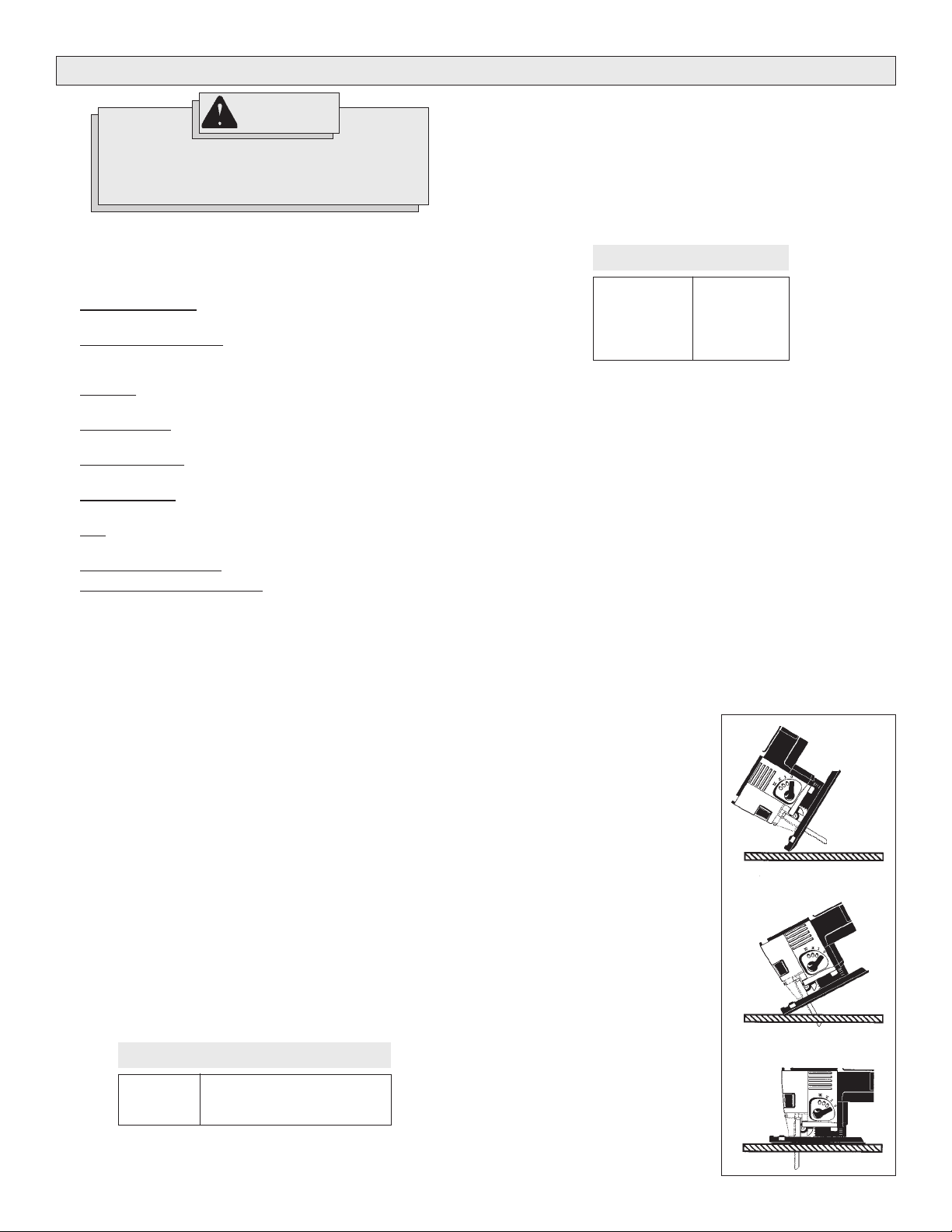

Plunge Cutting (Fig. 4)

These Jig Saws are well suited to making plunge cuts into soft materials without a pre-drilled hole. Harder materials

require a starter hole with a diameter

slightly over the width of the blade. To

make a plunge cut:

1. Move the shoe all the way back.

2. Set the orbital action selector lever

to 0.

3. Keep the power cord out of cutting

area.

4. Make sure nothing below the intended cut area will be damaged.

5. Without switching the tool on, place

the front edge of the shoe solidly

on workpiece.

6. Align the blade with the intended

cut line, but keep it above the

workpiece.

7. Using the front edge of the shoe as

a pivot, turn the tool on and gradually lower the blade into the

workpiece.

8. When the shoe is firmly against the

workpiece normal cutting may take

place.

l I I

0

l

0

Fig. 4

page 6

Page 7

MAINTENANCE

ACCESSORIES

WARNING!

To reduce the risk of injury, always unplug your

tool before performing any maintenance. Never

disassemble the tool or try to do any rewiring on

the tool's electrical system. Contact a

MILWAUKEE service facility for ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a regular maintenance program. Before use, examine the general condition of your tool. Inspect

guards, switches, tool cord set and extension cord for damage. Check

for loose screws, misalignment, binding of moving parts, improper mounting, broken parts and any other condition that may affect its safe operation. If abnormal noise or vibration occurs, turn the tool off immediately

and have the problem corrected before further use. Do not use a damaged tool. Tag damaged tools DO NOT USE until repaired

(see Repairs).

Under normal conditions, relubrication is not necessary until the motor

brushes need to be replaced. After six months to one year, depending

on use, return your tool to the nearest MILWAUKEE service facility for

the following:

Lubrication

Brush inspection and replacement

Mechanical inspection and cleaning (gears, spindles, bearings,

housing, etc.)

Electrical inspection (switch, cord, armature, etc.)

Testing to assure proper mechanical and electrical operation

WARNING!

To reduce the risk of injury, always unplug the

tool before attaching or removing accessories.

Use only specifically recommended accessories. Others may be hazardous.

For a complete listing of accessories refer to your MILWAUKEE Electric

Tool catalog. To obtain a catalog, contact your local distributor or a

service center listed on the back cover of this operators manual.

WARNING!

To reduce the risk of injury, electric shock and

damage to the tool, never immerse your tool in

liquid or allow a liquid to flow inside the tool.

Cleaning

Clean dust and debris from vents. Keep the tool handles clean, dry and

free of oil or grease. Use only mild soap and a damp cloth to clean your

tool since certain cleaning agents and solvents are harmful to plastics

and other insulated parts. Some of these include: gasoline, turpentine,

lacquer thinner, paint thinner, chlorinated cleaning solvents, ammonia

and household detergents containing ammonia. Never use flammable or

combustible solvents around tools.

Repairs

If your tool is damaged, return the entire tool to the nearest service

center listed on the back cover of this operators manual.

WARRANTY

Every MILWAUKEE tool is thoroughly inspected and tested before leaving our manufacturing facilities. Should any trouble develop, return the

complete tool prepaid to our Corporate Office, Branch Office/Service

Center or nearest Authorized MILWAUKEE Service Station. If inspection

shows the trouble is caused by defective workmanship or material, all

repairs will be made without charge, and the tool will be returned, transportation prepaid. Battery packs for cordless tools are warranted for

one year from the date of purchase.

This warranty does not apply where: (1) repairs or attempted repairs

have been made by persons other than MILWAUKEE personnel or Au-

thorized Service Station personnel; (2) repairs are required because of

normal wear; (3) the tool has been abused or involved in an accident; (4)

misuse is evident, such as caused by overloading the tool beyond its

rated capacity; (5) the tool has been used after partial failure or (6) the

tool has been used with an improper accessory. No other warranty,

written or verbal, is authorized.

page 7

Page 8

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT!

VOUS DEVEZ LIRE ET COMPRENDRE TOUTES LES INSTRUCTIONS

Le non-respect, même partiel, des instructions ci-après entraîne un risque de choc

électrique, d'incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS

AIRE DE TRAVAIL

1. Veillez à ce que laire de travail soit propre et bien éclairée.

Le désordre et le manque de lumière favorisent les accidents.

2. Nutilisez pas doutils électriques dans une atmosphère ex-

plosive, par exemple en présence de liquides, de gaz ou de

poussières inflammables. Les outils électriques créent des

étincelles qui pourraient enflammer les poussières ou les vapeurs.

3. Tenez à distance les curieux, les enfants et les visiteurs

pendant que vous travaillez avec un outil électrique. Ils

pourraient vous distraire et vous faire faire une fausse manoeuvre.

Installez des barrières ou des écrans protecteurs si nécessaire.

SÉCURITÉ ÉLECTRIQUE

4. Les outils mis à la terre doivent être branchés dans une

prise de courant correctement installée et mise à la terre

conformément à tous les codes et règlements pertinents.

Ne modifiez jamais la fiche de quelque façon que ce soit,

par exemple en enlevant la broche de mise à la terre.

Nutilisez pas dadaptateur de fiche. Si vous nêtes pas

certain que la prise de courant est correctement mise à la

terre, adressez-vous à un électricien qualifié. En cas de

défaillance ou de défectuosité électrique de loutil, une mise à la

terre offre un trajet de faible résistance à lélectricité qui autrement

risquerait de traverser lutilisateur.

5. Les outils à double isolation sont équipés dune fiche

polarisée (une des lames est plus large que lautre), qui ne

peut se brancher que dune seule façon dans une prise

polarisée. Si la fiche nentre pas parfaitement dans la prise,

inversez sa position ; si elle nentre toujours pas bien,

demandez à un électricien qualifié dinstaller une prise de

courant polarisée. Ne modifiez pas la fiche de loutil.

La double isolation élimine le besoin dun cordon dalimentation à

trois fils avec mise à la terre ainsi que dune prise de courant mise à

la terre.

6. Évitez tout contact corporel avec des surfaces mises à la

terre (tuyauterie, radiateurs, cuisinières, réfrigérateurs,

etc.). Le risque de choc électrique est plus grand si votre corps est

en contact avec la terre.

7. Nexposez pas les outils électriques à la pluie ou à leau. La

présence deau dans un outil électrique augmente le risque de choc

électrique.

8. Ne maltraitez pas le cordon. Ne transportez pas loutil par

son cordon et ne débranchez pas la fiche en tirant sur le

cordon. Nexposez pas le cordon à la chaleur, à des huiles, à

des arêtes vives ou à des pièces en mouvement. Remplacez

immédiate-ment un cordon endommagé. Un cordon

endommagé augmente le risque de choc électrique.

9. Lorsque vous utilisez un outil électrique à lextérieur,

employez un prolongateur pour lextérieur marqué « W-A »

ou « W ». Ces cordons sont faits pour être utilisés à lextérieur et

réduisent le risque de choc électrique.

SÉCURITÉ DES PERSONNES

en mouvement. Des vêtements flottants, des bijoux ou des

cheveux longs risquent dêtre happés par des pièces en mouvement.

12. Méfiez-vous dun démarrage accidentel. Avant de brancher

loutil, assurez-vous que son interrupteur est sur ARRÊT. Le

fait de transporter un outil avec le doigt sur la détente ou de brancher

un outil dont linterrupteur est en position MARCHE peut mener tout

droit à un accident.

13. Enlevez les clés de réglage ou de serrage avant de démarrer

loutil. Une clé laissée dans une pièce tournante de loutil peut

provoquer des blessures.

14. Ne vous penchez pas trop en avant. Maintenez un bon appui

et restez en équilibre en tout temps. Un bonne stabilité vous

permet de mieux réagir à une situation inattendue.

15. Utilisez des accessoires de sécurité. Portez toujours des

lunettes ou une visière. Selon les conditions, portez aussi un

masque antipoussière, des bottes de sécurité antidérapantes, un

casque protecteur et/ou un appareil antibruit.

UTILISATION ET ENTRETIEN DES OUTILS

16. Immobilisez le matériau sur une surface stable au moyen

de brides ou de toute autre façon adéquate. Le fait de tenir la

pièce avec la main ou contre votre corps offre une stabilité

insuffisante et peut amener un dérapage de loutil.

17. Ne forcez pas loutil. Utilisez loutil approprié à la tâche. Loutil

correct fonctionne mieux et de façon plus sécuritaire. Respectez

aussi la vitesse de travail qui lui est propre.

18. Nutilisez pas un outil si son interrupteur est bloqué. Un outil

que vous ne pouvez pas commander par son interrupteur est

dangereux et doit être réparé.

19. Débranchez la fiche de loutil avant deffectuer un réglage,

de changer daccessoire ou de ranger loutil. De telles mesures

préventives de sécurité réduisent le risque de démarrage accidentel

de loutil.

20. Rangez les outils hors de la portée des enfants et dautres

personnes inexpérimentées. Les outils sont dangereux dans

les mains dutilisateurs novices.

21. Prenez soin de bien entretenir les outils. Les outils de coupe

doivent être toujours bien affûtés et propres. Des outils bien

entretenus, dont les arêtes sont bien tranchantes, sont moins

susceptibles de coincer et plus faciles à diriger. Nutilisez pas un

outil défectueux. Fixez-y une étiquette marquée « Hors dusage »

jusquà ce quil soit réparé.

22. Soyez attentif à tout désalignement ou coincement des

pièces en mouvement, à tout bris ou à toute autre condition

préjudiciable au bon fonctionnement de loutil. Si vous

constatez quun outil est endommagé, faites-le réparer

avant de vous en servir. De nombreux accidents sont causés par

des outils en mauvais état.

23. Nutilisez que des accessoires que le fabricant recommande

pour votre modèle doutil. Certains accessoires peuvent convenir

à un outil, mais être dangereux avec un autre.

RÉPARATION

10. Restez alerte, concentrez-vous sur votre travail et faites

preuve de jugement. Nutilisez pas un outil électrique si

vous êtes fatigué ou sous linfluence de drogues, dalcool

ou de médicaments. Un instant dinattention suffit pour entraîner

des blessures graves.

11. Habillez-vous convenablement. Ne portez ni vêtements

flottants ni bijoux. Confinez les cheveux longs. Napprochez

jamais les cheveux, les vêtements ou les gants des pièces

page 8

24. La réparation des outils électriques doit être confiée à un

réparateur qualifié. Lentretien ou la réparation dun outil électrique

par un amateur peut avoir des conséquences graves.

25. Pour la réparation dun outil, nemployez que des pièces de

rechange dorigine. Suivez les directives données à la section « Réparation » de ce manuel. Lemploi de pièces non

autorisées ou le non-respect des instructions dentretien peut créer

un risque de choc électrique ou de blessures.

Page 9

RÈGLES DE SÉCURITÉ PARTICULIÈRE

1. Tenez l'outil par ses surfaces de prise isolées pendant toute opération où l'outil de coupe pourrait venir en contact avec un

câblage dissimulé. En cas de contact avec un conducteur sous tension, les pièces métalliques à découvert de l'outil transmettraient un choc

électrique à l'utilisateur.

2. Tenez les mains à l'écart des arêtes tranchantes et des pièces en mouvement.

3. Entretenez les étiquettes et marques di fabricant. Les indications qu'elles contiennent sont précieuses. Si elles deviennent illisibles ou se

détachent, faites-les remplacer gratuitement à un centre de service MILWAUKEE accrédité.

4. AVERTISSEMENT! La poussière degagée par perçage, sciage et autres travaux de construction contient des substances chimiques reconnues

comme pouvant causer le cancer, des malformations congénitales ou dautres troubles de reproduction. Voici quelques exemples de telles

substances :

Le plomb contenu dans la peinture au plomb.

Le silice cristallin contenu dans la brique, le béton et divers produits de maçonnerie.

Larsenic et le chrome servant au traitement chimique du bois.

Les risques associés à lexposition à ces substances varient, dépendant de la fréquence des travaux. Afin de minimiser lexposition à ces

substances chimiques, assurez-vous de travailler dans un endroit bien aéré et dutiliser de lequipement de sécurité tel un masque antipoussière

spécifiquement conçu pour la filtration de particules microscopiques.

Pictographie

Double Isolation

Courant alternatif ou direct

Ampères

Tours-minute à vide (RPM)

Underwriters Laboratories Inc.

l'Association canadienne de

normalisation (ACNOR)

DESCRIPTION FONCTIONNELLE

1

2

Cat No. 6276

Spécifications

No

de

Cat.

6266

6276

11

9

8

7

Volts

CA/CD

120

120

Ampères

5,7

5,7

11

Cycles

par

minute

25,4mm (1")

25,4mm (1")

10

Vide/

Coups/min

á vide

450-3 100

450-3 100

Cat No. 6266

9

1. Levier de tension Quik-Lok

2. Chape de lame transparente

3. Lame

4. Semelle

5. Réglage du mouvement orbital

6. Échelle d'inclinaison de semelle

7. Clé Hex

8. Collecteur de sciure

9. Interrupteur On/Off

10. Bouton de verrouillage

11. Indicateur du contôle électronique

de vitesse

3

5

4

6

1

8

2

7

6

3

4

5

page 9

Page 10

MISE À LA TERRE

CORDONS DE RALLONGE

AVERTISSEMENT!

Si le fil de mise à la terre est incorrectement raccordé,

il peut en résulter des risques de choc électrique. Si

vous nêtes pas certain que la prise dont vous vous

servez est correctement mise à la terre, faites-la

vérifier par un électricien. Naltérez pas la fiche du

cordon de loutil. Nenlevez pas de la fiche, la dent qui

sert à la mise à la terre. Nemployez pas loutil si le

cordon ou la fiche sont en mauvais état. Si tel

est le cas, faites-les réparer dans un centre-service

MILWAUKEE accrédité avant de vous en servir. Si la

fiche du cordon ne sadapte pas à la prise, faites

remplacer la prise par un électricien.

Outils mis à la terre :

Outils pourvus dune fiche de cordon à trois dents

Les outils marqués « Mise à la terre

requise » sont pourvus dun cordon

à trois fils dont la fiche a trois dents.

La fiche du cordon doit être branchée

sur une prise correctement mise à la

terre (voir Figure A). De cette façon,

si une défectuosité dans le circuit

électrique de loutil survient, le relais

à la terre fournira un conducteur à

faible résistance pour décharger le

courant et protéger lutilisateur contre

les risques de choc électrique.

La dent de mise à la terre de la fiche est reliée au système de mise à la

terre de loutil via le fil vert du cordon. Le fil vert du cordon doit être le seul

fil raccordé à un bout au système de mise à la terre de loutil et son autre

extrémité ne doit jamais être raccordée à une borne sous tension

électrique.

Votre outil doit être branché sur une prise appropriée, correctement

installée et mise à la terre conformément aux codes et ordonnances en

vigueur. La fiche du cordon et la prise de courant doivent être semblables

à celles de la Figure A.

Outils à double isolation :

Outils pourvus dune fiche de

cordon à deux dents

Les outils marqués « Double

Isolation » nont pas besoin dêtre

raccordés à la terre. Ils sont pourvus

dune double isolation conforme eux

exigences de lOSHA et satisfont aux

normes de lUnderwriters Laboratories, Inc., de lAssociation canadienne

de normalisation (ACNOR) et du

« National Electrical Code » (code national de lélectricité). Les outils à

double isolation peuvent être

branchés sur nimporte laquelle des

prises à 120 volt illustrées ci-contre

Figure B et C.

Fig. A

Fig. B

Fig. C

Si lemploi dun cordon de rallonge est nécessaire, un cordon à trois fils

doit être employé pour les outils mis à la terre. Pour les outils à double

isolation, on peut employer indifféremment un cordon de rallonge à deux

ou trois fils. Plus la longueur du cordron entre loutil et la prise de courant

est grande, plus le calibre du cordon doit être élevé. Lutilisation dun

cordon de rallonge incorrectement calibré entraîne une chute de voltage

résultant en une perte de puissance qui risque de détériorer loutil.

Reportez-vous au tableau ci-contre pour déterminer le calibre minimum

du cordon.

Moins le calibre du fil est élevé, plus sa conductivité est bonne. Par

exemple, un cordon de calibre 14 a une meilleure conductivité quun

cordon de calibre 16. Lorsque vous utilisez plus dune rallonge pour

couvrir la distance, assurez-vous que chaque cordon possède le calibre minimum requis. Si vous utilisez un seul cordon pour brancher

plusieurs outils, additionnez le chiffre dintensité (ampères) inscrit sur la

fiche signalétique de chaque outil pour obtenir le calibre minimal requis

pour le cordon.

Directives pour lemploi des cordons de rallonge

Si vous utilisez une rallonge à lextérieur, assurez-vous quelle est

marquée des sigles « W-A » (« W » au Canada) indiquant quelle est

adéquate pour usage extérieur.

Assurez-vous que le cordon de rallonge est correctement câblé et

en bonne condition. Remplacez tout cordon derallonge détérioré ou

faites-le remettre en état par une personne compétente avant de

vous en servir.

Tenez votre cordon de rallonge à lécart des objets ranchants, des

sources de grande chaleur et des endroits humides ou mouillés.

Calibres minimaux recommandés pour

signalétique

12,1 - 15,0

15,1 - 20,0

* Basé sur sur une chute de voltage limite de 5

volts à 150% de lintensité moyenne de courant.

les cordons de rallonge*

Fiche

Ampères

0 - 5,0

5,1 - 8,0

8,1 - 12,0

Longueur du cordon de rallonge (m)

7,6

15,2

16

16

16

16

14

14

12

12

10

10

22,8

16

14

12

10

10

30,4

14

12

10

10

--

45,7

12

10

--

--

--

60,9

12

--

--

--

--

LISEZ ATTENTIVEMENT CES INSTRUCTIONS

ET CONSERVEZ-LES POUR LES

CONSULTER AU BESOIN.

page 10

Page 11

MONTAGE DE L'OUTIL

AVERTISSEMENT!

Pour réduire les risques de blessures, débranchez

toujours loutil avant dy faire des réglages, dy attacher ou

den enlever les accessoires. Lusage daccessoires

autres que ceux qui sont spécifiquement recommandés

pour cet outil peut comporter des risques.

Fig. 1

Insertion de la lame de scie

1. Débranchez loutil avant dy insérer la lame ou de la remplacer.

2. Poussez le levier de tension Quik-Lok aussi loin que possible et

maintenez-le en place.

3. Insérez la lame dans la rainure du galet dappui et poussez-la

fermement dans le piston aussi loin que possible. Le talon de la lame

doit être inséré dans le piston.

4. Relâchez le levier de tension Quik-Lok et la lame sera maintenue en

place automatiquement.

5. Assurez-vous que la lame soit bien fixée. La rainure dans le piston

devra être à angle droit de la lame tel quindiqué à lillustration 2. Le

levier de tension Quik-Lok ne doit pas être manipulé si la commande

de loutil nest pas à la position OFF.

Fig. 2

Rainure

Réglage de la semelle (Fig. 3)

La semelle peut être inclinée jusquà 45° dun côté comme de lautre. Elle

peut aussi être poussée vers lavant ou larrière.

Fig. 3

La vis de

blocage de

la semelle

1. Choix de l'inclinaison pour les coupes à angle et les biseaux,

desserrez la vis de blocage de la semelle, poussez la base

vers larrière jusquà ce que les crans se dégagent. Inclinez la semelle

à langle de réglage choisi de 15°, 30° ou 45° indiqué à léchelle.

Replacez la base dans ses crans et serrez la vis de blocage. Si des

angles différents de ceux qui figurent à léchelle sont requis, inclinez

la semelle à langle requis et serrez la vis de blocage sans replacer

la base dans ses crans.

Si un angle très précis est requis, il est recommandé deffectuer une

coupe dessai et de revoir le réglage, si nécessaire.

2. Déplacement de la semelle vers l'arrière les coupes en

plongée ou en coin, desserrez la vis de blocage de la semelle et

poussez la semelle

sengager dans une rainure pour maintenir la semelle à la position 0°.

Emploi du couvre-semelle protecteur

Le couvre-semelle extra lisse protège contre les égratignures et les

marques de friction à la surface des matériaux. Pour le fixer à l'outil,

agrafez-en l'avant sur la semelle d'acier de l'outil. Ensuite, rabattez les

pattes arrières sur la semelle de l'outil. Assurez-vous que les pattes des

deux côtés du couvre-semelle sont rabattues en place.

Lorsque le couvre-semelle n'est pas requis, retirez-le de la semelle en

relevant d'abord les deux pattes arrières pour ensuite en dégrafer l'avant

et l'écarter de la semelle.

complètement vers larrière. La vis pourra alors

légèrement

Lame

page 11

Page 12

MANIEMENT

AVERTISSEMENT!

Pour minimiser les risques de blessures, portez

des lunettes à coques latérales. Débranchez loutil

avant de changer les accessoires ou deffectuer des

réglages.

La scie sauteuse 6266 et 6276 à mouvement orbital peut couper une

grande variété de matériaux y compris les bois, métaux et plastiques.

Les coupes peuvent être droites, en biseau ou en découpage. Les

caractéristiques remarquables de cette scie sauteuse comprennent:

Changement de lame rapide sans laide doutils, grâce au système

de changement de lame Quik-Lok.

Le mouvement orbital réglable de la lame assure une coupe plus

rapide car la lame mord dans le matériau en remontant seulement.

Cette technique est particulièrement utile pour dégrossir les planches

de bois.

Rétroaction électronique de lindicateur de vitesse pour maintenir la

vitesse de coupe préréglée.

Semelle inclinable à 45° des deux côtés pour les coupes en biseau.

Couvre-semelle protecteur pour éviter dégratigner la surface des

matériaux.

Ventilateur pour écarter la sciure et améliorer la visibilité de la ligne

de coupe.

Collecteur intégré pour linstallation dun aspirateur de poussière.

·

(Boyau facultatif).

Chape de lame transparente facilitant lévacuation de la sciure.

Mécanisme antivibration assurant un roulement plus doux et plus

silencieux.

Démarrage et arrêt de loutil

Modèle No 6266

1. Pour mettre loutil en marche, appuyez sur la détente dinterrupteur

«ON/OFF».

2. Pour arrêter loutil, relâchez la détente dinterrupteur «ON/OFF».

Modèle No 6276

1. Pour mettre loutil en marche, poussez linterrupteur «ON/OFF» en

avant pour que la lettre I apparaisse.

2. Pour arrêter loutil, poussez linterrupteur «ON/OFF» vers larrière

pour que la lettre O apparaisse.

Verrouillage de la détente dinterrupteur «ON/OFF»

Le bouton de verrouillage maintient la détente dinterrupteur à la position

ON en marche continue (modèle 6266 seulement).

1. Pour verrouiller la détente dinterrupteur «ON/OFF», appuyez sur le

bouton de verrouillage et en même temps, enfoncez la détente

dinterrupteur puis relâchez-la.

2. Pour déverrouiller la détente dinterrupteur «ON/OFF», appuyez sur

la détente et relâchez-la vivement. Le bouton de verrouillage va

alors se déclencher.

Réglage de fréquence des cycles/min.

La fréquence des cycles par minute peut être réglée à laide de lindicateur

de vitesse. Les chiffres de 1 à 7 sont imprimés sur lindicateur. Le chiffre

1 correspond à la vitesse minimale tandis que le chiffre 7 indique la

vitesse maximale. Les vitesses de coupe recommandées pour divers

matériaux sont indiquées ci-dessous. La vitesse de coupe idéale devrait

être déterminée par lusager selon les tâches spécifiques.

Bois 7

Métal 4-5

Plastique 2

page 12

Réglage du mouvement orbital

Lampleur du mouvement orbital peut être réglée à laide du levier sélecteur.

En général, un mouvement orbital ample (III) est recommandé pour les

matériaux mous, tandis quun mouvement orbital restreint (0) convient

aux matériaux durs. Si une coupe lisse est requise, il faut employer le

réglage (0) à mouvement orbital restreint. Les réglages du mouvement

orbital recommandables pour divers matériaux sont présentés ci-dessous.

Le mouvement orbital idéal devrait être déterminé par lusager selon les

tâches spécifiques. Le mouvement orbital peut être réglé même si loutil

est en marche.

Bois I I I Métal 0

Plastique I Coupe lisse 0

Pour faire la coupe

1. Réglez la fréquence des cycles et le mouvement orbital selon le

matériau à couper.

2. Placez la partie avant de la semelle sur le matériau et mettez loutil en

marche.

3. Tenez loutil fermement sur le matériau et guidez-le sur la ligne de

coupe. Ne forcez pas trop loutil dans le matériau, une pression

légère sur la lame assurera la vitesse de coupe optimale.

Techniques de coupe spéciales

1. Coupes rectilignes Pour réussir des coupes parfaitement droites,

fixez une languette de bois sur le matériau pour vous en servir

comme guide ou utilisez un guide-coupe parallèle (en accessoire).

2. Coupe en biseau Ajustez la semelle à langle voulu (voir Réglage

de la semelle).

3. Coupe près des obstacles Poussez la semelle vers larrière afin

daugmenter la maniabilité de la lame (voir Réglage de la semelle).

4. Coupe de tôle Le métal en feuille peut vibrer durant la coupe. Pour

minimiser la vibration, fixez la feuille de tôle sur une base en bois.

Coupe en plongée (Fig. 4)

Les scies sauteuses MILWAUKEE 6266 et 6276 sont idéales pour faire

des coupes en plongée dans les matériaux mous, sans quil soit nécessaire

de percer un trou-guide. Cependant,

pour les matériaux durs, il est nécessaire

de percer un trou-guide dun diamètre

légèrement supérieur à la largeur de la

lame. Pour réussir une coupe en plongée:

1. Poussez la semelle de la scie

complètement vers larrière.

2. Réglez le mouvement orbital à la position 0.

3. Tenez le cordon de loutil hors de la

ligne de coupe.

4. Assurez-vous que rien ne pourra

être endommagé par la lame sous

la surface du matériau.

5. Avant de mettre loutil en marche,

posez fermement le bord avant de

la semelle de la scie sur le matériau.

6. Alignez la lame sur la ligne de coupe

mais maintenez-la au-dessus du

matériau.

7. En vous servant du bord avant de

la semelle comme appui, pressez

sur la détente et abaissez

graduellement la lame dans le

matériau.

8. Lorsque la semelle sera rendue

fermement à plat sur le matériau,

continuez la coupe de façon

normale.

Fig. 4

Page 13

MAINTENANCE

ACCESSOIRES

AVERTISSEMENT!

Pour minimiser les risques de blessures,

débranchez toujours loutil avant dy effectuer des

travaux de maintenance. Ne faites pas vous-même

le démontage de loutil ni le rebobinage du système

électrique. Consultez un centre de service

MILWAUKEE accrédité pour toutes les réparations.

Entretien de loutil

Gardez loutil en bon état en adoptant un programme dentretien ponctuel.

Avant de vous en servir, examinez son état en général. Inspectez-en la

garde, interrupteur, cordon et cordon de rallonge pour en déceler les

défauts. Vérifiez le serrage des vis, lalignement et le jeu des pièces

mobiles, les vices de montage, bris de pièces et toute autre condition

pouvant en rendre le fonctionnement dangereux. Si un bruit ou une

vibration insolite survient, arrêtez immédiatement loutil et faites-le vérifier

avant de vous en servir de nouveau. Nutilisez pas un outil défectueux.

Fixez-y une étiquette marquée « HORS DUSAGE » jusquà ce quil soit

réparé (voir « Réparations »).

Normalement, il ne sera pas nécessaire de lubrifier loutil avant que le

temps ne soit venu de remplacer les balais. Après une période pouvant

aller de 6 mois à un an, selon lusage, retournez votre outil à un centre de

service MILWAUKEE accrédité pour obtenir les services suivants :

Lubrification

Inspection et remplacement des balais

Inspection et nettoyage de la mécanique (engrenages, pivots,

coussinets, boîtier etc.)

Inspection électrique (interrupteur, cordon, induit etc.)

Vérification du fonctionnement électromécanique

AVERTISSEMENT!

Pour minimiser les risques de blessures,

débranchez toujours loutil avant dy installer ou

den enlever les accessoires. Lemploi

daccessoires autres que ceux qui sont

expressément recommandés pour cet outil peut

présenter des risques.

Pour une liste complète des accessoires, prière de se reporter au catalogue MILWAUKEE Electric Tool. Pour obtenir un catalogue, il suffit de

contacter votre distributeur local ou l'un des centres-service énumérés

sur la page de couverture de ce manuel.

AVERTISSEMENT!

Pour minimiser les risques de blessures, choc

électrique et dommage à l'outil, n'immergez jamais

l'outil et ne laissez pas de liquide s'y infiltrer.

Nettoyage

Débarrassez les évents des débris et de la poussière. Gardez les

poignées de loutil propres, à sec et exemptes dhuile ou de graisse. Le

nettoyage de loutil doit se faire avec un linge humide et un savon doux.

Certains nettoyants tels lessence, la térébenthine, les diluants à laque

ou à peinture, les solvants chlorés, lammoniaque et les détergents

dusage domestique qui en contiennent pourraient détériorer le plastique

et lisolation des pièces. Ne laissez jamais de solvants inflammables ou

combustibles auprès des outils.

Réparations

Si votre outil doit être réparé, retournez-le en entier au centre-service le

plus près selon la liste apparaissant à la dernière page de ce manuel.

GARANTIE

Chaque outil fabriqué par MILWAUKEE est minutieusement vérifié avant

de quitter lusine. Sil survient un trouble, retournez loutil port payé au

siège social de la compagnie ou à une succursale ou un centre de

service MILWAUKEE accrédité. Si lexamen de loutil démontre que le

trouble est dû à un défaut de fabrication ou de matériaux, les réparations

seront effectuées gratuitement et loutil vous sera retourné aux frais de

la compagnie. Les batteries servant aux outils sans cordon sont garanties

pour un an à compter de la date dachat.

La présente garantie ne sapplique pas dans les cas suivants : (1) Des

réparations ont été effectuées ou tentées par dautres personnes que

des techniciens mandatés par MILWAUKEE ou ses centres de service

accrédités. (2) Les réparations sont rendues nécessaires par lusure

normale de loutil. (3) Loutil a été employé abusivement ou a été endommagé

accidentellement. (4) Lusage anormal ou la surcharge de loutil sont

évidents. (5) Loutil a été utilisé après une défaillance partielle. (6) Loutil

a été employé avec un accessoire non compatible. Nulle autre garantie,

tant écrite que verbale, nest valable.

page 13

Page 14

REGLAS GENERALES DE SEGURIDAD

¡ADVERTENCIA!

LEA Y ENTIENDA TODAS LAS INSTRUCCIONES

El no seguir las instrucciones a continuación puede ocasionar

una descarga eléctrica, incendio y/o lesiones graves.

GUARDE ESTAS INSTRUCCIONES

AREA DE TRABAJO

1. Mantenga el área de trabajo limpia e iluminada. Las mesas de

trabajo desordenadas y las áreas con poca iluminación propician los

accidentes.

2. No opere las herramientas con motor en ambientes

explosivos, tales como los ambientes con líquidos, gases o

polvo inflamables. Las herramientas con motor producen chispas

que pueden inflamar el polvo o los gases.

3. Mantenga a las personas alejadas mientras esté utilizando

una herramienta con motor. Las distracciones pueden causar la

pérdida del control de la herramienta. Proteja a las demás personas en

el área de trabajo contra escombros, tales como astillas y chispas.

Instale barreras si se necesitan.

SEGURIDAD ELECTRICA

4. Las herramientas conectadas a tierra deben estar enchufadas

en un toma corriente que esté instalado correctamente y

conectado a tierra de acuerdo con todos los códigos y

ordenanzas vigentes. Nunca retire la clavija de conexión a tierra

o modifique el enchufe de ninguna manera. No use enchufes

adaptadores. Consulte a un electricista capacitado si tiene

dudas para asegurar que el tomacorriente esté correctamente

conectado a tierra. Si las herramientas sufren fallas eléctricas, la

conexión a tierra proporciona una trayectoria de baja resistencia para

que el usuario no quede expuesto a la electricdad.

5. Las herramientas con aislamiento doble están equipadas con

un enchufe polarizado (una clavija es más ancha que la otra).

Hay una sola manera de introducir este enchufe en una toma

polarizada. Si el enchufe no se ajusta completamente en la

toma, dé vuelta el enchufe. Si el problema persiste, póngase

en contacto con un electricista calificado para que instale una

toma polarizada. No cambie la toma de ninguna manera. El

aislamiento doble elimina la necesidad de un cable de energía con

conexión a tierra con 3 alambres y la de un sistema de suministro de

energía con conexión a tierra.

6. Evite contacto físico con las superficies conectadas a tierra,

tales como tuberías, radiadores, cocinas y refrigeradores.

Existe un riesgo de un choque eléctrico mayor si su cuerpo está

expuesto a tierra.

7. No exponga las herramientas eléctricas a condiciones de lluvia

o humedad. El agua que entra en una herramienta eléctrica aumentará

el riesgo de choque eléctrico.

8. No maltrate el cable. Nunca use el cable para transportar las

herramientas ni para sacar el enchufe de la toma eléctrica.

Mantenga el cable lejos de calefacción, petróleo, bordes

afilados o cualquier parte movible. Reemplace inmediatamente

cualquier cable dañado. Los cables dañados aumentan el riesgo de

choque eléctrico.

9. Al operar una herramienta eléctrica a la intemperie, use un

cordón de extensión para la intemperie marcado W-A o W.

Estos cordones están aprobados para usos exteriores y reducen el

riesgo del choque eléctrico.

SEGURIDAD PERSONAL

10. Esté alerta. Revise su trabajo y use el sentido común. No opere su herramienta cuando esté cansado, distraído o bajo la

influencia de drogas alcohol o medicamentos. Un momento de

descuido cuando operando un herramienta electrica puede resultar en

lesiones graves.

11. Utilice ropa adecuada. No use ropa suelta o joyas. Mantenga el

cabello largo, ropa y guantes alejados de las partes móviles.

page 14

12. Evite los arranques accidentales. Verifique que el interruptor esté

apagado antes de enchufar la herramienta. Transportar la herramienta

por el gatillo o enchufarla con el interruptor encendido puede ocasionar

accidentes

13. Saque las llaves de ajuste antes de encender la herramienta.

Una llave sujeta a una parte en movimiento puede causar lesiones.

14. No se esfuerce, mantenga el control y el balance en todo

momento. Mantenga siempre una postura y un balance adecuados.

Una postura y un balance correctos otorga un mejor control ante

situaciones inesperadas.

15. Utilice el equipo de seguridad. Siempre use protección para

los ojos. Se debe usar una máscara contra el polvo, zapatos de

seguridad antidelizantes, casco y protector para los oídos, cuando las

condiciones así lo requieran.

USO Y MANTENIMIENTO DE LA HERRAMIENTA

16. Utilice abrazaderas u otra manera práctica para sujetar y apoyar

el material en una plataforma estable. Tener el material en la mano

o contra el cuerpo es inestable y puede causar la pérdida del control.

17. No fuerce la herramienta. Utilice la herramienta apropiada para

la aplicación. La herramienta realizará el trabajo de manera más eficaz

y segura, si la opera a la velocidad apropiada.

18. Si el gatillo no enciende o apaga la herramienta, no utilice la

herramienta. Una herramienta que no se puede controlar con el gatillo

es peligrosa y debe ser reparada.

19. Desconecte el enchufe de la fuente de energía antes de realizar

cualquier ajuste, cambiar los accesorios o almacenar la

herramienta. Tales medidas precautorias de seguridad reducen el

riesgo de encender la herramienta accidentalmente.

20. Almacene las herramientas que no se estén usando fuera del

alcance de los niños y de personas que no estén capacitadas.

Es peligroso permitir a los usuarios utilizar las herramientas, si no están

capacitados previamente.

21. Mantenga las herramientas en buenas condiciones. Las

herramientas cortadoras deben mantenerse afiladas y

limpias. Esto reduce el riesgo de que la herramienta se atasque y

facilita el control de la misma. No utilice una herramienta dañada.

Colóquele una etiqueta que diga No Debe Usarse hasta que sea

reparada.

22. Verique que las partes en movimiento estén alineadas y no

estén atascadas. También debe verificarse que las partes no

estén rotas o tengan cualquier otra condición que pueda afectar

el funcionamiento de la herramienta. Si está dañada, se debe

reparar la herramienta antes de utilizarla. Muchos accidentes se

deben al mantenimiento incorrecto de la herramienta.

23. Utilice solamente los accesorios recomendados por el

fabricante para ese modelo. Los accesorios que son apropiados

para una herramienta pueden aumentar el riesgo de lesiones cuando

se usan con otra herramienta.

SERVICIO

24. El servicio de mantenimiento debe ser realizado solamente

por personal técnico debidamente capacitado. El servicio o

mantenimiento realizado por personal no calificado puede aumentar el

riesgo de lesiones.

25. Cuando realice el servicio de mantenimiento, utilice solamente

repuestos idénticos. Siga las instrucciones en la sección de

mantenimiento de este manual. El uso de partes no autorizadas o

el incumplimiento de las instrucciones de mantenimiento puede aumentar

el riesgo de descarga eléctrica o lesiones.

Page 15

REGLAS ESPECIFICAS DE SEGURIDAD

1. Al realizar una operación donde la herramienta de corte puede tener contacto con un alambre escondido o su propio cablek

tome la herramienta por las superficies aisladas de agarre. El contacto con un alambre con corriente hará que las partes ezpuestas.

2. Mantenga las manos alejadas de todos los bordes cortadores y partes en movimiento.

3. Guarde las etiquetas y placas de especificaciones. Estas tienen información importante. Si son ilegibles o si no se pueden encontrar,

póngase en contacto con un centro de servicio de MILWAUKEE para una refacción gratis.

4. ¡ADVERTENCIA! Algunas partículas de polvo resultantes del lijado mecánico, aserrado, esmerilado, taladrado y otras actividades relacionadas

a la construcción, contienen sustancias químicas que se saben ocasionan cáncer, defectos congénitos u otros daños al aparato reproductivo.

A continuación se citan algunos ejemplos de tales sustancias químicas:

plomo proveniente de pinturas con base de plomo

sílice cristalino proveniente de ladrillos, cemento y otros productos de albañilería y

arsénico y cromo provenientes de madera químicamente tratada.

El riesgo que usted sufre debido a la exposición varía dependiendo de la frecuencia con la que usted realiza estas tareas. Para reducir la

exposición a estas sustancias químicas: trabaje en un área bien ventilada, y utilice equipo de seguridad aprobado como, por ejemplo, máscaras

contra el polvo que hayan sido específicamente diseñadas para filtrar partículas microscópicas.

Simbología

Doble aislamiento

Volts corriente alterna/

corriente directa

Amperios

No de revoluciones de carga

por minuto (RPM)

Underwriters Laboratories, Inc.

Asociación de Normas

Canadiense

DESCRIPCION FUNCIONAL

1

2

Cat No. 6276

9

7

Catálogo

no.

6266

6276

11

8

Especificaciones

Volts

ca/cd

Amperios

~

120

120

5,7

5,7

11

Carrera

25,4mm (1")

25,4mm (1")

10

Largo de

Carrera

450-3 100

450-3 100

Cat No. 6266

9

1. Palanca de fijación de la segueta

2. Cubierta transparente

3. Sequeta

4. Zapata

5. Placa base

6. Selector de carrera pendular

7. Llave Hexagonal

8. Canal de aspiración

9. Interruptor de encendido/apagado

10. Botón de enclavmiento

11. Control de velocidad electrónico

3

5

4

6

1

8

2

7

6

3

4

5

page 15

Page 16

TIERRA

EXTENSIÓNES ELÉCTRICAS

¡ADVERTENCIA!

Puede haber riesgo de descarga eléctrica si se

conecta el cable de conexión de puesta a tierra

incorrectamente. Consulte con un electricista

certificado si tiene dudas respecto a la conexión de

puesta a tierra del tomacorriente. No modifique el

enchufe que se proporciona con la herramienta. Nunca

retire la clavija de conexión de puesta a tierra del

enchufe. No use la herramienta si el cable o el enchufe

está dañado. Si está dañado antes de usarlo, llévelo a

un centro de servicio MILWAUKEE para que lo reparen.

Si el enchufe no se acopla al tomacorriente, haga que

un electricista certificado instale un tomacorriente

adecuado.

Herramientas con conexión a tierra:

Herramientas con enchufes de tres clavijas

Las herramientas marcadas con la

frase Se requiere conexión de

puesta a tierra tienen un cable de

tres hilo y enchufes de conexión de

puesta a tierra de tres clavijas. El

enchufe debe conectarse a un

tomacorriente debidamente

conectado a tierra (véase la Figura

A). Si la herramienta se averiara o

no funcionara correctamente, la

conexión de puesta a tierra proporciona un trayecto de baja resistencia

para desviar la corriente eléctrica de la trayectoria del usuario, reduciendo

de este modo el riesgo de descarga eléctrica.

La clavija de conexión de puesta a tierra en el enchufe está conectada

al sistema de conexión de puesta a tierra de la herramienta a través del

hilo verde dentro del cable. El hilo verde debe ser el único hilo conectado

al sistema de conexión de puesta a tierra de la herramienta y nunca se

debe unir a una terminal energizada.

Su herramienta debe estar enchufada en un tomacorriente apropiado,

correctamente instalado y conectado a tierra según todos los códigos y

reglamentos. El enchufe y el tomacorriente deben asemejarse a los de la

Figura A.

Herramientas con doble aislamiento:

Herramientas con clavijas de dos patas

Las herramientas marcadas con

Doble aislamiento no requieren

conectarse a tierra. Estas

herramientas tienen un sistema

aislante que satisface los

estándares de OSHA y llena los

estándares aplicables de UL (Underwriters Laboratories), de la

Asociación Canadiense de

Estándares (CSA) y el Código

Nacional de Electricidad. Las

herramientas con doble aislamiento

pueden ser usadas en cualquiera de

los toma corriente de 120 Volt

mostrados en las Figuras B y C.

Fig. A

Fig. B

Fig. C

Las herramientas que deben conectarse a tierra cuentan con clavijas de

tres patas y requieren que las extensiones que se utilicen con ellas sean

también de tres cables. Las herramientas con doble aislamiento y clavijas

de dos patas pueden utilizarse indistintamente con extensiones de dos a

tres cables. El calibre de la extensión depende de la distancia que exista

entre la toma de la corriente y el sitio donde se utilice la herramienta. El

uso de extensiones inadecuadas puede causar serias caídas en el

voltaje, resultando en pérdida de potencia y posible daño a la herramienta.

La tabla que aquí se ilustra sirve de guía para la adecuada selección de

la extensión.

Mientras menor sea el número del calibre del cable, mayor será la

capacidad del mismo. Por ejemplo, un cable calibre 14 puede transportar

una corriente mayor que un cable calibre 16. Cuando use mas de una

extensión para lograr el largo deseado, asegúrese que cada una tenga

al menos, el mínimo tamaño de cable requerido. Si está usando un cable

de extensión para mas de una herramienta, sume los amperes de las

varias placas y use la suma para determinar el tamaño mínimo del cable

de extensión.

Guías para el uso de cables de extensión

Si está usando un cable de extensión en sitios al aire libre, asegúrese

que está marcado con el sufijo W-A (W en Canadá) el cual indica

que puede ser usado al aire libre.

Asegúrese que su cable de extensión está correctamente cableado

y en buenas condiciones eléctricas. Cambie siempre una extensión

dañada o hágala reparar por una persona calificada antes de volver

a usarla.

Proteja su extensión eléctrica de objetos cortantes, calor excesivo

o areas mojadas.

Calibre mínimo recomendado para

cables de extensiónes eléctricas*

Amperes

(En la placa)

0 - 5,0

5,1 - 8,0

8,1 - 12,0

12,1 - 15,0

15,1 - 20,0

* Basado en limitar la caída en el voltaje a 5

volts al 150% de los amperes.

Largo de cable de Extensión en(m)

30,4

14

12

10

10

--

45,7

12

10

--

--

--

60,9

7,6

16

16

14

12

10

15,2

16

16

14

12

10

22,8

16

14

12

10

10

12

--

--

--

--

LEA Y GUARDE TODAS LAS INSTRUCCIONES

PARA FUTURAS REFERANCIAS.

page 16

Page 17

ENSAMBAJE DE LA HERRAMIENTA

¡ADVERTENCIA!

Para reducir el riesgo de lesiones, desconecte

siempre la herramienta antes de fijar o retirar

accesorios, o antes de efectuar ajustes. Utilice sólo los

accesorios específicamente recomendados. El uso de

otros accesorios puede ser peligroso.

Fig. 1

Colocación de la segueta

1. Desconecte la herramienta antes de insertar o cambiar la segueta.

2. Empuje la palanca tensora Quik-Lok

en posición tal como se muestra en la ilustración 2.

3. Coloque la segueta dentro de la canal en el rodillo de soporte y

empújela firmemente dentro del sujetador tanto como sea posible;

La entrada de la segueta debe quedar en el sujetador (vea la

ilustración 1).

4. Libere la palanca tensora Quik-Lok y la segueta quedará

automáticamente sujeta.

5. Verifique que la segueta esté sujeta firmemente; la muesca en el

sujetador estará en un ángulo con relación a la segueta, como el que

se muestra en la ilustración 2.

Fig. 2

Muesca

tanto como pueda y sosténgala

Ajustando la zapata (Fig. 3)

La zapata puede girarse hasta 45° en ambas direcciones y además

puede moverse hacia adelante o atrás.

Fig. 3

El tornillo que

sostiene la

zapata

1. Al fijar la zapata para realizar cortes en ángulo, afloje el tornillo

que sostiene la zapata, jale

hasta que las muescas de retención ya no actuen. Coloque la

zapata en el ángulo prefijado deseado (15°, 30° o 45°) como lo

marca la graduación. Empuje hacia atrás, hacia las muescas de

retención para que actuen, y apriete el tornillo. Si se desean ángulos

diferentes a los prefijados, coloque dicho ángulo y apriete el tornillo

sin que actuen las muescas de retención.

Si se requieren ángulos muy exactos, se recomienda hacer cortes

de prueba y hacer los ajustes necesarios.

2. Para mover la zapata hacia atrás para cortes interiores,

resaques o cortes en las esquinas, afloje el tornillo que sujeta

la zapata y corra la zapata

muesca y mantendrá la zapata a 0°.

Uso de la cubierta para zapata

La cubierta para zapata se usa para evitar que la superficie de la pieza

de trabajo se estropee o se raye. Para fijar la cubierta para zapata,

enganche el frente de la misma sobre el zapata de acero; en seguida

jale la parte de atrás de la cubierta y engánchela en la zapata de acero.

Asegúrese de que ambos lados de la cubierta se encuentren bien

colocados.

Cuando no se necesite la cubierta, retírela jalando hacia afuera las

lenguetas de la parte de atrás de la misma y separándola de la zapata de

acero. Desenganche el frente de la cubierta y retírela.

ligeramente la base hacia adelante,

hasta atrás. El tornillo entrará en una

Segueta

page 17

Page 18

OPERACION

¡ADVERTENCIA!

Para reducir el riesgo de lesiones, use siempre lentes

de seguridad o anteojos con protectores laterales.

Desconecte la herramienta antes de cambiar algún

accesorio o de hacerle algún ajuste.

La Sierra Caladora con acción orbital 6266 y 6266 puede cortar una gran

variedad de materiales incluyendo metal, madera y plásticos. Los cortes

pueden ser en linea recta, calados, curvos o resaques interiores. Algunas

características notables de esta sierra caladora son:

Con el

La

Un

La

La

El

sistema Quik-Lok, las seguetas se cambian rápidamente sin

necesidad de usar herramientas.

Acción Orbital Ajustable de la carrera de la segueta permite

cortar mas rápidamente al presionar la segueta contra el material a

cortar, únicamente cuando la segueta va hacia arriba en su carrera.

Esto es particularmente efectivo cuando se trozan tramos de madera

gruesos.

control de selección electrónico en el control de la velocidad,

mantiene la misma estable durante el corte, tal como fue

preestablecida.

zapata ajustable puede moverse hasta 45º en cualquier dirección

para cortes en ángulo.

cubierta antirayones de la zapata proteje la superficie de trabajo

contra trabadas o atorones de la segueta y rayones en la cubierta.

soplador del aserrín o polvo lo remueve de la superficie antes del

corte, para tener una mejor visibilidad.

Conector interconstruído para una manguera de aspiradora, con el

objeto de asistirse en la recolección del polvo o aserrín (la manguera

es opcional).

La cubierta transparente de la segueta mejora la extracción del

polvo.

Su mecanismo anti-vibratorio permite una operación mas suave y

silenciosa.

Ajustando la acción orbital

La cantidad de acción orbital puede ser ajustada con la palanca selectora.

En general, una acción orbital muy grande (lll) debe usarse en materiales

suaves y una acción orbital pequeña (0) debe usarse con materiales

duros. Cuando se requiera de un corte suave, no deben usarse órbitas

(0). A continuación se ilustran diferentes acciones orbitales con base

en diferentes composiciones del material a cortar. La acción orbital

óptima debe ser determinada por el usuario con base en los

requerimientos especiales del corte. La acción orbital puede ser ajustada

con la herramienta en operación o detenida.

Madera l l l Metal 0

Plástico l Corte suave 0

Realización del corte

1. Seleccione las carreras y la acción orbital, tomando en cuenta el

material que se va a cortar.

2. Coloque la herramienta con la parte frontal de la zapata sobre el

material y accione el interruptor.

3. Sujete firmemente la herramienta contra el material y guíela a través

de la linea de corte deseada. No la alimente muy fuertemente

contra el material, una ligera presión en la segueta hará que se

logre la velocidad óptima de corte.

Técnicas especiales de corte

1. Cortes rectosPara obtener un corte perfectamente recto, fije un

tramo de madera como guía, a todo lo largo de material a cortar o

use la guía paralela (accesorio).

2. Cortes en ánguloajuste la zapata al ángulo correcto (ver Ajustando

la zapata).

3. Cortes cerca de obstáculosmueva la zapata hacia atrás para

tener mayor área de libramiento de corte (ver Ajustando la zapata).

4. Cortando hojas de metallas hojas de metal pueden vibrar a la

hora de realizar el corte. Para minimizar estas vibraciones, sujete

con pinzas, la hoja de metal a una base de madera.

Encendido y apagado de la herramienta

Para el modelo N 6266

1. Para encender la herramienta, empuje el interruptor encendido/apagado.

2. Para detener la herramienta, empuje el interruptor encendido/apagado.

Para el modelo N 6276

1. Para encender la herramienta, empuje el interruptor encendido/

apagado hacia adelante hasta que I esté visible.

2. Para detener la herramienta, empuje el interruptor encendido/apagado

hacia atras hasta que 0 esté visible.

Asegurar el interruptor de encendido/apagado

El botón de seguridad mantiene el gatillo en la posición ENCENDIDO para

un uso continuo. (Solamente el modelo 6266)

1. Para asegurar el interruptor de encendido/apagado, sostenga el

botón de seguridad al presionar el interruptor encendido/apagado.

2. Para desbloquear el interruptor de encendido/apagado, presione el

interruptor de enciendido/apagado y suéltelo. El botón de seguridad saldrá

Ajustando las carreras por minuto

Las carreras por minuto pueden ajustarse usando la perilla selectora de

velocidad. En la perilla están indicados los números del 1 al 7, siendo el

1 el de la velocidad mas baja y el 7 el de la velocidad mas alta. Las

velocidades recomendadas para cortar diversos materiales se listan a

continuación. Las velocidades óptimas de corte deben ser determinadas

por el usuario con base en los requerimientos especiales del corte. Las

carreras por minuto pueden ser ajustadas con la herramienta en operación

o detenida.

Madera 7

Metal 4-5

Plástico 2

page 18

Cortes interiores o resaques (Fig. 4)

Las sierra caladoras MILWAUKEE 6266

y 6276 están bien adaptadas para

realizar cortes inclinación en materiales

suaves sin un agujero pre-perforado.

Los materiales más duros requieren de

esta perforación guía con un diámetro

ligeramente mayor que el ancho de la

segueta. Para realizar un corte interior:

1. Corra la zapata totalmente hacia

atrás.

2. Coloque en 0, el selector de acción

orbital.

3. Mantenga el cable eléctrico fuera del

área de corte.

4. Asegúrese que no haya nada que se

pueda dañar debajo de la superficie

de corte.

5. Antes de accionar el interruptor,

coloque firmemente la parte frontal

de la zapata sobre el material a cortar.

6. Alinee la segueta con la linea de corte

por realizar.

7. Usando la parte frontal de la zapata

como pivote, accione la herramienta

y baje gradualmente la segueta contra el material a cortar.

8. Una vez que la zapata esté apoyada

firmemente contra la superficie del

material, realice el corte en forma

normal.

Fig. 4

Page 19

MANTENIMIENTO

ACCESORIOS

¡ADVERTENCIA!

Para reducir el riesgo de lesiones, desconecte

siempre la herramienta antes de darle cualquier

mantenimiento. Nunca desarme la herramienta ni trate

de hacer modificaciones en el sistema eléctrico de

la misma. Acuda siempre a un Centro de Servicio

MILWAUKEE para TODAS las reparaciones.

Mantenimiento de las herramientas