Milwaukee 6215 User Manual

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Cat. No.

No de cat.

Cat. No.

6215

FPO

HEAVY-DUTY CHAIN SAW

EXTRA ROBUSTE SCIE À CHAÎNE

HEAVY DUTY SIERRA DE CADENA

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND

OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET

BIEN COMPRENDRE LE MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y

ENTENDER EL MANUAL DEL OPERADOR.

GENERAL SAFETY RULES

WARNING!

When using an electric chain saw, always follow basic safety precautions to

reduce the risk of fire, electric shock and personal injury.

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE. Before use, be sure everyone

using this tool reads and understands this manual as well as any labels packaged with or

attached to the tool.

1. Keep Work Area Clean.

Cluttered areas invite injuries.

Do not start cutting until you have a

clear work area, secure footing, and a

planned retreat path from the falling

tree.

2. Consider Work Area Environment.

Use extreme caution when cutting small

size brush and saplings because the

slender material may catch the saw

chain and be whipped toward you or

pull you off balance.

Do not operate a chain saw in a tree

unless specifically trained to do so.

When cutting a limb that is under ten-

sion be alert for spring back so that

you will not be struck when the tension

in the wood fibers is released.

Do not expose chain saw to rain.

Do not use chain saw in damp or wet

locations.

Do not use chain saw in presence of

flammable liquids or gases.

3. Guard Against Electric Shock.

Prevent body contact with grounded

surfaces such as metal pipes or wire

fences.

4. Keep Children Away.

Do not let visitors contact chain saw or

extension cord.

All visitors should be kept away from

work area.

5. Store Idle Chain Saw.

When not in use, chain saws should

be stored in a dry, and high or locked-

up place, out of the reach of children.

When storing saw, use a scabbard or

carrying case.

6. Dont Force Chain Saw.

It will do the job better and safer at the

rate for which it was intended.

7. Use Right Tool.

Cut wood only.

Do not use chain saw for purpose not

intended, for example, Dont use chain

saw for cutting plastic, masonry, or

non-wood building materials.

8. Dress Properly.

Do not wear loose clothing or jewelry.

They can get caught in moving parts.

Rubber gloves and non-skid footwear

are recommended when working outdoors.

Wear protective hair covering to con-

tain long hair.

9. Use Safety Equipment.

Wear safety glasses, safety footwear,

snug fitting clothing, protective gloves,

hearing protection and head protection.

10. Carry the chain saw by the front

handle with the saw stopped, finger off the switch, the guide bar

and saw chain to the rear.

11. Maintain Chain Saw With Care.

Inspect chain saw cords periodically

and if damaged, have repaired by authorized service facility.

Keep cord clear of the chain and op-

erator at all times.

Never carry saw by the cord or pull it

to disconnect from receptacle.

Keep cord from oil and sharp edges.

Inspect extension cords periodically

and replace if damaged.

Keep tools sharp and clean for better

and safer performance.

Follow instructions for lubricating and

changing accessories.

Keep handles dry, clean, and free from

oil and grease.

12. Disconnect chain saw when not in

use, before servicing, and when

changing accessories and attachments, such as saw chain and

guard.

13. Outdoor Use extension cords.

Use only extension cords intended for

use outdoors and so marked.

14. Stay Alert.

Watch what you are doing.

Use common sense.

Do not operate chain saw when you

are tired.

Keep all parts of the body away from the

saw chain when the motor is operating.

Before you start the saw, make sure the

saw chain is not contacting anything.

15. Check Damaged Parts.

Before further use of the chain saw, a

guard or other part that is damaged

should be carefully checked to determine that it will operate properly and

perform its intended function.

Check for alignment of moving parts,

binding of moving parts, breakage of

parts, mounting, and any other conditions that may affect its operation.

A guard or other part that is damaged

should be properly repaired or replaced

by an authorized service center unless otherwise indicated elsewhere in

this instruction manual.

Have defective switches replaced by

authorized service center.

Do not use chain saw if switch does

not turn it on and off.

Do not operate a chain saw that is dam-

aged, improperly adjusted, or is not

completely and securely assembled. Be

sure that the saw chain stops moving

when the trigger is released.

When servicing use only identical re-

placement parts.

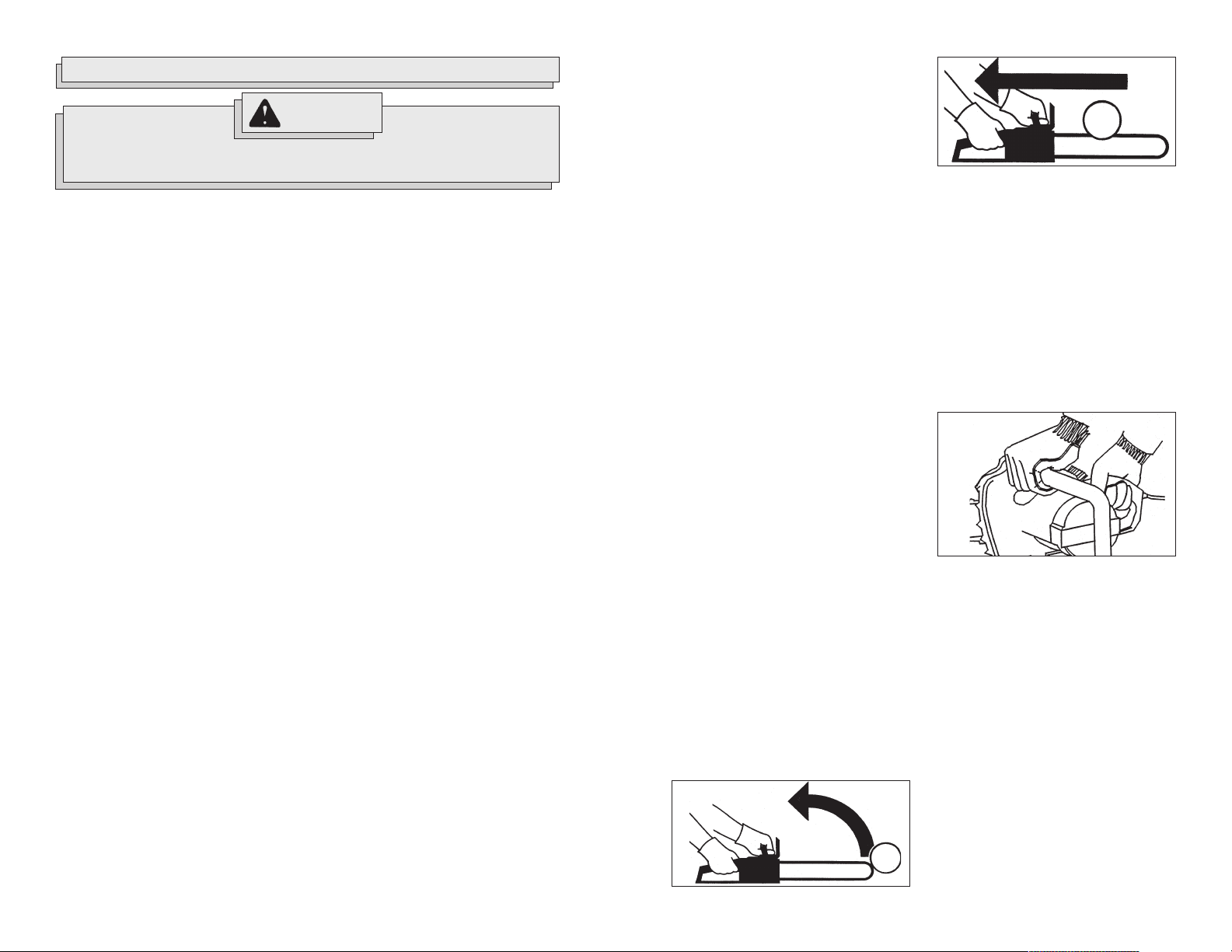

16. Guard Against Kickback.

WARNING: KICKBACK may occur when

the nose or tip of the guide bar touches

an object (Fig. 1), or when the wood

closes in and pinches the saw chain in

the cut (Fig. 2).

Fig. 1

Fig. 2

Tip contact in some cases may cause a

lightning fast reverse reaction, kicking

the guide bar up and back towards the

operator. Pinching the saw chain along

the top of the guide bar may push the

guide bar rapidly back towards the operator. Either of these reactions may

cause you to lose control of the saw

which could result in serious injury to user.

The following precautions should be

followed to minimize kickback:

A. Grip Saw Firmly.

B. Hold the chain saw firmly with both

hands when the motor is running. Use

a firm grip with thumbs and fingers en-

circling the chain saw handles (Fig. 3).

Fig. 3

C. Do not over reach.

D. Keep proper footing and balance at all

times.

E. Do not let the nose of the guide bar

contact a log, branch, ground or other

obstruction.

F. Do not cut above shoulder height.

G. Use devices such as low kickback chain,

guide bar nose guards, chain brakes

and special guide bars that reduce the

risks associated with kickback.

H. Only use replacement guide bars and

chains specified by the manufacturer

or the equivalent.

17. Power Supply

Connect chain saw to correct voltage,

that is, be sure that the voltage sup-

plied is the same as that specified on

the nameplate of the tool.

READ AND SAVE ALL INSTRUCTIONS

FOR FUTURE REFERENCE.

2 3

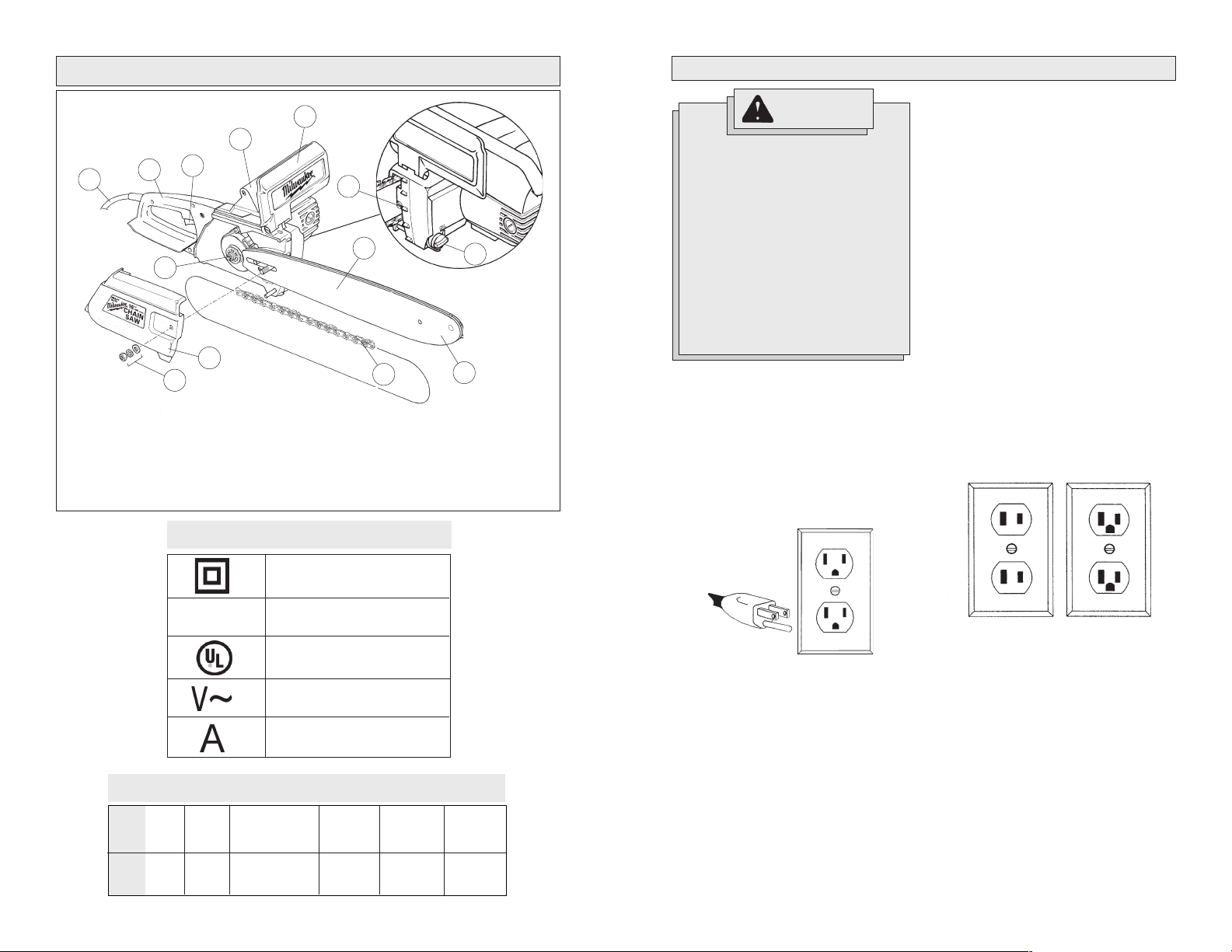

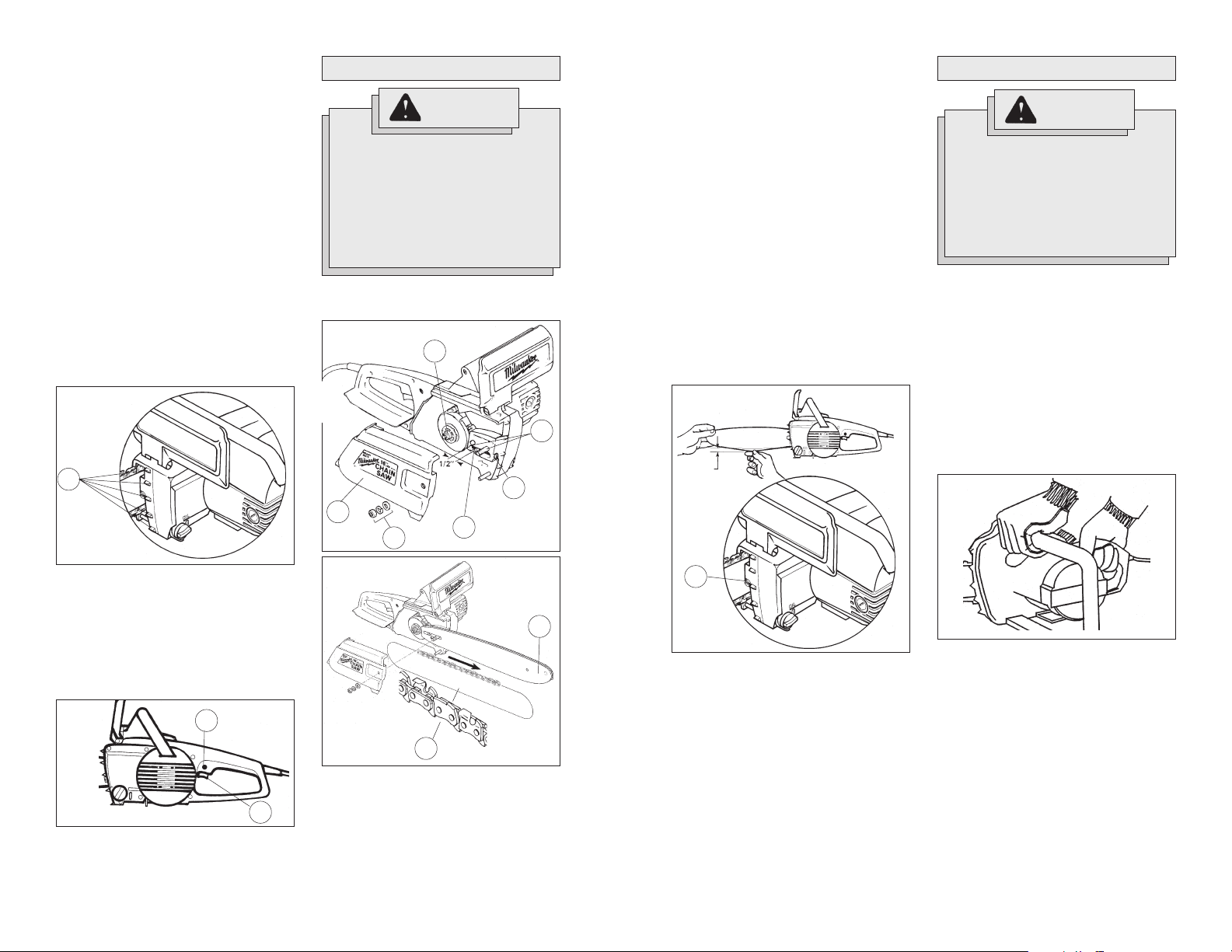

FUNCTIONAL DESCRIPTION

GROUNDING

3

1

1. Cord

2. Rear handle

3. Switch

4. Front handle

5. Hand guard / brake lever

6. Guide bar

7. Nose of guide bar

2

11

9

10

5

4

13

6

8

8. Saw chain

9. Sprocket cover

10. Sprocket cover nut and washers

11. Drive sprocket

12. Oil tank cap

13. Chain tension adjusting screw

Symbology

WARNING!

Improperly connecting the

grounding wire can result in the

risk of electric shock. Check with

a qualified electrician if you are in

doubt as to whether the outlet is

properly grounded. Do not modify

the plug provided with the tool.

12

7

Never remove the grounding

prong from the plug. Do not use

the tool if the cord or plug is damaged. If damaged, have it repaired

by a MILWAUKEE service facility

before use. If the plug will not fit

the outlet, have a proper outlet

installed by a qualified electrician.

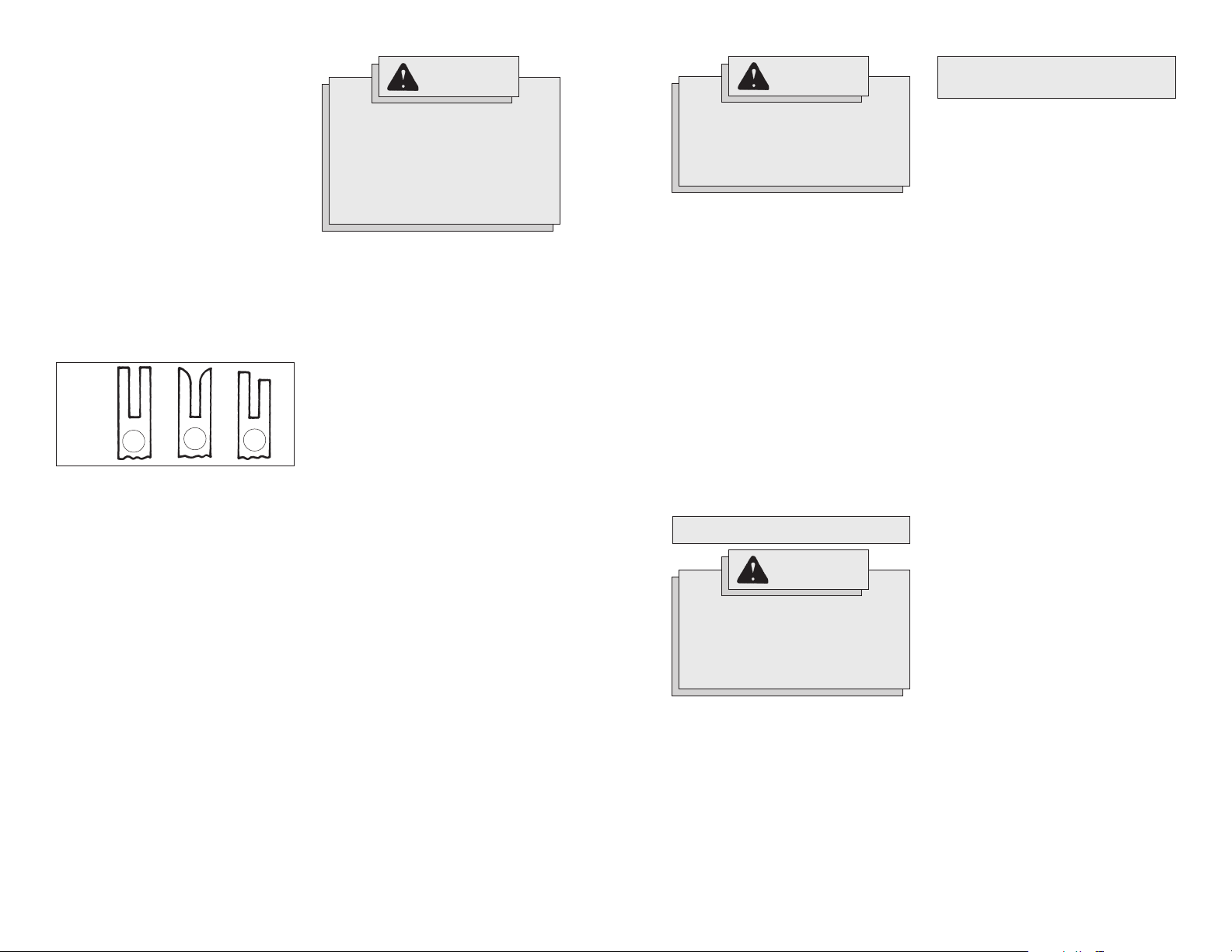

Grounded Tools:

Tools with Three Prong Plugs

Tools marked Grounding Required have

a three wire cord and three prong grounding plug. The plug must be connected to a

properly grounded outlet (See Figure A). If

the tool should electrically malfunction or

break down, grounding provides a low resistance path to carry electricity away from

the user, reducing the risk of electric shock.

The grounding prong in the plug is connected through the green wire inside the

cord to the grounding system in the tool.

The green wire in the cord must be the

only wire connected to the tool's grounding system and must never be attached to

an electrically live terminal.

Your tool must be plugged into an appropriate outlet, properly installed and

grounded in accordance with all codes and

ordinances. The plug and outlet should look

like those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked Double Insulated do not require grounding. They have a special

double insulation system which satisfies

OSHA requirements and complies with the

applicable standards of Underwriters Laboratories, Inc., the Canadian Standard Association and the National Electrical Code.

Double Insulated tools may be used in either of the 120 volt outlets shown in

Figures B and C.

Cat.

No.

6215

Volts

AC

120

FPM

Amps

13

Double Insulated

Feet per minute

Underwriters

Laboratories, Inc.

Volts Alternating Current

Amperes

Specifications

Chain Speed

1800 ft./min.

549 m/min.

4 5

Guide

Bar Size

16"

406 mm

Oil Tank

Capacity

6 1/2 oz.

190 ml

Chain

Type

3/8" Pitch

Chain

Fig. A

Fig. B

Fig. C

EXTENSION CORDS

Grounded tools require a three wire extension cord. Double insulated tools can

use either a two or three wire extension

cord. As the distance from the supply outlet increases, you must use a heavier

gauge extension cord. Using extension

cords with inadequately sized wire causes

a serious drop in voltage, resulting in loss

of power and possible tool damage. Refer

to the table shown to determine the required minimum wire size.

The smaller the gauge number of the wire,

the greater the capacity of the cord. For

example, a 14 gauge cord can carry a

higher current than a 16 gauge cord. When

using more than one extension cord to make

up the total length, be sure each cord contains at least the minimum wire size required. If you are using one extension cord

for more than one tool, add the nameplate

amperes and use the sum to determine the

required minimum wire size.

Guidelines for Using Extension Cords

If you are using an extension cord out-

doors, be sure it is marked with the

suffix W-A (W in Canada) to indicate that it is acceptable for outdoor

use.

Be sure your extension cord is prop-

erly wired and in good electrical

condition. Always replace a damaged

extension cord or have it repaired by a

qualified person before using it.

Protect your extension cords from

sharp objects, excessive heat and

damp or wet areas.

Recommended Minimum Wire

Gauge for Extension Cords*

Nameplate

Amperes

0 - 2.0

2.1 - 3.4

3.5 - 5.0

5.1 - 7.0

7.1 - 12.0

12.1 - 16.0

16.1 - 20.0

* Based on limiting the line voltage drop to

five volts at 150% of the rated amperes.

Extension Cord Length

25'

18

18

18

18

16

14

12

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE.

50'

18

18

18

16

14

12

10

75'

18

18

16

14

12

10

100'

18

16

14

12

10

150'

16

14

12

12

CHAIN SAW TERMINOLOGY

Bucking

The process of cross cutting a felled tree

or log into lengths.

Chain Brake

A device used to stop the chain saw.

Chain Saw Powerhead

A chain saw without the saw chain and

guide bar.

Clutch

A mechanism for connecting and disconnecting a driven member to and from a rotating source of power.

Drive Sprocket or Sprocket

The toothed part that drives the saw chain.

Felling

The process of cutting down a tree.

Felling Back Cut

The final cut in a tree felling operation made

on the opposite side of the tree from the

notching undercut.

Front Handle

The support handle located at or toward

the front of the chain saw.

Front Handle Guard

A structural barrier between the front

handle of a chain saw and the guide bar,

typically located close to the hand position

on the front handle and sometimes employed as an activating lever for a chain

brake.

Guide Bar

A solid railed structure that supports and

guides the saw chain.

Kickback

The backward or upward motion, or both

of the guide bar occurring when the saw

chain near the nose of the top area of the

guide bar contacts any object such as a

log or branch, or when the wood closes in

and pinches the saw chain in the cut.

Kickback, Pinch (Fig. 4)

The rapid push back of the saw which can

occur when the wood closes in and

pinches the moving saw chain in the cut

along the top of the guide bar.

Fig. 4

Kickback, Rotational (Fig. 5)

The rapid upward and backward motion of

the saw which can occur when the moving saw chain near the upper portion of

the tip of the guide bar contacts an object,

such as a log or branch.

Fig. 5

Low-Kickback Chain

A chain that complies with the kickback

performance requirements of ANSI B175.12000 when tested on a representative

sample of chain saws.

Normal Cutting Position

Those positions assumed in performing the

bucking and felling cuts.

Notching Undercut

A notch cut in a tree that directs the trees

fall.

Oiler Control

A system for oiling the guide bar and saw

chain.

Rear Handle

The support handle located at or toward

the rear of the saw.

6 7

Reduced Kickback Guide Bar

A guide bar which has been demonstrated

to reduce kickback significantly.

Replacement Saw Chain

A chain that complies with the kickback

performance requirements of ANSI B175.12000 when tested with specific chain

saws. It may not meet the ANSI performance requirements when used with other

saws.

Saw Chain

A loop of chain having cutting teeth, that

cut the wood, and that is driven by the

motor and is supported by the guide bar.

Spiked Bumper (Spike) (Fig. 6)

The pointed tooth or teeth (A)for use when

felling or bucking to pivot the saw and

maintain position while sawing.

Fig. 6

A

TOOL ASSEMBLY

WARNING!

To reduce the risk of injury,

always unplug tool before performing any assembly, adjustments, maintenance or service.

Contact a MILWAUKEE service

facility for ALL repairs. Use only

specifically recommended

accessories. Others may be

hazardous.

Mounting the guide bar and chain to

the power head unit (Fig. 8 & 9)

Fig. 8

F

E

C

B

A

D

3. Fit guide bar onto the two mounting

studs (E) and fit the chain tensioning

pin (D) into the smaller hole in the guide

bar.

4. Fit chain over the drive sprocket (F)

with the cutting edges facing the direction of rotation (G).

5. Fit the chain into the groove in the top

of the guide bar, start from the back

and work toward the front. Rotate the

nose sprocket (H) if necessary.

6. Replace sprocket cover.

Adjusting chain (Fig.10)

1. Loosen retaining nut on sprocket cover

and retighten finger tight.

2. Remove slack in chain by pulling up on

nose and adjusting the tensioning

screw (A) so that the chain touches

the bottom of the guide bar along the

entire length.

Fig. 10

1/8"

OPERATION

WARNING!

To reduce the risk of injury, wear

safety goggles or glasses with

side shields. Always unplug the

saw before attaching or removing accessories. The use of any

accessory other than those specifically recommended for use

with this saw may be hazardous.

Cutting with the chain saw

This chain saw is designed to cut wood

and wood products only. Do not use this

saw to cut wood or wood products if nails,

screws, metal plates, or any other material other than wood is in the material. You

may damage the tool and may cause personal injury.

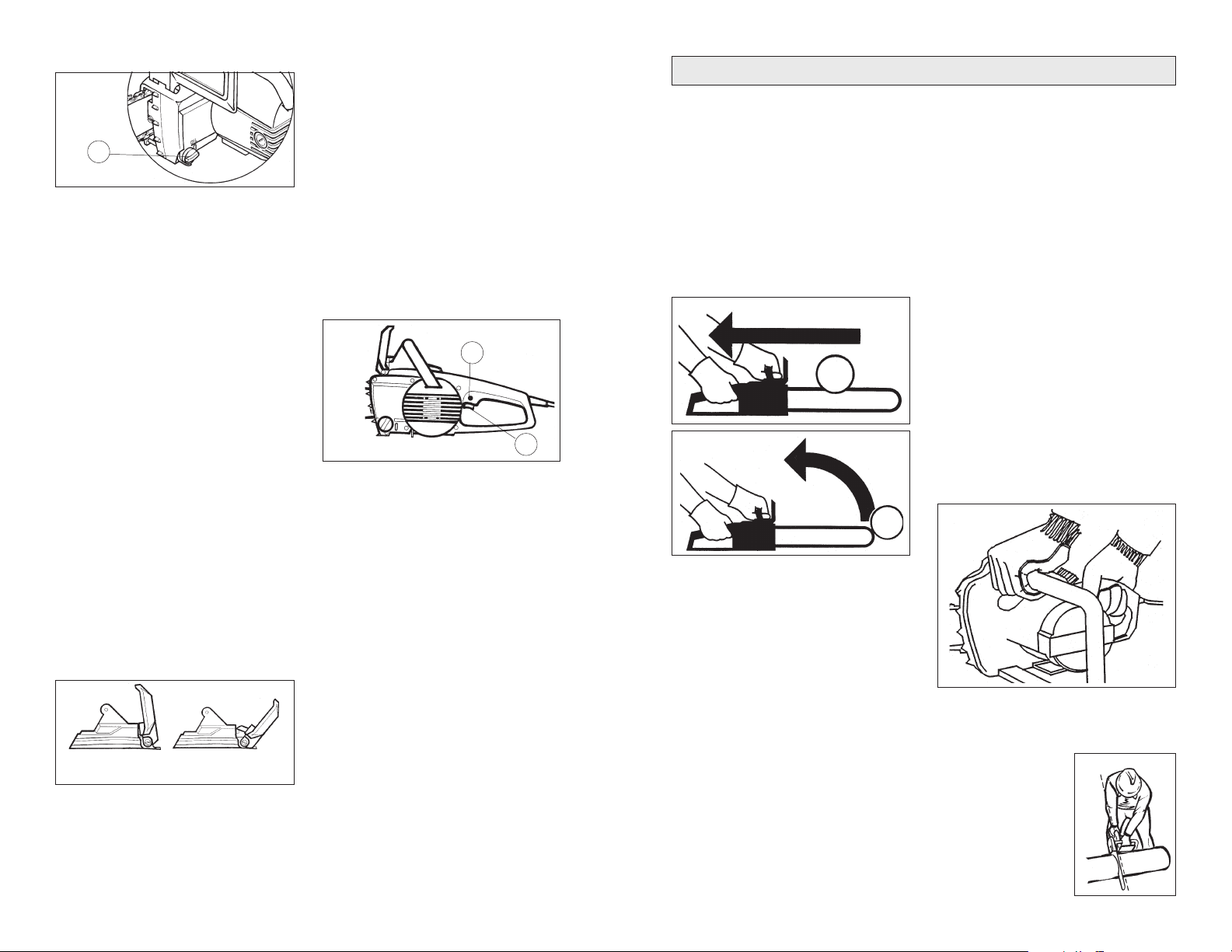

Holding the chain saw (Fig. 11)

Always grip each handle with the thumb

and fingers encircling the handle as

shown.

Fig. 11

Switch Linkage

The mechanism that transmits motion from

a trigger to the switch.

Switch (Fig. 7)

A device that when operated will complete

or interrupt an electrical power circuit to

the motor of the chain saw (A).

Fig. 7

B

A

Switch Lockout (Fig. 7)

A movable stop (B) that prevents the unintentional operation of the switch until manually actuated.

Fig. 9

A

G

3. While supporting the saw by the nose,

pull down on chain. If the chain will

clear the guide bar by about 1/8" and

snap back to the bottom of the guide

bar, the chain is properly tensioned.

H

1. Remove retaining nut and washers (A)

and remove the sprocket cover (B).

2. Adjust the chain tensioning screw (C)

so that the chain tensioning pin (D) is

about 1/2" from the sprocket side of

the slot as shown.

8 9

Tighten retaining nut firmly with the

wrench provided.

4. Run the saw without cutting, unplug

the saw and recheck the tension before use.

NOTE: Too much tension will burn the

guide bar and damage the chain. Too

little tension will allow the chain to leave

the guide bar and may cause personal

injury. A new chain will stretch when

used and will require readjustment later.

Using the chain saw

Always be sure of your footing and hold

the chain saw firmly with both hands while

the motor is running.

Chain oil (Fig. 12)

Fig. 12

A

Proper lubrication prolongs chain and guide

bar life. In warm weather use a SAE-30

weight oil. In colder weather use SAE-20

or SAE-10 weight oil. Use only clean oil to

prevent damage to the automatic oiler. Unscrew the cap (A) and fill oil tank before

use.

Automatic oiler

Catalog number 6215 Chain Saw is

equipped with an automatic oiler. The oiler

is preset at the factory to provide continuous guide bar lubrication while the saw is

running. To check if oiler is working properly, hold the nose of the chain saw about

4" from the log and run the chain saw. If

the oiler is working properly the log should

be spotted with oil.

Chain brake (Fig. 13)

The chain saw is equipped with a brake

that is actuated by the movement of the

hand guard/brake. The movement of the

hand guard/brake opens a spring loaded

switch that interrupts the power and mechanically stops the chain until the hand

guard/brake is returned to the operating

position.

NOTE: Do not attempt to remove the chain

brake from the saw. Using the chain saw

without a chain brake will prohibit the users

ability to stop the chain abruptly and may

increase the risk of personal injury.

Fig. 13

Operating

position

Braking

position

Adjusting chain brake

The brake should be checked for normal

operation before each period of use.

Push the hand guard/ brake into the braking position.

If the brake doesn't stop the chain abruptly

when it is applied, the brake needs

adjusting. Take the saw to an authorized

MILWAUKEE service center for repair and/

or adjustment.

Starting and stopping the chain saw

(Fig. 14)

To start the chain saw, push in the lockout

button (A) and pull the trigger (B).

To stop the chain saw, release the trigger.

Fig. 14

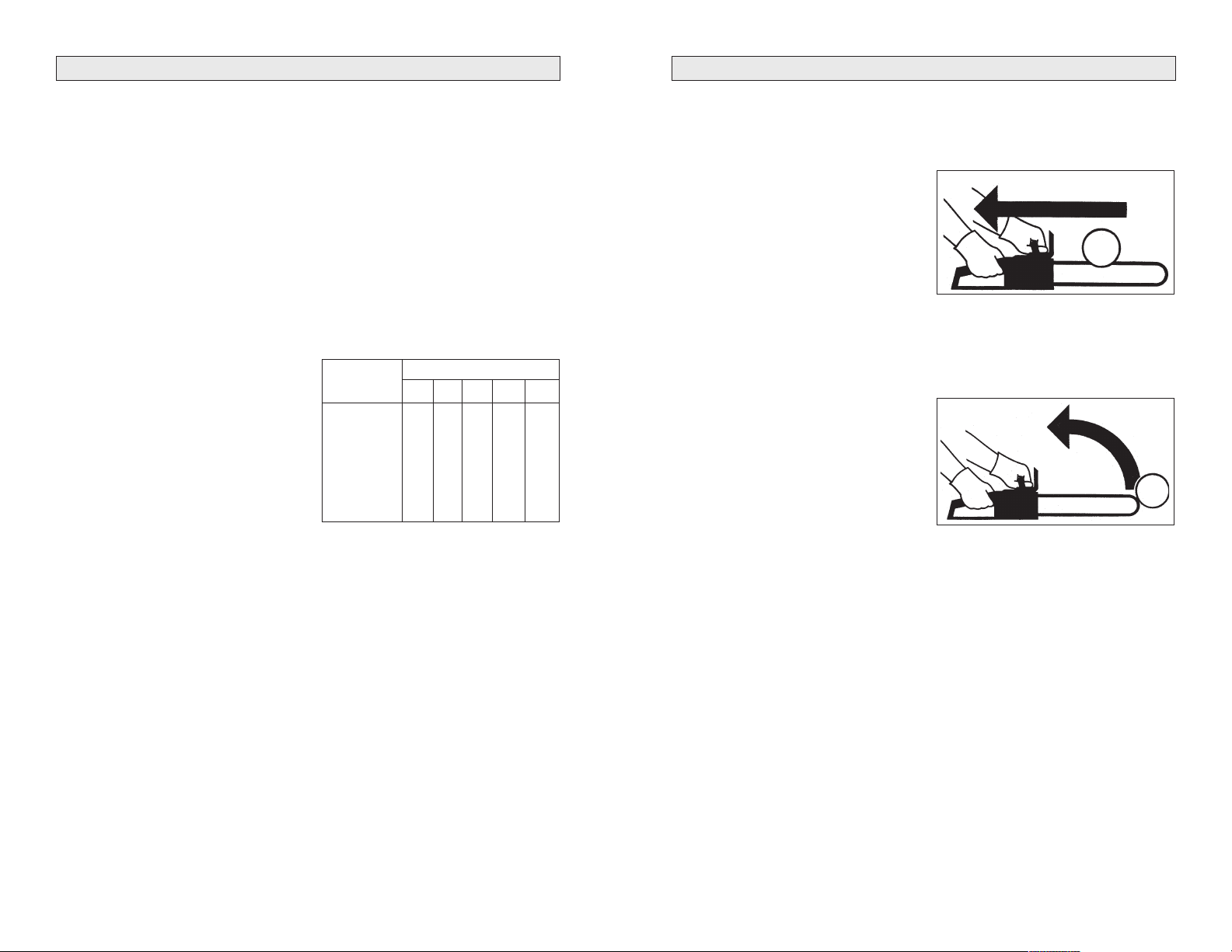

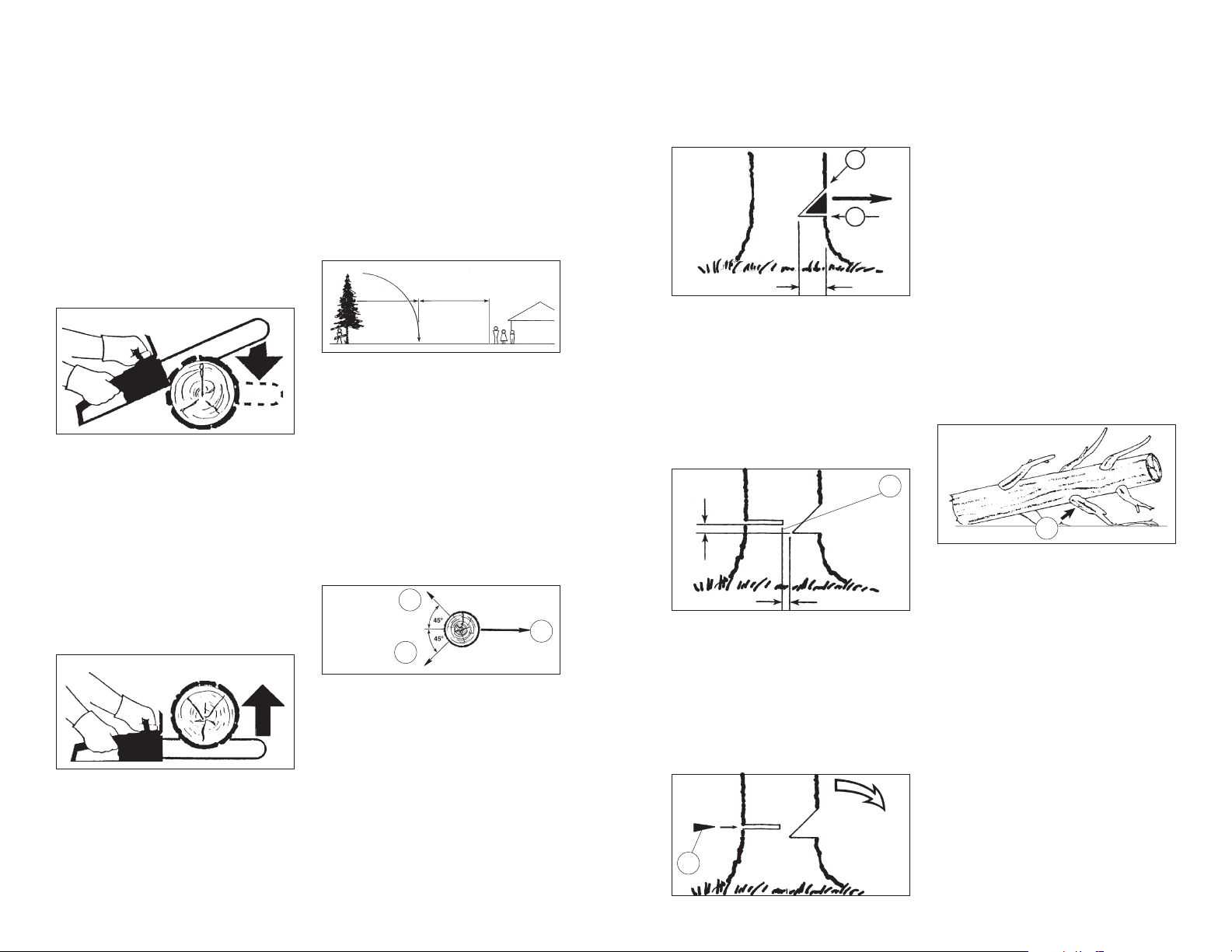

Beware of Kickback (Fig. 15 & 16)

"Kickback" is the term used to describe the

sudden, rapid backward and/or upward

motion of the chain and guide bar. Pinch

Kickback (Fig. 15) is the rapid backward

movement of the saw which can occur

when the wood closes in and pinches the

moving saw chain in the cut along the top

of the guide bar. Rotational Kickback

(Fig. 16) is the rapid upward and backward motion of the saw which can occur

when the moving saw chain near the upper portion of the tip of the guide bar contacts an object, such as a log or branch.

Fig. 15

Pinch Kickback

APPLICATIONS

A

B

10 11

Fig. 16

Reducing the chance kickback

Use recommended guide bar and chain,

others may not reduce kickback.

Make sure chain is sharp and properly

lubricated. Dull, improperly sharpened,

and/or unlubricated chains can cause

kickback.

Allow saw to come to full speed be-

fore applying it to the cut.

Keep saw running when removing it

from the cut.

Reducing the chance of pinch kickback

Always try to cut in a downward motion,

with the bottom side of the chain and guide

bar. This will reduce the chance of kickback in two ways:

If you are cutting downward on

branches or bucked logs , the cut will

tend to open up as you go and reduce

the chance of pinching the chain and

guide bar.

Rotational

Kickback

If the guide bar and chain are pinched

the saw will tend to be pulled into the

wood and not thrown toward you.

Reducing the chance of rotational

kickback

Do not cut with the tip of the guide bar.

Check the work area and avoid acci-

dentally brushing the tip against wood.

Cut one piece of wood at a time and

check to make sure that while cutting

one piece that the nose doesn't accidently come in contact with another

piece of wood or other obstruction.

Preparing for Kickback

The operator should do everything possible to reduce the chance of kickback (see

above). The operator should also do everything possible to be prepared for kickback if it occurs.

Correct grip (Fig. 17)

The correct grip will help the operator keep

control of the saw. Fig. 17 shows the correct grip on the saw with the thumb and

fingers encircling the front handle.

Fig. 17

Body position (Fig. 18)

Plant feet firmly on solid ground.

Hold saw with left arm straight with

elbow locked.

Stand to left side of

cut, out of the kickback path of the

saw.

Cut within a com-

fortable controlled

reaching distance

at chest height or

below.

Fig. 18

Basic cuts

1. Support log in a stable position.

2. Check for adequate clearance for cut.

3. Allow saw to come to full speed before cutting.

Overbucking, or cutting down through

log (Fig. 19)

1. Place lower end of spiked bumper

against the log.

2. Pivot saw into the cut and allow it to cut

its way down.

3. Reposition spiked bumper lower down

and repeat working down the log until

through the cut.

Fig. 19

Underbucking, or cutting up from the

bottom of a log (Fig. 20)

Most cuts should be made according to the

overbucking instructions. But, in some situations, it may be necessary to cut with the

top of the guide bar.

1. Be prepared for a "pushing" action from

the saw. Keep in mind instructions

listed under "preparing for kickback".

2. Allow saw to come to full speed.

3. Lift the saw into the cut in a controlled

motion.

Fig. 20

Felling a Tree

Work area (Fig. 21)

Do not fell trees by roads, power lines,

or buildings without permission from

appropriate authorities. Traffic control

or other preparations may be necessary. If a felled tree contacts a power

line do not go near it. Notify the power

company and provide a warning for

others.

Keep bystanders, coworkers, pets etc.

at a distance at least twice the height

of the tallest tree being felled.

Fig. 21

When bucking and felling operations are

being performed by two or more persons at the same time, the felling operation should be separated from the

bucking operation by a distance of at

least twice the height of the tree being

felled.

Check intended cut area for nails, fence

wire, stones etc. and remove these

materials before cutting.

Retreat path (Fig. 22)

Before beginning to fell a tree, clear

retreat paths (A) at 45º angles to the

line of the fall (B).

Fig. 22

A

B

A

The operator should be on the uphill

side of the terrain when felling a tree.

Toward the end of the cut, be prepared

for the tree to roll or slide down the hill.

The wind speed and direction and the

shape of the tree and its limbs will affect the direction of the fall. If unsure

of any this information, call a professional for help.

Notching (Fig. 23)

1. Make a lower horizontal notching cut

about 1/3 of the way through the tree

(A). This will help to avoid pinching of

the saw chain or guide bar when the

second cut is made.

Fig. 23

2. Make an angled cut to finish the notch

(B).

Felling back cut (Fig. 24 & 25)

1. Make a horizontal felling back cut 2"

above the initial notching cut so that

there will be a 2" "hinge" (A) created in

the tree. Do not cut through the hinge.

The hinge prevents the tree from twisting and falling in the wrong direction

when felled.

Fig. 24

2"

NOTE: When cutting larger diameter

trees, as the felling back cut

progresses, drive nonmetallic (wood

or plastic) wedges into the felling back

cut (B). These wedges help to keep

the felling back cut open and reduce

the risk of the tree "leaning back" onto

the guide bar and chain. Continue to

add wedges as needed until felling back

cut creates the 2" "hinge".

Fig. 25

B.

A.

A

2"

2. Usually the tree will begin to fall as you

complete the felling back cut. However

if it does not, remove the saw and drive

nonmetallic wedges (B) into the felling

back cut until the tree begins to fall.

3. Remove the saw from the cut, stop the

motor and put the saw down. Watch

out for falling limbs and move away

from falling tree following the retreat

path. Watch your footing as you move

away from the tree.

Limbing a tree (Fig. 26)

"Limbing" is removing the branches from a

fallen tree.

1. Cut the smaller upper limbs of the tree

first and let the larger lower limbs hold

the tree off of the ground.

2. Cut limbs under tension in a direction

so that the tension causes the cut to

open up rather than pinch the chain

and guide bar.

Usually this means cut limbs under tension from the bottom (A).

Fig. 26

A

3. Do not remove the larger supporting

limbs until the tree is bucked into shorter

logs. See directions below.

B

12 13

Bucking a log

When bucking a log, (cutting it into lengths)

it is important to make sure your footing is

firm and your weight is evenly distributed.

In general, try to have the log raised and

supported near the cut. Having the log

raised and supported near the cut will reduce binding and kickback.

If bucking log on hill (Fig. 27)

The operator should be on the uphill side

of the cut so when the cut off piece rolls,

it rolls away from the operator. Do not let

the chain come into contact with the

ground. Toward the end of the cut reduce

cutting pressure, maintain firm grip, and be

prepared for log to roll away from the saw

and the operator.

Fig. 27

After completing the cut, wait for the saw

chain to stop before moving the saw. Always stop the motor before continuing to

another tree.

If log supported along entire length

(Fig. 28)

If log supported along entire length, such

as on the ground, cut from the top (A) roll

log over and finish the cut. Rolling the log

over and finishing the cut from the top will

prevent the cutting into the ground where

the dirt and stones will dull the chain.

Fig. 28

A

If log supported on one end (Fig. 29)

If log supported on one end cut 1/3 of the

way through the log from the bottom (A)

and finish the cut from the top (B). Cutting

this way will make the cut off portion fall

away cleanly and easily.

Fig. 29

B

A

If log supported on both ends (Fig. 30)

If log supported on both ends cut 1/3 of the

way through the log from the top (A) and

finish the cut from the bottom (B). Use extra caution to make sure that the chain saw

does not bind up in the cut.

Fig. 30

A

B

MAINTENANCE

Under normal usage, your chain saw will

require regular inspection and maintenance.

Examine the saw for dirt and debris that

might prevent safety and anti-kickback devices from working properly. Inspect the

saw and its safety devices to determine

that it will operate properly. Failure to follow the maintenance procedures indicated

below or the removal of safety devices

may increase the risk of injury.

Cleaning guide bar, chain and chain

brake

Remove the guide bar and chain after each

use or as needed to clean out chips and

debris from the sprocket area. Clean guide

bar groove, soak in light oil and wipe clean.

Clean out chips and debris from the chain

brake after each use or as needed. Check

the brake for normal operation before each

use. See "Cleaning" for further cleaning

instructions.

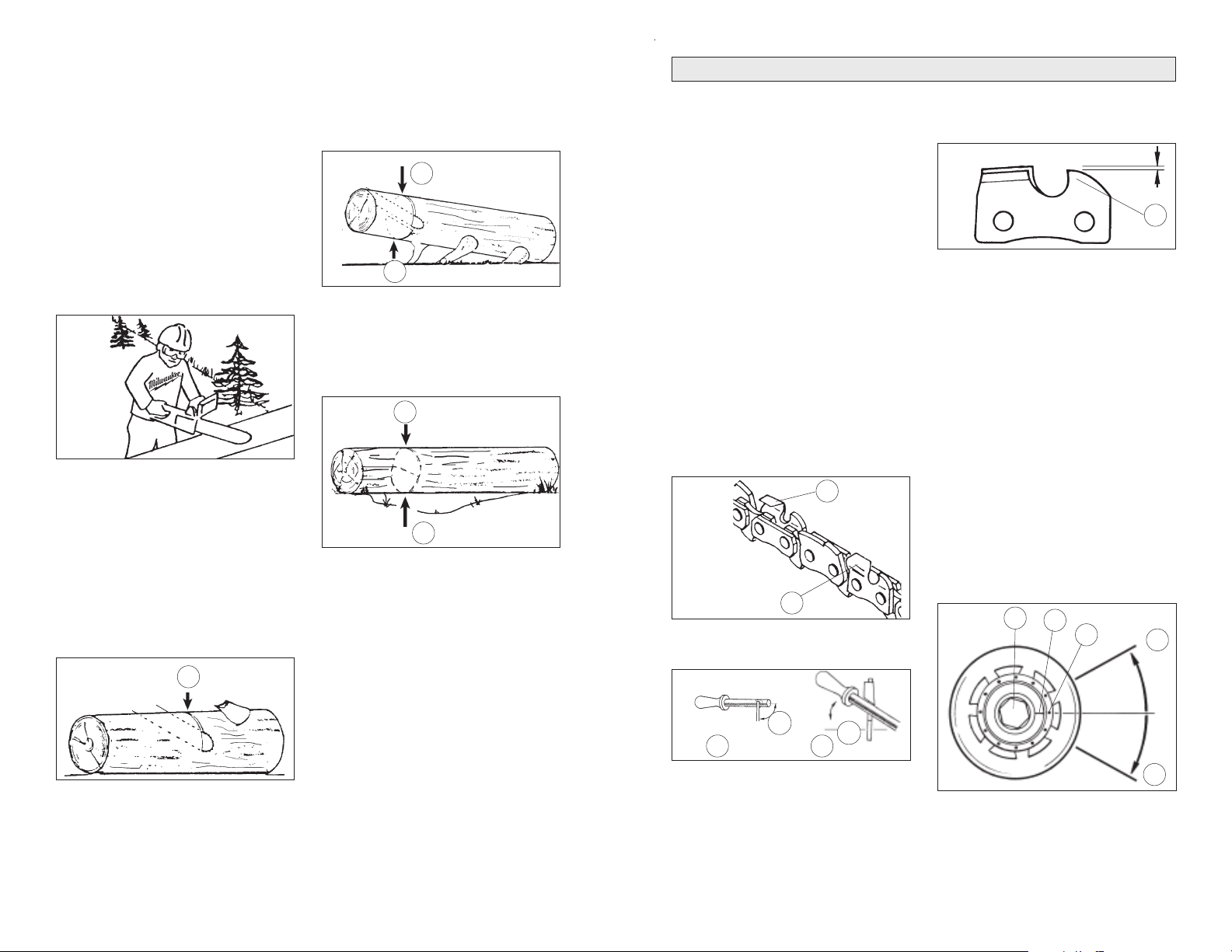

Sharpening chain (Fig. 31 & 32)

Use a 5/32" diameter round file to sharpen

cutter links (A).

Fig. 31

Fig. B shows the link from the front.

Fig. C shows the link from the top.

Fig. 32

A

A

Setting the Depth (Fig. 33)

The front part (A) of the cutter link is designed to limit the depth of cut of the tooth.

Fig. 33

A

If the tooth is limited too much, the chain

saw will not cut as effectively as it

can.

If the tooth is not limited enough, the

tooth will take too big a bite and contribute to kickback.

File the front of the cutter link so that it is

.025" lower than the cutting tooth.

The Clutch (Fig. 34)

This chain saw is equipped with a disc

clutch designed to protect the motor from

overload. It has been preset at the factory.

The clutch should slip when the saw is

bogged down in a cut. If the clutch slips

during a normal cut, or does not slip when

the saw is bogged down in a cut, adjust it

as follows.

1. Engage the brake.

2. Remove the sprocket cover.

3. Note the stamped mark on the flange

(B).

Fig. 34

A

B

C

D

90°

B

Replacing the chain

To replace the chain, refer to instructions

under Assembly. Use only Low-Kickback

saw chains that meet the ANSI B175.12000 kickback requirements, other chains

may not reduce kickback. Refer to your

MILWAUKEE catalog for proper replacement parts.

14 15

30°

C

E

4. Rotate the adjusting bolt flange (A) so

that the mark on the flange (B) lines up

with the next reference mark on the

thrust washer (C).

If the clutch is slipping during a normal

cut, tighten the adjusting bolt flange to

the next mark clockwise (E).

If the clutch is not slipping when it

should, for example when the saw is

bogged down in a cut, loosen the adjusting bolt flange to the next mark counterclockwise (D).

5. Replace the sprocket cover and make

a few test cuts and readjust if necessary.

Tighten the clutch only enough that it

will not slip during a normal cut, but slips

when the saw is bogged down. If repeated slippage occurs after adjusting,

take the chain saw to an authorized

MILWAUKEE repair facility for adjustment or repair.

Inspecting guide bar (Fig. 35)

Periodically inspect the guide bar for wear.

A, B, and C show cross-section view of

guide bars.

Fig. 35

A

A shows a guide bar in good condition.

The edges that the chain moves on are

square and even.

B shows a guide bar that the edges

are rounded and worn. If the guide bar

looks like this it should be replaced.

C shows a guide bar that one edge is

worn unevenly. If the guide bar looks

like this it should be replaced.

B

C

WARNING!

To reduce the risk of injury,

always unplug your tool before

performing any maintenance.

Never disassemble the tool or try

to do any rewiring on the tool's

electrical system. Contact a

MILWAUKEE service facility for

ALL repairs.

Maintaining Tools

Keep your tool in good repair by adopting a

regular maintenance program. Before use,

examine the general condition of your tool.

Inspect guards, switches, tool cord set and

extension cord for damage. Check for

loose screws, misalignment, binding of

moving parts, improper mounting, broken

parts and any other condition that may affect its safe operation. If abnormal noise

or vibration occurs, turn the tool off immediately and have the problem corrected

before further use. Do not use a damaged

tool. Tag damaged tools DO NOT USE until

repaired (see Repairs).

Under normal conditions, relubrication is

not necessary until the motor brushes

need to be replaced. After six months to

one year, depending on use, return your

tool to the nearest MILWAUKEE service

facility for the following:

Lubrication

Brush inspection and replacement

Mechanical inspection and cleaning

(gears, spindles, bearings, housing,

etc.)

Electrical inspection (switch, cord,

armature, etc.)

Testing to assure proper mechanical

and electrical operation

WARNING!

To reduce the risk of injury,

electric shock and damage to the

tool, never immerse your tool in

liquid or allow a liquid to flow

inside the tool.

Cleaning

Clean dust and debris from vents. Keep

the tool handles clean, dry and free of oil

or grease. Use only mild soap and a damp

cloth to clean your tool since certain cleaning agents and solvents are harmful to plastics and other insulated parts. Some of

these include: gasoline, turpentine, lacquer

thinner, paint thinner, chlorinated cleaning

solvents, ammonia and household detergents containing ammonia. Never use flammable or combustible solvents around

tools.

Repairs

If your tool is damaged, return the entire

tool to the nearest service center.

ACCESSORIES

WARNING!

To reduce the risk of injury,

always unplug the tool before

attaching or removing

accessories. Use only specifically

recommended accessories.

Others may be hazardous.

For a complete listing of accessories refer

to your MILWAUKEE Electric Tool catalog

or go on-line to www.milwaukeetool.com.

To obtain a catalog, contact your local distributor or a service center.

Cat. No. 48-58-0030

3/8" (9.5 mm) Pitch chain

Cat. No. 48-09-5051

16" (406) Guide bar

FIVE YEAR TOOL

LIMITED WARRANTY

Every MILWAUKEE tool is tested before

leaving the factory and is warranted to be

free from defects in material and workmanship. MILWAUKEE will repair or

replace (at MILWAUKEEs discretion),

without charge, any tool (including battery

chargers) which examination proves to be

defective in material or workmanship from

five (5) years after the date of purchase.

Return the tool and a copy of the purchase

receipt or other proof of purchase to a

MILWAUKEE Factory Service/Sales

Support Branch location or MILWAUKEE

Authorized Service Station, freight prepaid

and insured. This warranty does not cover

damage from repairs made or attempted

by other than MILWAUKEE authorized

personnel, abuse, normal wear and tear,

lack of maintenance, or accidents.

Battery Packs, Flashlights, and Radios are

warranted for one (1) year from the date

of purchase.

THE REPAIR AND REPLACEMENT REMEDIES

DESCRIBED HEREIN ARE EXCLUSIVE. IN NO

EVENT SHALL MILWAUKEE BE LIABLE

FOR ANY INCIDENTAL, SPECIAL, OR

CONSEQUENTIAL DAMAGES, INCLUDING

LOSS OF PROFITS.

THIS WARRANTY IS EXCLUSIVE AND IN

LIEU OF ALL OTHER WARRANTIES, OR

CONDITIONS, WRITTEN OR ORAL,

EXPRESSED OR IMPLIED FOR

MERCHANTABLILITY OR FITNESS FOR

PARTICULAR USE OR PURPOSE.

This warranty gives you specific legal

rights. You may also have other rights that

vary from state to state and province to

province. In those states that do not allow

the exclusion of implied warranties or

limitation of incidental or consequential

damages, the above limitations or

exclusions may not apply to you. This

warranty applies to the United States,

Canada, and Mexico only.

16 17

Loading...

Loading...